Patents

Literature

57results about How to "Improve mechanical bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

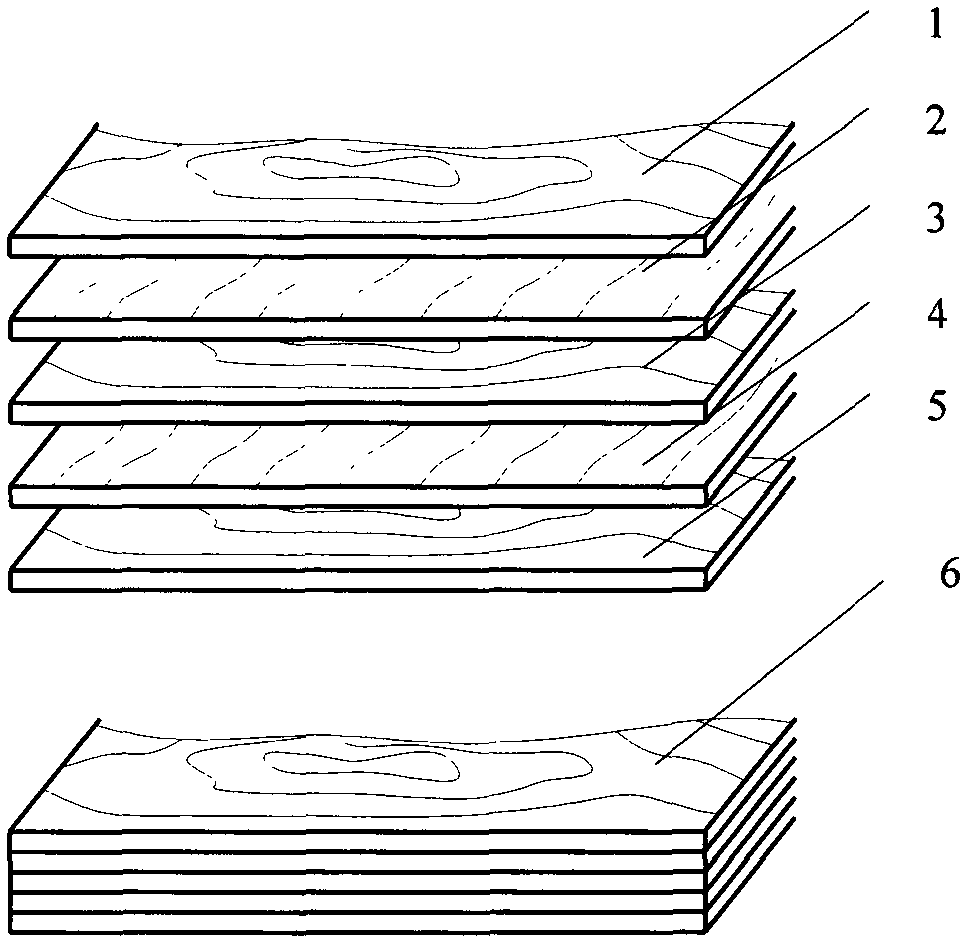

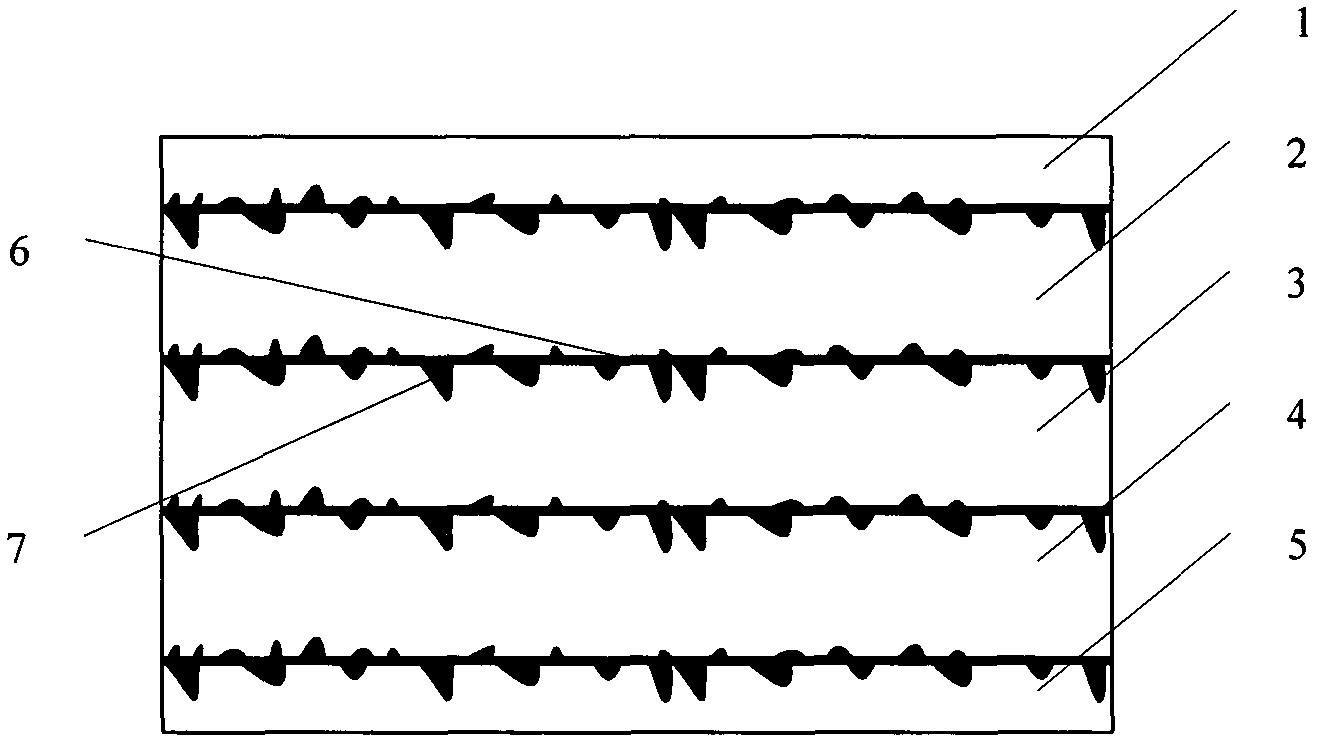

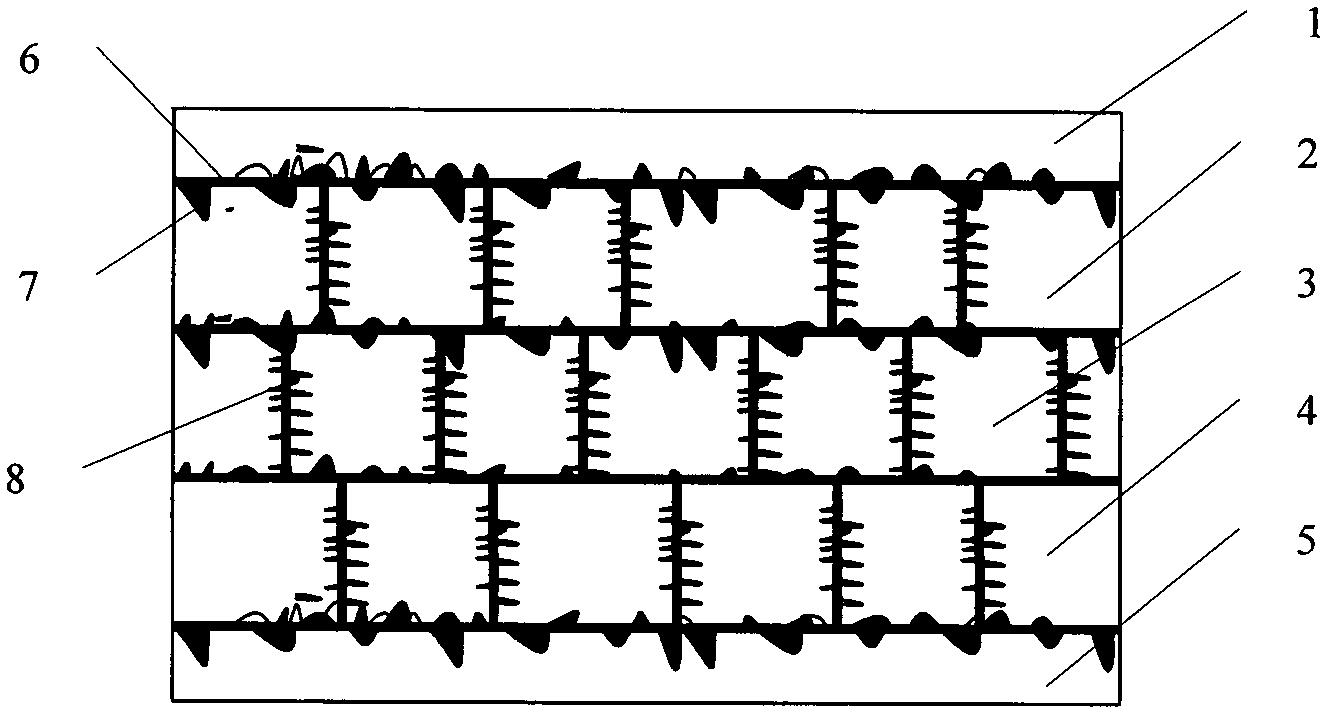

Gluing method for wood veneer

InactiveCN103072161AGood gluing propertiesHigh strengthLaminationLamination apparatusWood veneerPunching

The invention discloses a gluing method for a wood veneer. The wood veneer which is manually punched is used as a basic constitution unit and a to-be-glued object. The wood veneer is subjected to random or regular punching treatment along the thickness direction of the veneer by adopting the mechanical methods of drilling and punching or physical methods of laser drilling and microwave drilling, and the size, shape, depth and number of holes are not limited. The wood veneer which is subjected to punching is glued, the adjacent glue layers are connected together to form a three-dimensional reticular-layered glue layer composite structure, mechanical rivet force is formed, and the gluing strength is accordingly improved. Glue liquid penetrates into the wood veneer via the periphery of manually holes, and the body strength of the wood veneer is strengthened. A manufacturing method of the wood veneer comprises the following steps of (1) veneer manufacturing; (2) veneer drying; (3) veneer glue application; (4) assembly; (5) gluing; and (6) post treatment. The wood veneer manufactured by the gluing method has the characteristics of high gluing strength, good water resistance, high compressive strength and good size stability.

Owner:唐忠荣

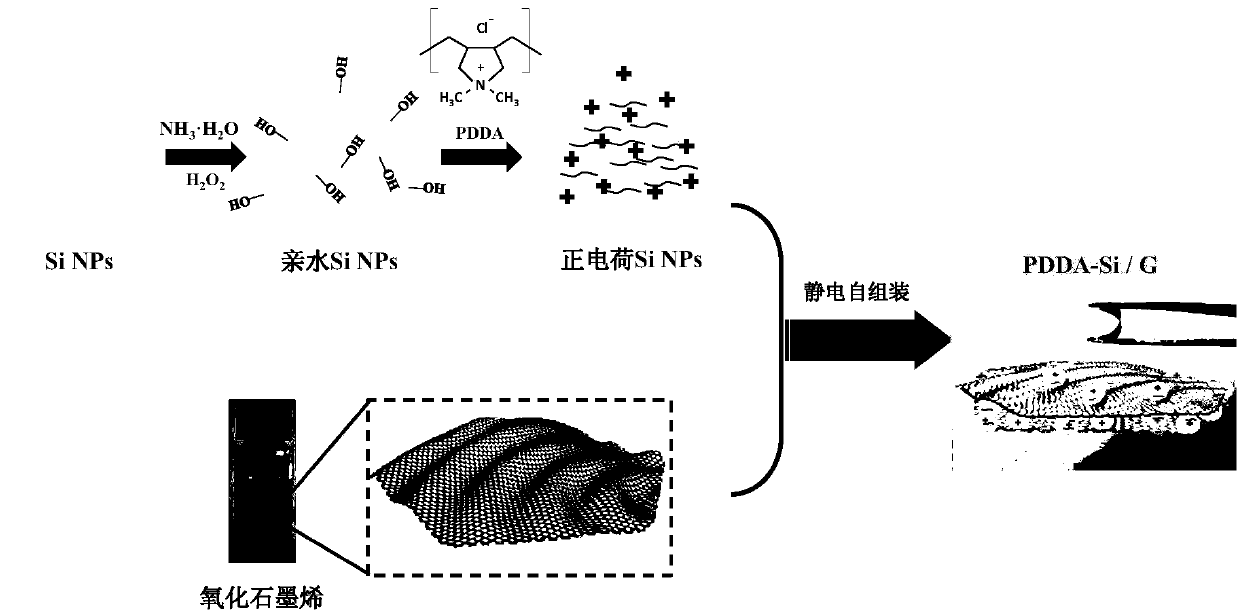

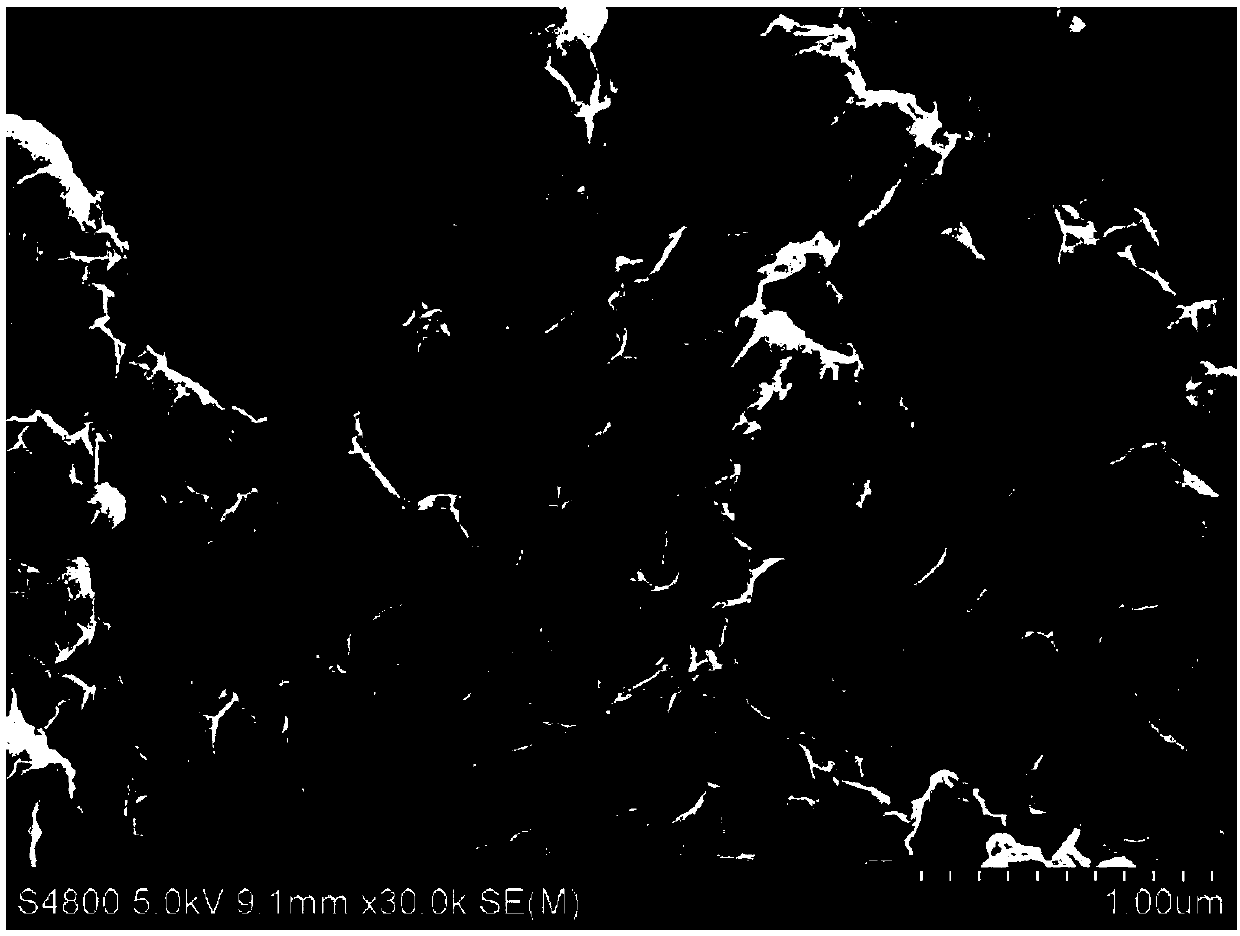

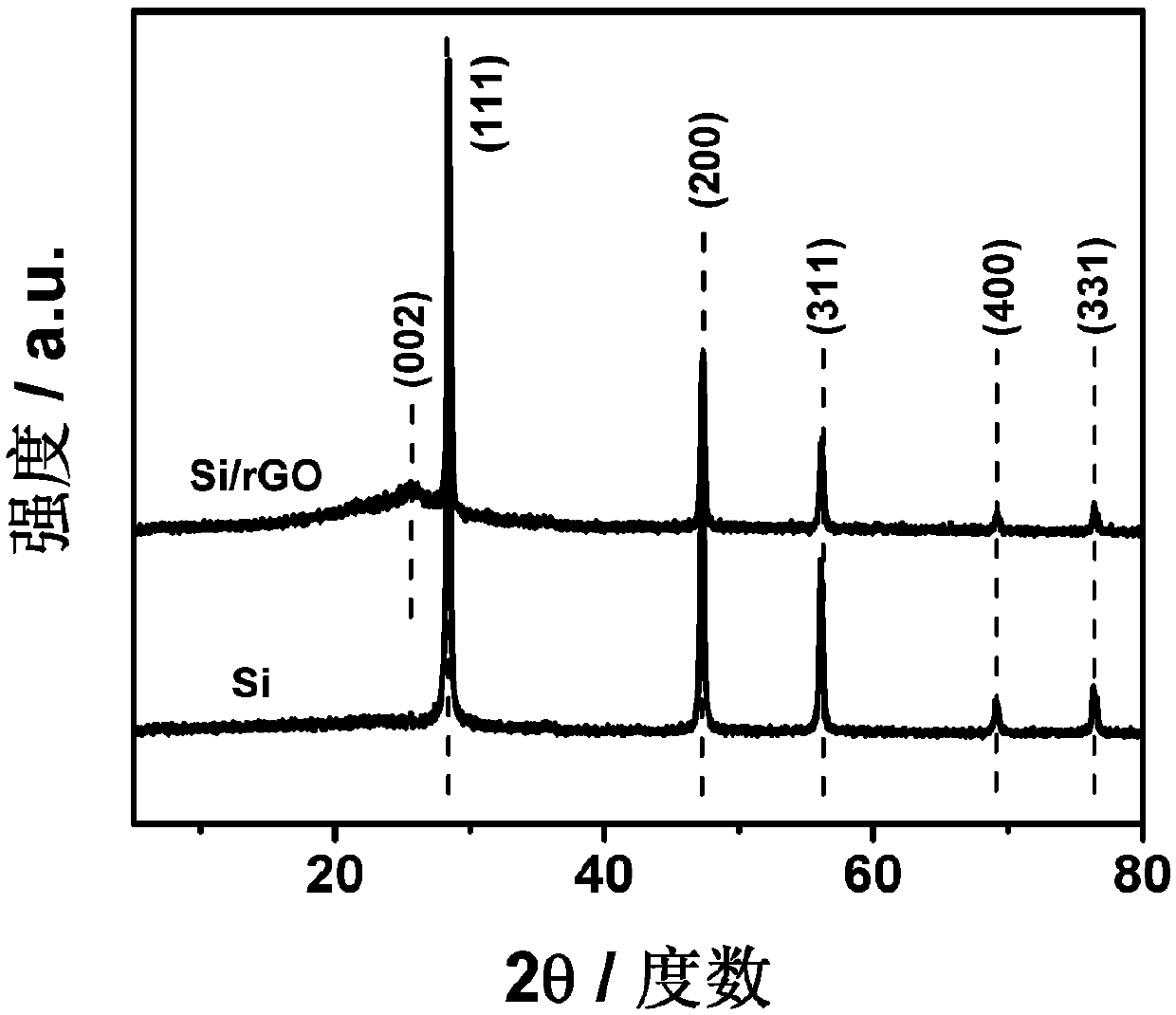

Preparation method of flexible self-supporting silicon/graphene cathode material of lithium ion battery

InactiveCN109524641AHigh bonding strengthHigh mechanical flexibilityMaterial nanotechnologyCell electrodesFiltrationOxide composite

The invention discloses a preparation method of a flexible self-supporting silicon / graphene cathode material of a lithium ion battery. The method comprises the following steps: I, dispersing nano silicon particles in a mixed solution to be heated and cleaned and centrifugalized; II, dispersing the centrifugalized precipitate in a polydiene dimethyl ammonium chloride solution to obtain the nano silicon particles with positive charges; III, dropwise adding the nano silicon particles into a graphene oxide solution and carrying out suction filtration to obtain a silicon / graphene oxide composite film; and IV, thermally treating the silicon / graphene oxide composite film at a high temperature to obtain the flexible self-supporting silicon / graphene cathode material. The nano silicon particles withpositive charges and the graphene oxide with negative charges are self-assembled statically to botain the flexible self-supporting silicon / graphene cathode material which is excellent in mechanical flexibility. An electrode of the lithium ion battery can be directly prepared without adding a binder and conducting carbon black, so that the problem that the electrochemical property is reduced by adding the binder is solved, and the service life of the lithium ion battery is prolonged while the high capacity of the lithium ion battery is ensured.

Owner:XIAN UNIV OF SCI & TECH

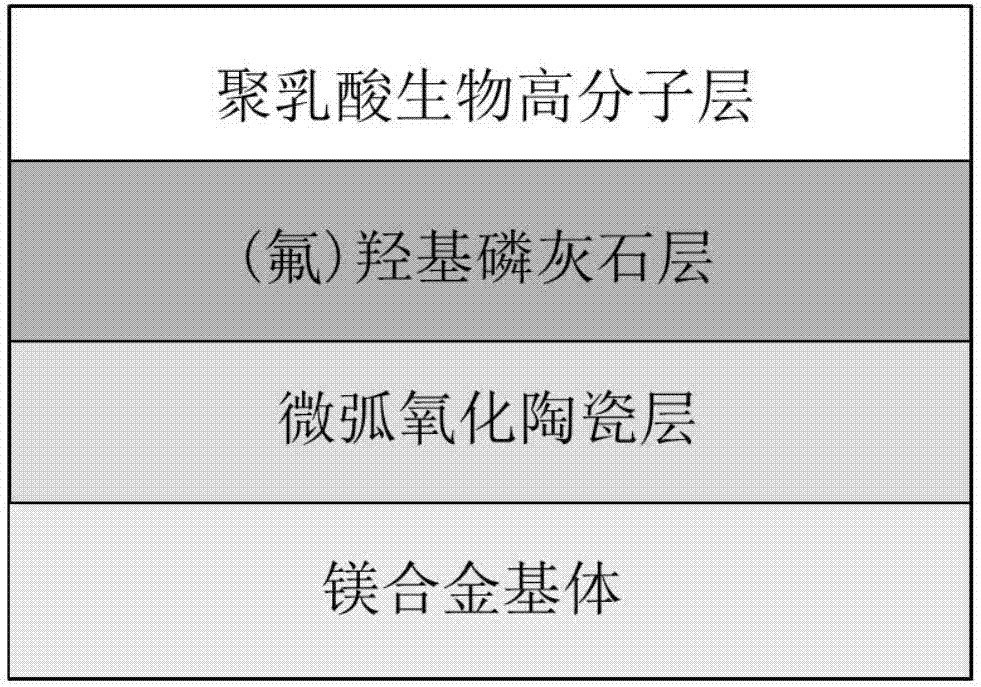

Magnesium alloy implant composite material and preparation method and application thereof

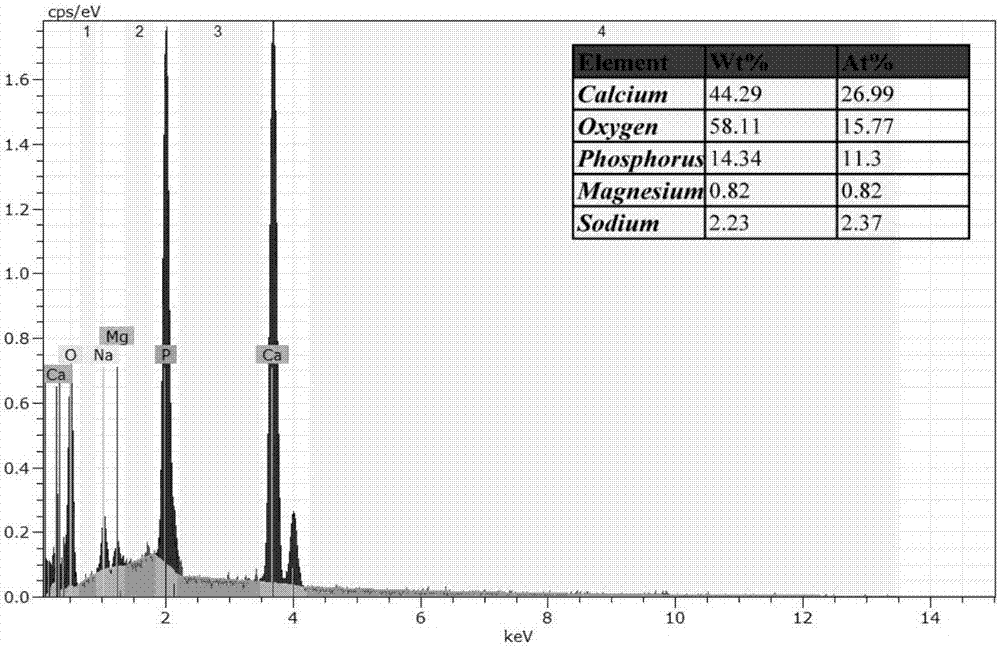

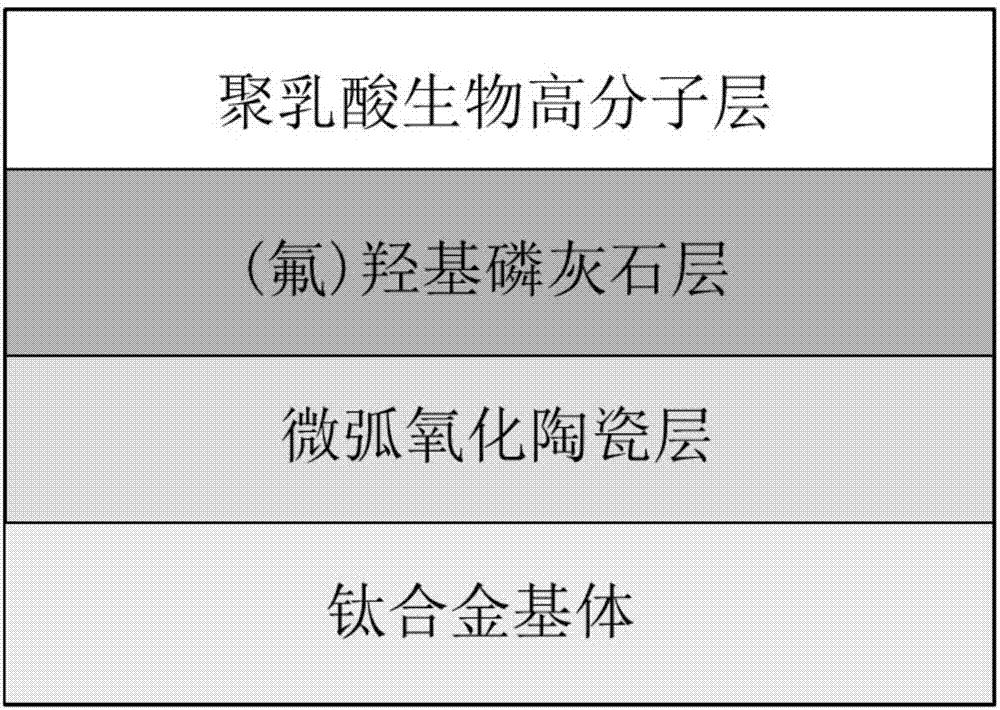

InactiveCN106902391AHigh structural precisionGood biocompatibilityAnodisationDetails involving processing stepsPlasma electrolytic oxidationMicro arc oxidation

The invention discloses a magnesium alloy implant composite material and a preparation method and application thereof. The magnesium alloy implant composite material is prepared by the following steps of: by taking a model manufactured from magnesium alloy powder through 3D printing as a magnesium alloy implant substrate, forming a micro-arc oxidation layer on the surface of the magnesium alloy implant substrate through a micro-arc oxidation method; then forming a hydroxyapatite layer or a hydroxyfluorapatite layer on the surface of the micro-arc oxidation layer by means of an electrochemical deposition method; and finally, immersing the surface of the hydroxyapatite layer or the hydroxyfluorapatite layer to form a polylactic acid layer. According to the material provided by the invention, individual development of the magnesium alloy implant material is realized from data acquisition of an original damaged bone structure to preparation of a final multi-coating composite material, so that the high quality magnesium alloy implant composite material is obtained. A polarizing test shows that the anti-corrosive property of the material can be enhanced by four orders of magnitudes, and osteoblast cultivation shows that the magnesium alloy composite material has a better osteocyte promoting ability.

Owner:ZHEJIANG UNIV OF TECH

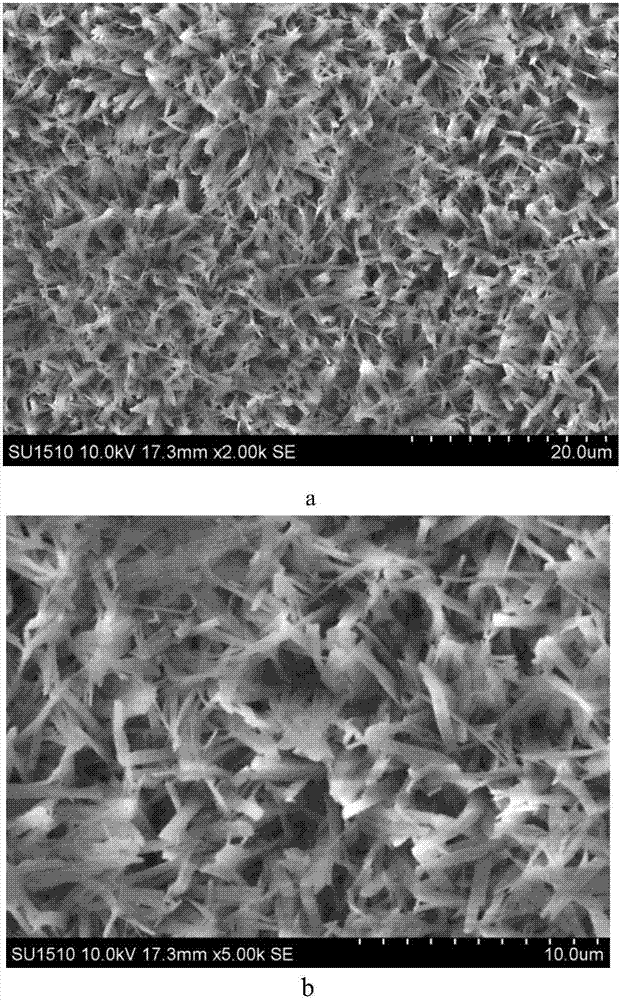

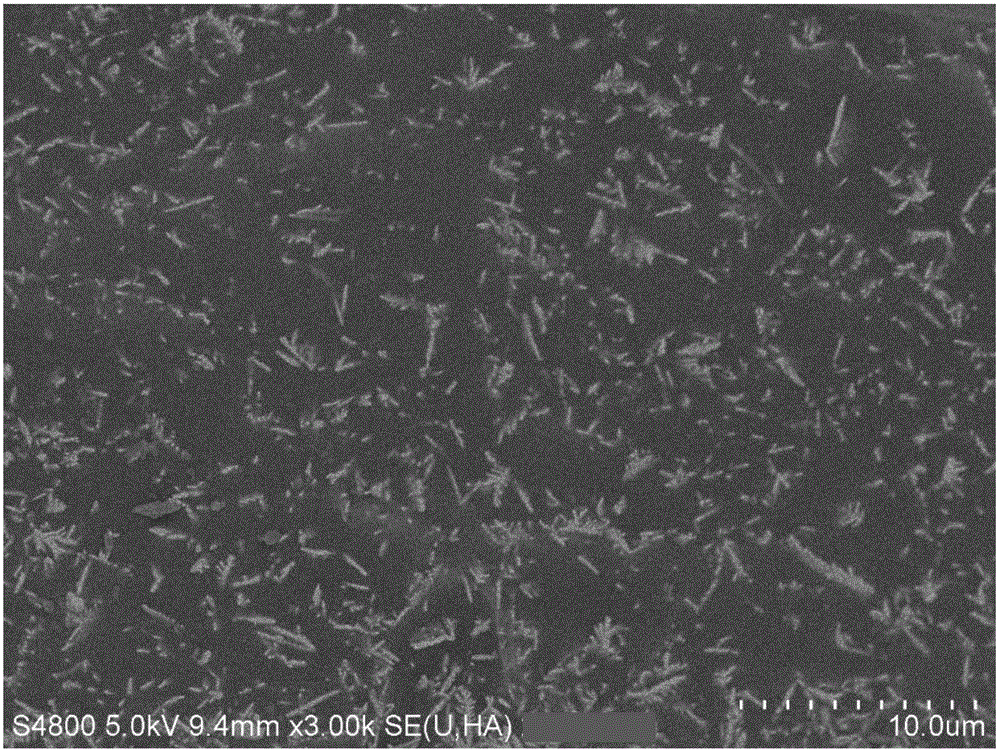

Preparation method of titanium surface multilevel porous structure

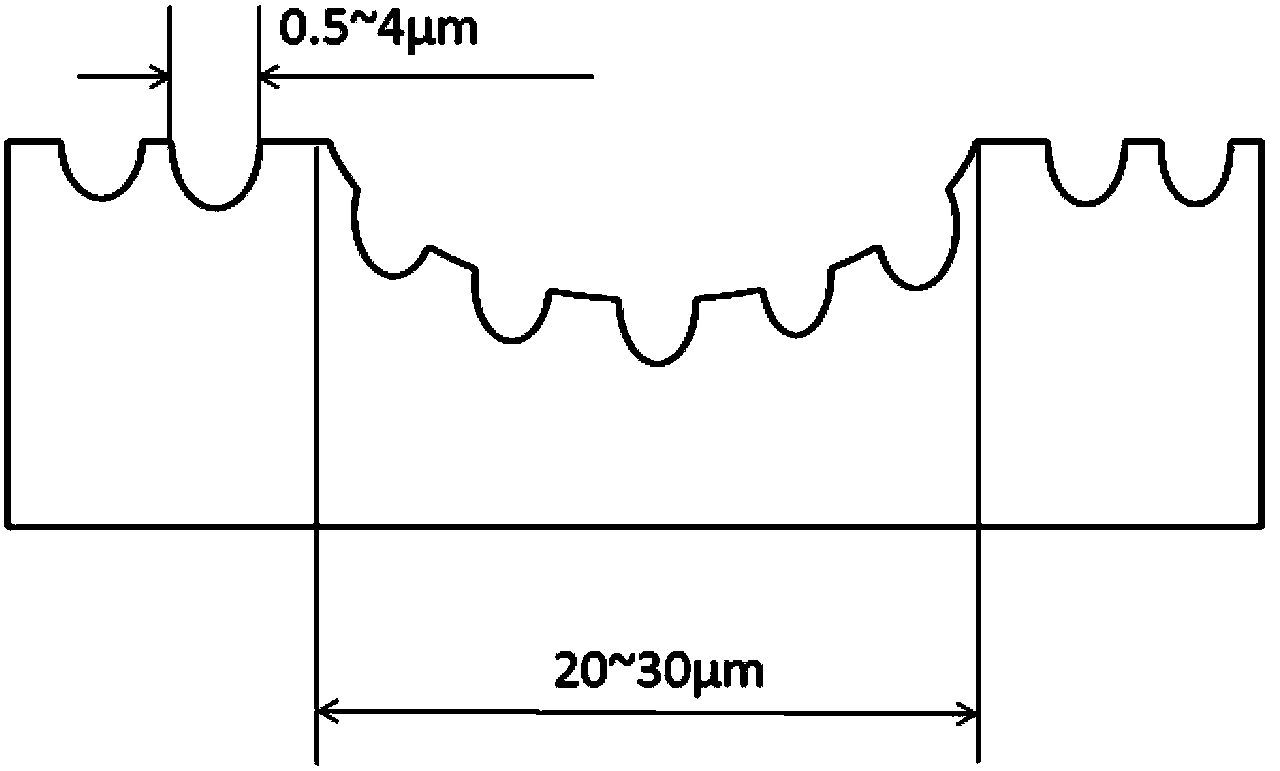

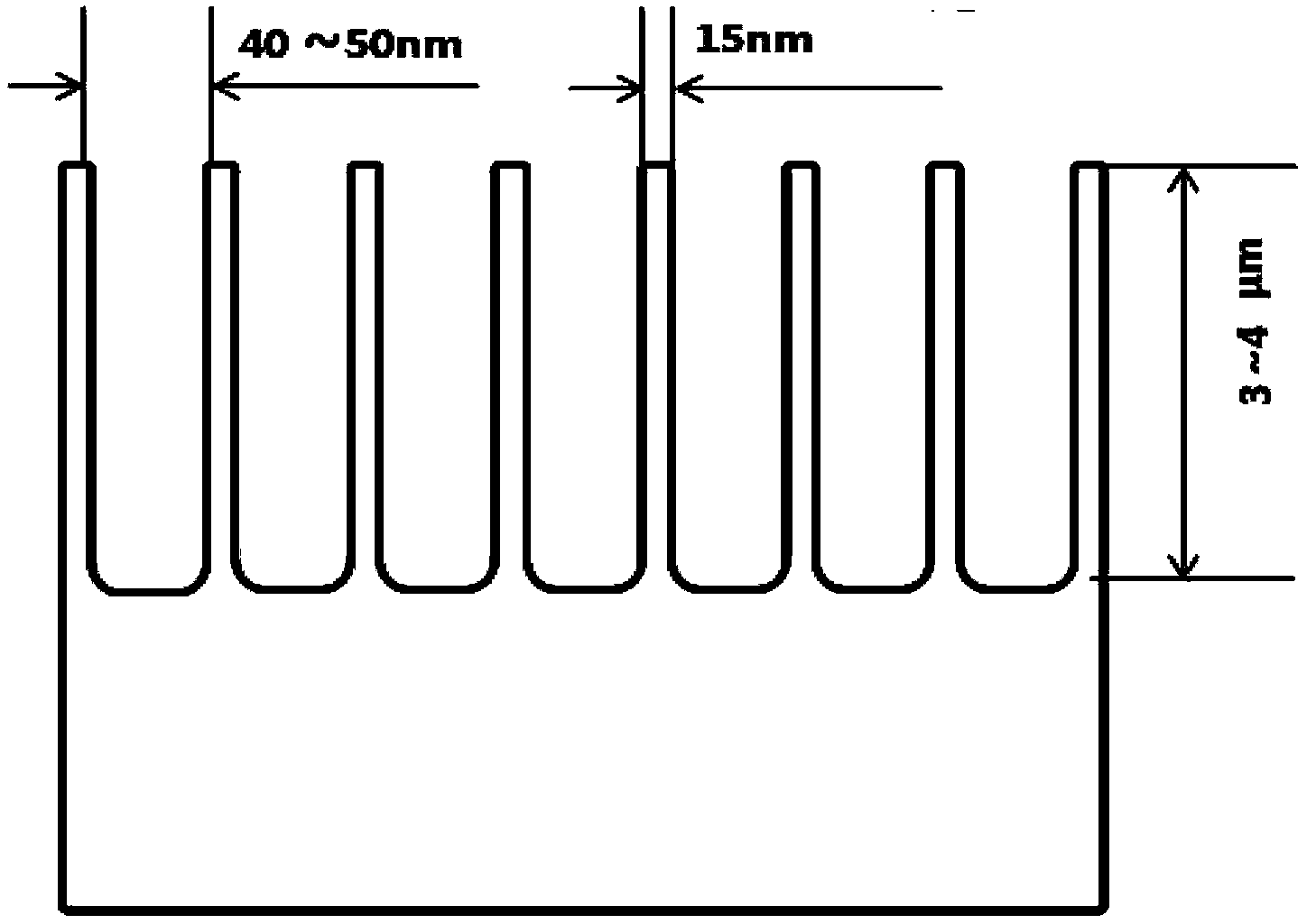

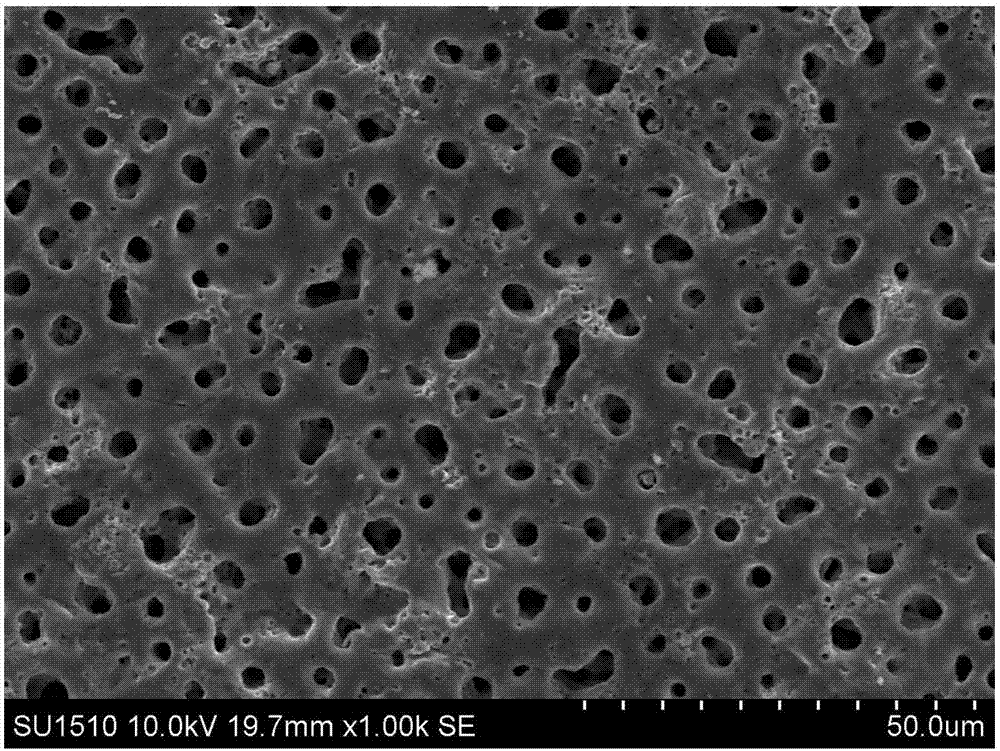

InactiveCN103361703AIncrease roughnessHigh adsorption rateSurface reaction electrolytic coatingTitanium alloyMedical treatment

In order to solve the problems that existing titanium and titanium alloys have low bioactivity and low bonding strength with bone tissues, the invention relates to a preparation method of a titanium surface multilevel porous structure. The method comprises: 1. polishing a titanium material by 240-mesh, 600-mesh and 1000-mesh metallographical sandpaper hierarchically, then performing ultrasonic cleaning with acetone and alcohol in order at room temperature, and conducting drying so as to obtain a treated titanium material; 2. carrying out sand blasting treatment with aluminum oxide particles; 3. soaking the titanium material subjected to the sand blasting treatment in a sulfuric acid solution; 4. taking the acid-etched titanium material as the anode, and taking platinum as the cathode, placing them in an NH4F aqueous solution, and conducting anodic oxidation treatment, thus obtaining the anode oxidized titanium material; and 5. cleaning the anode oxidized titanium material with an NaOH solution, deionized water and anhydrous ethanol, and performing drying, thus obtaining the titanium surface multilevel porous structure with high bioactivity and high bonding strength with bone tissues. The method provided in the invention is applied in the biomedical field.

Owner:HARBIN INST OF TECH

Titanium alloy implant composite material and preparation and application thereof

InactiveCN106902390AHigh structural precisionGood biocompatibilityImage enhancementDetails involving processing stepsBone structureMicro arc oxidation

The invention discloses a titanium alloy implant composite material and preparation and an application thereof. The titanium alloy implant composite material is prepared by the following steps of: by taking a model manufactured from titanium alloy powder through 3D printing as a titanium alloy implant substrate, forming a micro-arc oxidation layer on the surface of the titanium alloy implant substrate through a micro-arc oxidation method; then forming a hydroxyapatite layer or a hydroxyfluorapatite layer on the surface of the micro-arc oxidation layer by means of an electrochemical deposition method; and finally, immersing the surface of the hydroxyapatite layer or the hydroxyfluorapatite layer to form a polylactic acid layer. According to the material provided by the invention, individual development of the titanium alloy implant material is realized from data acquisition of an original damaged bone structure to preparation of a final multi-coating composite material, so that the high quality titanium alloy implant composite material is obtained. A polarizing test shows that the anti-corrosive property of the material can be enhanced by 2-3 orders of magnitudes, and osteoblast cultivation shows that the titanium alloy composite material has a better osteocyte promoting ability.

Owner:ZHEJIANG UNIV OF TECH

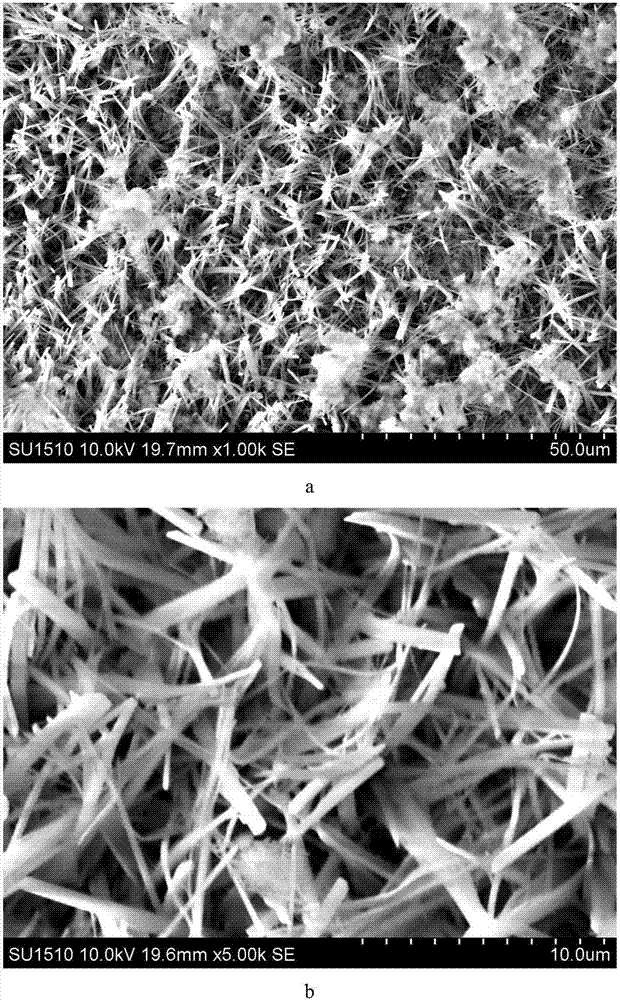

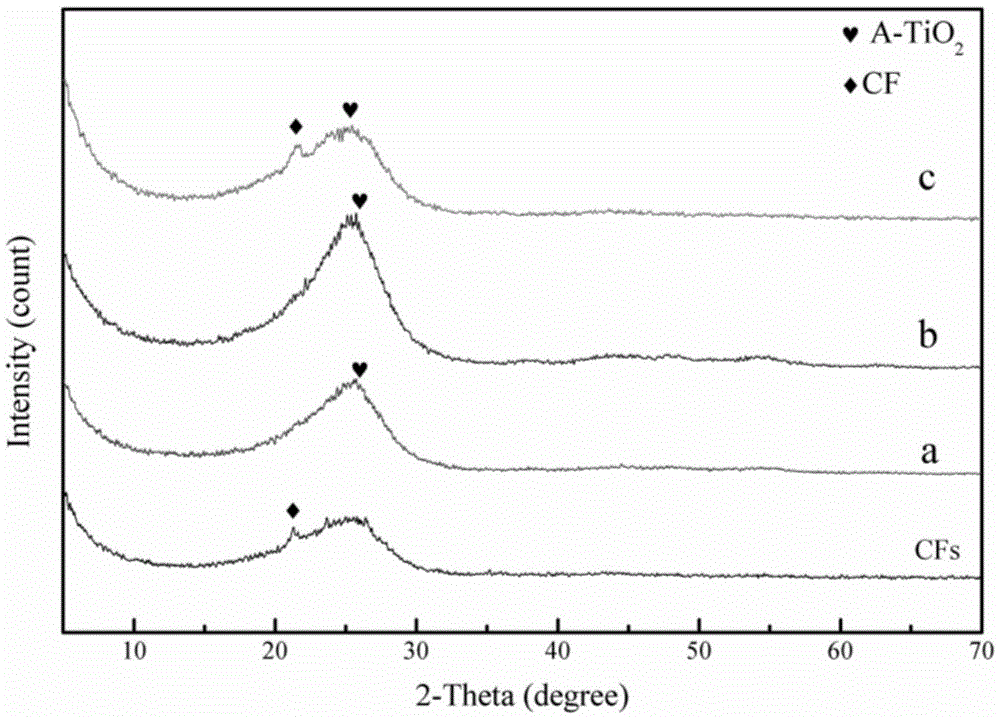

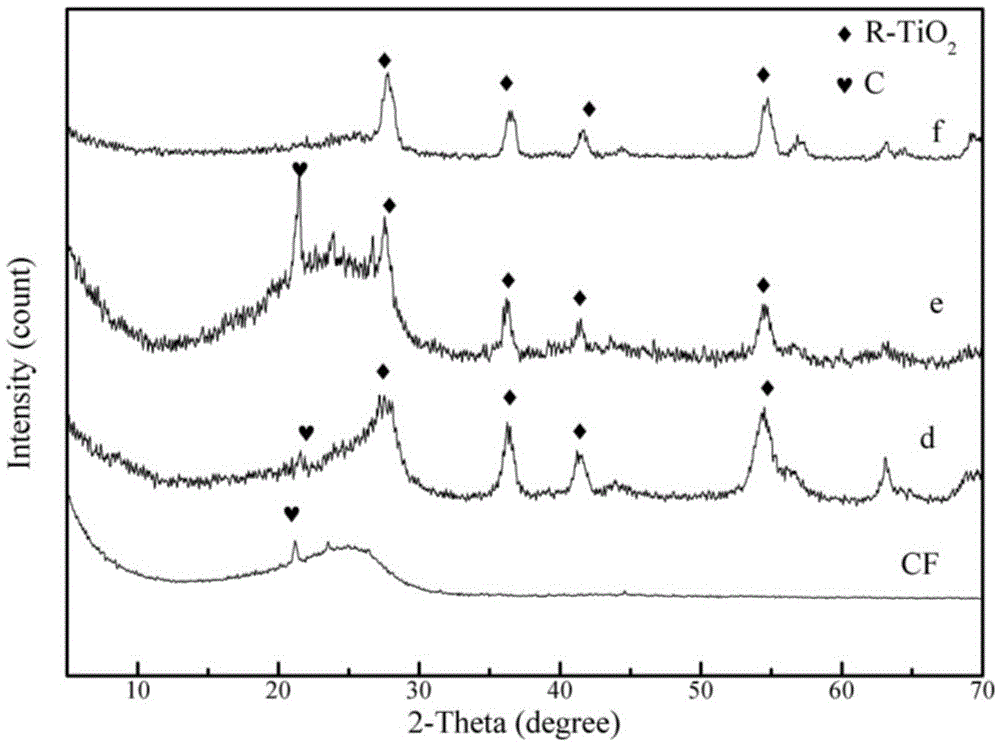

Preparation method of titanium-dioxide-modified carbon-fiber-reinforced resin-base composite material

The invention discloses a preparation method of a titanium-dioxide-modified carbon-fiber-reinforced resin-base composite material. The preparation method comprises the following steps: pretreating carbon fibers with concentrated nitric acid under certain conditions, and carrying out hydrothermal reaction on the pretreated carbon fibers and a titanium source in a water solution using concentrated hydrochloric acid as an acidic medium; and after the reaction finishes, sufficiently washing the modified fibers, drying, and preparing the reinforced resin-base composite material by using the modified carbon fibers as reinforcing fibers. The tensile strength of the modified carbon-fiber-reinforced resin-base composite material is enhanced by 134.8-153.1%; the porosity is reduced from 45.7-40.5% to 19.3%-15.6%; the pore size distribution is uniform; and the friction factor of the reinforced resin-base composite material is kept at 0.12-0.14, and the abrasion loss is lowered by 37.1-50.3%, thereby sufficiently embodying the excellent friction reduction action of the modified carbon fibers applied to a wet friction material.

Owner:SHAANXI UNIV OF SCI & TECH

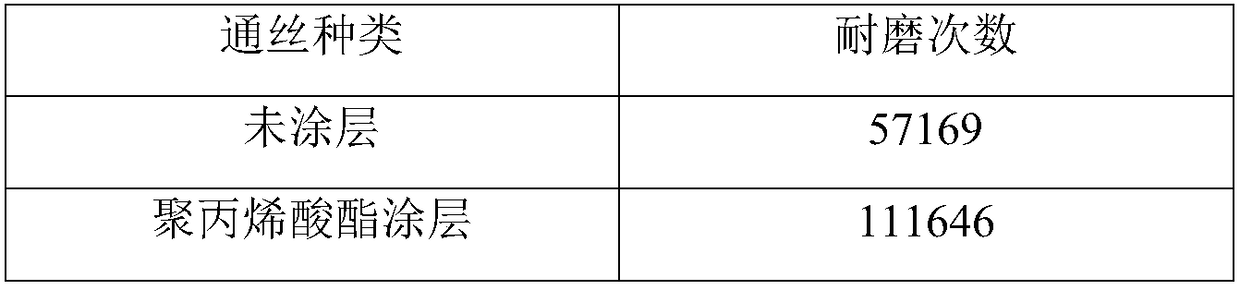

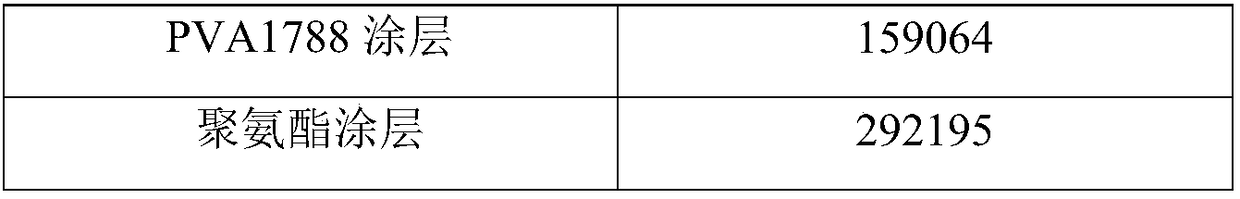

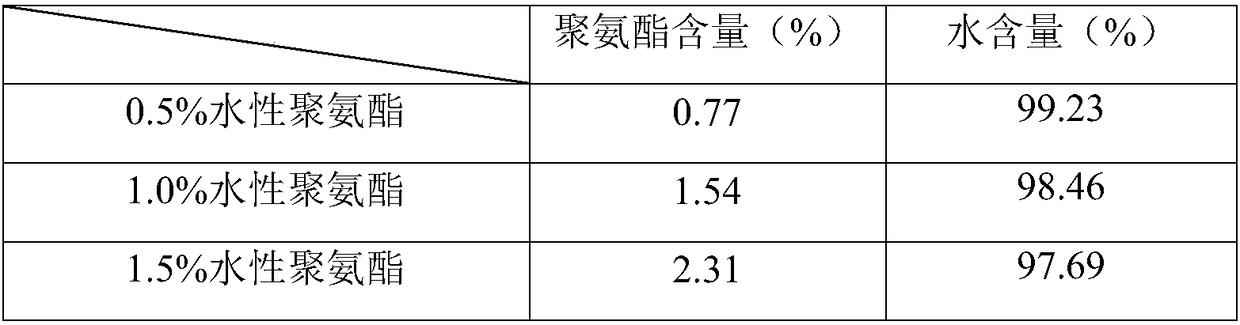

Coating method capable of improving wear resistance of polyester harness cord

ActiveCN108221389AGood film formingImprove permeabilityJacquardsAbrasion resistant fibresPolyesterSolubility

The invention relates to a coating method capable of improving wear resistance of a polyester harness cord. The method comprises the following steps: waterborne polyurethane size is taken as coating size, the pretreated polyester harness cord is impregnated in the coating size for padding, then drying and heat setting are performed, and the coated polyester harness cord is obtained; or the waterborne polyurethane size is taken as pre-applied primer size, another size is taken as the coating size, the pretreated polyester harness cord is impregnated in the pre-applied primer size for padding, and drying is performed; then the polyester harness cord is impregnated in the coating size for padding, drying and heat setting are performed, and the coated polyester harness cord is obtained. Selected waterborne polyurethane is safe, non-toxic and good in film forming property, the solubility parameter of waterborne polyurethane is close to that of polyester, and waterborne polyurethane has excellent adhesion and can effectively improve the adhesion effect between other coatings and polyester fibers; permeability of the polyester harness cord is good, coated property is good, and a uniform coating which is smooth, soft, not prone to yellowing and is resistant to wear, heat and light can be formed on the surface of the polyester harness cord.

Owner:DONGHUA UNIV

Method for performing surface modification on metal by ultrasonic nano-welding

ActiveCN102500912ATake full advantage of enhancementsGood interface wettabilityNon-electric welding apparatusMechanical bondMetal substrate

The invention relates to a method for performing surface modification on a metal by ultrasonic nano-welding and belongs to the technical field of nanomaterials. The method comprises the following steps: cleaning a to-be-treated region of the surface of the metal, coating a nanopowder material on the metal surface after cleaning, and performing ultrasonic nano-welding process on the nanopowder material on the metal surface to obtain a modified metal surface. The method is simple to operate and has controllable welding parameters. The nanomaterial and the welding region of the metal substrate form a local miscible body, leading to good interface infiltration, which enhances mechanical bonding effect and gives full play to reinforcement function of the nanomaterial. The nanomaterial is distributed densely and uniformly on the metal surface, and the surface is smooth and clean and has no cracks or air hole.

Owner:SHANGHAI JIAO TONG UNIV

Method for improving field emission performance of carbon nano tube film

InactiveCN101615544AGood adhesionReduce contact resistanceNanostructure manufactureCold cathode manufactureCarbon nanotubeNanometre

A method for improving field emission performance of a carbon nano tube film in the technical field of nano materials comprises the following steps: plating a metal thin film on a plane substrate; depositing the carbon nano tube film on the metal film; carrying out ultrasound nano welding on the metal film and the carbon nano tube film, thus obtaining the carbon nano tube film with improved field emission performance. The method of the invention forms excellent mechanical and electric contact between the carbon nano tube film and the metal film, thus obtaining a field emission component with low starting electric field, large emission current density and good current stability.

Owner:SHANGHAI JIAO TONG UNIV

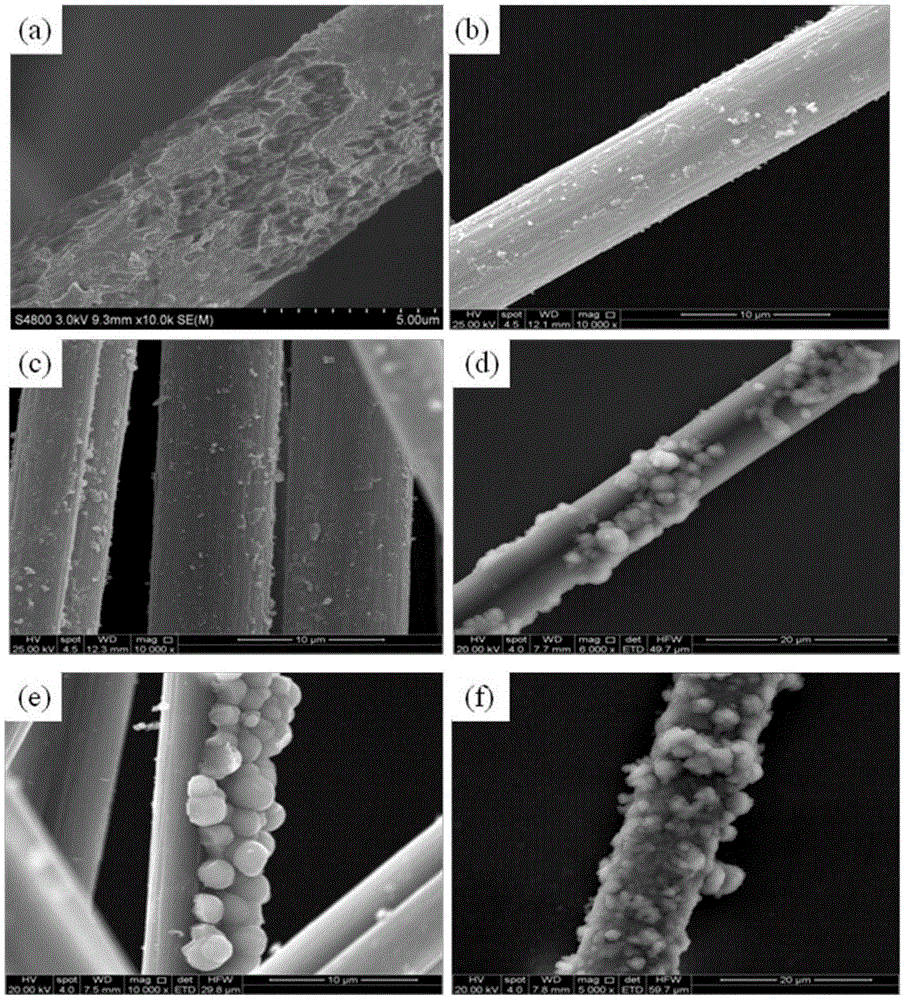

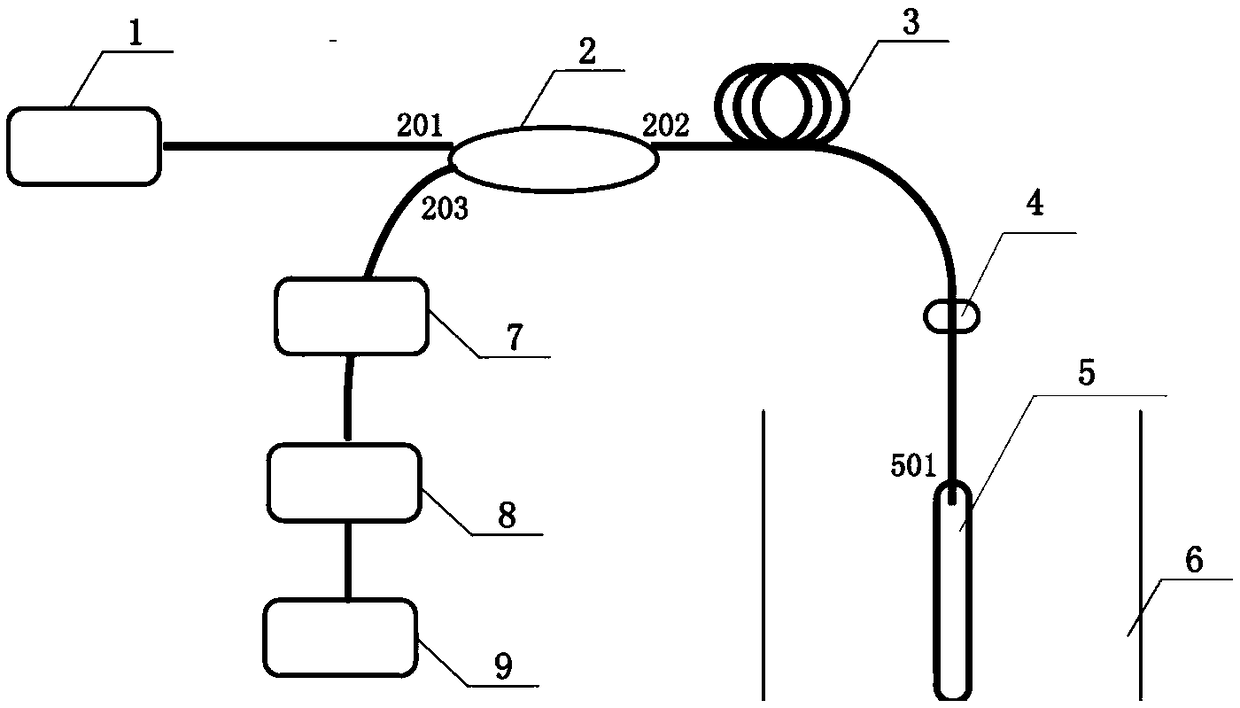

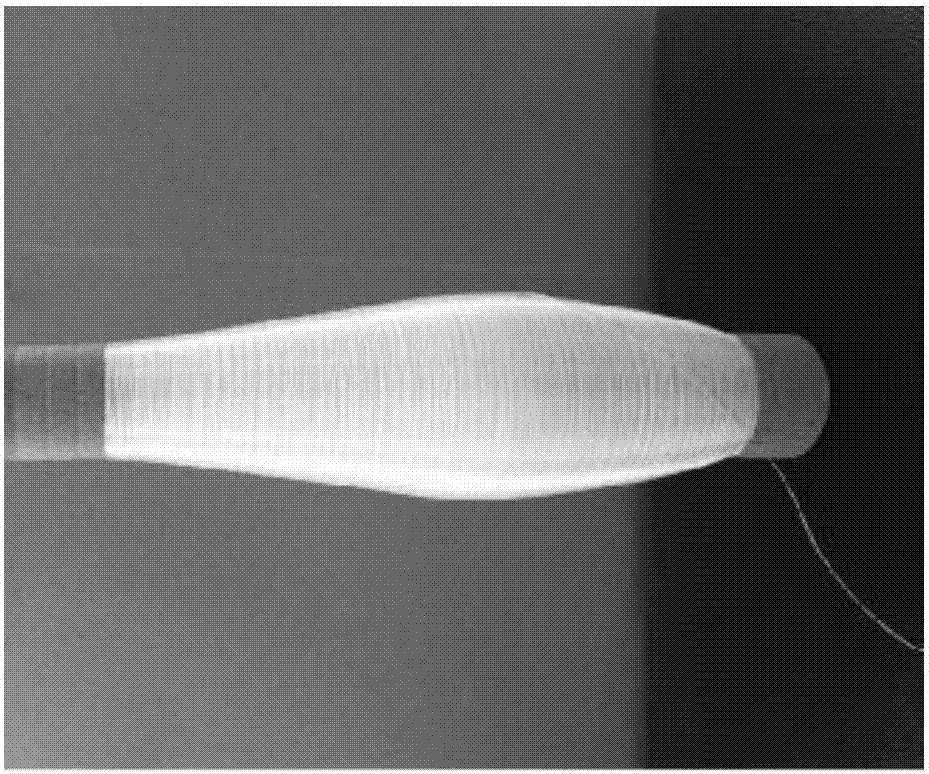

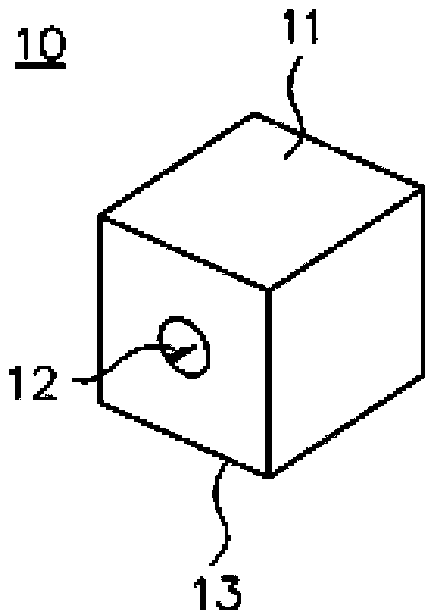

Hydrogel fiber based on luminescent MOFs (Metal organic Frameworks), preparation method therefor and sensing device

PendingCN109211859AGood light guideImprove permeabilityFluorescence/phosphorescencePigtailMetal-organic framework

The invention discloses a hydrogel fiber based on luminescent MOFs, a preparation method therefor and a sensing device. The preparation method comprises the following steps of: uniformly mixing MOFs microcrystal grains into hydrogel precursors; injecting the hydrogel precursors into a coaxial double barrel; extruding a core-package structure cylinder with suitable size from the outlet of the barrel by an extrusion method or a biomaterial 3D printer; inserting one end of a common quartz fiber coaxially into the side core layer of the core-package structure cylinder; and obtaining the hydrogel fiber with a common fiber pigtail after curing. The sensing device comprises an excitation light source, a Y-type fiber, a delay fiber, a fiber connection, a hydrogel fiber, a long pass filter, a fluorescence spectrometer, and a signal processing unit. According to the overall technical scheme, high-selectivity fluorescence sensing of all-fiber can be constructed and realized, and in situ, real-time, remote and even living body fluorescence detection and sensing are realized, and the sensing applicability of the luminescent MOFs material is improved.

Owner:SOUTH CHINA UNIV OF TECH

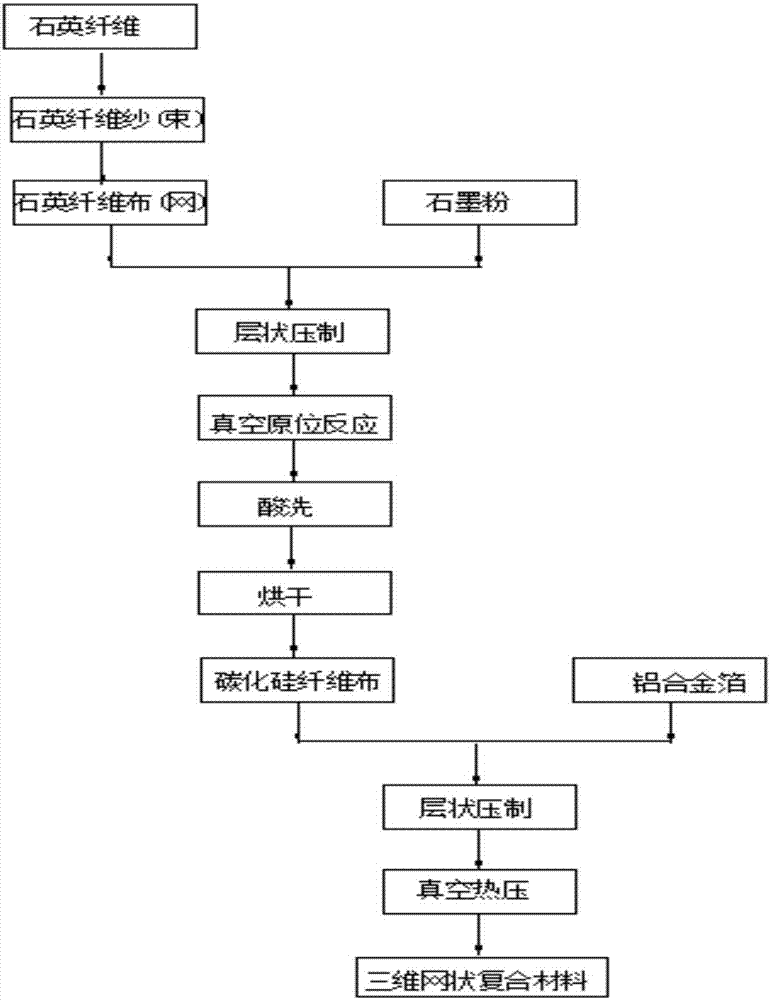

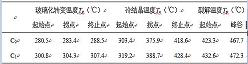

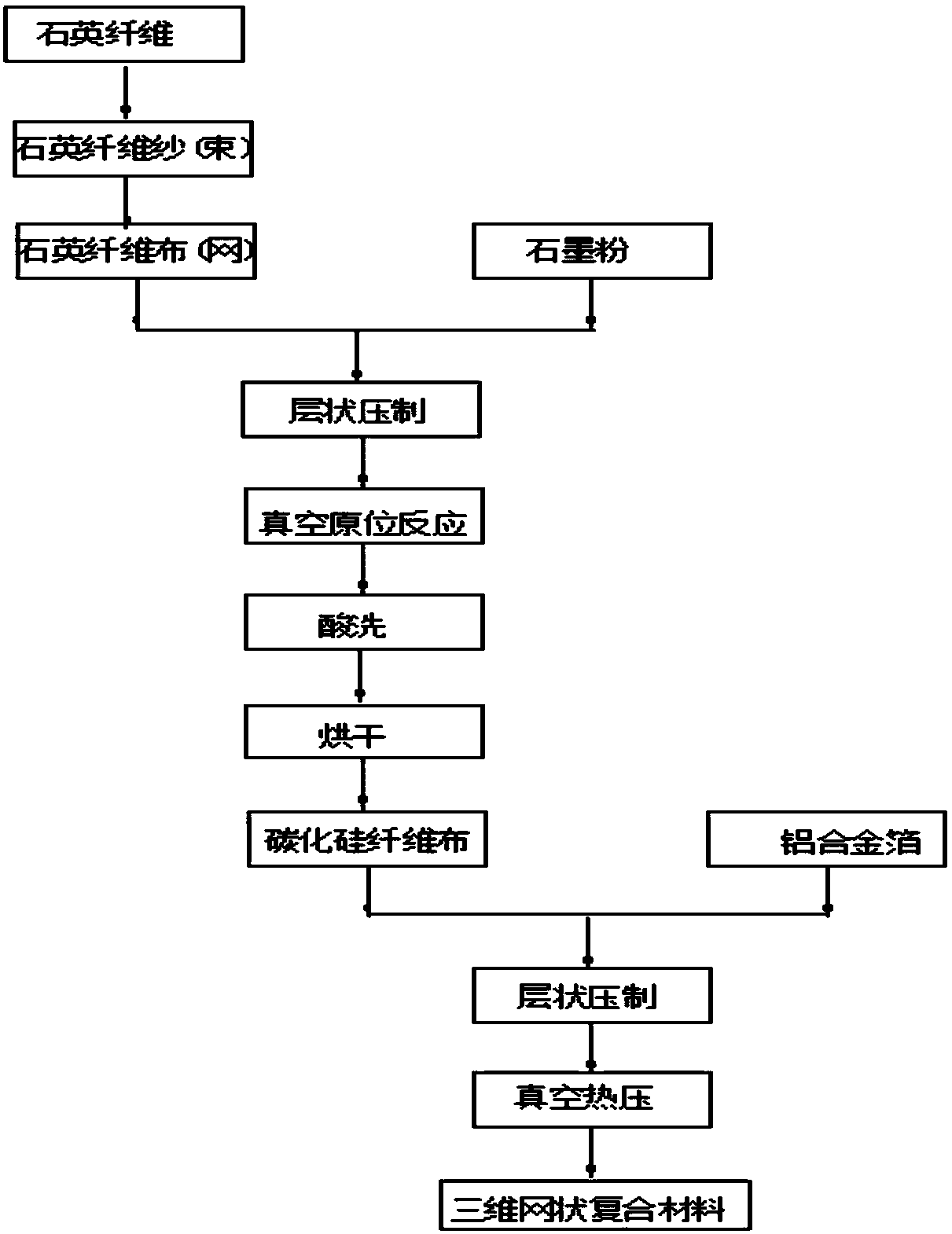

Preparation method for silicon carbide fiber bundle enhanced aluminum matrix composite

ActiveCN107513675AReduce preparation energy consumptionSimple preparation stepsFiber bundleThermal expansion

The invention discloses a preparation method for a silicon carbide fiber bundle enhanced aluminum matrix composite. Quartz fiber bundles are adopted to be woven into fiber cloths, the fiber cloths and graphite powder are pressed in a layered mode to form silicon carbide fiber cloths, aluminum or an aluminum alloy foil and the silicon carbide fiber cloths are subjected to layered alternate overlapping, a prefab before composite pressing and sintering is obtained, the prefab is subjected to pressing, sintering and cooling, and a filament silicon carbide fiber bundle net-shaped enhanced aluminum matrix composite is obtained. The volume fraction of silicon carbide fiber in the prepared silicon carbide fiber bundle net-shaped enhanced aluminum matrix composite is 50-60%. The compactness of the composite is 95.5-98.7%, the density is 2.80-2.90 g / cm<3>, the anti-bending elasticity modulus is 109-136 Gpa, the heat conductivity of the composite is high and not less than 170 W / (m.K), and the coefficient of thermal expansion is (8.5-12.5)x10<-6> / K and adjustable. Compared with a current used aluminum silicon carbide composite, the heat conductivity is high, the volume fraction of an enhancesome SiC is large, and the cost of the silicon carbide fiber bundle enhanced aluminum matrix composite is lower than the cost of an aluminum diamond composite.

Owner:武汉强英新材料有限公司

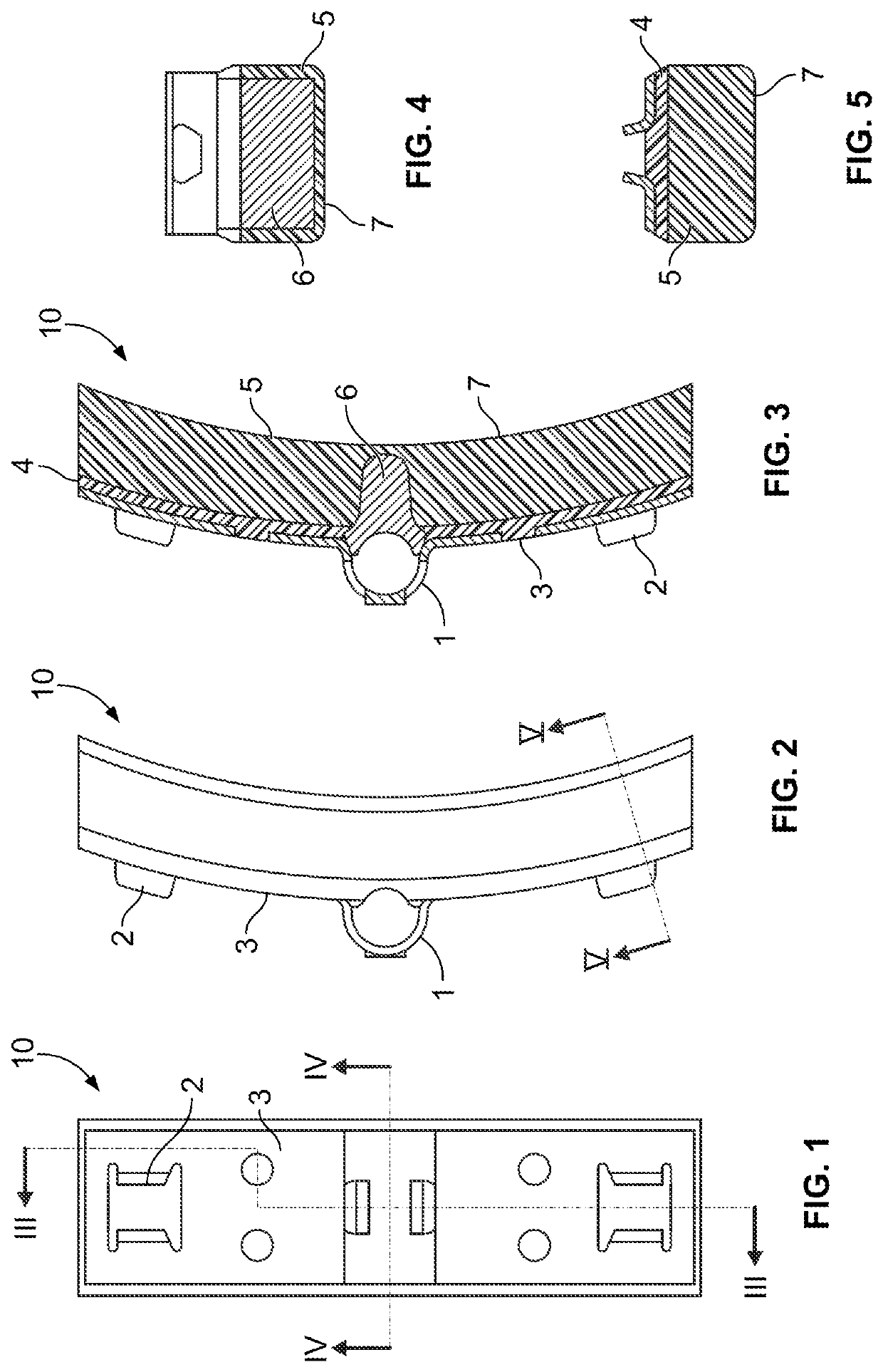

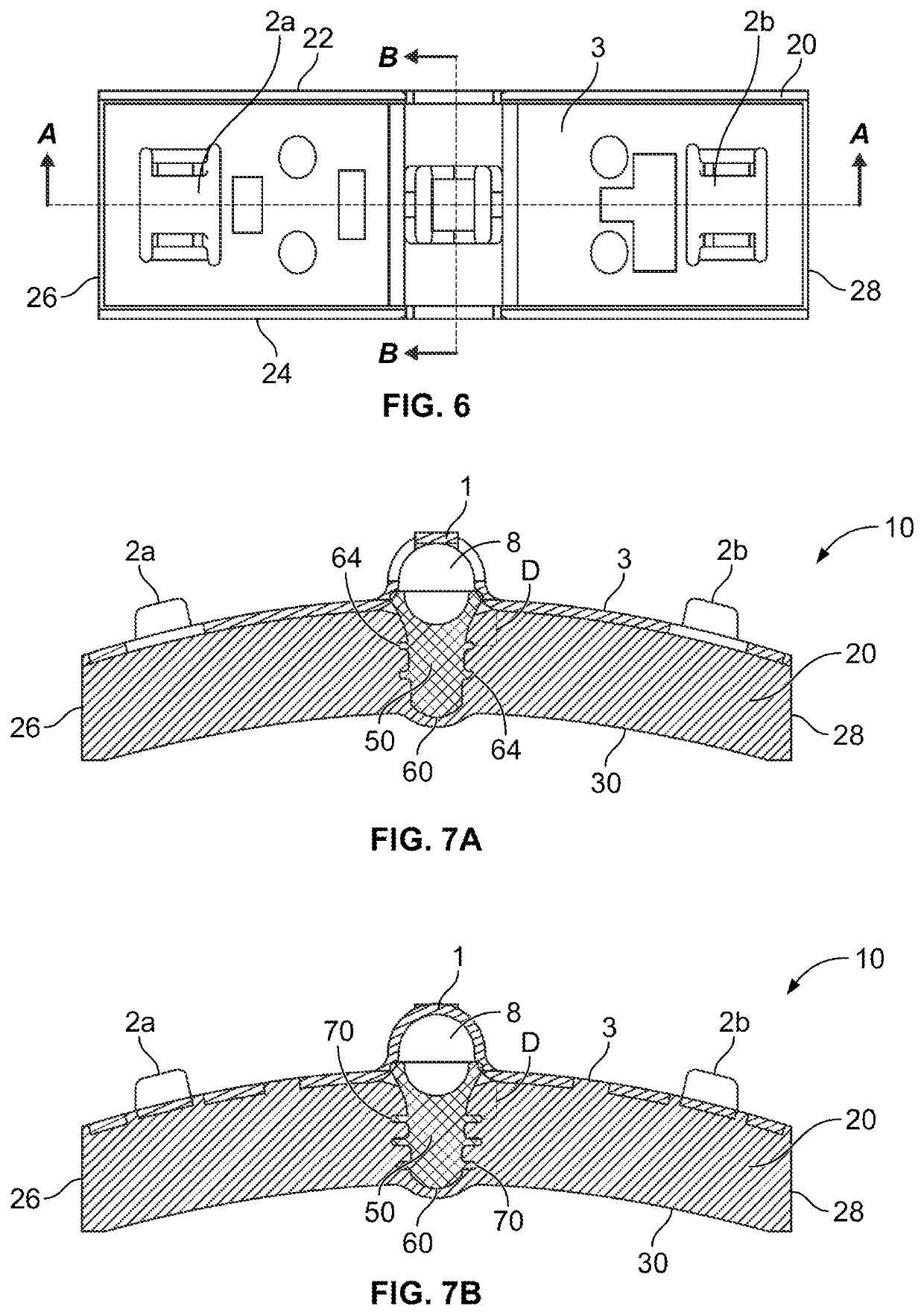

Perforated laminated polymeric foam articles

ActiveUS20110076446A1Improve adhesionEnhancing vapor transferSynthetic resin layered productsLaminationPolymer scienceAdhesive

A polymeric foam article has at least two thermoplastic polymer foams in layered orientation, each of the thermoplastic polymer foams having an adjoining surface that contains a polymer skin, a thickness dimension perpendicular to the adjoining surface, perforations that are less than one millimeter in diameter that penetrate through the adjoining surface to a depth less than the thickness dimension of the foam, where the adjoining surface of one thermoplastic polymer foam is adjacent and adhered to the adjoining surface of another thermoplastic polymer foam with an adhesive thereby affixing the thermoplastic polymer foams to one another.

Owner:DOW GLOBAL TECH LLC

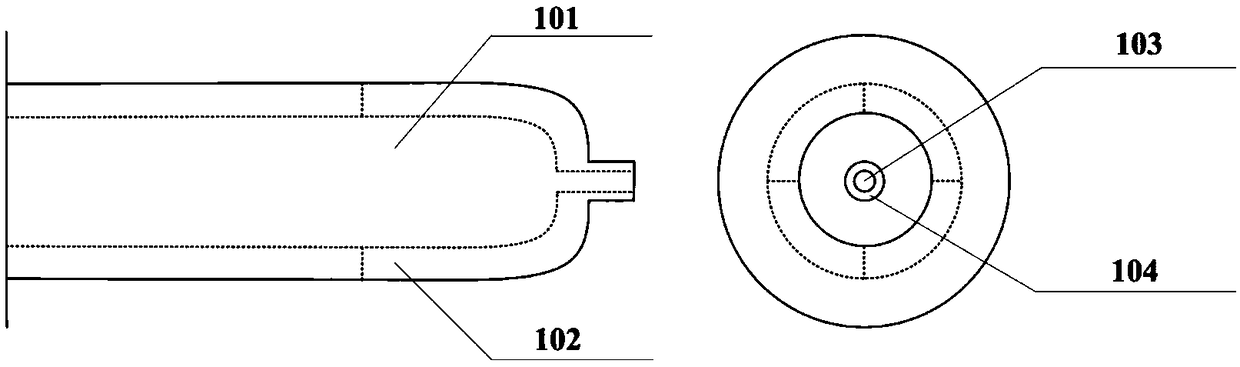

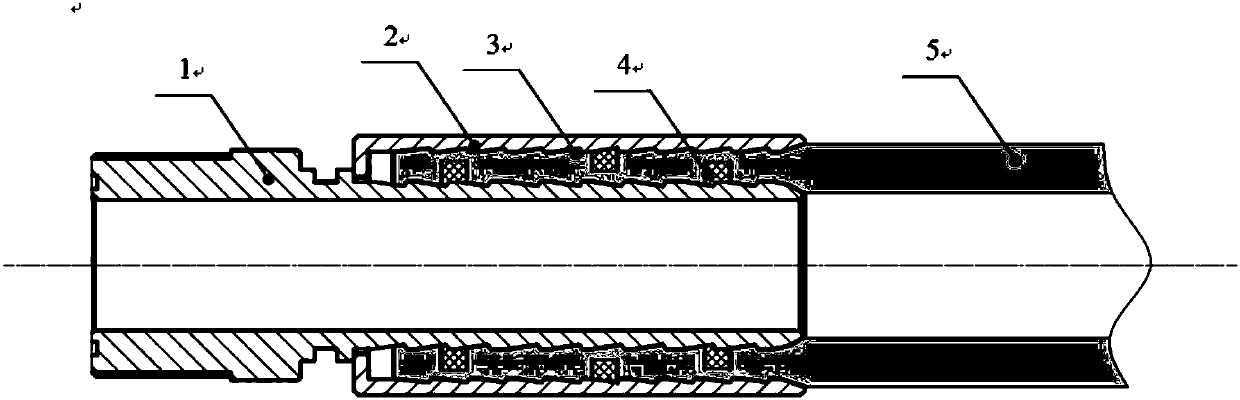

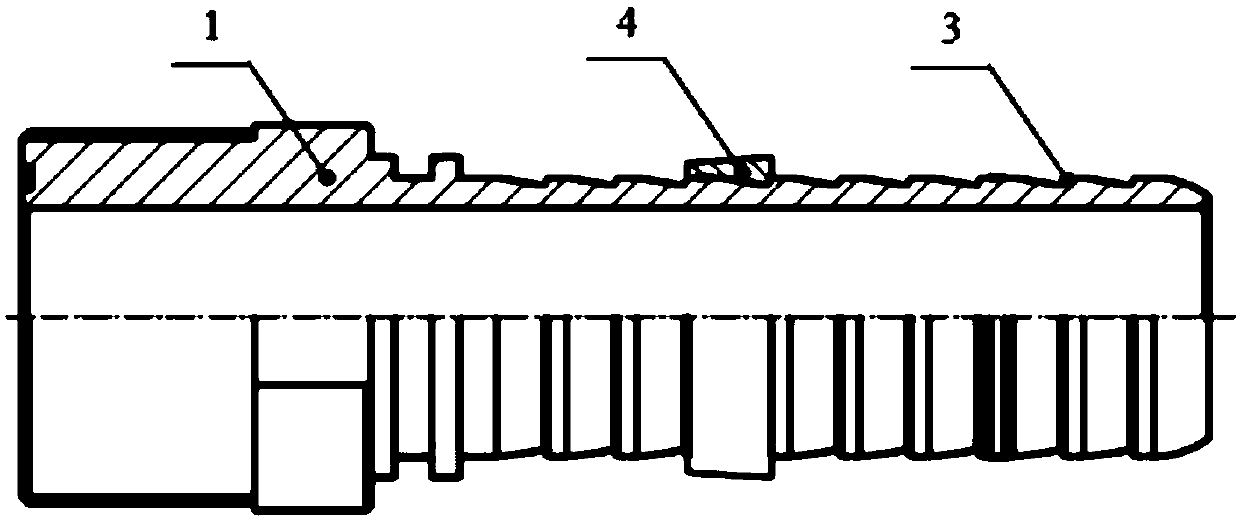

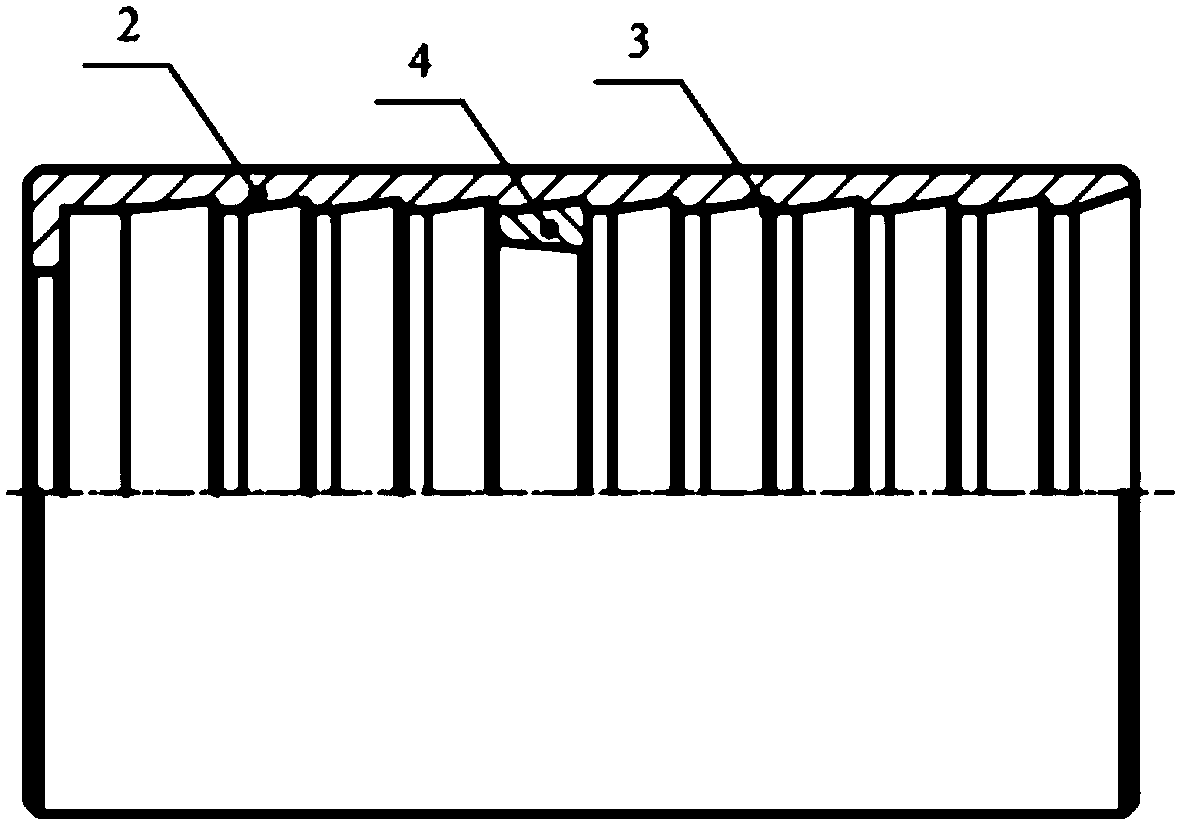

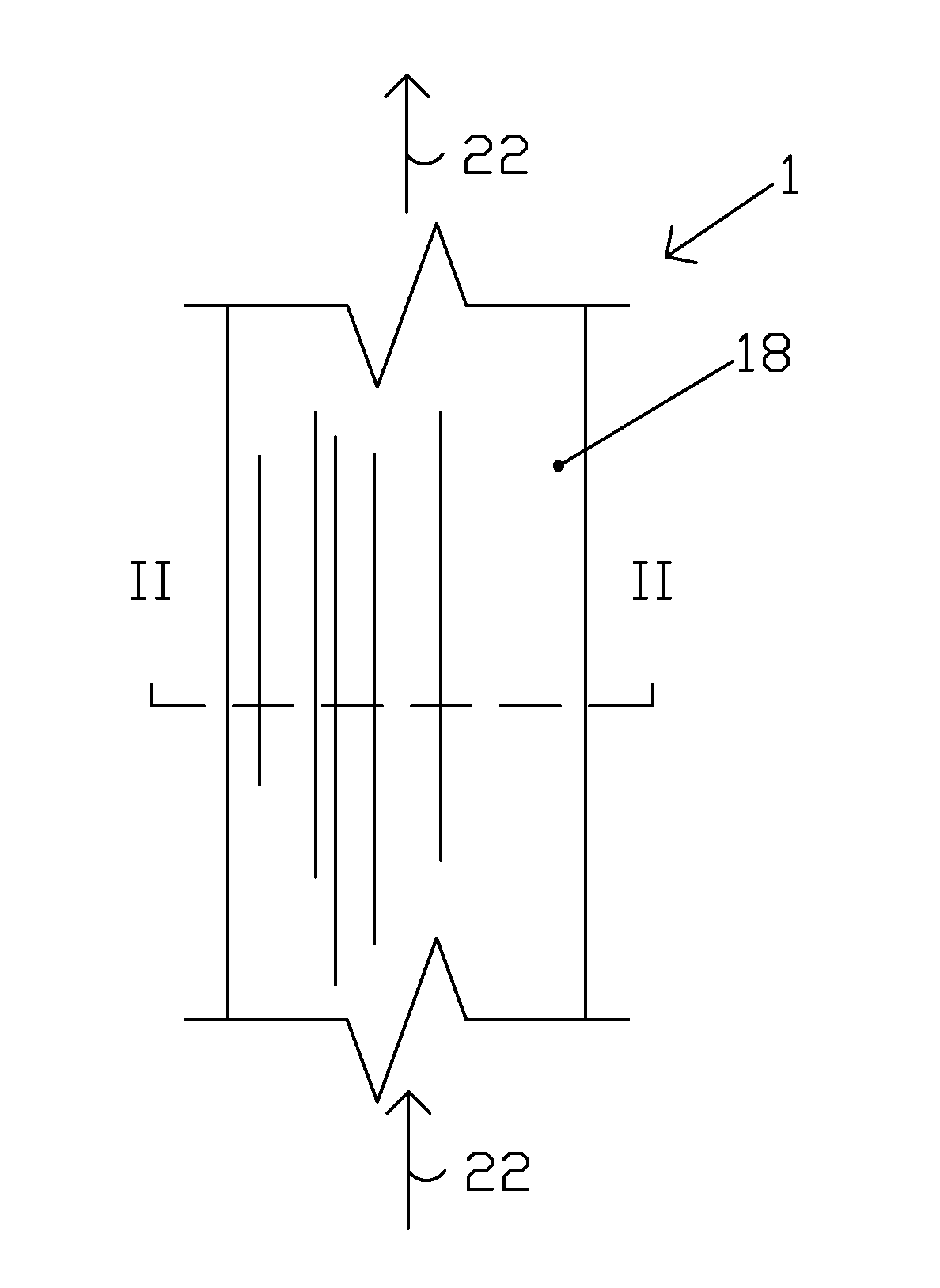

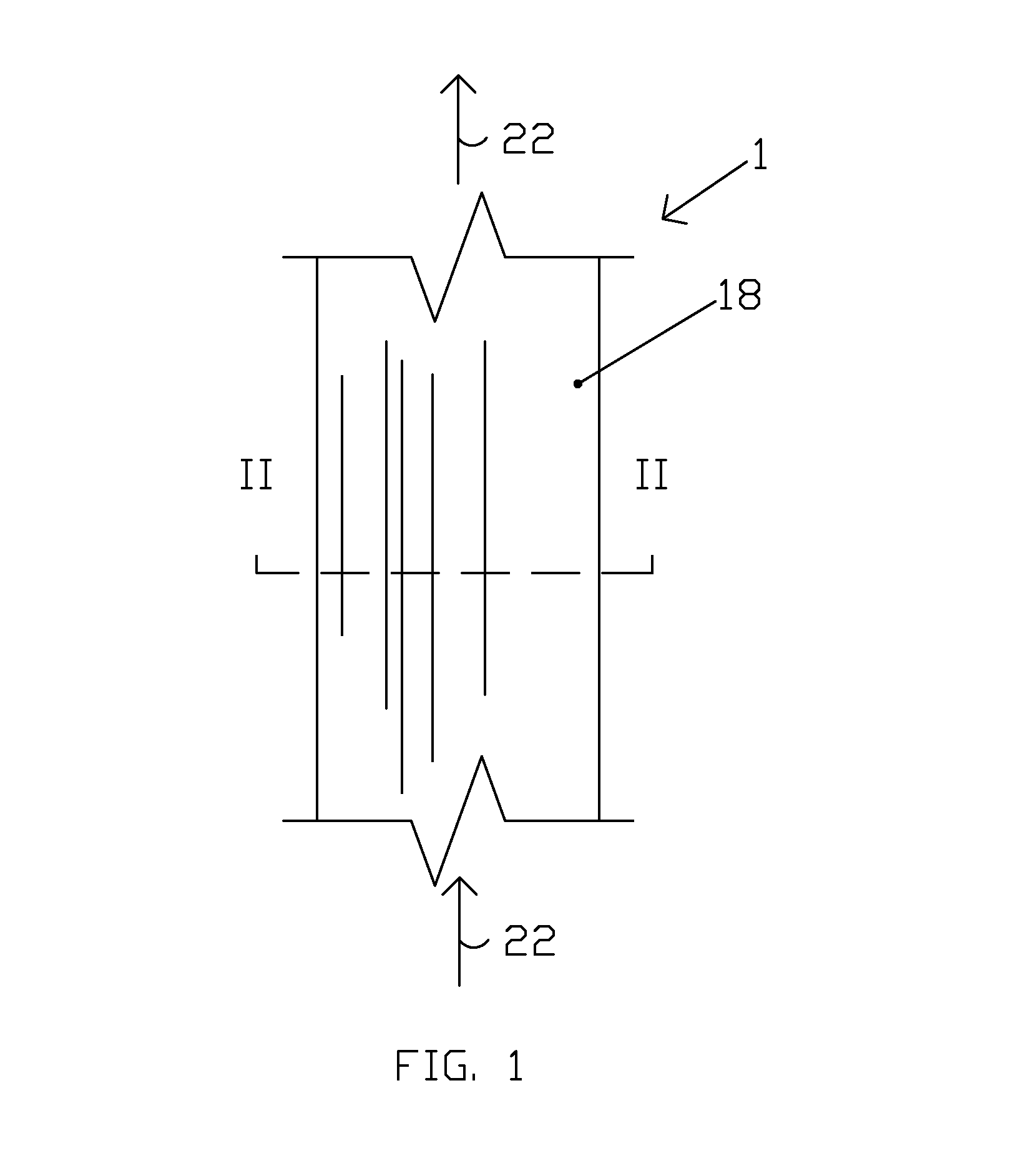

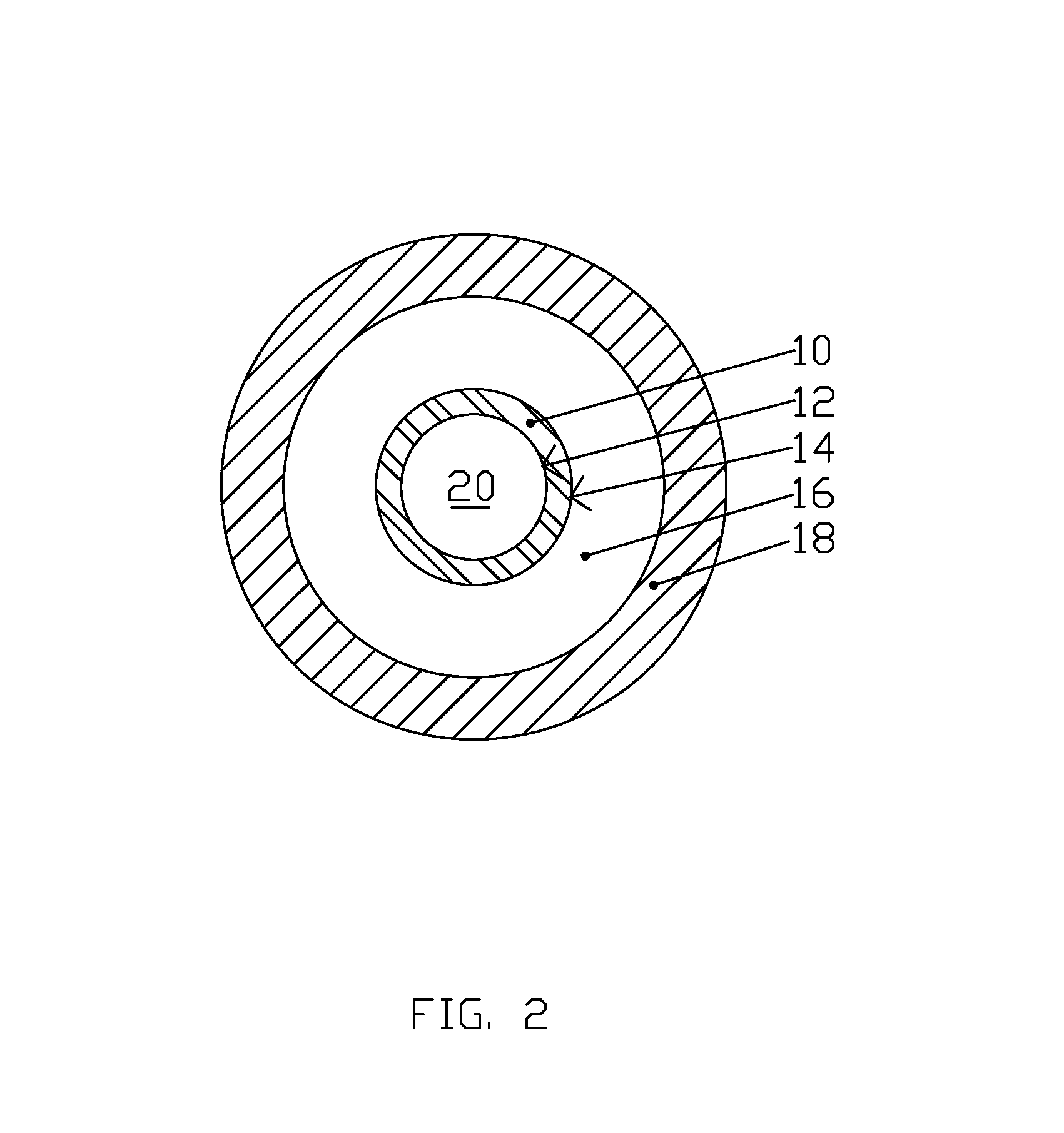

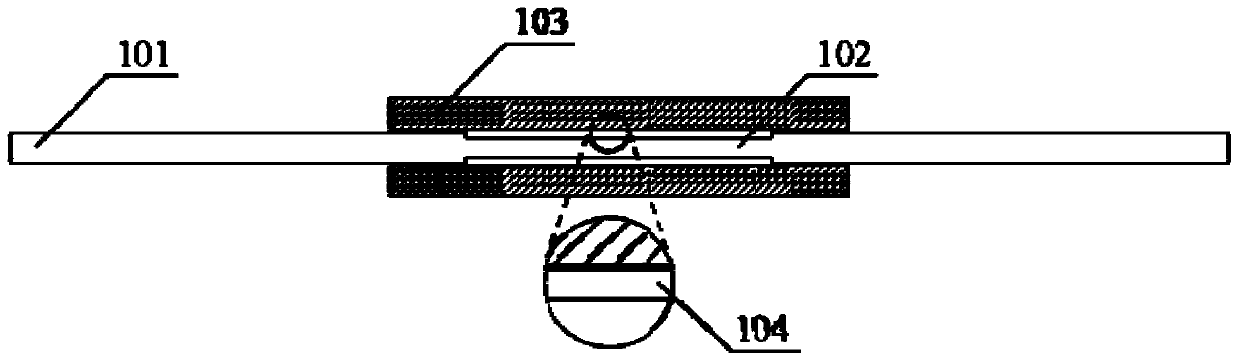

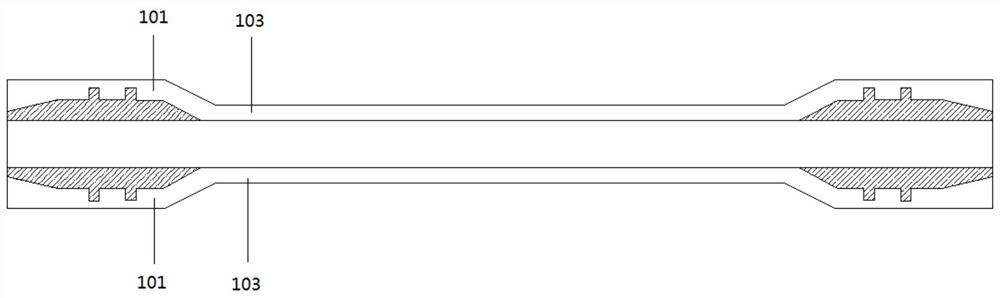

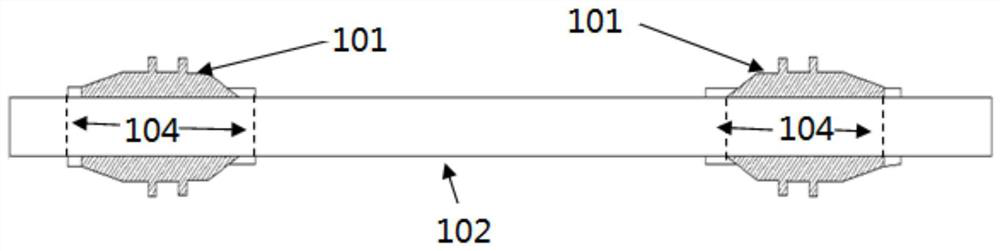

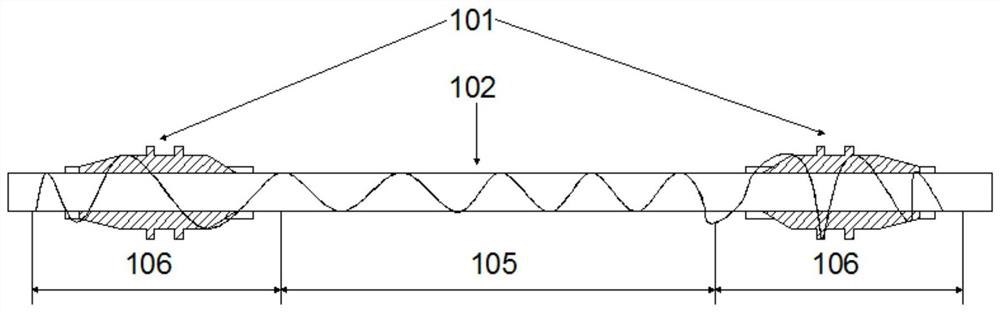

Thermoplastic composite pipe with sealing and buckling joint, and manufacturing method

ActiveCN107631118AImprove sealingImprove mechanical bondingGeneral water supply conservationPipe connection arrangementsControl engineeringShape-memory alloy

The invention discloses a thermoplastic composite pipe with a sealing and buckling joint, and a manufacturing method. The thermoplastic composite pipe comprises a buckling joint comprising a core pipe, and the outer diameter of the right side of the core pipe is smaller than the outer diameter of the left side of the core pipe; the right outer wall of the core pipe is sheathed with a casing, and the inner wall of the sleeve is provided with a sawtooth groove; the outer wall of the core pipe is provided with a sawtooth groove, and an assembly cavity is formed between the inner wall of the casing and the outer wall of the core pipe, and fit to the wall size of the composite pipe on the right side of the buckling joint; and the outer wall of the sawtooth groove in the outer wall of the core pipe and the inner wall of the sawtooth groove in the inner wall of the casing are both provided with shape memory alloy rings of which the outer walls are fit to the composite pipe, so that the mechanical binding force between the metal core pipe or the casing and the composite pipe is improved effectively, and the purpose of improving the sealing performance of the buckling joint is achieved. Themethod is simple and effective, and high in manufacturing efficiency, and additional energy consumption is not required.

Owner:TUBULAR GOODS RES INST OF CNPC +1

Ceramic coating and process for applying the same

InactiveUS20160305651A1Reduce corrosionReduce erosionLiquid surface applicatorsBoiler flue tubes/fire tubesCeramic coatingComposite ceramic

A dual color sprayed on composite ceramic coating configured and formulated to protect fireside boiler tubing while also acting as a visual inspection aid. The coating is an environmentally safe, non-reactive, water soluble composite ceramic that will withstand operating temperatures up to 2000° F. (1093° C.). This coating is ideal for fluidized bed boilers and coal fired utility boilers experiencing tube erosion, corrosion and slagging. This sprayed-on ceramic coating system allows for fast application rates reducing equipment down time. The composite ceramic coating is a high solids system that will withstand severe thermal cycling from −300° F. (−185° C.) to 1600° F. (871° C.). This composite system is applied in two distinct colors to enable easy visual inspection of coating thickness.

Owner:FIRESIDE COATINGS INC

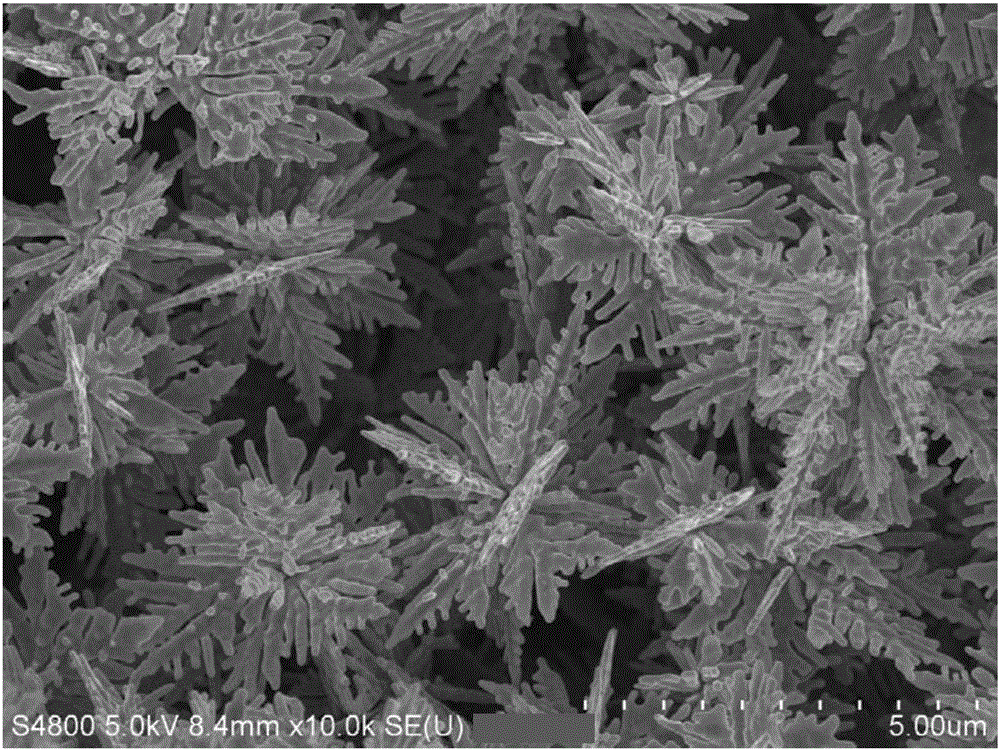

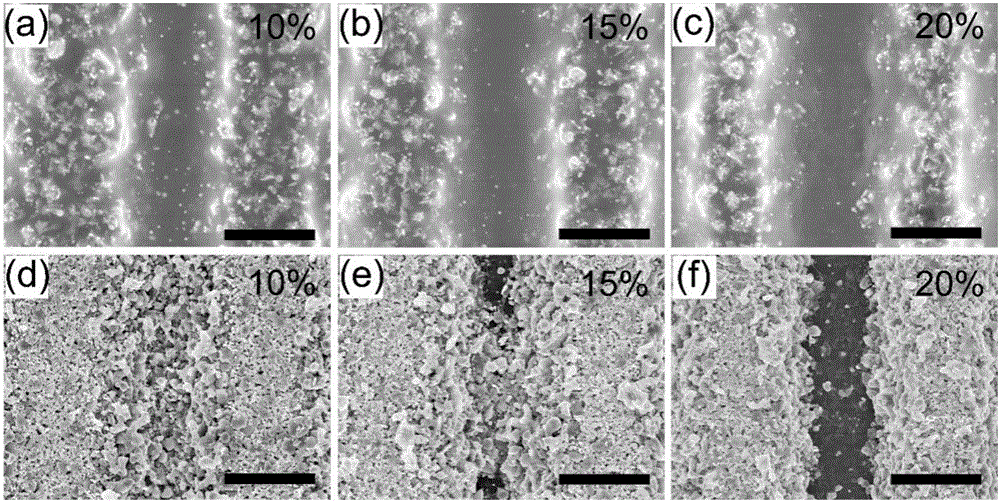

Conductive composite material and preparation method thereof, and preparation method for conductive line

ActiveCN105006270AReduce energy transferSmall thermal deformationNon-conductive material with dispersed conductive materialPrinted circuit manufactureLaser etchingPolymer resin

The invention discloses a conductive composite material and a preparation method thereof, and a preparation method for a conductive line. The conductive material comprises a substrate, and metal particles uniformly dispersed in the substrate, the diameter of the metal particles is from 100 nm to 10 <mu>m, the substrate is polymer resin, and the metal particles are metal particles with three-dimensional fractal layered structures. The conductive material is used for laser etching, the micro-nano metal particles with the three-dimensional fractal layered structures are employed as the conductive filling material, the unique geometric shapes of the metal particles are employed so that ablation occurs more easily under the effect of laser compared with conventional filling material particles, and finer wiring effect can be realized under low laser power; the same conductivity is reached by adopting less metal particles than the conventional filling material particles so that the required laser etching energy is less; and the content of the metal particles is less so that the bonding force in conductive slurry and the bonding force between the conductive slurry and a matched insulation substrate can be both greatly increased.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

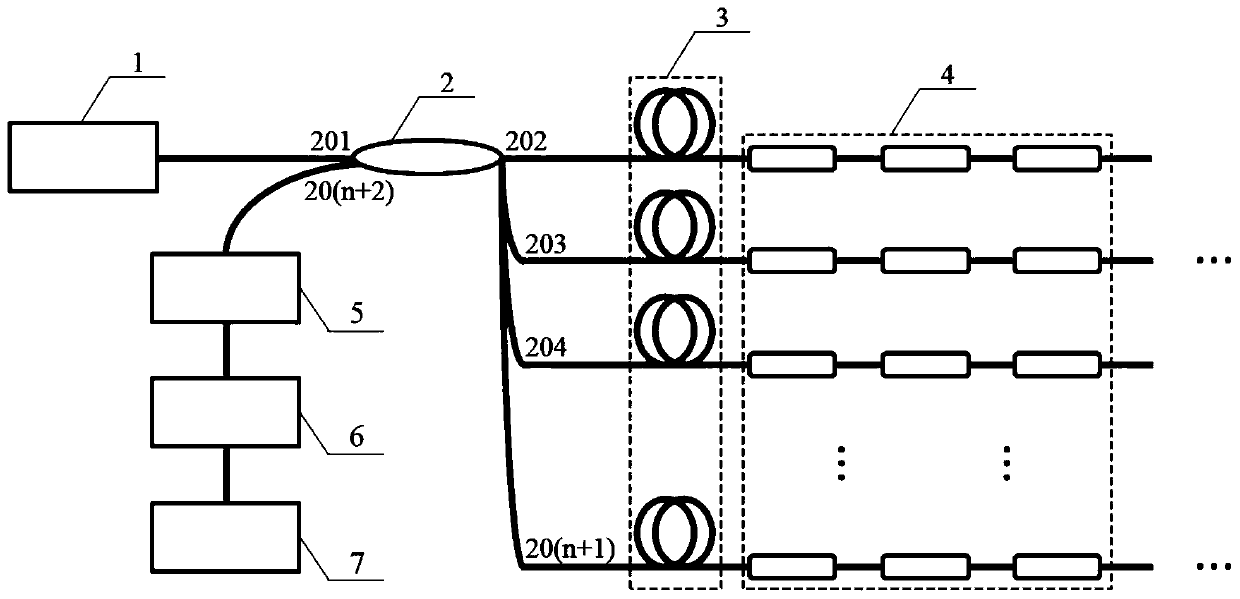

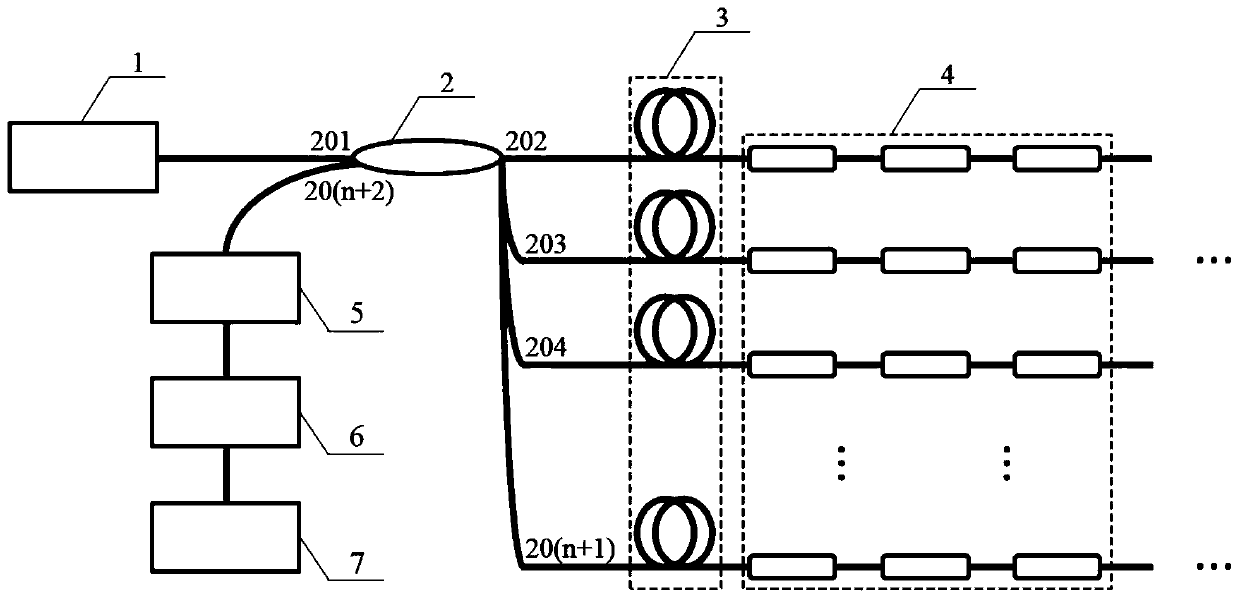

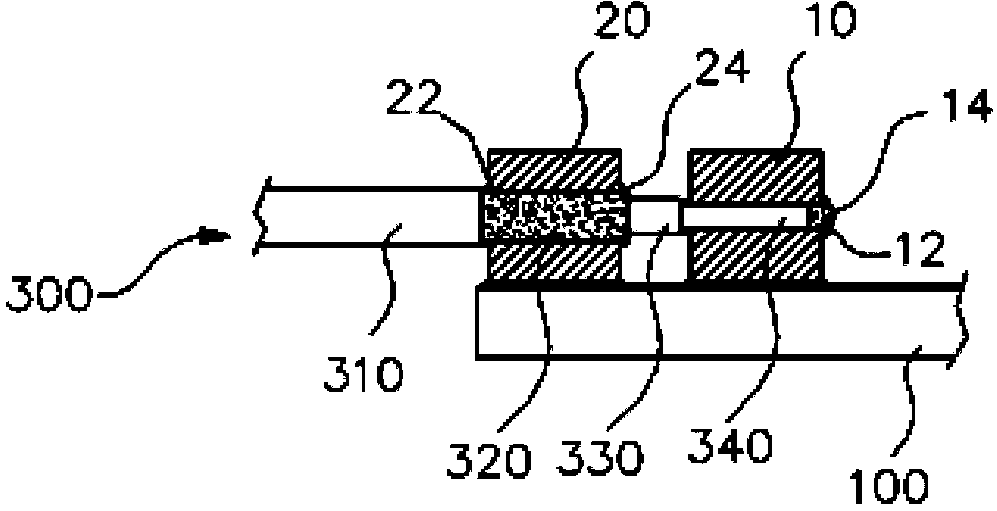

Composite fiber based on luminescent metal organic frame material and preparation method thereof, and application to multi-parameter distributed fiber fluorescence sensing system

PendingCN109916870AEasy to operateImprove sensor applicabilityFluorescence/phosphorescenceOptical instrumentFluorescence sensing

The invention discloses a composite fiber based on a luminescent metal organic frame material and a preparation method thereof, and an application to a multi-parameter distributed fiber fluorescence sensing system. The system includes an excitation light source, a fiber coupler, a delay fiber, sensing units, a long pass filter, a fluorescence spectrometer and a signal processing unit, wherein thesensing unit is a luminescent MOFs composite fiber prepared through a casing method, and the multi-parameter distributed fiber fluorescence sensing network can be formed by cascading and paralleling the multiple sensing units containing different luminescent MOFs. The system is advantaged in that composition of the luminescent MOFs and the fibers is realized, the method is simple, cost is low, thesensing units for detecting different analytes can be prepared according to actual needs and are combined with other optical instrument components to form a sensing system, further real-time in-situremote online fluorescence detection and sensing are realized simultaneously at multiple points, and the sensing application of the illuminating MOFs is greatly improved.

Owner:SOUTH CHINA UNIV OF TECH

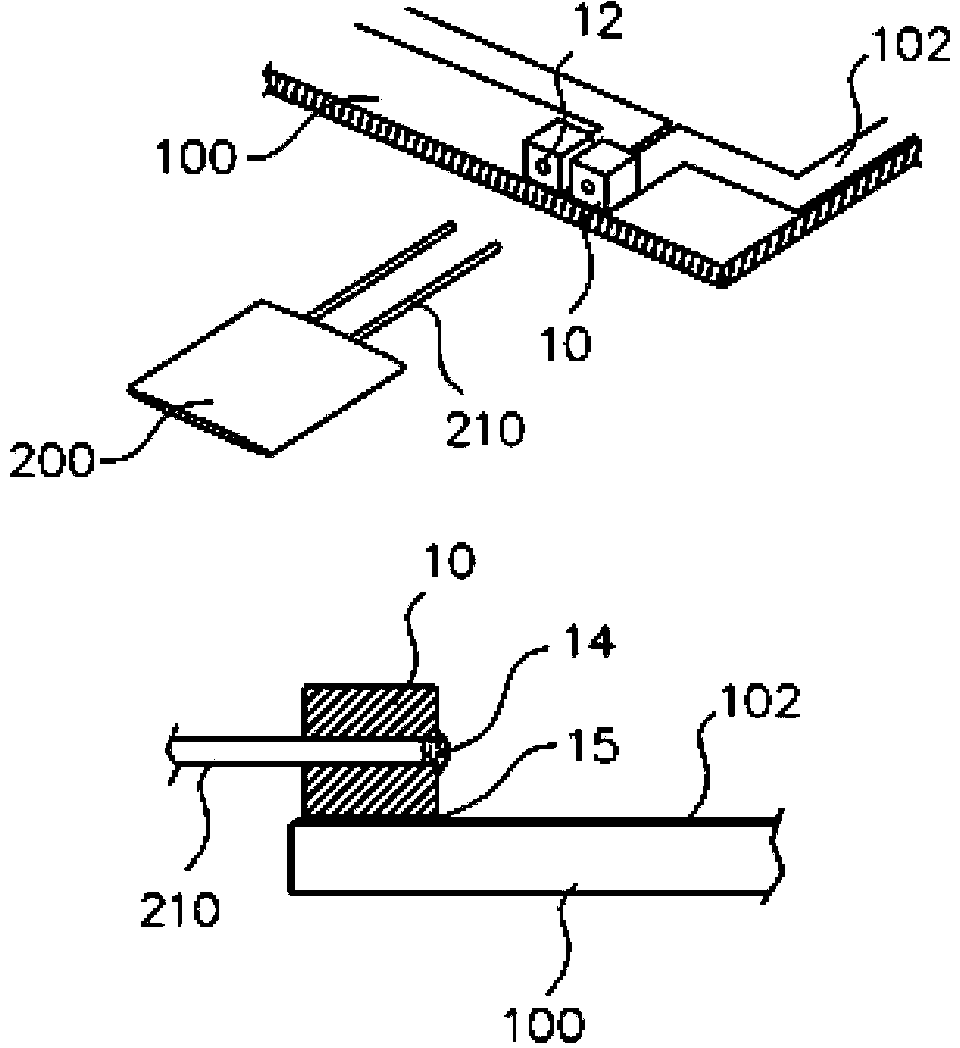

Metal terminal block adapted for surface mounting and method of mounting the same

ActiveCN103187640AIncrease ground areaSave additional operating costsFinal product manufacturePrinted circuit aspectsSurface mountingThree dimensional shape

Provided is a metal terminal block adapted for surface mounting, which includes a metal body having a three-dimensional shape, an outer surface of which includes at least one portion appropriate for vacuum pickup. The metal terminal block provided on a reel carrier through taping is picked up through the vacuum pickup on the portion of the outer surface of the metal body and is mounted on a conductive pattern of a circuit board through the surface mounting. A back surface of the metal terminal block is adhered to the conductive pattern through reflow soldering. The metal body has an insertion recess extending from a surface to an opposite surface thereto, or an insertion hole passing through a surface to an opposite surface thereto.

Owner:JOINSET +2

Multifunctional surface enhanced Raman substrate material, and preparation method and application thereof

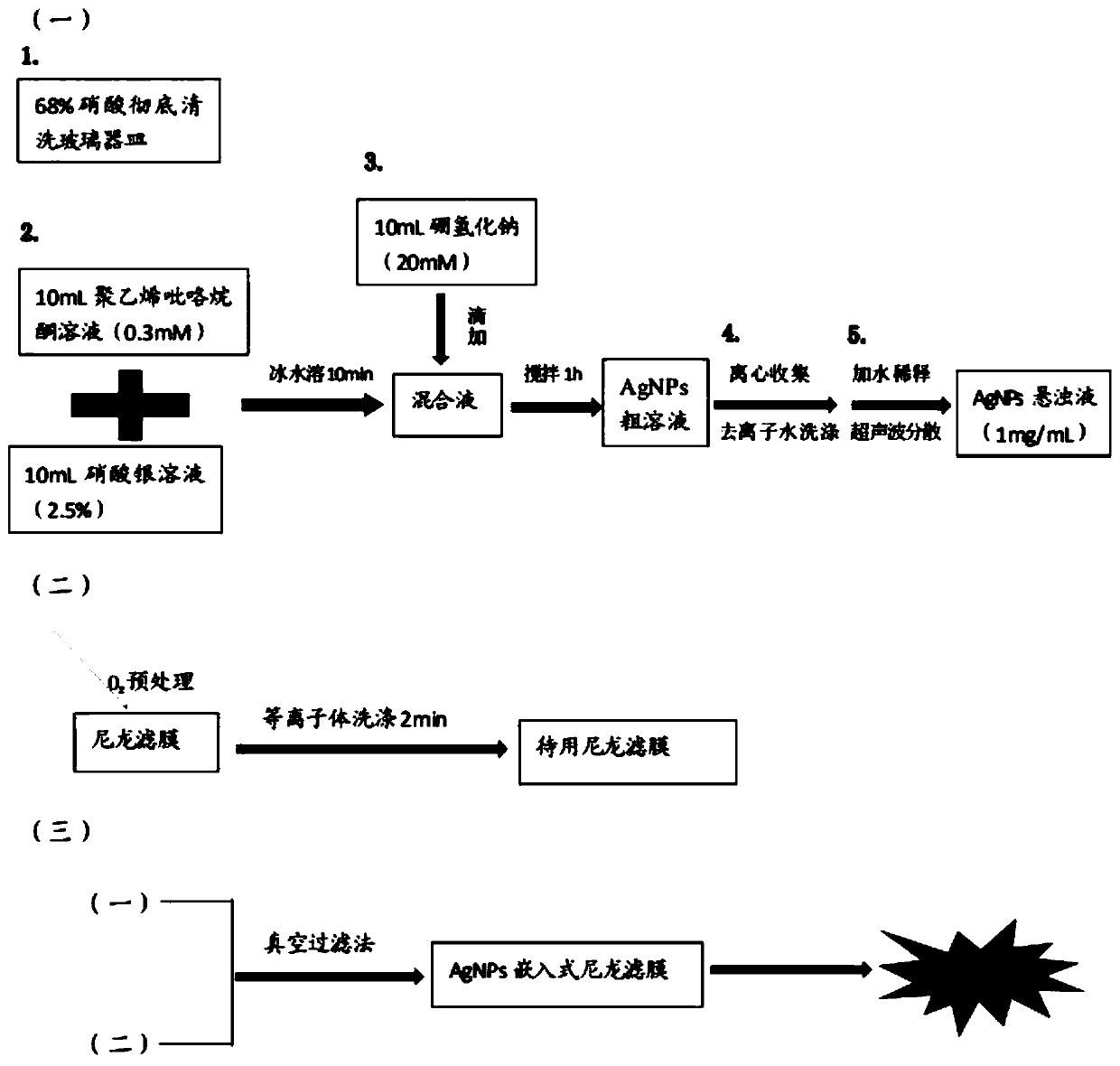

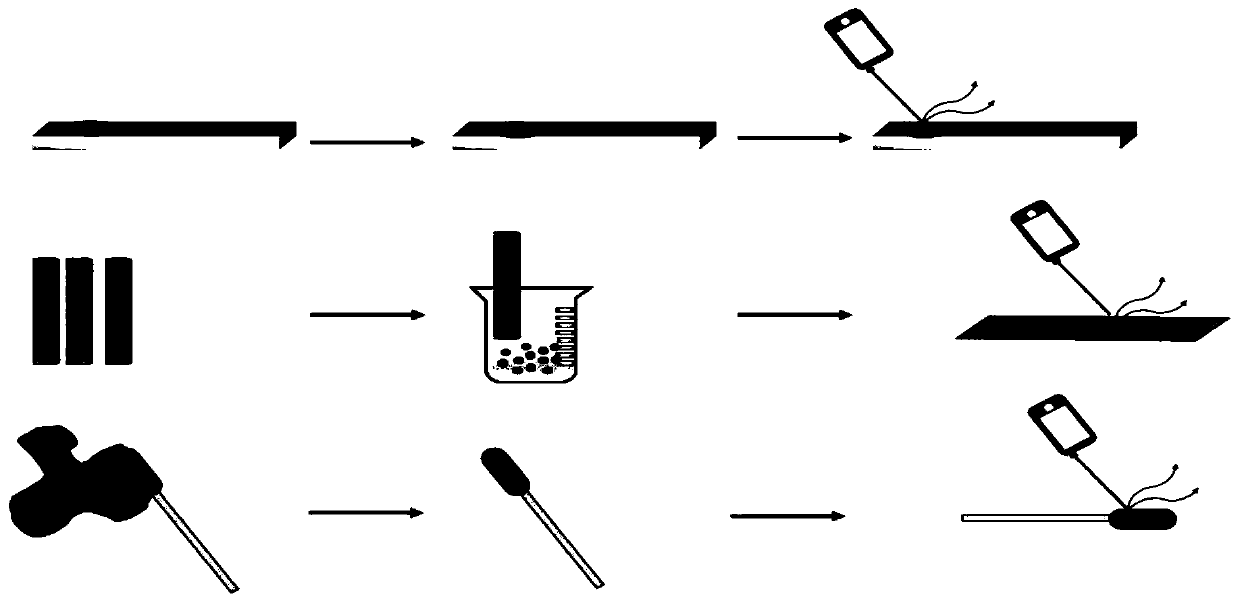

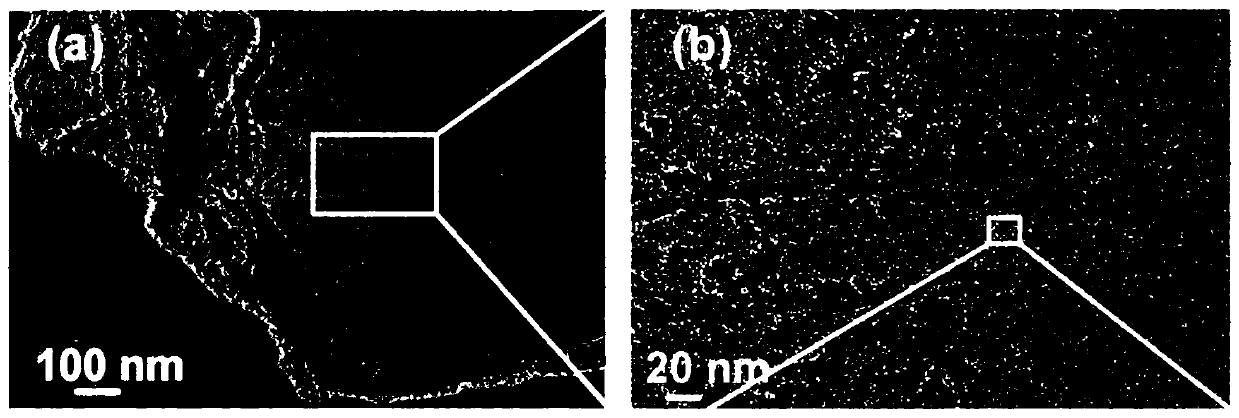

PendingCN110308138AEfficient packagingHigh detection sensitivityMaterial nanotechnologyRaman scatteringFiltrationOxygen

The invention discloses a multifunctional surface enhanced Raman substrate material, and a preparation method and an application thereof. The material is formed by combining a nylon filter membrane and nano-silver embedded into micropores of the nylon filter membrane. The preparation method comprises the following steps: (1) preparing AgNPs suspension liquid; (2) pretreating the nylon filter membrane: firstly carrying out pretreatment by using oxygen, and then carrying out cleaning by using plasmas; (3) preparing a multifunctional surface enhanced Raman substrate: carrying out solid-liquid separation on the AgNPs suspension liquid prepared in the step (1) in a vacuum suction filtration mode through the nylon filter membrane obtained in the step (2), then taking out the nylon filter membrane embedded with AgNPs, and carrying out air drying. The vacuum suction filtration method is adopted; the packaging performance is good, the stability is improved; the substrate distribution is uniform; the sensitivity is high; the signal consistency is good; the nylon filter membrane is adopted as a carrying material; the anti-friction performance is achieved; the material can be repeatedly used;the cost is low; and the preparation process is simple. Meanwhile, the multi-appearance and multi-function design is also suitable for practical application in the POCT field.

Owner:FOOD INSPECTION CENT OF CIQ SHENZHEN +1

Super-thick metal anticorrosive coat and preparation technology thereof

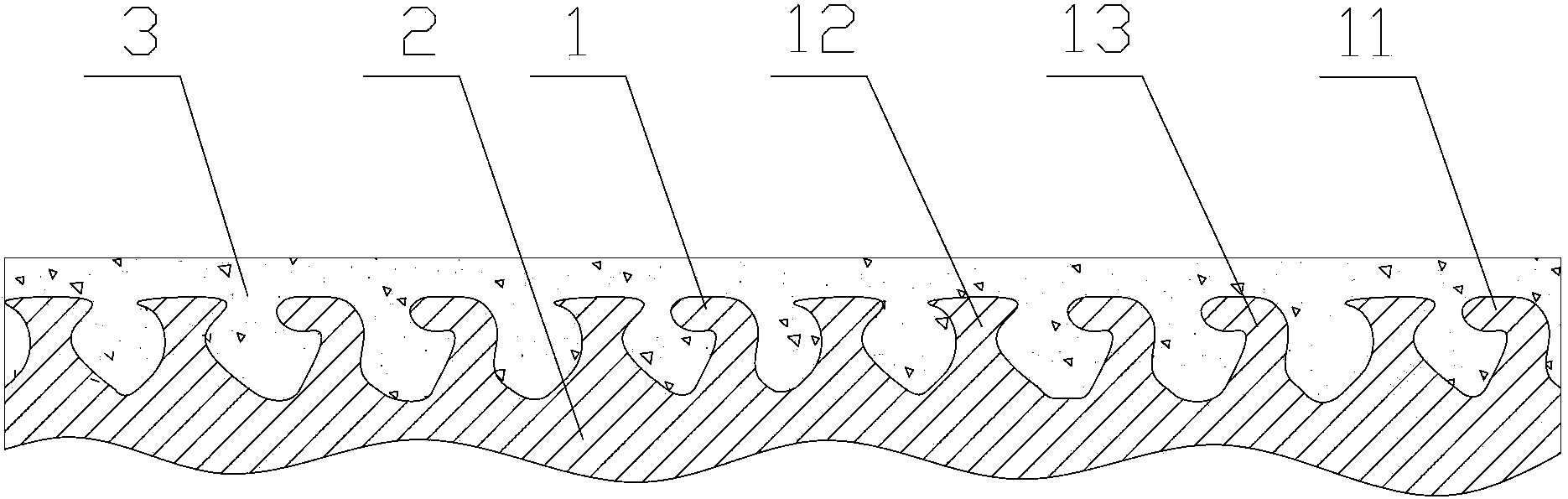

ActiveCN103434204AImprove mechanical bondingGood technical effectMetal layered productsHeavy dutyToughness

The invention relates to metal surface anticorrosion and long-acting heavy duty anticorrosion, and discloses a super-thick metal anticorrosive coat and a preparation technology thereof. The super-thick metal anticorrosive coat comprises a metal substrate (2), a metal surface anchor hook layer (1) and an anticorrosive metal layer (3), the toughness of the surface of the metal substrate (2) is 150-1400mum, and the metal substrate (2) has an embedded anchoring connection with the anticorrosive metal layer (3) through the metal surface anchor hook layer (1). The preparation technology comprises the following steps: 1, preparing anchor grains having a roughness of 150-1400mum on the surface of the metal substrate (2); 2, pressuring the anchor grains on the metal substrate (2) to form the metal surface anchor hook layer (1); and 3, preparing the anticorrosive metal layer (3). The arrangement of the metal surface anchor hook layer in the invention obviously reinforces a mechanical binding force between the metal surface anchor hook layer and the anticorrosive metal layer, and provides a necessary condition for the preparation of thicker coats.

Owner:ZHEJIANG CTB WAVEFORM STEEL WEB

Metal foil current collector for battery

ActiveCN107681159AExcellent intrinsic conductivity and mechanical self-dispersion propertiesAvoid microcoalescingElectrode carriers/collectorsCvd grapheneMetal foil

The invention discloses a metal foil current collector for a battery and belongs to the technical field of electrochemistry. The metal foil current collector is technically characterized in that a nano carbon coating is arranged on the surface of the metal foil current collector; and the coating contains a graphene carbon nanotube hybrid prepared through a high-temperature chemical vapor deposition method. Graphene and a carbon nanotube in the graphene carbon nanotube hybrid are connected through a form of a covalent bond, so that the metal foil current collector has excellent intrinsic conductivity and mechanical self-dispersion characteristics, and micro coalescence of a carbon nanostructure is avoided. In assembly and operation processes of the battery, direct mechanical bonding and conductive interconnection of the current collector and positive active material particles can be effectively improved and the wetting characteristics of an electrolyte can be strengthened through the nano carbon coating on the surface of the metal foil current collector; and the metal foil current collector has important value to reduction of the impedance characteristic of the battery and improvement of the high current charge-discharge capability and the cycling stability of the battery.

Owner:TSINGHUA UNIV

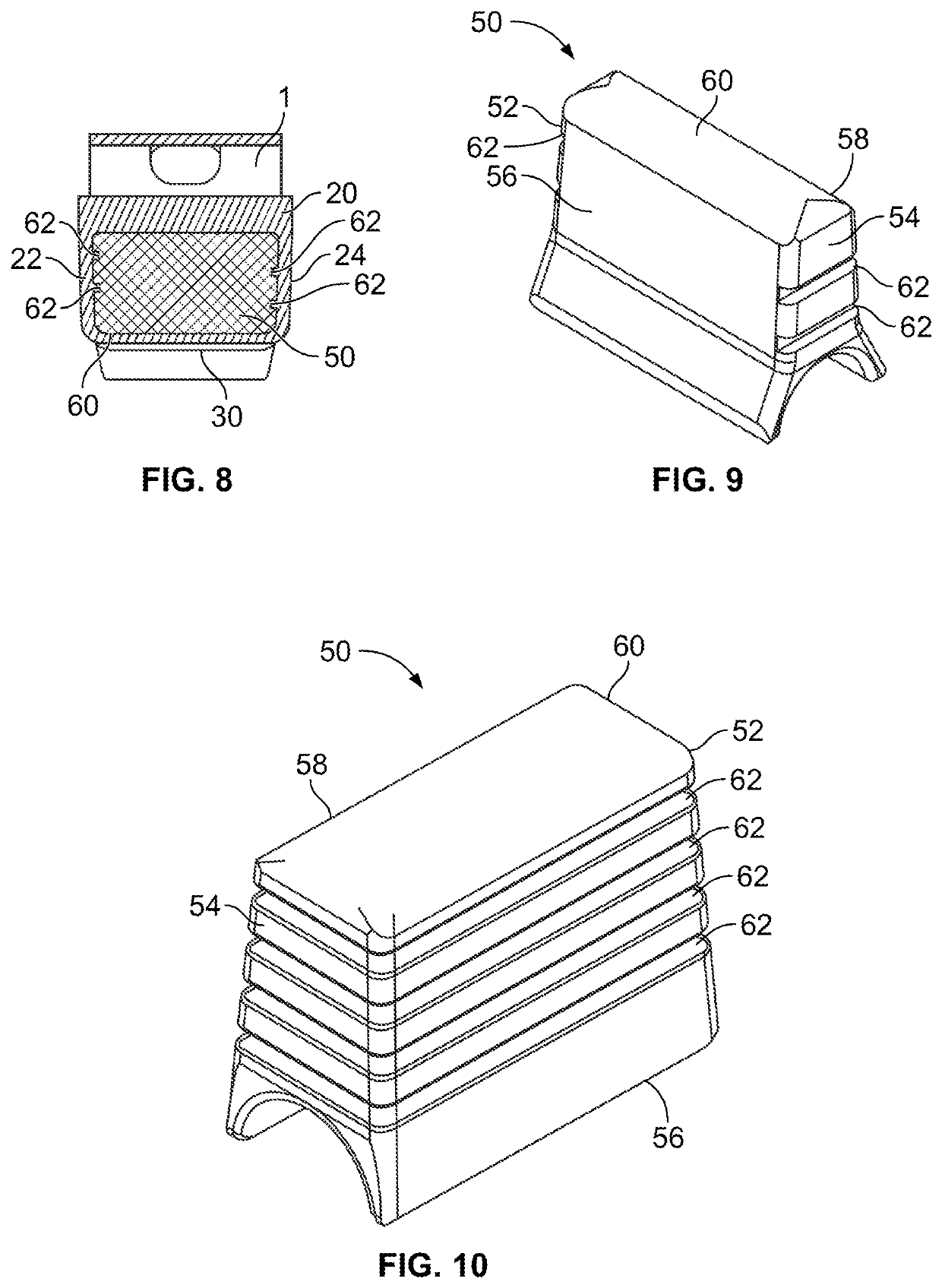

Friction device with bonding inserts

ActiveUS20220049749A1Improve mechanical bondingImprove pull-off strengthBraking membersFriction liningEngineeringMechanical engineering

Owner:RFPC HLDG CORP

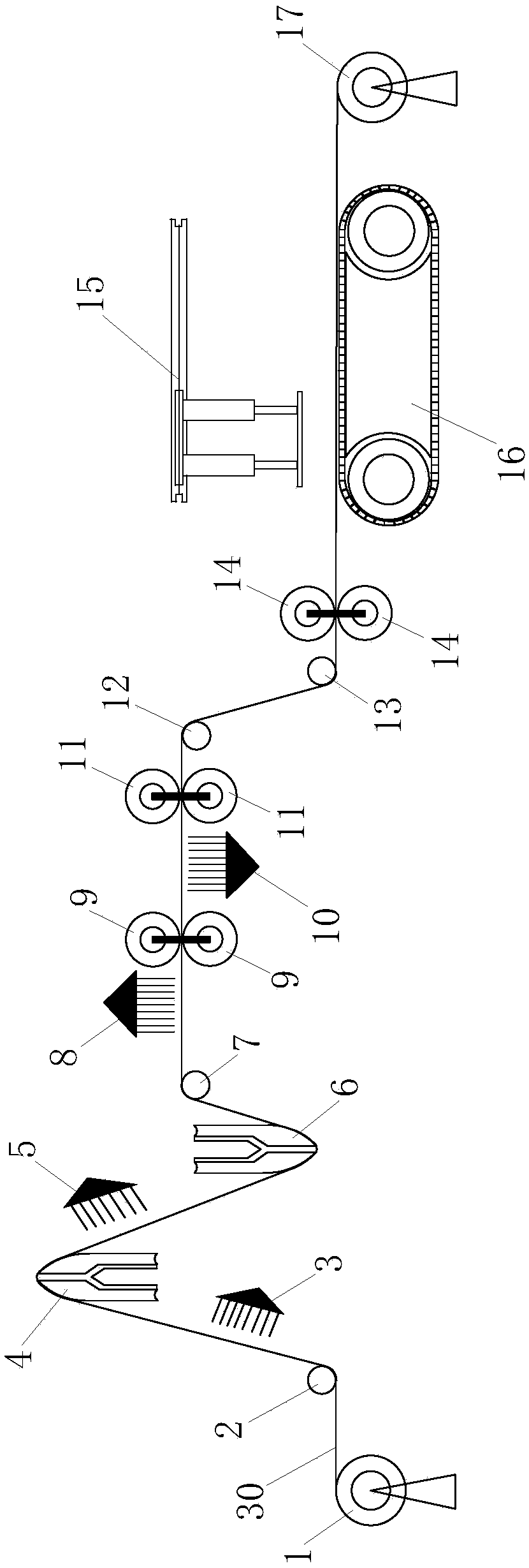

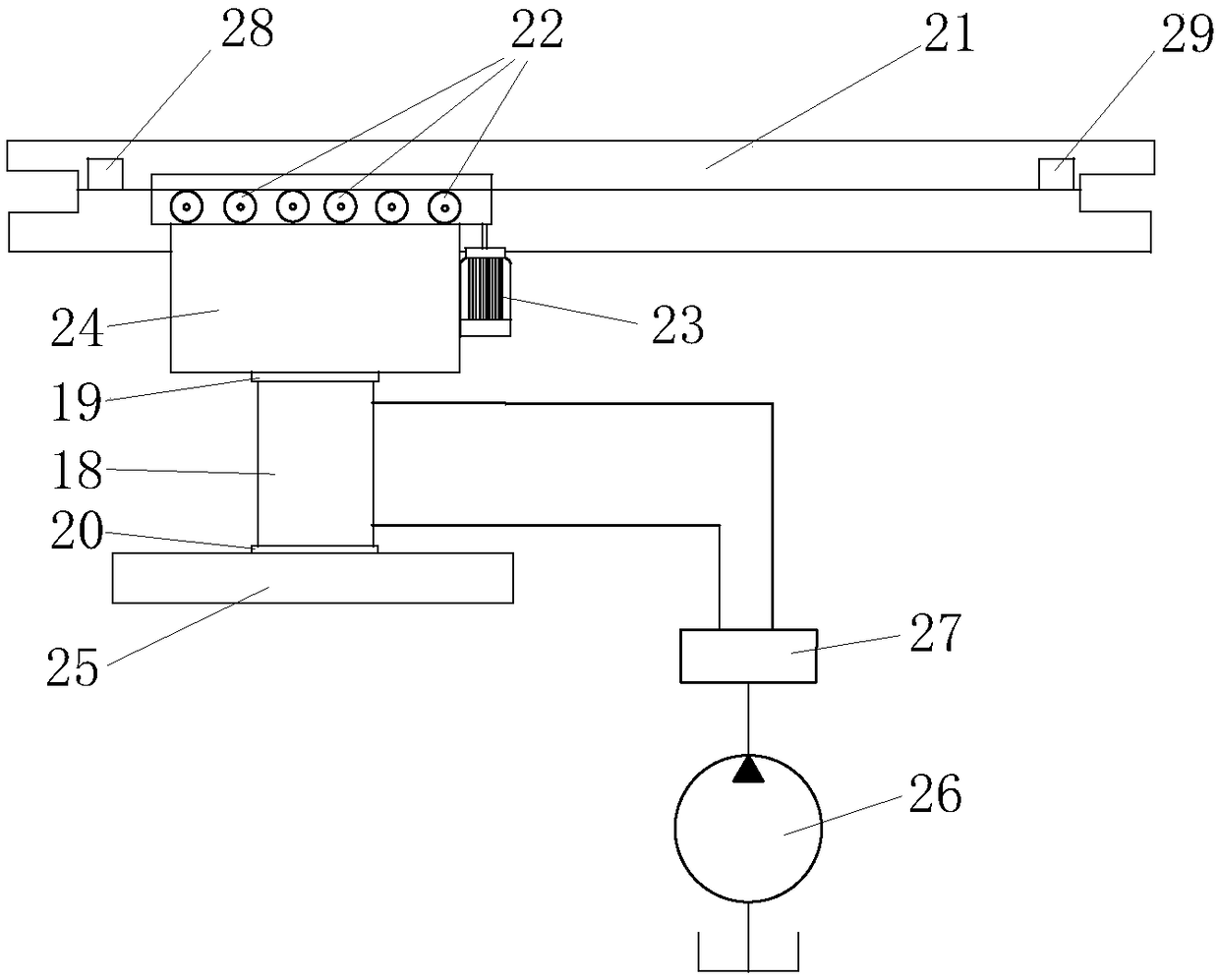

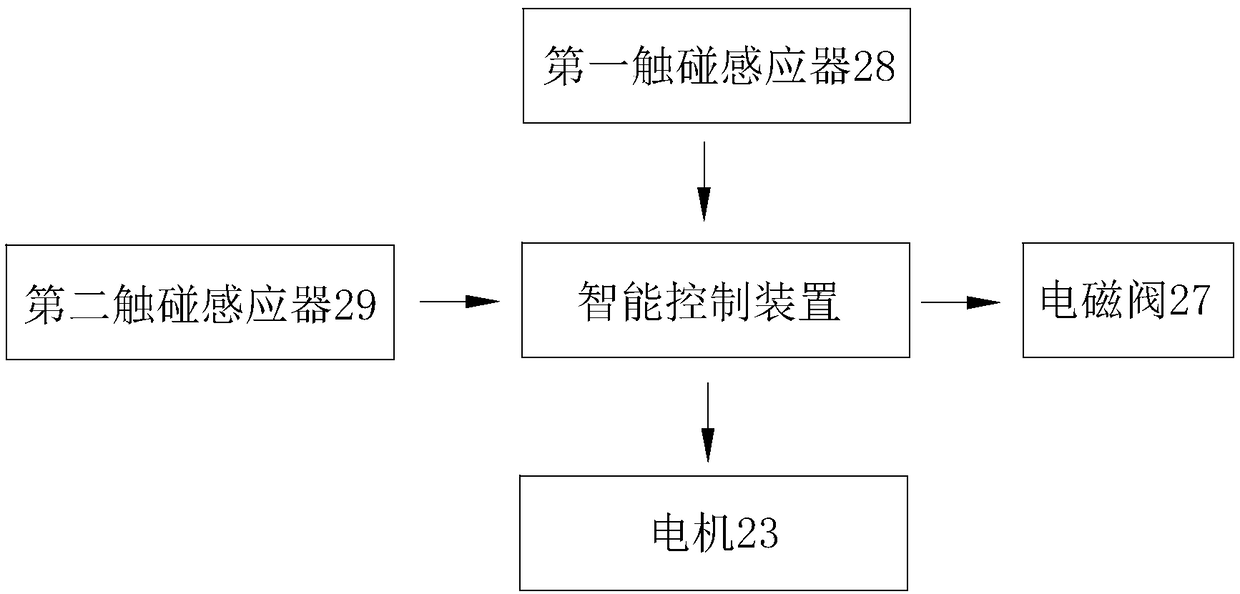

Carbon fiber polyamide prepreg preparation device and preparation method thereof

The invention provides a carbon fiber polyamide prepreg preparation device and a preparation method thereof and solves the technical problems that existing equipment has the problems of complex steps, environmental pollution and low heating and producing efficiency, and resin and carbon fiber are uneven in adhesion and further has weaker combining capacity and larger porosity and the like. The carbon fiber polyamide prepreg preparation device is sequentially provided with a carbon fiber belt wheel, a first tension wheel, a first infrared heater, a first U-shaped molten resin spray head, a second infrared heater, a second U-shaped molten resin spray head, a second tension wheel, a third infrared heater, a first heating roller, a fourth infrared heater, a second heating roller, a third tension wheel, a fourth tension wheel, a cooling roller, a press machine, a conveyer belt and a transmission roller from left to right. Furthermore, the invention provides carbon fiber pretreatment, molten resin preparation and carbon fiber traction and fixation and the like. The carbon fiber polyamide prepreg preparation method can be widely applied to the field of carbon fiber resin based compositematerials.

Owner:SHANDONG UNIV

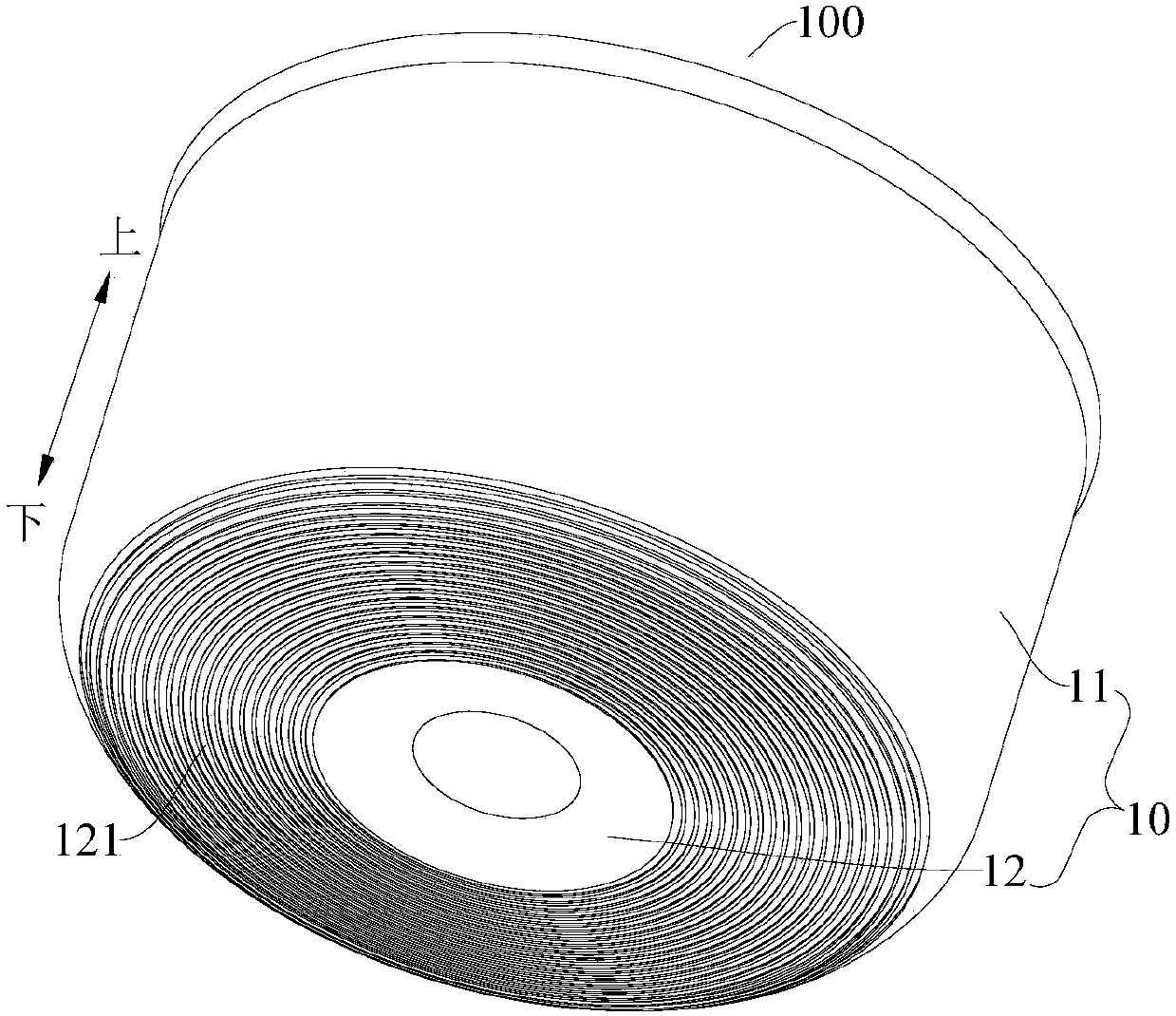

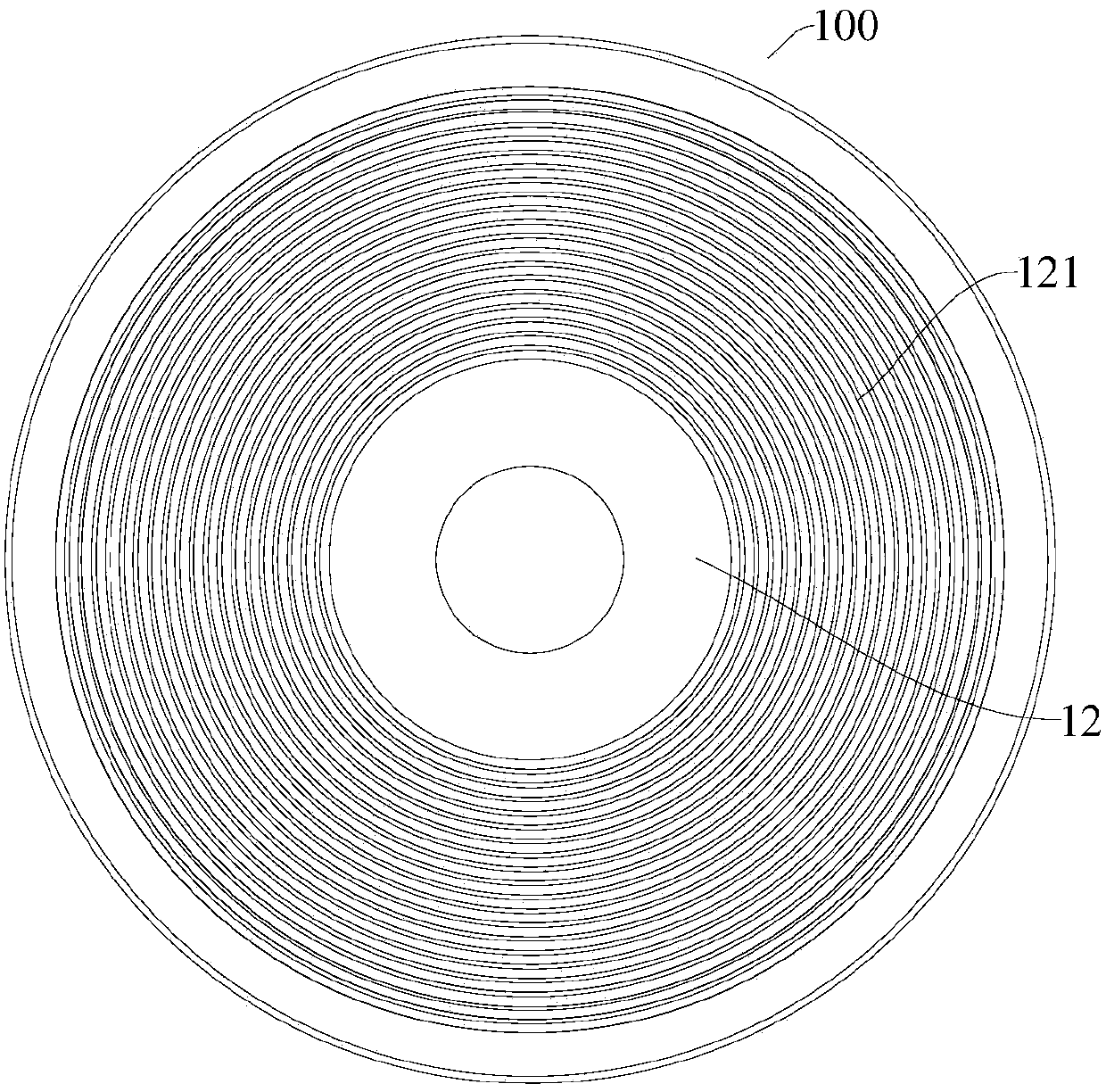

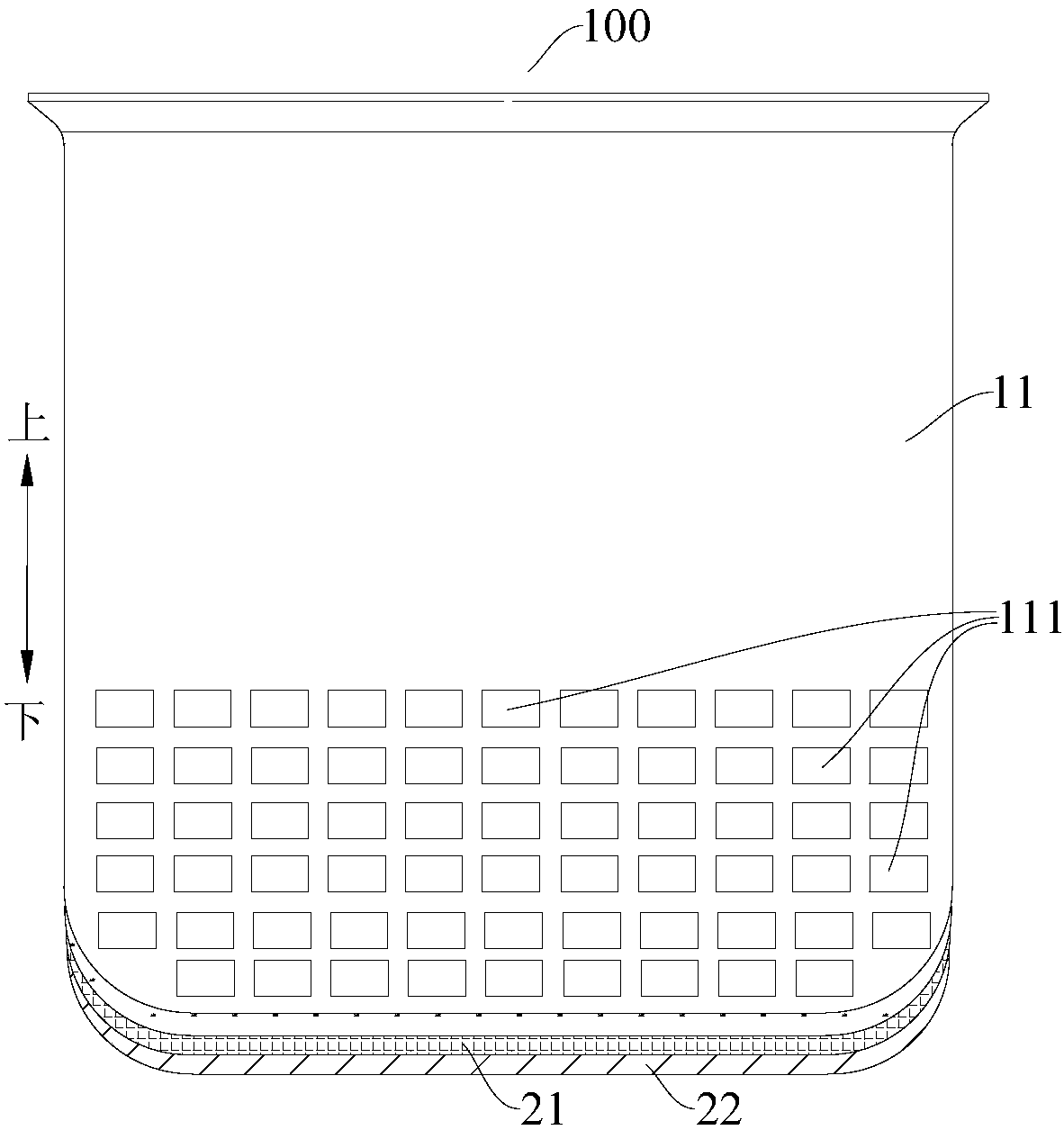

Pot, electric rice cooker provided with same, and preparation method of pot

ActiveCN107638061AIncrease the outer surface areaImprove permeabilityCooking-vessel materialsMolten spray coatingHeating effectEngineering

The invention discloses a pot, an electric rice cooker provided with the pot, and a preparation method of the pot. The pot comprises a pot body, wherein the pot body is provided with first grooves which sink inwards relative to the outer surface of a bottom wall and / or first bulges which protrude out of the outer surface of the bottom wall, and a magnetic conductive metal layer is arranged on theouter surface of the pot body. According to the pot provided by the embodiment of the invention, the first bulges and / or the first grooves are arranged on the outer surface of the pot body, thus the area of the outer surface of the pot can be increased, the mechanical binding capacity of the magnetic conductive metal layer and the pot body is greatly increased, the magnetic conductive metal layeron the pot body has the effects of reducing noises and realizing silencing, and also has relatively high magnetic permeability, thus the thermal conductivity of the pot is improved, and further, the heating effect of the pot is improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

Perforated laminated polymeric foam articles

ActiveUS8075989B2Improve adhesionEnhancing vapor transferSynthetic resin layered productsLaminationPolymer scienceAdhesive

A polymeric foam article has at least two thermoplastic polymer foams in layered orientation, each of the thermoplastic polymer foams having an adjoining surface that contains a polymer skin, a thickness dimension perpendicular to the adjoining surface, perforations that are less than one millimeter in diameter that penetrate through the adjoining surface to a depth less than the thickness dimension of the foam, where the adjoining surface of one thermoplastic polymer foam is adjacent and adhered to the adjoining surface of another thermoplastic polymer foam with an adhesive thereby affixing the thermoplastic polymer foams to one another.

Owner:DOW GLOBAL TECH LLC

Preparation method of enameled furnace holder

Owner:QINGDAO TIANDI CASTING CO LTD

Methods for oxidation treatment of CBN abrasive particle and for preparation of ceramic binder CBN grinding tool by using CBN abrasive particle

The invention discloses methods for oxidation treatment of a CBN abrasive particle and for preparation of a ceramic binder CBN grinding tool by using the CBN abrasive particle. The methods are characterized in that a uniform and compact film is formed on the surface of the CBN abrasive particle with granularity of 70 to 150 mu m through oxidation treatment of the CBN abrasive particle at a temperature of 850 to 1050 DEG C, thereby improving bonding strength of glass powder on the CBN abrasive particle and enhancing bending strength and wear resistance of the ceramic binder CBN grinding tool. Compared with a CBN grinding tool prepared from an unoxidized CBN abrasive particle, the CBN grinding tool prepared from the CBN abrasive particle having undergone oxidation treatment has the following characteristics: a structure is uniform, bonding strength between a binder and the CBN abrasive particle is high, bending strength of the grinding tool is great, and high speed grinding requirements of the CBN grinding tool are met.

Owner:XI AN JIAOTONG UNIV

Abrasion-resistant and ultraviolet-aging-resistant epoxy composite material and preparation method thereof

InactiveCN110698817AImprove wear resistanceImproved performance against UV agingResin matrixSports equipment

The invention provides an abrasion-resistant and ultraviolet-aging-resistant epoxy composite material and a preparation method thereof. The abrasion-resistant and ultraviolet-aging-resistant epoxy composite material is prepared from the materials of an epoxy resin matrix material and a TiO2 / Ti3C2 nano-composite material uniformly dispersed in the epoxy resin matrix material, wherein the TiO2 / Ti3C2nano-composite material accounts for 0.1-3 wt% of the epoxy resin matrix material, and the epoxy composite material is obtained by curing the TiO2 / Ti3C2 nano-composite material and epoxy resin in thepresence of a quaternary ammonium salt. The preparation method of the epoxy composite material is simple, and raw materials are easily available. The abrasion-resistant and ultraviolet-aging-resistant epoxy composite material prepared by the preparation method has a lower abrasion rate than ordinary epoxy materials, and meanwhile the ultraviolet-aging resistance is excellent, the tensile strengthis further improved to a certain extent, and the abrasion-resistant and ultraviolet-aging-resistant epoxy composite material is particularly suitable for being used in abrasion-resistant devices, such as the manufacture of abrasion-resistant automotive parts and abrasion-resistant sports equipment.

Owner:JIAXING UNIV

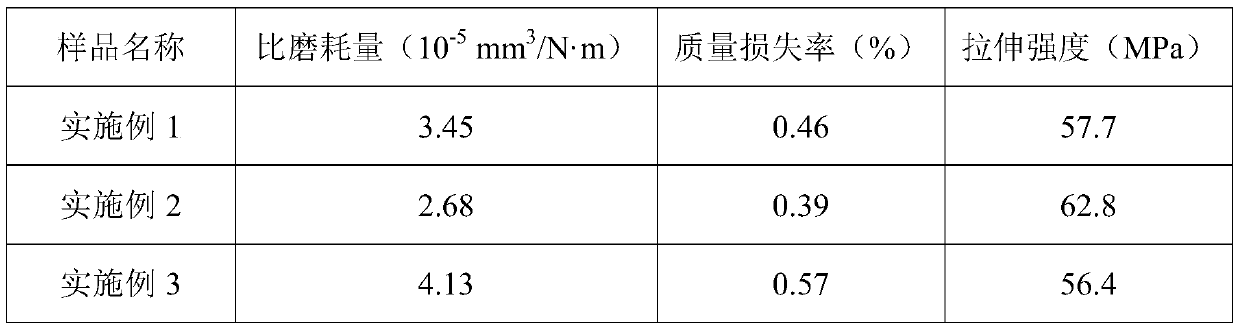

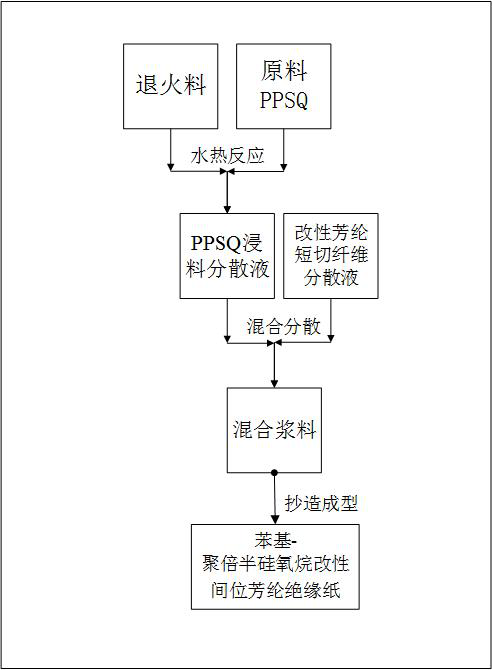

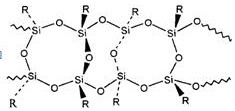

Preparation method of phenyl-polysilsesquioxane modified meta-aramid insulating paper

InactiveCN111636240AImprove mechanical bondingImprove mechanical propertiesMagnesium silicatesNon-fibrous pulp additionPaper sheetPapermaking

The invention relates to a preparation method of phenyl-polysilsesquioxane modified meta-aramid insulating paper, and belongs to the technical field of insulating materials. According to the method, phenyl-polysilsesquioxane (PPSQ) and meta-aramid fibers are modified, a conventional paper sheet forming method is adopted, and a modified insulating paper handsheet is obtained through the processes of dispersion in deionized water, fiber dissociation, mixing and stirring, filtering, papermaking, paper forming, drying, hot pressing and the like. Due to the addition of the PPSQ, a larger structuralspace is locally provided for the meta-aramid fibers, the free volume of the whole system is increased, the intermolecular structure of the meta-aramid fibers is improved, the tightness between molecular chains of the meta-aramid fibers is enhanced, the structure between paper becomes more compact, the interpermeability between the chains of the aramid fibers is further enhanced, the stress can be better transferred, the performance loss such as interphase layering is effectively prevented, and the bonding capacity between macromolecules of the aramid fibers is firmer. And meanwhile, the insulating paper prepared by the method has relatively high thermal aging resistance, and the thermal stability and the like are also improved.

Owner:SOUTHWEST UNIVERSITY

A kind of preparation method of silicon carbide fiber bundle reinforced aluminum matrix composite material

ActiveCN107513675BReduce preparation energy consumptionSimple preparation stepsFiber bundleThermal expansion

Owner:武汉强英新材料有限公司

Forming method of composite material tie rod and composite material tie rod

ActiveCN110315774BIncreased ability to withstand external loadsImprove molding efficiencyCosmonautic propulsion system apparatusBridge structural detailsYarnUltimate tensile strength

Owner:NORTH CHINA INST OF AEROSPACE ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com