A balanced handling trolley for paving stone slabs

A handling trolley, balanced technology, applied in the field of balanced handling trolleys for slate paving, can solve the problems of increased manual labor, low efficiency, poor effect, etc., and achieves the effect of reducing manual labor and convenient loading and unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

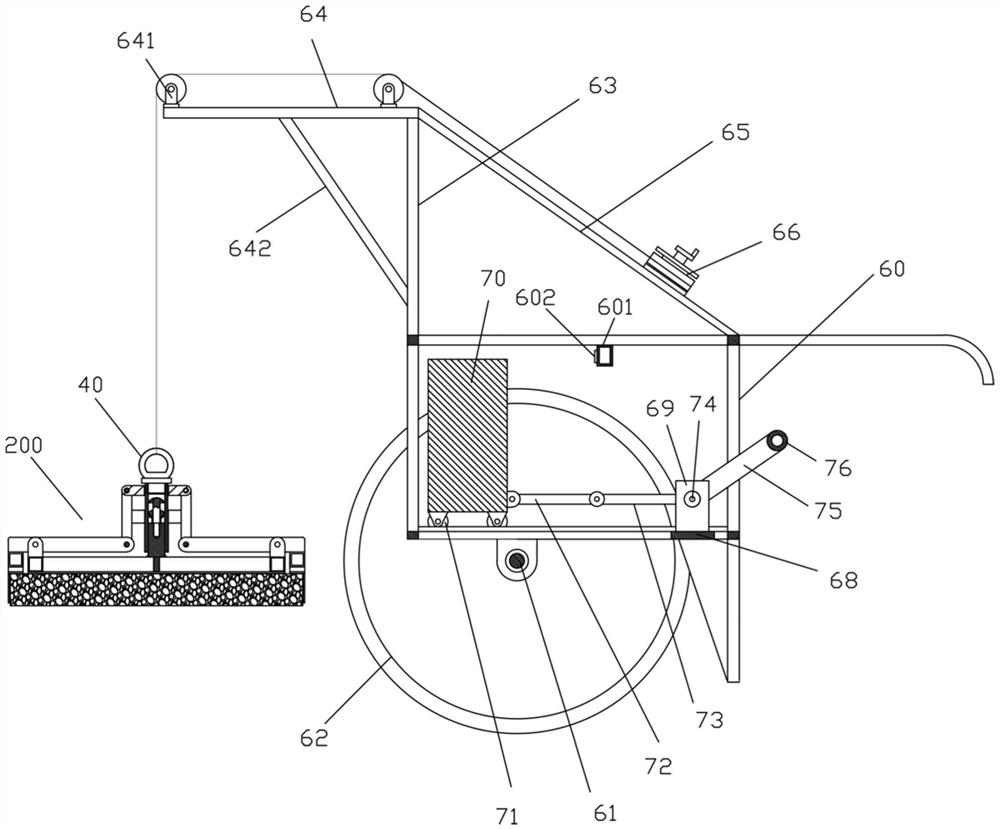

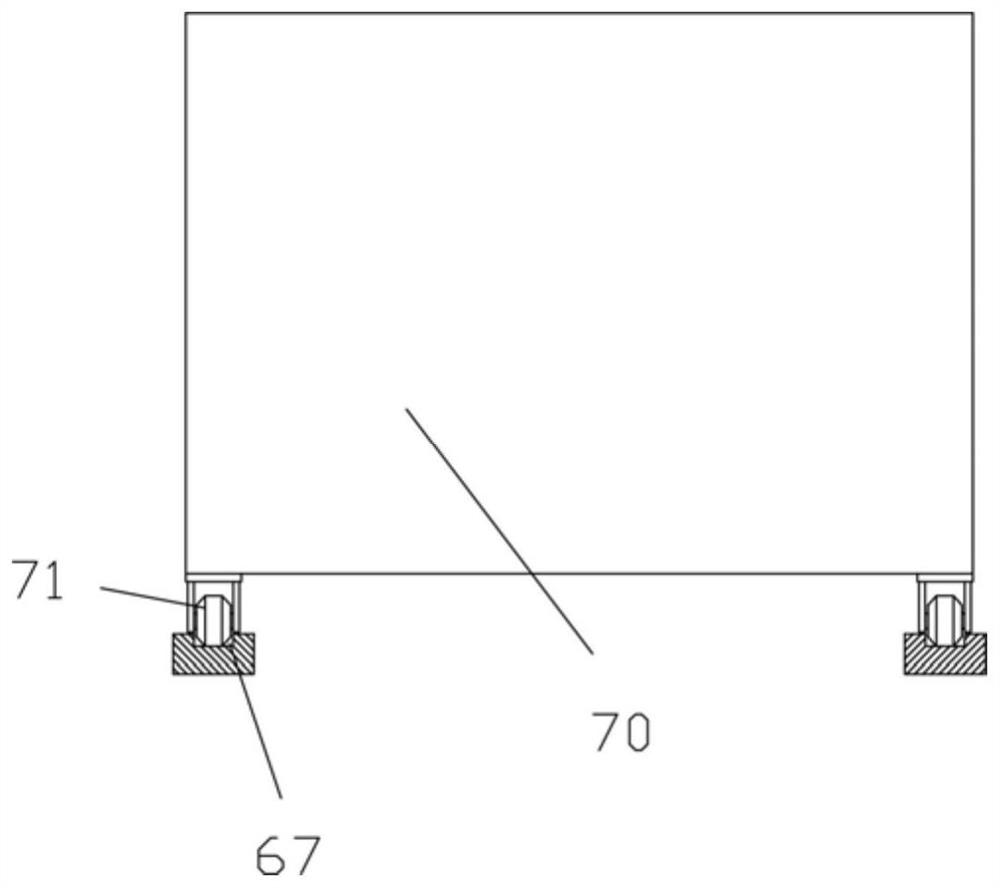

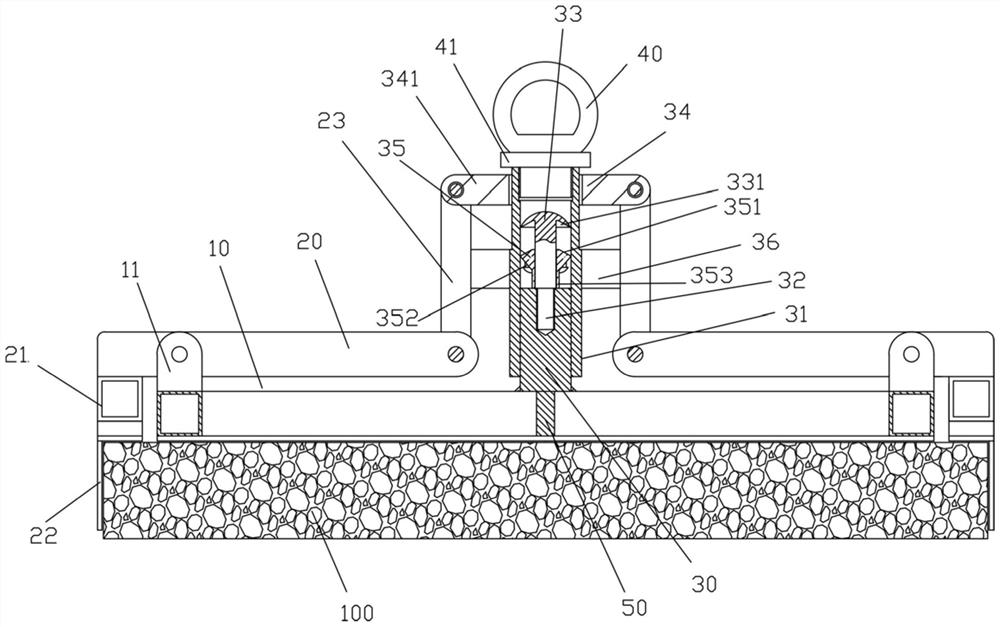

[0031] Examples, see e.g. Figures 1 to 5 As shown, a balanced handling trolley for paving stone slabs includes a trolley frame 60 and a grabbing mechanism 200;

[0032] The bottom of the cart frame 60 is provided with a transmission shaft 61 extending forward and backward, and the end of the transmission shaft 61 is hinged with a wheel 62 through a bearing;

[0033] The top surface of the top beam at the front of the cart frame 60 is fixed with a vertical column 63, the top of the vertical column 63 is fixed with a horizontal fixed beam 64 extending forward, and the rear end of the horizontal fixed beam 64 is fixed with a diagonal. To the front end of the beam 65, the rear end of the inclined beam 65 is fixed on the top beam at the rear of the cart frame 60, and the left and right parts of the top surface of the horizontal fixed beam 64 are fixed with a pulley seat 641, and the inclined beam The rear portion top surface of 65 is fixed with hand winch 66, and the wire rope of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com