Fabric drum shaft conveying device

A technology of cloth reel shaft and conveying device, which is applied in the direction of conveyor control device, conveyor, conveyor objects, etc., can solve the problems of increasing manual labor, trouble in handling, etc., and achieve the effect of reducing manual labor and convenient transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

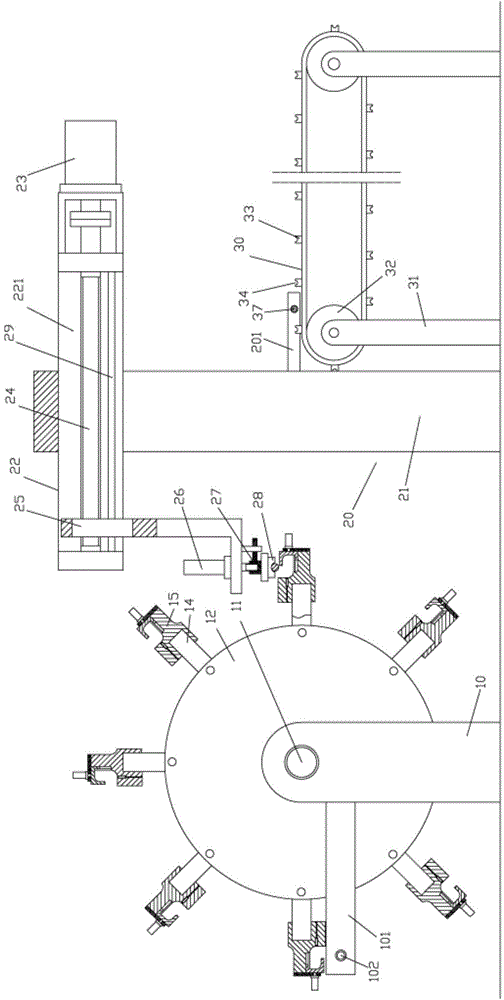

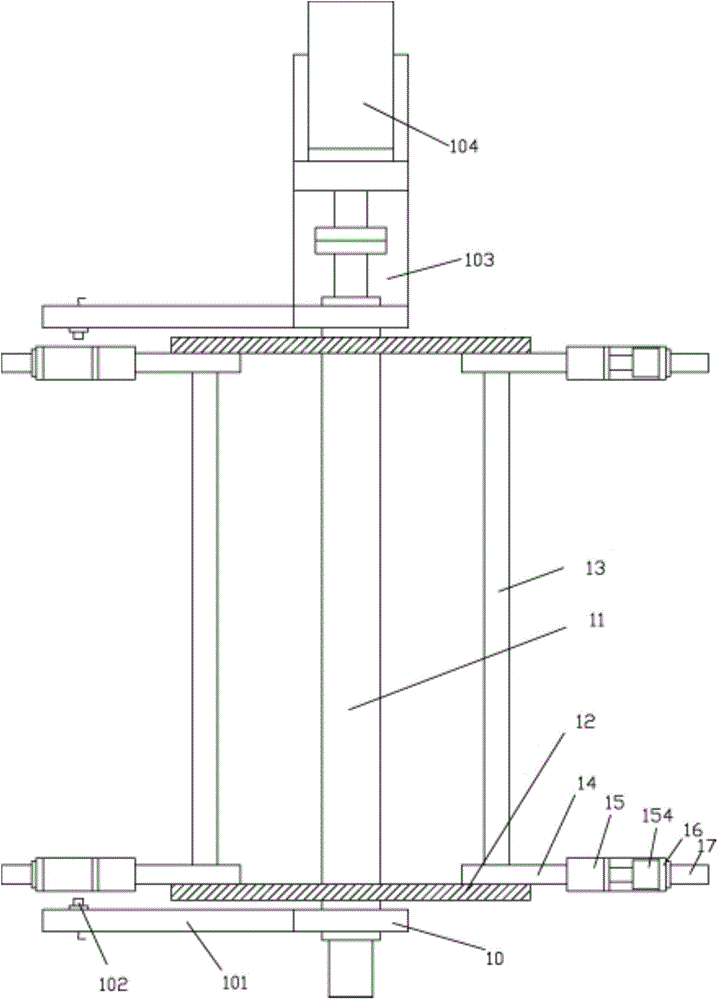

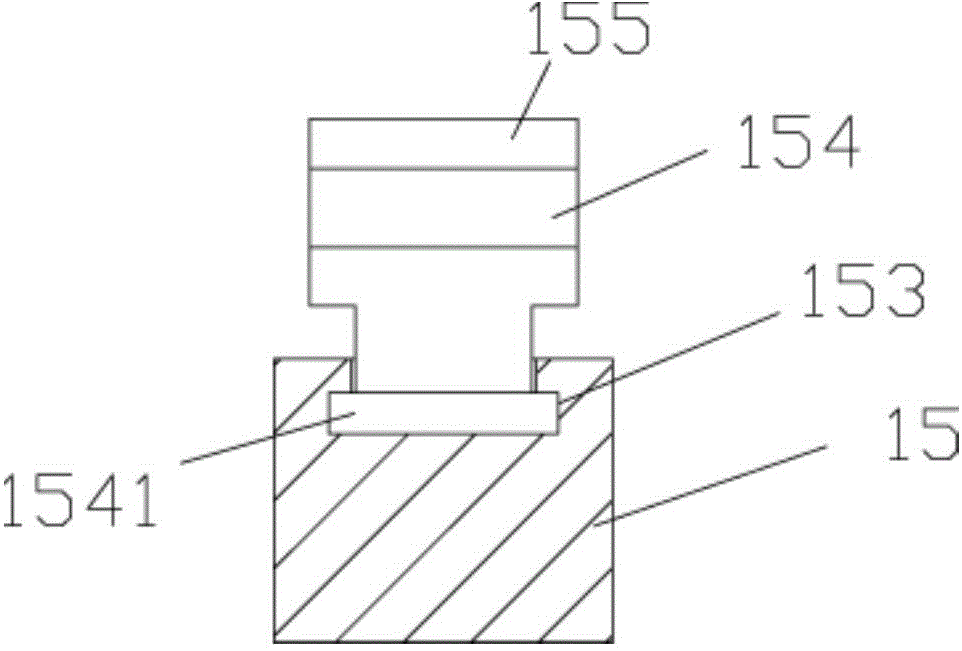

[0024] Example: see Figures 1 to 6 As shown, a cloth reel shaft conveying device includes a connecting bracket 10, a conveyor belt 30 and an extraction support frame 20. The connecting bracket 10 is hinged at the two ends of the middle rotating shaft 11, and the connecting bracket 10 is fixed on the ground. Two circular discs 12 are fixed on the rotating shaft 11, and the two ends of a plurality of transverse connecting rods 13 are respectively fixed on the corresponding circular discs 12, and all transverse connecting rods 13 are evenly distributed on both sides with the intermediate rotating shaft 11 as the central axis. On a circular disc 12, a grabbing arm 14 is fixed on the transverse connecting rod 13, and the grabbing block 15 is fixed on the end of the grabbing arm 14, and the extraction support frame 20 is fixed on the front bottom surface of the connection bracket 10, and the extraction support frame The front portion of 20 is fixed with driving roller support frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com