Narrow strip sealing accessory system for edge sealing machine and narrow strip edge sealing method

An edge banding machine and narrow strip technology, applied in the field of furniture, can solve the problems affecting product production efficiency, product quality, automatic edge banding of automatic linear edge banding machines, poor quality stability, etc., to improve edge banding quality, reduce production costs, The effect of beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

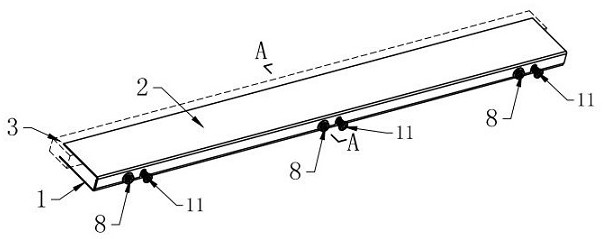

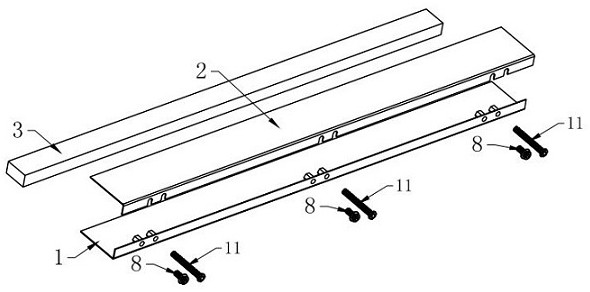

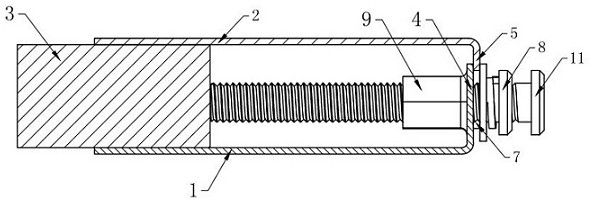

[0039] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 In common, a blocking machine is a closed strip attached system comprising a fixed bottom plate 1 and a top plate 2, and the width of the bottom plate 1 and the top plate 2 is not less than 50 mm. The top plate 2 is located above the bottom plate 1. The bottom plate 1 and the top plate 2 are provided with a gap for fixing the narrow strip 3. The upper side of the bottom plate 1 is provided with a side panel 4, and a connecting plate 5 is provided on the lower side of the top plate 2, and the connecting plate 5 corresponds to the position of the side panel 4, and the side panel 4 and the connecting plate 5 are fixed by the connector, thereby Fix the bottom plate 1 and the top plate 2 together. The bottom plate 1 is set to the connecting plate 5. The top plate 2 and the side panel 4 are also provided, and the top plate 2 is buckled on the bottom plate 1 such that the connecting plate 5 is set in parallel to the side p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com