Conductive composite material and preparation method thereof, and preparation method for conductive line

A conductive composite material and wiring technology, which is applied to conductive materials, circuits, and printed circuits dispersed in non-conductive inorganic materials, can solve the problems of low yield rate and high process control requirements, and achieve small thermal shock and high applicability Wide, to achieve the effect of light and thin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

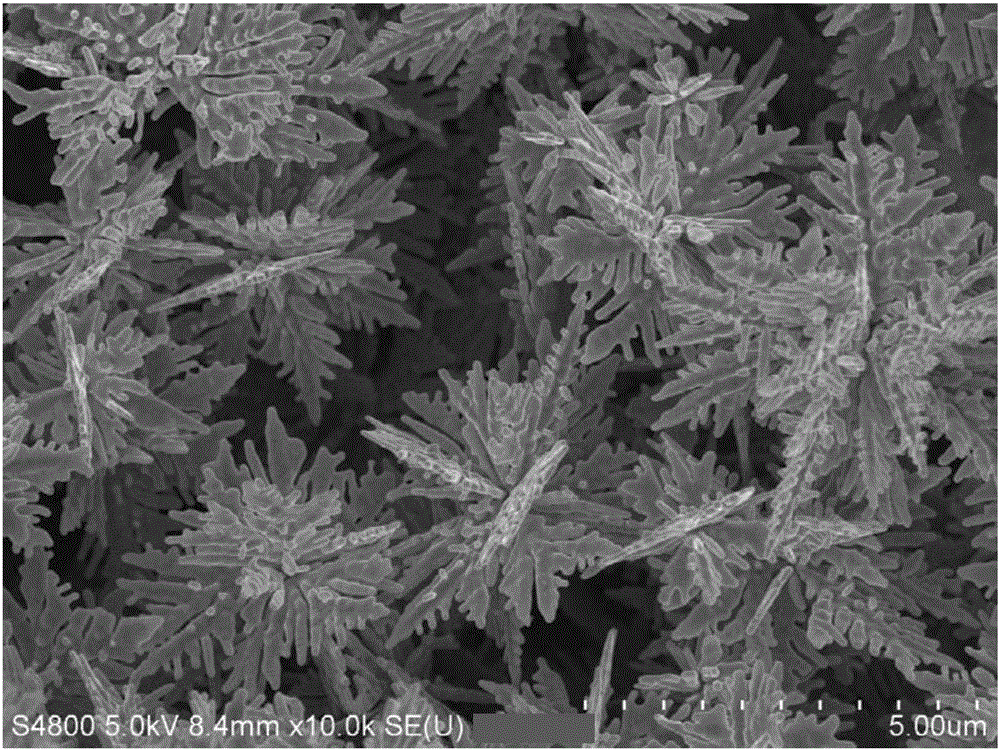

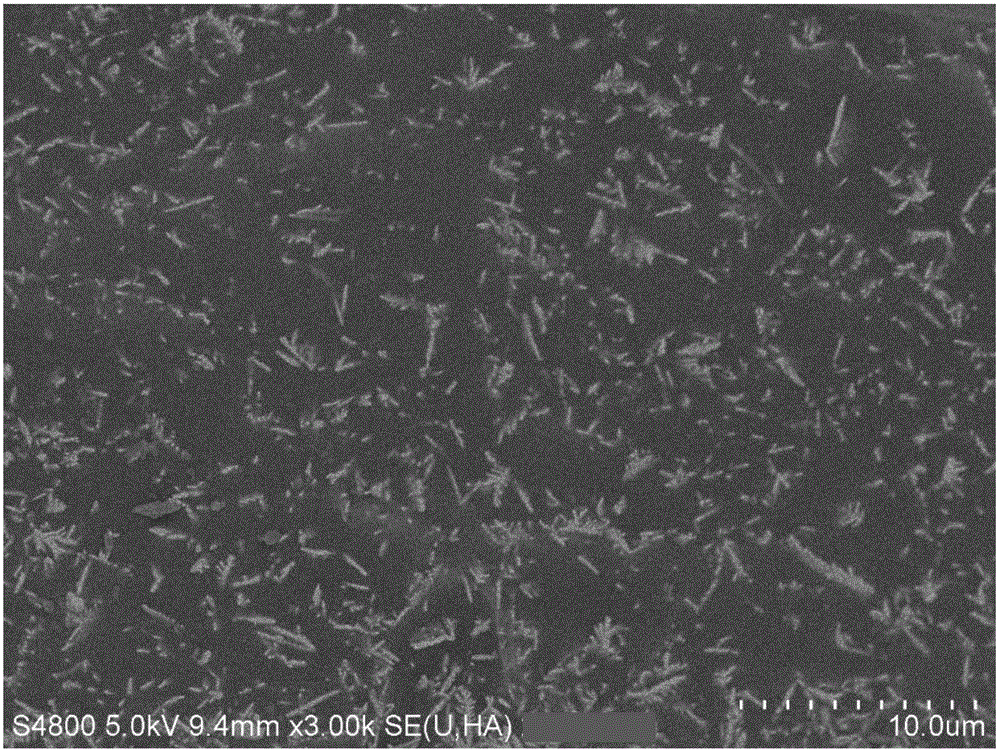

[0036] Micro-nano (diameter between 100 nanometers and 10 microns) metal particles with a three-dimensional fractal hierarchical structure are selected as conductive fillers. The morphology of the metal particles is as follows: figure 1 As shown, it has a three-dimensional dendrite structure. Based on the weight of the conductive composite material to be prepared, 50 wt% silver particle conductive filler is dispersed in the polyester resin matrix to prepare a low-power laser-etched conductive composite material. The conductive silver paste made of conductive composite material was printed on the glass substrate by screen printing, the average thickness of the silver paste line was 15 microns, and the initial width and spacing of the silver paste were set to 50 microns. The printed samples were heat-treated at 150°C for 15 minutes, and laser etching was performed after complete curing. The SEM image of the cross-section of the sample before laser etching figure 2 As shown, t...

Embodiment 2

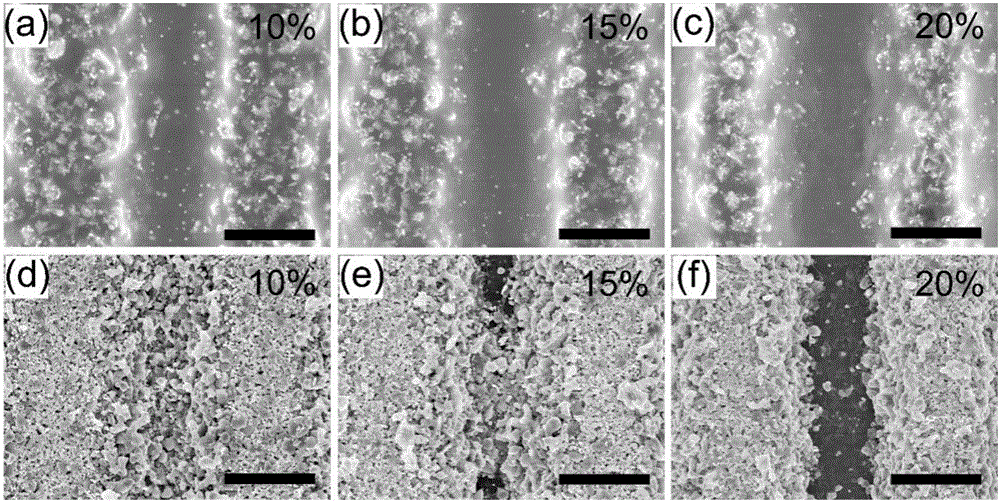

[0040] Micro-nano (diameter between 100 nanometers and 10 micrometers) metal particles with a three-dimensional fractal hierarchical structure are selected as conductive fillers. Based on the weight of the conductive composite material to be prepared, 50 wt% silver particle conductive filler is dispersed in the polyester resin matrix to prepare a low-power laser-etched conductive composite material. The conductive silver paste made of conductive composite material was printed on the PET substrate by screen printing, the average thickness of the silver paste line was 15 microns, and the initial width and spacing of the silver paste were set to 50 microns. The printed samples were heat-treated at 150°C for 15 minutes, and laser processing was performed after complete curing. During laser etching, the laser wavelength is selected to be 532 nm, and the laser power is selected to be 20% (the maximum laser power is 20 watts). The SEM image of the sample after laser etching is as fo...

Embodiment 3

[0042] Micro-nano (diameter between 100 nanometers and 10 micrometers) metal particles with a three-dimensional fractal hierarchical structure are selected as conductive fillers. Based on the weight of the conductive composite material to be prepared, the conductive filler of silver particle conductive filler with a weight percentage of 40wt% is dispersed in the polyester resin matrix to prepare a low-power laser-etched conductive composite material. The conductive silver paste made of conductive composite material was printed on the PET substrate by screen printing, the average thickness of the silver paste line was 15 microns, and the initial width and spacing of the silver paste were set to 50 microns. The printed samples were heat-treated at 150°C for 15 minutes, and laser processing was performed after complete curing. During laser etching, the laser wavelength is selected to be 532 nm, and the laser power is selected to be 20% (the maximum laser power is 20 watts). The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com