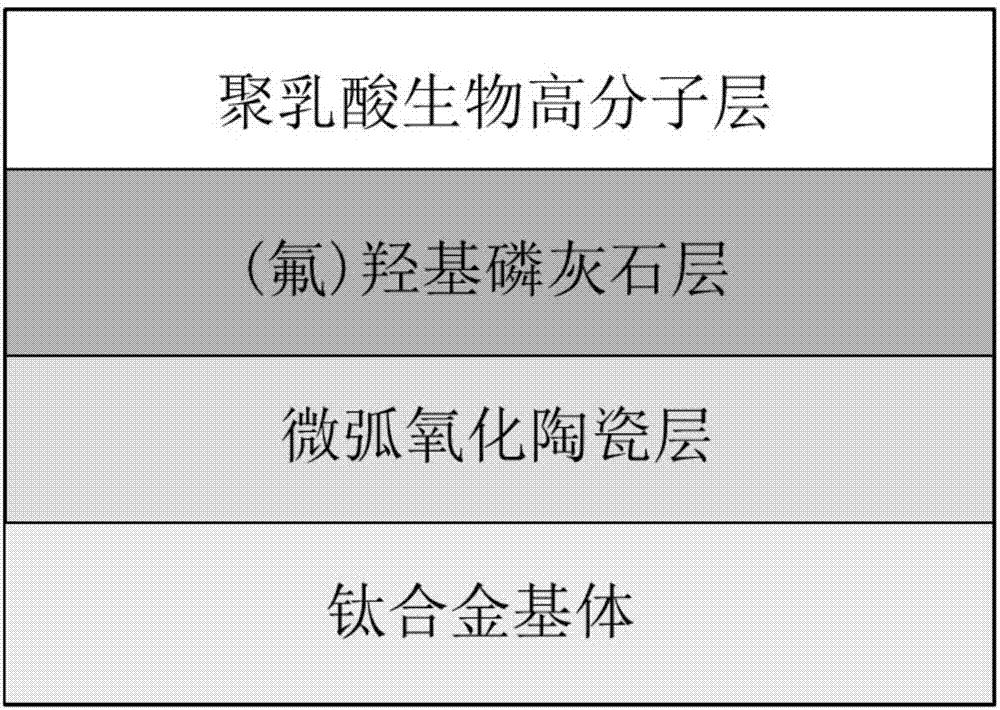

Titanium alloy implant composite material and preparation and application thereof

A technology of composite materials and titanium alloys, applied in the direction of electrolytic inorganic material coating, prosthesis, details involving processing steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Preparation of titanium alloy implant base

[0042] (1) CT scan the patient's bone structure (GE LightSpeed 16-slice spiral CT) to collect damaged bone structure data, and save the data in DICOM format;

[0043] (2) Input the obtained CT scan data into the Materialise three-dimensional modeling software (MaterialiseMagics20), perform threshold division, and then use the area growth method to remove the noise of the imported image, remove redundant data, and segment the damaged bone structure area;

[0044] (3) Use Materialise three-dimensional modeling software to open calculations to obtain the three-dimensional structure data of the damaged bone structure, and then input the obtained three-dimensional data into the UG software (NX9.0) to obtain the digital three-dimensional model of the bone defect, and carry out the repair design of the bone defect;

[0045] (4) Use computer-aided software (CAD) (AutoCAD2010) to design the bone defect module according to the design of bo...

Embodiment 2

[0064] Steps (1) to (4) are the same as the conditions in Example 1;

[0065] Step (5) Change the laser power in step (5) of Example 1 to 250W, the scanning speed of 1300mm / s, the annealing temperature to 700°C, and the holding time for 7 hours;

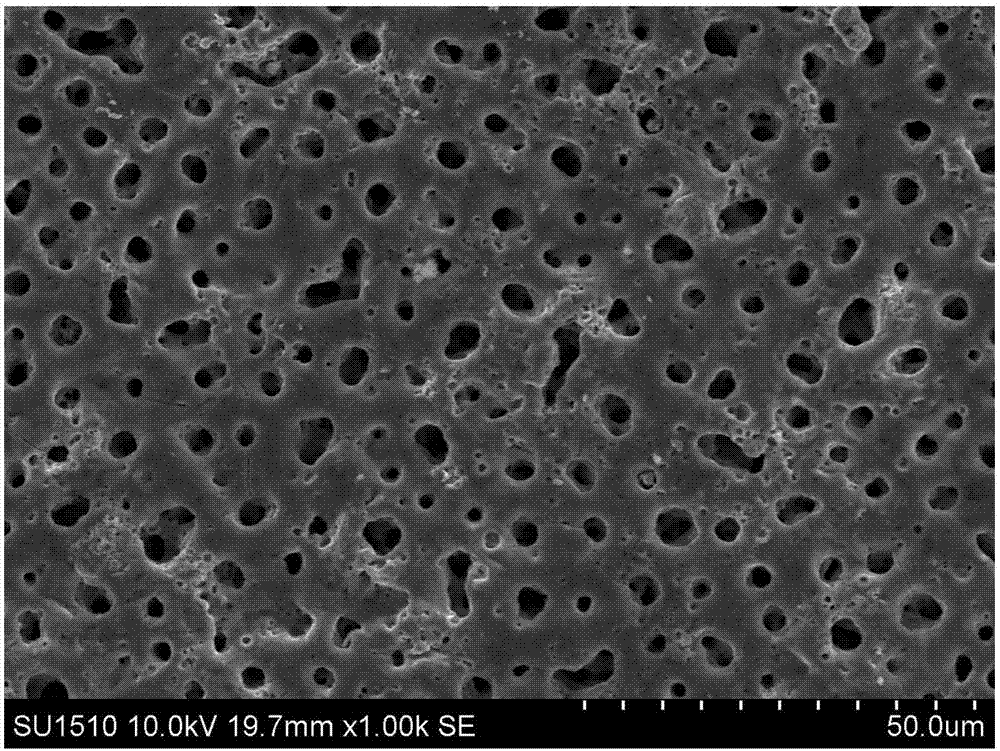

[0066] Step (6) Change the composition of the micro-arc oxidation solution in step (6) of Example 1 to: 8g / L Na 2 SiO 3 , 10g / LNa 3 PO 4 , 8g / L NaOH, 3g / L KF, 3g / L Na 2 CO 3 , 1g / L KOH, 50mL / L absolute ethanol, the solvent is deionized water, the pH value is natural. The control parameters of micro-arc oxidation are changed to: frequency is 550Hz, micro-arc time is 15min, duty cycle is 15%, current density is 15A / cm 2 , The other conditions remain unchanged; the titanium alloy implant matrix / micro-arc oxide film layer is obtained, and the contact angle diagram is shown Figure 4 Shown.

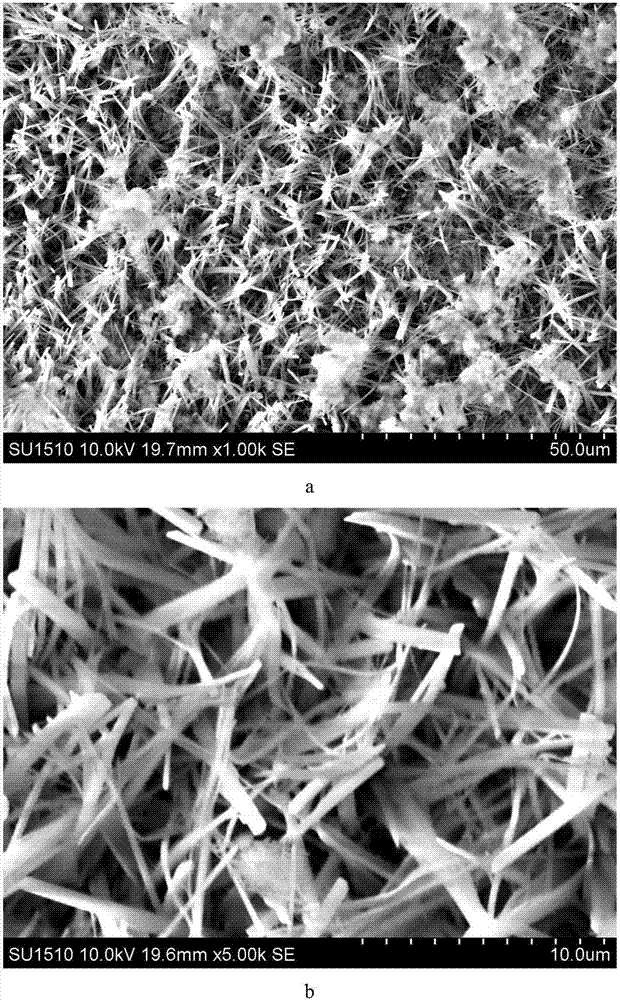

[0067] Step (7) Change the composition of the electrochemical deposition solution in step (7) of Example 1 to: 0.042mol / L Ca(NO 3 ) 2 , 0.025mol / L NH 4 H 2...

Embodiment 3

[0073] Steps (1) to (4) are the same as the conditions in Example 1;

[0074] Step (5) Change the laser power in step (5) of Example 1 to 250W, the scanning speed is 1500mm / s, the annealing temperature is changed to 800°C, and the holding time is 8 hours;

[0075] Step (6) Change the composition of the micro-arc oxidation solution in step (6) of Example 1 to: 12g / L Na 2 SiO 3 , 12g / LNa 3 PO 4 , 10g / L NaOH, 7g / L KF, 8g / L Na 2 CO 3 , 5g / L KOH, 100mL / L absolute ethanol, deionized water as solvent, natural pH. The control parameters of micro-arc oxidation are changed to: frequency is 650Hz, micro-arc time is 30min, duty cycle is 30%, current density is 25A / cm2, and other conditions remain unchanged;

[0076] Step (7) Change the composition of the electrochemical deposition solution in step (7) of Example 1 to: 0.042mol / L Ca(NO 3 ) 2 , 0.025mol / L NH 4 H 2 PO 4 , 0.5mol / L NaNO 3 , 50mL / L absolute ethanol, 50mL / L hydrogen peroxide, 0.006mol / L alkylphenol polyoxyethylene ether OP-21, 0.0008m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com