Patents

Literature

267results about How to "Reduce thermal shock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

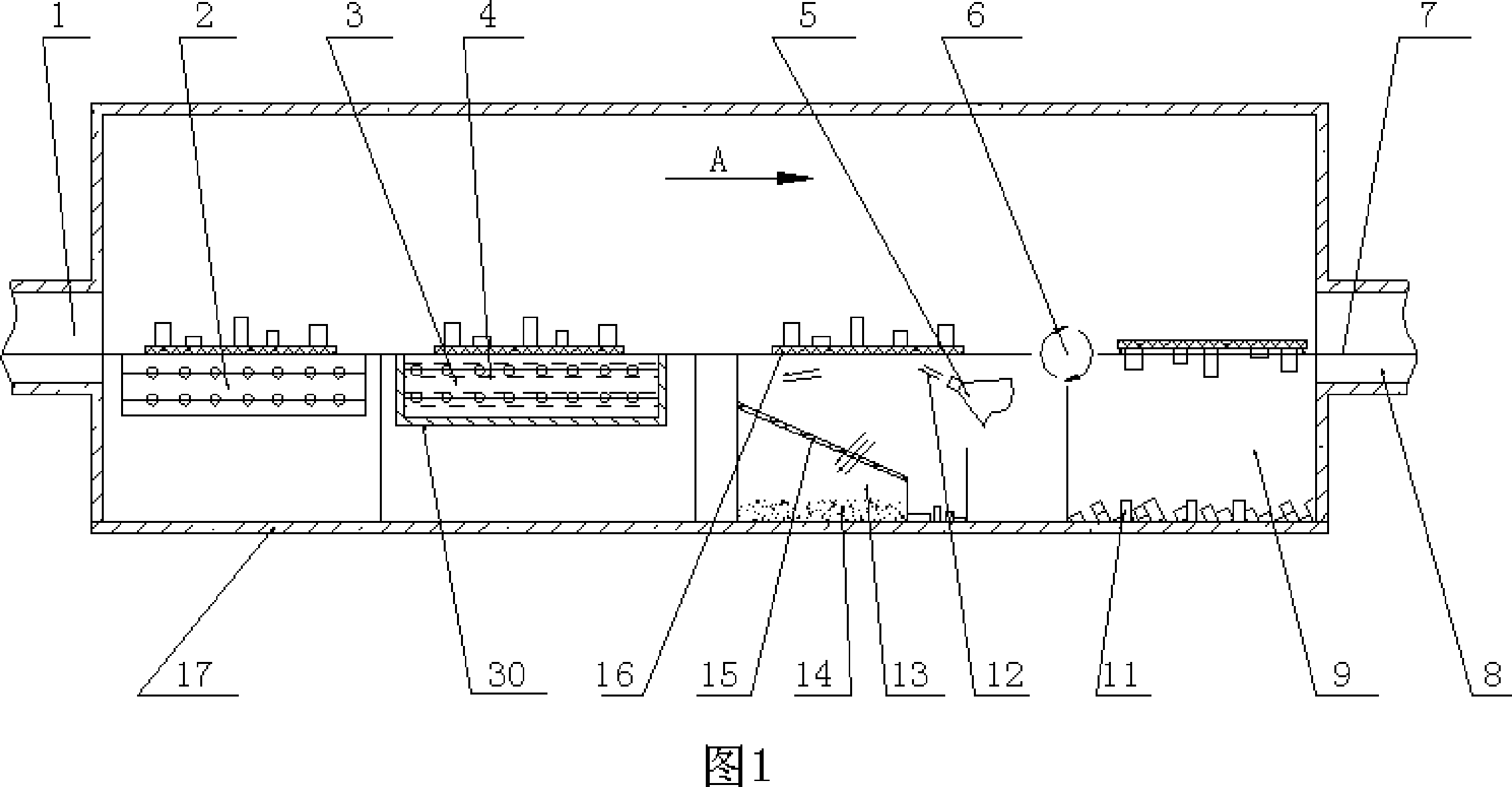

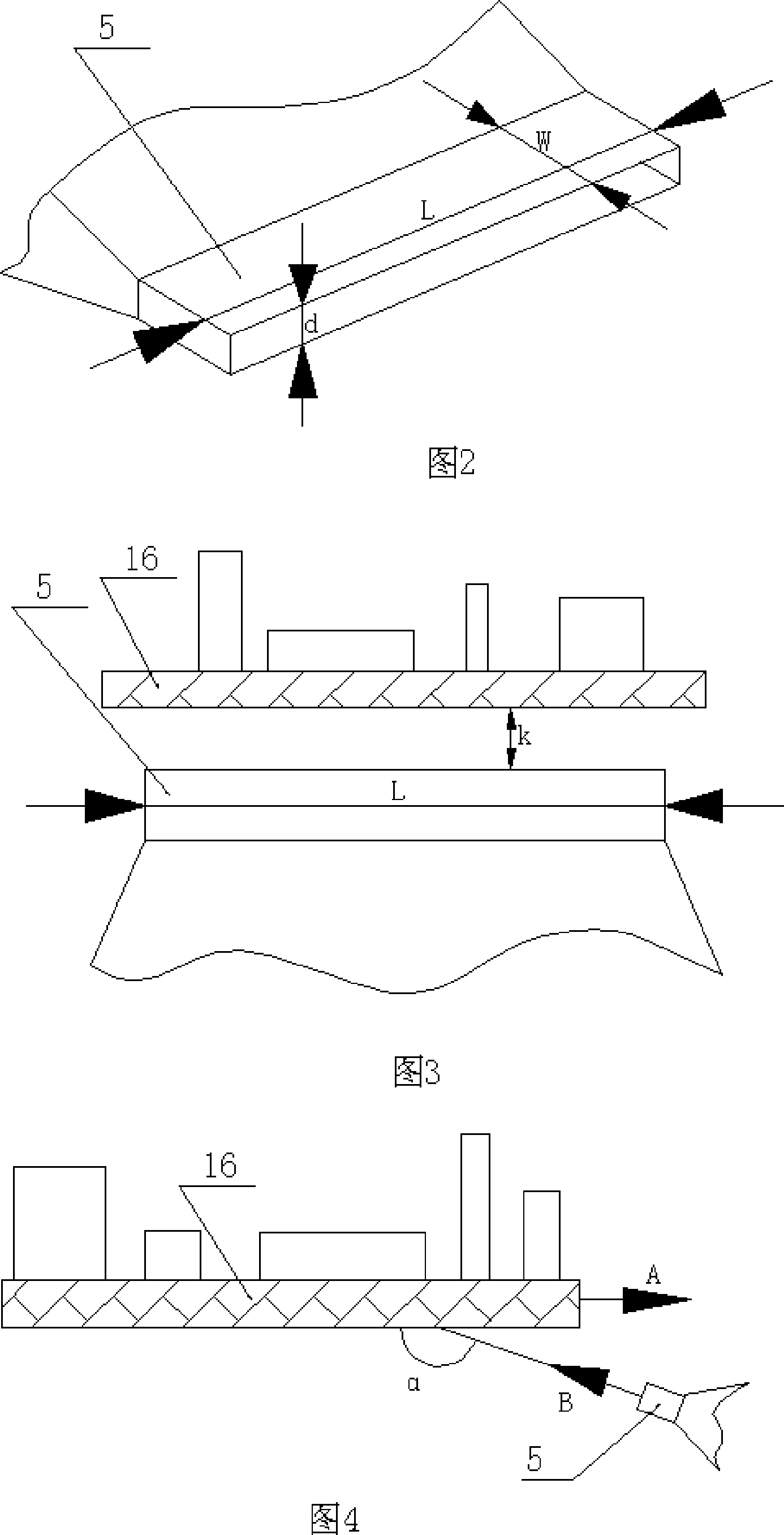

Circuit board element and welding flux separating and recovery method and device thereof

InactiveCN101112728AReduce thermal shockImprove uptimeSolid waste disposalSoldering auxillary devicesRecovery methodEngineering

The invention relates to recycle and reuse technology of electronic castoff, in particular to a method and a device to remove the element and separate the welding material from the circuit board. The invention discloses the method and the device which separates and recycles the welding material and removes the elements on the circuit board with high efficiency. The technic proposal of the invention adopts the melting welding material as the heating medium and heats the welding pots on the welding surface of the circuit board; the welding material is separated from the circuit board by utilizing the special nozzle to spray high-temperature high-pressure gas; finally, the circuit board is turned over and vibrated, separating the element from the circuit board. The invention has the beneficial effects that the element is subject to small heat impact during the removal process, the element after removal has high intact rate and repeated ratio, and the new impurity is not brought in during the removal process. The invention has the advantages of complete separation of welding pot, high removal ratio of elements, low energy consumption, environment-friendship, etc.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

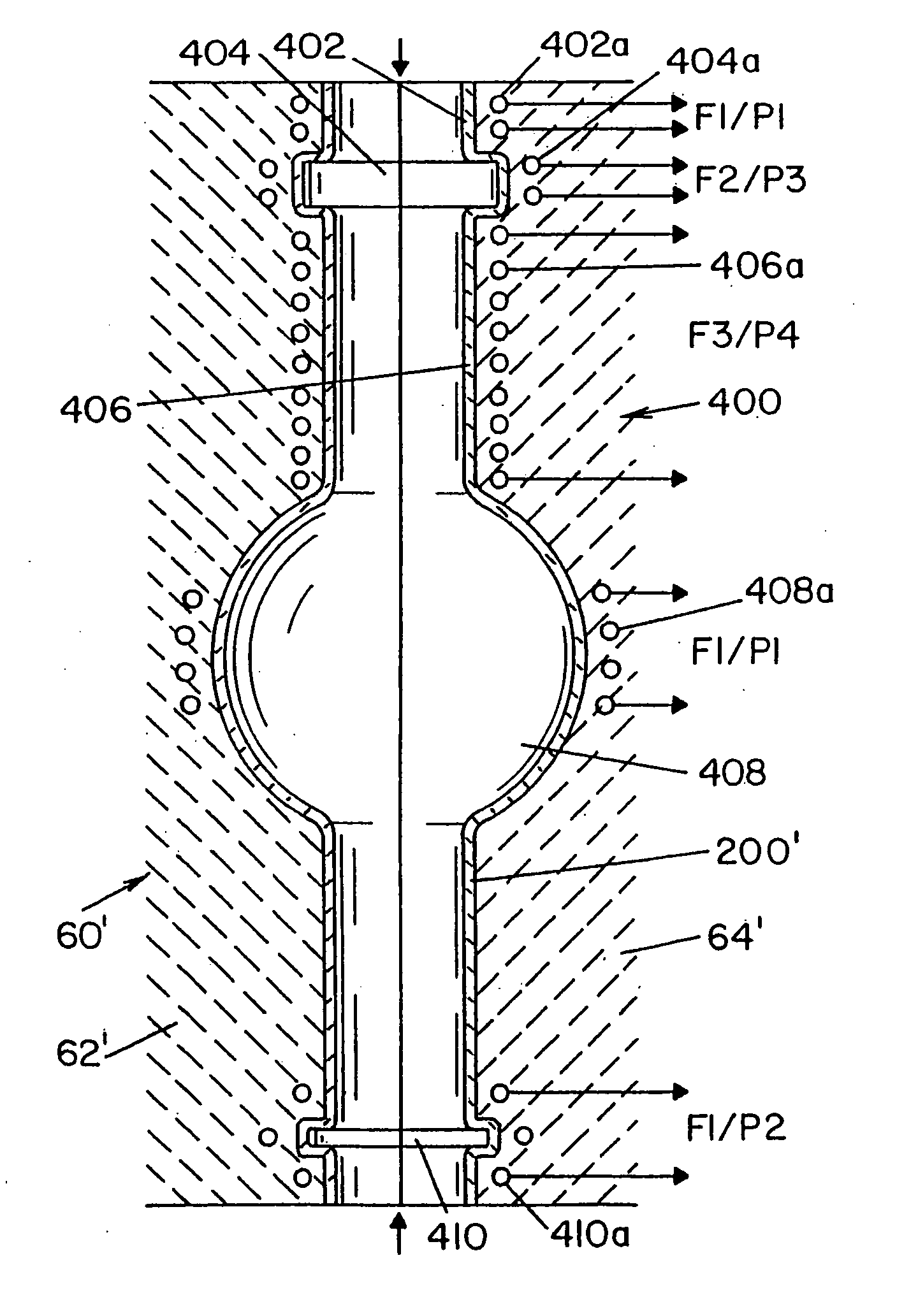

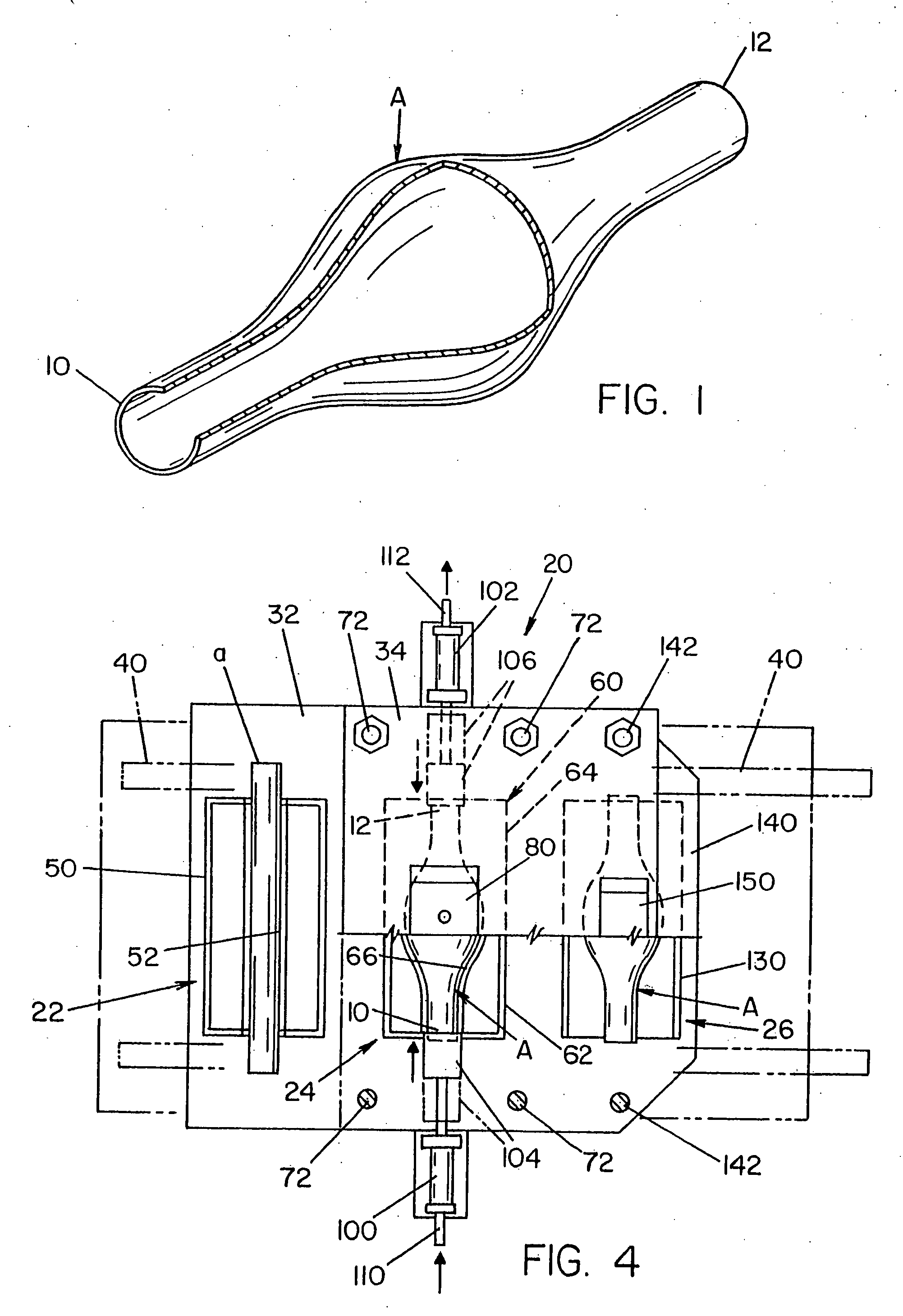

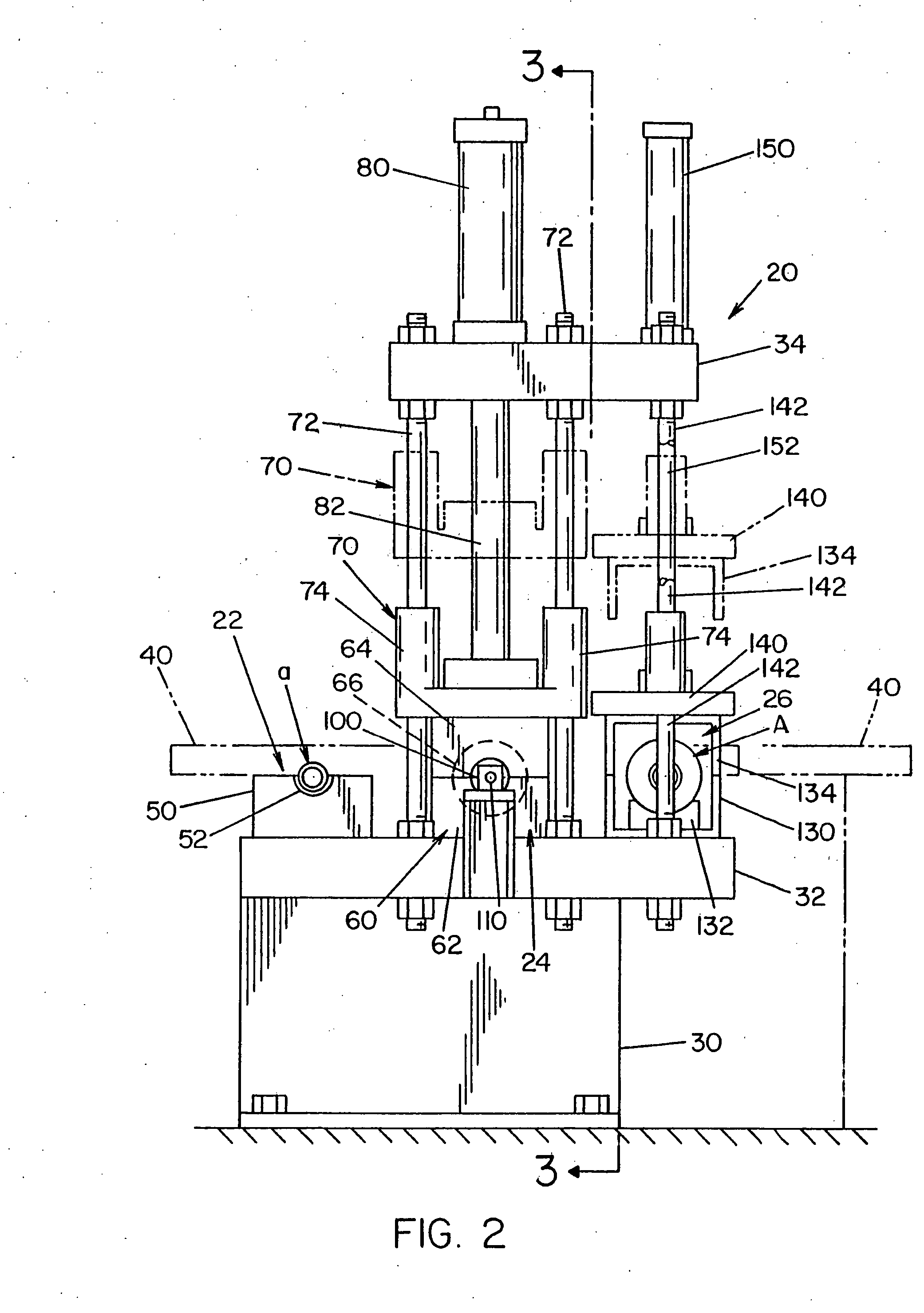

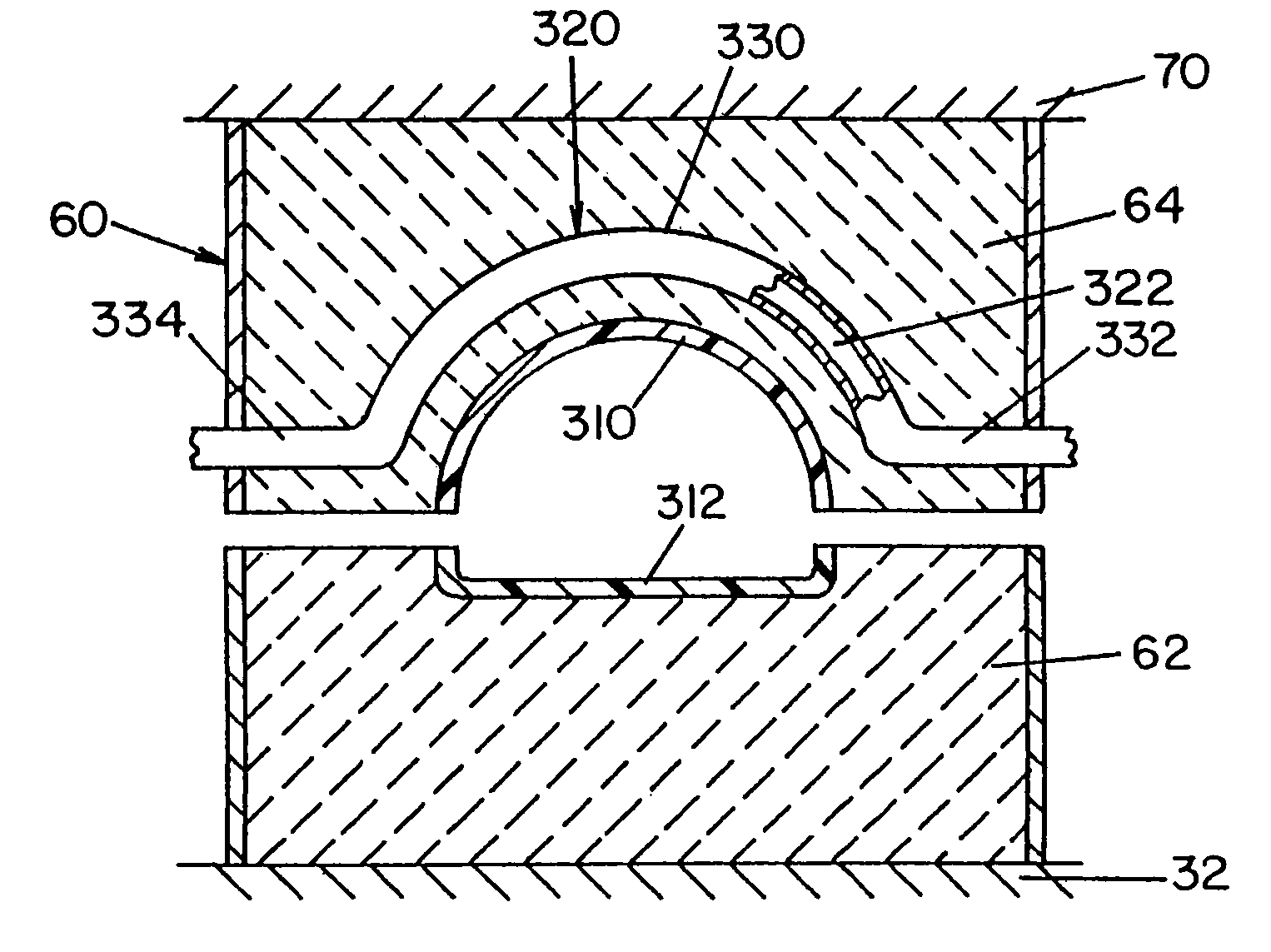

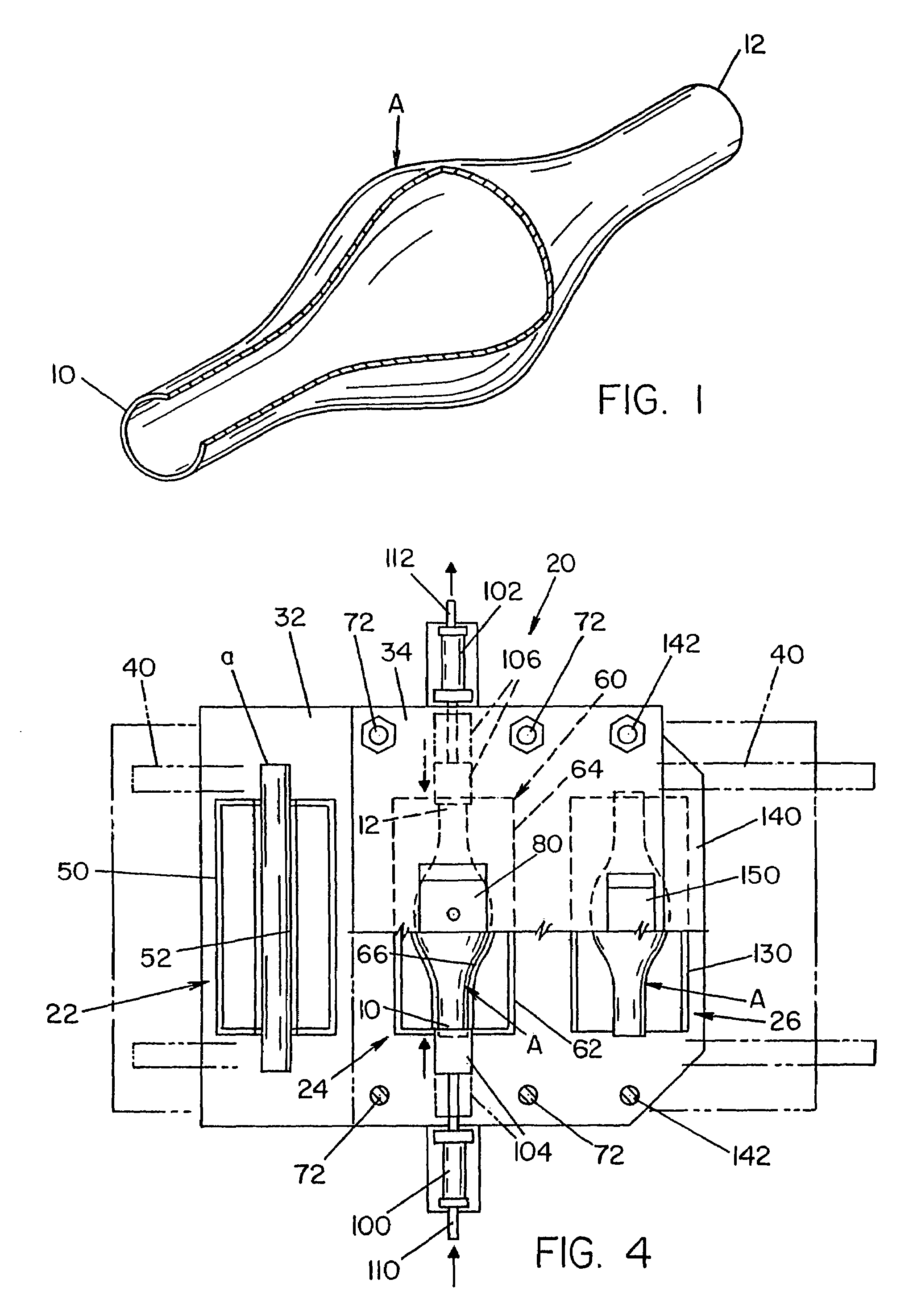

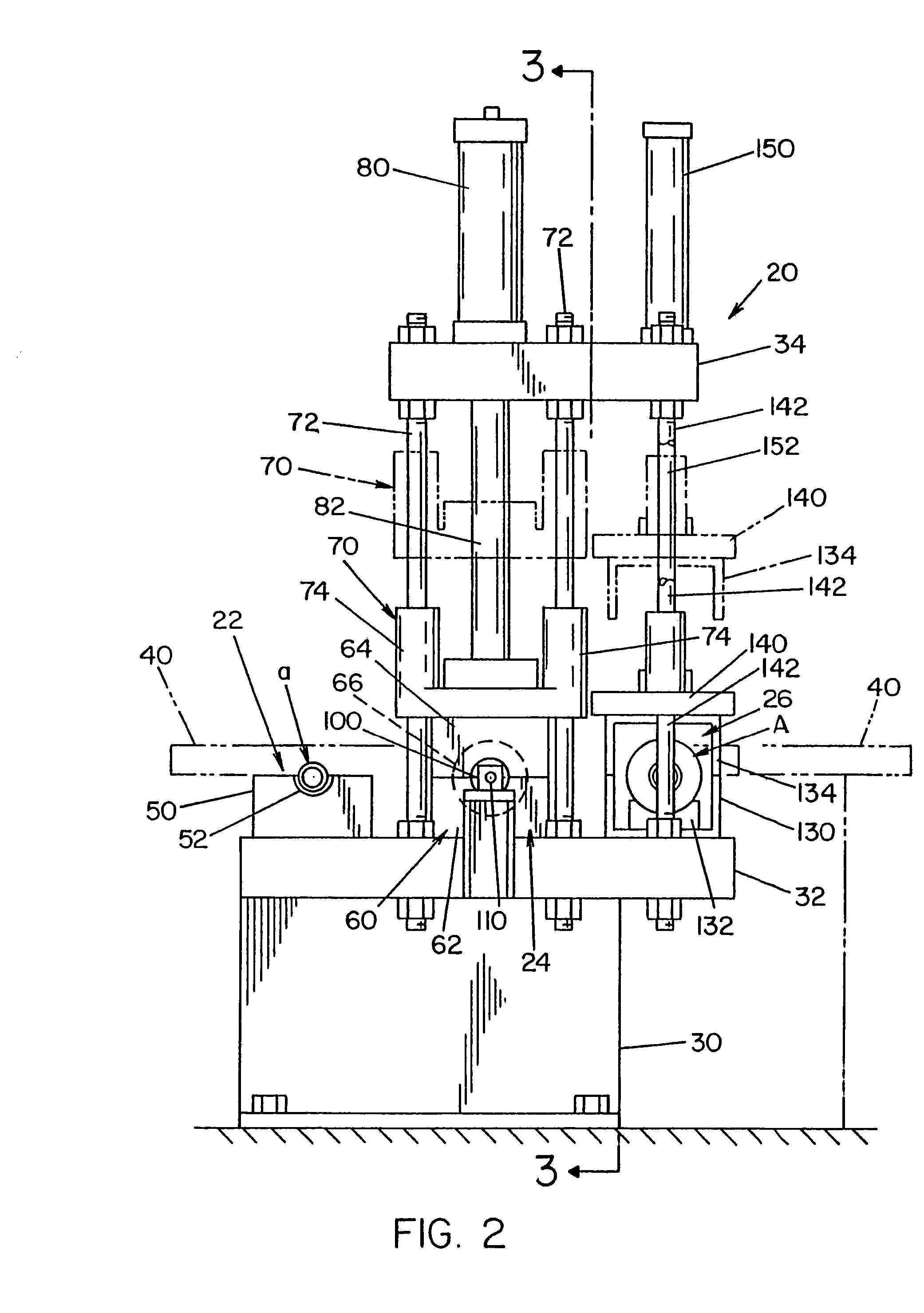

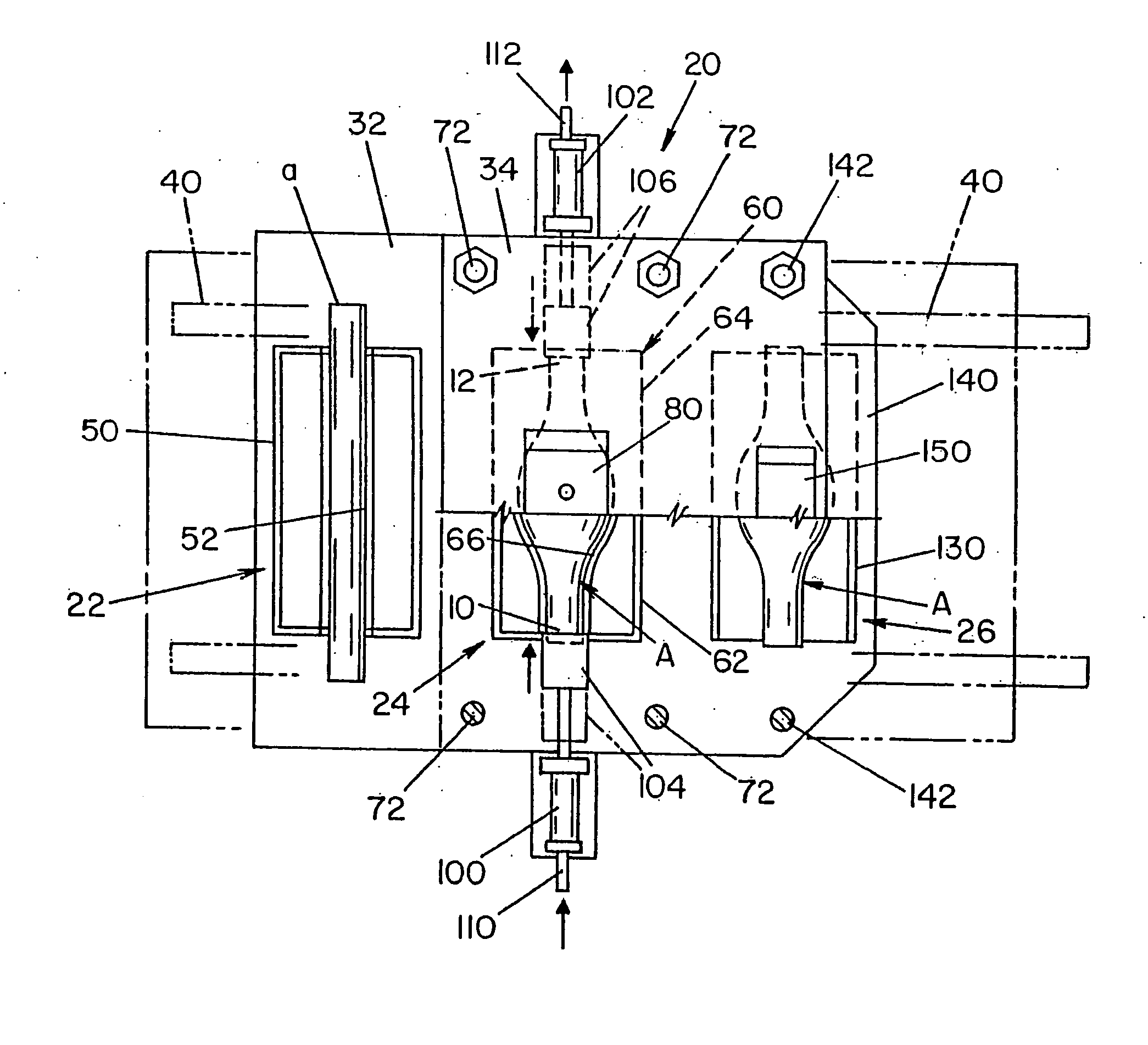

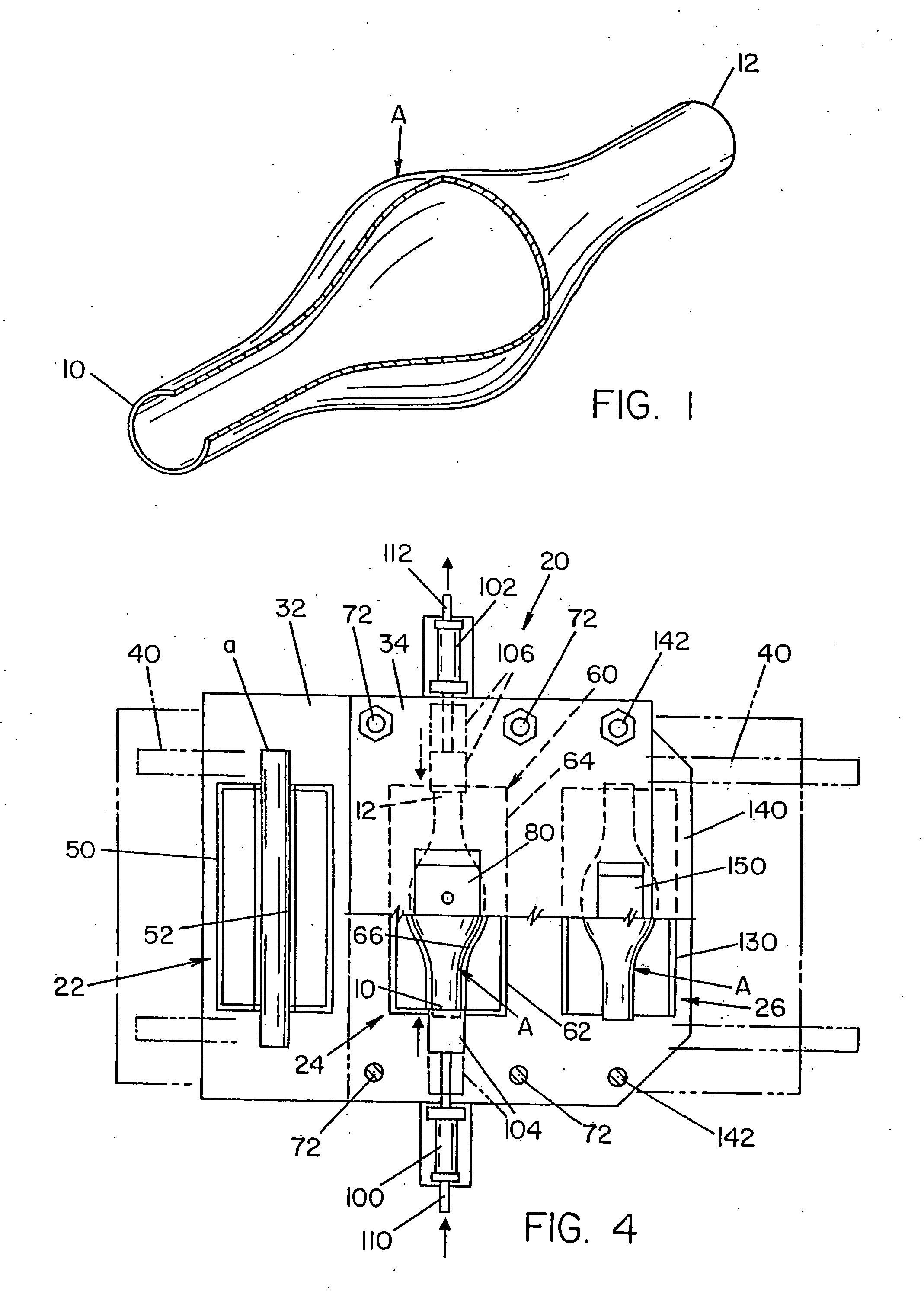

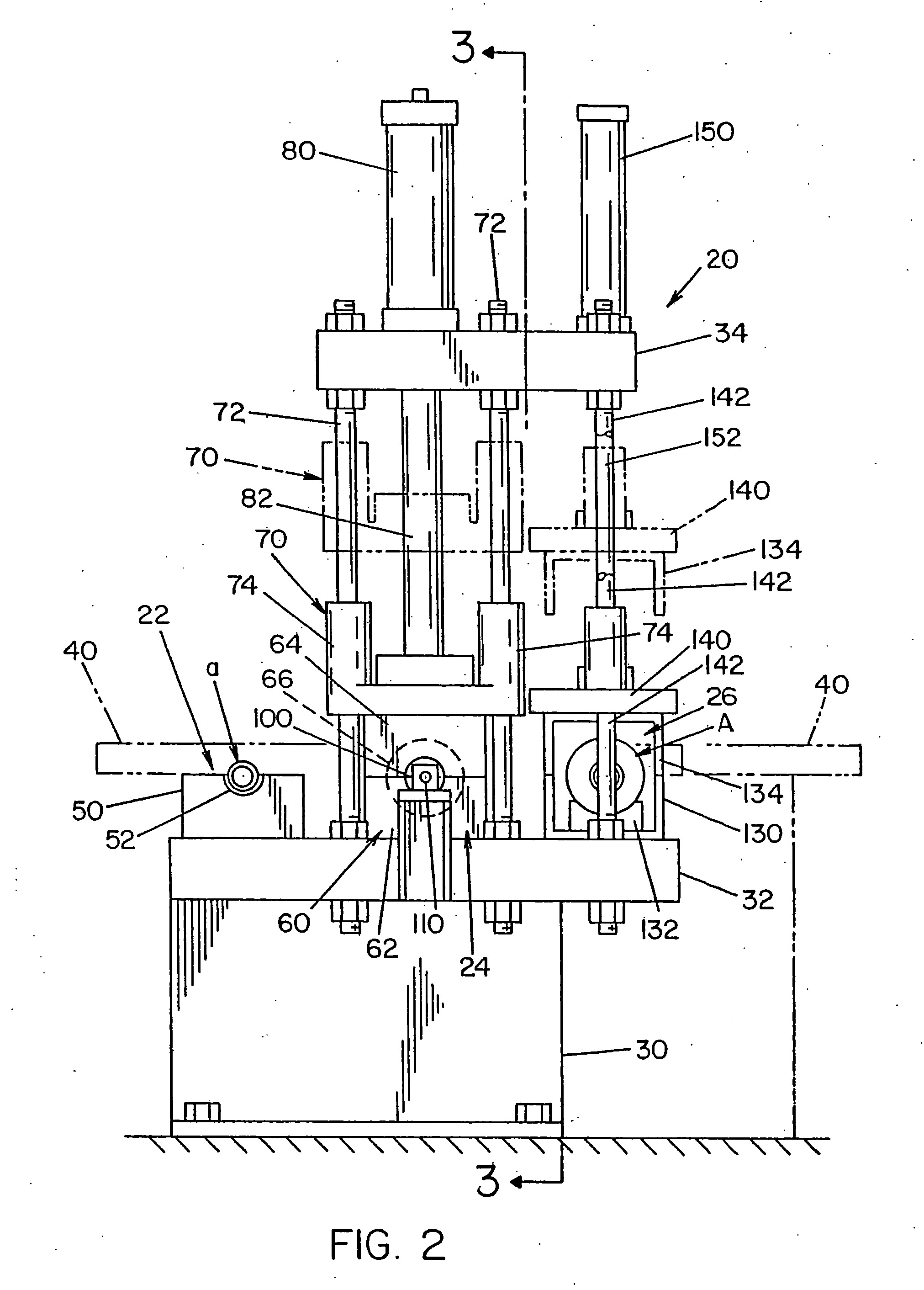

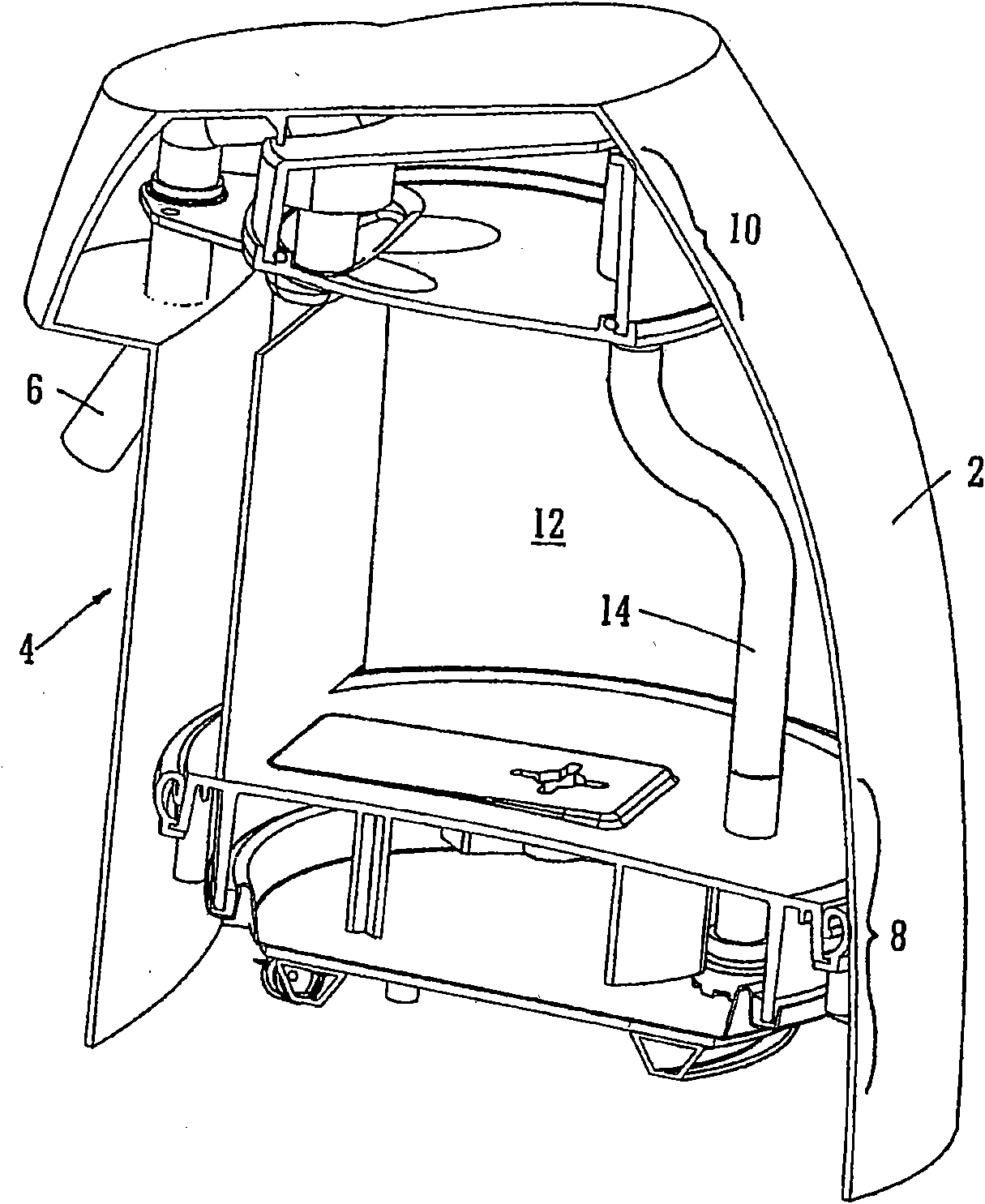

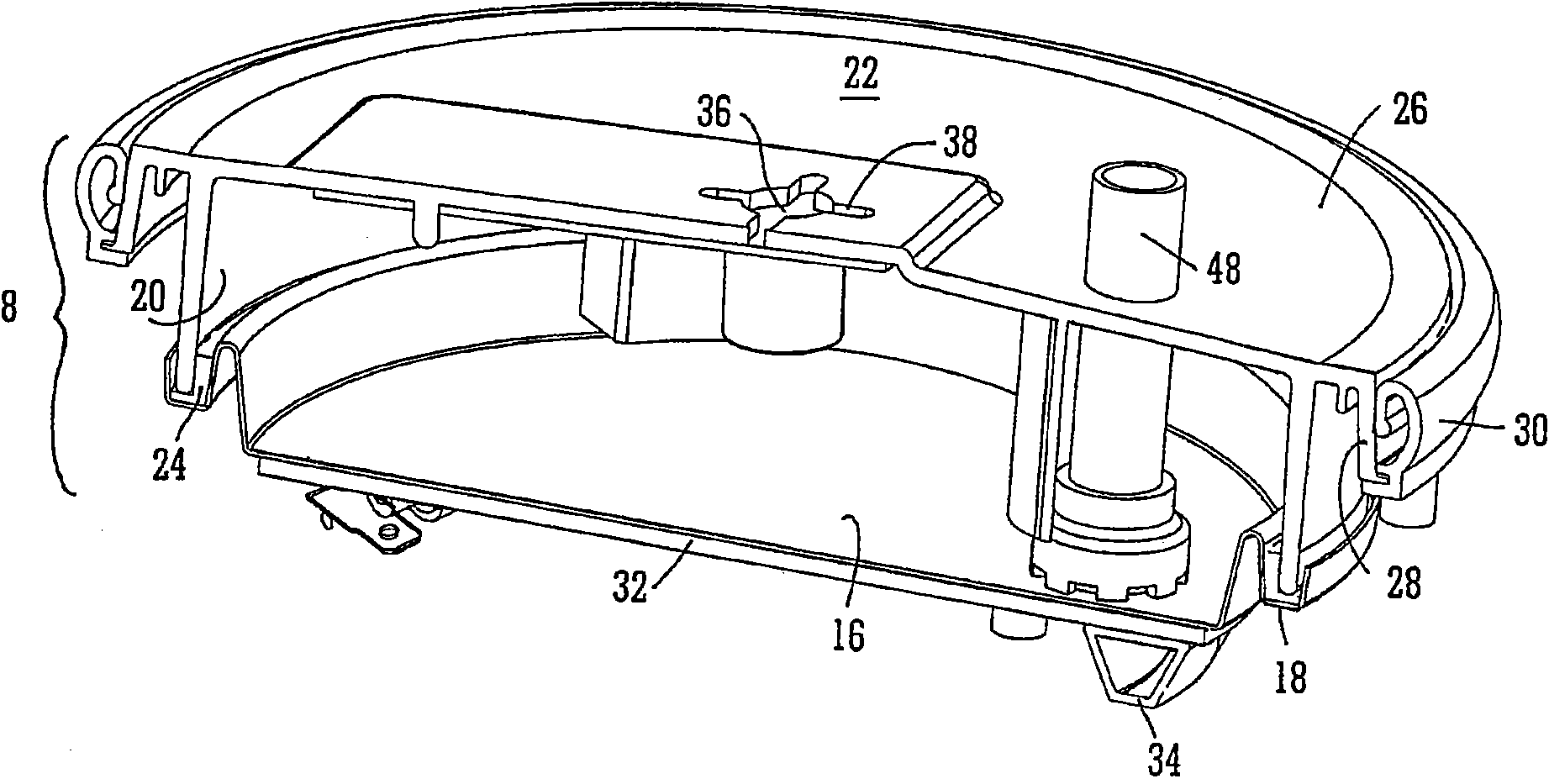

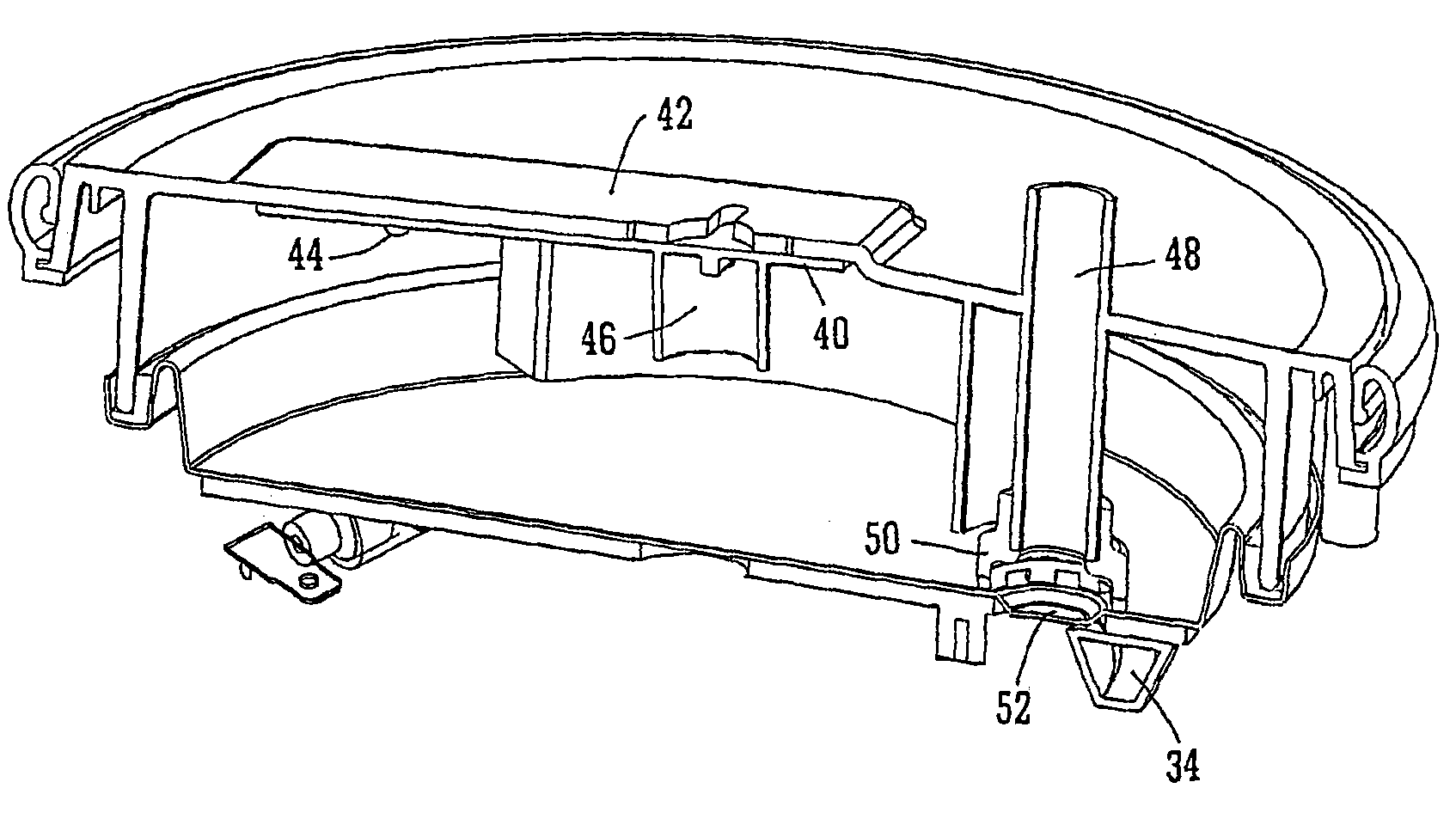

Method of forming a tubular blank into a structural component and die therefor

InactiveUS20040200550A1Reduce tooling costsImprove design flexibilityShaping toolsFurnace typesHigh pressureMetal

A method of forming an elongated metal blank into a structural component having a predetermined outer configuration. The method includes providing a shape imparting cavity or shell section formed from a rigid material which includes an inner surface defining the predetermined shape, placing the metal blank into the cavity or shell section, and forming the metal blank into the component by heating axial portions of the metal blank and forcing a fluid at a high pressure into the metal blank until the metal blank at least partially conforms to at least a portion of the inner surface of the cavity or shell section to form the structural component.

Owner:HOT METAL GAS FORMING IP2 INC +1

Method of forming a tubular blank into a structural component and die therefor

A method of forming an elongated metal blank into a structural component having a predetermined outer configuration. The method includes providing a shape imparting cavity or shell section formed from a rigid material which includes an inner surface defining the predetermined shape, placing the metal blank into the cavity or shell section, and forming the metal blank into the component by heating axial portions of the metal blank and forcing a fluid at a high pressure into the metal blank until the metal blank at least partially conforms to at least a portion of the inner surface of the cavity or shell section to form the structural component.

Owner:HOT METAL GAS FORMING IP2 INC +1

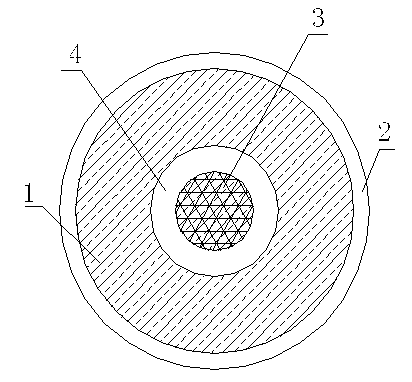

Phase-change energy storage microcapsules and preparation method thereof

ActiveCN102977857AIncreased heating and cooling cycle lifeReduce thermal shockHeat-exchange elementsMicroballoon preparationPhysicsChemistry

The invention provides phase-change energy storage microcapsules comprising a first phase-change material, a first wall capsules coated on the first phase-change material, and sub-microcapsules distributed in the first phase-change material. The sub-microcapsules comprise a second phase-change material and second wall capsules coated on the second phase-change material. Also, the invention provides a method for preparing the phase-change energy storage microcapsules provided by the invention. The method comprises the steps such as sub-microcapsule preparation, first phase-change material coating, first wall capsule preparation, and the like. The phase-change energy storage microcapsules provided by the invention have the advantages of failure resistance, long service life, and good stability.

Owner:领致热能新电器(江苏)股份有限公司

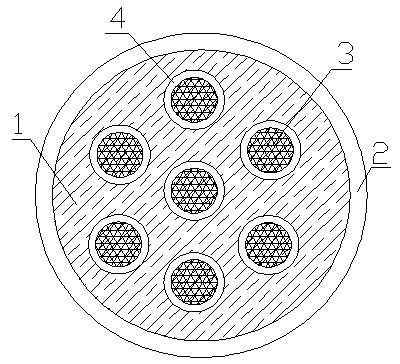

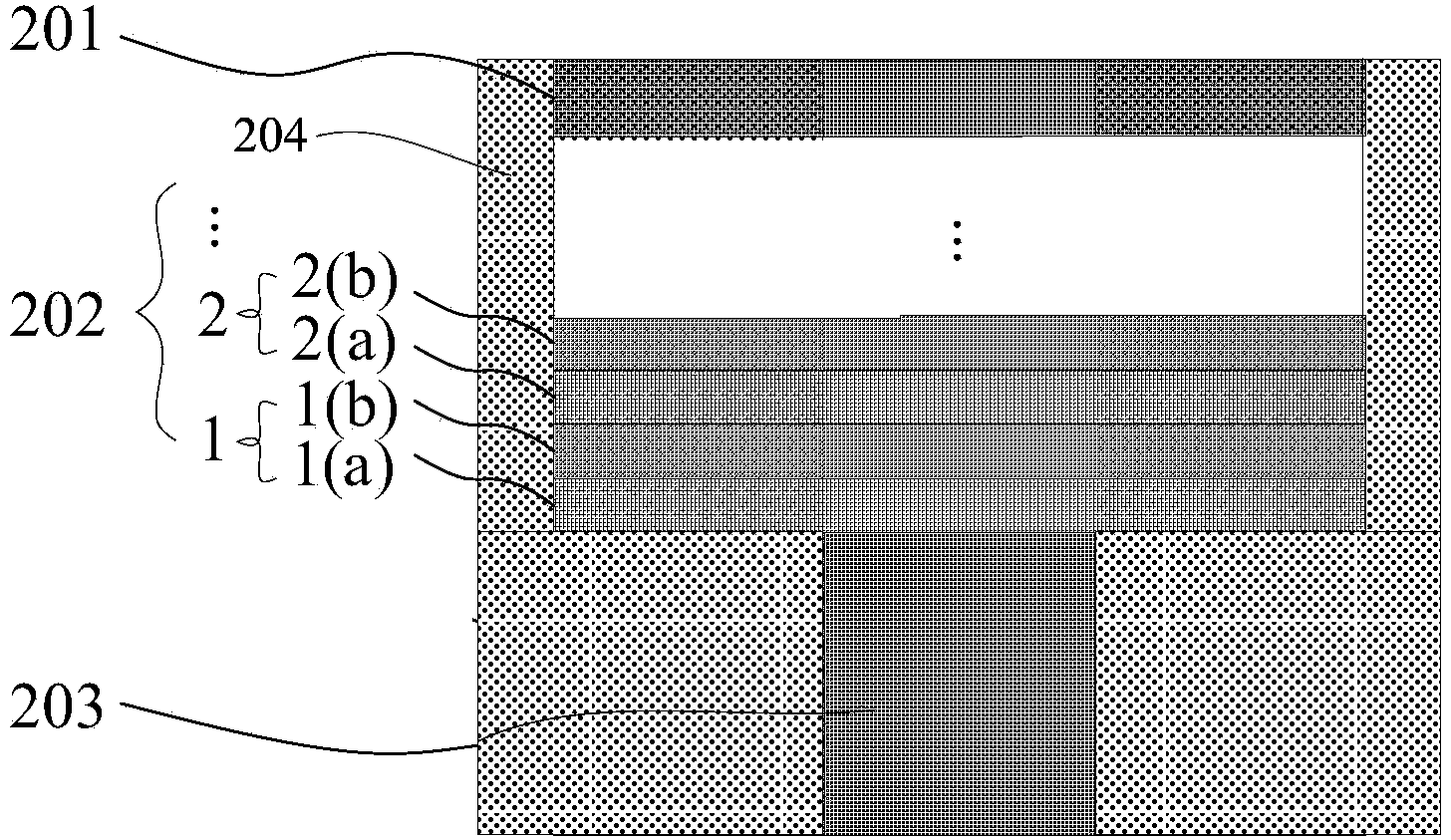

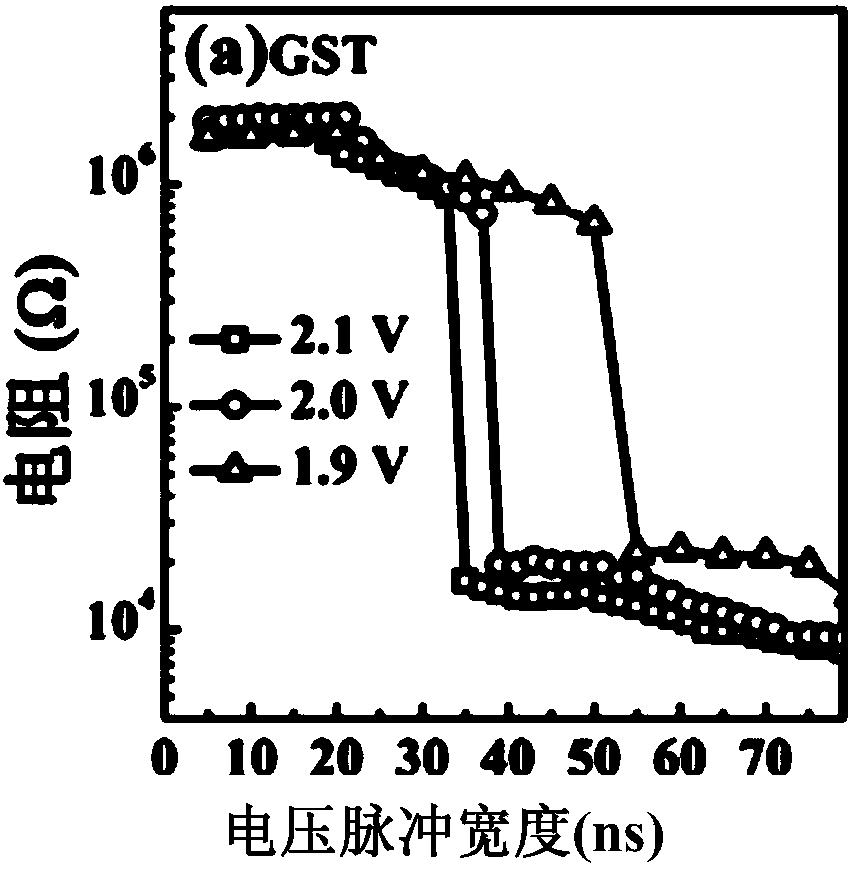

Phase change memory unit and method for manufacturing phase change memory unit

InactiveCN103794723AManufacturing process compatibleReduce power consumptionElectrical apparatusPhase-change memoryMedia layer

The invention provides a phase change memory unit and a method for manufacturing the phase change memory unit. A memory medium layer of the phase change memory unit is a superlattice thin film structure which is composed of an Sb[x]Te[1-x] layer and a Ti[y]Te[1-y] layer, and then a stable layered (Sb[x]Te[1-x])-(Ti[y]Te[1-y]) phase change material is obtained, wherein 0.4<=x<=0.8, 0.33<=y<=0.56, the thickness of the Sb[x]Te[1-x] layer is between 1 nm and 10 nm, and the thickness of the Ti[y]Te[1-y] layer is between 1 nm and 10 nm. The phase-change mechanism of the superlattice (Sb[x]Te[1-x])-(Ti[y]Te[1-y]) phase change material manufactured with the method is completely different from that of a traditional Ge-Sb-Te phase change material, and thus an obtained phase change memory device has the advantages of being lower in power consumption, higher in phase change speed, higher in retentivity, longer in service life and the like.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

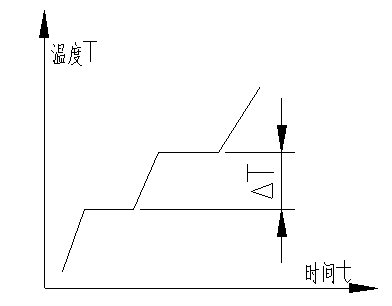

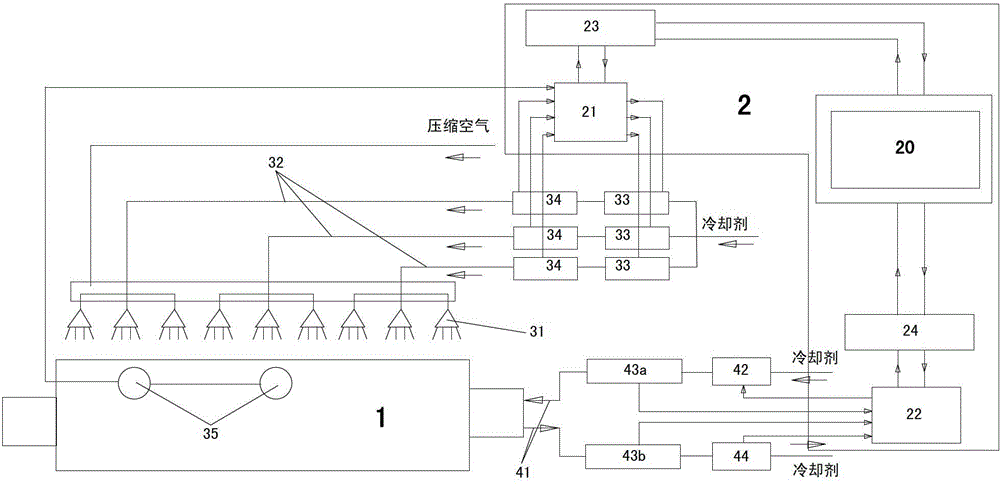

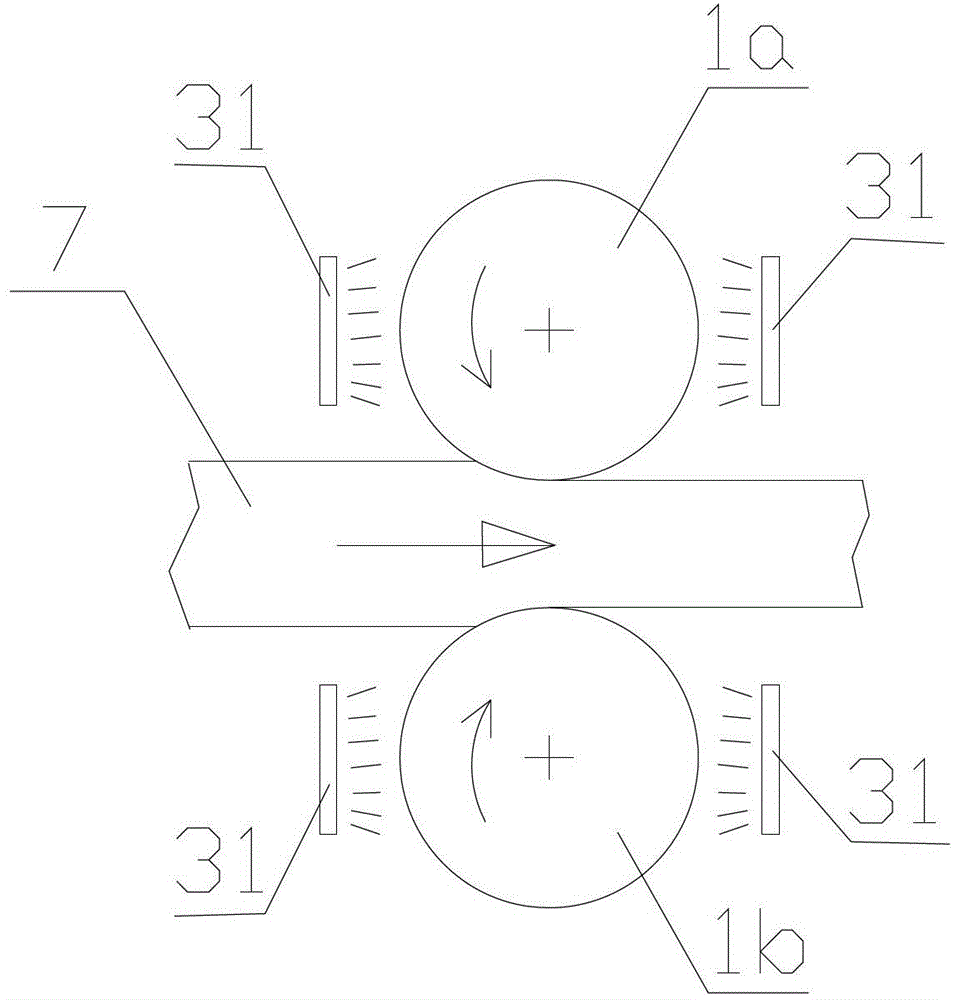

Roller cooling system and cooling control method thereof

ActiveCN103143570AReal-time detection of temperatureTemperature calculationTemperature control deviceRollsControl systemClosed loop

The invention discloses a roller cooling system and a cooling control method thereof. The roller cooling system adopts a system combined with exterior cooling and interior cooling, and the roller cooling control method is realized through a feedback-control loop consisting of a series of instrument equipment and a closed loop control system consisting of roller cooling control models. With the use of the method, the roller surface temperature and the roller interior temperature can be detected, fed back and calculated, moreover, each area of the roller surface is controlled alone through the closed loop control system; the heat convexities in the radial direction of the roller and in the peripheral and axial directions of the roller surface can be effectively controlled; the heat shock is reduced; and the service life of the roller is effectively prolonged by more than one time according to the field application statistics. The control models are simple and convenient to set and adjust, can precisely control the roller surface aerosol cooling injection amount, and guarantees no affection of rolling mill coolant on the surface quality of a continuous casting billet in the rolling mill position.

Owner:BERIS ENG & RES CORP +1

Simple method for manufacturing ceramic-metal composite wear-resistant part

The invention discloses a simple method for manufacturing a ceramic-metal composite wear-resistant part. The simple method for manufacturing the ceramic-metal composite wear-resistant part is characterized by comprising the following steps of obtaining a steel wire gauze, stamping a groove in the steel wire gauze, filling ceramic particles in the groove after surface wetting treatment is conducted on the ceramic particles, taking another steel wire gauze to cover the first steel wire gauze so that the groove can be shielded and scattering of the ceramic particles can be avoided, fixing the steel wire gauze with the ceramic particles fixed on a corresponding position, need to be enhanced, of the mold cavity wear-resistant part, and pouring and casting matrix metal liquid to obtain the wear-resistant part. The simple method for manufacturing the ceramic-metal composite wear-resistant part has the advantages of being even in distribution of the ceramic particles, firm in combination with matrix metal, capable of giving full play to the characteristics of ceramic and metal and achieving high-resistant performance and high-impact-resistant performance, simple, easy and convenient to operate, capable of being produced in large scale or in batch, and low in cost.

Owner:CHONGQING LUOMAN NEW MATERIAL TECH CO LTD

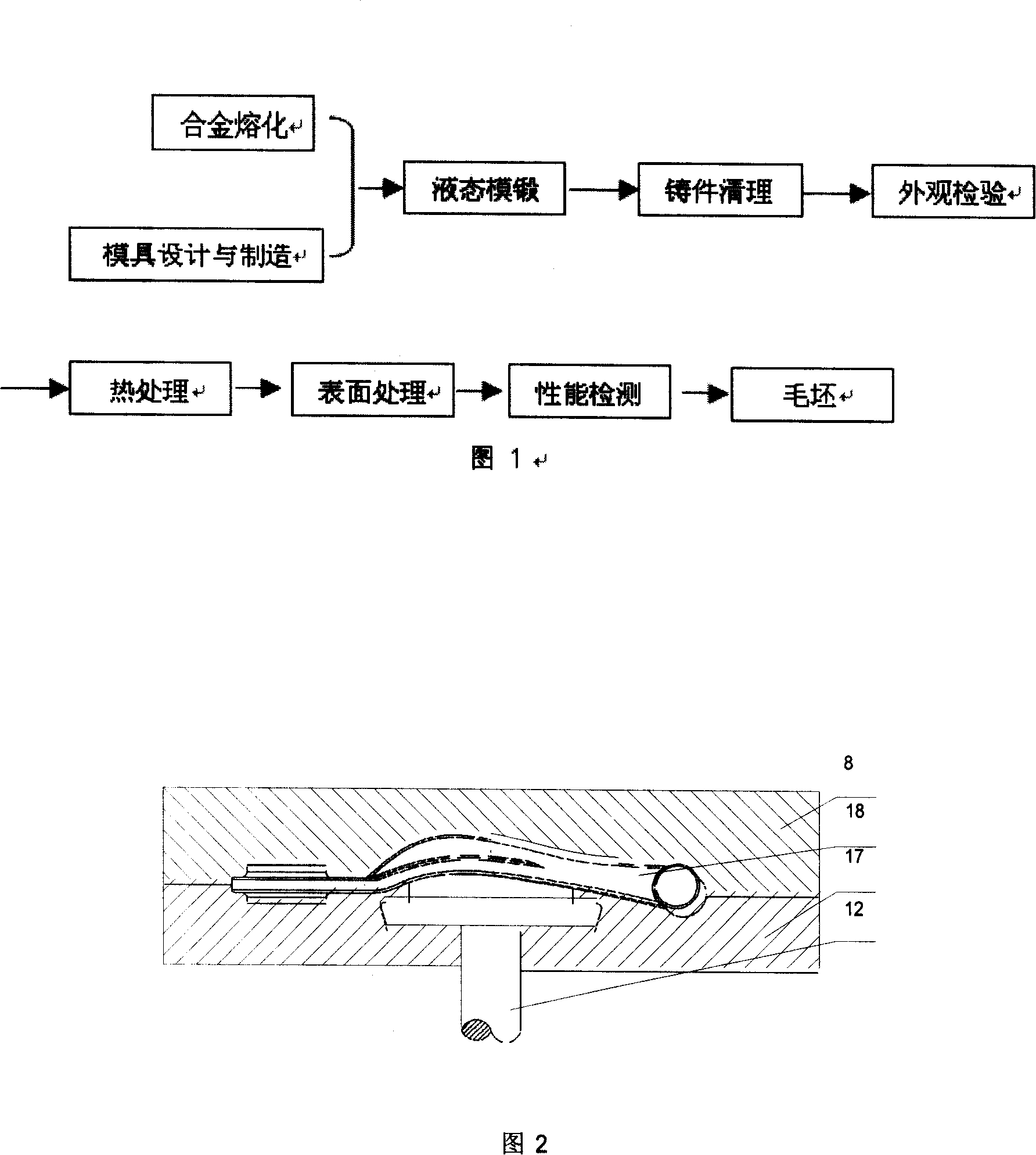

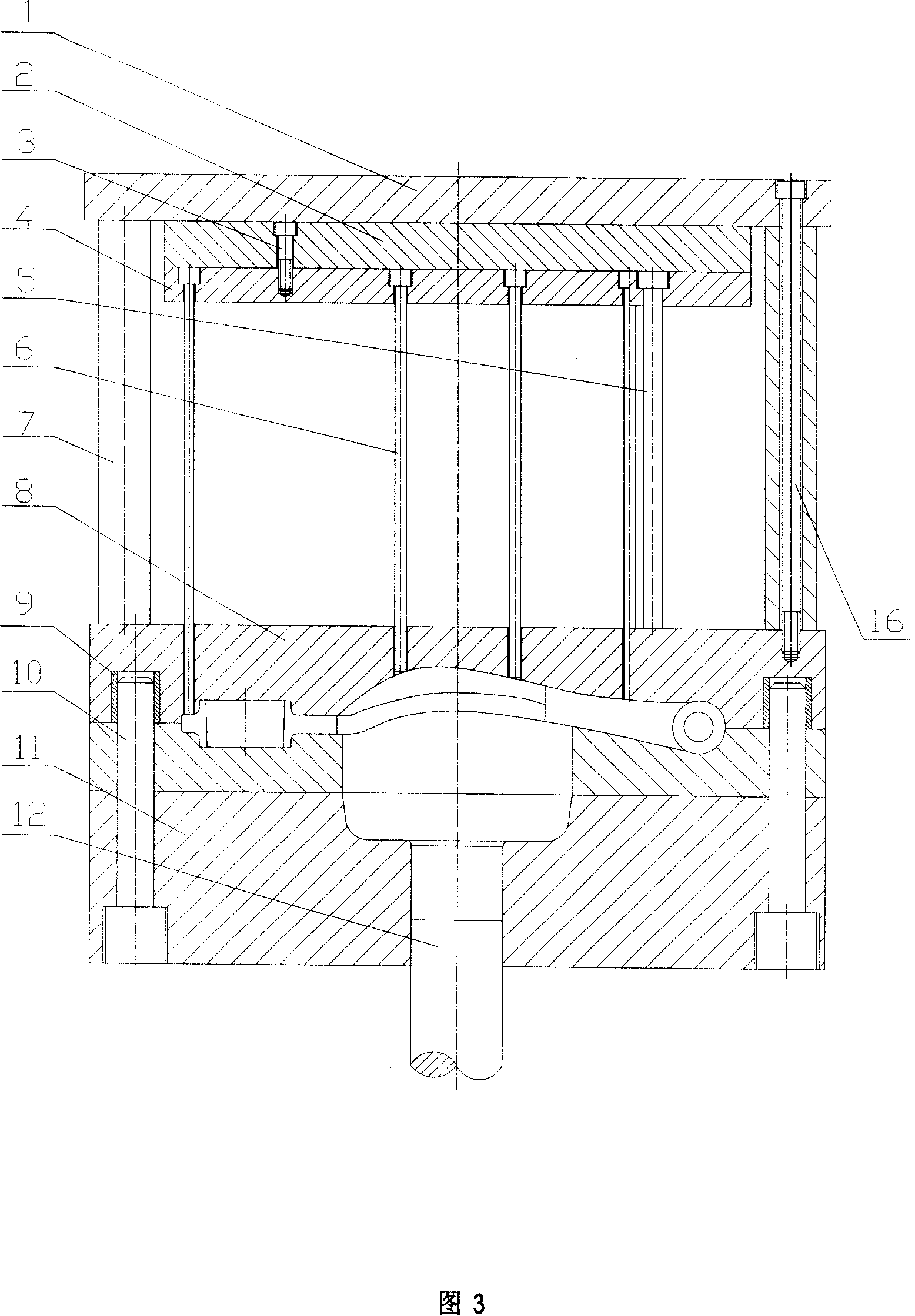

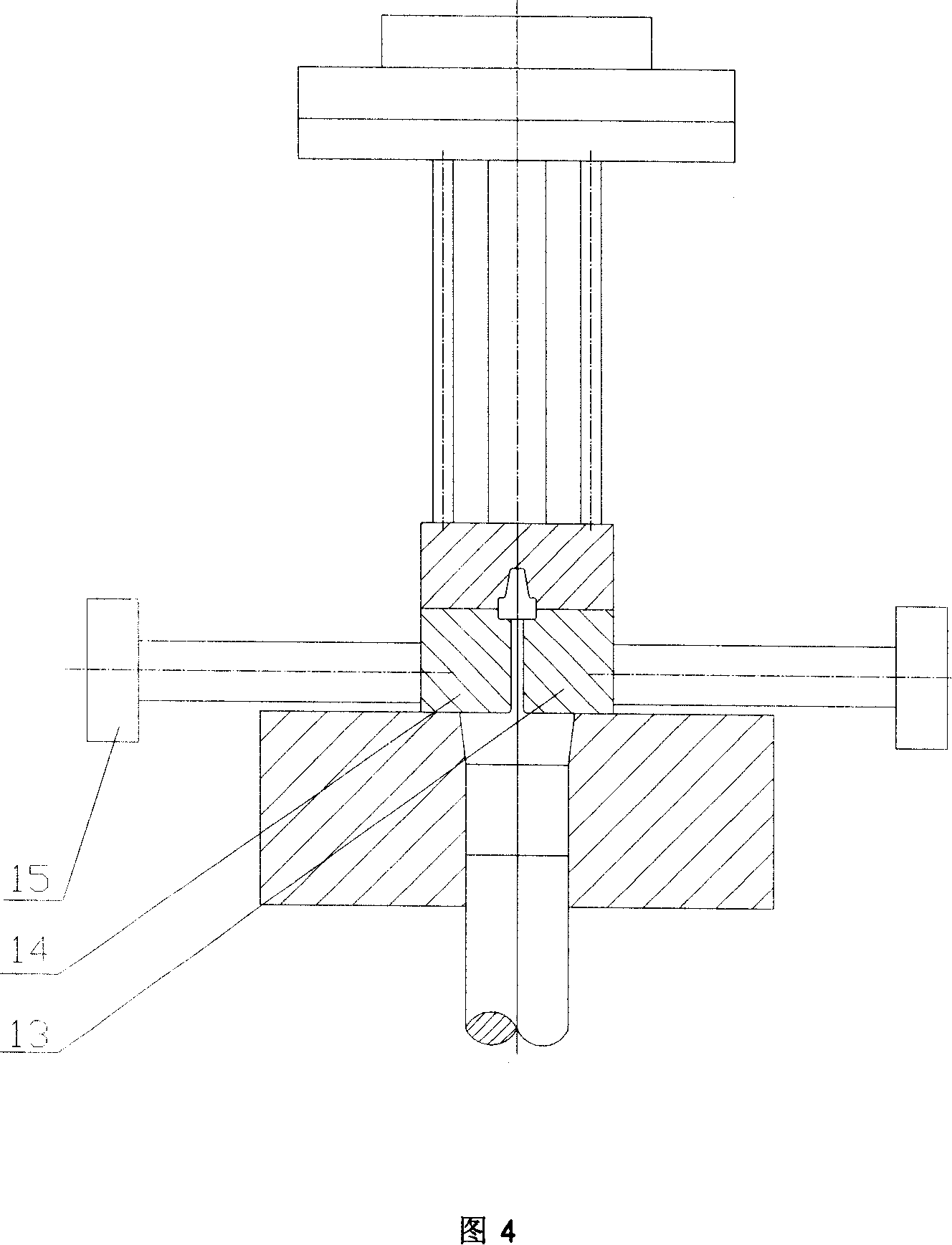

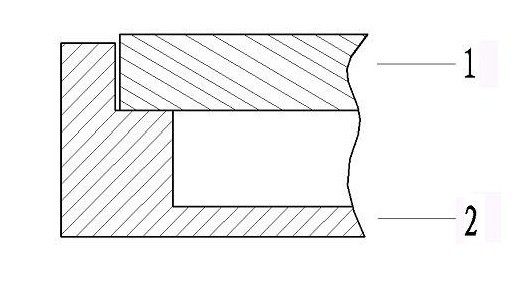

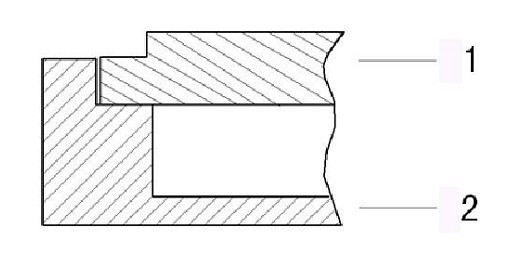

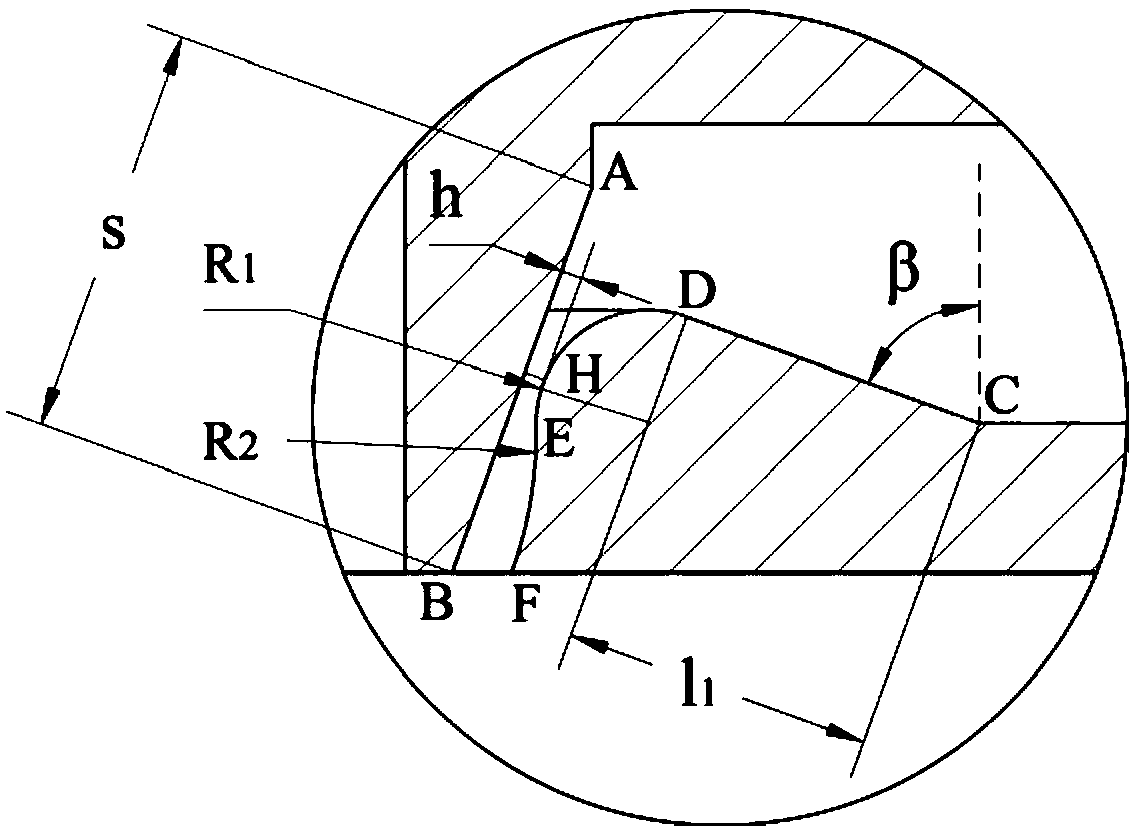

Aluminum alloy precast-forging forming technique and mold thereof

The invention relates to a forging technology and a device, in particular to aluminum alloy liquid forging molding technology and a module. In light of the technical problems that the prior art adopts complex module and process not suitable for aluminum alloy liquid forging, etc., the invention provides the forging module with simple structure and easy operation as well as the aluminum alloy liquid forging molding technology with reasonable process. The main technical proposal of the invention is as follows: a lower left module and a lower right module are arranged and fixed on a lower template in parallel, and a cylinder bottom punch gets through the lower template and is arranged between the lower left module and the lower right module; liquid aluminum alloy is injected into a cavity through a pouring port between the lower left module and the lower right module; an upper module is arranged on the lower left module and the lower right module and a pillar is also arranged and fixed; when in forging, the cylinder bottom punch conducts upward squeezing movement on liquid aluminum alloy; after meeting forging requirement, pressure can be maintained for 30 to 50 minutes.

Owner:宁波拓普隔音系统有限公司

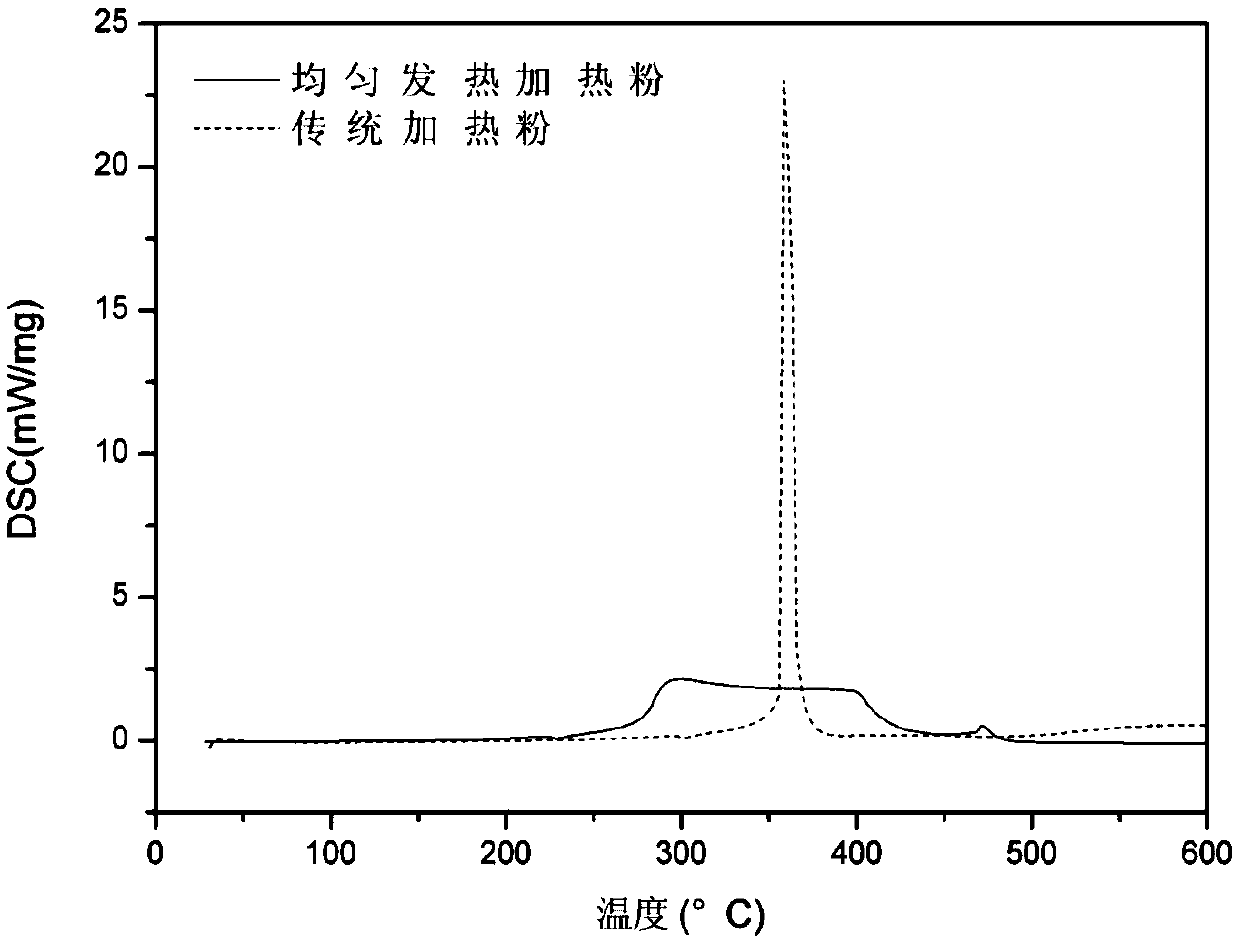

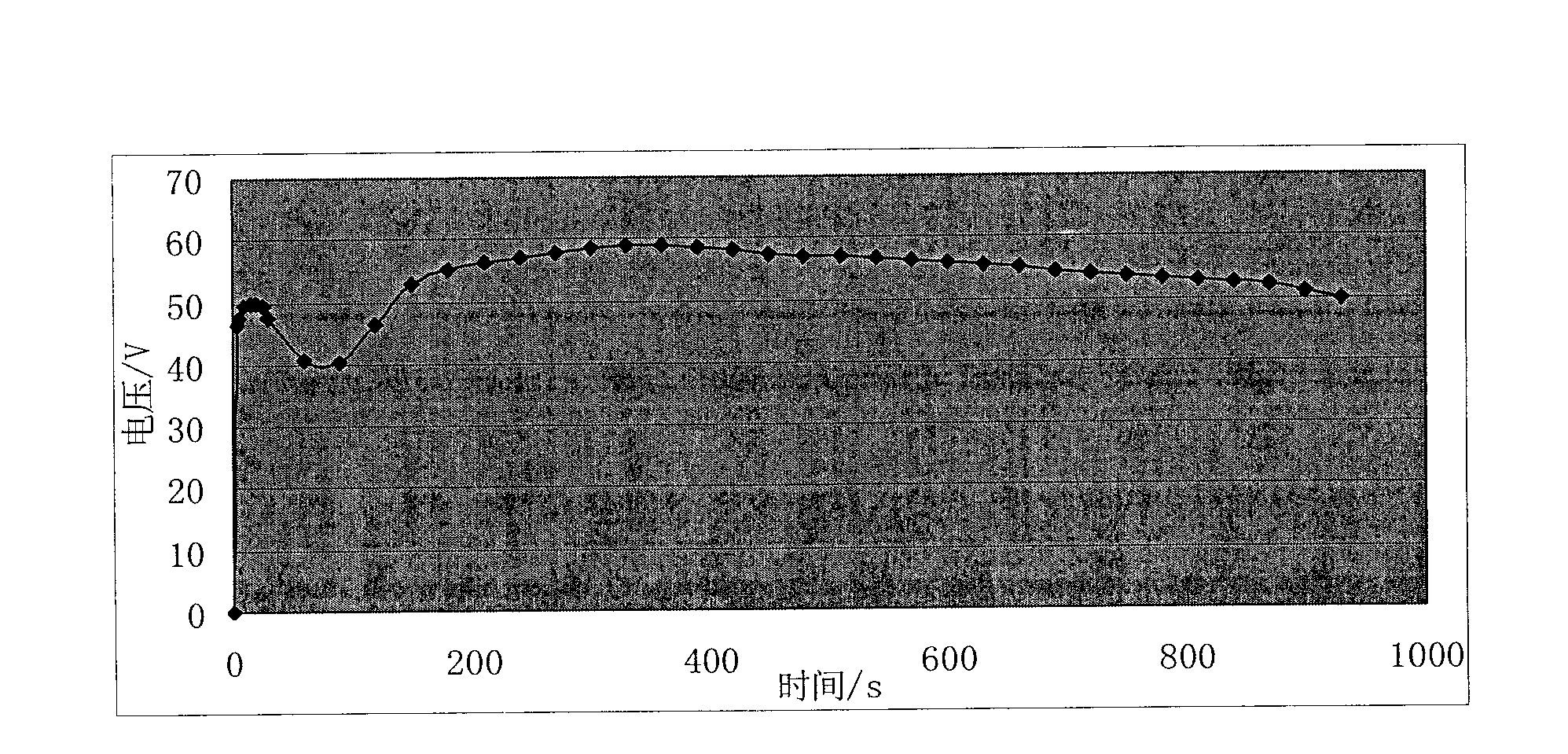

Manufacturing method for heating material uniformly heating used for thermal battery and application thereof

ActiveCN109546173AGood dispersionThe initial redox temperature value advancesDeferred-action cellsPrimary cell maintainance/servicingHigh energyFreeze-drying

The invention relates to a manufacturing method for a heating material uniformly heating used for a thermal battery and application thereof. The method comprises: pouring analytical pure grade potassium perchlorate into a high-energy ball-milling cup, adding appropriate water to prepare a slurry, placing a zirconia ball, performing high-energy ball milling, and then putting ball-milled powders into a freeze dryer to dehydrate, and then crushing using a pulverizer to obtain ultrafine potassium perchlorate, pouring active iron powders into an inert atmosphere glove box, adding an inorganic potassium salt, and then mixing the active iron powders and the inorganic potassium salt using a physical or chemical method, to form potassium-containing iron powders; finally, mixing the ultrafine potassium perchlorate and the potassium-containing iron powders according to a certain ratio. The method is beneficial to widening a heating region of a heating material, to release heat more uniformly, thereby weakening thermal shock amount on a positive electrode material of a thermal battery in an initial working phase of the material, and improving utilization rate of the positive electrode materialof the battery.

Owner:航天江南集团有限公司 +1

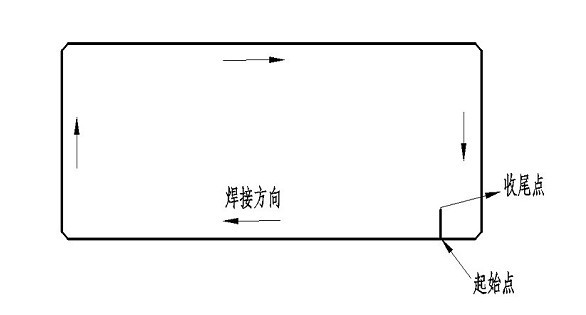

Shell for packaging microwave assembly and laser sealing method of shell

InactiveCN102496552AControlled Thermal ShockReduce thermal shockTransit-tube vessels/containersVessels or leading-in conductors manufactureMicrowaveThermal impact

The invention relates to a shell for packaging a microwave assembly and a laser sealing method of the shell. The shell for packaging the microwave assembly comprises an aluminum silicon alloy shell and a 4047 aluminum alloy cover plate, wherein the aluminum silicon alloy shell is abutted with the 4047 aluminum alloy cover plate. The laser sealing method comprises the following steps of: cleaning the aluminum silicon alloy shell and the 4047 aluminum alloy cover plate by using acetone, then abutting the aluminum silicon alloy shell with the 4047 aluminum alloy cover plate by using a tool, then fixing the aluminum silicon alloy shell and the 4047 aluminum alloy cover plate by using an Nd:YAG laser, and continuously integrally welding the shell by using the Nd-YAG laser, welding from the bottom of the aluminum silicon alloy shell until reaching the surface of the 4047 aluminum alloy cover plate, wherein the two welding processes are carried out in a nitrogen protective gas. The invention is used for carrying out sealing by using the laser, is easy to realize, has good sealing property and controllable welding depth, can be used for repaired for two times, has little thermal impact to a substrate and a chip because local heating is adopted in the welding process, can realize automatic operation, and has no soldering flux pollution and high reliability.

Owner:WUXI HUACE ELECTRONICS SYST

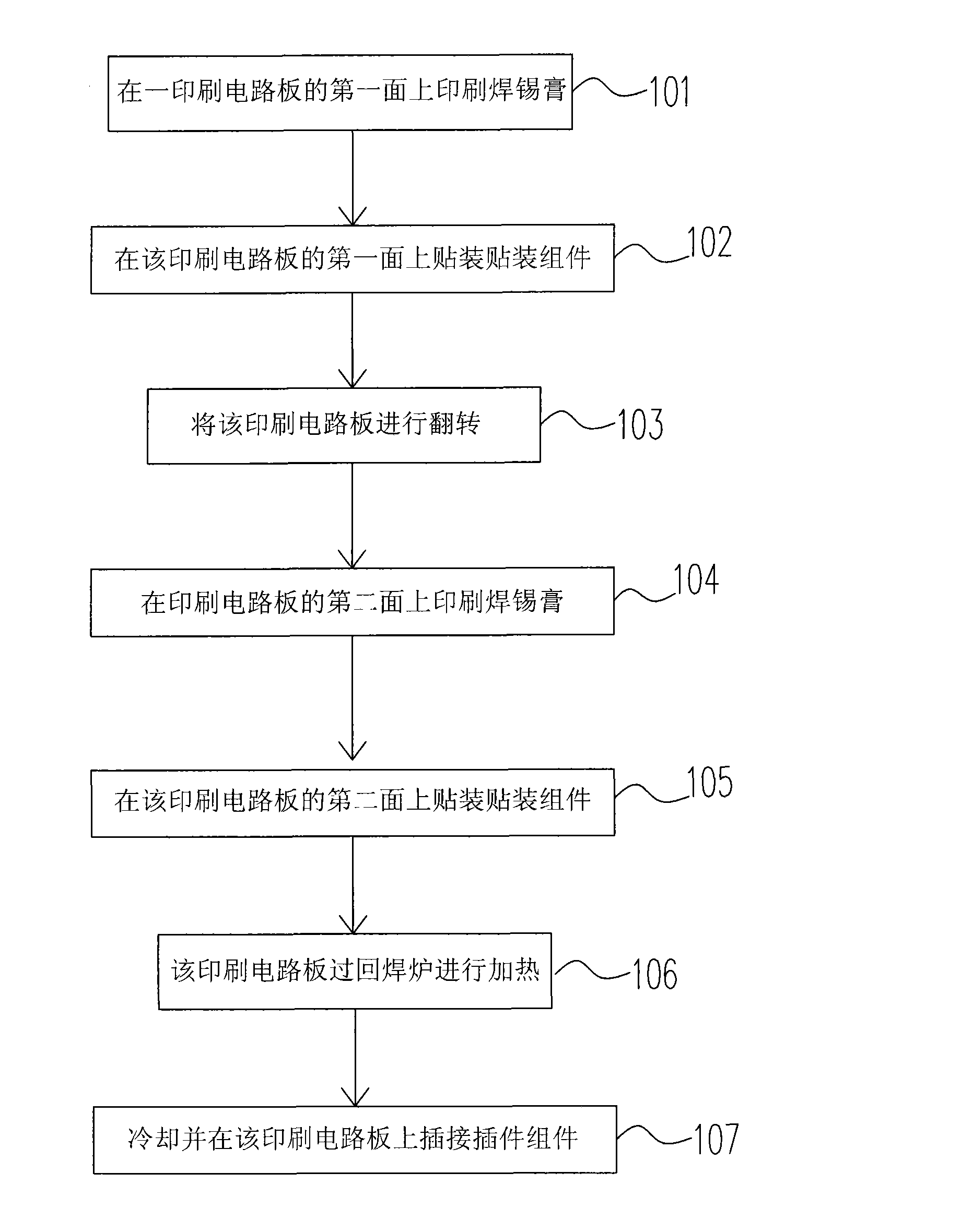

Bifacial circuit board surface assembly process

InactiveCN101528006AReduce thermal shockReduce oxidationPrinted circuit assemblingSolder pasteReflow oven

The invention provides a bifacial circuit board surface assembly process, wherein the process mainly comprises the following steps: firstly, assembling assembly parts on the first surface of a printed circuit board printed with solder paste; secondly, overturning the printed circuit board by a tilter, assembling the assembly parts on the second surface of the printed circuit board printed with the solder paste; thirdly, passing the assembled printed circuit board through a reflow oven, and welding the assembled parts on the printed circuit board; and finally, inserting plug-in assembly parts in the printed circuit board. In the bifacial circuit board surface assembly process of the invention, the printed circuit board only passes through the reflow oven once, the printed circuit board has the advantages of less heat shock, less oxygenation, no circular flow and less printed circuit board damage.

Owner:MITAC COMP (SHUN DE) LTD

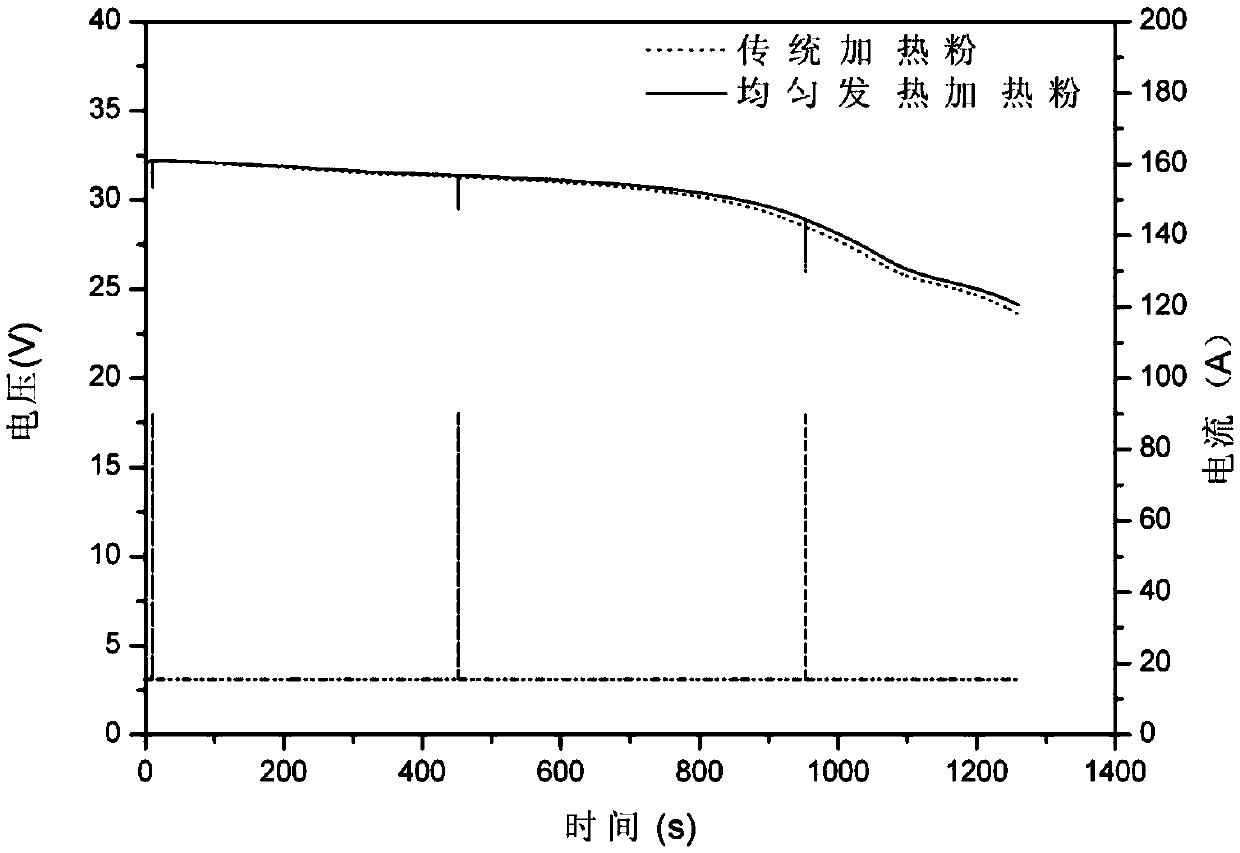

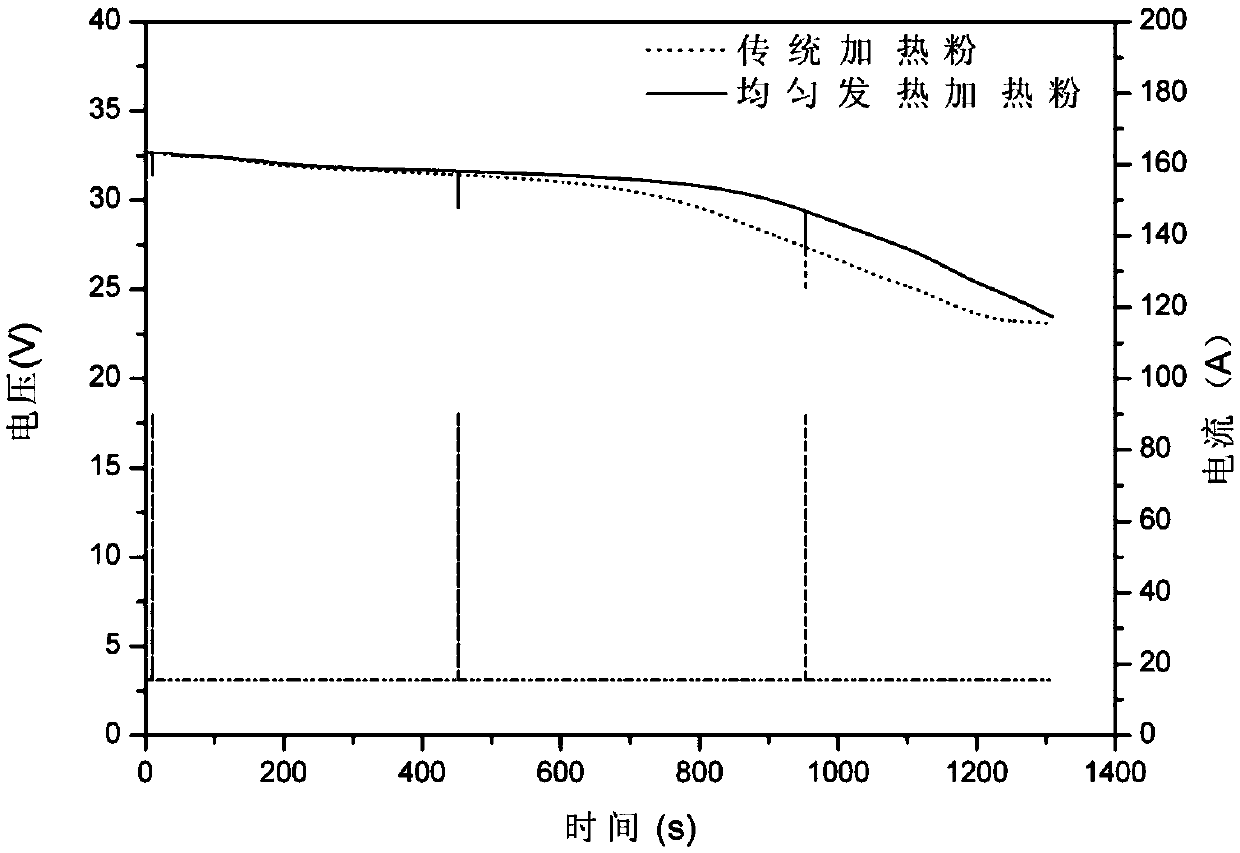

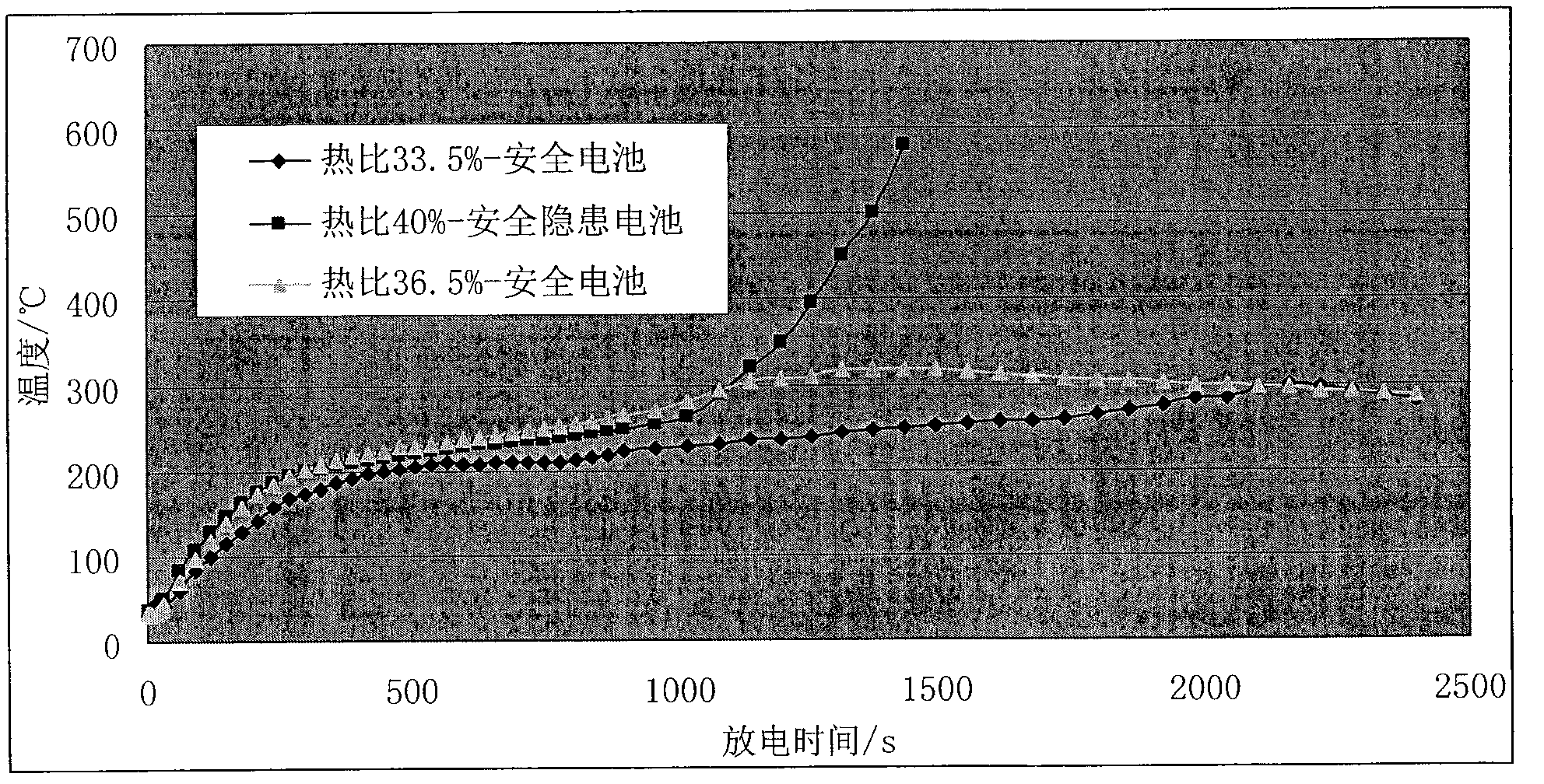

Cell unit for thermal cell with high specific energy

InactiveCN102856565AIncrease profitImprove conductivityDeferred-action cellsCell electrodesThermal impactOptimal weight

The invention relates to the field of thermal cell, and provides a cell unit for thermal cell with high specific energy (75 Wh / kg). The invention is characterized in that: (1) the optimal content of heating powder in the cell unit is 30-39 wt.% in the thermal balance design of the cell unit, and when the content of heating powder in the cell unit is above 40 wt.%, potential safety hazards are present in the thermal cell; (2) the optimal weight ratio of LiSi anode and CoS2 cathode is 1: 2.5 to 1: 3.5 in the compatibility design of cell unit for Li(Si) / LiCl-LiBr-LiF / CoS2 electrochemical system thermal cell; (3) 2-10% of LiCl-LiBr-LiF tertiary lithium electrolyte is added to the anode material for promoting conductivity and increasing the utilization rate of the anode active material; and (4) a graphite isolation material with good conductivity is arranged between the cathode sheet and the heating sheet for reducing thermal impact of the heating sheet on the cathode material and increasing the utilization rate of the cathode active material.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

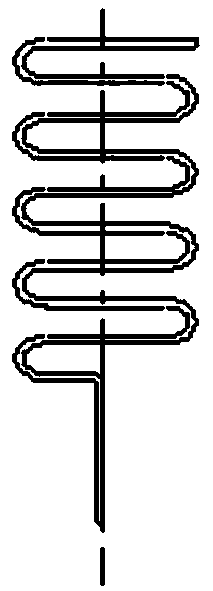

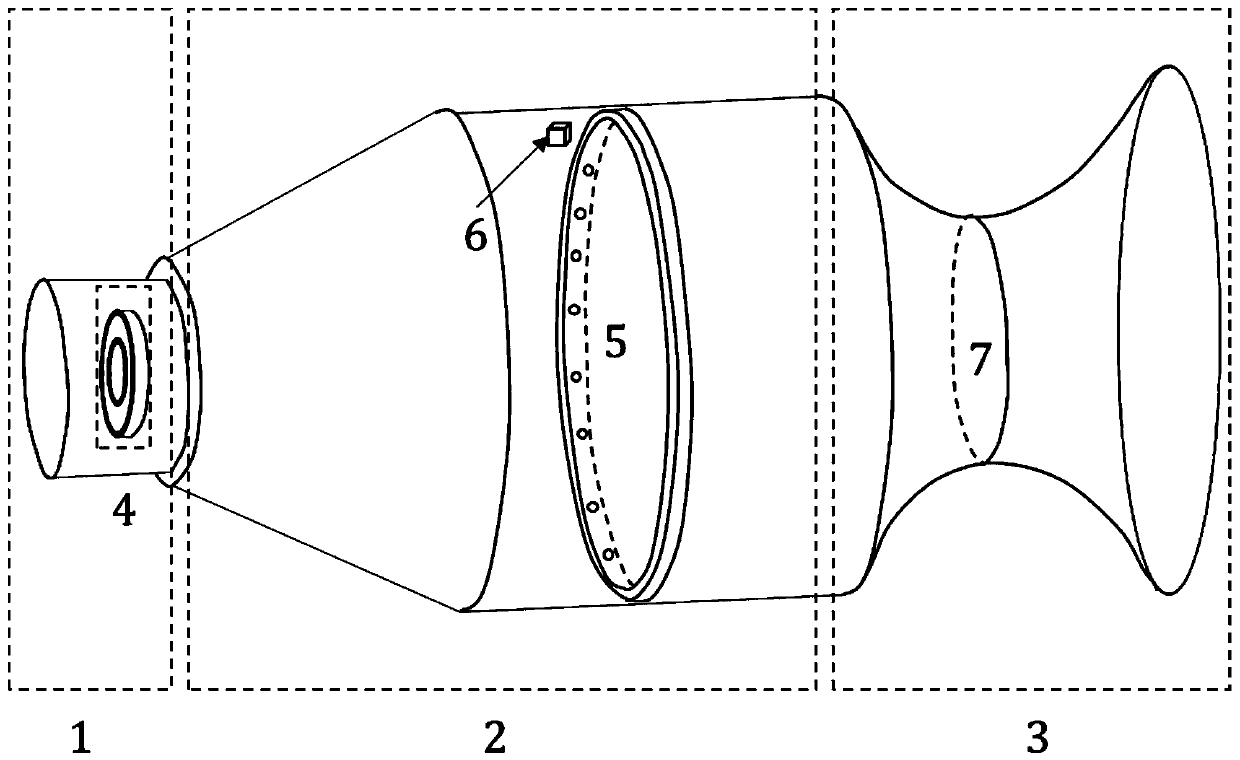

Hollow cathode heater and hollow cathode structure

ActiveCN109599309AEasy processing and assemblyHigh mechanical strengthMachines/enginesDischarge tube hollow cathodesThermal shockLife span

The present invention discloses a hollow cathode heater and a hollow cathode structure, the heater comprises an inner ceramic skeleton (4), a heating wire (5) and an outer ceramic sleeve (6); outer side of the inner ceramic skeleton (4) and / or inner side of the outer ceramic sleeve (6) has a first a structure; the first structure is any one or any combination of a protrusion, a groove or a smoothsurface; the outer ceramic sleeve (6) is nested outside the inner ceramic skeleton (4), a first space is surrounded and formed between the outer side of the inner ceramic skeleton (4) and the inner side of the outer ceramic sleeve (6) through the first structure. The hollow cathode heater is easy to process and assemble, has high mechanical strength and high reliability, and has a serpentine heating wire, with induced magnetic fields at adjacent positions cancelling each other, can effectively reduce an induced voltage and an induced current generated by the induced magnetic fields at the ignition moment, reduce thermal shock of the heating wire and improve reliability and life span of a space electric propulsion system.

Owner:SHANGHAI INST OF SPACE PROPULSION

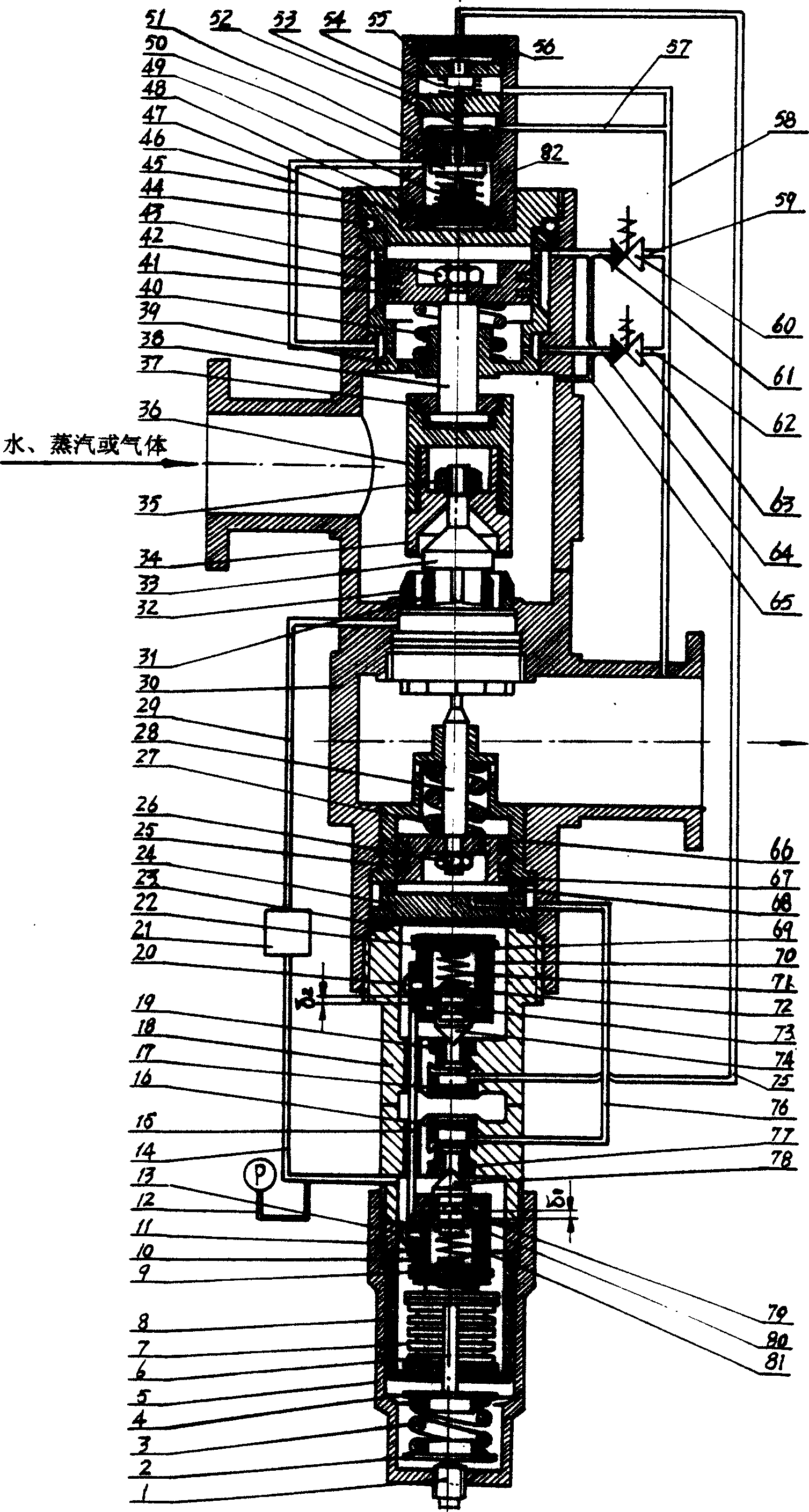

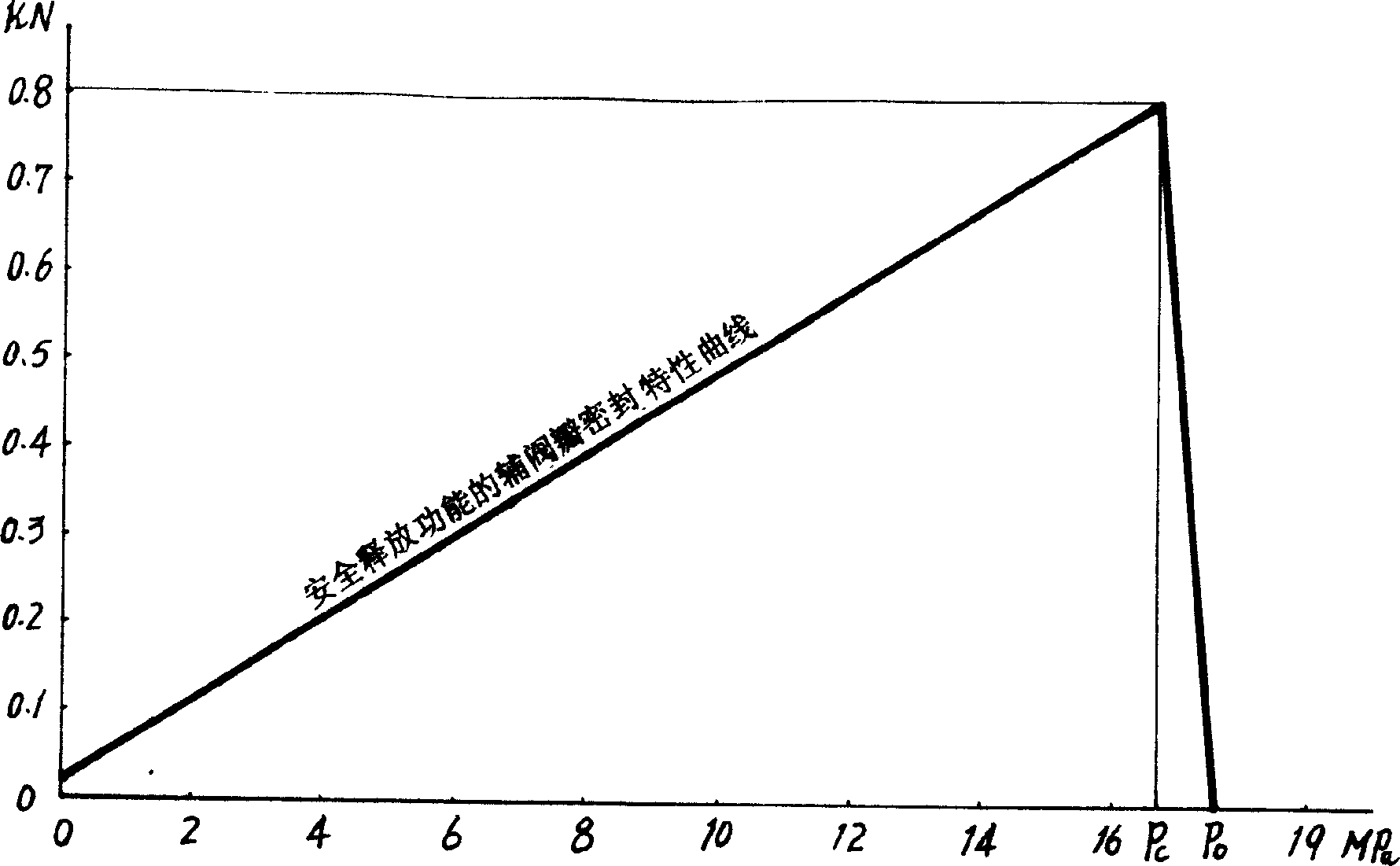

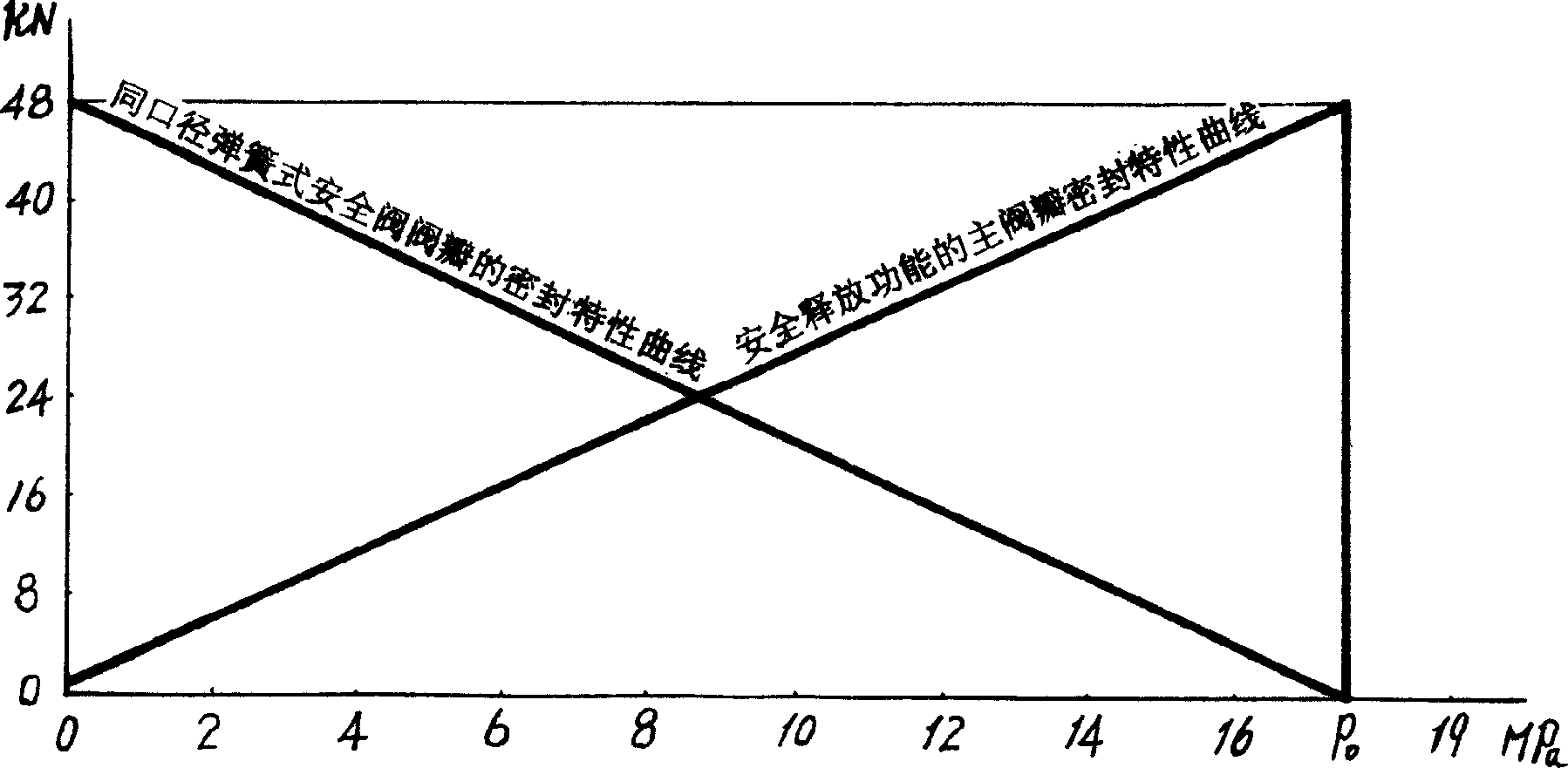

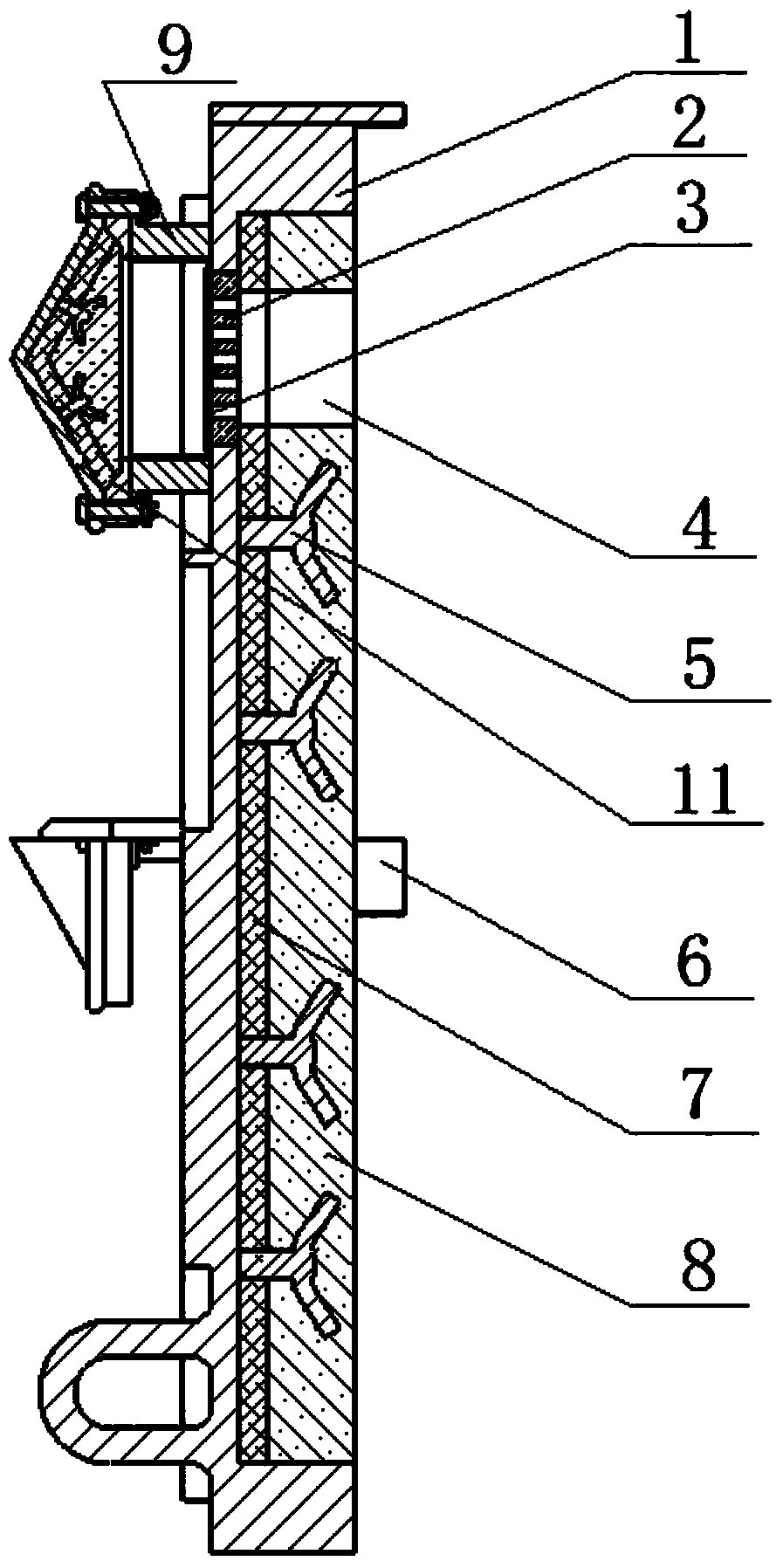

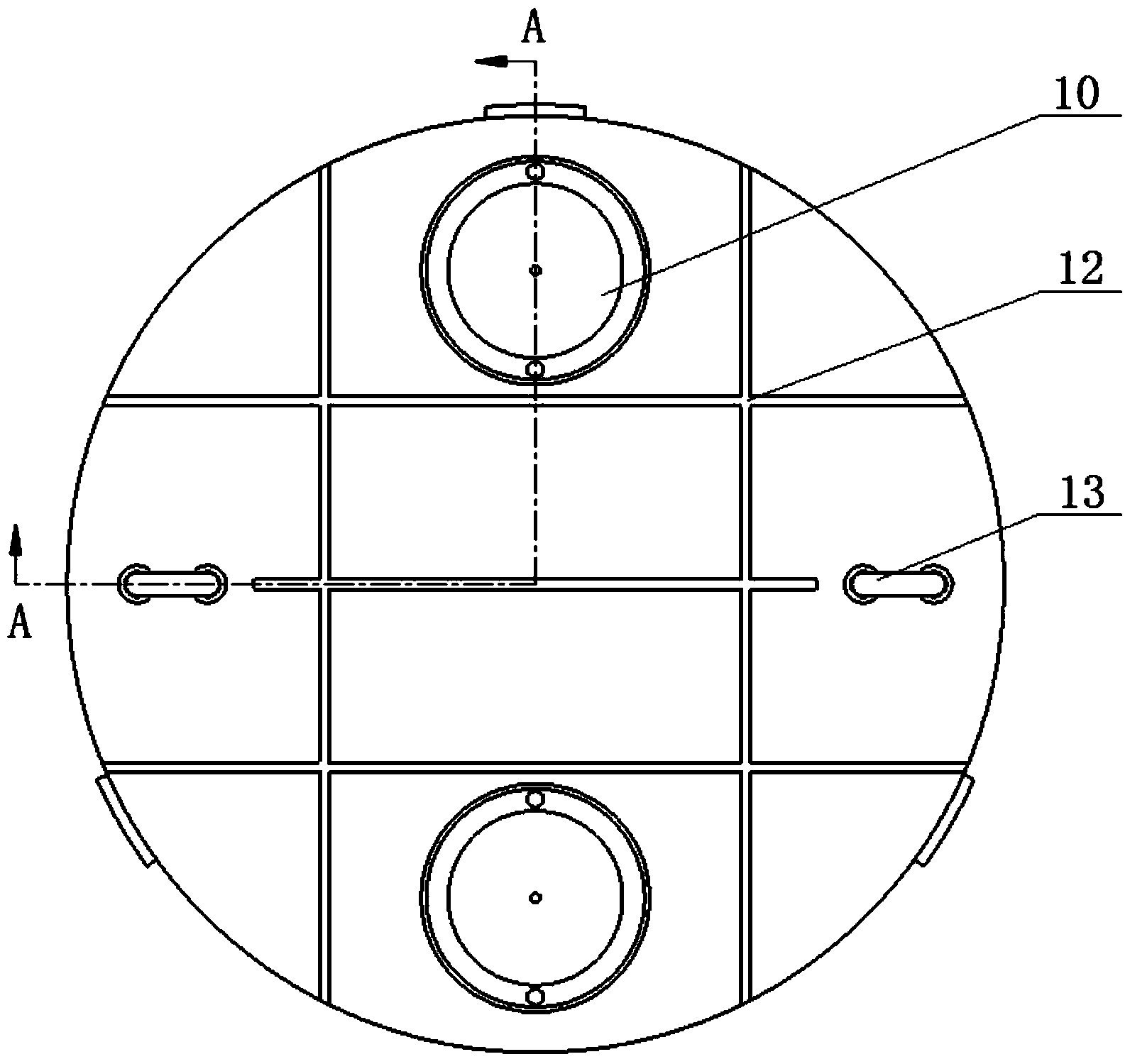

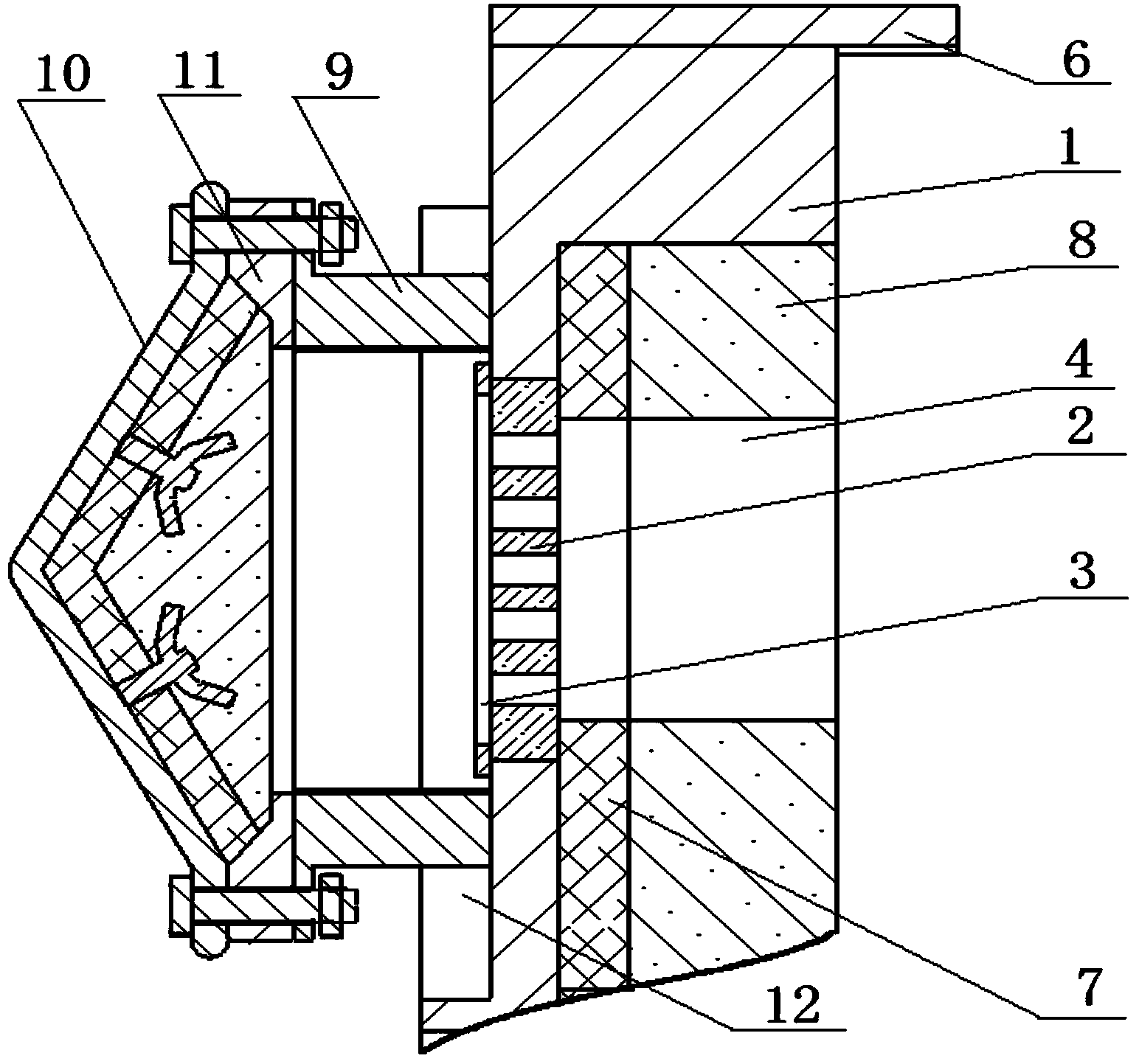

Safety valve for nucleus

A high-safety valve for nuclear power unit is composed of three functional modules: safety release, fast isolation and forced opening or closing. It has a primary valve and a secondary valve. When external valve flap is closed, the safety release and secondary valve can be cut off at the same time. Its advatnages are small size, light weight, high reliability and long service life.

Owner:川开阀门有限责任公司

Liquid heating apparatus

Owner:STRIX LTD

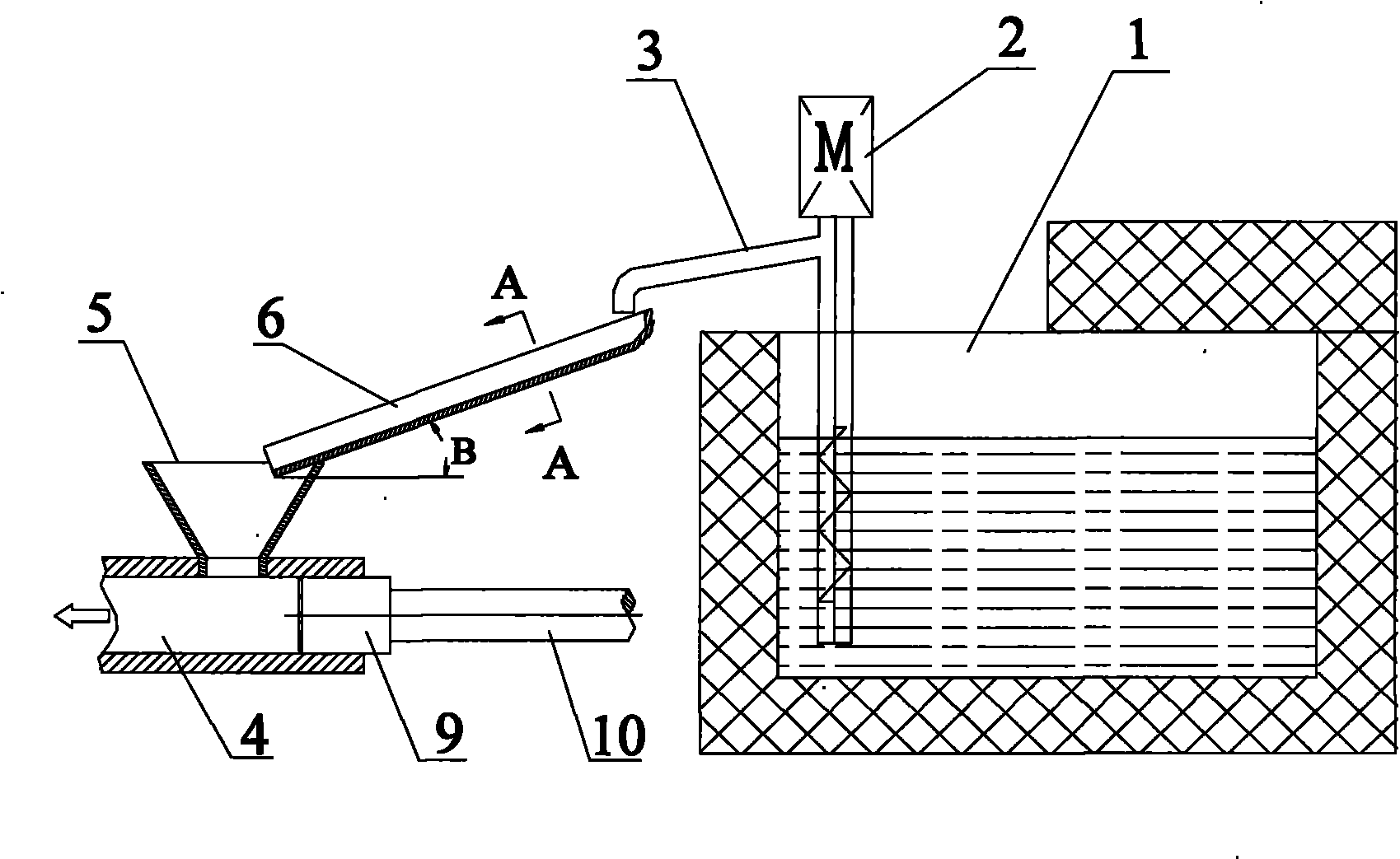

Ultra-low speed aluminum alloy die-casting system

The invention provides an ultra-low speed aluminum alloy die-casting system. The system comprises an aluminum alloy die casting machine and a heat preserving furnace, wherein the heat preserving furnace is provided with a quantitative pouring pump, wherein the quantitative pouring pump is connected with a liquid conveying pipeline; the outlet end of the liquid conveying pipeline is provided with a liquid conveying groove connected to a funnel on a die-casting chamber channel; a refractory mortar layer is laid on the surface of the liquid conveying groove; a release coating layer is sprayed on the surface of the refractory mortar layer; a release coating layer is uniformly coated on the surface of the funnel; the thickness of the release coating layer is between 3 and 5 millimeters; and an included angle between the liquid conveying groove and an ejection horizontal plane is between 15 and 25 degrees. The invention also provides an alloy melt temperature control range and an operation specification for the heat preserving furnace of the system. Through system setting, molten metal flows through a chute and the funnel before casting; and due to the adoption of small-angle ultra-low speed die casting and shaping, the molten metal flows stably without eddy current or splashing, gas inclusion in a shaping process is decreased, the surface of a casting molded by die casting is flat and smooth, crystal particles are fine and air holes inside a product have a small number of defects.

Owner:DONGGUAN EONTEC CO LTD

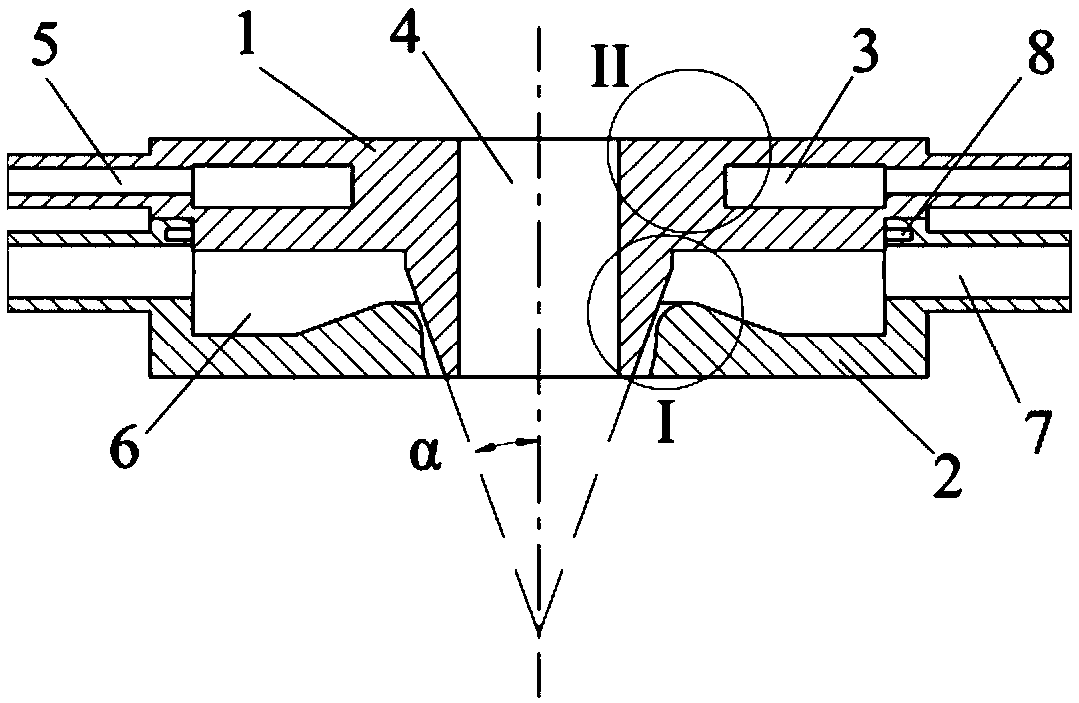

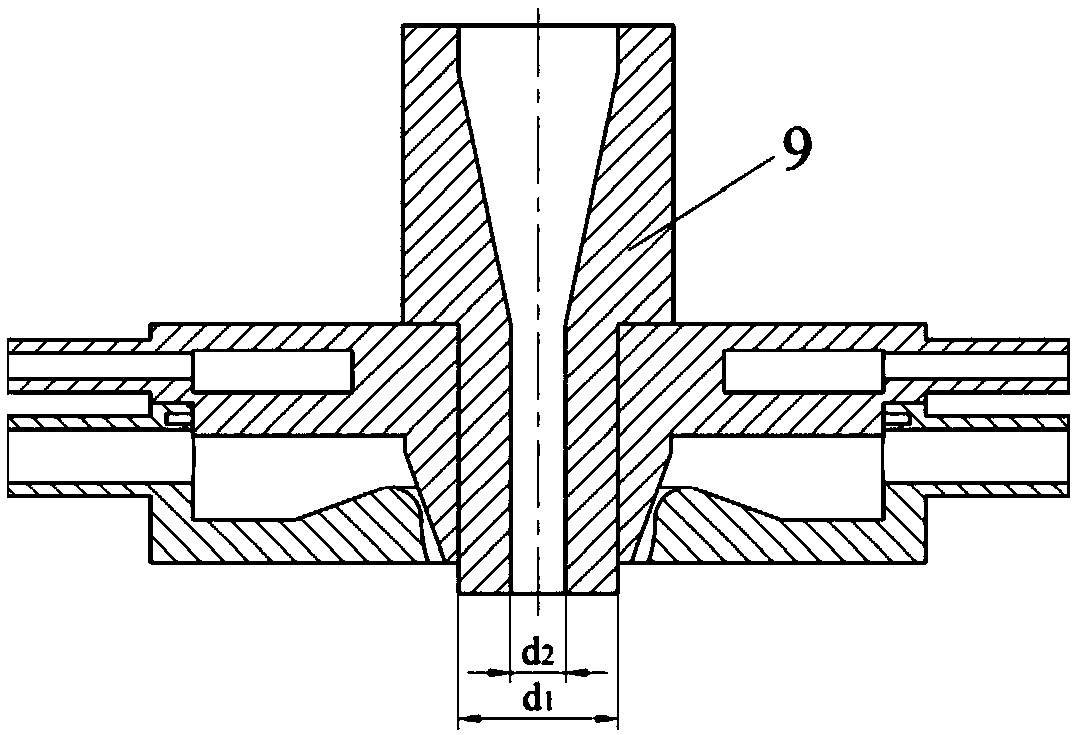

Supersonic gas atomization spraying disc for metal powder preparation

ActiveCN109570518AThroat width adjustableAdjustable Mach numberIncreasing energy efficiencyMetallurgyThermal deformation

The invention relates to a supersonic gas atomization spraying disc for metal powder preparation. The supersonic gas atomization spraying disc for metal powder preparation comprises a spraying disc upper lip and a spraying disc lower lip. An annular cooling water cavity is formed inside the spraying disc upper lip. A center hole which penetrates through the thickness of the spraying disc upper lipis formed in the center of the spraying disc upper lip and used for allowing a flow guide nozzle to be placed. A gas inlet pipeline which is used for being connected with an external gas source is arranged on the spraying disc lower lip. An annular gas cavity can be formed after the spraying disc lower lip and the spraying disc upper lip are assembled, and a nozzle which is of a semi-Laval structure is formed in an outlet of the annular gas cavity after the spraying disc upper lip and the spraying disc lower lip are assembled. According to the supersonic gas atomization spraying disc for metal powder preparation, the thermal deformation of the spraying disc is reduced by circulating cooling water, the sealing performance of the whole spraying disc structure is protected, and the service life of the spraying disc is prolonged. The spraying disc upper lip and the spraying disc lower lip are assembled to form the nozzle which is of the circular seam type semi-Laval structure, and the width of the throat portion of the nozzle is adjustable. According to the supersonic gas atomization spraying disc for metal powder preparation, a technological adjustment window is wide, the gas consumption is low, the gas flow inside the spraying disc is uniform, and the fine powder yield can be substantially improved.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

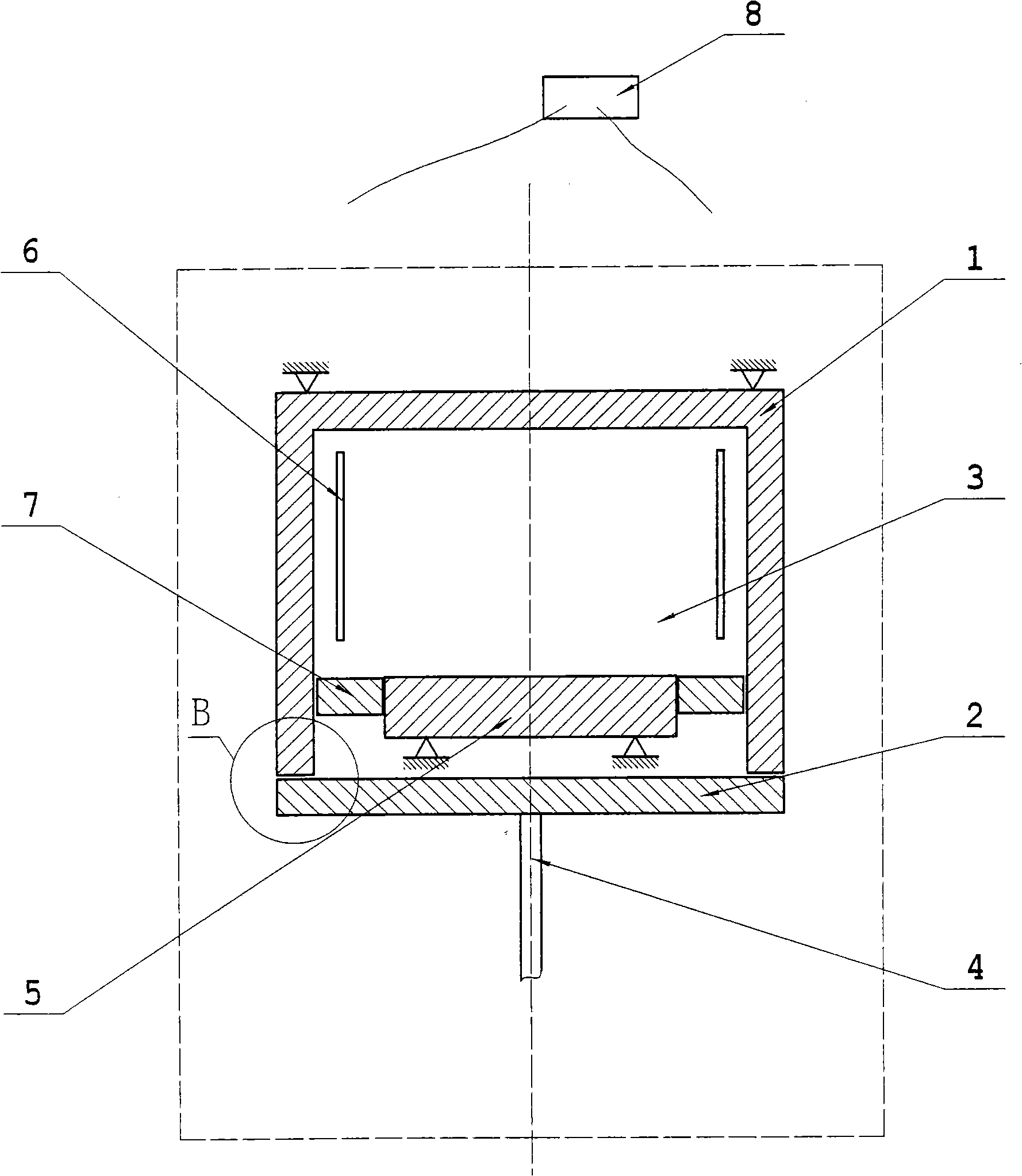

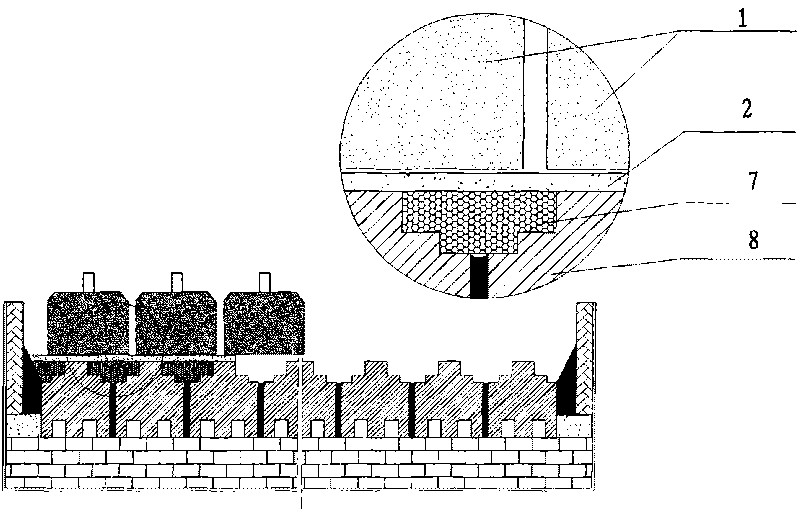

Polysilicon directional long crystal thermal field

InactiveCN101323973AReduce weightEasy to integratePolycrystalline material growthSingle crystal growth detailsEngineeringCrystal growth

The invention discloses a thermal field structure for directional crystal growth of polysilicon, which belongs to the technical field of the thermal field structures for the directional growth of solar polysilicon crystals, and consists essentially of a heat preserving and insulating cage body (1), a heater (6) and a heat exchange platform (5) that are arranged inside the heat preserving and insulating cage body (1), a heat preserving and insulating substrate (2) that is arranged in the bottom of the heat preserving and insulating cage body (1), can move upwards and downwards in the vertical direction and has a supporting guide rod (4), and a heat preserving and insulating clapboard (7) that is arranged between the lateral surface of the heat preserving and insulating cage body (1) and the heat exchange platform (5), etc. The heat preserving and insulating cage body (1) and the heat preserving and insulating substrate (2) form a chamber (3), the heater (6) and the heat preserving and insulating substrate (2) are respectively controlled by an external controller (8). Through the elevating structure of the heat preserving and insulating substrate that is arranged in the bottom of the heat preserving and insulating cage body, the technical means that are required for the directional crystal growth of the polysilicon are obtained, the dynamic adjustment in the control can be easily realized, and consequently the crystal growth speed can be realized maximally.

Owner:杭州志在材料科技有限公司

Method for preparing originated multi-section yttrium vanadate laser crystal

ActiveCN101880908AMeet application needsReduced interfacial absorptionPolycrystalline material growthBy pulling from meltYttriumHigh power lasers

The invention relates to a method for preparing an originated multi-section yttrium vanadate laser crystal. By utilizing a flux growth method, an undoped yttrium vanadate crystal with a certain thickness is grown at two ends of a rare earth-doped yttrium vanadate laser crystal so as to prepare the multi-section yttrium vanadate laser crystal. The surface adsorption of the prepared undoped crystal or neodymium-doped crystal is less than 2,150ppm / cm, and the crystal can meet the application requirement of high-power lasers.

Owner:FUJIAN CASTECH CRYSTALS

Double-layer jacketed high-temperature fused salt storage tank

ActiveCN107380780AConducive to free expansionAvoid stressThermal insulationHeat storage plantsBiochemical engineeringMolten salt

The invention discloses a double-layer jacketed high-temperature fused salt storage tank. The double-layer jacketed high-temperature fused salt storage tank comprises a tank body, a tank top and a tank bottom, the tank body comprises an inner tank body and an outer tank body, a jacketed space is formed between the inner tank body and the outer tank body, a heat preservation layer is arranged on the inner side, in the jacketed space, of the outer tank body, and an air layer is reserved between the heat preservation layer and the inner tank body. A double-layer structure is adopted for the tank body, and a combined type heat preservation structure is formed by the heat preservation layer and the air layer, so that high temperature is prevented from affecting the outer tank body, the inner tank body is enabled to expand freely without being limited by the heat preservation layer, heat preservation materials of the tank top, a tank wall and the tank bottom are mounted in an outer steel shell, influences on performance of the heat preservation materials caused by the fact that exiting external heat preservation materials are arranged externally are avoided, and service lives of the heat preservation materials are prolonged.

Owner:CHINA CHENGDA ENG +1

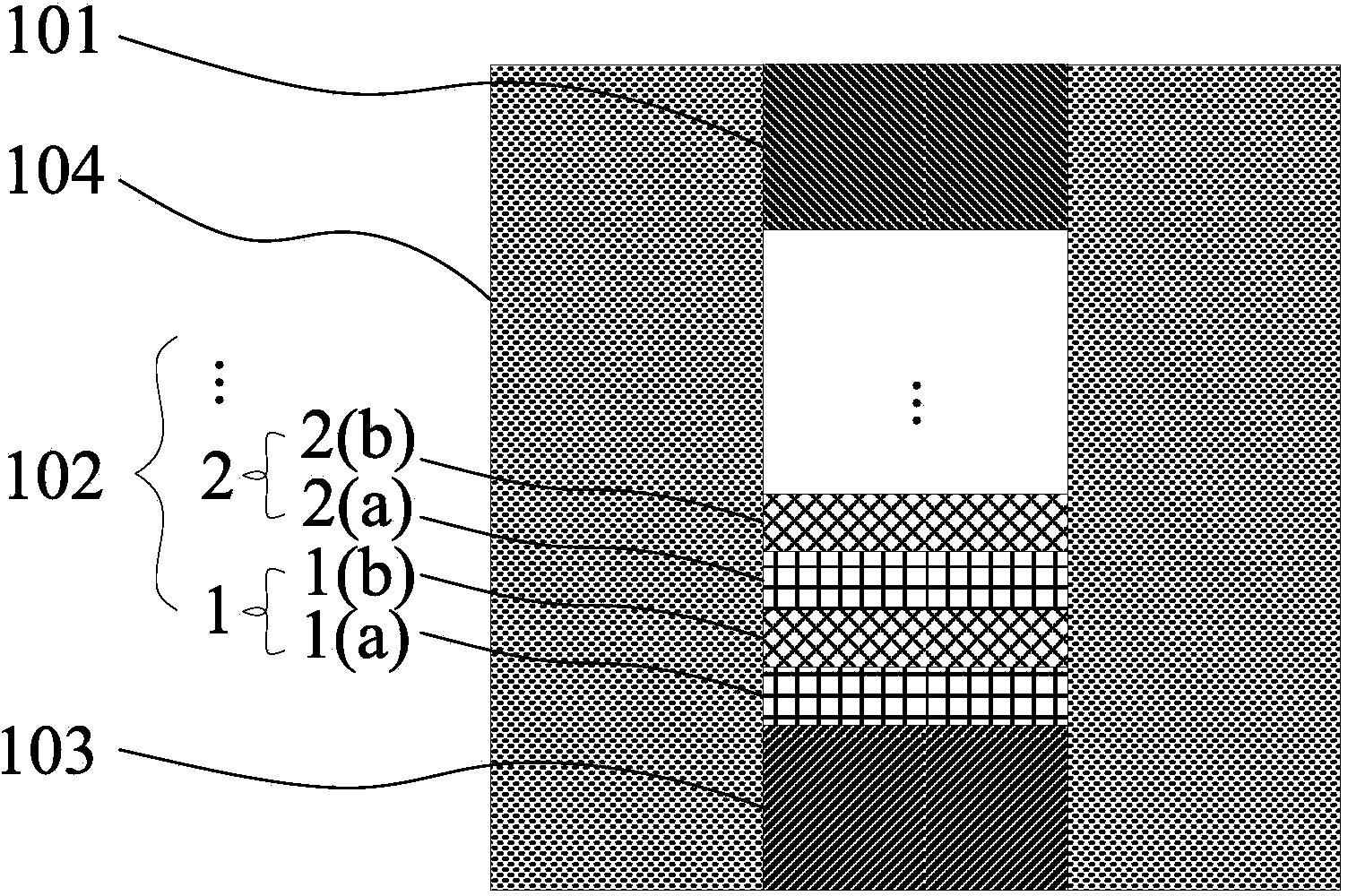

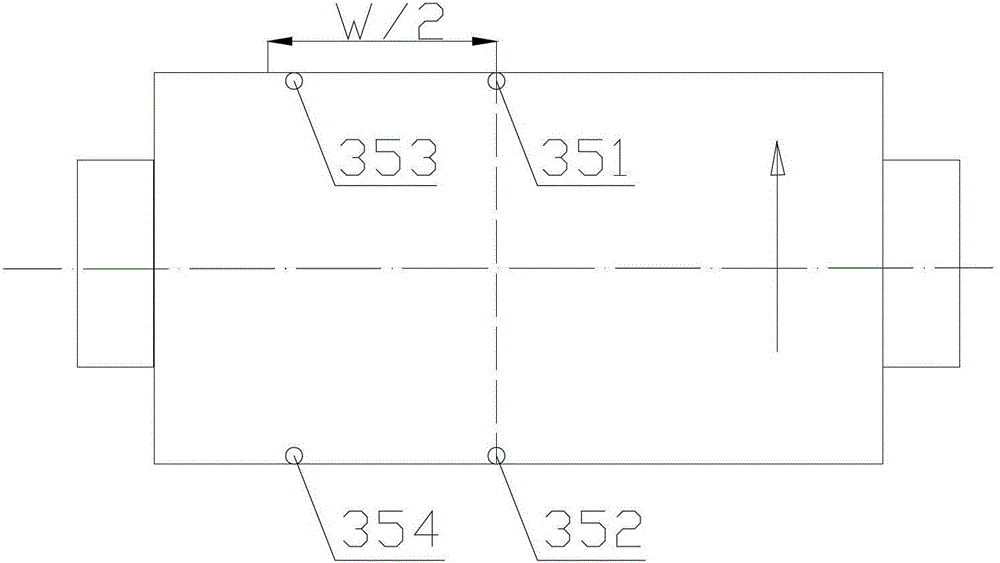

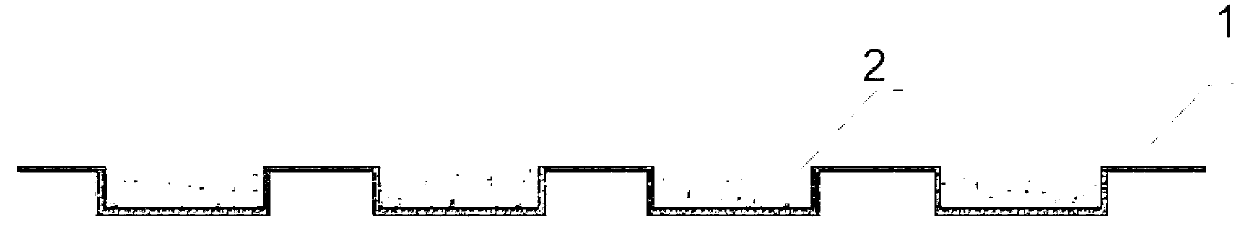

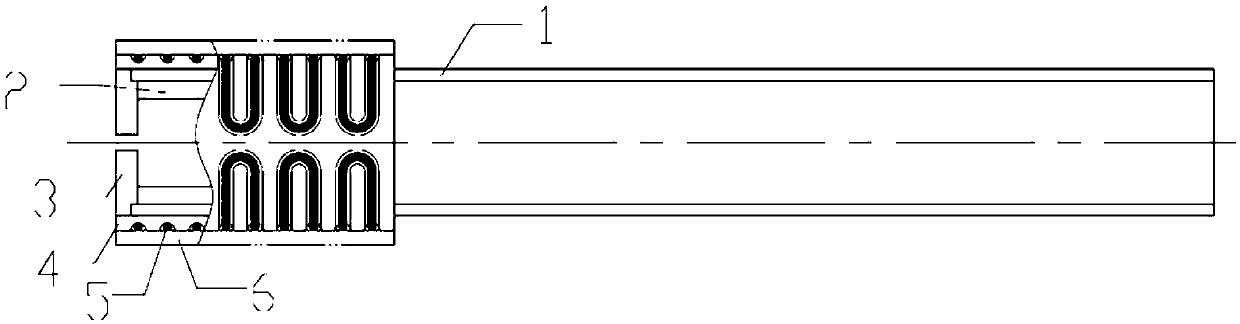

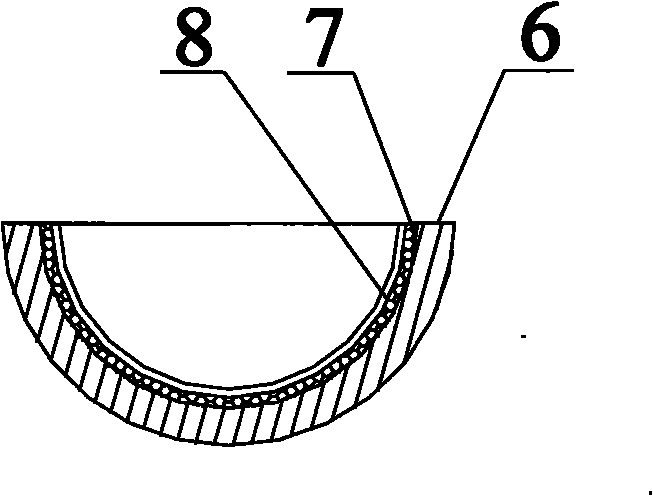

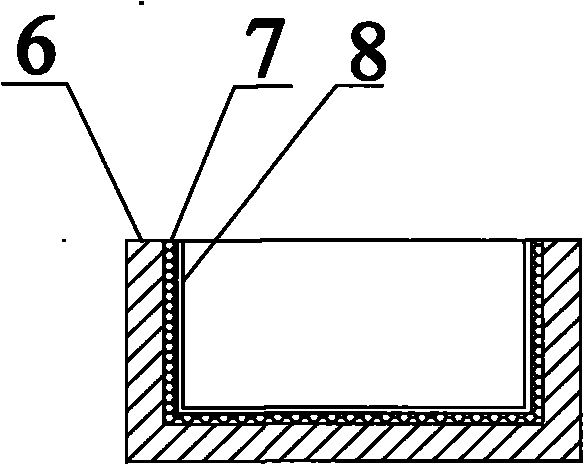

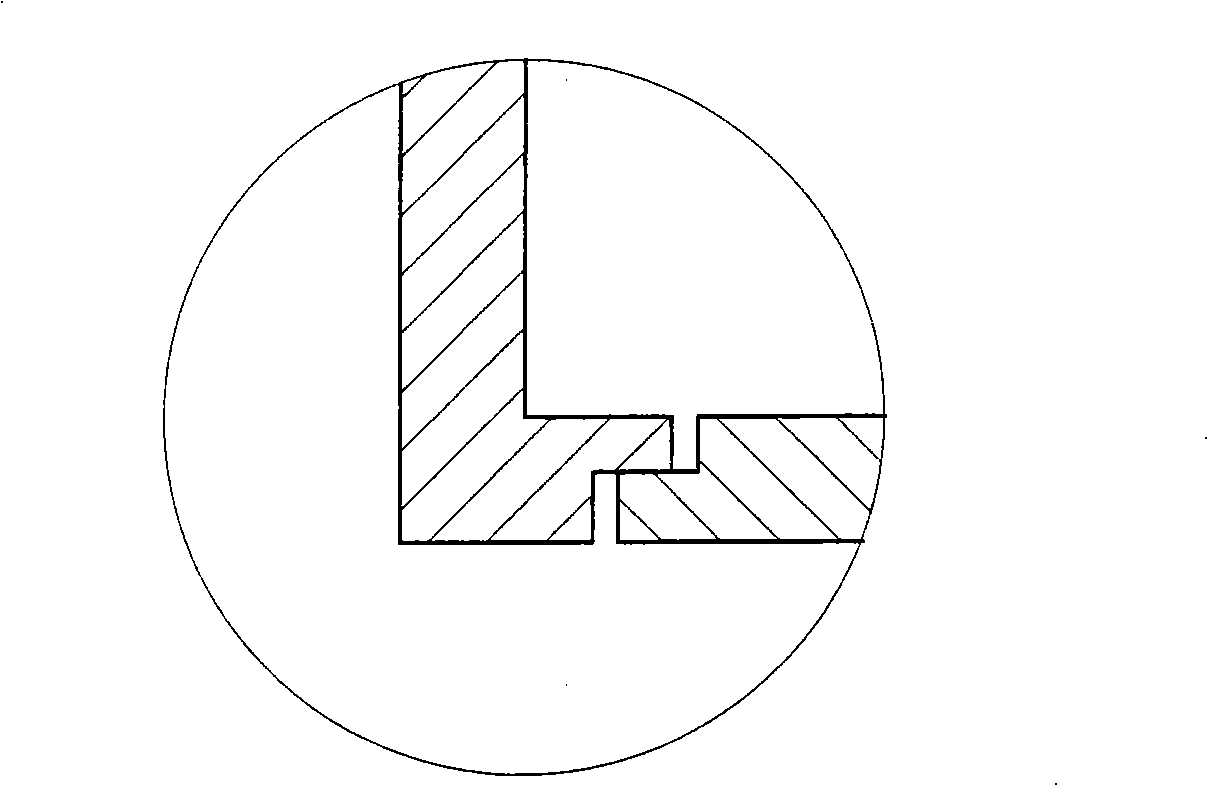

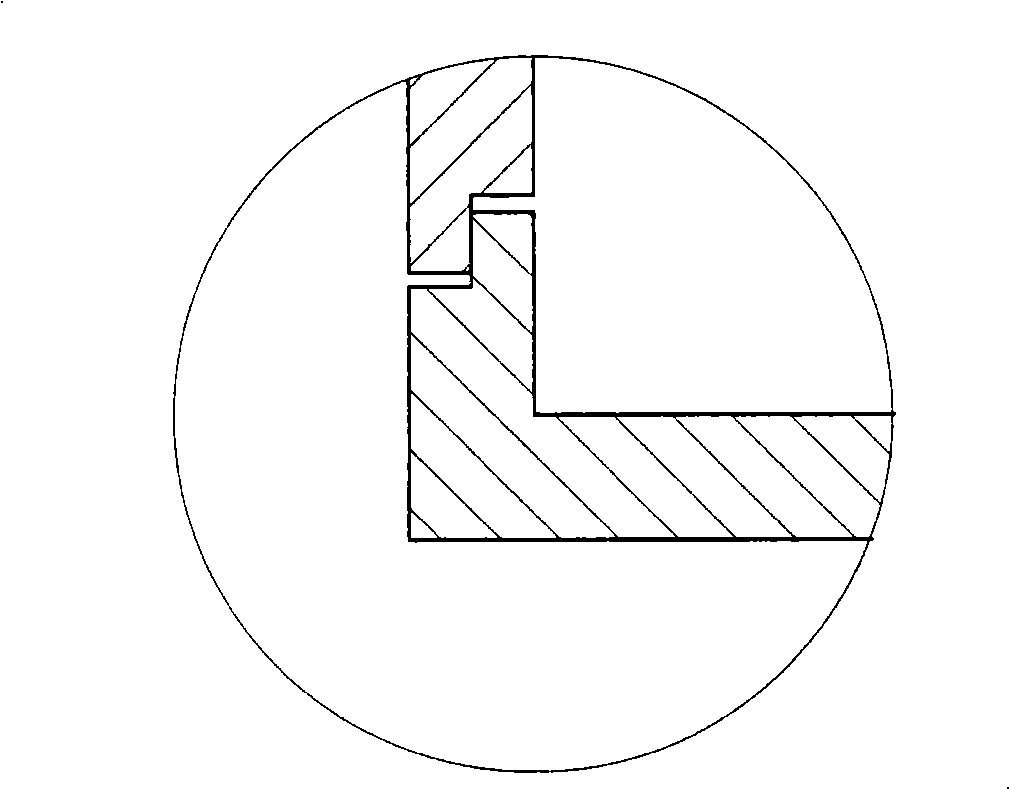

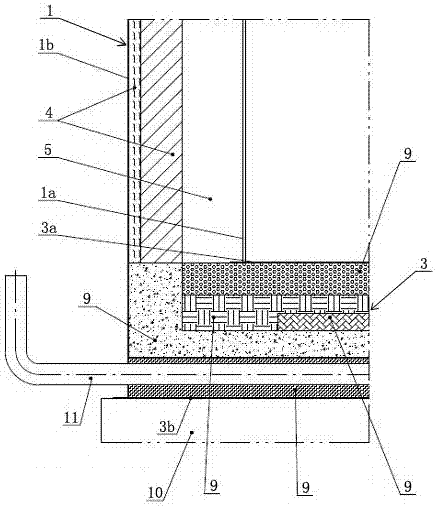

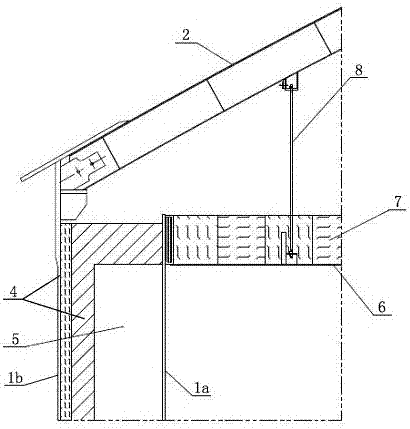

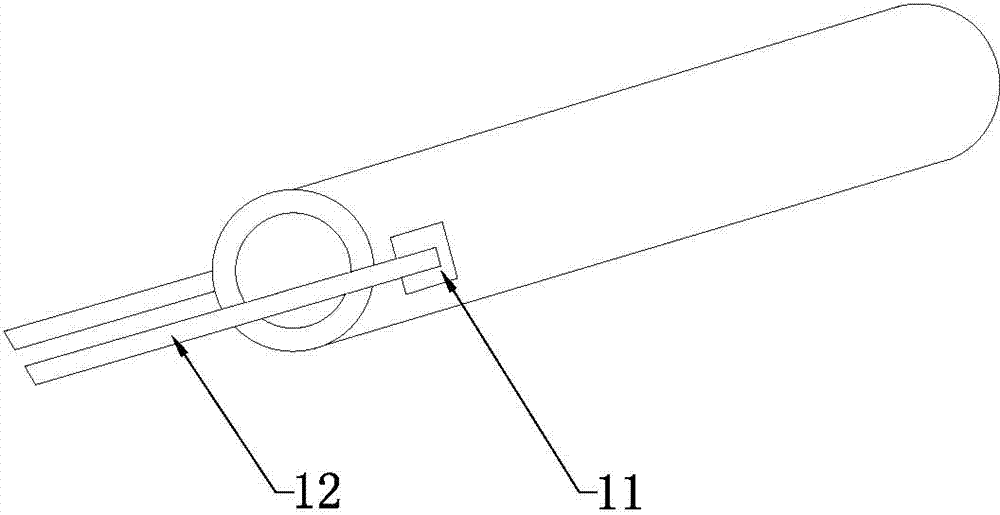

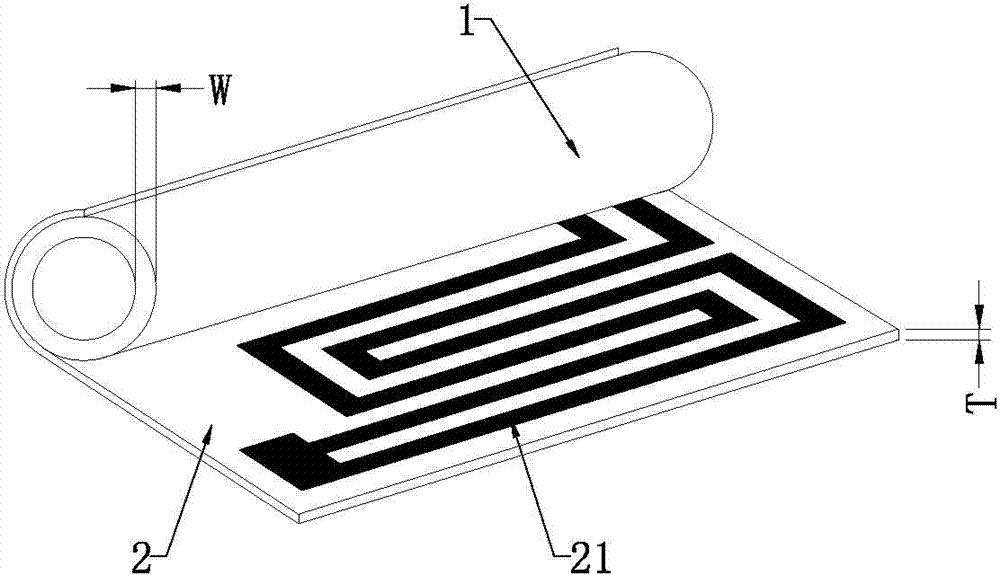

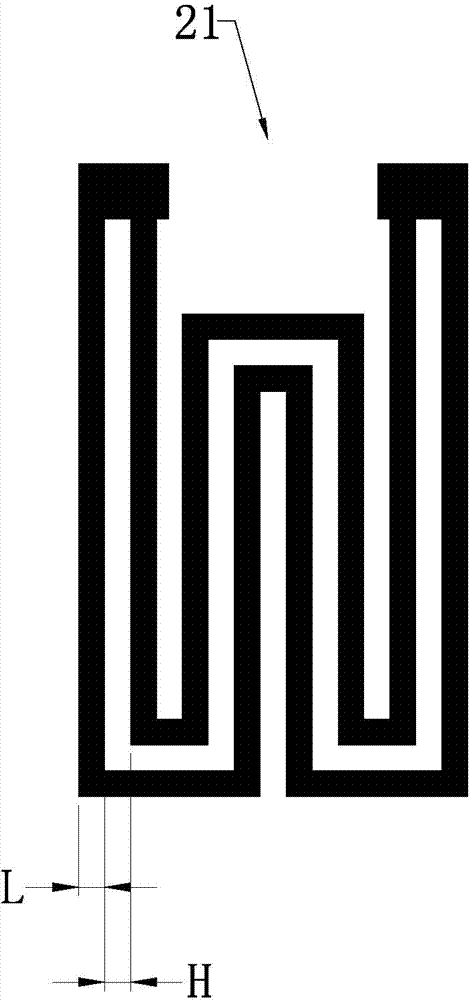

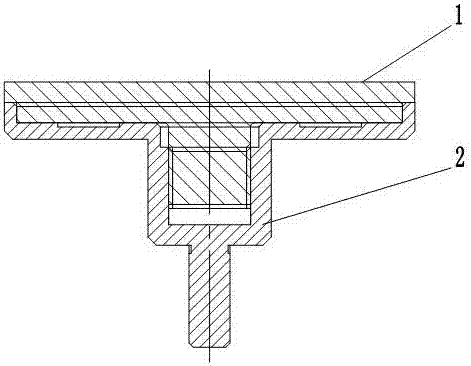

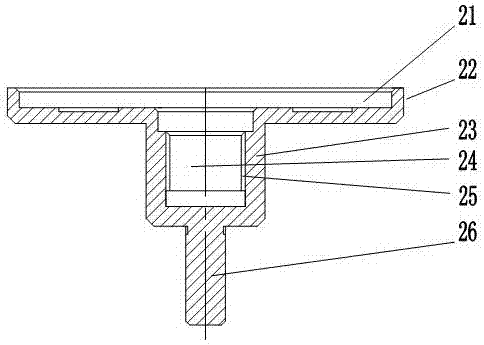

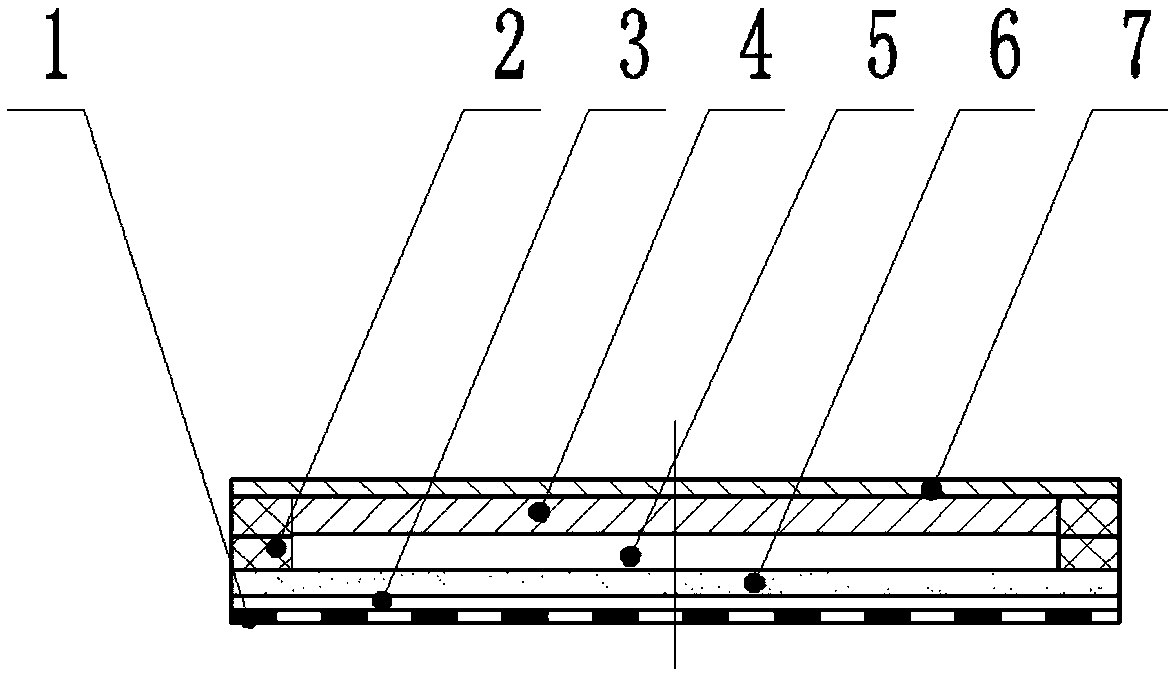

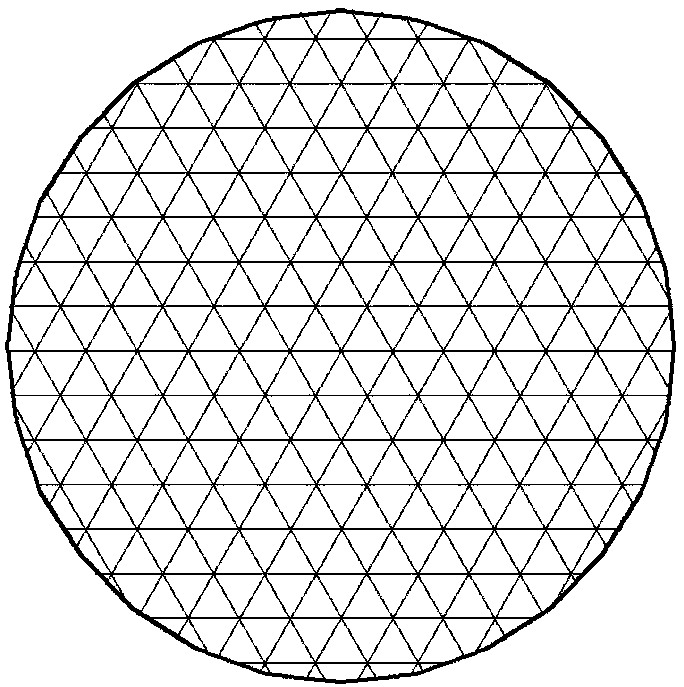

Large power ceramic heating unit

ActiveCN103546998AGuaranteed current carrying capacityUniform temperatureHeating element materialsCeramic substrateAlumina ceramic

The invention relates to the technical field of ceramic heating units, in particular to a large power ceramic heating unit. The large power ceramic heating unit comprises an aluminum oxide ceramic core and an aluminum oxide ceramic substrate, thick film heating circuits are printed on the inner side face of the aluminum oxide ceramic substrate, the thick film heating circuits are of a reciprocating inflection structure, the distance H is formed between two adjacent thick film heating circuits, the aluminum oxide substrate wraps the outer side face of the aluminum oxide ceramic core in a reeling shape, the width L of wires of the thick film heating circuits is 0.3-1.3mm, and the ratio H / L of the distance H formed by the thick film heating circuits and the width L of the wires of the thick is 0.5-1.5; the thickness T of the aluminum oxide substrate is 0.3-0.8 mm, and the ratio W / T of the thickness of the wall of the aluminum oxide ceramic core and the thickness T of the aluminum oxide substrate is 2-5. When the large power ceramic heating unit works, the power of the large power ceramic heating unit can be more than 3000W, the breakthrough that a small-sized heating unit carries out large-power heating is achieved, the temperature of the surface of the heating unit is kept uniform, generated bubbles are small and are not prone to being attached to the surface of the heating unit, and durability is extraordinary.

Owner:KEY MATERIAL

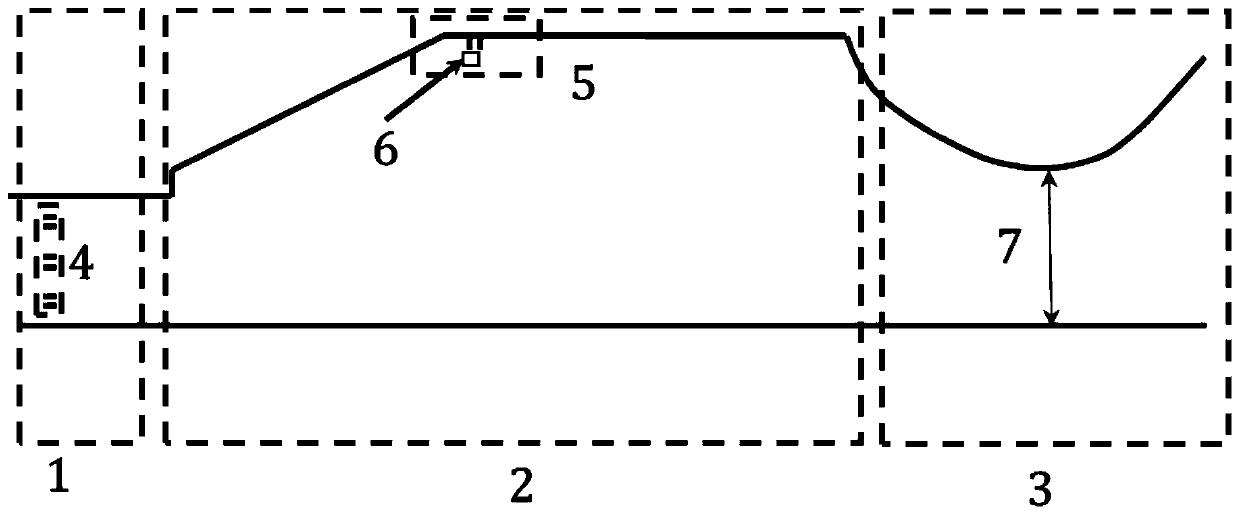

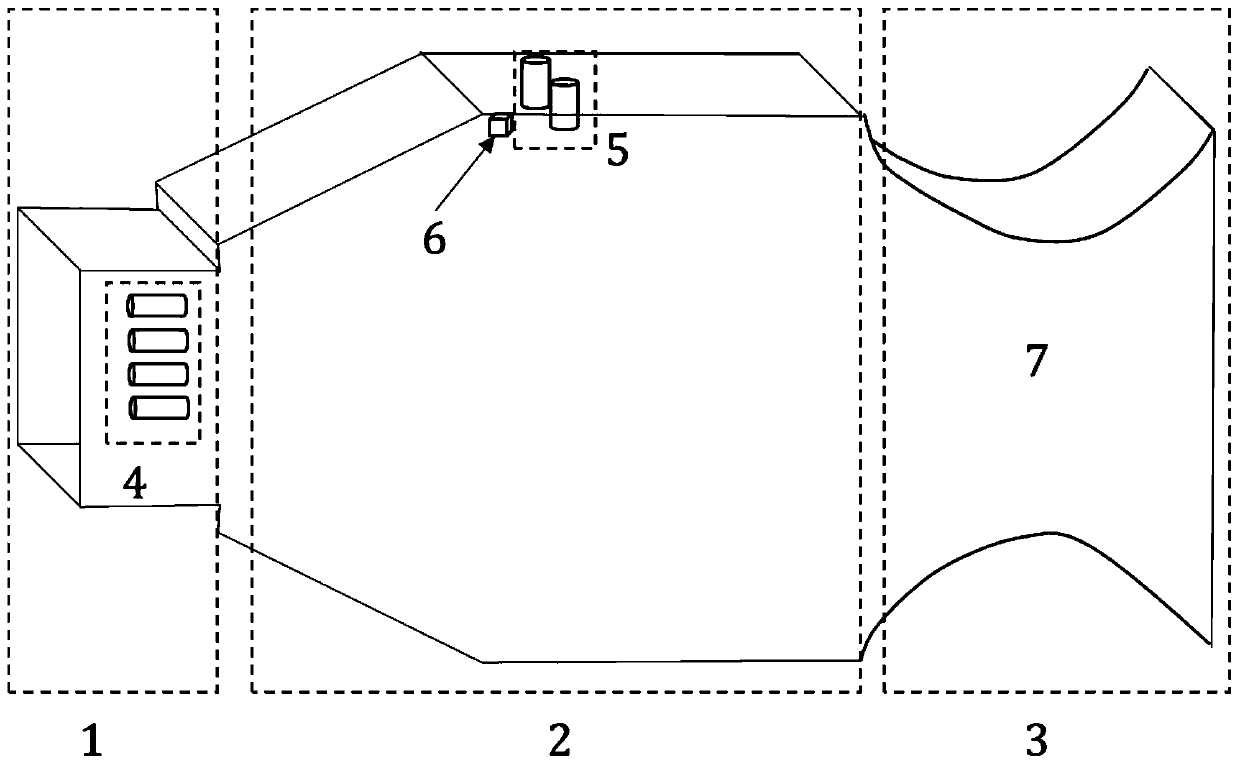

Combustion chamber of wide speed range ramjet engine and working method thereof

ActiveCN110541773AImprove reliabilityVersatilityTurbine/propulsion fuel supply systemsContinuous combustion chamberRamjetCombustion chamber

The invention provides a combustion chamber of a wide speed range ramjet engine and a working method thereof, wherein the combustion chamber comprises an air inlet connecting section (1), a forward-inclined concave combustion chamber (2) and a tail nozzle (3), wherein the air inlet connecting section (1), the forward-inclined concave combustion chamber (2) and the tail nozzle (3) are arranged successively; the air inlet connecting section (1) is a bridge component, through which a variable supersonic air inlet outlet is connected with the combustion chamber inlet, the area of the forward-inclined concave combustion chamber (2) is larger than that of the air inlet connecting section (1); the air inlet connecting section (1), the forward-inclined concave combustion chamber (2) and the tail nozzle (3) as well as the structure of the combination of the air inlet connecting section (1), the forward-inclined concave combustion chamber (2) and the tail nozzle (3) is symmetrical with a centralplane, or rotationally symmetrical with a central axis.

Owner:SHANGHAI JIAO TONG UNIV

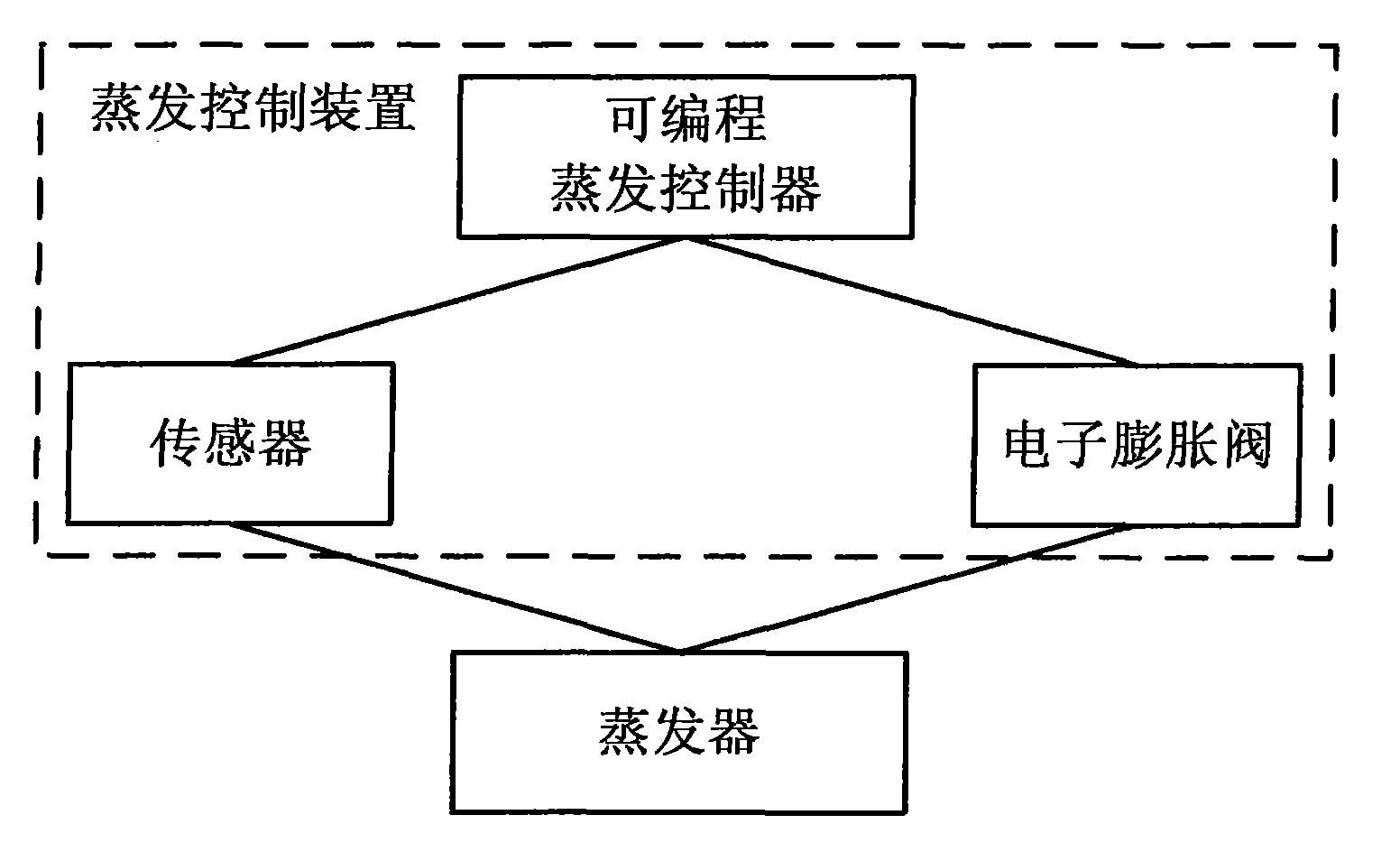

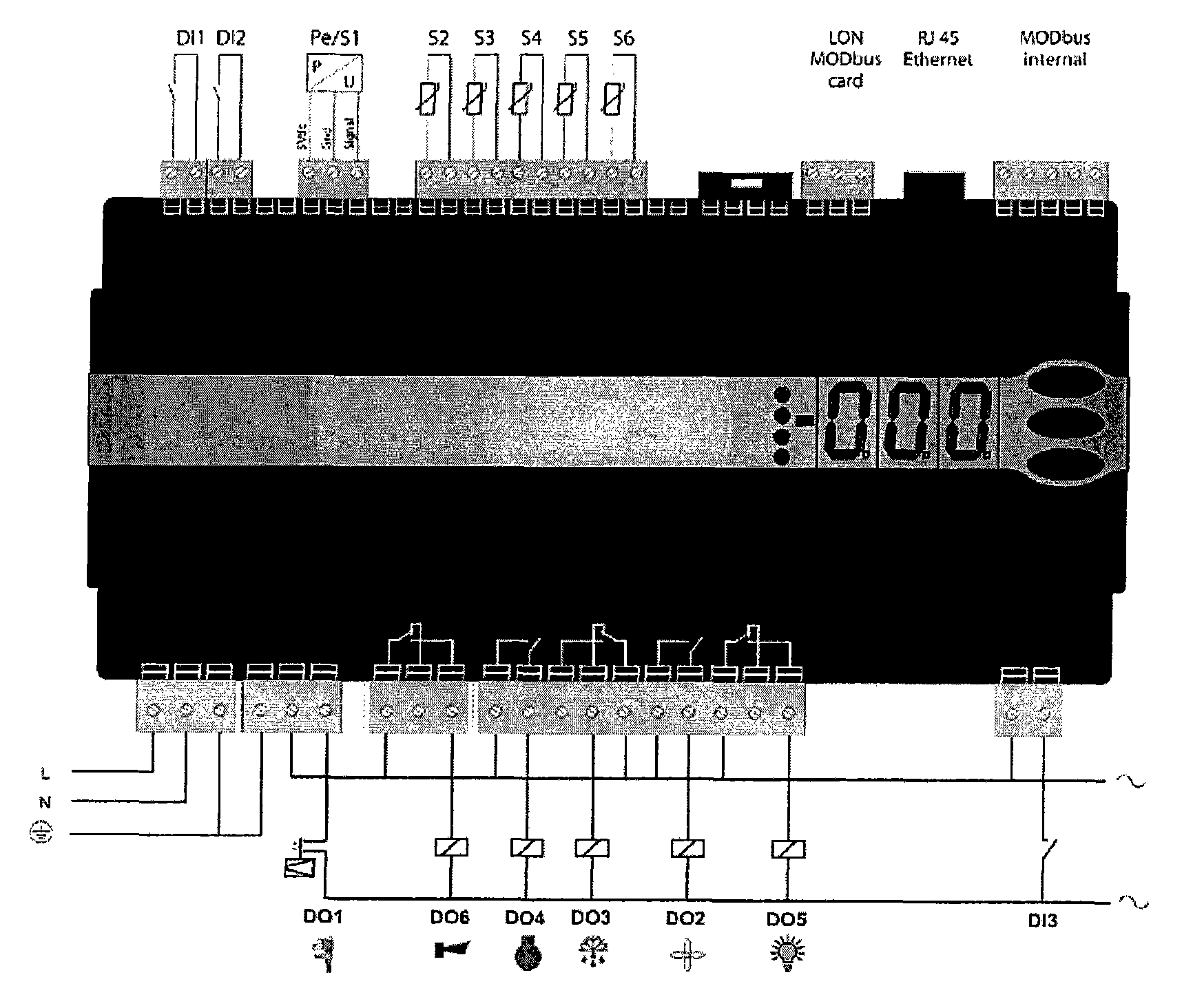

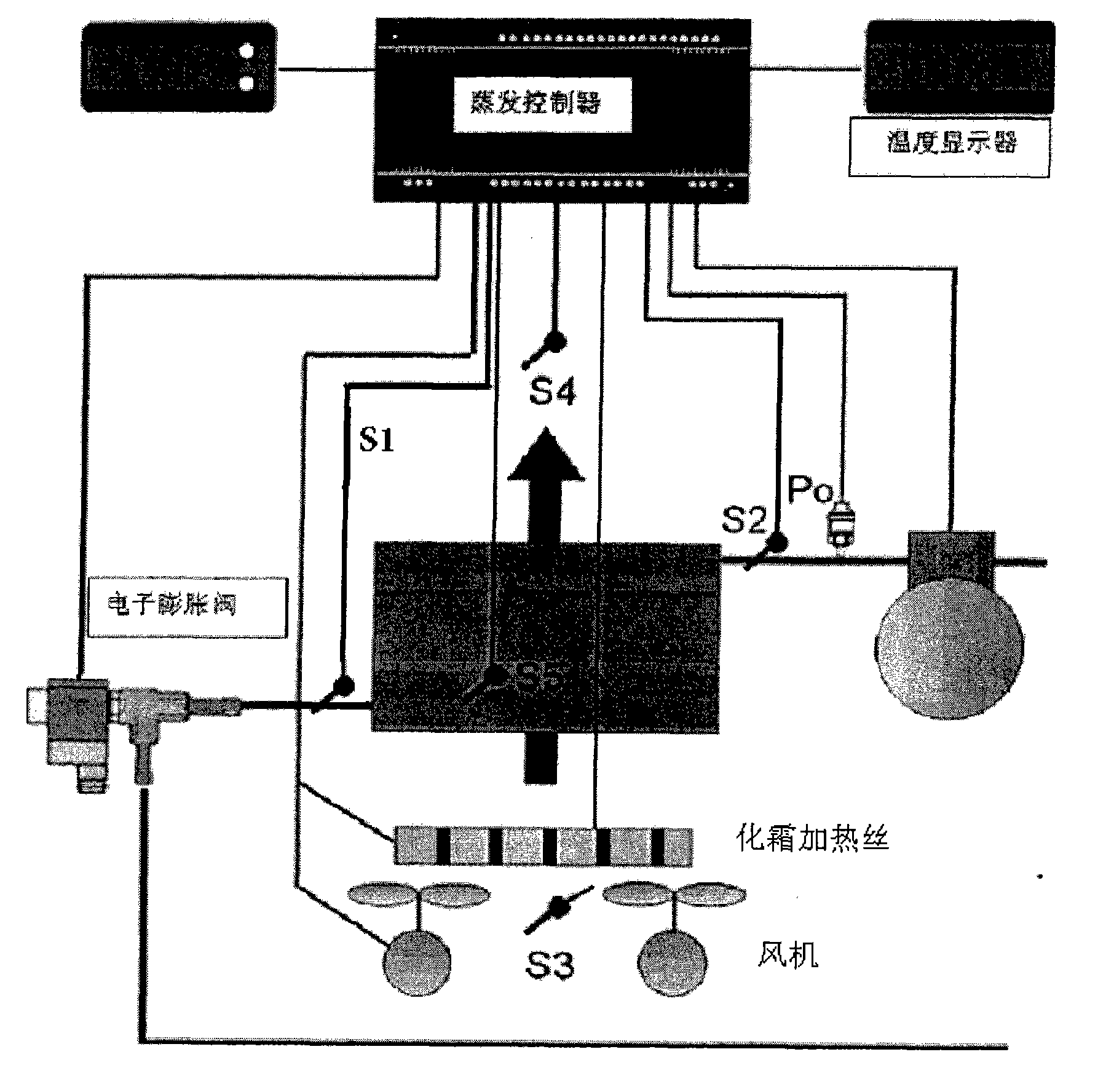

Evaporation control device used in refrigerating system

InactiveCN102116550APrecisely adjust the amount of refrigerantSmall temperature fluctuationsRefrigeration safety arrangementProgrammable logic controllerEvaporation

The invention discloses an evaporation control device used in a refrigerating system, comprising a programmable evaporation controller, an electronic expansion valve and a sensor, wherein, the programmable evaporation controller is connected with the electronic expansion valve, and is connected with an evaporator through the sensor; and the electronic expansion valve is arranged on a refrigerant input pipeline of the evaporator; the sensor is used for detecting the temperature and the pressure in the evaporator, and outputting the detected temperature and pressure signals to the programmable evaporation controller; the programmable evaporation controller is used for receiving the detected temperature and pressure signals detected by the sensor; the opening and closing of the electronic expansion valve as well as the opening time and the opening of the electronic expansion valve are controlled according to the signals; and the electronic expansion valve is used for controlling the amount of the refrigerant entering into the evaporator under the control of the programmable evaporation controller, thus realizing the accurate control on the temperature in the evaporator. By utilizing the evaporation control device provided by the invention, the accurate control on the temperature and the pressure is realized, the reaction sensitivity is improved, and the energy consumption is lowered.

Owner:DANFOSS SHANGHAI AUTOMATIC CONTROLS

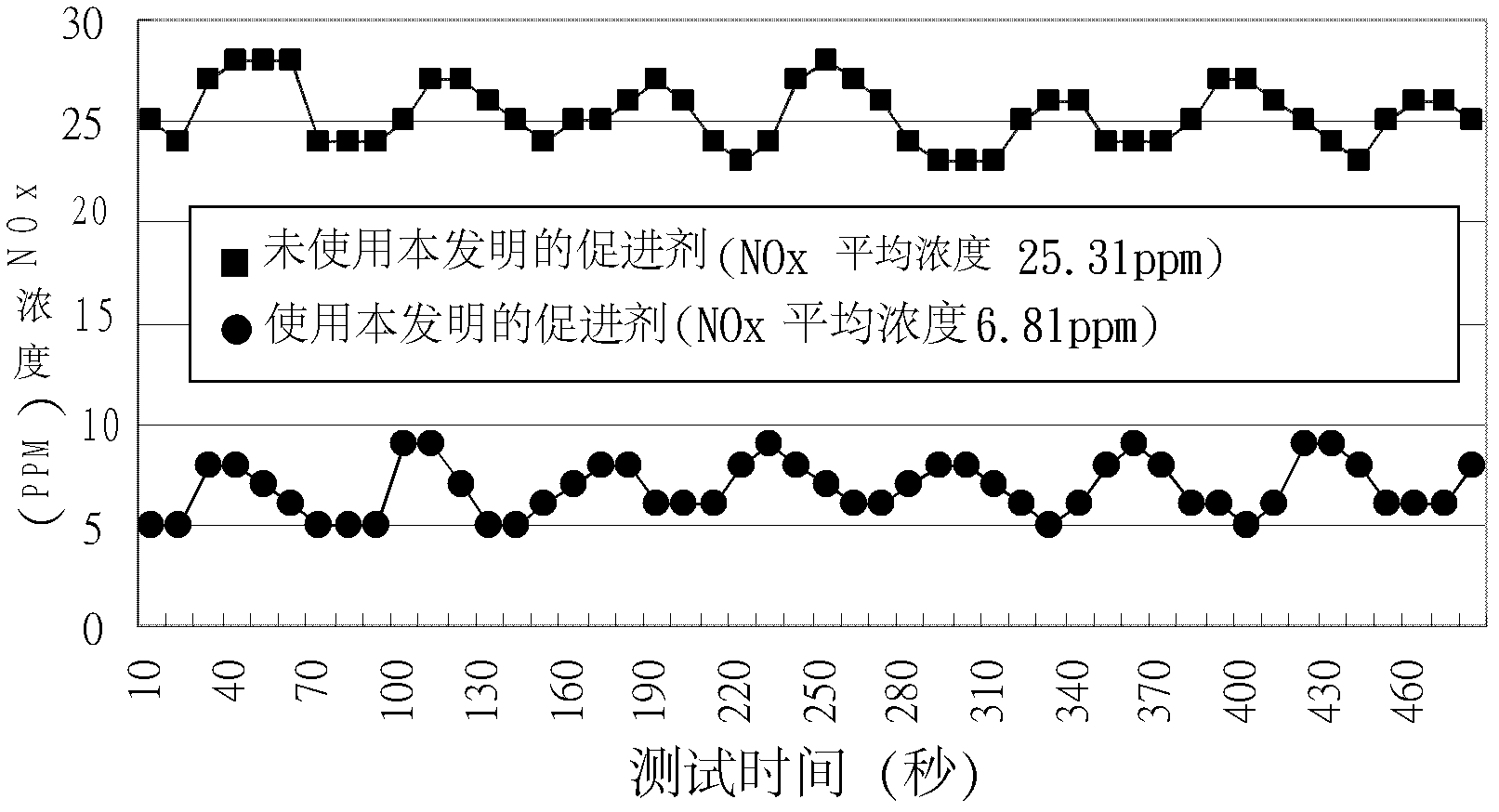

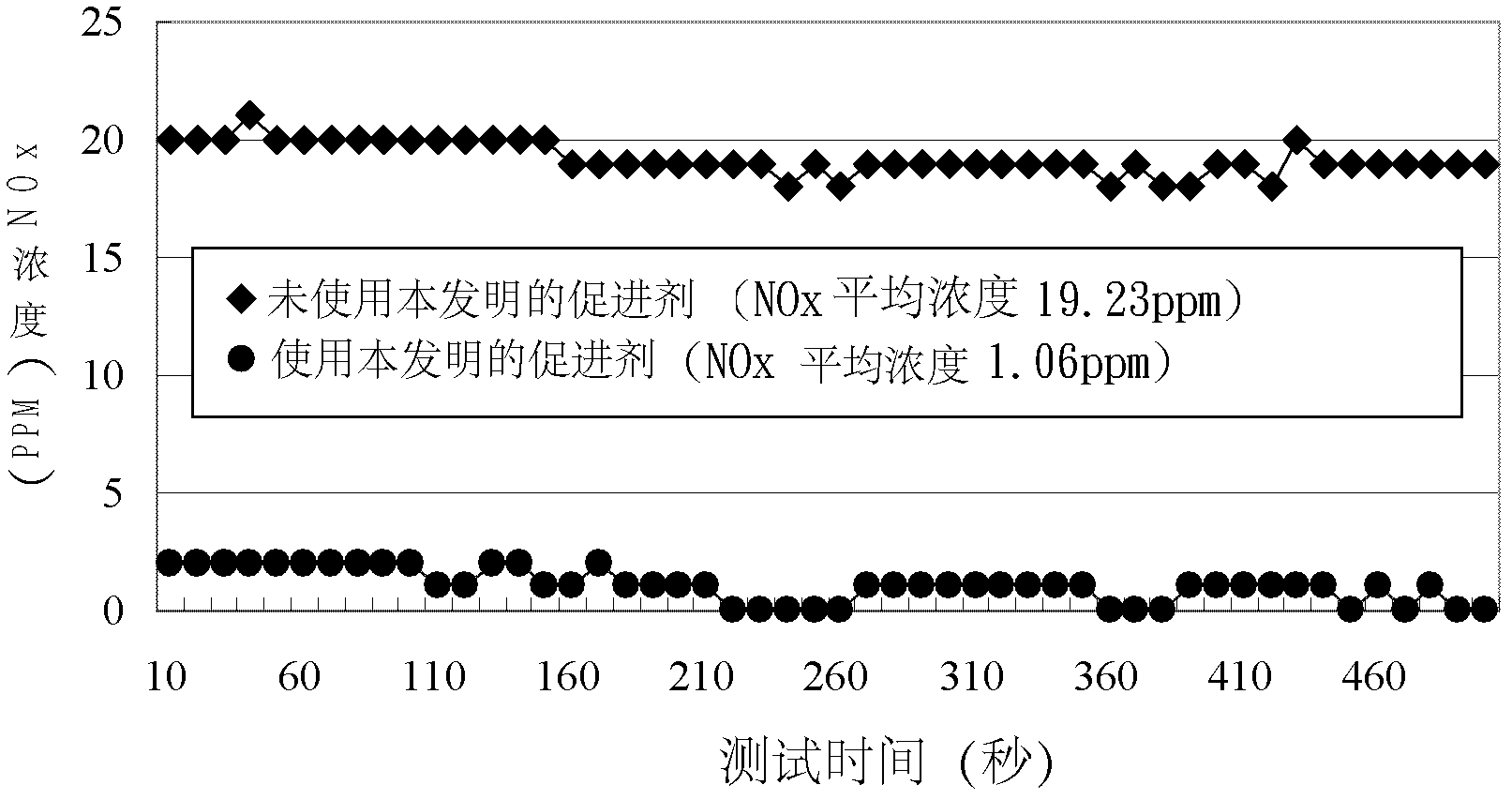

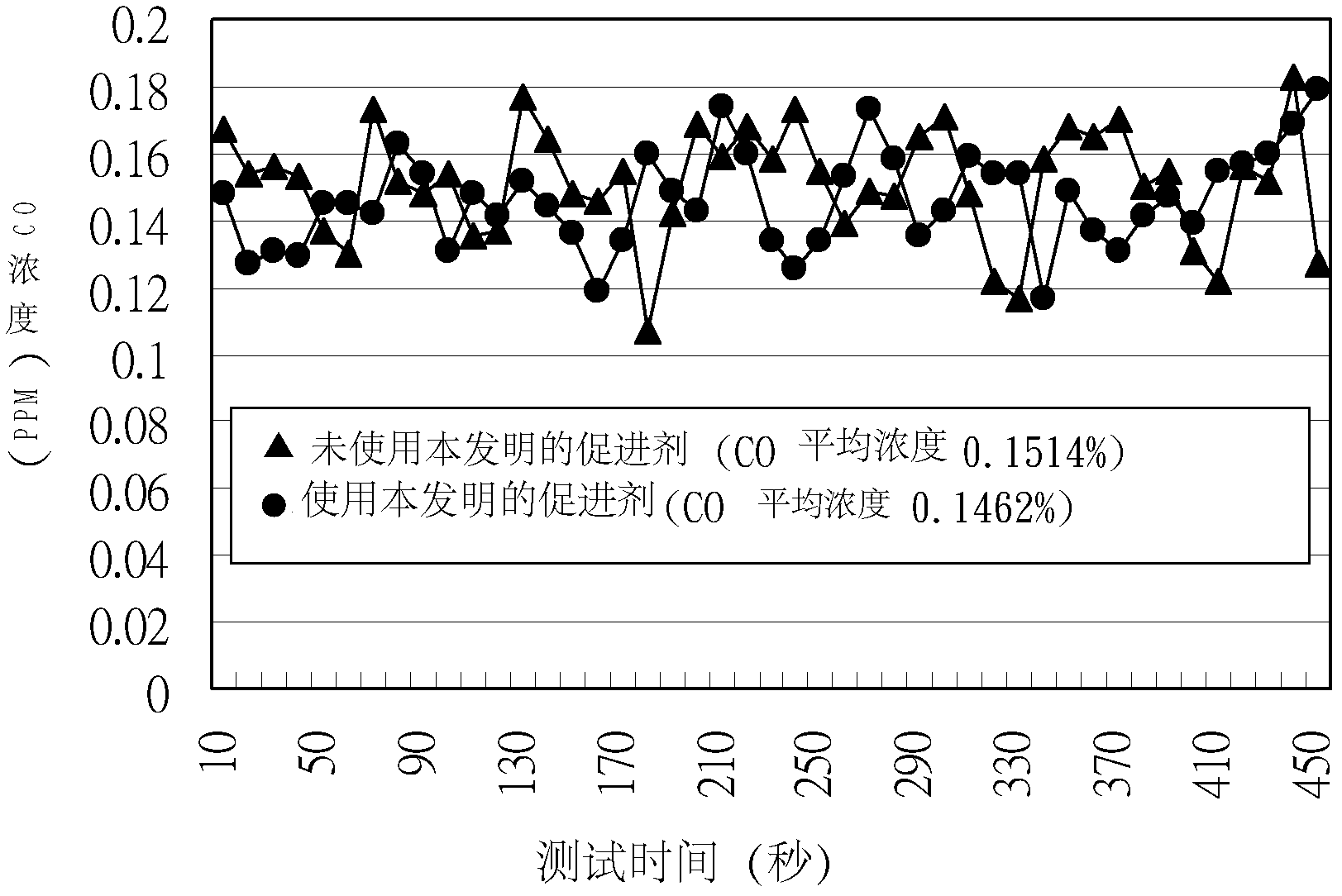

Heat transfer enhancing agent

InactiveCN103102871ALow costImprove convenienceMaterial nanotechnologyHeat-exchange elementsEngineeringHeat transfer efficiency

Owner:黄彦豪 +1

Method for roasting aluminum electrolytic bath with polymorphic structure cathode

InactiveCN101724859AAvoid thermal shockSolve the problem of uneven distribution of cathode currentThermal shockElectrolyte

The invention discloses a method for roasting an aluminum electrolytic bath with a polymorphic structure cathode, which comprises the following steps of: filling a concave part on the surface of the polymorphic structure cathode with aluminum powder or aluminum blocks with shapes corresponding to that of the concave part to ensure that the filled surface and a convex surface of the polymorphic cathode are in the same horizontal plane; paving a layer of coke particles on a plane of the cathode; hanging an anode on the layer of the coke particles, and electrifying and roasting the aluminum electrolytic bath until 60 to 70 percent of the area of the surface of the cathode reaches or exceeds 900 DEG C; and when over 60 percent of the area in the electrolytic bath has a fused electrolyte with the thickness of 10 centimeters, infusing the electrolyte into the electrolytic bath to perform a wet method or adopt a dry method to start the roasting. The aluminum block / powder-coke particle composite roasting technique is favorable for the even distribution of the current and the temperature on the surface of the cathode and the reduction of heat vibration, thereby not only preventing an aluminum liquid roasting method from performing thermal shock on an inner lining of the cathode, but also solving the problems of uneven distribution of the current of the cathode and the like caused by large differences of the coke particle thickness when the aluminum electrolytic bath with the polymorphic structure cathode singly adopts coke particle roasting, and improving the roasting quality of the inner lining of the cathode.

Owner:CENT SOUTH UNIV

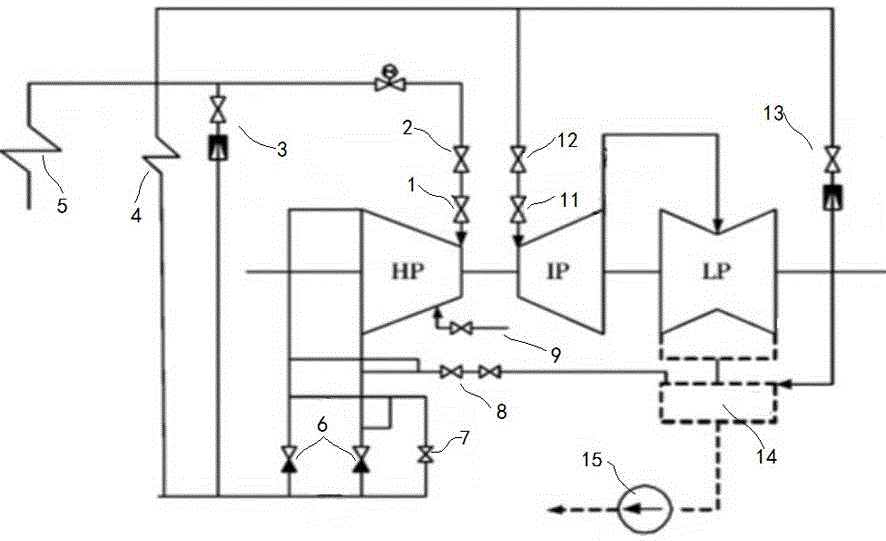

Auxiliary steam intermediate pressure cylinder starting method for steam turbine

ActiveCN106285796AFlexible start and stopAvoid the weakness of low load adaptabilityMachines/enginesEngine startersDynamic balanceGrid connection

Provided is an auxiliary steam intermediate pressure cylinder starting method for a steam turbine. The method comprises the steps of arranging pipelines, vacuumizing the steam turbine, starting a high pressure cylinder backward warming valve, conducting impulse starting on the steam turbine, conducting a dynamic balance test, a no-load test and an electrical test on a unit shaft system and conducting unit grid-connection and initial load loading. By means of system modification and logical configuration mode changing, intermediate pressure cylinder steam turbine impulse starting is conducted by means of auxiliary steam, and an electric generator no-load stage test is completed. Due to the fact that a boiler participates in the starting process of the steam turbine when the boiler is not subjected to ignition, starting and stopping of the steam turbine are flexible, no-load operation is not limited by time, and the defect that the steam turbine is poor in low-load adaptability in high pressure cylinder and intermediate pressure cylinder starting modes is avoided. Furthermore, the starting cost is reduced, a cylinder is heated uniformly, and the safety of the starting process of the steam turbine is greatly improved.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

Combined atomization centrifugal rotating disk

The invention discloses a combined atomization centrifugal rotating disk. The combined atomization centrifugal rotating disk comprises a centrifugal disk and a centrifugal tray. The centrifugal disk is detachably and coaxially nested and connected to the centrifugal tray. The bottom end of the centrifugal tray is in threaded connection with a motor shaft. As the combined atomization centrifugal rotating disk provide by the invention is of a combined structure, and the defects of an adopted single structure is hard to machine, high in manufacturing cost and short in service life are avoided. The combined atomization centrifugal rotating disk is widely applied to atomization powder making of different kinds of metals or alloys. Even if in the atomization process of high-melting-point alloy materials, the centrifugal disk cannot be broken due to heat impact. The rotating disk can make a metal melt be distributed on the surface of the metal melt uniformly to form a layer of complete liquid film and be split into finer liquid drops under the action of centrifugal force, and then the liquid drops are cooled and condensed into micro powder in the flying process.

Owner:SOUTH CHINA UNIV OF TECH

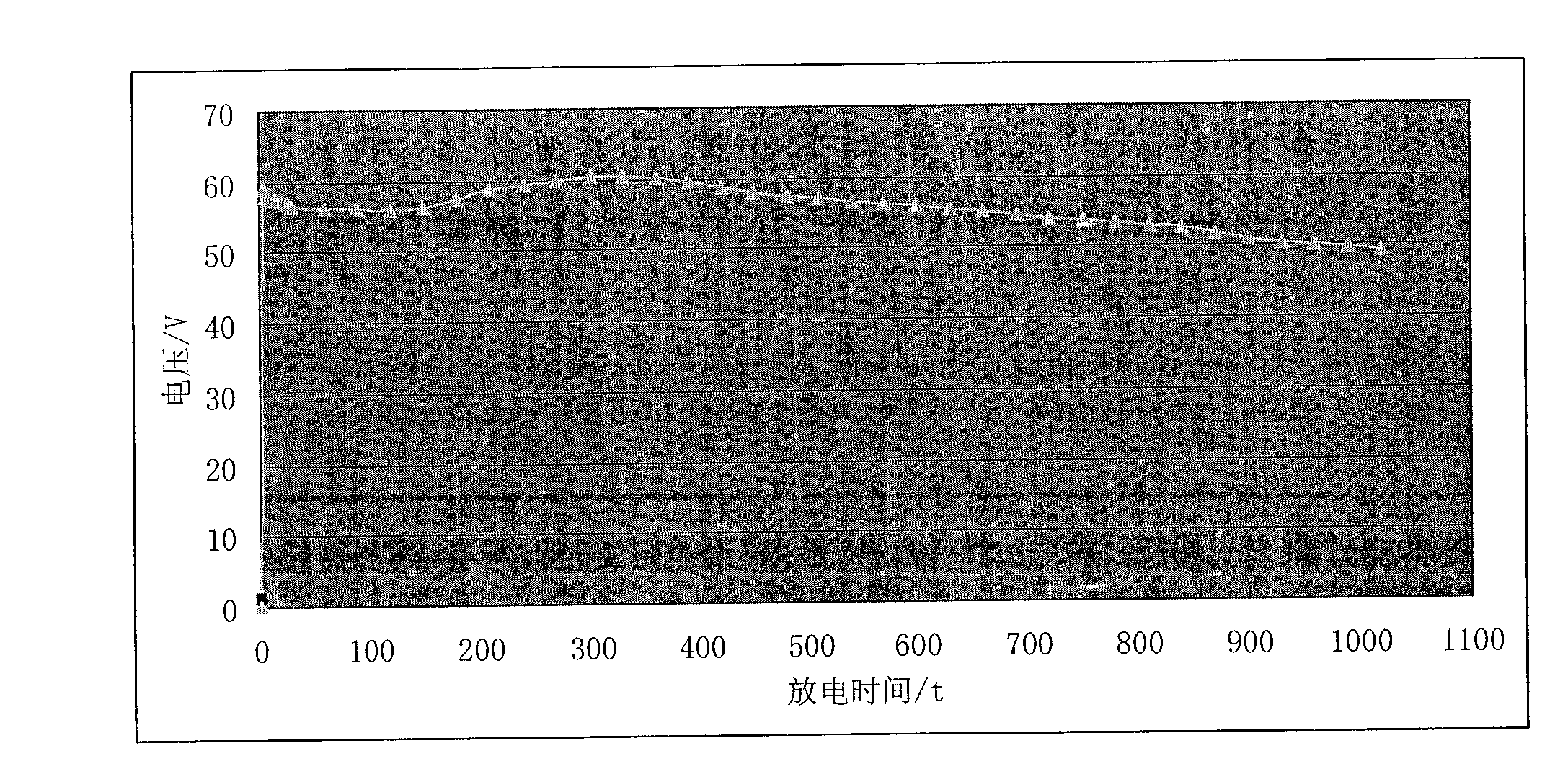

Single battery being capable of resisting overloading and high-spinning and being high in capacity

InactiveCN108232222AIncrease positive conductivityReduce thermal shockDeferred-action cellsCell electrodesCurrent collectorAsbestos

The invention provides a single battery being capable of resisting overloading and high-spinning and being high in capacity. A preparation method includes the steps of: successively tightly laminatinga nickel square-mesh net, a graphite sheet, positive powder, insulation powder, a negative pole sheet and a current collector; surrounding and compacting the outer rings of the insulation powder andthe negative pole sheet by a current blocking ring which is produced by mixing and pulping MgO and asbestos according to mass ratio of 2:1 and punching the mixture into a ring; the insulation powder is a mixture of LiCl-LiBr-LiF ternary eutectic substance and MgO according to the mass ratio of 1:1-1:1.5, wherein the mixture is compressed to form an insulation layer being 0.4-0.6 mm in thickness; the positive powder is a CoS2 / FeS2 mixture according to the mass ratio of 1:1, wherein the positive powder also contains insulation powder accounting for 15-18% by mass of the positive powder and lithium oxide accounting for 2-5% by mass of the positive powder. The single battery has strong anti-severe environment capability, can output stable voltage and is high in specific energy, and also satisfies the demand of resisting overloading and high-spinning and being long in service life.

Owner:北方特种能源集团有限公司西安庆华公司

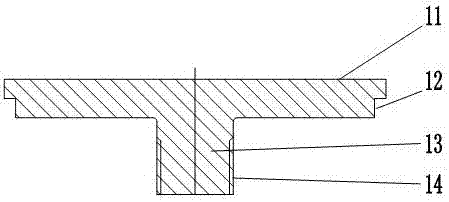

Insulation cover for sealing tank mouth of torpedo car

The invention provides an insulation cover for sealing a tank mouth of a torpedo car, which can effectively reduce heat loss in a process of transporting hot metal. The insulation cover comprises a steel shell, honeycomb firebricks, annular cover plates, stepped holes, riveting pieces, positioning supports, an inner-layer refractory material, an outer-layer refractory material, rain baffling devices, an annular positioning piece, cuboid rib plates and U-shaped lifting lugs. The stepped holes formed in the insulation cover disclosed by the invention can stabilize the air pressure in a tank cavity and lower thermal shock on materials of the insulation cover on the premise of guaranteeing reduction of thermal radiation passing through the tank mouth to play a role of protection; the firebricks are in shapes of circular honeycombs, and made of refractory clays, thereby capable of having a thermal shunting effect to effectively alleviate the thermal shock on a cap body; the rib plates are arranged to reinforce the strength of the insulation cover so as to facilitate heat dissipation. The insulation cover disclosed by the invention is simple in structure, convenient to operate, capable of effectively reducing the thermal radiation of the tank mouth and obvious in energy-saving effect.

Owner:UNIV OF SCI & TECH LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com