Patents

Literature

41results about How to "Lower eutectic point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

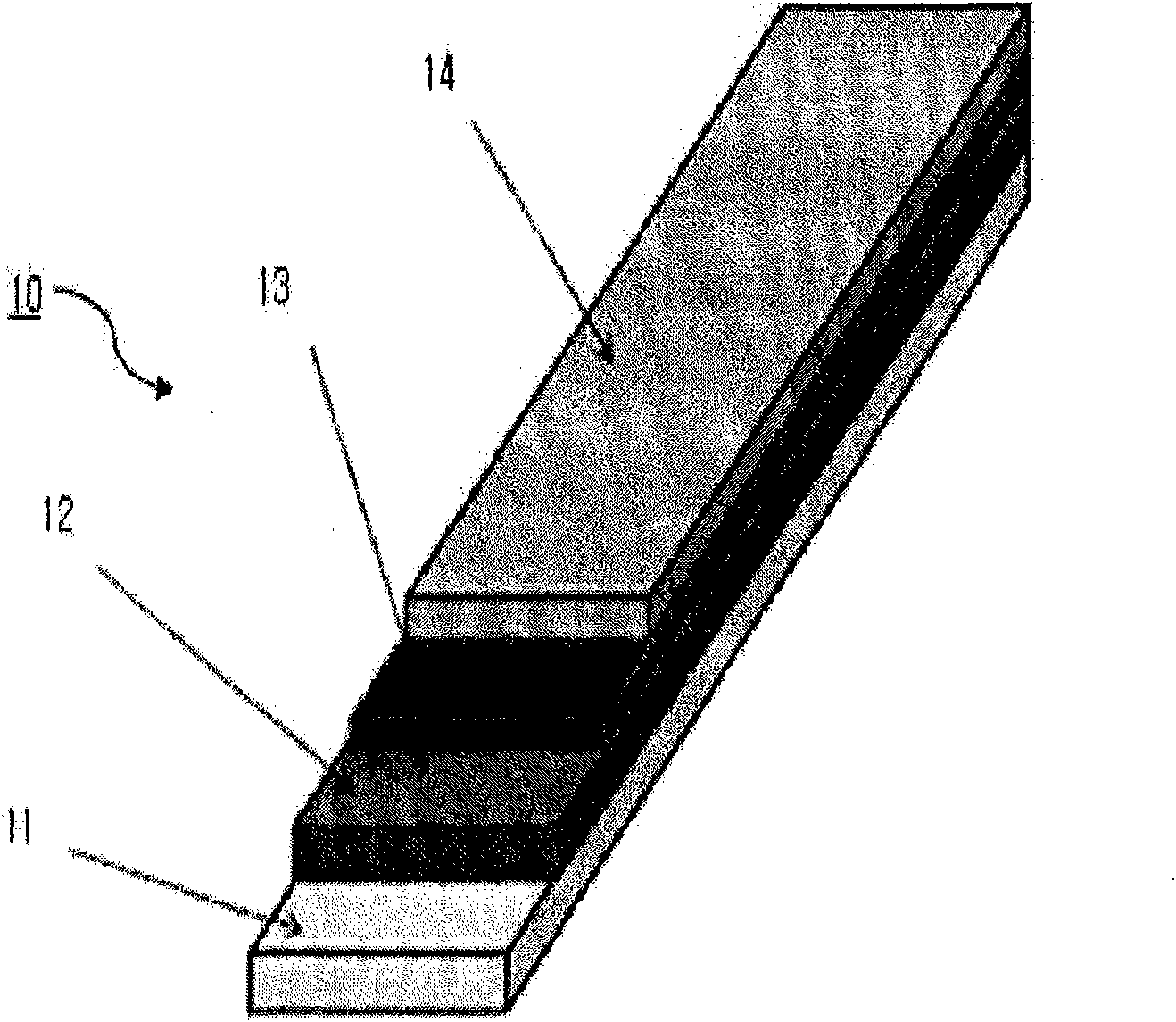

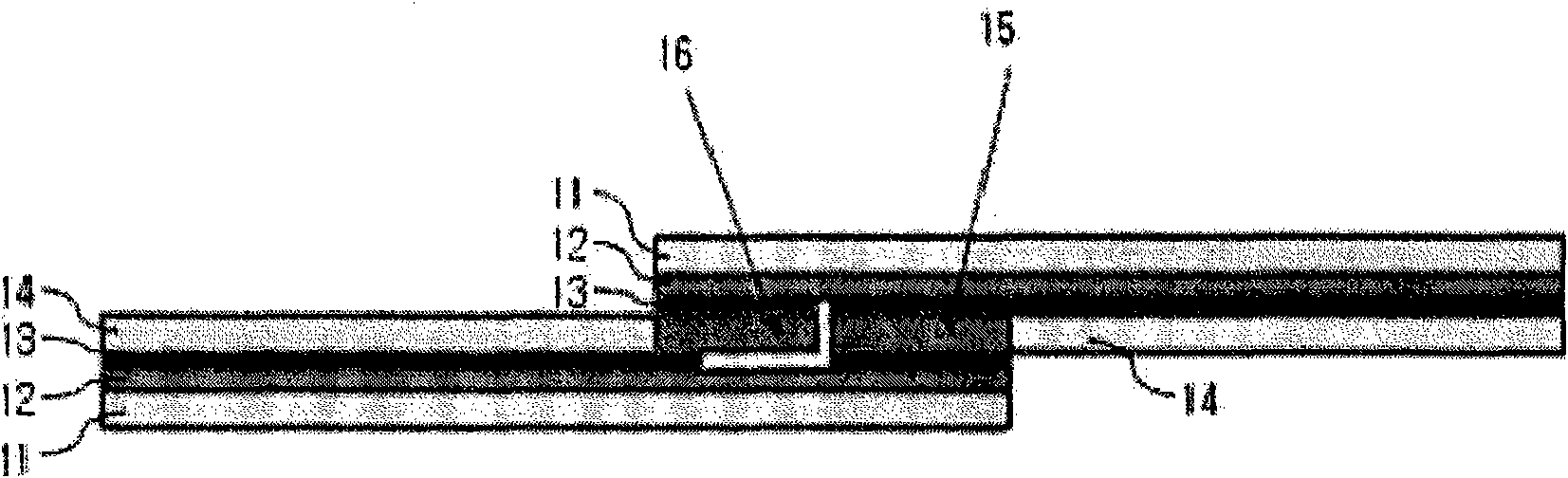

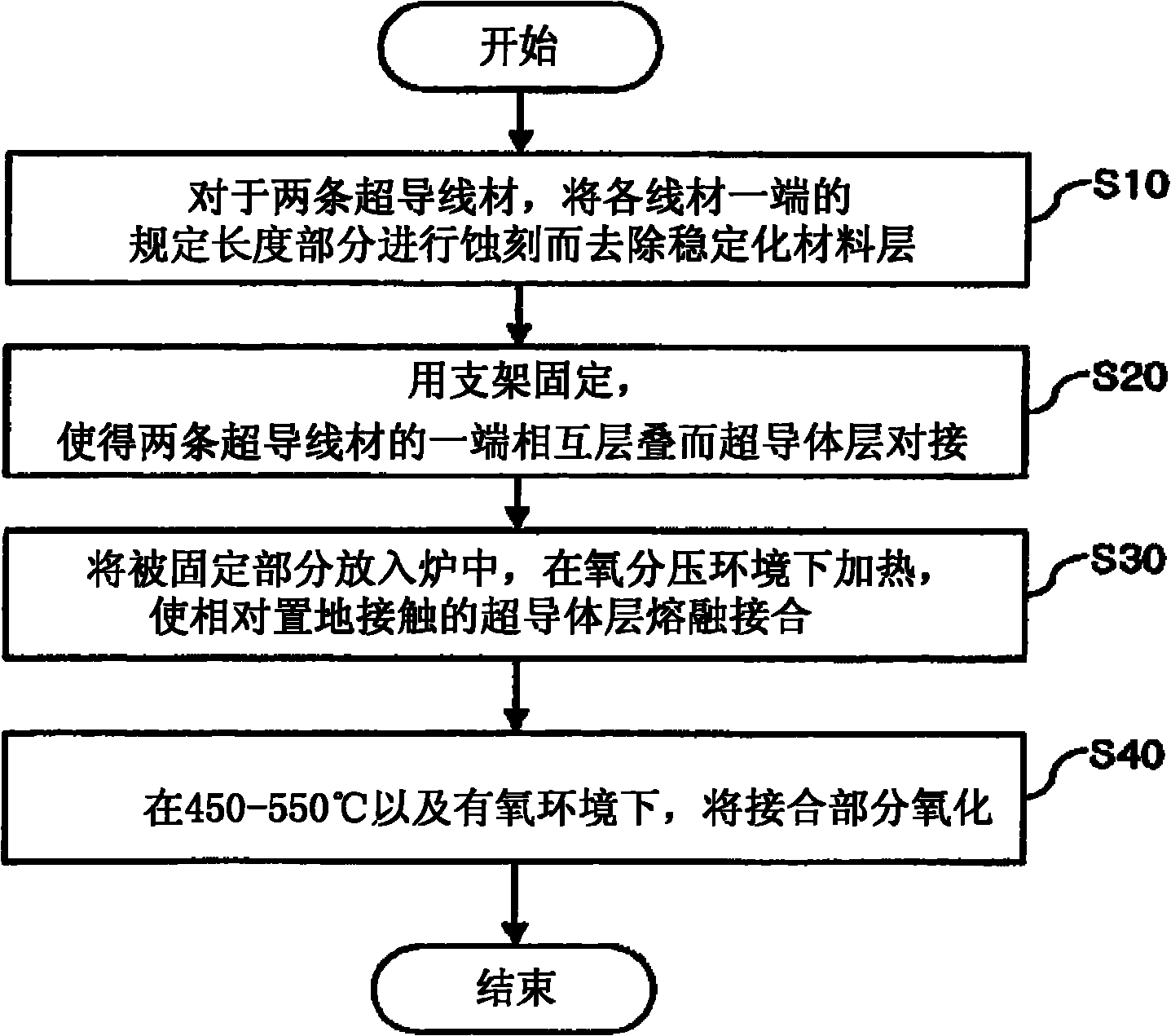

Method for joining second-generation high-temperature superconducting wires by melting diffusion

InactiveCN101971273ALower eutectic pointSuperconductors/hyperconductorsSuperconductor detailsHigh-temperature superconductivityHot Temperature

The present invention relates to a welding method for a second generation high temperature superconducting wire including a substrate, a buffer layer, a superconductor layer, and a stabilizing material layer, wherein parts of the stabilizing material layers contained in two strands of the second generation high temperature superconducting wire are removed, the superconductor layers of two strands of the second generation high temperature superconducting wire exposed by the removal of the stabilizing material layer abut each other and are heated to the melting point of the superconductor layer to melt-diffuse the abutting superconductor layers and weld two strands of the second generation high temperature superconducting wire together. Subsequently, the welded portion is oxygenation-annealed under an oxygen atmosphere to recover superconducting properties of the second high temperature superconducting wire. The above-described configuration of the present invention enables superconductor layers to directly abut each other and to be melt-diffused without using a mediator, thus producing a wire having a full length with a rare junction resistance as compared to a normal conduction junction method. Specifically, the present invention brings a partial oxygen pressure to a nearly vacuum state to lower the melting point, thereby enabling junction processes to be performed without melting a stabilizing material layer containing silver (Ag).

Owner:K·约恩

Electrolyte for high-power start-stop battery and power lithium battery

ActiveCN109713366ALower impedanceLong cycle lifeSecondary cells servicing/maintenanceHigh temperature storageMethyl carbonate

An electrolyte for a high-power start-stop battery comprises the following components, per 100 parts by weight, 14 to 20 parts of lithium salt, 70 to 85 parts of organic solvent, and 1 to 10 parts offunctional additives. The organic solvent comprises the following components, by weight accounting for the total weight of the electrolyte: 12 to 20 parts of ethylene carbonate EC, 5 to 11 parts of propylene carbonate PC, 10 to 20 parts of ethyl methyl carbonate EMC, 14 to 22 parts of propyl acetate PA, and 12 to 20 parts of propyl propionate PP. The lithium ion battery electrolyte of the invention can be reduced in electrical conductivity under a low-temperature condition, and improved in the low-temperature interface membrane impedance so as to be improved in the charging and discharging power characteristic at low temperature, further improves the high-temperature stability of the lithium salt and the interface membrane, is reduced in high-temperature side reaction, and improves the high-temperature storage and high-temperature cycle performance of the battery.

Owner:FENGFAN

Medium-temperature color glaze formula and sintering process thereof

The invention discloses a medium-temperature color glaze formula and a sintering process thereof, wherein the parent glaze of the formula contains the following raw materials by weight percent: 35-45% of potassium-sodium integrated feldspar, 6-8% of kaolin, 13-18% of quartz, 10-15% of limestone, 0-8% of talcum, 0-6% of zinc oxide and 0-6% of barium carbonate. The formula is characterized in that the potassium-sodium integrated feldspar is selected in stead of potassium feldspar or solidum feldspar in combination with the local material reality, so that the production cost and sintering temperature are reduced, and simultaneously, the eutectic point of potassium and sodium is low, the melting range is wide, the solution viscosity is reduced slowly as the temperature rises, and the shrinkage of the glaze can be reduced; meanwhile, the mechanical properties, melting performance and thermal stability of the glaze layer are improved, and the dilatation coefficient of the glaze can be reduced to prevent crazing; and in addition, the elasticity of the glaze is improved, the glossiness of the glaze layer is improved, the surface tension of the glaze is reduced and the generation of the intermediate layer is promoted.

Owner:福建省德化县科力陶瓷厂

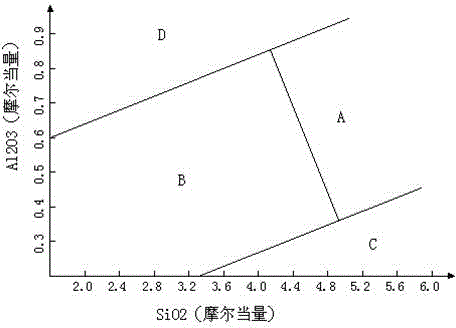

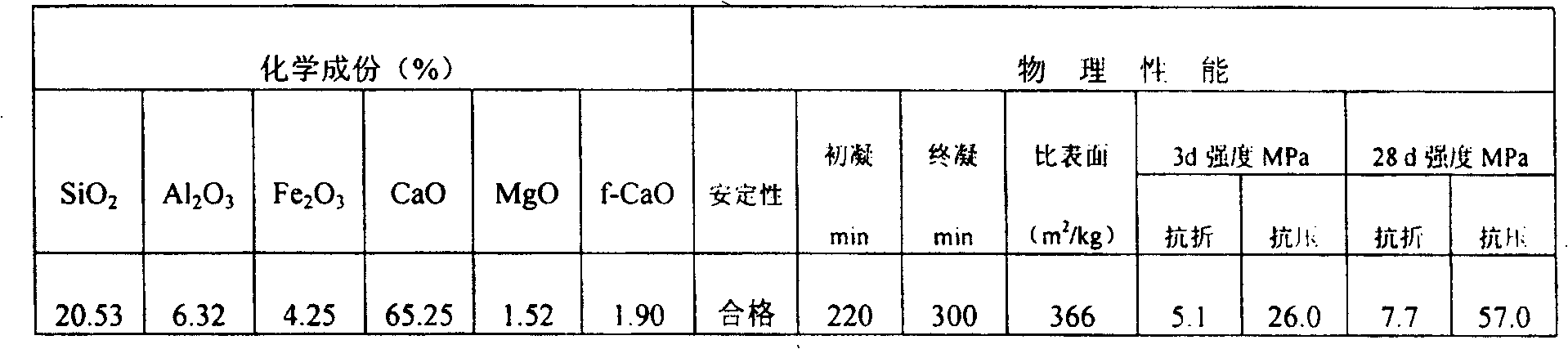

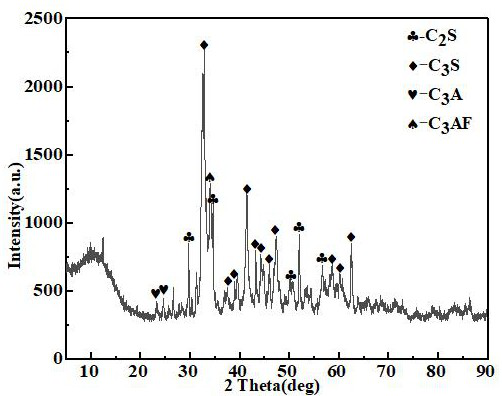

Preparation method of radiation-proof cement clinker mineral phase system

The invention discloses a preparation method of a radiation-proof cement clinker mineral phase system, which comprises the following steps of: (1) raw material preparation: raw materials are uniformly mixed according to a ratio, and are ground until the amount of residues on a 180-mesh square hole sieve is less than or equal to 10%; and (2) high temperature sintering: the ground powder in the step 1 is pressed into cylindrical test pieces, and the cylindrical test pieces are placed in a corundum crucible and are calcinated for 1 to 3 hours at a high temperature in a reheating test furnace to obtain the desired mineral phase system. The raw materials are calcium carbonate, alumina, and boron oxide, or calcium carbonate, alumina, boron oxide, and iron oxide. Through the mineral phase systemprepared by the preparation method disclosed by the invention, neutrons can be absorbed, the heat consumption of a cement clinker preparation process is reduced, the normal setting and hardening of cement are promoted, the strength of cement is improved, the mass concrete cracks can be inhibited, and the durability of concrete is improved. The method provided by the invention is simple in process, is easy to control and adapts to large-scale industrial production.

Owner:湖北湖大天沭新能源材料工业研究设计院有限公司

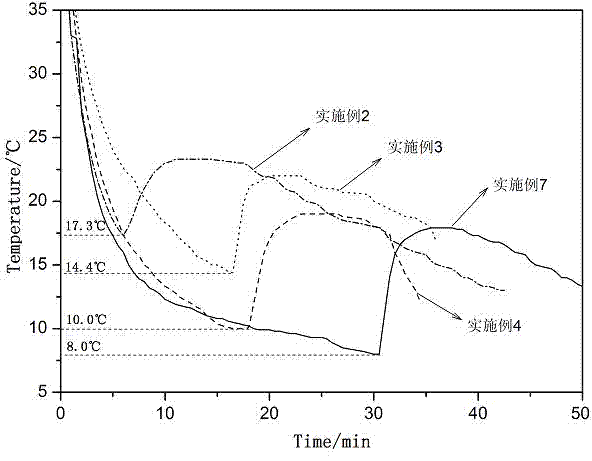

Phase change energy storage material for heat preservation at night and preparation method

InactiveCN103205242ALower eutectic pointLower melting temperatureHeat-exchange elementsCalcium Chloride HexahydrateMagnesium chloride hexahydrate

The invention relates to a phase change energy storage material for heat preservation at night. The medium consists of a CaC12-MgCl2-H2O water salt system and a nucleating agent; the CaC12-MgCl2-H2O water salt system consists of 80-95 % of calcium chloride hexahydrate, 1-7 % of magnesium chloride hexahydrate and 3-15 % of deionized water by mass; and the content of the nucleating agent is 0.5-2.0 % of the total amount of the CaC12-MgCl2-H2O water salt system. The phase change energy storage material has the advantages of high phase change latent heat, relatively low melting temperature and adjustable solidification temperature, can be used for avoiding the phase separation phenomenon, and can be applied to different seasons and different regions.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

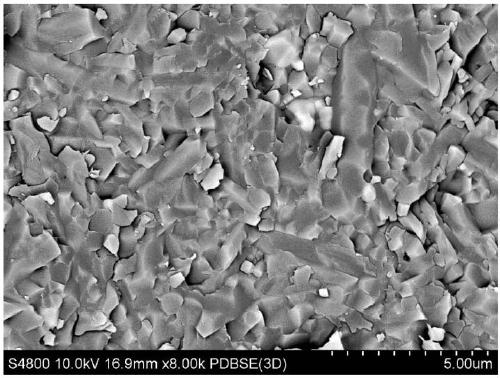

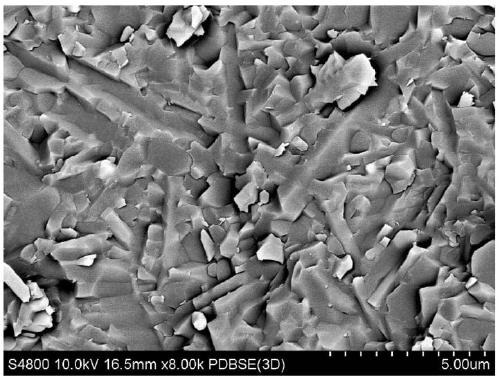

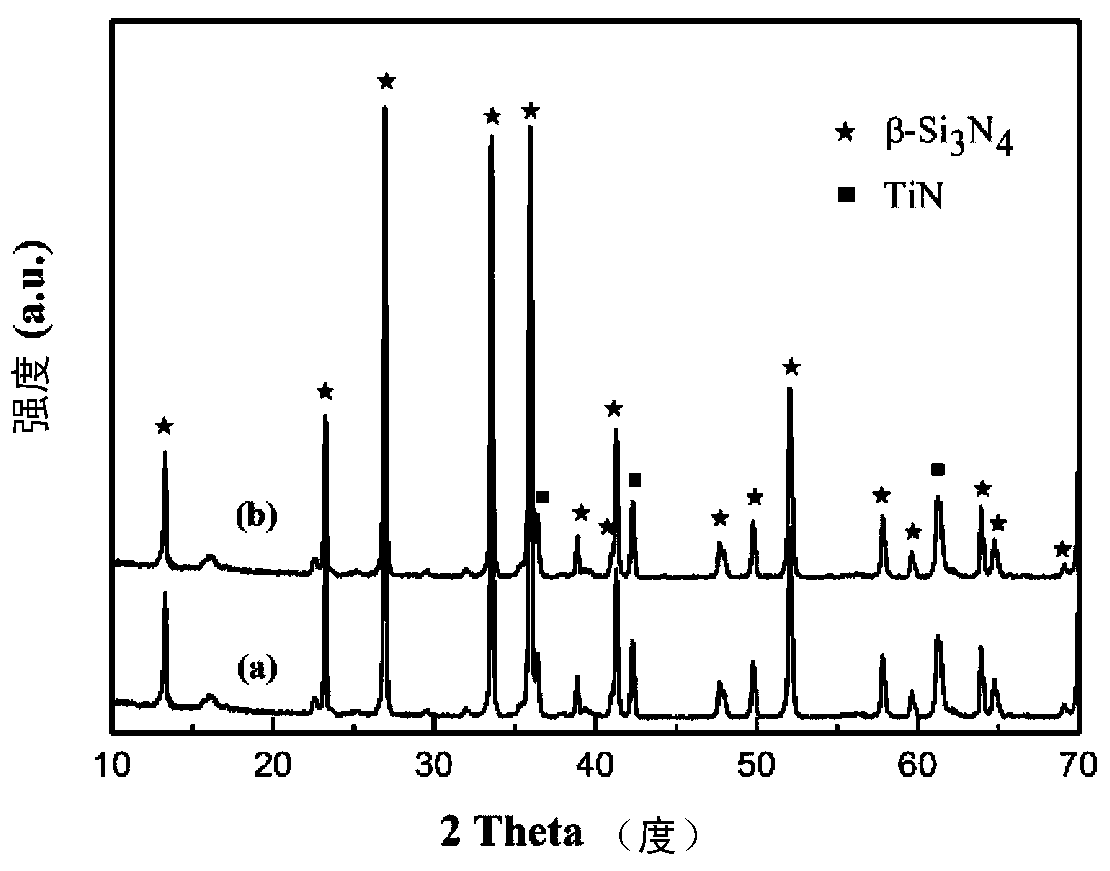

Method for preparing high-heat-conductivity silicon nitride ceramic through normal pressure sintering

The invention relates to a method for preparing high-heat-conductivity silicon nitride ceramic through normal pressure sintering. The method includes the steps that with the total material mass being100%, 95-70% of silicon nitride powder and 5-30% of sintering aids are evenly mixed to obtain ceramic mixed powder, and the sintering aids are a mixture with TiO2 as a main sintering aid and at leastone of Y2O3, Sc2O3, Sm2O3, Lu2O3, Er2O3, MgO, Mg2Si and MgSiN2 as an auxiliary sintering aid; the obtained ceramic mixed powder is molded to obtain a ceramic biscuit; the obtained ceramic biscuit is subjected to normal pressure sintering under 1600-1800 DEG C, so that dense silicon nitride ceramic is obtained. The method can be used for obtaining the dense silicon nitride ceramic with a certain heat conductivity level and excellent mechanical properties.

Owner:浙江多面体新材料有限公司

Preparation method of jade cracked ice glazed porcelain

InactiveCN107417110ASoft glaze lusterJade texture effect is goodCeramic materials productionClaywaresCeramic glazeWollastonite

The invention discloses a preparation method of jade cracked ice glazed porcelain. The preparation method comprises the steps of preparing a biscuit of the porcelain, applying glaze of 0.8-2mm to the surface of the biscuit to make a green body, and firing the green body to prepare the porcelain. The following raw materials of the glaze are added according to parts by weight: 70-80 parts of anorthite, 15-20 parts of barium carbonate, 0-0.5 part of zinc oxide, 0-0.5 part of zirconium oxide, 5-10 parts of wollastonite, 10-15 parts of boron oxide, 20-30 parts of neodymium oxide, 0-1 part of white mica and 5-10 parts of titanium stones. In the preparation method, the expansion coefficient of a glaze layer is greater than the coefficient of thermal expansion of the biscuit and in the firing process, as the expansion coefficients are different, the tensile stress of the porcelain occurs, the glaze splits and cracks are formed; meanwhile, the glaze layer can generate silicate neodymium crystals, so that small crystal patterns show up in the ice cracks, and therefore, the ornamental value is improved.

Owner:任合超

Production method of water-soluble fertilizer containing trace elements

The invention discloses a production method of a high-tower type water-soluble fertilizer containing trace elements. The production method comprises the steps: adding an ammonium nitrate raw material and ammonium phosphate salts into water, melting with the melting temperature of larger than or equal to 135 DEG C and less than 150 DEG C, then mixing the co-molten material slurry after melting with fertilizers needed for production of the compound fertilizer, adding water-soluble trace element-containing compounds, after uniformly mixing, emulsifying to form an emulsion material slurry, granulating, and cooling to obtain the water-soluble fertilizer. The content of zinc is controlled in 500-700 ppm. The water-soluble fertilizer produced by the method has the advantages of uniform nutrients, smooth and round appearance, rapid dissolving speed and good water solubility, and allows water insoluble substances to be within 3.0%. The production method belongs to a novel, environmental-protection and low-energy-consumption production method for high-tower production of particle water-soluble fertilizers.

Owner:GUIGANG BATIAN ECOLOGY

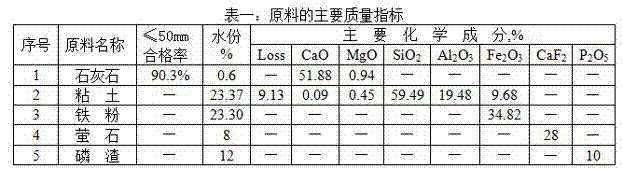

Novel energy-saving consumption-reducing dry-process cement clinker and preparation method thereof

The invention discloses a novel energy-saving consumption-reducing dry-process cement clinker. The cement clinker is prepared from a raw material through sintering, wherein the raw material is mainly composed of limestone, an argillaceous material and a ferruginous material. The cement clinker is characterized in that the silica modulus of the cement clinker is no more than 2.1, the aluminum-oxygen modulus of the cement clinker is no less than 1.2 and less than 1.4, and a saturation ratio is 0.86 to 0.96. The invention also discloses a preparation method for the cement clinker. The cement clinker enables coal consumption in preparation of the clinker to be effectively reduced and has performance equivalent to performance of conventional cement clinker.

Owner:胡长庚

High-voltage porcelain insulating semiconductor glaze

The invention relates to the technical field of semiconductor glaze, and in particular relates to a high-voltage porcelain insulating semiconductor glaze. The semiconductor glaze is prepared from the following components in parts by weight: 25-35 parts of high-potassium and low-iron feldspar, 8-14 parts of mud, 4-10 parts of Dongsheng soil, 1-4 parts of calcined talc, 20-30 parts of quartz powder, 2-4 parts of barium carbonate, 12-18 parts of iron oxide red, 1-3 parts of chrome oxide green, 9-12 parts of titanium dioxide and 1-2 parts of spodumene. The semiconductor glaze is high in structure stability, fine in surface and glossy in surface, the eutectic point is reduced, and the melting efficiency is improved; and meanwhile, the combining capacity of the semiconductor glaze after being glazed is improved by adopting the Dongsheng soil and mud.

Owner:CHONGQING PIGEON ELECTRIC PORCELAIN CO LTD

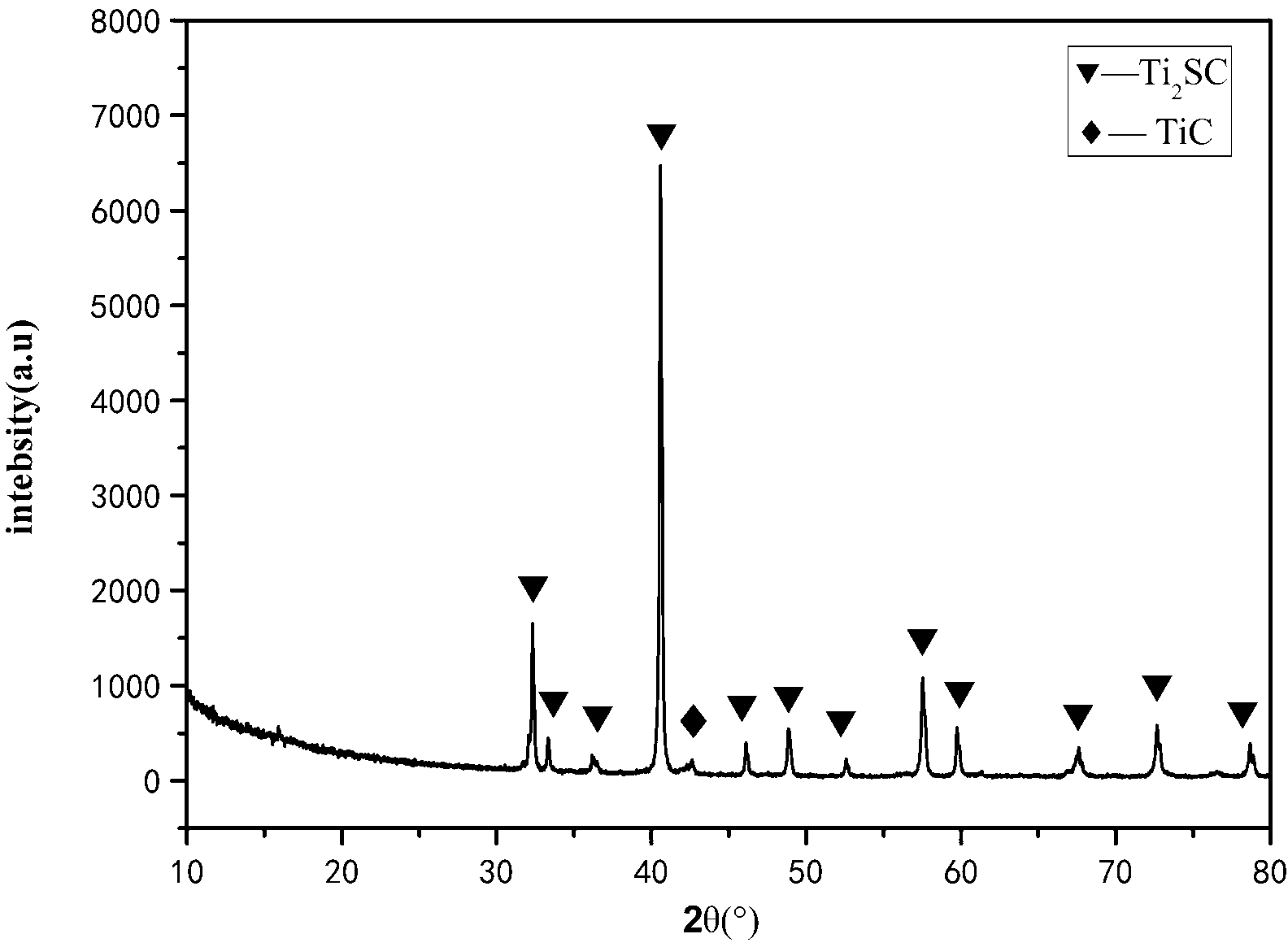

Preparation method of ternary layered carbide Ti2SC (titanium sulfur carbide) material

InactiveCN103253667ALower eutectic pointSynthesis temperature is lowOxy/sulfo carbidesAl powderCarbide

The invention relates to a preparation method of a ternary layered carbide Ti2SC (titanium sulfur carbide) material. Al (aluminum) is used as an assistant, and a high-temperature high-pressure synthesis method is used for preparing a compact Ti2SC material. Raw materials include Ti (titanium) powder, S (sulfur) powder, C (carbon) powder and Al powder, and the mol ratio of the four raw materials is as follows: Ti: S: C: Al=2: (1-1.4): 1: (0.1-0.2). The Ti2SC block material synthesized by the method is compact in structure, and the content of Ti2SC is more than 80 percent by weight; Al is used as the assistant, so that the melting point can be lowered; and by adopting the high-temperature high-pressure sintering method, the volatilization of the S powder can be maximally inhibited, and the Ti2SC material can be rapidly sintered and synthesized.

Owner:WUHAN UNIV OF TECH

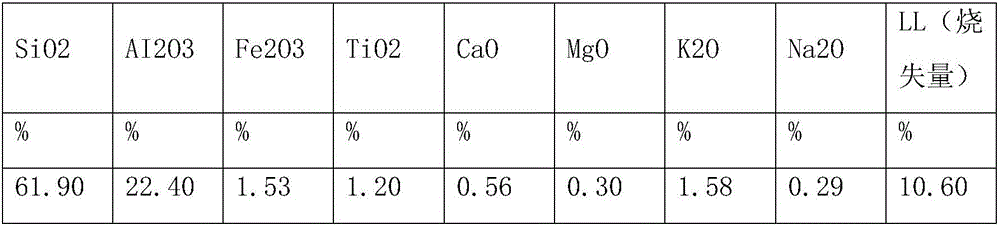

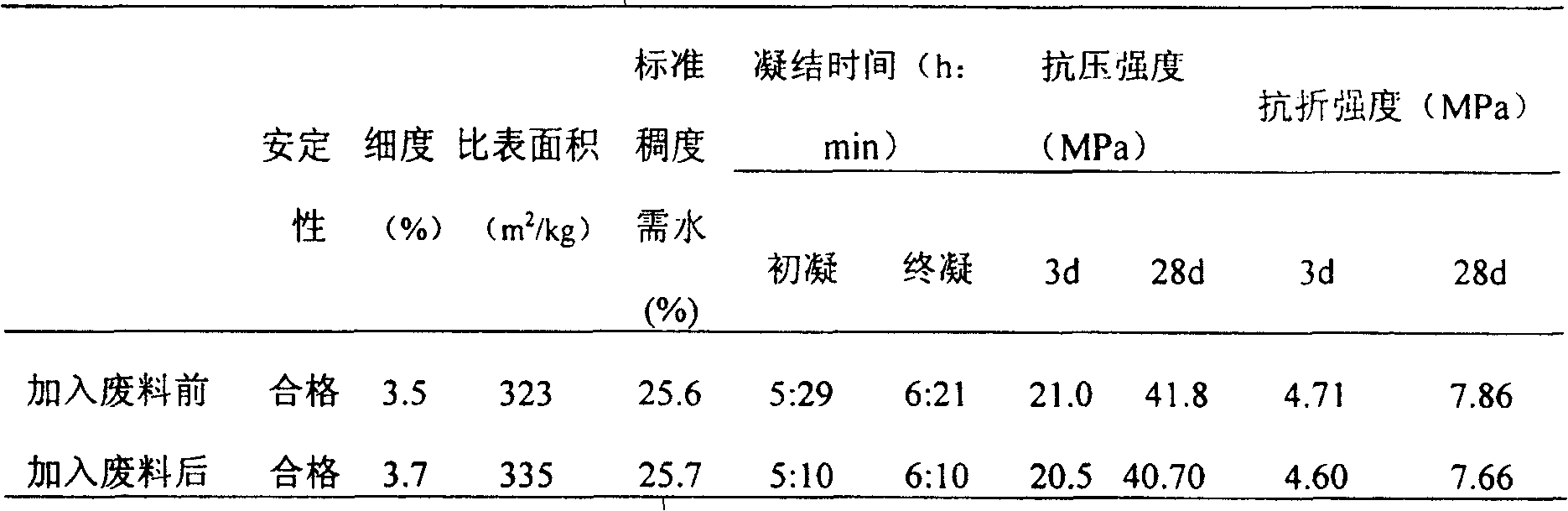

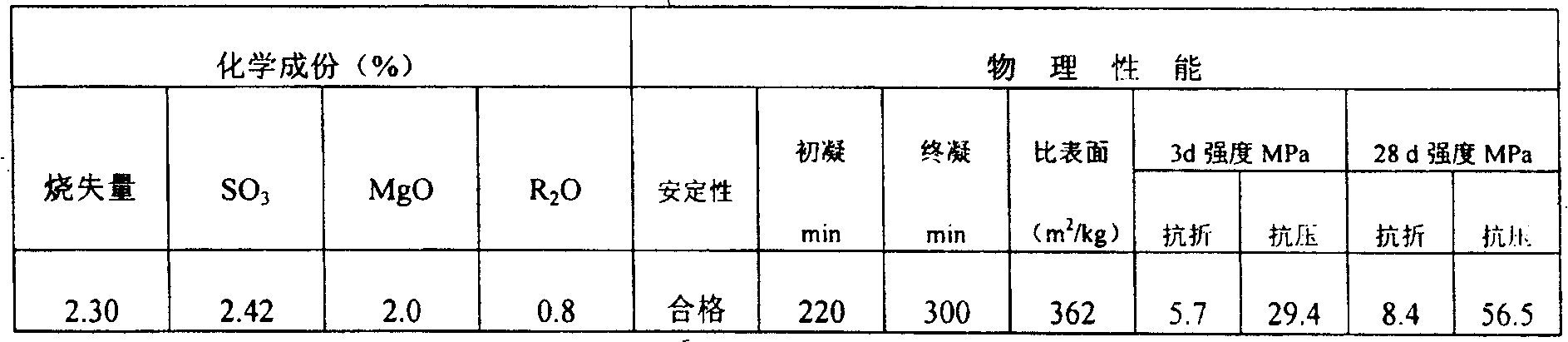

Process of preparing portland cement with waste ceramic tile polishing material

InactiveCN100412020CNo harmful effects on product qualityIncrease productionCement productionPortland cementSlag

The present invention discloses process of preparing Portland cement with waste ceramic tile polishing material. Portland cement clinker in 77-84 wt%, setting retarder gypsum in 3-6 wt% and mixed material in 10-20 wt% are mixed and ball milled in a ball mill to form Portland cement of specific surface area 350 sq m / kg, where the mixed material comprising waste ceramic tile polishing material of 3-6 wt%, mineral slag of 4-8 wt% and flyash of 3-6 wt%. Using waste ceramic tile polishing material as partial material for Portland cement can dispose waste, save resource and raise production efficiency.

Owner:SOUTH CHINA UNIV OF TECH

Low-dielectric wollastonite series low-temperature co-fired ceramic material and preparation method thereof

ActiveCN114573333AComposition controllableImprove cooling effectCeramic materials productionWollastoniteMillimetre wave

The invention discloses a low-dielectric wollastonite series low-temperature co-fired ceramic material and a preparation method thereof, and relates to the technical field of electronic materials. The formula of the ceramic material comprises the following components: CaxSiO3, awt% of SiO2, bwt% of R2O, cwt% of Bi2O3, dwt% of B2O3 and ewt% of MO, wherein x is more than or equal to 0.9 and less than or equal to 1.1, 0lt A < = 30, 1 < = b < = 5, 0lt; c < = 3, 0lt; d < = 6, 0 < = e < = 10; r2O is at least one of Li2O and K2O; and MO is one or more of ZnO, MgO, BaO, CoO, CuO, La2O3 and MnO2. The low-temperature co-fired ceramic material provided by the invention meets the requirements of low dielectric, low loss and low-temperature sintering, and can be applied to the fields of millimeter wave LTCC devices and the like.

Owner:JIAXING GLEAD ELECTRONICS CO LTD

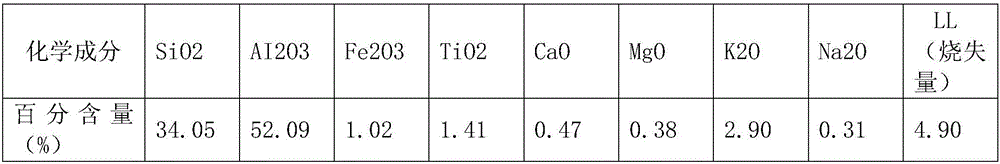

Preparation method of boron mud based sintered brick

InactiveCN108178614AFacilitated DiffusionPlay a role in burningCeramic materials productionClaywaresBrickSlag

The invention discloses a preparation method of a boron mud-based sintered brick, and belongs to the technical field of building materials. Steel slag and kerosene are firstly mixed, ball-milled, andburnt in pure oxygen, and combustion residue is collected; boron mud, magnesia, fly ash, water, a nutrient solution and Bacillus bacillus are mixed for fermentation to obtain fermented homogenate, thecombustion residue, a rare earth oxide, boron oxide, the fermented homogenate, carbon black and a catalyst are ball-milled and mixed to obtain a ball abrasive, and the ball abrasive is extruded, molded, dried at a low temperature, sintered twice in an argon gas protected state at different temperature conditions, cooled in a furnace to room temperature, and discharged to obtain the boron mud-based sintered brick. The boron mud-based sintered brick obtained by the method has excellent mechanical properties.

Owner:周荣

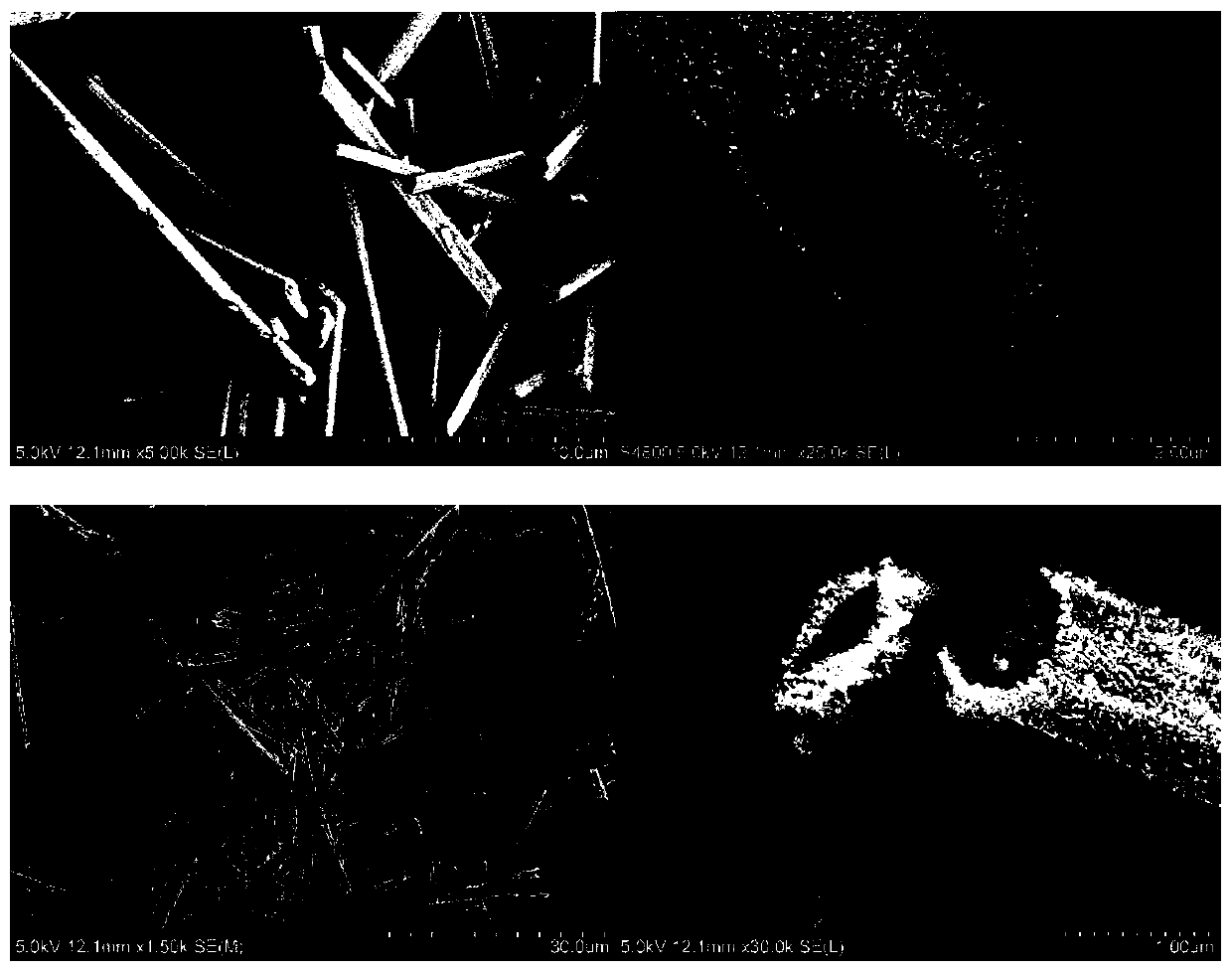

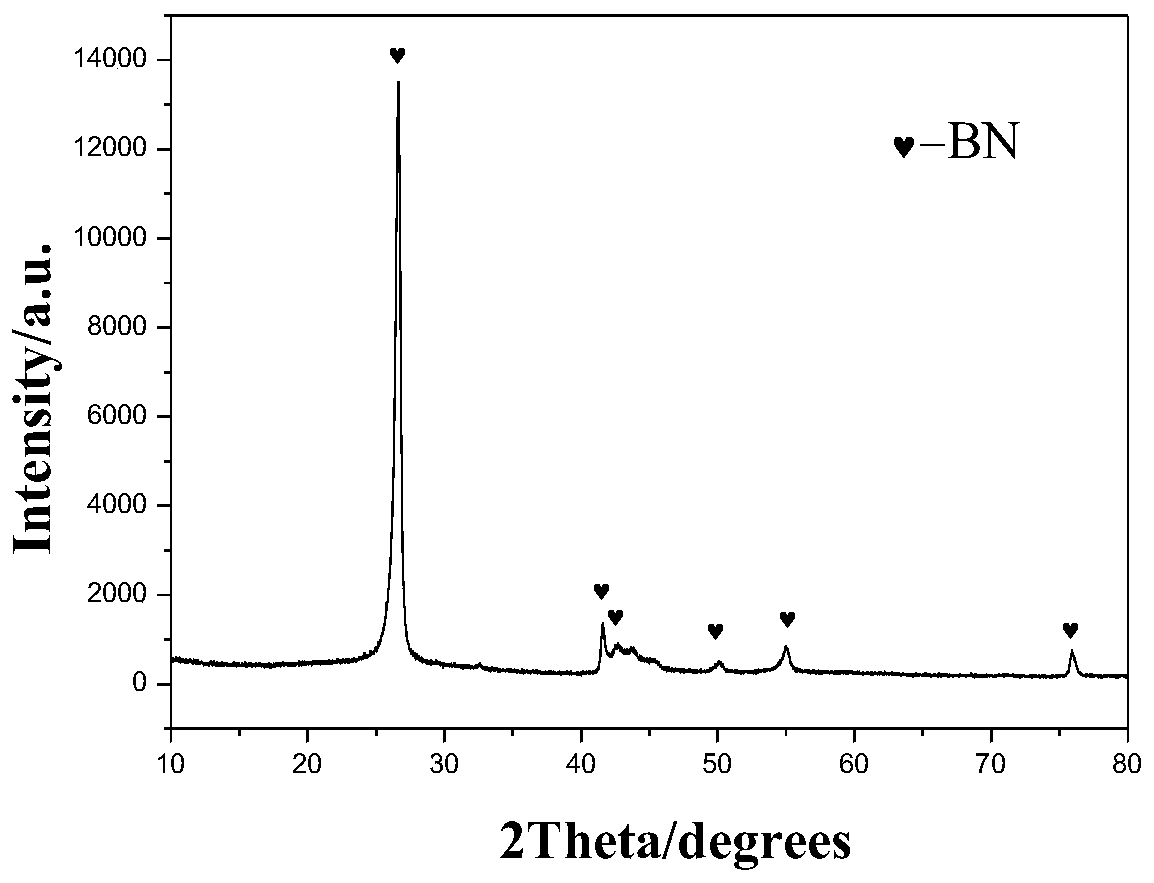

Preparation method of one-dimensional hierarchical-structure thin-wall BN microtube, and product thereof

ActiveCN110817814AHigh purityFacilitate large-scale industrial productionMaterial nanotechnologyPhysical/chemical process catalystsTube furnaceBoron containing

The invention relates to a preparation method of a hierarchical-structure thin-wall BN microtube. The preparation method mainly comprises the following steps: putting a boron-containing precursor intoa tube furnace, introducing nitriding reaction gas, carrying out heating to 1000-1200 DEG C, and keeping the temperature for 2 hours or more to obtain a large batch of high-quality one-dimensional boron nitride hierarchical-structure materials. According to the method, a substrate is not needed; the preparation method is simple and effective in process and low in energy consumption and uses cheapand non-toxic raw materials; and the purity of a purified target product is high, which is favorable for batch production of the boron nitride micro-nano hierarchical structure materials.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

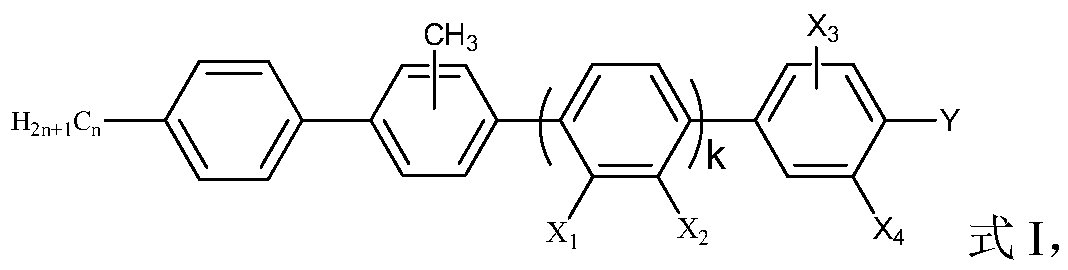

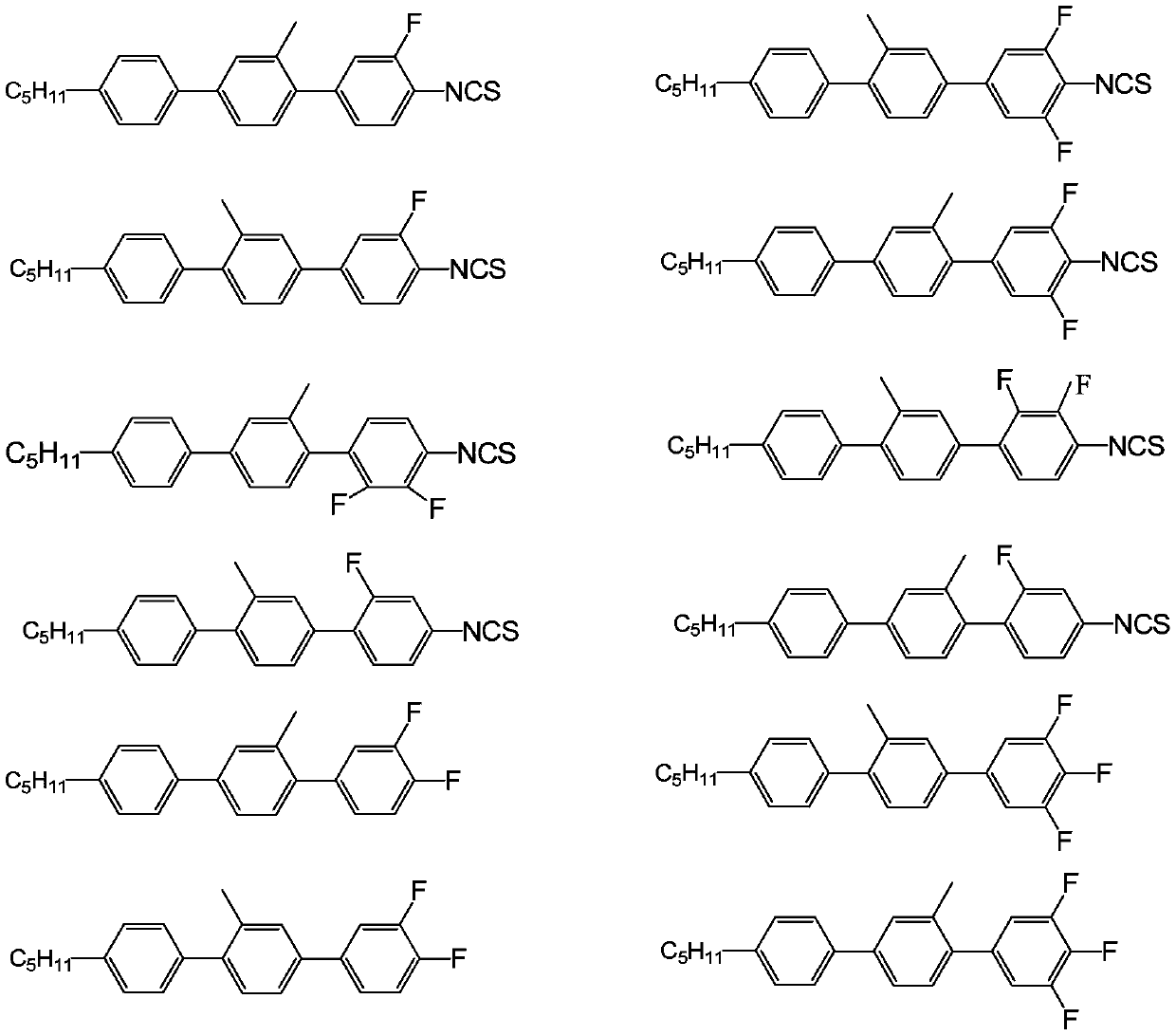

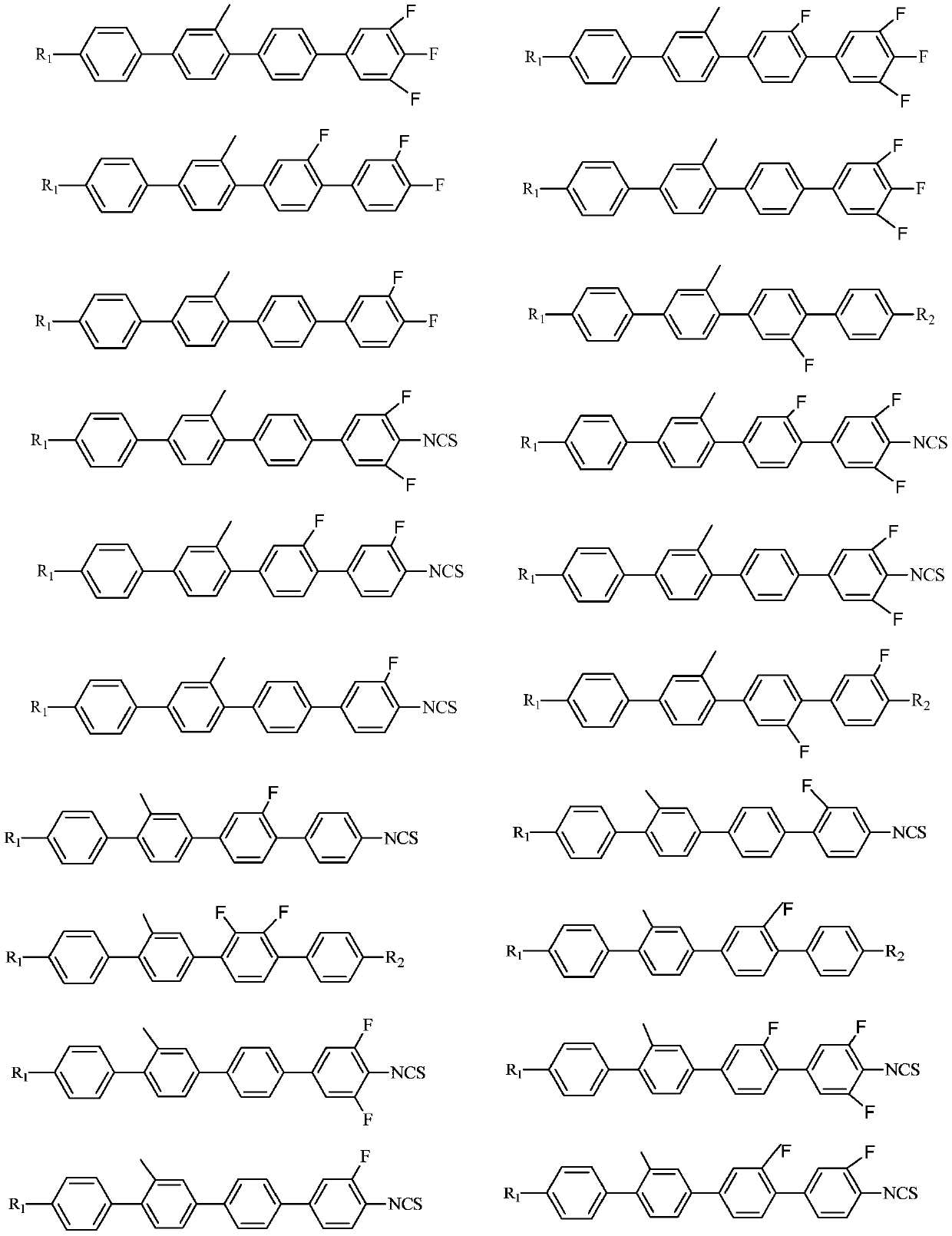

Side methyl polybiphenyl liquid crystal compound, liquid crystal composition and application of composition

ActiveCN110760311ALow melting pointLower eutectic pointLiquid crystal compositionsWaveguide type devicesCrystallographyPhysical chemistry

The invention discloses a side methyl polybiphenyl liquid crystal compound, a liquid crystal composition and an application of the composition. A structure of the liquid crystal compound is represented by a formula I shown in the specification, wherein n is an integer of 1 to 7; X1 to X4 are each independently selected from a H atom, a F atom or a Cl atom; k is 0 or 1; Y is NCS, a F atom or an R group; and R is one selected from the group consisting of a straight-chain alkyl group containing 1-6 carbon atoms, an alkenyl-contained straight-chain alkyl group containing 1-6 carbon atoms, and a straight-chain alkyl group containing 1-6 carbon atoms, wherein the a H atom on the alkyl chain of the straight-chain alkyl group is replaced by 1-2 fluorine atoms or one methyl. The compound provided by the invention and other materials are mixed to prepare the liquid crystal composition material with a <delta>n value of greater than 0.35, the microwave phase modulation amount is improved, and themicrowave wave frequency insertion loss amount is reduced.

Owner:WUHAN POLYTECHNIC UNIVERSITY

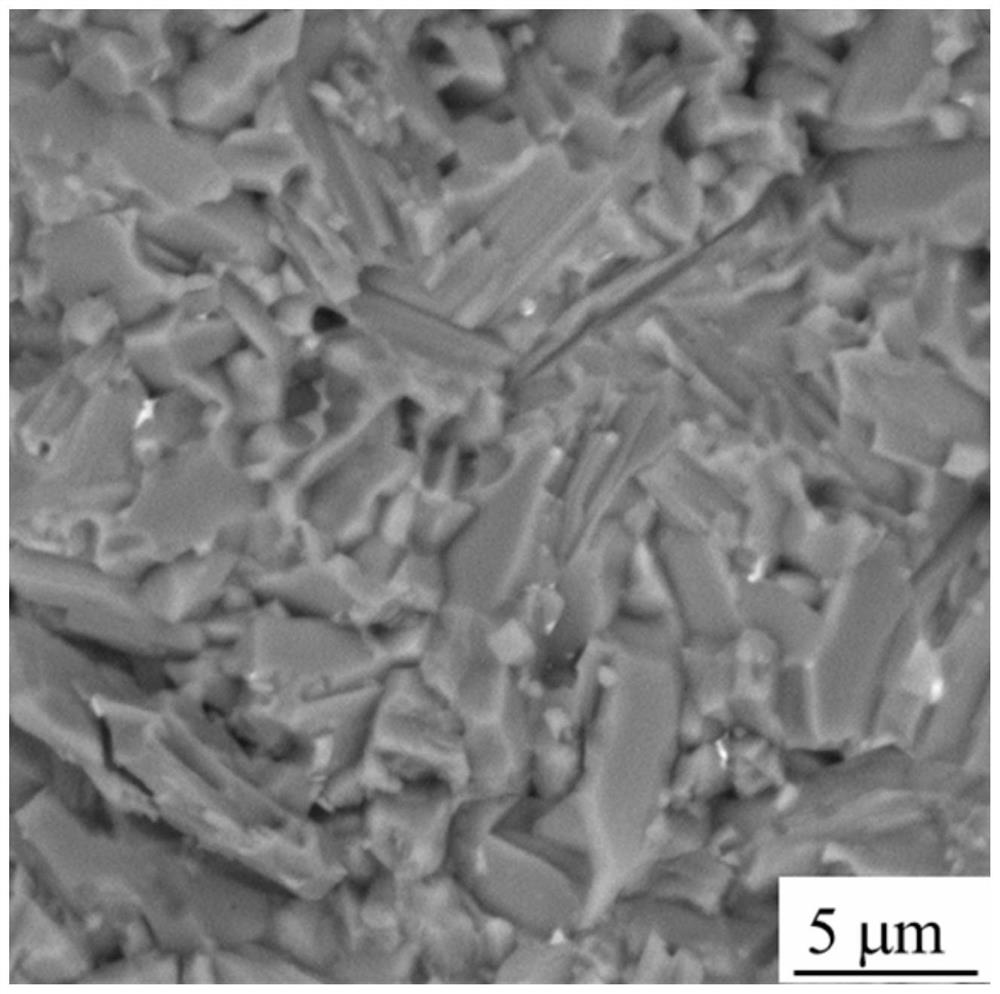

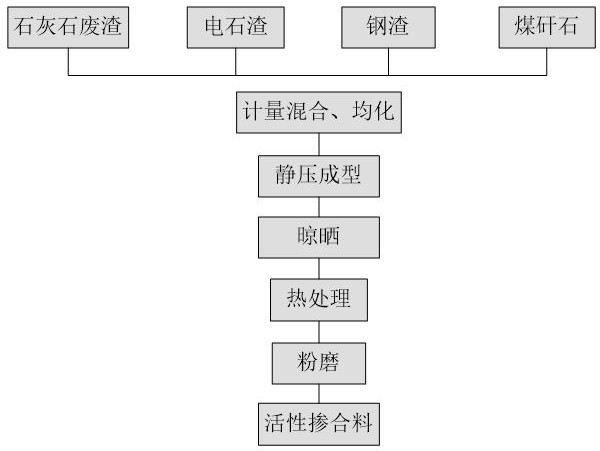

Active admixture and preparation method thereof

The invention relates to an active admixture and a preparation method thereof, and belongs to the technical field of building material production and the technical field of industrial solid waste resource utilization. The active admixture is prepared from the following raw materials in percentage by mass through crushing, mixing, profiling, heat treatment and grinding. The active admixture comprises the following components in percentage by weight: 45-60 wt% of limestone waste residue, 5-10 wt% of carbide slag, 10-20 wt% of steel slag, and 20-30 wt% of coal gangue. According to the active admixture prepared by the method, solid waste is used as a raw material, steel slag is used as a mineralizer, carbide slag slurry is used as an adhesive, a mineralizer and an adhesive do not need to be additionally added, and the product performance is stable. Meanwhile, the medium heat activation temperature is low, the production cost is low, the process is simple, and high economic benefits are achieved.

Owner:KUNMING UNIV OF SCI & TECH +1

High voltage porcelain insulating semiconductor glaze

The invention relates to the technical field of semiconductor glaze, and in particular relates to a high-voltage porcelain insulating semiconductor glaze. The semiconductor glaze is prepared from the following components in parts by weight: 25-35 parts of high-potassium and low-iron feldspar, 8-14 parts of mud, 4-10 parts of Dongsheng soil, 1-4 parts of calcined talc, 20-30 parts of quartz powder, 2-4 parts of barium carbonate, 12-18 parts of iron oxide red, 1-3 parts of chrome oxide green, 9-12 parts of titanium dioxide and 1-2 parts of spodumene. The semiconductor glaze is high in structure stability, fine in surface and glossy in surface, the eutectic point is reduced, and the melting efficiency is improved; and meanwhile, the combining capacity of the semiconductor glaze after being glazed is improved by adopting the Dongsheng soil and mud.

Owner:CHONGQING PIGEON ELECTRIC PORCELAIN CO LTD

Ladle filter sand

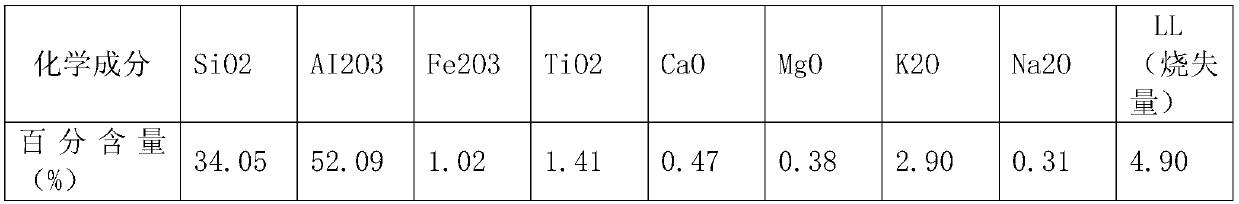

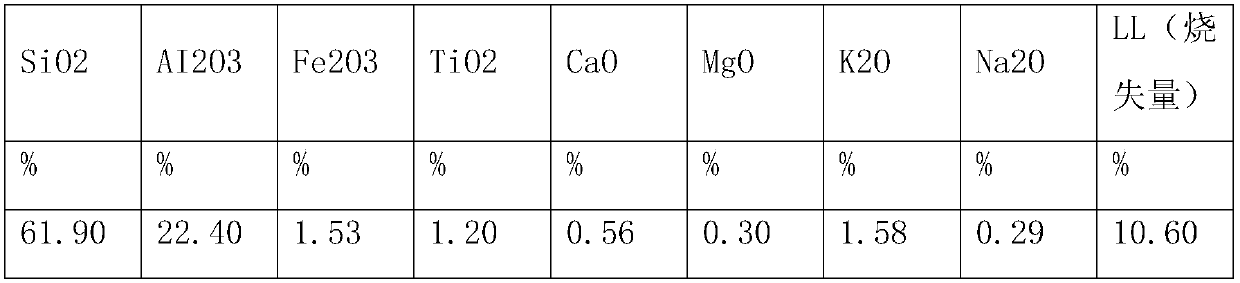

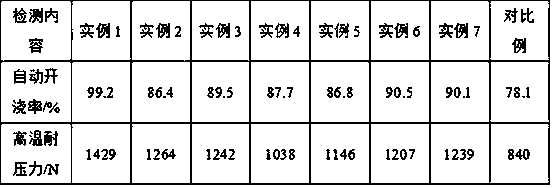

The invention discloses a ladle filter sand, and belongs to the technical field of metallurgical assistants. The ladle filter sand developed in the invention comprises kyanite, bauxite, feldspar, micapowder, a charred rice husk material, Al8B4C7, magnesia and mirabilite. The raw materials are mixed, undergo ball-milling, and then are sieved to obtain the ladle filter sand. The charred risk husk material is obtained through the following steps: mixing rice husks with nano-iron powder, transferring the obtained mixture into a carbonizing furnace, performing heat insulation carbonization in an argon gas protection state for 2-4 h, continuously heating the carbonizing furnace, performing a high temperature reaction, performing furnace cooling to room temperature, pickling the obtained reaction product, and drying the pickled reaction product. The ladle filter sand obtained in the invention has the advantages of excellent automatic casting ratio and excellent resistance to high temperature.

Owner:郭舒洋

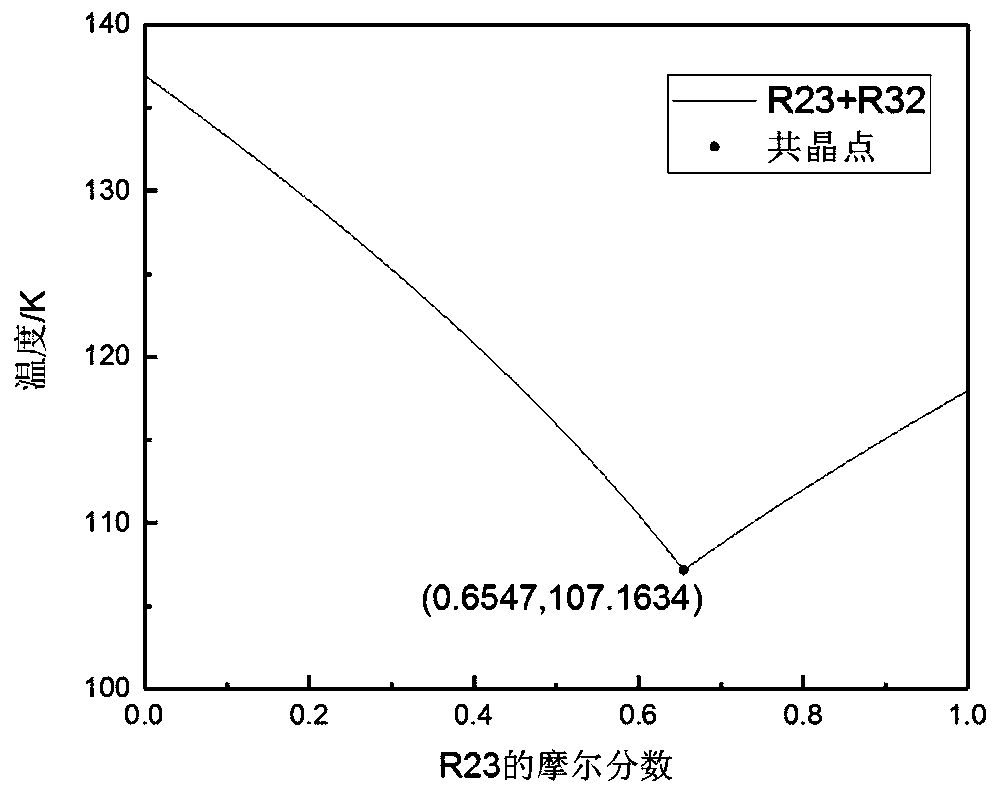

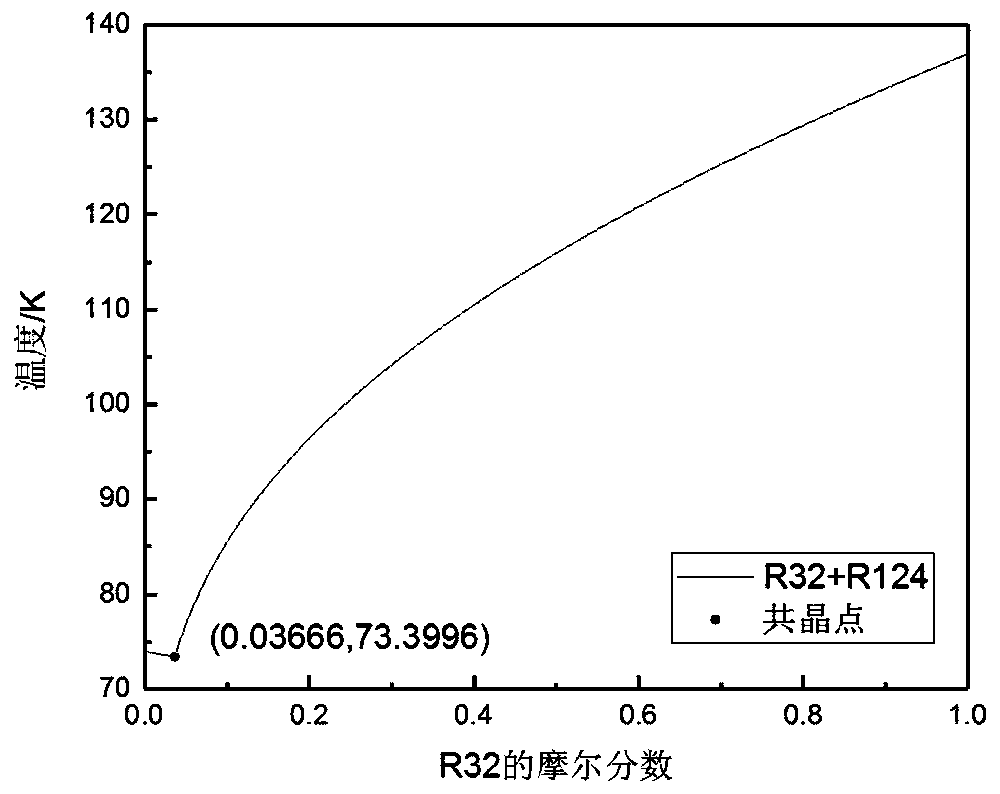

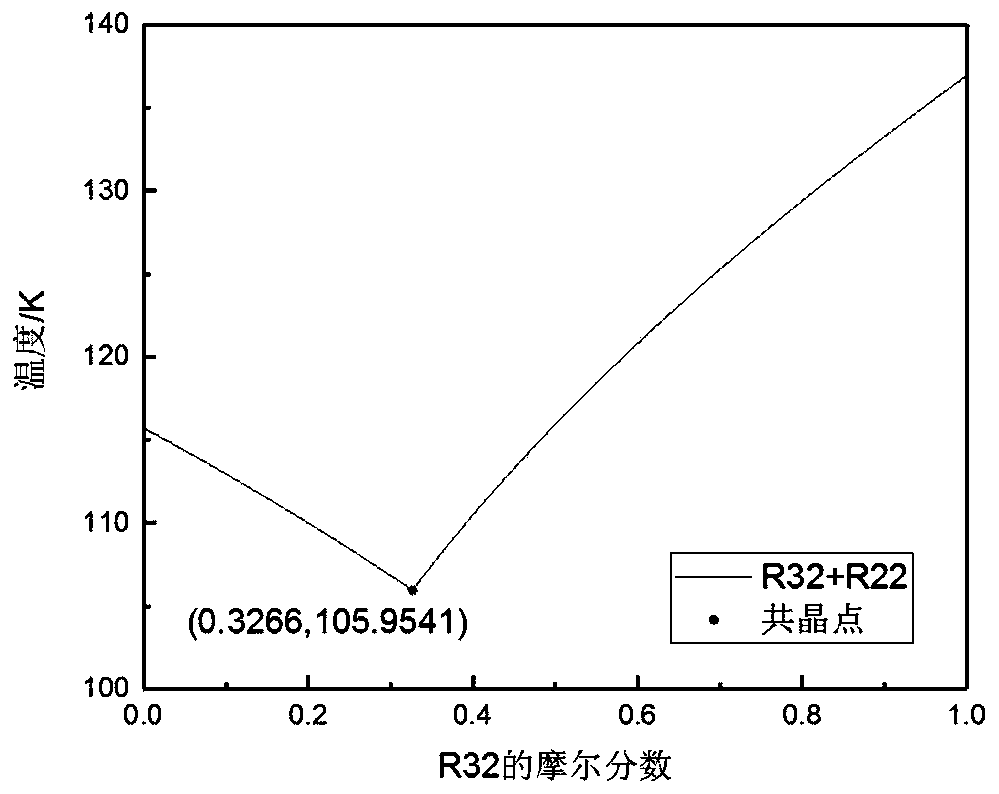

Mixed non-combustible cold storage medium

The invention provides a mixed non-combustible cold storage medium, comprising at least two of carbon trifluoride, carbon difluoride, trifluoroiodomethane, difluorochloromethane, 2-chloro-1,1,1,2-tetrafluoroethane, methylfluoride, perfluoropropane and carbon tetrafluoride. According to the multi-component non-combustible cold storage medium provided by the invention, two or more non-combustible working media are mixed, so that the defects that an existing liquefied air energy storage medium is relatively high in freezing point, has flammability and the like are overcome. Besides, the mixed non-combustible cold storage medium provided by the invention can also comprise one or more of dichlorodifluoromethane, chlorotrifluoromethane and monochlorodifluoromethane according to different use temperatures, so that the eutectic temperature point of the energy storage medium is further reduced.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

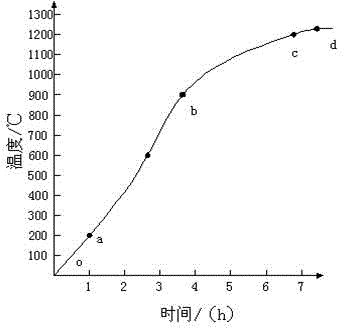

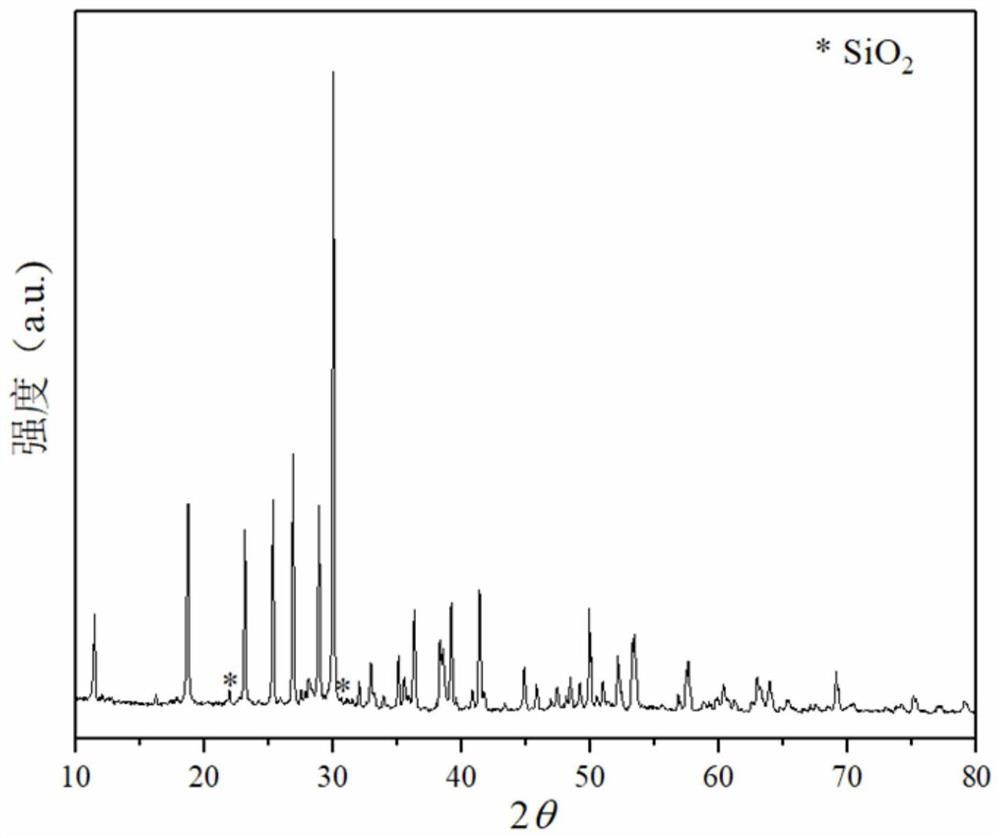

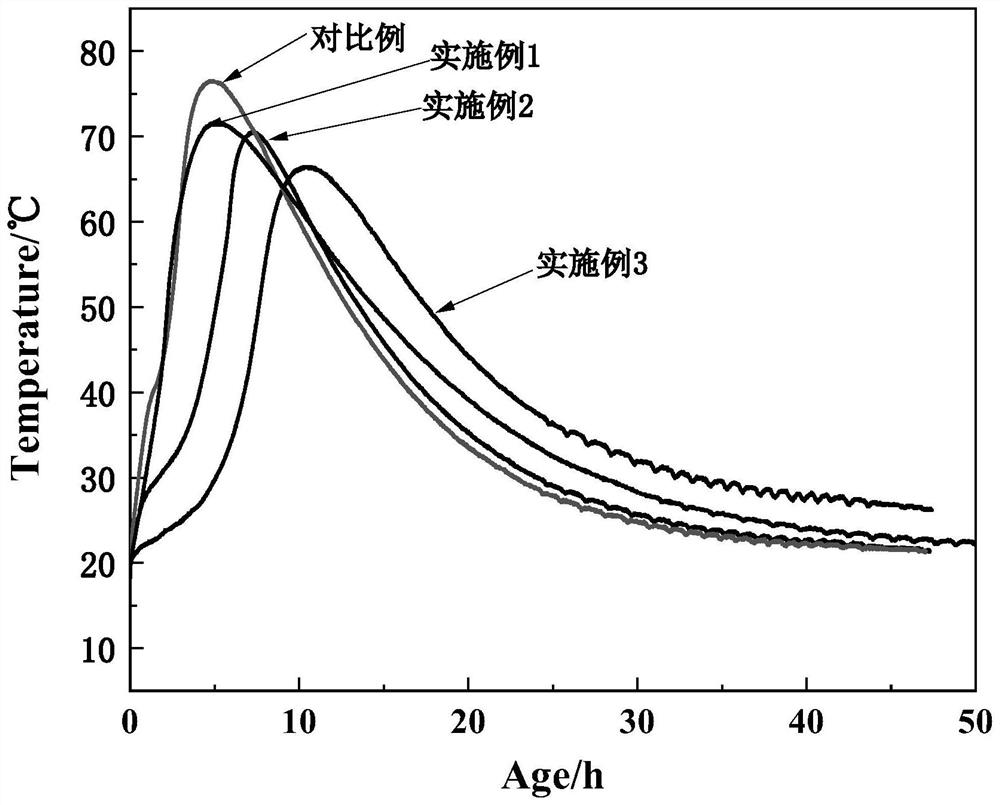

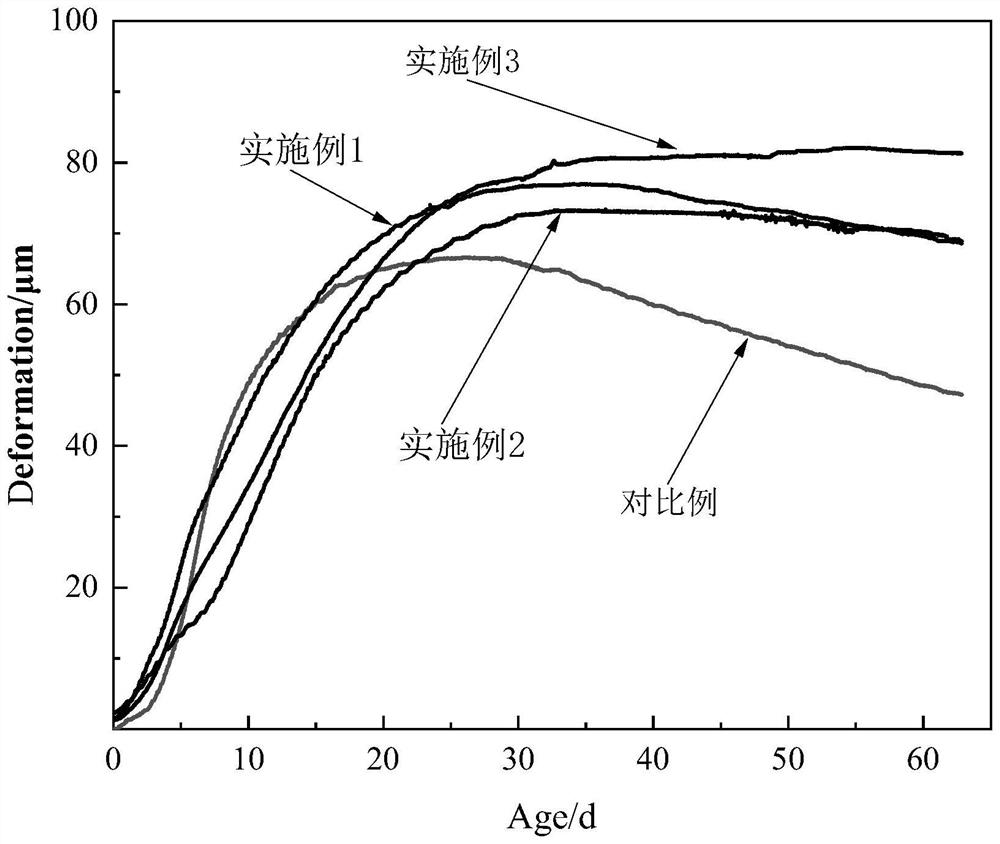

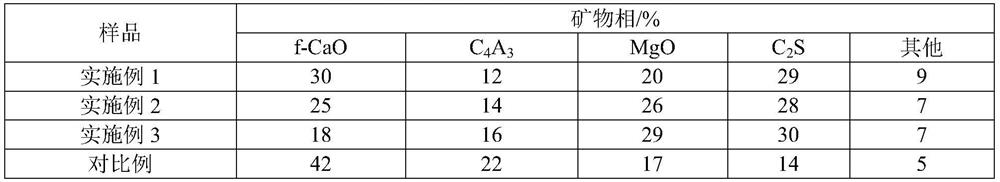

Multi-component composite reinforced anti-cracking agent for concrete and preparation method of multi-component composite reinforced anti-cracking agent

ActiveCN114477829AReduce the rate of hydrationLower eutectic pointSolid waste managementSlagPhosphogypsum

The invention discloses a multi-component composite reinforced anti-cracking agent for improving the anti-cracking performance of concrete and a preparation method of the multi-component composite reinforced anti-cracking agent. The anti-cracking agent is prepared from the following raw materials in parts by weight: 55-80 parts of dolomite, 1-5 parts of phosphogypsum, 0-5 parts of phosphorus slag, 10-15 parts of fly ash, 0-25 parts of limestone, 0.5-1 part of a hydration slow-release agent and 0.5-1.5 parts of a mineralizing agent. The preparation method comprises the following steps: uniformly mixing the raw materials, calcining at 1150-1300 DEG C for 60-90 minutes, quenching and cooling to below 400 DEG C, and grinding until the 80 mu m screen residue is less than or equal to 10%, thereby obtaining the multi-component composite reinforced anti-cracking agent finished product. The use amount of the anti-cracking agent in the concrete is 5-8% of the use amount of the cementing material. The multi-component composite reinforced anti-cracking agent disclosed by the invention has the advantages of low hydration heat release, long expansion lasting time, high concrete later strength and the like, and can be widely applied to concrete structures with high cracking risks, such as mass concrete, thin-wall structures, super-long structures and the like.

Owner:西安建祥建材科技有限公司

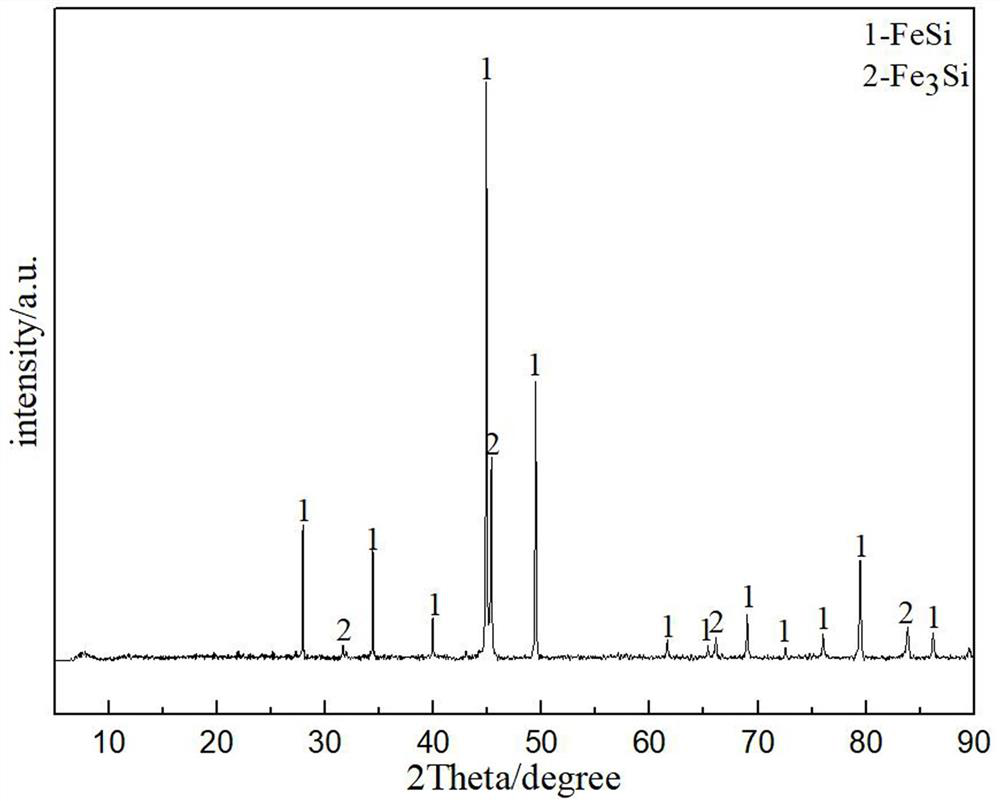

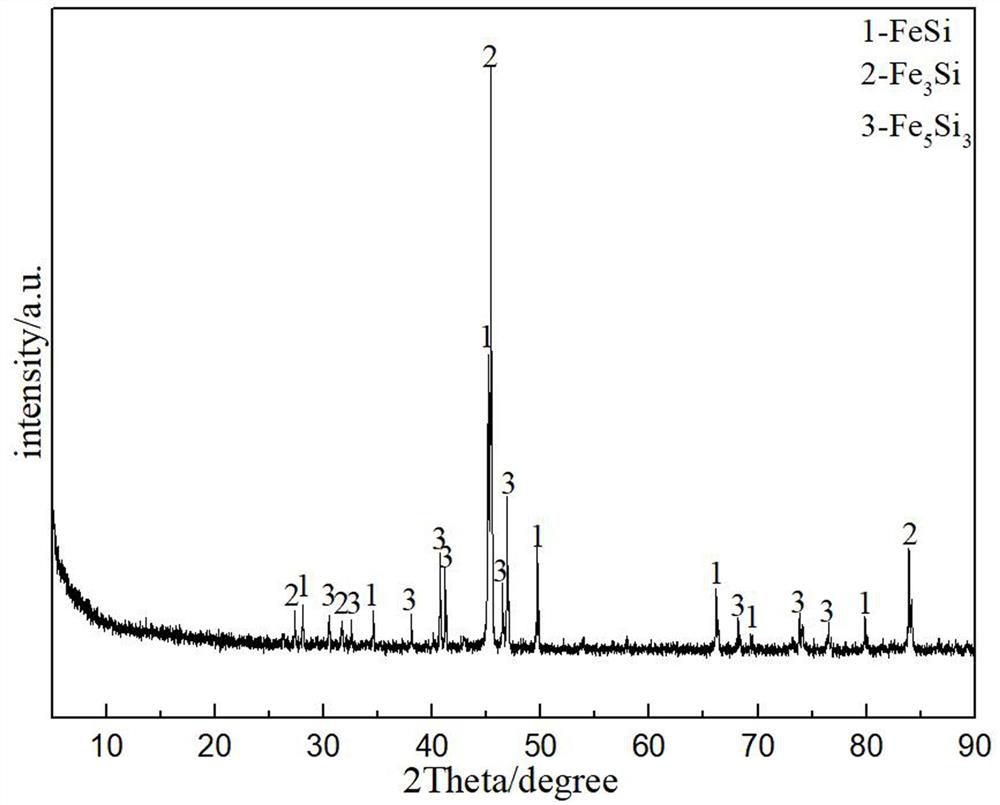

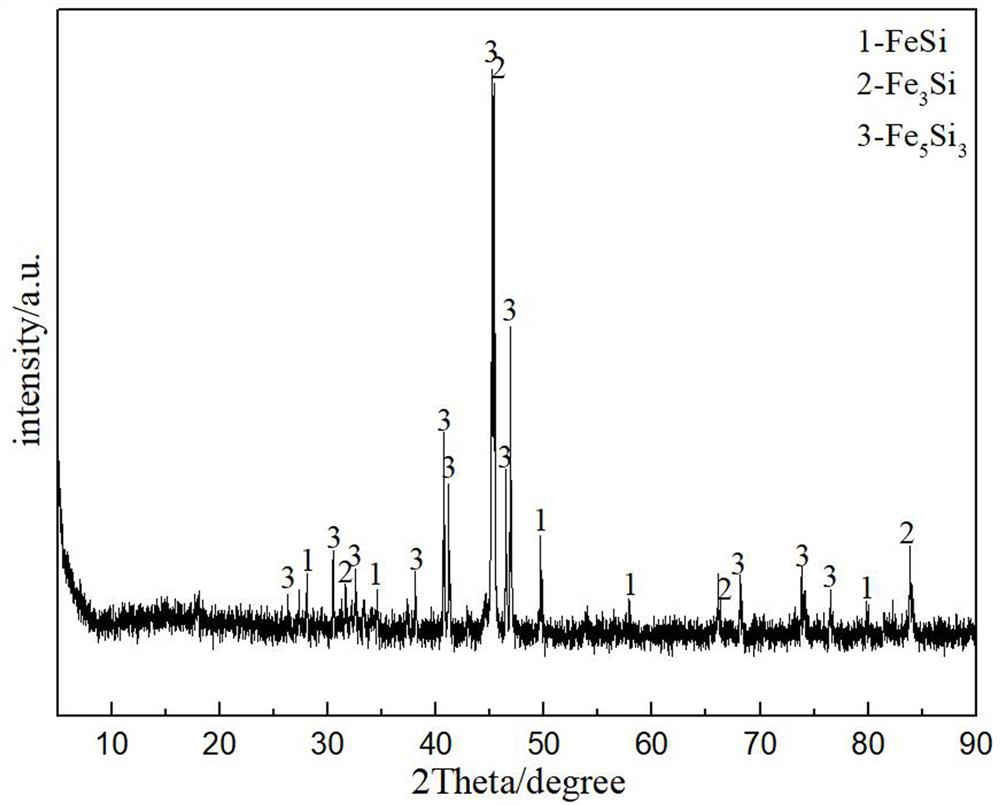

Method for preparing iron silicon from molten salt electric deoxidised copper slag

The invention belongs to the field of copper slag resource utilization, and discloses a method for preparing iron silicon from molten salt electric deoxidised copper slag. The method comprises the following steps of firstly, carrying out mechanical ball milling treatment on the copper slag to obtain copper slag powder; carrying out magnetic separation treatment on the copper slag powder to obtain magnetic separation tailings, pressing the magnetic separation tailings into sheets to prepare cathode sheets, and sintering the cathode sheets under the protection of inert gas; under the protection of the inert gas, enabling electrolyte to be pretreated to obtain molten salt electrolyte, and placing the cathode sheets in the molten salt electrolyte for electrolysis; and under the protection of the inert gas, taking out a cathode product after electrolysis, cooling to room temperature, washing, and carrying out vacuum drying to obtain an iron-silicon-based alloy. According to the method, comprehensive recycling of metal iron and silicon resources in the copper slag can be achieved, the operation process is simple, compared with the prior art, the recycling cost is reduced, no harmful gas is discharged, and the product purity is high.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Environment-friendly composite spheroidizing agent applied to thick and big ductile iron

The invention relates to an environment-friendly composite spheroidizing agent applied to thick and big ductile iron. The composite spheroidizing agent comprises, by weight, 78-90 parts of spheroidizing agents, 5-20 parts of melt-resisting agents, 1-5 parts of dreg removing agents, 2-8 parts of purifying agents, 1-6 parts of desulfurizing agents and 2-5 parts of nucleating agents. The spheroidizing agent has the advantages shown by rear earth and magnesium during spheroidizing, and overcomes the defects of the rear earth and the magnesium. The magnesium is a primary spheroidizing element according to its ratio in the composite spheroidizing agent, while the rare earth has a secondary assisted spheroidizing function. The composite spheroidizing agent has good effects in desulfurizing, deoxidizing, iron liquid purifying, interference element eliminating, eutectic point reducing and supercooling degree increasing, and has the following effects on the performance of the ductile iron: improving casting mobility, reducing temperature of iron liquid oxidation films, changing shrinkage characters of ductile iron, reducing shrinking and loosening, improving mechanical performance, refining graphite and improving abrasive resistance.

Owner:TIANJIN YUTIAN ALLOY MFG

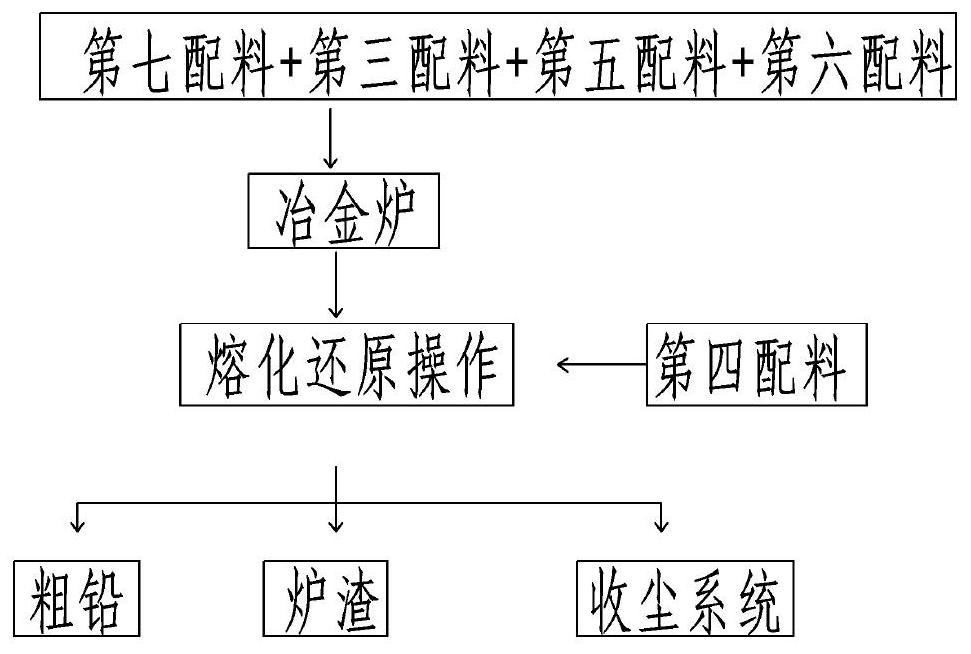

Waste lead-acid storage battery and lead-containing waste regenerated reduced lead ingredient and preparation method

PendingCN113621810ALow costLow melting pointWaste accumulators reclaimingProcess efficiency improvementCinderChemistry

The invention relates to the field of lead-zinc smelting secondary lead metallurgy, in particular to a waste lead-acid storage battery and lead-containing waste regenerated reduced lead ingredient and a preparation method thereof. The waste lead-acid storage battery and lead-containing waste regenerated reduced lead ingredient comprises a first ingredient, a second ingredient, a third ingredient, a fourth ingredient, a fifth ingredient, a sixth ingredient and a seventh ingredient, wherein the first ingredient comprises scrap iron, the second ingredient comprises coal, the third ingredient comprises the first ingredient and the second ingredient, the fourth ingredient comprises the first ingredient and iron ore cinder, the fifth ingredient comprises scorched particles, the sixth ingredient comprises return slag, and the seventh ingredient comprises a main material. The preparation method comprises the following steps of A, preparing the materials; B, preparing equipment; C, adding the third ingredient, the fifth ingredient, the sixth ingredient and the seventh ingredient into a furnace and smelting; D, raking the liquid surface with a rake, and adding a fourth ingredient when dense smoke emerges from the rake, when it is observed that the liquid level in the furnace is bright and boiling does not occur, adding of the fourth ingredient is stopped; and E, carrying out furnace discharging. According to the scheme, the regeneration and reduction cost of the waste lead-acid storage battery and the lead-containing waste is reduced.

Owner:尤全仁

Method for extracting vanadium from vanadium titano-magnetite smelting slag through roasting and ultrasonic leaching

InactiveCN112961988AReduce dosageLower apparent activation energyProcess efficiency improvementSlagMagnetite

The invention discloses a method for extracting vanadium from vanadium titano-magnetite smelting slag through roasting and ultrasonic leaching, and relates to the technical field of metallurgy. The method for extracting the vanadium from the vanadium titano-magnetite smelting slag through roasting and ultrasonic leaching comprises the following steps that the vanadium titano-magnetite smelting slag is pretreated; an additive and an oxidizing agent are added into the pretreated vanadium titano-magnetite smelting slag, and roasting is conducted; sulfate is added into a roasted material, uniformly mixing is conducted, and the material is wet with water; and concentrated sulfuric acid is added, ultrasonic treatment is conducted for 1-2 h, solid-liquid separation is conducted, and leaching liquid and leaching residues are obtained. According to the method for extracting the vanadium from the vanadium titano-magnetite smelting slag through roasting and ultrasonic leaching, vanadium in the vanadium titano-magnetite smelting slag can be fully extracted through the pretreatment, roasting and ultrasonic extraction processes, the extraction rate is increased, the acid consumption is reduced, and the roasting temperature is reduced.

Owner:LIUPANSHUI NORMAL UNIV

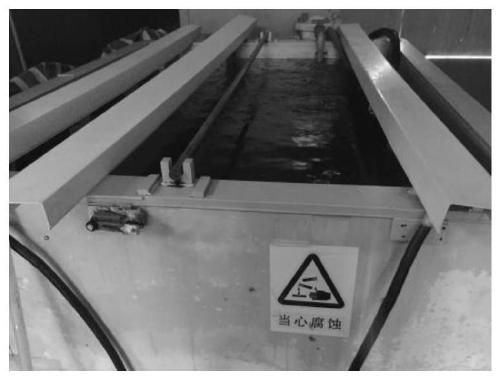

Mixed alkali for removing titanium alloy surface oxides and titanium alloy surface oxide removal method

The invention relates to the technical field of titanium alloy processing, in particular to mixed alkali for removing titanium alloy surface oxides and a titanium alloy surface oxide removal method. The mixed alkali for removing the titanium alloy surface oxides comprises the following components in percentage by mass: 40-45% of NaOH, 50-55% of KOH and 5-10% of Na2CO3. According to the mixed alkali for removing the titanium alloy surface oxides, three common alkaline substances are used, so that the mixed alkali is cheap and easy to obtain, and the formula is simple. During use, eutectic melting is carried out at a lower temperature, the titanium alloy surface oxides can be completely removed, acid washing is not needed subsequently, any adverse effect on the titanium alloy is avoided, themixed alkali is suitable for the treatment of titanium alloy material cost and semi-finished products, and the quality stability of the titanium alloy product is improved.

Owner:河南航天精工制造有限公司

An electrolyte and power lithium battery for high-power start-stop batteries

ActiveCN109713366BLower eutectic pointLow viscositySecondary cells servicing/maintenanceElectrolytic agentPropanoic acid

An electrolytic solution for a high-power start-stop battery, the electrolytic solution comprising 100 parts by weight includes the following components by weight: 14-20 parts of lithium salt, 70-85 parts of organic solvent and functional additives 1-10 parts; the organic solvent is composed of the following components, each component accounts for 12-20 parts of ethylene carbonate EC, 5-11 parts of propylene carbonate PC, ethyl methyl carbonate EMC 10‑20 parts, Propyl Acetate PA 14‑22 parts and Propyl Propionate PP 12‑20 parts. The lithium-ion battery electrolyte of the present invention can effectively reduce the conductivity of the electrolyte at low temperature, improve the impedance of the interface film at low temperature, and then improve the charge and discharge power characteristics at low temperature, and further improve the high-temperature stability of the lithium salt and the interface film, reducing the The high-temperature side reaction of the electrolyte improves the high-temperature storage and high-temperature cycle performance of the battery.

Owner:FENGFAN

A method for extracting vanadium from vanadium-titanium magnetite

ActiveCN107217159BImprove leaching rateLower apparent activation energyProcess efficiency improvementSlagMass ratio

The invention relates to a method for vanadium extraction from vanadium-titanium magnetite. According to the technical scheme of the method, vanadium-titanium magnetite concentrate is grinded till the vanadium-titanium magnetite concentrate with the particle size being smaller than 0.074 mm accounts for 60% or more by weight firstly, and vanadium-titanium magnetite concentrate powder is obtained; burdening is conducted according to the mass ratio of the vanadium-titanium magnetite concentrate powder to a roasting additive being 1:(0.04-0.06), even mixing is conducted, and a mixture is obtained; then the mixture is heated till the temperature is 850-1000 DEG C, heat preservation is conducted for 0.5-1.5 h, cooling is conducted till the temperature reaches the room temperature, and roasting slag is obtained; and then according to the liquid-solid ratio being (2-3):1 L / Kg, the roasting slag is placed into a sulfuric acid solution with the volume concentration being 10-20%, stirring is conducted, solid-liquid separation is conducted, and a leaching solution and leaching slag are obtained. The roasting additive is a mixture of sylvite and NaF, wherein the mass ratio of the sylvite to the NaF is 1:(0.5-2), and the sylvite is one or more of KCl, K2CO3, K2SO4 and KNO3. The method for vanadium extraction from the vanadium-titanium magnetite has the characteristics that the using quantity of the additive is low, the roasting temperature is low, the roasting time is short, the leaching rate of vanadium is high, and pollution is small.

Owner:WUHAN UNIV OF SCI & TECH

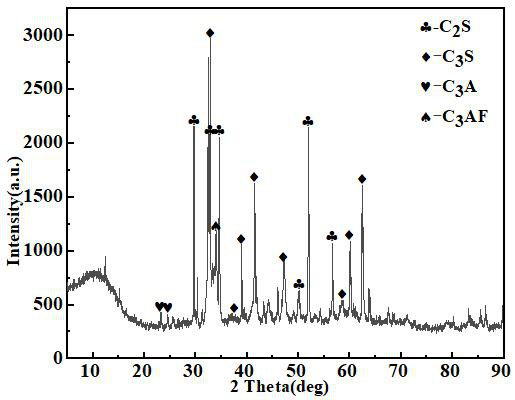

Preparation method of radiation-proof cement clinker mineral phase system

The invention discloses a preparation method of a radiation-proof cement clinker mineral phase system, which comprises the following steps of: (1) raw material preparation: raw materials are uniformly mixed according to a ratio, and are ground until the amount of residues on a 180-mesh square hole sieve is less than or equal to 10%; and (2) high temperature sintering: the ground powder in the step 1 is pressed into cylindrical test pieces, and the cylindrical test pieces are placed in a corundum crucible and are calcinated for 1 to 3 hours at a high temperature in a reheating test furnace to obtain the desired mineral phase system. The raw materials are calcium carbonate, alumina, and boron oxide, or calcium carbonate, alumina, boron oxide, and iron oxide. Through the mineral phase systemprepared by the preparation method disclosed by the invention, neutrons can be absorbed, the heat consumption of a cement clinker preparation process is reduced, the normal setting and hardening of cement are promoted, the strength of cement is improved, the mass concrete cracks can be inhibited, and the durability of concrete is improved. The method provided by the invention is simple in process, is easy to control and adapts to large-scale industrial production.

Owner:湖北湖大天沭新能源材料工业研究设计院有限公司

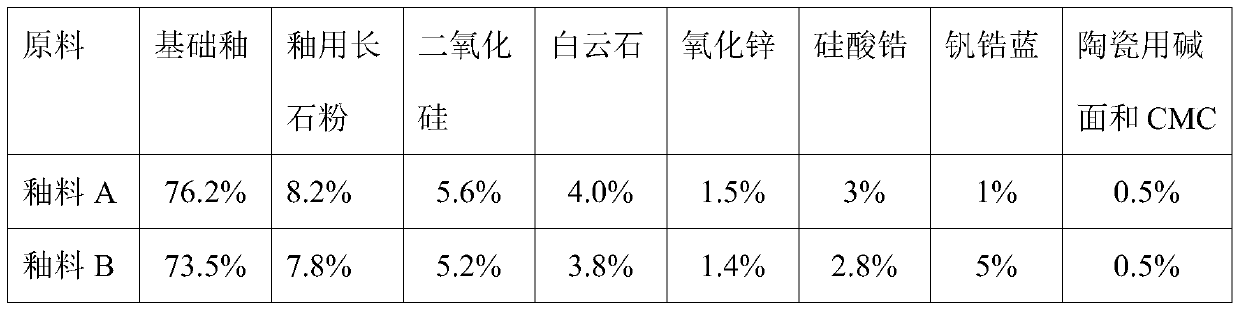

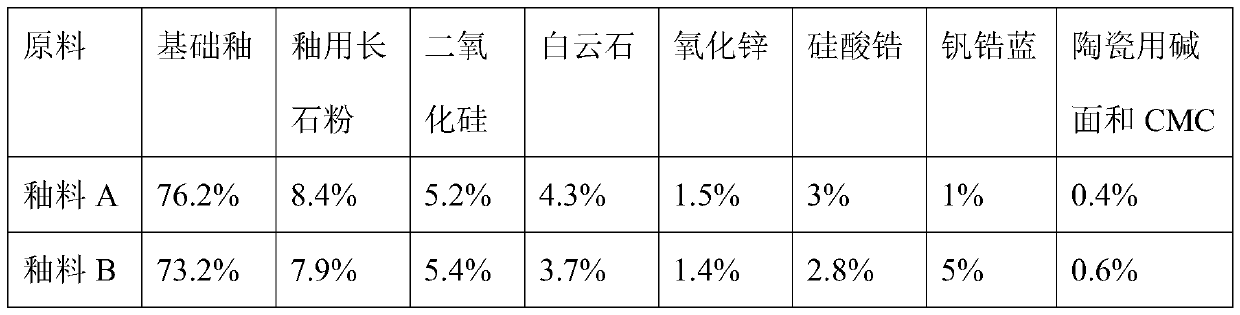

A kind of preparation method of blue gradient glaze sanitary ceramics

The invention discloses a preparation method of blue gradient glaze sanitary ceramic. A glaze material is prepared from basic glaze, silicon dioxide, dolomite, zinc oxide, zirconium silicate, feldsparpowder for glaze, vanadium-zirconium blue and the like; glaze slurry A and glaze slurry B, which have different vanadium-zirconium blue content, are prepared through the glaze material; the glaze slurry A and the glaze slurry B are sprayed on the surface of a sanitary ceramic white body in sequence, wherein the spraying amount of the glaze slurry A is gradually reduced from the top to the bottomof a white body spraying region and the spraying amount of the glaze slurry B is gradually increased from the top to the bottom of the white body spraying region; then the glazed white body is fired in a tunnel kiln at 1202 DEG C to 1250 DEG C for 15h to 18h to obtain a blue gradient glaze sanitary ceramic product. The obtained product meets the processing and utilization performance requirementsof the sanitary ceramic, has a good gradient effect and an extremely good decoration effect, and meets the requirements of individualized bathrooms.

Owner:JOMOO KITCHEN & BATHROOM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com