Preparation method of one-dimensional hierarchical-structure thin-wall BN microtube, and product thereof

A hierarchical structure, micro-tube technology, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., to achieve the effect of improving yield and purity, improving product purity, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

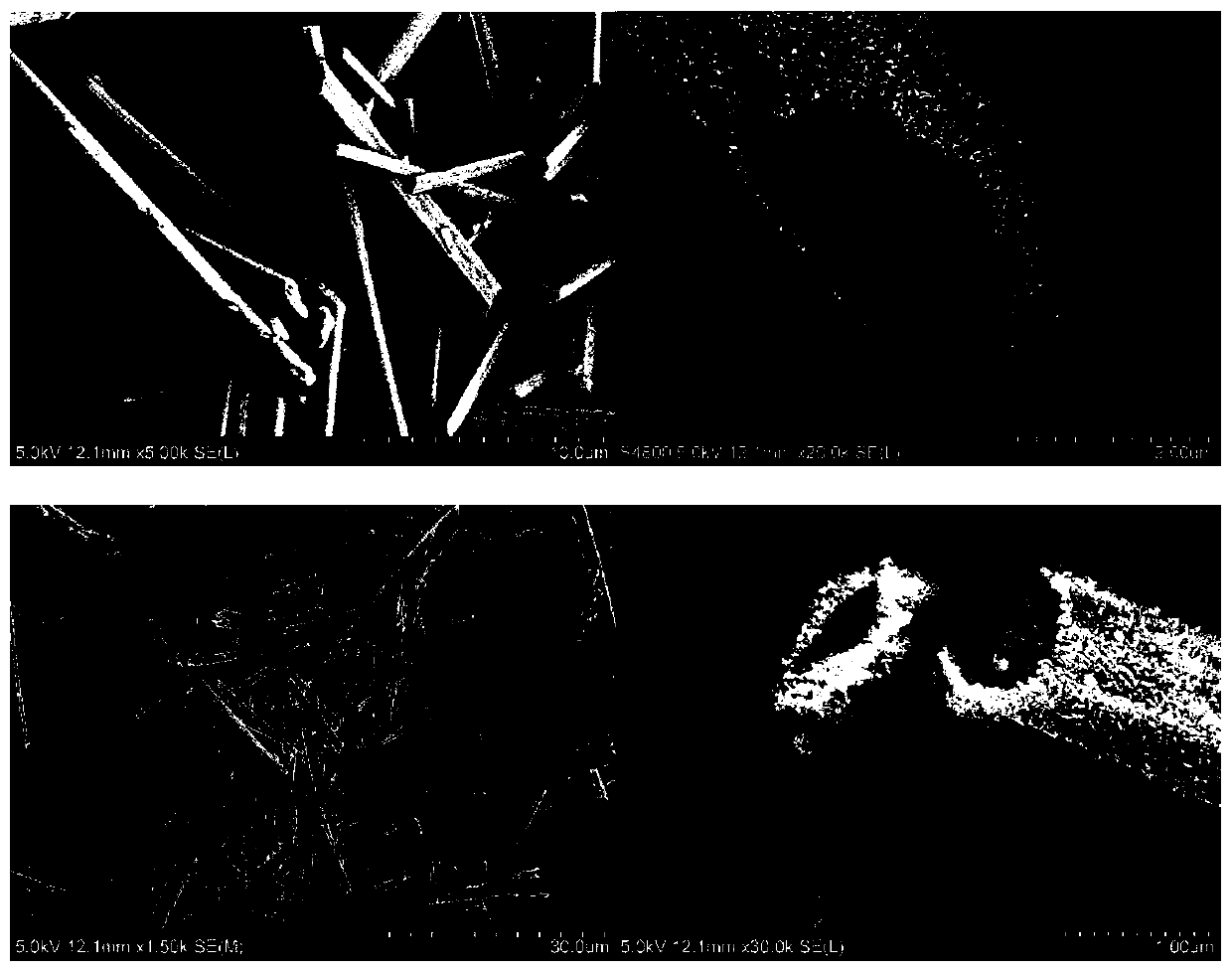

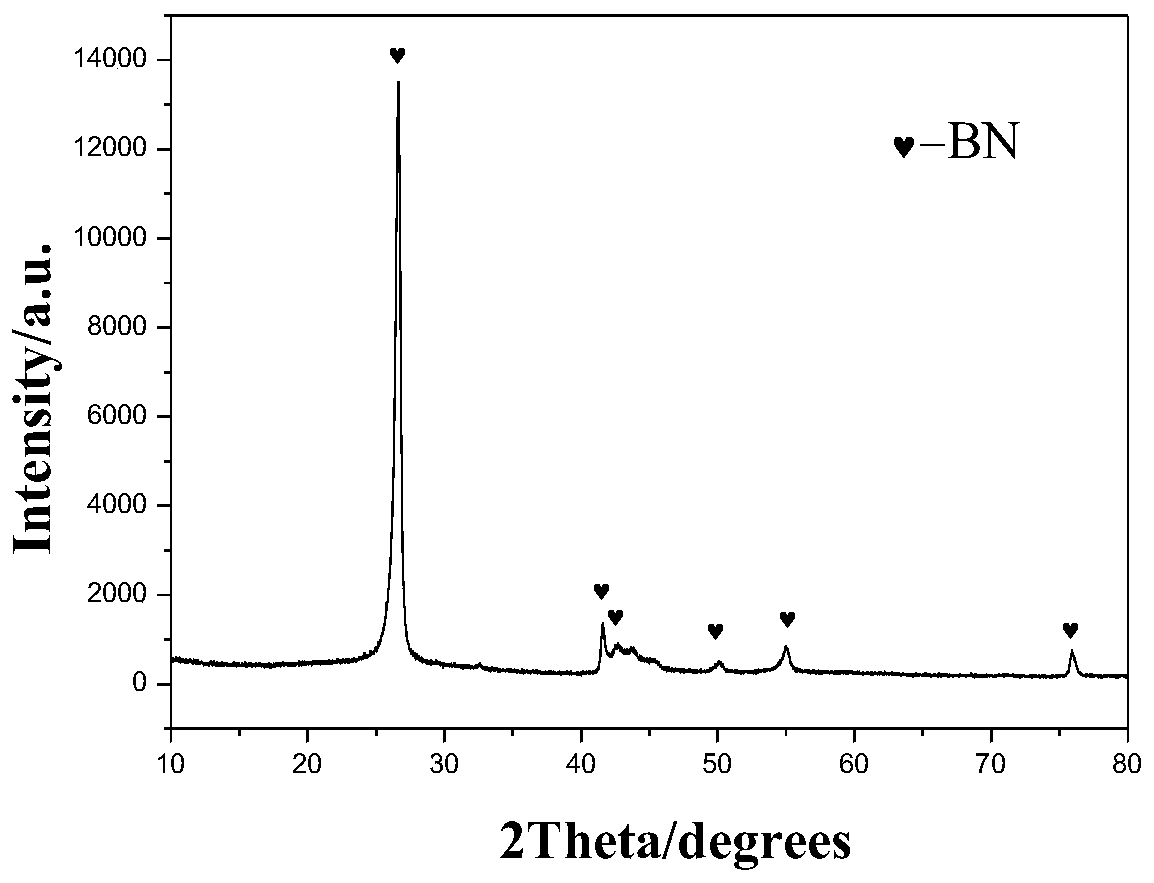

[0036] A method for preparing a thin-walled BN micron square tube with a one-dimensional hierarchical structure, comprising the following steps:

[0037] (1) According to MgCl 2 ·6H 2 O, H3 BO 3 With the molar ratio of fluxing agent NaCl 1:3.2:4.5, take by weighing 29.664g H 3 BO 3 and 30.5gMgCl 2 ·6H 2 O, 39.487gNaCl, after mixing, fully grind for 15min, put it into a muffle furnace and heat it to 1000°C, keep it warm for 6 hours, and cool to room temperature with the furnace to obtain the precursor;

[0038] (2) Take the above-prepared precursors and evenly scatter them in the alumina ark, put them into the tube furnace, pass through the ammonia gas after vacuuming, keep the temperature at 1150°C for 5h, cool down to 200°C with the furnace, and close Breathing valve, naturally cool to room temperature, obtain crude product;

[0039] (3) Disperse the crude product in 150ml of distilled water, add 100ml of 12mol / L hydrochloric acid, heat and stir at 80°C for 12h, then w...

Embodiment 2

[0045] A method for preparing a thin-walled BN micron square tube with a one-dimensional hierarchical structure, comprising the following steps:

[0046] (1) According to MgCl 2 ·6H 2 O, H 3 BO 3 With the molar ratio of flux KCl 1:3:5, weigh 18.54g H 3 BO 3 , 20.33 g MgCl 2 ·6H 2 O and 37.25g KCl were mixed and ground for 15 minutes, put into a muffle furnace and heated to 1000°C, kept for 5 hours, and cooled to room temperature with the furnace to obtain the precursor;

[0047] (2) Take the above-prepared precursors and evenly scatter them in the alumina ark, put them into the tube furnace, pass through the ammonia gas after vacuuming, keep the temperature at 1200°C for 2h, cool down to 200°C with the furnace, and close Breathing valve, naturally cool to room temperature, obtain crude product;

[0048] (3) Disperse the crude product in 150ml of distilled water, add 100ml of 12mol / L hydrochloric acid, heat and stir at 80°C for 12h, then wash with deionized water and ce...

Embodiment 3

[0051] A preparation method of a one-dimensional hierarchical structure thin-walled BN microtube, which comprises the following steps:

[0052] (1) According to MgCl 2 ·6H 2 O, H 3 BO 3 With the molar ratio of fluxing agent NaCl 1:3.5:5.5, weigh 21.63g H 3 BO 3 , 20.33 g MgCl 2 ·6H 2 O and 32.175g NaCl, mixed and fully ground for 15 minutes, put into a muffle furnace and heated to 800°C, kept for 4 hours, and cooled to room temperature with the furnace to obtain the precursor;

[0053] (2) Take the above-prepared precursors and evenly scatter them in the alumina ark, put them into the tube furnace, pass through the ammonia gas after vacuuming, keep the temperature at 1100°C for 3h, cool down to 200°C with the furnace, and close Breathing valve, naturally cool to room temperature, obtain crude product;

[0054] (3) Disperse the crude product in 150ml of distilled water, add 100ml of 12mol / L hydrochloric acid, heat and stir at 80°C for 12h, then wash with deionized water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com