Automatic sensor detection machine

A detection machine and sensor technology, applied in printing, sorting, etc., can solve the problems of low enterprise efficiency, waste of manpower and material resources of production enterprises, unstable quality, etc., and achieve the effect of improving product quality and reducing manual labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below according to the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

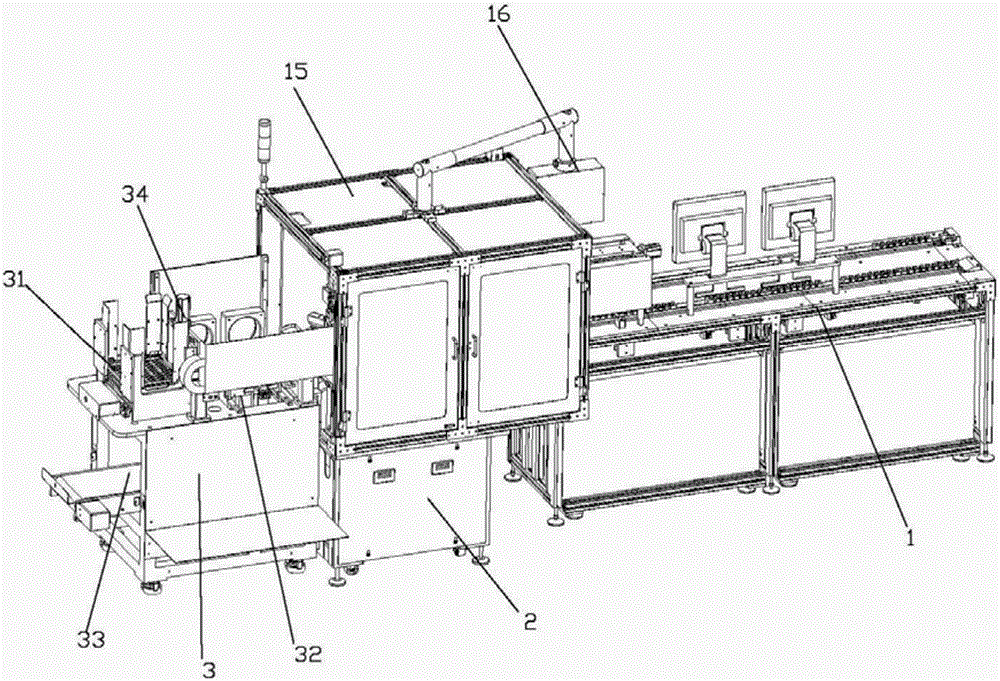

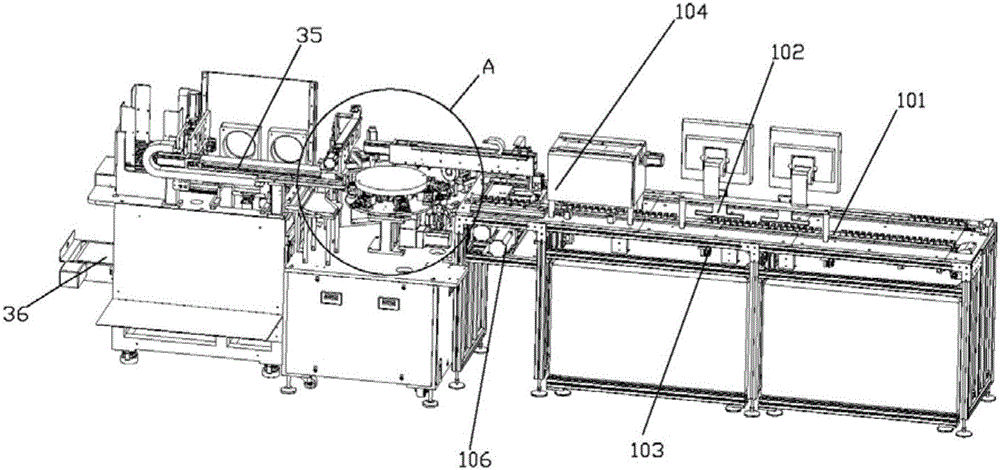

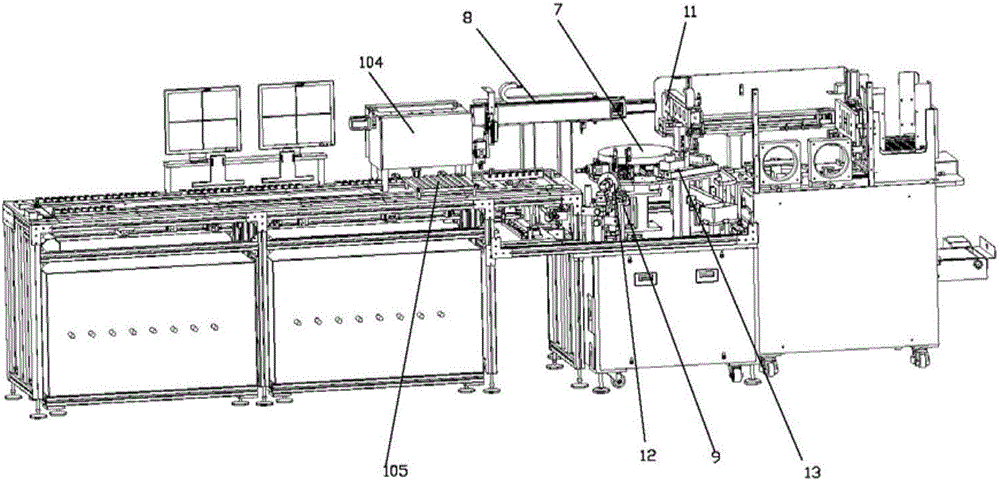

[0026] like figure 1 and figure 2 As shown, a sensor automatic detection machine includes a front-end circulating feeding unit 1, a middle multi-station turntable detection unit 2, and a rear-end material arrangement box unit 3. Products are transported by the front-end circulating feeding unit 1 and passed through the magnetic After the electrical parameter detection, the sorting enters the feeding station of the middle multi-station turntable detection unit 2, and the product passes through the detection station of the parameters related to the mechanical shape accuracy of the middle multi-station turntable detection unit 2, and the relevant parameters of the product are checked. After the detection, the defective product is pushed into the NG material box, and the qualified pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com