Patents

Literature

1099results about How to "Reduce the amount of manual labor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

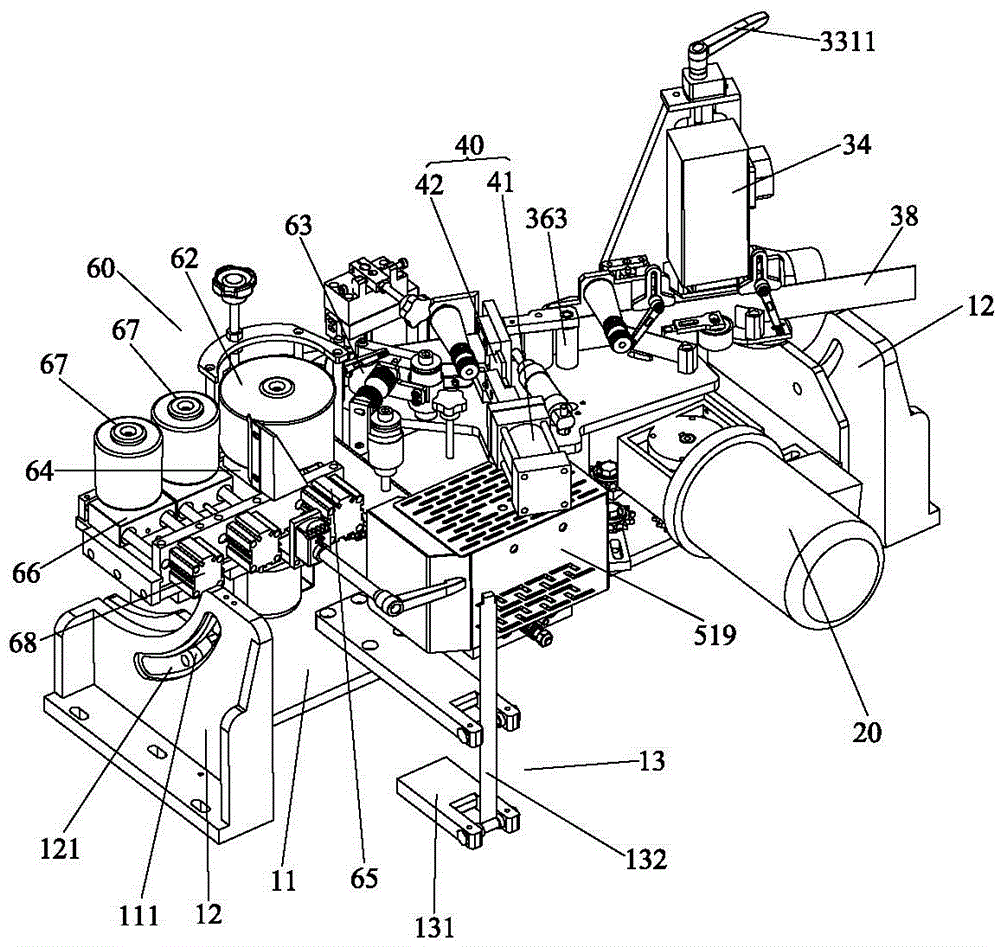

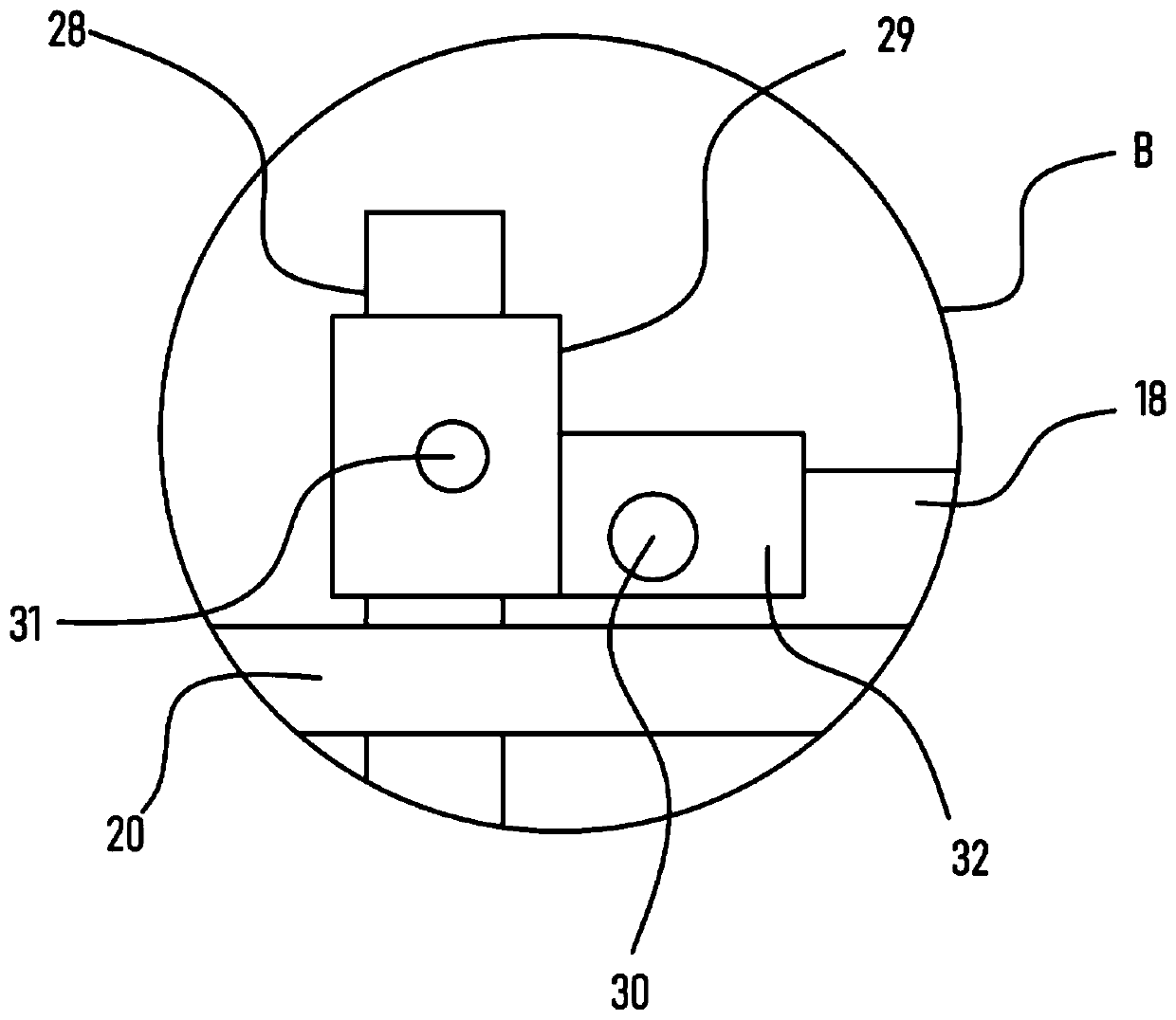

Charged coupled device (CCD) automated detecting device for connector

InactiveCN103101643ARealize detection automationImprove detection efficiencyPackaging automatic controlUsing optical meansComputer hardwareMobile device

The invention discloses a charged coupled device (CCD) automated detecting device for a connector. The CCD automated detecting device for the connector comprises a device base, a feeding device, a mobile device, CCD detecting devices, a defective product pushing device and a good product packaging device, wherein the feeding device, the mobile device, the CCD detecting devices, the defective product pushing device and the good product packaging device are arranged on the device base in sequence. Thereby, by means of the mutual interaction of the feeding device, the mobile device, the CCD detecting device, the defective product pushing device and the good product packaging device, the connector prepared to be detected can be moved from the feeding device to the mobile device, and the connector can be driven by the mobile device to penetrate through the transverse CCD detecting device and the vertical CCD detecting device sequentially to be detected. Therefore, the automated detection of the connector is achieved and the phenomenon of leak detection caused by man-made reasons in the process of manual detection can be avoided, detecting efficiency and qualified rate of the connector are improved and manual workload and production cost can be reduced.

Owner:DONGGUAN KECHENDA ELECTRONICS TECH

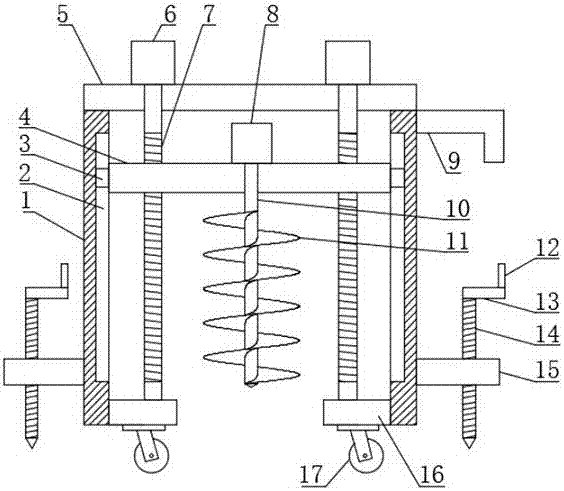

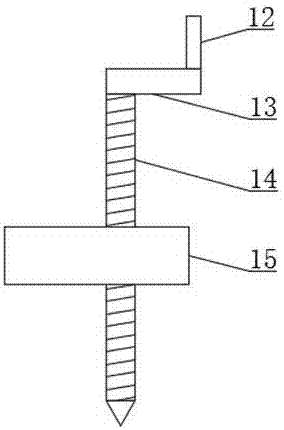

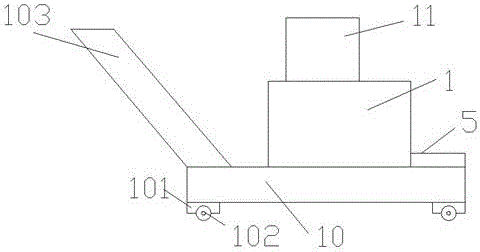

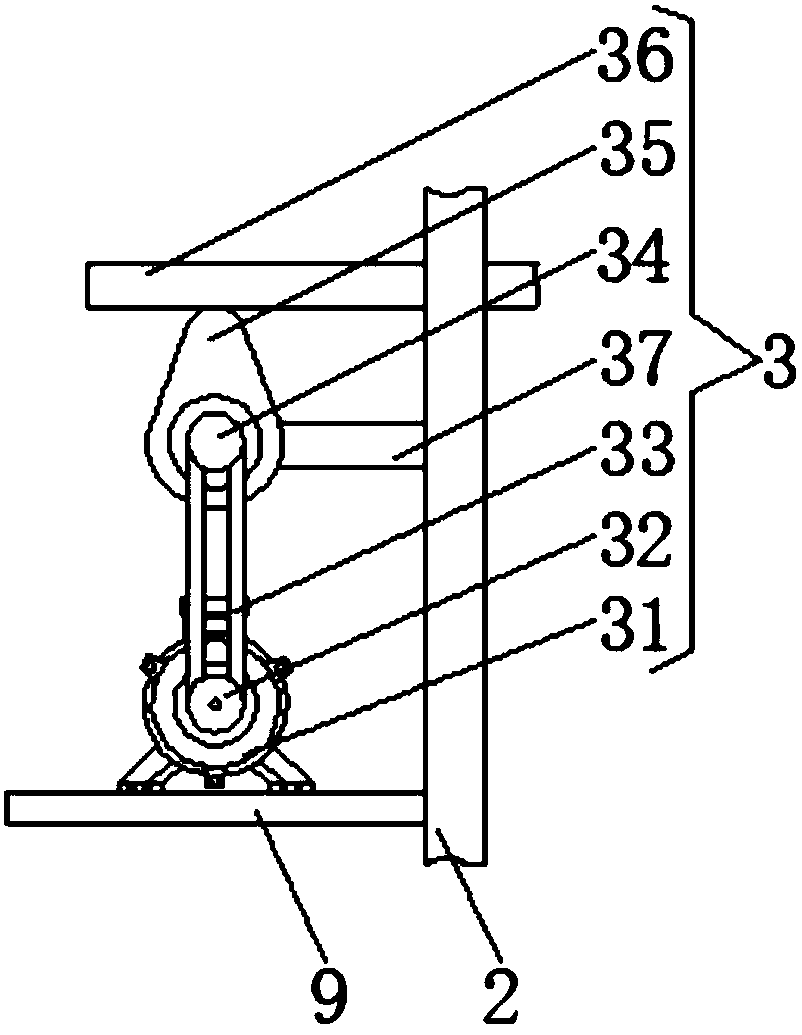

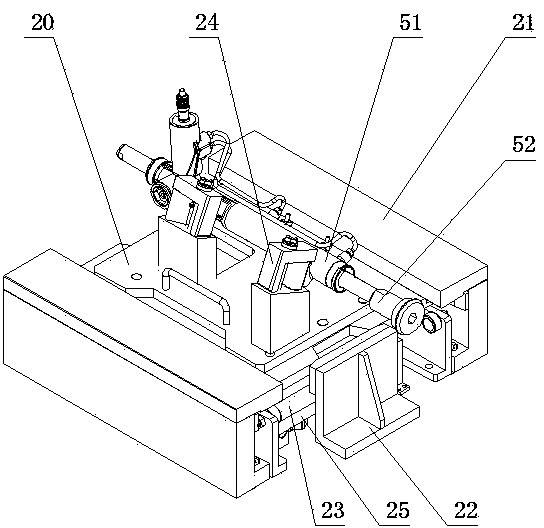

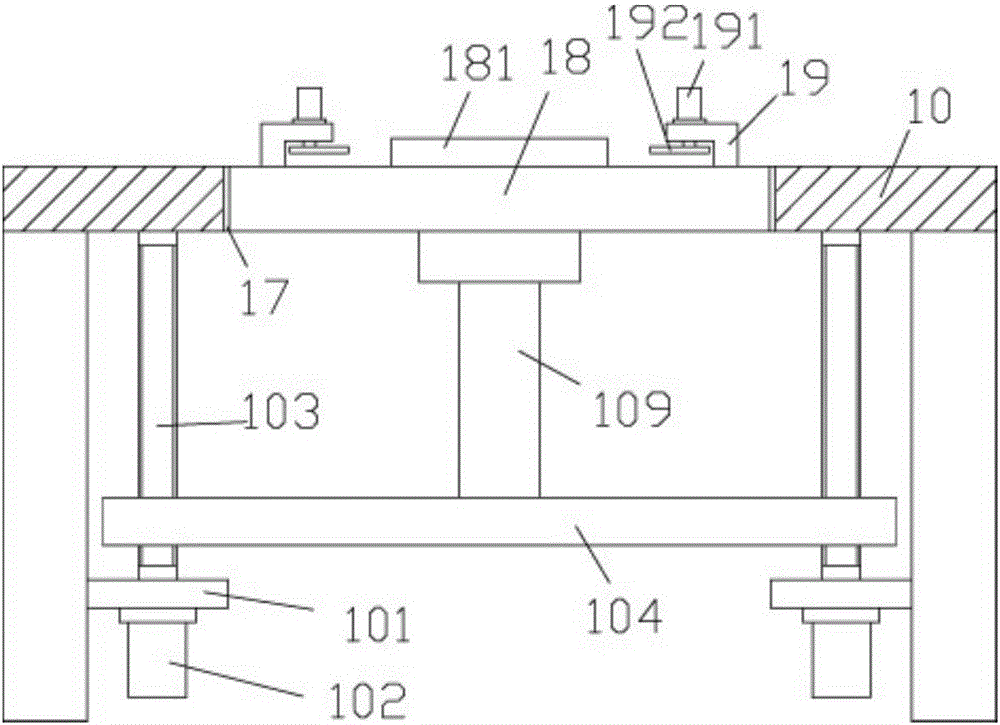

Agricultural sapling earth auger provided with fixing device

InactiveCN107333493AReduce the amount of manual laborAvoid position shiftPlantingFurrow making/coveringArchitectural engineeringSeedling

The present invention discloses an agricultural saplings digging machine with a fixed device, including the top board, which is fixed on the left and right sides of the top plate with a branch board.There is a lifting plate connection. The top motor is set on the top of the lifting board. The second motor bottom motor shaft is connected with a drill rod. The drill rod is equipped with a spiral blade. The spiral blade is located below the lifting plate.In a motor, the first motor bottom motor axis is connected to a lifting screw, which connects the lifting screw through the lifting plate and the lifting plate thread, which is fixed at the bottom of the lift plate with a base, which rotates the bottom of the lift screw and the base.The present invention drives up and down the upper and lower movements through the rotation of the lifting screw, which makes the spiral blade move the pits automatically. There is no need to control manual control during the pit process, reducing the amount of labor labor.

Owner:YANCHENG CITY LONG XIANG MACHINERY MFG PLANT

Preparation method of alumina foam ceramic

The invention discloses a preparation method of alumina foam ceramic, and relates to the technical field of production of high-tech ceramic product foam ceramic. The preparation method comprises the steps of stirring polyether or polyester polyol with a catalyst, a surfactant and a foaming agent, adding nano magnesium oxide and alumina ceramic powder, uniformly stirring, adding a curing agent, completely and uniformly mixing, reacting and curing in a shaping container, implementing perforation treatment on a cured foam ceramic sponge, and sintering at high temperature to obtain the alumina foam ceramic. The preparation method disclosed by the invention, which directly forms a three-dimensional reticulated foam ceramic green body, can greatly reduce production process, guarantee uniform and consistent alumina foam ceramic structure prepared, greatly reduce manpower demand and manual labor, shorten production cycle, and can also improve stability of product performance.

Owner:JIANGSU WEISHI STRUCTURAL CERAMICS

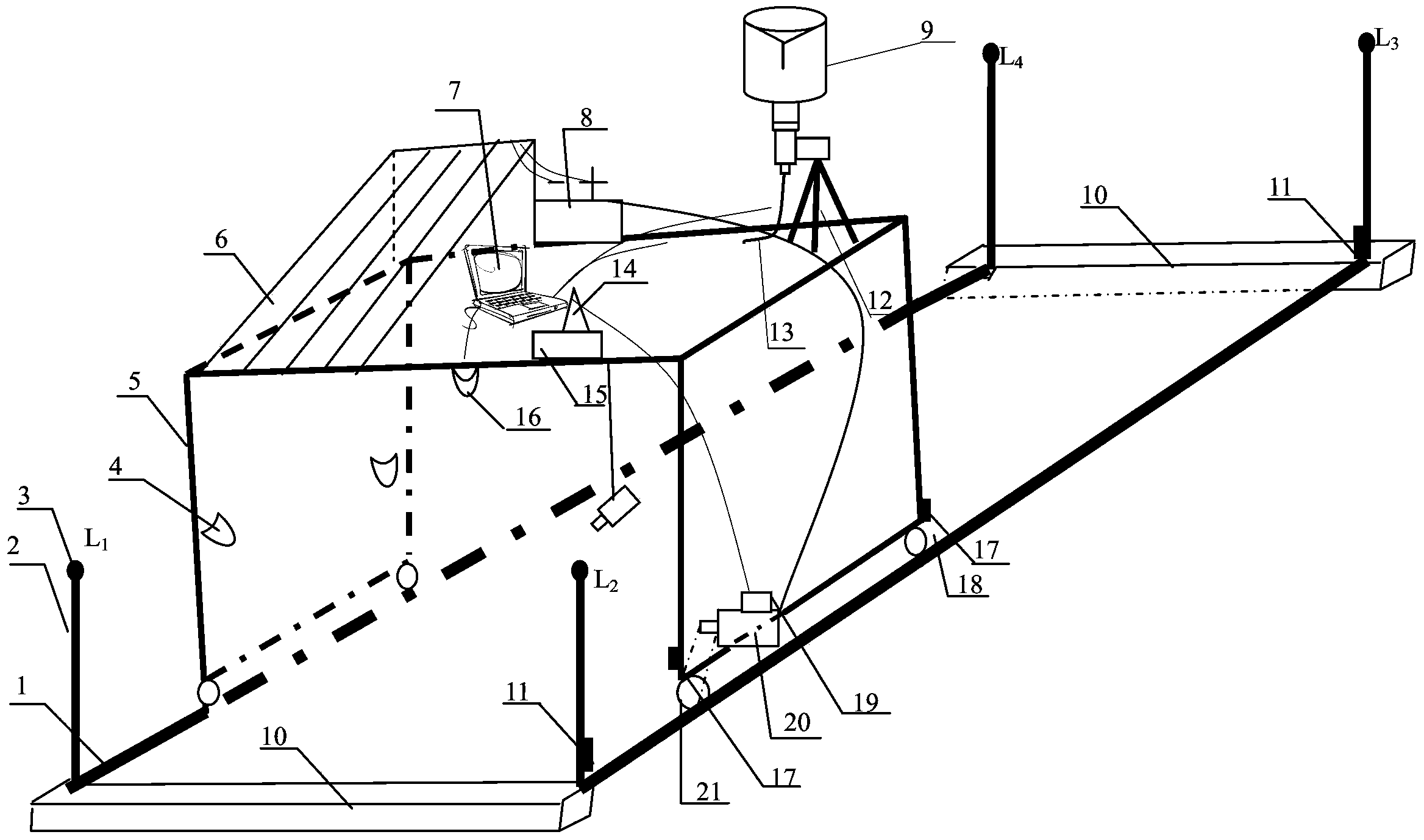

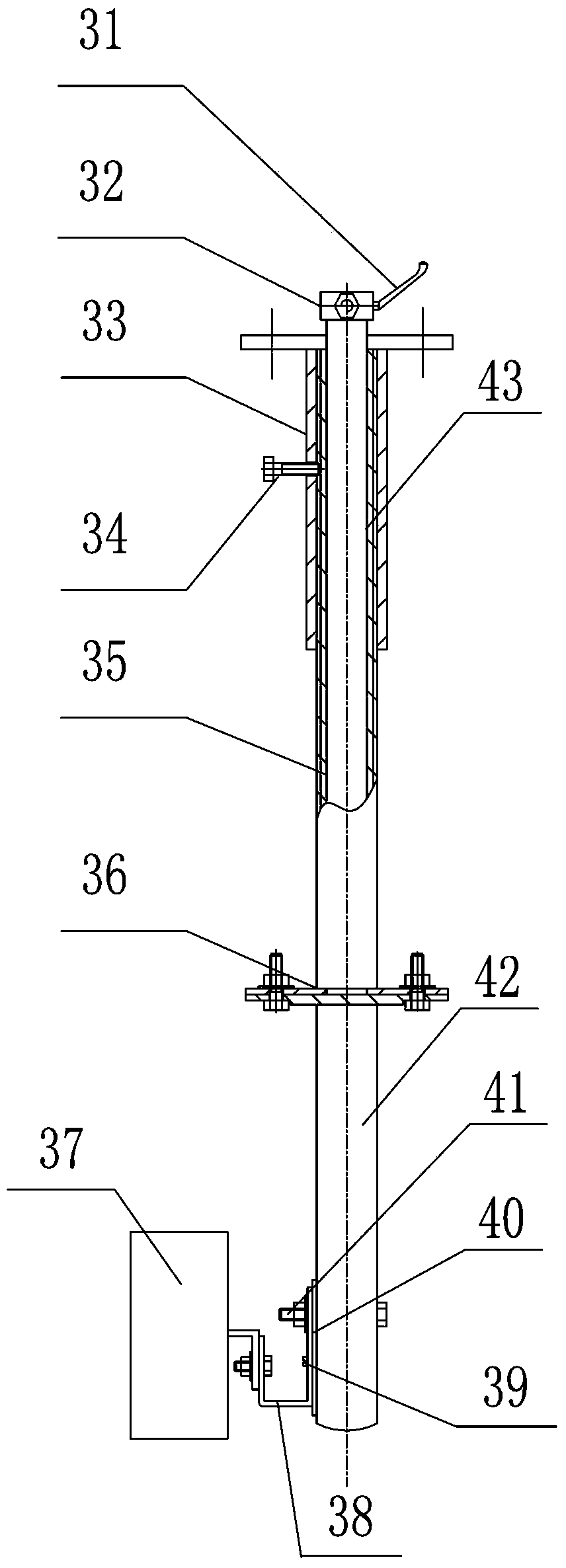

Real-time monitoring method for growth characters of tea trees in intensive cultivation

ActiveCN103439265AAchieve high quality and high yieldImprove qualityUsing subsonic/sonic/ultrasonic vibration meansColor/spectral properties measurementsBudTea leaf

The invention discloses a real-time monitoring method for growth characters of tea trees in intensive cultivation. The method comprises the following steps: performing real-time data acquisition by a tea tree living body growth character data acquisition device based on online location, transmitting the acquired data to an artificial comprehensive management center through a wireless communication way to process, wherein the acquired data comprises current location data acquired by a locating mechanism, fresh tea leaves spectrum data acquired by a high spectrum imaging sensor, and average growth height of fresh tea leaves measured by an ultrasonic wave sensor, and judging the best fresh tea leaf picking time based on that the data and a picking judgment model established off line are combined by the artificial comprehensive management center. The picking judgment model comprises a bud size growth measurement model based on average growth height, a yield correlation model and a quality correlation model based on the high spectrum image data. The real-time monitoring method for the growth characters of the tea trees in intensive cultivation is beneficial to realizing of intensive cultivation and automation in planting of the tea trees.

Owner:湖南星索尔航空科技有限公司

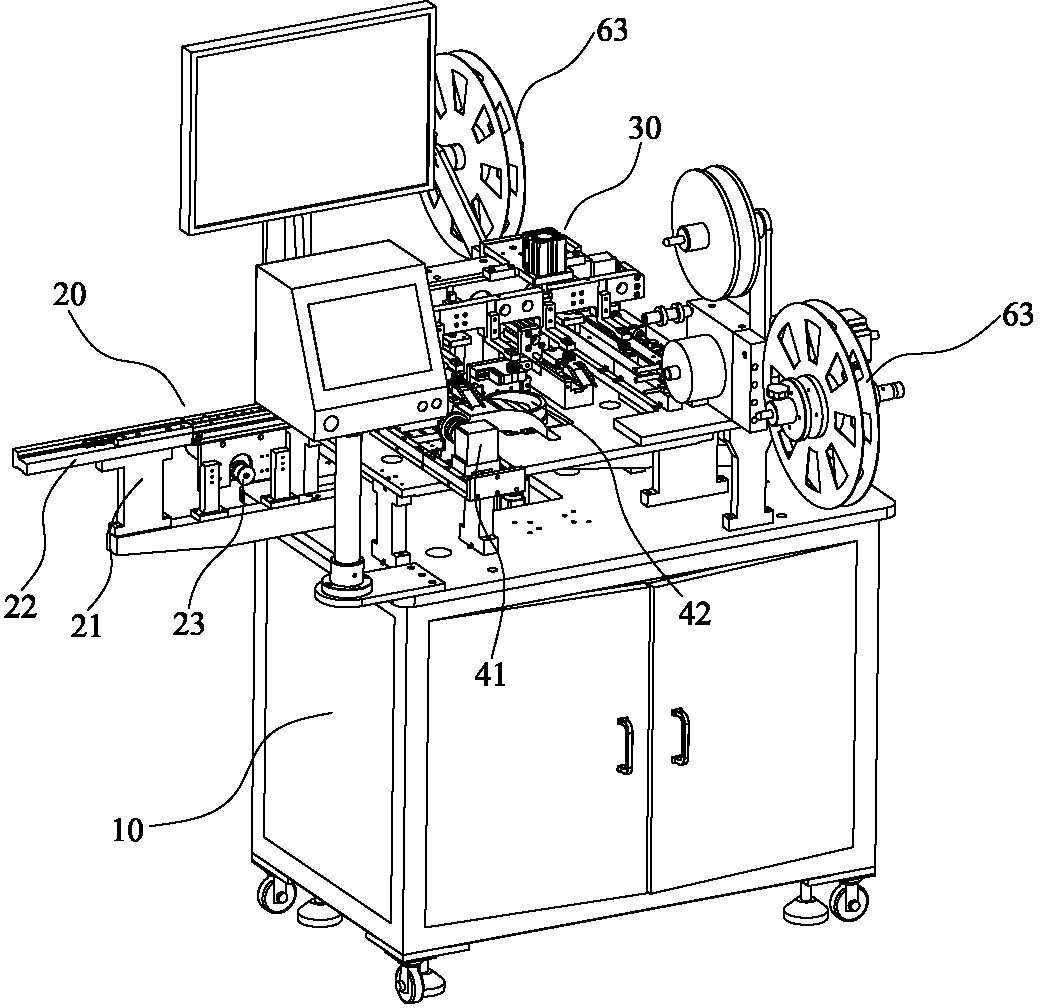

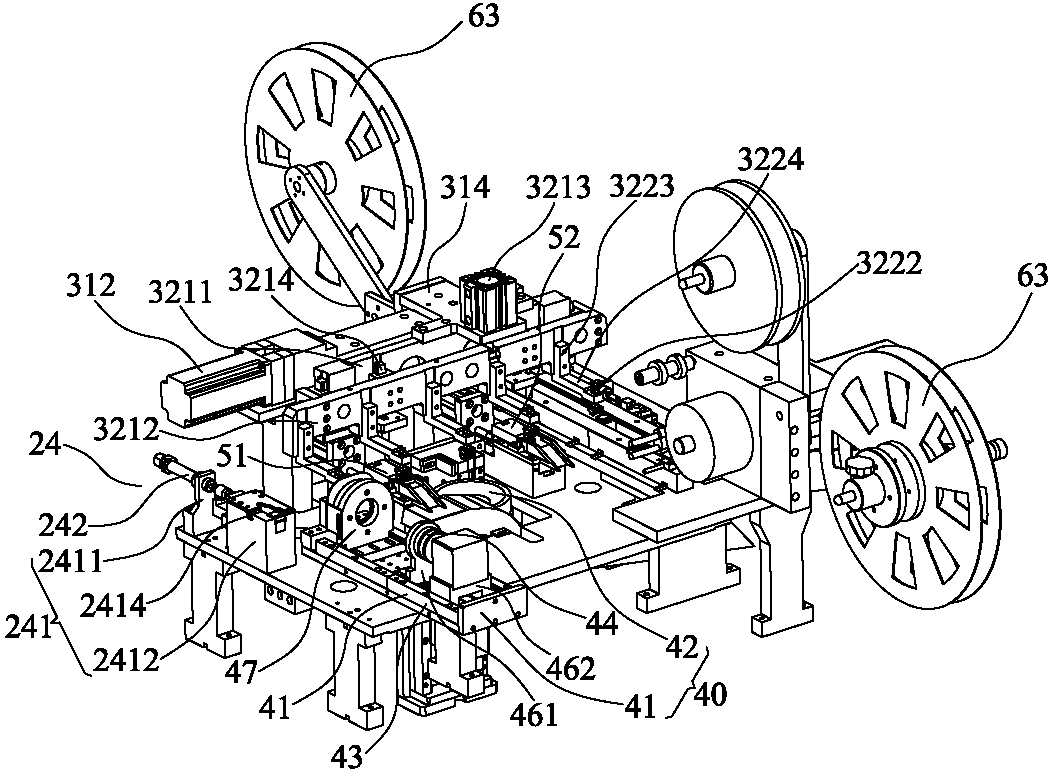

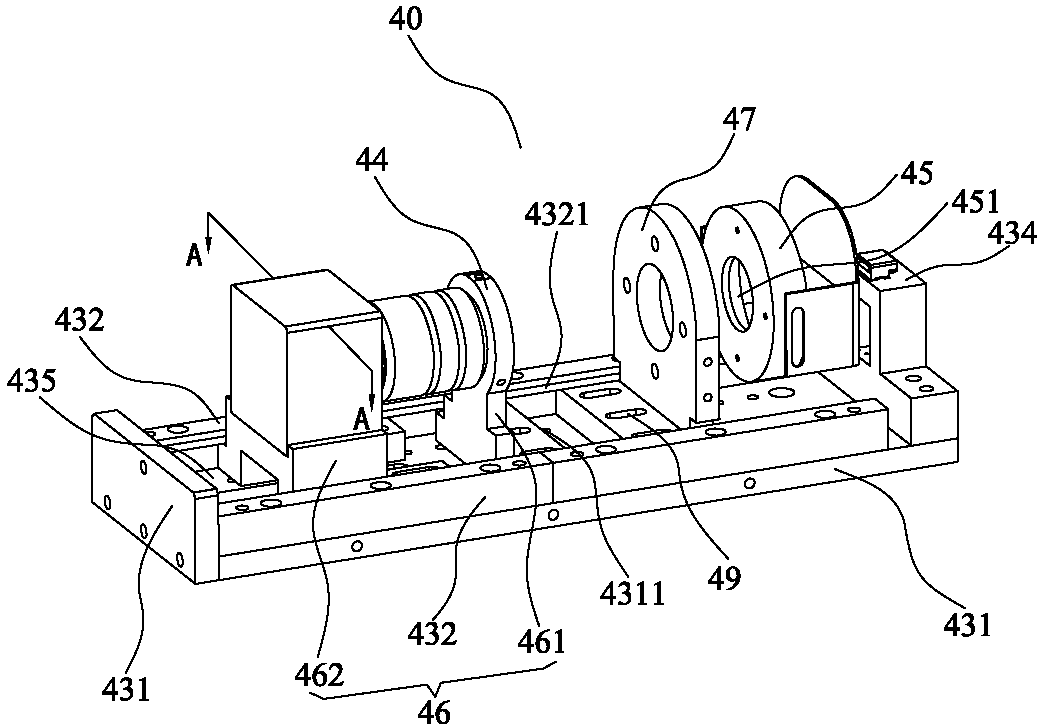

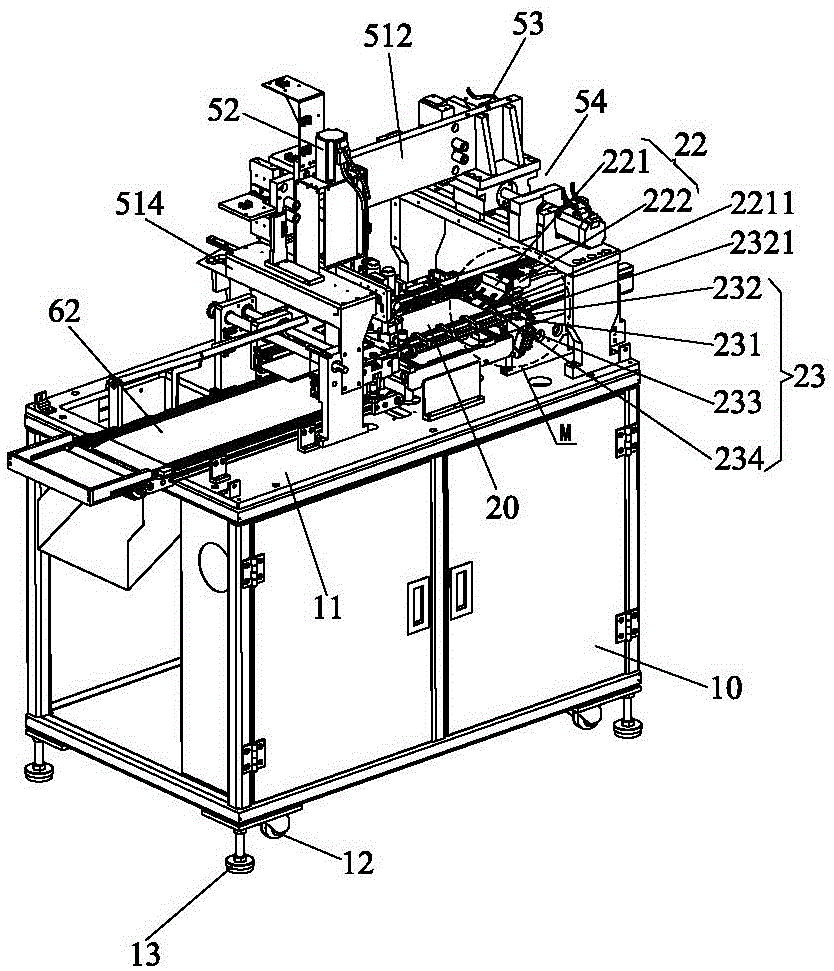

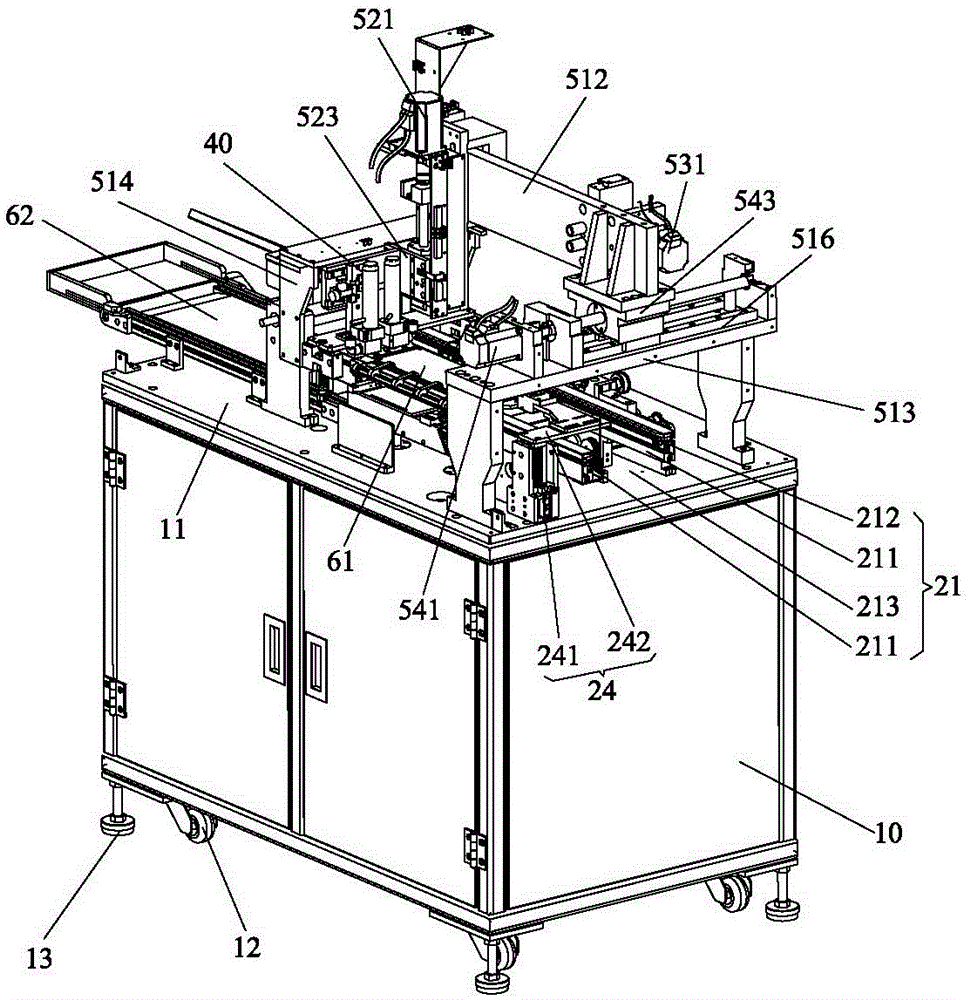

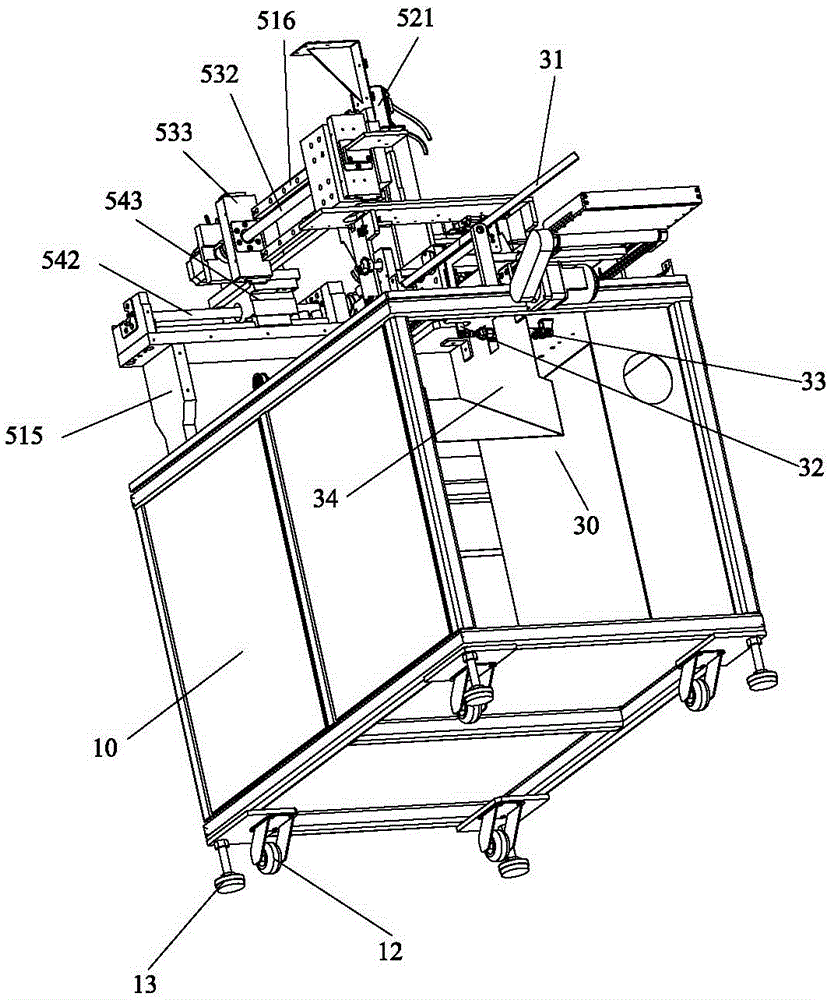

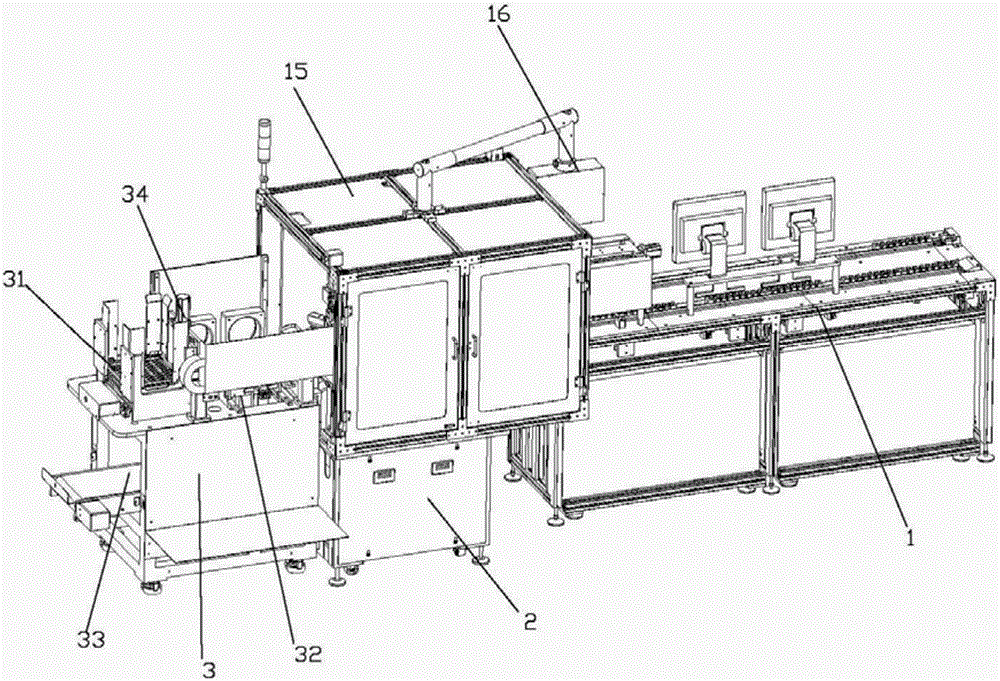

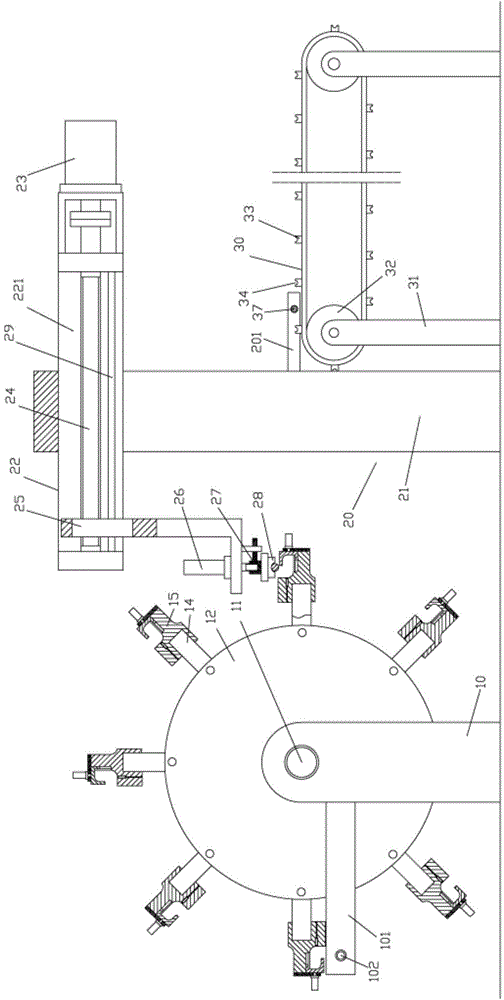

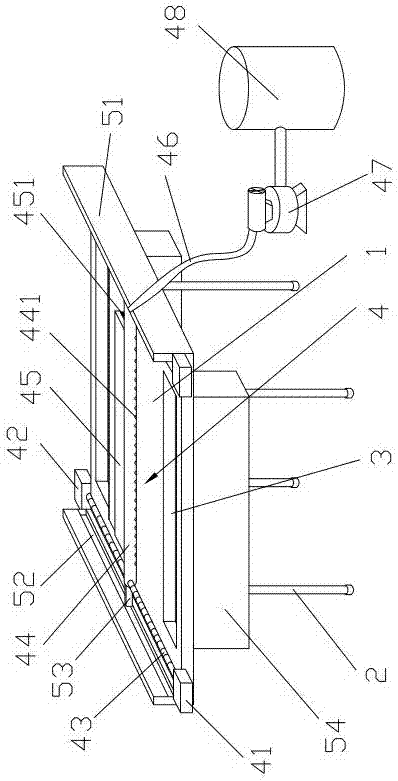

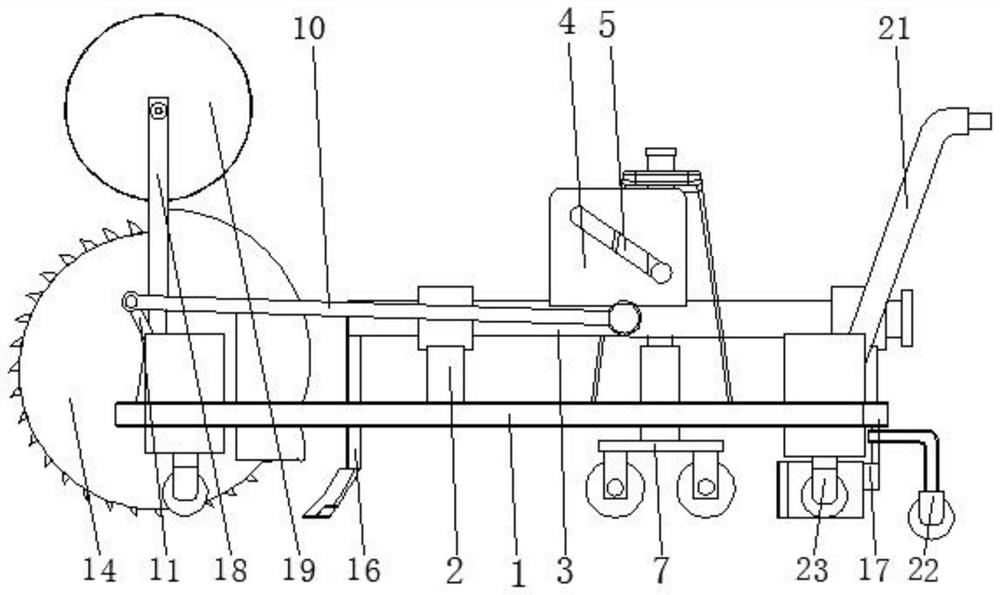

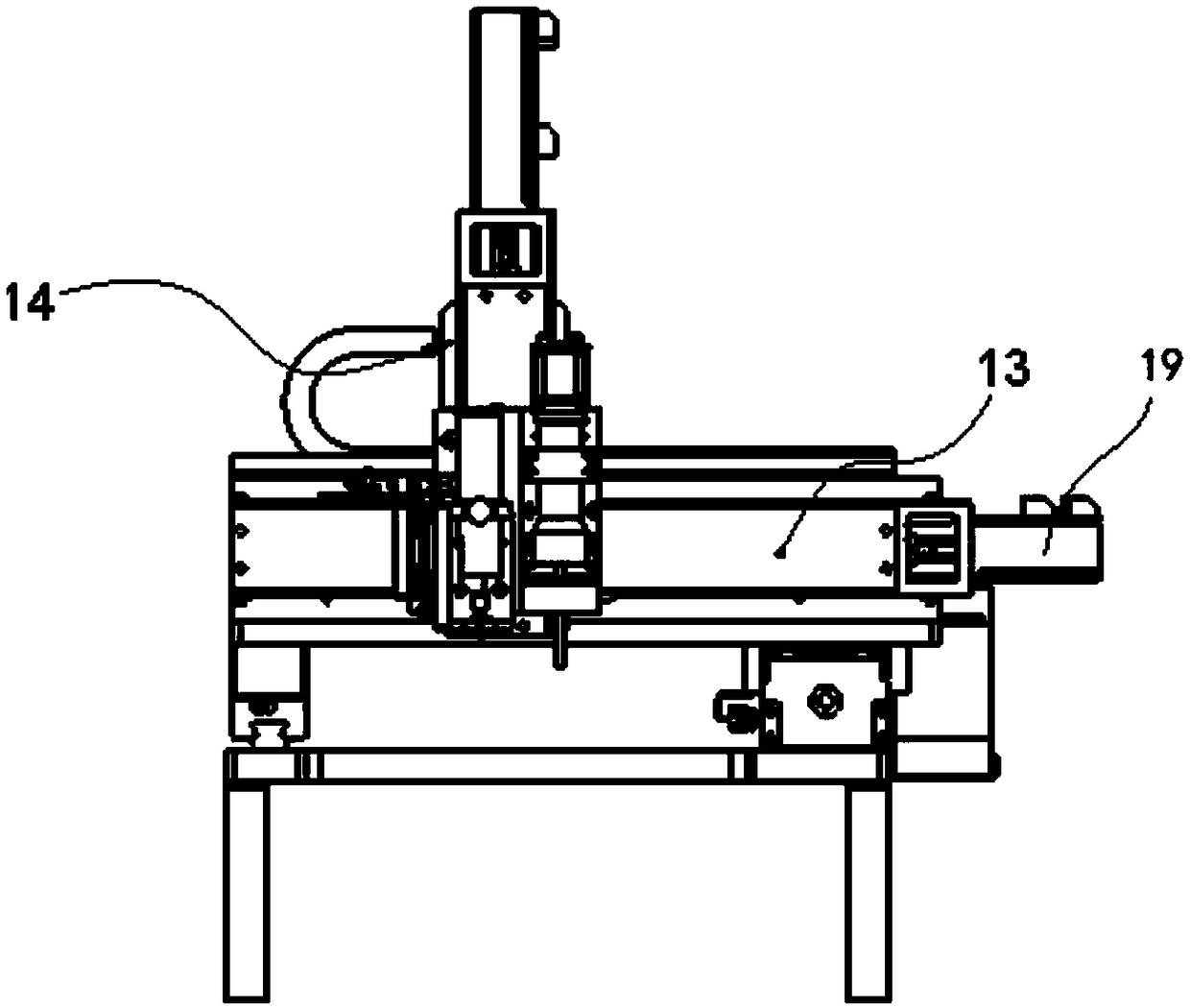

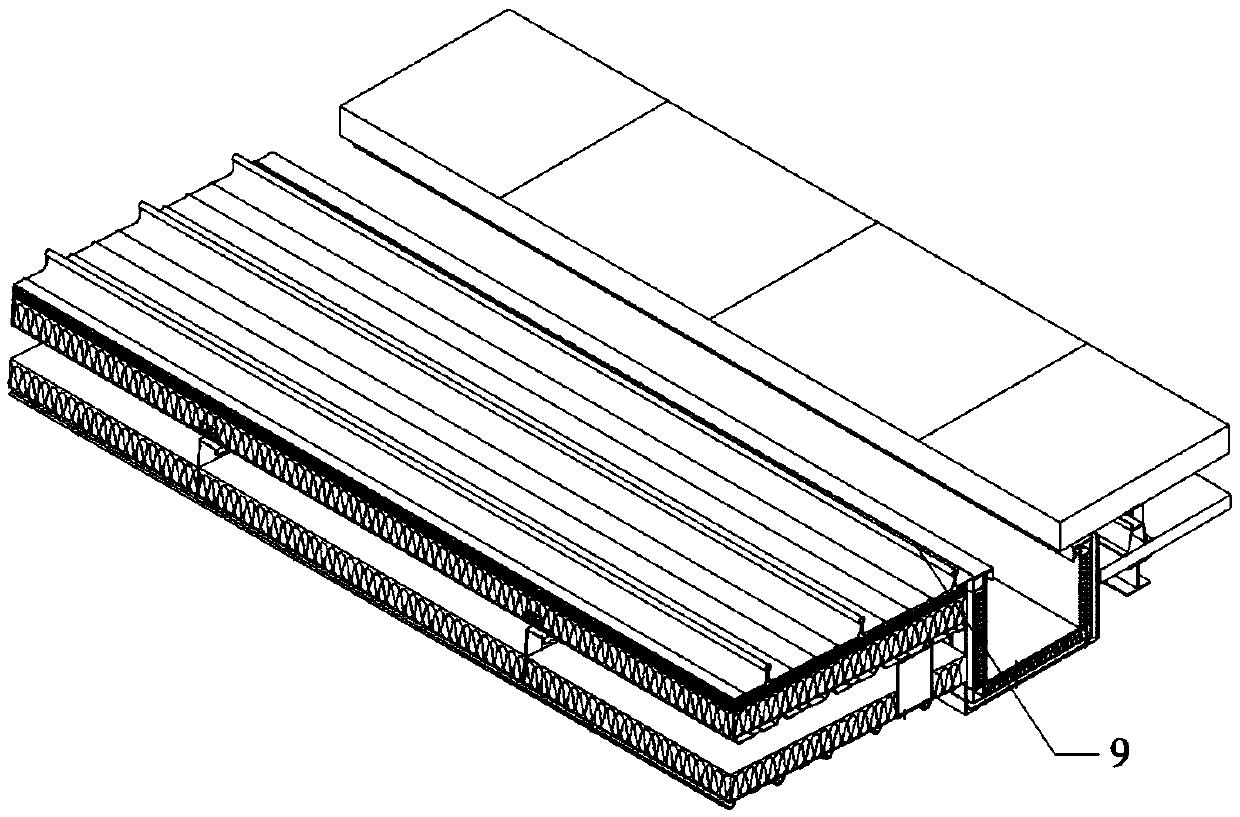

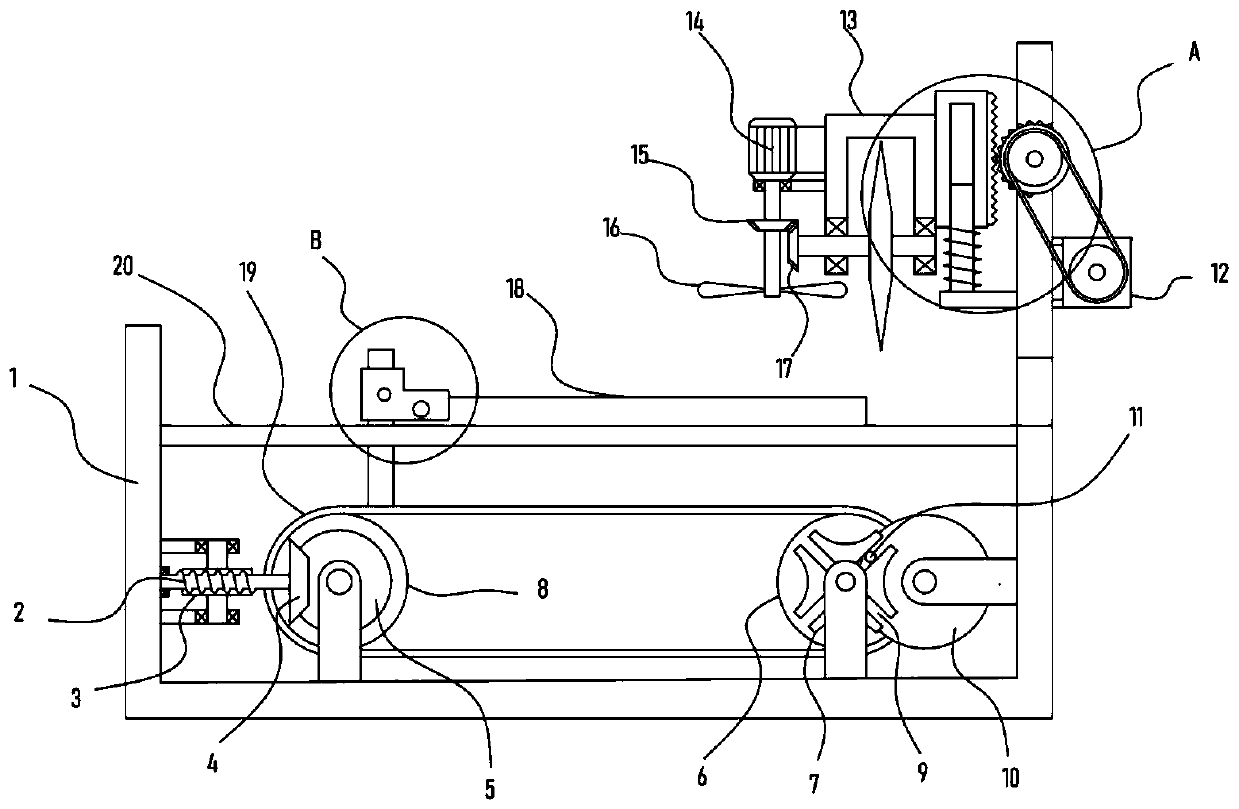

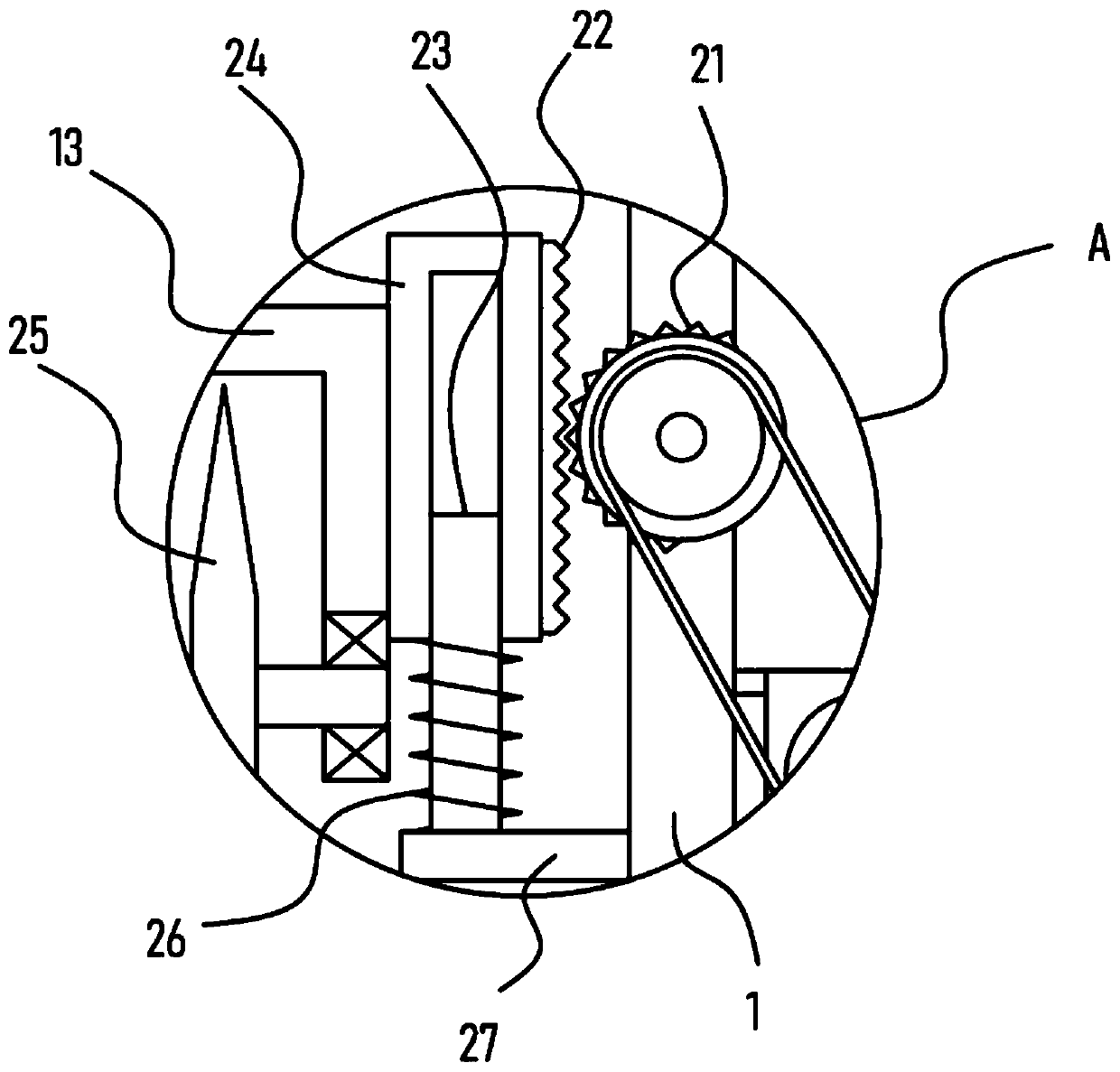

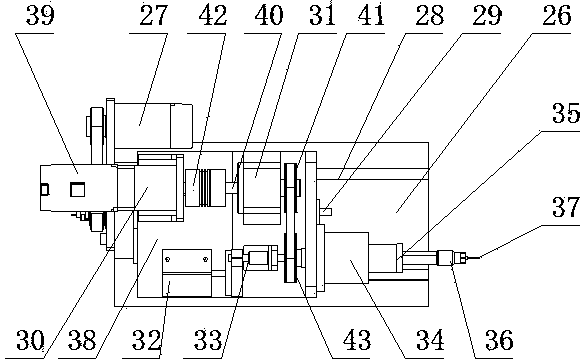

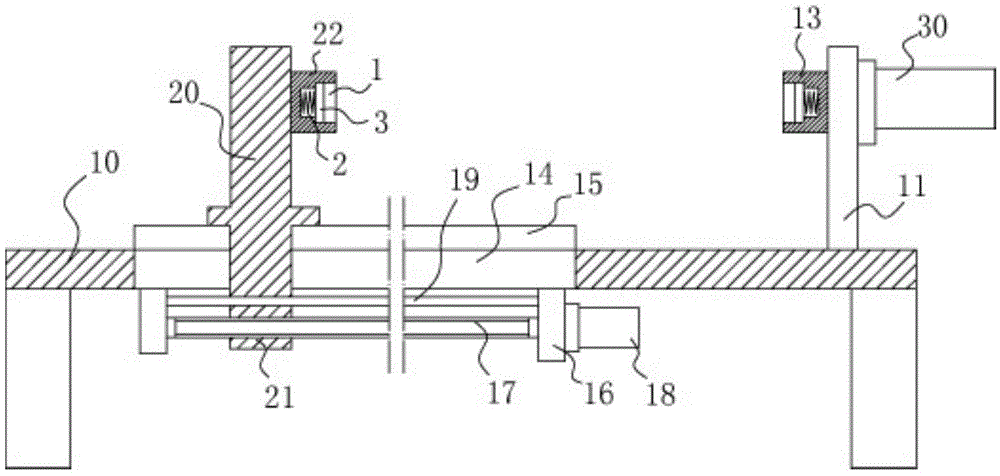

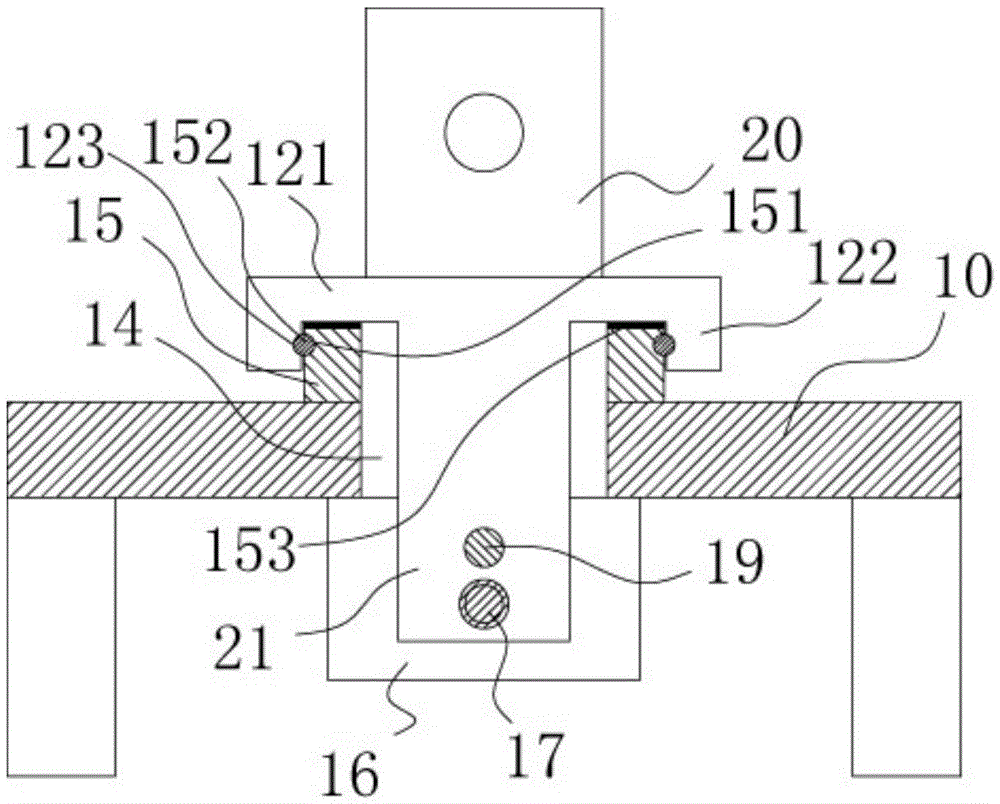

Full-automatic board separating machine

InactiveCN105150251AReduce the amount of manual laborHigh split efficiencyMetal working apparatusProcess engineeringWaste material

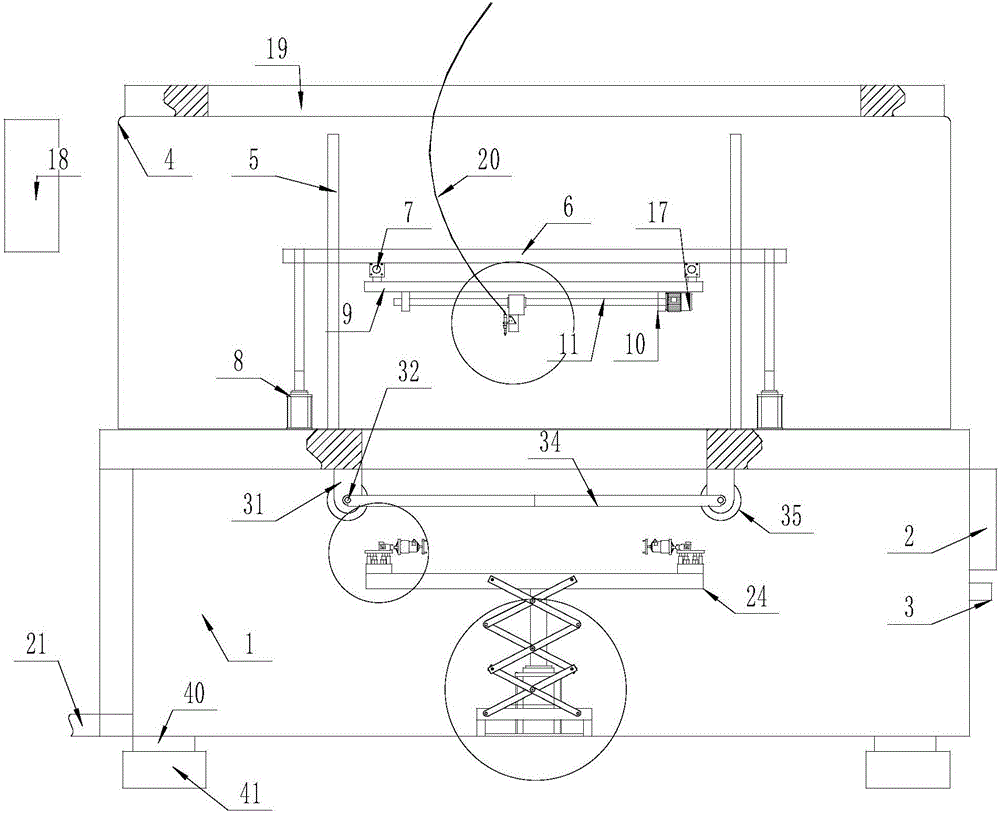

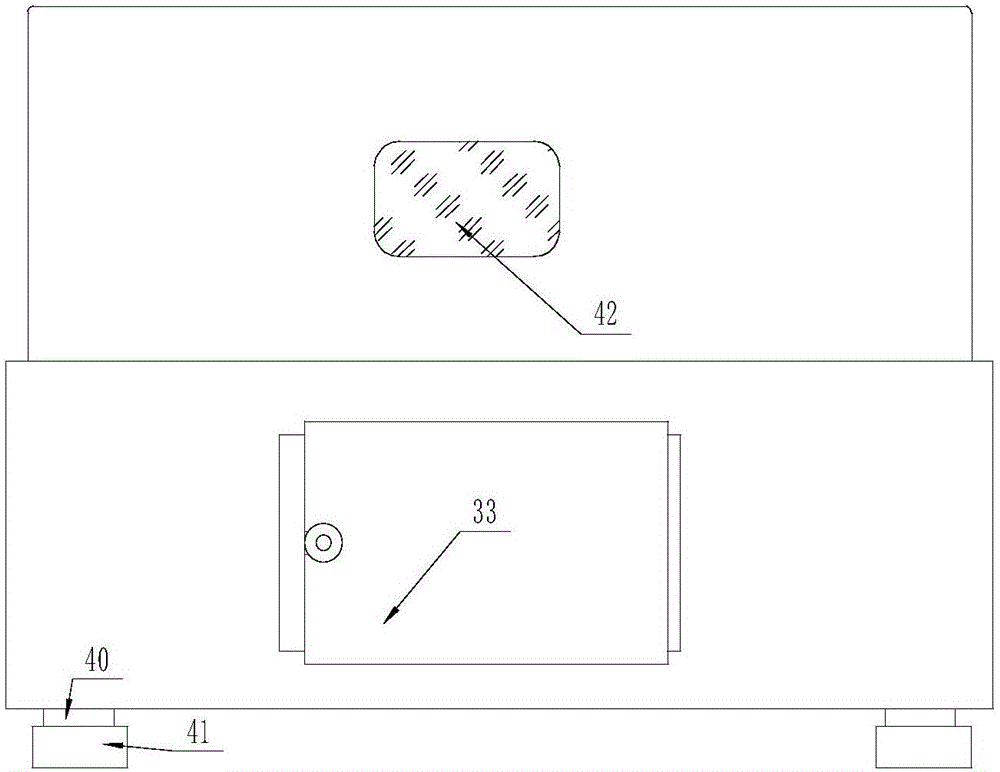

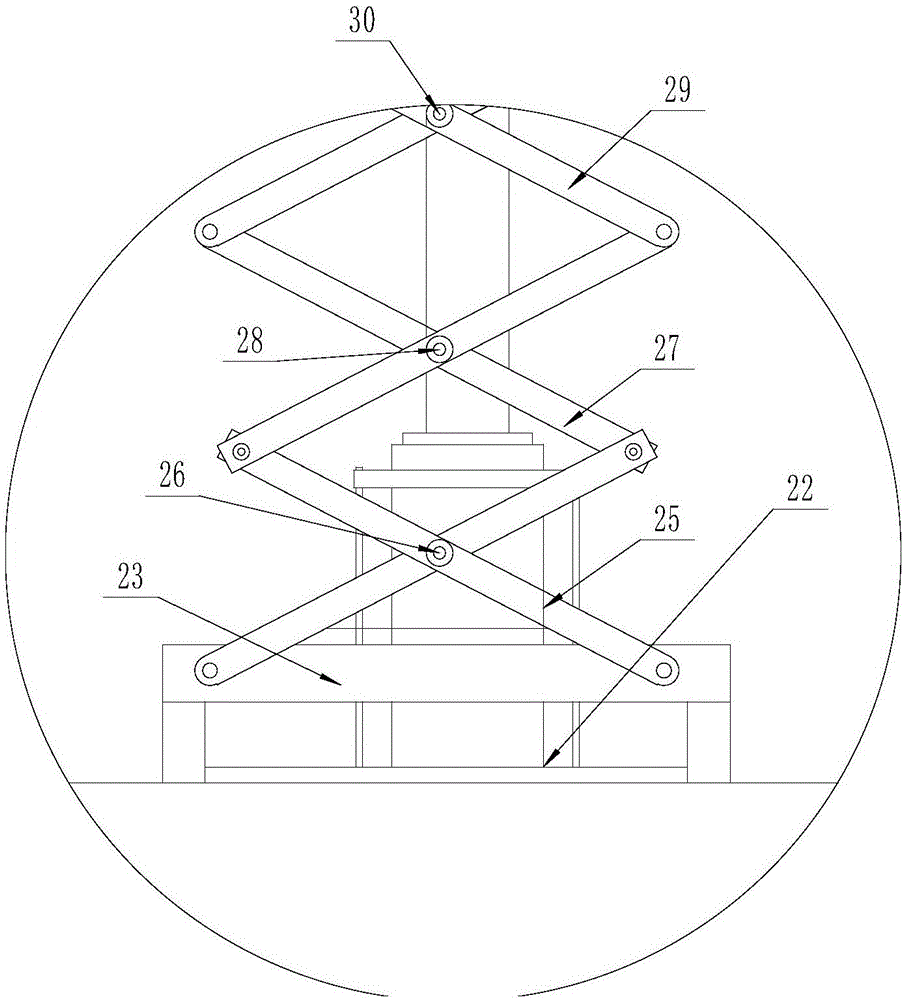

The invention discloses a full-automatic board separating machine. The full-automatic board separating machine comprises a machine base, a feeding device, a waste material collecting mechanism, cutting tools, a moving device and a conveying device. The feeding device is used for conveying circuit boards to be cut, the waste material collecting mechanism is used for collecting cutting waste materials, the moving device is used for driving the cutting tools to move, and the conveying device is used for conveying the cut circuit boards. In this way, the feeding device, the waste material collecting mechanism for collecting the cutting waste materials, the cutting tools, the moving device driving the cutting tool to move and the conveying device for conveying the cut circuit boards are combined to form the board separating machine, the board separating machine achieves feeding, cutting, waste material collecting and circuit board conveying automation, and the sum of labor is reduced; the two cutting tools are used for cutting at the same time, and therefore the board separating efficiency is improved effectively; in addition, the driving mode of moving the cutting tools in multiple directions enlarges the cutting range, and the board separating machine can cut the large circuit boards and is wider in application range.

Owner:ACBEL ELECTRONICS DONG GUAN

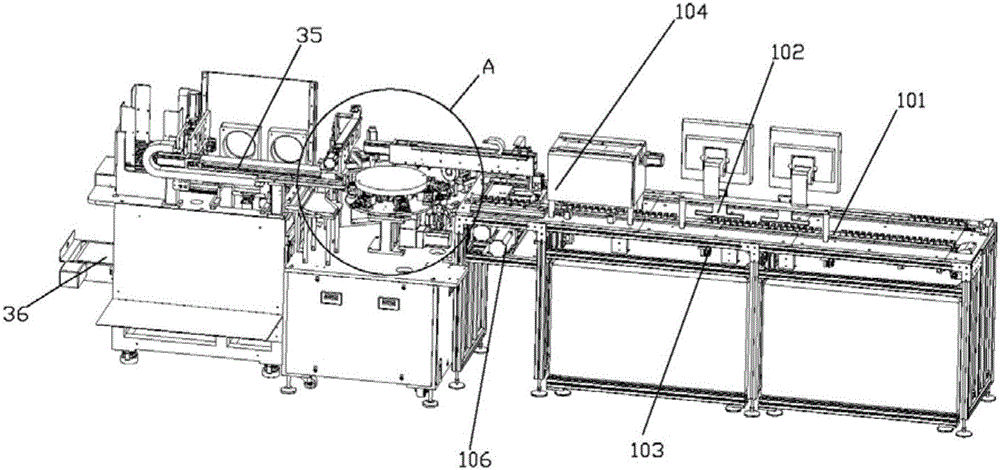

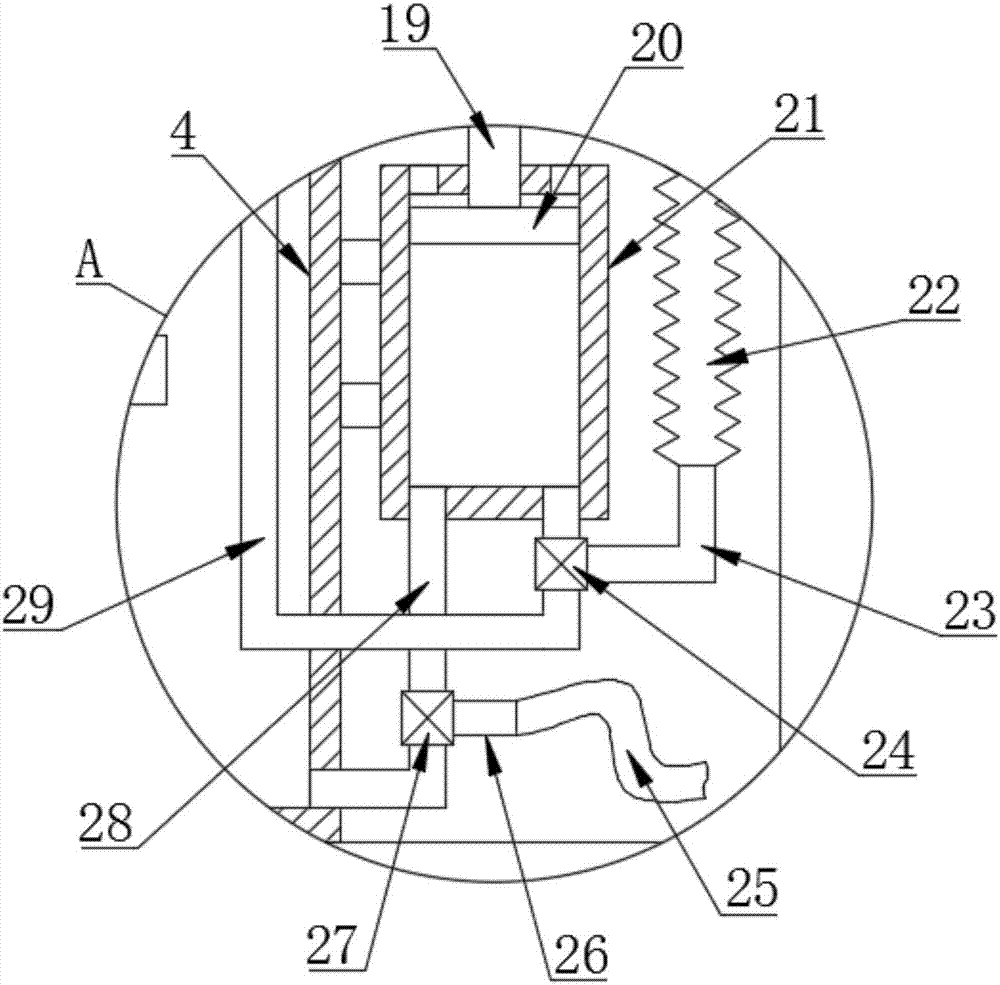

Automatic sensor detection machine

InactiveCN106733733AReduce the amount of manual laborImprove detection efficiencyPrintingSortingElectricityEngineering

The invention discloses an automatic sensor detection machine. The automatic sensor detection machine comprises a front end circulation type feeding unit, a middle multi-station rotary disc type detection unit and a rear end material arranging and box discharging unit. Products are conveyed through the front end circulation type feeding unit, subjected to magneto-electricity parameter detection and sorted and enter a feeding station of the middle multi-station rotary disc type detection unit, the products pass a mechanical appearance precision related parameter detection station of the middle multi-station rotary disc type detection unit and are subjected to related parameter detection, then defective products are pushed into an NG material box, qualified products are conveyed to a next station, a clamping mechanism on the middle multi-station rotary disc type detection unit is used for rotating the products by 90 degrees, and after the products are rotated by 90 degrees, a code spraying device is used for conducting code spraying on the products, the products obtained after code spraying are conveyed to a discharging station, and a discharging clamping device on the discharging station conducts flow division on the products according to parameter specifications. The whole detecting, sorting and code spraying processes are automatically operated, the manual work labor amount is greatly reduced, the product detecting, sorting and code spraying efficiency is improved, sorting is conducted after layer-by-layer detection, and the product quality is improved.

Owner:东莞市五鑫自动化科技有限公司

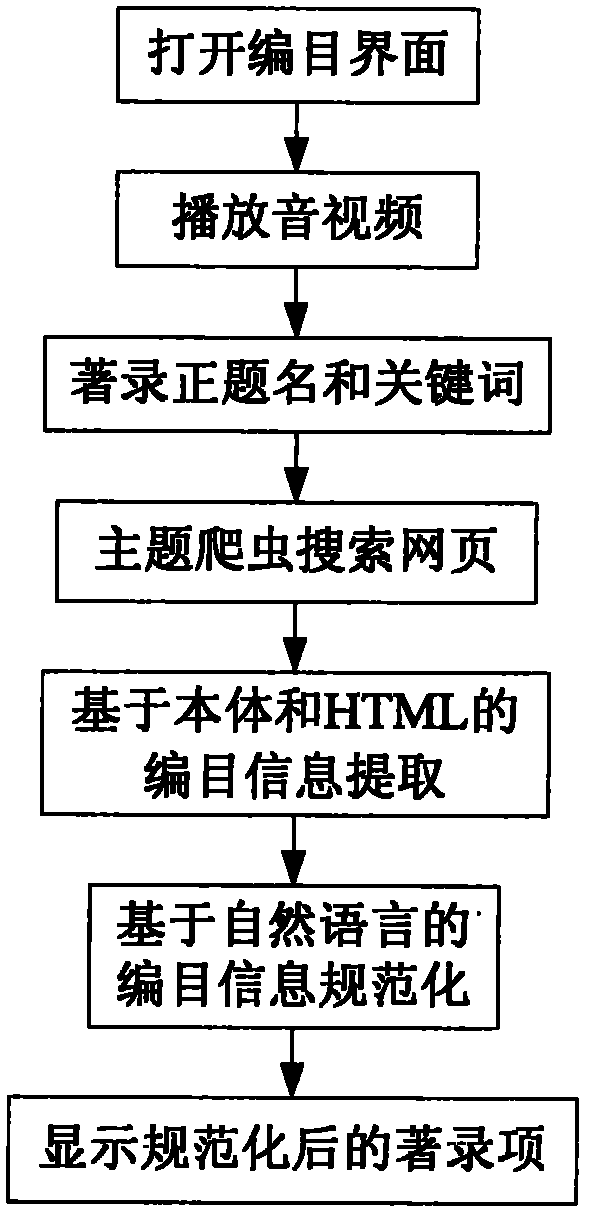

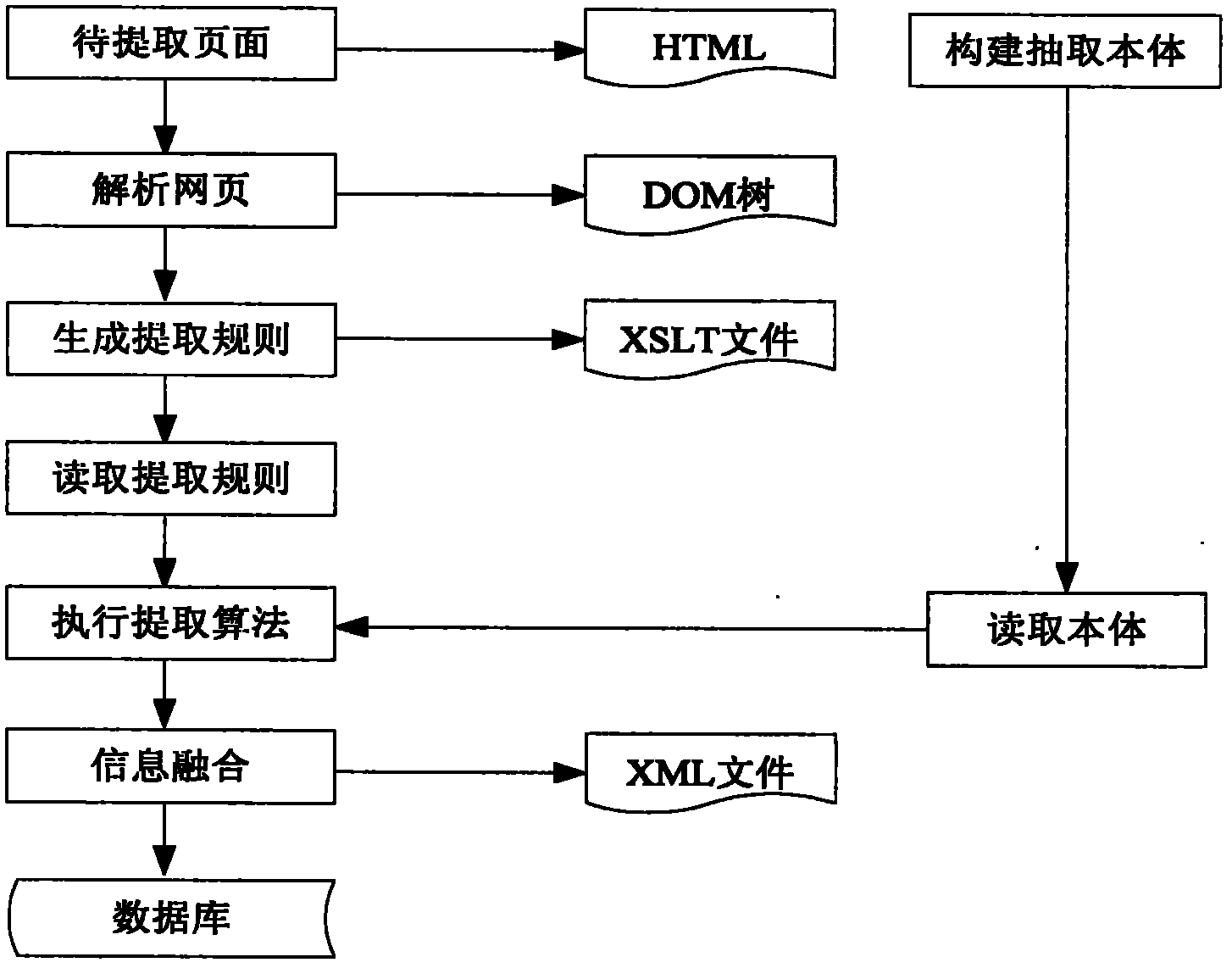

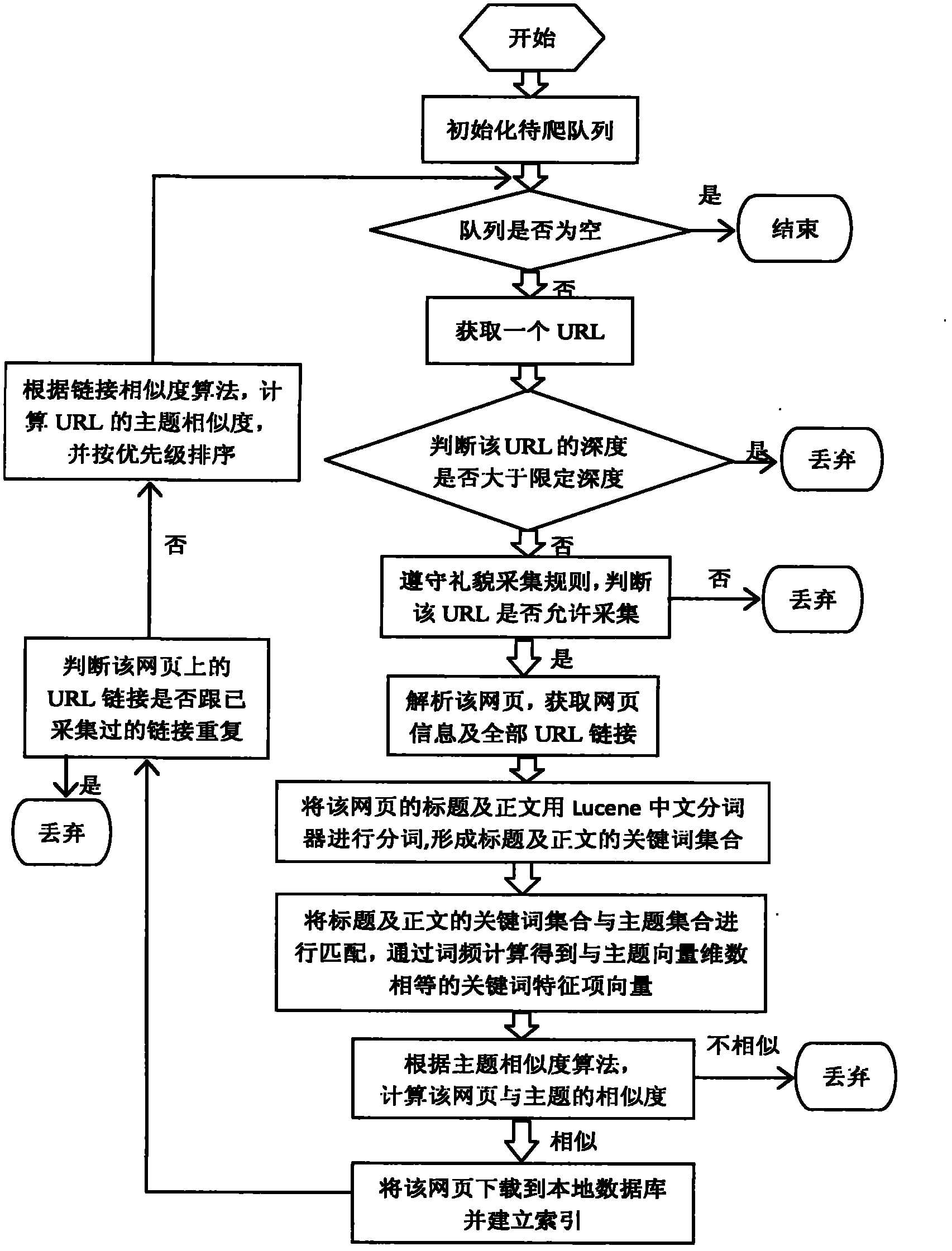

Audio/video intelligent catalog information acquisition method facing to wide area network

InactiveCN101968819AAdapt to different needsAdapt to the environmentSpecial data processing applicationsUniform resource locatorFile area network

The invention relates to an audio / video intelligent catalog information acquisition method facing to a wide area network, belonging to the field of computer application, which is characterized in that a weighting algorithm based on position factors of keyword characteristic items is offered; different weighting factors are endowed to the characteristics of different positions in a file so that the theme similarity of webpage contents can be more accurately calculated; a link with higher theme similarity is optimally selected by comprehensively utilizing three aspects of the factors of the similarity of the webpage contents, the URL (Uniform Resource Locator) catalog level information of an ultra-link and the anchor text information of the ultra-link; the cataloguing information of the searched theme webpage is automatically extracted by adopting an information extraction method based on the body and HTML (Hypertext Markup Language); and the extracted cataloguing information is standardized by adopting an improved semantic similarity calculation method. The invention has the advantages that the description item information can be intelligently and automatically provided to a lister; the labor capacity of workers is reduced; the cataloguing efficiency is enhanced; and the method can adapt to different requirements of professional and non-professional listers and wide area network environment.

Owner:COMMUNICATION UNIVERSITY OF CHINA

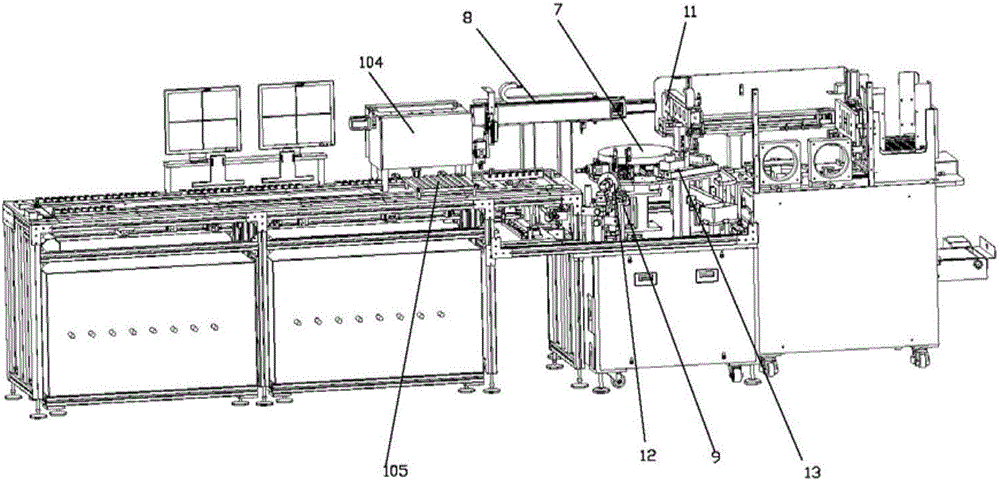

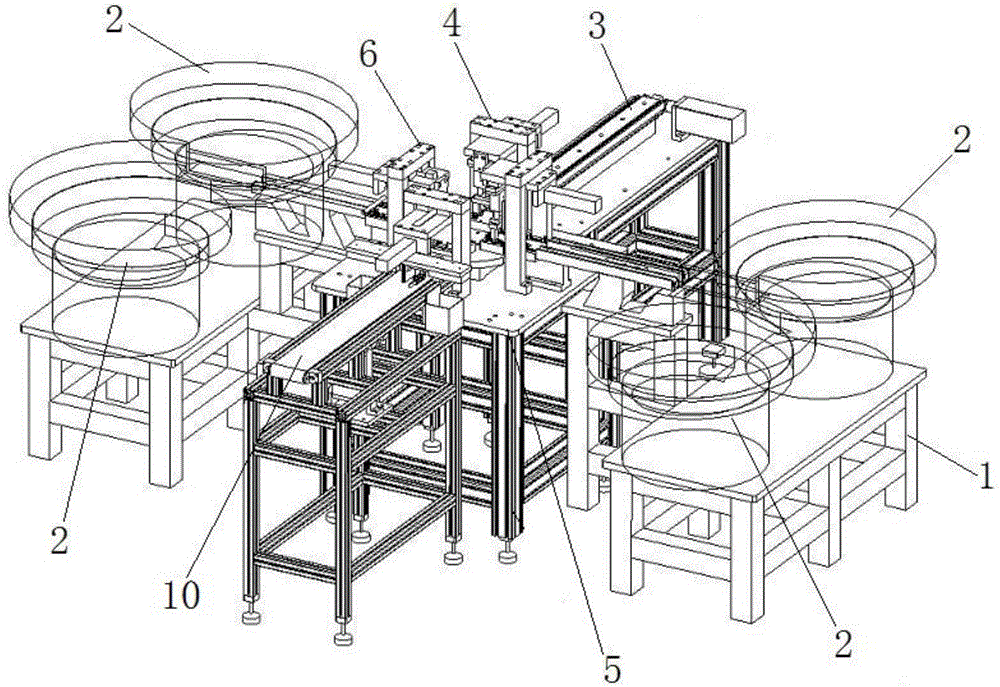

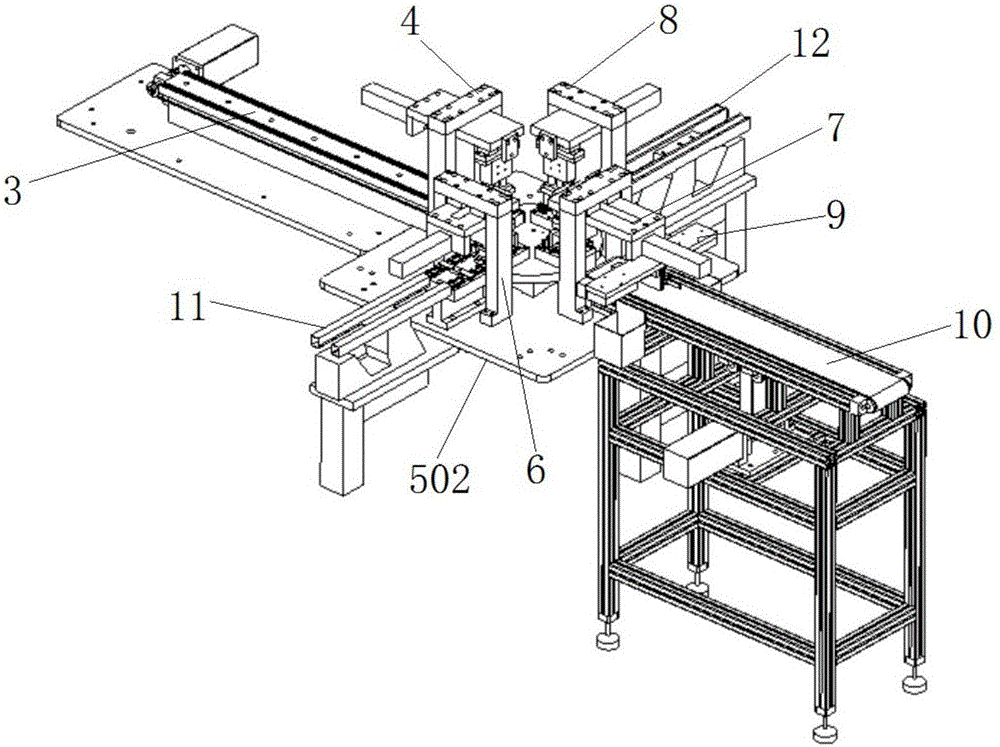

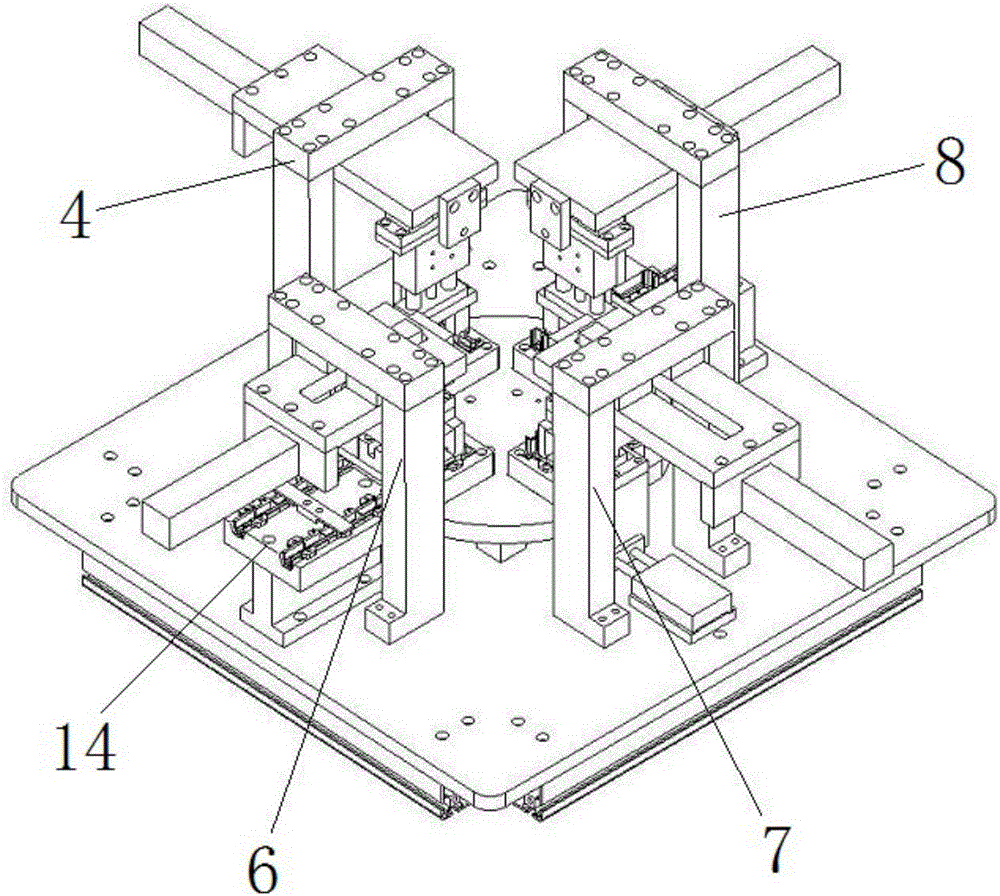

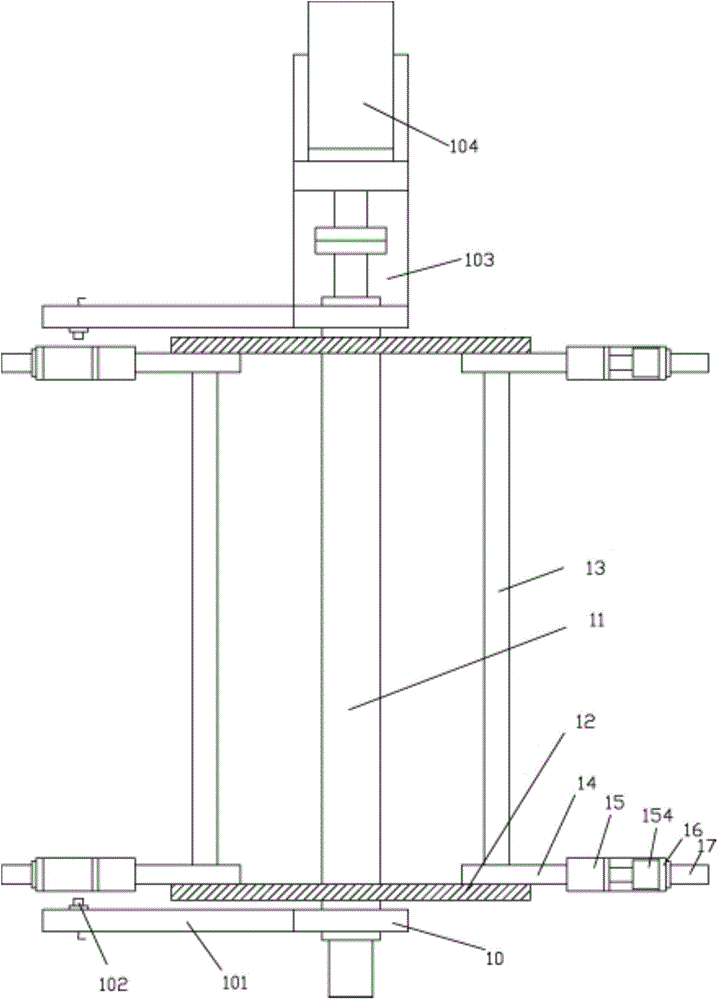

Automatic multi-station carbon brush assembly machine

ActiveCN106451025AIncrease productivityPrecise positioningContact member cases/bases manufactureMetal working apparatusEngineeringAssembly machine

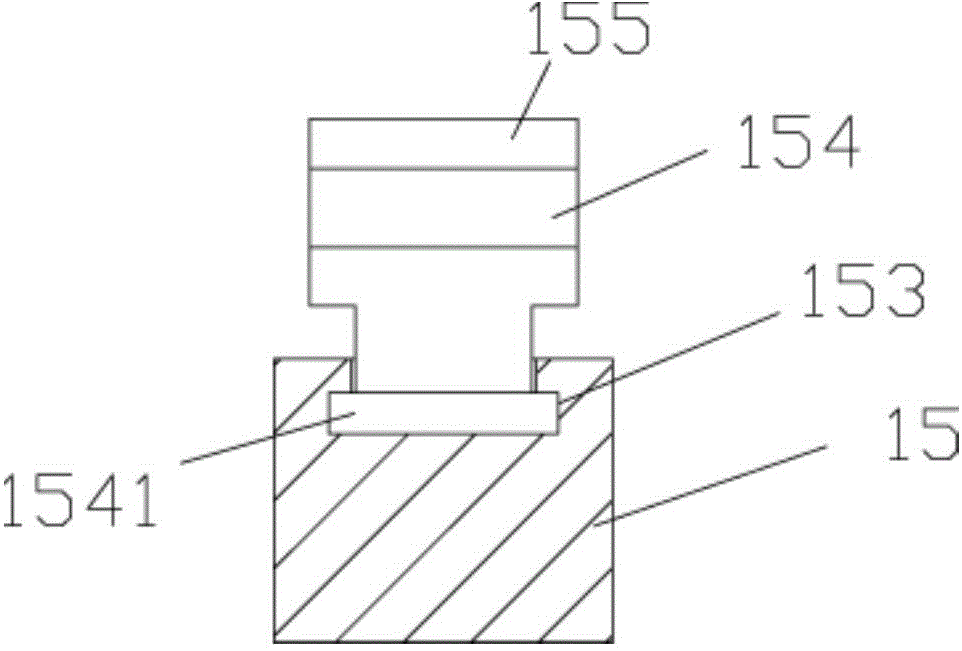

The invention belongs to the technical field of carbon brush production equipment and discloses an automatic multi-station carbon brush assembly machine. The automatic multi-station carbon brush assembly machine comprises a frame, an index plate, a feeding device, a first assembly station, a second assembly station, a third assembly station and a fourth assembly station. The fourth assembly station is connected with the feeding device used for conveying finished carbon brush products. Each of the first assembly station, the second assembly station, the third assembly station and the fourth assembly station comprises a support, a slide seat, a driving device, a lifting platform and a mechanical claw, wherein the slide seat is horizontally arranged on the support. The fourth assembly station further comprises a detection device and a push-out device, the detection device comprises a retractable execution device and a push block, the retractable execution device and the push block are in mutual connection, and a push fork plate matched with a carbon brush part is arranged on the push block. By arrangement of four stations, assembly of different parts and detection of finished products are completed, high automation degree and high efficiency are realized, and carbon brush assembly rate and yield are increased effectively.

Owner:太仓克米特自动化设备有限公司

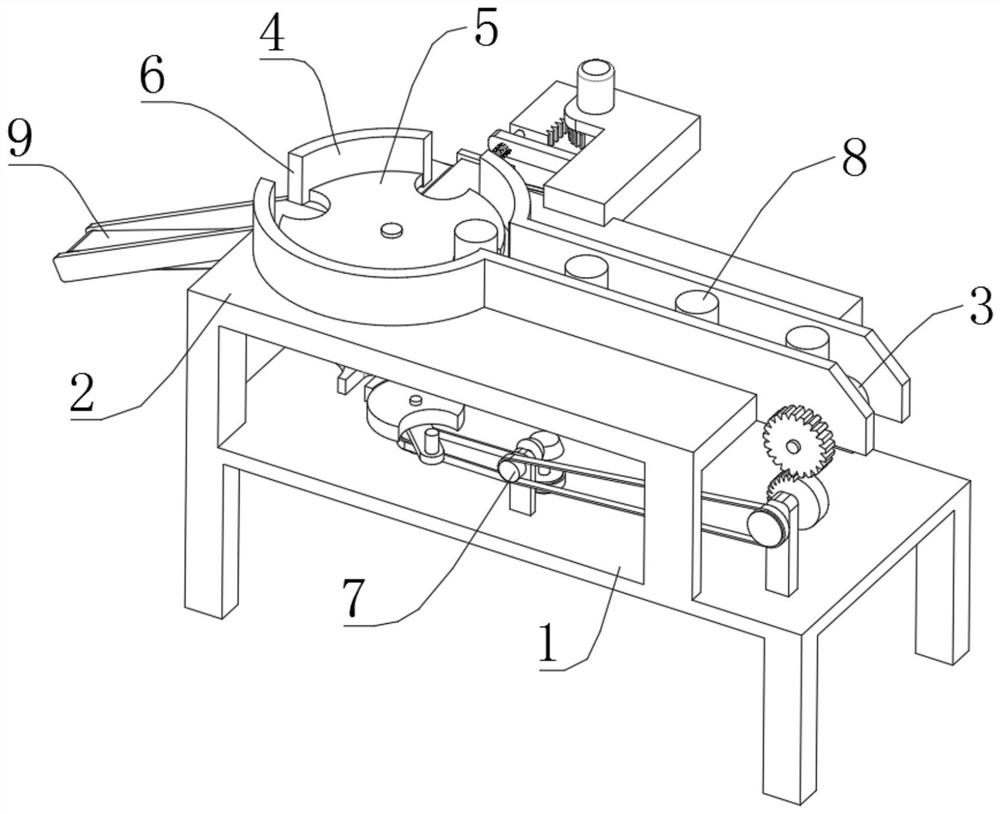

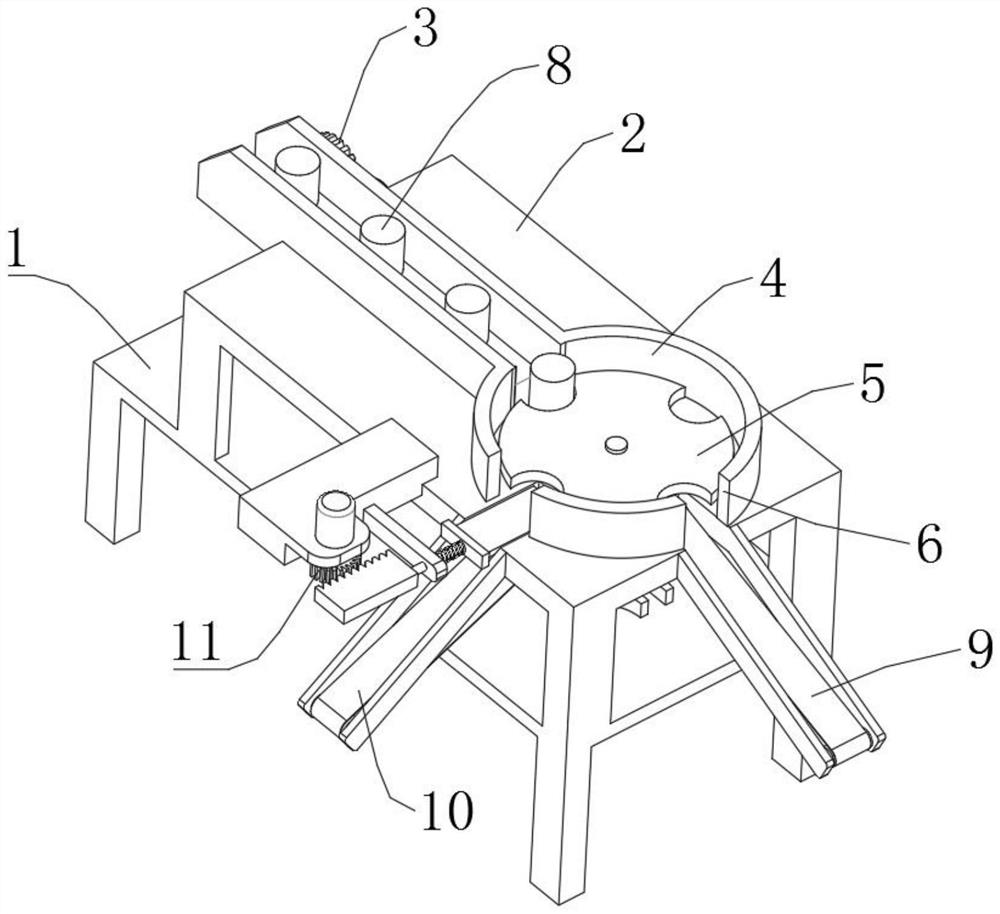

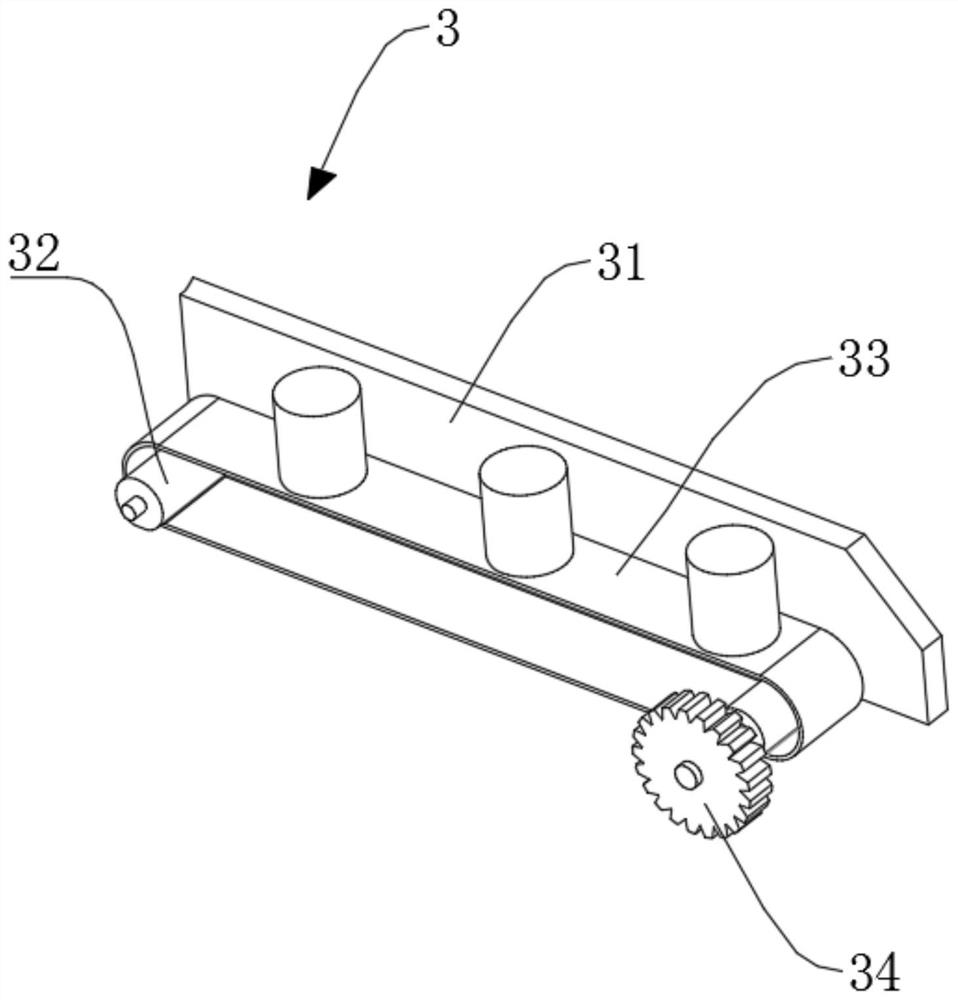

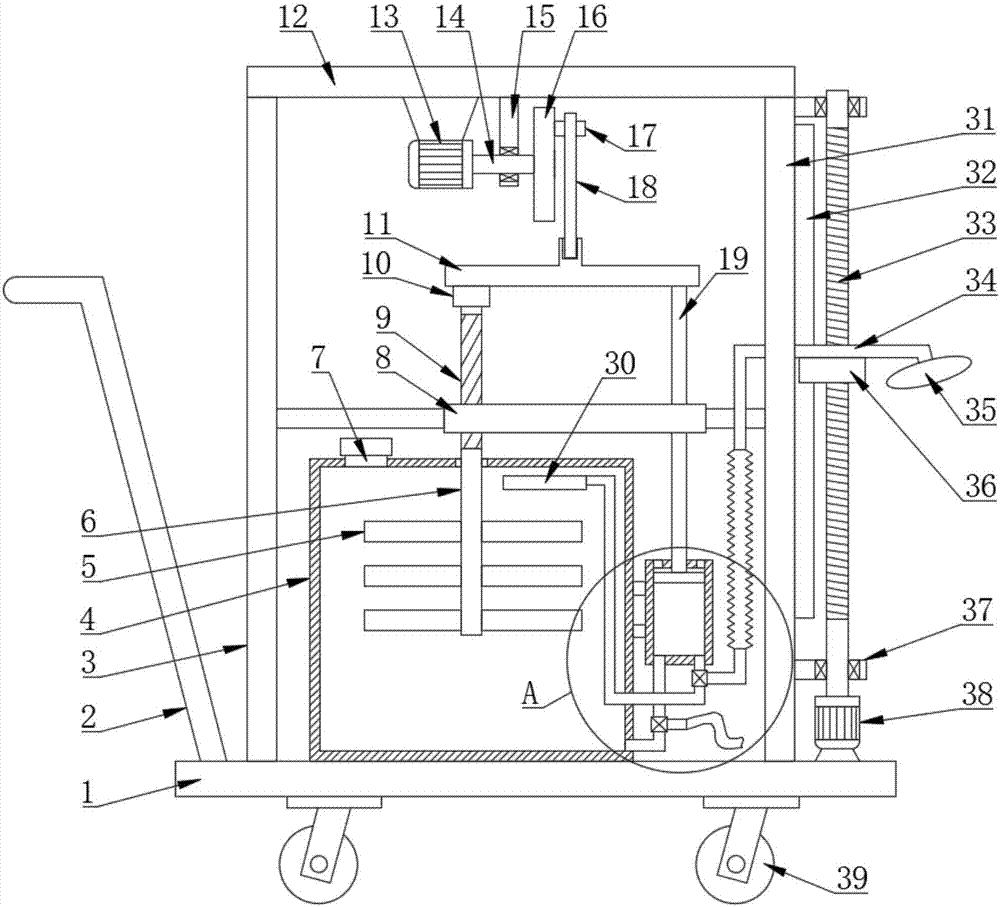

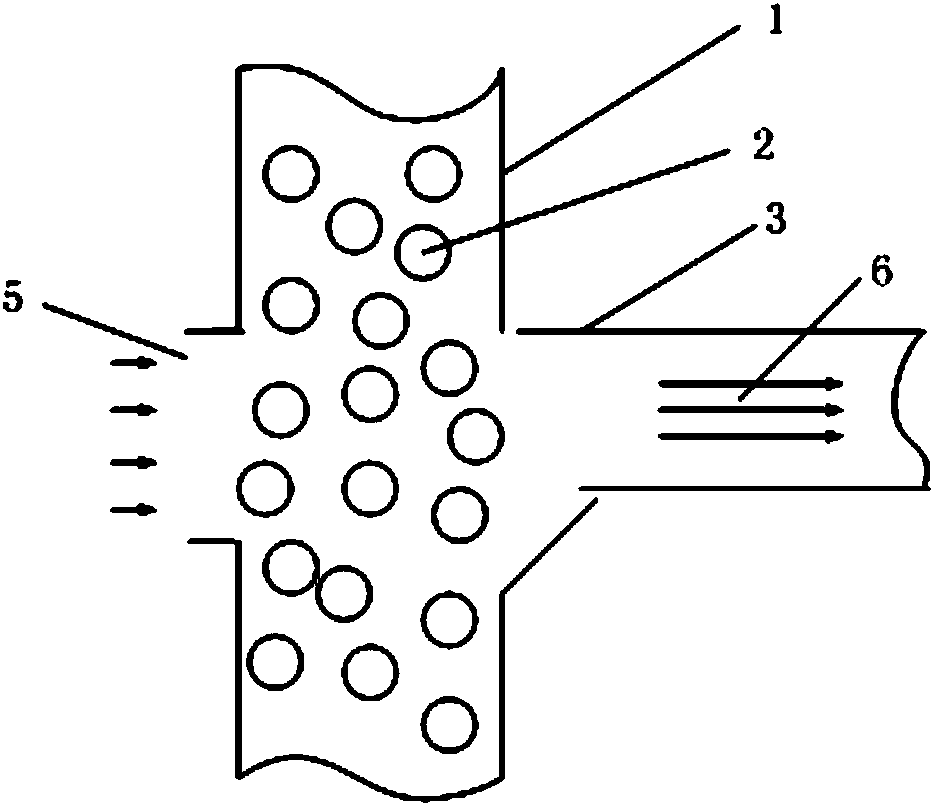

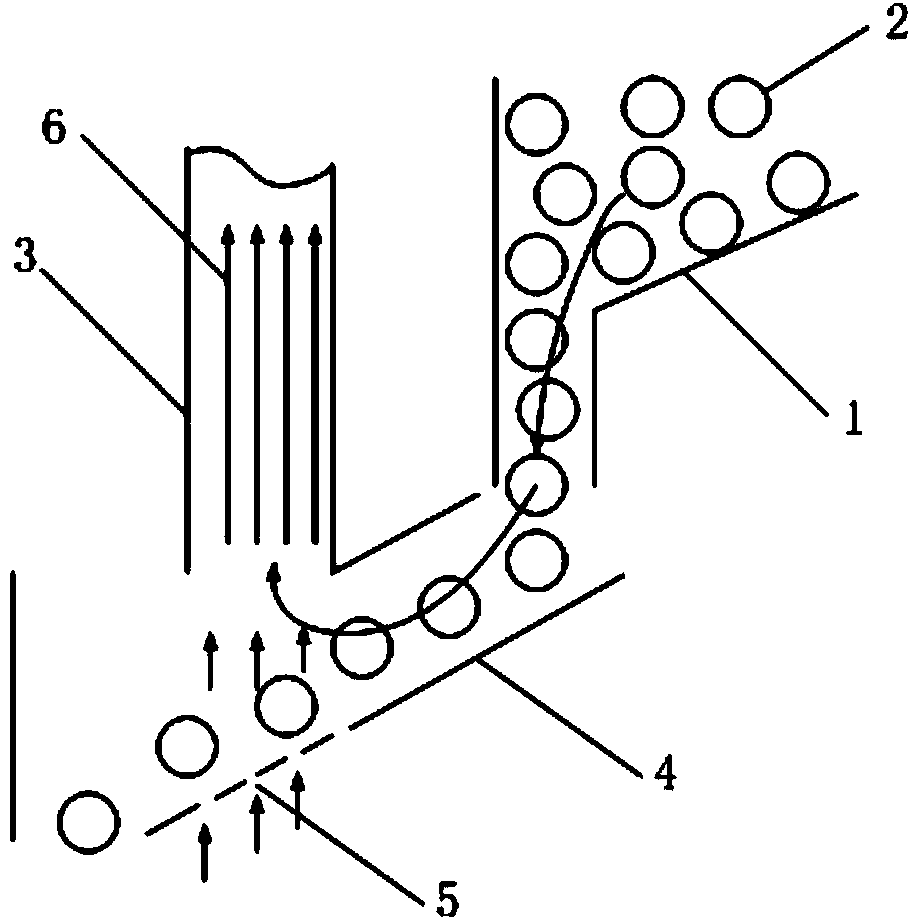

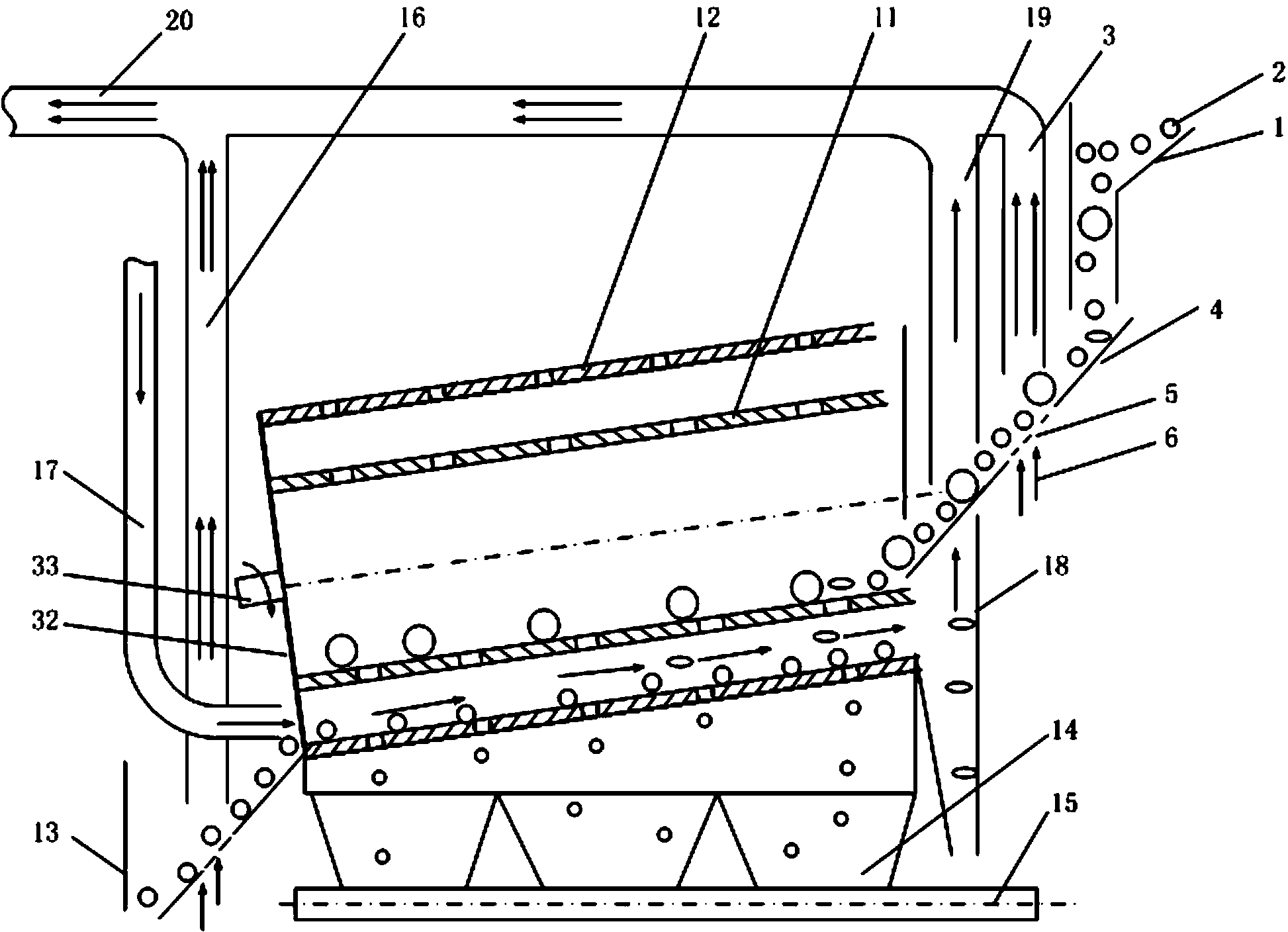

Casting carrying and separating equipment

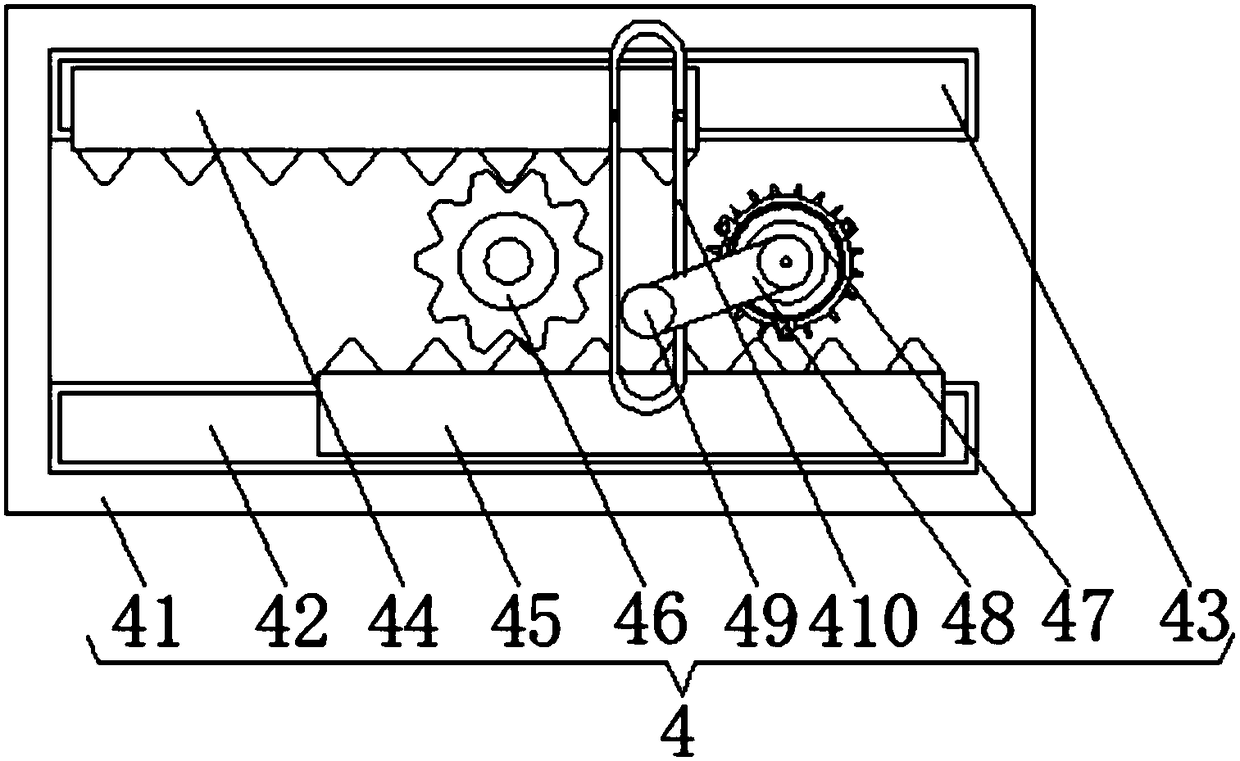

PendingCN111776686ARealize automatic feeding processOrderly arrange the dischargeConveyor partsGear wheelWorkbench

The invention relates to the technical field of casting separation, in particular to casting carrying and separating equipment. The casting carrying and separating equipment comprises a supporting frame. A workbench is installed at the top of the supporting frame. A feeding mechanism is installed at one end of the workbench and comprises a fixed frame plate, two conveying rollers, a conveying beltand a transmission gear. An installation seat is installed at the output end of the conveying belt and is fixedly connected with the top of the workbench. A material separating mechanism is installedon the inner side of the installation seat and comprises a material separating disc. A rotary shaft is fixedly installed at the bottom of the material separating disc. A rotary seat is fixedly installed at the bottom end of the rotary shaft. A plurality of butt joint grooves are formed in the outer extending part of the rotary seat. A rotary disc is arranged on the outer extending part of the rotary seat. The bottom of the rotary disc is fixedly provided with a fixed plate. One end of the top of the fixed plate is fixedly provided with a lug. By means of the equipment, perfect cooperation ofautomatic feeding, automatic separating and automatic discharging of castings is achieved, the manual labor amount is greatly saved, the castings can be arranged and discharged in order, and accumulation is avoided.

Owner:林素芹

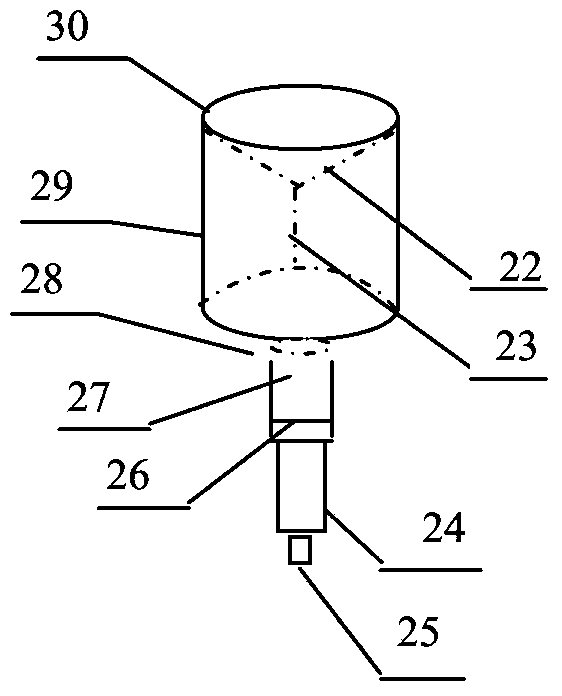

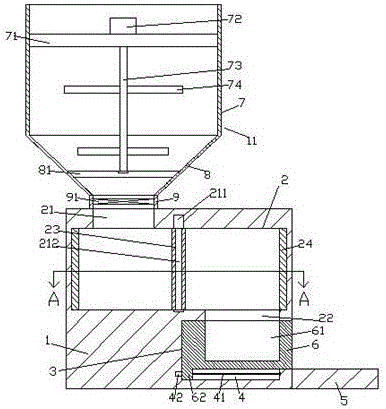

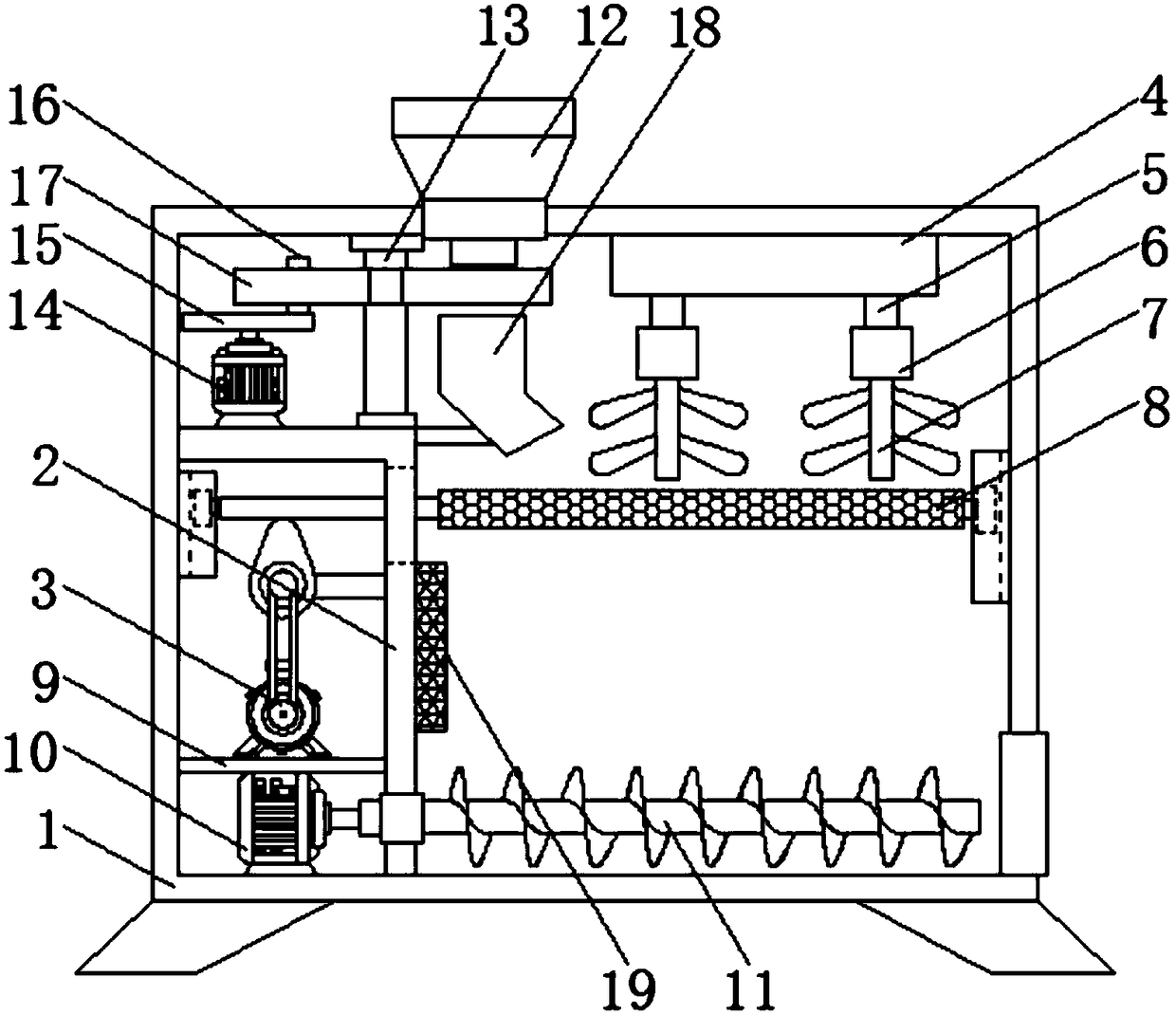

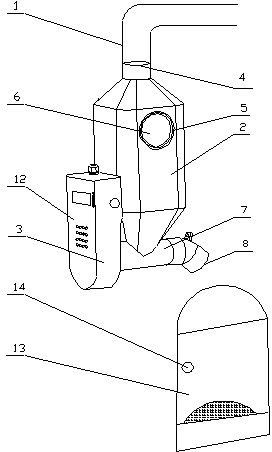

Height-adjustable automatic water-feeding mixing and spraying device of pesticide

ActiveCN107960393AAvoid depositionEasy to sprayTransportation and packagingRotary stirring mixersSpray nozzleEngineering

The invention discloses a height-adjustable automatic water-feeding mixing and spraying device of pesticide. The device comprises a base, and the top of the base is fixedly provided with a pesticide box; the right wall of the pesticide box is also fixedly connected with a pressurization cylinder through a bracket, a water inlet pipe is connected to the left side of the bottom of the pressurizationcylinder, penetrates through the side wall of the pesticide box and is connected to the lower right corner of the interior of the pesticide box, a second three-way valve is arranged on the water inlet pipe, a right end port of the second three-way valve is connected with a water feeding pipe, and the right end of the water feeding pipe is connected with a water feeding hose; a circulating pipe isconnected to the right side of the bottom of the pressurization cylinder, penetrates through the side wall of the pesticide box and is connected to the top of the interior of the pesticide box, a water outlet end of the pesticide box is also fixedly connected with a first spraying nozzle, the circulation pipe is provided with a first three-way valve, and a right end port of the first three-way valve is connected with a water outlet pipe. According to the device, the three different functions of water feeding, pesticide cycle mixing and automatic pesticide spraying can be controlled and achieved by adjusting the communicating directions of the first three-way valve and the second three-way valve, the device is easy to operate and convenient to use, the work efficiency is greatly improved,and the manual labor amount is reduced.

Owner:浙江中日弹簧有限公司

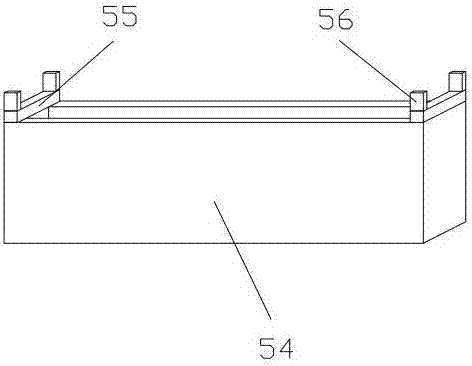

Fabric drum shaft conveying device

ActiveCN104860047AEasy to carryReduce the amount of manual laborConveyorsControl devices for conveyorsEngineeringSupport plane

Owner:启东市固德防水布有限公司

Porcelain molding cleaning equipment with remote control function

ActiveCN106493843ARealize automatic cleaningWith remote control functionWork holdersAuxillary shaping apparatusMicrocontrollerRemote control

The invention discloses porcelain molding cleaning equipment with a remote control function. The equipment comprises an equipment bench, a microcontroller, a signal transmitter and a protection cover located on the equipment bench, wherein the size of the protection cover is matched with that of the equipment bench; a supporting structure is fixed to the bottom face of the equipment bench, a cleaning mechanism and a clamping mechanism are fixed to the equipment bench, an automatic feeding mechanism and a closing mechanism are arranged in the equipment bench, and a charging mechanism is arranged outside the equipment bench. The porcelain molding cleaning equipment has the advantages that porcelain can be placed on a feeding plate, automatic cleaning can be achieved by replacing a fixture matched with the porcelain, and meanwhile the equipment has the remote control function, is more convenient and more rapid to operate and can reduce the manual labor amount.

Owner:WENZHOU CHONGYA ELECTRONICS TECH

Fabric tailoring table with cleaning device

InactiveCN107953404APrevent fallingEffective protectionSevering textilesMetal working apparatusFluteBristle

The invention mainly discloses a fabric cutting table with a cleaning device. Its technical proposal includes a workbench and a support frame. Both sides of the workbench are provided with chip falling grooves. The workbench is provided with a cleaning device. The cleaning device includes The driver, the chip suction pipe and the cleaning brush are respectively located on the left and right sides of the workbench. The driver is connected to the chip suction pipe. The driver drives the chip suction pipe to move back and forth on the workbench. The chip suction pipe is connected to the chip suction pump through the connecting pipe. The outlet end of the chip suction pump is connected with the first collection box, the bottom of the chip suction pipe is uniformly provided with chip suction holes, the cleaning brush is detachably connected with the chip suction pipe, and the bottom surface of the cleaning brush is provided with bristles. The invention has a simple structure, and through the joint action of the chip suction pipe and the cleaning brush, it is convenient to remove waste cloth and broken threads on the workbench, greatly improving the cleaning speed and efficiency, reducing the amount of manual labor, and saving manpower.

Owner:王丽春

Bridge pavement maintenance equipment

ActiveCN106758884ARealize automatic control of quantitative supply workAvoid pollutionBridge erection/assemblyRoads maintainencePavement maintenanceAutomatic control

The invention discloses bridge pavement maintenance equipment. The bridge pavement maintenance equipment comprises a base plate, a cone frustum arranged on the base plate and a hopper arranged on the cone frustum, wherein corner columns are arranged at four corners at the bottom of the base plate, wheels are arranged at the bottoms of the corner columns, a handle is fixedly connected to the left end of the base plate, the top end face of the base plate is fixedly connected with the bottom end face of the hopper, the hopper comprises a first bucket part, a second bucket part and a third bucket part, the second bucket part is arranged at the bottom of the first bucket part, the third bucket part is arranged at the bottom of the second bucket part, a first accommodating cavity is arranged in the cone frustum, the top of the left side of the first accommodating cavity is provided with a first port communicated with the third bucket part, the bottom of the right side of the first accommodating cavity is provided with a second port, a second accommodating cavity is arranged in the cone frustum at the bottom of the second port, and a slide groove is arranged in the cone frustum at the bottom of the second accommodating cavity. The bridge pavement maintenance equipment is simple in structure, capable of achieving automatic control, convenient to operate, capable of reducing labor force and worker labor intensity, capable of automatically controlling stirring and discharge and high in cleanliness.

Owner:SHENZHEN YUETONG CONSTR ENG CO LTD

Environment-friendly type composite grain scalping machine

ActiveCN103521452AImprove cleaning efficiencyReduce dustSievingGas current separationBaghouseAgricultural engineering

The invention discloses an environment-friendly type composite grain scalping machine. The environment-friendly type composite grain scalping machine comprises a multi-layer circular cylindrical screen, a negative pressure winnowing and dust removing device, an organic impurity processing device and a cloth bag dust removing device, wherein the cloth bag dust removing device comprises a draught fan and a cloth bag dust remover, the negative pressure winnowing and dust removing device is arranged on a grain inlet and a grain outlet, and a negative pressure wind pipe is connected with an inlet pipeline of the cloth bag dust remover. The environment-friendly type composite grain scalping machine has the advantages of being high in grain scalping efficiency, clean in cleaned grain, little in raised dust, environmentally friendly and the like, organic impurities can be removed, and the safety of grain which is put in storage is ensured.

Owner:XIAN XIN GU CORN PROD

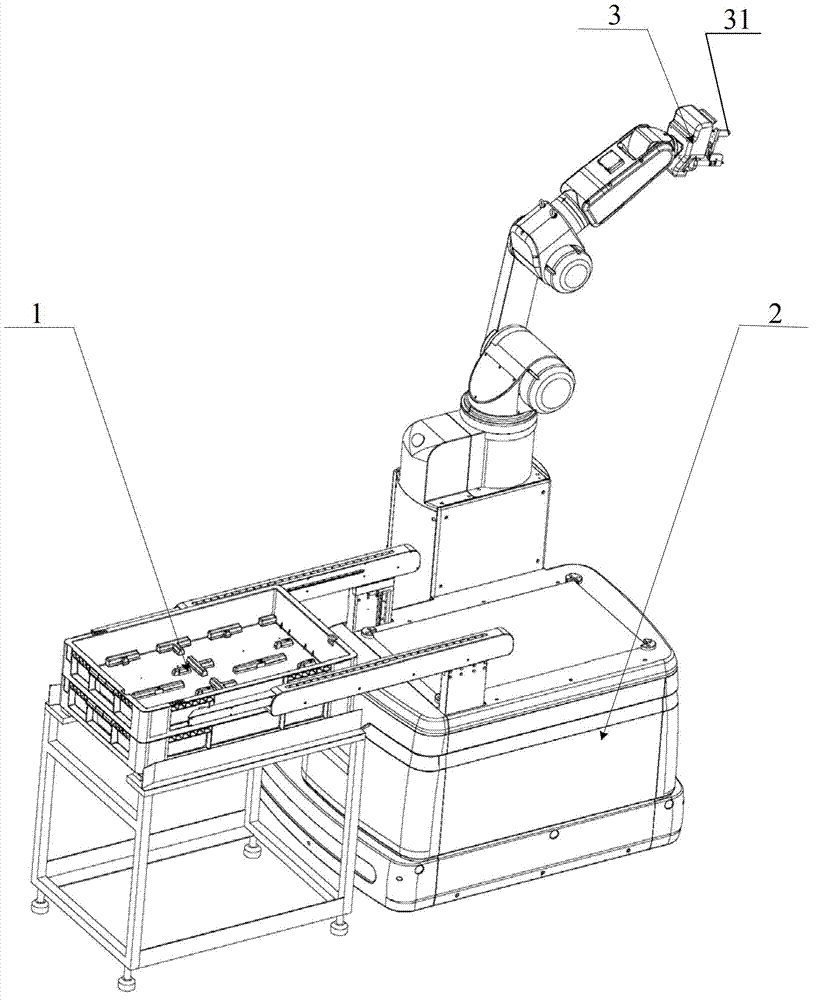

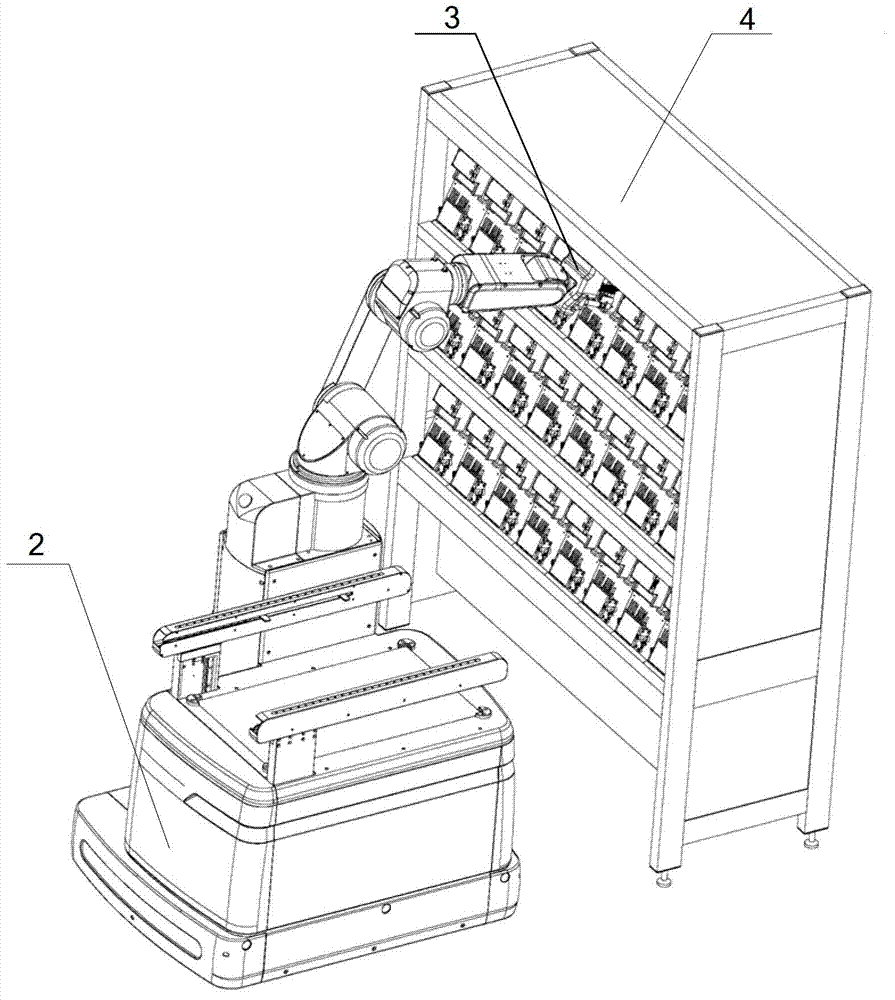

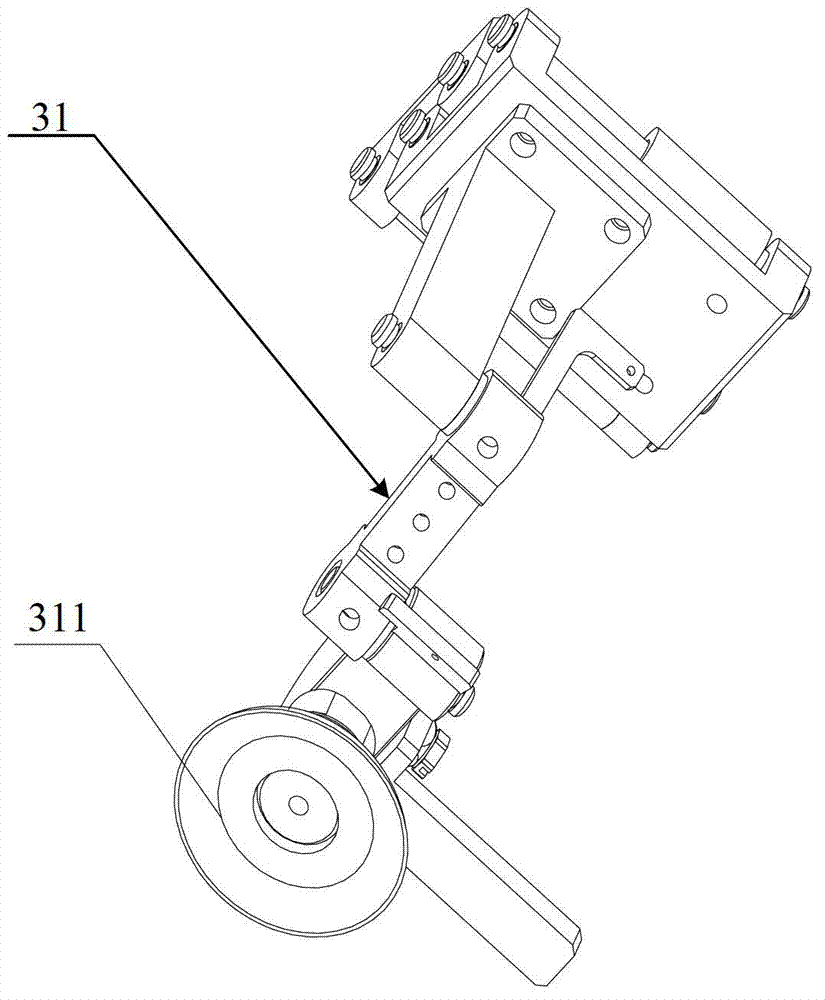

Control method and control system for electric energy meter verification robot

InactiveCN102788966AReduce the amount of manual laborImprove work efficiencyProgramme-controlled manipulatorElectrical measurementsElectricity meterElectric energy

The invention discloses a control system for an electric energy meter verification robot. The control system comprises a base plate, a manipulator, a verification device, a master control computer and a servo system. The base plate is provided with a position for storing an electric energy meter transfer box, and the electric energy meter transfer box with an electric energy meter position is arranged on the base plate. The manipulator is used for taking and putting an electric energy meter and cooperates with the electric energy meter verification device to complete part of electric energy meter detection items, and a video acquisition device used for acquiring image information is arranged on the manipulator. The verification device is provided with an electric energy meter position and used for holding the electric energy meter to be detected. The master control computer is used for receiving the image information acquired by the video acquisition device, comparing the image information with preset standard information, computing positional deviation according to the difference value between the image information and preset standard information, and sending signals. The servo system is used for receiving the signals of the master control computer and controlling operations of the base plate and the manipulator. By the aid of the control system for the electric energy meter verification robot, manual labor for taking, putting and detecting the electric energy meter can be effectively reduced, and working efficiency can be improved. The invention further provides a control method for the electric energy meter verification robot.

Owner:CHONGQING ELECTRIC POWER RES INST +2

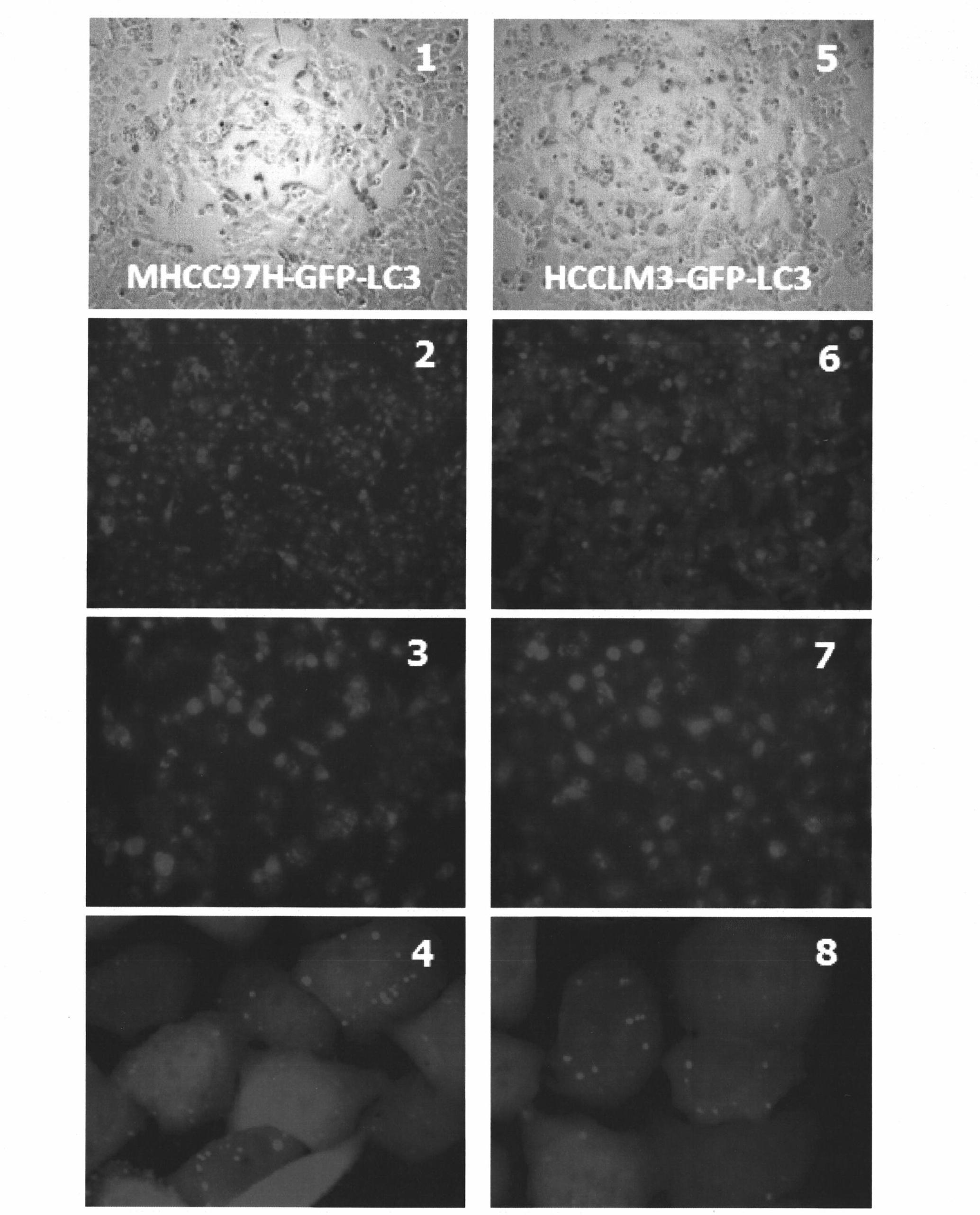

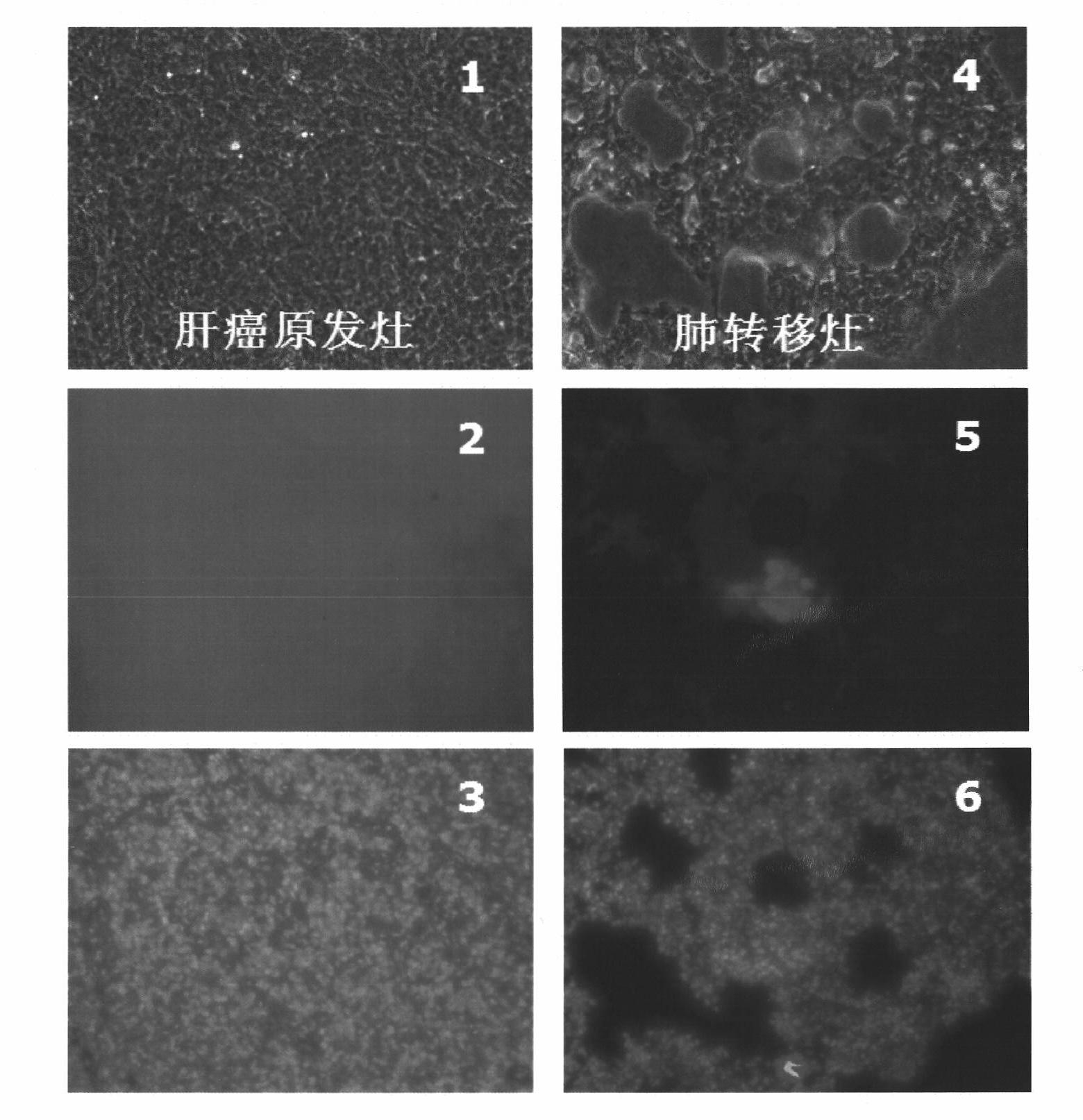

High metastatic potential hepatoma cell line capable of steady autophagy indication, and establishment method and application method thereof

InactiveCN102115730AHigh metastatic potentialDynamic observation of autophagy changesMicrobiological testing/measurementMicroorganism based processesMorphological filterIn vivo

The invention belongs to the field of biomedical science, and aims to provide a high metastatic potential hepatoma cell line capable of steady autophagy indication, and an establishment method and an application method thereof. Lentivirus expression vectors containing EGFP (enhanced green fluorescent protein)-LC3 (light chain 3) autophagy reporter genes are constructed and used to infect hepatoma cells with high metastatic potential, so that host cells can express the EGFP-LC3 steadily and efficiently and indicate autophagy changes of the hepatoma cells steadily. To apply the cell line, metastasis research models can be established in vitro and in vivo for the observation on autophagy changes during metastasis, and the cell autophagy changes can be analyzed rapidly and quantitatively by adopting an image analysis method based on Top-hat operators and morphological filter. The high metastatic potential hepatoma cell line has the characteristics that autophagy indication is conducted steadily, reliably and sensitively in a real-time manner, the metastasis occurs definitely, the autophagy is quantified rapidly and accurately, the operation is simple and convenient, and the like, and can greatly facilitate correlation study on autophagy and metastasis.

Owner:ZHONGSHAN HOSPITAL FUDAN UNIV

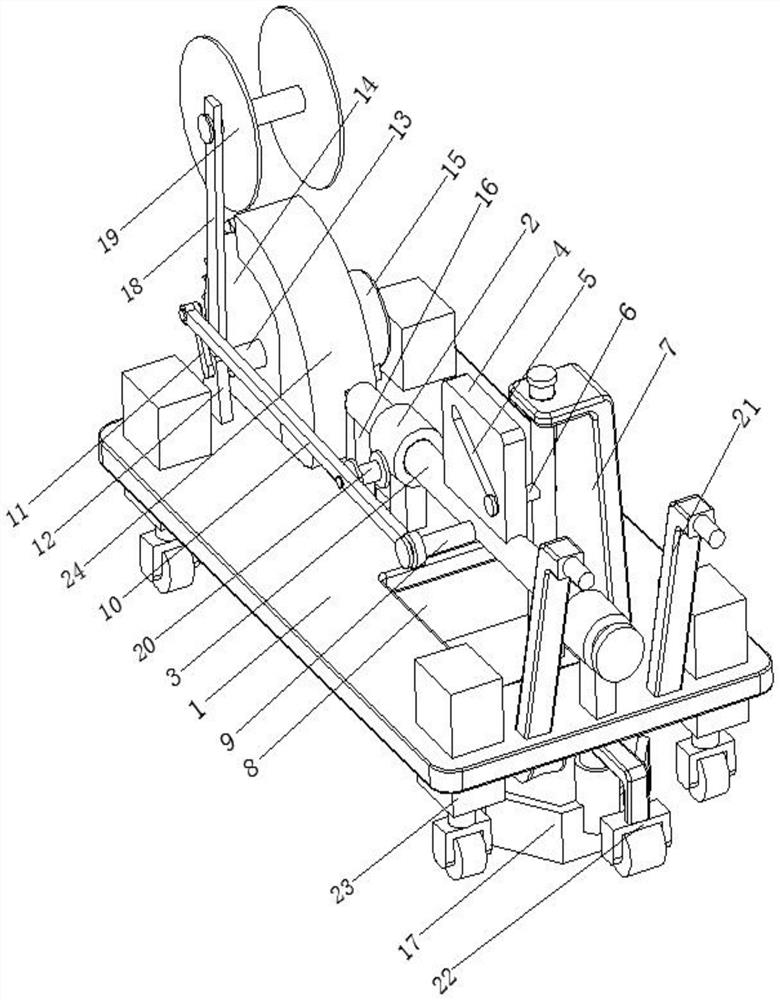

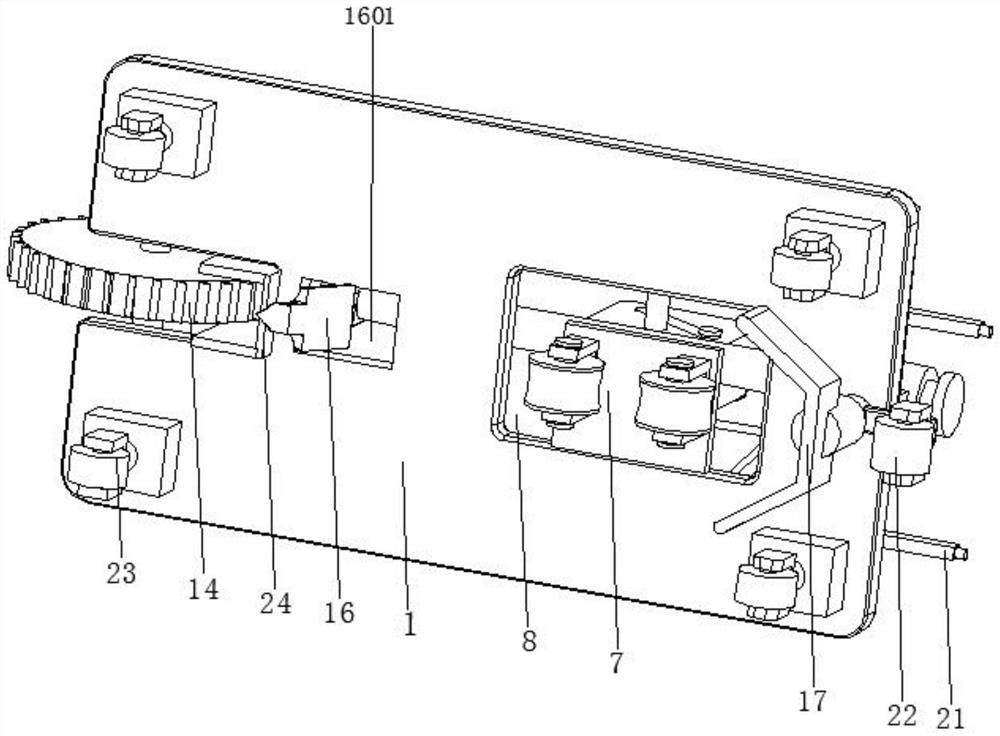

Automatic cable laying machine

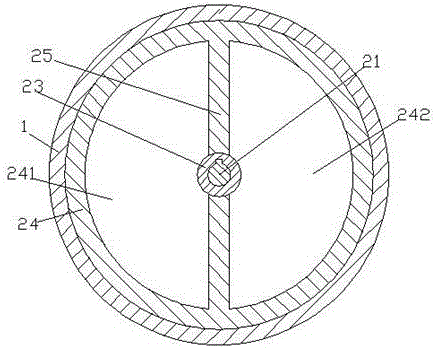

InactiveCN112195993ARealize the function of automatic slottingNo manualSoil-shifting machines/dredgersApparatus for laying cablesStructural engineeringMechanical engineering

The invention discloses an automatic cable laying machine. The automatic cable laying machine comprises a bottom plate, wherein a linear inclined sliding hole is formed in the surface of a rectangularblock; a connecting sliding rod is slidably connected to the surface of the rectangular block and is located in the linear inclined sliding hole; a cable pressing device is arranged on one side of the top of the bottom plate and is located at one end of the connecting sliding rod; a grooving rotary disc is fixedly connected to the center of the surface of a rotary shaft; a digging device is fixedly connected to the position, close to the grooving rotary disc, of one end of the sliding rod; a burying device is fixedly connected to the position, away from the grooving rotary disc, of the bottomof the bottom plate; and a compacting wheel is fixedly connected to the position, close to the bottom of the bottom plate, of the top of the surface of the burying device. The invention relates to the technical field of cable laying. According to the automatic cable laying machine, the effect of integrating grooving, cable laying, burying and compacting is achieved, the amount of manual labor isreduced, the time and the labor are saved, the integration of grooving, cable laying, burying and compacting is achieved, and the working efficiency and the using performance are improved.

Owner:韩爱强

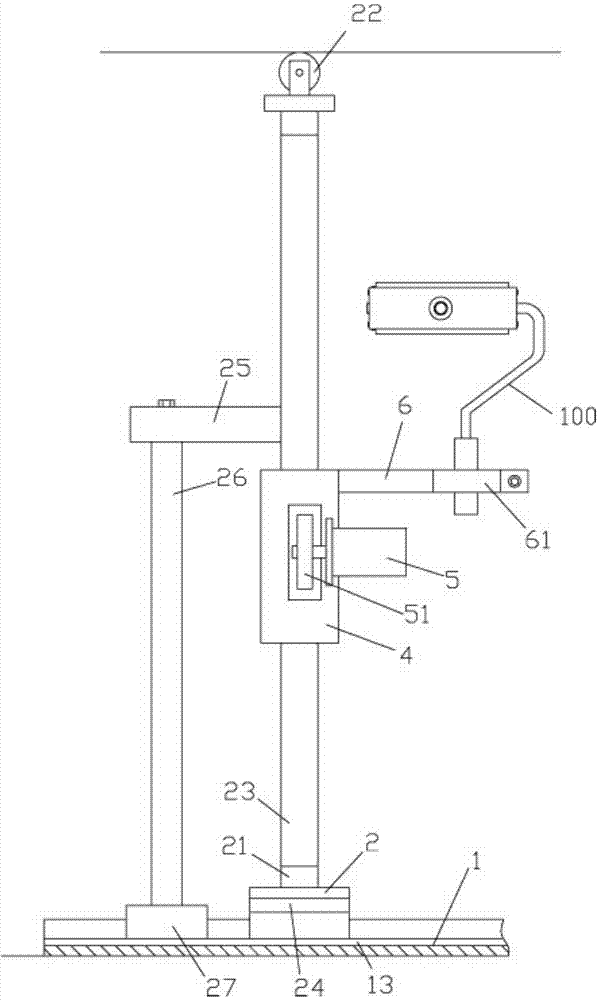

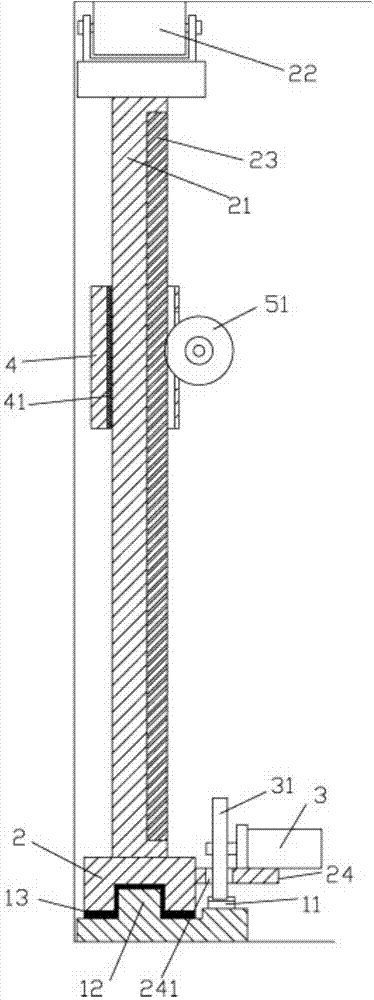

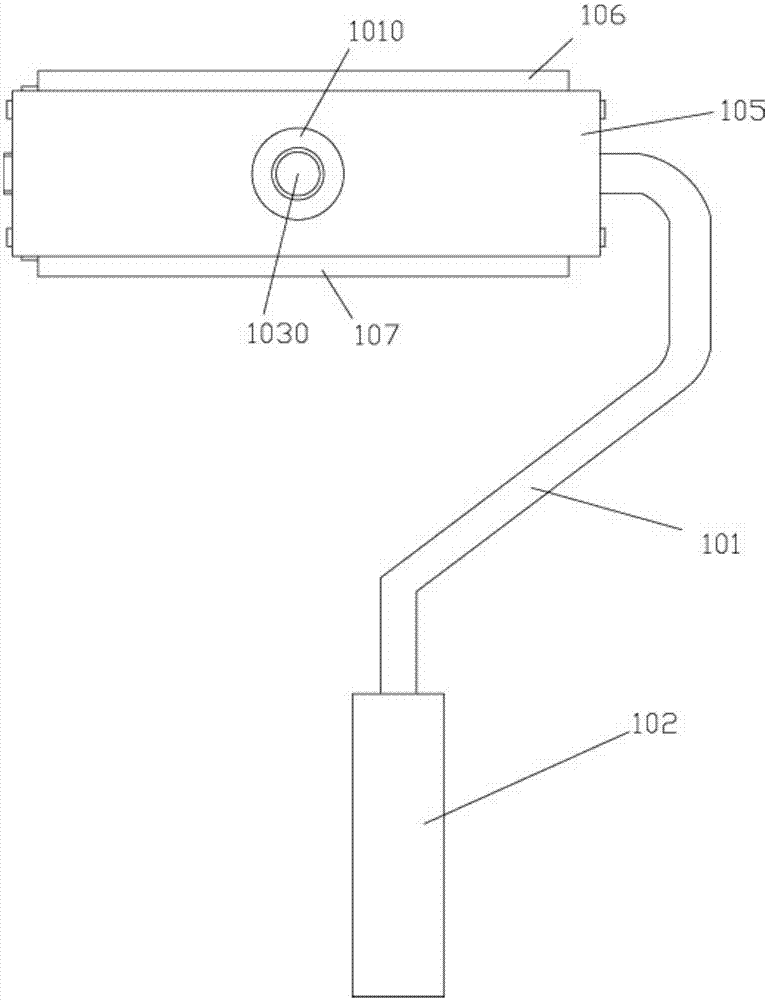

Automatic rolling brush device

InactiveCN104328896AGood effectReduce the amount of manual laborBuilding constructionsElectric machineryBrush device

The invention discloses an automatic rolling brush device, which comprises a lower rail, wherein a lower part slide block is arranged on the lower rail, an operation rack parallel to the lower rail is fixedly arranged on the lower rail, a transverse servo motor is fixedly arranged on the lower part slide block, a transverse operation gear is fixedly arranged on an output shaft of the transverse servo motor, the transverse operation gear is engaged with the operation rack, the top surface of the lower part sliding block is fixedly provided with a vertical transverse rod, the top of the vertical transverse rod is hinged to a support rolling wheel, the support rolling wheel is pressed and leaned on the top surface of a roof, a vertical rack is fixedly arranged in the vertical transverse rod, a sliding sleeve is inserted in the vertical transverse rod in a sleeving way, a vertical servo motor is fixedly arranged on the sliding sleeve, a vertical gear is fixedly arranged on an output shaft of the vertical servo motor, the vertical gear is engaged with the vertical rack, a clamping frame is fixedly arranged on the sliding sleeve, and a rolling brush is fixedly arranged in the clamping frame. The automatic rolling brush device has the advantages that the leftward rightward and upward moving can be automatically carried out, the automatic wall painting can be carried out when a rolling tube brush is arranged on the automatic rolling brush device, the effect is good, and the manual work quantity is reduced.

Owner:ZHEJIANG TONGTAI CONSTR GRP

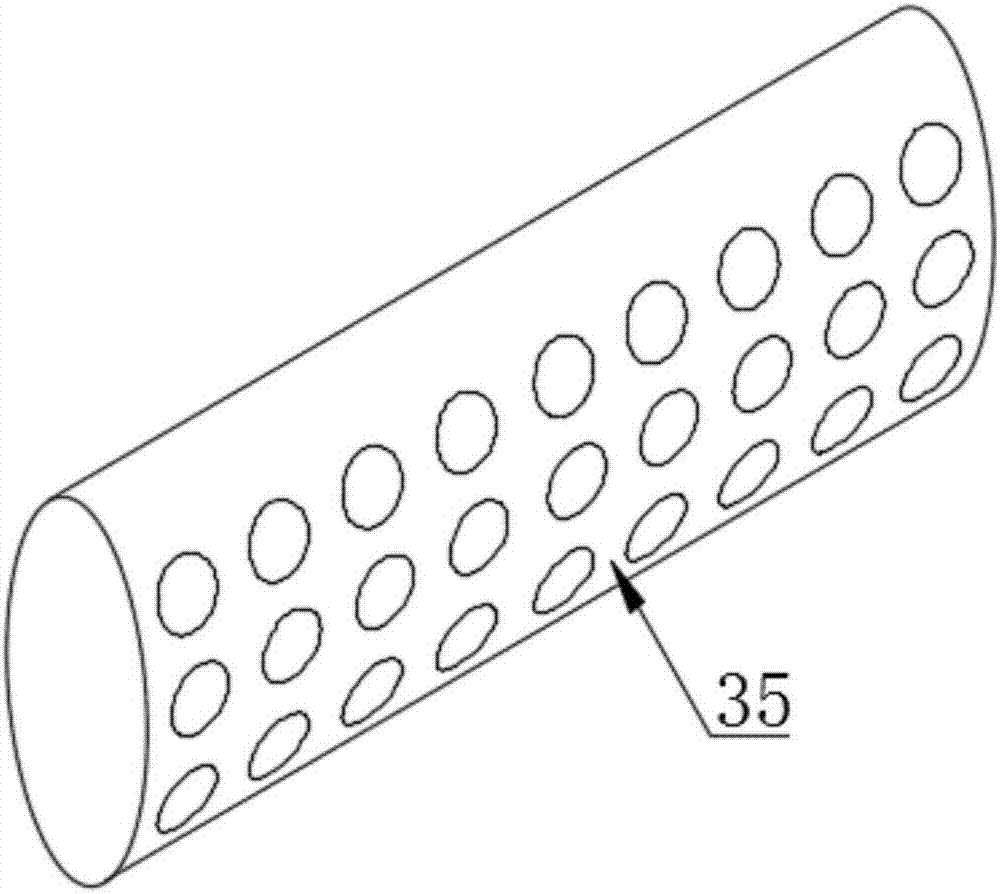

Preparation method of silicon carbide foamed ceramic

The invention discloses a preparation method of silicon carbide foamed ceramic, and relates to the field of production technologies of high-technology ceramic products-foamed ceramics. The preparation method comprises the steps of stirring polyester or polyester polyol with a catalyst, a surfactant and a foaming agent, adding silicon carbide, kaolin, alumina powder and silica solution to stir evenly, adding a curing agent to mix evenly and placing in a forming container for reaction and solidification, tapping the solidified foamed ceramic sponge, and carrying out high-temperature sintering to obtain the silicon carbide foamed ceramic. According to the preparation method, a three-dimensional foam-shaped ceramic body is directly formed through polymerization reaction and foaming process, so that the production process is greatly decreased, the obtained silicon carbide foamed ceramic has even and consistent structure, the manpower demand and the manpower labor can be greatly decreased, the production period is shortened and the performance stability of the product can be improved at the same time.

Owner:JIANGSU WEISHI STRUCTURAL CERAMICS

Sieving method for processing sweet potato powder

InactiveCN108188023AHigh speedReduce the amount of manual laborSievingScreeningEngineeringFeeding tube

The invention discloses a sieving method for processing sweet potato powder. The sieving method comprises the steps that the sweet potato powder is poured from a feeding hopper, and a rotary table isdriven by rotation of a motor to rotate; a rotating rod is driven by the rotation of the rotary table to perform circular motion, and a grooved pulley is driven by the rotating rod to perform intermittent rotation, so that the bottom of the feeding hopper is intermittently blocked; the sweet potato powder is fell down to the surface of a sieving mesh through a feeding tube, a first belt pulley isdriven by the work of a vibrating motor to rotate, and a second belt pulley is driven by the rotation of the first belt pulley to rotate through a belt. According to the sieving method for processingthe sweet potato powder, the sieving mesh is driven by the work of the vibrating motor to move and sieve the sweet potato powder, manual sieving is not required, the labor capacity is reduced, the speed of sieving is accelerated, and the working efficiency is improved; and the rate of feeding is controlled to enable the sweet potato powder to be intermittently and continuously fed, the stacking ofthe sweet potato powder due to too fast feeding is prevented to lead the device cannot work normally, and the use effect of the device is improved.

Owner:安吉县安信信息有限公司

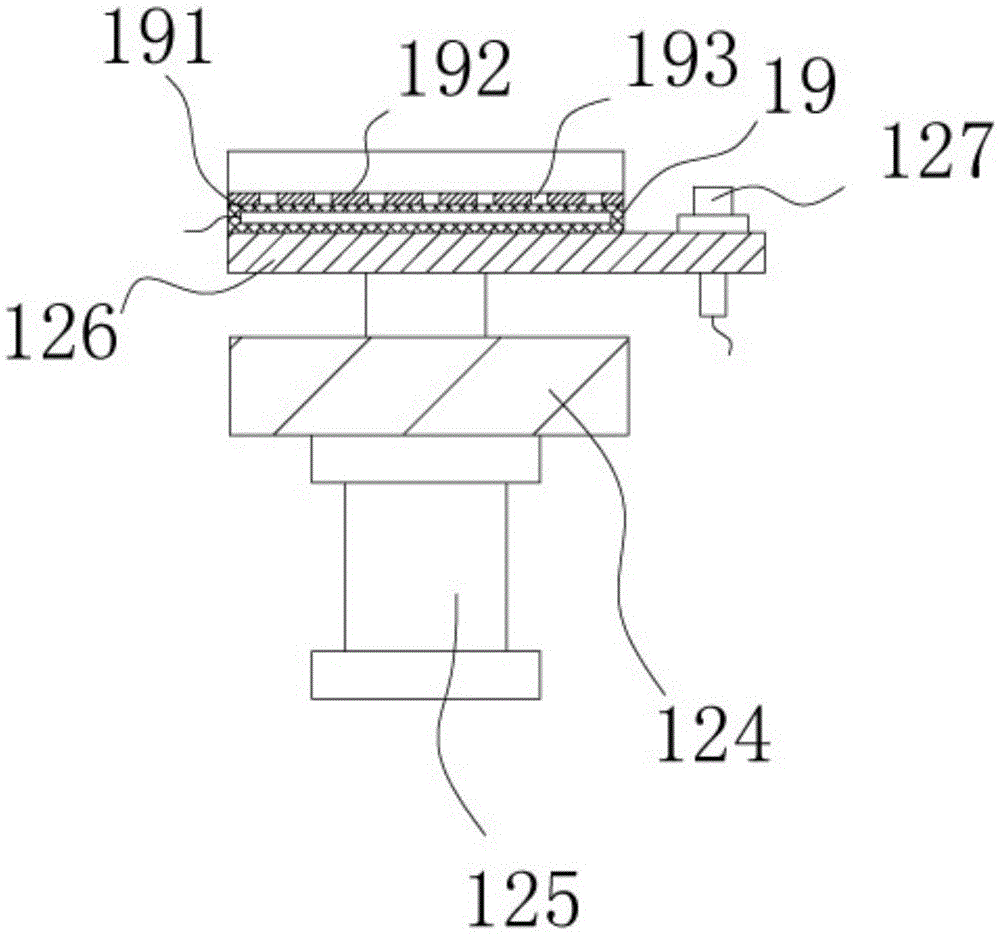

Visual-positioning dispensing system and method

PendingCN109201413APrevent overflowImprove work efficiencyLiquid surface applicatorsCoatingsImaging processingMachine vision

The invention discloses a visual-positioning dispensing system, comprising a camera mechanism, a dispensing mechanism, a three-axis mechanism, a computer and a controller. The invention also disclosesa visual-positioning dispensing method. The method comprises the following steps: shooting photos of sheet-like parts, reading photographed images to establish coordinate systems of the images, determining a conversion relationship between the coordinate systems, performing threshold segmentation on pictures of the to-be-dispensed areas of the sheet-like parts, and extracting the dispensing positions of the to-be-dispensed areas; and transmitting the data of the dispensing positions to the controller, controlling the three-axis system to move to the designated positions to complete dispensing. According to the invention, based on autonomous positioning and automatic dispensing of machine vision and image processing, compensation for the deviation of the dispensing positions is realized inthe manner of the cooperation of the machine vision and the three-axis mechanism, so overflowing of dispensing glue to other positions can be avoided, and product yield is improved; and the visual-positioning dispensing system and method of the invention have the advantages of simple structure, high degree of automation and convenient operation, reduces manual labor and production cost, and improves the efficiency of dispensing work.

Owner:苏州华智诚精工科技有限公司

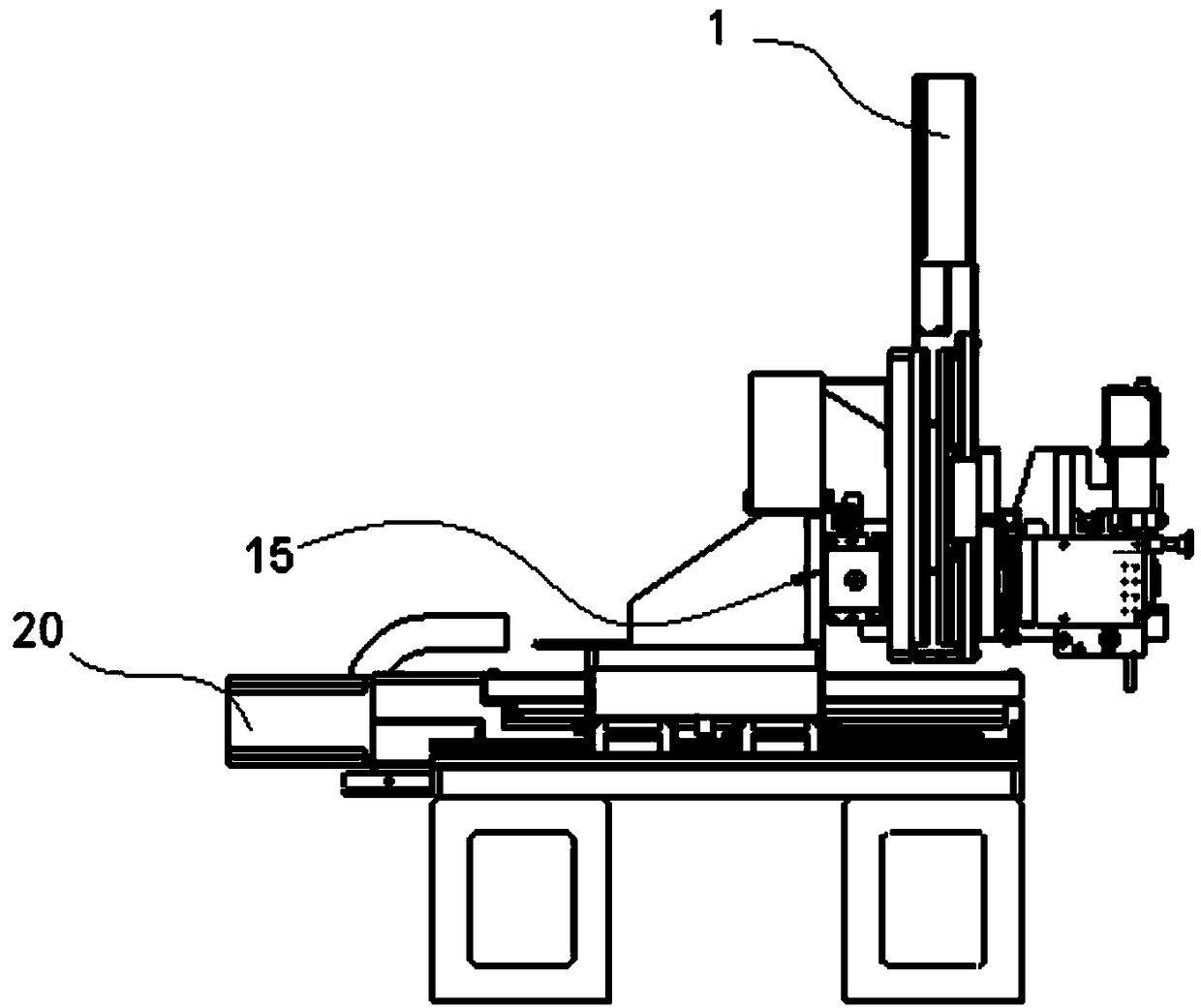

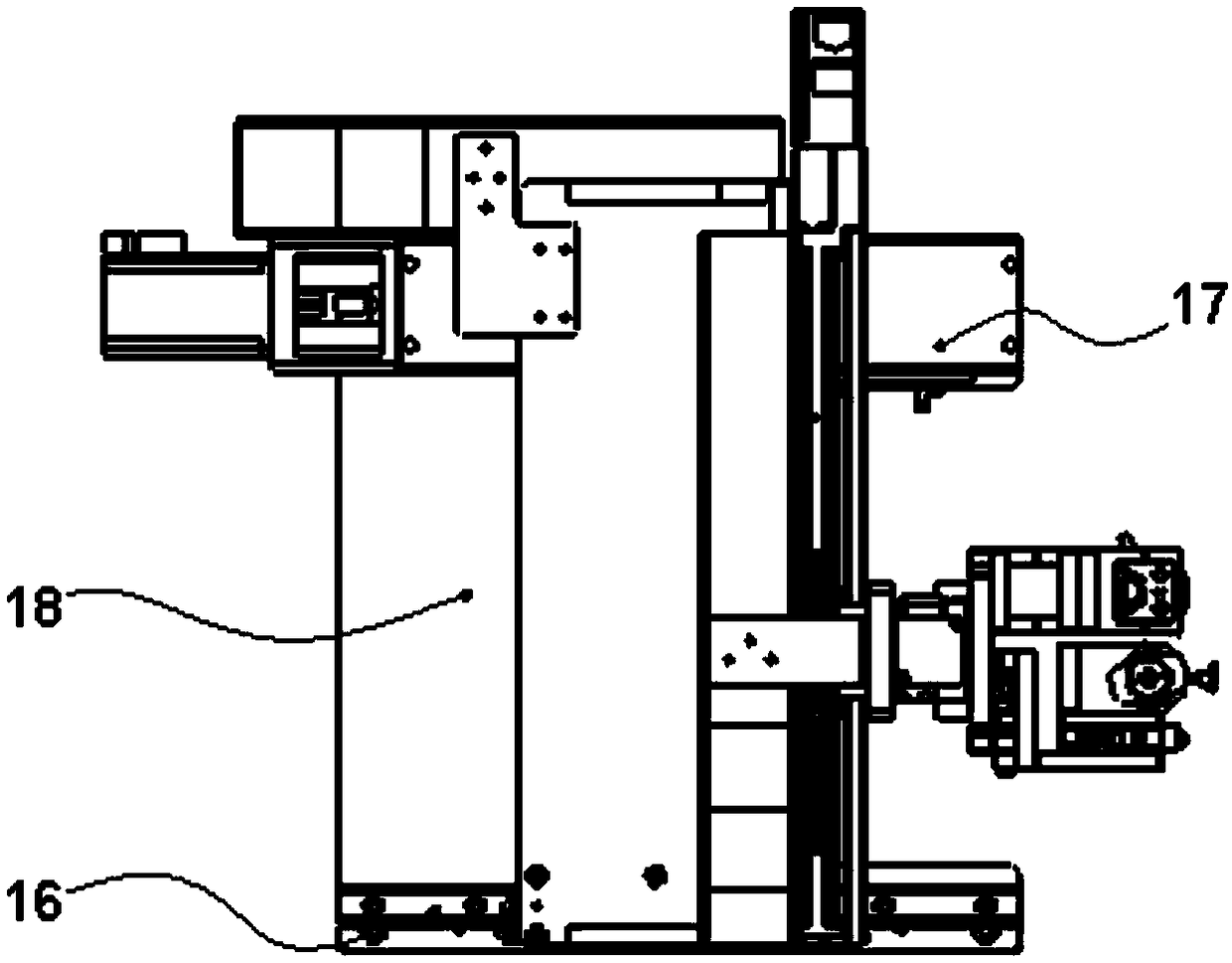

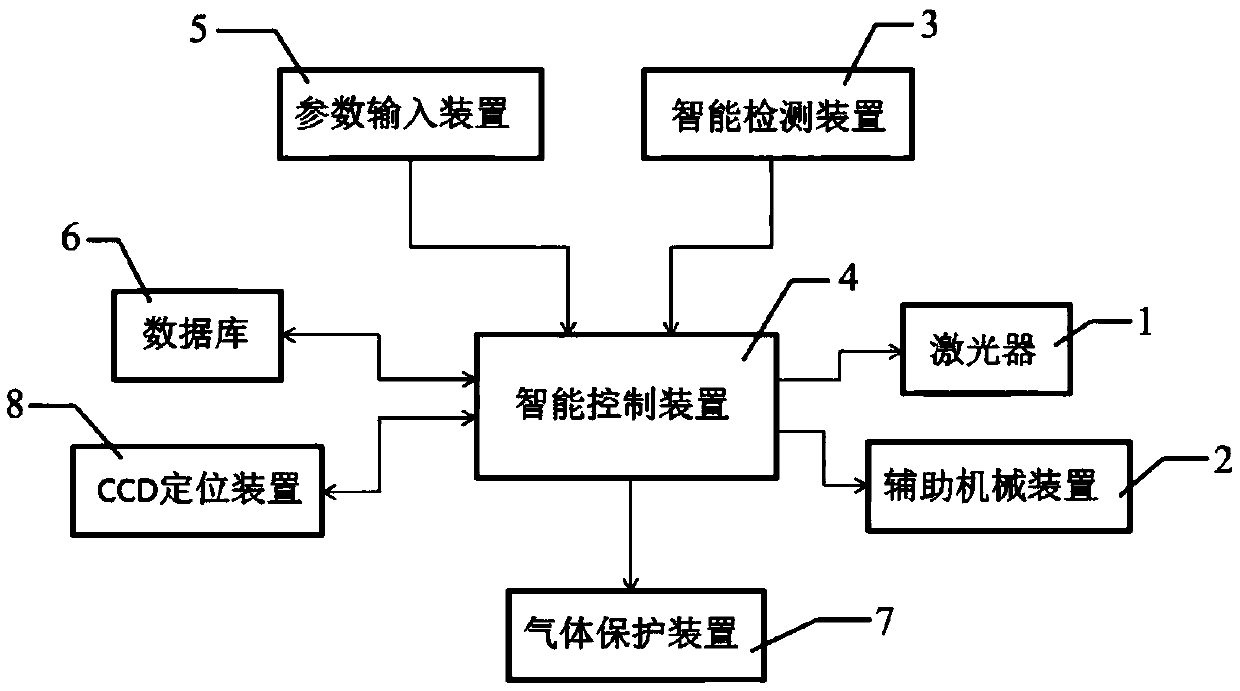

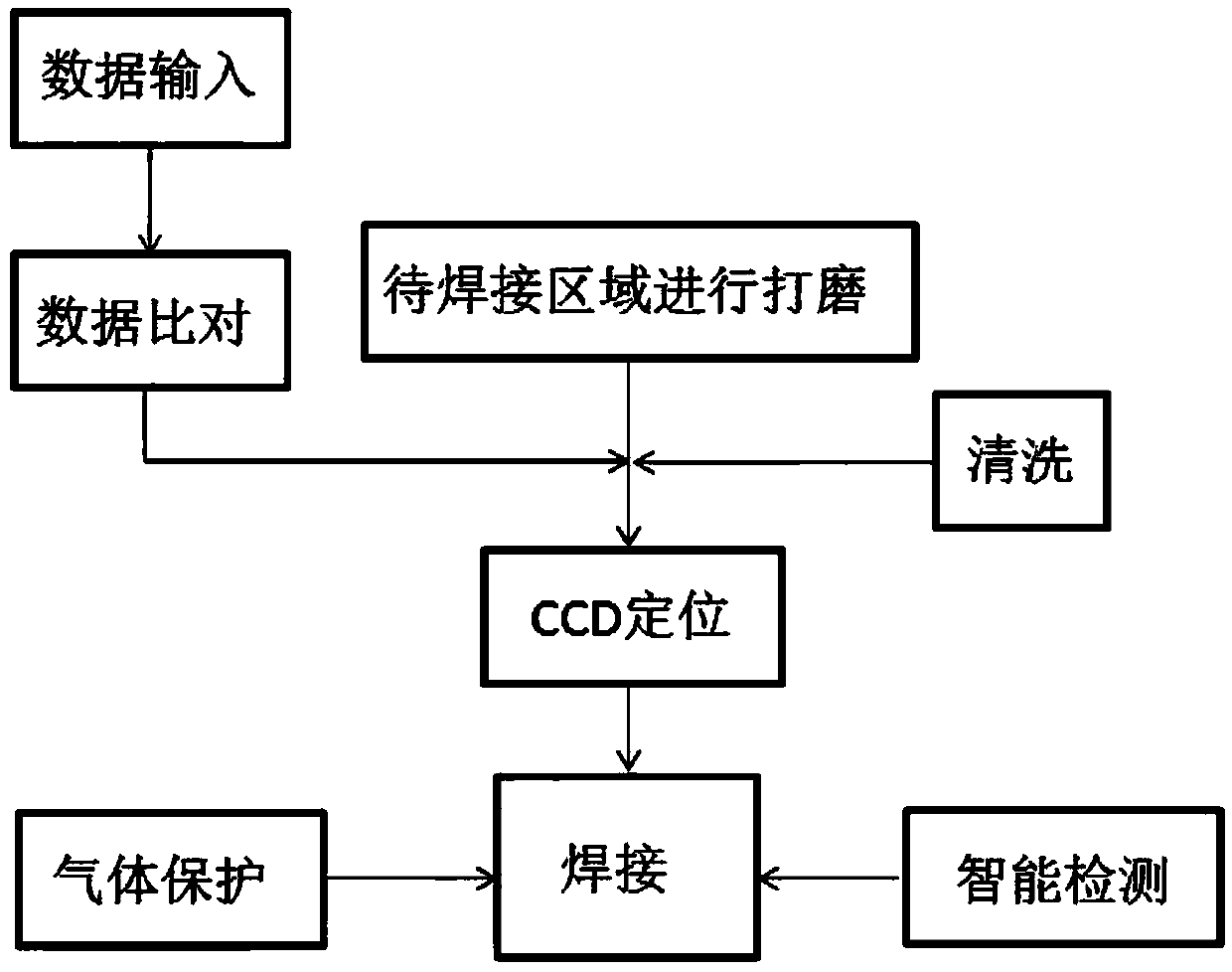

Intelligent laser welding system and operation method thereof

InactiveCN105499805AEfficient weldingImprove welding qualityLaser beam welding apparatusEngineeringIntelligent control

The invention discloses an intelligent laser welding system and an operation method thereof. The intelligent laser welding system comprises a laser device, an auxiliary mechanical device, an intelligent detection device and an intelligent control device, wherein the laser device and the intelligent detection device are mounted on the auxiliary mechanical device, and the laser device, the auxiliary mechanical device and the intelligent detection device are electrically connected with the intelligent control device. The method for laser welding of a metal structure by the intelligent laser welding system includes the steps of 1) polishing a to-be-welded area of the metal structure; 2) adopting laser as a welding heat source and welding the metal structure by the laser device; 3) monitoring welding quality in real time by the intelligent detection device while welding. The intelligent laser welding system and the method thereof have the advantages that high-efficiency high-quality metal structure welding can be achieved to improve welding quality of metal structures of constructions and the like, so that intelligent, big-data and real-time monitoring welding can be achieved.

Owner:SHANDONG YABAITE SCI & TECH CO LTD

Cylindrical ceramic product clamping device with heating device

ActiveCN105665195AEasy to sprayReduce the amount of manual laborLiquid surface applicatorsSpraying apparatusEngineeringStile

The invention discloses a cylindrical ceramic product clamping device with a heating device. The cylindrical ceramic product clamping device comprises a rack. A right supporting plate is fixed to the right side of a top plate of the rack. Two rodless air cylinders are fixed to the middle portion of the top plate of the rack. The bottom of a left supporting block is fixed to sliding blocks of the two rodless air cylinders. Two transverse guide strips are fixed to the middle portion of the top plate of the rack. A left rotating connecting block corresponding to a right rotating connecting block is hinged to the right side wall of the left supporting block. Step concave holes are formed in the right end face of the left rotating connecting block and the left end face of the right rotating connecting block. The transverse guide strips are parallel to the rodless air cylinders. Connecting slipping parts are arranged on the two sides of the middle portion of the left supporting block. The outer bottom face of the right end of each connecting slipping part is provided with a lateral connecting part extending downwards. A strip-shaped cylindrical ceramic product can be clamped and rotated, spraying and painting are facilitated, and the painted or sprayed part on the outer side wall of the strip-shaped cylindrical ceramic product is dried, and the manual labor amount is greatly reduced through the device.

Owner:重庆博视知识产权服务有限公司

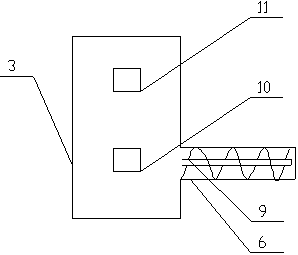

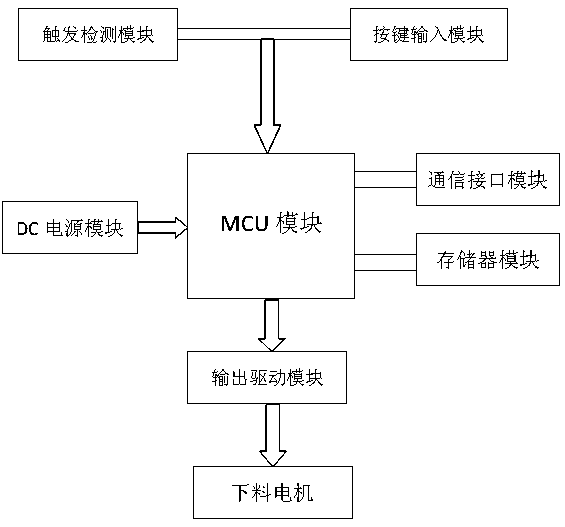

Intelligent sow feeding system and controlling method

ActiveCN103947571AAccurate feeding amountReasonable weight controlAnimal feeding devicesEar tagElectric machinery

The invention discloses an intelligent sow feeding system and a controlling method. The system comprises a controller, a feeding pipe, a storehouse connected with the controller, a discharging unit and a touching sensor, wherein the storehouse is connected with the feeding pipe; the controller comprises a mainboard controlling module, a controlling panel and a blanking motor; the mainboard controlling module is connected with the touching sensor, the controlling panel and the blanking motor respectively; input signals are received by the touching sensor and transmitted to the mainboard controlling module to control the blanking of the blanking motor; the system reduces the opportunities of people contacting with fodder, so that germ infection is further reduced. The invention further discloses the controlling method of the system. According to the invention, the mainboard controlling module judges whether key values exist, so that feeding mode can be selected and feeding parameters are set; the remaining capacity of auto-updated sow feeding in one day is read by the controller from the mainboard controlling module, and the mainboard controlling module starts or closes a triggering switch according to the triggering signals of the counters of the touching sensor and the mainboard controlling module, so that feeding restriction is realized, and the use of electronic ear tags is avoided.

Owner:广东广兴牧业机械设备有限公司

Grooving, gluing and band pressing mechanism of edge sealing band

ActiveCN105563608AImprove edge banding efficiencyImprove edge qualityLiquid surface applicatorsWood working apparatusElectric machineStructural engineering

The invention discloses a grooving, gluing and band pressing mechanism of an edge sealing band. The grooving, gluing and band pressing mechanism comprises a rack, a transmission mechanism, a grooving mechanism, a cut-off mechanism, a bevel edge sealing glue supply mechanism and a band pressing guide mechanism. The transmission mechanism is mounted at the bottom of the rack and provided with a plurality of rotary shafts, and a roller is arranged on one rotary shaft in a sleeved manner. The grooving mechanism comprises a bottom plate, a feeding backup plate, a motor fixing seat, a grooving motor, a grooving cutter and a band pressing assembly. The cut-off mechanism comprises a drive air cylinder and a cutter mounted at the shaft end of the drive air cylinder. The bevel edge sealing glue supply mechanism comprises a glue storage box, a glue supply seat, a glue supply column, a glue stop column, a glue feeding piece and a glue scraping mechanism. The band pressing guide mechanism comprises a guide motor, a main pressing wheel mounted at the shaft end of the guide motor and a guide wheel rotationally arranged at the side of the glue scraping mechanism. Thereby, the mechanisms are combined into the grooving, gluing and band pressing mechanism of the edge sealing band, automatic edge sealing is achieved, manual labor is reduced, edge sealing efficiency and edge sealing quality are improved, and cost is reduced.

Owner:NANXING MACHINERY CO LTD

Plate cutting device for metal product machining

InactiveCN111496307ARealize equidistant automatic cutting effectImprove cutting efficiencyShearing machinesFeeding apparatusKnife bladesMachining

The invention discloses a plate cutting device for metal product machining, and relates to the technical field of metal product machining. The plate cutting device comprises a supporting frame; a supporting plate is horizontally fixed to the supporting frame, a push plate vertically penetrates through a strip-shaped through hole, one end of the push plate is fixedly connected with a clamping mechanism, and the other end of the push plate is fixed to a conveying belt; a stepping mechanism used for driving a rotating wheel I is arranged on the supporting frame, a cutting mechanism used for cutting a metal plate is arranged on the supporting frame, and a lifting mechanism used for driving the cutting mechanism to move vertically is arranged on the supporting frame. According to the plate cutting device for the metal product machining, the metal plate is cut through the arranged cutting mechanism, the arranged stepping mechanism can drive the clamping mechanism to drive the metal plate todo transverse equal-interval stepping movement, the lifting mechanism drives a blade in the cutting mechanism to vertically ascend and descend in a reciprocating mode, and the equal-interval automaticcutting effect on the metal plate is achieved; and the cutting efficiency of the metal plate is greatly improved, the automation degree is high, and the manual labor amount is greatly reduced.

Owner:长兴锐锋机械有限公司

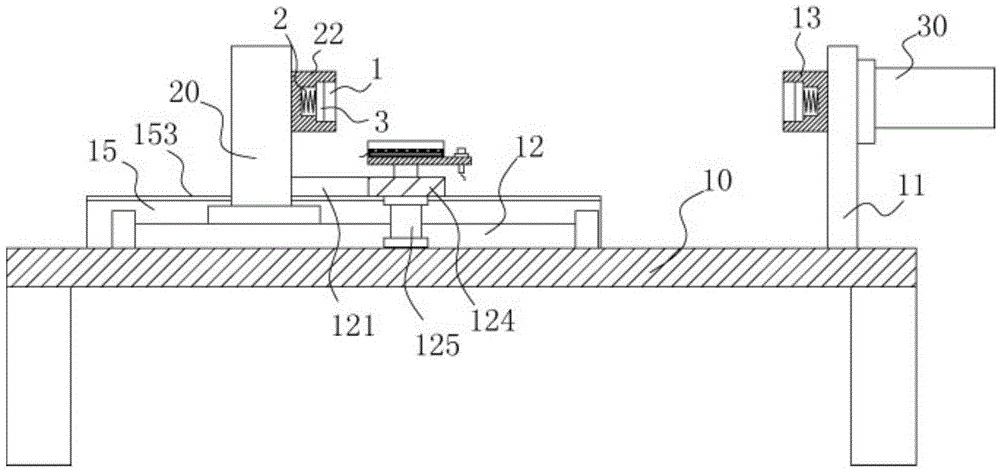

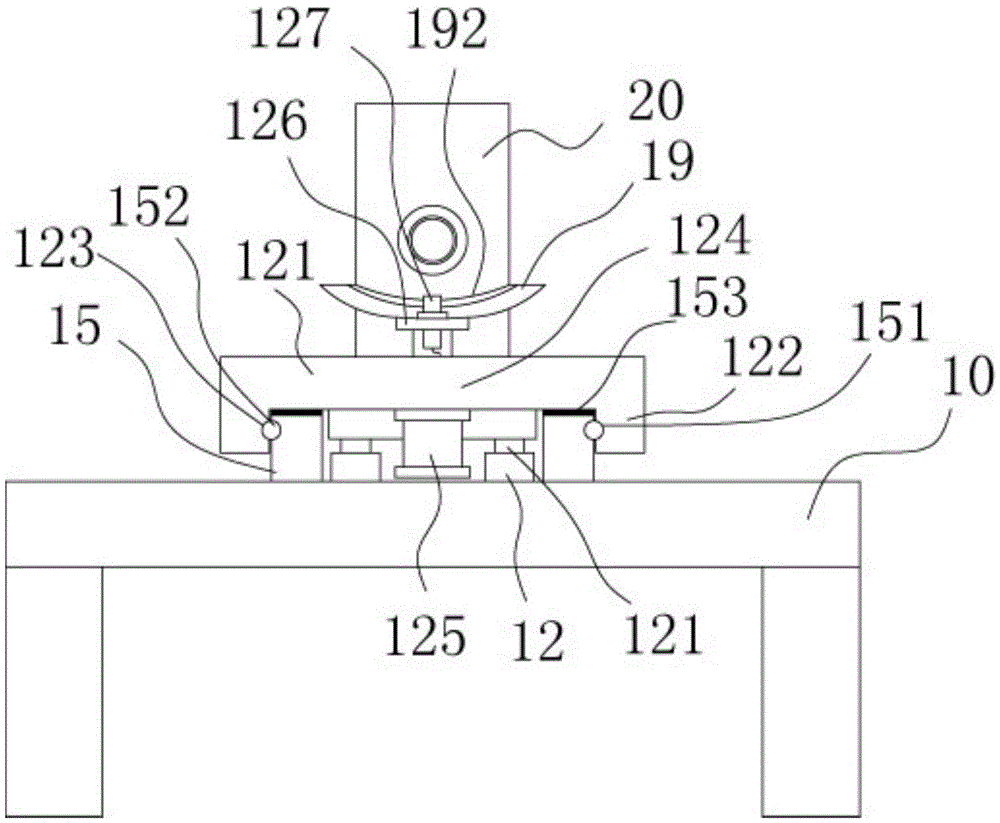

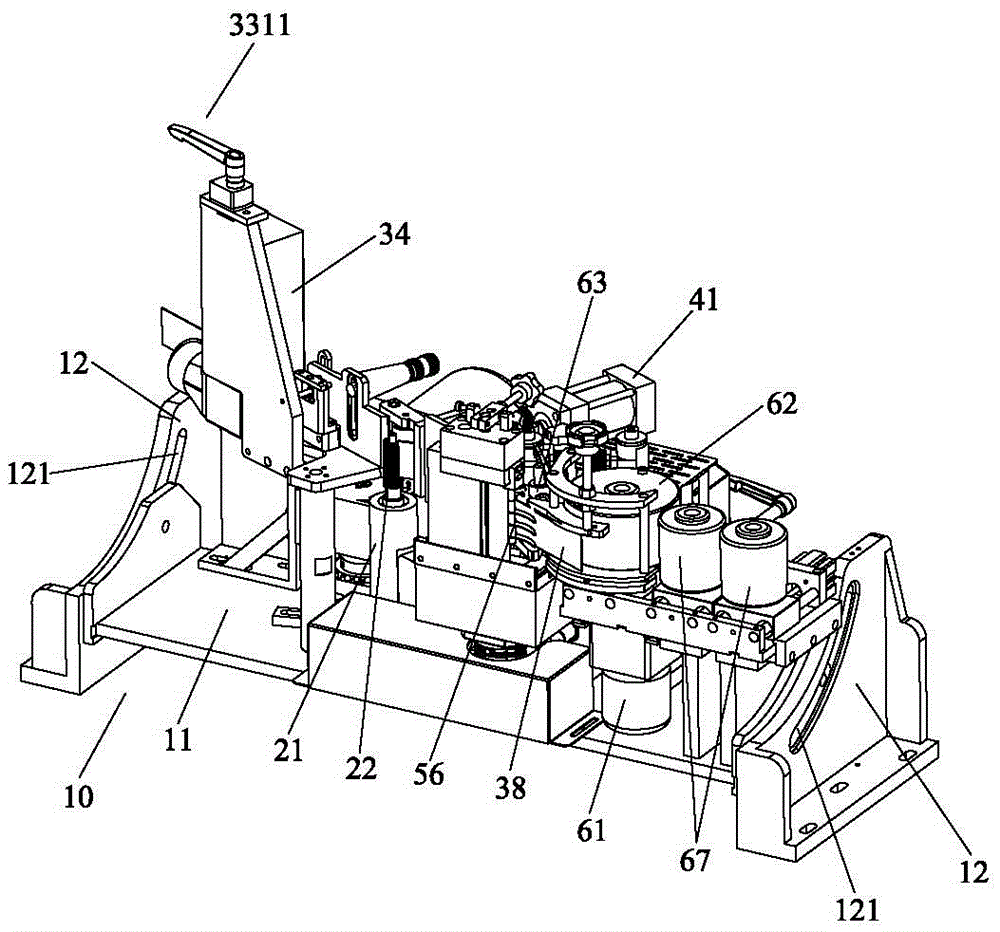

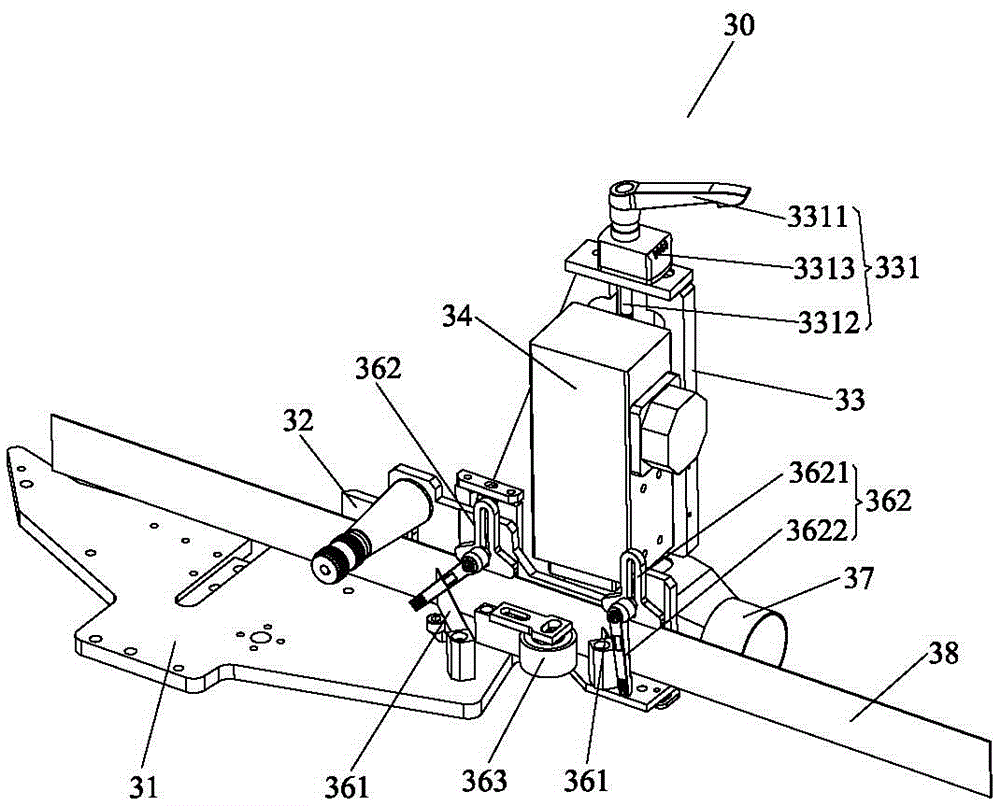

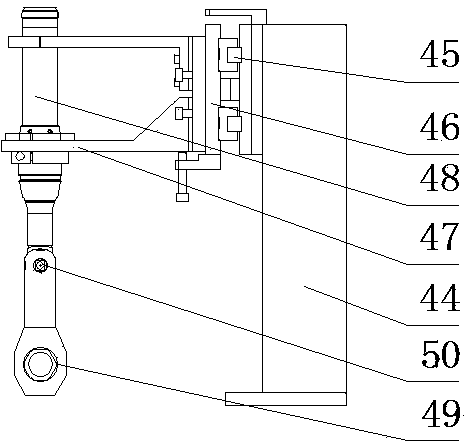

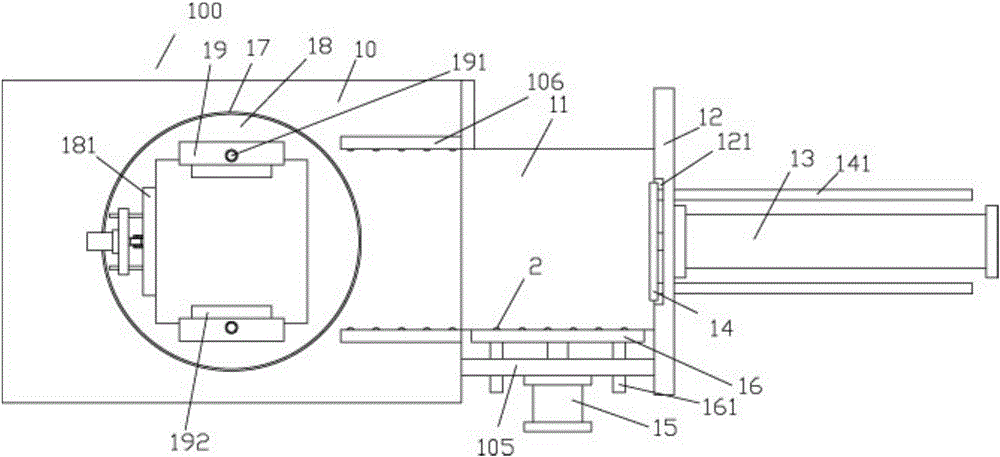

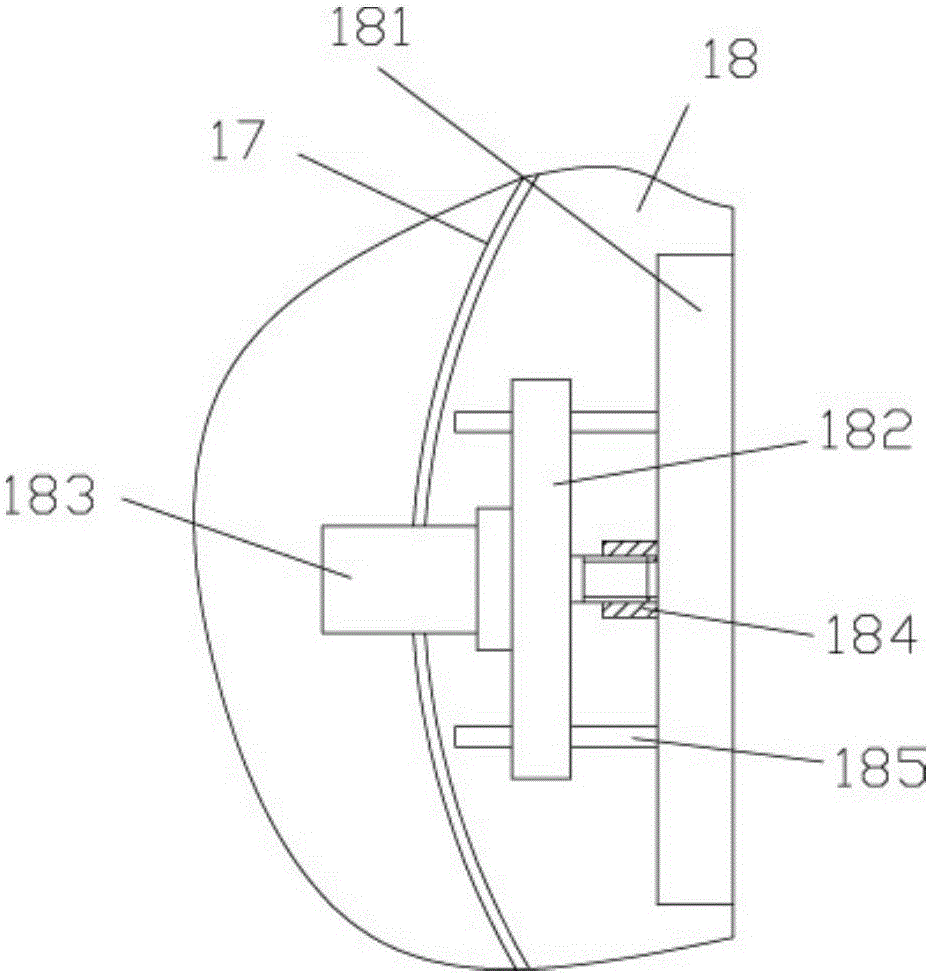

Automatic detecting and adjusting machine table for gear and rack meshing gap of automobile steering device

ActiveCN104359443AEasy to adjustHigh degree of automationMeasurement devicesPush and pullAutomatic testing

The invention relates to an automatic detecting and adjusting machine table for a gear and rack meshing gap of an automobile steering device and belongs to the field of gear and rack meshing detection equipment for automobile steering devices. The detecting and adjusting machine table comprises a machine frame, a program control box, a rack push and pull rotating device, a locating and clamping device, a screw plug rotation adjusting device and a nut locking device. The rack push and pull rotating device is arranged on a work table top at the front end of the program control box, the locating and clamping device is arranged on one side of the rack push and pull rotating device, the screw plug rotation adjusting device is arranged at the front end of the locating and clamping device, and the nut locking device is arranged at the upper portion of the screw plug rotation adjusting device through an installation frame. The automatic detecting and adjusting machine table for the gear and rack meshing gap of the automobile steering device has the advantages of being high in adjusting speed and automation degree and reliable in quality, solves the problems that the labor amount is large, efficiency is low, and a detecting result has large errors due to the fact that an existing detecting manner requires a large amount of time and manual operation all the time, and is particularly suitable for automatic detection and adjusting use of the gear and rack meshing gap of the automobile steering device.

Owner:湖北唯思凌科装备制造有限公司

Horizontal cylindrical ceramic product clamping device

ActiveCN105618301AEasy to sprayEasy to paintLiquid surface applicatorsSpraying apparatusEngineeringDrive motor

The invention discloses a horizontal cylindrical ceramic product clamping device. The horizontal cylindrical ceramic product clamping device comprises a rack, wherein the right side of the top plate of the rack is fixedly provided with a right supporting plate; a drive motor is fixedly arranged on the right side wall of the right supporting plate; a right rotary connecting block is hinged on the left side wall of the right supporting plate; the right end of the right rotary connecting block is provided with a spline shaft hole; the output shaft of the drive motor is a spline shaft; the spline shaft is in plug bush in the spline shaft hole; the middle part of the top plate of the rack is provided with a transverse sliding through slot; the right supporting plate is positioned at the right side of the transverse sliding through slot; transverse guide bars are fixedly arranged on the top surfaces of the top plates of the rack bodies at the two sides of the transverse sliding through slot; two connecting blocks are fixedly arranged on the bottom surface of the top plate of the rack; and the two ends of a transmission screw are hinged on the two connecting blocks. The horizontal cylindrical ceramic product clamping device can be used for clamping and rotating of long-strip-shaped cylindrical ceramic products, so that the cylindrical ceramic products are conveniently sprayed and painted, and therefore, manual labor is greatly reduced, and the production efficiency is improved.

Owner:连云港石港高压电瓷有限公司

Conveying and lifting mechanism for laser-cut steel plates

The invention discloses a conveying and lifting mechanism for laser-cut steel plates. The conveying and lifting mechanism for the laser-cut steel plates comprises a rack. A feeding guide plate is fixed to the middle of the right side of a top plate of the rack. A connecting and supporting plate is fixed to the right side of the feeding guide plate. A pushing air cylinder is fixed to the middle of the right side of the connecting and supporting plate. A push rod of the pushing air cylinder penetrates through the connecting and supporting plate and is fixedly provided with a pushing plate. A side wall supporting air cylinder is arranged in the position, in front of the feeding guide plate, of the rack. A side supporting plate is fixed to a push rod of the side wall supporting air cylinder, and the side supporting plate is close to the feeding guide plate. A round vertical through hole is formed in the middle of the top plate, and a round lifting plate is inserted in the round vertical through hole in a sleeved mode. The conveying and lifting mechanism is installed at an automatic polishing device, can automatically convey the steel plates placed on the feeding guide plate and lift the steel plates to the polishing portion in clamping and fixing modes so that the steel plates can be polished, and is high in efficiency and good in effect, the situation that workers perform fixation with bolts is avoided, and the manual labor quantity is greatly reduced.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com