Process for removing chloride from zinc dross

A zinc scum and removal technology, which is applied in the field of comprehensive utilization of slag, can solve the problems of low efficiency and high production cost, and achieve the effect of comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

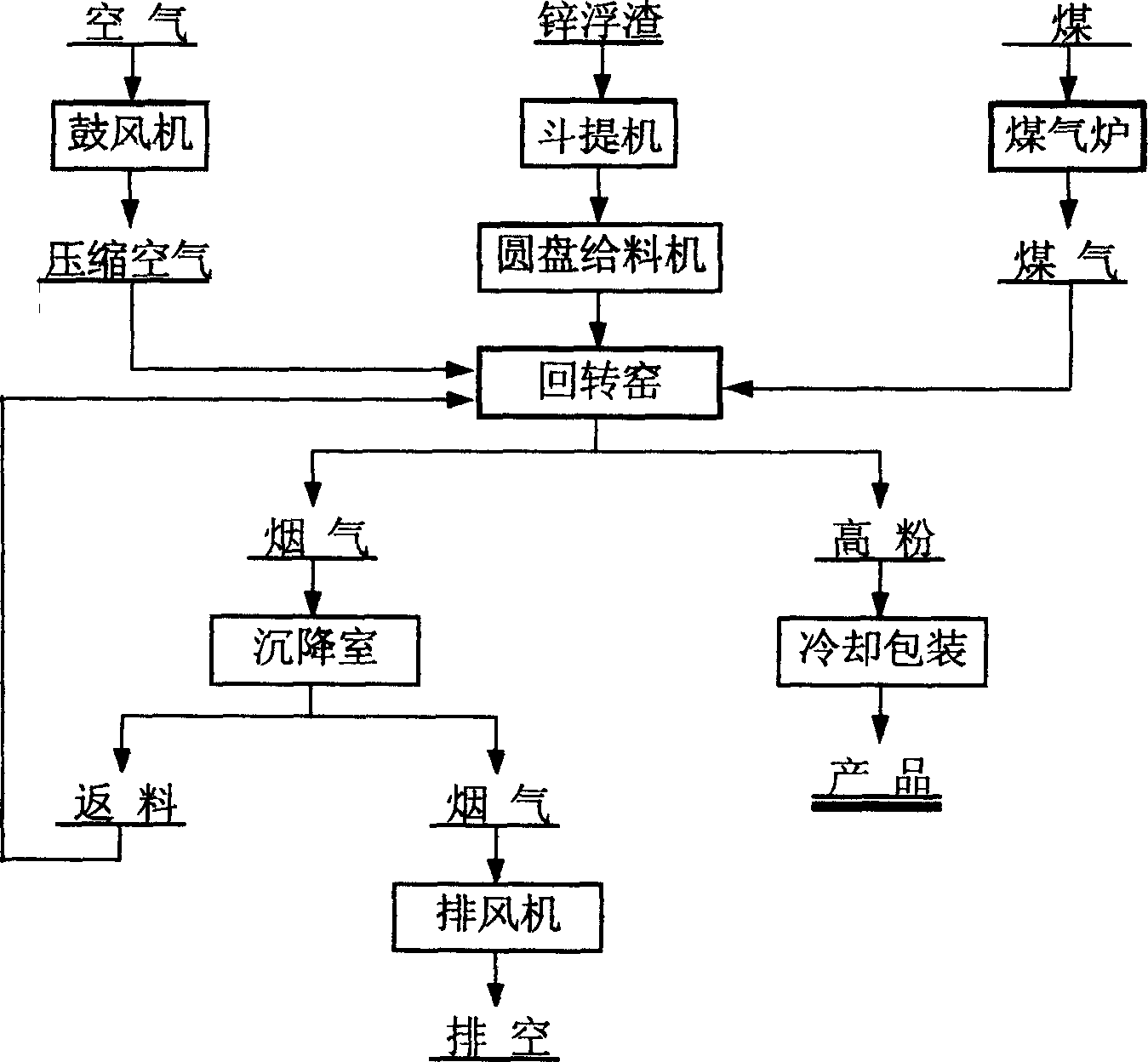

Method used

Image

Examples

Embodiment 1

[0029] Add zinc scum with chlorine content of 1.891%, zinc content of 74.51%, dry weight of 5.01 tons, and moisture content of 25% in the rotary kiln, and feed the above-mentioned water gas as fuel, and the amount of gas introduced is calculated according to the amount of gas (Nm 3 ): zinc scum (dry weight, ton)=(400~500): 1. Gas outlet pressure is 30mmH 2 O, the prepared water gas contains 3.5% water vapor, and the blast pressure is 70mmH 2 O, the average total heating (residence) time of zinc scum from the kiln tail to the kiln head in the rotary kiln is 3 hours, the high temperature zone temperature of the rotary kiln is 1150 ℃, and the material is 30 minutes in the high temperature residence time to obtain chlorine content 0.047%, zinc Dechlorinated zinc oxide with a content of 76.15%, the zinc oxide weighs 4.51 tons.

Embodiment 2

[0031] Put chlorine content 2.551%, zinc content 74.48%, dry weight 6.53 tons, water content is 24.5% zinc scum into the rotary kiln, pass into the above-mentioned water gas combustion, gas feed rate according to gas volume (Nm 3 ): zinc scum (dry weight, ton)=(400~500): 1. Gas outlet pressure is 35mmH 2 O, the prepared water gas contains 7.6% water vapor, and the blast pressure is 80mmH 2 O, the total heating (residence) time of zinc scum in the rotary kiln was 3 hours, the high temperature zone temperature of the rotary kiln was 1200 ℃ of temperature, and the high temperature residence time was 45 minutes to obtain the dechlorinated zinc oxide of chlorine content 0.044%, zinc content 76.23%, Zinc oxide weighs 5.88 tons.

Embodiment 3

[0033] Add zinc scum with chlorine content of 2.652%, zinc content of 74.71%, dry weight of 5.65 tons, and moisture content of 27.35% in the rotary kiln, and feed the above-mentioned water gas for combustion. 3 ): zinc scum (dry weight, ton)=(400~500): 1. Gas outlet pressure is 40mmH 2 O, the prepared water gas contains 9.8% water vapor, and the blast pressure is 80mmH 2 O, zinc scum total heating (residence) time 3 hours in rotary kiln, 1100 ℃ of temperature of high temperature band temperature of rotary kiln, high temperature residence time 60 minutes, obtain the dechlorination zinc oxide of chlorine content 0.049%, zinc content 76.33%, Zinc oxide weighs 5.10 tons.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com