Conveying and lifting mechanism for laser-cut steel plates

A laser cutting and steel plate technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of inability to meet the height, reduce efficiency, affect use, etc., and achieve the effect of reducing manual labor, good effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

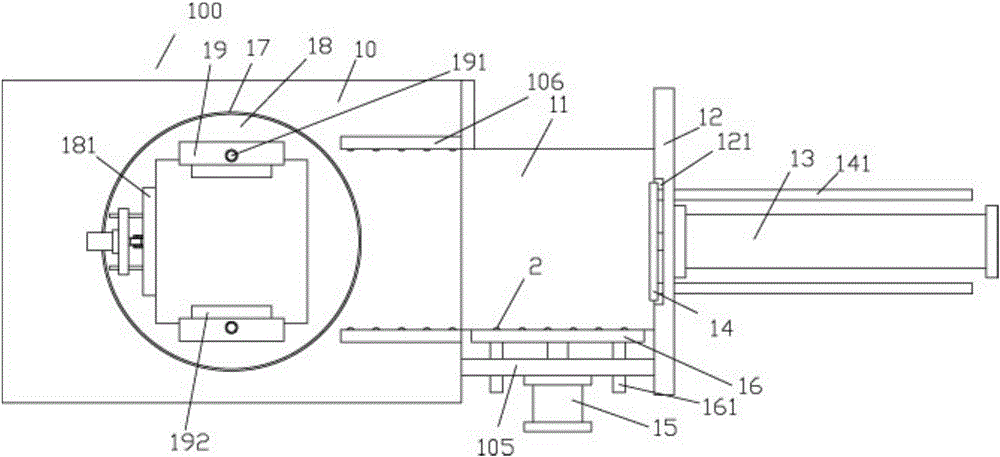

[0025] Examples, see e.g. Figure 1 to Figure 4 As shown, a laser cutting steel plate conveying and lifting mechanism includes a frame 100, the middle part of the right side of the top plate 10 of the frame 100 is fixed with a feed guide plate 11, and the right side of the feed guide plate 11 is fixed with a connecting support plate body 12, the middle part of the right side of the connection support plate body 12 is fixed with a pusher cylinder 13, the push rod of the pusher cylinder 13 passes through the connection support plate body 12 and is fixed with a push plate 14, the machine at the place ahead of the feed guide plate 14 The frame 100 is provided with a side wall support cylinder 15, and a side support plate 16 is fixed on the push rod of the side wall support cylinder 15, and the side support plate 16 is close to the feeding guide plate 14;

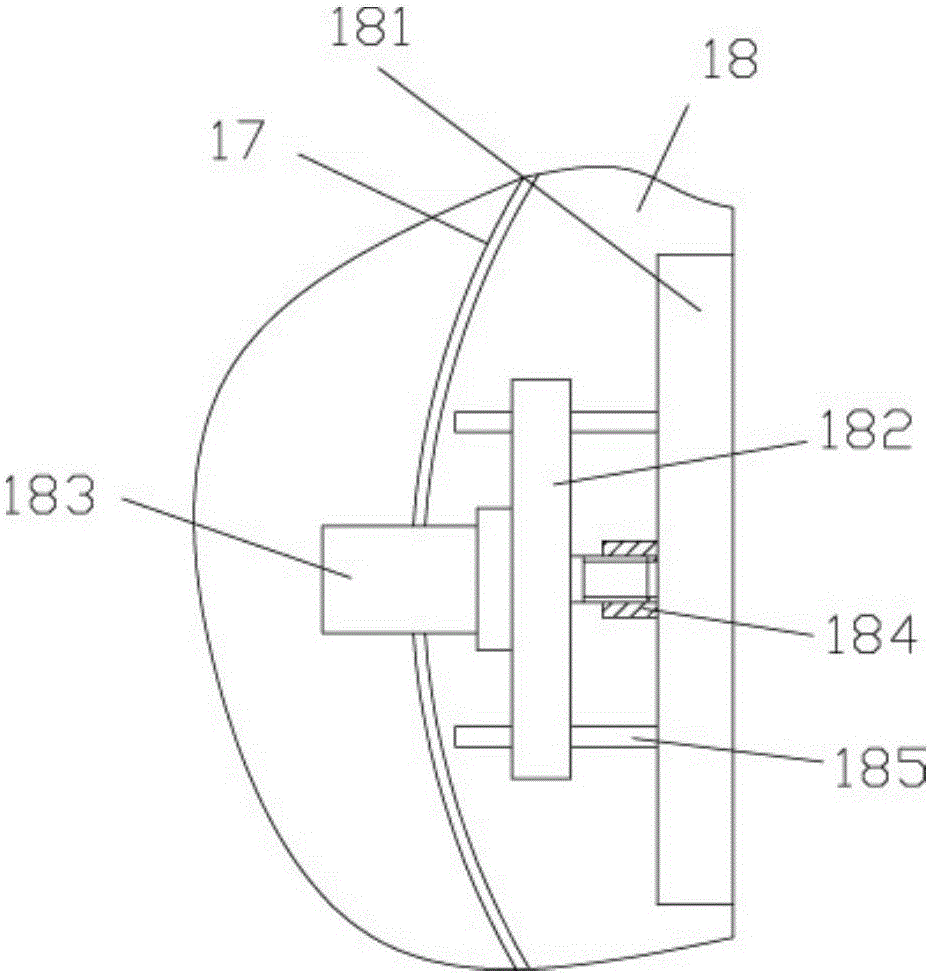

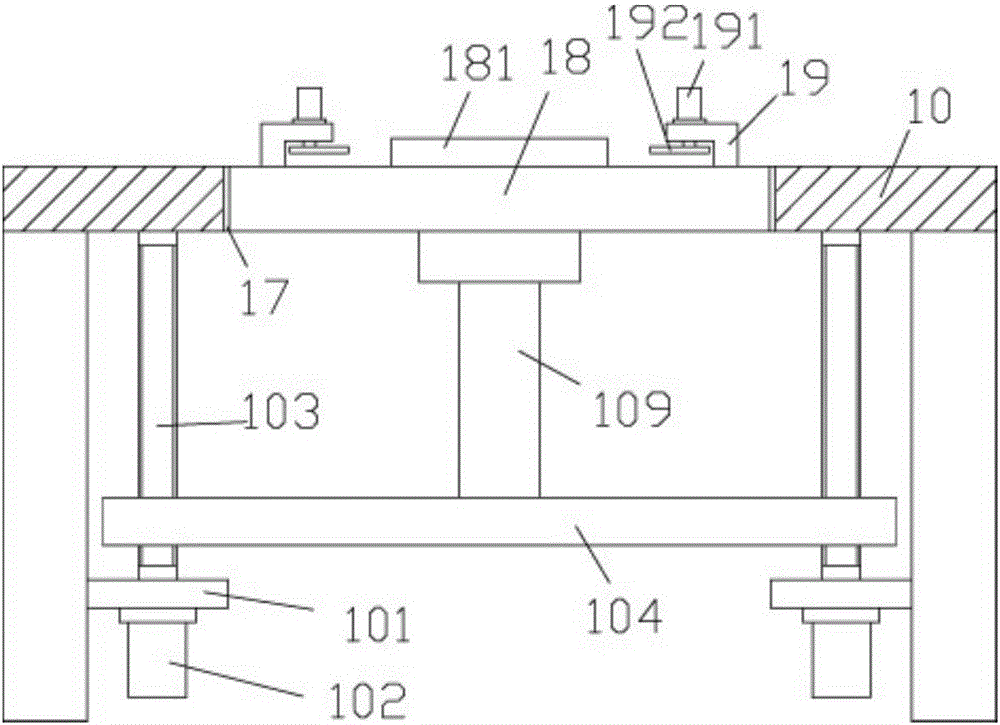

[0026] The middle part of the top plate 10 has a circular vertical through hole 17, a circular lifting plate 18 is inserted in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com