Stone unloader and unloading method

A technology of unloading machine and stone slab, which is applied in the direction of stone processing tools, stone processing equipment, conveyors, etc., can solve the problems of large dust, injury accidents and dangers at the work site, and achieve the effect of high work efficiency and guarantee of personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

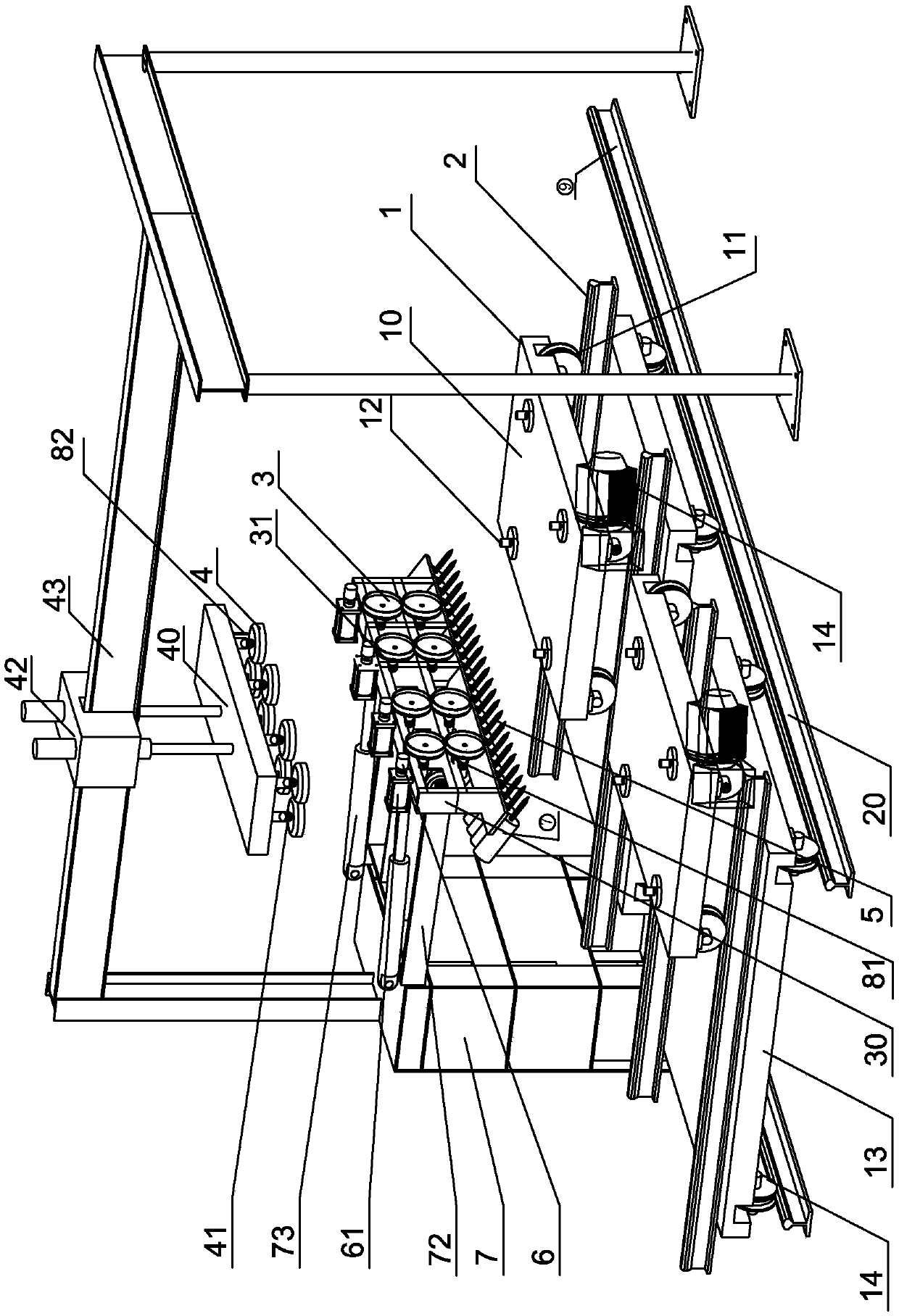

[0039] Embodiment 1, with reference to attached Figure 1-5 .

[0040] The stone unloading machine provided by the invention includes a transport trolley, a rail system, a working device and a plate removing device.

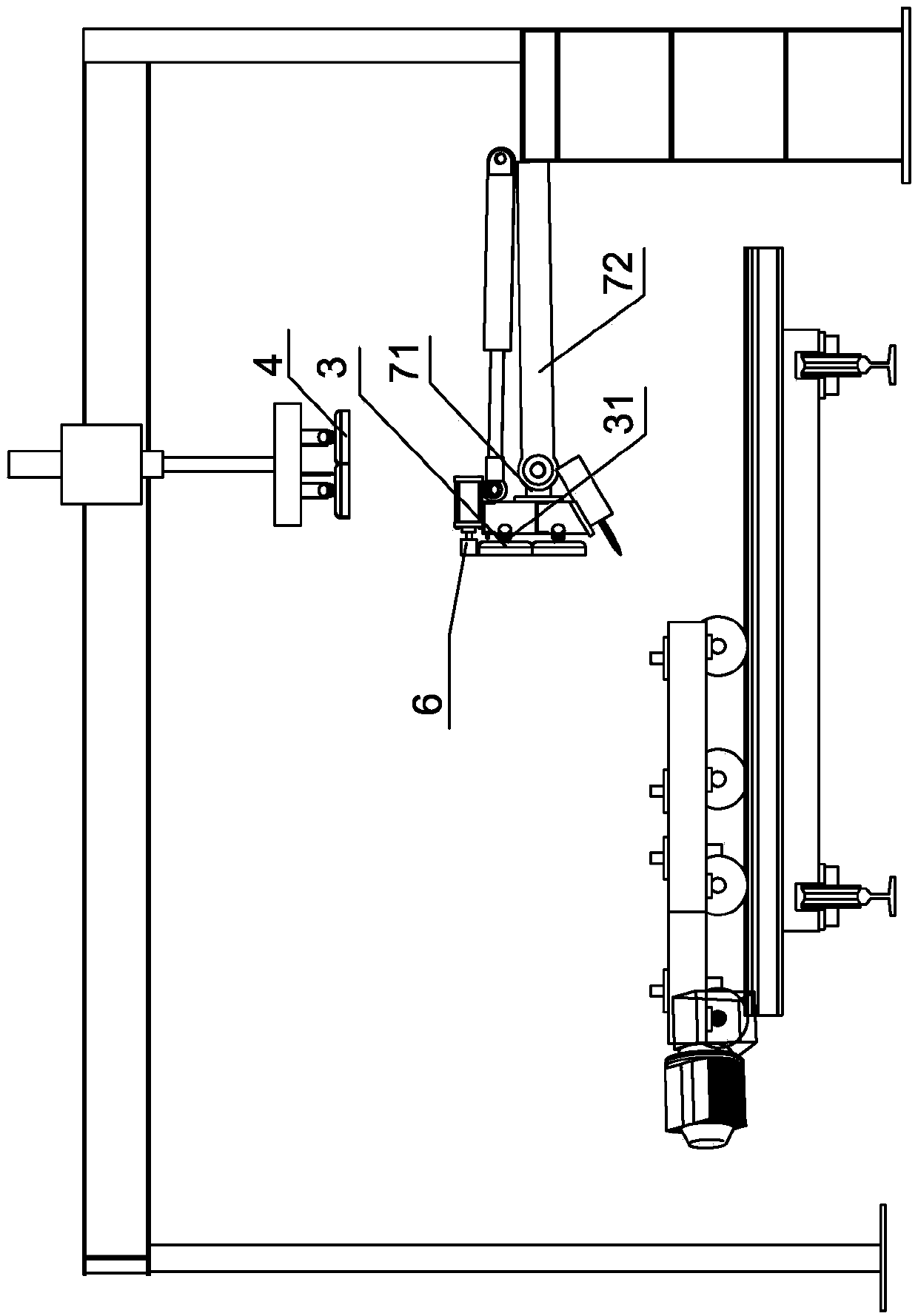

[0041] The working device includes a slate bottom chisel mechanism, a slate breaking mechanism and a first slate sucker 3 .

[0042] The stone slab bottom chisel mechanism is arranged in front of the lower end of the stone slab 101 transported to the stone slab processing position on the trolley 1 corresponding to transporting stone materials, and is used to process the lower end 103 connected between the stone slab 101 at the processing position and its stone bottom plate 102 for convenience. A weak connection that breaks off.

[0043] The slate breaking mechanism is used to push back the slate 101 that is processed to be easily broken and break it from the lower end 103 .

[0044] The first slate suction cup is set to be able to correspond to the vertical sl...

Embodiment 2

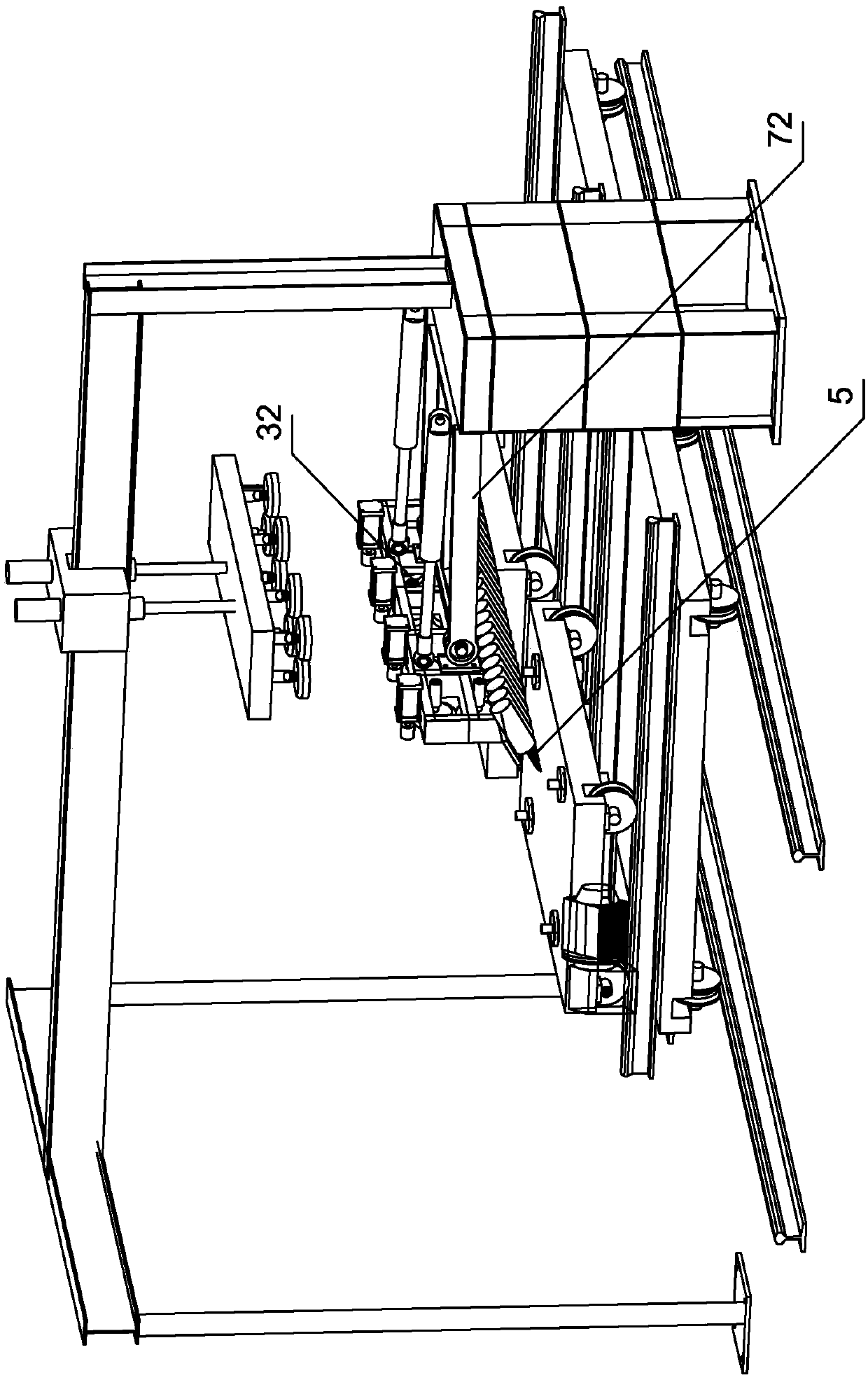

[0061] Embodiment 2, with reference to attached Figure 6-10 .

[0062] In this embodiment, the bottom chisel mechanism is not installed on the mounting frame 30, and is not lifted along with the first slate suction cup, but is mounted on its mounting bracket 50, and the mounting bracket 50 is directly fixed on the fixing frame 7 superior.

[0063] In addition, the first transfer mechanism is a linear motion mechanism, including on the lifting mechanism 74, the mounting frame 30 is installed on the lifting mechanism 74, and the mounting frame of the second working suction cup 4 in the slate removal device is a rotatable mounting frame. When receiving slabs as figure 1 The vertical state, when the slate is put down, it is driven by the motor to turn it into a horizontal state. This elevating mechanism 74 can have pulley device 75 to drive elevating. If necessary, the elevating mechanism 74 may be connected with a forward and backward movement or / and a left and right movemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com