Station for applying fluid substances to stone materials

A technology of processing station and station, applied in the direction of surface coating liquid device, manufacturing tool, ceramic molding machine, etc., can solve the problems of poor speed and quality of labor and environmental health intervention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

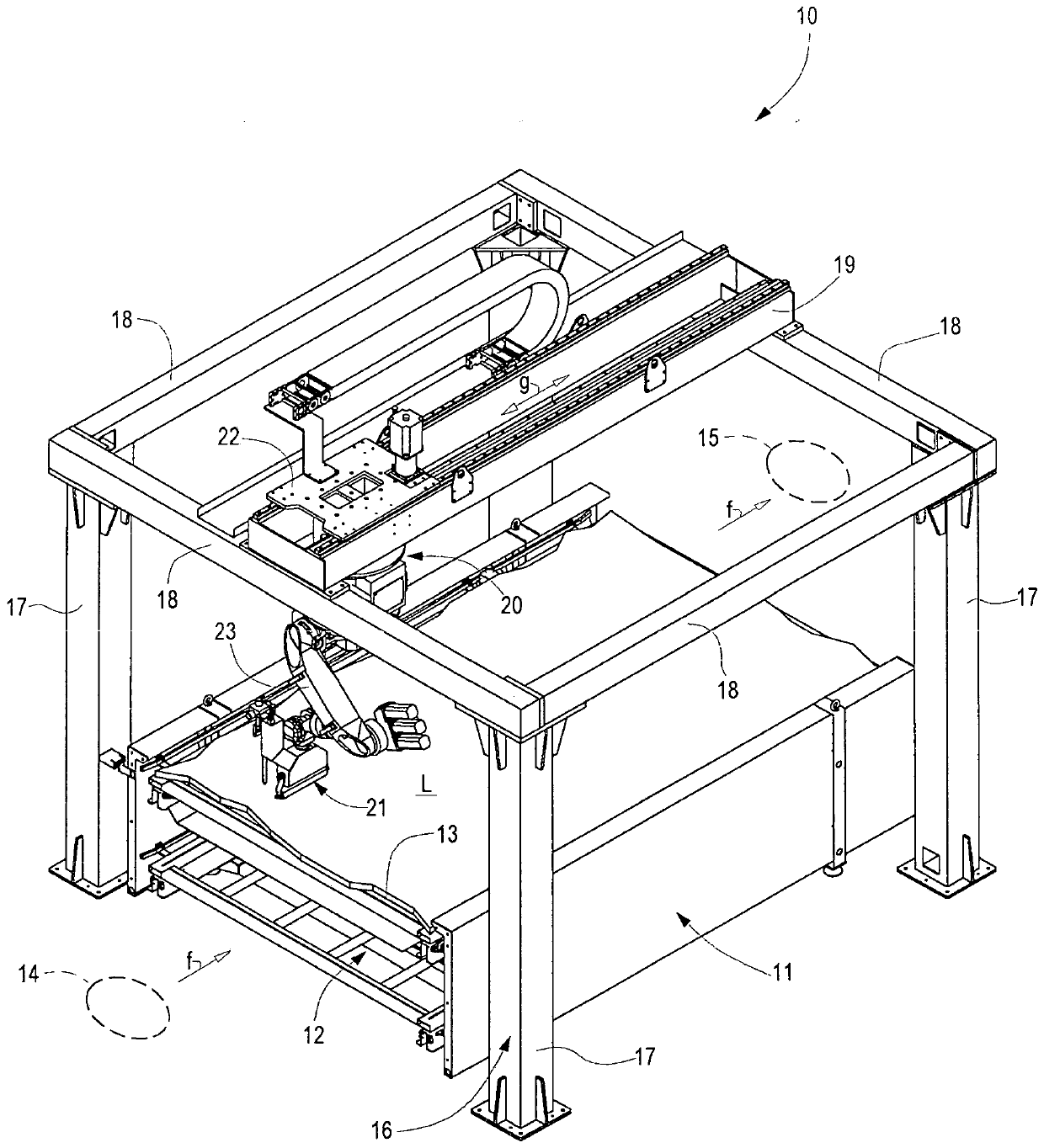

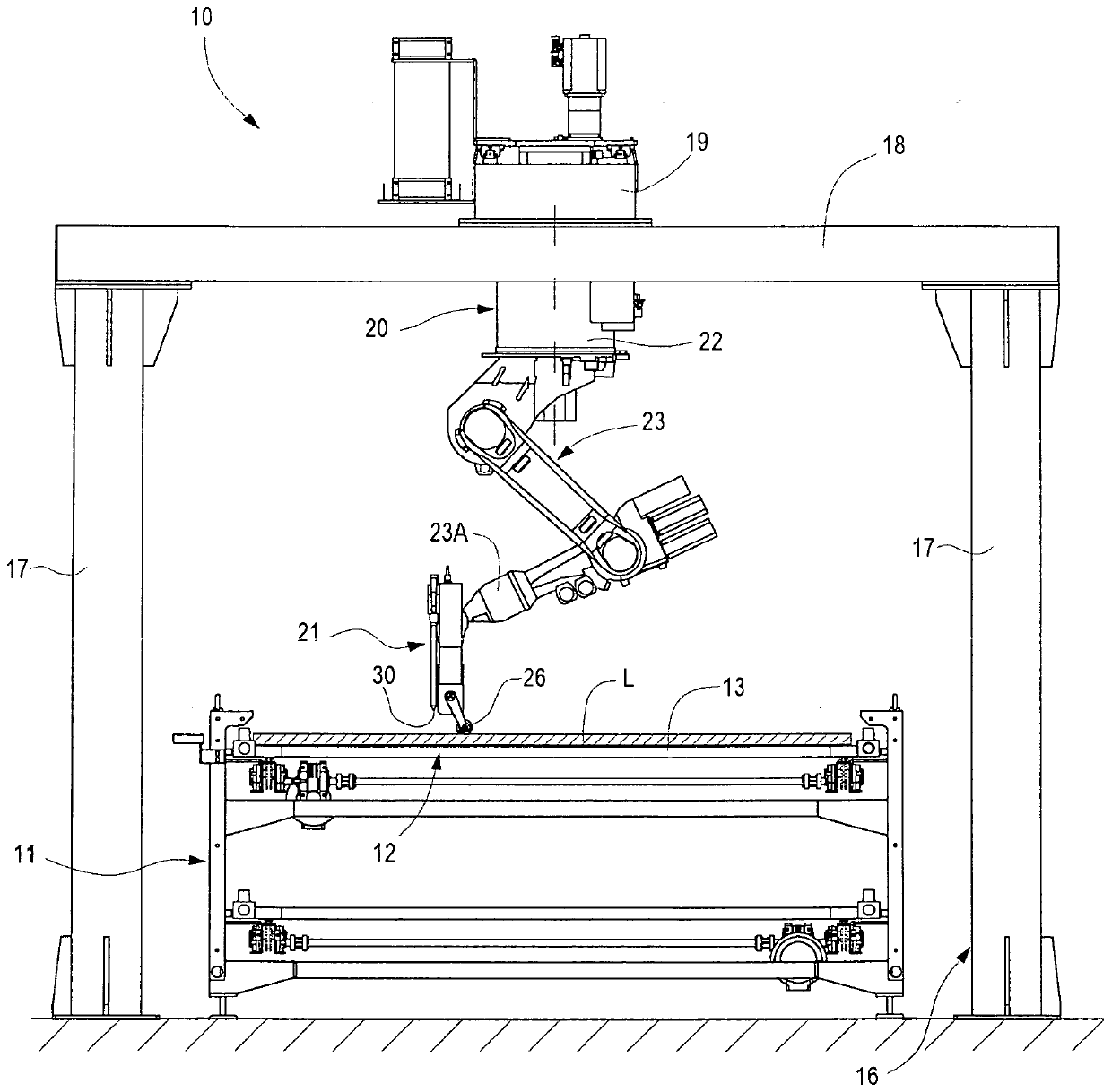

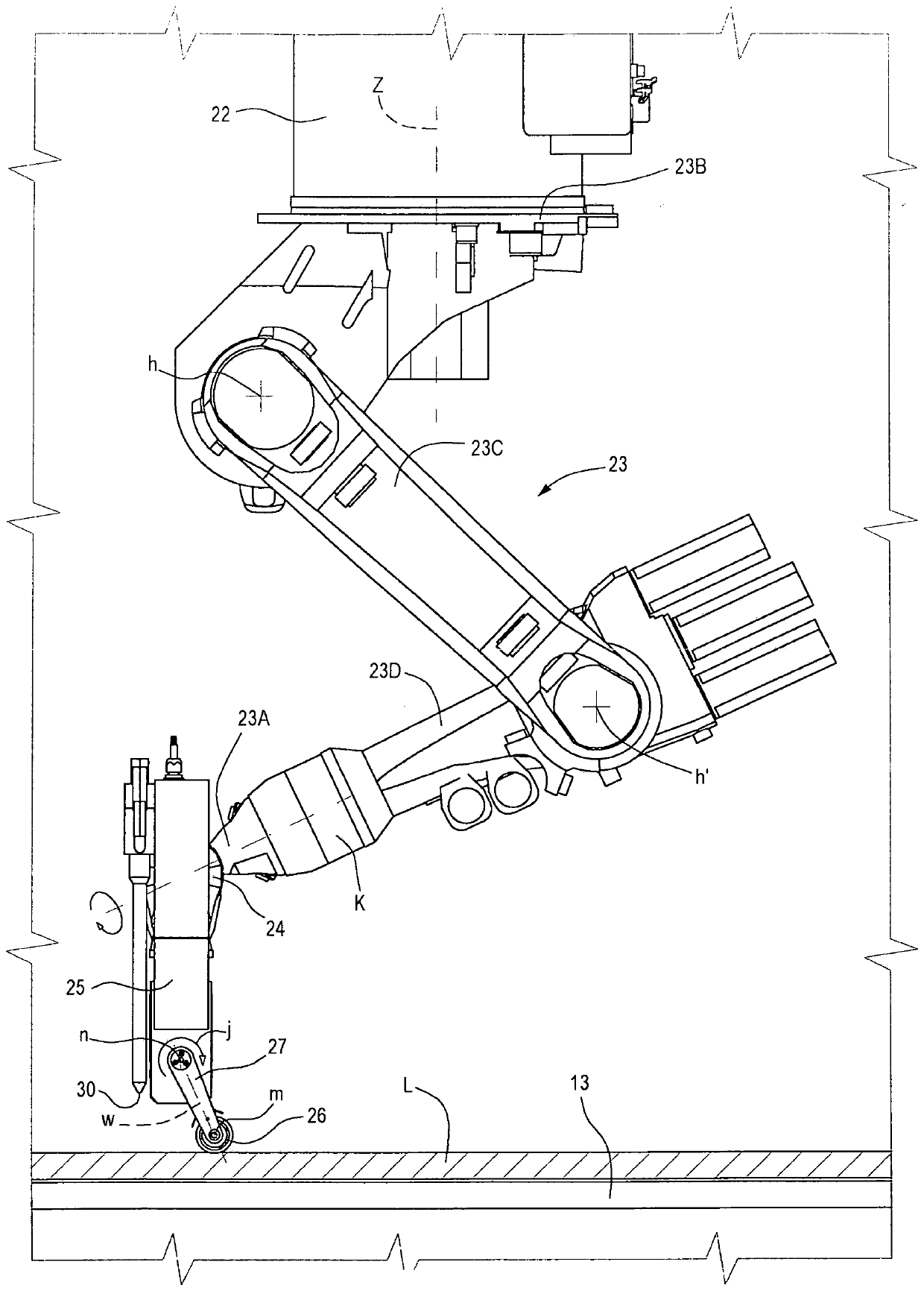

[0079] Referring to the drawings, the reference numeral 10 generally designates a station for applying a fluid substance to a slab of stone material according to the invention. More specifically, the station is a resin finishing station for slabs of stone.

[0080] For example, a resin finishing station is inserted into a resin finishing production line (not shown in the drawings), and the resin finishing production line includes various processing stations, such as a loading station, a slab drying station (which includes, for example, one or more drying oven), resin finishing station, resin catalyst station, second resin finishing station and second catalyst station (optional), and unloading station. Obviously other stations may be provided in combination with the stations listed above.

[0081] The resin finishing station 10 may be provided with means for applying the reinforcing mesh or sheet to the slab, these means not shown in the figures.

[0082] The resin finishing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com