Single battery being capable of resisting overloading and high-spinning and being high in capacity

A single battery, high-capacity technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as reduced utilization of positive active materials, short circuit of thermal battery stacks, and potential safety hazards, and achieves the benefits of working reliability, The effect of increasing the conductivity of the positive electrode and reducing the labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

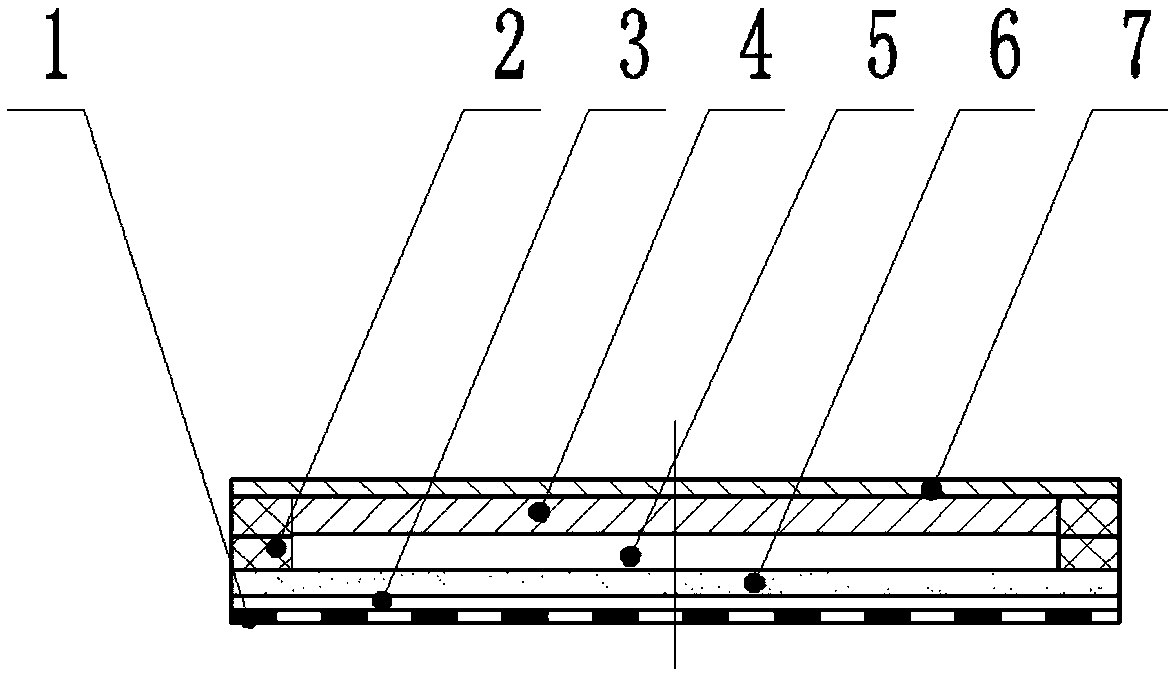

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

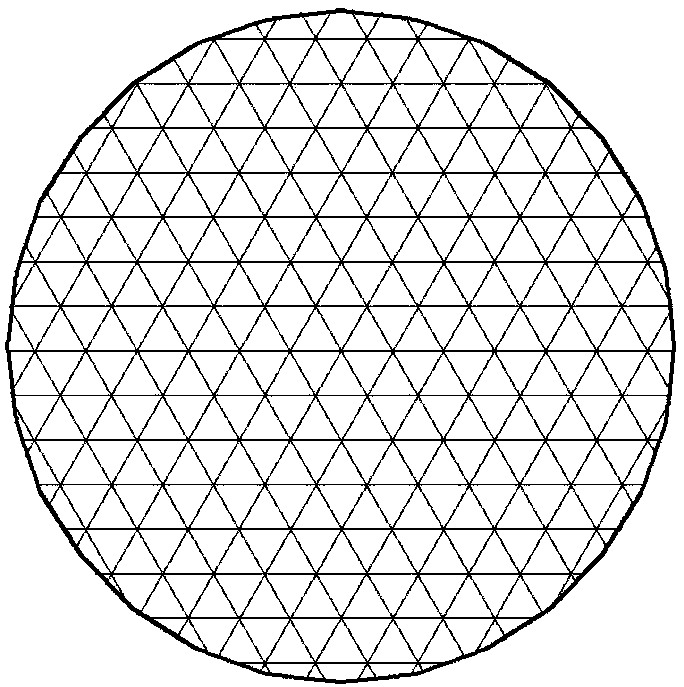

[0023] The thermal battery unit battery provided by the invention is composed of 7 kinds of materials and components, including choke ring, nickel square mesh, graphite sheet, current collecting sheet, negative electrode sheet, separator powder and positive electrode powder. Its structure solves the technical problem that the thermal battery can work stably and work for a long time in the environment of high overload before activation and high spin after activation.

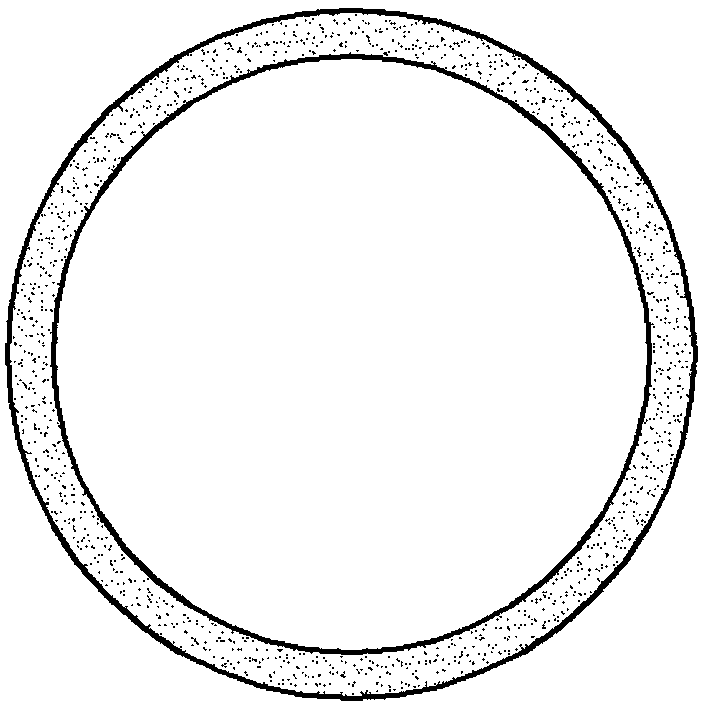

[0024] The single battery has a choke ring structure, and the choke ring is mainly composed of light magnesium oxide and asbestos paper for thermal batteries. The two are mixed according to the mass ratio of 2:1, beaten, and finally punched into a ring shape through papermaking.

[0025] The spacer powder is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com