Method for roasting aluminum electrolytic bath with polymorphic structure cathode

An aluminum electrolytic cell and cathode technology, which is applied in the field of aluminum electrolysis, can solve the problems of uneven distribution of cathode current, achieve the effects of overcoming uneven distribution of cathode surface temperature, uniform distribution of current and temperature, and overcoming local concentration of current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

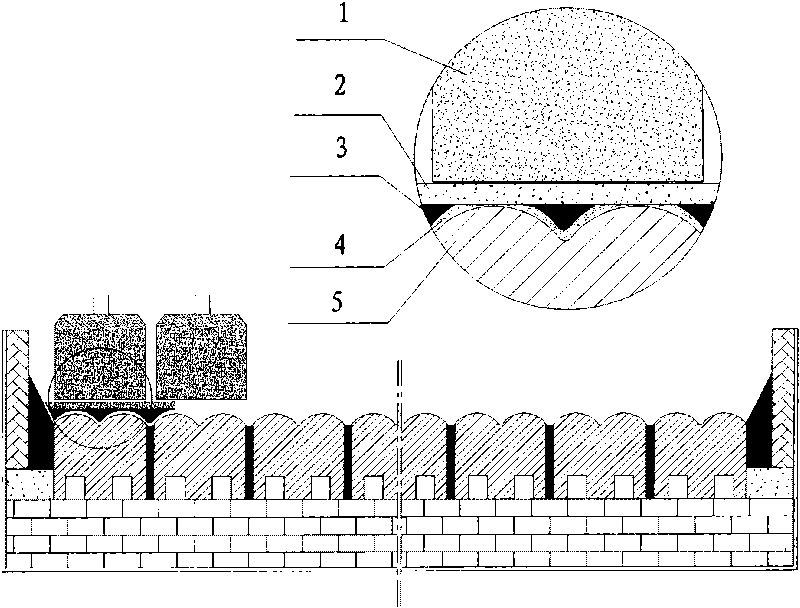

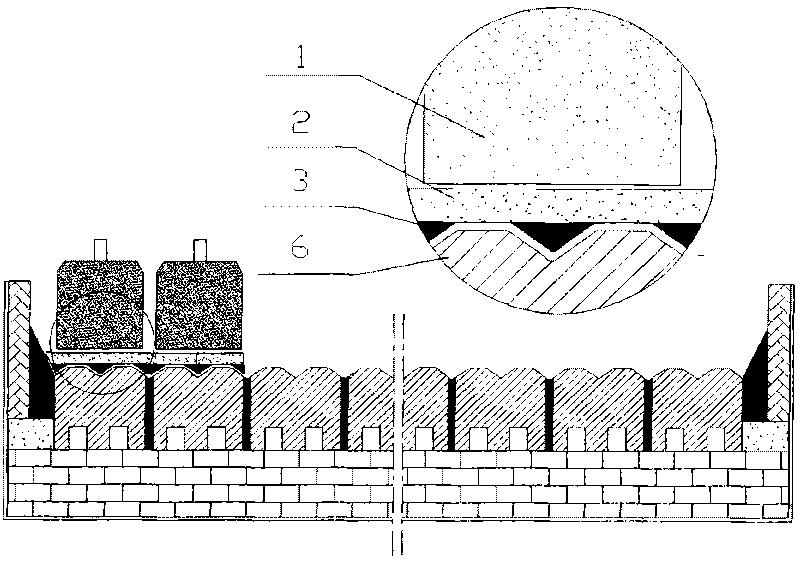

[0023] Taking the 300kA curved surface cathode and mesh cathode prebaked aluminum electrolytic cell as an example, for the curved surface cathode 5 (such as figure 1 ) and mesh cathode 6 (such as figure 2 ), the shape of the aluminum block coincides with the curved surface or the upper surface of the mesh cathode such as figure 1 and 2 As shown in the aluminum block 3, before laying the aluminum block 3, a layer of graphite powder or metal aluminum powder 4 with a thickness of 0.5 to 1 cm can be sprinkled on the curved surface cathode surface (such as figure 1 ), or directly lay the aluminum block on the cathode recess, so that the upper surface of the cathode is on the same horizontal plane, and then lay a layer of coke particles 2 with a thickness of 1 to 3 cm on the horizontal surface of the cathode after the aluminum block is filled (the particle size of the coke powder is 0.1 ~ 3mm), hang the anode 1, install the shunt, connect the anode guide rod and the anode bus bar...

Embodiment 2

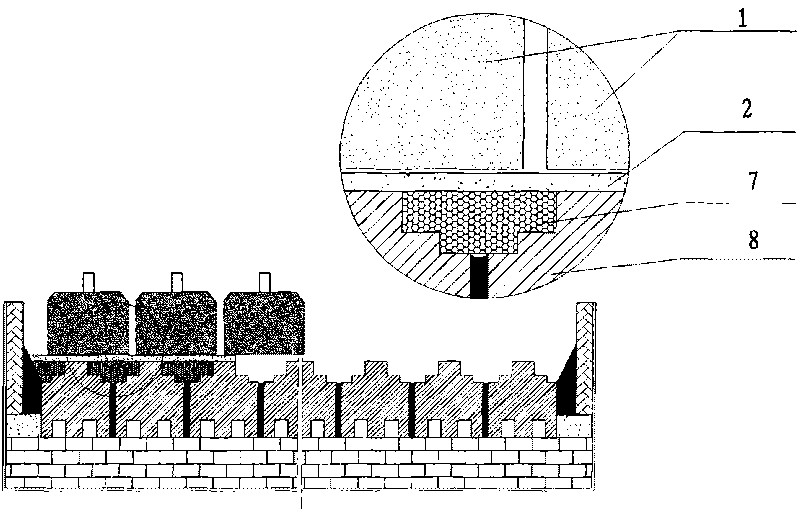

[0025] Taking the 300kA trenched (protruded) cathode prebaked aluminum electrolytic cell as an example, for the trenched (protruded) cathode 8 (such as image 3 ), use aluminum powder 7 (0.1-5mm in particle size) to fill in the concave of the cathode, so that the upper surface of the cathode is on the same horizontal plane, and then lay a layer of coke particles 2 with a thickness of 1-3 cm on the horizontal surface of the cathode (the particle size of the coke powder is about 1~3mm), hang the anode 1, install the shunt piece, connect the anode guide rod and the anode busbar with a soft busbar, place the thermocouple according to the predetermined position, pile up the electrolyte block and put it in the furnace, bake it for 60~70h after power on, and the cell voltage From the initial 4.0 ~ 4.2V (impulse voltage is about 5.1 ~ 5.3V) gradually reduced to 2.1 ~ 2.3V, until the cryolite between the middle seam and the anode seam melts into a certain height (10 ~ 15cm) of electroly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com