Automatic detecting and adjusting machine table for gear and rack meshing gap of automobile steering device

A technology of automobile steering gear, rack and pinion, applied in the direction of instruments, measuring devices, etc., can solve the problems of low efficiency, large error of detection results, large labor load, etc., and achieve product quality assurance, fast adjustment speed, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

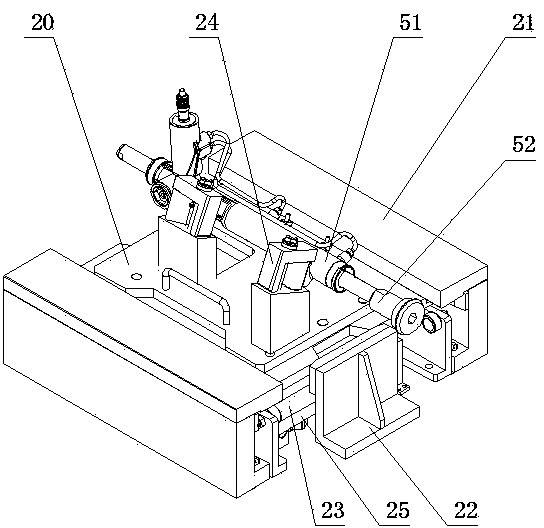

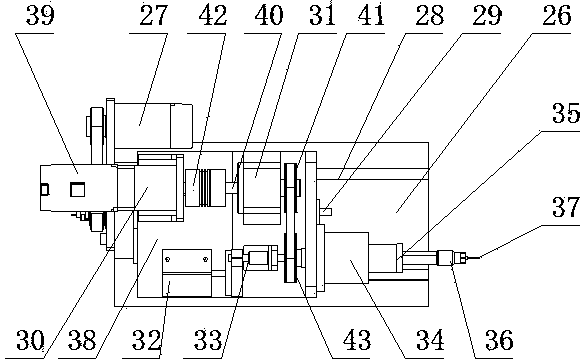

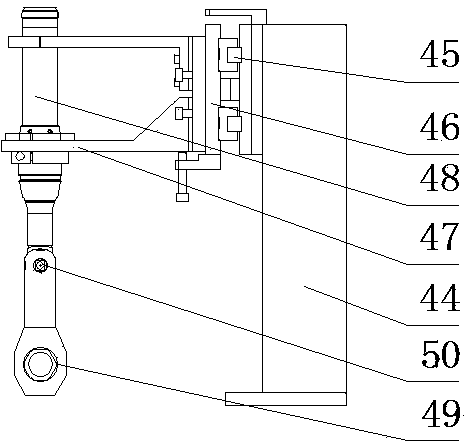

[0020] The automobile steering gear rack meshing gap automatic detection and adjustment machine includes a frame 1, a program control box 2, a rack push-pull rotation device 3, a positioning clamping device 4, a screw plug rotation adjustment device 5 and a nut locking device 6. A program control box 2 is installed on the working table of the frame 1, and a rack push-pull rotating device 3 is installed on the working table at the front end of the program control box 2. The rack push-pull rotating device 3 is composed of a base plate 7, a slide rail 8, a bearing support seat 9, a motor support seat 10, a pull pressure sensor 12, a torque sensor 13, a shaft coupling 14, an electric cylinder 15, an electric cylinder support 16 and a servo motor A17 constitute. A slide frame 18 is installed on the base plate 7 through the slide rail 8, and a clamping cylinder 19 is installed on one side of the slide frame 18 through a bearing support seat 9, and a cylinder jaw 11 is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com