Liquid gallium alloy and preparation method thereof

A preparation method, the technology of gallium alloy, applied in the field of gallium alloy and its preparation, can solve the problems of strong explosion, limited range of use, spontaneous combustion when exposed to air, etc., and achieve the effects of simplifying the structure, improving operability, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Measure 75 parts of gallium with a purity of >99%, 10 parts of indium with a purity of >99%, 7 parts of tin with a purity of >99%, and 8 parts of zinc with a purity of >99% according to mass percentage. First heat gallium to 29°C to make it melt, stop heating, pour liquid gallium into a stainless steel container, and then pour indium, tin and zinc into the stainless steel container. At normal temperature, use a stainless steel spoon to mix and stir until the four raw materials are completely dissolved into liquid, that is, the liquid gallium alloy of the present invention is prepared.

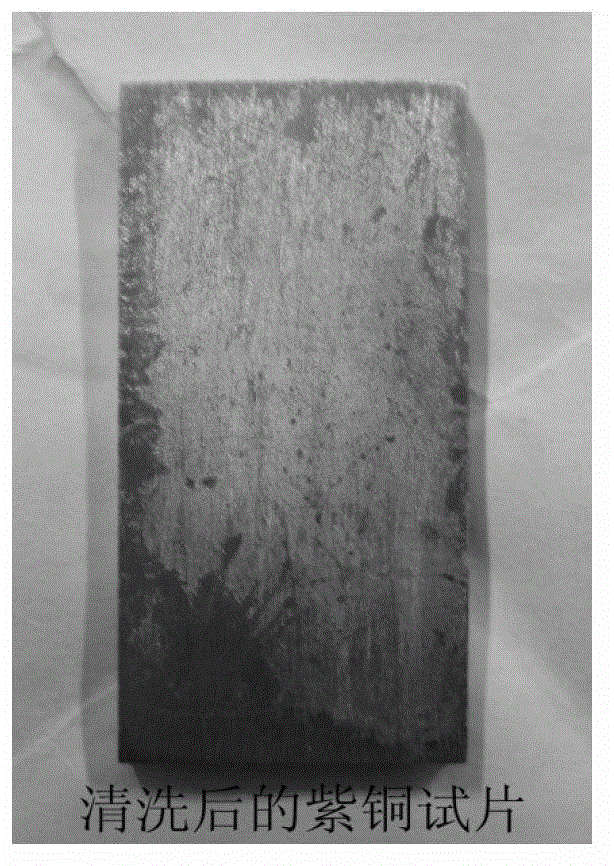

[0040] 1. Measure the freezing point of the prepared liquid gallium alloy: at room temperature, pour the prepared liquid gallium alloy into a small beaker, put the small beaker on the iron stand, and clamp the upper end of the thermometer with the iron clip of the iron stand to make the thermometer The bottom of the thermometer is immersed in the liquid gallium alloy, and the bottom of t...

Embodiment 2

[0061] According to mass percentage, 71.5 parts of gallium with a purity of >99%, 20 parts of indium with a purity of >99%, 1 part of tin with a purity of >99%, and 7.5 parts of zinc with a purity of >99% were measured. First heat gallium to 29°C to melt it, stop heating, pour liquid gallium into a stainless steel container, and then pour indium, tin and zinc into the stainless steel container. At normal temperature, use a stainless steel spoon to mix and stir until the four raw materials are completely dissolved into liquid, that is, the liquid gallium alloy of the present invention is prepared.

[0062] The same test method as in the first embodiment can be used, and the physical characteristics of the liquid gallium alloy prepared in embodiment 2 are as follows: the freezing point is 5°C; at normal temperature 20°C, the density is 6.46g / cm 3 , with a conductivity of 3.4×10 6 S / m. The liquid gallium alloy prepared in Example 2 has obvious corrosion to aluminum; it has no c...

Embodiment 3

[0064] Measure 68 parts of gallium with a purity of >99%, 18.5 parts of indium with a purity of >99%, 11 parts of tin with a purity of >99%, and 2.5 parts of zinc with a purity of >99% according to mass percentage. First heat gallium to 29°C to melt it, stop heating, pour liquid gallium into a stainless steel container, and then pour indium, tin and zinc into the stainless steel container. At normal temperature, use a stainless steel spoon to mix and stir until the four raw materials are completely dissolved into liquid, that is, the liquid gallium alloy of the present invention is prepared.

[0065] The same test method as in Example 1 can be used to obtain, and the physical properties of the liquid gallium alloy prepared in Example 2 are as follows: the freezing point is 5 ° C; at 20 ° C at normal temperature, the density is 6.46 g / cm 3 , with a conductivity of 3.4×10 6 S / m. The liquid gallium alloy prepared in Example 3 has obvious corrosion to aluminum; it has no corrosi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com