Blast furnace oxygen enrichment coal powder injection device and method off-line assembly and disassembly thereof

A technology of blast furnace coal injection and blast furnace, applied in blast furnace, blast furnace details, blast furnace parts, etc., can solve problems such as damage, achieve the effects of avoiding heat flow impact, speeding up oxidation speed, and solving temperature rise problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

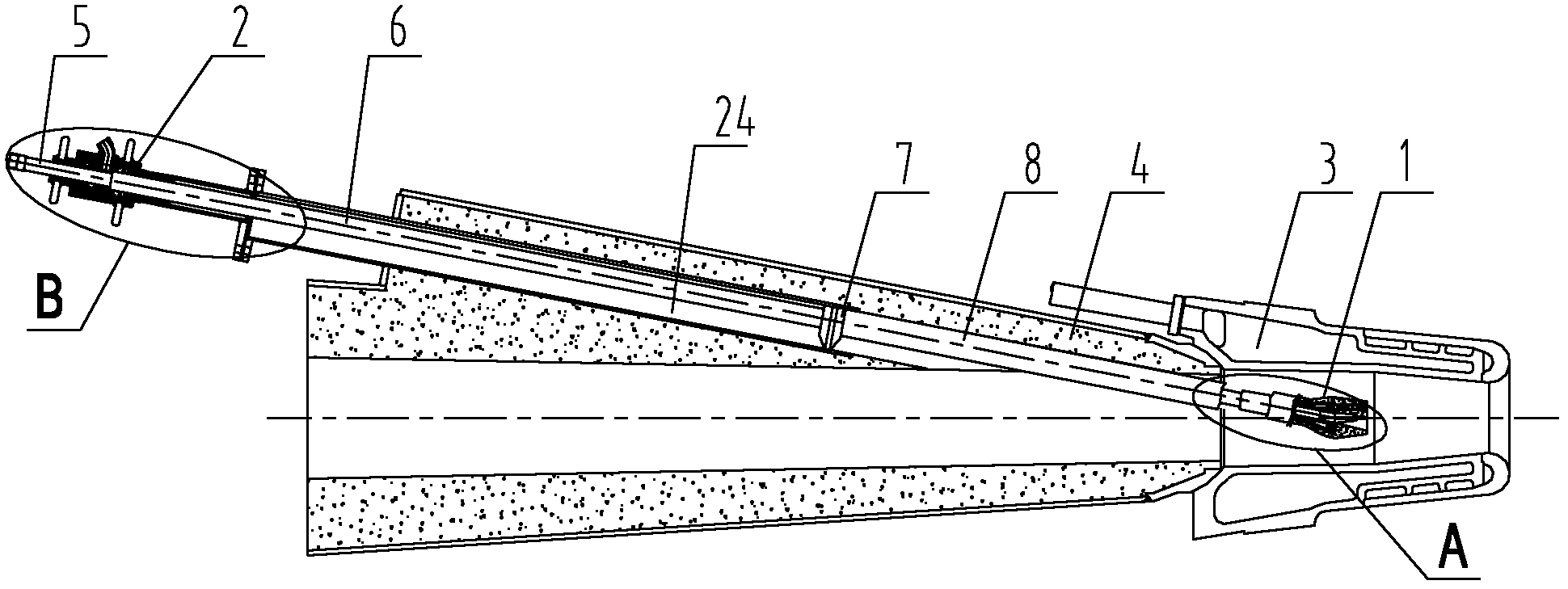

[0039] Such as figure 1 As shown, the blast furnace oxygen-enriched coal injection device is at least composed of an oxygen-enriched burner 1, a sealing device 2, a tuyere 3, an air supply branch pipe 4, a spray gun 5, a casing 6, a positioning member 7, and a protective tube 8, specifically including:

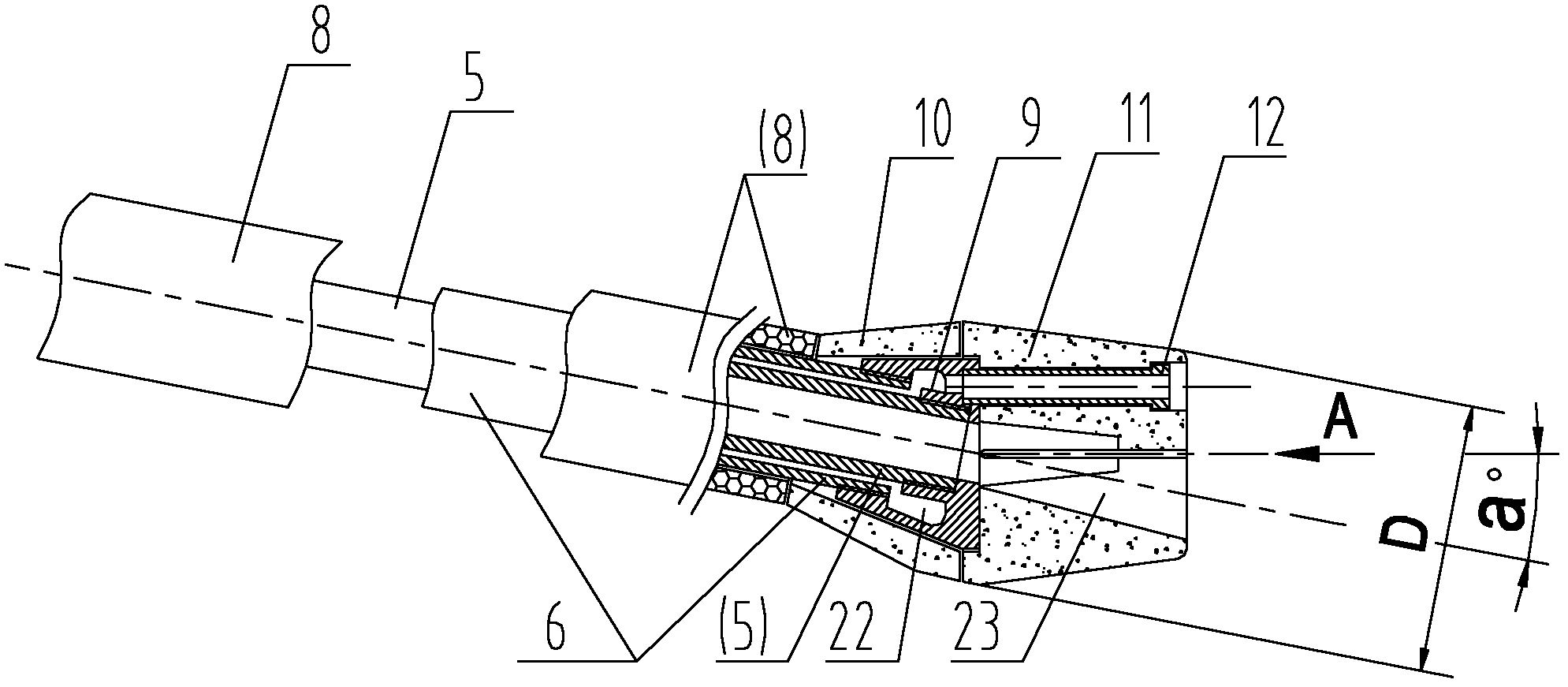

[0040] ——The oxygen-enriched burner 1 is installed at the outlet end of the spray gun 5 and the sleeve pipe 6 .

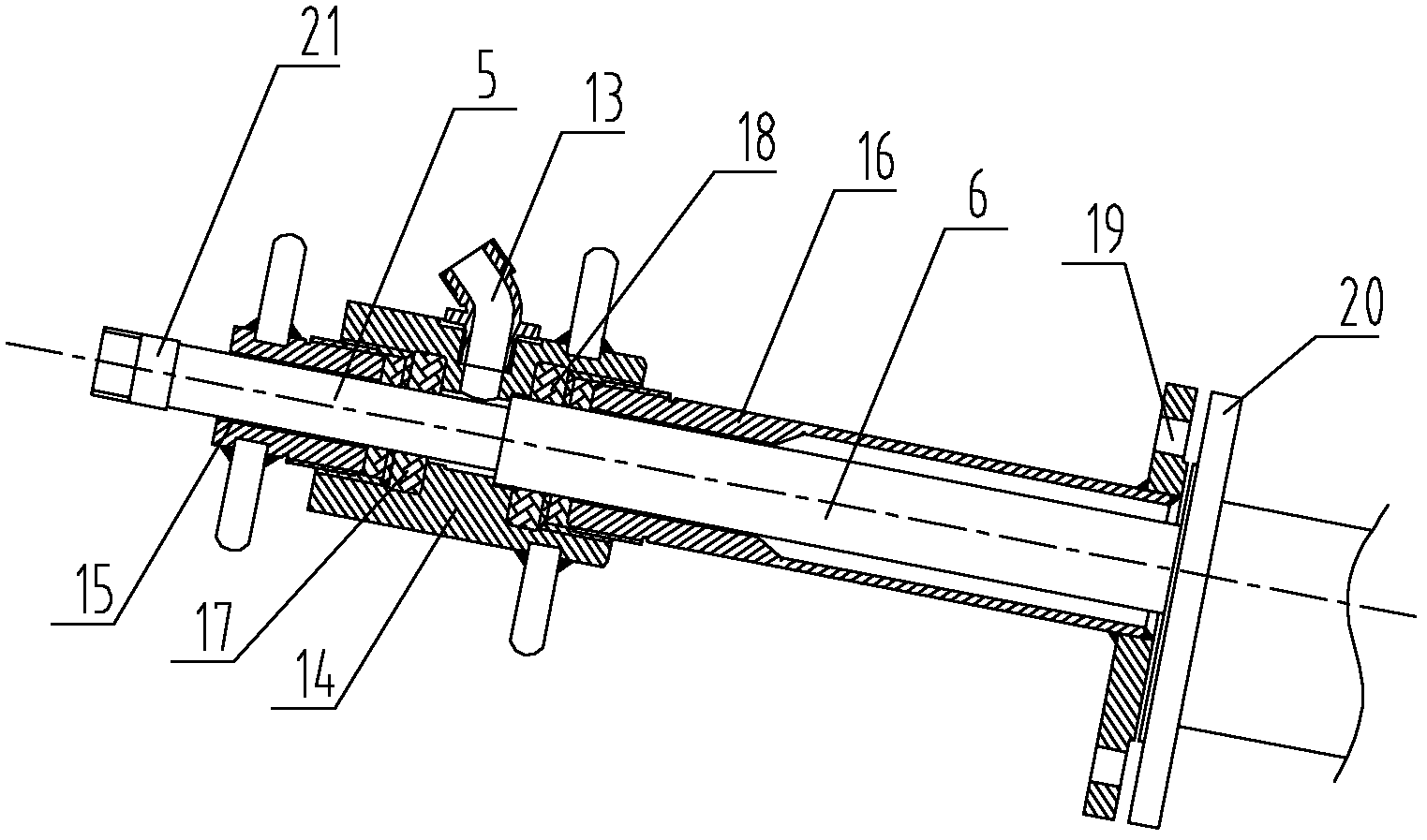

[0041] - The sealing device 2 locks and seals the spray gun 5 and the casing 6 at the same time, such as image 3 shown. Or the casing 6 is locked and sealed separately, such as Figure 5 shown.

[0042] - Oxygen enters from the oxygen interface 13, such as image 3 , 5 As shown, and through the gap between the spray gun 5 and the casing 6, it reaches the annular cavity 22 of the seat 9 of the oxygen-enriched burner 1, as figure 2 shown. Coal powder enters from the connector 21 entrance of spray gun 5 tail ends, as image 3 , 5 As shown, enter the coal ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com