Patents

Literature

82 results about "Partial oxygen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The partial pressure of oxygen, also known as PaO2, is a measurement of oxygen pressure in arterial blood. It reflects how well oxygen is able to move from the lungs to the blood, and it is often altered by severe illnesses. The PaO2 is one of the components measured in an arterial blood gas...

Catalyst for low-temperature denitration of flue gas and preparation method thereof

InactiveCN101468314AIncrease oxygen vacanciesImprove adsorption capacityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFlue gasActive component

The invention discloses a catalyst for low-temperature flue gas denitration, and a preparation method thereof. The method adopts a selective catalytic reduction (SCR) technique, takes vanadium oxide as an active component and titanium oxide as a carrier, and substitutes fluorine for partial oxygen in an oxide catalyst, so as to prepare the catalyst, wherein the vanadium oxide as the active component is loaded on the carrier by an impregnation method; the titanium oxide as the carrier is prepared by a sol-gel method; and the substitution of fluorine for oxygen can be carried out when the titanium oxide as the carrier is prepared, or when the vanadium oxide as the active component is loaded, or when the titanium oxide as the carrier is prepared and the vanadium oxide as the active component is loaded. The catalyst remarkably improves low-temperature denitration activity and catalytic capability, can reach the NO removal rate of over 90 percent at a temperature over 200 DEG C, has strong industrial application value, and can be widely applied to the NH3 selective catalytic reduction of nitrogen oxides in flue gas.

Owner:NANJING UNIV OF SCI & TECH

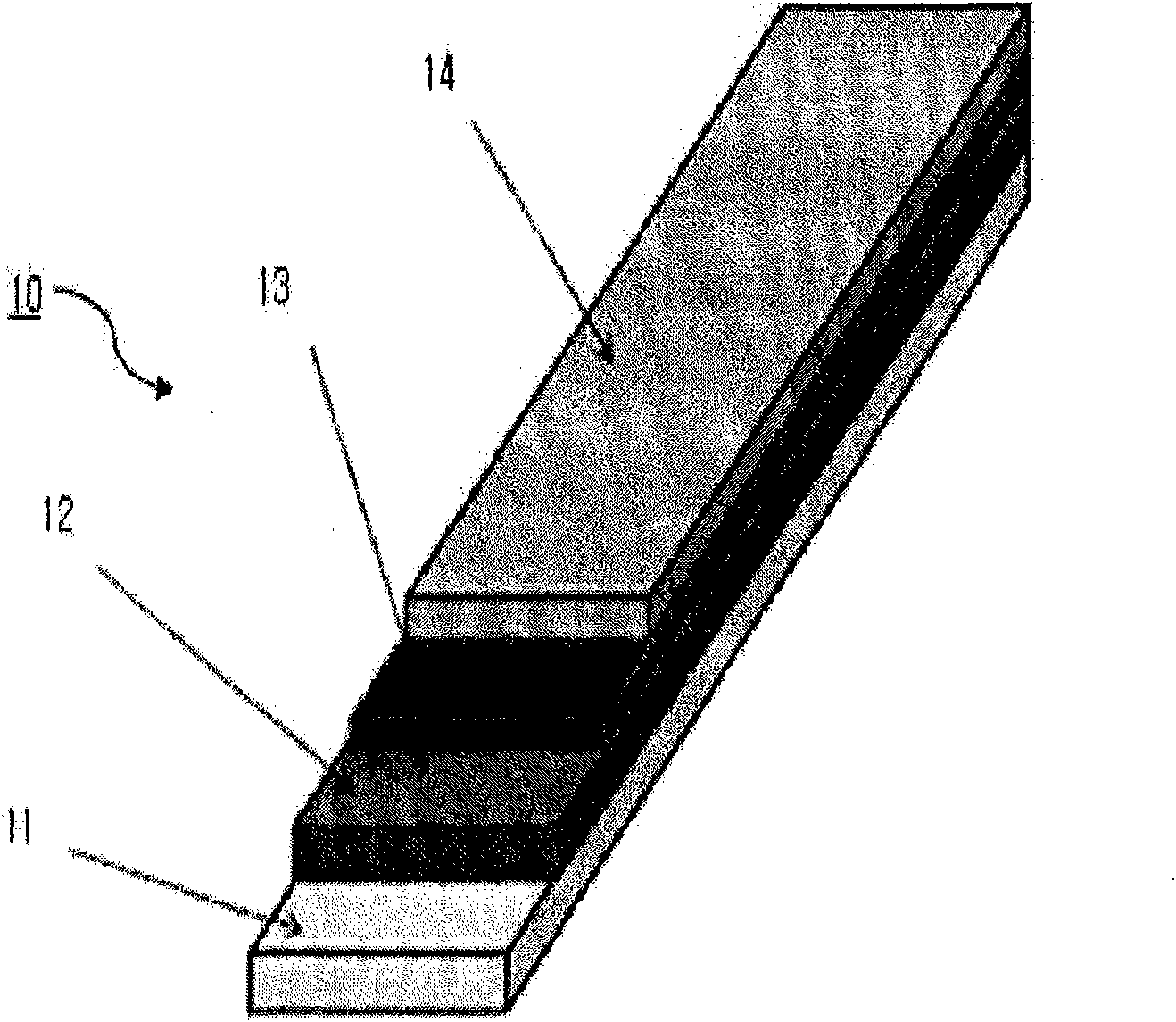

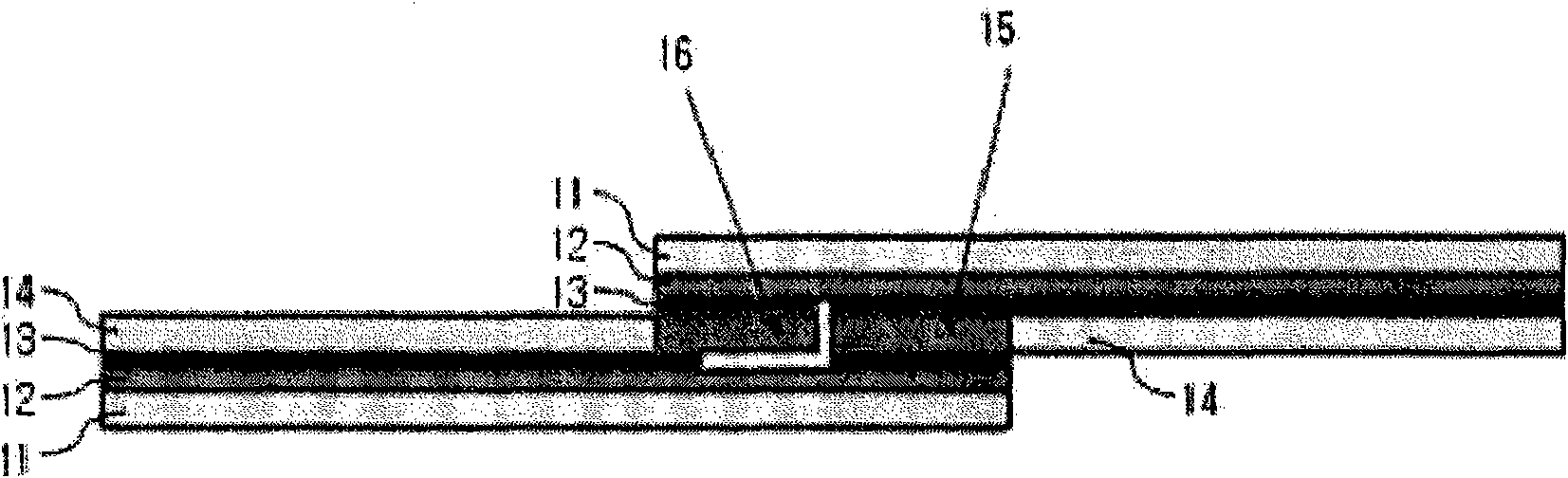

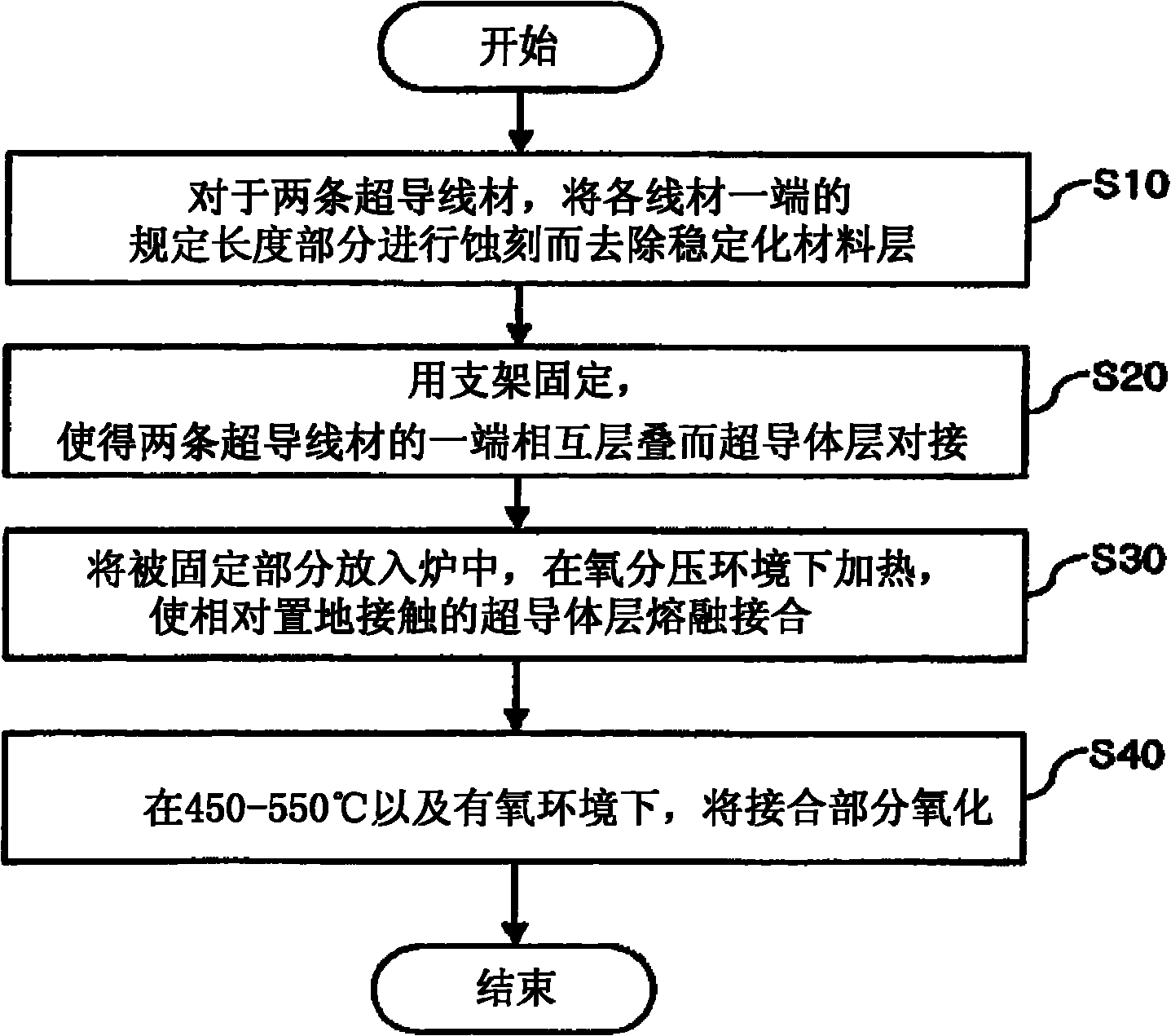

Method for joining second-generation high-temperature superconducting wires by melting diffusion

InactiveCN101971273ALower eutectic pointSuperconductors/hyperconductorsSuperconductor detailsHigh-temperature superconductivityHot Temperature

The present invention relates to a welding method for a second generation high temperature superconducting wire including a substrate, a buffer layer, a superconductor layer, and a stabilizing material layer, wherein parts of the stabilizing material layers contained in two strands of the second generation high temperature superconducting wire are removed, the superconductor layers of two strands of the second generation high temperature superconducting wire exposed by the removal of the stabilizing material layer abut each other and are heated to the melting point of the superconductor layer to melt-diffuse the abutting superconductor layers and weld two strands of the second generation high temperature superconducting wire together. Subsequently, the welded portion is oxygenation-annealed under an oxygen atmosphere to recover superconducting properties of the second high temperature superconducting wire. The above-described configuration of the present invention enables superconductor layers to directly abut each other and to be melt-diffused without using a mediator, thus producing a wire having a full length with a rare junction resistance as compared to a normal conduction junction method. Specifically, the present invention brings a partial oxygen pressure to a nearly vacuum state to lower the melting point, thereby enabling junction processes to be performed without melting a stabilizing material layer containing silver (Ag).

Owner:K·约恩

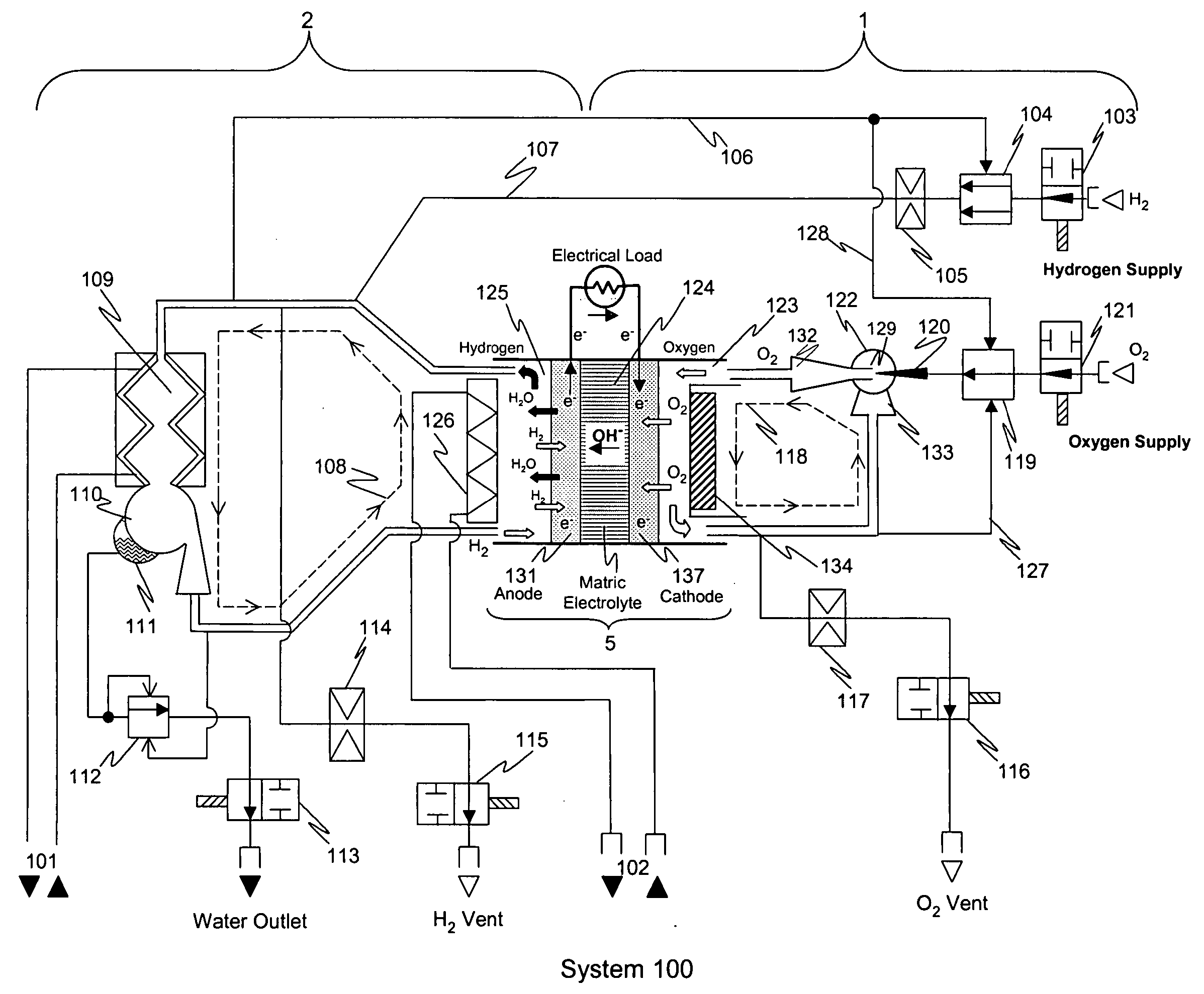

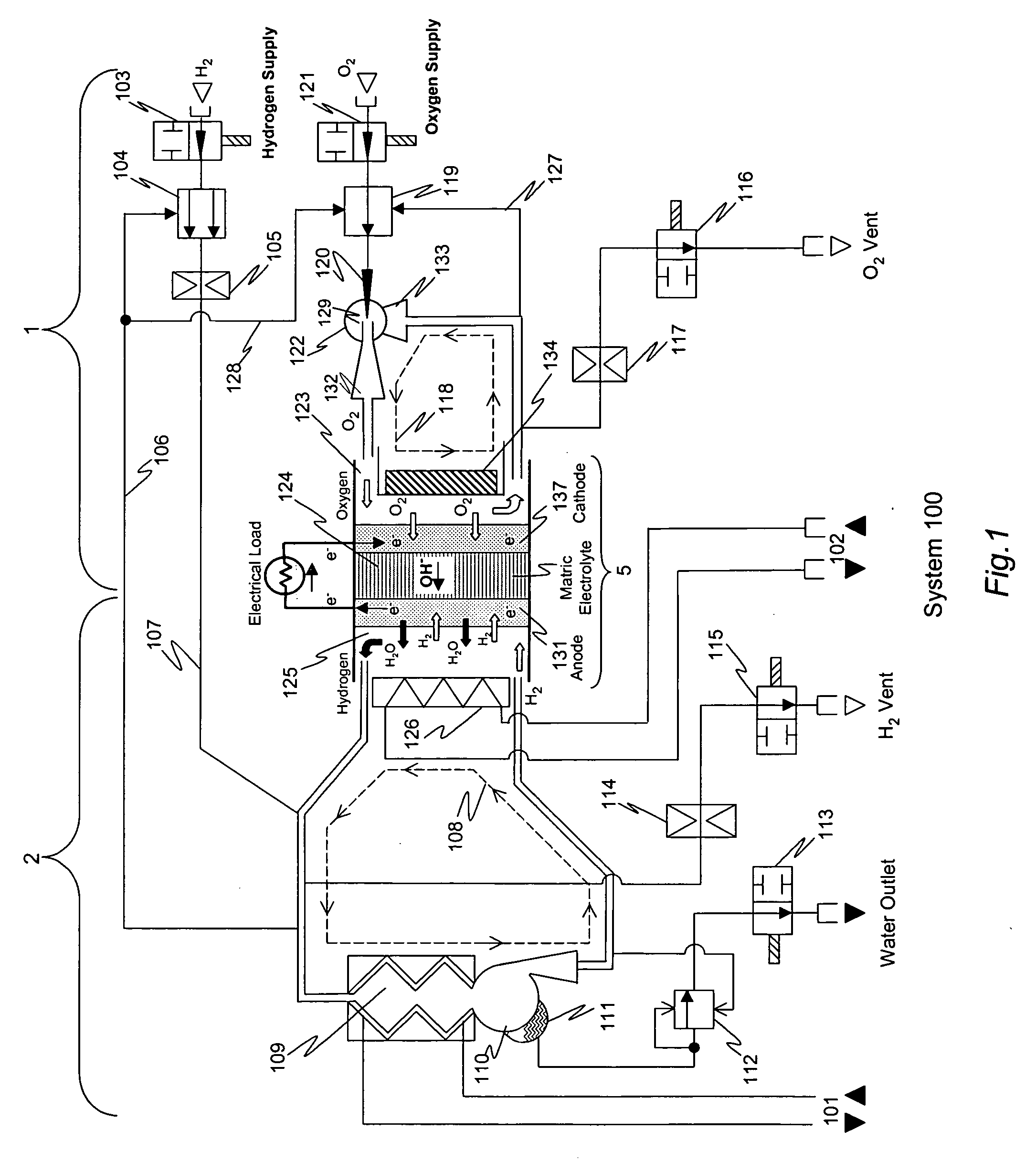

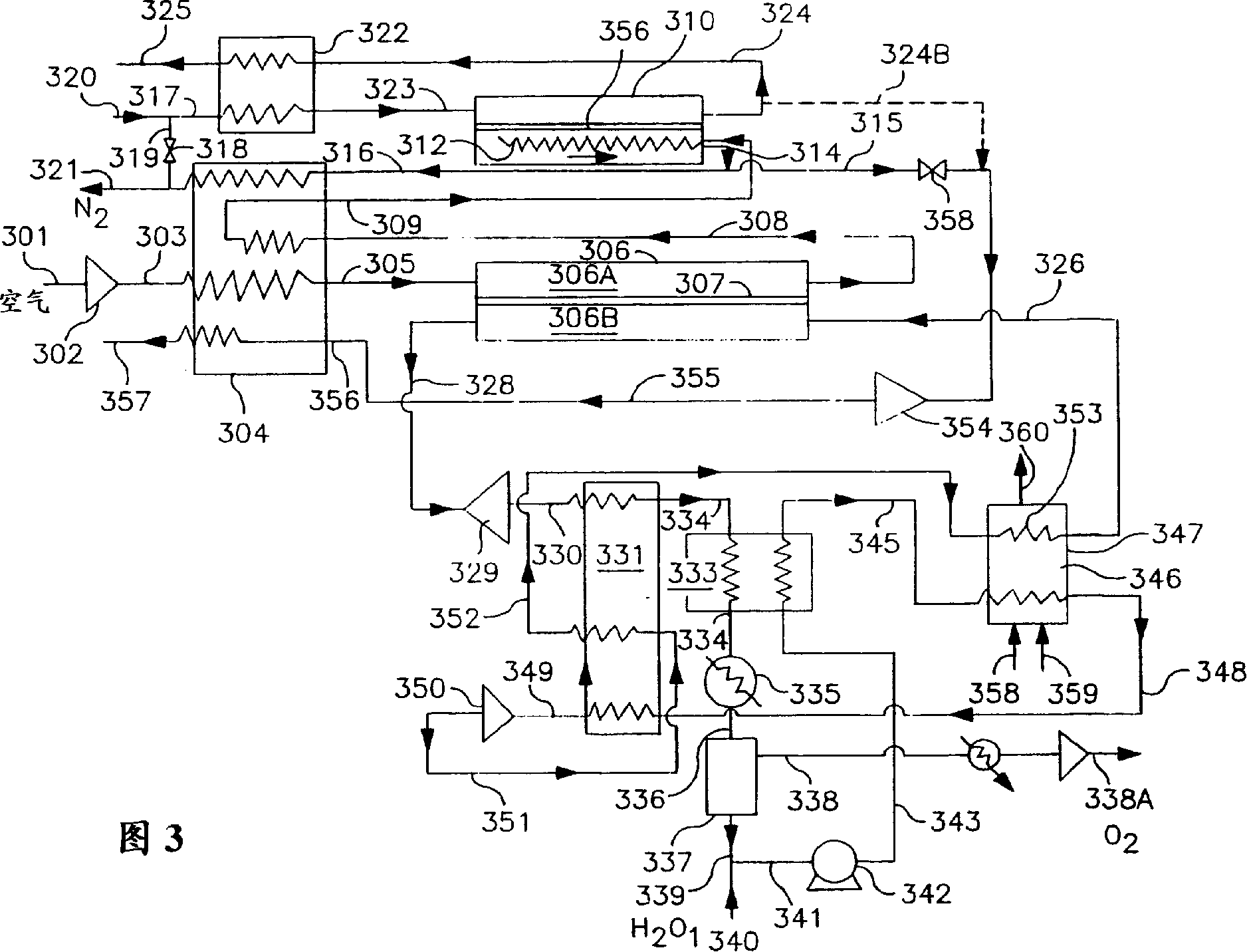

Alkaline electrolyte fuel cells with improved hydrogen-oxygen supply system

InactiveUS20050112454A1Electrolyte holding meansFuel cell auxillariesElectrochemical responseFuel cells

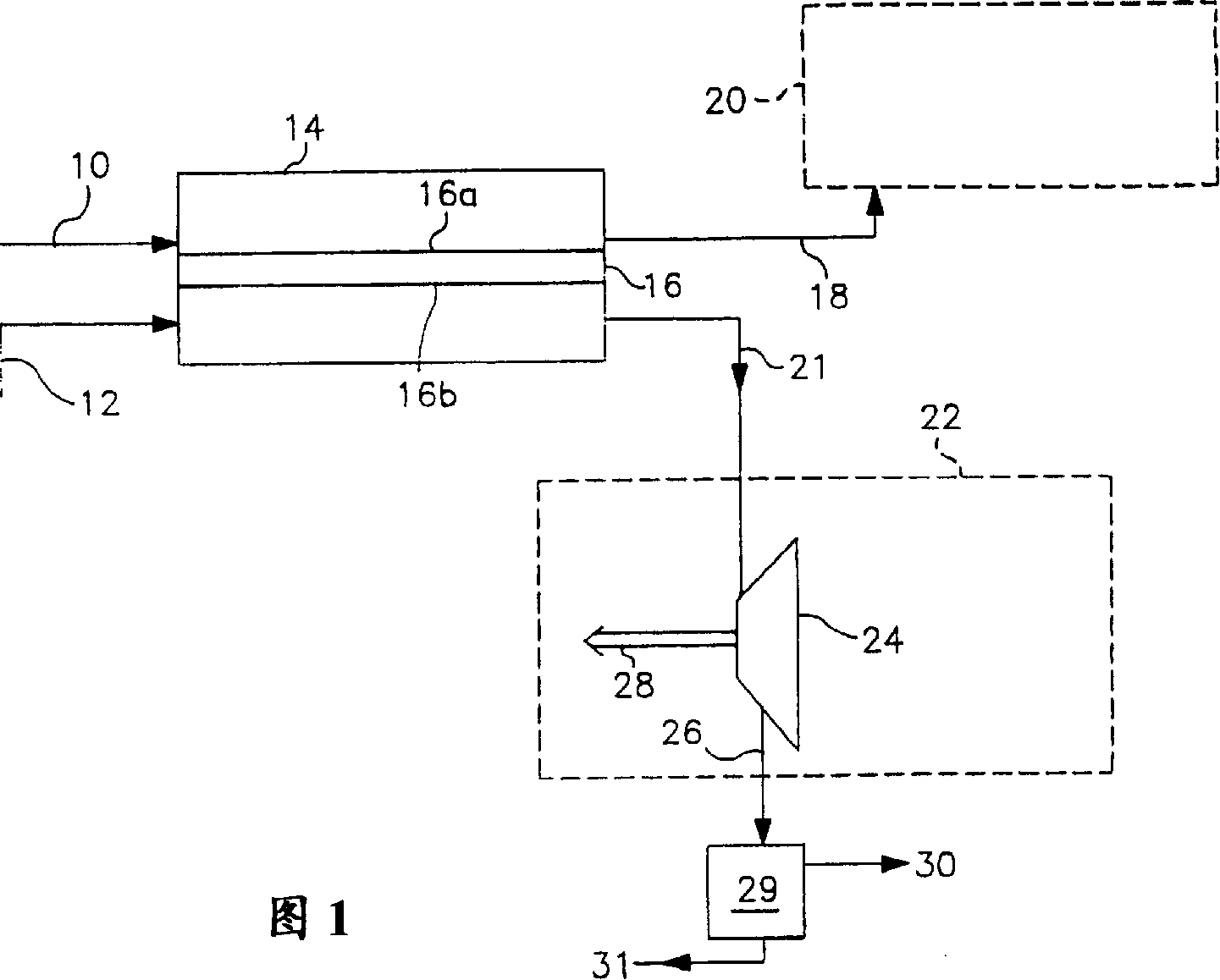

A recirculating hydrogen-oxygen alkaline fuel-cell (AFC) includes an alkaline matrix electrolyte interposed between a porous anode and porous cathode, and an oxygen flow network in fluid connection with the porous cathode. The oxygen flow network has an input portion for supplying oxygen and an output portion for removing oxygen and reaction products after electrochemical reaction. A hydrogen flow network is in fluid connection with the porous anode. The hydrogen network has an input portion for supplying hydrogen and an output portion for removing hydrogen and reaction products after electrochemical reaction. At least one of the oxygen flow network and the hydrogen flow network includes a feedback conduit to form a recirculation loop. The recirculation loop feeds back a portion of the hydrogen or oxygen flow after electrochemical reaction to the input portion.

Owner:ENER1

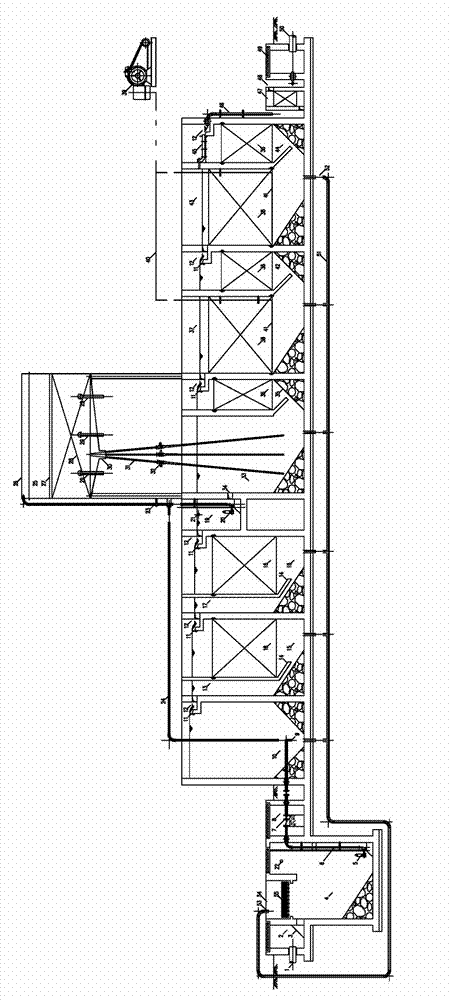

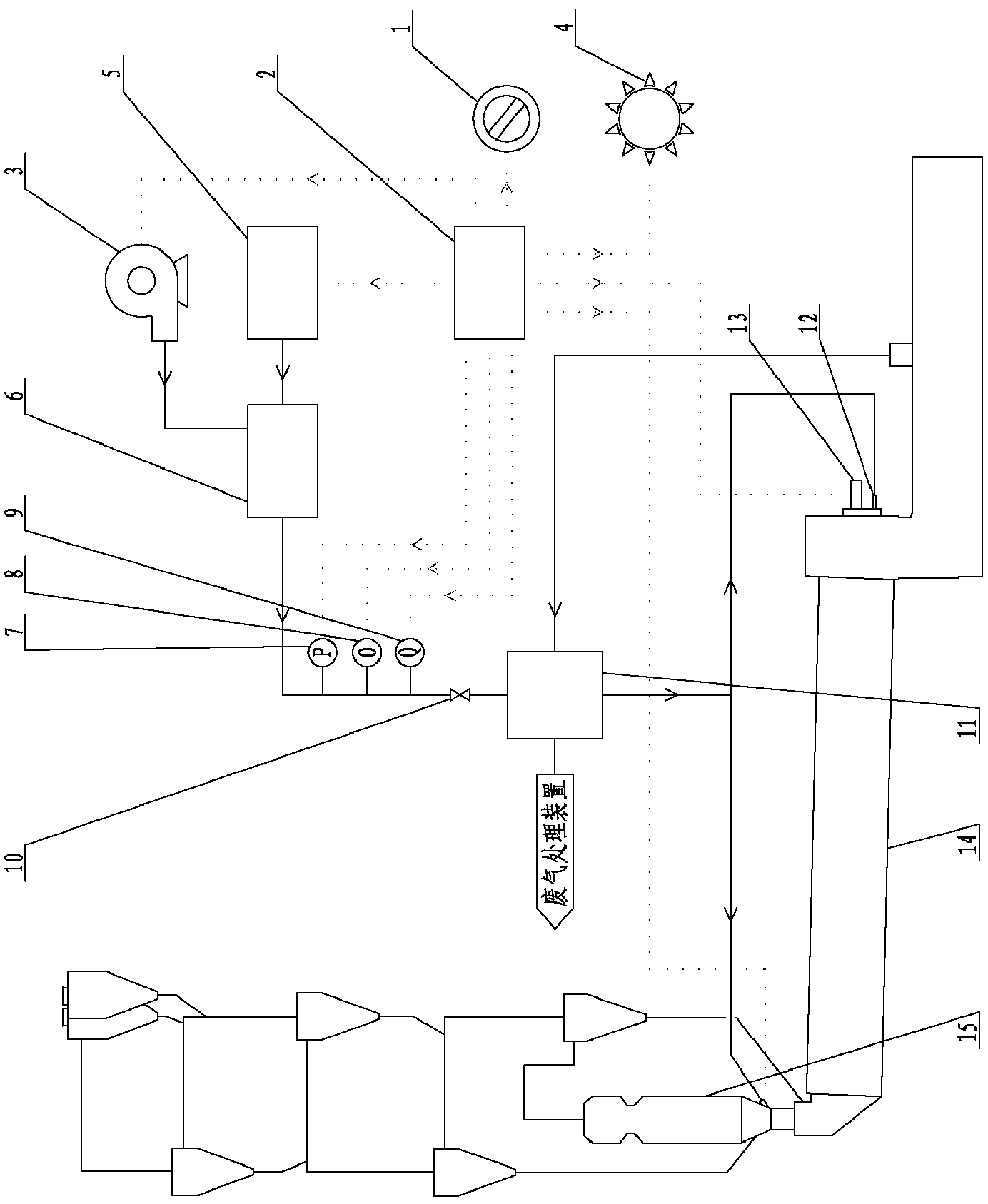

Municipal life wastewater treatment system with high efficiency and low energy consumption

ActiveCN102775025AImprove biodegradabilityHigh removal rateMultistage water/sewage treatmentFiltrationPhosphate

The invention relates to a municipal life wastewater treatment system with high efficiency and low energy consumption. The system comprises a reinforcement pretreatment part, a jet-type aeration biological filter part and a composite-type biological contact oxidation pond part. Multistage oxygen deficiency treatment, anaerobic treatment, aerobic treatment, sedimentation and filtration are adopted, reinforcement pretreatment and partial oxygen deficiency-anaerobic treatment are carried out on the wastewater, most organic pollutant can be removed and degraded, and the biodegradability of the wastewater is improved, partial aerobic treatment, oxygen deficiency treatment, anaerobic treatment, sedimentation and filtration treatment are carried out on the jet-type aeration biological filter pond, a great amount of organic pollutant, ammonia nitrogen and phosphate is removed, partial aerobic treatment, oxygen deficiency treatment, anaerobic treatment, sedimentation and filtration treatment are carried out on the composite-type biological contact oxidation pond, partial organic pollutant remained in the wastewater is removed and degraded, so that the pollutant removing rate of the domestic wastewater is improved. The system is small in occupied area, low in investment, low in operation cost and convenient in maintenance and management, and reaches the standard A of Discharge Standard of Pollutants for Municipal Wastewater Treatment Plant (GB18918-2002).

Owner:陈秋竹

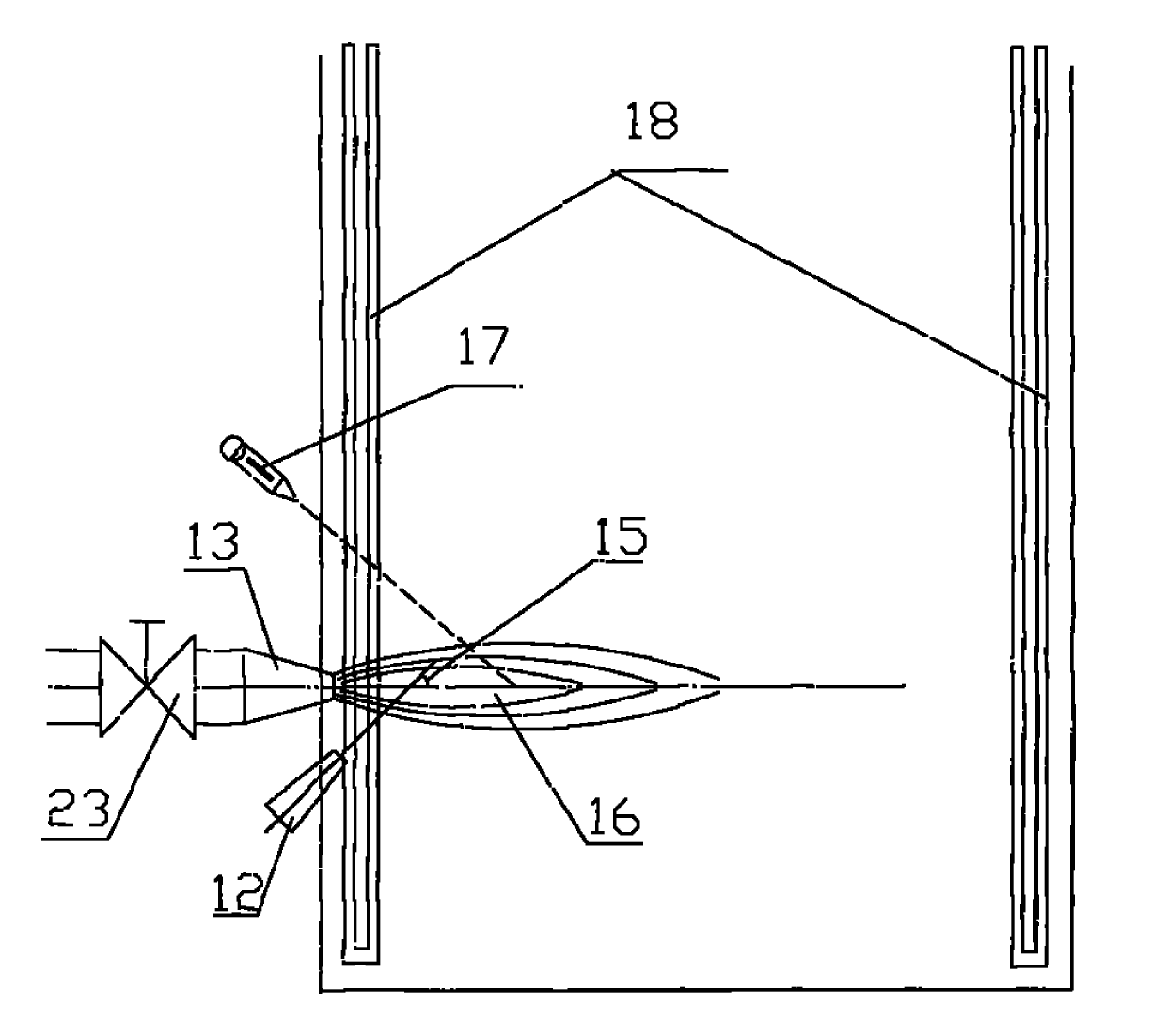

Method and device for improving heat efficiency of combustion furnace by oxygen-rich partial oxygen-enriched jet flow combustion supporting

InactiveCN101776277AIncrease heat radiationIncrease temperatureIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplyAir volumeJet flow

The invention discloses a method for improving the heat efficiency of a combustion furnace by oxygen-rich partial oxygen-enriched jet flow combustion supporting, which comprises the following steps of: introducing a fuel and an oxygen-rich gas into the combustion furnace respectively; and gathering the fuel and the oxygen-rich gas together for combustion, wherein the oxygen-rich gas is pressurized first, then is jetted into a fuel flow area at a linear velocity which is 1.2 to 4.0 times the flow velocity of the fuel by forming an angle of 10 to 45 degrees with the jetted fuel, and is mixed with the fuel for combustion, and the entering position of the oxygen-rich gas is an area which is between the top end of a combustion flame and a jet tip and is 1 / 4 to 4 / 2 away from the jet tip of a fuel nozzle. The invention also provides a device for improving the heat efficiency of the combustion furnace by the oxygen-rich partial oxygen-enriched jet flow combustion supporting. The method and the device has the following advantages that: by using a special oxygen-rich jet flow nozzle and a heat radiation principle, not only the duel energy-saving efficiencies of reducing the combustion-supporting air volume and completely combusting the fuel are kept, but also the temperature of a combustion flame area can be raised to the utmost extent, so the flue gas heat radiation is improved to the utmost extent.

Owner:魏伯卿

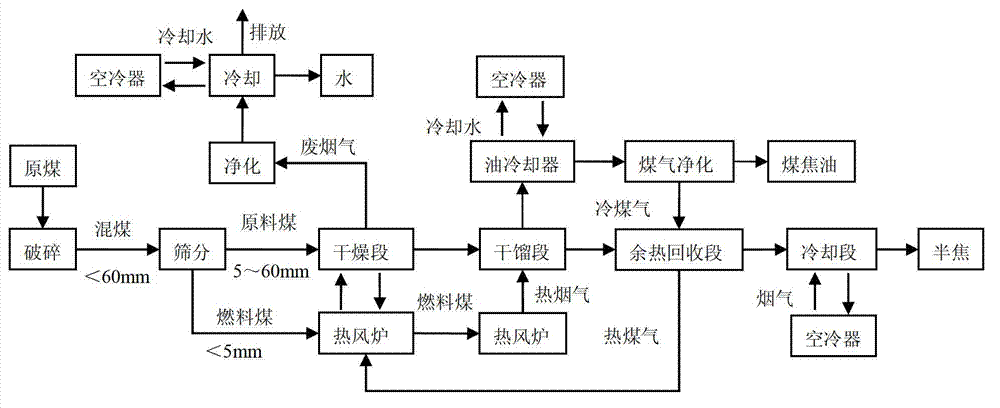

Brown coal low temperature carbonization method

InactiveCN102965128AReduce moisture contentReduce energy consumptionDirect heating destructive distillationEnergy inputHeat carrierCarbonization

The invention discloses a brown coal low temperature carbonization method. The method comprises the following steps of: by a gas heat carrier, firstly, heating the coal under the condition of isolating air, removing more than 90% of total moisture, crystal water and partial oxygen-containing functional groups which have influence on the coal heat value, and enriching the coal heating constituents; and further heating the coal to form solid semicoke, purifying the separated volatile constituent substance to recycle coal tar and coal gas products, recycling the afterheat of the high temperature semicoke and cooling the semicoke to collect the semicoke. The obtained semicoke has the advantages of high heat value, excellent stability and non-reabsorption and the like. The method is simple in technology, low in energy consumption, pollution-free and high in product quality, capable of realizing industrial large-scale production, and easy to generalize widely.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

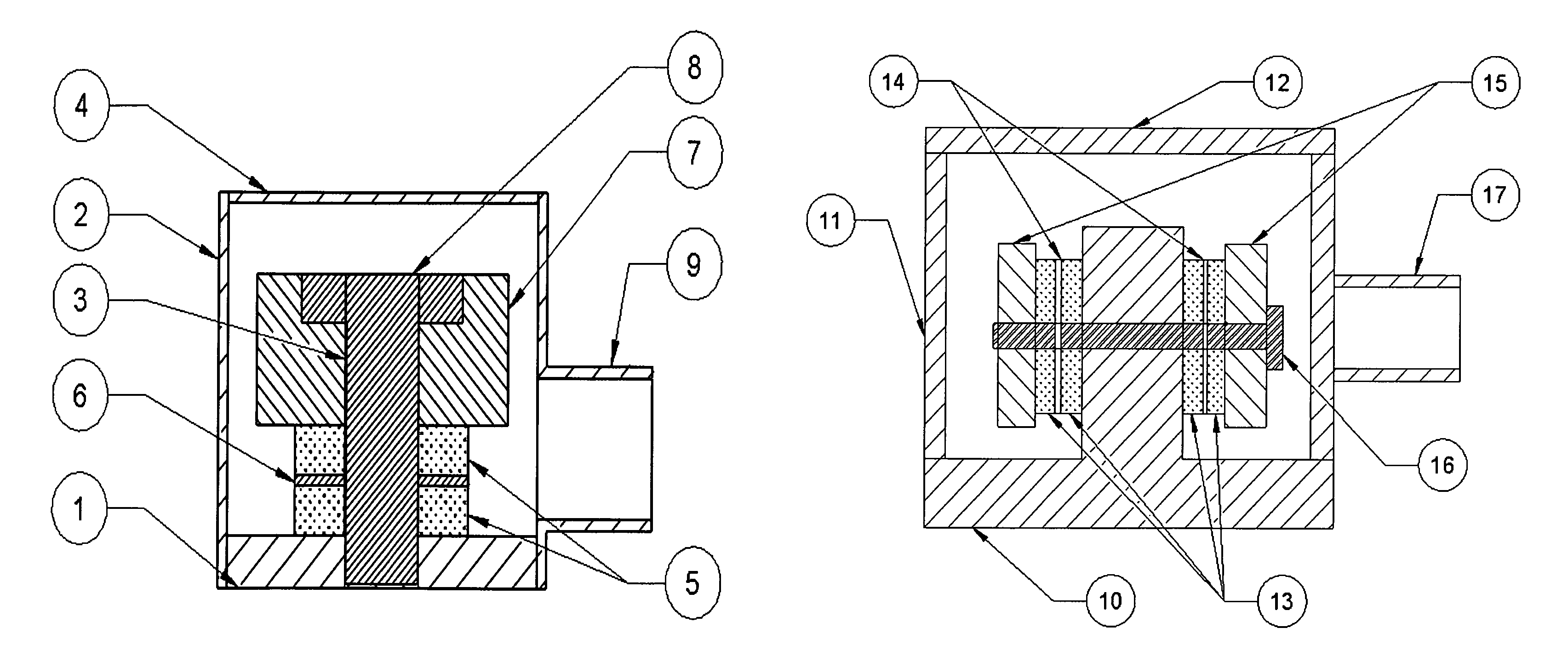

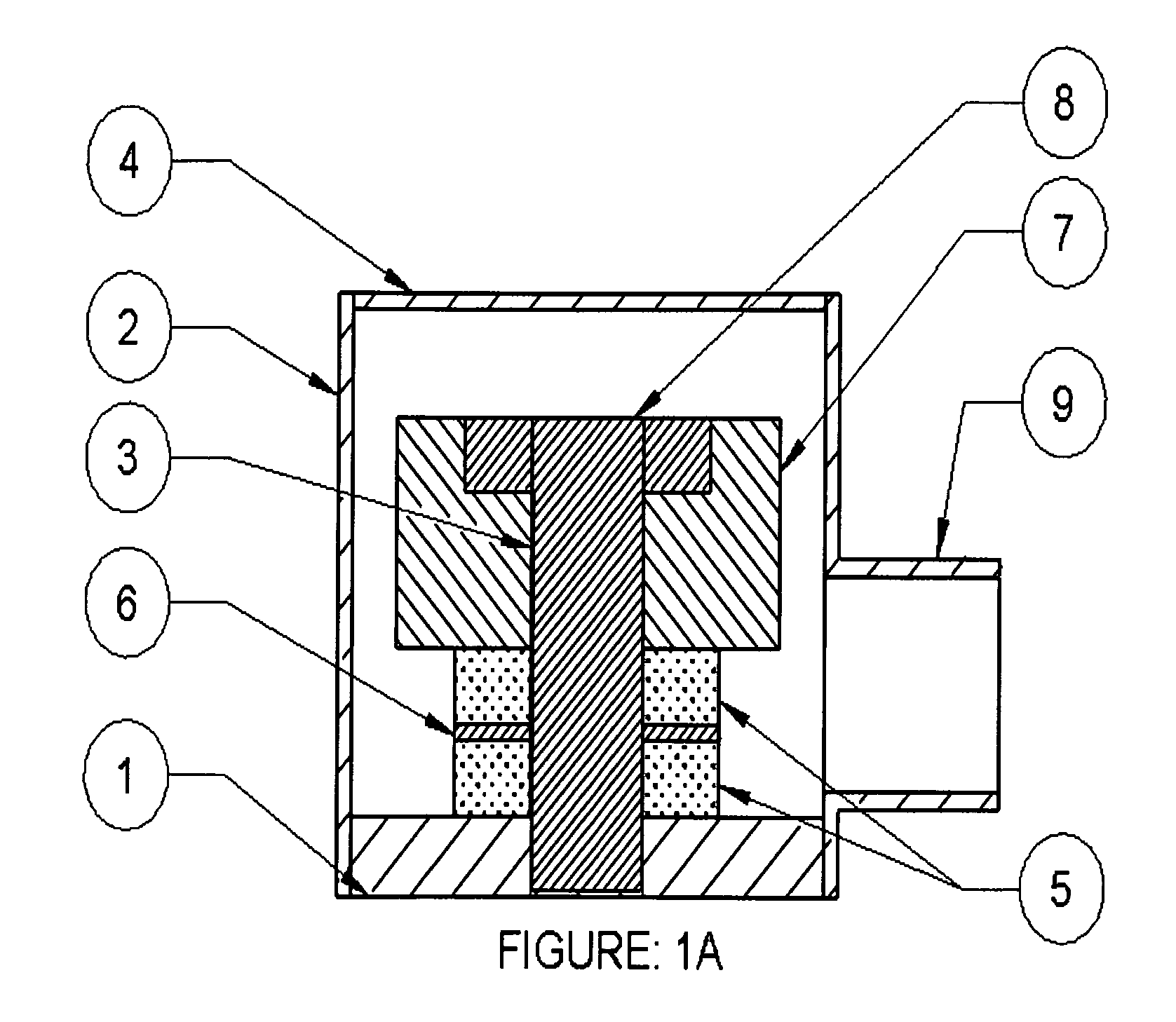

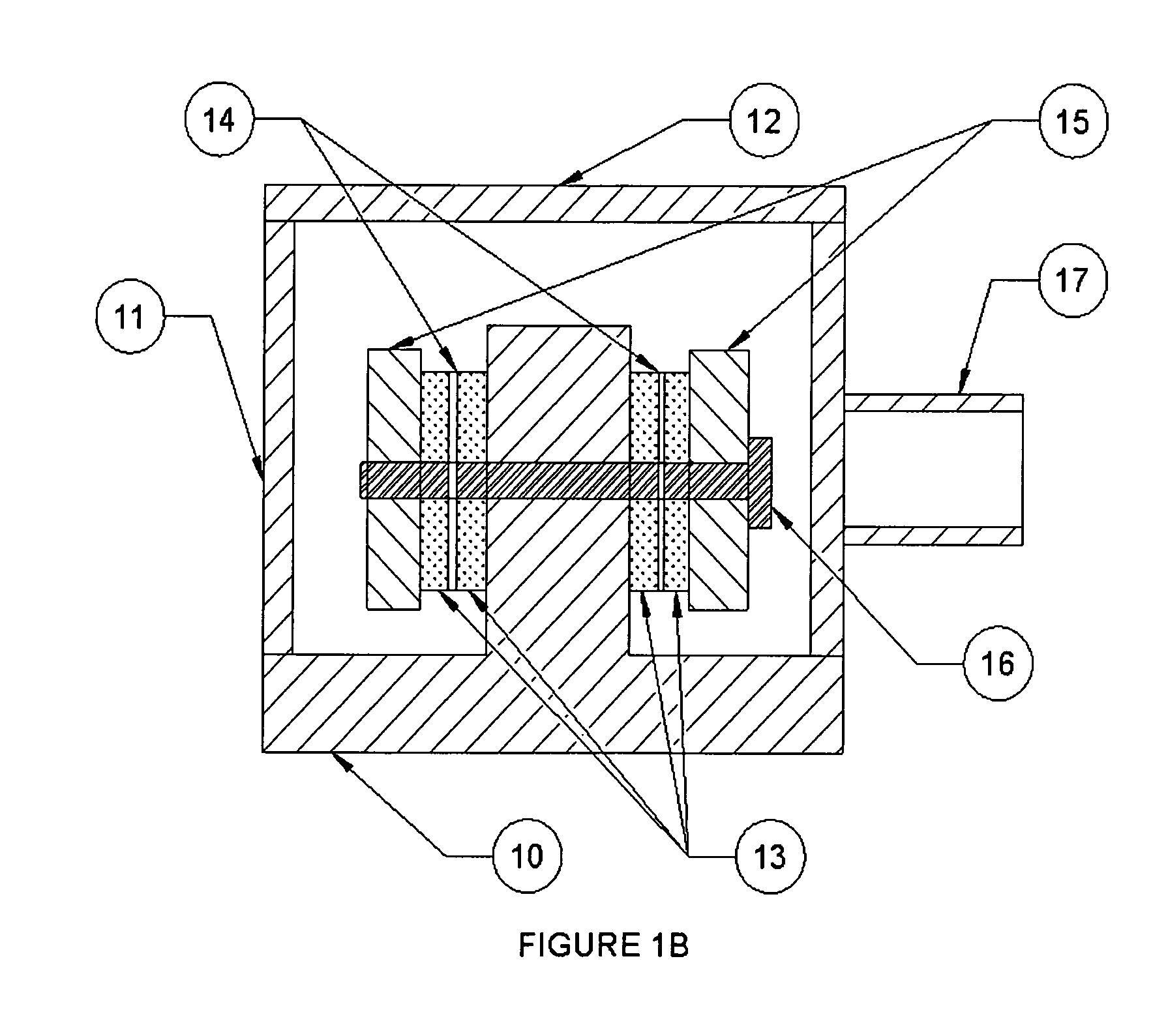

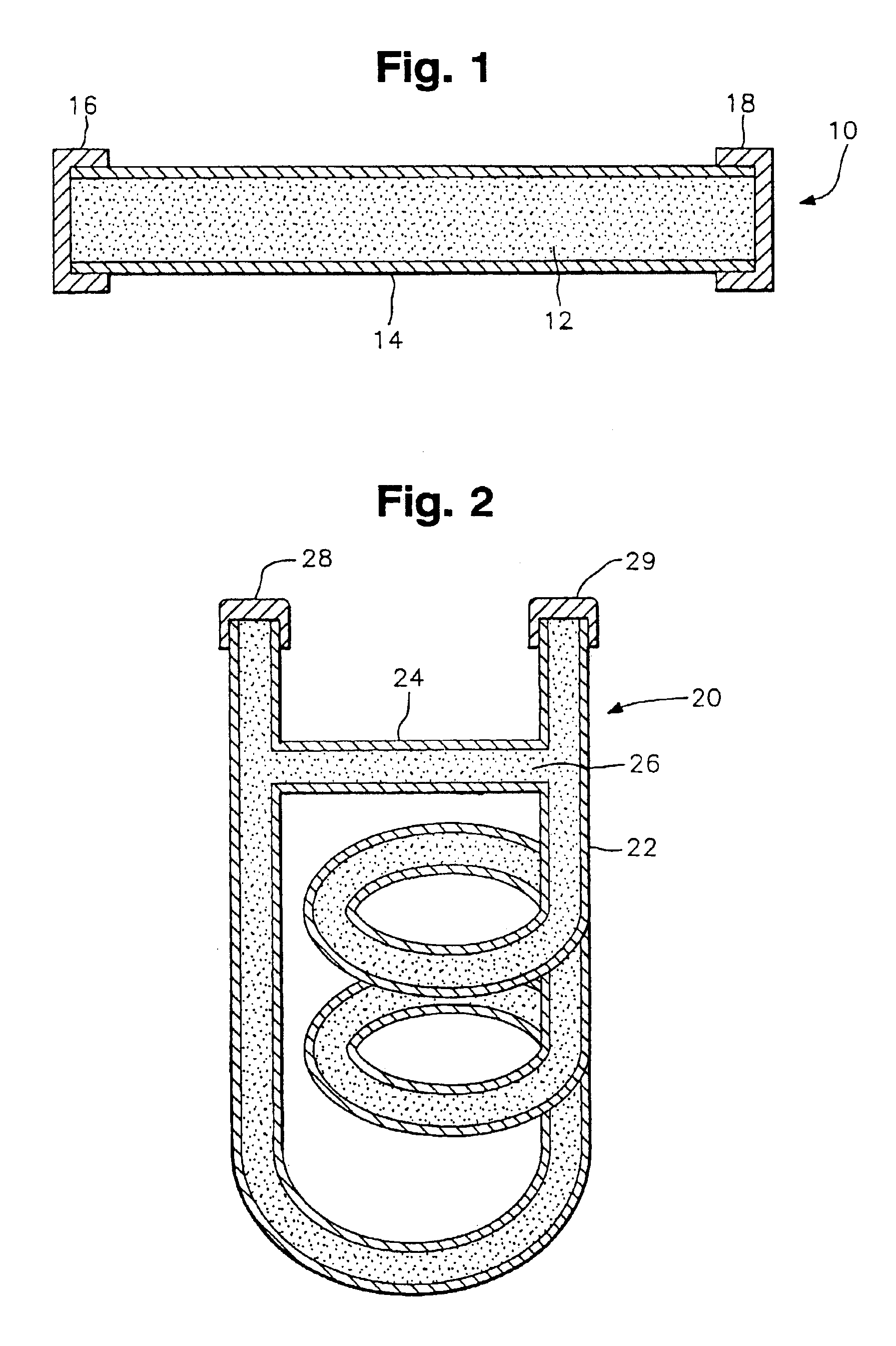

Accelerometer for high temperature applications

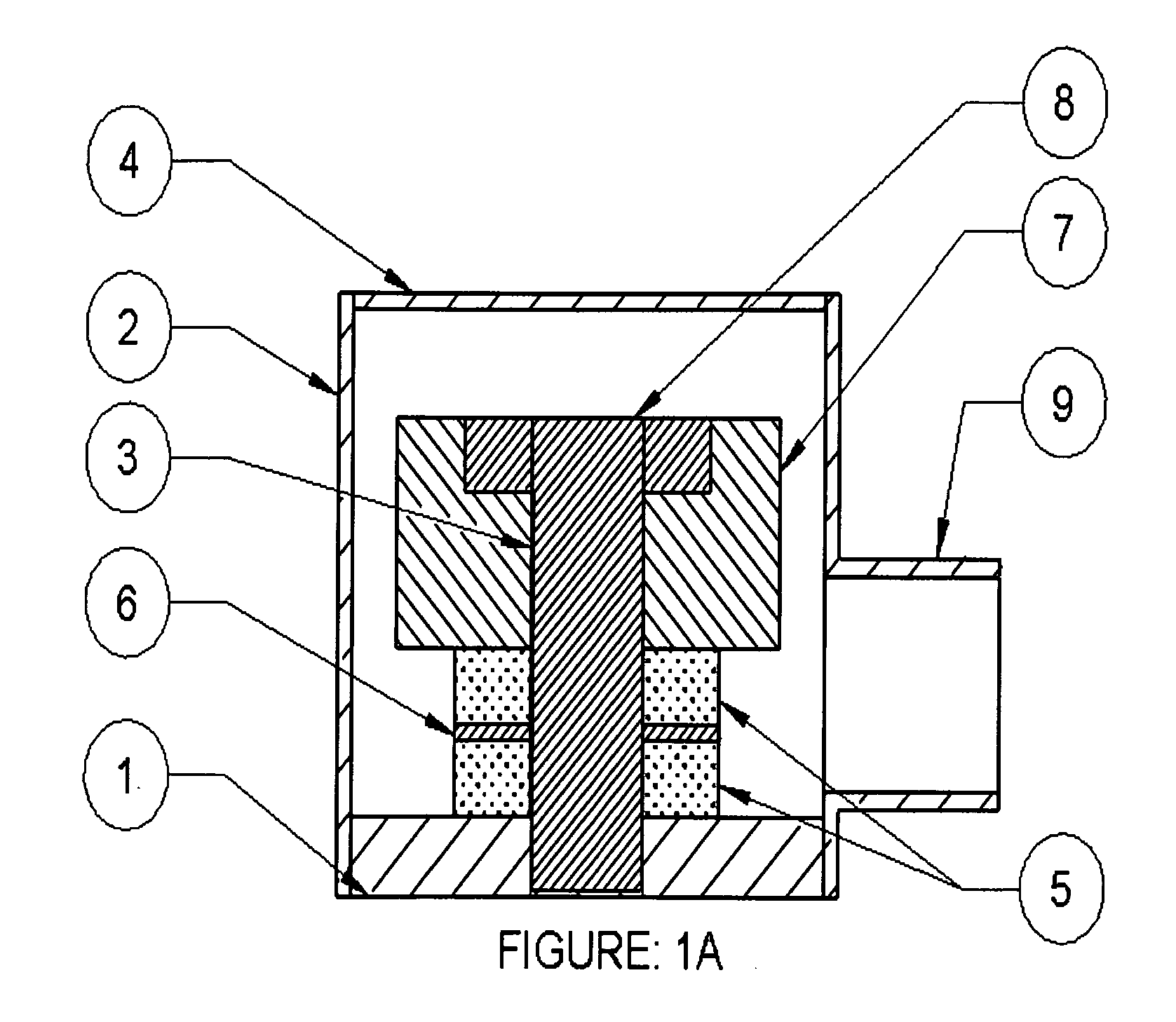

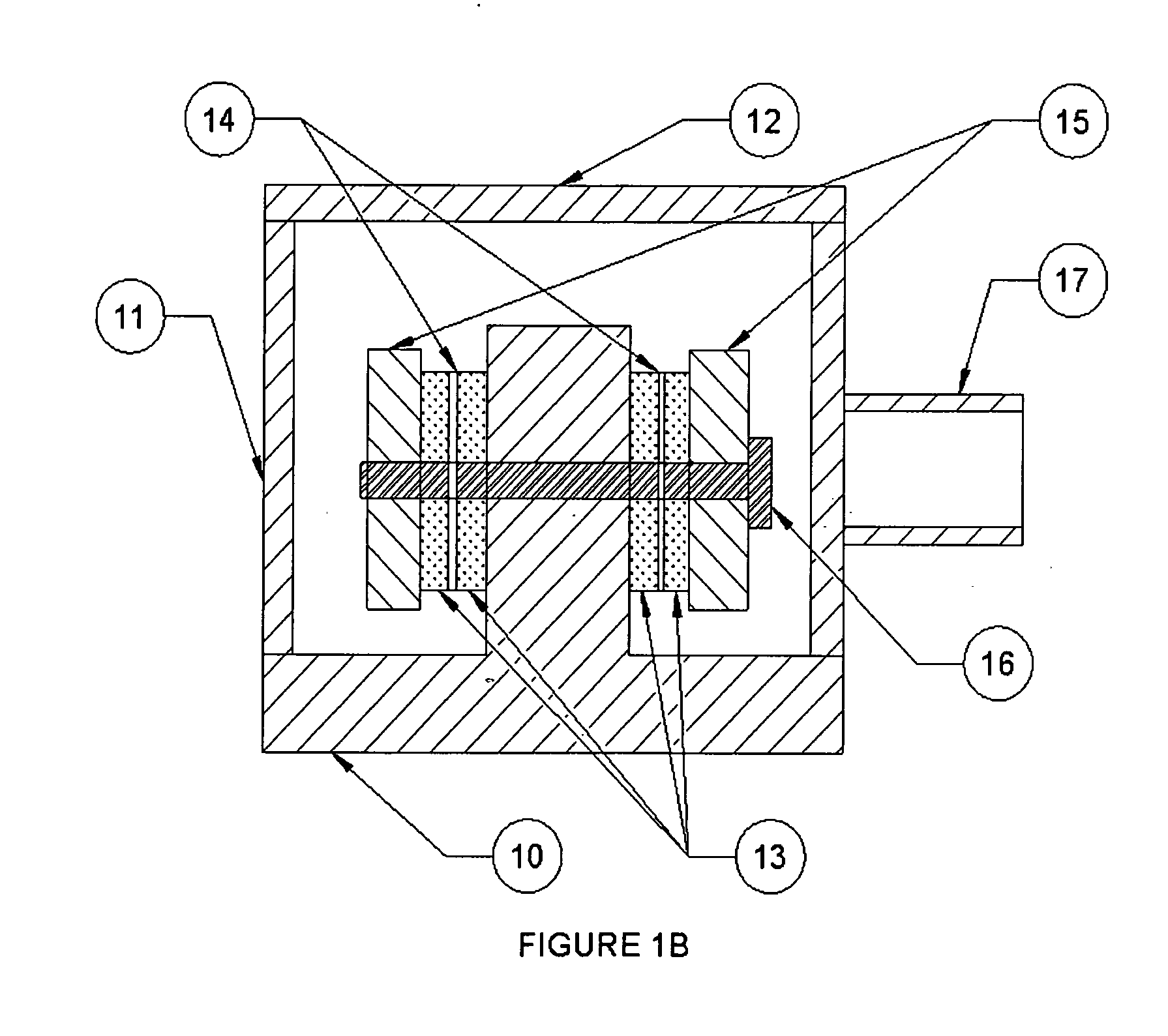

ActiveUS20120204644A1Improve performanceDelay agingPiezoelectric/electrostrictive device manufacture/assemblyAcceleration measurement using interia forcesAccelerometerAlloy

This invention is for a hermetic piezoelectric accelerometer sensor that can operates at high temperatures without the degradation observed on the piezoelectric elements, due to Oxygen depletion of the piezoelectric materials, when they are exposed to high temperatures, in reducing atmospheres, or low partial Oxygen pressure, inside a sealed housing. When a piezoelectric element loses Oxygen, becomes more electrically conductive, and this severe loss in resistivity, exacerbated with the increase of the temperature, makes the sensor inoperable, unreliable, or with permanent damage. The accelerometer of this invention operates effectively over a wide range of temperatures, including high temperatures above 1600° F., depending of the piezoelectric element used on the construction. The housing of the accelerometer uses a small section of metal made with Silver (or Silver alloys) to allow Oxygen diffusion through the metal, when it is exposed to high temperature. This permits that the construction of the accelerometer housing, can be sealed hermetically; and the piezoelectric elements of the sensor have increased lifetime, with enough partial pressure of Oxygen inside the housing.

Owner:DYTRAN INSTR

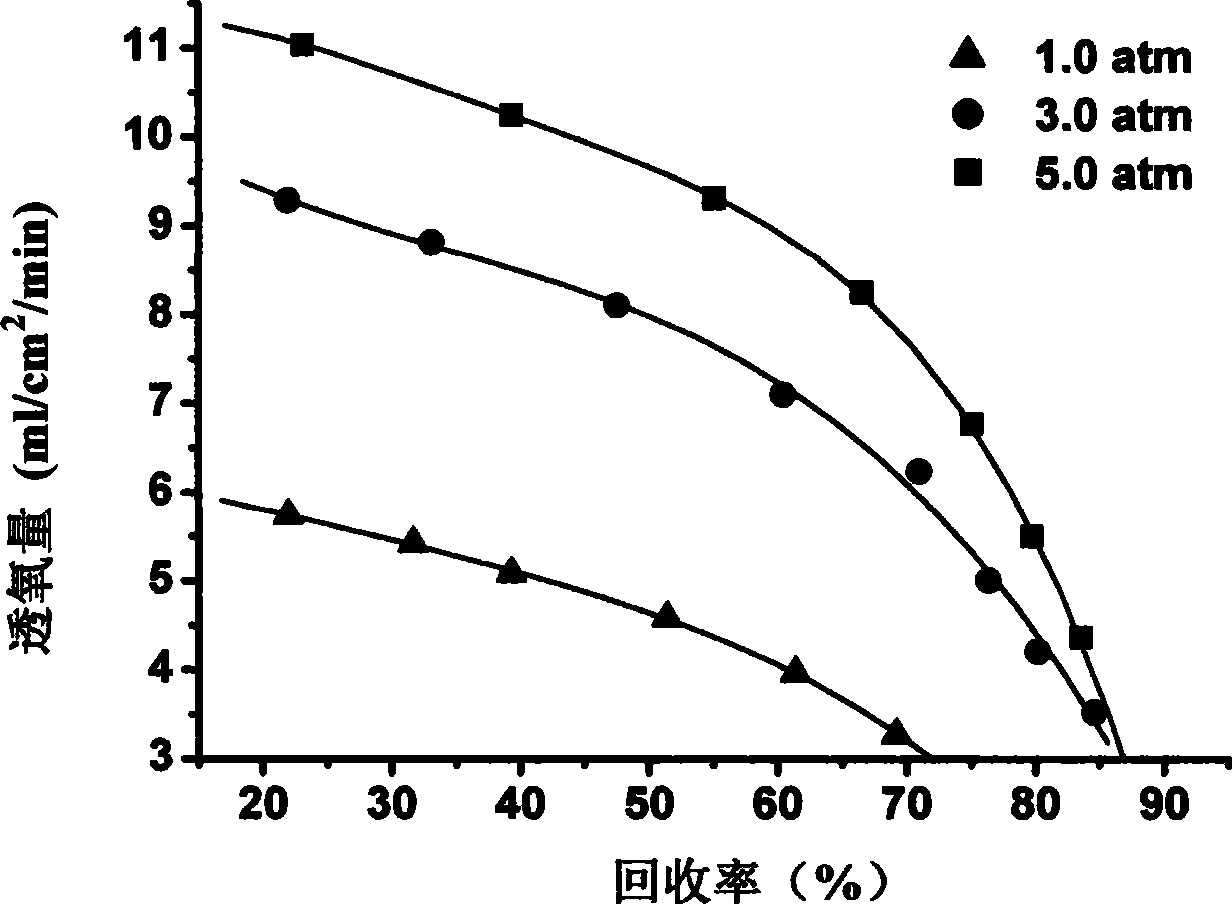

Method for preparing oxygen and nitrogen by air separation

InactiveCN101450792AEfficient separationSeparation and energy savingNitrogen purification/separationChemical industryElectrical conductorSorbent

The invention provides a method for producing oxygen and nitrogen through air separation. The whole process is carried out on a platform consisting of a mixed-conductor oxygen-permeable ceramic membrane separator and a pressure swing adsorption separator taking complex metal oxide as oxygen absorbent. The process comprises the following concrete steps: most oxygen in the air is adsorbed by a mixed-conductor oxygen-permeable ceramic membrane; the remained air is oxygen-deficient air; the pressure swing adsorption separator taking the complex metal oxide as the absorbent adsorbs oxygen in the oxygen-deficient air; and the oxygen is desorbed under the lower pressure between 1 Pa and 100 kPa to ensure that the remaining gas after adsorption is mainly nitrogen, so as to obtain high-purity nitrogen. The method has the advantages that the method can efficiently separate the oxygen from oxygen-containing gas and separate oxygen and nitrogen from the air in an energy-saving way.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

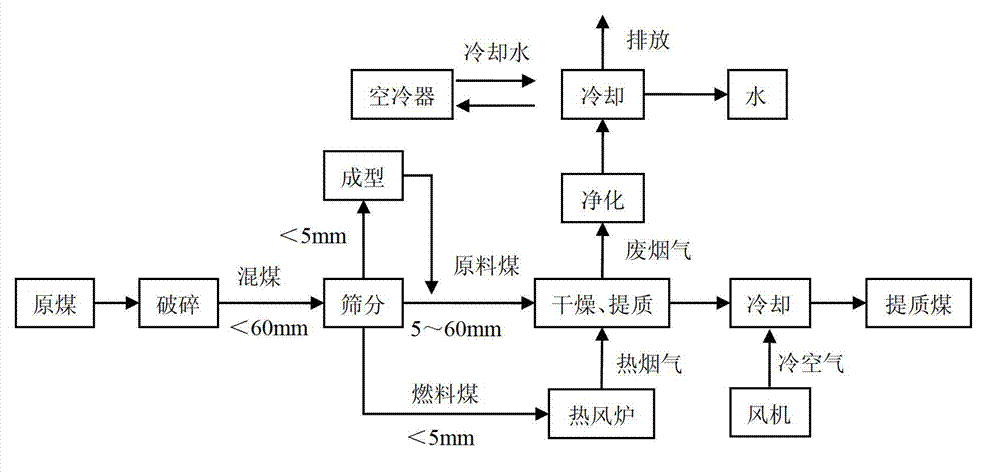

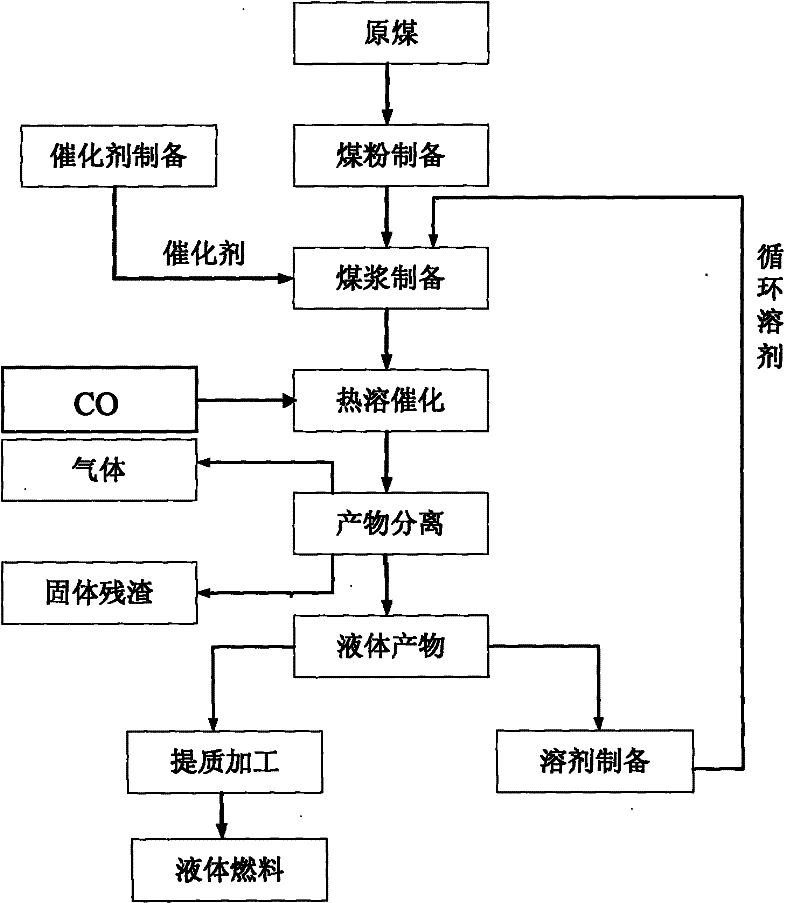

Brown coal modification and upgrading method

The invention discloses a brown coal modification and upgrading method. The method comprises the following steps of: by a gas heat carrier, firstly, heating the coal to 180-300 DEG C under the condition of isolating air; and removing more than 90% of total moisture, crystal water and partial oxygen-containing functional groups which have influence on the coal heat value, and enriching the coal heating constituents, wherein the heat value is improved to be more than 500kcal / kg, the moisture content is less than 8%, and the medium-high heat value power coal index is satisfied. The modified coal has the characteristics of high heat value, excellent stability, poor water absorption property and the like; and meanwhile, in the technology, industrial water is not needed, and generation of waste water and emission of harmful gas are avoided, so that the technology is simple, economic and convenient, and is easy to generalize widely.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

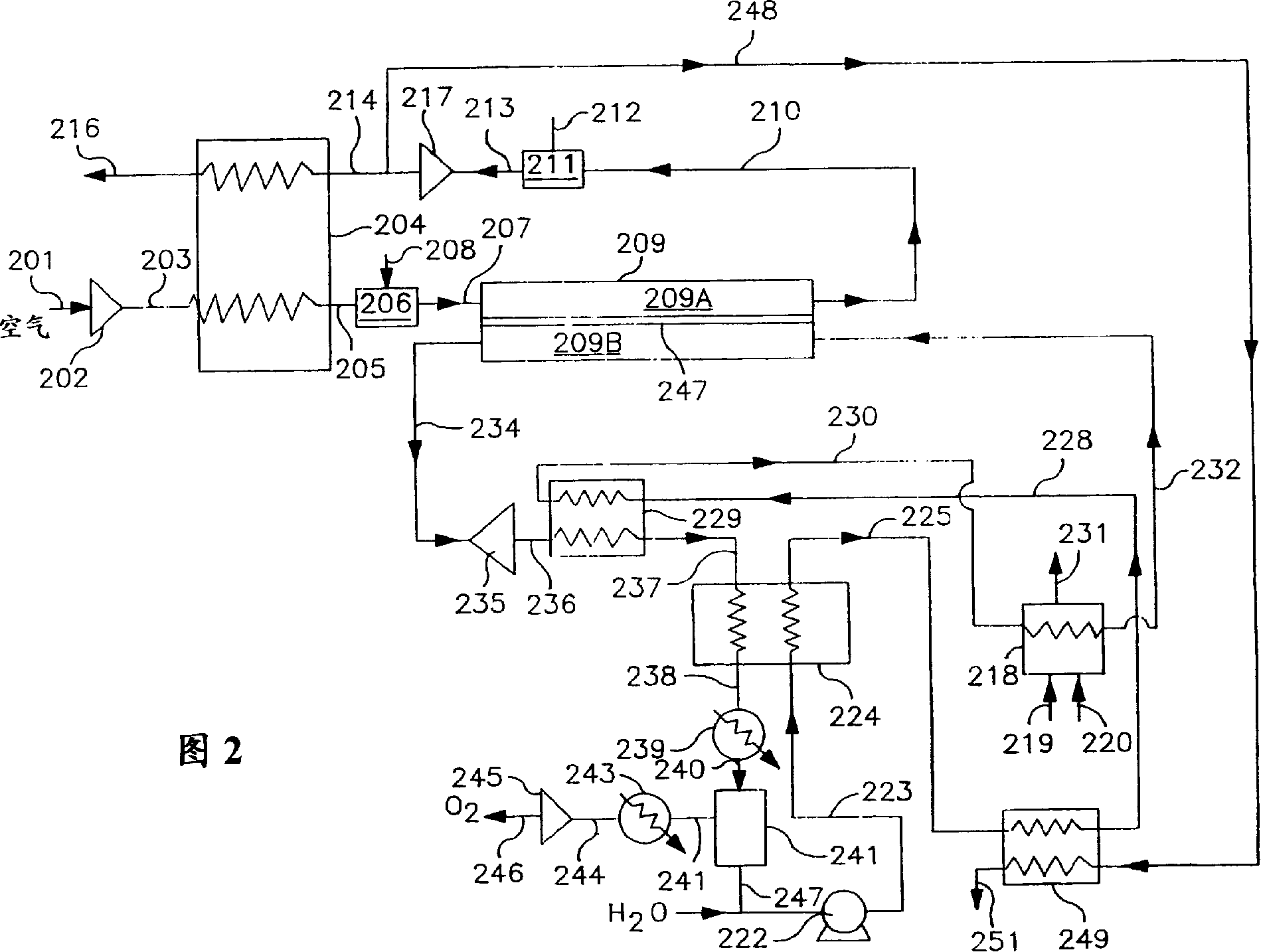

Thermally powered oxygen/nitrogen plant incorporating an oxygen selective ion transport membrane

InactiveCN1279627AEasy to manufactureAvoid stressSpecific gas purification/separationNitrogen purification/separationNitrogen gasExothermic reaction

A low energy cost process for the co-production of oxygen and nitrogen product gases employs a fuel feed tube (506) which extends into oxygen selective ion transport membrane (424) whereby fuel (440) is introduced adjacent its closed end and flows concurrently with oxygen containing gas in annulus (510) and an oxygen selective ion transport membrane having separator section (436) and reactor section (438). Oxygen-containing feedstock (406) is compressed and then contacts cathode side (426) of separator section (436) where a portion of the oxygen is transported to anode side (428) and recovered as an oxygen product gas. Substantially the remainder of the oxygen is transported from cathode side (426) to anode side (428) and exothermically reacted with a fuel. Hot nitrogen rich product gas is expanded into a turbine to generate the power necessary to compress the feedstock.

Owner:PRAXAIR TECH INC

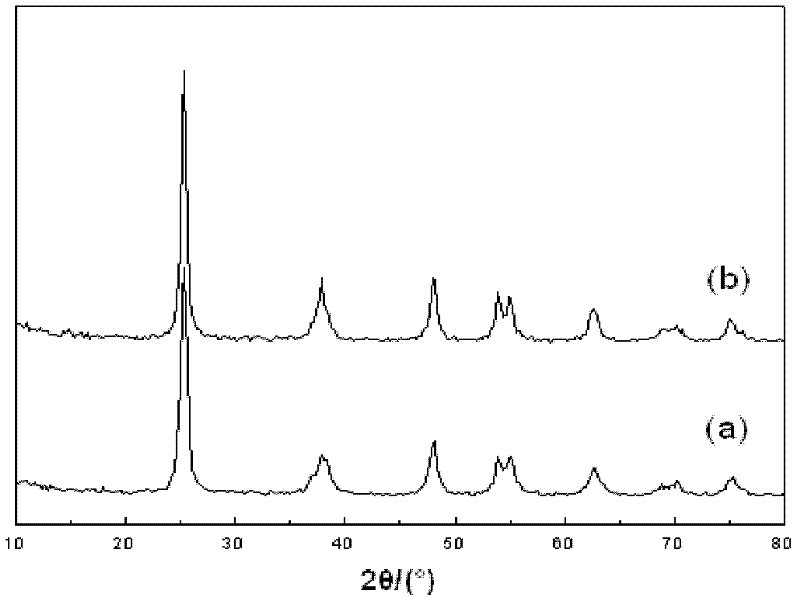

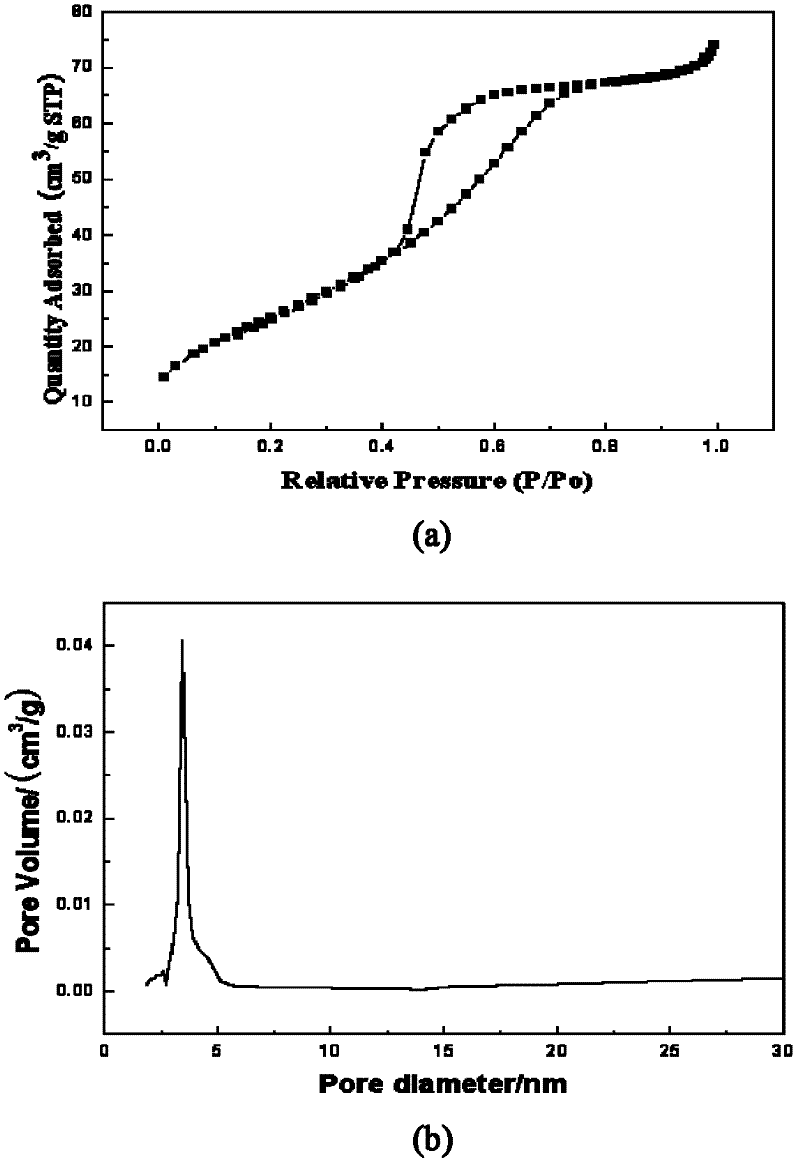

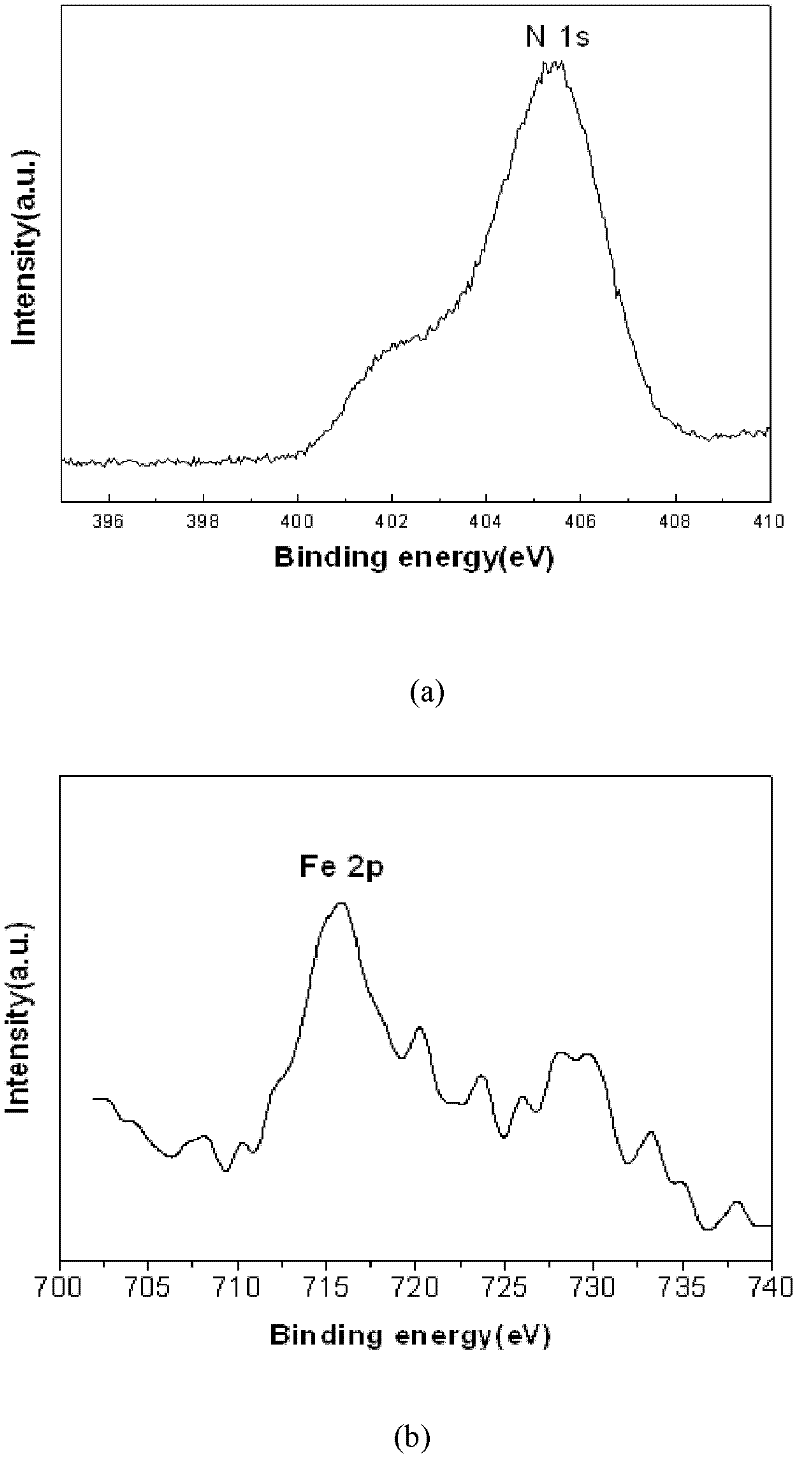

Method for fast sol-gel preparation of iron-nitrogen co-doped mesoporous nano-titanium dioxide

InactiveCN102285686AOvercome the shortcoming of long experiment periodEasy to operateMaterial nanotechnologyTitanium dioxideHydrolysatePolyacrylamide

The invention discloses a method for preparing iron-nitrogen codoped mesoporous nano titanium dioxide by a fast sol-gel method. In the method, a polymer with a molecular weight of 2*10<4>-3*10<6> is used as a template agent, and simultaneously, the template agent reacts with titanium-source hydrolysate to form a hydrogen bond so as to be fast gelated; and simultaneously, an iron source and a nitrogen source are uniformly dispersed in a uniform gel system, and then codoped mesoporous titanium dioxide is obtained by calcination. In the method, the iron element and nitrogen source are codoped and enter crystal lattices of nano titanium dioxide, wherein Fe<3+> becomes a center of capturing photoelectrons, thereby prolonging the survival time of photoholes; nitrogen atoms substitute partial oxygen atoms, so that the forbidden band width of titanium dioxide is reduced, the photoresponse range is enlarged, and titanium dioxide has a certain absorption in a visible light range; and simultaneously, on the basis of the traditional sol-gel method, the defect of long preparation period is overcome by using the method disclosed by the invention. A sample prepared by using high polymers such as polyacrylamide and the like as the template agent has mesopore duct and large specific surface area, and the photocatalysis efficiency is improved.

Owner:XI AN JIAOTONG UNIV

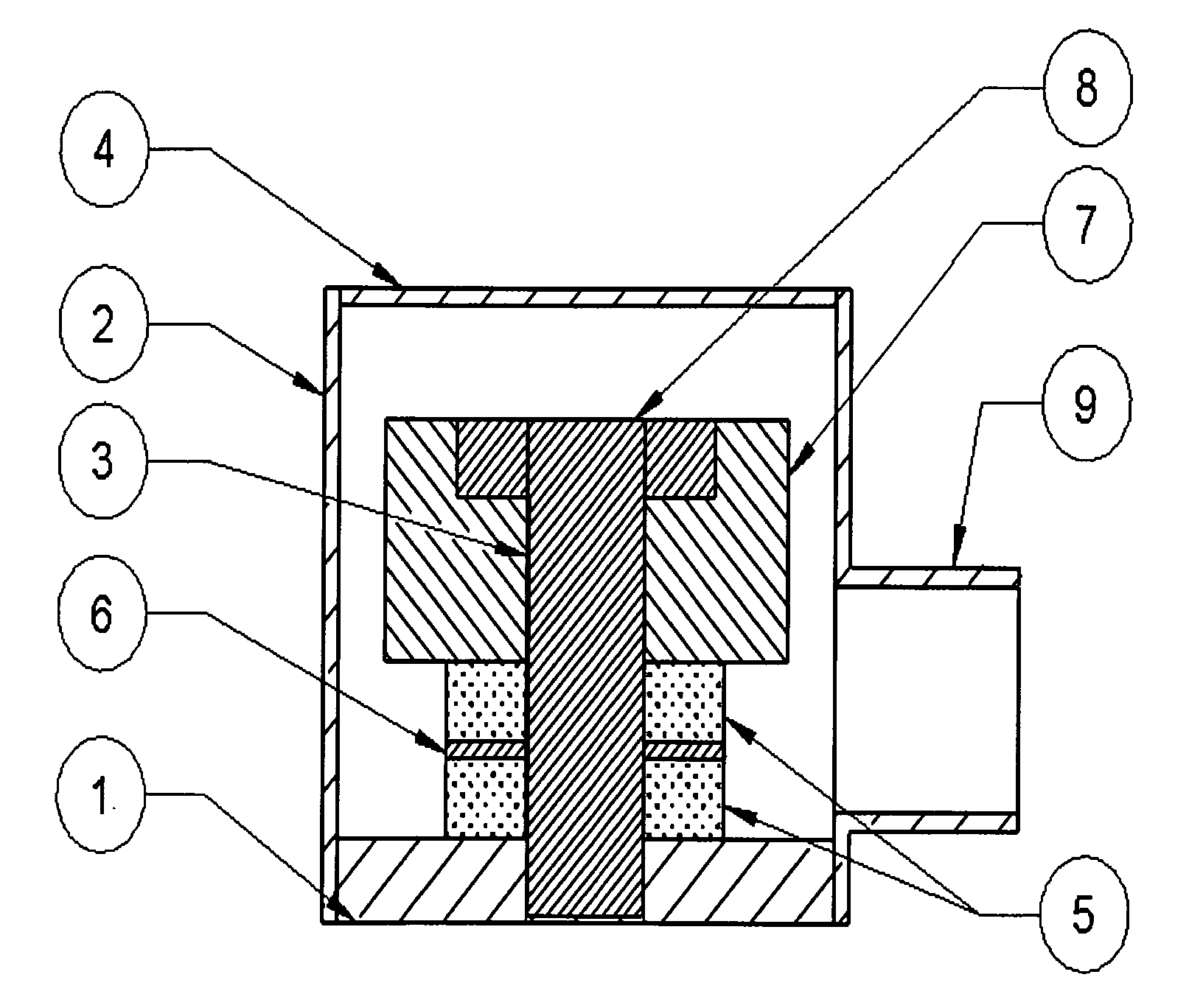

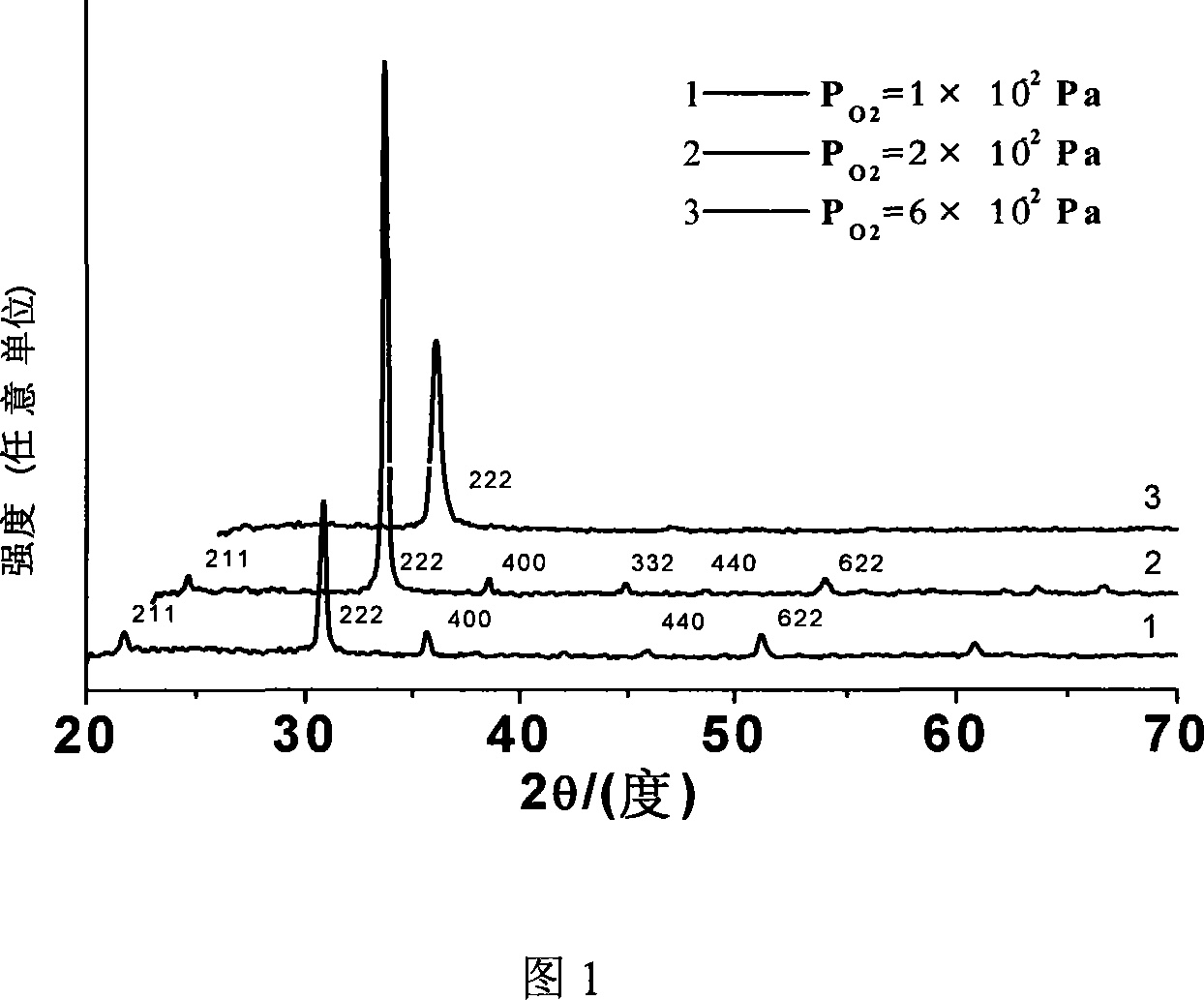

Sintering method of high-magnetic-permeability MnZn ferrite material

The invention discloses a sintering method of a high-magnetic-permeability MnZn ferrite material, which comprises the following four stages: a. first temperature rise stage; b. second temperature rise stage; c. holding stage; and d. cooling stage. Since the temperature and partial oxygen pressure are controlled in the whole sintering process of temperature rise, holding and cooling, the high-magnetic-permeability MnZn ferrite can be obtained at lower sintering temperature. The sintering method of the high-magnetic-permeability MnZn ferrite has the advantages of low sintering temperature and short sintering period, and greatly lowers the sintering cost of the MnZn ferrite.

Owner:苏州天源磁业股份有限公司

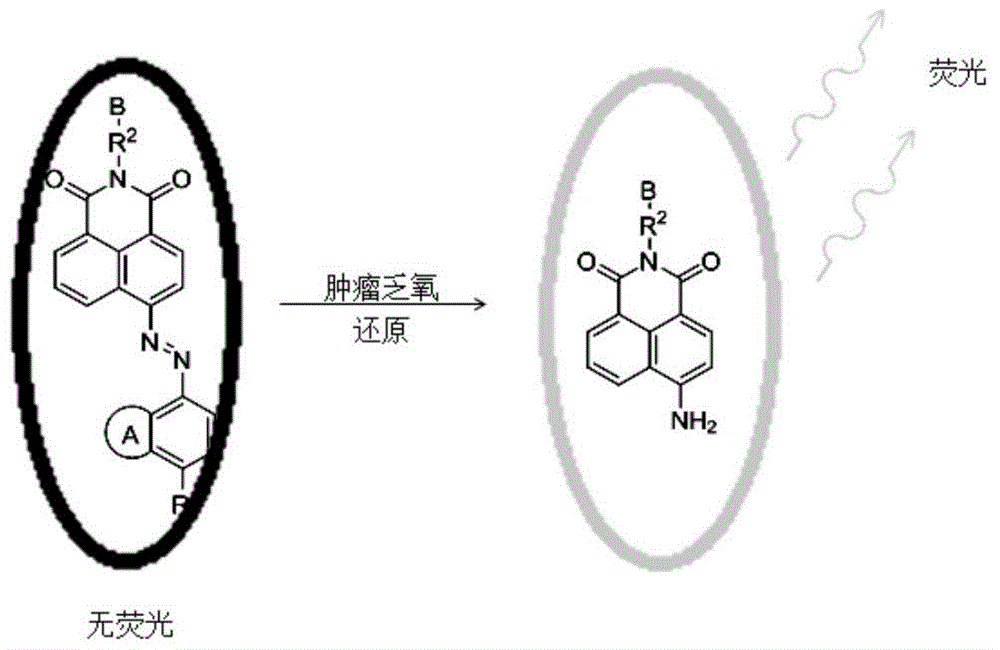

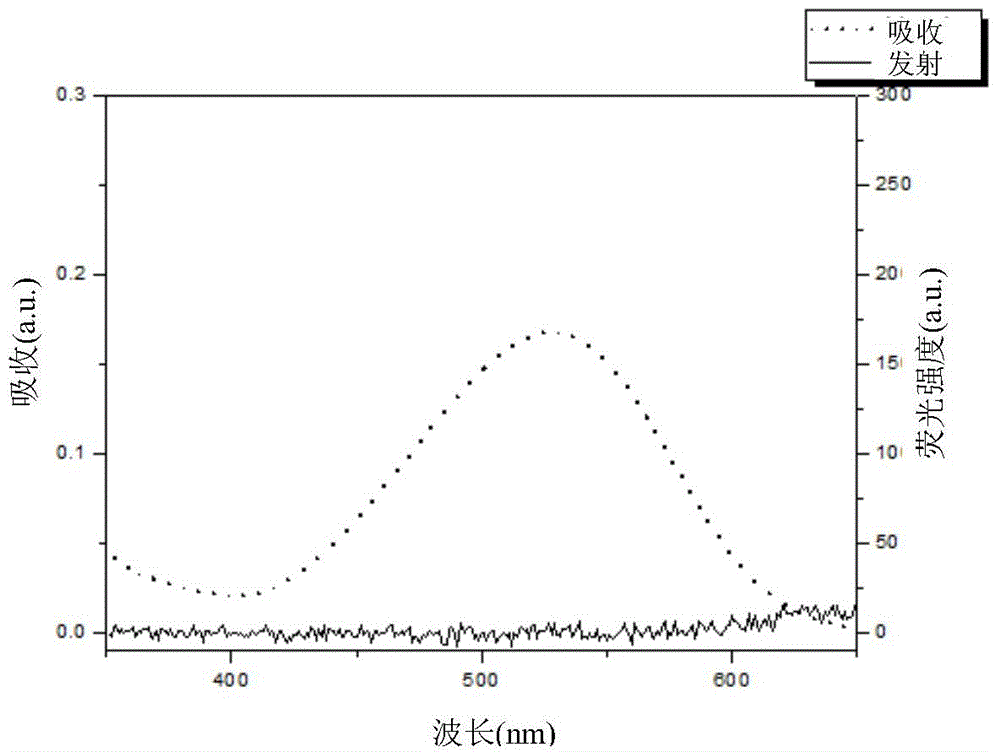

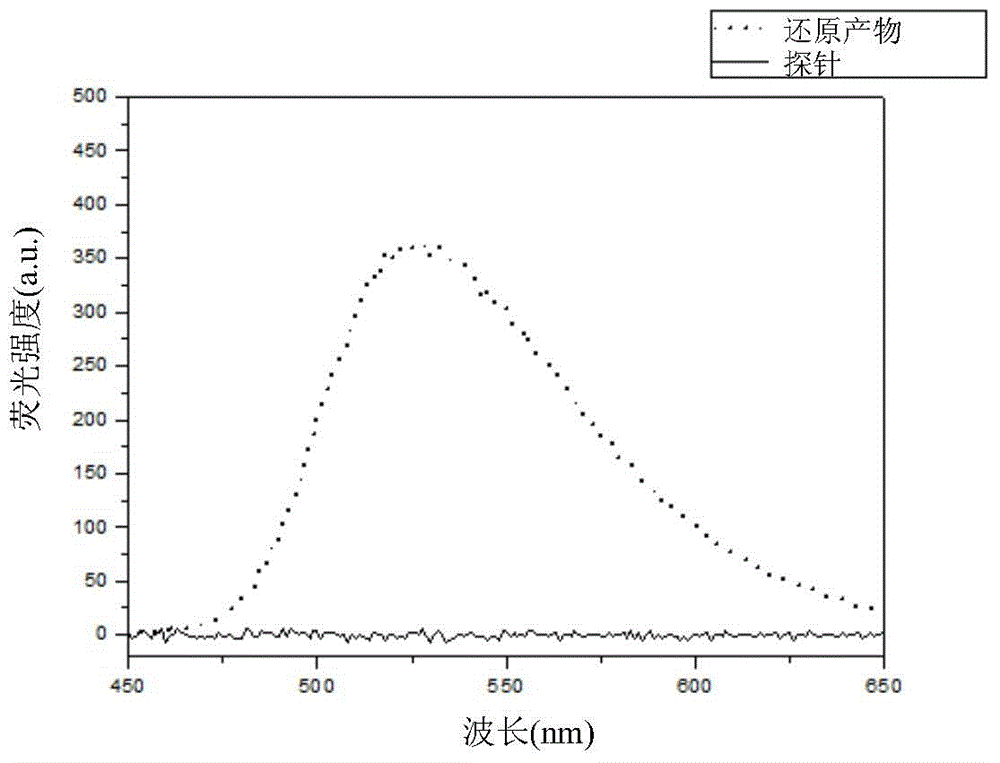

Compound for detecting tumor hypoxia and preparation method thereof

ActiveCN104945322AGroup 3/13 element organic compoundsFluorescence/phosphorescenceFluorescenceLiving body

The invention relates to a compound for detecting tumor hypoxia disclosed as Formula I, a preparation method and application thereof, and a kit containing the compound. The groups in the formula are disclosed in the specification. The compound can be used for detecting hypoxia of tumor tissues, can respond to changes of partial oxygen pressure and reducibility of partial tissues, and provides conditions for early detection of cancers. The compound has the advantages of novel structure, simple synthesis process, high detection sensitivity, high fluorescence enhancement multiple, no trauma and the like, and can be used for cell detection and even living body detection.

Owner:EAST CHINA UNIV OF SCI & TECH

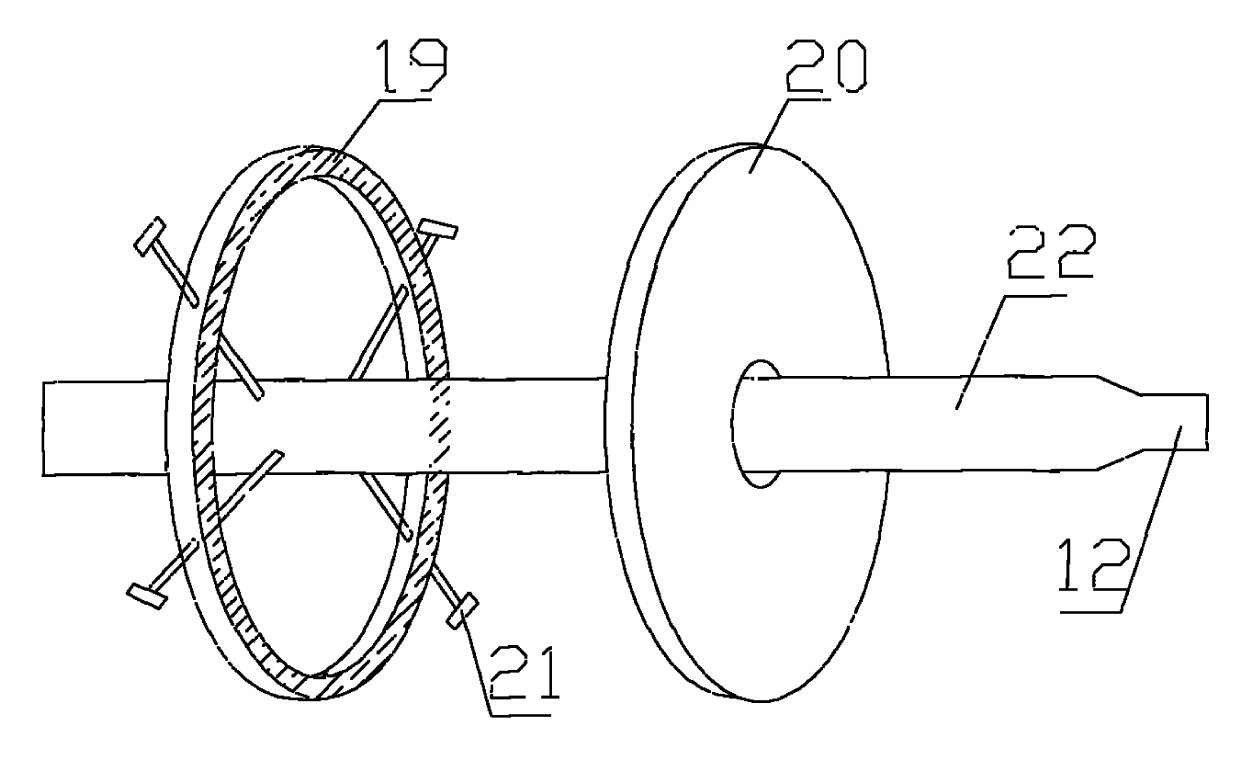

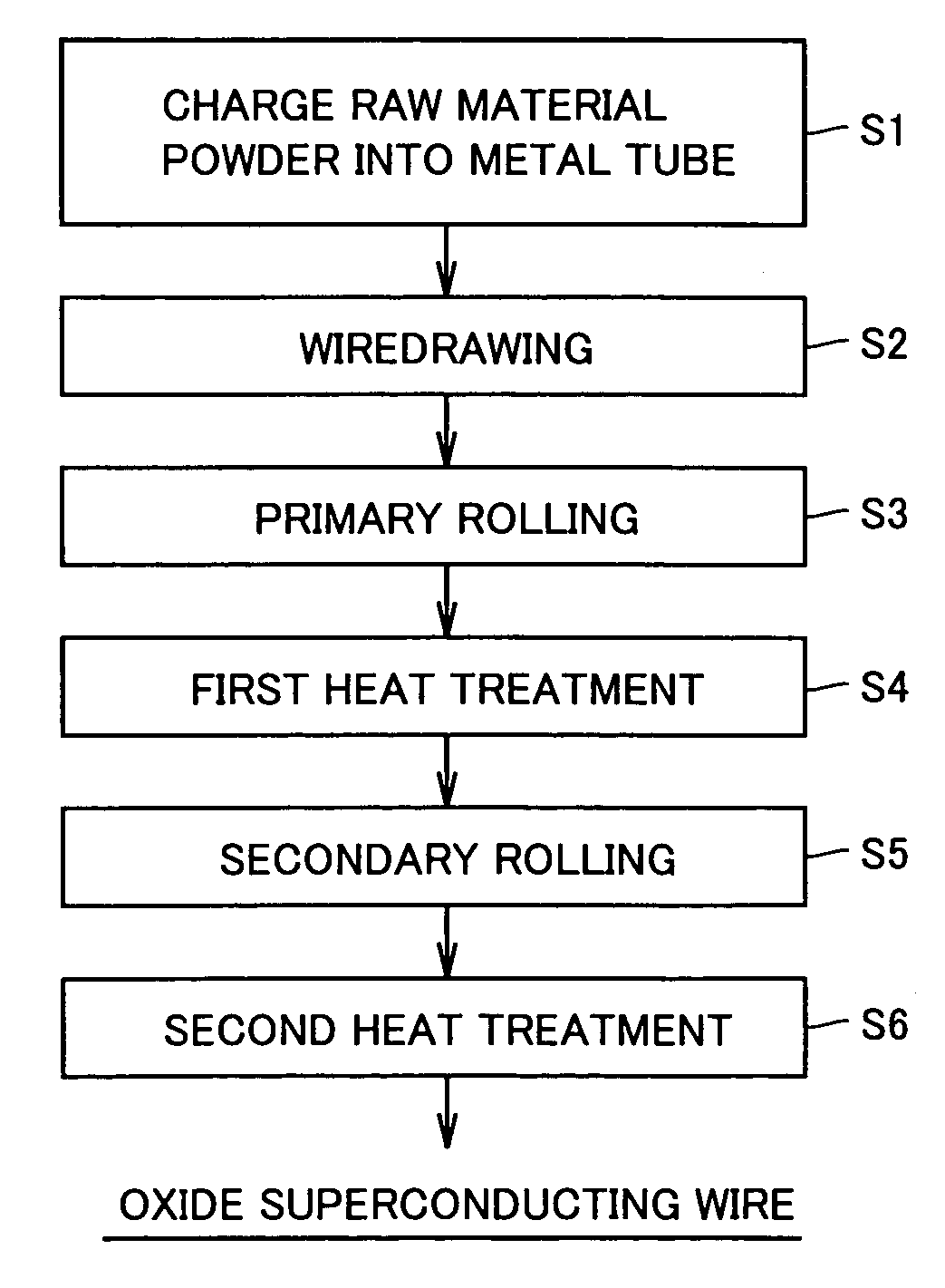

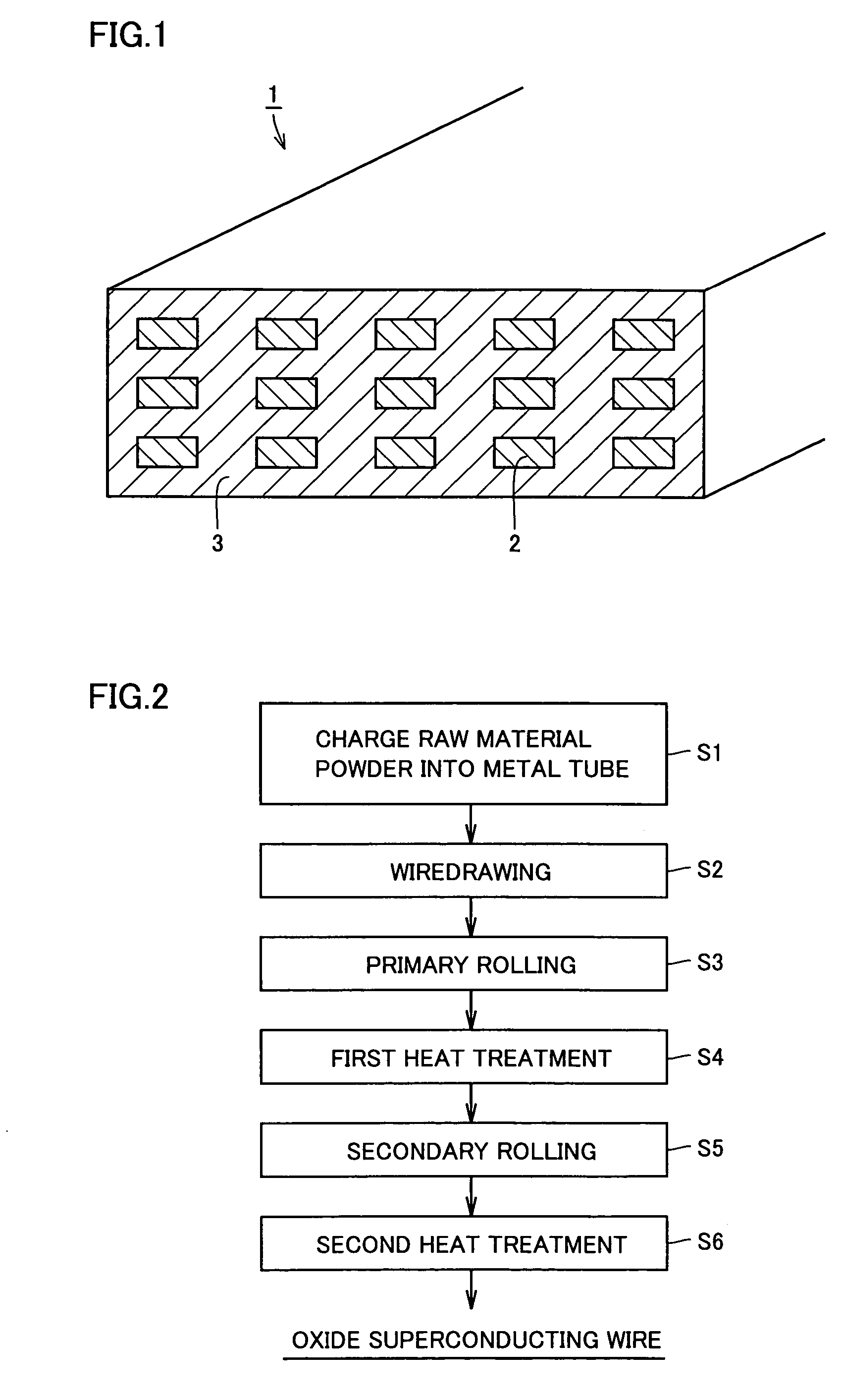

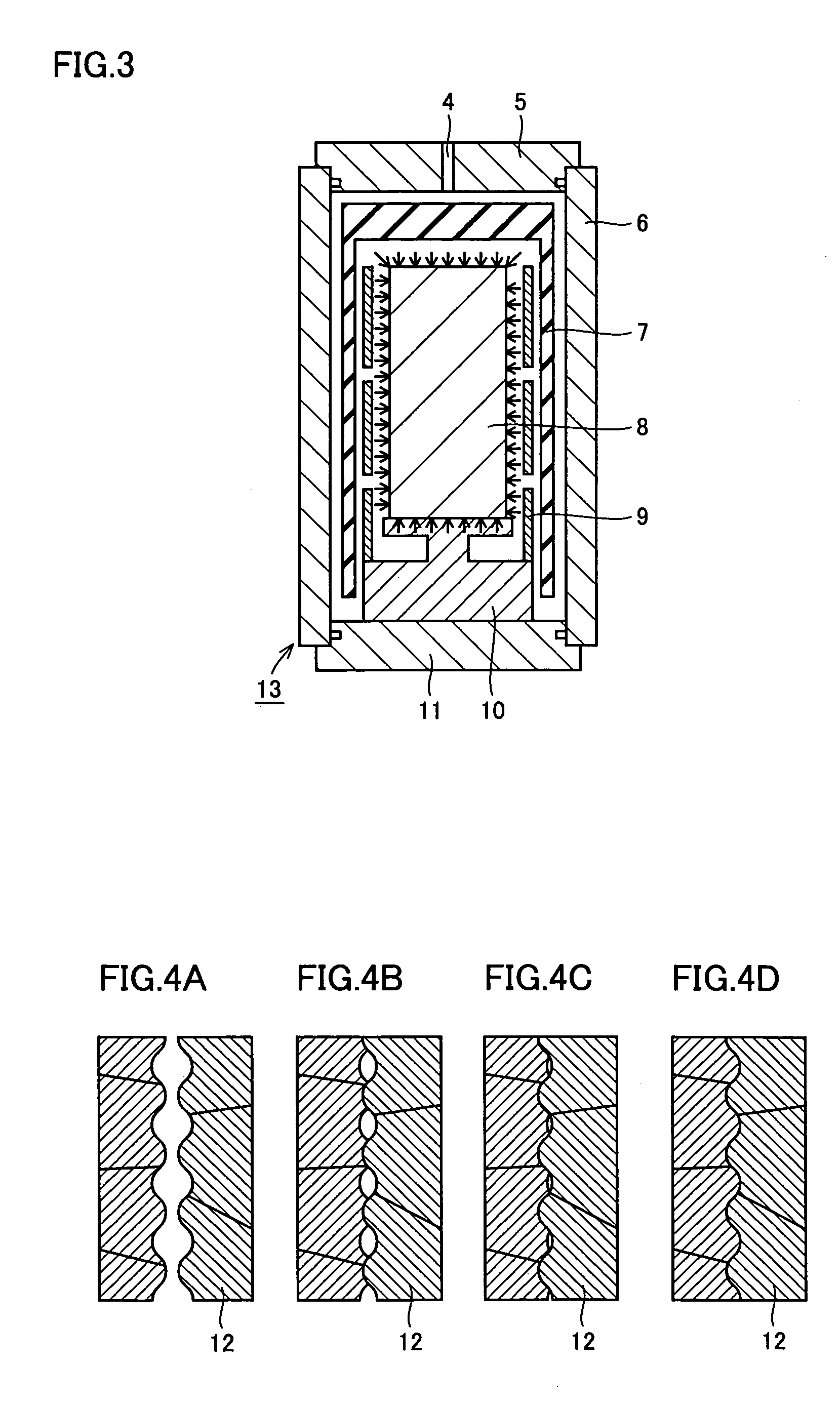

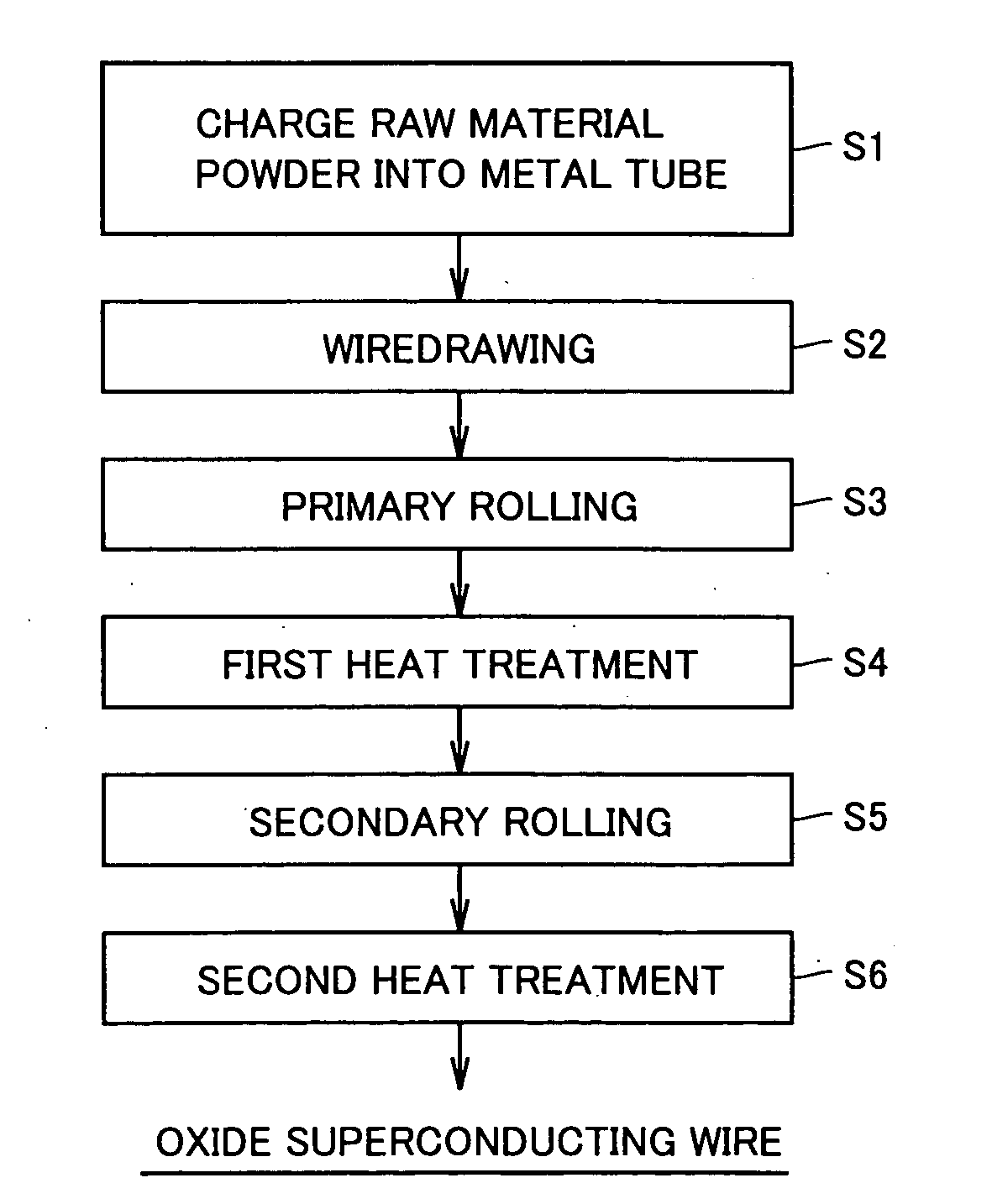

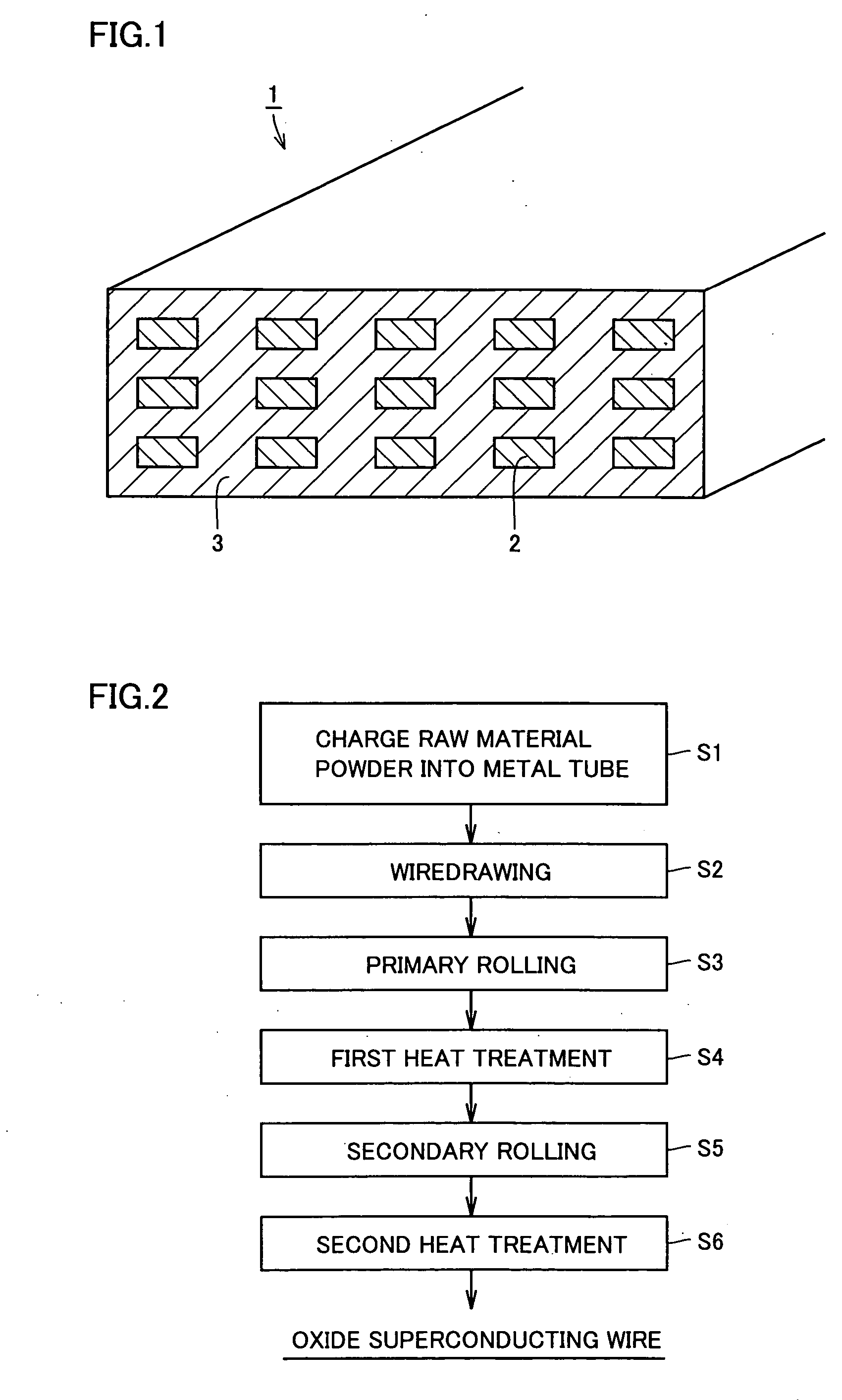

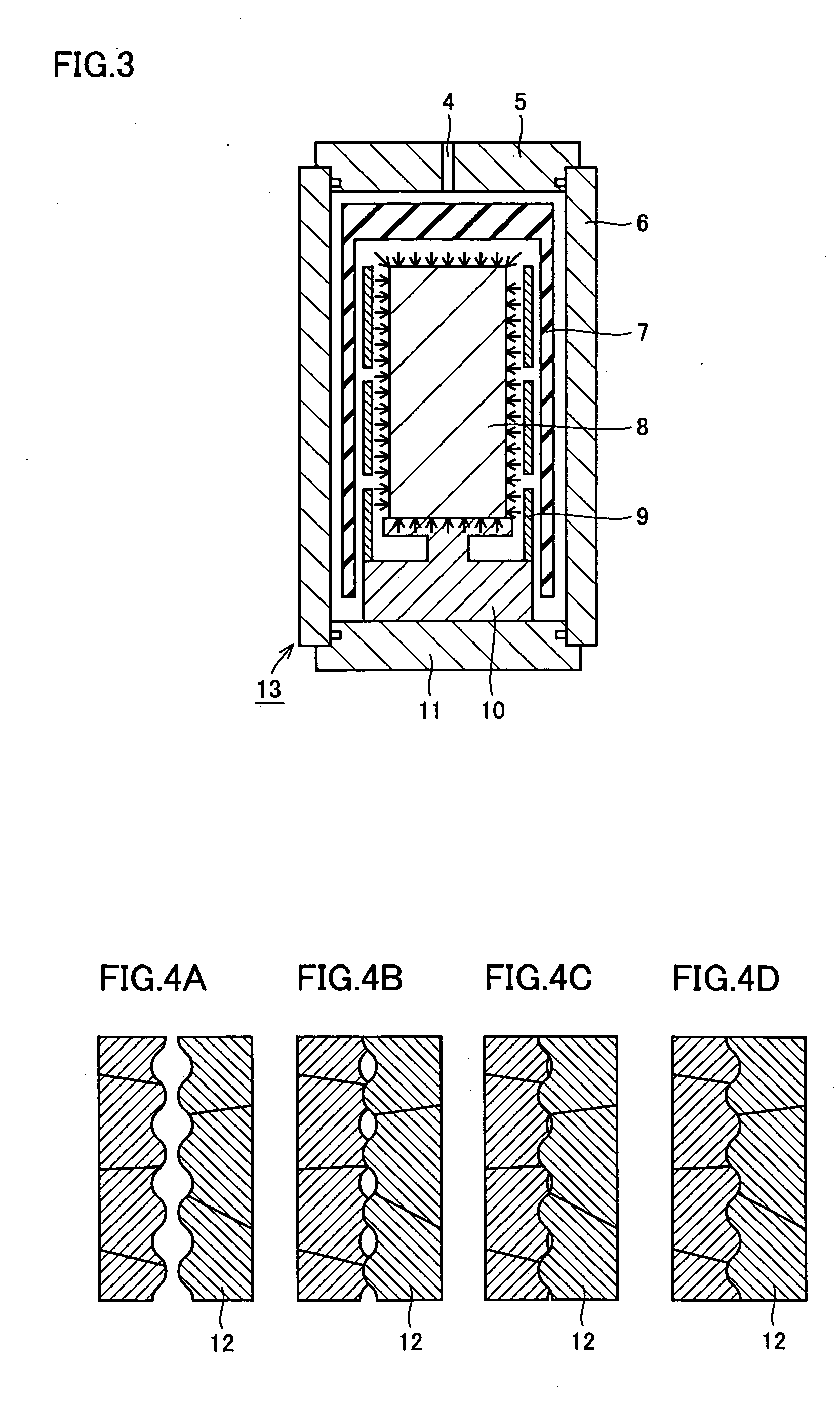

Method of manufacturing oxide superconducting wire

InactiveUS6993823B2High densityEasy to controlLine/current collector detailsSuperconductors/hyperconductorsBlistersMaterials science

The inventive method of manufacturing an oxide superconducting wire comprises a step (S1, S2) of preparing a wire formed by covering raw material powder of an oxide superconductor with a metal and a step (S4, S6) of heat-treating the wire in a pressurized atmosphere, and the total pressure of the pressurized atmosphere is at least 1 MPa and less than 50 MPa. Thus, formation of voids between oxide superconducting crystals and blisters of the oxide superconducting wire is suppressed while the partial oxygen pressure can be readily controlled in the heat treatment, whereby the critical current density can be improved.

Owner:SUMITOMO ELECTRIC IND LTD

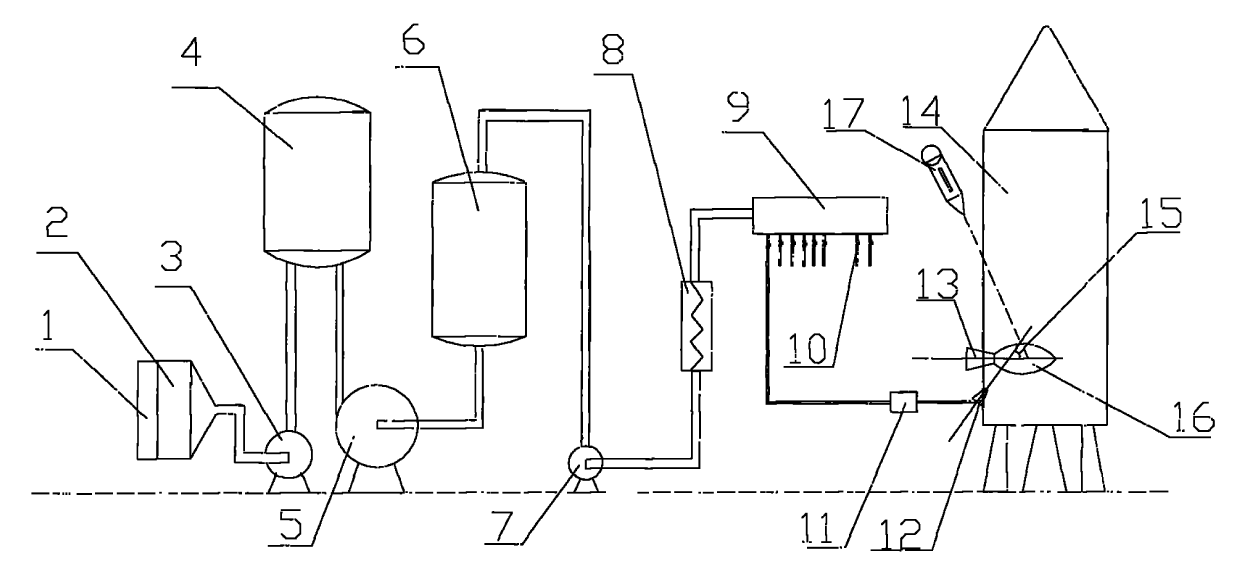

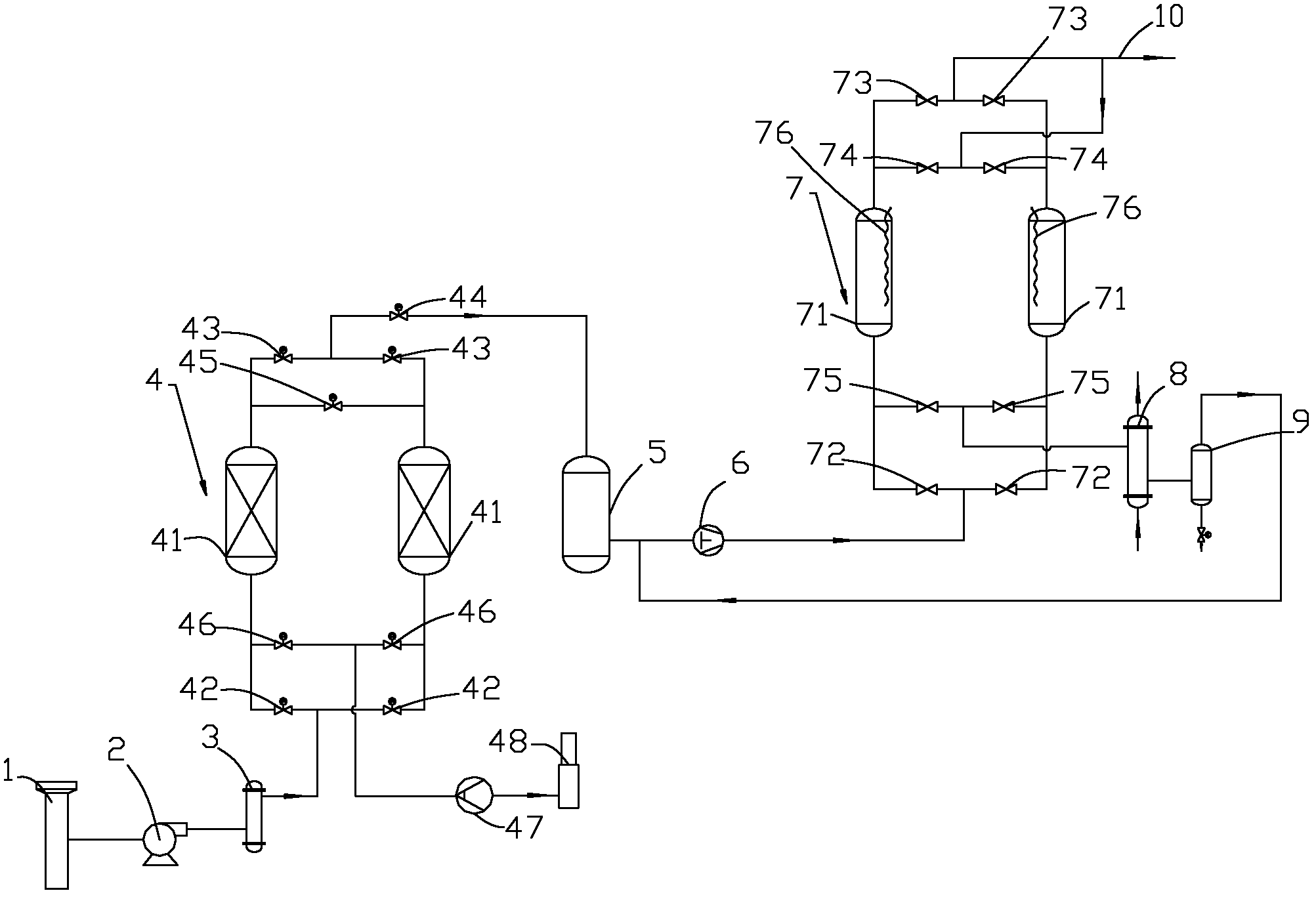

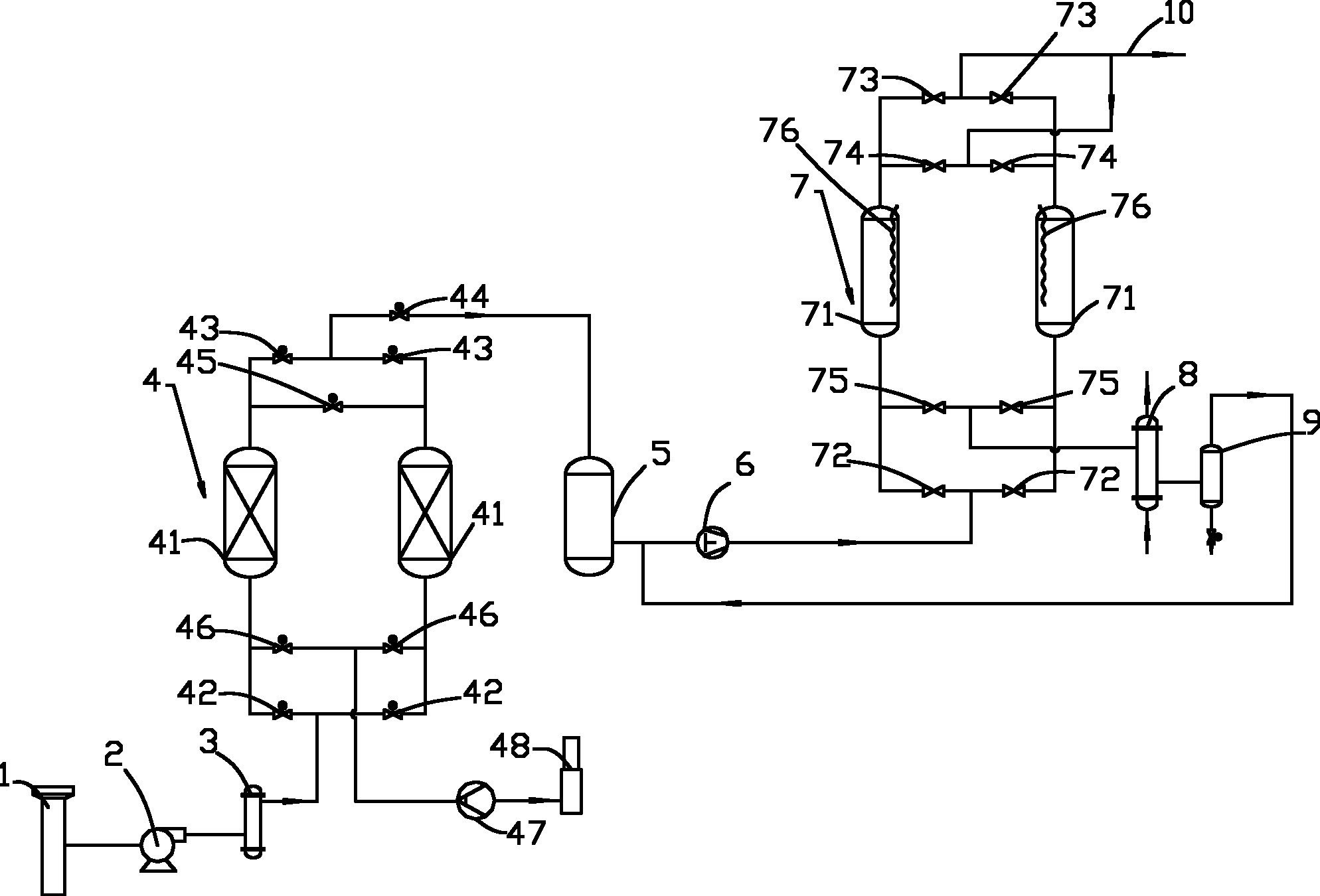

Oxygen generating device special for ozone device

InactiveCN102580457AGuaranteed wasteDispersed particle separationOzone preparationEngineeringEnvironmental engineering

The invention discloses an oxygen generating device special for an ozone device, which sequentially comprises a filtering silencer, a gas blower, a cooler, an adsorption tower group, an oxygen buffering tank, an oxygen compressor, a drying tower group, a water cooler and a gas-water separator from upper position to lower position. The gas is filtered and then blown into the cooler by the gas blower, and enters the adsorption tower with moisture, nitrogen, carbon dioxide and other impurities in the gas adsorbed. The oxygen flows out from the adsorption tower, enters the oxygen buffering tank and is sent into the drying towers after being pressurized by the oxygen compressor, and the oxygen special for the ozone device is obtained after drying. One drying tower in the drying tower group is used for drying the oxygen, simultaneously the other drying tower can be purged for regenerating by partial oxygen special for the ozone device, the regenerated gas can enter the oxygen compressor after being performed with water cooling and gas-water separation and then reenters the drying towers for drying after being pressurized by the compressor, so that oxygen special for the ozone device can be obtained, and no oxygen discharging waste can be achieved.

Owner:SUZHOU SUJING PROTECTIVE ATMOSPHERE

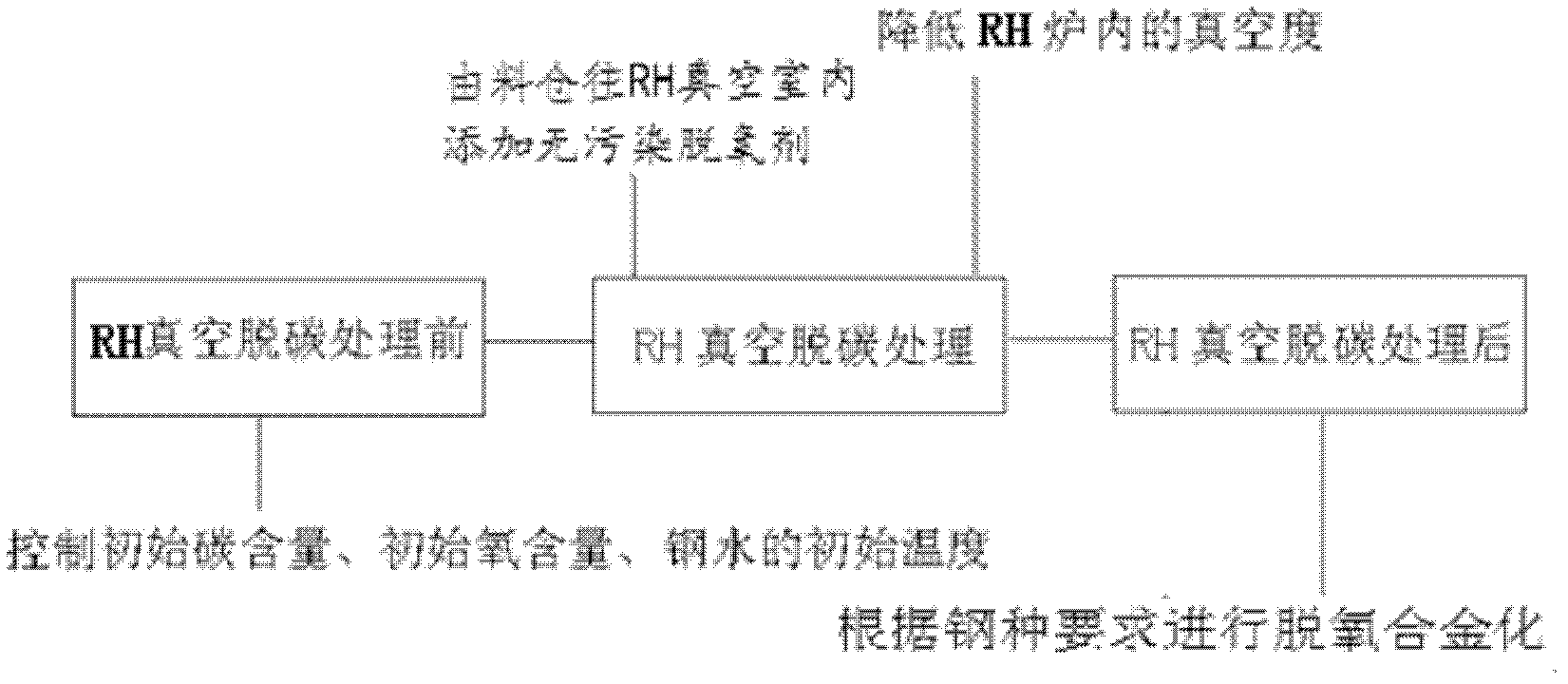

Process method for reducing RH vacuum decarbonization end-point oxygen content of ultra-low-carbon steel

The invention provides a process method for reducing RH vacuum decarbonization end-point oxygen content of ultra-low-carbon steel and belongs to the technical field of production and processing of ultra-low-carbon steel. The process method comprises the following steps: 1) in an early period of RH vacuum decarbonization, adding a pollution-free deoxidant from a feed bin to a vacuum chamber, and removing partial oxygen from the steel; 2) further reducing vacuum degree for deep carbonization; and 3) after the RH vacuum decarbonization treatment is finished, using aluminum particles as a final deoxidant, and deoxidizing and alloying other alloy elements according to steel grade requirements. By the process method, the RH decarbonization end-point oxygen content can be reduced, and the active oxygen content of molten steel is controlled to be 250-400ppm when the RH decarbonization is finished, so that the consumption of final deoxidizing aluminum particles is reduced, the inclusion content in the molten steel is reduced, the cleanness of the molten steel is improved, the production cost is reduced and the quality of the ultra-low-carbon steel is obviously improved.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

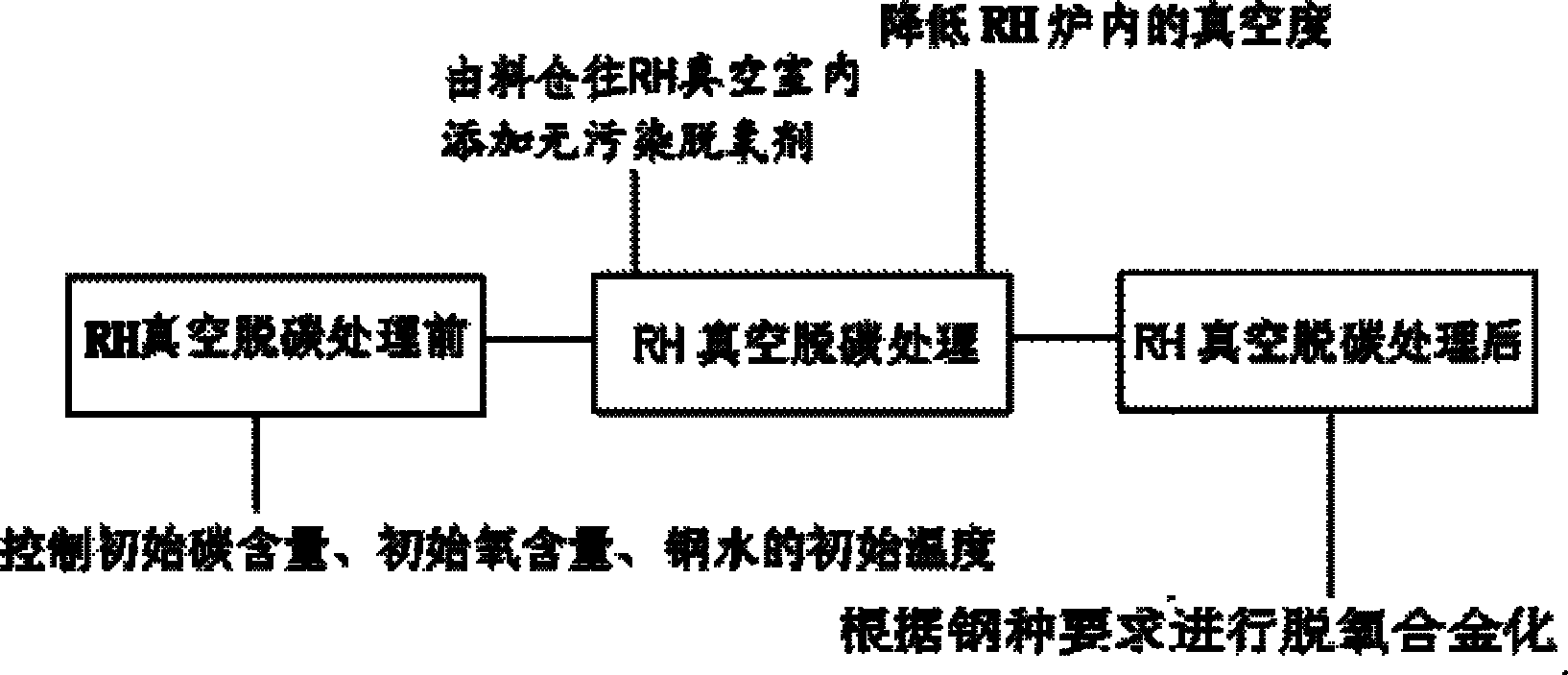

Process for removing chloride from zinc dross

A chlorine peeling method in zinc dross. The steps comprises adding zinc dross, which contains more than 1.8% chlorine and 20-30% water, into rotary kiln; blowing air and fuel of coal gas that contains 3-10% steam, in which inward flux of coal gas accords to coal content (Nm3) : zinc dross (dry weight, t) =(400-500):1, discharge pressure of coal gas is 30-40mmH2O and blast pressure is 30-120mmH2O; using steam in coal gas and partial oxygen to achieve to antichloration and zinc dross staying in rotary kiln for 3h from head to tail, in which when rotary kiln heating-up to 1000-1200 Deg. C, staying in hot zone for 30-90 minutes. The method effectively expels chlorine in zinc dross and achieves comprehensive utilization of zinc dross. The content of chlorine in zinc oxide after antichloration drops to less than 0.05%, ratio of antichloration is more than 98% and content of calcine zine exceeds 77.0% (ZnO>95.0%).

Owner:云南会泽铅锌矿

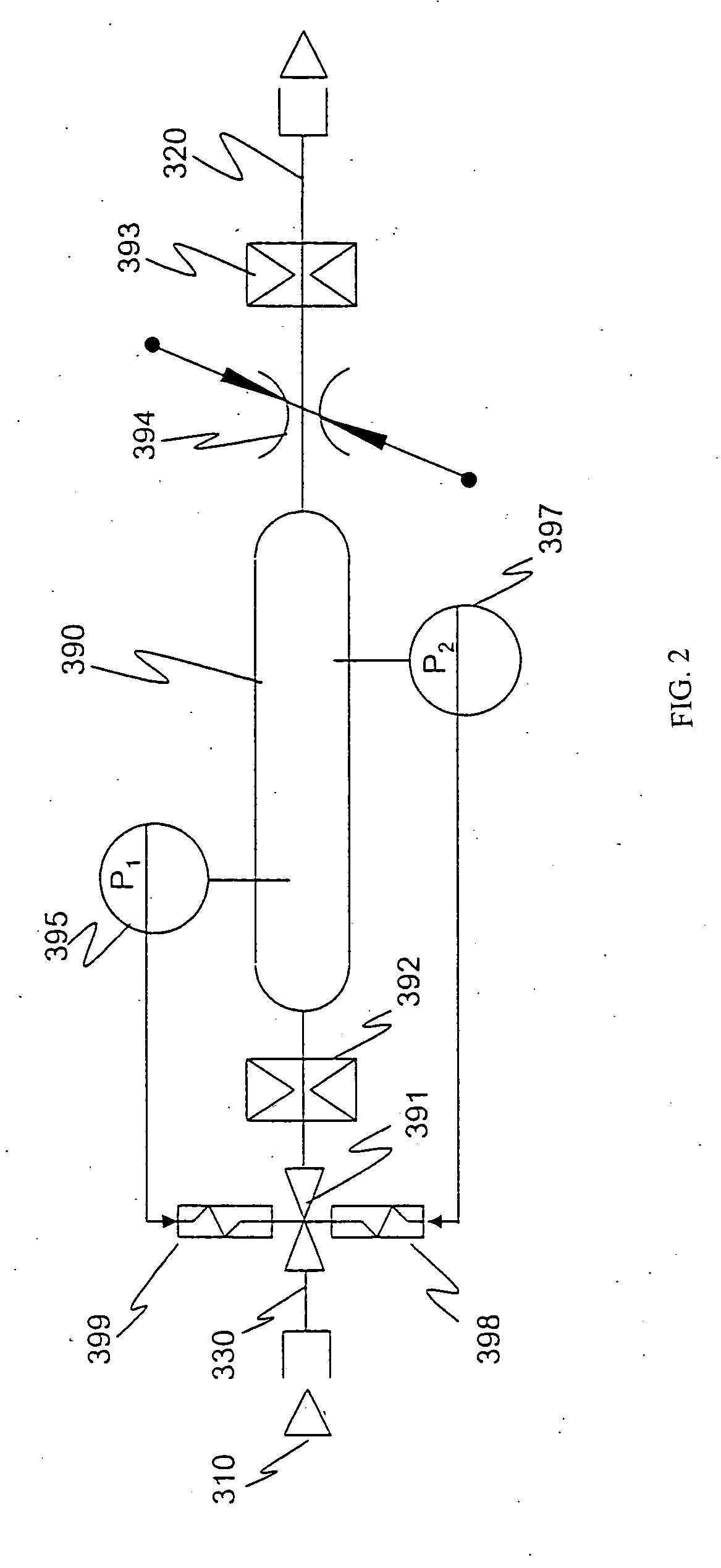

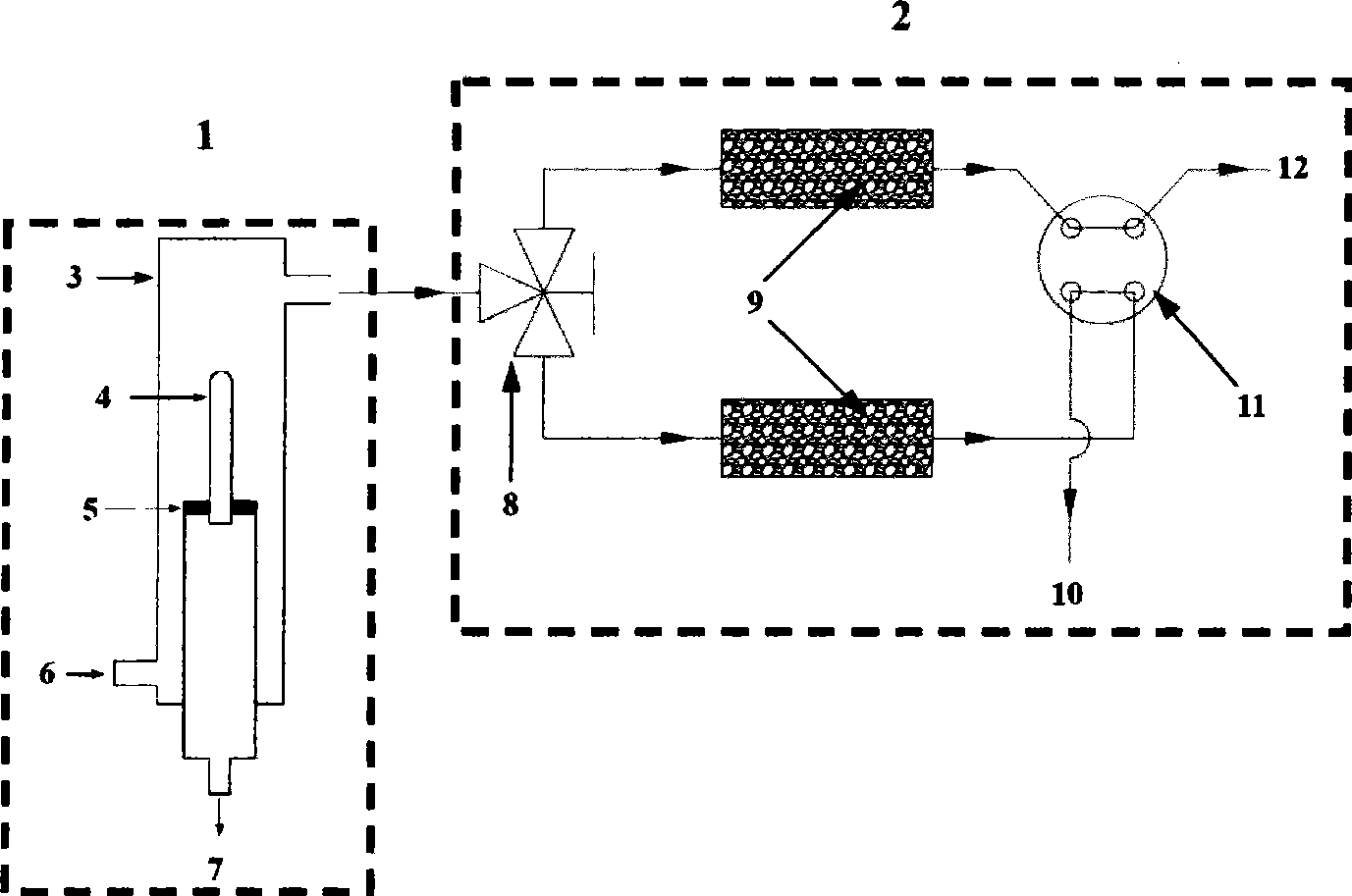

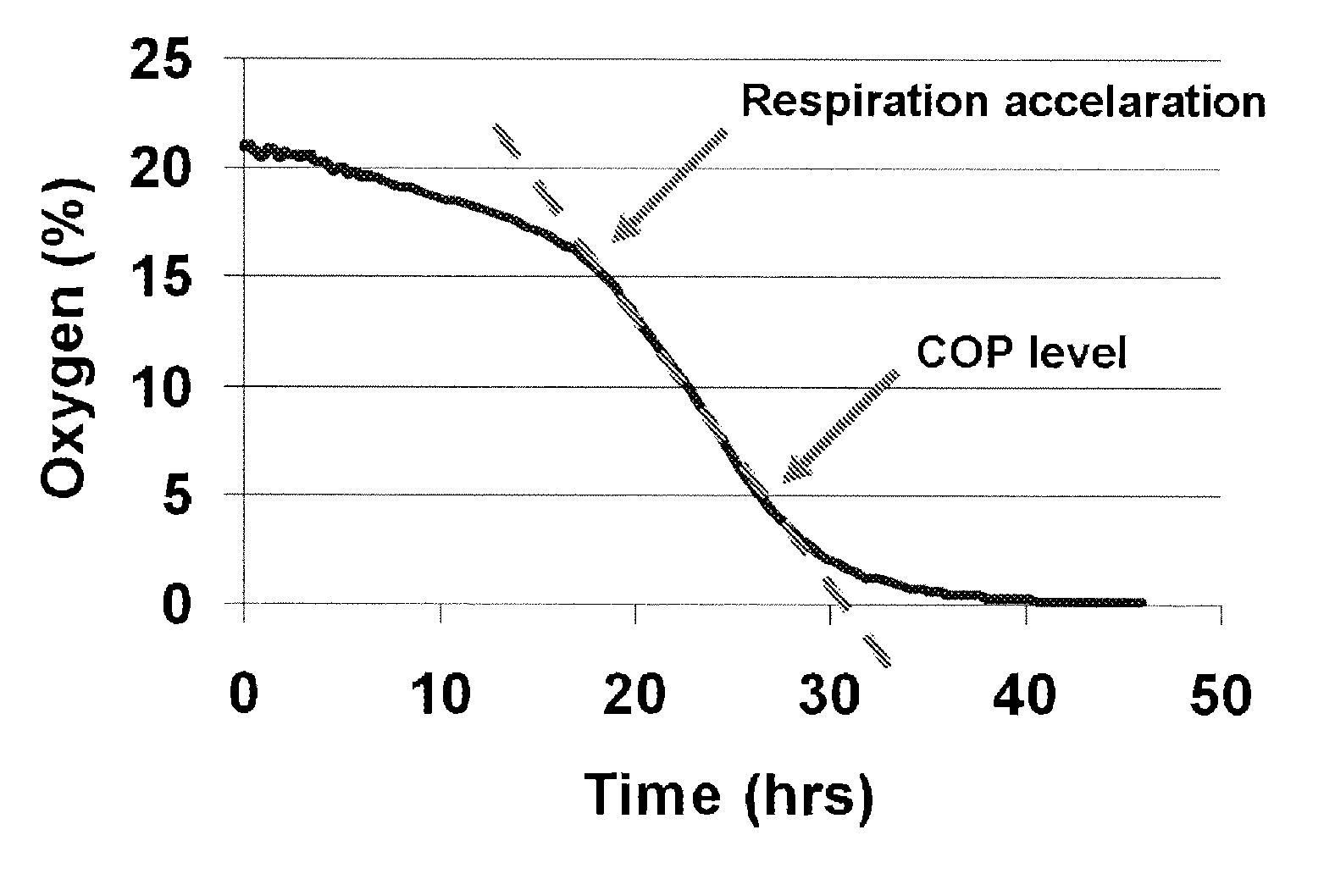

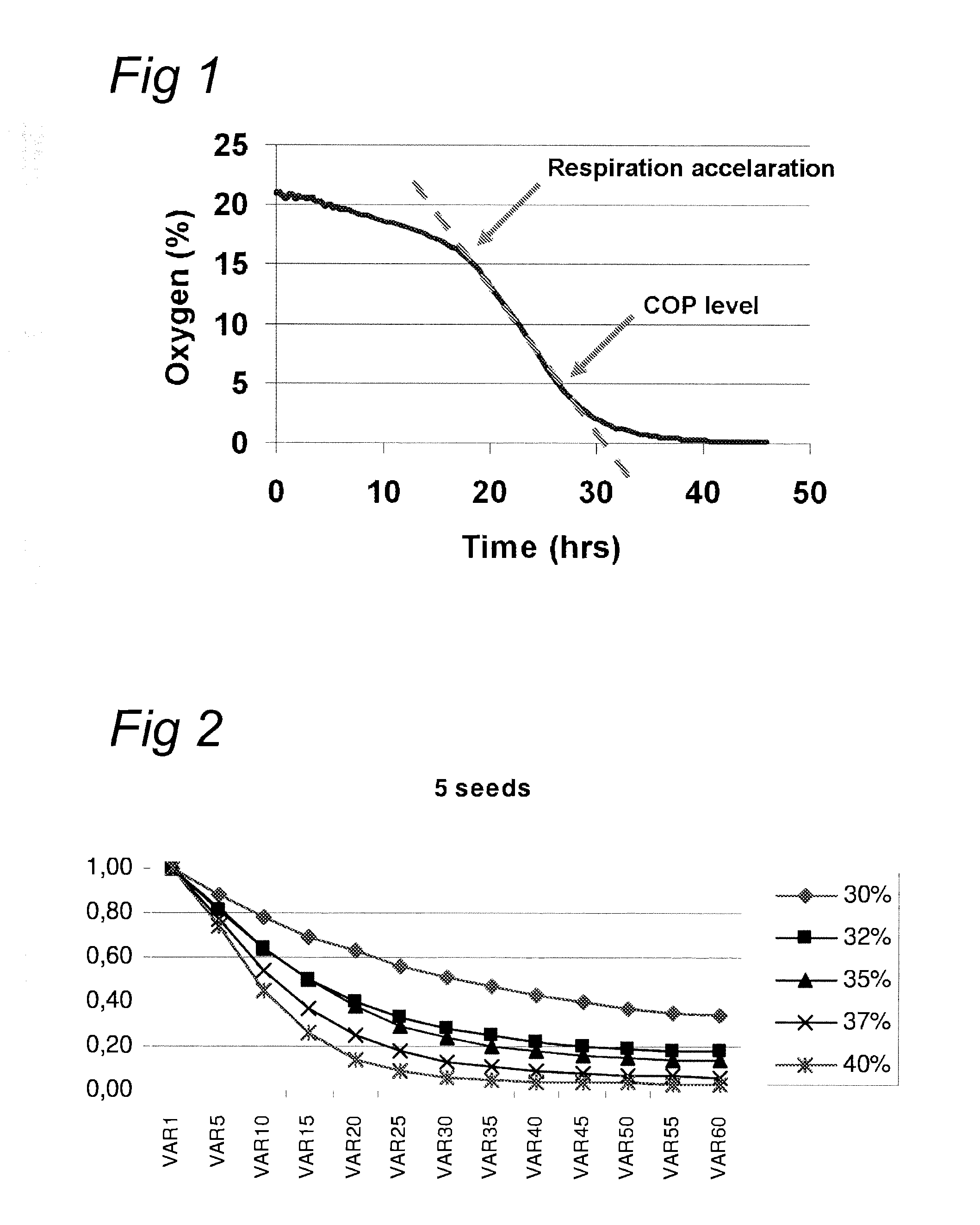

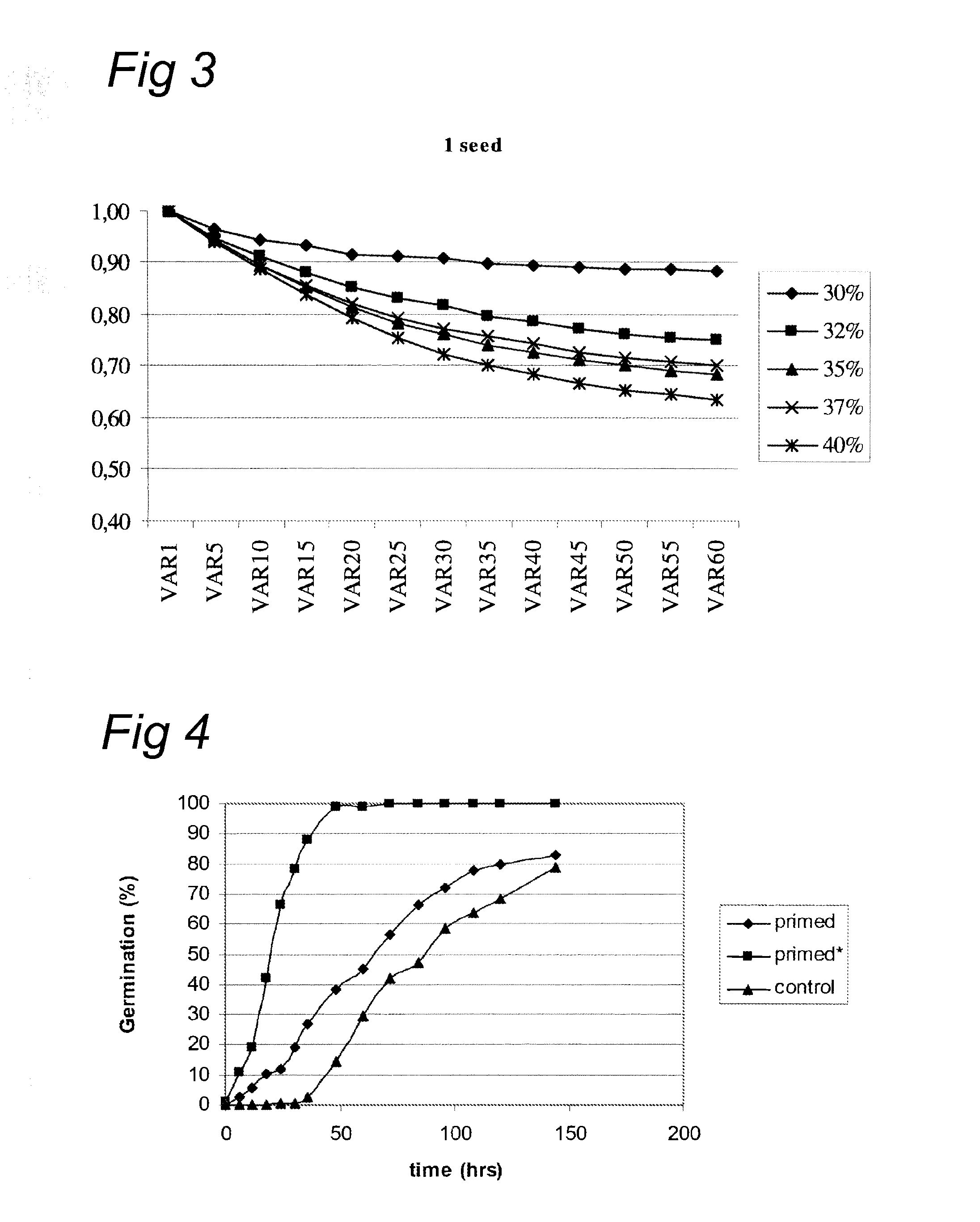

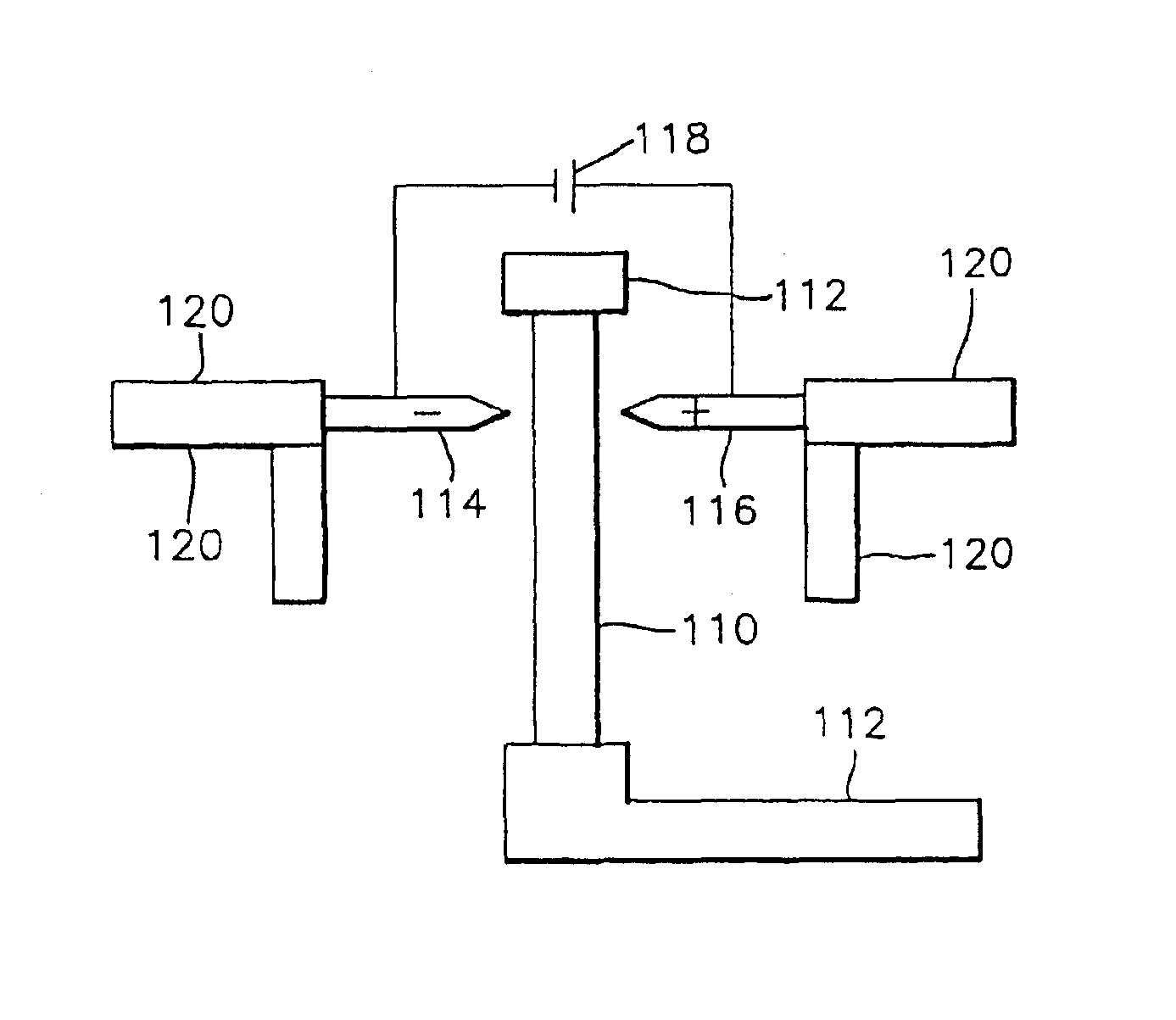

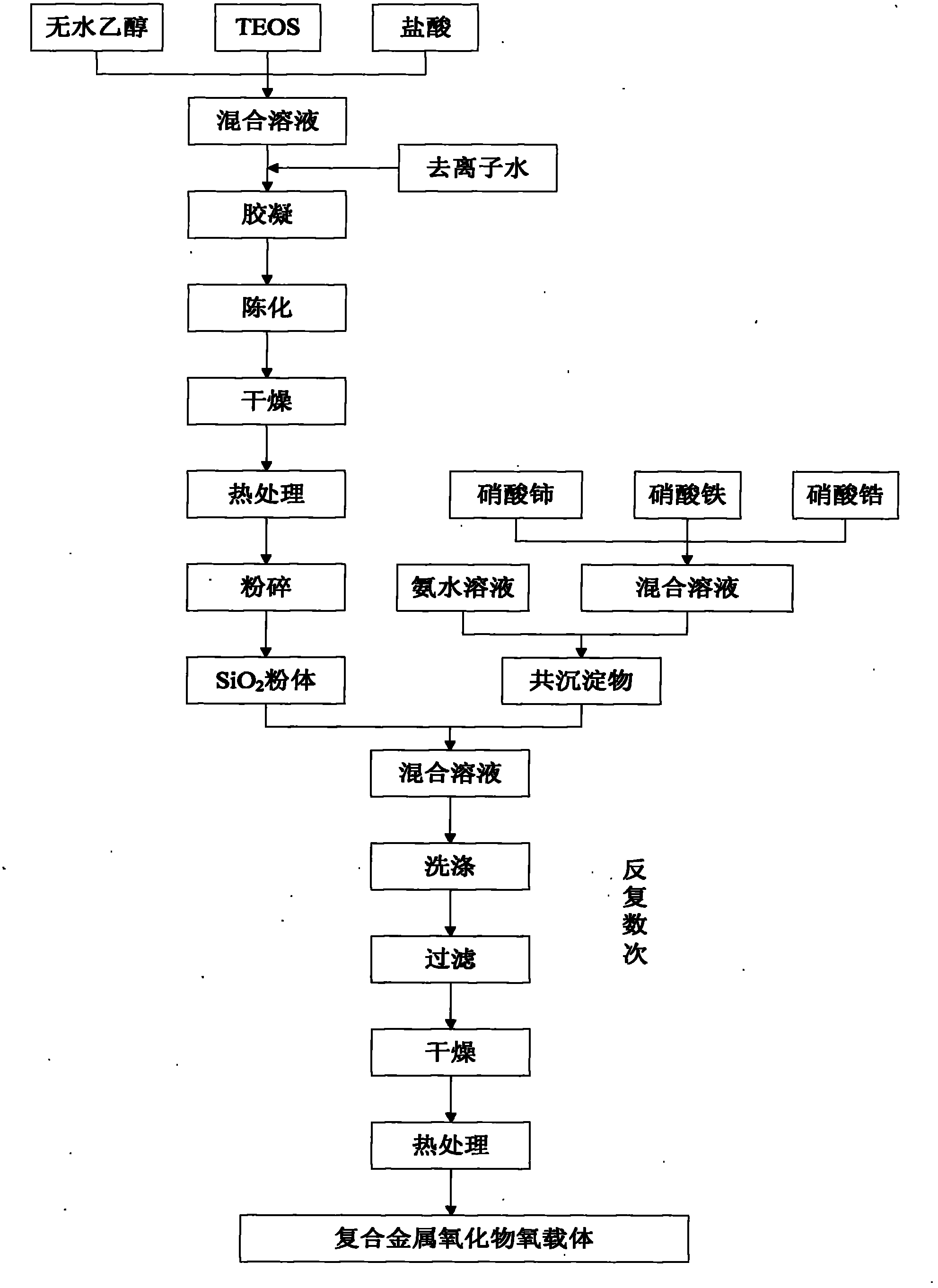

Oxygen-controlled priming of seed

ActiveUS8381438B2Avoid elevationPlant phenotype modificationSeed arrangmentsFluorescencePlanting seed

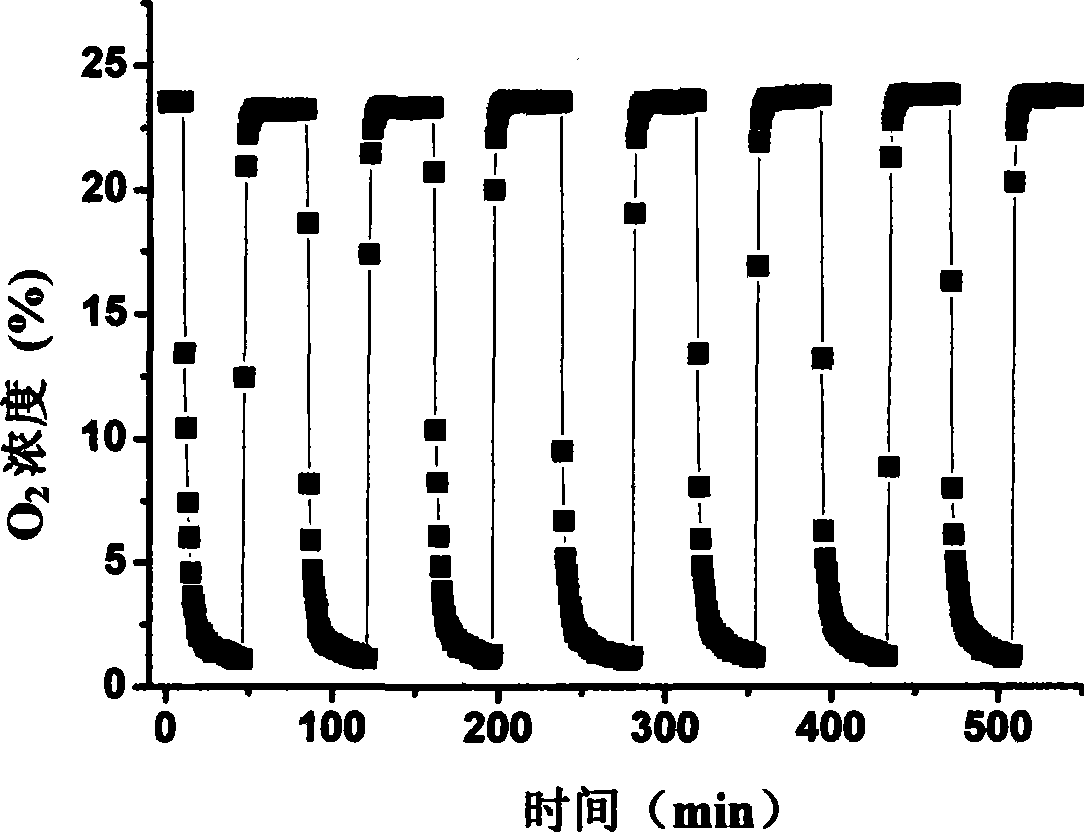

The present invention relates the methods, compositions and devices for priming of plant seed, preferably seed of crop plants, and seeds obtained with the methods, compositions and devices, wherein the metabolic activity necessary for germination of the seed is not controlled by water but rather by the partial oxygen pressure and / or partial carbon dioxide pressure. In the methods of the invention, the partial oxygen or carbon dioxide pressure may be measured by oxygen / carbon dioxide sensitive fluorescent dye. The invention further relates to processes for producing a primed seed lot of a plant species and to a container comprising primed seed under an atmosphere with a partial oxygen pressure that is below the critical oxygen pressure.

Owner:FYTAGORAS BV

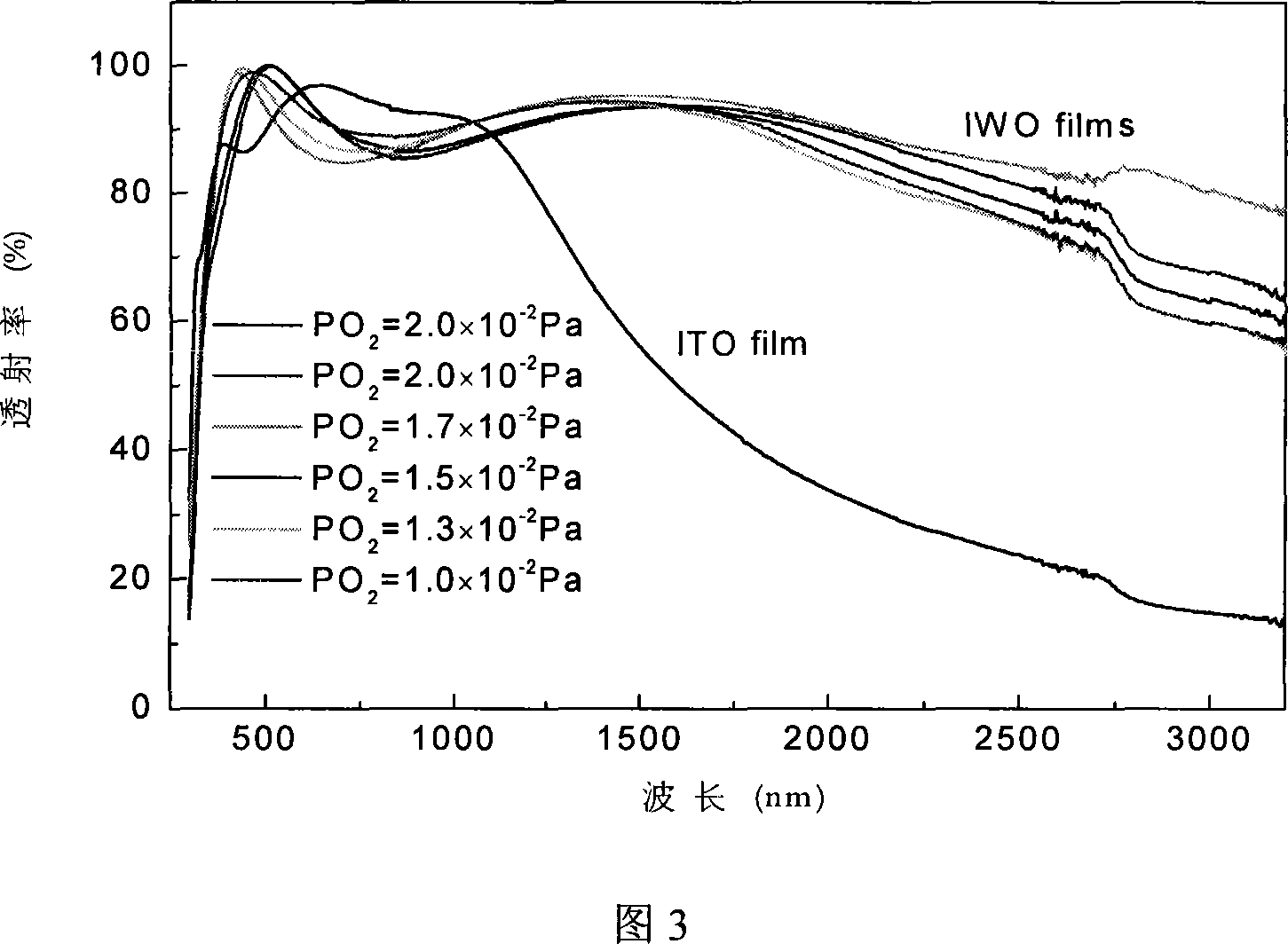

Near-infrared high-transmission rate and multi-crystal transparent conductive oxide film and its making method

InactiveCN101079382AOptimized areaGood optical clarityFinal product manufactureVacuum evaporation coatingIndiumCharge carrier mobility

The invention discloses a making method of near infrared high-transmissivity polycrystalline transparent conductive oxide film, which is characterized by the following: adopting conductive oxide film as doped indium oxide and M (M is W and Mo); using common glass as base; reacting indium metal to dop W or Mo insert target under 300-500 deg.c through DC magnetic sputtering technique; obtaining the In2O3:M film with polycrystalline structure under fitful sputtering pressure, partial oxygen pressure, sputtering current and sputtering voltage; fitting for applying in the solar energy battery domain.

Owner:FUDAN UNIV

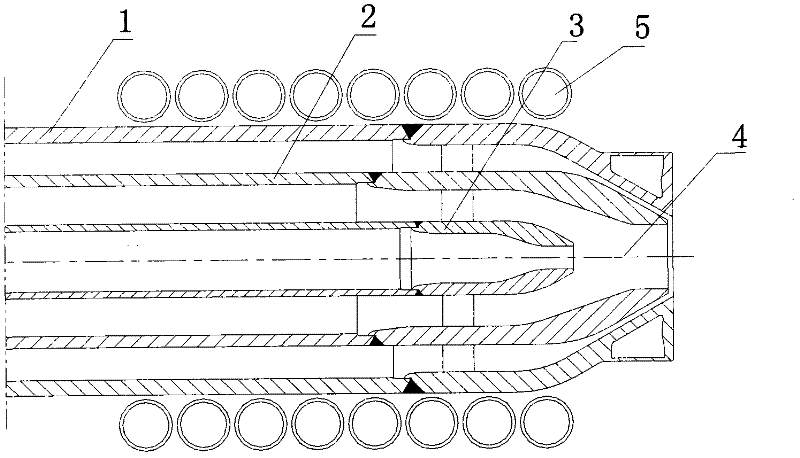

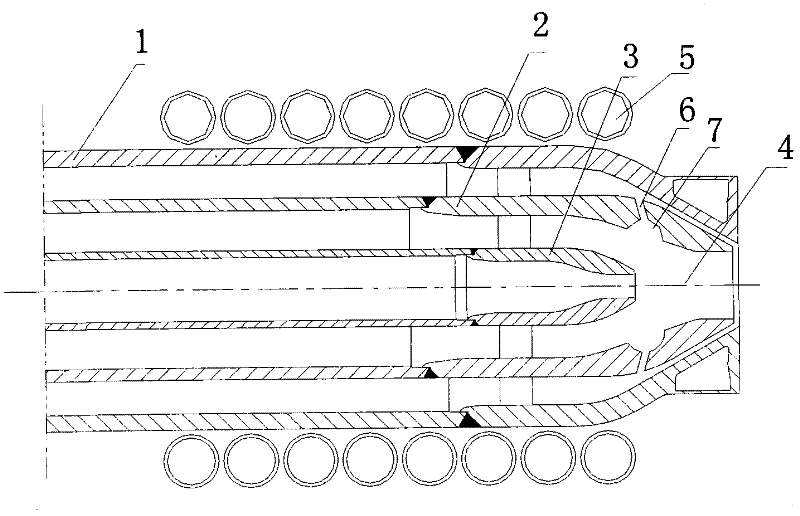

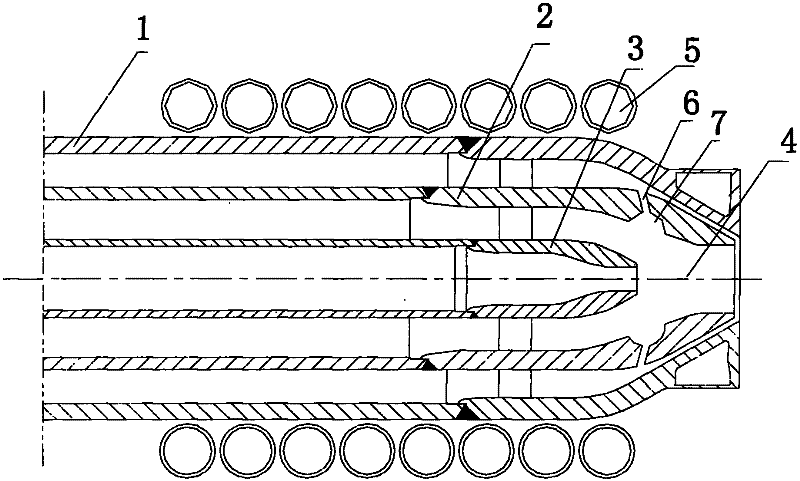

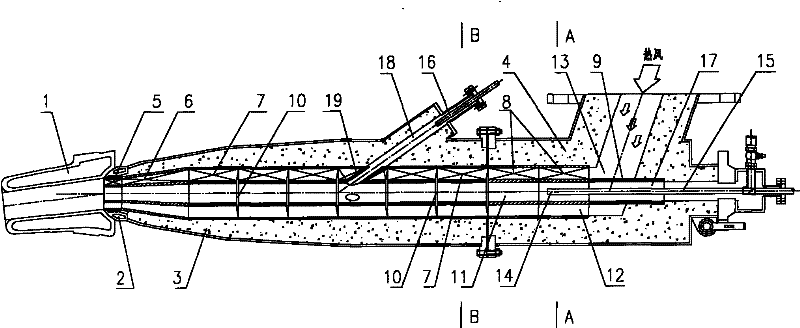

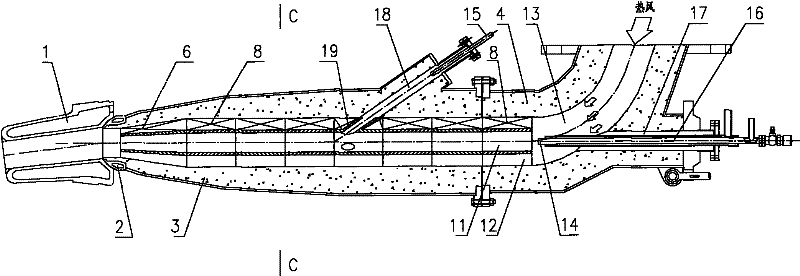

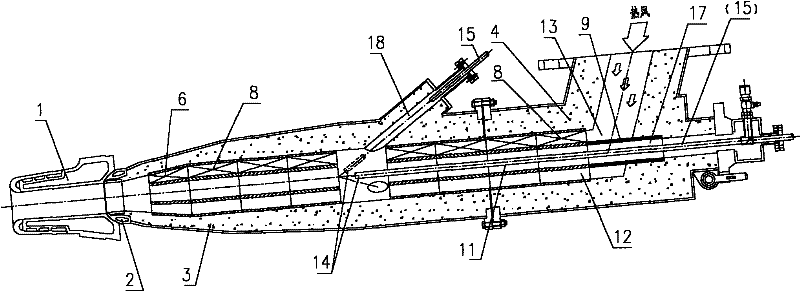

Process burner of water-coal slurry gasification furnace

InactiveCN102250644AAvoid direct contactReduce wearLiquid spraying apparatusGranular/pulverulent flues gasificationEngineeringCoal slurry

The invention relates to a process burner of a water-coal slurry gasification furnace. The process burner comprises an outer spray head and a middle spray head, wherein the outer spray head is used for oxygen circulation; the middle spray head is located inside the outer spray head and used for water-coal slurry circulation; an oxygen introduction part communicated with a chamber of the outer spray head is arranged on the middle spray head and is used for introducing oxygen in the chamber of the outer spray head into a chamber of the middle spray head; the oxygen introduction part is composed of an introduction hole and a buffering ring; the introduction hole is communicated with the chamber of the outer spray head and the buffering ring; and the buffering ring is communicated with the chamber of the middle spray head. Through the structure design, partial oxygen in the outer spray head is introduced into the chamber of an inner spray head, so that an oxygen layer is formed close to the inner wall of the inner spray head, and the oxygen layer can prevent direct contact between the water-coal slurry flowing through the middle spray head and the inner wall of the chamber of the middle spray head, thereby reducing the wearing of the water-coal slurry to the inner wall (inner chamber) of the chamber of the middle spray head, prolonging the maintenance period caused by the inner chamber wearing of the middle spray head, lowering investment and operation cost, and especially lowering the operation cost significantly.

Owner:李西静

Accelerometer for high temperature applications

ActiveUS8375793B2Improve performanceDelay agingPiezoelectric/electrostrictive device manufacture/assemblyAcceleration measurement using interia forcesElectricityAccelerometer

This invention is for a hermetic piezoelectric accelerometer sensor that can operates at high temperatures without the degradation observed on the piezoelectric elements, due to Oxygen depletion of the piezoelectric materials, when they are exposed to high temperatures, in reducing atmospheres, or low partial Oxygen pressure, inside a sealed housing. When a piezoelectric element loses Oxygen, becomes more electrically conductive, and this severe loss in resistivity, exacerbated with the increase of the temperature, makes the sensor inoperable, unreliable, or with permanent damage. The accelerometer of this invention operates effectively over a wide range of temperatures, including high temperatures above 1600° F., depending of the piezoelectric element used on the construction. The housing of the accelerometer uses a small section of metal made with Silver (or Silver alloys) to allow Oxygen diffusion through the metal, when it is exposed to high temperature. This permits that the construction of the accelerometer housing, can be sealed hermetically; and the piezoelectric elements of the sensor have increased lifetime, with enough partial pressure of Oxygen inside the housing.

Owner:DYTRAN INSTR

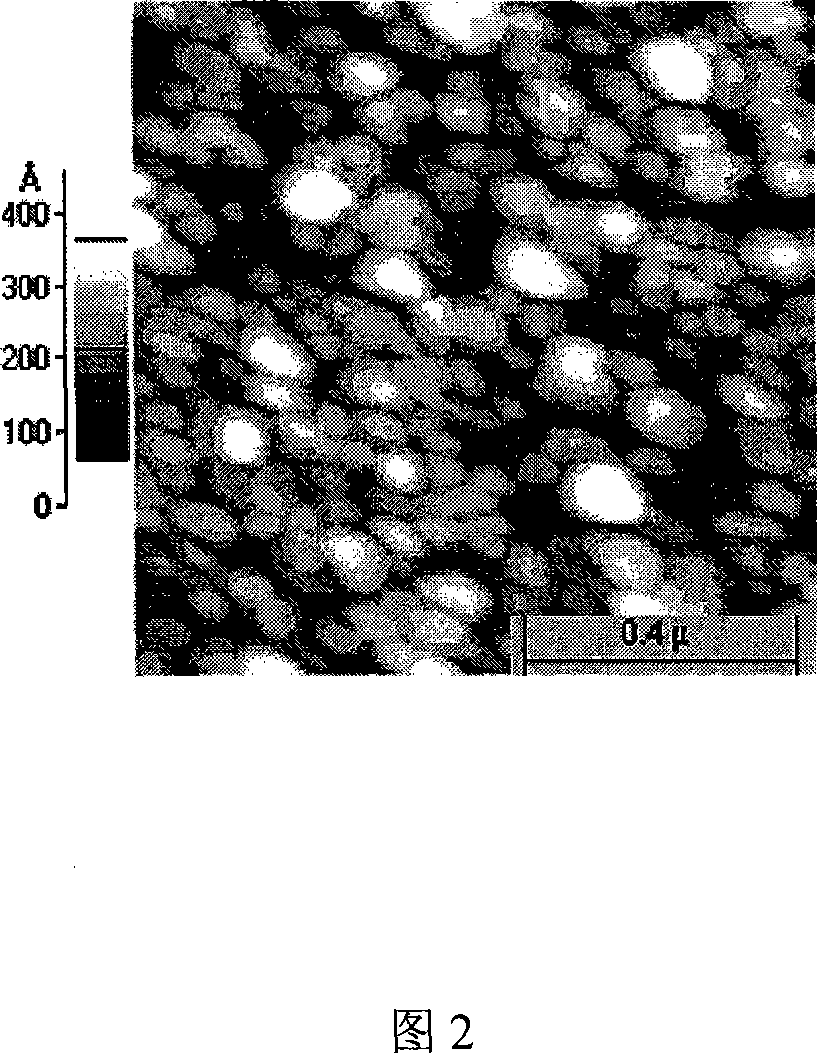

High-TC superconducting ceramic oxide products and macroscopic and microscopic methods of making the same

InactiveUS6949490B2Strong pinning effectLittle dangerSuperconductors/hyperconductorsSuperconductor detailsInsulation layerElectron

High-Tc superconducting ceramic oxide products and macroscopic and microscopic methods for making such high-Tc superconducting products. Completely sealed high-Tc superconducting ceramic oxide provides are made by a macroscopic process including the steps of pressing a superconducting ceramic oxide powder into a hollow body of a material inert to oxygen; heat treating the superconducting ceramic oxide powder packed body under conditions sufficient to sinter the ceramic oxide powder; and then sealing any openings of the body. Optionally, a waveform or multiple pulses of alternate magnetic filed can be applied during the heat treatment. The microscopic method of producing a high-Tc superconducting ceramic oxide product includes the steps of making a high-Tc superconducting ceramic oxide thin film; optionally sintering the deposited thin film in a magnetic filed; and removing partial oxygen content of the thin film by a scanning tunneling electron treatment machine to form a microscopic insulation layer between two high-Tc superconducting domains of the thin film.

Owner:WANG PENGHUA

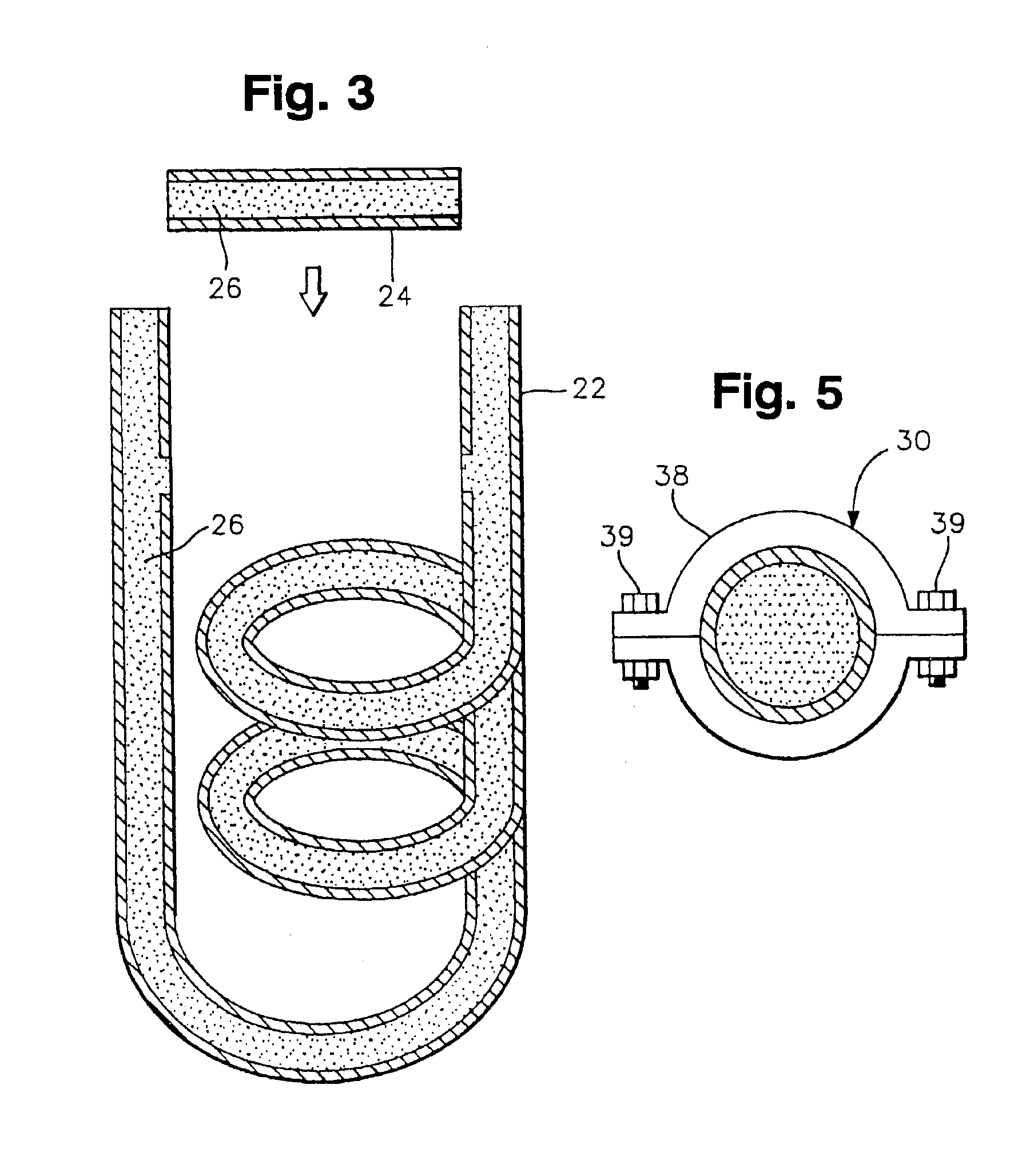

Oxygen carrier for preparing synthesis gas by catalytic partial oxidation of methane

InactiveCN102092683ALow costEasy to industrializeHydrogenCatalyst activation/preparationPartial oxidationCombustion

The invention discloses a cerium-iron-zirconium based composite oxygen carrier material with Al2O3, MgO and SiO2 as carriers, which is used for transmission of partial oxygen in a partial oxidation process. In the invention, three common cheap oxides are used as carriers, cerium-iron-zirconium of certain proportion and the carriers are mixed with a coprecipitation method or a sol-gel method so as to prepare the cerium-iron-zirconium based composite metallic oxide carrier with different carriers. The carrier is beneficial to improvement of oxygen storage capacity and cycle performance of the oxygen carrier, can improve the combustion efficiency of fuels at the same time of obviously reducing the cost, achieves the purpose of modification, and is easy to use in amplified production, wherein MgO is an alkaline oxide, Al2O3 is a neutral oxide and SiO2 is an acidic oxide.

Owner:KUNMING UNIV OF SCI & TECH

Air supplying device of blast furnace as well as combustion method and oxygen-enriching method of injected coal powder thereof

The invention provides an air supplying device of a blast furnace. Pipeline bricks are wholly or partially installed from a channel opening of a peephole to a whole hot air channel of a belly pipe outlet so that the hot air channel is divided into inner and outer two layers, namely a central channel and an annular channel; and hot air is wholly or partially isolated between the central channel and the annular channel. According to a combustion method of injected coal powder provided by the invention, a spraying gun is inserted to the central channel to carry out coal powder injection; after the injected coal powder is partially combusted or heated in the central channel, the injected coal powder and the hot air coaxially enter into an air opening and the furnace to be completely combusted. According to an oxygen-enriching method provided by the invention, oxygen gas is limited in the central channel to be mixed with less hot air so that a partial oxygen-enriched atmosphere which is good for combusting the coal powder is formed. A secondary coal injection technology which is firstly proposed and reliably realized and is carried out at the outlet of the central channel since the first coal injection patent technology in 1926 is also called as a coaxial coal injection technology.

Owner:张昭贵

Method of manufacturing oxide superconducting wire

InactiveUS20040237294A1Reduce in quantityFormation of blister is suppressedLine/current collector detailsSuperconductors/hyperconductorsBlistersHeat treated

The inventive method of manufacturing an oxide superconducting wire comprises a step (S1, S2) of preparing a wire formed by covering raw material powder of an oxide superconductor with a metal and a step (S4, S6) of heat-treating the wire in a pressurized atmosphere, and the total pressure of the pressurized atmosphere is at least 1 MPa and less than 50 MPa. Thus, formation of voids between oxide superconducting crystals and blisters of the oxide superconducting wire is suppressed while the partial oxygen pressure can be readily controlled in the heat treatment, whereby the critical current density can be improved.

Owner:SUMITOMO ELECTRIC IND LTD

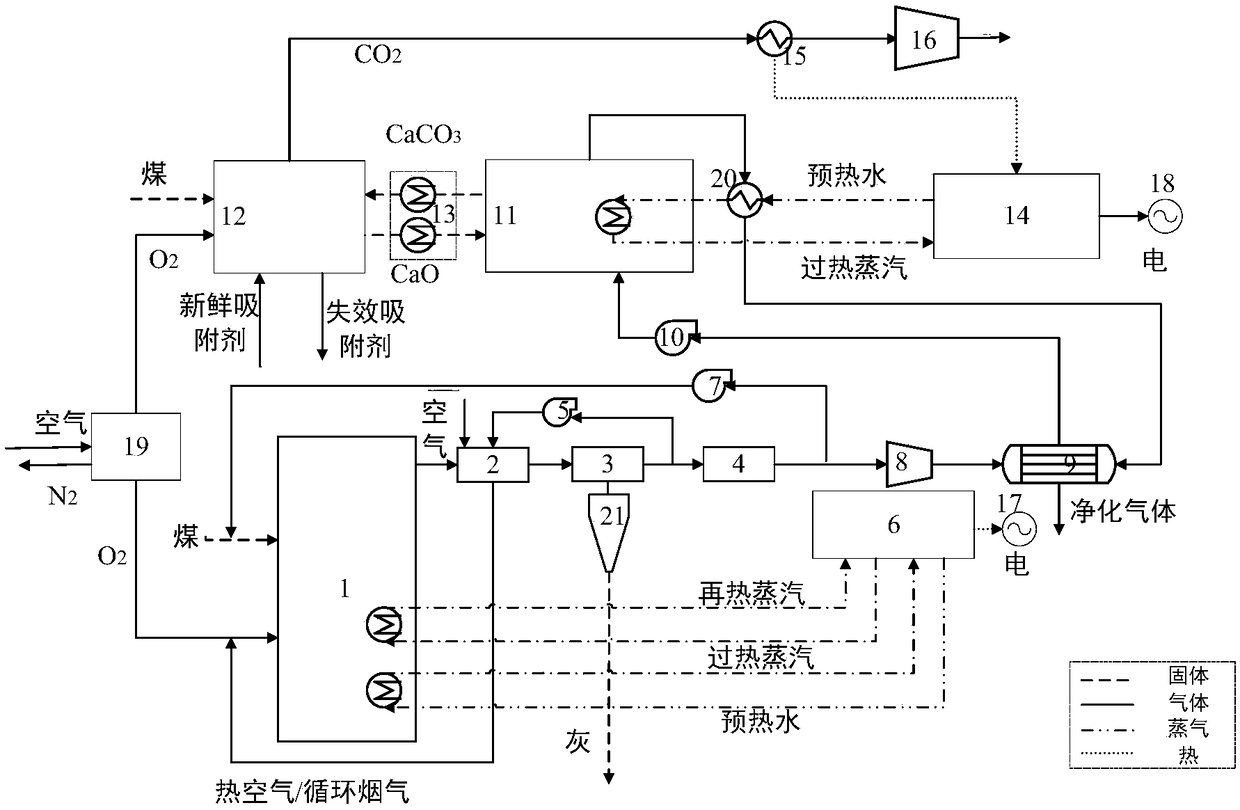

Power generation system with partial oxygen-enriched combustion combined with calcium-based chain and CO2 capturing method

PendingCN108729965AReduce energy consumptionLower requirementGas treatmentDispersed particle separationHigh carbonFlue gas

The invention discloses a power generation system with partial oxygen-enriched combustion combined with a calcium-based chain and a CO2 capturing method. Through a partial oxygen-enriched method in which a mixture of air, oxygen and recycled flue gas serves as a combustion improver, the CO2 gas concentration of flue gas of a boiler outlet is increased to 30%-60%, the flue gas enters a chemical chain combustion post-capturing device based on a calcium base, the calcium-based reactivity is greatly improved, the CO2 capturing efficiency reaches 95% or above, and the gross generation is increased.According to the power generation system, the oxygen generation cost, the carbon carrier cost, energy consumption and the CO2 capturing efficiency are all balanced, so that the comprehensive efficiency is the optimized, two advanced carbon capturing techniques of partial oxygen-enriched combustion and the calcium-based chemical chain are combined, and the power generation system and the CO2 capturing method have the advantages of good economical efficiency, simple process, low energy consumption, high carbon capturing efficiency and the like.

Owner:SOUTH CHINA UNIV OF TECH

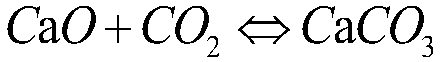

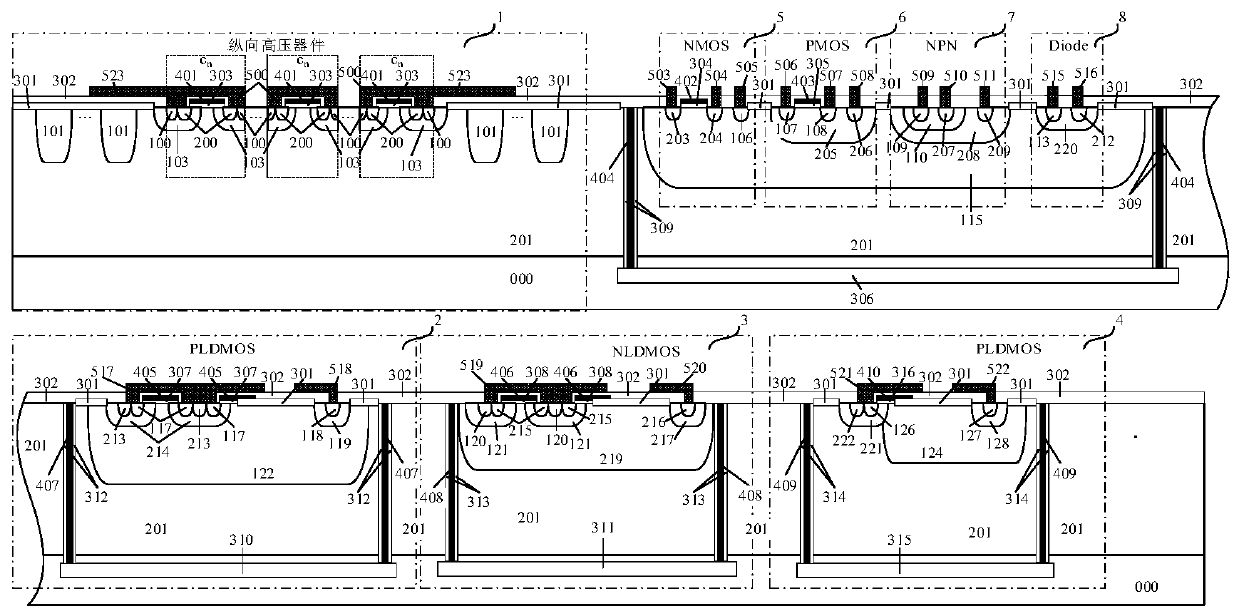

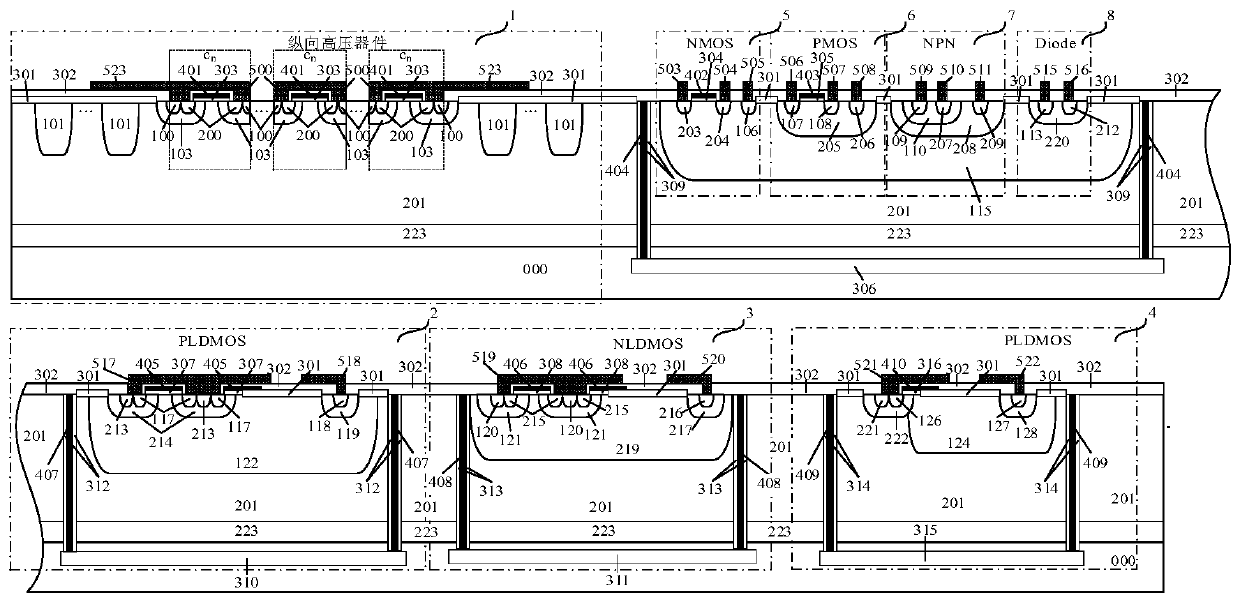

Integrated power semiconductor device and manufacturing method thereof

The invention provides an integrated power semiconductor device and a manufacturing method thereof. The semiconductor device comprises a longitudinal high-voltage device, a first high-voltage pLDMOS device, a high-voltage nLDMOS device, a second high-voltage pLDMOS device, a low-voltage NMOS device, a low-voltage PMOS device, a low-voltage NPN device and a low-voltage Diode device which are integrated on the same chip. The first high-voltage pLDMOS device, the high-voltage nLDMOS device, the second high-voltage pLDMOS device, the low-voltage NMOS device, the low-voltage PMOS device, the low-voltage NPN device and the low-voltage Diode device are all isolated through media. The first high-voltage pLDMOS device and the high-voltage nLDMOS device adopt a multi-channel design, and the second high-voltage pLDMOS device adopts a single-channel design. The invention provides a partial oxygen burying integration technology, an oxygen burying layer is formed by adopting ion implantation and other modes, the technology can integrate a transverse high-voltage device, the longitudinal high-voltage device and a low-voltage device, and problems of current leakage and crosstalk are avoided. Compared with the transverse high-voltage device, by using the semiconductor device of the invention, an on-resistance is low and an occupied chip area is small.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

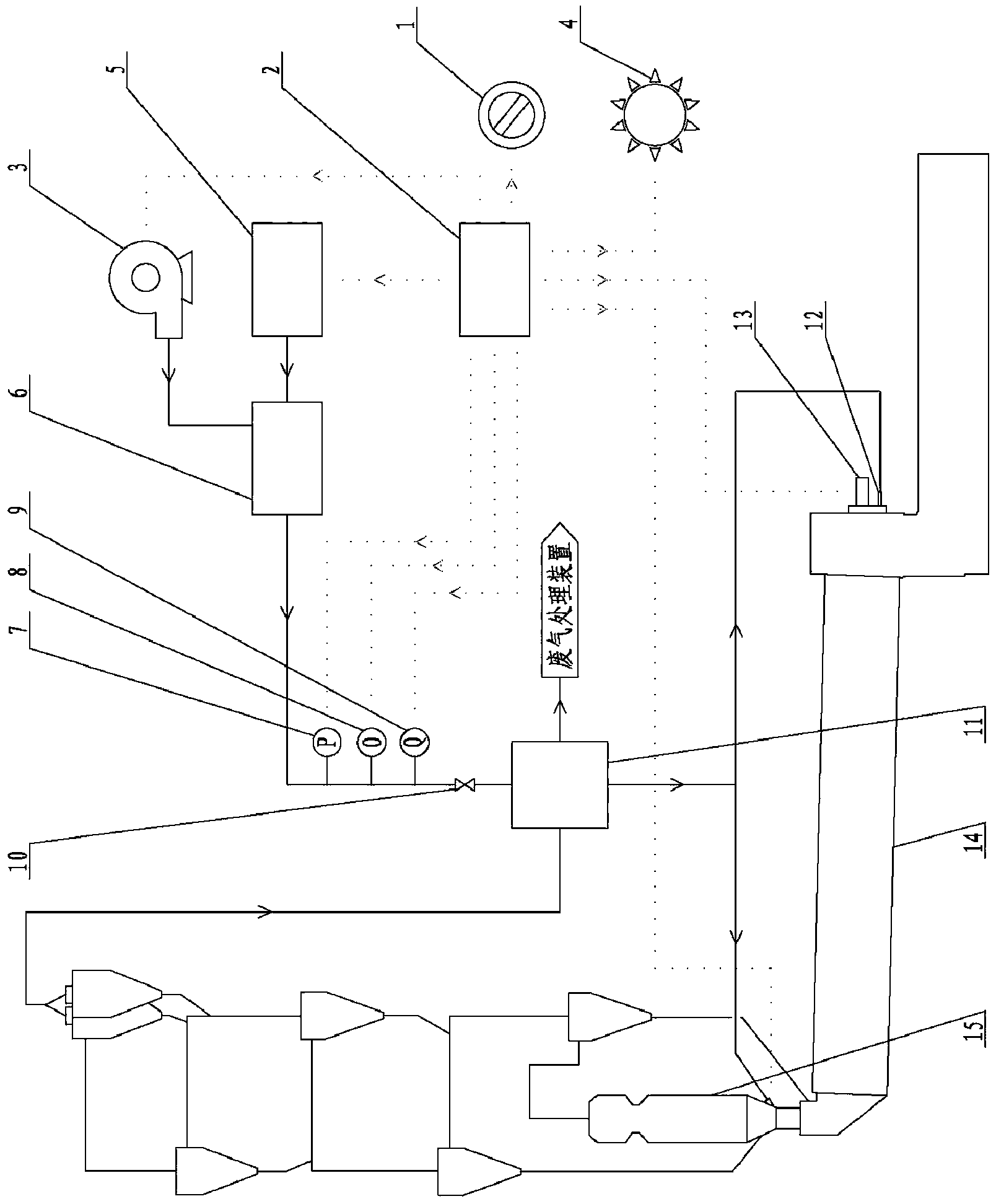

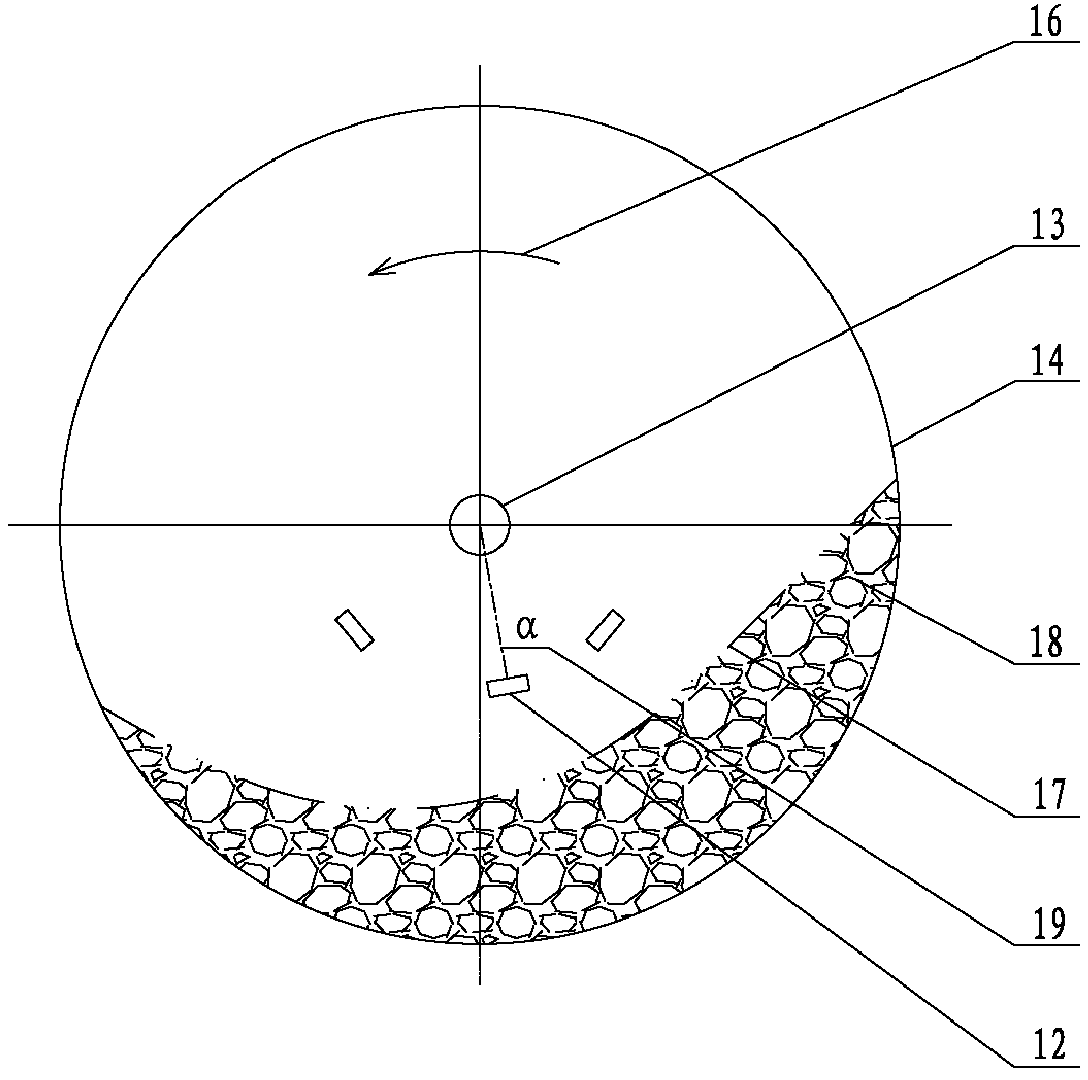

Energy-saving emission-reducing partial oxygen-increasing combustion-supporting device used for cement kiln

InactiveCN103175394AAbsorb moreReduce the temperatureRotary drum furnacesIndirect carbon-dioxide mitigationFully developedEngineering

An energy-saving emission-reducing partial oxygen-increasing combustion-supporting device used for a cement kiln is placed beside the cement kiln. A VPSA oxygen enrichment generation device of the energy-saving emission-reducing partial oxygen-increasing combustion-supporting device is connected with an oxygen enrichment control device. The oxygen enrichment control device is connected with an air blower and connected with an oxygen enrichment preheater through an oxygen conveying pipeline. An oxygen enrichment pressure transmitter, an oxygen enrichment concentration transmitter, an oxygen enrichment flow rate transmitter and a control valve are respectively arranged on the oxygen conveying pipeline. A smoke inlet of the oxygen enrichment preheater is connected with high-temperature waste gas of the cement kiln, and an oxygen enrichment gas outlet is connected with an oxygen enrichment jet nozzle. The oxygen enrichment jet nozzle is arranged on the lower half portion of a rotary kiln combustion device. According to the energy-saving emission-reducing partial oxygen-increasing combustion-supporting device used for the cement kiln, not only can materials absorb more effective heat energy as much as possible, but also the temperature in the upper portion of the cement kiln can be reduced effectively and fuel can be burnt fully, timely and completely with less combustion air. Moreover, performance of high-quality fuel can be fully developed so that usage of poor-quality fuel becomes possible. Smoke dust, dust, CO, CO2, NOX and the like are reduced. The energy-saving emission-reducing partial oxygen-increasing combustion-supporting device used for the cement kiln has remarkable comprehensive energy-saving emission-reducing benefit.

Owner:DALIAN EAST NEW ENERGY DEV

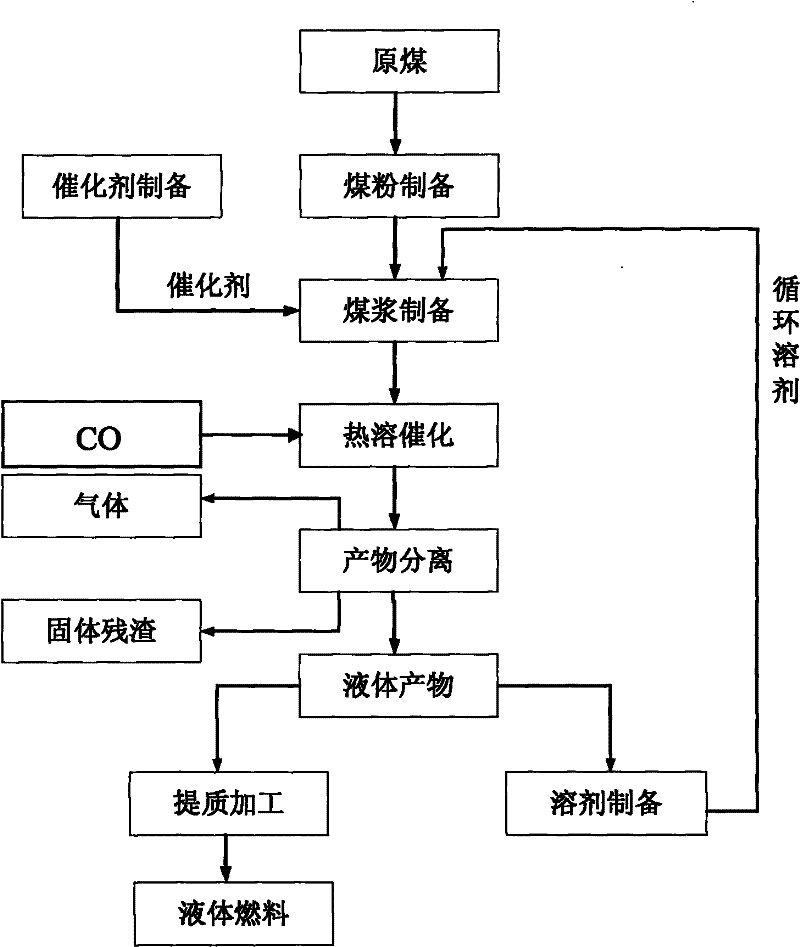

Lignite solubilizing and catalytic liquefaction method in non-hydrogen atmosphere

InactiveCN102191075AMild reaction conditionsSimple operation processLiquid hydrocarbon mixture productionChemical reactionHydrogen atmosphere

The invention belongs to the technical field of coal chemical processing and discloses a lignite solubilizing and catalytic liquefaction method in non-hydrogen atmosphere. The method comprises the following steps: preparing coal powder, preparing coal slurry, performing thermal dissolution and catalysis, and separating the thermal dissolution liquefied product, wherein in the coal powder preparation step, the water content of coal powder is no less than 8w%; and in the thermal dissolution and catalysis step, CO gas is introduced. In the method, CO is used as medium, thus the solvent can be optimized and the quality of liquefaction oil can be increased; H2O required by the reaction comes from the lignite with rich water, thus the limit on the water of lignite can be lowered, the heating drying of lignite can be eliminated and the energy consumption can be reduced; the water production rate in the liquefaction of lignite can be reduced, thus water pollutions can be reduced; the chemical reaction is utilized to generate active hydrogen which is easy to react with coal, thus the yield of liquefaction oil can be increased and coal is easy to dissolve; and CO is used to remove partial oxygen and sulfur in the coal structure and the consumption of hydrogen can be reduced. The operational process is simple, safe and stable, the localization degree of equipment is high, the investment is low and the cost is low.

Owner:ZHAOQING SHUNXIN COAL CHEM TECH

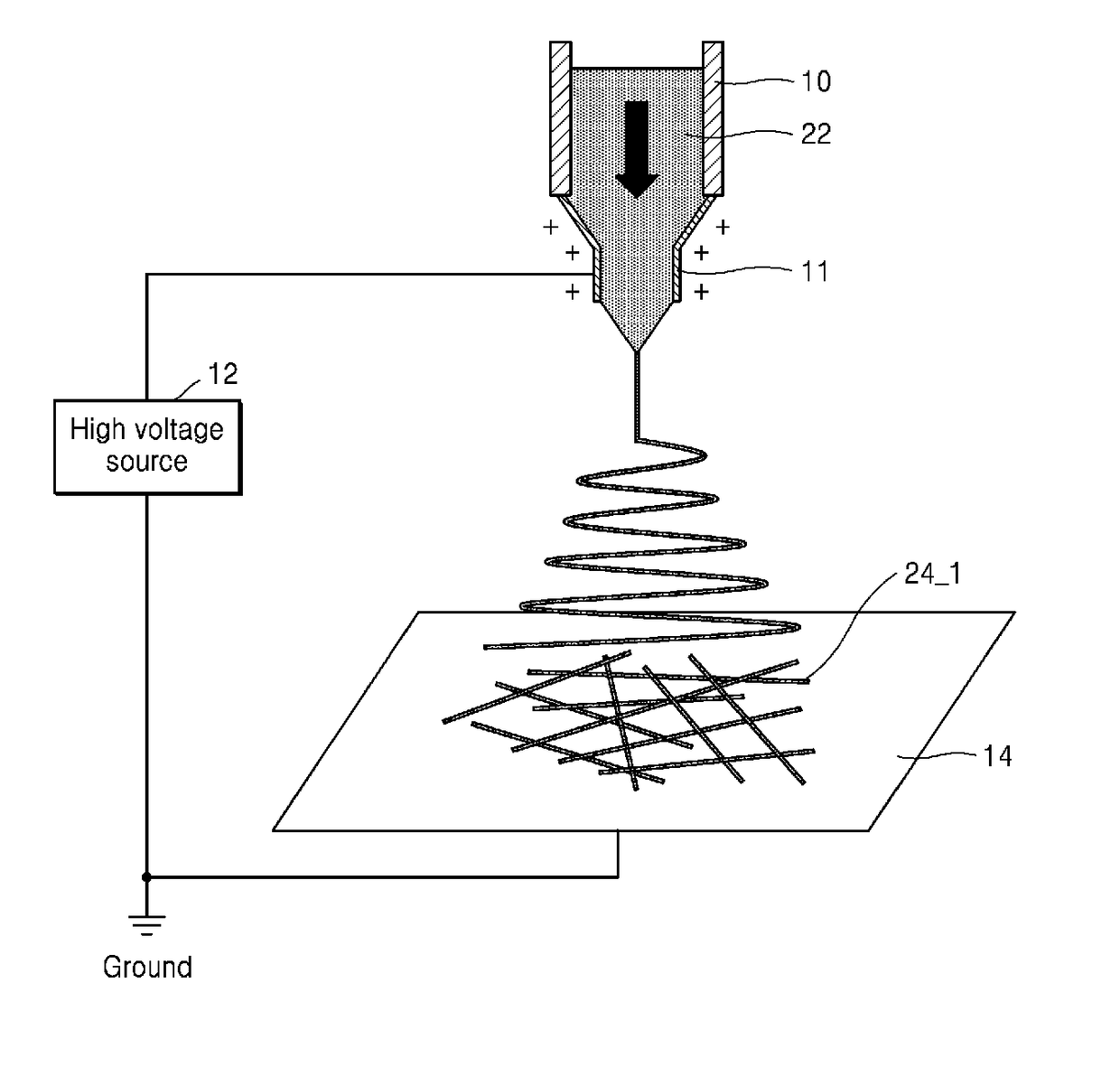

Metal-carbon nanofiber and production method thereof

ActiveUS20180200788A1Function increaseReduced usabilityTransportation and packagingMetal-working apparatusNanofiberOxidation resistant

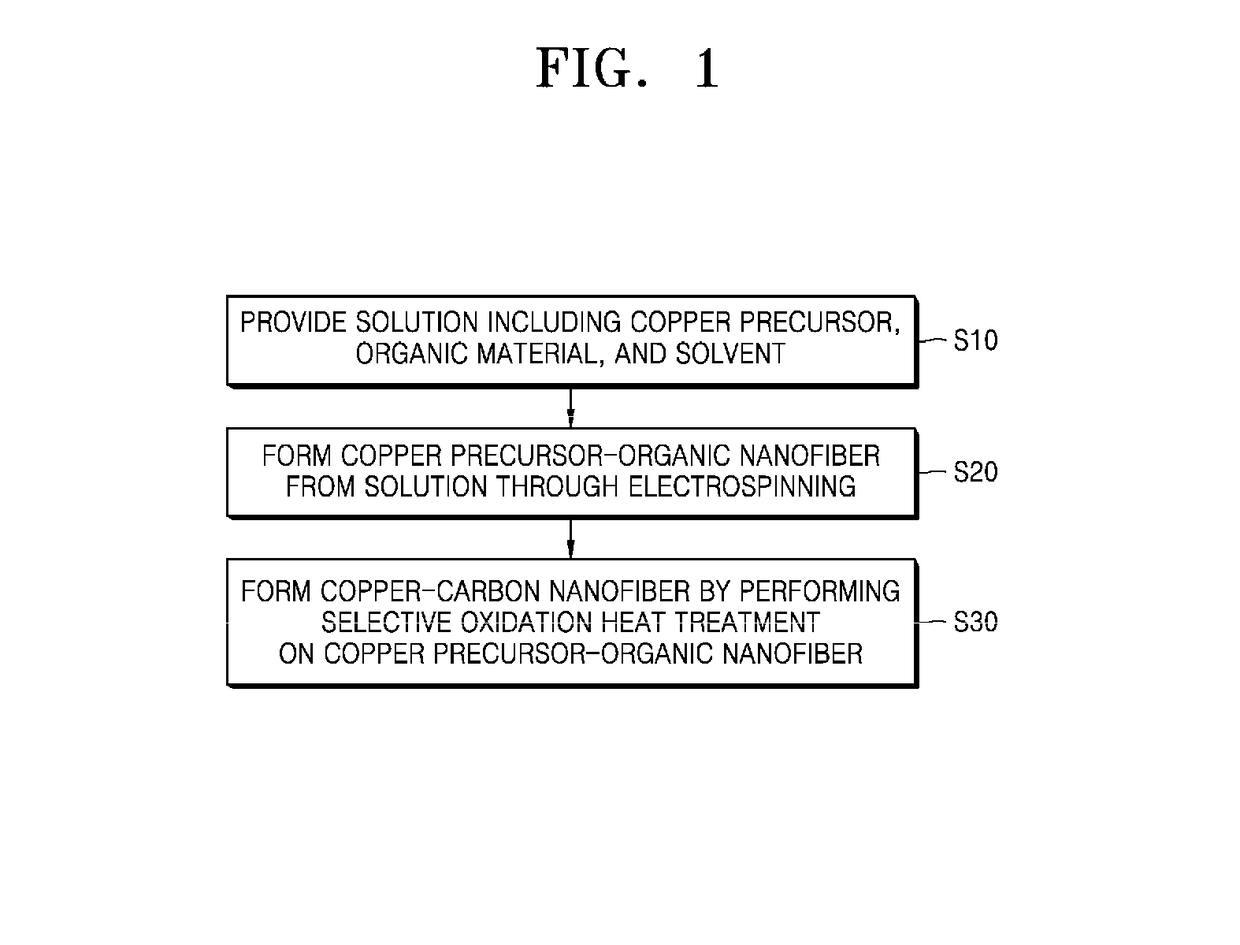

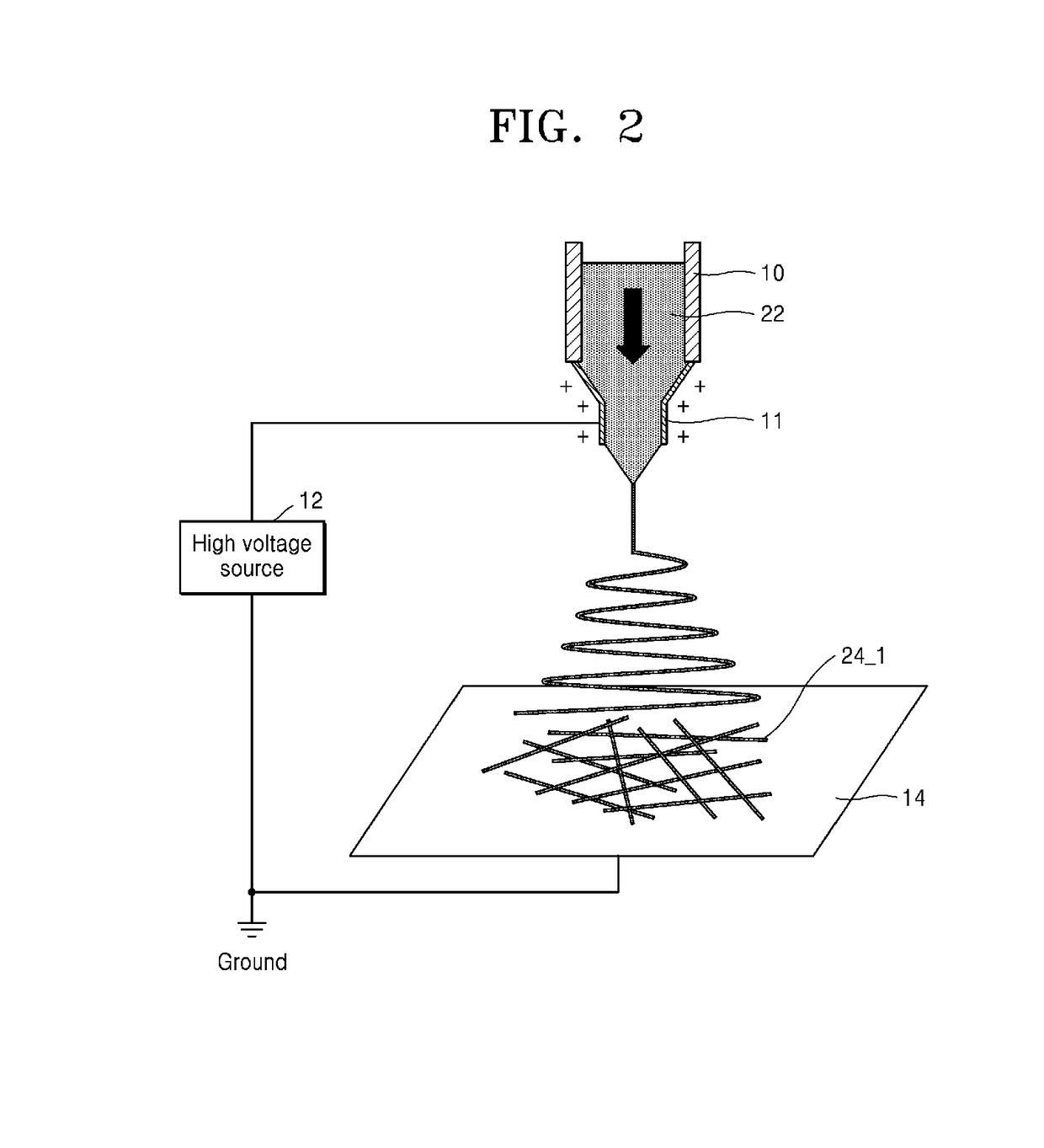

The present invention provides a production method of copper-carbon nanofibers, which can realize oxidation-resistant characteristics and process simplification, the production method comprising the steps of: forming a metal precursor-organic nanofiber comprising a metal precursor and an organic substance; and forming a metal-carbon nanofiber by performing a selective oxidation heat treatment to the metal precursor-organic nanofiber so as to simultaneously oxidize carbon of the organic substance and reduce the metal precursor to a metal, wherein the metal has a lower oxidation resistance than the carbon; the selective oxidation heat treatment is performed through a singly heat treatment step, not a plurality of heat treatment steps; and metal-carbon nanofibers with different structures may be formed according to the amount of partial oxygen pressure under which the selective oxidation heat treatment is performed.

Owner:SEOUL NAT UNIV R&DB FOUND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com