Patents

Literature

64results about How to "Improve edge banding efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

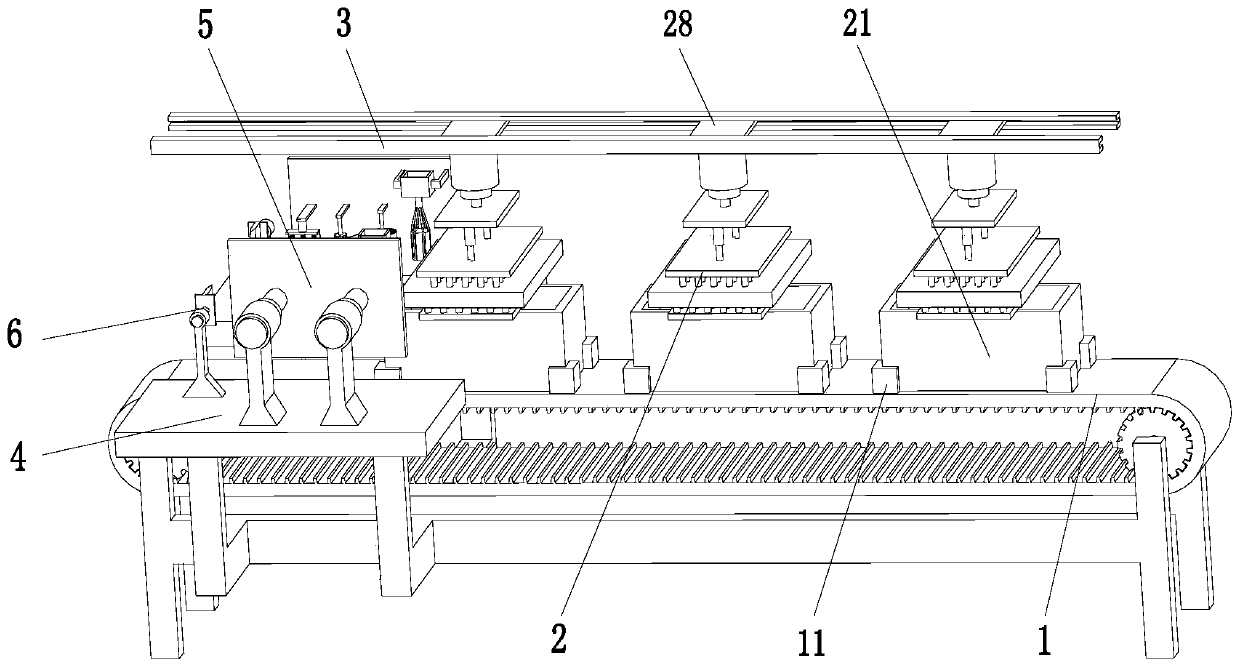

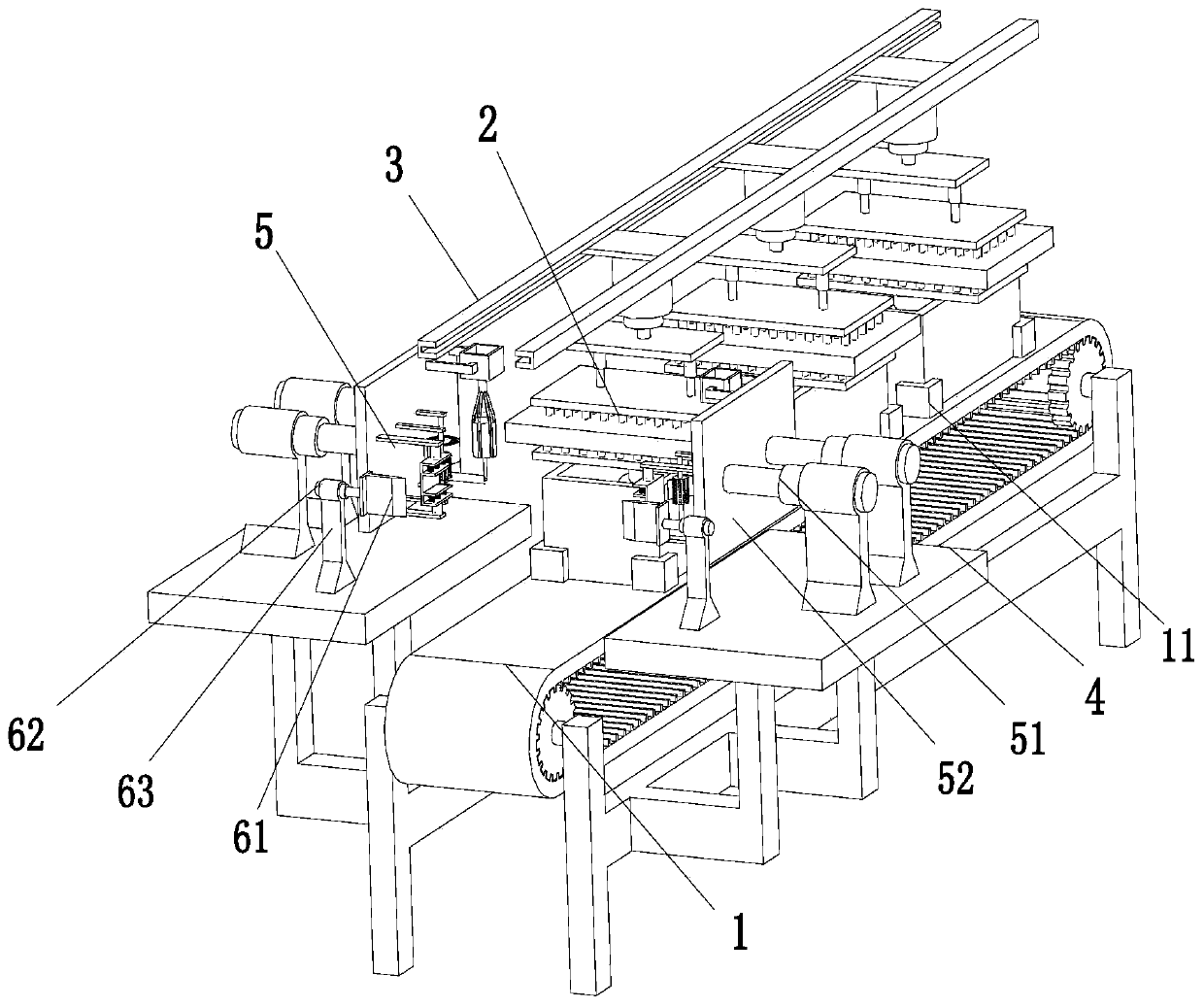

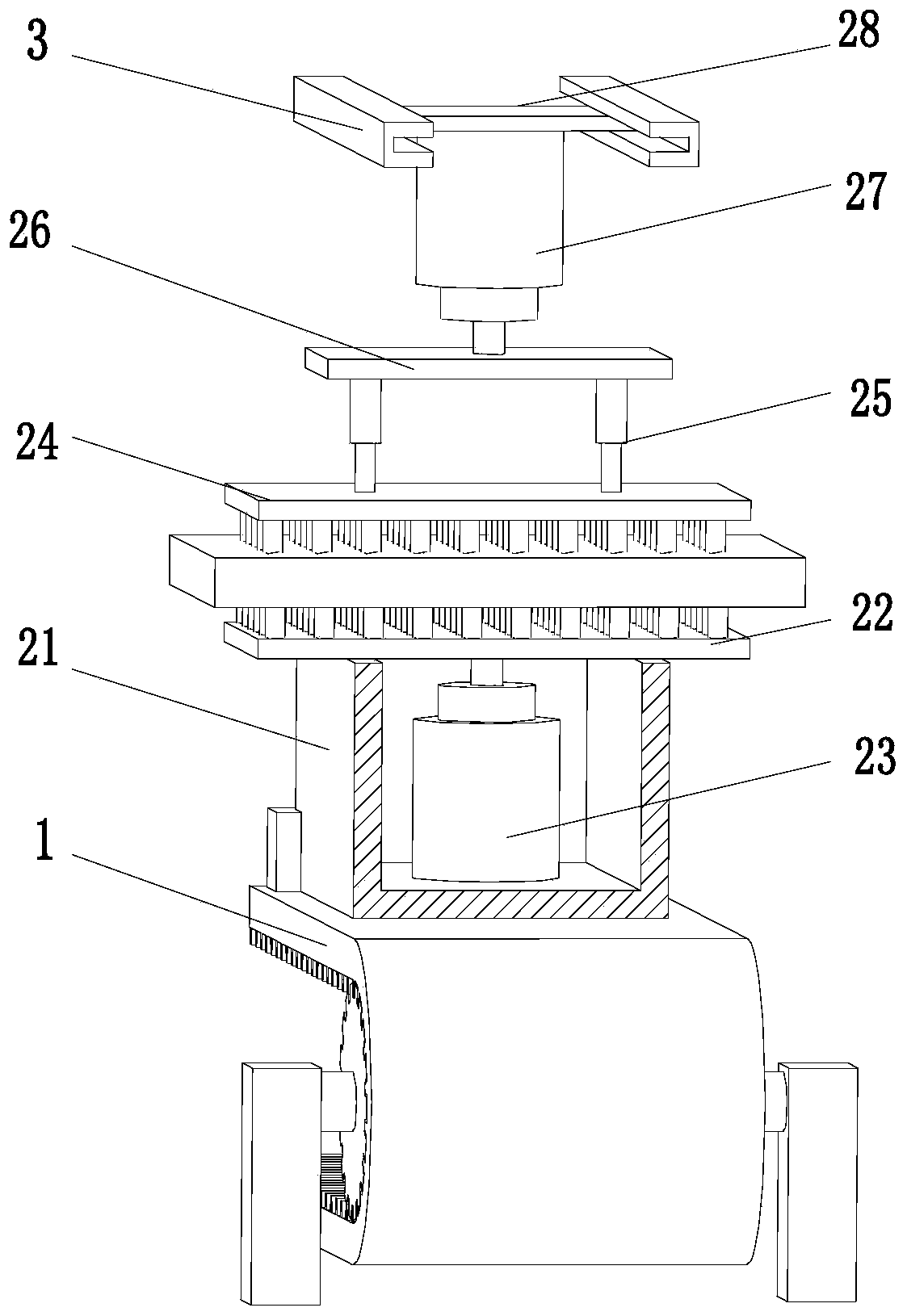

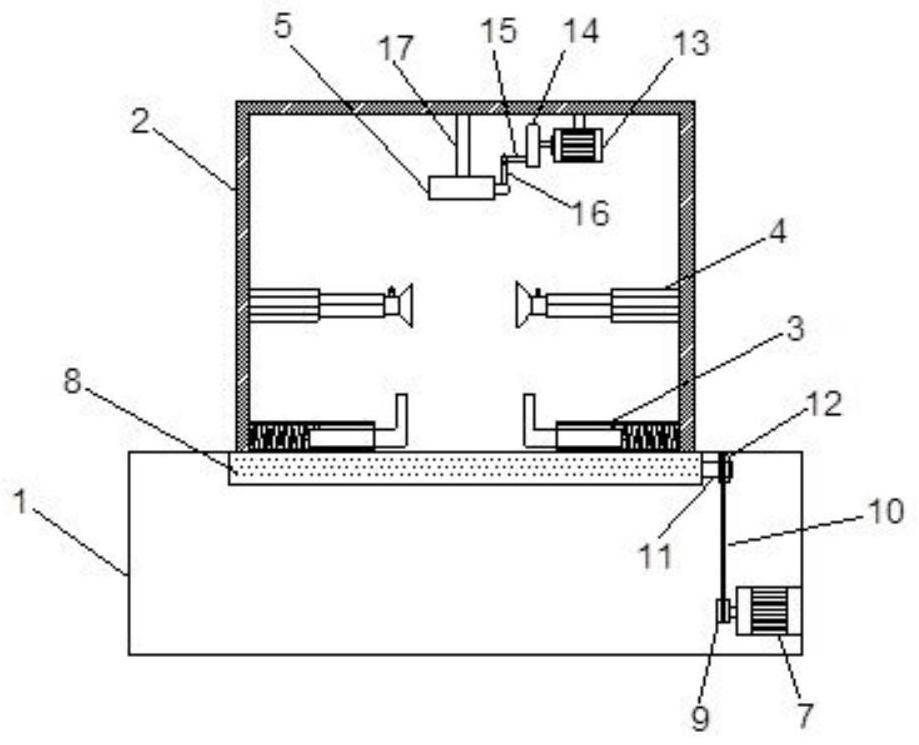

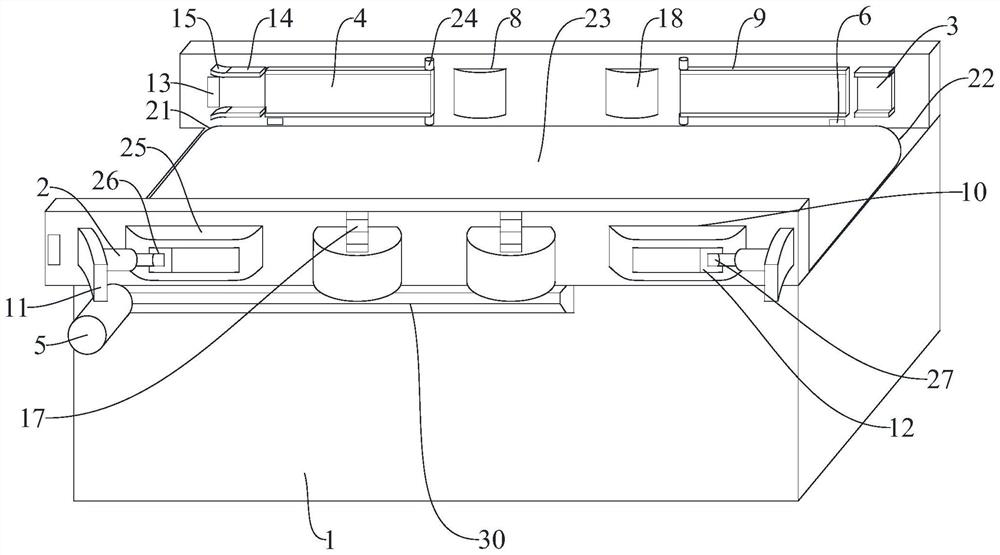

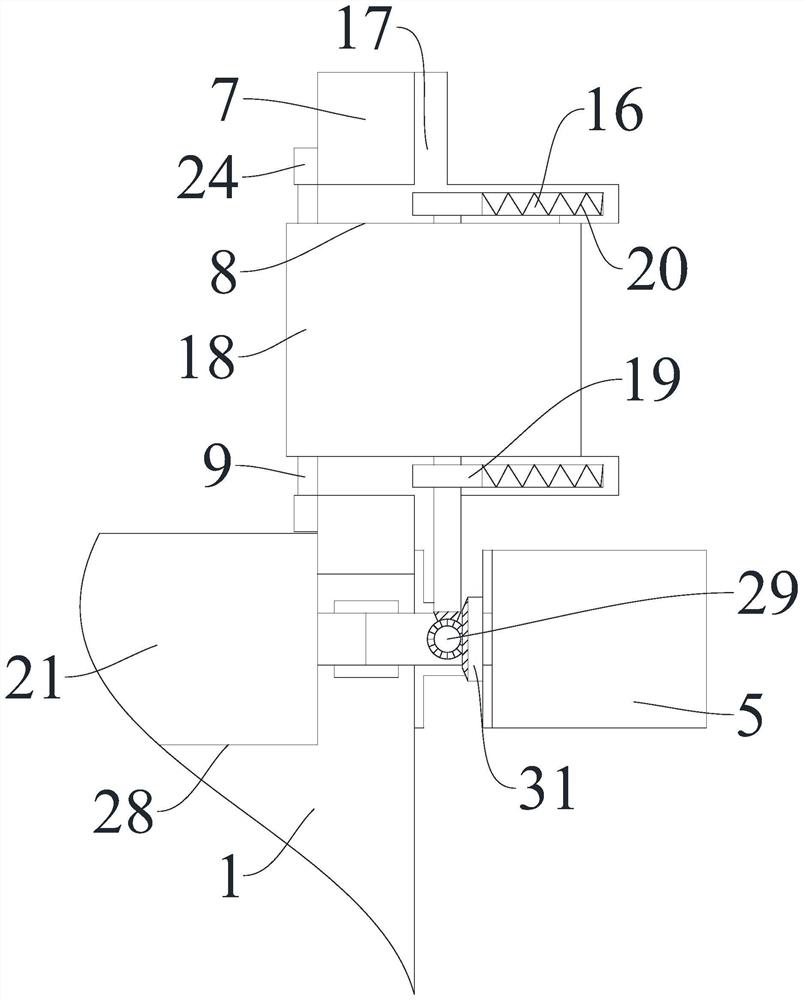

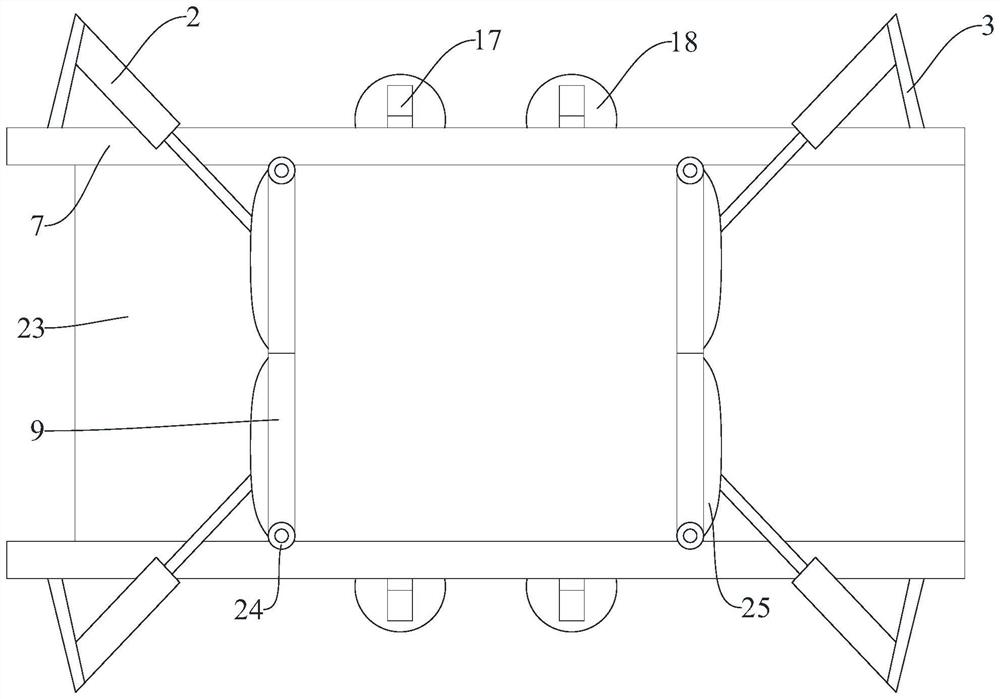

Automatic edge banding machine for plywood manufacturing

ActiveCN110524670ASolve the problem that the edge banding efficiency is low and cannot be processed in batchesImprove edge banding efficiencyOther plywood/veneer working apparatusDomestic articlesEngineeringEdge banding

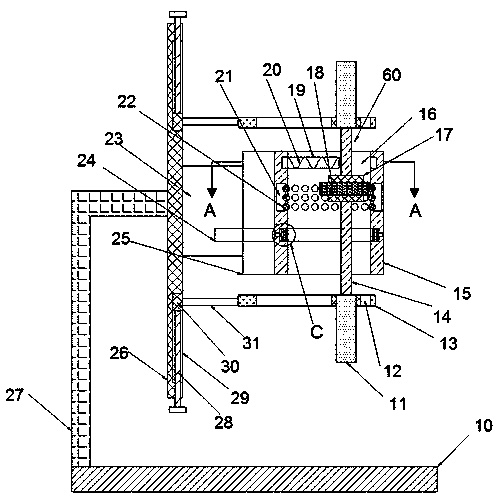

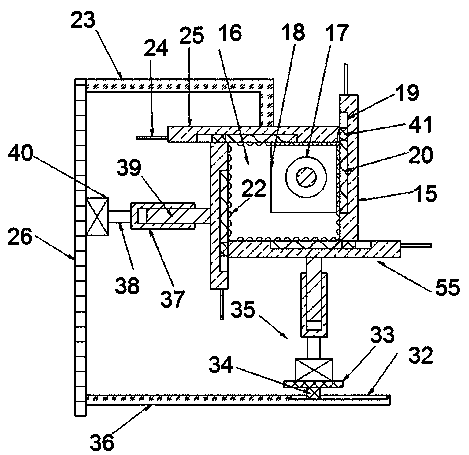

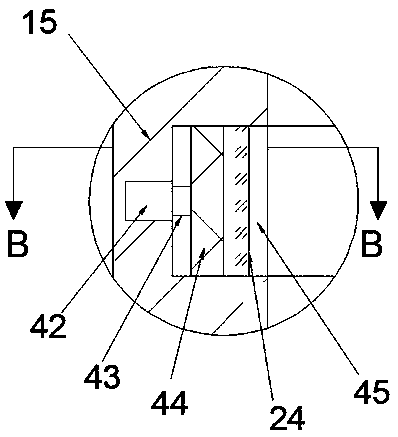

The invention relates to an automatic edge banding machine for plywood manufacturing. The machine comprises a conveying belt, clamping mechanisms, electric sliding rails, workbenches, a laminating device and a shearing mechanism, the conveying belt is fixed to the ground through a support. The clamping mechanisms are arranged above the conveying belt; the clamping mechanisms are uniformly arrangedat the top of the conveying belt; the electric sliding rails are symmetrically arranged above the clamping mechanisms; the tops of the electric sliding rails are mounted on a fixed surface such as awall surface; the tops of the clamping mechanisms are connected with the middles of the electric sliding rails in a sliding fit mode. The workbenches are symmetrically arranged on the front side and the rear side of the left end of the conveying belt, the lower ends of the workbenches are installed at the lower end of the left side of the conveying belt, the bottom of the attaching device is installed on the right side of the tops of the workbenches, the shearing mechanism is arranged on the right side of the attaching device, and the bottom of the shearing mechanism is installed on the left sides of the tops of the workbenches. The machine can solve the problems that when plywood edge sealing is conducted manually, the steps are tedious, and edge sealing treatment of large-batch plywood cannot be conducted.

Owner:广东优逸智能家私有限公司

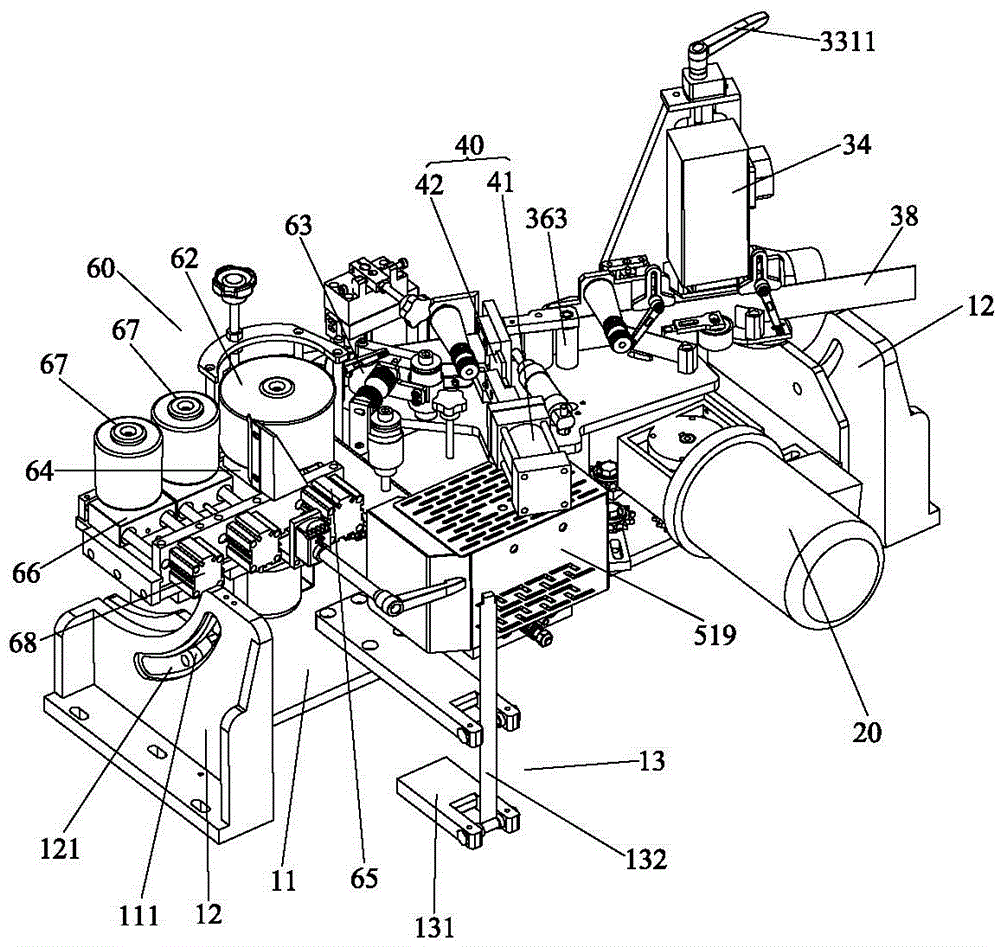

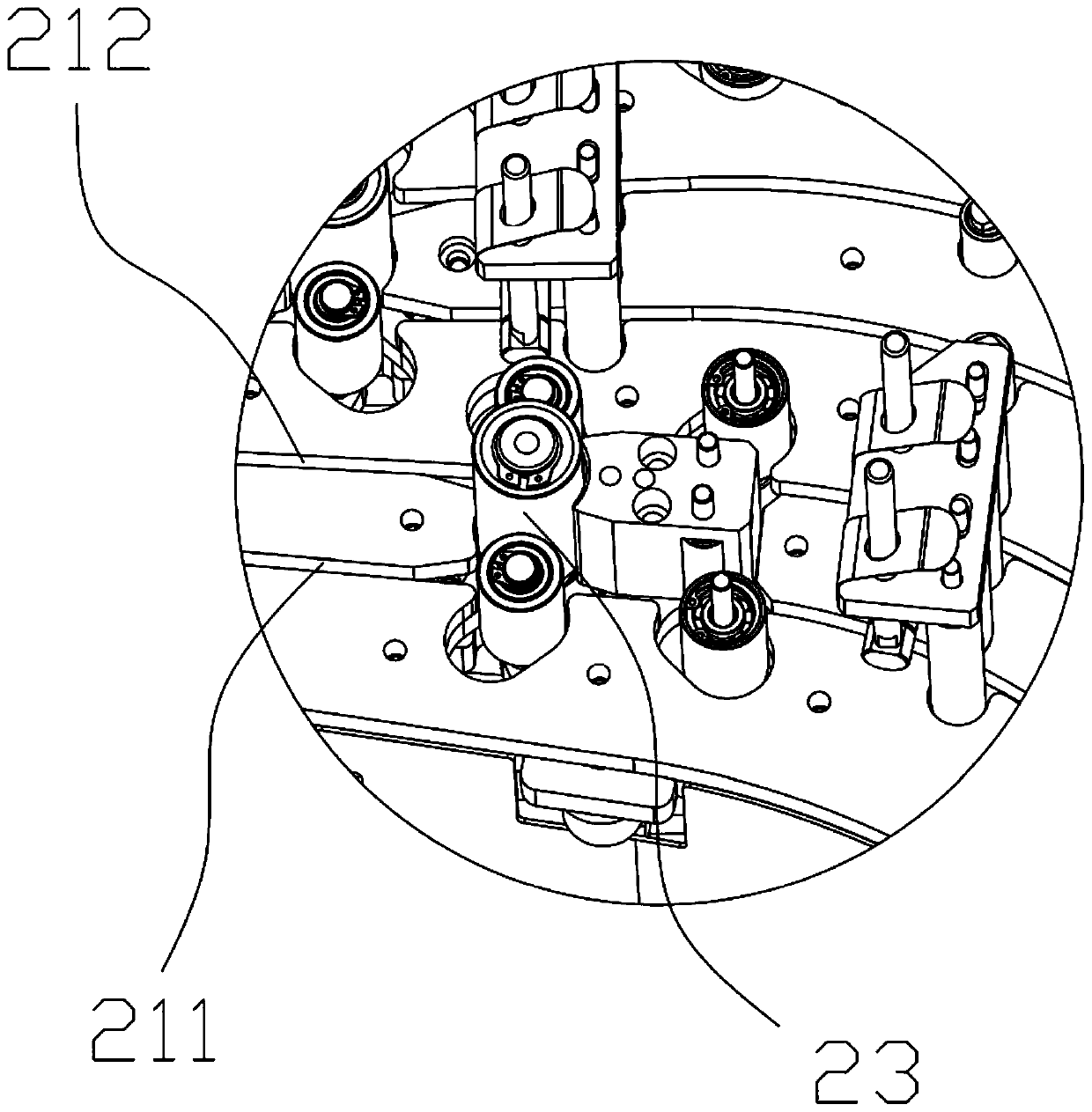

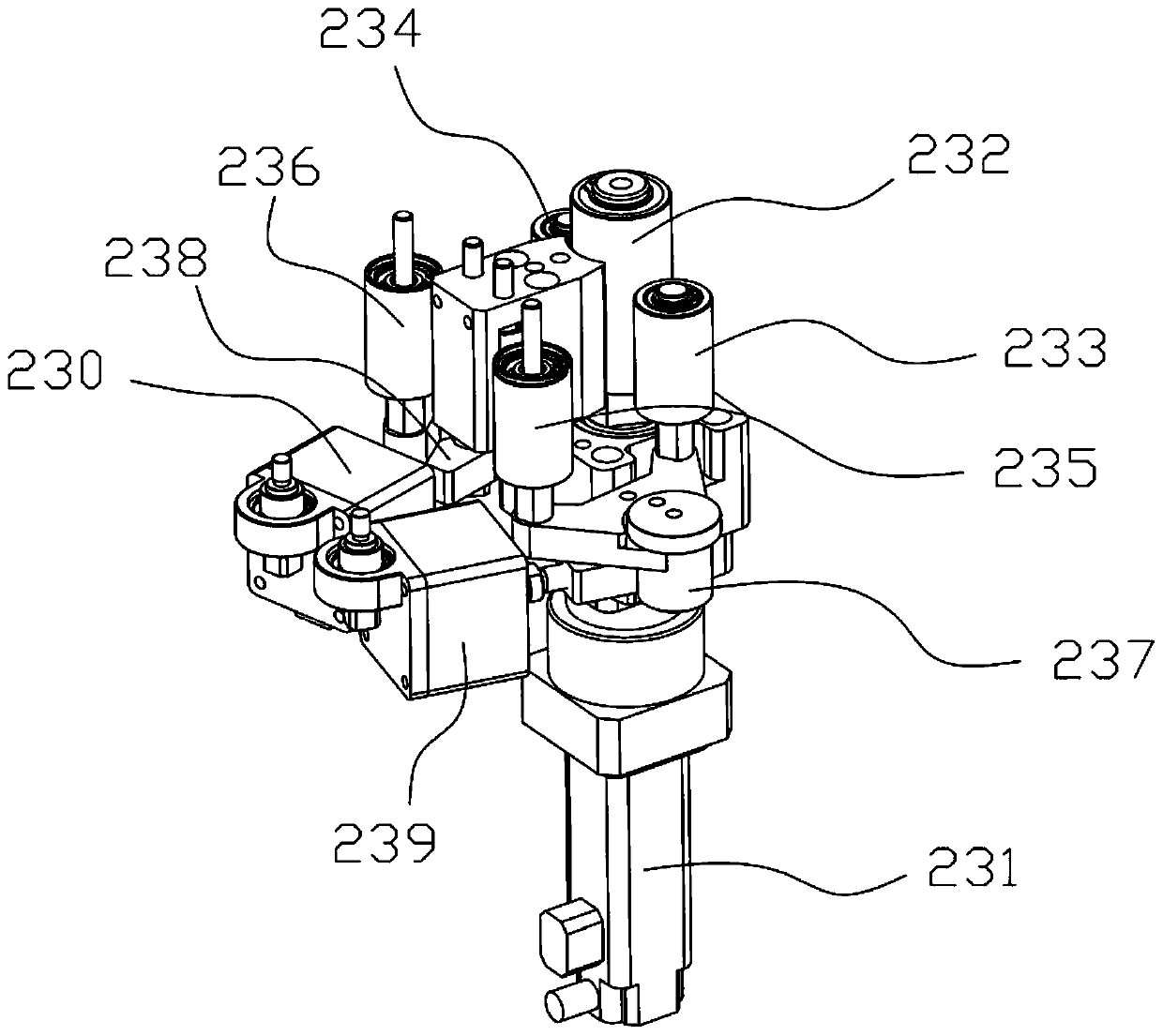

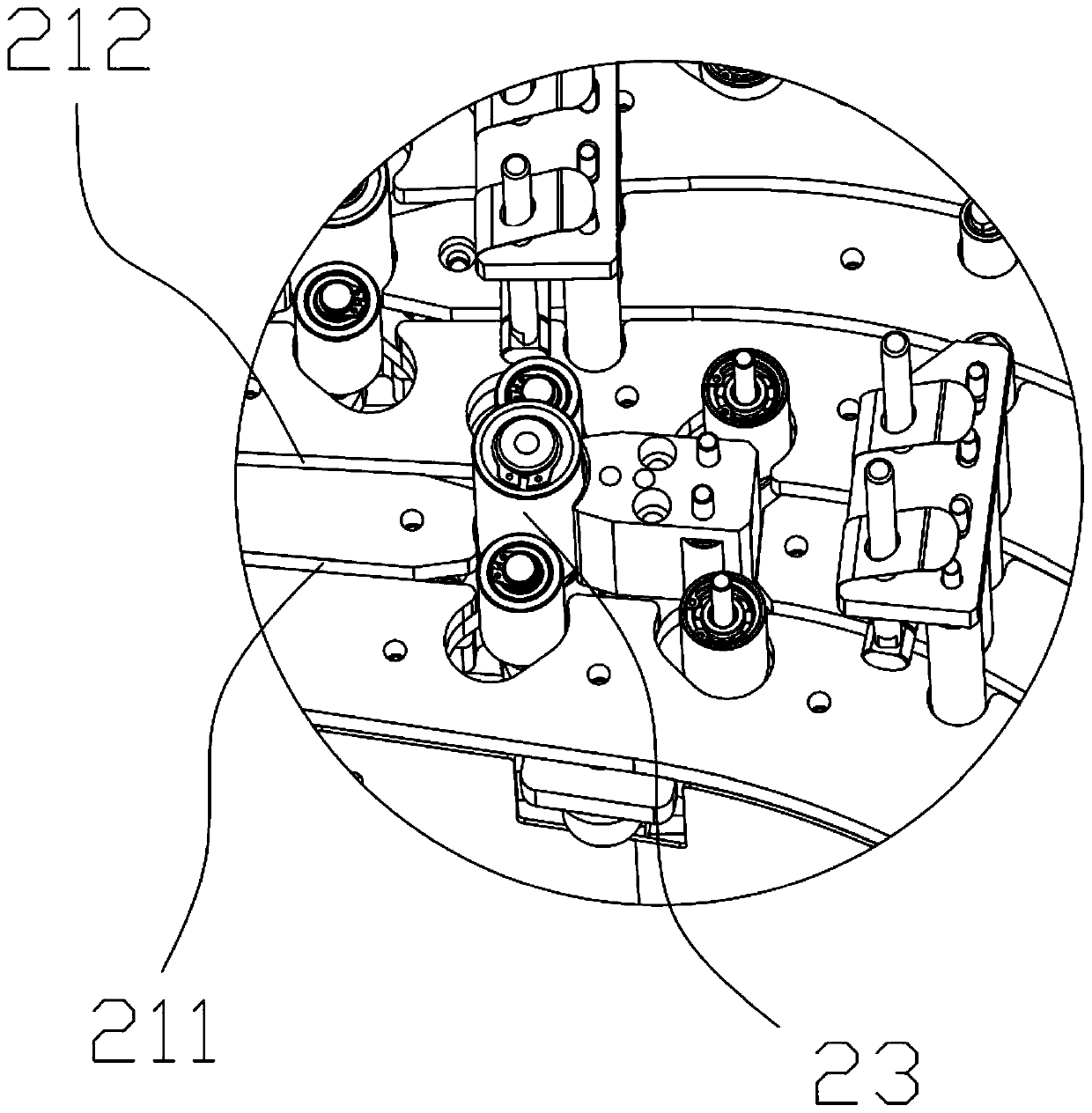

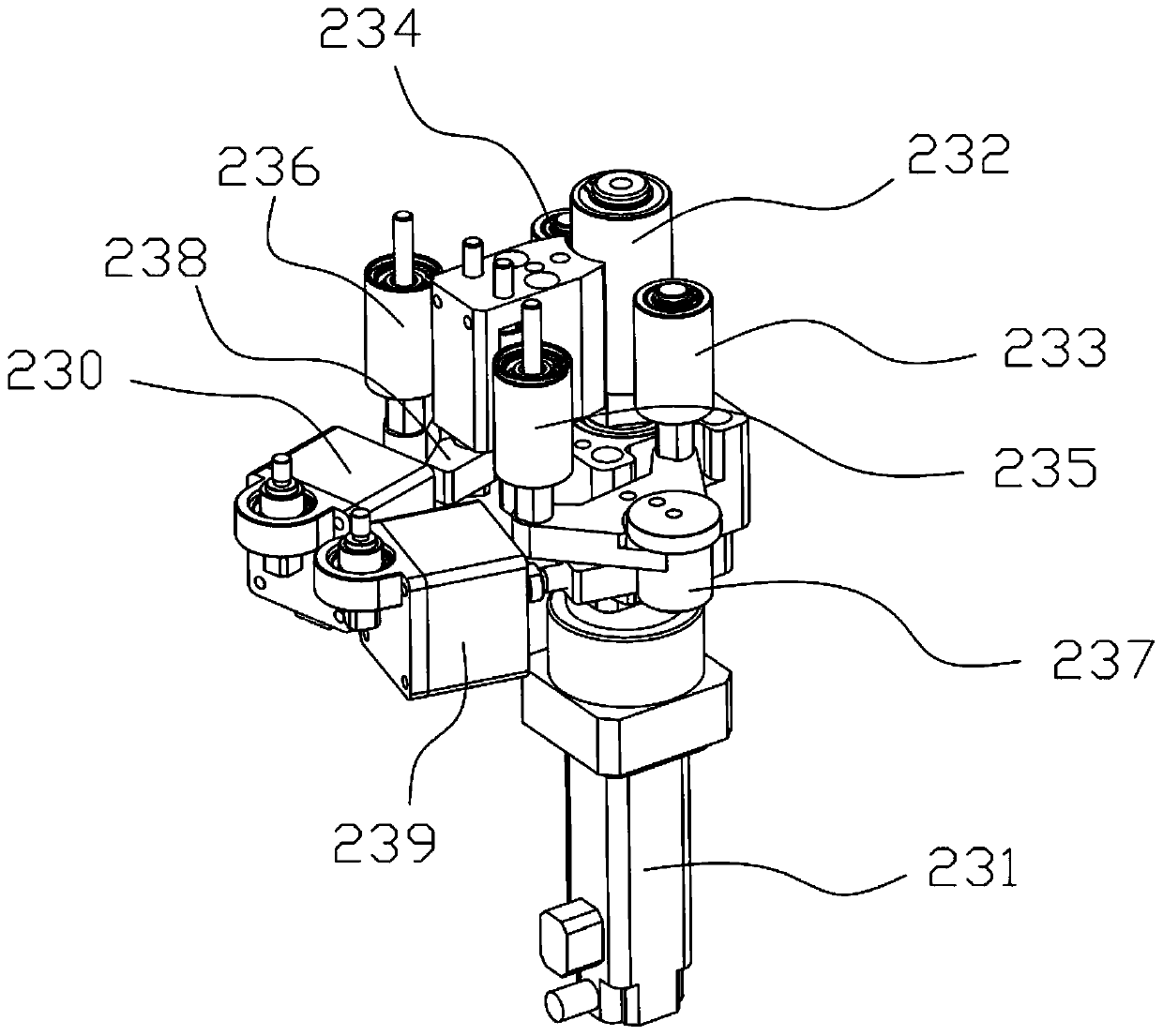

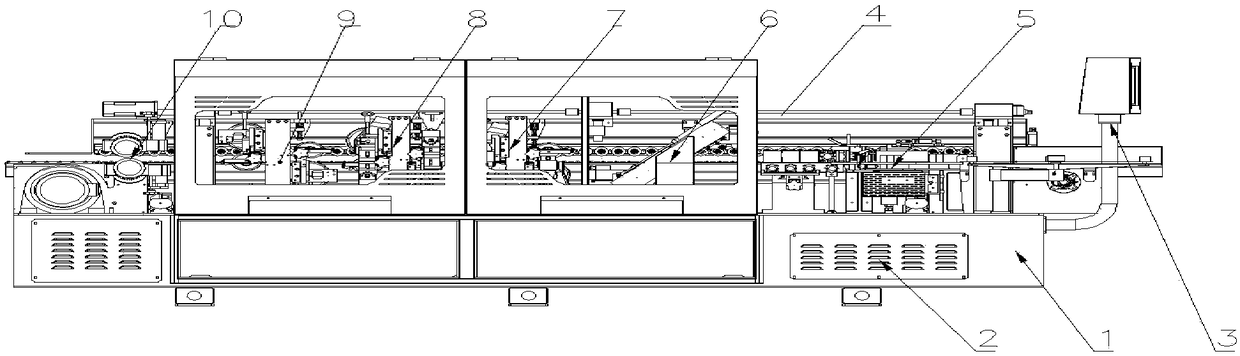

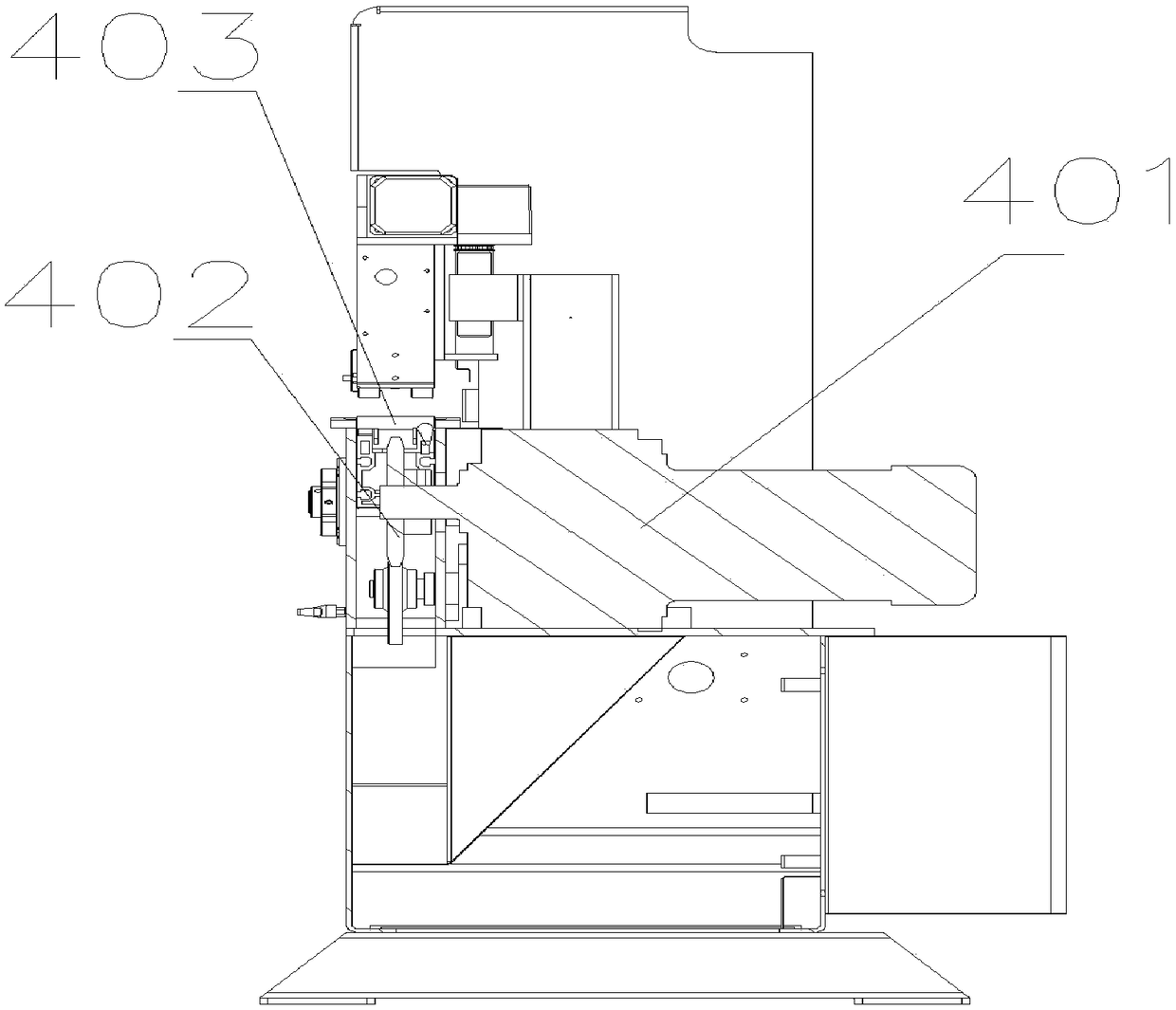

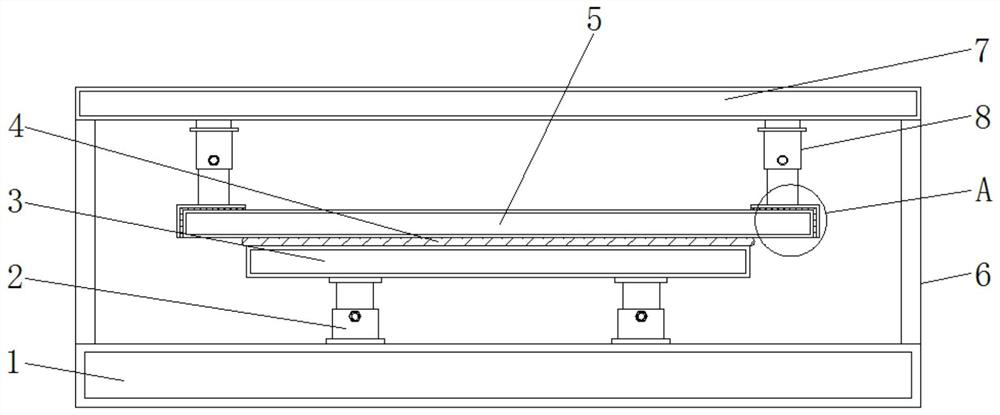

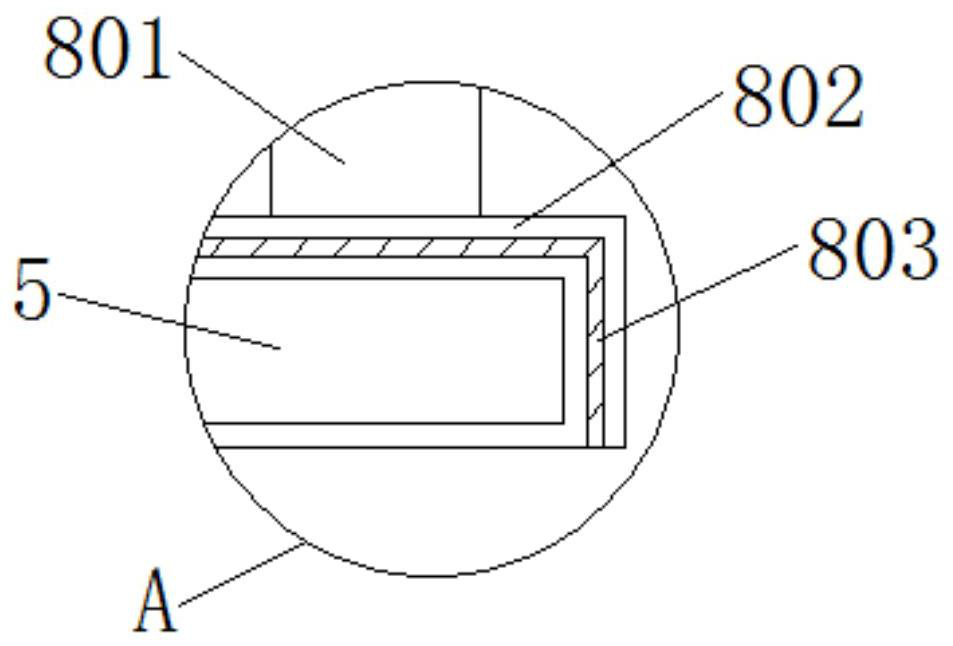

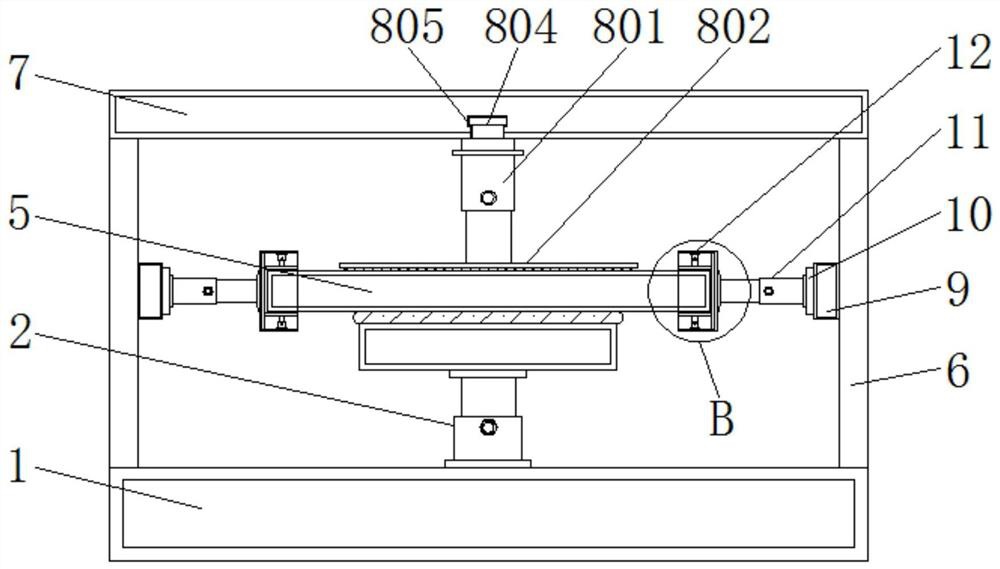

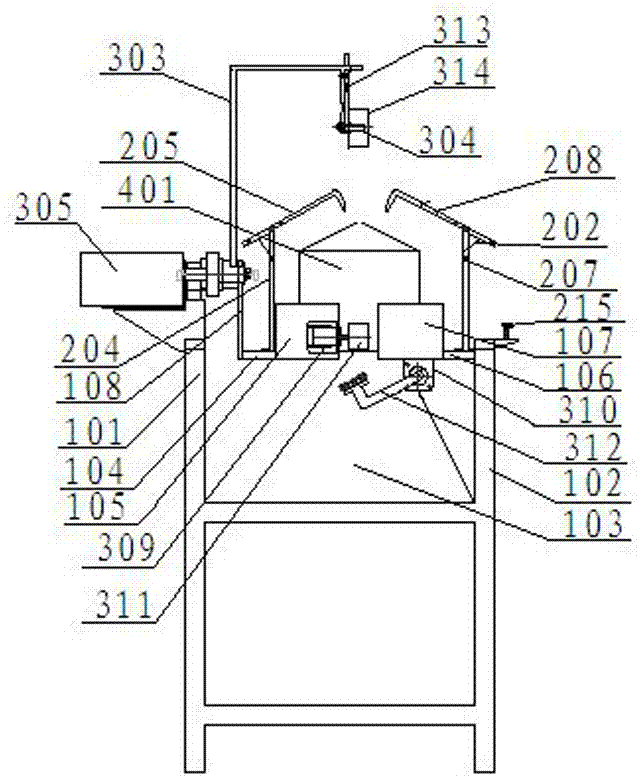

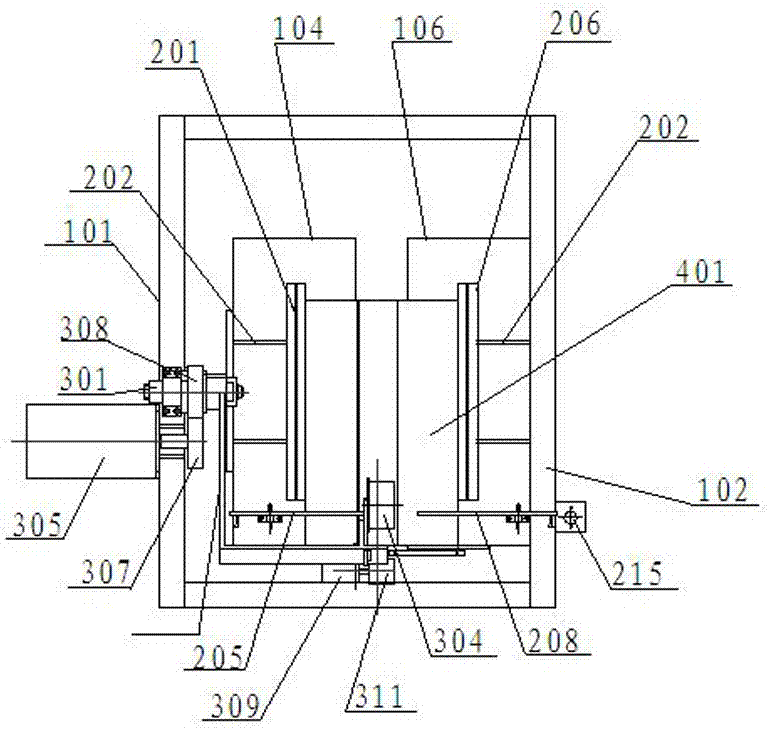

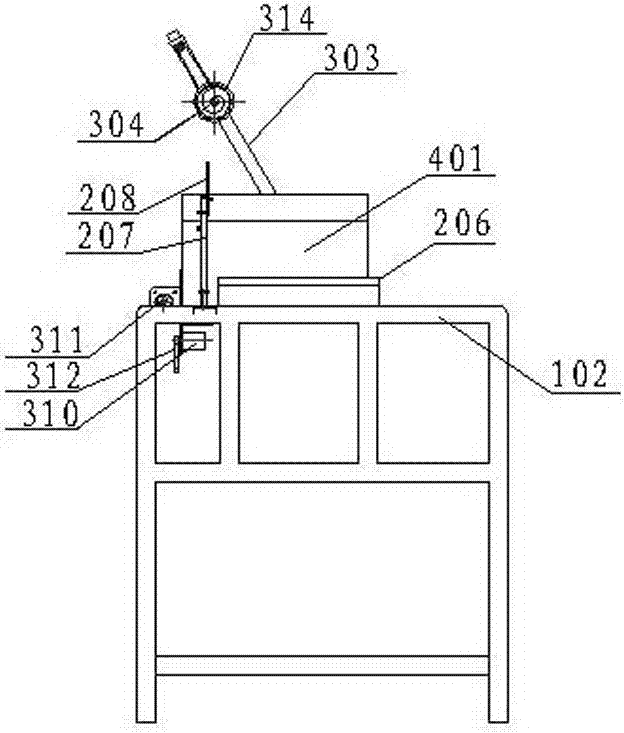

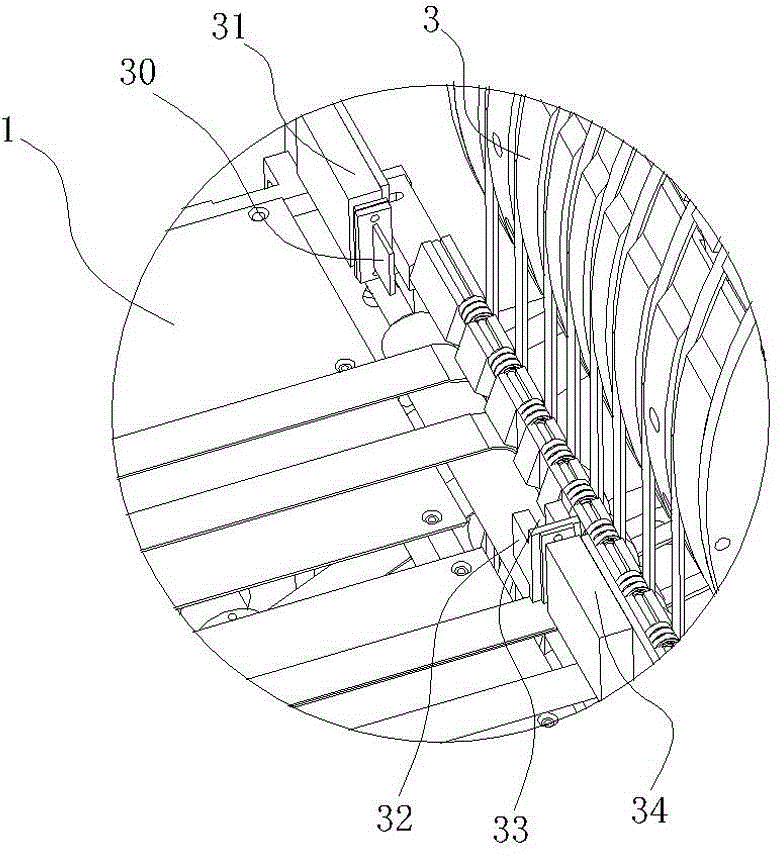

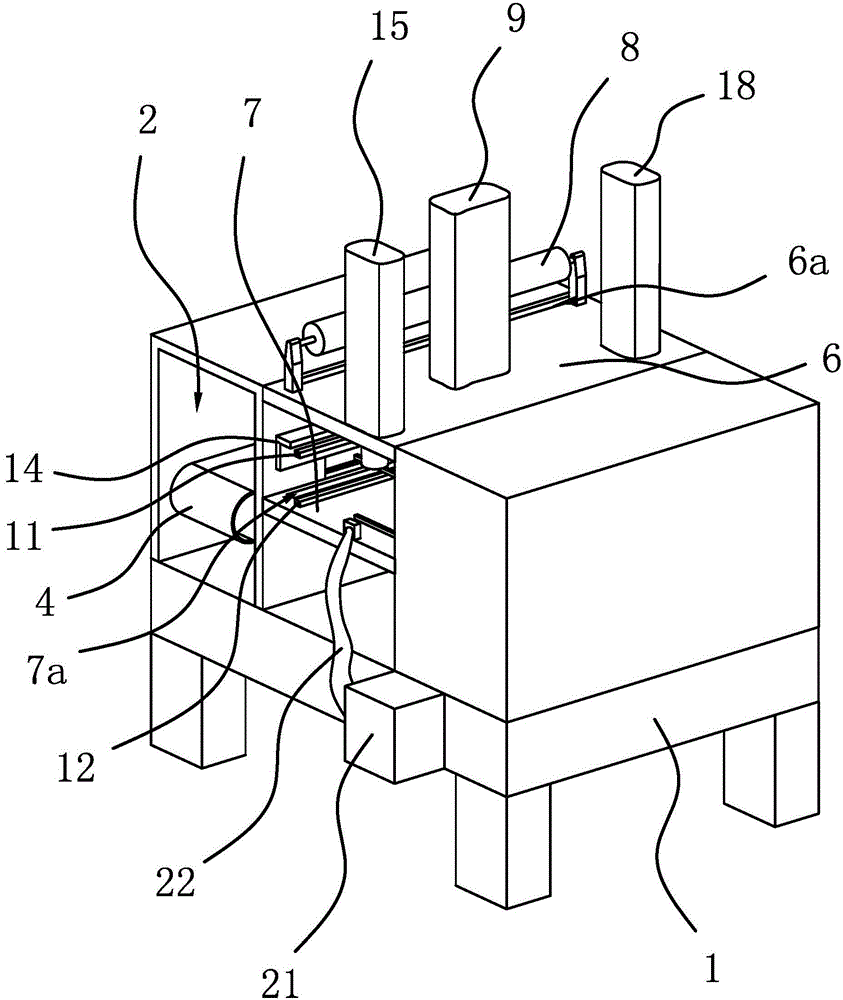

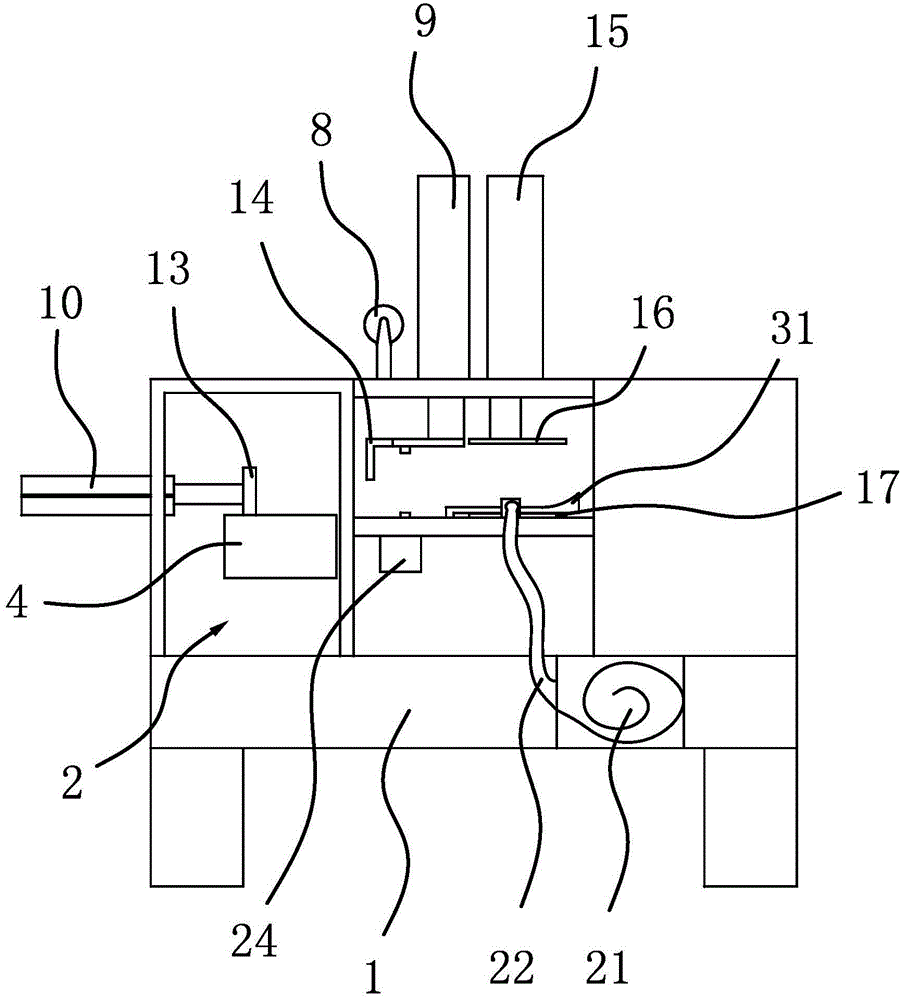

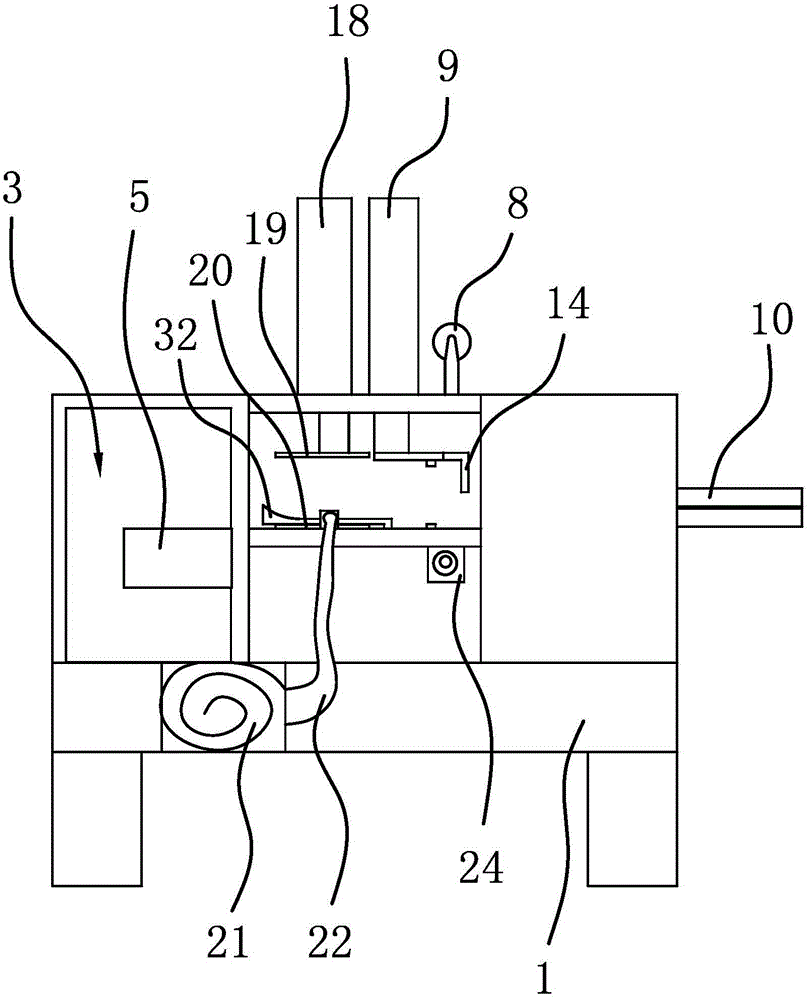

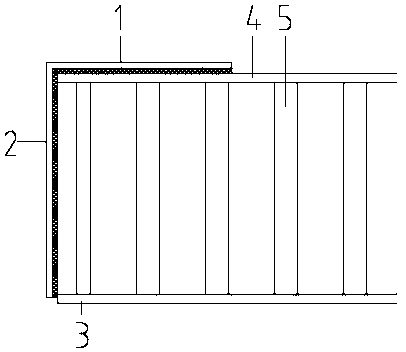

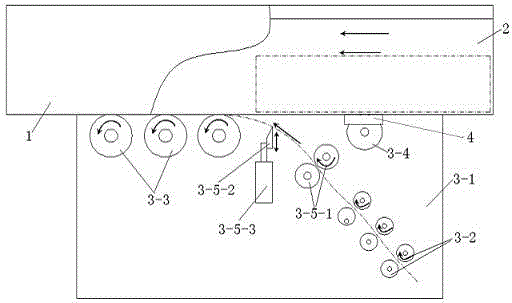

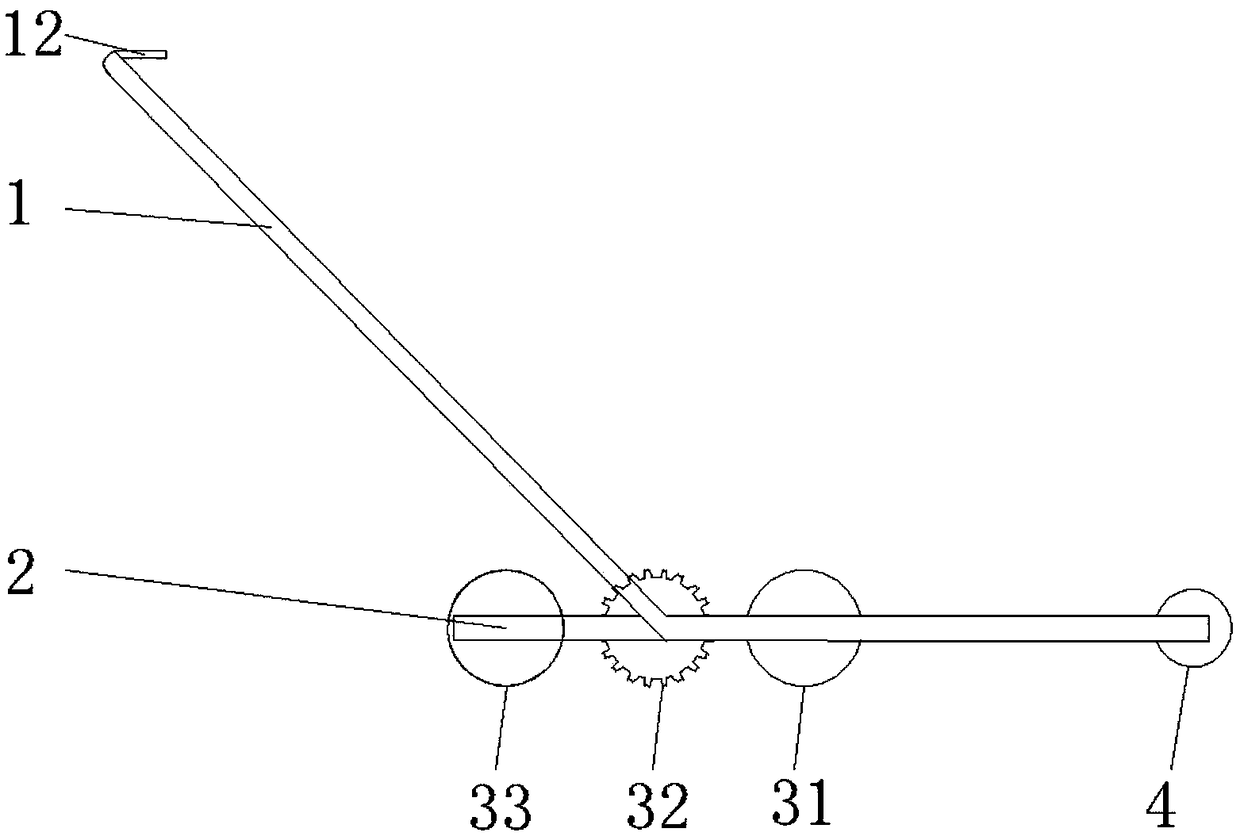

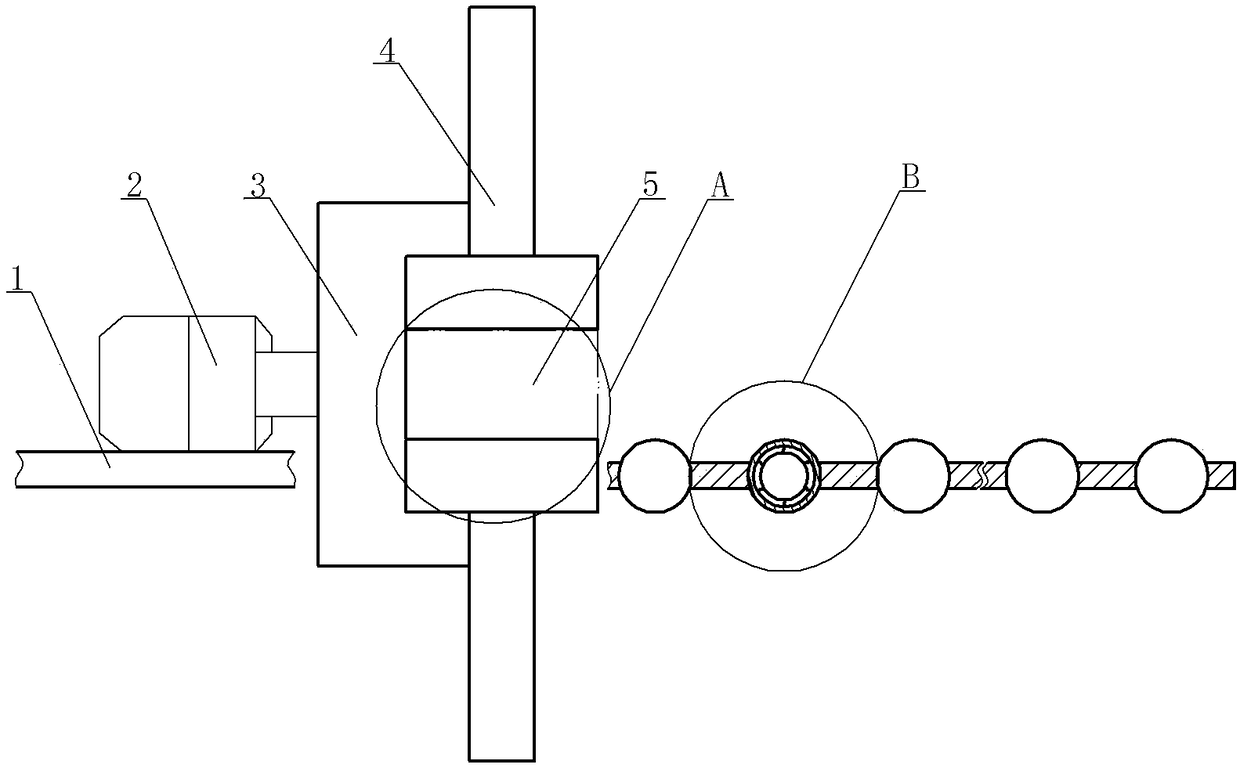

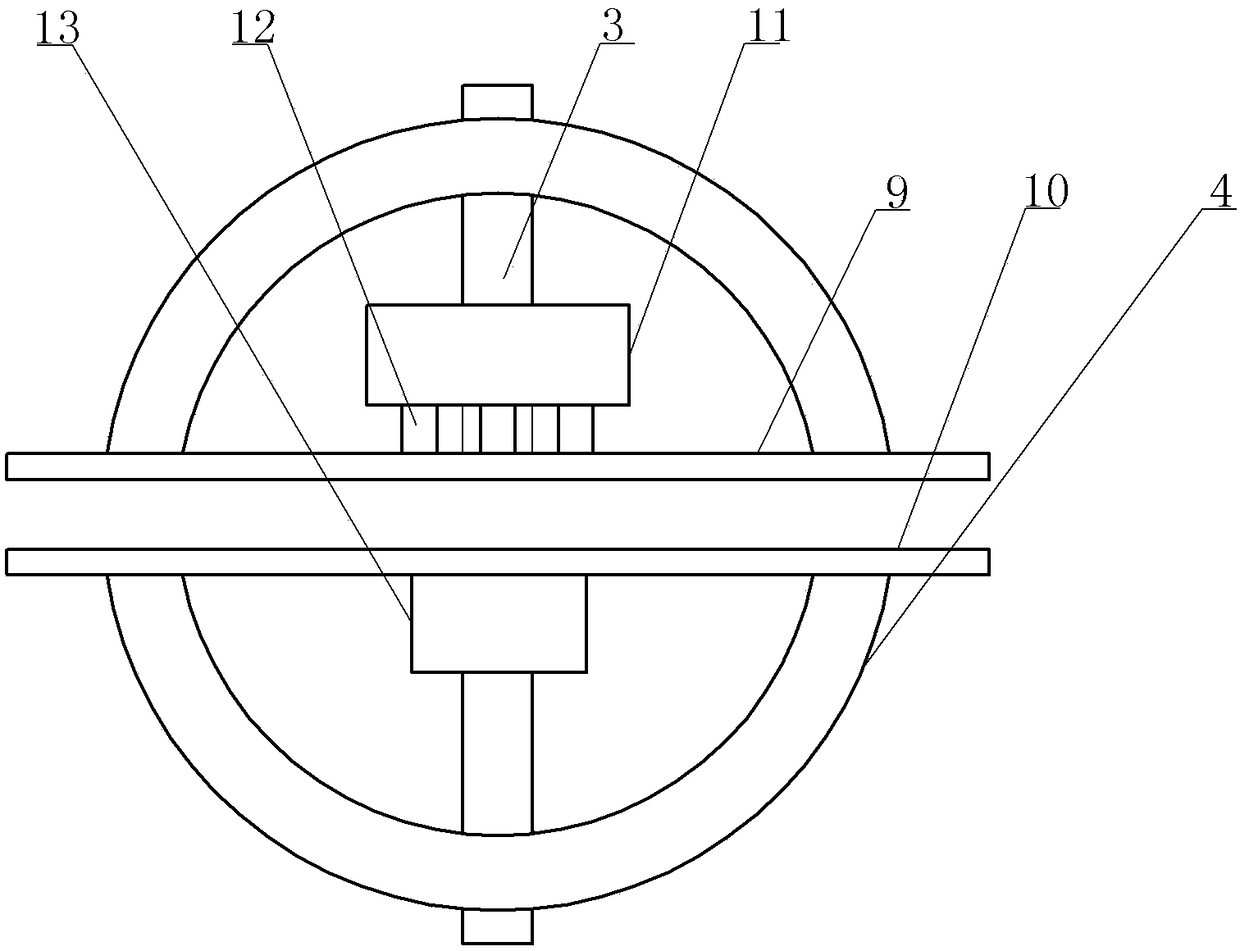

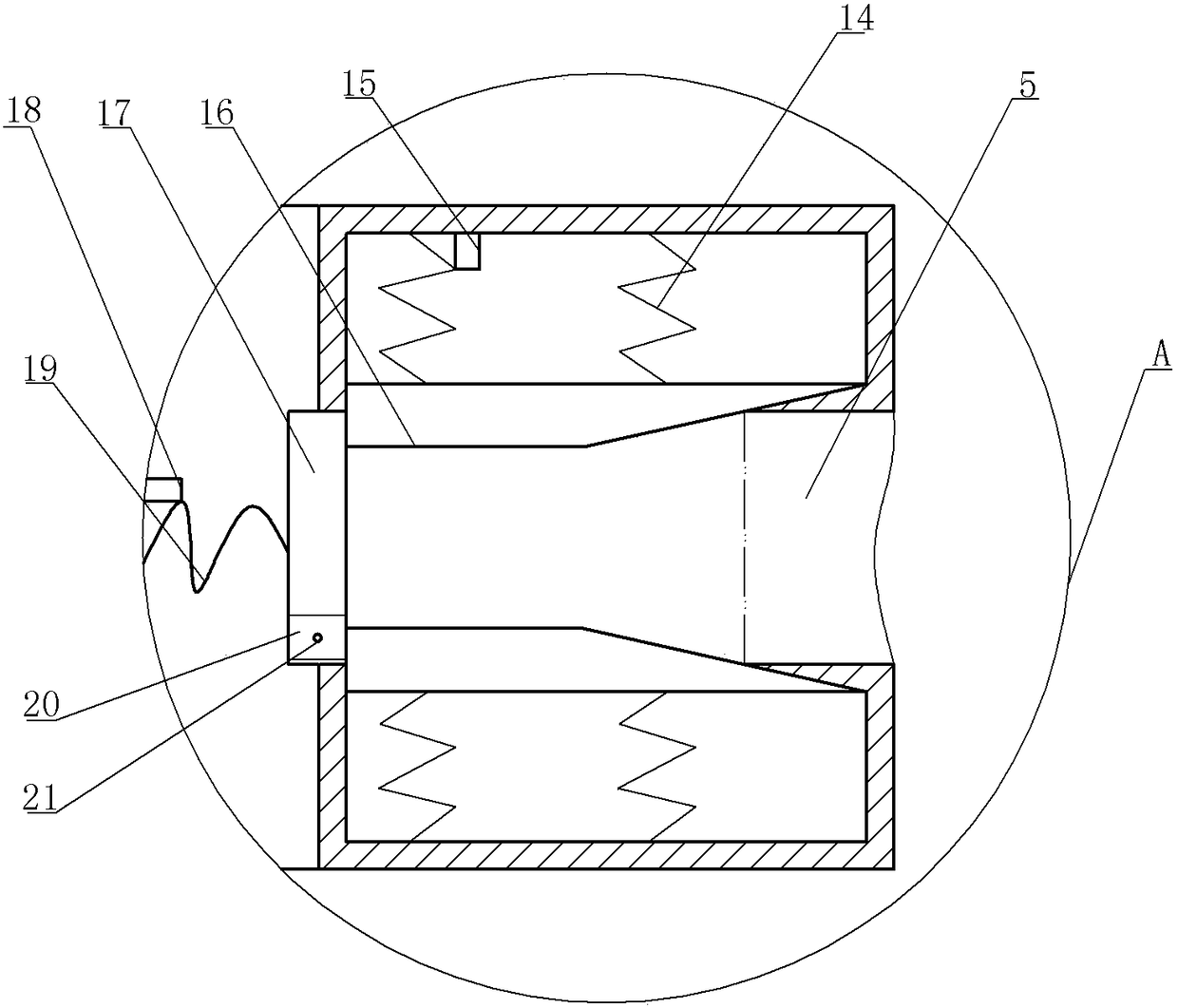

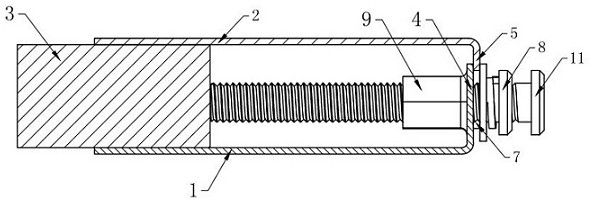

Grooving, gluing and band pressing mechanism of edge sealing band

ActiveCN105563608AImprove edge banding efficiencyImprove edge qualityLiquid surface applicatorsWood working apparatusElectric machineStructural engineering

The invention discloses a grooving, gluing and band pressing mechanism of an edge sealing band. The grooving, gluing and band pressing mechanism comprises a rack, a transmission mechanism, a grooving mechanism, a cut-off mechanism, a bevel edge sealing glue supply mechanism and a band pressing guide mechanism. The transmission mechanism is mounted at the bottom of the rack and provided with a plurality of rotary shafts, and a roller is arranged on one rotary shaft in a sleeved manner. The grooving mechanism comprises a bottom plate, a feeding backup plate, a motor fixing seat, a grooving motor, a grooving cutter and a band pressing assembly. The cut-off mechanism comprises a drive air cylinder and a cutter mounted at the shaft end of the drive air cylinder. The bevel edge sealing glue supply mechanism comprises a glue storage box, a glue supply seat, a glue supply column, a glue stop column, a glue feeding piece and a glue scraping mechanism. The band pressing guide mechanism comprises a guide motor, a main pressing wheel mounted at the shaft end of the guide motor and a guide wheel rotationally arranged at the side of the glue scraping mechanism. Thereby, the mechanisms are combined into the grooving, gluing and band pressing mechanism of the edge sealing band, automatic edge sealing is achieved, manual labor is reduced, edge sealing efficiency and edge sealing quality are improved, and cost is reduced.

Owner:NANXING MACHINERY CO LTD

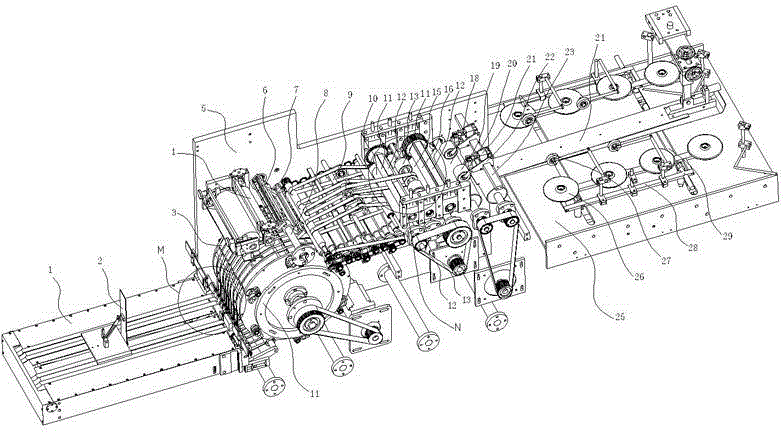

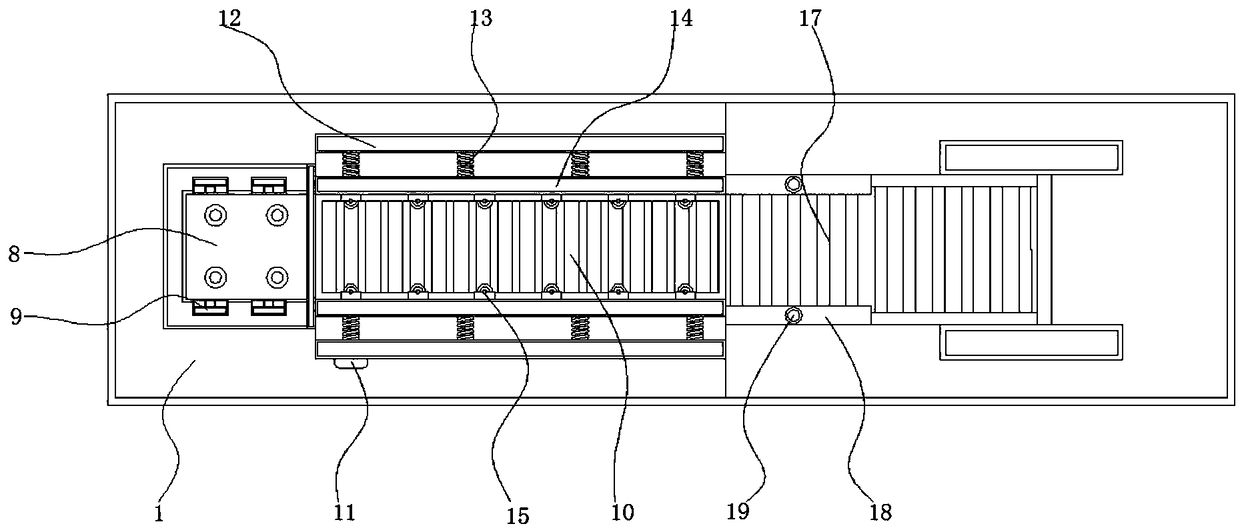

Machining method of automatic edge banding machine

ActiveCN111391061ASolve the problem of blocked edge banding efficiencyImprove edge banding efficiencyOther plywood/veneer working apparatusProfiling/shaping machinesWire cuttingStructural engineering

The invention relates to the technical field of edge banding machines, in particular to a machining method of an automatic edge banding machine. The method comprises the following steps that A, when amaterial passes through a band supply mechanism, the band supply mechanism conveys a material band to working areas of a band cutting mechanism and a glue supply mechanism from an external band storage mechanism; B, when the material passes through a flat cutting and head aligning mechanism, redundant sidebands at the two ends of a workpiece located on a conveying mechanism are cut off through the flat cutting and head aligning mechanism; C, when the material passes through a fine trimming mechanism, the fine trimming mechanism cuts upper and lower sidelines of the sidebands of the workpieceon the conveying mechanism to form arcs; D, when the material passes through a copying trimming mechanism, copying trimming is conducted on sharp edges of the two ends of the workpiece located on theconveying mechanism; and E, when the material passes through an edge scraping mechanism, arc edges of the workpiece located on the conveying mechanism are scraped for trimming. The machining method ofthe automatic edge banding machine solves the problem that the edge banding efficiency of the edge banding machine is hindered.

Owner:NANXING MACHINERY CO LTD

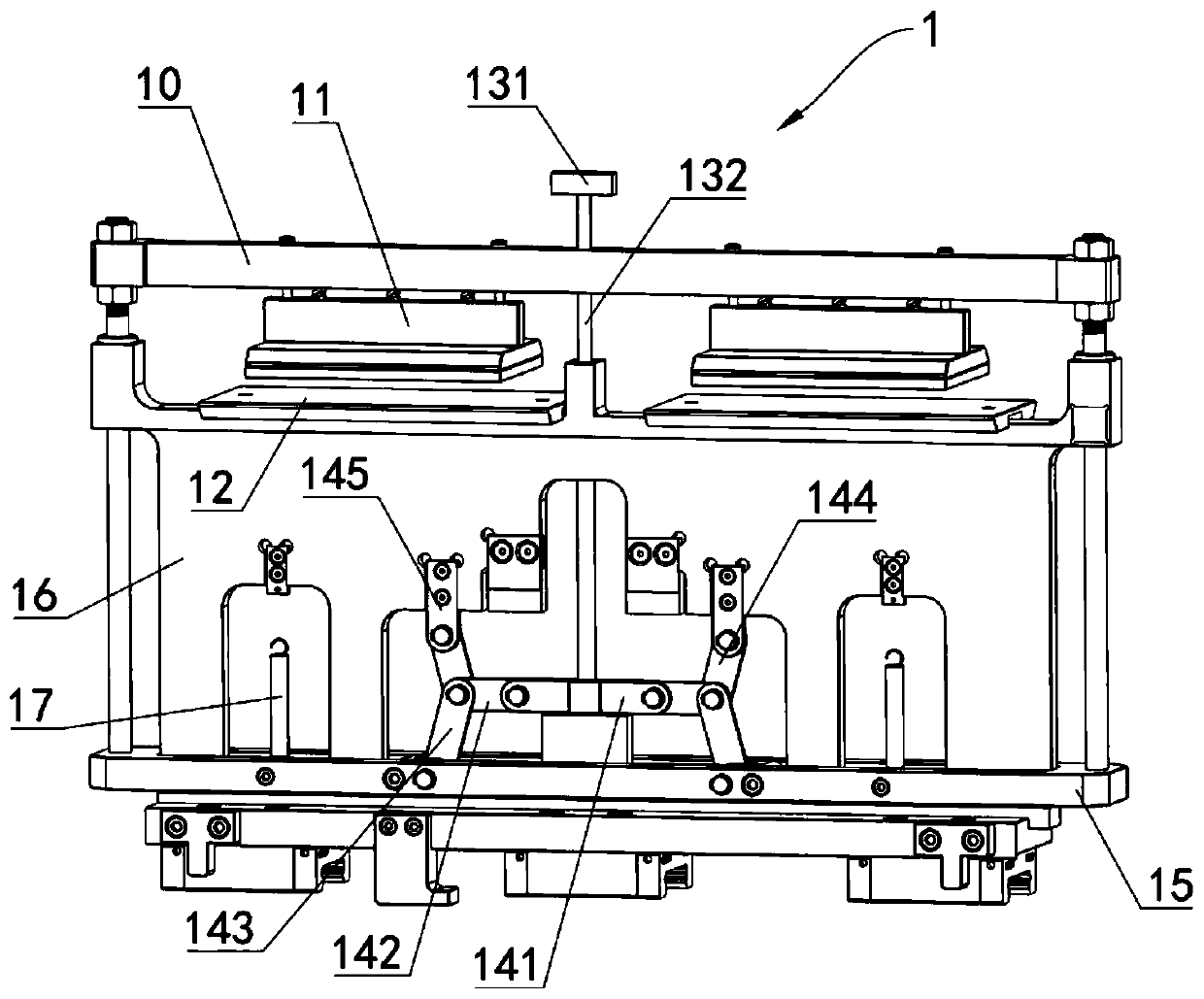

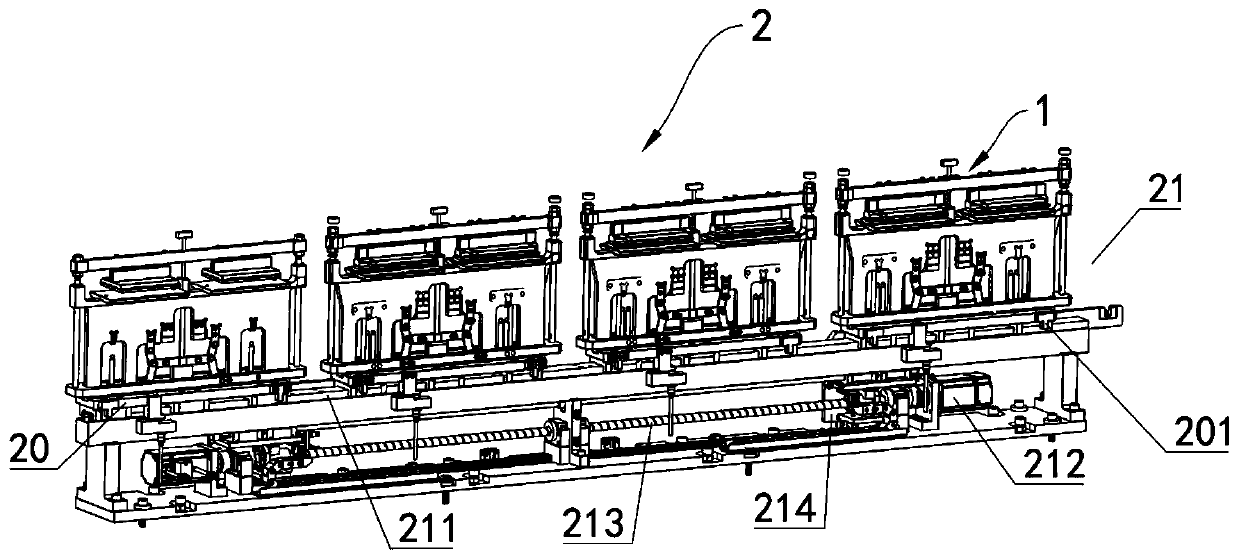

Gluing and edge sealing production line

PendingCN111229531AHigh precisionFully automatedLiquid surface applicatorsCoatingsProduction lineIndustrial engineering

The invention relates to the technical field of cell production, and discloses cell jigs and a gluing and edge sealing production line. The gluing and edge sealing production line comprises a cuttingdevice, a first skirt edge shaping device, a gluing device, a gluing detection device and a folded edge shaping device, wherein the gluing device comprises a photographing positioning module and two gluing modules. By adopting the gluing and edge sealing production line provided by the invention, the skirt edge of a cell can be subjected to cutting, shaping, gluing, gluing detection and folded edge shaping treatment in sequence, and automation of gluing and edge sealing of the cell is achieved; a feeding device can convey at least two cells to a jig reflow device at a time, and the gluing andedge sealing efficiency of the cells is improved; and in addition, the gluing device provided by the invention conducts gluing on the skirt edges of the two cells through the two gluing modules correspondingly, each gluing module comprises a gluing assembly, gluing is conducted on the upper surfaces and the lower surfaces of the skirt edges of the cells, the outer walls of the skirt edges of the cells are wrapped with glue sprayed out from the upper surfaces and / or the lower surfaces, and the gluing precision is improved.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

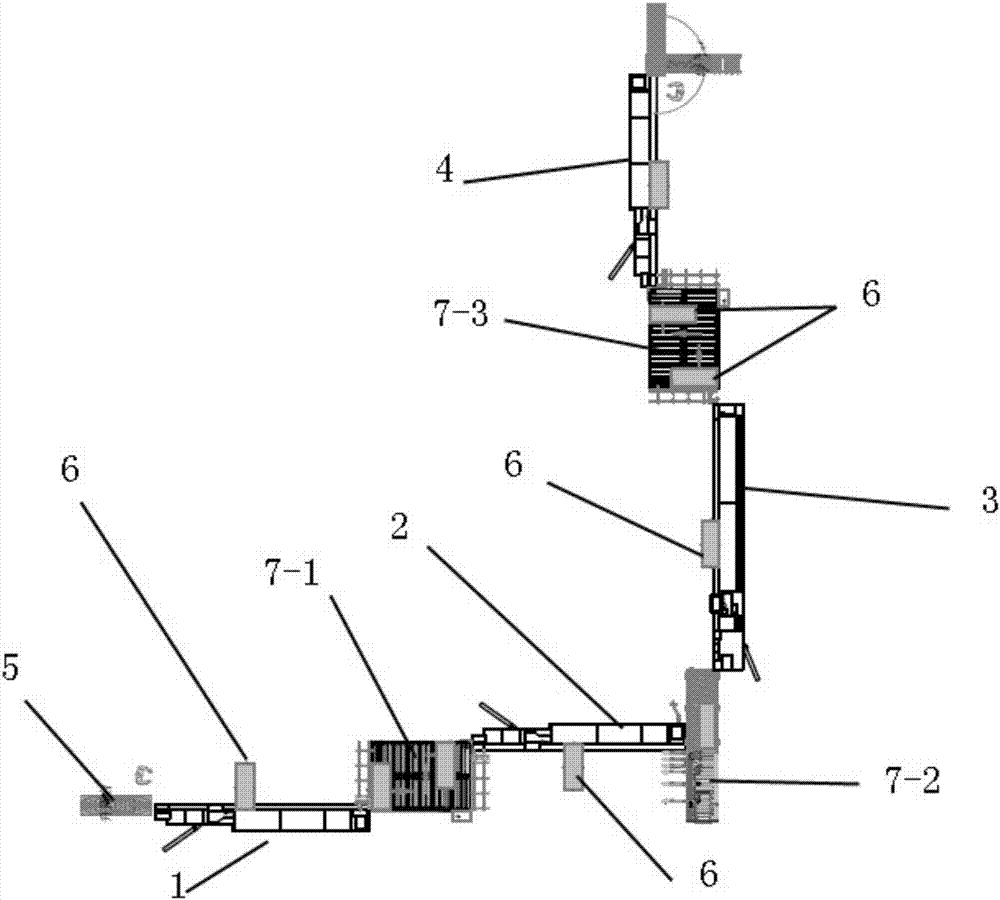

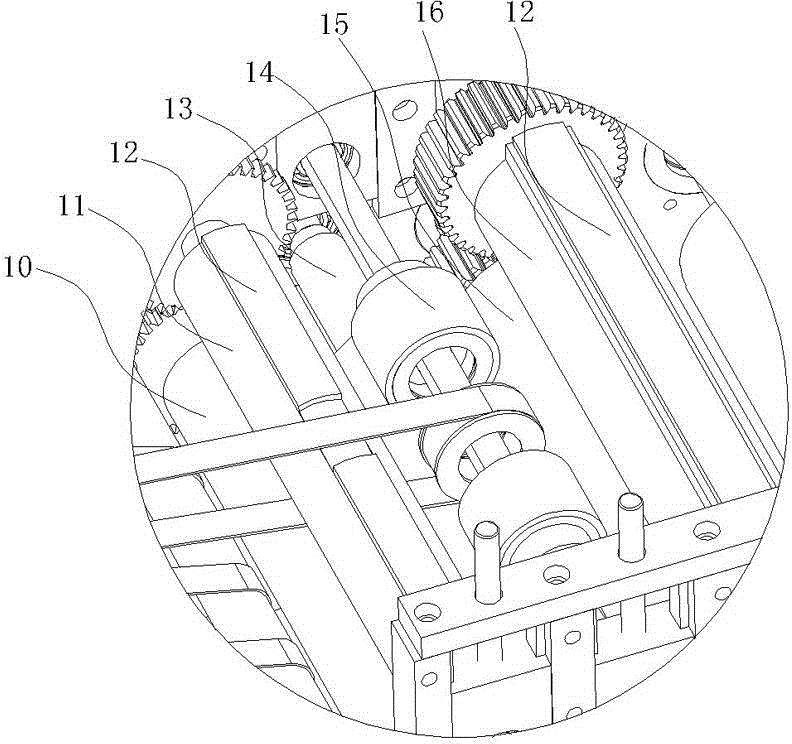

Edge sealing method of L-shaped four-machine connecting edge sealing machine

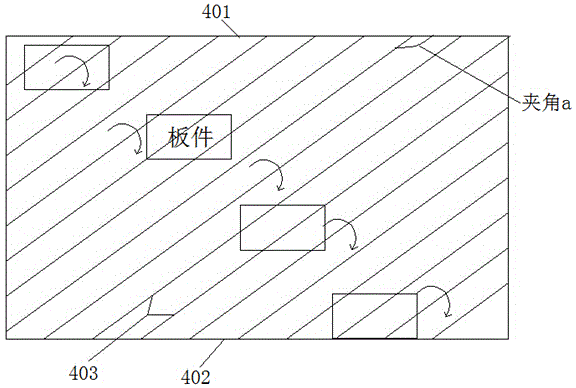

PendingCN106863541ALow shape requirementImprove edge banding efficiencyWood working apparatusDomestic articlesEngineeringEdge banding

The invention discloses an edge sealing method of an L-shaped four-machine connecting edge sealing machine. The four-machine connecting edge sealing machine comprises a first edge sealing machine body, a second edge sealing machine body, a third edge sealing machine body and a fourth edge sealing machine body which are in an L-shaped connecting shape. The edge sealing method comprises the following steps that (1) a lifting table ascends to the height of the feeding face of the first edge sealing machine body, and a plate is placed on an automatic feed mechanism; (2) the automatic feed mechanism conveys the plate to the first edge sealing machine body, and the edge a is sealed; (3) the plate with the edge a sealed is conveyed to the second edge sealing machine body through a first conveying device set, and the edge b is sealed; (4) the plate with the edge b sealed is conveyed to the third edge sealing machine body through a second conveying device set, and the edge c is sealed; and (5) the plate with the edge c sealed is conveyed to the fourth edge sealing machine body through a third conveying device set, and the edge d is sealed. According to the edge sealing method of the L-shaped four-machine connecting edge sealing machine, the edge sealing efficiency is high, the requirement for the shape of the plate is not high, a special-shaped plate (such as an L-shaped plate) with two sets of edges parallel can be sealed, and meanwhile the situation that edge sealing is adjusted through rotation for the plate in the edge sealing process is not needed.

Owner:FOSHAN BEITE OFFICE SYST EQUIP CO LTD

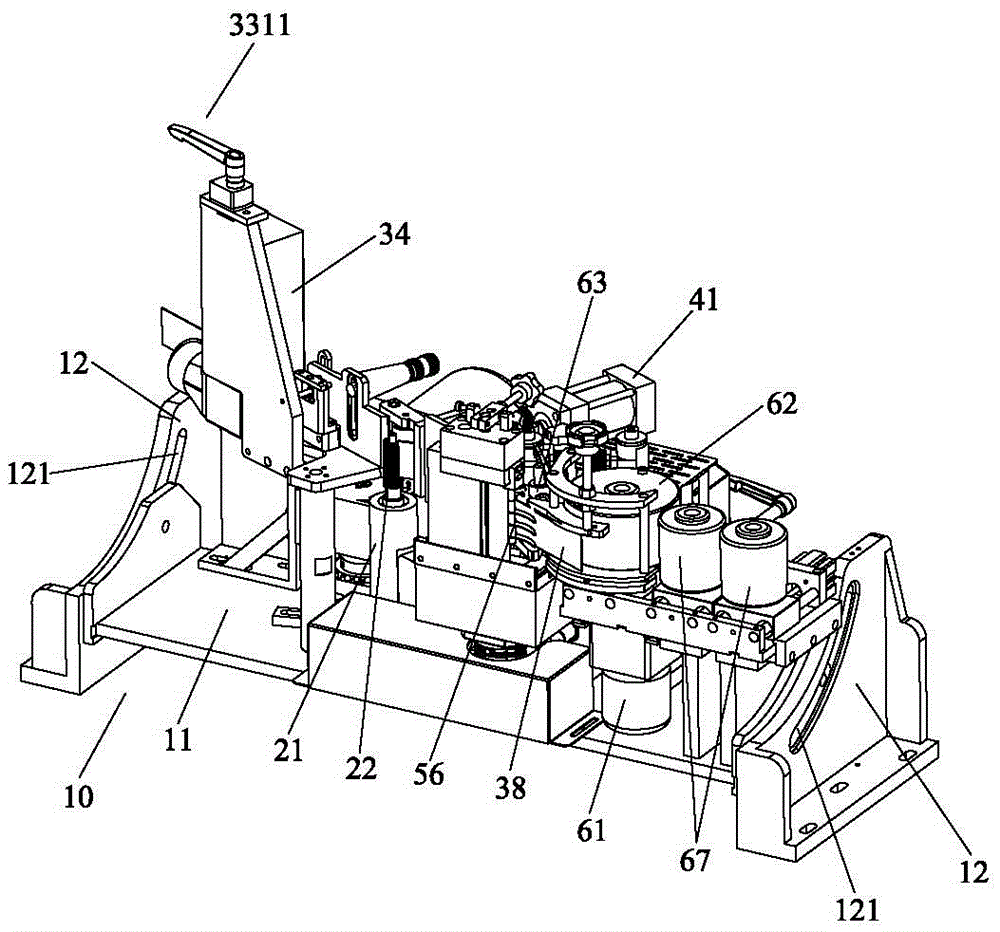

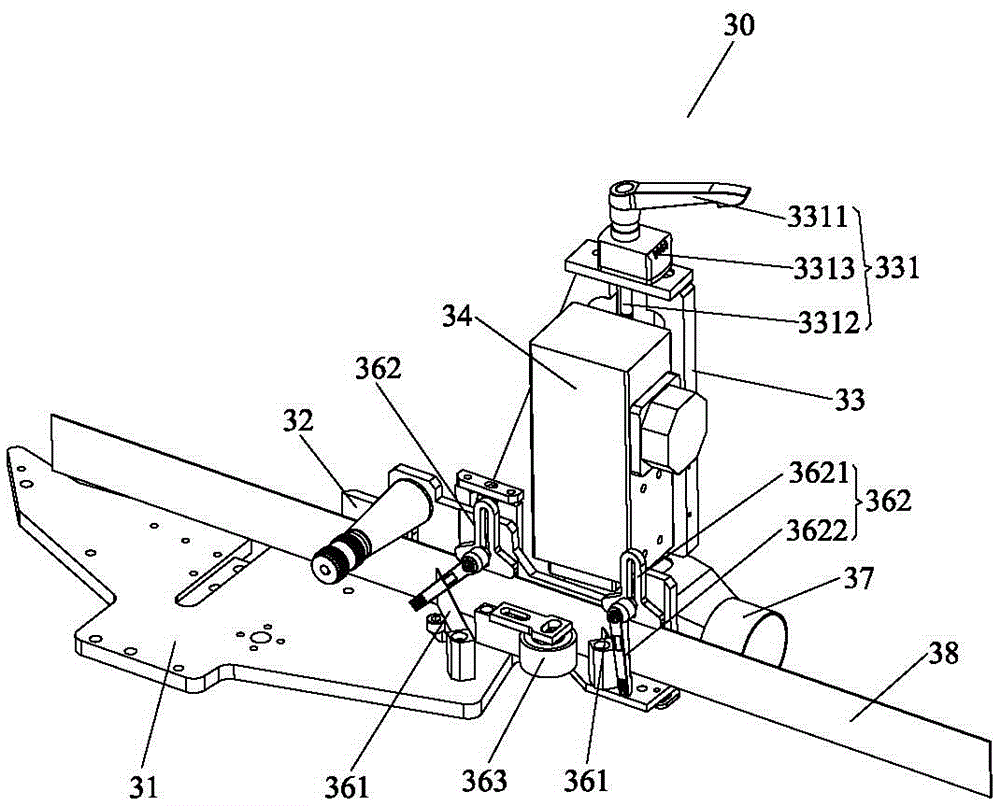

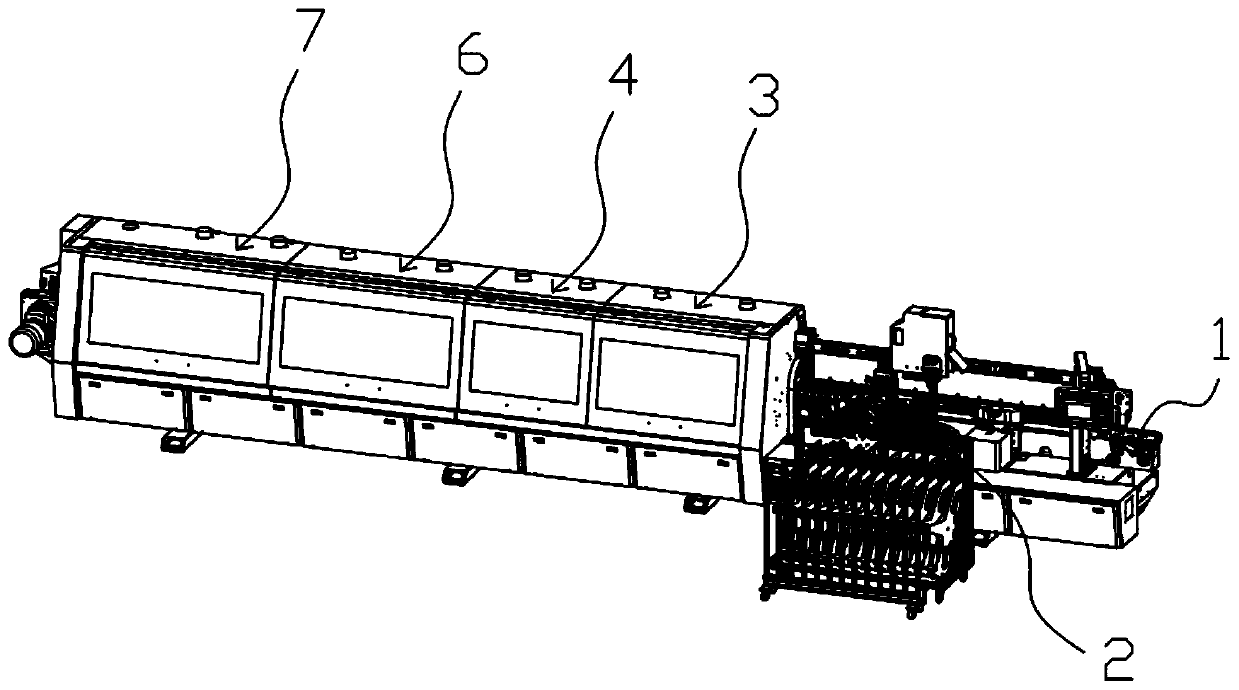

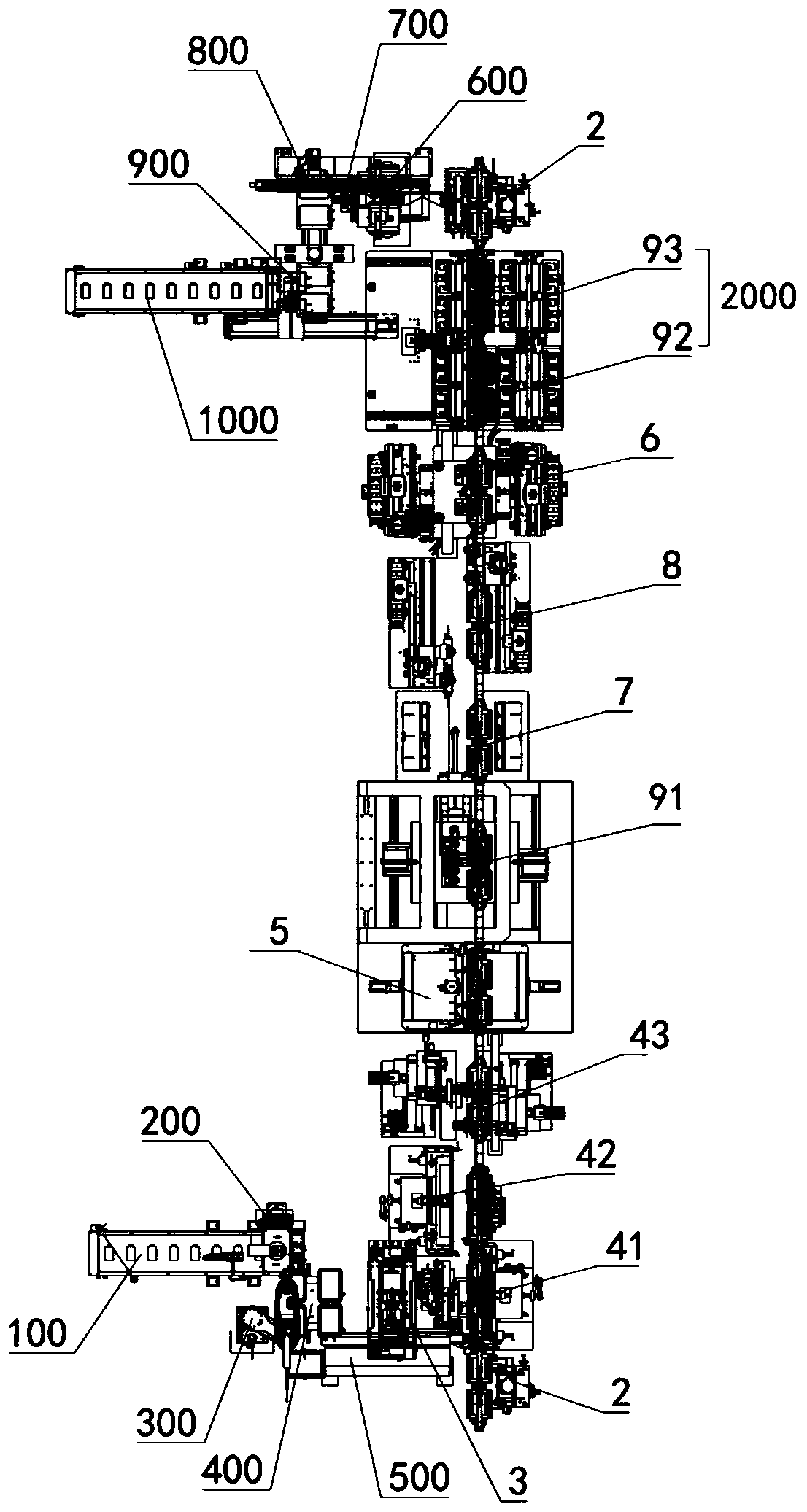

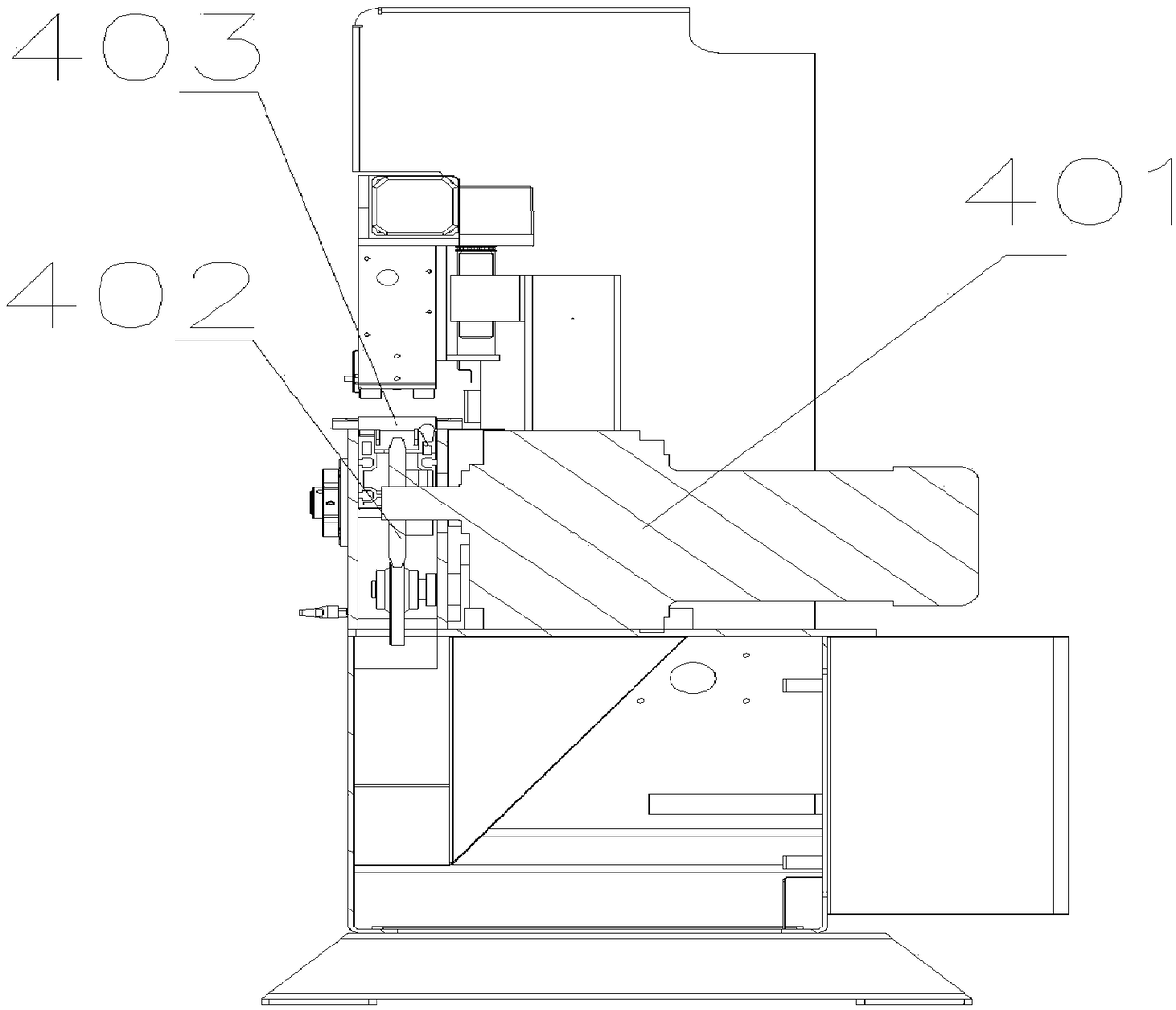

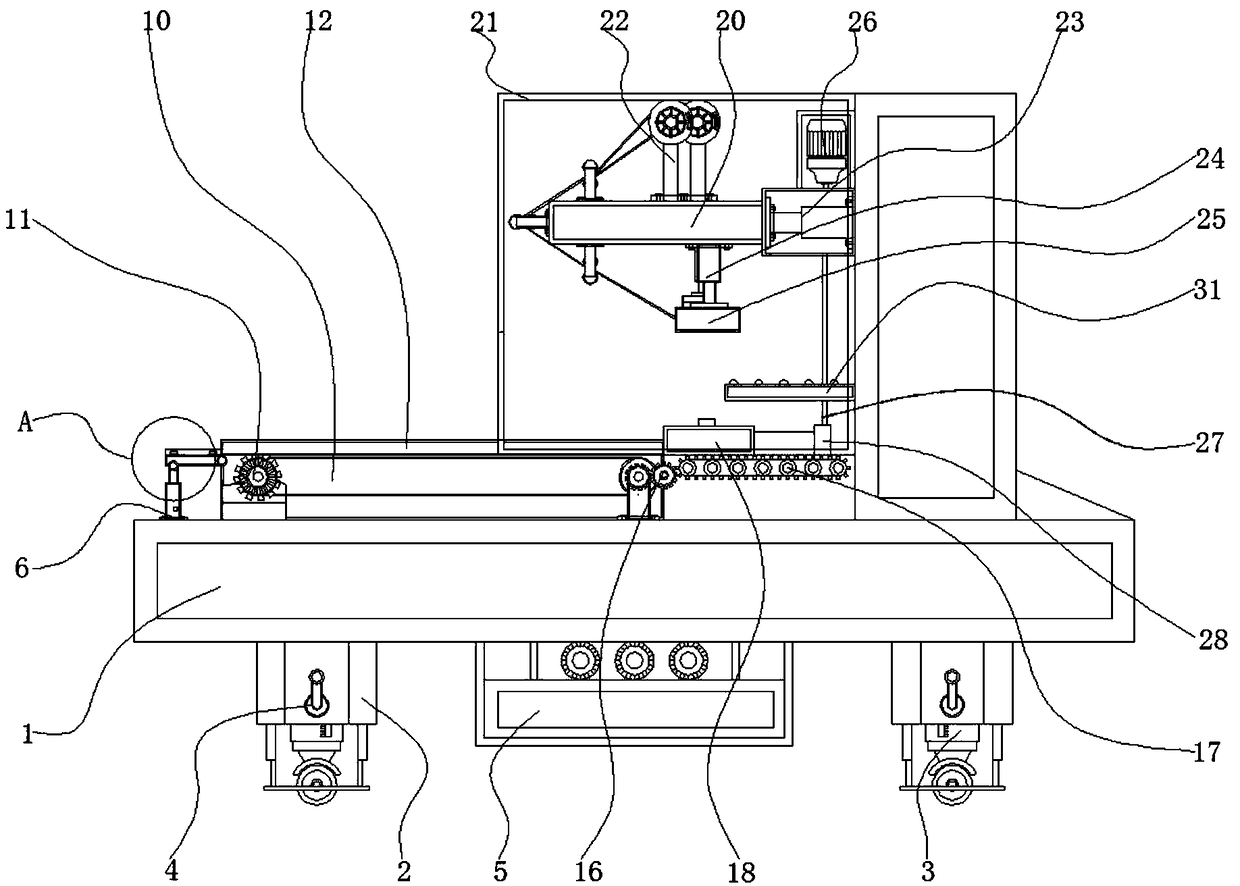

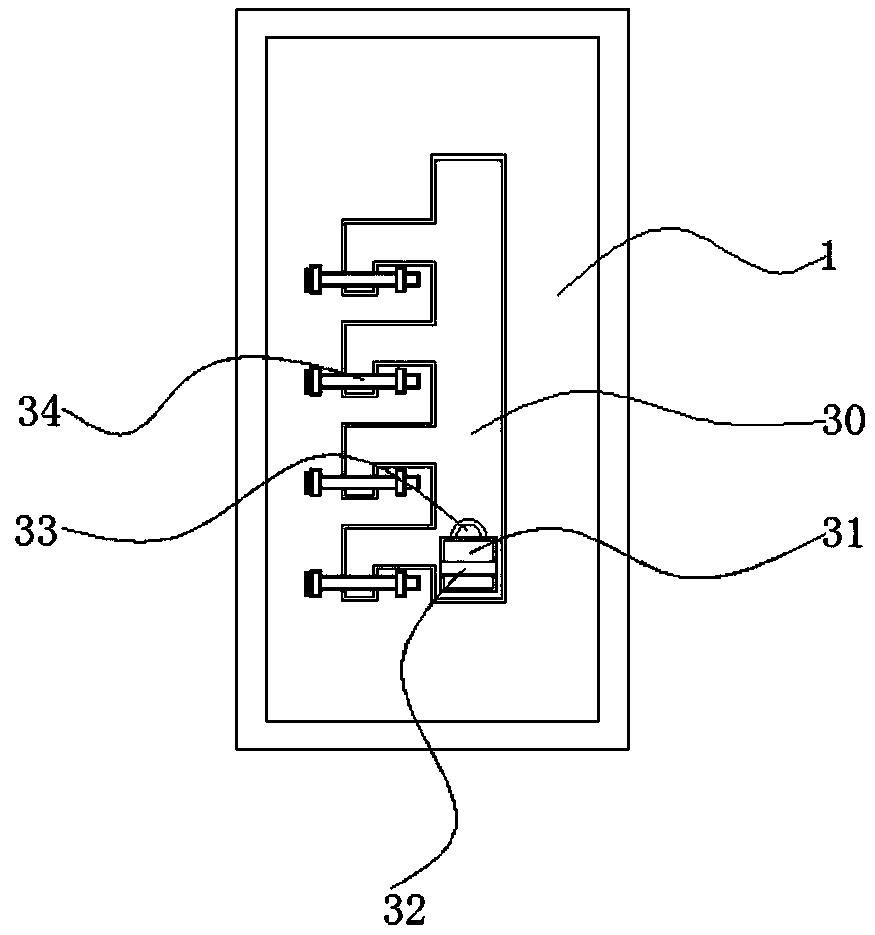

Automatic edge banding machine, control system and processing method

ActiveCN111516092ASolve the problem of blocked edge banding efficiencyImprove edge banding efficiencyOther plywood/veneer working apparatusProgramme controlControl systemEngineering

The invention relates to the technical field of edge banding machines, in particular to an automatic edge banding machine, a control system and a processing method. The automatic edge banding machinecomprises a tape supply mechanism, a flat cutting and head aligning mechanism, a finishing mechanism, a profiling and edge trimming mechanism and an edge scraping mechanism. The automatic edge bandingmachine, the control system and the processing method aim to solve the problem that the edge banding efficiency of the edge banding machine is limited.

Owner:NANXING MACHINERY CO LTD

Skirt board edge-banding structure of skirt board edge-banding machine

The invention provides a skirt board edge-banding structure of a skirt board edge-banding machine. The skirt board edge-banding structure is characterized in that two parallel side edges to be machined of a skirt board are respectively provided with a heating device and an edge press wheel component, along the moving direction of the skirt board, the edge press wheel component is arranged in front of the heating device, and the heating device is acted on at least one side surface of the side edge to be machined of the skirt board; and the edge press wheel component consists of a first edge press wheel and a second edge press wheel which are arranged in pair, and the first edge press wheel and the second edge press wheel are respectively arranged at two sides of the side edge to be machined of the skirt board to grind the softened side edge to be machined to deform, so that the surfaces of two sides of the side edge to be machined are glued together, and the edge of the skirt board can be banded.

Owner:SUZHOU LIANGCAI LOGISTICS TECH

Wood straight edge sealing method

InactiveCN108340468ARealize fully automated intelligent processingNo manual operation requiredPolishing machinesProfiling/shaping machinesEngineeringEdge banding

The invention relates to a wood straight edge sealing method. The method mainly solves the problems that in the prior art, a manual edge sealing machine is complex in structure, very inconvenient in operation and poor in trimming and edge sealing effects. A wood straight edge sealing device is adopted and comprises a machine frame, an electrical cabinet, a control panel, a feeding mechanism, an edge sticking and gluing mechanism, a front-and-back aligning mechanism, a rough repairing mechanism, a fine repairing mechanism, an edge scraping mechanism and a polishing mechanism. The problems thatin the prior art, the manual edge sealing machine is complex in structure, very inconvenient in operation and poor in trimming and edge sealing effects are well solved, and the method can be used foredge sealing of wood.

Owner:黄扑文

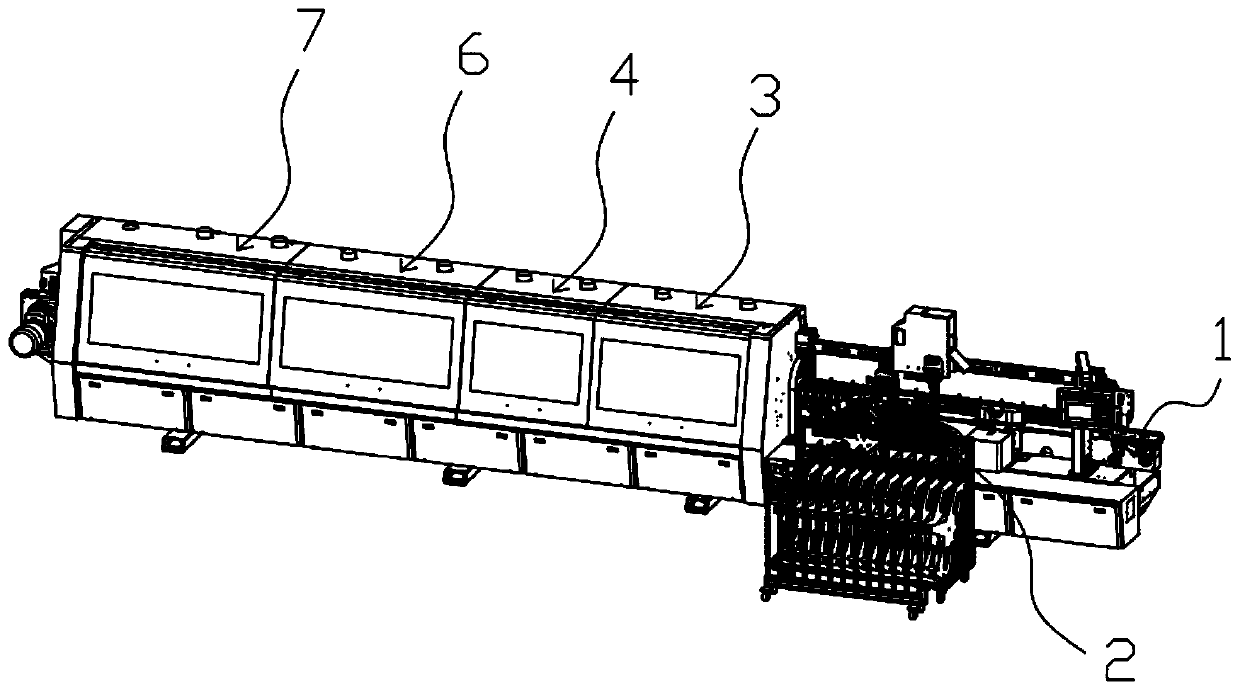

Wood straight edge-sealing equipment

InactiveCN108381729ARealize fully automated intelligent processingNo manual operation requiredPolishing machinesProfiling/shaping machinesEdge bandingEngineering

The invention relates to wood straight edge-sealing equipment. The wood straight edge-sealing equipment mainly aims at solving the problems that a manual edge-sealing machine is complicated in structure, quite inconvenient to operate and poor in edge trimming and sealing effects in the prior art. According to the technical scheme, the wood straight edge-sealing equipment comprises a machine frame,an electrical cabinet, a control panel, a conveying mechanism, an edge gluing mechanism, a front-back alignment mechanism, a rough trimming mechanism, a fine trimming mechanism, a scraping mechanismand a polishing mechanism, wherein the control panel is installed at one end of the machine frame, the electrical cabinet is arranged in the machine frame, the conveying mechanism for conveying wood is arranged on the upper end face of the machine frame, and the edge gluing mechanism, the front-back alignment mechanism, the rough trimming mechanism, the fine trimming mechanism, the scraping mechanism and the polishing mechanism are sequentially arranged in the conveying direction of the conveying mechanism. By means of the technical scheme, the problems are well solved, and the wood straight edge-sealing equipment can be used for edge-sealing of wood.

Owner:黄扑文

Edge sealing technology for furniture plates and specialized edge sealing device thereof

InactiveCN112643819AStable supportIncrease frictionOther plywood/veneer working apparatusDomestic articlesElectric machineStructural engineering

The invention discloses an edge sealing technology for furniture plates and a specialized edge sealing device thereof, and relates to the technical field of edge sealing of plates. The specialized edge sealing device comprises a worktable, a positioning mechanism and an edge sealing mechanism, wherein support columns are mounted in the middle of the upper part of the worktable; a bearing plate is fixed on the support columns; an anti-skid pad is hinged to the upper side of the bearing plate; a plate main body is arranged on the anti-skid pad; side plats are fixed to the two sides of the upper part of the worktable; a top plate is fixed to the top parts of the side plates; the positioning mechanism is mounted below the top plate; motor mounting bases are mounted on the inner sides of the side plates; linear motors are mounted on the inner sides of the motor mounting bases; and an electric telescopic rod is mounted on one side, close to the plate main body, of the each linear motor. The edge sealing technology for the furniture plates and the specialized edge sealing device thereof disclosed by the invention have the beneficial effects that through movement of the linear motors in the motor mounting bases, the device conveniently drives the electric telescopic rods to be horizontally moved, and thus, convenience is provided for driving horizontal movement of the edge sealing mechanism, and the edge sealing mechanism can perform comprehensive edge sealing on the outer side faces of the plate main body.

Owner:浙江美约风家居股份有限公司

Surrounding type outer packing carton edge sealing machine

The invention discloses a surrounding type outer packing carton edge sealing machine. The edge sealing machine comprises a supporting frame, clamping mechanisms and an edge sealing mechanism. A left support and a right support are arranged on the left side and the right side of the supporting frame correspondingly and extend upwards. Edge sealing surrounding space that the edge sealing mechanism surrounds an outer packing carton is formed by the left support, the position, between the left support and the right support, of the supporting frame and the right support. A left bottom plate and a right bottom plate which are used for containing and supporting the outer packing carton and arranged at intervals are arranged in the edge sealing surrounding space. A left limiting plate and a right limiting plate are arranged on the front side of the left bottom plate and the front side of the right bottom plate correspondingly. The two clamping mechanisms are mounted on the upper surface of the left bottom plate and the upper surface of the right bottom plate correspondingly and can fix, tightly press and flatten the outer packing carton. The edge sealing mechanism is mainly composed of a rotary assembly and a cutoff assembly. The rotary assembly comprises a main shaft, a shaft sleeve, an L-shaped rotating rod, an adhesive tape rolling wheel and a drive motor. The cutoff assembly comprises a first motor, a second motor, an oval block and a cutoff rod. The structure is simple, and the edge sealing efficiency is high.

Owner:SICHUAN ENG TECHN COLLEGE

Paper-bag forming machine

ActiveCN103909682ARealize the purpose of edge bandingImprove edge banding efficiencyPaper-makingBox making operationsEngineeringMechanical engineering

The invention discloses a paper-bag forming machine which comprises a forming mechanism, a feeding mechanism, a snapping mechanism, an edge sealing mechanism and an output mechanism. The forming mechanism, the feeding mechanism, the snapping mechanism, the edge sealing mechanism and the output mechanism are arranged on a frame in sequence. The edge sealing mechanism comprises a barrel and a batch setting mechanism which is arranged between the edge sealing mechanism and the output mechanism. The batch setting mechanism comprises a counting photocell eye and a first air cylinder, the counting photocell eye is arranged on one side of the barrel, the first air cylinder is arranged on the front portion of the counting photocell eye, a push plate is mounted on a push rod of the first air cylinder which is connected with the counting photocell eye through a controller, an edge sealing slot is formed in the barrel surface of the barrel, one side of the edge sealing slot is provided with a transitional surface lower than the barrel surface of the barrel, an in-groove scraper matched with the transitional surface is arranged on the upper side of the barrel through a first rotating shaft, the first rotating shaft is in synchronous reverse transmission with the barrel, a second rotating shaft is arranged in the barrel, an edge sealing clamping plate extending into the edge sealing slot is arranged on the second rotating shaft, and the second rotating shaft is driven to rotate through a driving device and drives the edge sealing and clamping plate to swing in the edge sealing slot. By the arrangement, high production efficiency and bag forming quality can be achieved.

Owner:WENZHOU RUIZHI PACKING MACHINERY

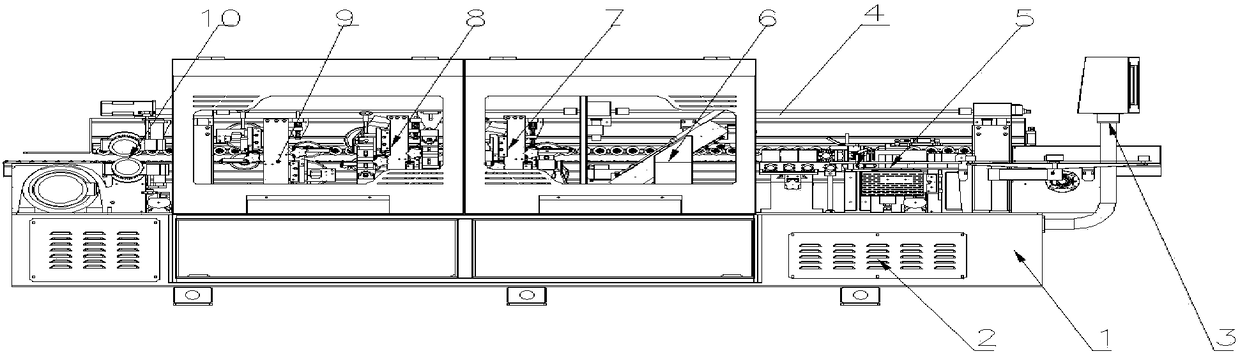

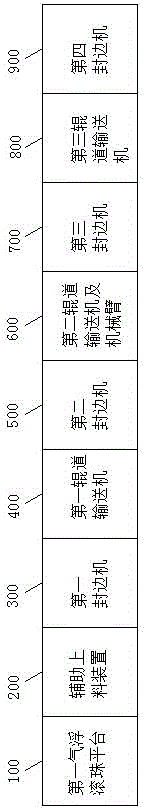

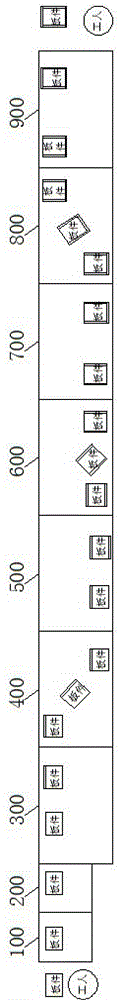

Novel continuous edge sealing system for kitchen cabinet plates and continuous edge sealing method for novel continuous edge sealing system

ActiveCN105479584AReduce collision damage rateReduce labor intensityWood working apparatusDomestic articlesEngineeringUltimate tensile strength

The invention relates to a novel continuous edge sealing system for kitchen cabinet plates and a continuous edge sealing method for the novel continuous edge sealing system. The novel continuous edge sealing system comprises a first gas-flotation rolling ball platform, an auxiliary loading device, a first edge sealer, a first roller conveyor, a second edge sealer, a second roller conveyor, a third edge sealer, a third roller conveyor and a fourth edge sealer which are sequentially arranged; a mechanical arm used for regulating a placement direction of plates is arranged above the second roller conveyor; the third edge sealer and the third edge sealer are positioned at the same side; and the second edge sealer and the fourth edge sealer are positioned at the other side opposite to the first edge sealer. According to the novel continuous edge sealing system for kitchen cabinet plates and the continuous edge sealing method for the novel continuous edge sealing system, the defects in the prior art are solved, continuous edge sealing for four ends of the same kitchen cabinet plate are realized, a collision damage rate of plates is reduced, labor intensity and production cost are reduced, and the edge sealing efficiency is improved.

Owner:合肥志邦家居有限公司

Alternately complementary edge sealing cycle device and edge sealing method based on same

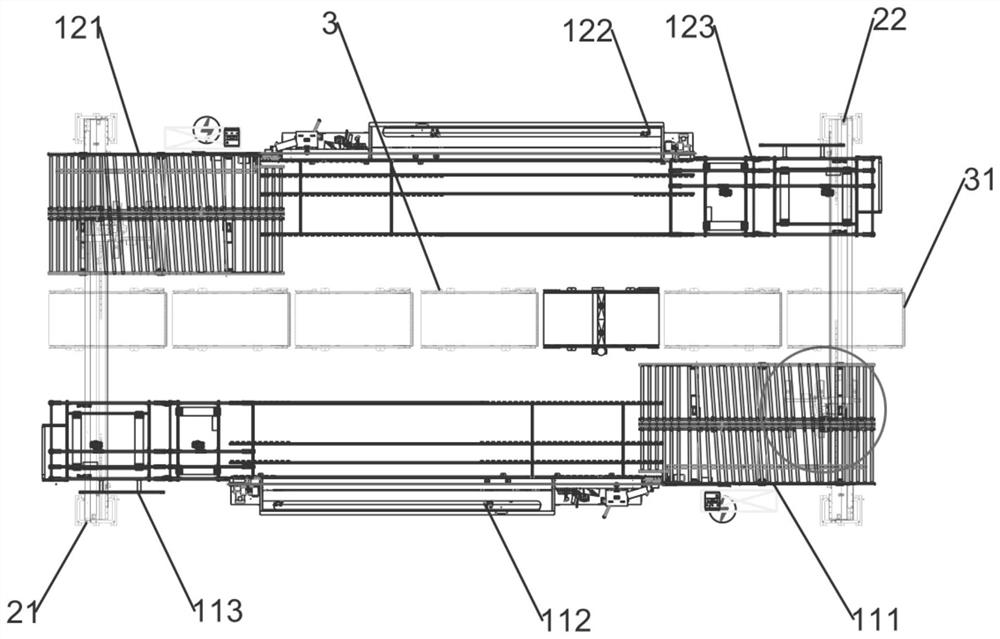

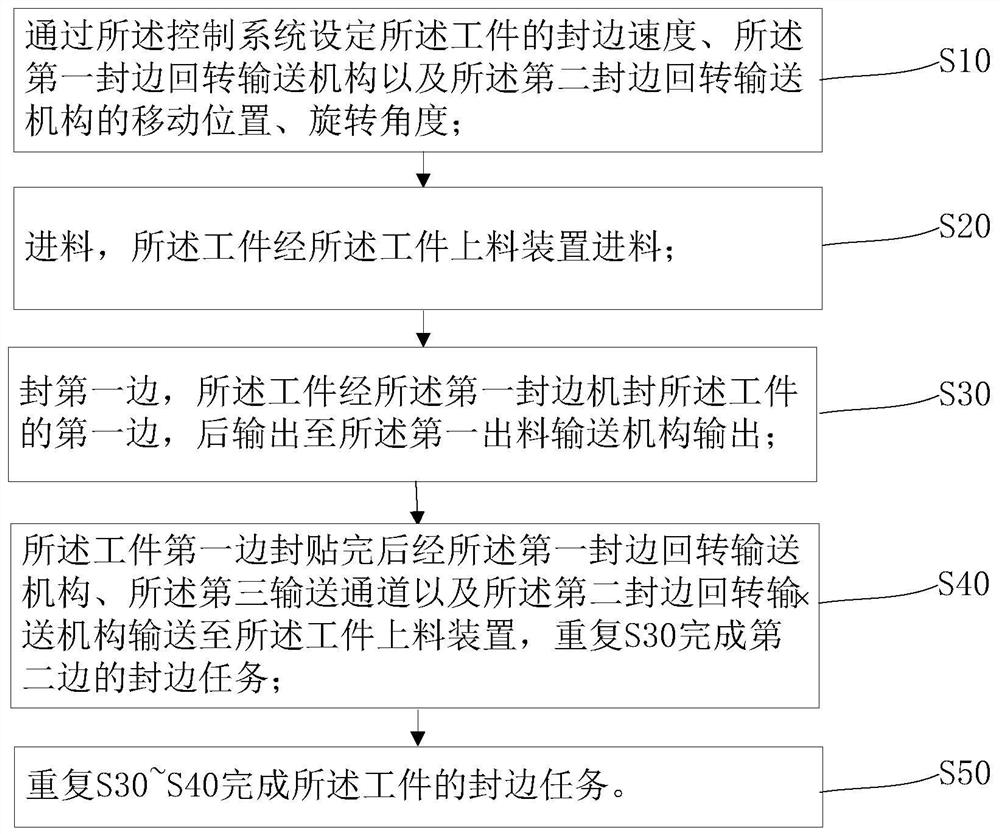

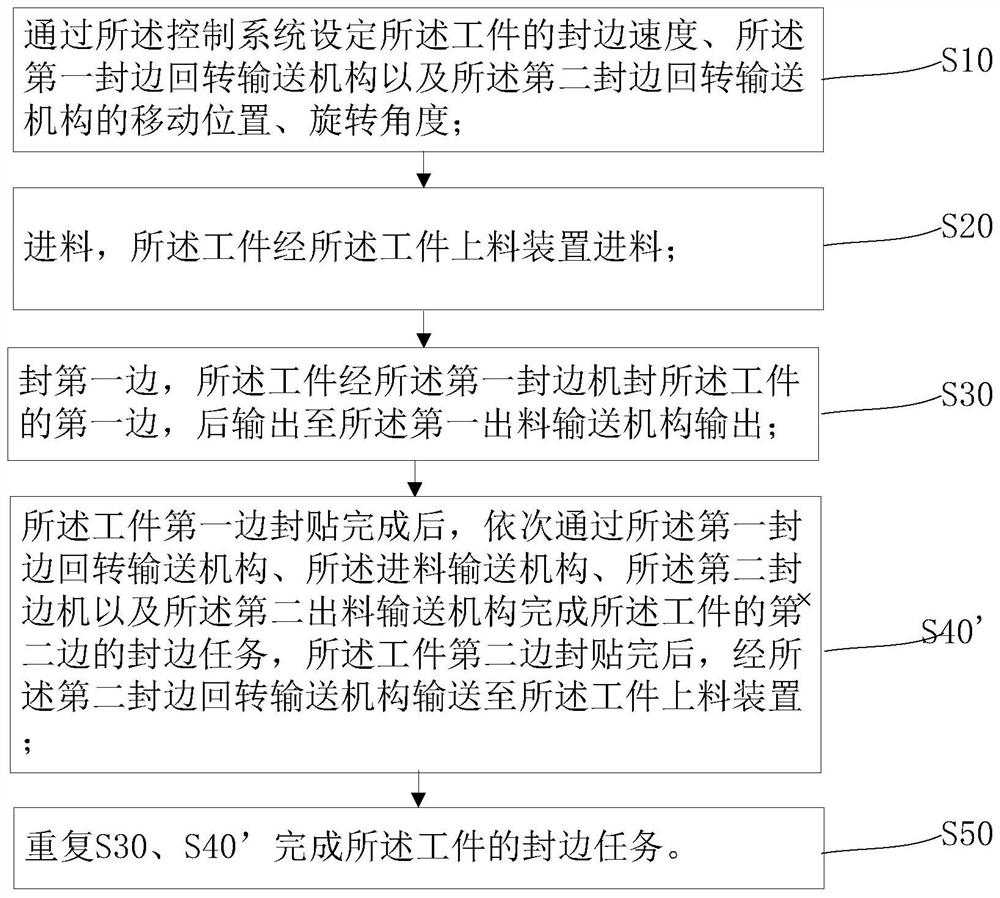

ActiveCN111941583AReduce the number of revolutionsIncrease flexibilityWood working apparatusDomestic articlesStructural engineeringMechanical engineering

The invention provides an alternately complementary edge sealing cycle device and an edge sealing method based on the same. The device comprises edge sealing channels, a first edge sealing rotary conveying mechanism, a second edge sealing rotary conveying mechanism and a third conveying channel, wherein the edge sealing channels comprise a first edge sealing channel and a second edge sealing channel, the output end of the first edge sealing channel is connected to the input end of the second edge sealing channel, the output end of the second edge sealing channel is connected to the input channel of a first edge sealing machine, the third conveying channel is arranged between the first edge sealing channel and the second edge sealing channel, and the third conveying channel is parallel to the first edge sealing channel and the second edge sealing channel. According to the double-channel rapid edge sealing cycle device and the edge sealing method, the double-channel rapid edge sealing cycle device is formed by splicing two independent workpiece edge sealing machines, the third conveying channel is arranged between the two edge sealing machines to form a series-parallel connection structure of the two edge sealing machines, so that the two independent edge sealing machines can be independently used and can also be connected in series for cyclic use, and an edge sealing scheme is added.

Owner:NANTONG YUETONG CNC EQUIP CO LTD

Jean fabric packing machine

ActiveCN104554887ARealize edge bandingImprove edge banding efficiencyPackaging by pressurising/gasifyingWrapper twisting/gatheringEngineeringEdge banding

The invention provides a jean fabric packing machine, belongs to the technical field of mechanisms, and aims at solving the problem that the coiled jean fabric cannot be quickly packed in the prior art. The jean fabric packing machine comprises a rack; a feeding opening and a discharging opening are formed in the rack; a first conveyor belt is arranged between the feeding opening and the sidewall of the rack; a second conveyor belt is arranged between the discharging opening and the other sidewall of the rack. The jean fabric packing machine is characterized in that an upper mounting plate and a lower mounting plate which are arranged in parallel are fixed on the rack; a film uncoiling roller is arranged on the upper surface of the upper mounting plate; an upper through hole and a lower through hole through which a film passes are respectively formed in the upper mounting plate and the lower mounting plate; a side thermal sealing mechanism and an end thermal sealing mechanism are arranged between the upper mounting plate and the lower mounting plate; a slitting mechanism is arranged on the lower surface of the lower mounting plate; an automatic blanking mechanism is arranged on the upper surface of the lower mounting plate. The jean fabric packing machine has the advantage that the side sealing side and the end sealing side of the coiled jean fabric can be quickly packed.

Owner:HAINING DENIM WEAVING CO LTD

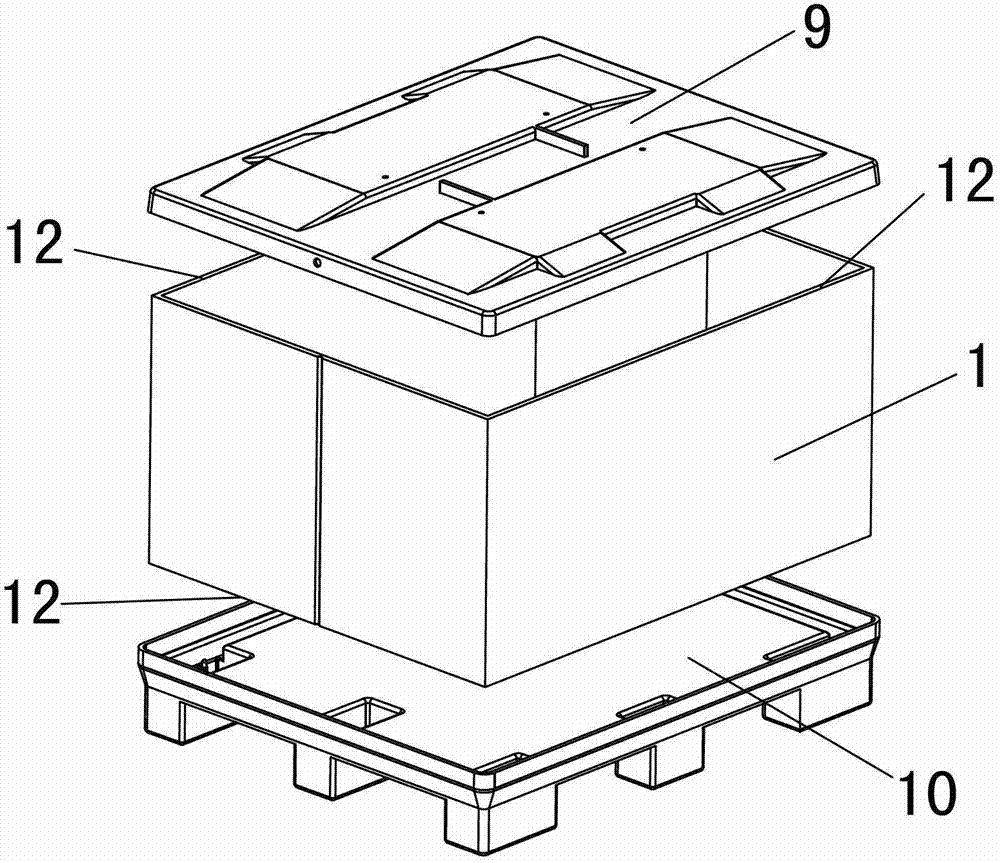

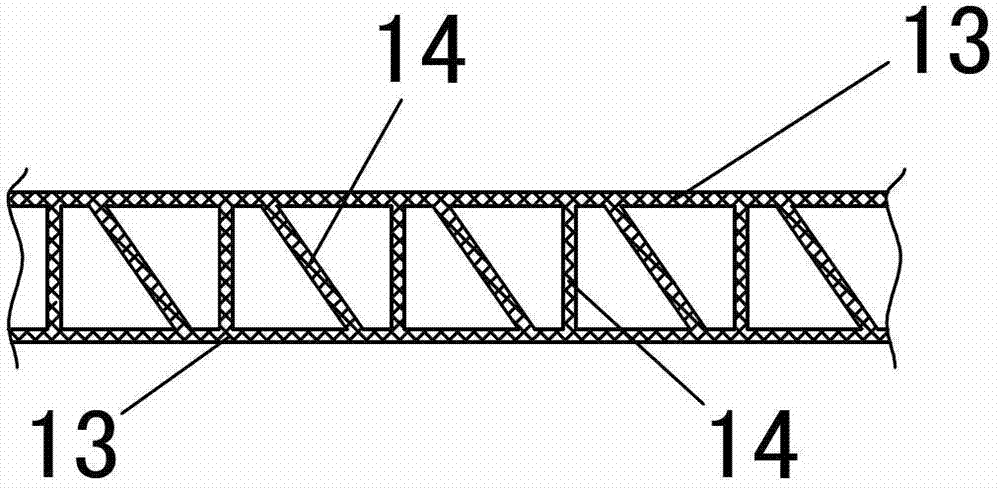

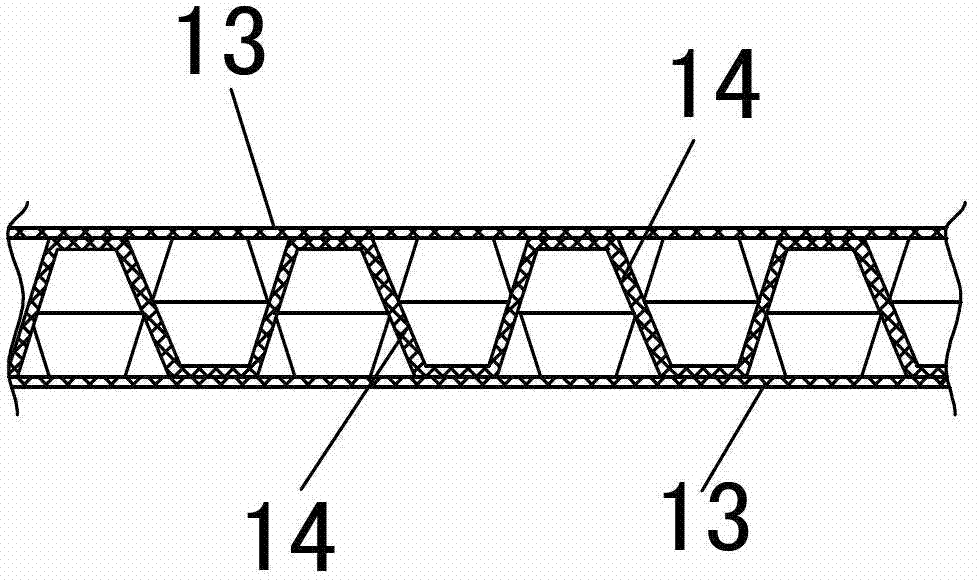

Edge-sealing process for honeycomb plate without sealing edge

InactiveCN111331869AEasy to implementImprove edge banding efficiencyFlat articlesDomestic articlesAdhesiveHoneycomb

The invention discloses an edge-sealing process for a honeycomb plate without a sealing edge. The edge-sealing process for the honeycomb plate without the sealing edge comprises the following steps: customizing an L-shaped sectional material comprising a first side plate and a second side plate according to the plate shape dimensions of the honeycomb plate without the sealing edge at first, and then coating the surrounding of a back plate, and side surfaces of the honeycomb plate without the sealing edge with a structural adhesive; and then enabling the first side plate and the second side plate to correspond to the back plate and the side surfaces of the honeycomb plate without the sealing edge separately, adhering the L-shaped sectional material to the side surfaces of the honeycomb plate without the sealing edge separately, and obtaining the honeycomb plate taking the second side plate of the L-shaped sectional material as the sealing edge. According to the edge-sealing process forthe honeycomb plate without the sealing edge, edge-sealing for the honeycomb plate is realized from another aspect; and the whole edge-sealing process is easy to realize and high in edge-sealing efficiency, and moreover, higher quality and uniformity of the product subjected to the edge-sealing are achieved.

Owner:成都都江堰市嘉业铝塑有限公司 +1

Woodworking edge sealing equipment

InactiveCN110539384AImprove edge banding efficiencyImprove practicalityWood working apparatusDomestic articlesWoodworkingElectrical and Electronics engineering

The invention discloses woodworking edge sealing equipment. The equipment comprises a main support plate; four detecting plates are arranged on the right side of the main support plate; the detectingplates are divided into a fixed plate and three movable plates; first chutes are formed in one side end surfaces of the detecting plates; first slide blocks are slidingly arranged in the first chutes;one side end surfaces of the first slide blocks are fixedly connected with one side end surfaces of the other detecting plates; and a working cavity penetrating up and down is formed among the four detecting plates. Woods can be automatically wrapped according to sizes; then, glue is automatically coated; after cutting of edge sealing strips, the edge sealing strips are fixed on the edges of thewoods through pressing to finish the edge sealing; the synchronous sealing of four edges of the woods is realized to improve the edge sealing efficiency; and the woods in a certain size range can be automatically adjusted for edge sealing to improve the practicability.

Owner:浦江县阿语机械科技有限公司

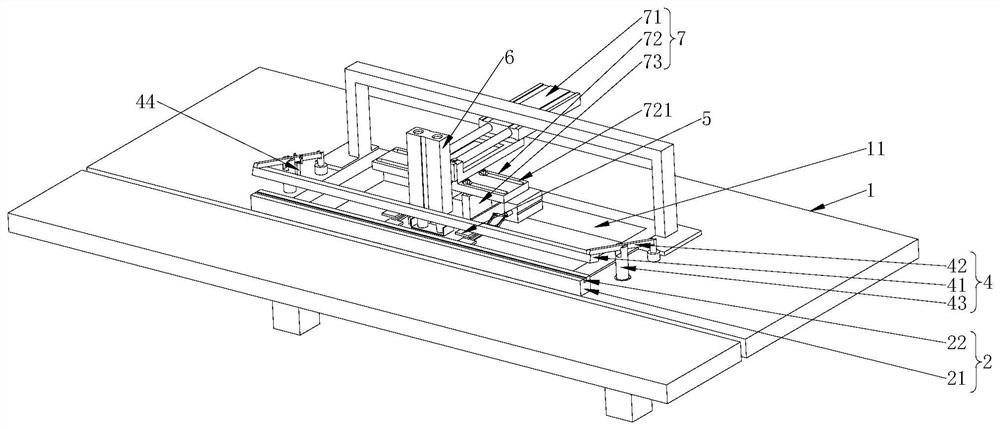

Edge banding process for furniture panels and its special edge banding device

ActiveCN103112076BSimple structureEasy to operateWood working apparatusDomestic articlesWorkmanshipEdge banding

The invention relates to furniture sheet material edge banding workmanship. The furniture sheet material edge banding workmanship is characterized in that the workmanship is carried out according to the following steps: a) a sheet material is adsorbed on a liftable delivery platform through an adsorption disc and is delivered to the next conveyor through a conveyer belt on the platform; b) the sheet material moving along with the conveyor is pre-pressed on a material discharge side of the conveyor, so that flatness of the sheet material which enters a downward moving conveying process is guaranteed; c) the sheet material is conveyed to the next conveying platform from the prior conveyor and is rolled through a material rolling guide wheel on a feeding side of the conveying platform; d) the sheet material is conveyed to enter a specific edge banding device from the next conveying platform, and the edge banding is carried out on the sheet material. The sheet material moves along the next conveying platform, edge banding strips are adsorbed from sides of the sheet material and are tightly pressed through edge banding pressing wheels, so that edge banding of the sheet material is finished. The furniture sheet material edge banding workmanship is simple and convenient to achieve. The machining equipment is simple in structure, simple and convenient to operate and capable of effectively improving edge banding efficiency and guaranteeing smooth operation of production of sequential products.

Owner:福田家居用品江苏有限公司

Safety type corner edge sealing machine capable of preventing hands from being clamped

ActiveCN109366682AShorten the timePrevent movementWood working apparatusDomestic articlesEngineeringEdge banding

The invention relates to a safety type corner edge sealing machine capable of preventing hands from being clamped. The machine comprises a main body, an extending-out rotating arm, an air pump and a material pushing air rod, a support is arranged below the main body, and a moving wheel is arranged in the support, the main body and the support are connected through screws, the support is movably connected with the moving wheel, the extending-out rotating arm penetrates through the front end of the support, and extends out of the rotating arm and is movably connected with the bracket, the air pump is arranged on the inner side of the support, and the air pump is connected with the main body through the screw, the pushing air rod is arranged above the main body, and a discharging plate is arranged above the pushing air rod, and the pushing air rod is connected with the main body through the screw. The safety type corner edge banding machine has the advantages of being capable of preventing hands from being clamped, an anti-collision layer is arranged, so that the possibility of collision between the sealed object and the material clamping plate can be prevented, so that the possibility that the cut-out of the object to be sealed is expanded is reduced, and the sealing opening of the glue is reduced, and the probability of defective products produced by the device is also reduced.

Owner:杨辉

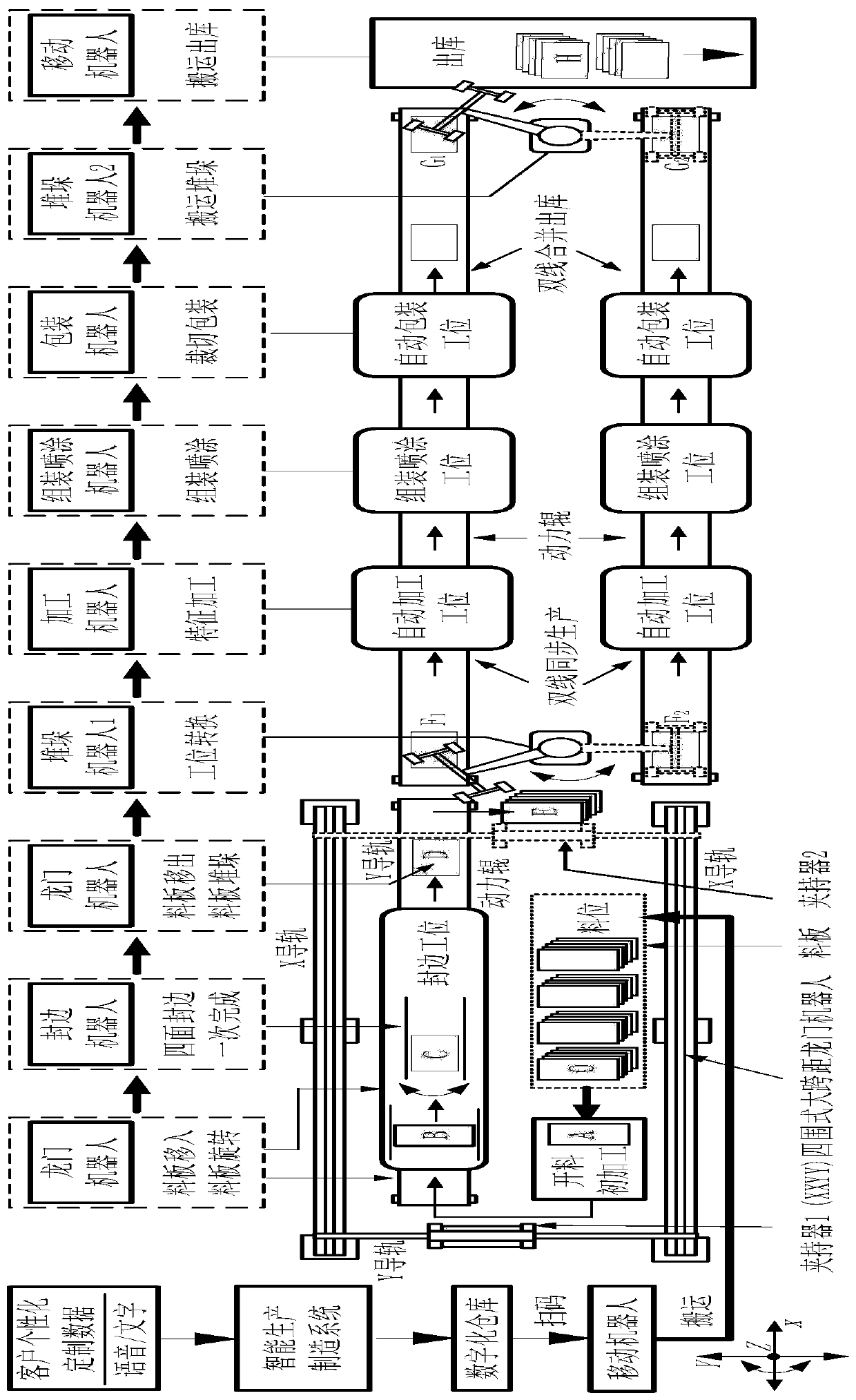

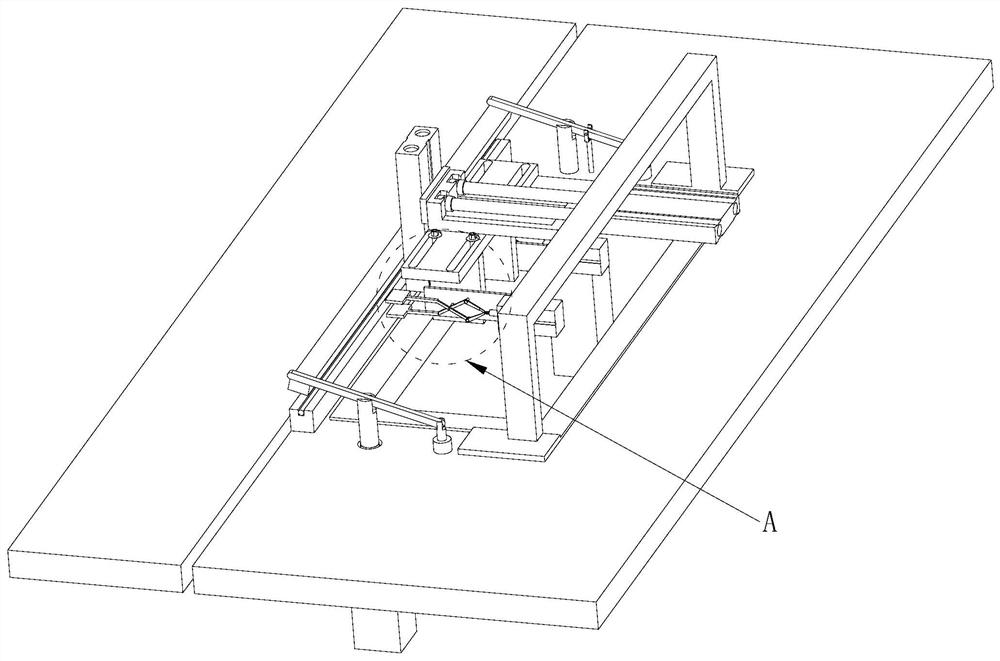

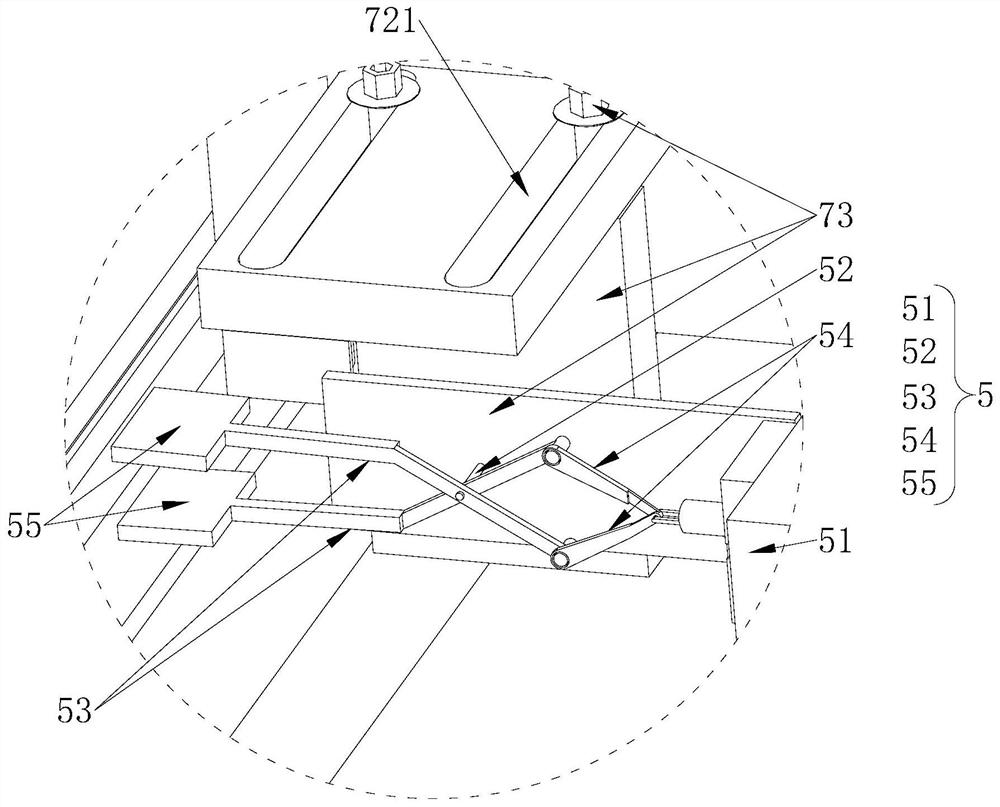

Woodworking furniture production line based on customer customization

InactiveCN110161988AImprove edge banding efficiencyImprove work efficiencyTotal factory controlProgramme total factory controlMobile robotPersonalization

The invention discloses a woodworking furniture production line based on customer customization, which comprises an intelligent production line capable of unidirectionally moving to achieve four-sideedge sealing of a material. The intelligent production line is provided with an intelligent production manufacturing system for controlling the work; the intelligent production line comprises an all-around large-span gantry robot for clamping and conveying the material, a four-side wide and narrow-line edge sealing robot for performing four-side edge sealing on the material, a stacking robot for stacking the material, and a two-line flow processing line for processing, assembling, spraying, and packaging the material. The intelligent production manufacturing system can receive customer customization data and convert the customization data to a corresponding instruction to be sent to a mobile robot and the intelligent production line, woodworking furniture customization can be realized, thematerial plate handling efficiency and the layout compactness are improved, and one-time four-side edge sealing is realized when the material plate moves unidirectionally, idle running is reduced, and the edge sealing efficiency is improved.

Owner:CHINA UNIV OF MINING & TECH

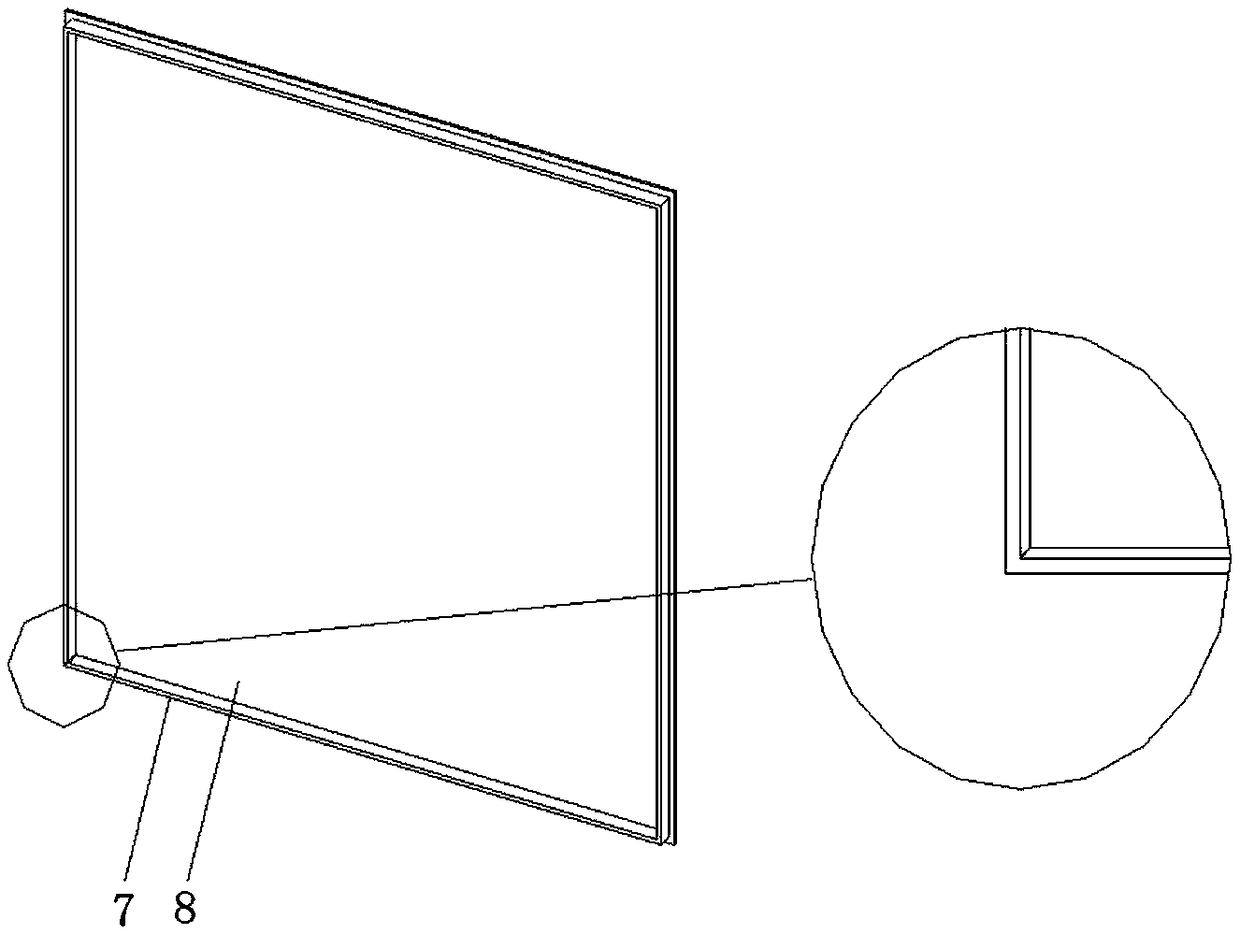

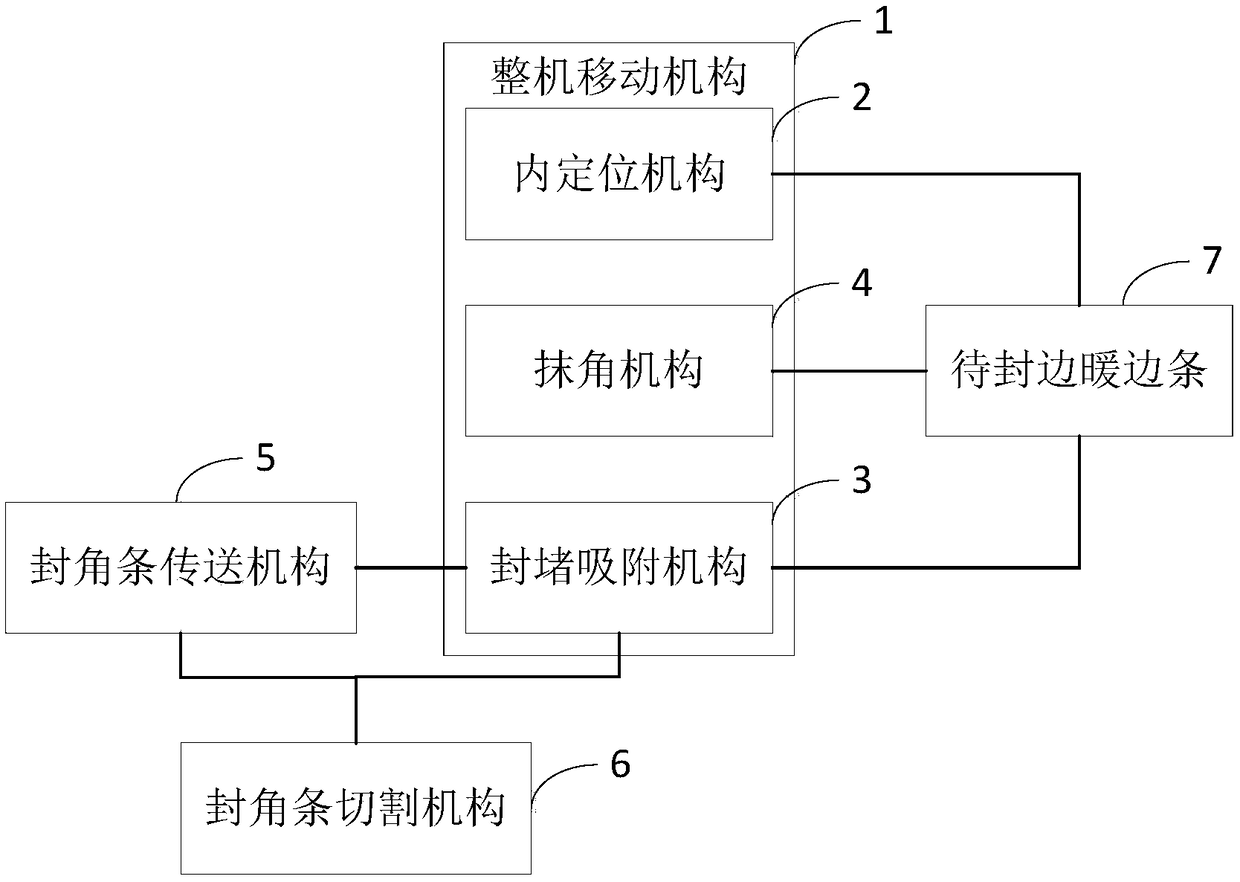

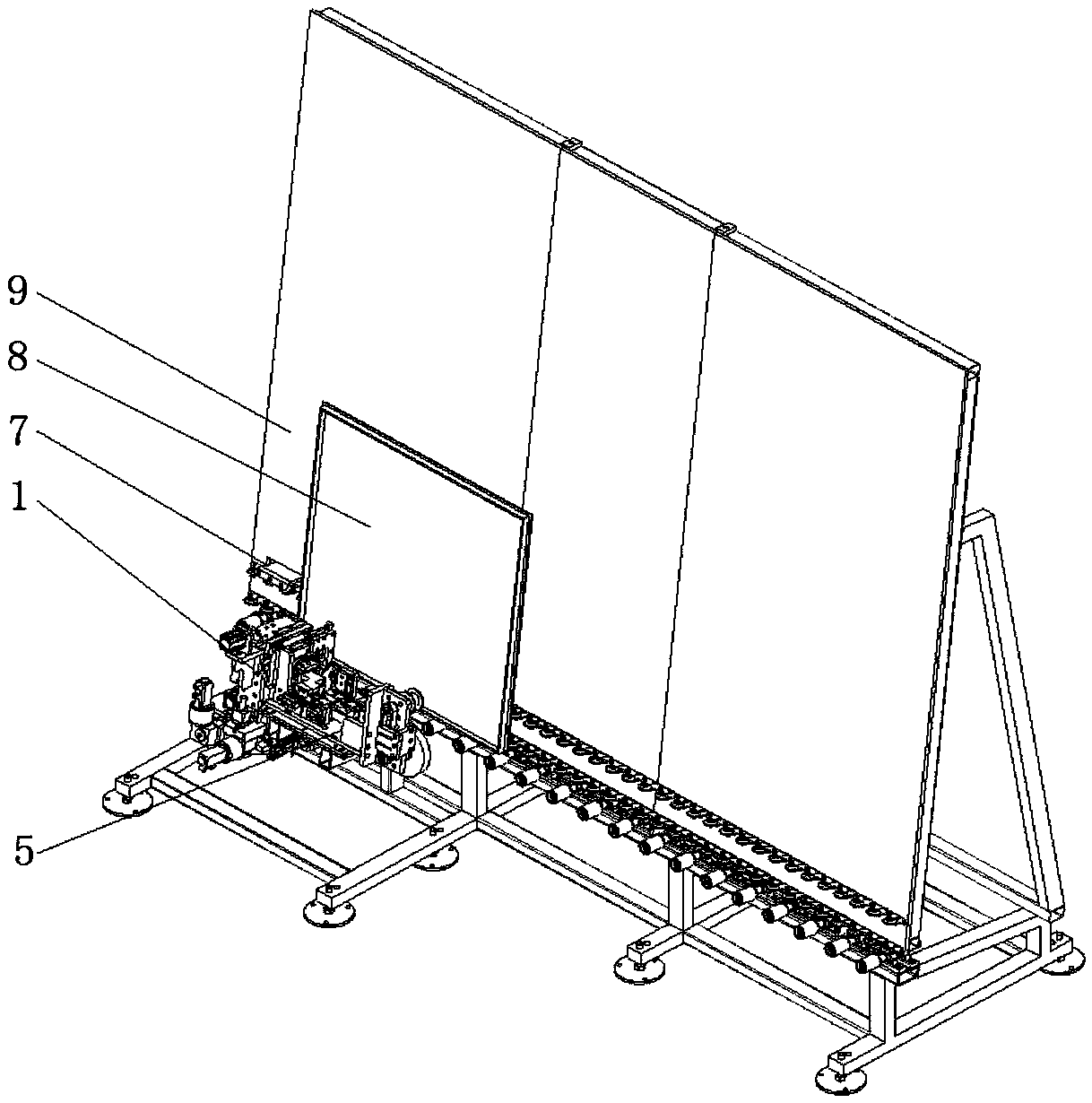

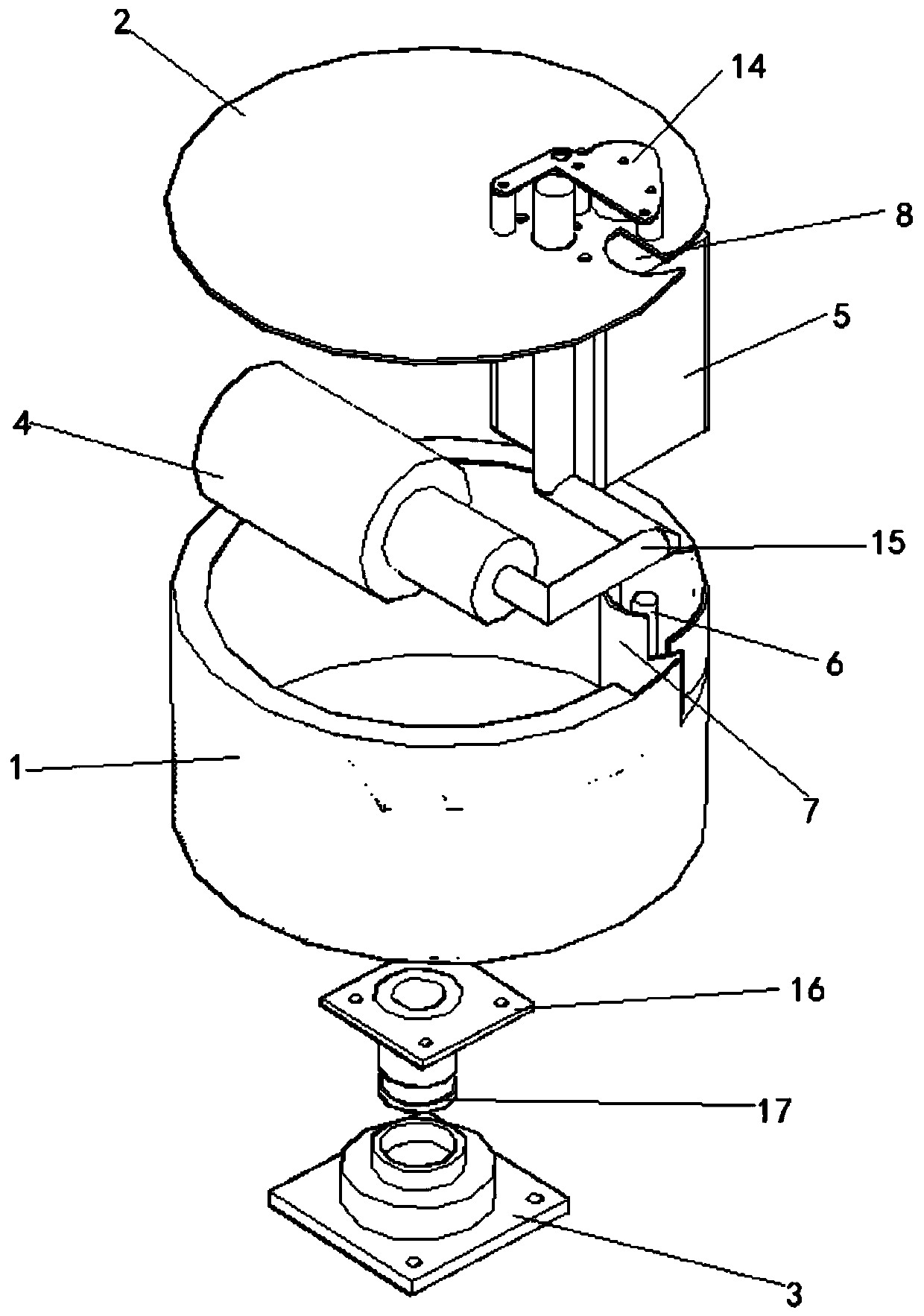

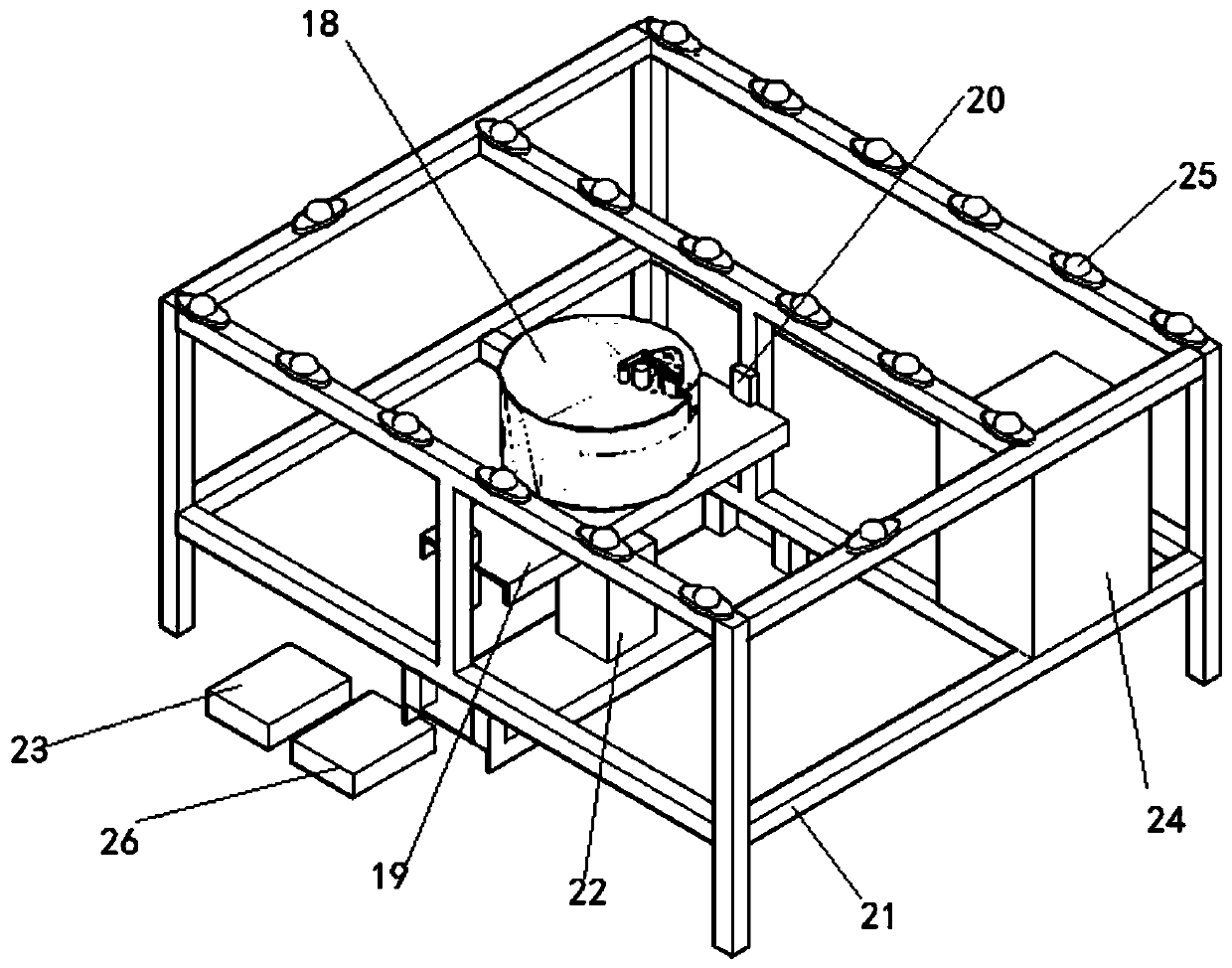

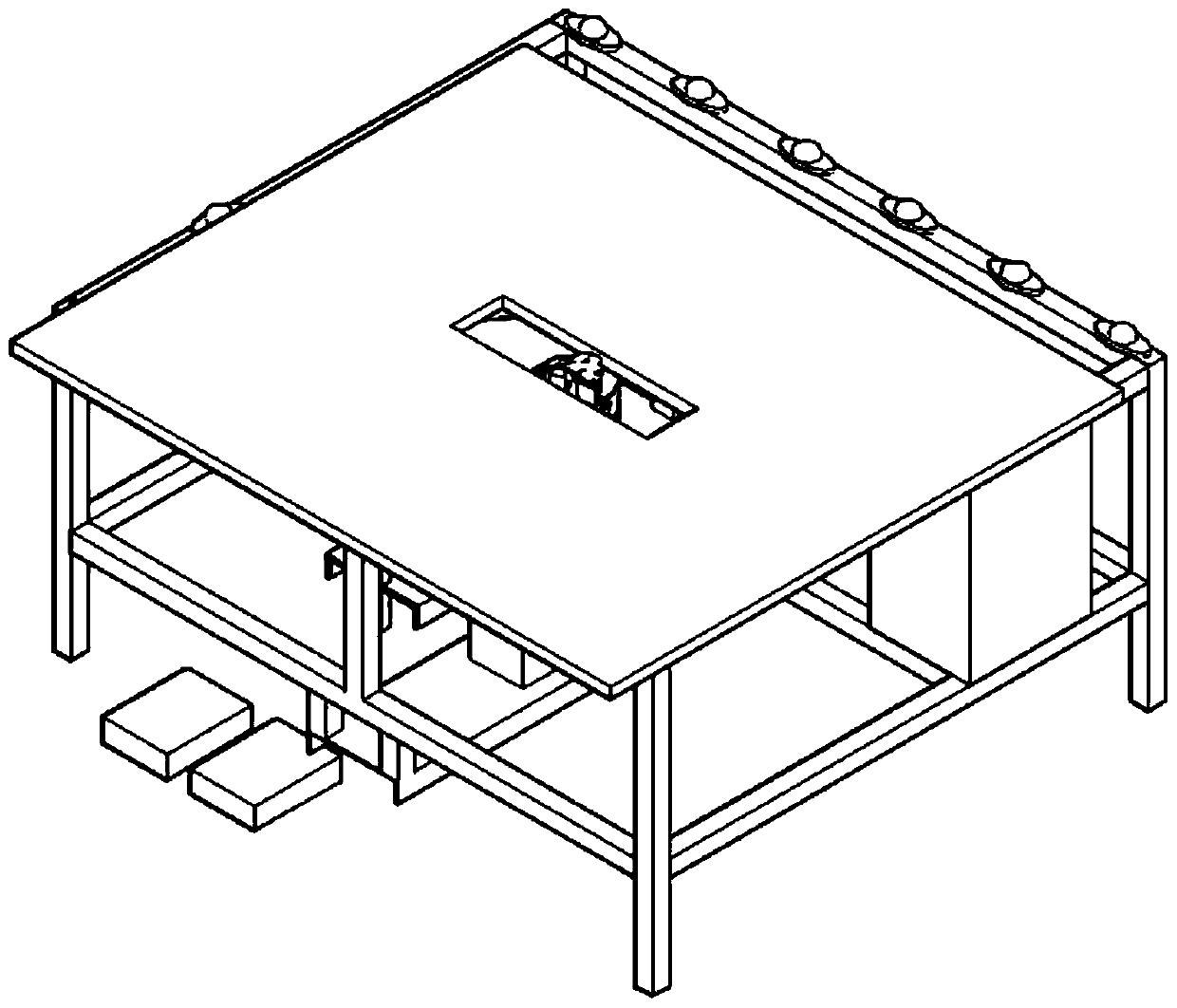

Angle part edge sealing machine for warm edge strip

ActiveCN108409165AImprove efficiencyQuality improvementGlass reforming apparatusPhotovoltaic energy generationEngineeringEdge banding

The invention discloses an angle part edge sealing machine for a warm edge strip. The angle part edge sealing machine comprises a complete machine moving mechanism, an inner positioning mechanism, a blockage absorption mechanism, an angle erasing mechanism, an angle seal strip conveying mechanism and an angle seal strip cutting mechanism, wherein the angle part edge sealing machine for the warm edge strip is used for supporting and protecting foot parts of the warm edge strip through an inner positioning stopper block in the inner positioning mechanism so as to avoid the phenomenon that the warm edge strip is ejected aslant in an edge sealing process; angle seal strips which are cut are adhered to angle positions of the warm edge strip through the blockage absorption mechanism; the angle seal strips are rolled and pressed through an angle erasing wheel so as to realize angle erasing and edge sealing operations. In addition, the angle seal strip conveying mechanism and the angle seal strip cutting mechanism are also arranged, so that a set of full automatic processes including stripping, conveying, cut-off and adhesion on the rolled edge sealing strip can be formed, so that the edgesealing efficiency and quality of the warm edge strip are greatly improved; therefore, for the characteristic of the foot part positions of the warm edge strip, the edge sealing processing on the angle parts of the warm edge strip is automatically realized, the edge sealing efficiency is improved, the effect is better, and the precision is higher.

Owner:TENON BEIJING EQUIP

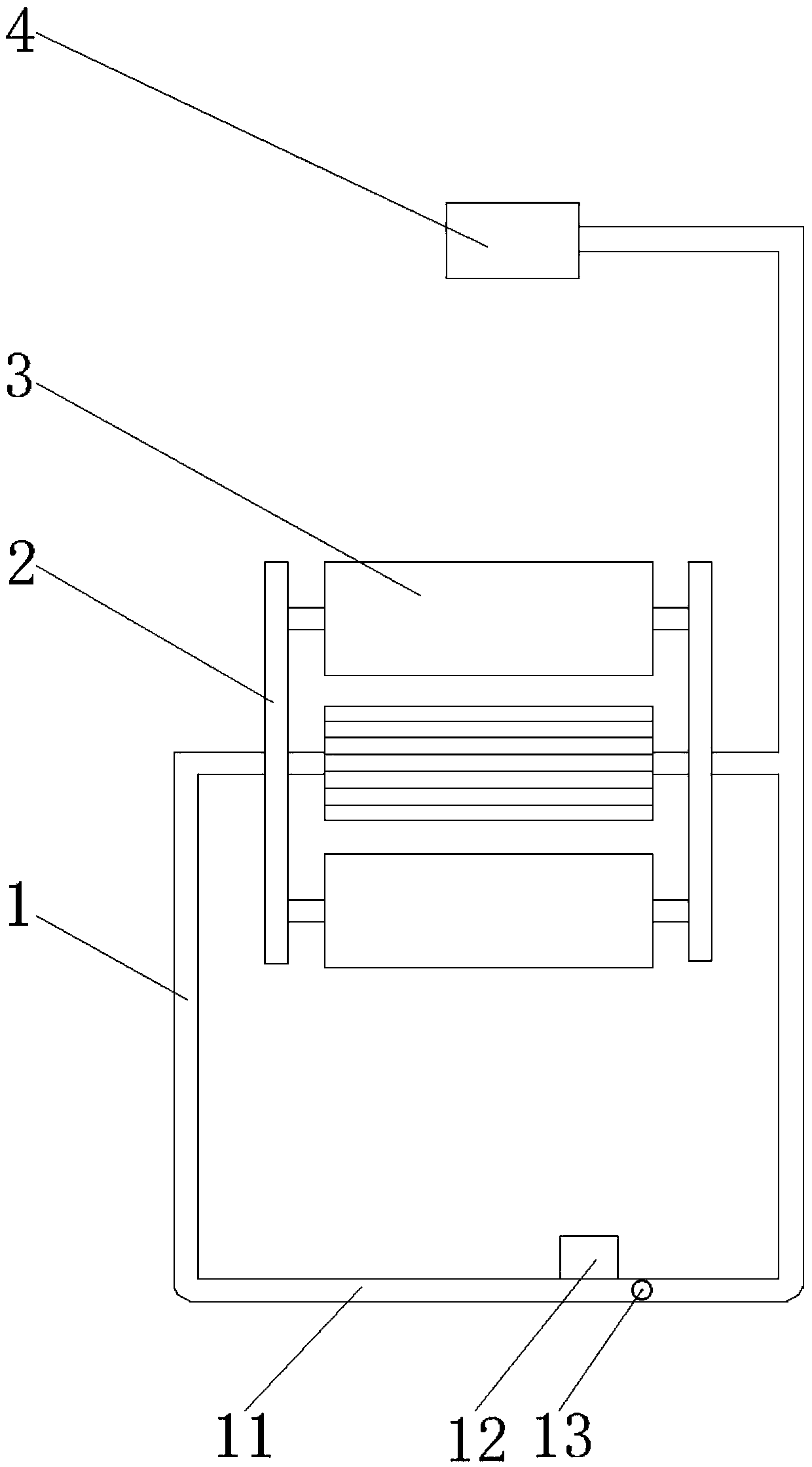

Internal edge sealing device

PendingCN111152326ASimplified volumeSimple structureWood working apparatusDomestic articlesDrive shaftElectric machinery

The invention relates to the technical field of mechanical equipment, in particular to an internal edge sealing device. The internal edge sealing device comprises an edge sealing machine. An adjustable air blower, a motor and a roller III are arranged in an outer shell, and a half-arc-shaped guide plate is arranged near the roller III. A semicircular groove is formed in the edge of an upper cover,and a roller I is fixedly arranged on one side of the semicircular groove. A roller II is fixedly arranged on one side of the roller I, and a transmission shaft is fixedly arranged near the roller II. A power shaft is fixedly arranged near the transmission shaft, and a glue pressing roller is fixedly arranged near the power shaft. An air pipe is arranged between the glue pressing roller and the semicircular groove, and the lower part of the air pipe is connected with the adjustable air blower. The lower part of the power shaft is connected with the motor. A rotation shaft is fixedly arrangedon the outer side face of the bottom surface in the outer shell, and the other end of the rotation shaft is fixed on a bearing seat. The internal edge sealing device uses mechanical edge sealing instead of manual edge sealing, cancels gluing equipment, simplifies the volume and structure of the equipment, reduces the equipment cost, and improves the edge sealing efficiency.

Owner:NOVAH SHANGHAI OFFICE SYST

Edge sealing device for SBS modified asphalt waterproof roll

InactiveCN108819264AImprove the effect of edge bandingGuaranteed temperatureBituminous waterproofingDisplay device

The invention discloses an edge sealing device for an SBS modified asphalt waterproof roll. The edge sealing device comprises a support, connection rods, a pressing wheel and a heating wheel, whereinan operation rod is arranged on the upper end of the support; a temperature display and an adjusting valve are arranged on the right end of the operation rod; two connection ends of the support are separately provided with the connection rods; the pressing wheel comprises a first rolling pressing wheel, a sawtooth-shaped pressing wheel and a second rolling pressing wheel which are parallelly arranged between the two connection rods; a pressing shaft of the pressing wheel is fixedly arranged on the connection rods; a temperature sensor is arranged in the heating wheel; and the temperature sensor is connected with the temperature display. The edge sealing device has the advantages that the temperature of the heating wheel is controlled through arrangement of the temperature display, the adjusting valve and the pressing wheel; and not only is the edge sealing effect improved, but also the construction efficiency is greatly improved.

Owner:ANHUI KUAILAI WATERPROOFING & ANTI CORROSION

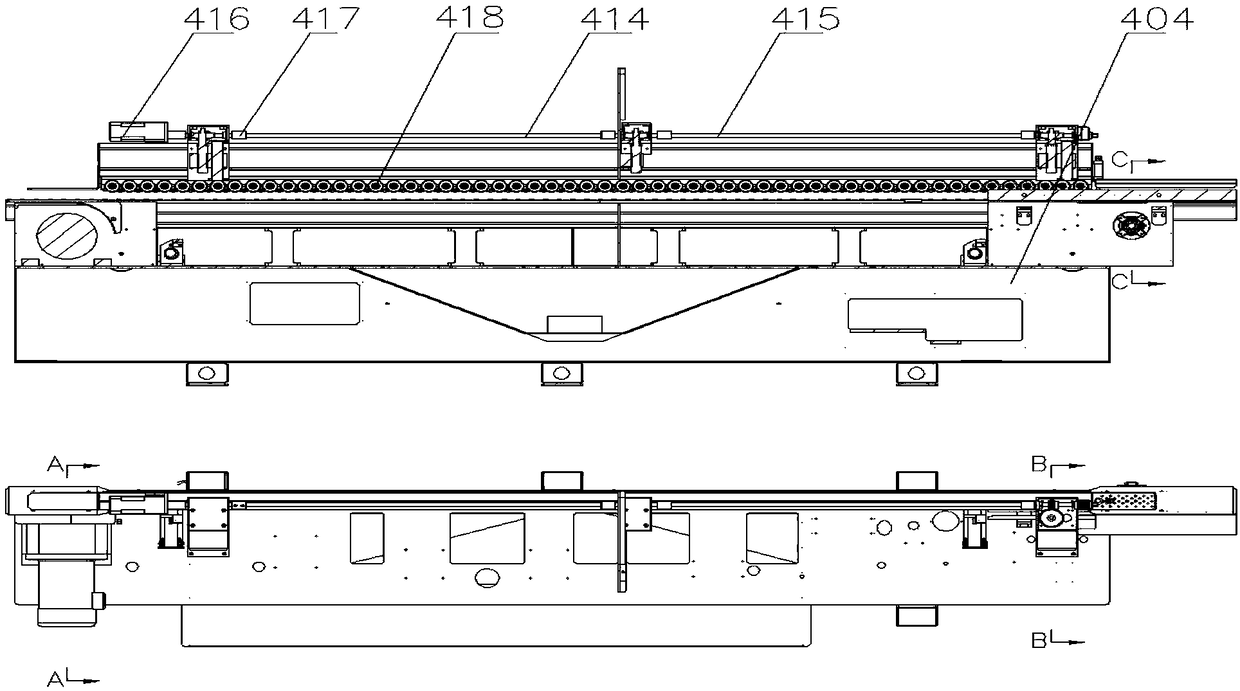

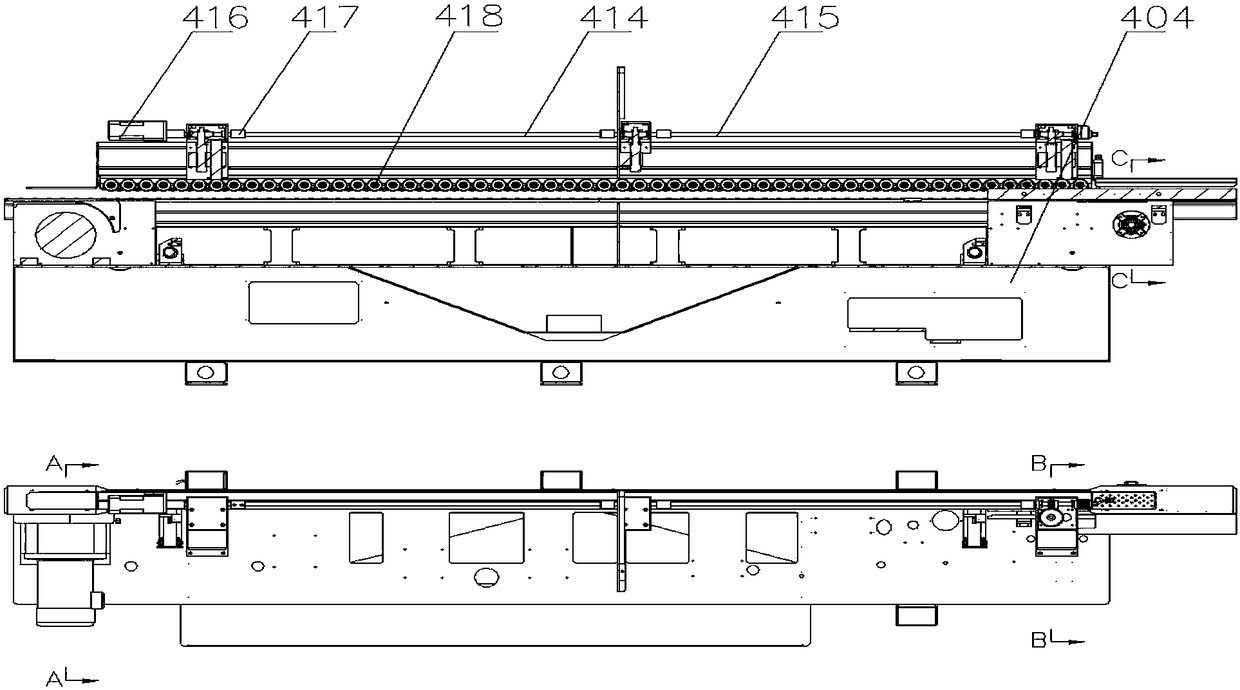

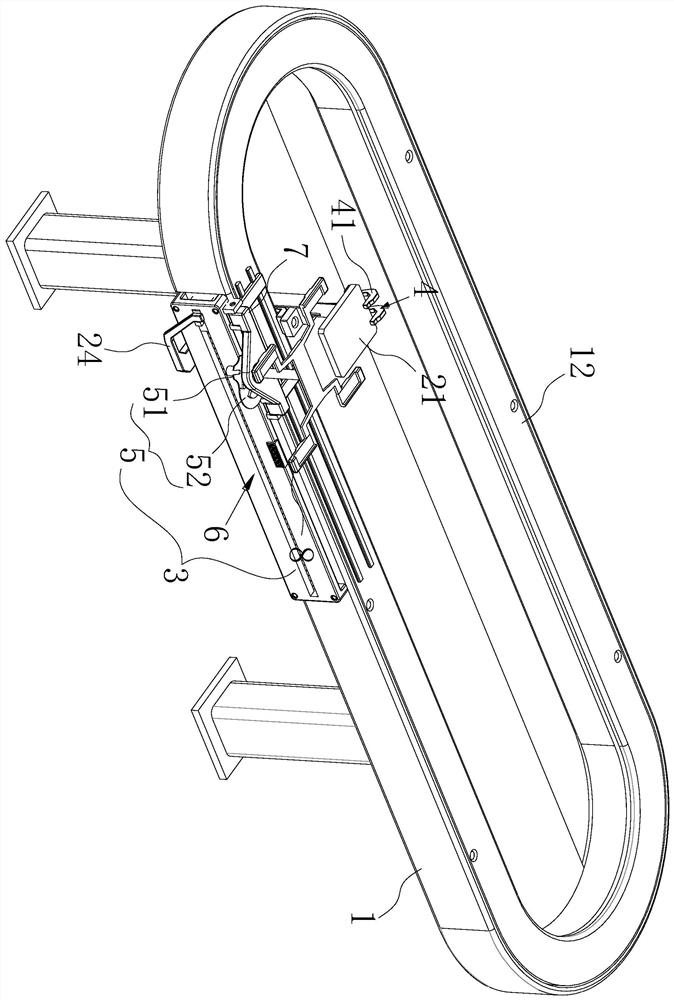

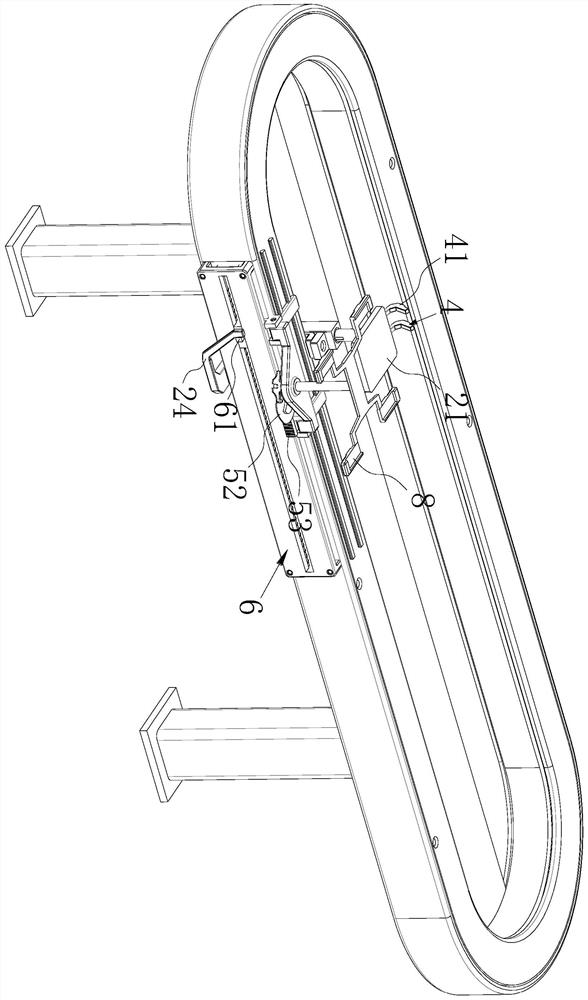

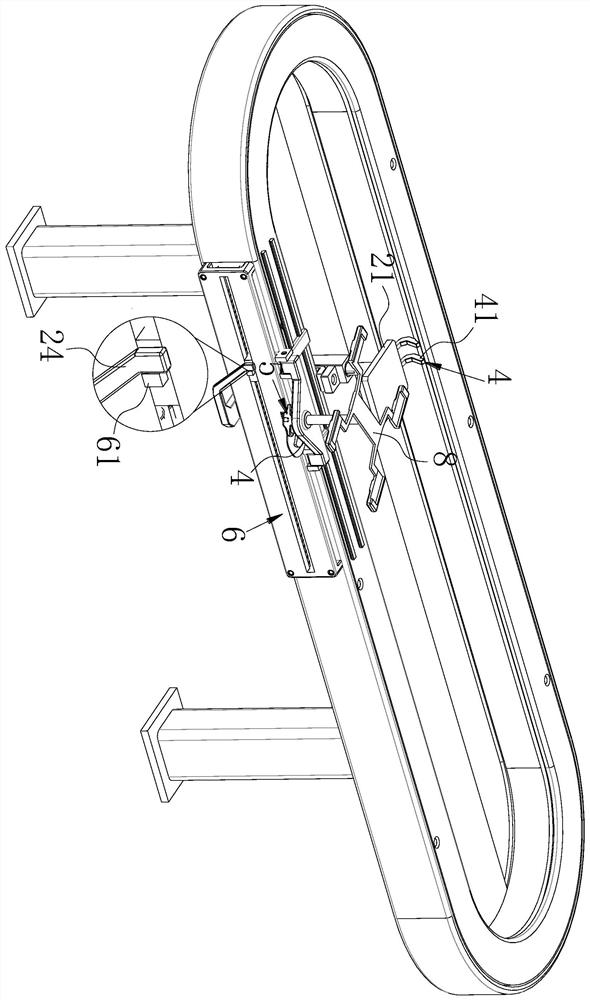

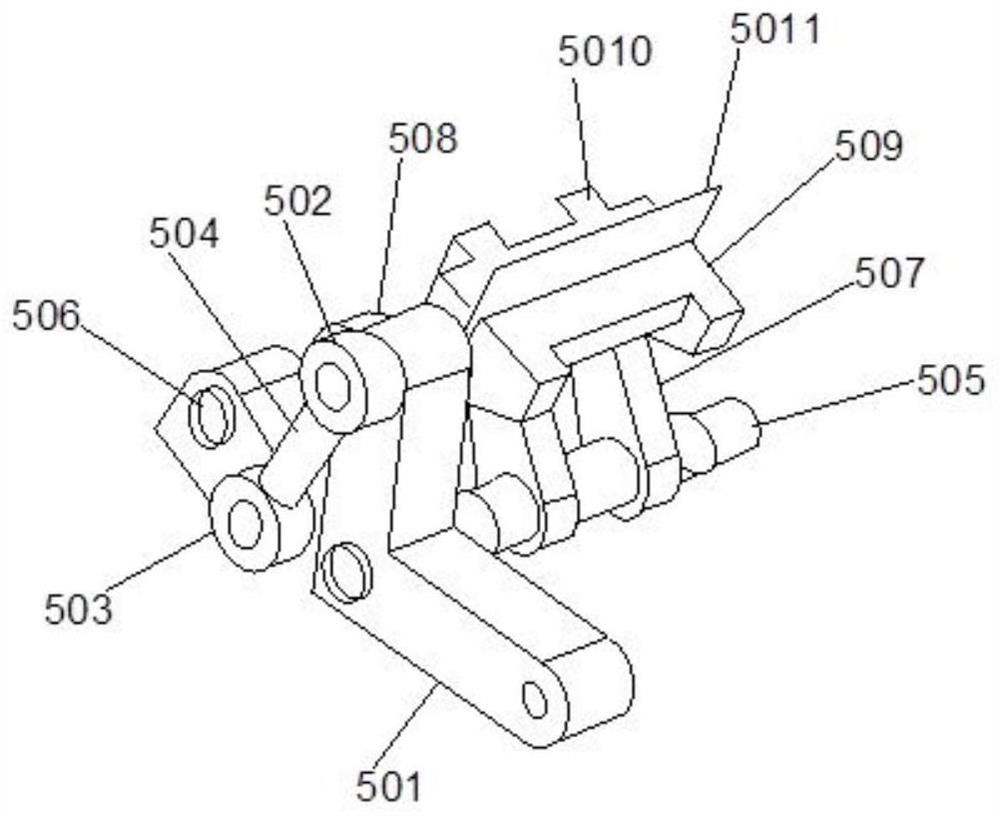

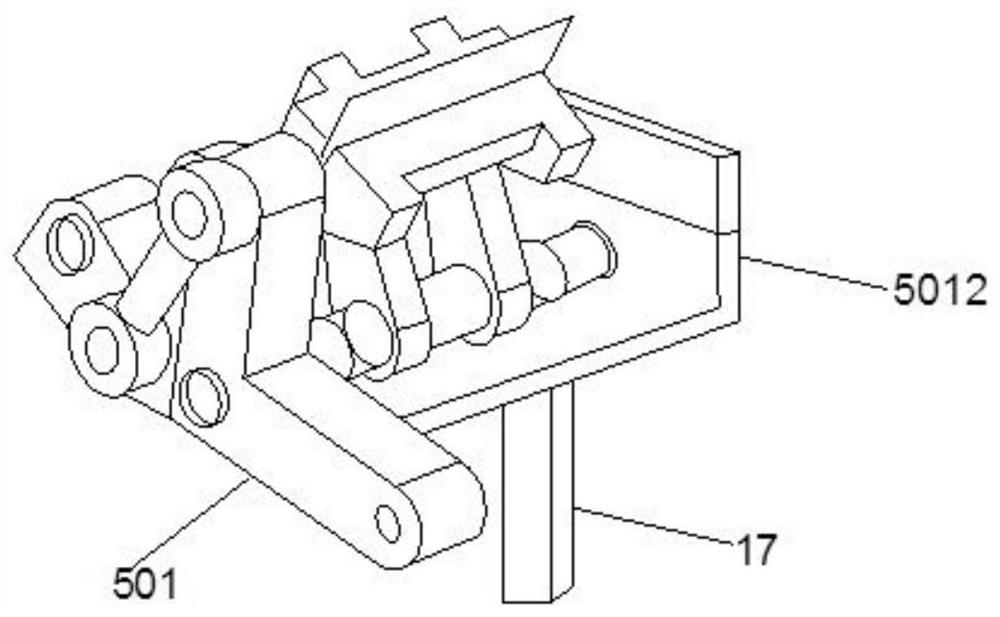

Feeding system of furniture edge banding machine

ActiveCN113581811AAvoid disadvantagesImprove edge banding efficiencyConveyorsWood working apparatusWood plankEdge banding

The invention discloses a feeding system of a furniture edge banding machine. The feeding system of the furniture edge banding machine comprises a track frame mounted at one side of an edge banding machine body; a board feeding mechanism and an edge changing mechanism are respectively arranged on the track frame; the board feeding mechanism moves along the track frame and is used for clamping a wooden board; the edge changing mechanism comprises an unlocking assembly and a material supporting frame; the unlocking assembly is used for enabling the board feeding mechanism to relieve the clamping on a target; and the material supporting frame is used for supporting the wooden board when the board feeding mechanism relieves the locking. According to the feeding system of the furniture edge banding machine, the wooden board is placed on the material supporting frame, and the board feeding mechanism can lock the wooden board located on the material supporting frame, so that the wooden board is carried and fed into the edge banding machine body to be subjected to edge banding treatment; when the wooden board is circulated to the edge changing mechanism again along with the conveyance of the track frame, the unlocking assembly relieves the locking of the board feeding mechanism on the wooden board; and meanwhile, the rotating assembly drives the material supporting frame to rotate so that the edges of the wooden board can be changed, so that the defects of a furniture edge sealing machine at the present stage are overcome, and edge sealing of the four side edges of the wooden board can be achieved through one-time board repairing.

Owner:滁州松鼠家具有限公司

Board edge sealing process

InactiveCN111687962APrevent moisture absorptionShort curing timeOther plywood/veneer working apparatusDomestic articlesAdhesiveFirming agent

The invention discloses a board edge sealing process. The process includes the following steps: firstly, grooving, wherein grooves with the size of 10-15 mm are formed in the four edges of a board; secondly, adhesive preparation, wherein the proportion of epoxy resin to a curing agent is 5:1-5:3, a defoaming agent accounting for 3-5% of the total weight of an adhesive solution and a preservative accounting for 5-8% of the total weight of the adhesive solution are added, and uniform stirring is performed to prepare an edge sealing adhesive; thirdly, adhesive filling, wherein the edge sealing adhesive prepared in the second step is uniformly applied into the grooves formed in the board in the first step; fourthly, adhesive solidifying, wherein the temperature of the board is controlled to be80-100 DEG C, and the edge sealing adhesive is pressed; and fifthly, forming, wherein after the edge sealing adhesive is completely solidified, the sealed edges are polished until the edges of the board are flat and smooth. Compared with the prior art, the process has the advantages that the process is simple, edge sealing is stable, and the edges are smoother and more attractive.

Owner:广东菲力绿色板业有限公司

Flip-side structure for production of door panels

ActiveCN108249133AAccurate and stable turningShorten the timeConveyorsConveyor partsControl engineeringEngineering

The invention relates to the technical field of door and window manufacturing, and discloses a flip-side structure for production of door panels. The flip-side structure comprises a rack, a supportingframe and a servo motor, the servo motor is fixed to the rack, the supporting frame and the rack are rotatably connected, and a rotating shaft is fixed to the supporting frame and is fixedly connected with an output shaft of the servo motor; the rotating shaft is slidably connected with an upper pressing plate, a plurality of air cylinders are fixed to the rotating shaft, piston rods of the air cylinders are fixedly connected with the upper pressing plate, and a lower pressing plate fixed to the rotating shaft is arranged below the upper pressing plate; the rotating shaft is slidably connected with a pushing plate in the horizontal direction, the pushing plate is provided with a first compressed spring and a first button switch, the pushing plate is provided with a groove in the width direction, and the rotating shaft is provided with a protruding block matched with the groove; and a spring abutting against the rotating shaft is fixed to the protruding block, the rack is rotatably connected with a plurality of conveying rollers located on the opposite side of the rotating shaft, and the conveying rollers are driven by a bidirectional motor fixed to the rack. The flip-side structure for production of the door panels is simple in structure and can flip the door panels.

Owner:CHONGQING SHUANGCHI DOORS & WINDOWS

Packaging bag packaging cutting device

PendingCN113955229AImprove edge banding efficiencyNormal repetitive workWrapper twisting/gatheringEngineeringThermal shrinkage

The invention discloses a packaging bag packaging cutting device. The packaging bag packaging cutting device comprises a supporting seat, a thermal shrinkage mechanism, an extrusion mechanism, a mechanical claw and a lifting material pushing mechanism. The thermal shrinkage mechanism is arranged on the supporting seat and used for heating a packaging bag to achieve thermal shrinkage edge sealing. The extrusion mechanism is used for extruding the packaging bag together with the thermal shrinkage mechanism. The mechanical claw is used for clamping remaining materials so that the remaining materials of the packaging bag can be intercepted. The lifting material pushing mechanism can ascend and descend so as to push the remaining materials down from the mechanical claw. According to the packaging bag packaging cutting device, the mechanical claw is used for grabbing and intercepting the remaining materials, and then the lifting material pushing mechanism is used for pushing down the remaining materials on the mechanical claw, so that the mechanical claw normally and repeatedly works, and thus the edge sealing efficiency is improved.

Owner:广东享尔实业有限公司

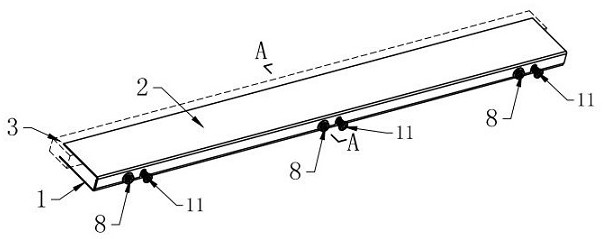

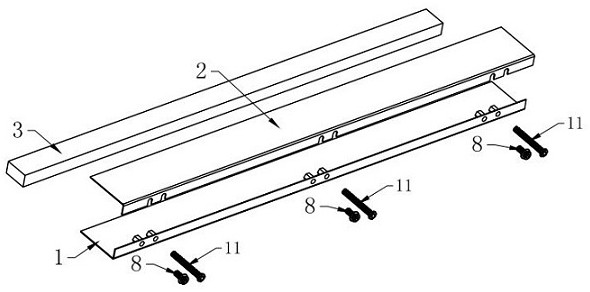

Narrow strip sealing accessory system for edge sealing machine and narrow strip edge sealing method

ActiveCN114030052ARealize automatic edge bandingImprove edge qualityWood working apparatusDomestic articlesMechanical engineeringPhysics

The invention relates to the technical field of furniture, in particular to a narrow strip sealing accessory system for an edge sealing machine and a narrow strip edge sealing method. The narrow strip sealing accessory system comprises a bottom plate and a top plate, wherein a gap for fixing a narrow strip is formed between the bottom plate and the top plate; the bottom plate is provided with a side plate, a connecting plate is arranged on the top plate, and the side plate and the connecting plate are fixedly connected through a connecting piece; and the side plate is provided with a second screw hole, and a depth adjusting bolt is installed in the second screw hole. The narrow strip edge sealing method comprises the steps that a narrow strip is fixed to the narrow strip sealing accessory system, the side portion, which is to be subjected to edge sealing, of the narrow strip extends out of the narrow strip sealing accessory system, and a complete plate with the width not less than 50 mm is integrally formed; and the fixed narrow strip and the narrow strip sealing accessory system are installed on an automatic linear edge sealing machine, and edge sealing is conducted on the narrow strip. According to the system and the method, the edge sealing machine can be used for conducting automatic edge sealing on narrow strips with the width less than 45 mm and different thicknesses, the adaptability is high, the edge sealing efficiency and the edge sealing quality of the narrow strips are obviously improved, and the edge sealing cost is reduced.

Owner:SHANDONG DONGYU HONGXIANG CABINET MATERIAL CO LTD

A fast packaging machine

ActiveCN112158409BPrevent crushingImprove accuracyWrapper twisting/gatheringDrive wheelElectric machine

The invention discloses a fast packaging mechanical device; it includes a base and a casing; a first motor is provided at the bottom of the base near one end, and a drive sprocket is connected to the output shaft of the first motor, and the drive sprocket is matched and connected with a chain. The other end of the chain is connected with a driven sprocket, and the driven wheel sprocket is connected with a roller, and the roller is driven and connected with a conveyor belt, and the conveyor belt is arranged on the top of the base; the housing cover is arranged above the conveyor belt; Two sets of fixing mechanisms are arranged symmetrically on both sides of the housing near the bottom, and two sets of crimping mechanisms are arranged symmetrically above the fixing mechanism; the fixing mechanism and the creasing mechanism are arranged to improve the accuracy and efficiency of edge sealing; The mechanical edge banding mechanism achieves a high level of synchronization in the coordinated movement, reduces the difficulty of control, is safe and efficient to use, reduces maintenance during use, and has low cost of use.

Owner:河南鸿旗自动化科技有限公司

Electric control edge sealing device for plate processing

ActiveCN114179189AIncrease squeezeImprove edge banding efficiencyWood working apparatusDomestic articlesTransmission beltElectric machinery

The invention relates to the technical field of plate processing equipment, in particular to an electric control edge sealing device for plate processing, which comprises an operation platform, an electric control hydraulic support rod, an electric heating edge sealing plate, a driving motor and an infrared monitoring module. The electric control edge sealing device for plate processing is composed of the operation platform with the surface provided with a bottom conveying belt mechanism and the side guide plate, edge sealing strips are guided and extruded through the transverse guide frame and the transverse extrusion cover on the inner side of the side guide plate, and therefore extrusion transmission is conducted on the two sides of a moving plate; the first electric heating edge sealing plate is matched to heat the transverse guide frame, so that the extrusion force and the edge sealing efficiency of the front side and the rear side of the plate are improved, and the machining efficiency is greatly improved; the overturning extrusion plate controlled by the electric control hydraulic supporting rod is installed on the outer side face of the side guide plate, edge sealing is conducted on the periphery of the plate, the angle of the plate does not need to be adjusted, energy consumption is greatly reduced, and production efficiency is more excellent.

Owner:嘉美瑞智能家居科技东台有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com