Patents

Literature

191results about How to "High structural precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

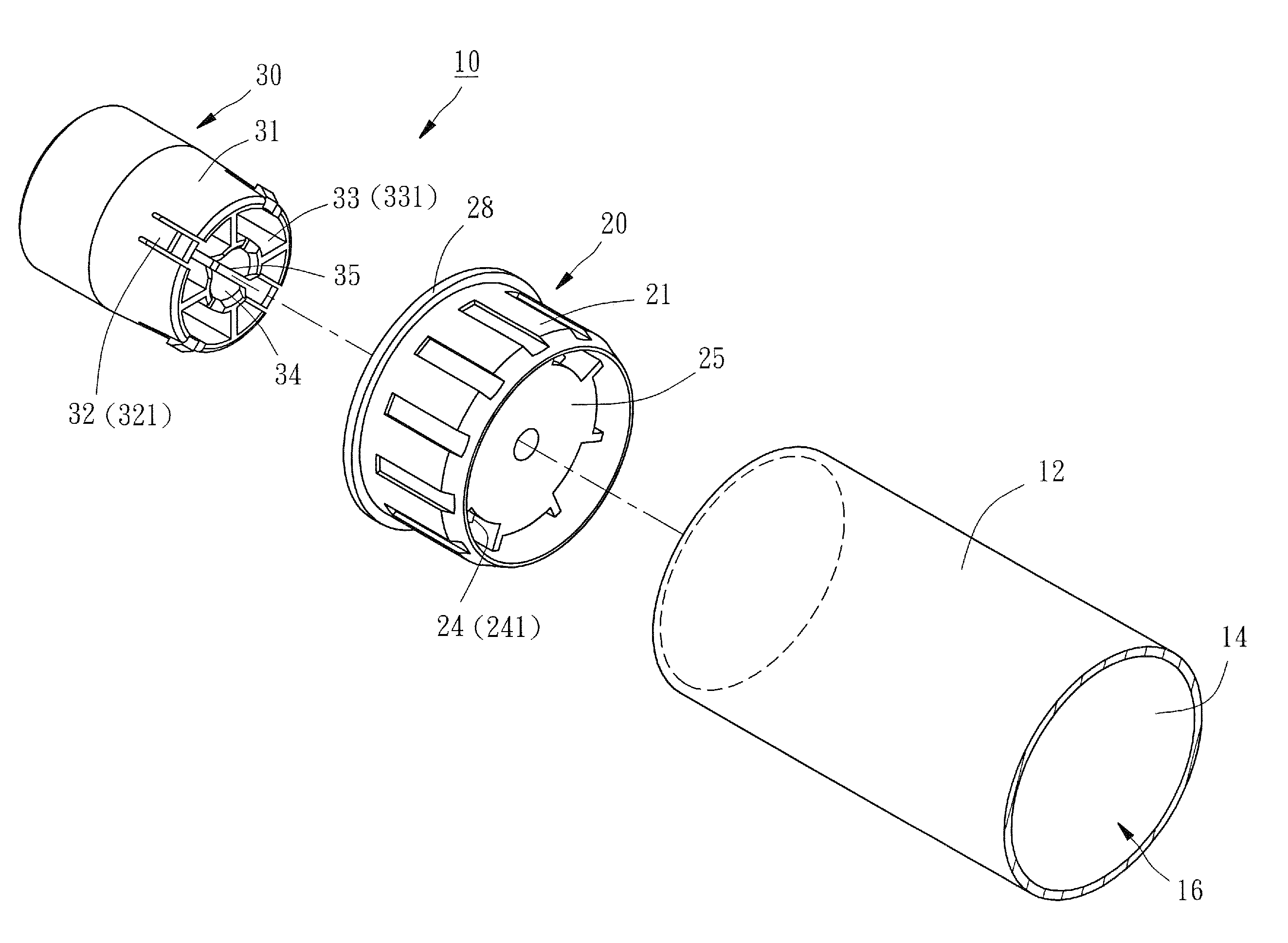

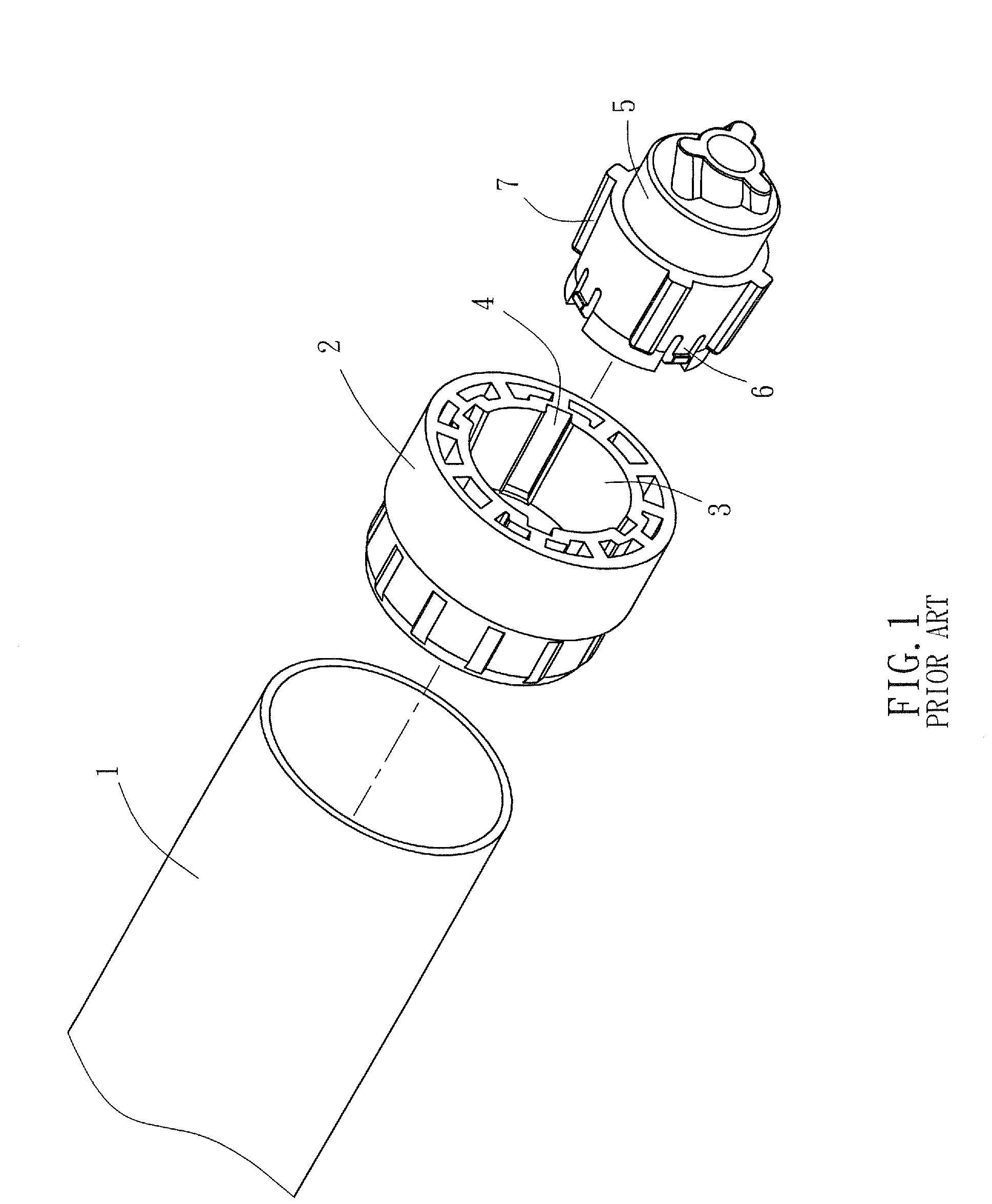

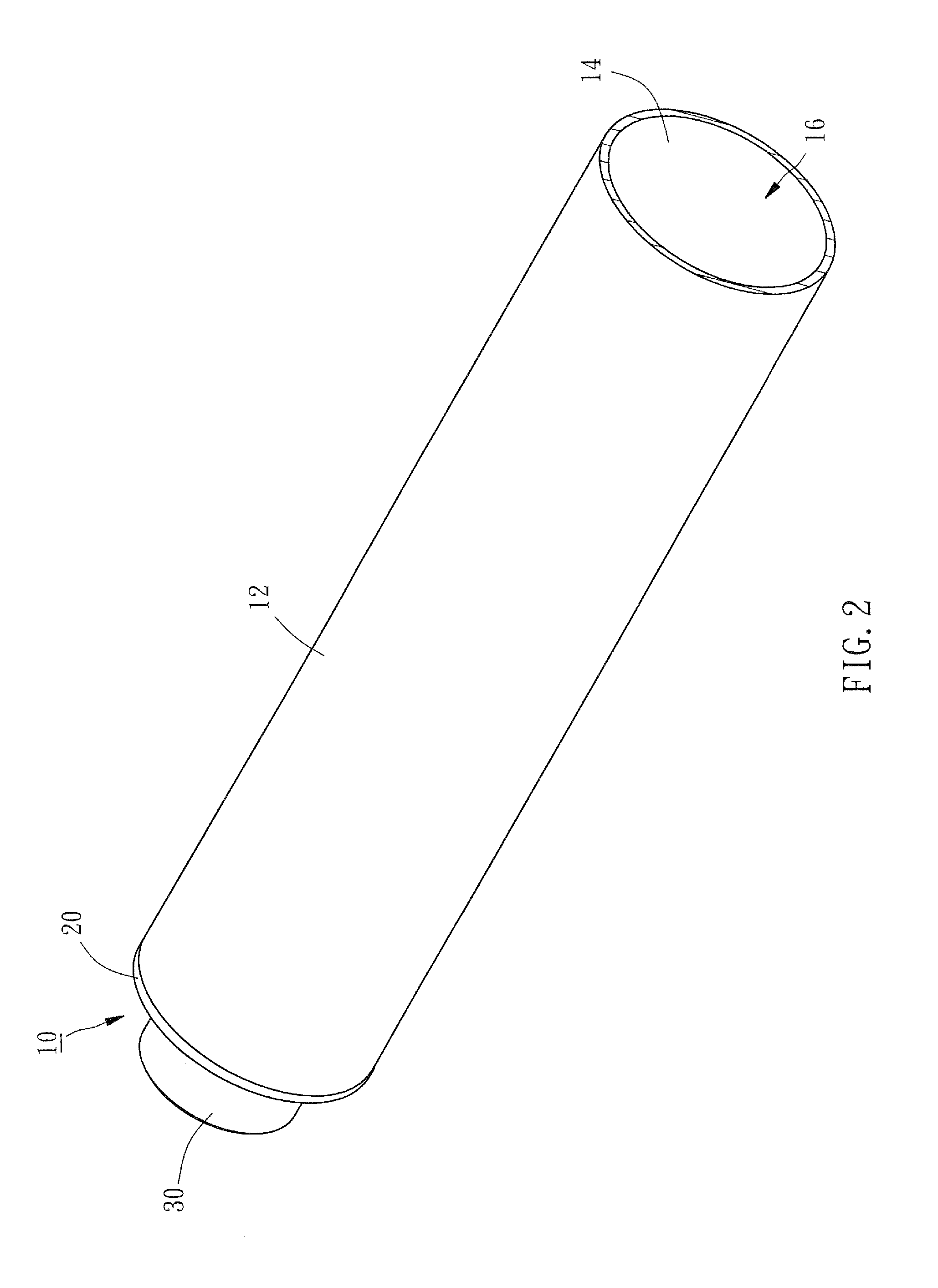

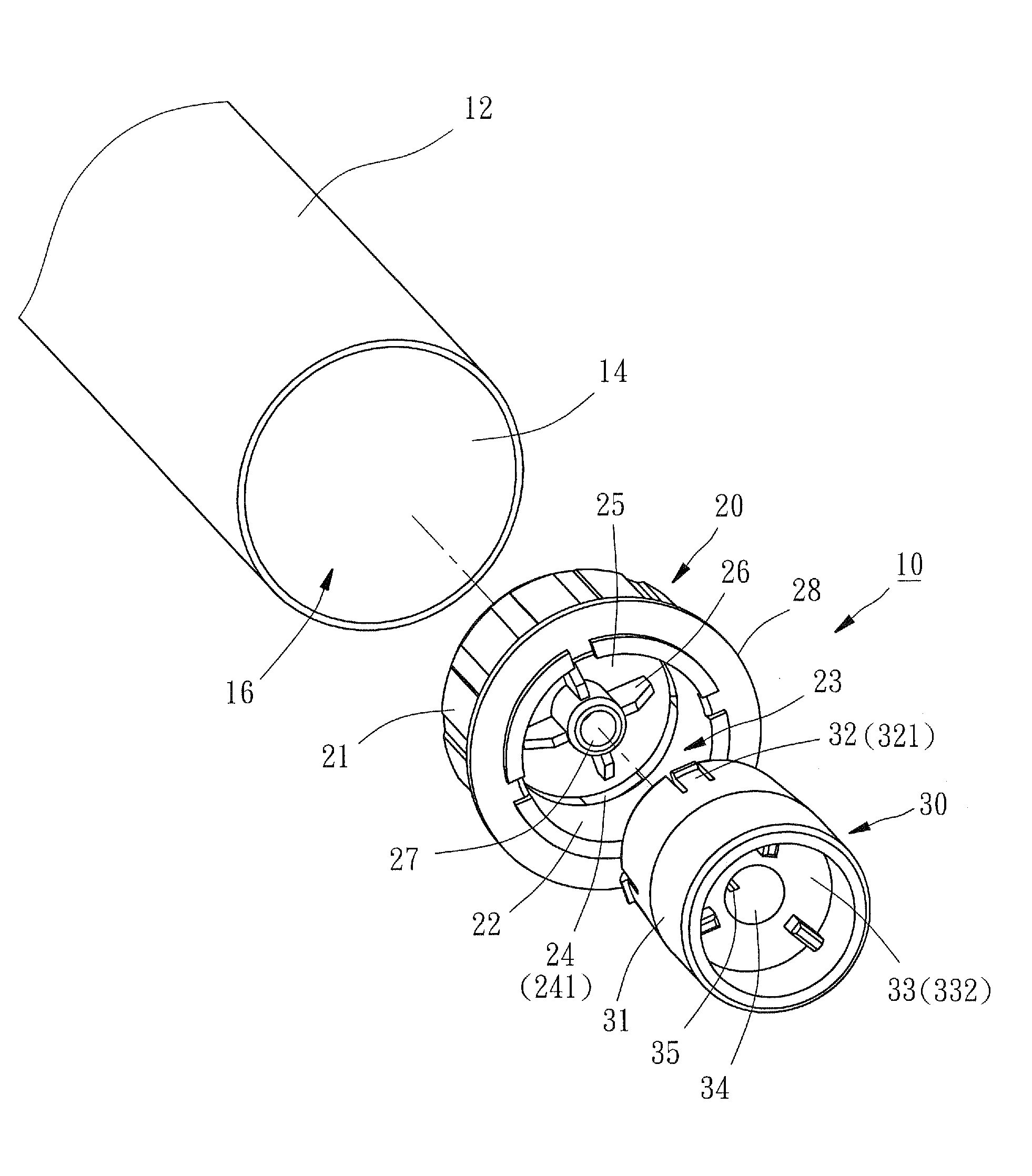

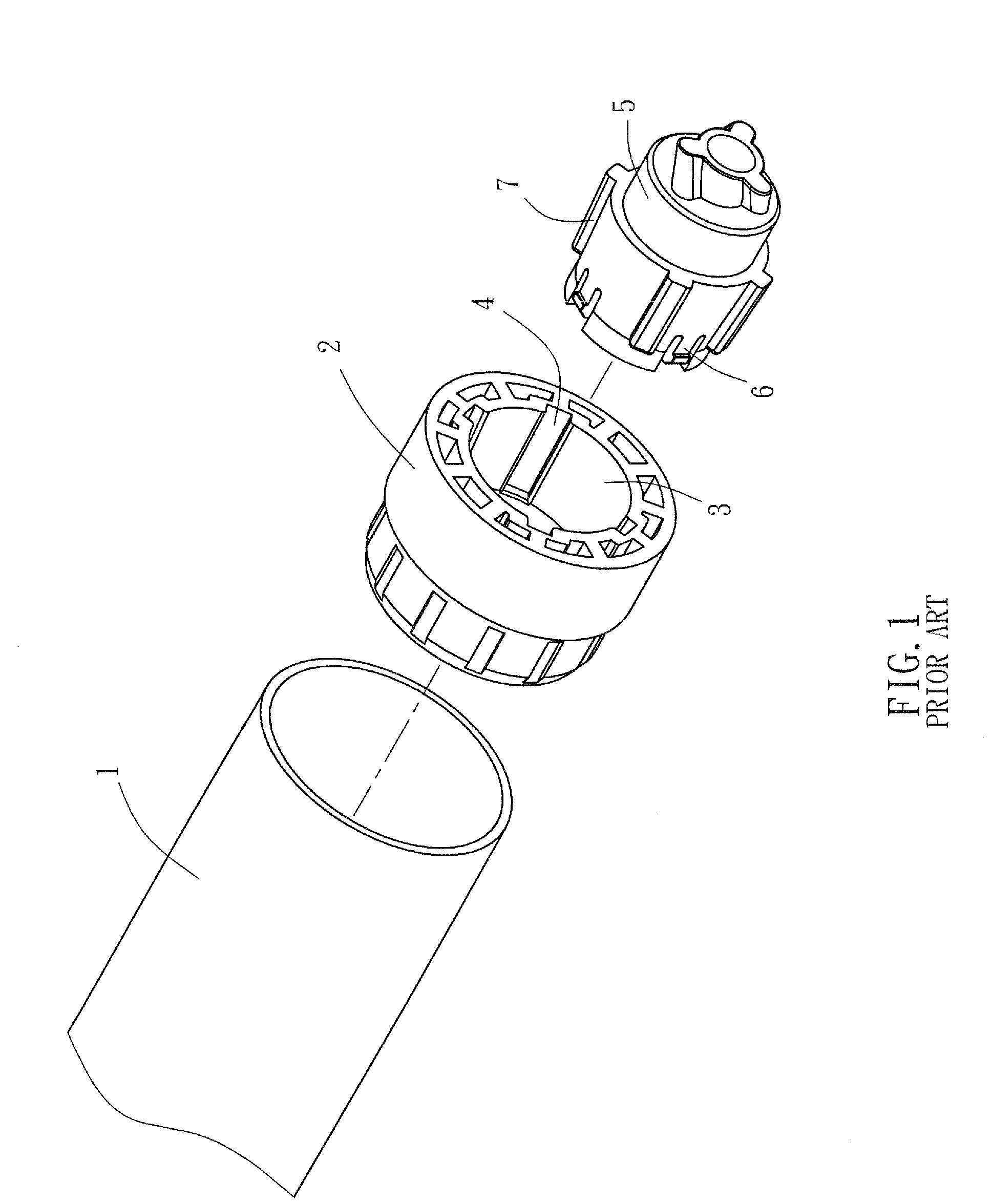

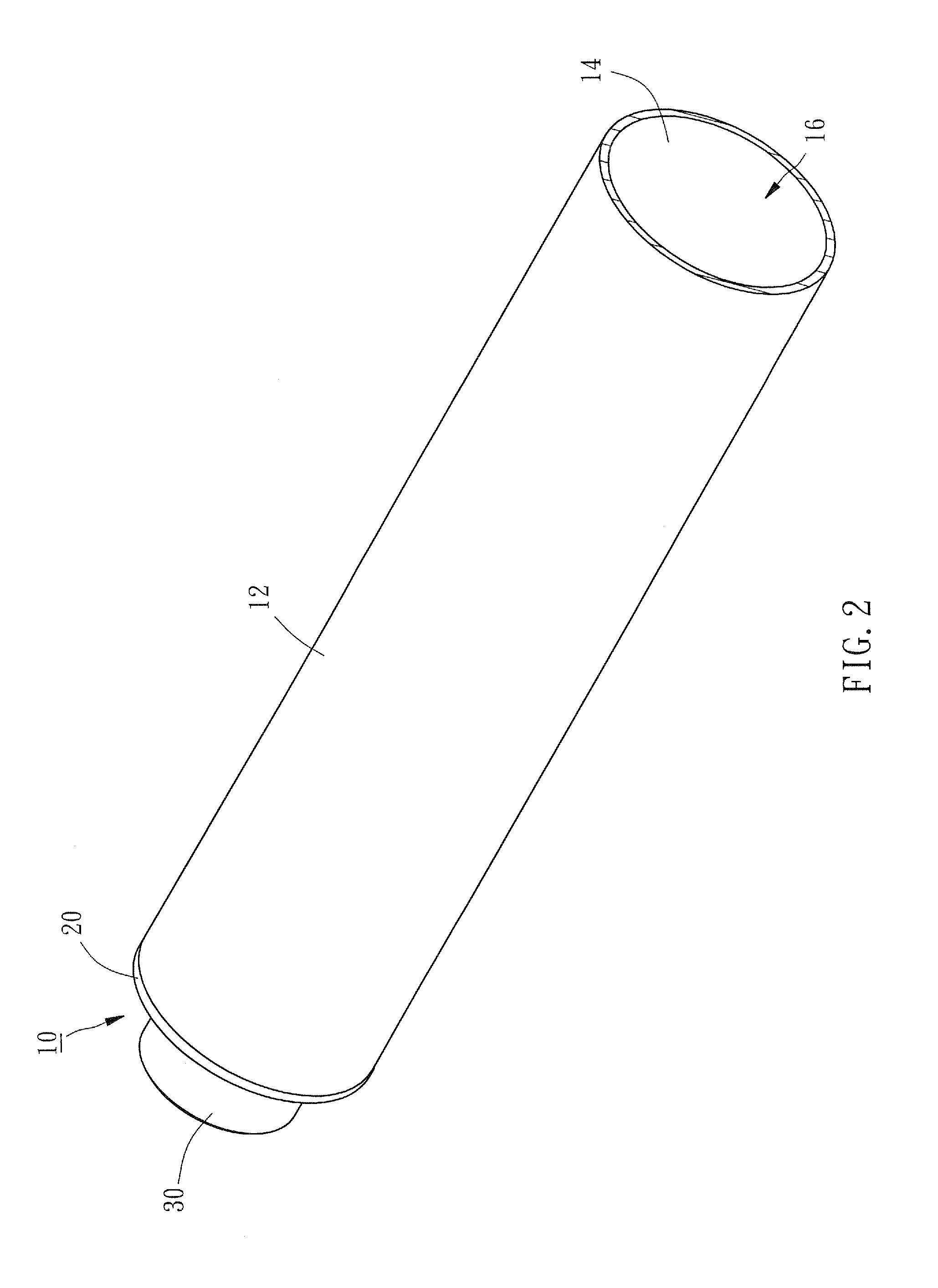

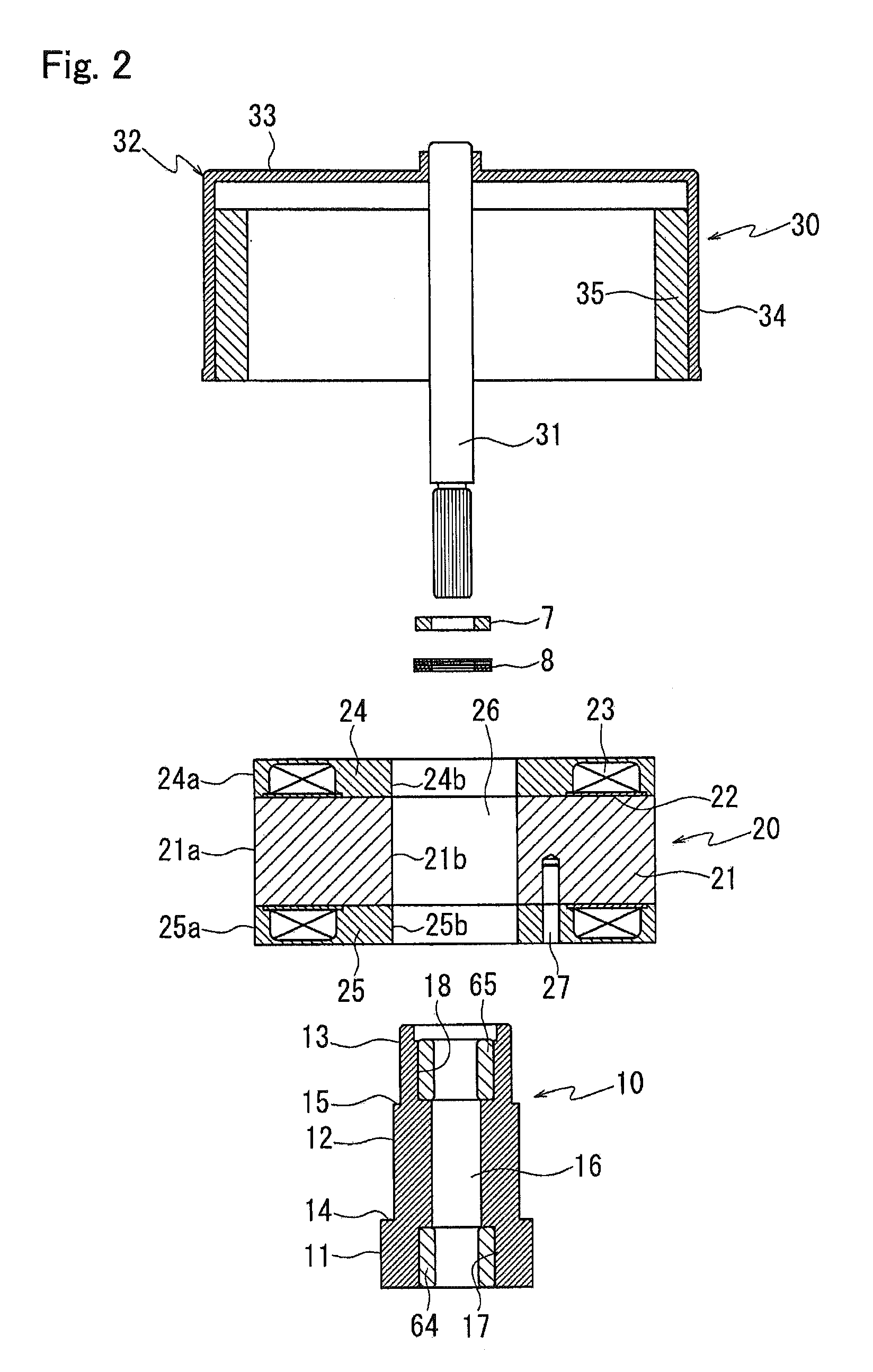

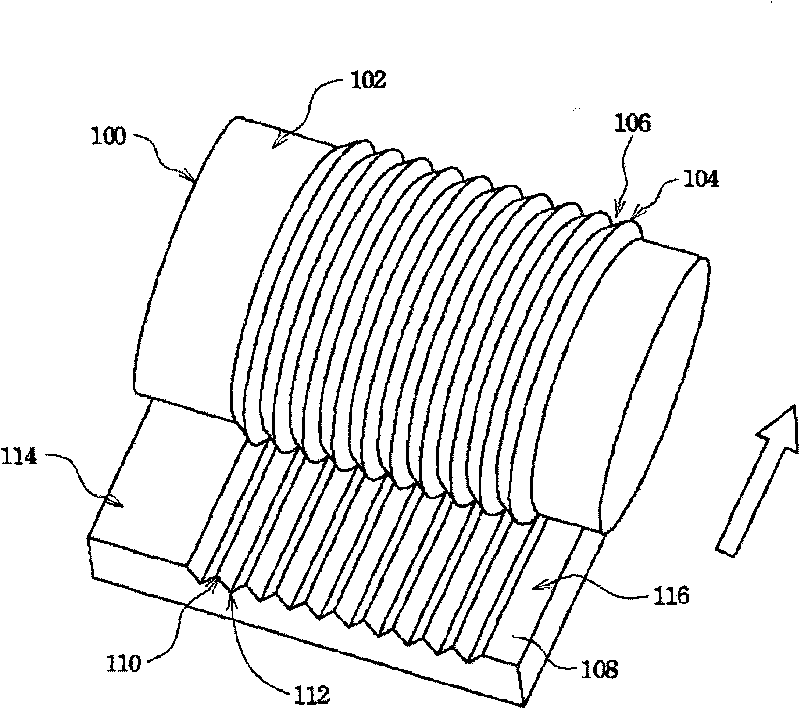

Supporting apparatus for a photosensitive drum

InactiveUS7630667B2High structural precisionImprove structural strengthElectrographic process apparatusCorona dischargeEngineeringMechanical engineering

Owner:GEN PLASTIC INDAL

Supporting apparatus for a photosensitive drum

InactiveUS20080279584A1High structural precisionImprove structural strengthElectrographic process apparatusCorona dischargeEngineeringHigh intensity

Owner:GEN PLASTIC INDAL

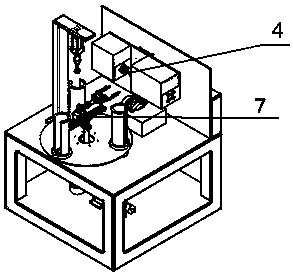

Continuous lens automatic grinding method

InactiveCN109500690AImprove edge qualityHigh structural precisionEdge grinding machinesGrinding drivesCyclic processEngineering

The invention discloses a continuous lens automatic grinding method. A feeding position, a discharging position and a material placing and collecting position are circularly and uniformly distributedon a horizontal rotary disk with the center of the rotary disk as the center. The one-off lens processing circulating process comprises the steps of overlapping and placing corresponding lenses into the material placing and collecting position; controlling the rotary disk to horizontally rotate by 120 degrees to switch the material placing and collecting position to the feeding position; taking out the lenses on the uppermost portion one by one, and clamping and conveying the lenses to a corresponding processing part structure to conduct grinding processing; clamping and conveying the ground and processed lenses to the discharging position to conduct overlapping in sequence; taking out the previous cycle of the lenses from the material placing and collecting position and placing the next cycle of the lenses into the material placing and collecting position in the lens grinding process; controlling the rotary disk to continue rotating by 120 degrees after completion of grinding of all the lenses during one-off cycle to rotate and switch the overlapped ground lenses from the discharging position to the material placing and collecting position and then taking out the lenses to complete the cycle. The continuous lens automatic grinding method has the advantage that the processing efficiency of the lenses can be improved.

Owner:CHONGQING UNIV OF TECH

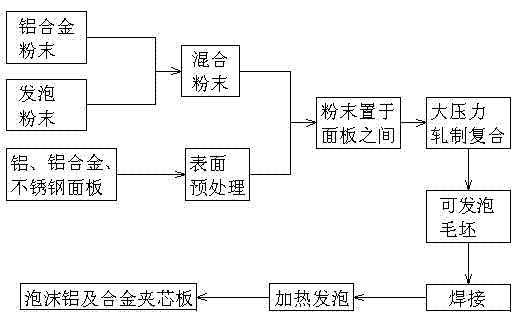

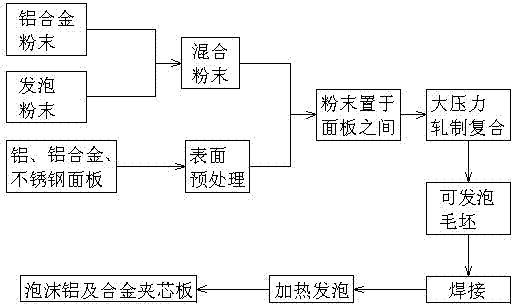

Preparation method of foamed aluminum and alloy sandwich plate

The invention discloses a preparation method of a foamed aluminum and alloy sandwich plate, which is characterized by comprising the following steps: (1) coating: selecting an aluminum and alloy panel, and compressing the aluminum and alloy panel and foaming powder to prepare a foamed aluminum and alloy sandwich plate blank; (2) welding: sanding and cleaning the welding surface of the foamed aluminum and alloy sandwich plate blank, clamping and positioning the foamed aluminum and alloy sandwich plate blank, and welding to obtain the foamed aluminum and alloy sandwich plate blank satisfying the specification and dimension requirements; (3) foaming: heating the welded foamed aluminum and alloy sandwich plate blank in a heating furnace at 300-600 DEG C for 10-40 minutes; and (4) cooling: cooling the heated foamed aluminum and alloy sandwich plate in the heating furnace, thus obtaining the well-welded foamed aluminum and alloy sandwich plate satisfying the specification and dimension requirements. The preparation method has the advantages of convenient preparation process and low processing cost; and the obtained foamed aluminum and alloy sandwich plate has fine performance.

Owner:SUZHOU UNIV

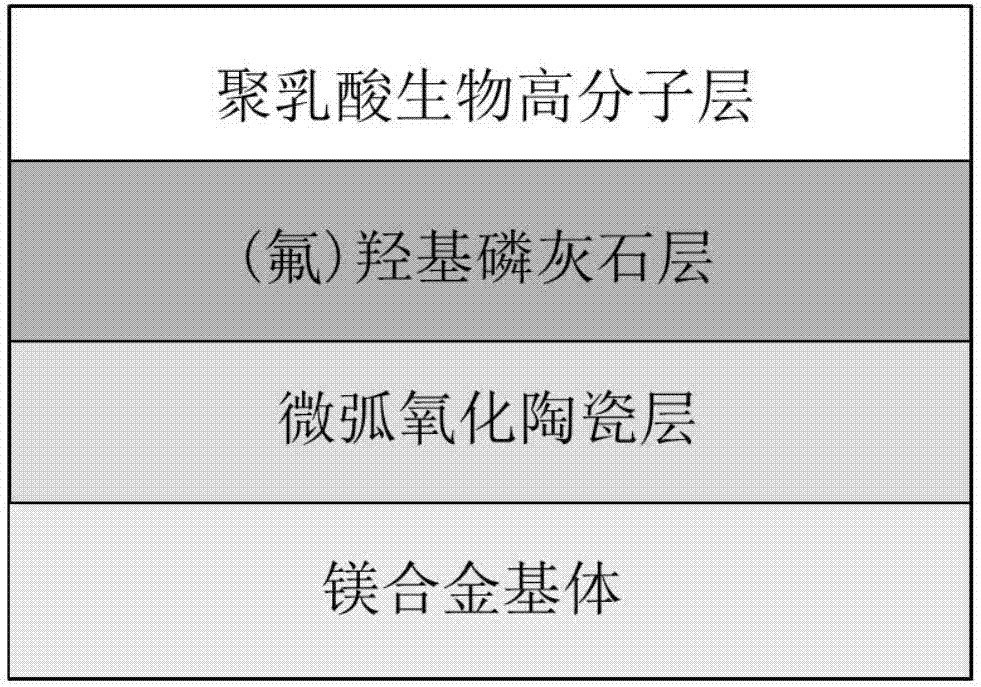

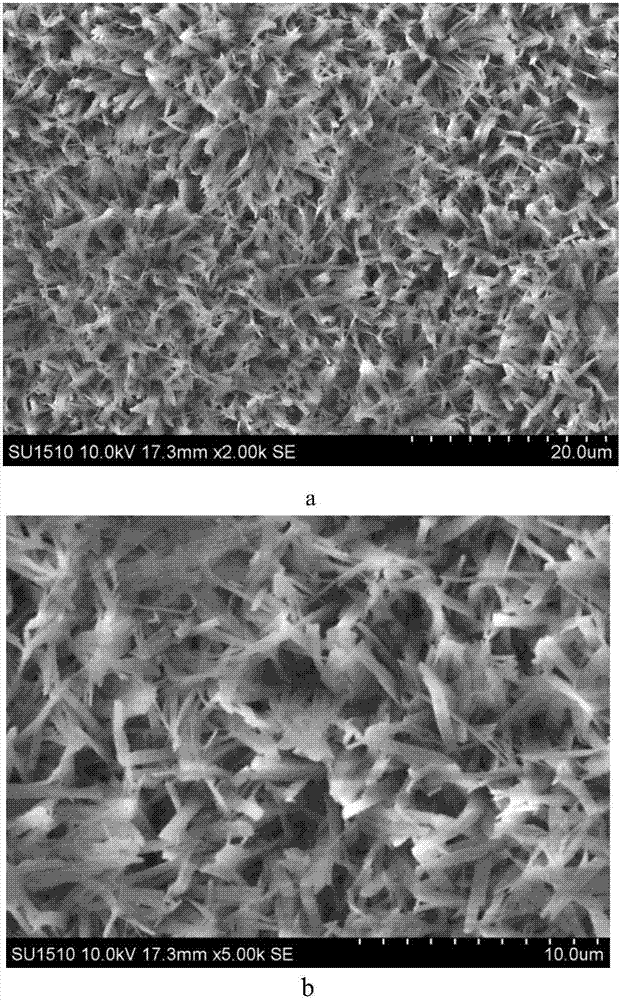

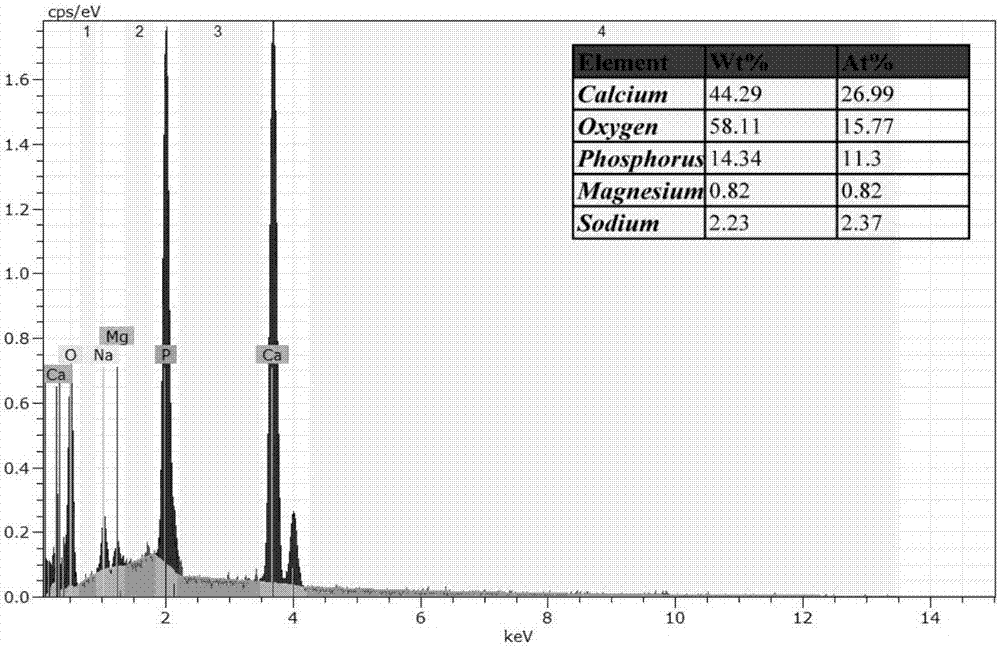

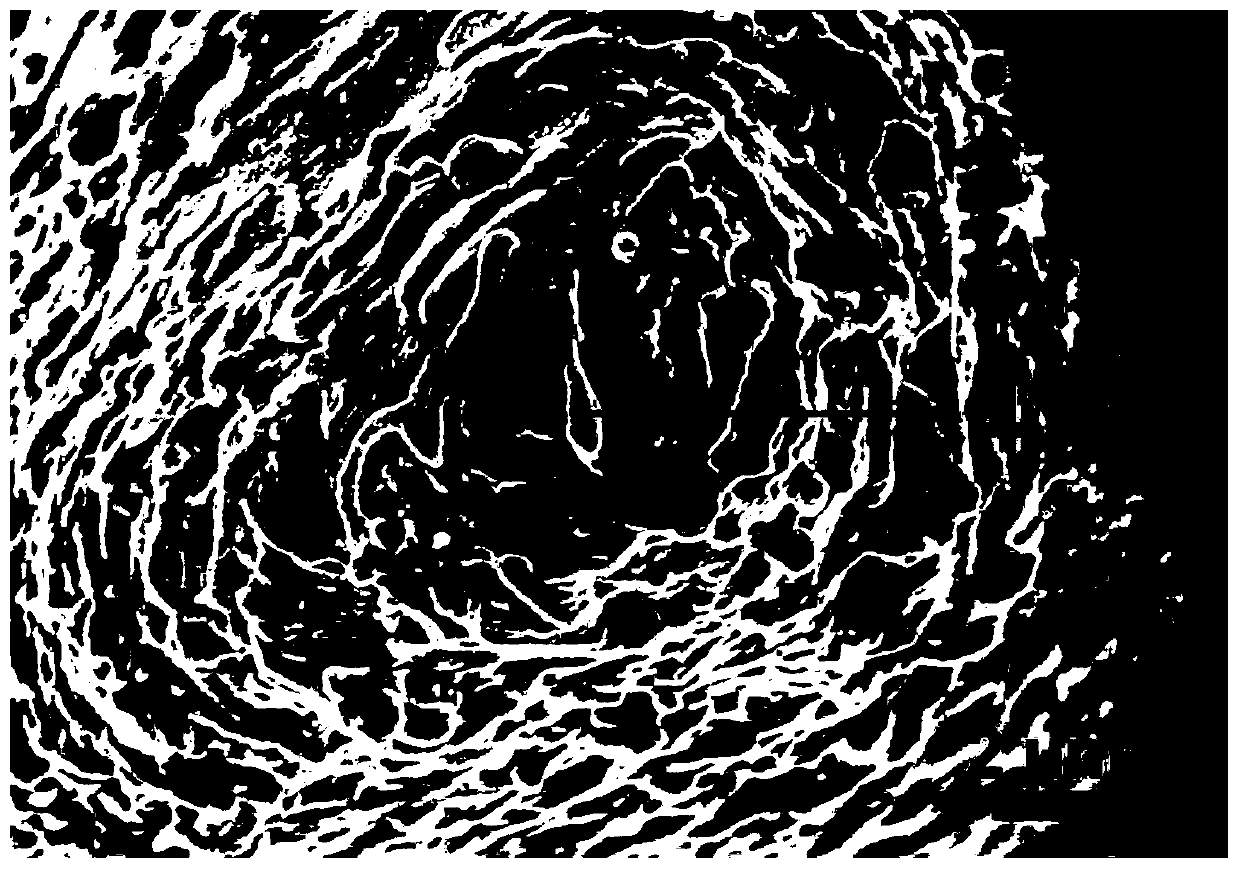

Magnesium alloy implant composite material and preparation method and application thereof

InactiveCN106902391AHigh structural precisionGood biocompatibilityAnodisationDetails involving processing stepsPlasma electrolytic oxidationMicro arc oxidation

The invention discloses a magnesium alloy implant composite material and a preparation method and application thereof. The magnesium alloy implant composite material is prepared by the following steps of: by taking a model manufactured from magnesium alloy powder through 3D printing as a magnesium alloy implant substrate, forming a micro-arc oxidation layer on the surface of the magnesium alloy implant substrate through a micro-arc oxidation method; then forming a hydroxyapatite layer or a hydroxyfluorapatite layer on the surface of the micro-arc oxidation layer by means of an electrochemical deposition method; and finally, immersing the surface of the hydroxyapatite layer or the hydroxyfluorapatite layer to form a polylactic acid layer. According to the material provided by the invention, individual development of the magnesium alloy implant material is realized from data acquisition of an original damaged bone structure to preparation of a final multi-coating composite material, so that the high quality magnesium alloy implant composite material is obtained. A polarizing test shows that the anti-corrosive property of the material can be enhanced by four orders of magnitudes, and osteoblast cultivation shows that the magnesium alloy composite material has a better osteocyte promoting ability.

Owner:ZHEJIANG UNIV OF TECH

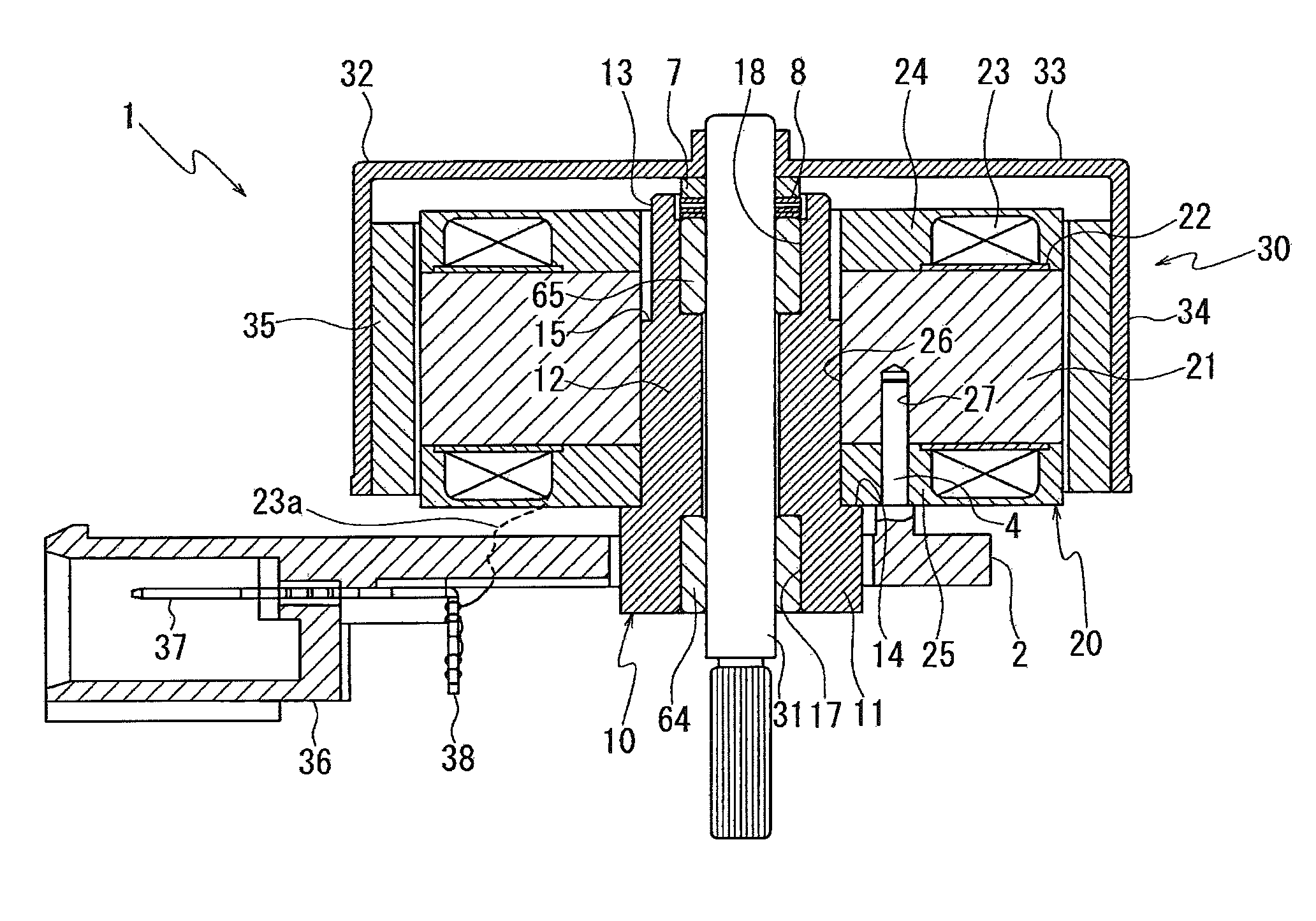

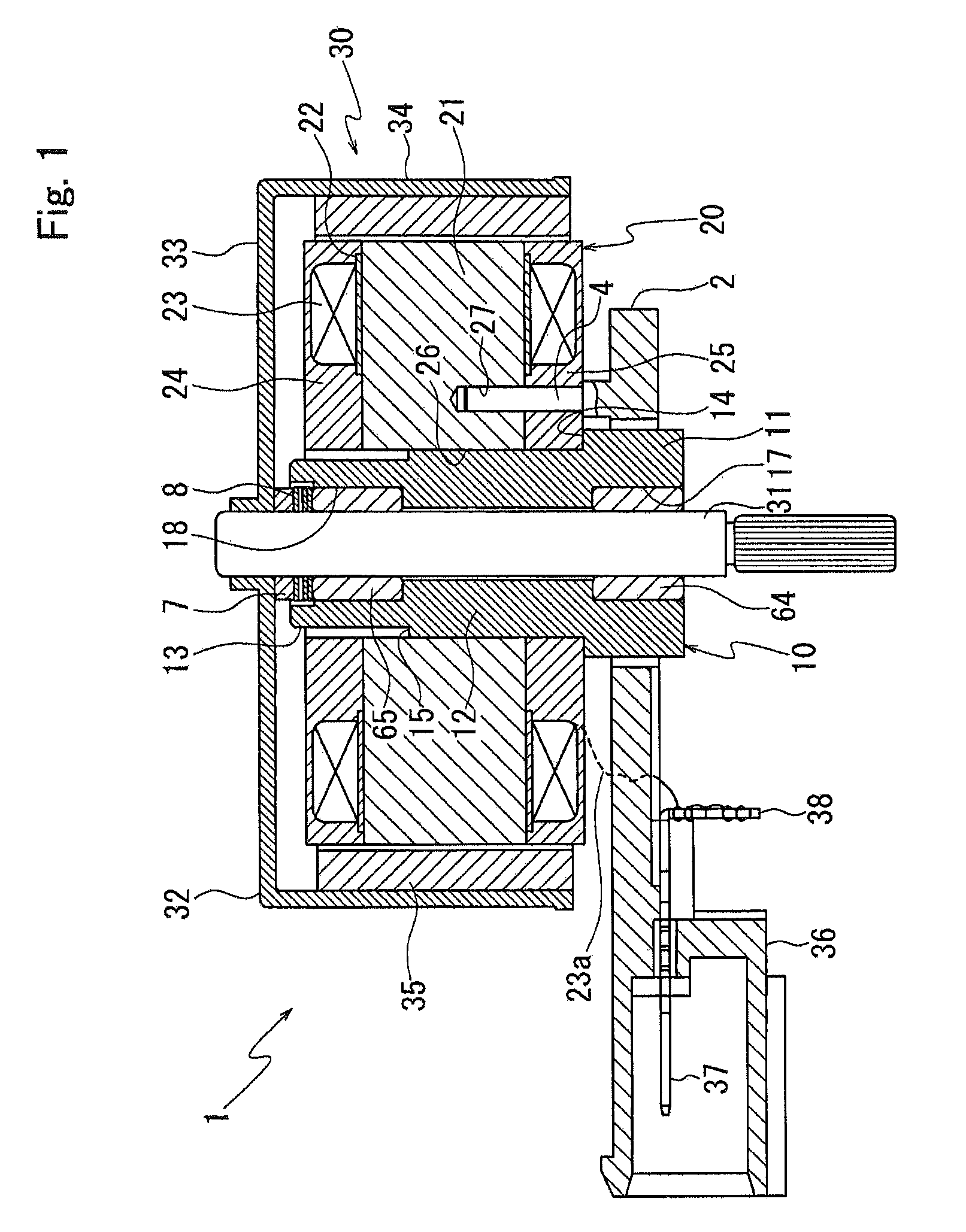

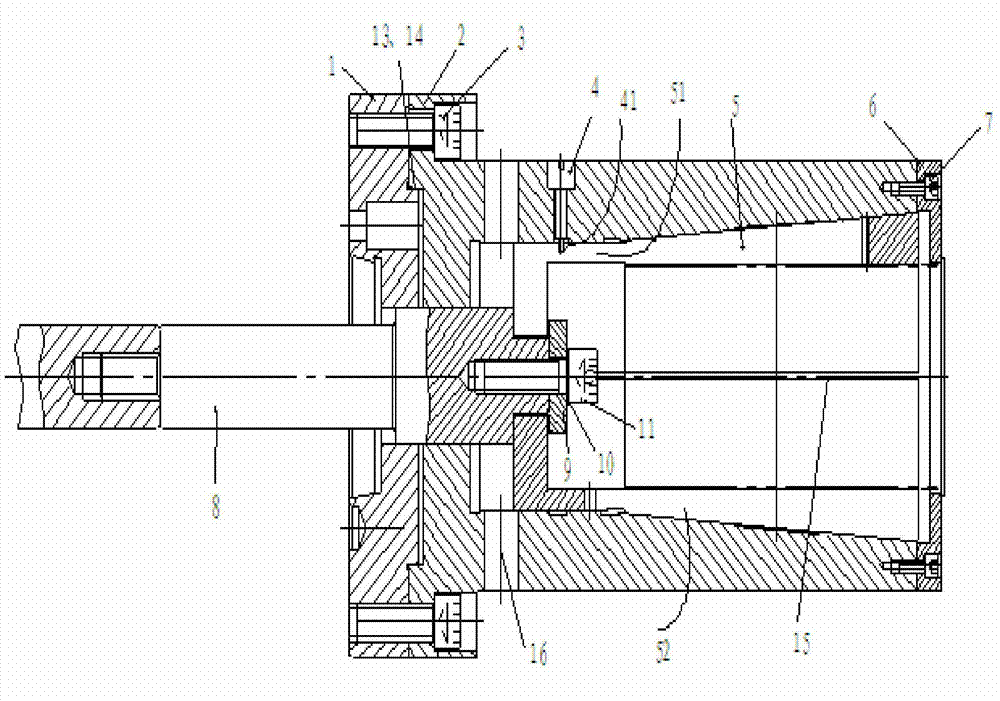

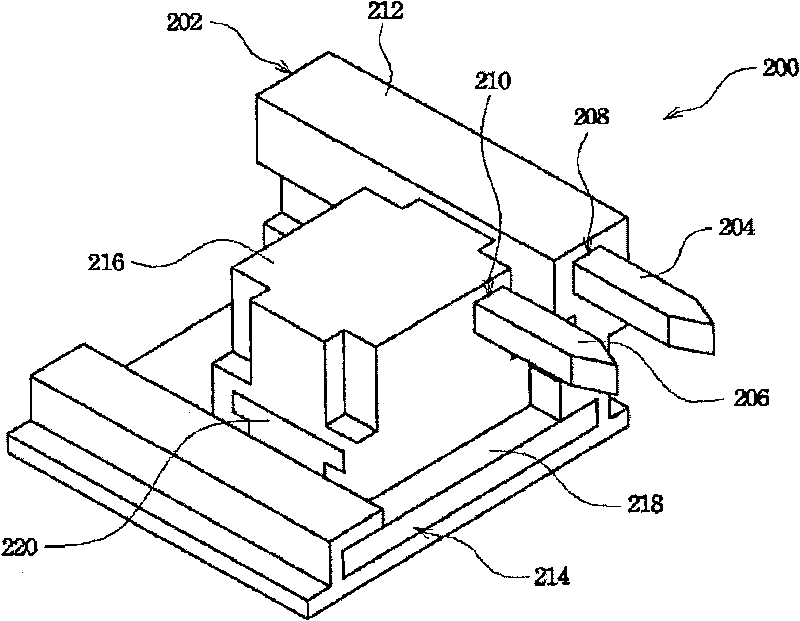

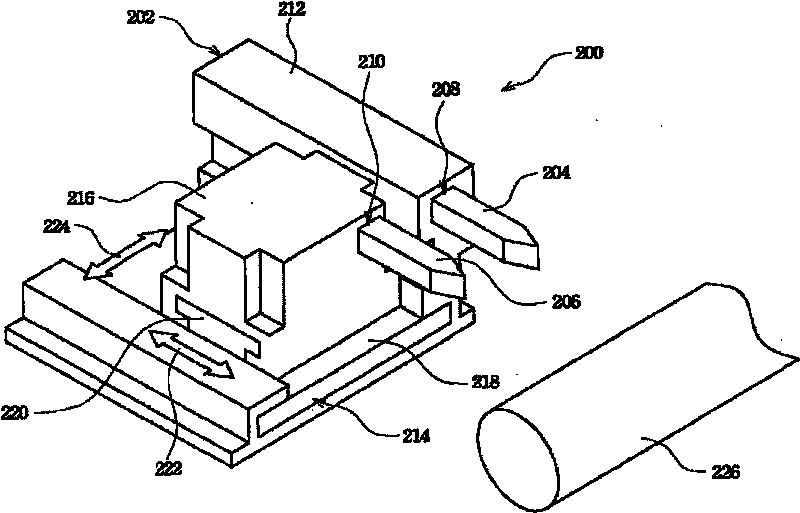

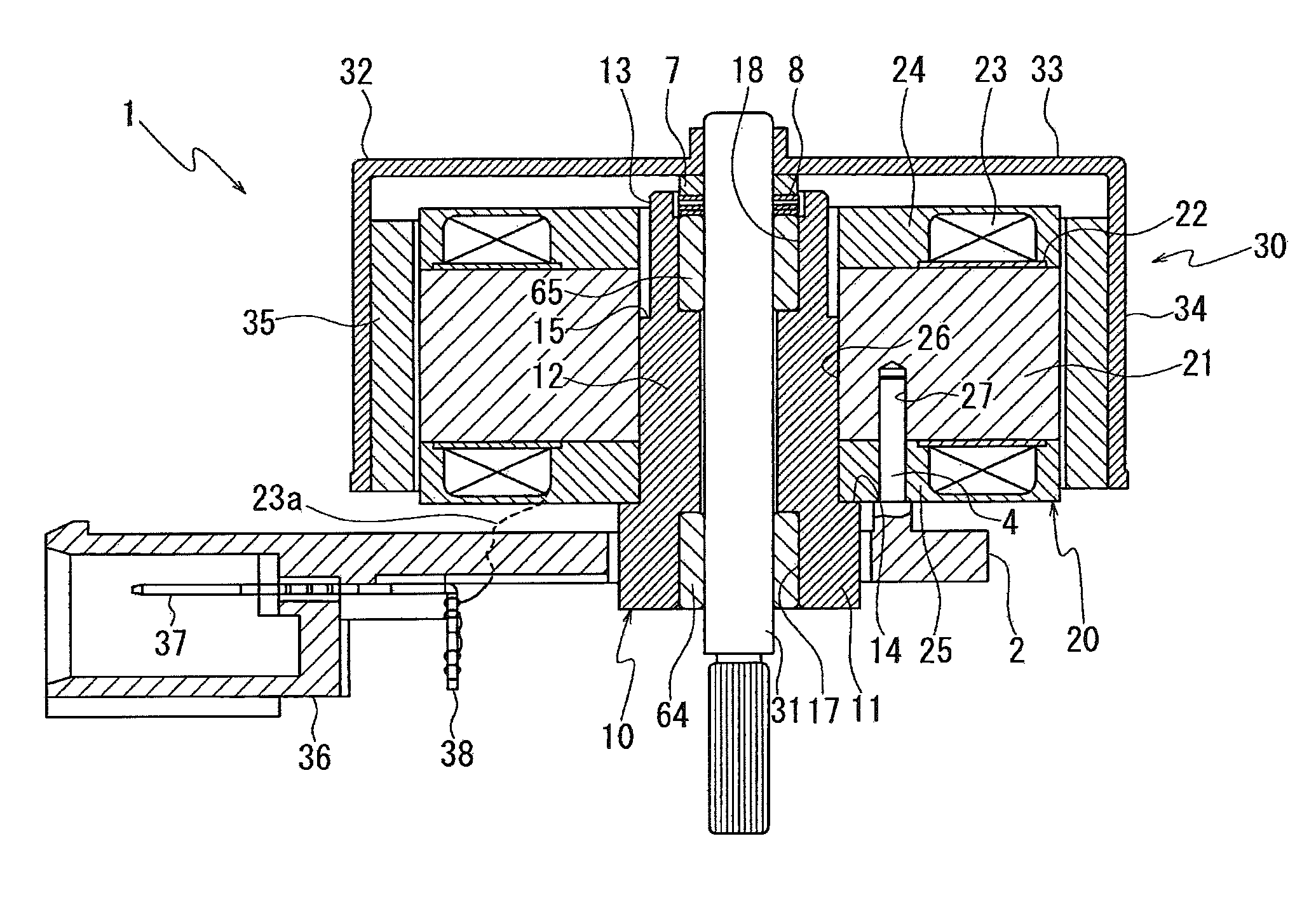

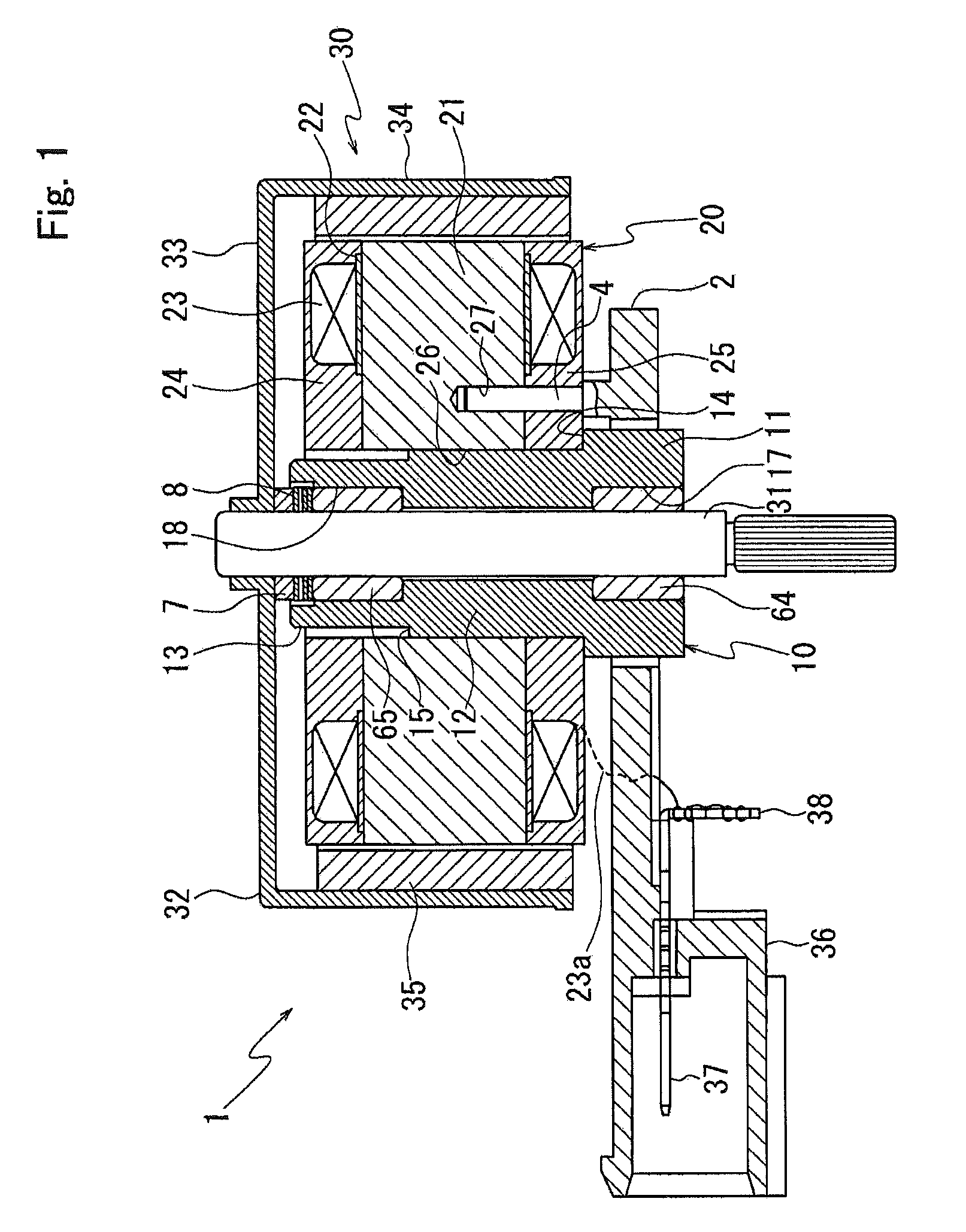

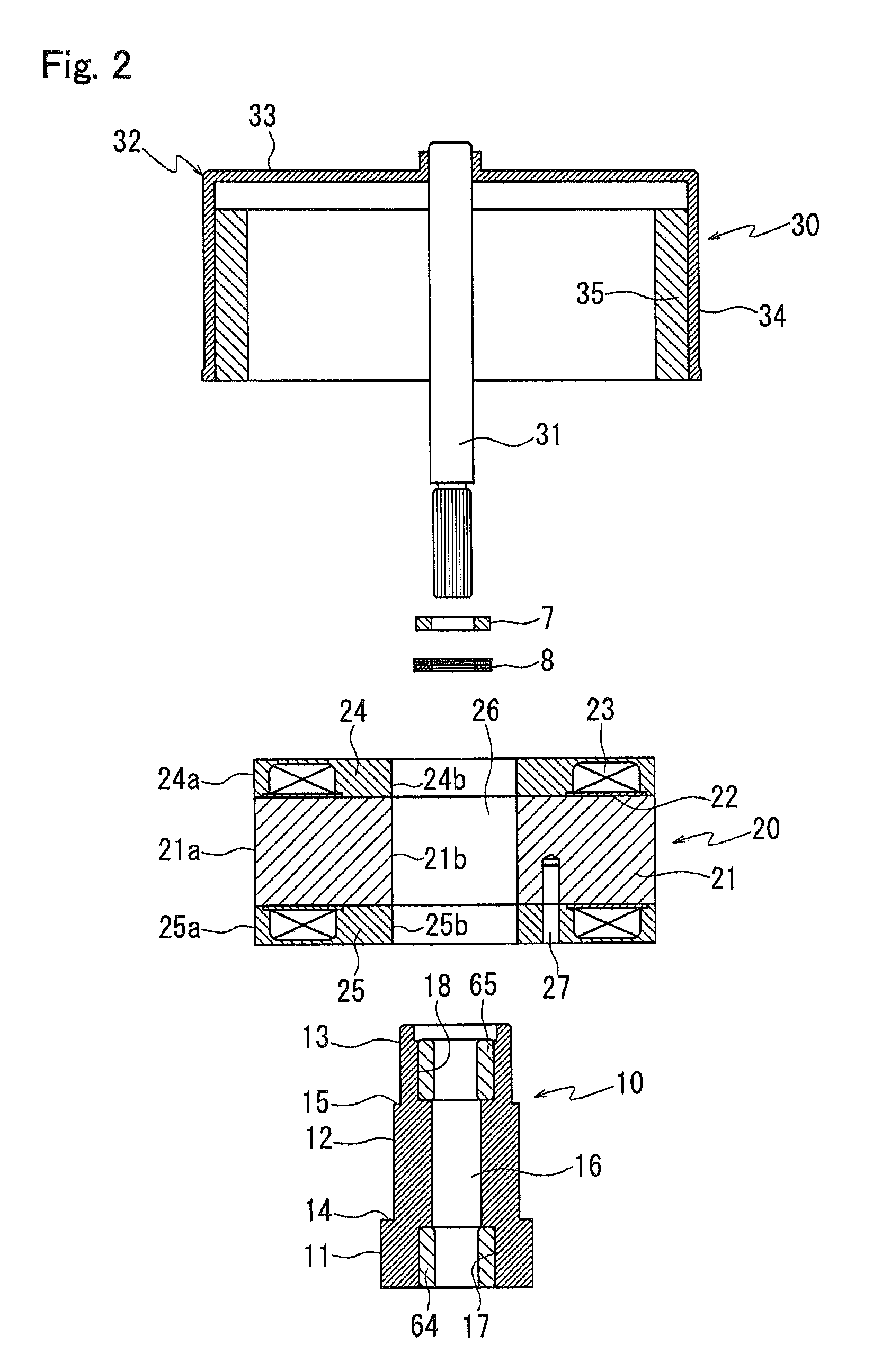

Motor

InactiveUS20100133928A1Small sizeHigh structural precisionWindings insulation shape/form/constructionMagnetic circuit characterised by insulating materialsMagnetStator

A motor may include a motor base plate, a bearing holder provided with a through hole whose both ends hold bearings and vertically disposed with respect to the motor base plate, a stator provided with a center hole and fixed to an outer peripheral face of the bearing holder, and a rotor having a shaft supported by the bearings, a rotor case fixed to the shaft, and a magnet fixed on an inner peripheral face of the rotor case. The bearing holder may be provided with a stepped part, protruded toward a radial direction. The stator may be provided with a first resin block structured so that an end face on a motor base plate side of the stator core is molded with resin to cover a coil wound around the stator core, and inner peripheral faces of the stator core and the first resin block structure the center hole, and the center hole of the stator is press-fitted and fixed to the bearing holder until an end face of the first resin block is abutted with the stepped part.

Owner:NIDEC SANKYO CORP

Technique for processing connecting rod bearing shell

The invention discloses a processing technique of a connecting rod bush. According to working procedure sequence, the processing technique of the connecting rod bush includes the following steps: casting a rough part which needs to be provided with a technical chuck; placing the rough part in open air alone for 50-70 days for natural inactivation; milling the rough part into two halfliners, and placing the halfliners in a workshop for 35-45 days for natural inactivation; combining the two halfliners into a whole by a clamping band, roughly lathing an internal circle and an external circle and keeping a margin of 5-7mm; roughly milling a bush mouth; placing the bush in a processing workshop alone for 3 days for natural inactivation; semi-finish turning of the internal circle and the external circle; semi-finish milling of the bush mouth; lathing an anti-change groove on the technical chuck, correcting and finely turning the internal circle and the external circle, with machining precision being IT8-IT5, and cutting off the technical chuck; drilling an assemble hole of the connecting rod bush and righting the shape of the assemble hole; finish-milling the bush mouth and a bush mouth inclined plane. The invention provides a processing technique of a connecting rod bush product which has long service life and can lead to high running precision of a crank link mechanism.

Owner:JIER MACHINE TOOL GROUP

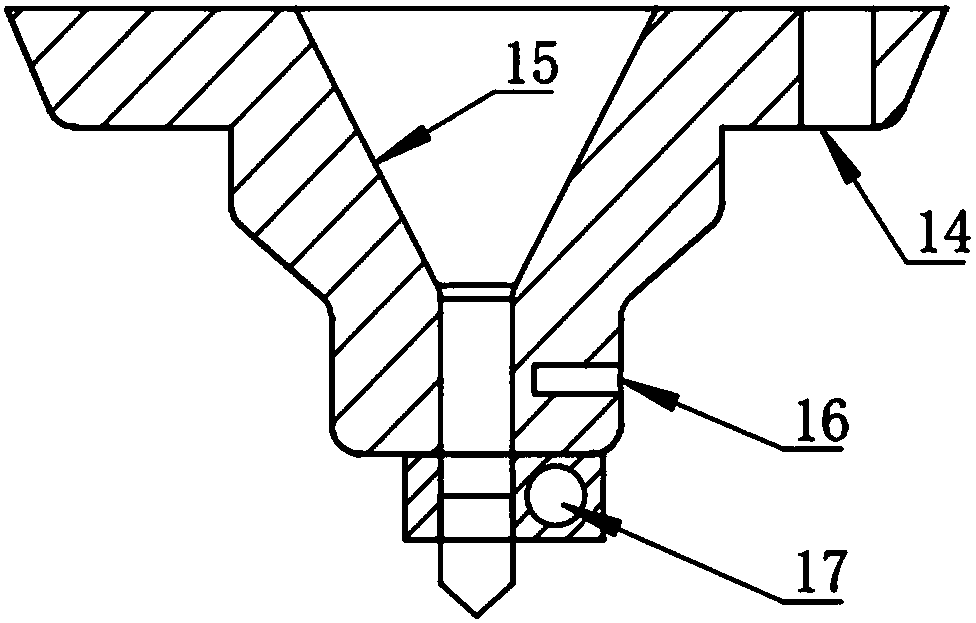

Special tooling for turning high-precision thin-wall cylinder liner bores

InactiveCN104493600AReliable positioning and clampingUniform clamping forcePositioning apparatusMetal-working holdersCircular coneEngineering

The invention discloses a special tooling for turning high-precision thin-wall cylinder liner bores, which comprises an internal taper sleeve, an elastic clamp and an axial positioning disk, the left end of the internal taper sleeve is connected with a spindle flange, the right end of the internal taper sleeve is connected with the axial positioning disk, the right side of the internal taper sleeve is provided with a taper hole, the taper hole is connected with a cylindrical hole of the left side, the sidewall of one side of the cylindrical hole is provided with a guide hole, a vent hole is formed in the left side of the guide hole, the elastic clamp comprises an internal cylindrical hole and an external conical surface, the external conical surface is connected with an external cylindrical surface, a pull rod holder is arranged on the external cylindrical surface, the pull rod holder is provided with a pull rod-fixing hole, a washer is arranged at the right side of the pull rod-fixing hole, the outer diameter of the washer is greater than the inner diameter of the pull rod-fixing hole, the excircle of the end of an oil cylinder pull rod is matched with the pull rod-fixing hole, the end of the oil cylinder pull rod is provided with a threaded hole, and the oil cylinder pull rod is connected with the washer. The structural precision of the special tooling is high, a thin-wall cylinder liner can be positioned and clamped reliably, clamping stress is uniform, the deformation of the thin-wall cylinder liner caused by clamping force is reduced, and the precision requirement of workpieces is met.

Owner:JINAN FIRST MACHINE TOOL GROUP

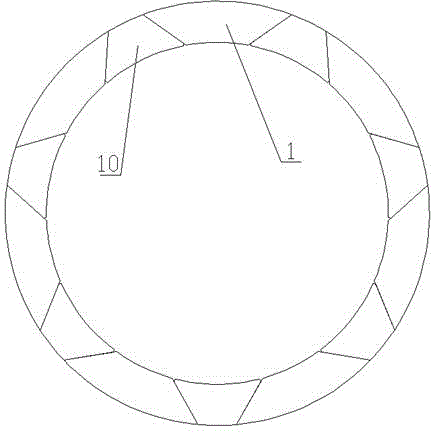

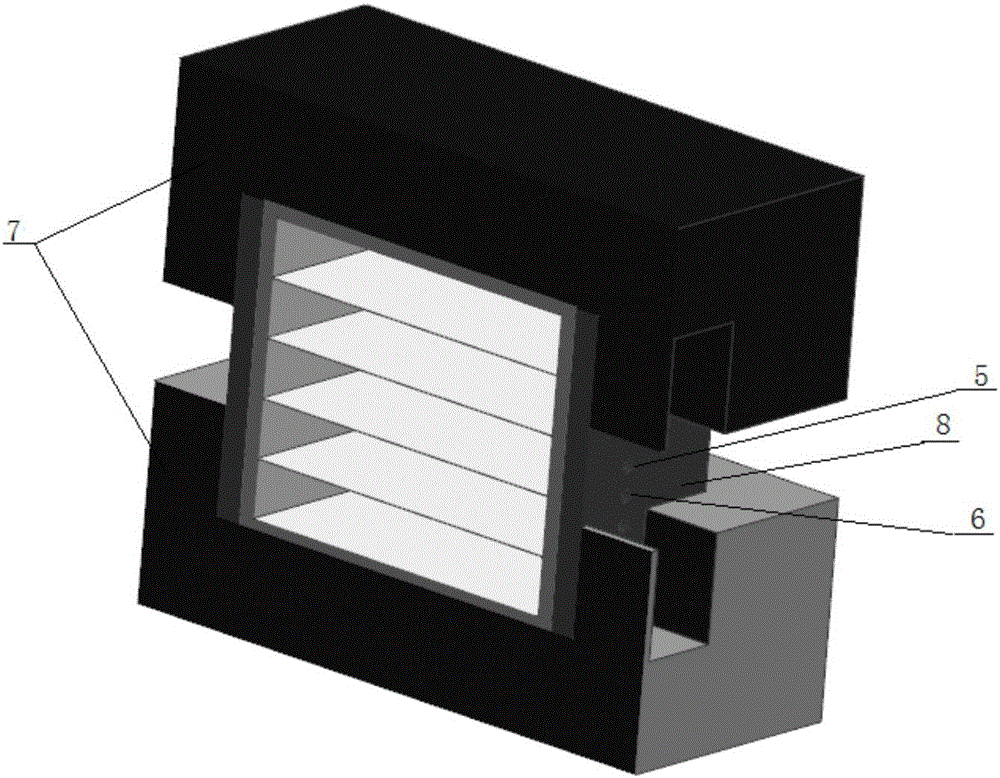

Tire vulcanization inner mould

The invention relates to a tire vulcanization inner mould, and belongs to the field of tire production equipment. The tire vulcanization inner mould is characterized in that a piston rod and a base are fixedly connected, a wedge-shaped surface of the base is alternately provided with a narrow tile side guide rail and a wide tile side guide rail, and the narrow tile side guide rail is matched with a narrow tile side sliding block fixed on a narrow drum tile support; the wide tile side guide rail is matched with a wide tile side sliding block fixed on a narrow drum tile support, a limiting disc is sheathed on the piston rod, the circumference of the upper side surface of the limiting disc is alternately provided with a narrow tile bottom sliding block and a wide tile bottom sliding block, and the narrow tile bottom sliding block and the wide tile bottom sliding block are respectively matched with a narrow tile bottom guide rail and a wide tile bottom guide rail fixed on the narrow drum tile support and the wide drum tile support. The tire vulcanization inner mould provided by the invention has the advantages that a mechanical mechanism is adopted to realize the radial dilatation of the mould, the structure precision is high, problems of the existing vulcanization technology that the expansion of a capsule is not thorough and the structure is asymmetric are fundamentally solved, the vulcanization pressure is greatly improved, vulcanized manufacture of the tire can be preformed for a long time, and the problems in the original technology that the service life of the capsule is long and the capsule needs to be frequently changed is solved.

Owner:三角(威海)华盛轮胎有限公司 +1

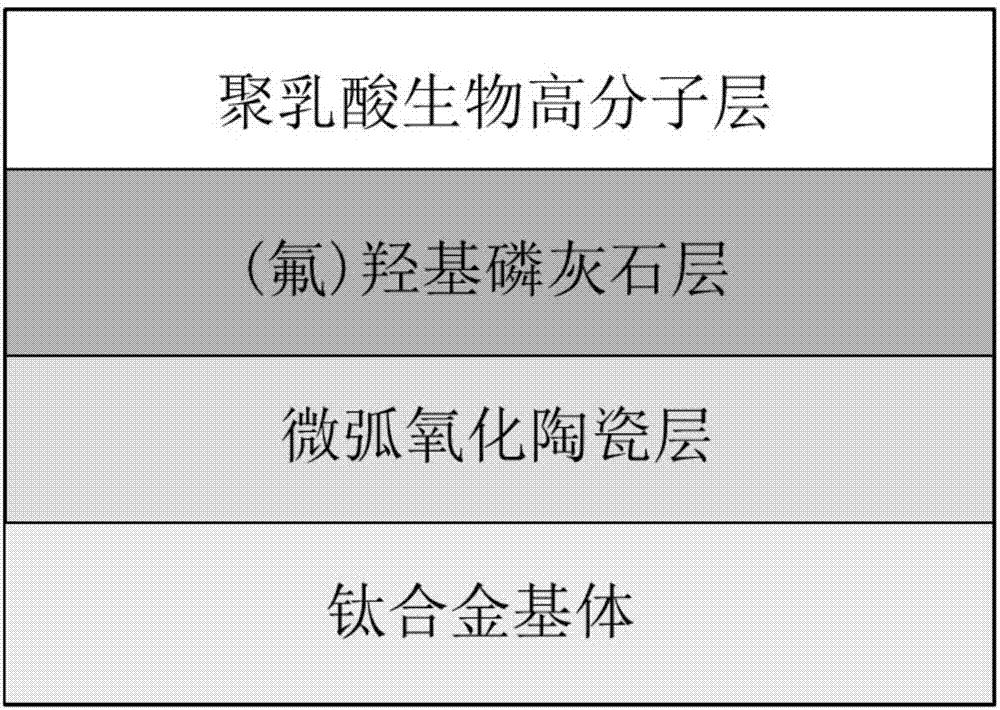

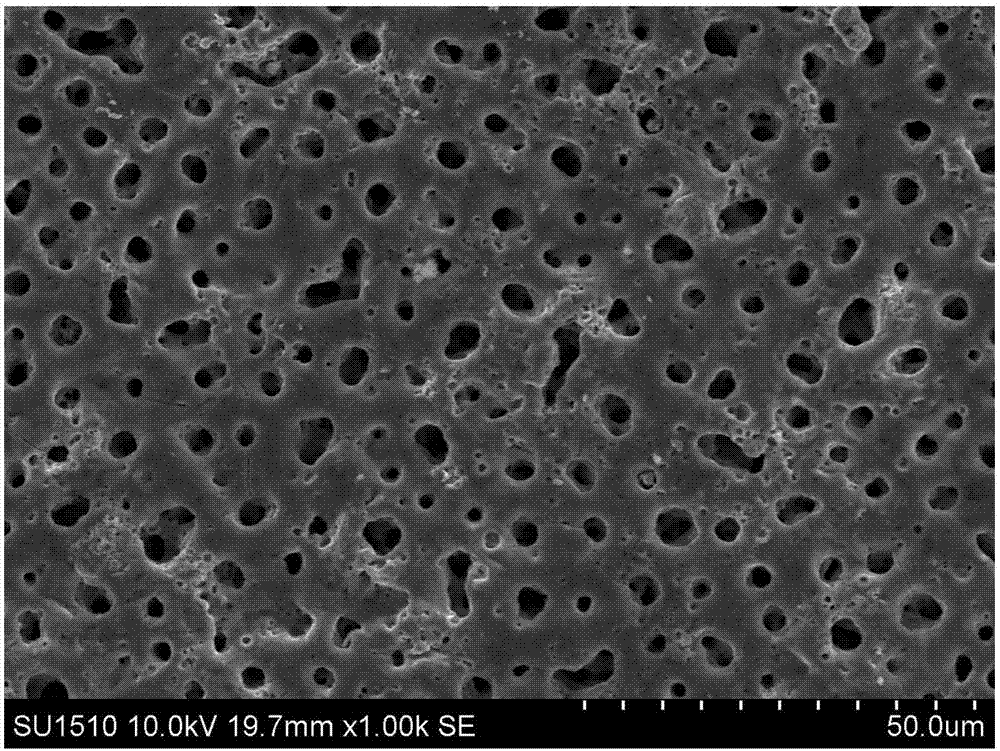

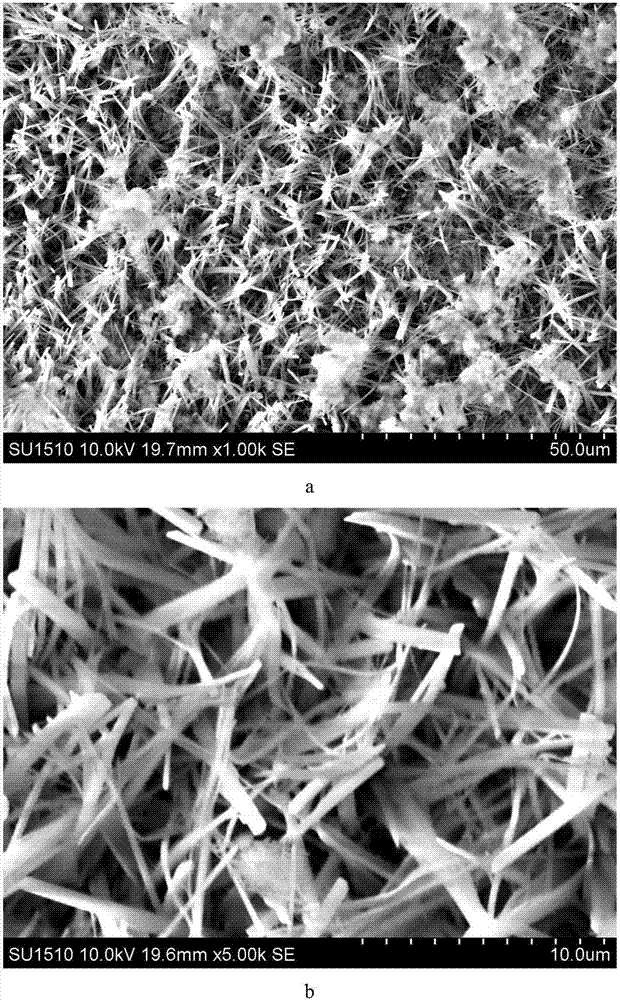

Titanium alloy implant composite material and preparation and application thereof

InactiveCN106902390AHigh structural precisionGood biocompatibilityImage enhancementDetails involving processing stepsBone structureMicro arc oxidation

The invention discloses a titanium alloy implant composite material and preparation and an application thereof. The titanium alloy implant composite material is prepared by the following steps of: by taking a model manufactured from titanium alloy powder through 3D printing as a titanium alloy implant substrate, forming a micro-arc oxidation layer on the surface of the titanium alloy implant substrate through a micro-arc oxidation method; then forming a hydroxyapatite layer or a hydroxyfluorapatite layer on the surface of the micro-arc oxidation layer by means of an electrochemical deposition method; and finally, immersing the surface of the hydroxyapatite layer or the hydroxyfluorapatite layer to form a polylactic acid layer. According to the material provided by the invention, individual development of the titanium alloy implant material is realized from data acquisition of an original damaged bone structure to preparation of a final multi-coating composite material, so that the high quality titanium alloy implant composite material is obtained. A polarizing test shows that the anti-corrosive property of the material can be enhanced by 2-3 orders of magnitudes, and osteoblast cultivation shows that the titanium alloy composite material has a better osteocyte promoting ability.

Owner:ZHEJIANG UNIV OF TECH

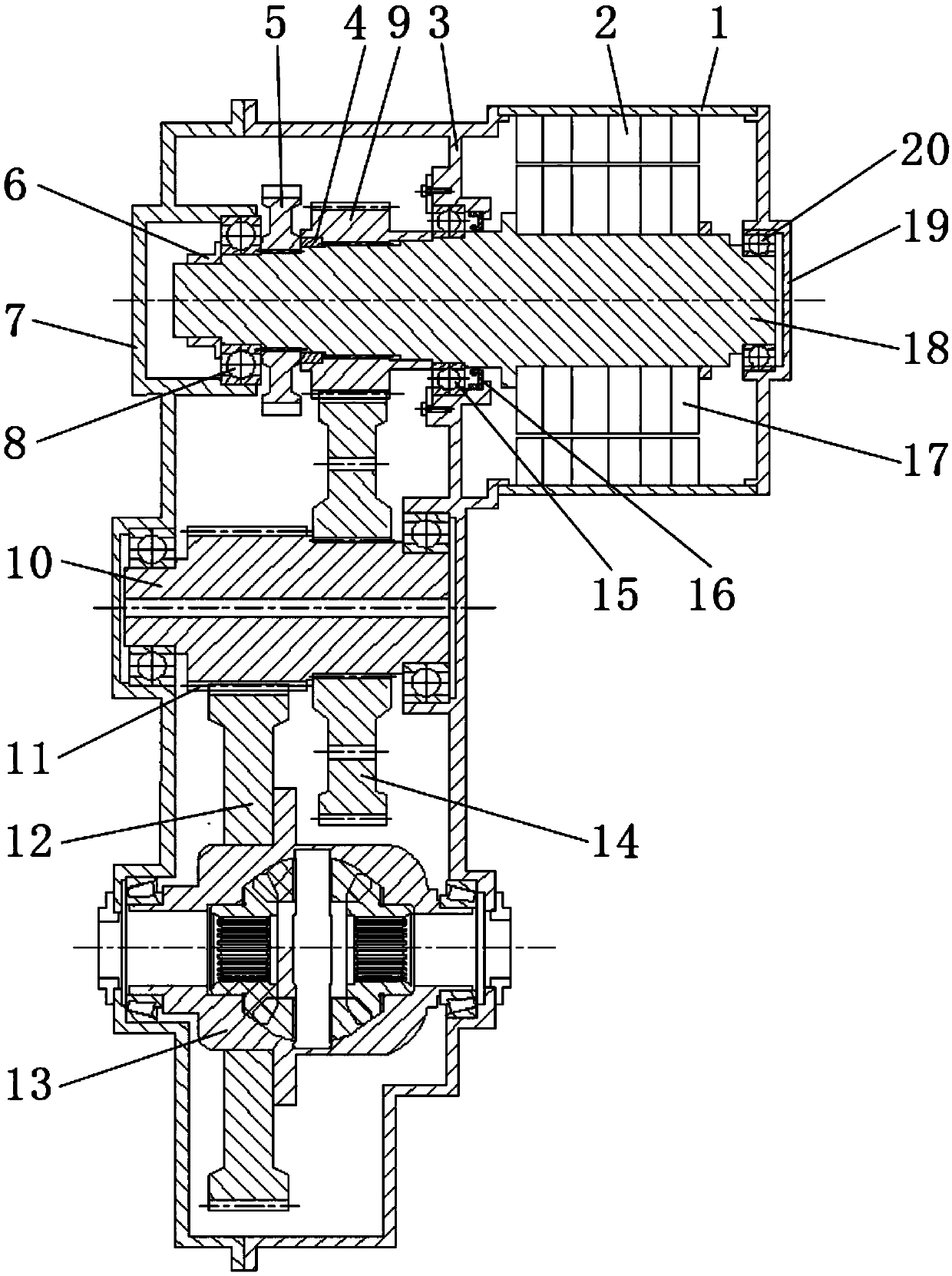

Integrated electric driving power assembly

PendingCN108674179ASimple structureHigh structural precisionElectric propulsion mountingGearing controlElectric drivePowertrain

The invention discloses an integrated electric driving power assembly. The problems of larger axial dimension and larger weight of an electric driving power assembly in the prior art are solved. The integrated electric driving power assembly comprises a motor and a gearbox; an output shaft of the motor and an input shaft of the gearbox are integrally made to form a spindle of the power assembly; aparking gear is arranged in the gearbox; and the parking gear is fixedly mounted on the spindle. According to the integrated electric driving power assembly, the axial dimension of the power assemblyis obviously reduced to be beneficial for realizing the light weight of the power assembly and the layout of the power assembly in a vehicle.

Owner:JING JIN ELECTRIC TECHNOLOGIES (BEIJING) CO LTD

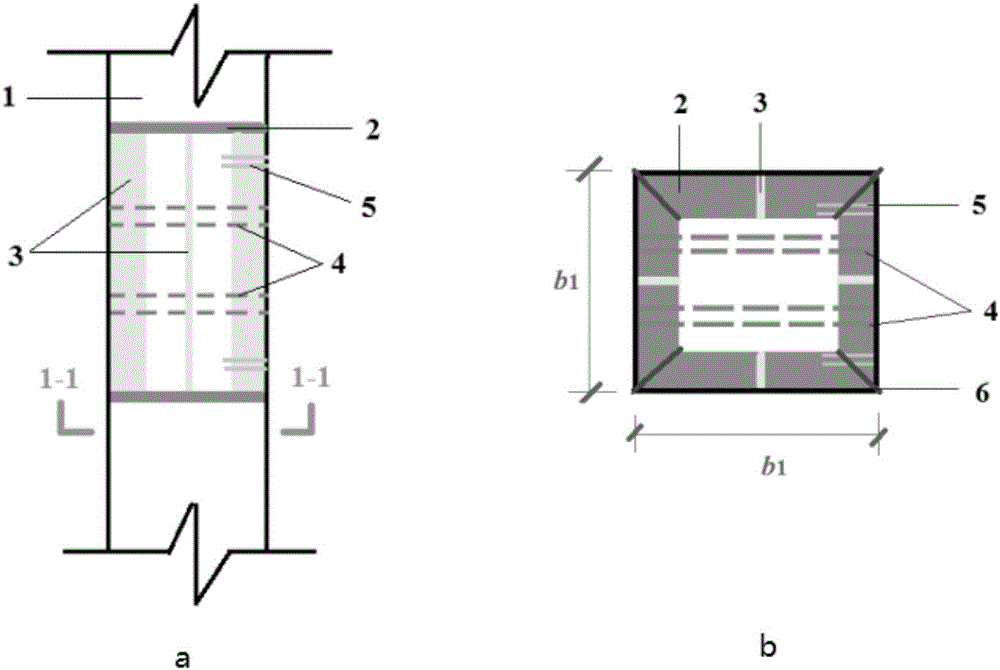

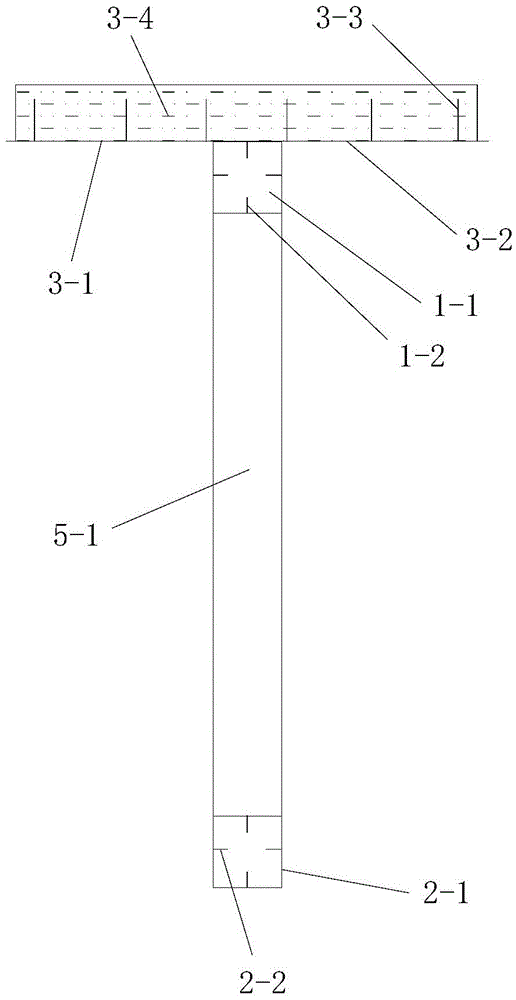

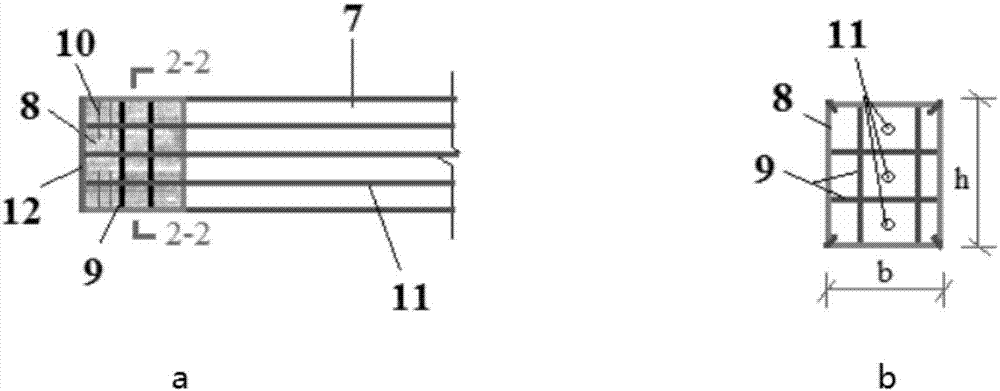

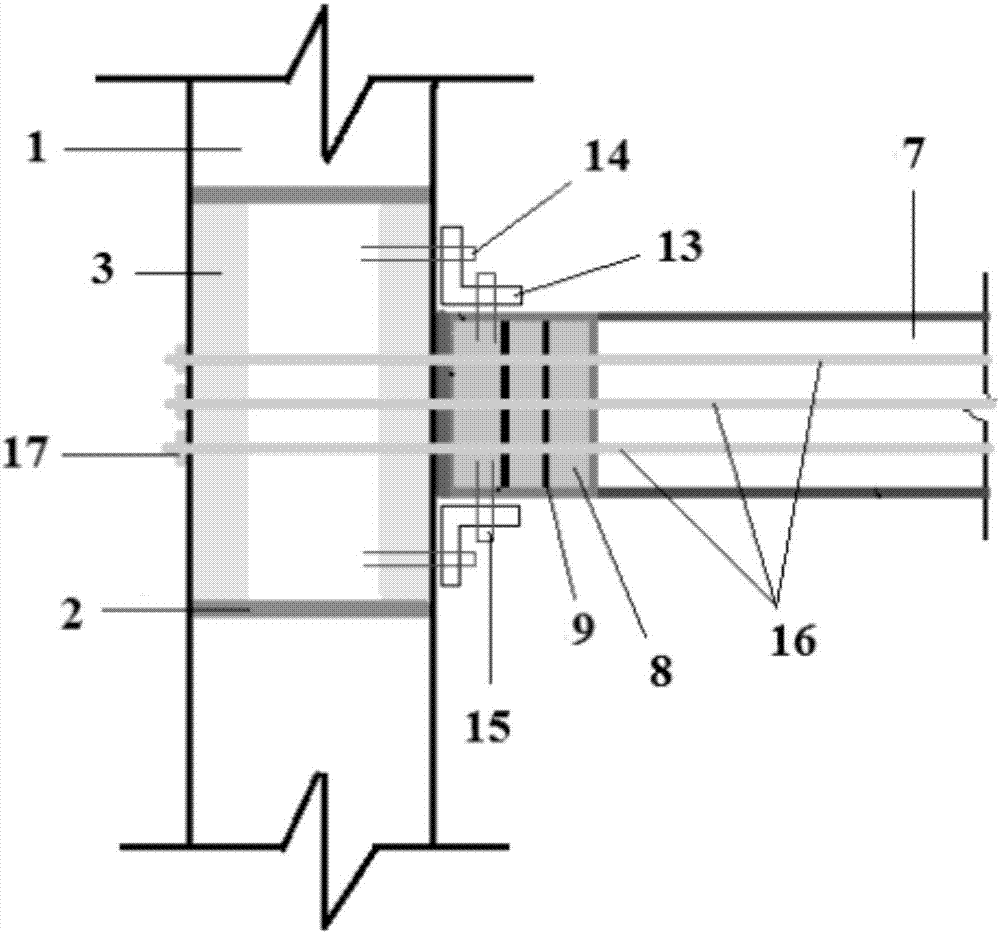

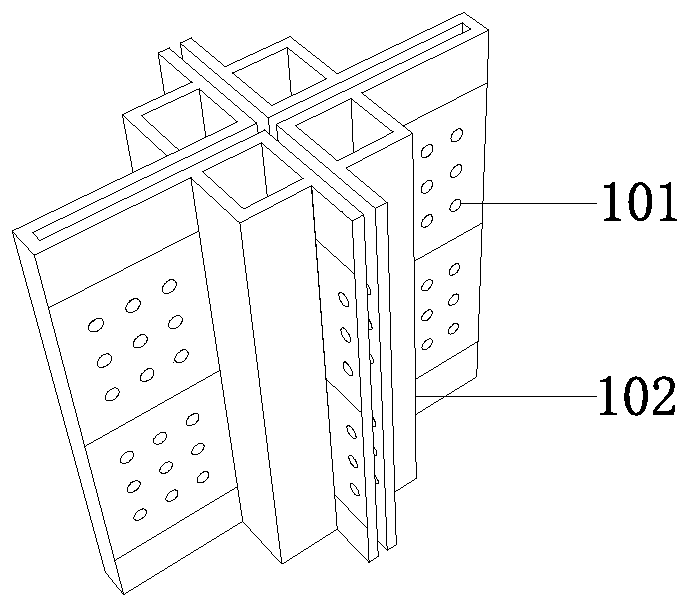

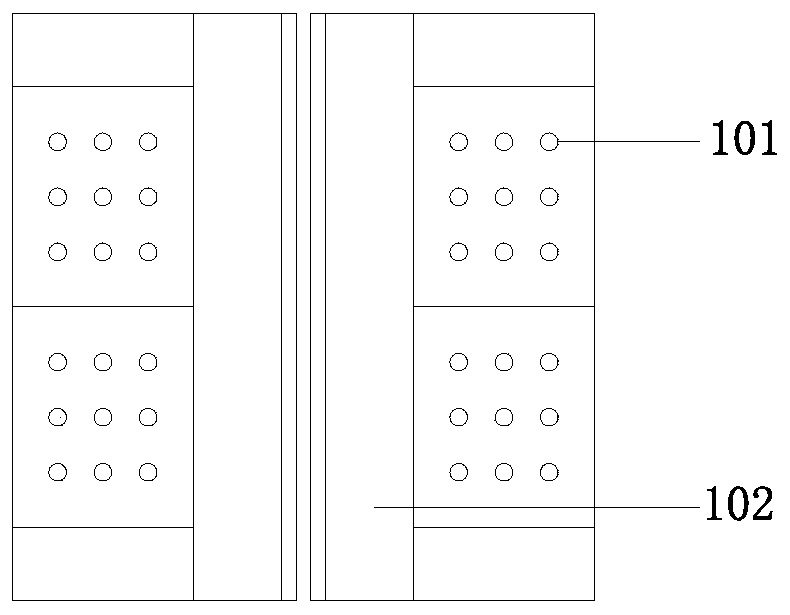

Prestress assembly type high-performance concrete-filled square steel tubular column-concrete beam joint and construction method thereof

InactiveCN106836490AImprove ductilityReduce stress concentrationBuilding constructionsConcrete beamsPre stress

The invention provides a prestress assembly type high-performance concrete-filled square steel tubular column-concrete beam joint. The joint comprises a concrete-filled square steel tubular column, reinforced concrete beams and prestressing tendons, wherein prestressing tendon channels matched with one another are arranged in the concrete-filled square steel tubular column and the reinforced concrete beams; the concrete-filled square steel tubular column is connected with the insides of the reinforced concrete beams through the prestressing tendons penetrating through the prestressing tendon channels; the concrete-filled square steel tubular column is connected with outsides of the reinforced concrete beams through angle steel. The main construction steps are as follows: (1) manufacturing of the concrete-filled square steel tubular column; (2) manufacturing of the concrete beams; (3) on-site mounting. Compared with common beam-column joints, the joint has the advantages that the ductility is good, construction is simple and convenient, members are easy to replace, the anti-seismic performance is good and the like.

Owner:WUHAN UNIV

Device and method for processing roller micro groove

InactiveCN101722316AReduce lossReduce processing costsTool holdersTurning machinesEngineeringTool holder

The invention discloses a device and a method for processing a roller micro groove. The device for processing the roller micro groove at least comprises: a cutter holder, wherein one side of the tool holder is at least provided with a plurality of cutter fixing openings; and a plurality of cutters which are fixedly arranged in the cutter fixing openings in a corresponding manner, wherein each cutter is provided with a knifing and a nose radius, the knifings are different from each other and the same goes for the nose radii, and these cutters can cut the surface of a roller simultaneously.

Owner:INNOLUX CORP

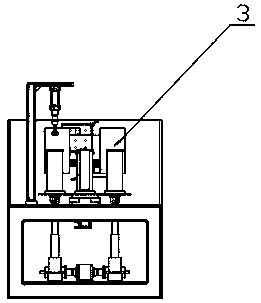

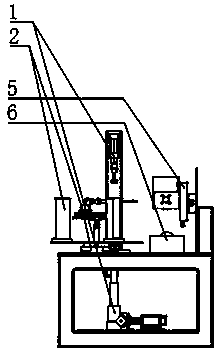

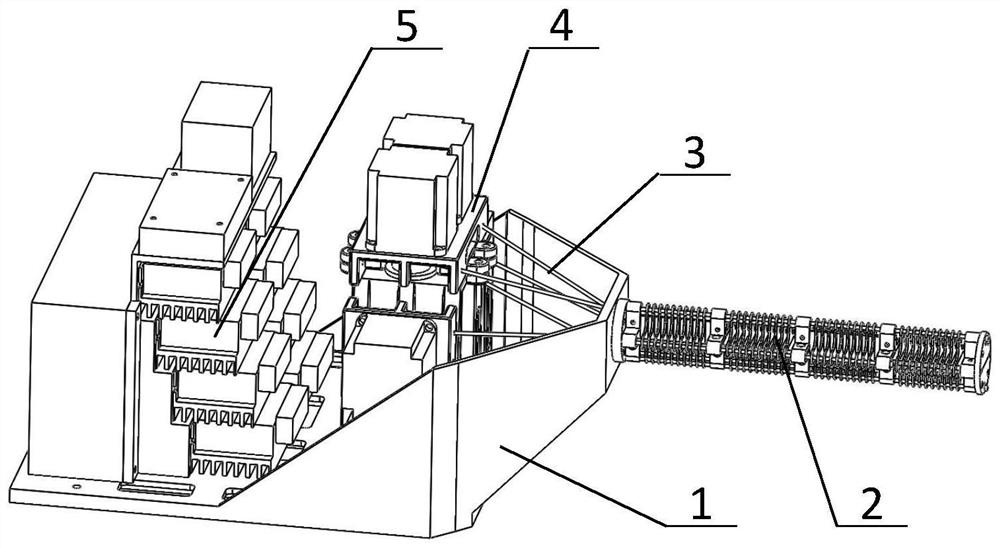

Full-automatic lens edge grinding machine

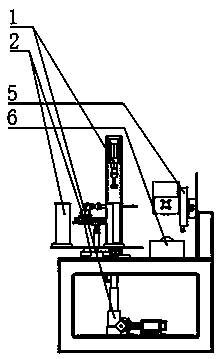

InactiveCN109318078AImprove edge qualityHigh structural precisionEdge grinding machinesGrinding carriagesQuality controlEngineering

The invention discloses a full-automatic lens edge grinding machine. The full-automatic lens edge grinding machine comprises a rack, and is characterized in that an automatic material charging and discharging mechanism, a rotary worktable, a lens clamping device, a cross-shaped sliding table feeding mechanism and a grinding mechanism are arranged on the rack; a material charging station, a material discharging station and a material spreading and collection station are distributed along the periphery of the rotary worktable; besides, a mechanical arm device is arranged on the rack corresponding to the rotary worktable; the automatic material charging and discharging mechanism comprises a lens absorbing mechanism at the upper end; the lend absorbing mechanism is arranged on the rack on oneside of the material charging station correspondingly and is used for lifting a lens on the top end of the material charging station to the clamping end of the mechanical arm device; the cross-shapedsliding table feeding mechanism is located on the horizontal side of the rotary worktable; the lens clamping device is fixedly arranged on the working end of the cross-shaped sliding table feeding mechanism; and the grinding mechanism is arranged below the lens clamping device. The full-automatic lens edge grinding machine has the advantages that the automation degree is high; quality control on the lens is more stable; the production efficiency is higher; and the cost is lower.

Owner:CHONGQING UNIV OF TECH

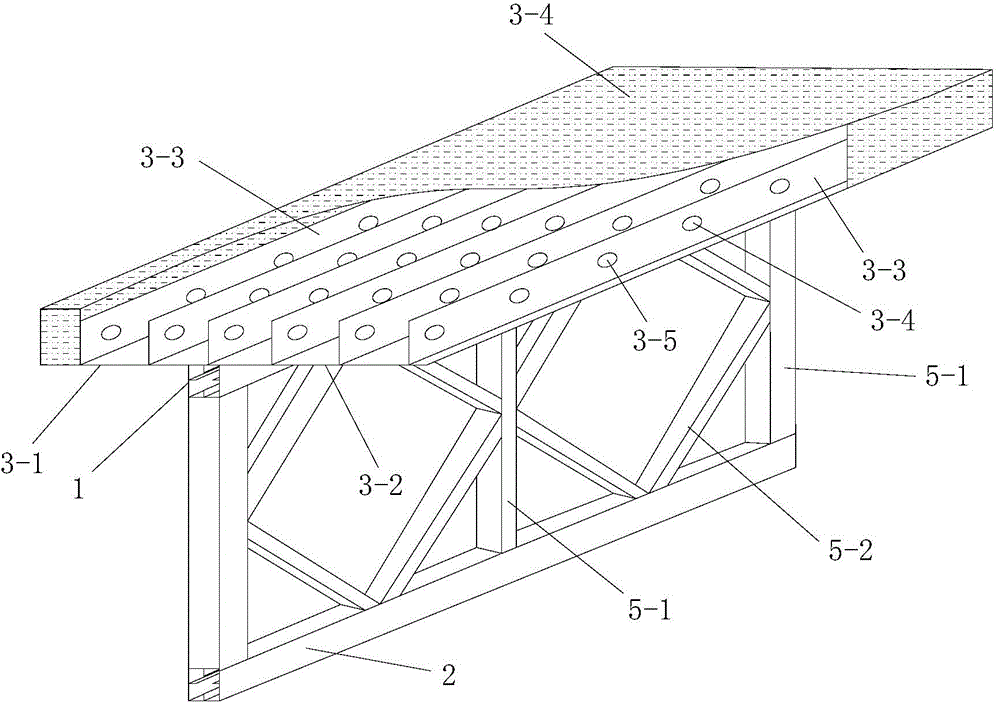

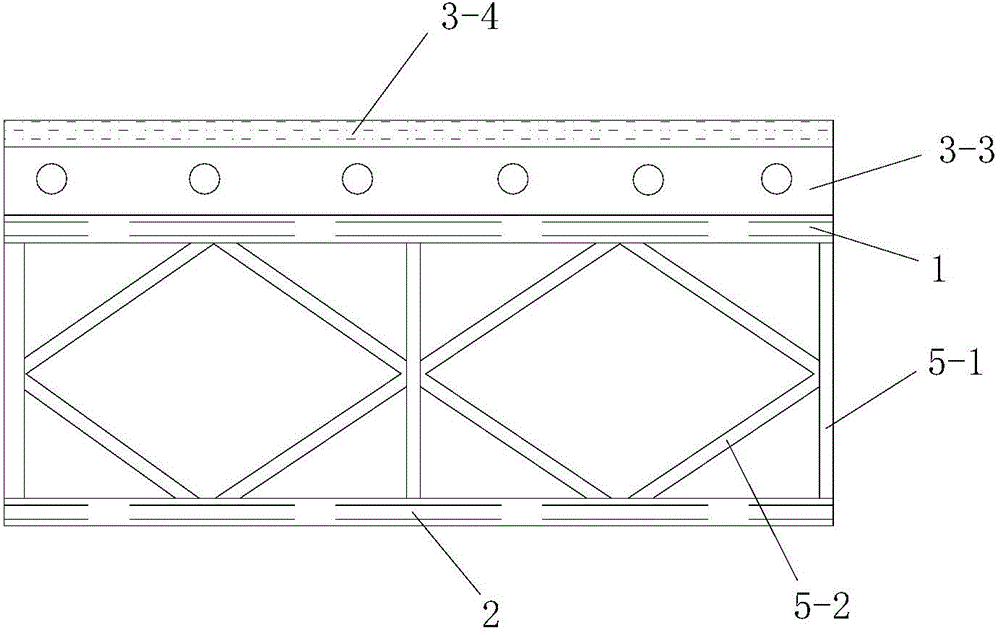

T-shaped plate girder segment prefabricating unit based on steel truss and combined bridge deck slab

InactiveCN104088221ASimple structureReasonable designBridge structural detailsSheet steelBridge deck

The invention discloses a T-shaped plate girder segment prefabricating unit based on a steel truss and a combined bridge deck slab. The T-shaped plate girder segment prefabricating unit comprises a lower force bearing structure and the combined bridge deck slab arranged on the lower force bearing structure, and the combined bridge deck slab and the lower force bearing structure are both arranged in the longitudinal bridge direction; the lower force bearing structure is a planar truss composed of an upper chord rod, a lower chord rod and a web rod, the upper chord rod comprises a first rectangular steel tube, and the lower chord rod comprises a second rectangular steel tube; the combined bridge deck slab comprises a bottom supporting steel plate, a plurality of upper longitudinal ribs arranged on the bottom supporting steel plate, and a concrete bridge deck slab arranged on the bottom supporting steel plate in a pouring mode, the upper longitudinal ribs are arranged in the concrete bridge deck slab in a pouring mode, and the upper longitudinal ribs are long-strip-shaped steel plates with the middles provided with a plurality of through holes; the bottom supporting steel plate is a rectangular supporting steel plate formed by connecting a left extension steel plate, a right extension steel plate and a first rectangular steel tube. The T-shaped plate girder segment prefabricating unit is simple in structure, reasonable in design, easy and convenient to construct, good in overall mechanical property and capable of improving the structure accuracy and construction convenience of a steel and concrete combined bridge.

Owner:CHANGAN UNIV

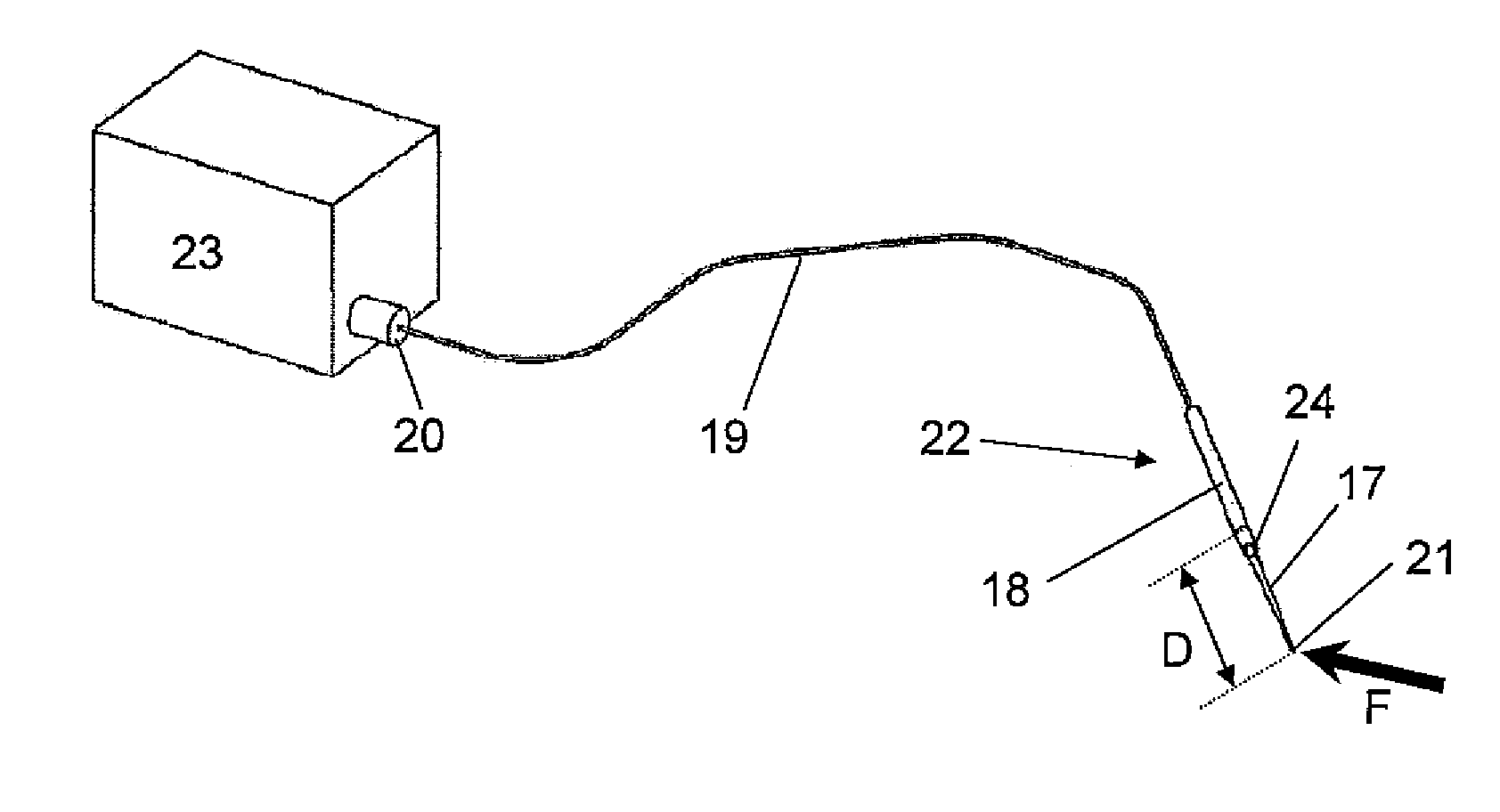

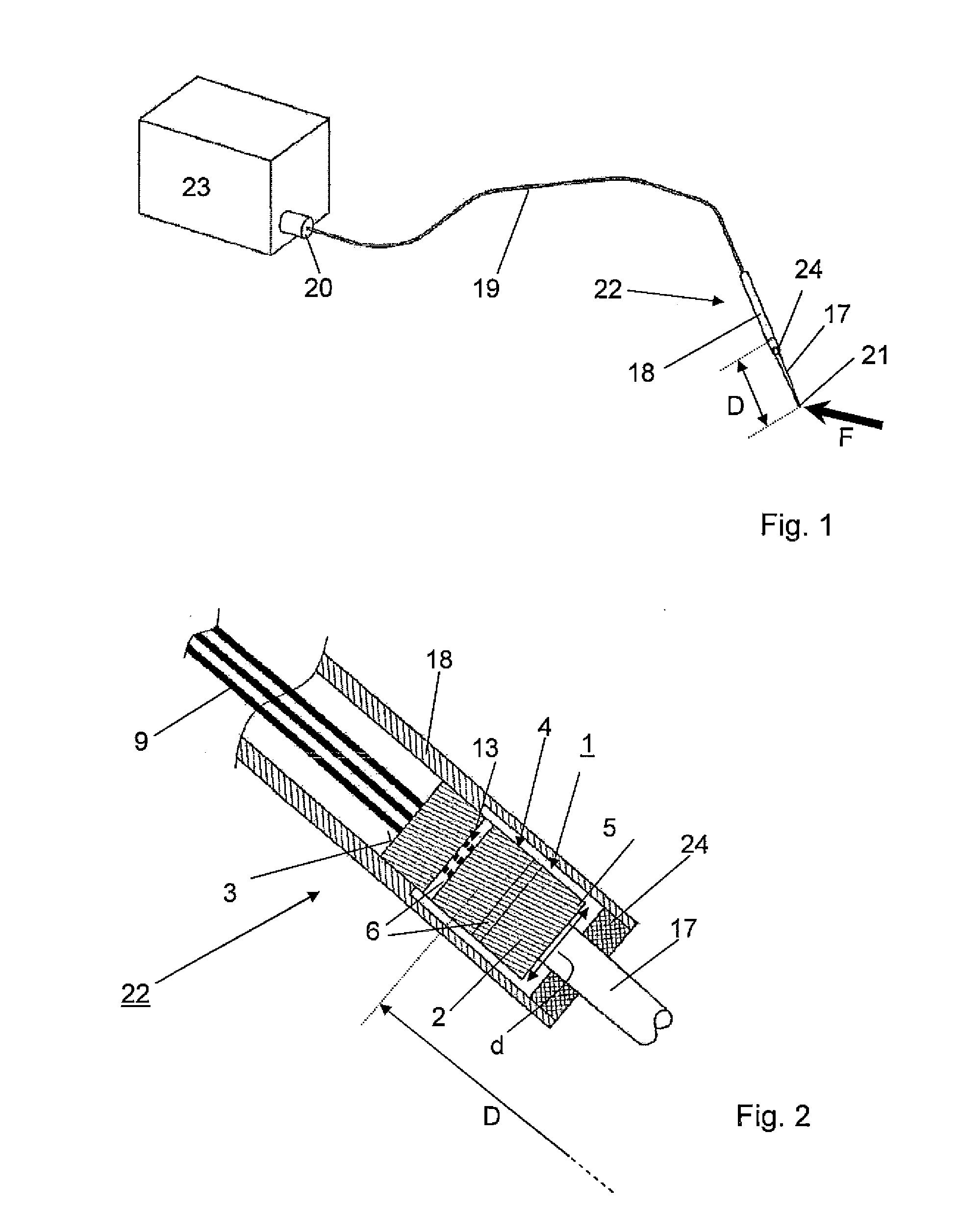

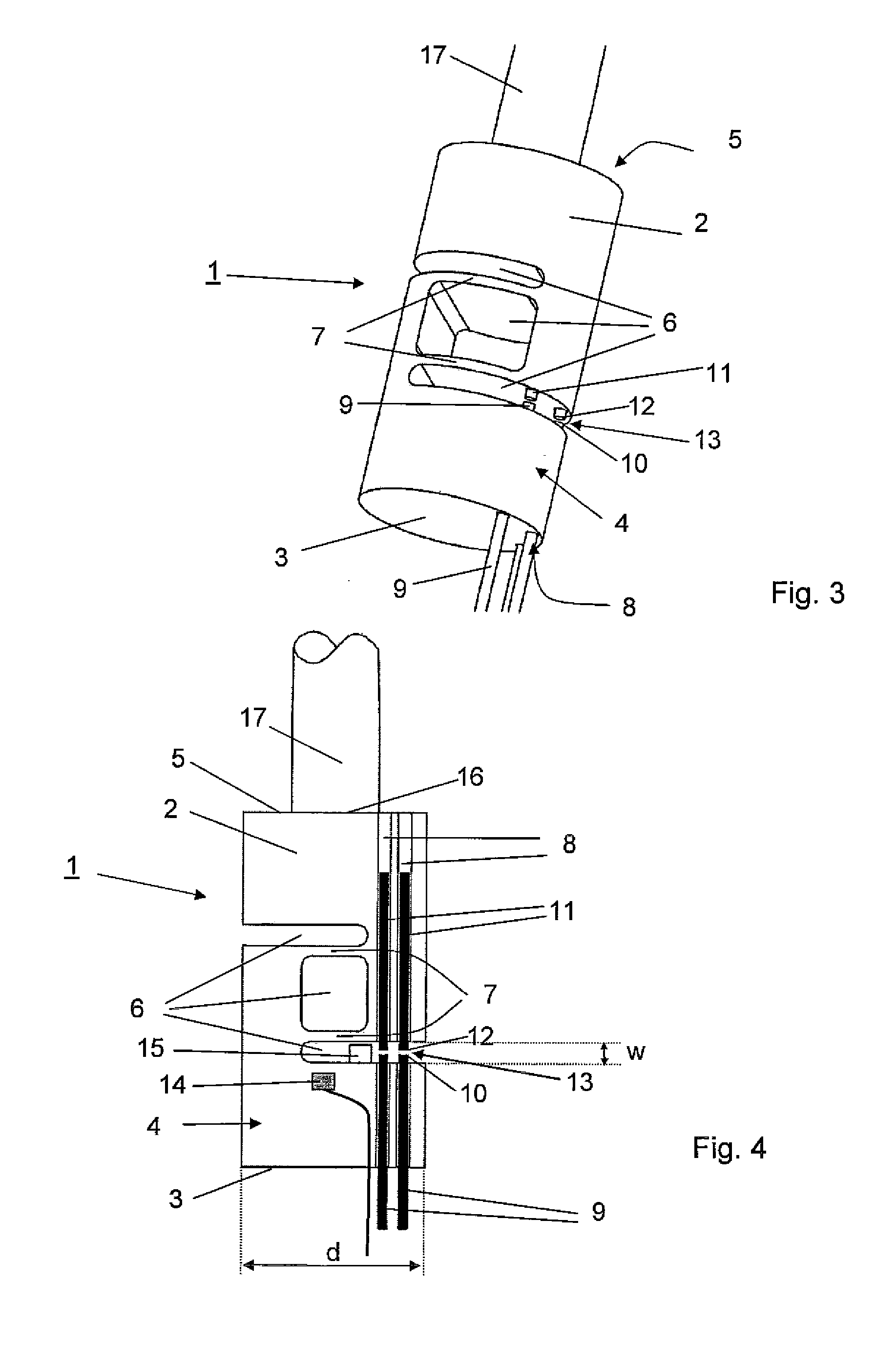

Optical force sensing element and microsurgical instrument

ActiveUS20130204142A1Reduce manufacturing costImprove sensing accuracySurgeryApparatus for force/torque/work measurementEngineeringMechanical engineering

An optical force sensing element for microsurgical instruments and methods measures force F in three orthogonal directions and includes a monolithic cylinder structure, a cylindrical surface and a top surface that absorbs and transmits the force F. Three punch-like notches, all being parallel to the y-direction, are spaced apart along the z-axis and form two blades between the first and second notch and between the second and the third notch. Three channels parallel to the z-axis extend from the bottom surface to the top surface and cross the first notch while bypassing the other two notches. Three optical fibres, each fixed in one of the three channels, all entering the structure from the bottom surface, cross the first notch and end at or near the top surface while being interrupted in the first notch and forming two surfaces of each fibre that define a Fabry-Perot interferometric cavity.

Owner:SENSOPTIC

Motor

InactiveUS7994663B2Small sizeHigh structural precisionMagnetic circuit characterised by insulating materialsMechanical energy handlingEngineeringBlock structure

A motor may include a motor base plate, a bearing holder provided with a through hole whose both ends hold bearings and vertically disposed with respect to the motor base plate, a stator provided with a center hole and fixed to an outer peripheral face of the bearing holder, and a rotor having a shaft supported by the bearings, a rotor case fixed to the shaft, and a magnet fixed on an inner peripheral face of the rotor case. The bearing holder may be provided with a stepped part, protruded toward a radial direction. The stator may be provided with a first resin block structured so that an end face on a motor base plate side of the stator core is molded with resin to cover a coil wound around the stator core, and inner peripheral faces of the stator core and the first resin block structure the center hole, and the center hole of the stator is press-fitted and fixed to the bearing holder until an end face of the first resin block is abutted with the stepped part.

Owner:SANKYO SEIKI MFG CO LTD

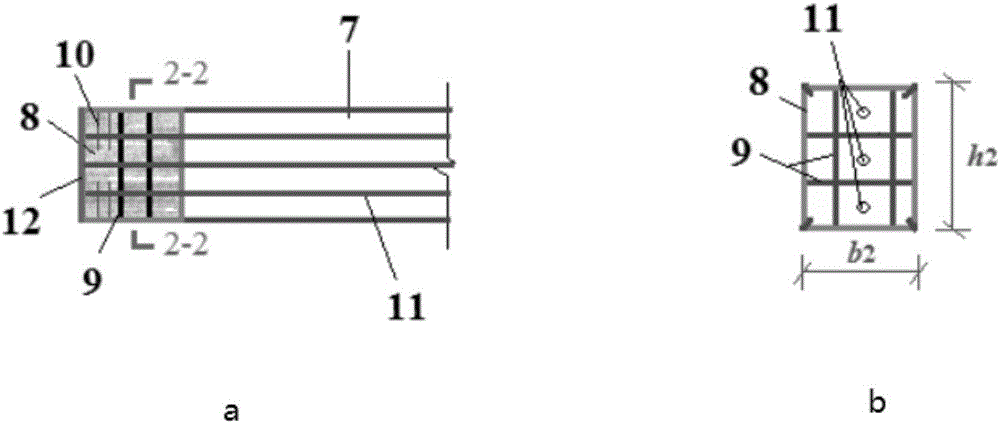

Pre-stress fabricated high-performance circular steel tube concrete pillar-concrete beam node and construction method thereof

InactiveCN106968332AImprove ductilityReduce stress concentrationBuilding constructionsConcrete beamsPre stress

The invention provides a pre-stress fabricated high-performance circular steel tube concrete pillar-concrete beam node. The node comprises a concrete pillar, reinforced concrete beams and prestressed tendons; prestressed tendon hole passages which are mutually matched are formed in the concrete pillar and the reinforced concrete beams correspondingly; the square steel tube concrete pillar and the interiors of the reinforced concrete beams are connected through the prestressed tendons penetrating through the prestressed tendon hole passages; and the square steel tube concrete pillar and the exteriors of the reinforced concrete beams are connected through angle iron. According to the main construction steps of the pre-stress fabricated high-performance circular steel tube concrete pillar-concrete beam node, (1) the steel tube concrete pillar is manufactured; (2) the concrete beams are manufactured; and (3) on-site mounting is conducted. Compared with a common beam pillar node, the fabricated node has the advantages that ductility is good, construction is easy and convenient, components are easy to replace, and seismic performance is good.

Owner:WUHAN UNIV

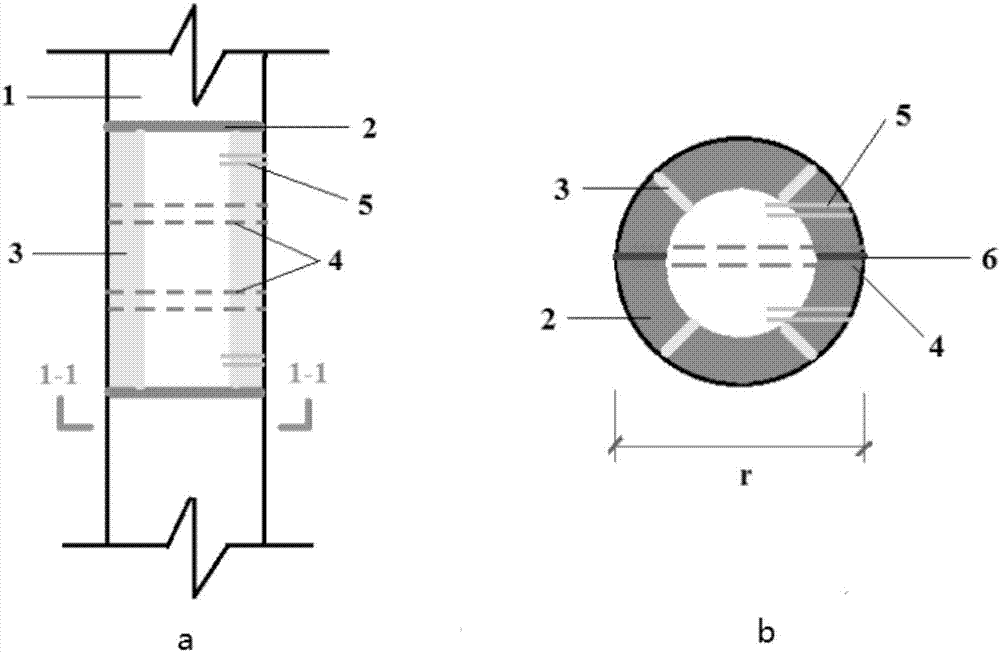

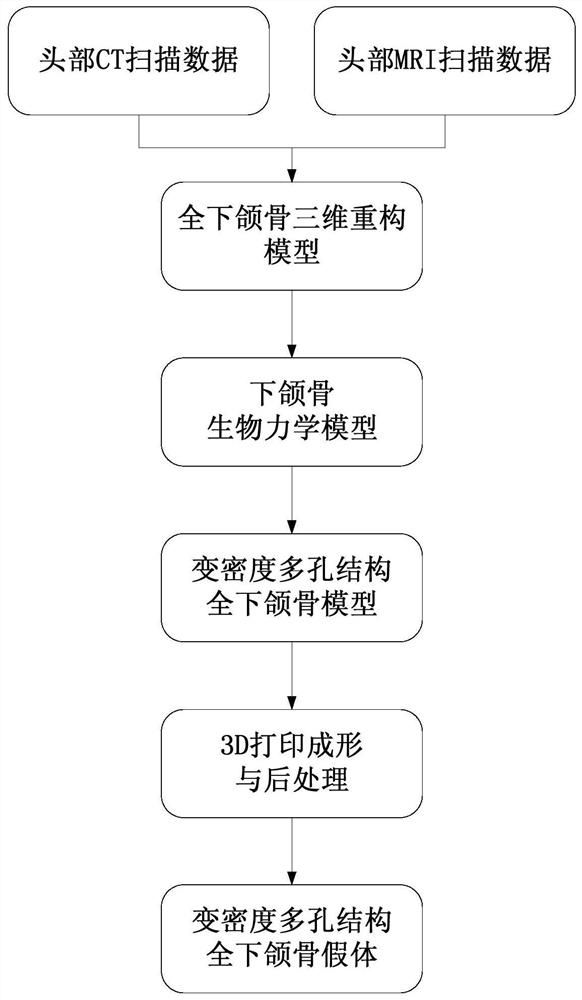

Method for forming complete mandible prosthesis with variable-density porous structure

ActiveCN111759541AHigh structural precisionImprove accuracyBone implantIncreasing energy efficiencyMuscle tissueBone structure

The invention discloses a method for forming a complete mandible prosthesis with a variable-density porous structure. For an injured mandible, head CT and MRI data are obtained respectively, and a three-dimensional model of a mandible bone structure and three-dimensional models of articular cartilage, ligament and muscle tissue of the mandible are respectively established; through three-dimensional image fusion and mirror repair, a complete three-dimensional reconstruction model of the mandible is obtained; the stress distribution of the mandible is obtained; according to the stress distribution of the mandible, the three-dimensional model of the mandible bone structure is taken as an object of optimization design, a circular hole is taken as a filling unit, a topology optimization designis carried out, and finally a complete mandible prosthesis model with a variable-density porous structure is obtained; and titanium alloy powder is processed, cleaning, annealing heat treatment, wirecutting and de-supporting, sandblasting and polishing treatment are carried out, and the final complete mandible prosthesis with the variable-density porous structure is obtained. The variable-densityporous structure obtained by the method is closer to the mechanical properties of natural bones, and the biocompatibility is better.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

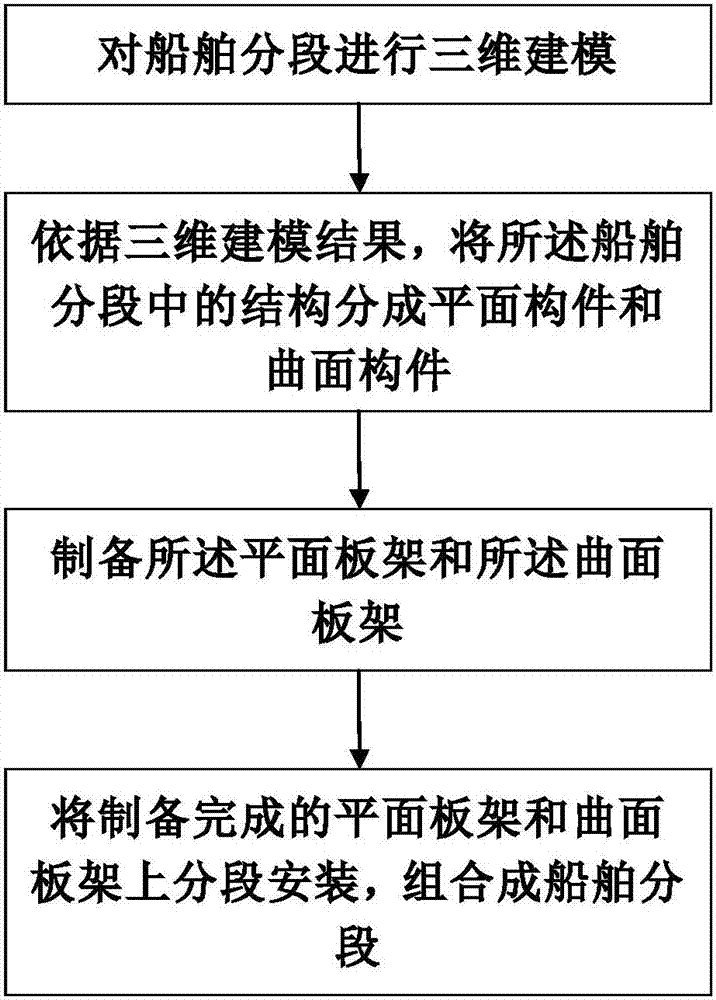

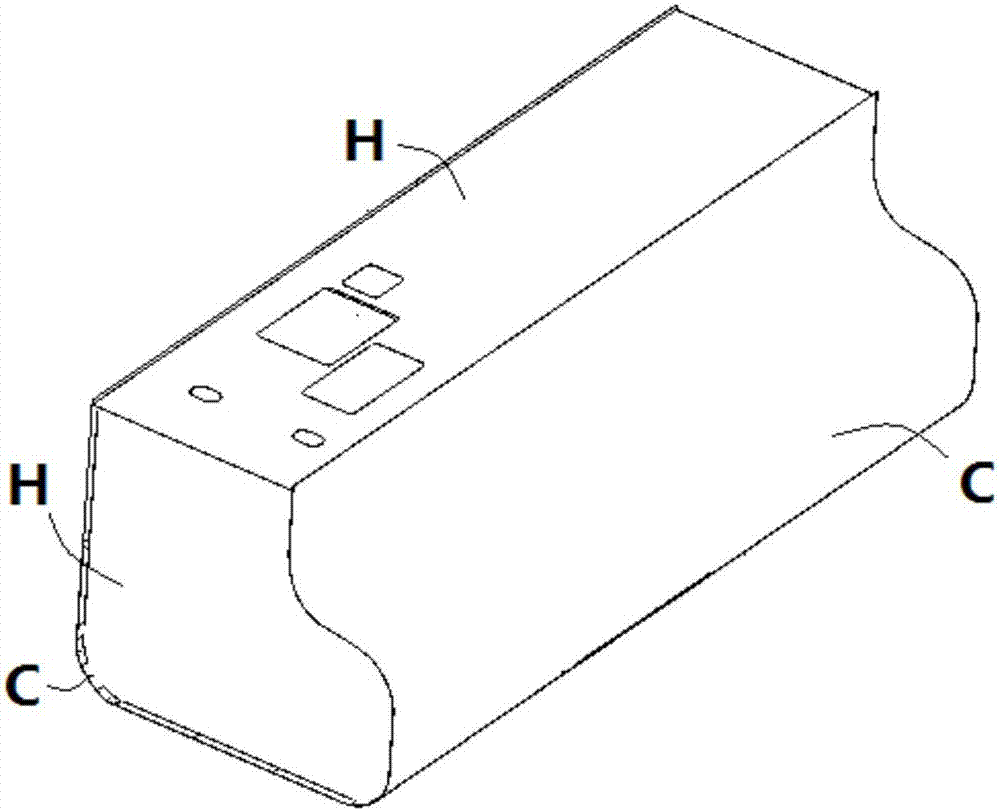

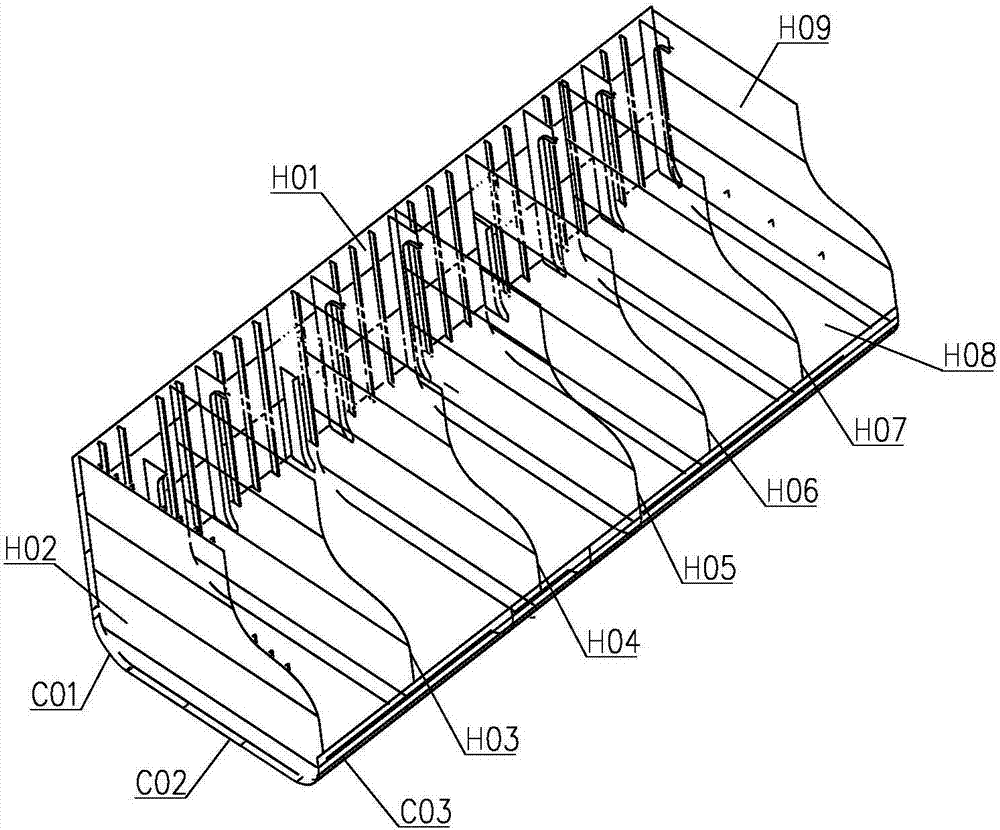

Rapid manufacturing method for ship block

ActiveCN107140112APrecise structureClear structureVessel partsManufacturing technologyLinear control

The invention belongs to the technical field of ship manufacturing and discloses a rapid manufacturing method for a ship block. The rapid manufacturing method comprises the following steps: carrying out three-dimensional modeling on a ship block; dividing the structure in the ship block into a planar component and a curved surface component according to a three-dimensional modeling result; dividing the planar component into a plurality of planar plate frames according to the positions of the planar component and the curved surface component in a three-dimensional model, a mounting sequence and a connecting relation of the components, and dividing the curved surface components into a plurality of curved surface plate frames; processing the planar plate frames and the curved surface plate frames; and sectionally mounting the processed planar plate frames and curved surface plate frames, and combining, so as to form the ship block. The rapid manufacturing method is a sectional manufacturing method, the processing efficiency, manicuring precision and linear control reliability of a large-sized catamaran are improved.

Owner:WUCHANG SHIPBUILDING IND

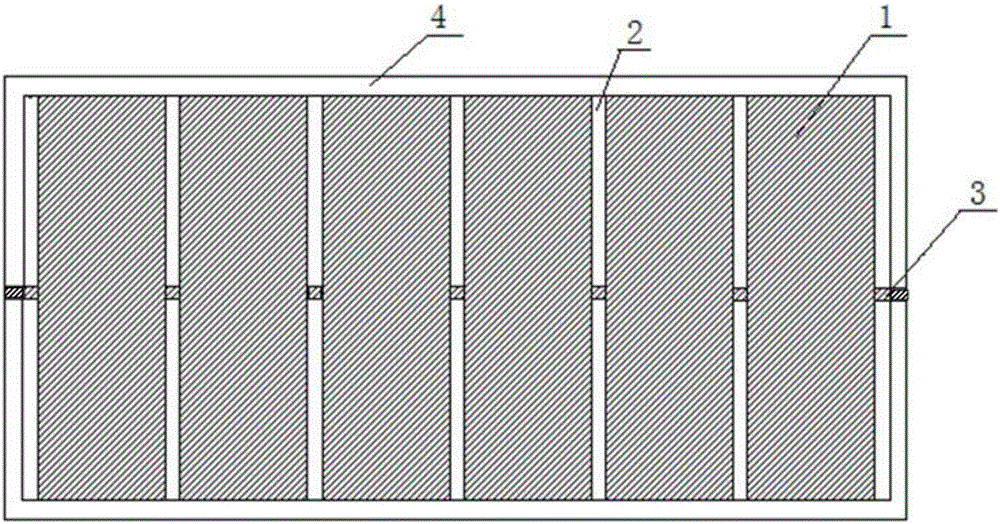

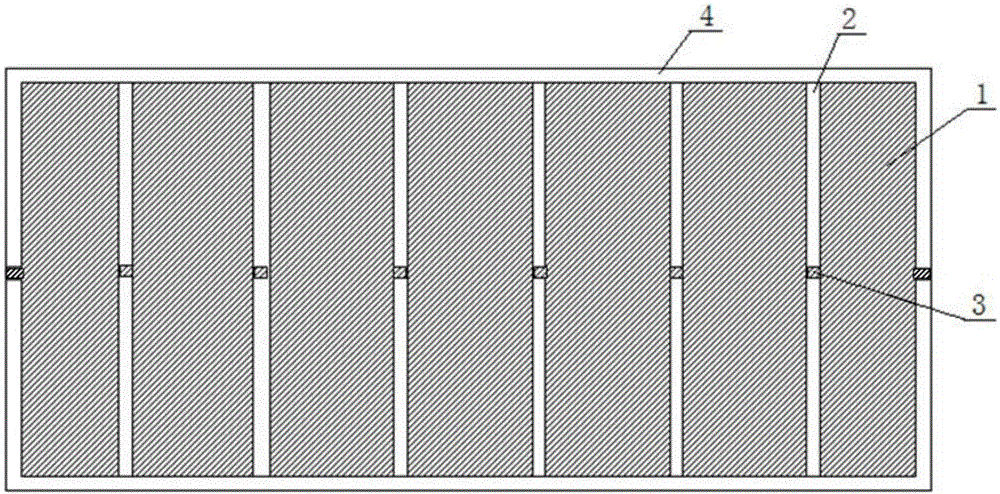

Method for manufacturing grid rudder

The invention discloses a method for manufacturing a grid rudder, which relates to the field of metal processing. The method comprises the steps of (a) dividing one surface of a billet material into a plurality of stop welding flux coating areas (1) and a plurality of diffusion areas (2) which are distributed at intervals for each other, forming vent grooves, applying stop welding fluxes, then aligning with four sides of the other billet material, and sealing and welding, so as to form billet bags; (b) putting a plurality of billet bags into a mold in parallel and at intervals, respectively putting border billets on both ends of two adjacent billet bags, and making the projections of the diffusion areas (2) in billet pieces of the two adjacent billet bags keep parallel and distribute at intervals on a plane parallel to the billet bags; and (c) applying pressure to the mold, then leading air between the two adjacent billet bags, and then leading air to the vent groove (3) in the billet piece of each billet bag. The grid rudder prepared by using the method has the advantages of good integrality and high material utilization.

Owner:北京普惠三航科技有限公司 +1

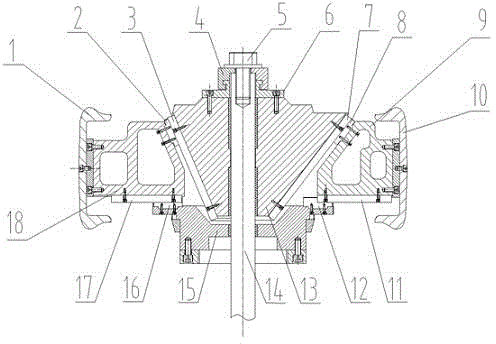

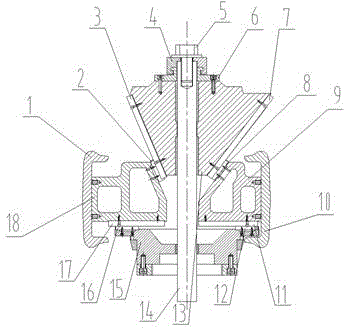

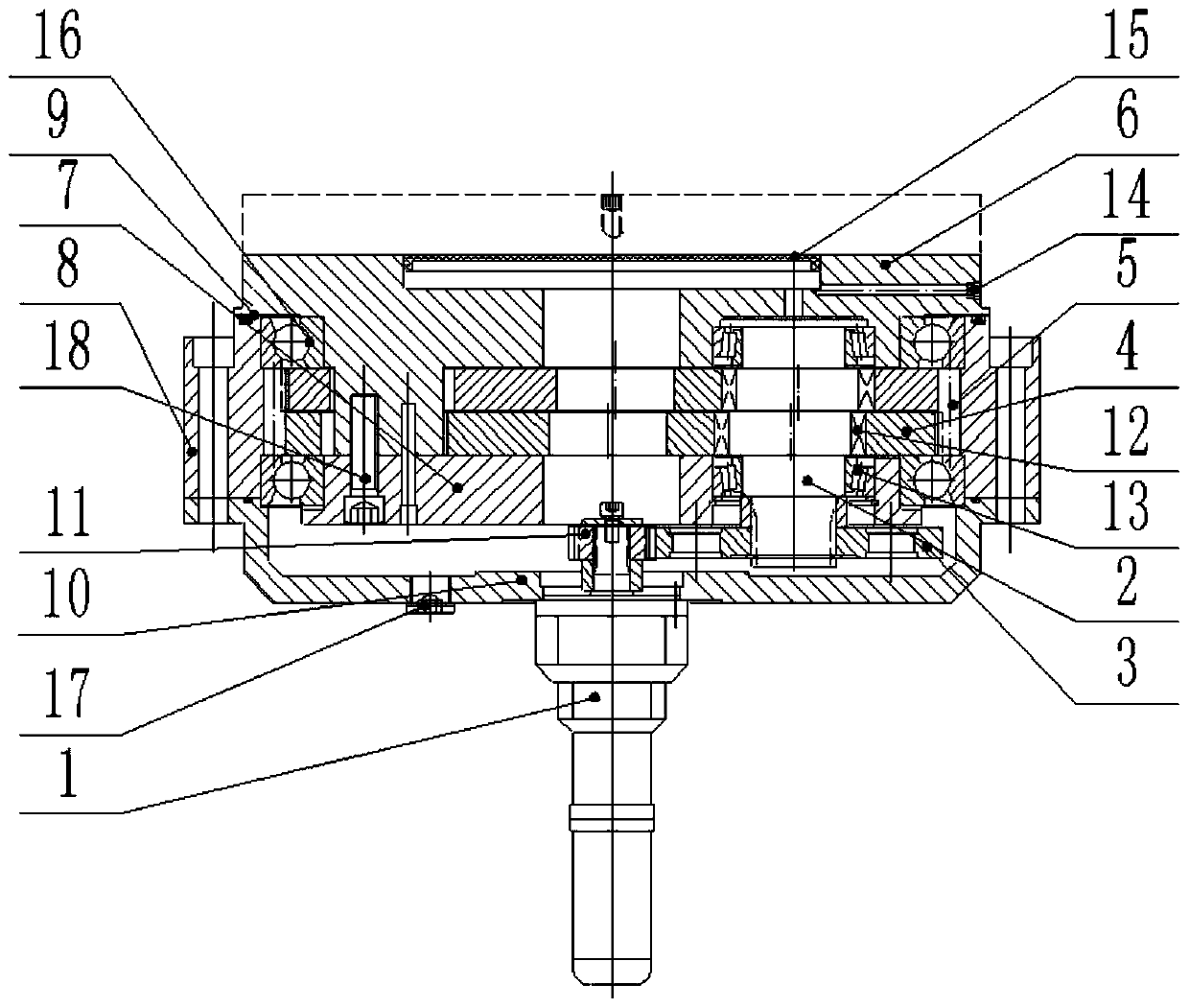

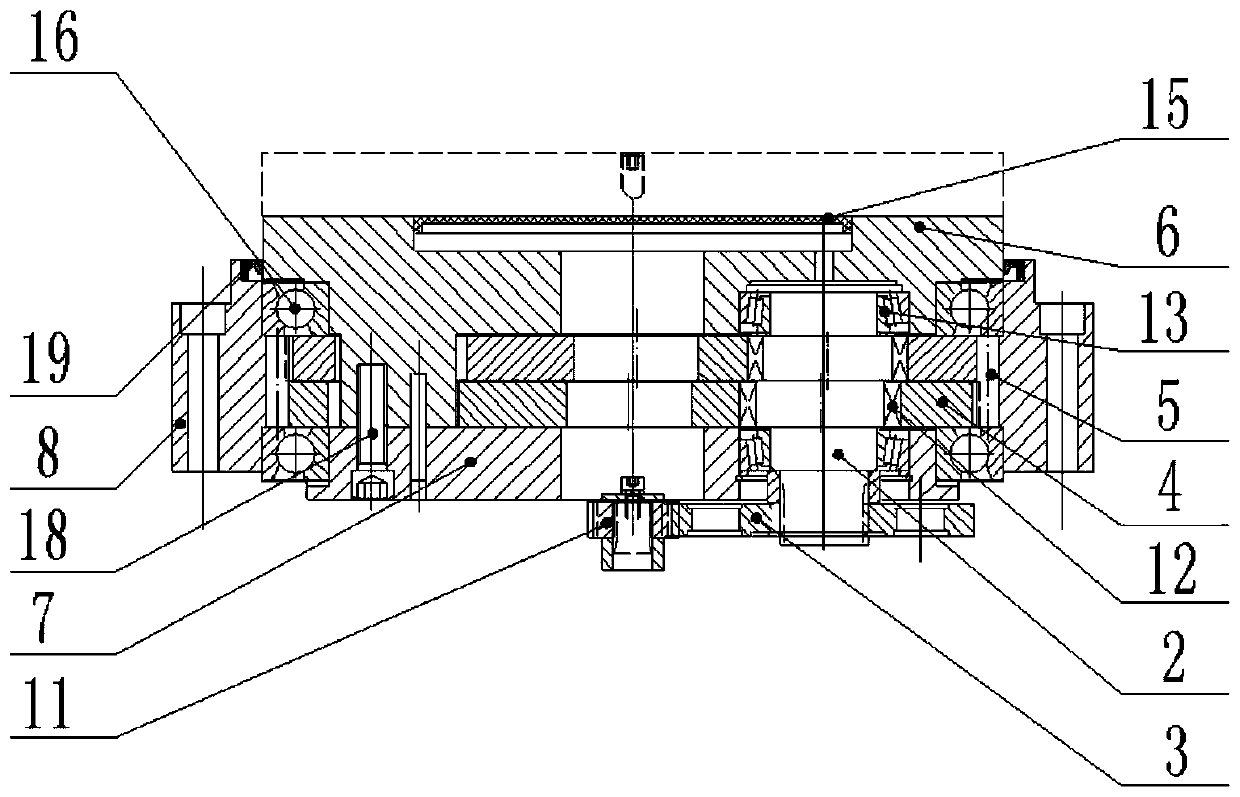

Precise transmission speed reducer

InactiveCN109899456ALarge hysteresisSmall hysteresisGear lubrication/coolingToothed gearingsBall bearingGear wheel

The invention relates to a precise transmission speed reducer. The speed reducer comprises an input gear shaft, a crankshaft is arranged on one side of the input gear shaft, the crankshaft is sequentially provided with an output disc, two cycloidal gears, a rigid disc and a planetary gear in a penetrating manner from top to bottom, two eccentric parts are arranged in the middle of the crankshaft,conical roller bearings are arranged between the output disc and the upper end of the crankshaft and between the rigid disc and the lower end of the crankshaft, the two cycloidal gears are located onthe periphery of the two eccentric parts of the crankshaft, the cycloidal gears are placed in the direction that the circumference difference is 180 degrees, roller bearings are arranged between the cycloidal gears and the crankshaft, the planetary gear is fixed to the crankshaft, the planetary gear is engaged with the gear of the input gear shaft, and the rigid disc is fixed to the output disc. Aneedle gear shell is included, the needle gear shell is engaged with the cycloidal gears through needle gear pins arranged on the inner circumference, and angular contact ball bearings are arranged between the needle gear shell and the rigid disc and between the needle gear shell and the output disc. The speed reducer is large in transmission ratio, high in bearing capacity, high in transmissionprecision, high in transmission efficiency, long in service life and small in return difference.

Owner:ZHONGNENG TIANJIN INTELLIGENT TRANSMISSION EQUIP CO LTD

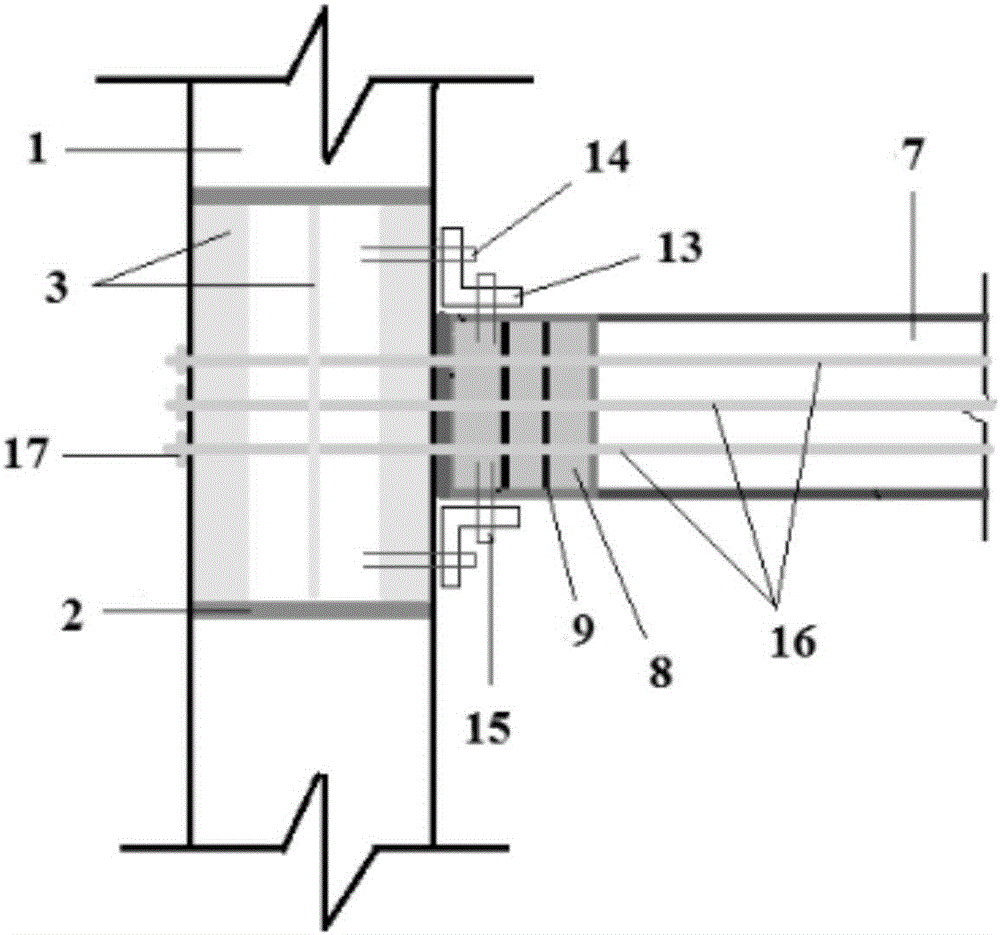

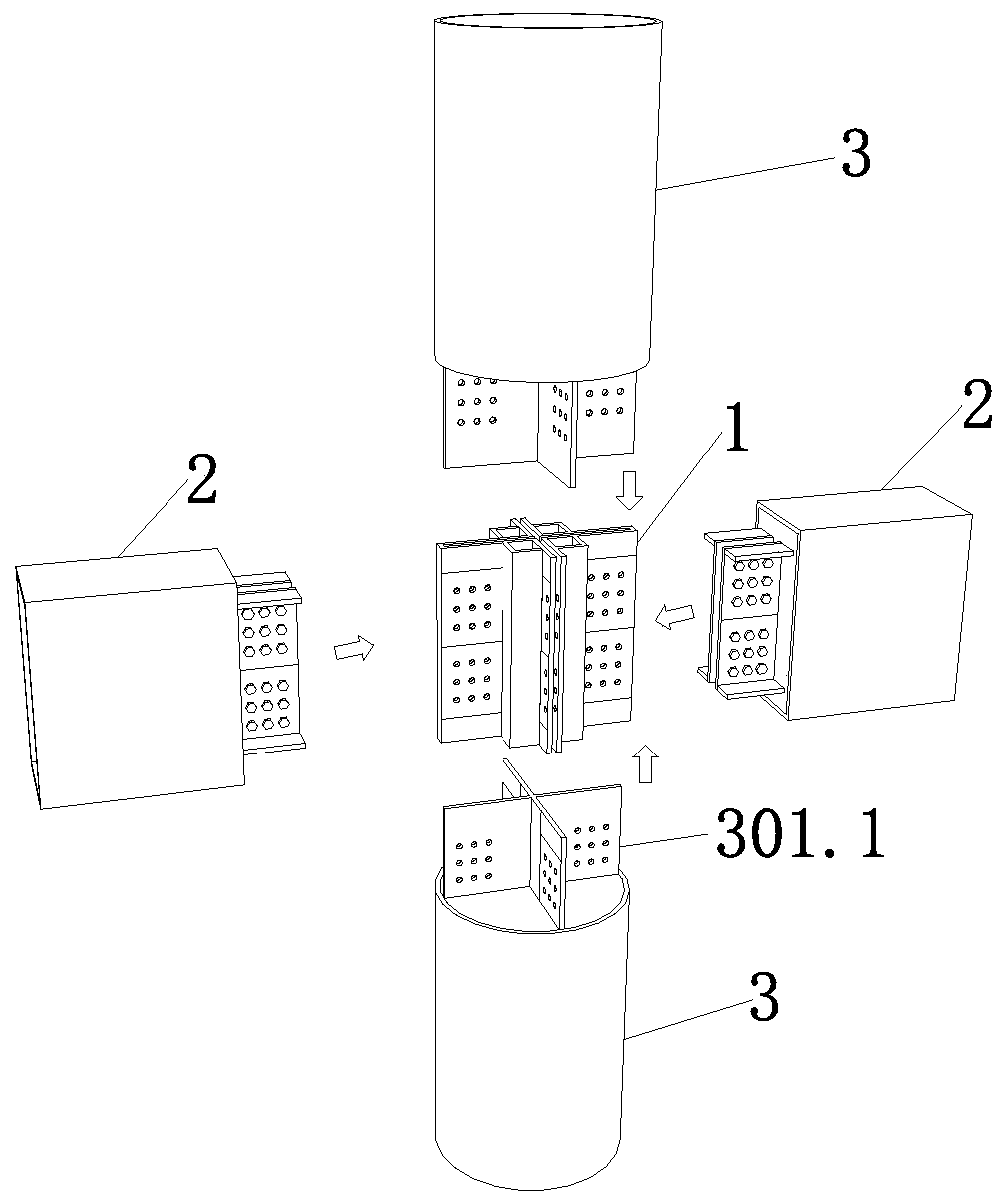

Fiber reinforce plastic (FRP) sectional material beam column joint capable of being assembled rapidly

The invention discloses a fiber reinforce plastic (FRP) sectional material beam column joint capable of being assembled rapidly. The FRP sectional material beam column joint capable of being assembledrapidly comprises a FRP pipe concrete column with an embedded cross-shaped FRP sectional material, a box groove FRP sectional material concrete combined beam, a prefabricated joint and a matched bolt. A joint body is composed of two same parts and is assembled with the embedded cross-shaped FRP sectional material, and the beam is connected with the joint through an end part pre-embedded groove shape steel plate. The main construction method of the FRP sectional material beam column joint capable of being assembled rapidly comprises the steps that a column prefabricated FRP pipe and the cross-shaped FRP sectional material are placed in position; the joint is assembled correspondingly with the cross-shaped FRP sectional material extending from the column and the beamless connection direction bolt is tightened; the beam is hoisted in position, the beam end groove steel plate and the joint are opposite to a reserved bolt hole and the bolt is tightened; and a template is arranged in a supporting mode, and concrete in the column and the concrete at the joint are poured. The FRP sectional material beam column joint capable of being assembled rapidly is simple in construction and convenient to construct, can greatly improve the construction efficiency, and is easy to control the quality. Meanwhile, a force transferring route of the joint is distinct, the good energy consumption is achieved, and the safety of a main body structure can be well guaranteed.

Owner:WUHAN UNIV

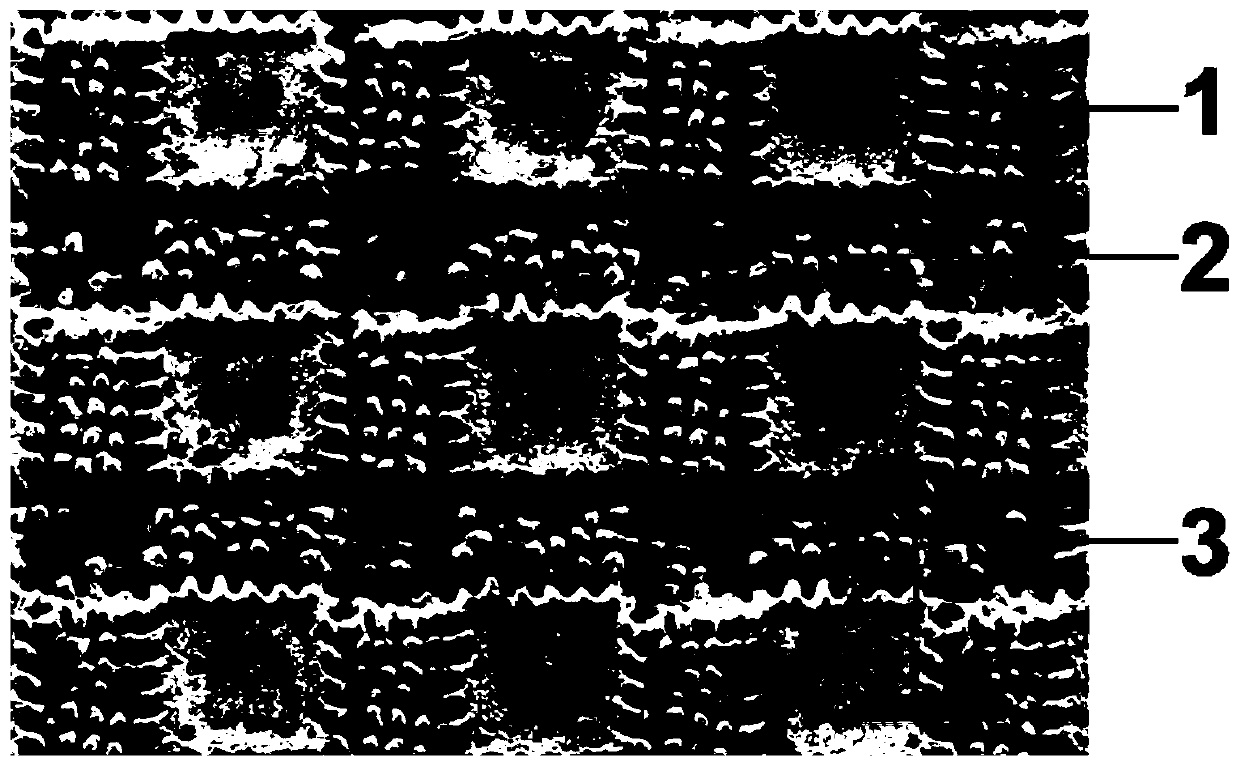

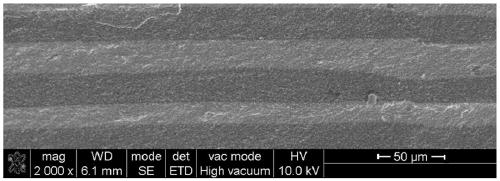

Material surface micro-nano composite strengthening boiling structure as well as preparation method and application thereof

ActiveCN109974512ALittle motor blockMultiple Vaporization CoresHeat transfer modificationLaser beam welding apparatusMicro nanoNanometre

The invention discloses a material surface micro-nano composite strengthening boiling structure as well as a preparation method and application of the material surface micro-nano composite strengthening boiling structure. The material surface micro-nano composite strengthening boiling structure comprises a base material and a micro-nano composite structure formed on the surface of the base material. The micro-nano composite structure comprises micro mastoids, communication-type grooves and nano-folds, wherein the micro mastoids are formed in the communication-type grooves, and the surfaces ofthe micro mastoids are provided with nano-fold shapes. The preparation method of the material surface micro-nano composite strengthening boiling structure comprises the following step of forming a micro-nano composite strengthening boiling structure on the base material through a laser integrated etching method. The material surface micro-nano composite strengthening boiling structure has multi-scale micron and nanometer characteristics in different levels.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

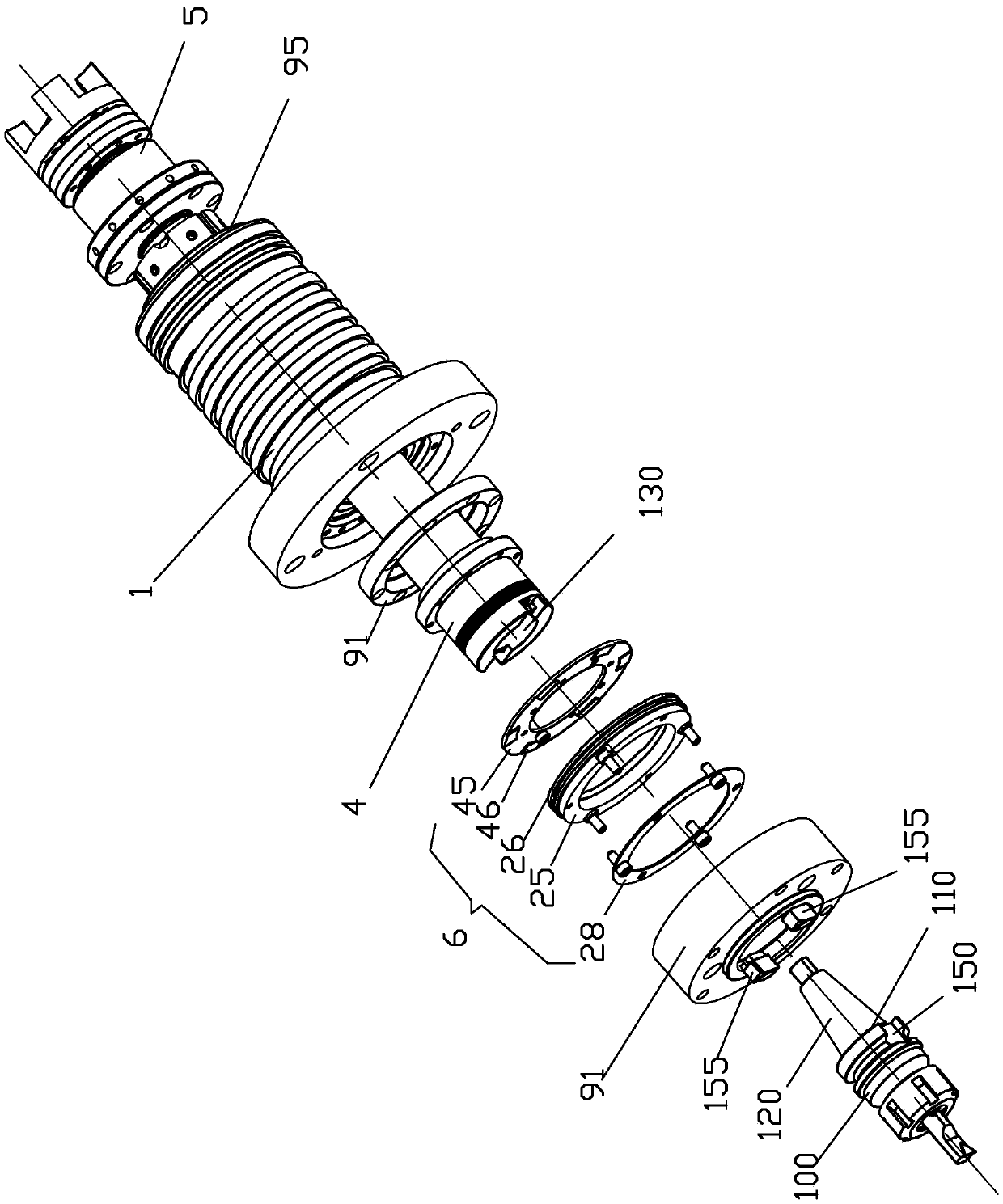

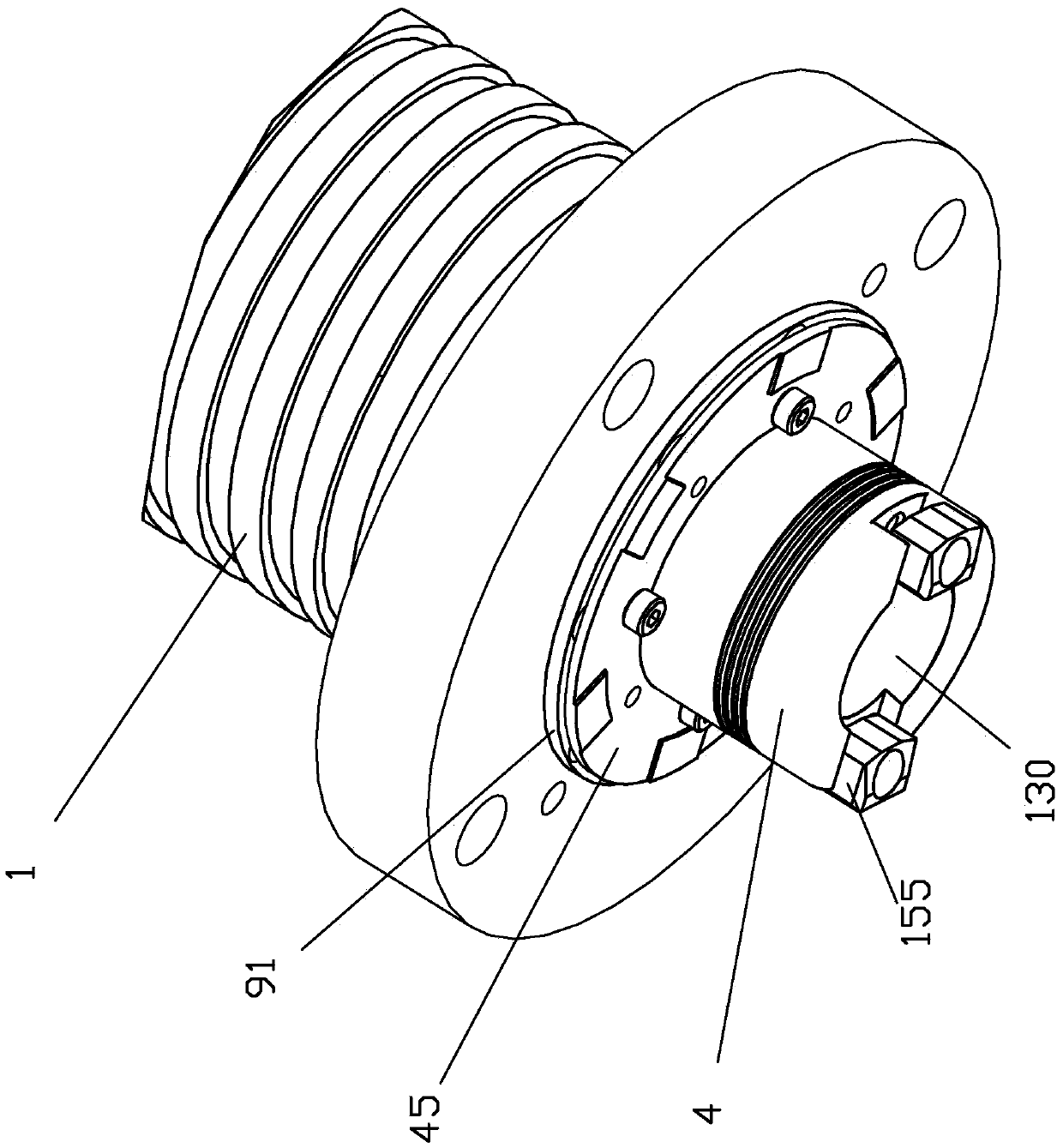

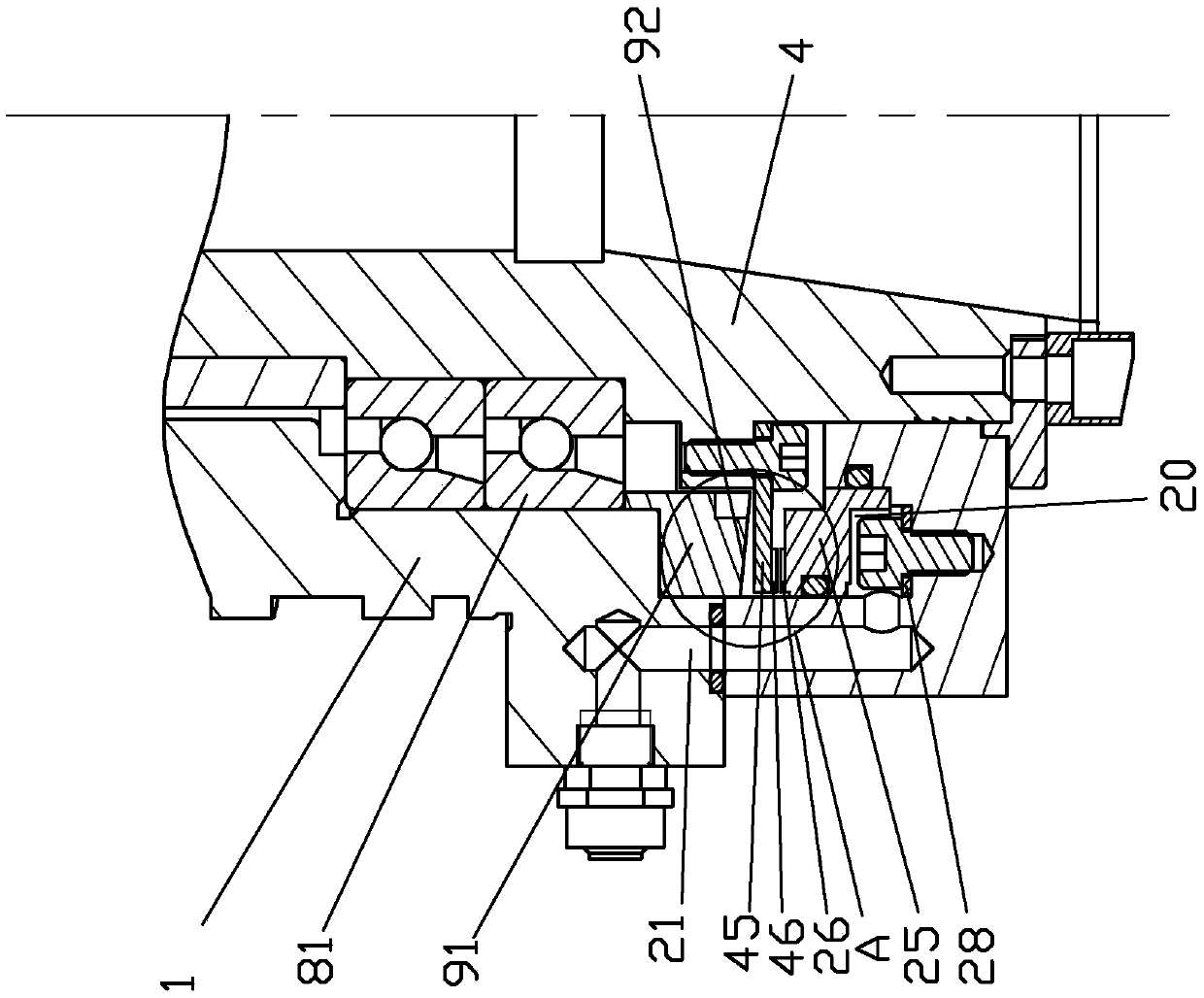

Integrated combined main shaft of mill combined machining center

ActiveCN105499610ARepeat targeting progress improvedImprove rigidityLarge fixed membersEngineeringPiston

The invention discloses an integrated combined main shaft of a mill combined machining center. The integrated combined main shaft comprises a main shaft box, a front end cover, a back end cover, a main shaft core, a main shaft driving mechanism, a locking device and a broach releasing mechanism. As a first annular tooth disc and a second annular tooth disc which are fixed between a piston disc controlled through hydraulic pressure to move back and forth and an annular rotating disc fixed to the main shaft core are engaged, the repetitive positioning accuracy of the rotating angle of the main shaft are further improved; after meshing is carried out, moving is continuously carried out, the annular rotating disc is tightly pressed to a front bearing gland, and the effect of improving the rigidity of the main shaft core is achieved.

Owner:广东今科机床有限公司

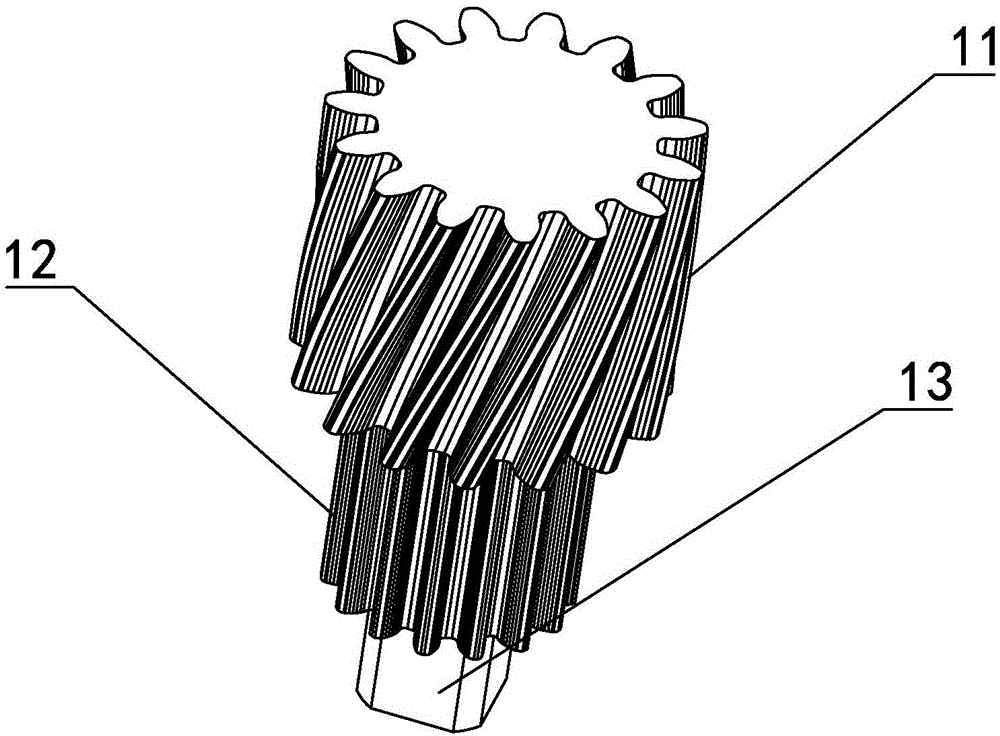

Mold and method for machining multi-section part with spiral tooth structure

ActiveCN106734819AHigh structural precisionSave manpower and material resourcesForging/hammering/pressing machinesWheelsMaterial resourcesGear tooth

The invention discloses a mold for machining a multi-section part with a spiral tooth structure. The mold comprises an upper mold, a lower mold, a punch and an ejector rod, and is characterized in that a second mold cavity and a third mold cavity overlapped up and down are formed in the lower mold; the inner wall of the second mold cavity is provided with a corresponding gear tooth structure; the third mold cavity is a quadrangular structure; a first mold cavity is formed in the upper mold; the inner wall of the first mold cavity is provided with a corresponding spiral tooth structure; a pressing device is arranged above the upper mold; a jacking module is arranged between the upper mold and the lower mold; the punch is vertically arranged above the first mold cavity; the ejector rod is vertically arranged below the third mold cavity; the punch, the first mold cavity, the second mold cavity, the third mold cavity and the ejector rod are arranged by sharing one central axis; the diameter of the first mold cavity is larger than the diameter of a material to be machined; the diameter of the material is larger than the diameter of the second mold cavity; and the diameter of the second mold cavity is larger than the diameter of the third mold cavity. The mold can integrally machine-shape a multi-section part with the spiral tooth structure by adopting the material; the obtained multi-section part with the spiral tooth structure is high in precision; and a lot of manpower and material resources are saved.

Owner:YEG TECH NINGBO CO LTD

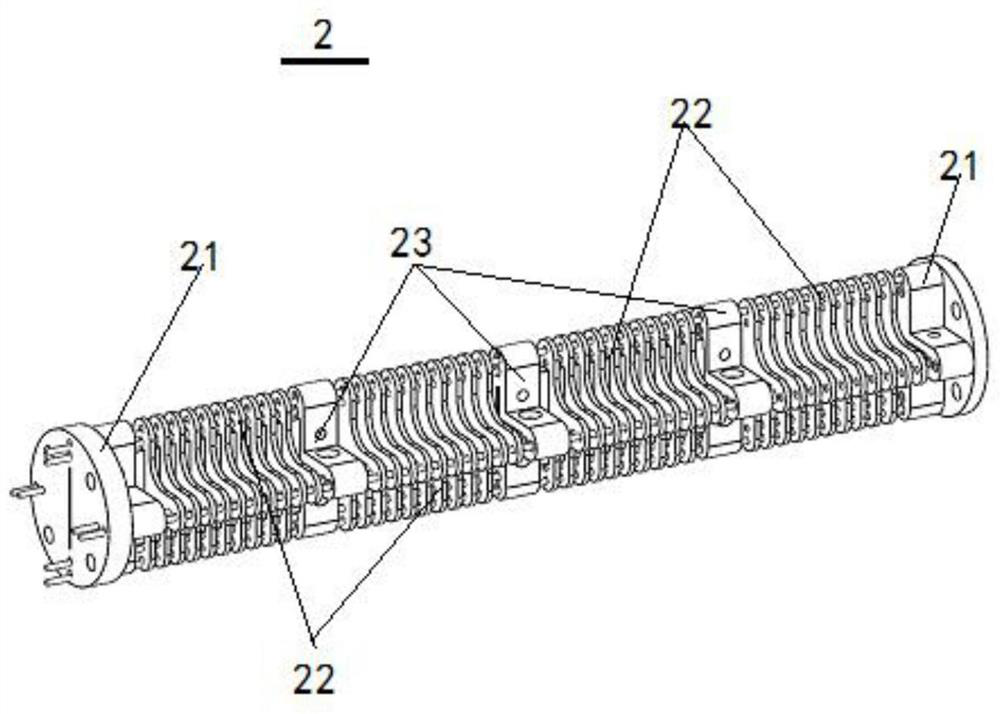

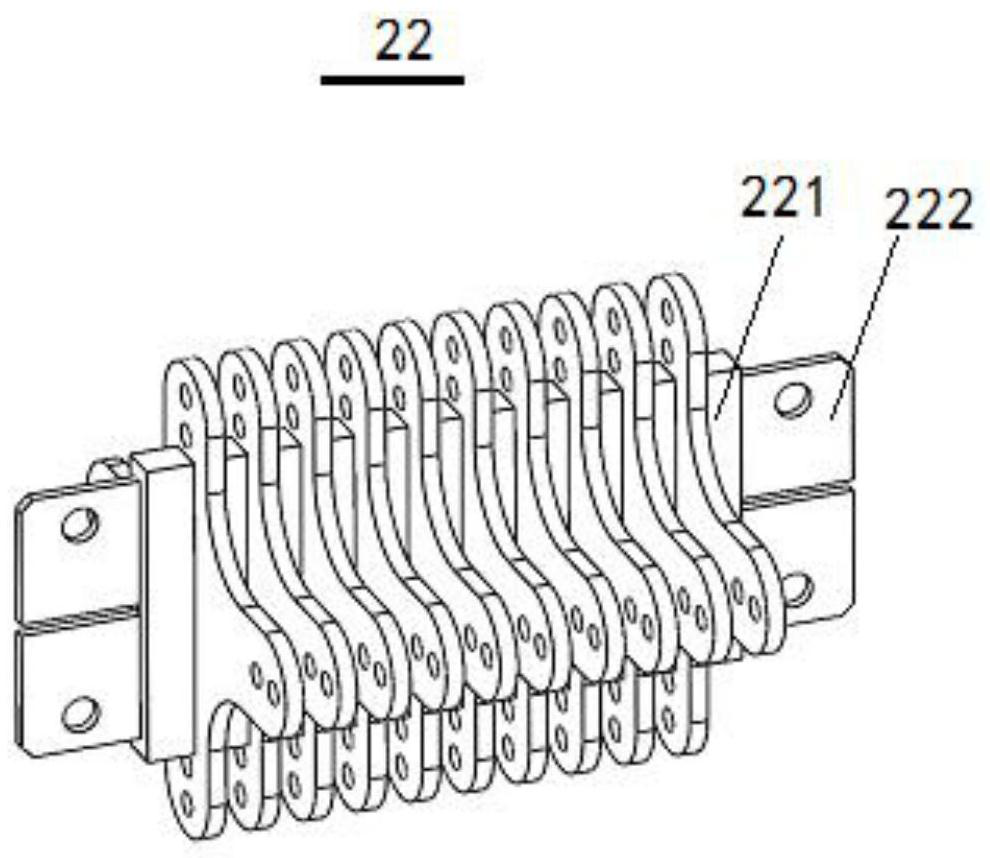

Bionic crossed fishbone-shaped continuum robot mechanical arm

ActiveCN113370198AIncrease flexibilityHigh precisionProgramme-controlled manipulatorControl engineeringElectric machinery

The invention provides a bionic crossed fishbone-shaped continuum robot mechanical arm. The bionic crossed fishbone-shaped continuum robot mechanical arm comprises a box body, a flexible mechanical arm, a driving rope, a driving motor module and a control module, and the control module controls the driving rope to drive the flexible mechanical arm to act through the driving motor module; the flexible mechanical arm comprises an end cover, a plurality of fishbone-imitating basic modules and a plurality of middle connecting discs, and every two adjacent fishbone-imitating basic modules are connected in series in a crossed mode through the corresponding middle connecting disc; and the fishbone-imitating basic module comprises a rigid-flexible bionic fish skeleton and a spring steel sheet. According to the mechanical arm, bending movement in all directions can be completed, deformation of the driving rope in the movement process of the mechanical arm is closer to a circular arc through a specific rigid-flexible mixed bionic fish skeleton structure, the deformation is better matched with a theoretical model assumption condition, therefore the tail end position of the mechanical arm is more accurate, and the problem that a mechanical arm of a traditional continuum robot is large in motion error is well solved.

Owner:YANSHAN UNIV

Preparation method of gradient functional ceramic

The invention relates to the technical field of ceramic preparation, particularly to a preparation method of gradient functional ceramic. According to the invention, slurry and the process parametersof 3D printing are optimized, and particularly, sintering additives in ceramic composite powder in the slurry and the exposure energy of 3D printing are optimized; a blank is printed by adopting exposure energy corresponding according to different slurry; the blank obtained by 3D printing is uniform and has high forming rate; and a ceramic formed by degreasing and sintering the blank under certainconditions is small in deformability, high in structural and dimensional precision, good in interlayer cohesiveness and high in density and bending strength. The gradient functional ceramic preparedthrough the method is high in forming efficiency and forming size precision; the structure of the gradient functional ceramic can be accurately regulated and controlled; functionalization is achieved;the material cost of the ceramic can be reduced; and production efficiency is improved.

Owner:GUANGDONG UNIV OF TECH

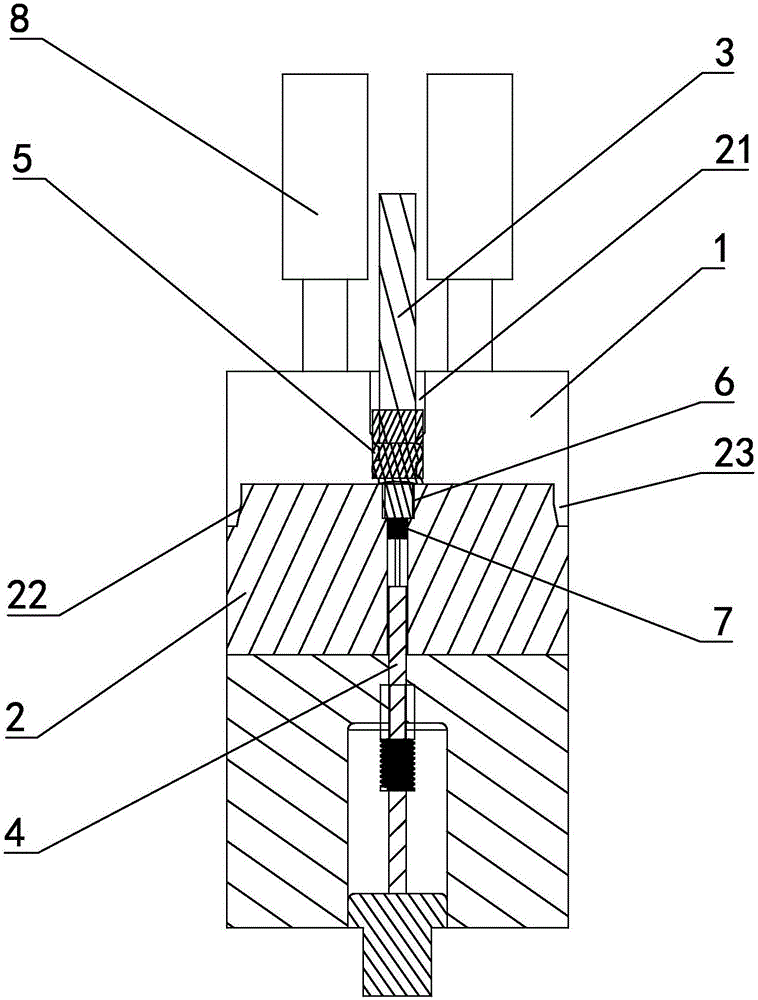

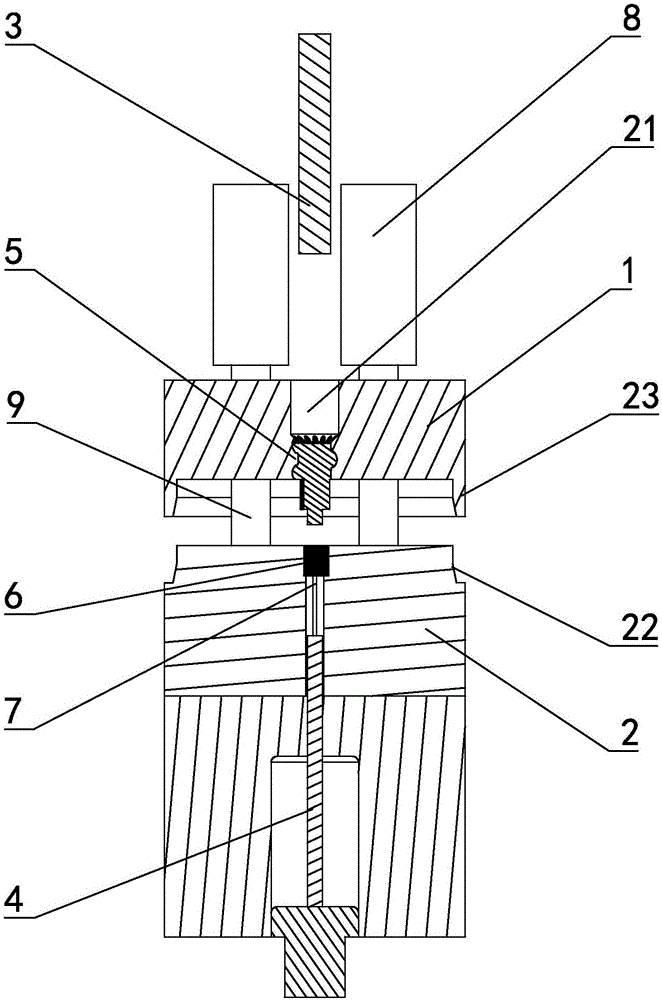

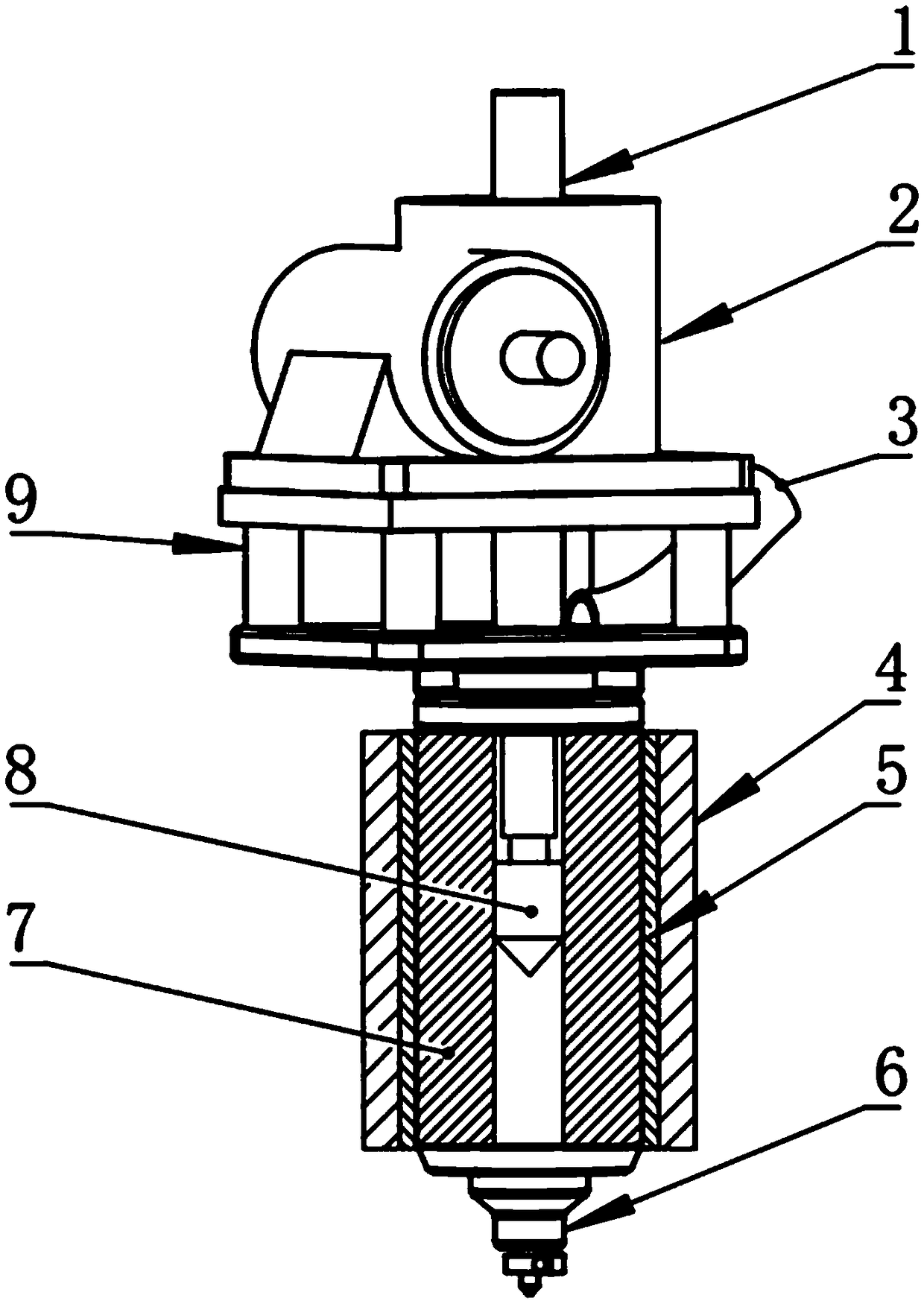

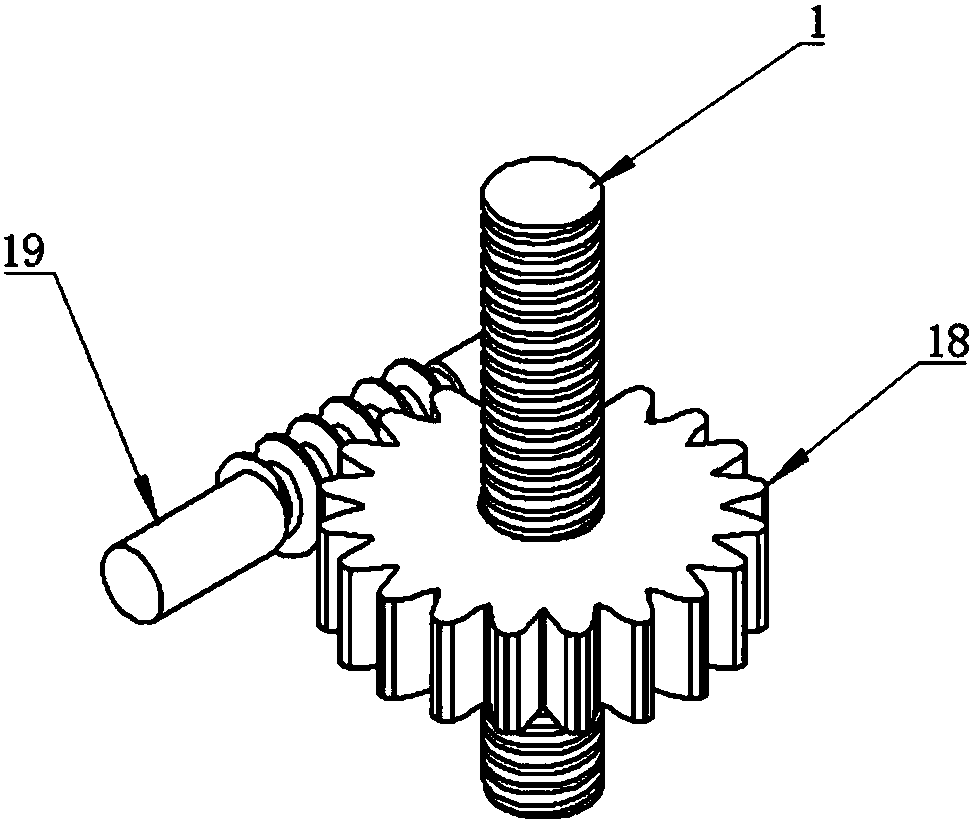

Gradient heating nozzle device for fused deposition metal 3D printing

The invention discloses a gradient heating nozzle device for fused deposition metal 3D printing. The gradient heating nozzle device comprises an extruding assembly, a charging barrel and a nozzle body. The extruding assembly is connected with the charging barrel through a fixing connecting part. The tail end of the charging barrel is connected with the nozzle body. The extruding assembly comprisesa worm, a worm wheel, a lead screw and a piston. The worm wheel is engaged with the worm through gear teeth. The worm wheel drives the lead screw through threads. The tail end of the lead screw is connected with the piston. The worm rotates to drive the worm wheel to rotate, the worm wheel rotates to drive the lead screw to move, and then the piston is driven to move. The charging barrel is provided with a feeding inlet and a heat insulation heating assembly. The heat insulation heating assembly comprises a heating layer and a heat insulation layer. The heating layer is tightly attached to the outer wall of the charging barrel. The heating layer and the charging barrel are wrapped with the heat insulation layer together. The nozzle body is provided with a temperature sensor and a heatingpipe. The heating temperature of the heating pipe is higher than that of the heat insulation heating assembly, and gradient heating is formed.

Owner:SHANTOU UNIV

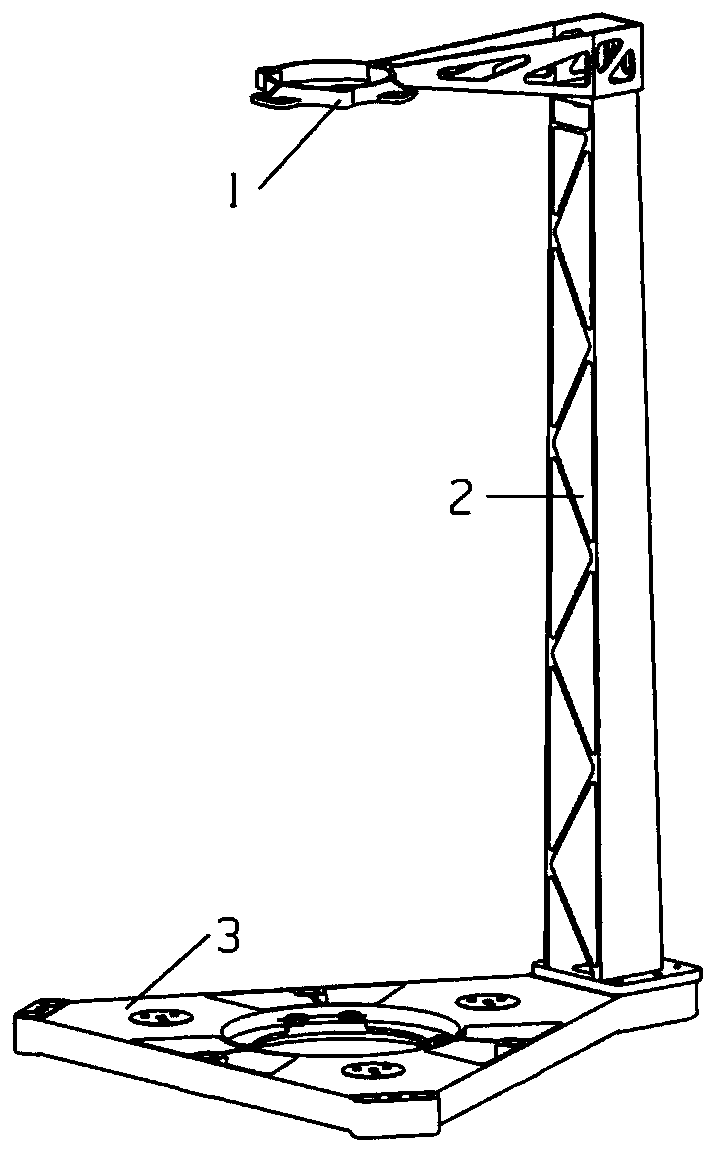

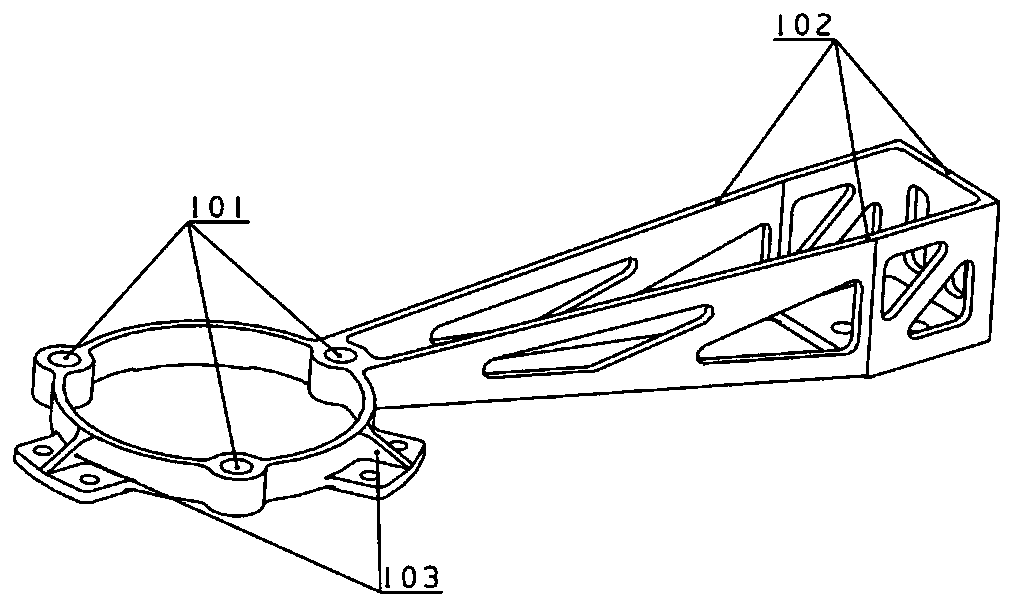

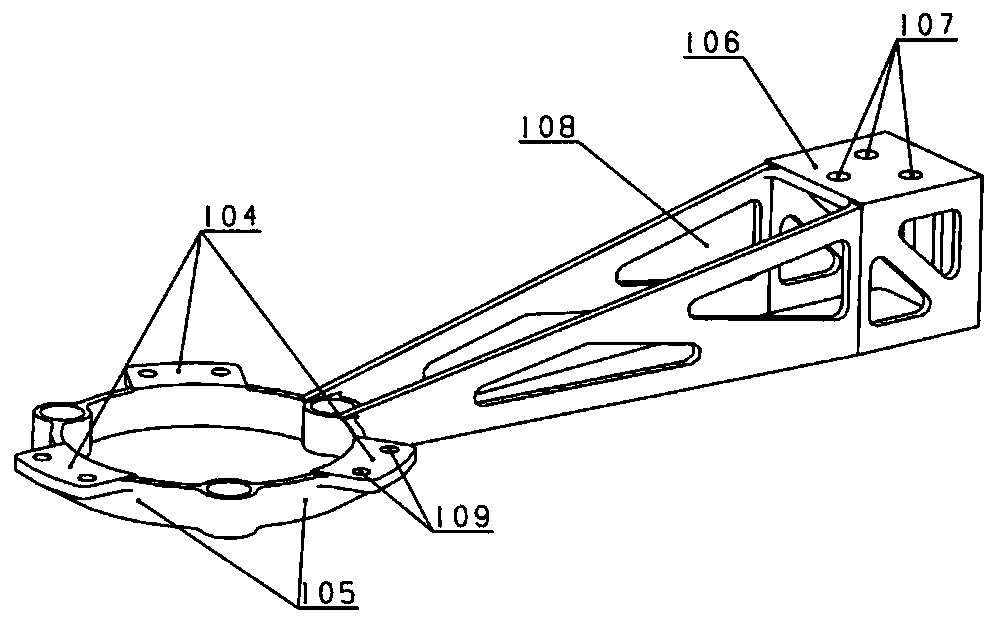

Single rod type main bearing structure applicable to micro-nano remote sensing camera

The invention discloses a single rod type main bearing structure applicable to a micro-nano remote sensing camera, relates to the technical field of space optical remote sensing, and solves the problems that the existing coaxial space camera main support structure is high in weight and large in shading ratio and process difficulty, an integrated formation structure is too high in production cost and long in processing period and the like. According to the single rod type main bearing structure applicable to the micro-nano remote sensing camera disclosed by the invention, a secondary mirror bracket and a support rod are in flanged connection; the support rod and a main backplate are in flanged connection; due to adoption of a split type structure, instead of an integrated structure, the processing difficulty of silicon carbide can be greatly reduced; the production period and the manufacturing cost are greatly reduced; the low-cost and short-period requirements of micro-nano load are satisfied; a countersunk bottom hole and an embedded part are pre-punched on a silicon carbide material; an epoxy resin adhering manner is adopted; and the problems that the process of directly processing a threaded hole in the silicon carbide material is high and damage is easily caused can be avoided. By means of the single rod type main bearing structure applicable to the micro-nano remote sensing camera disclosed by the invention, the structural precision and the stability are improved; the structural part number and the manufacturing process are simplified; and the processing period and theprocessing cost are shortened.

Owner:CHANGGUANG SATELLITE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com