Patents

Literature

37results about How to "The reaction environment is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

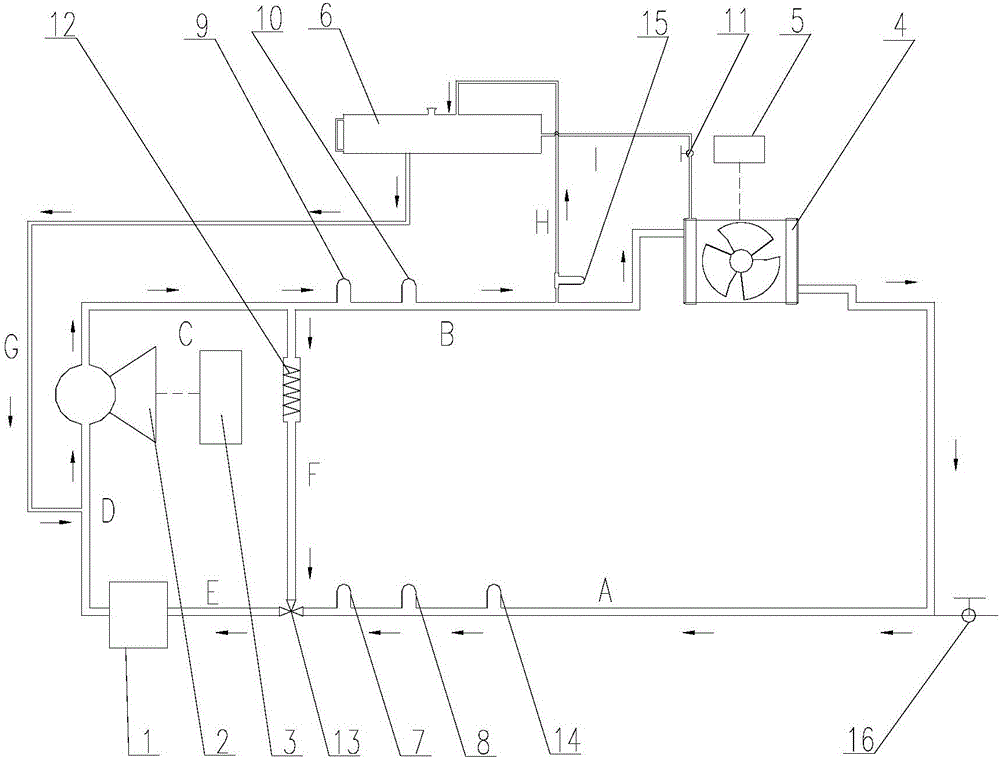

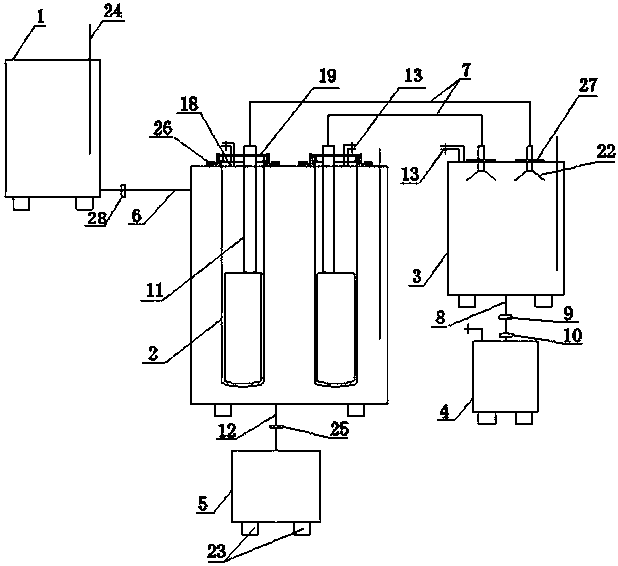

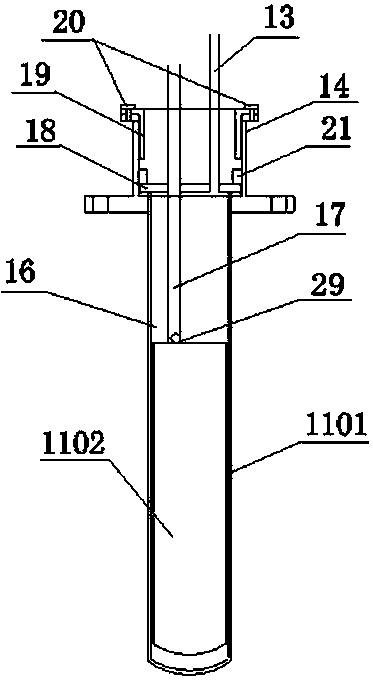

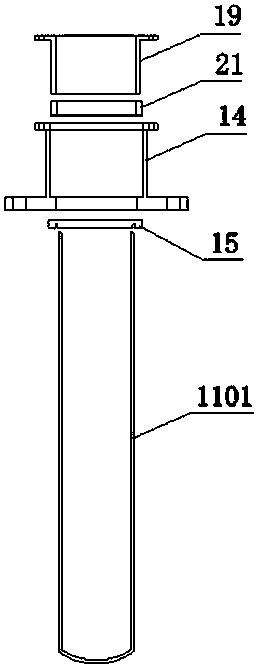

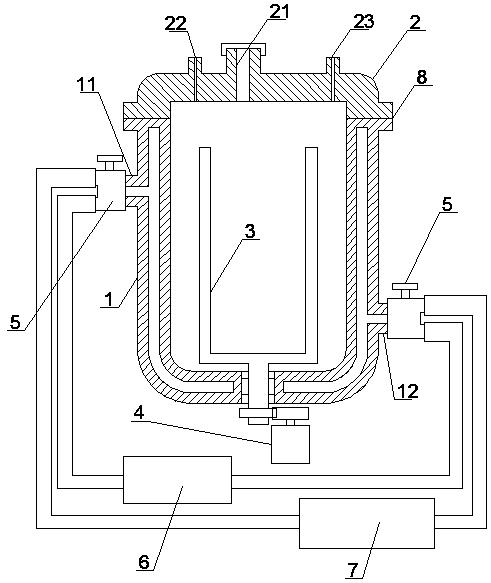

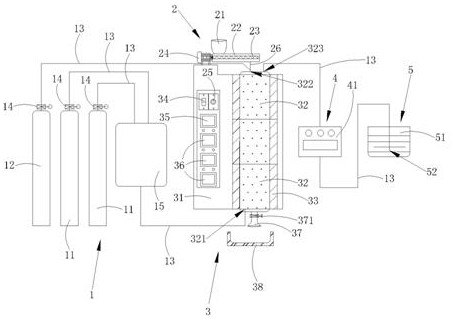

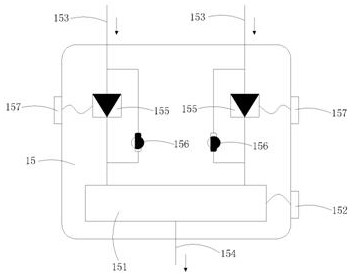

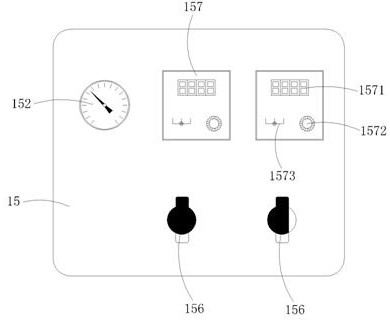

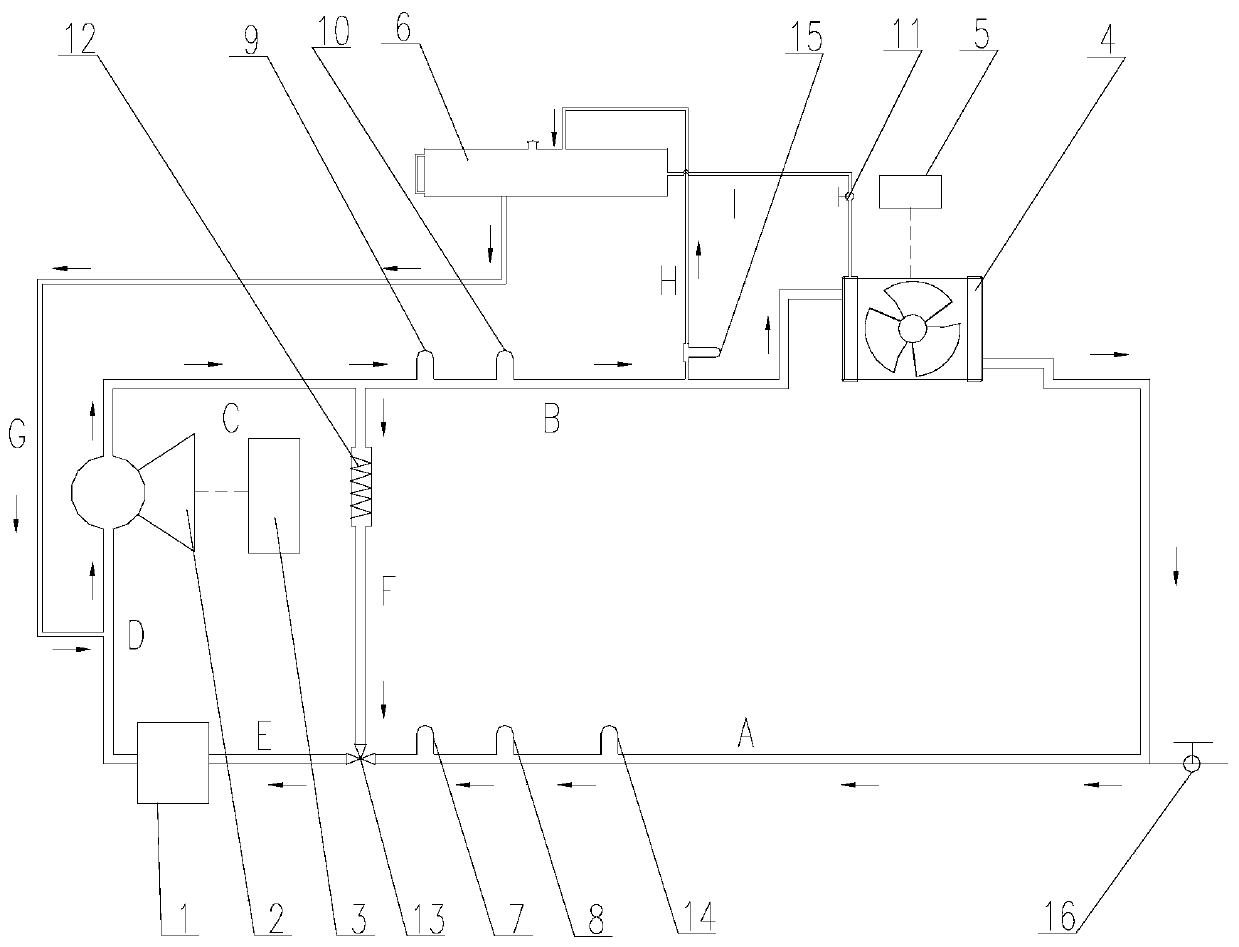

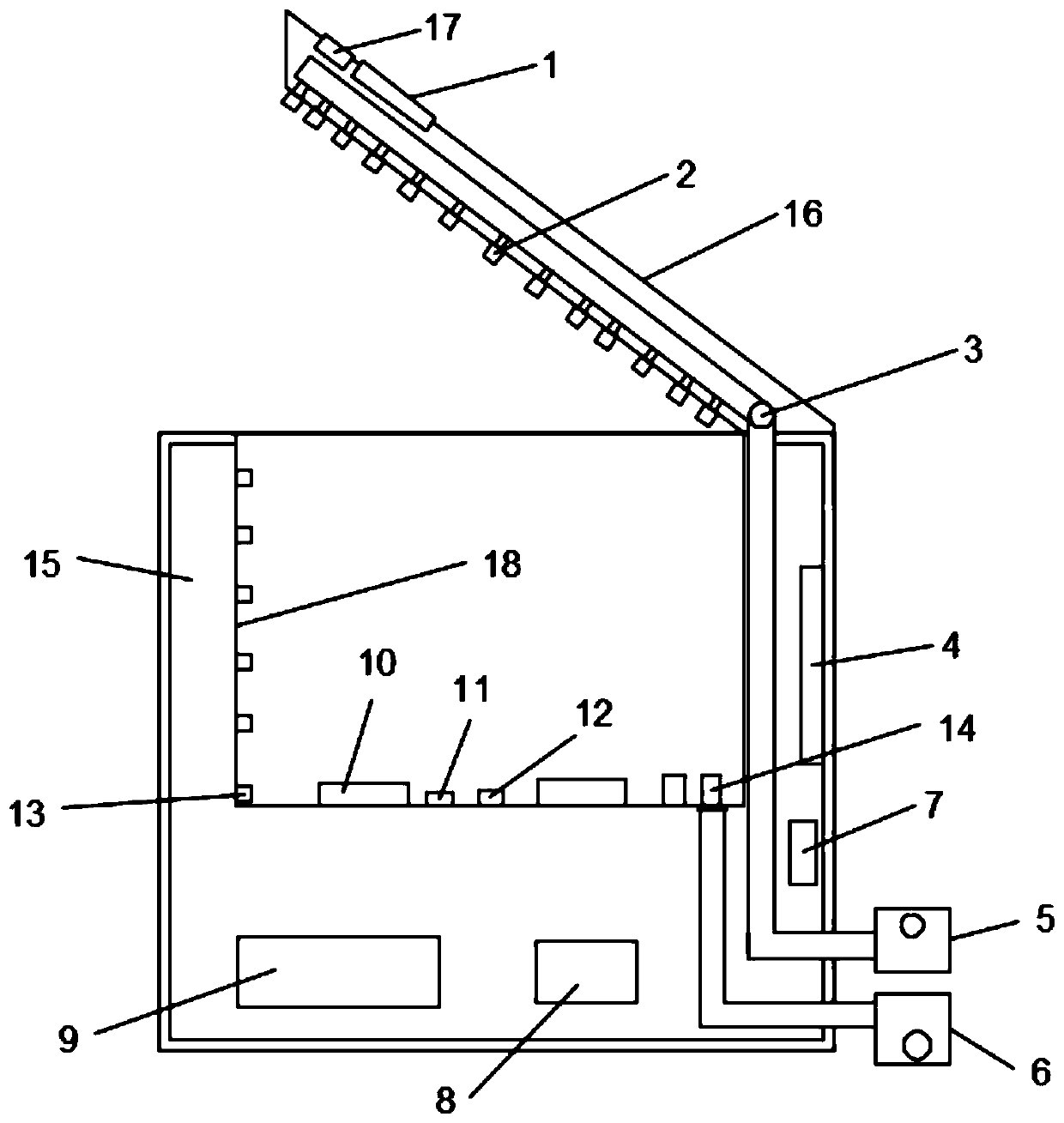

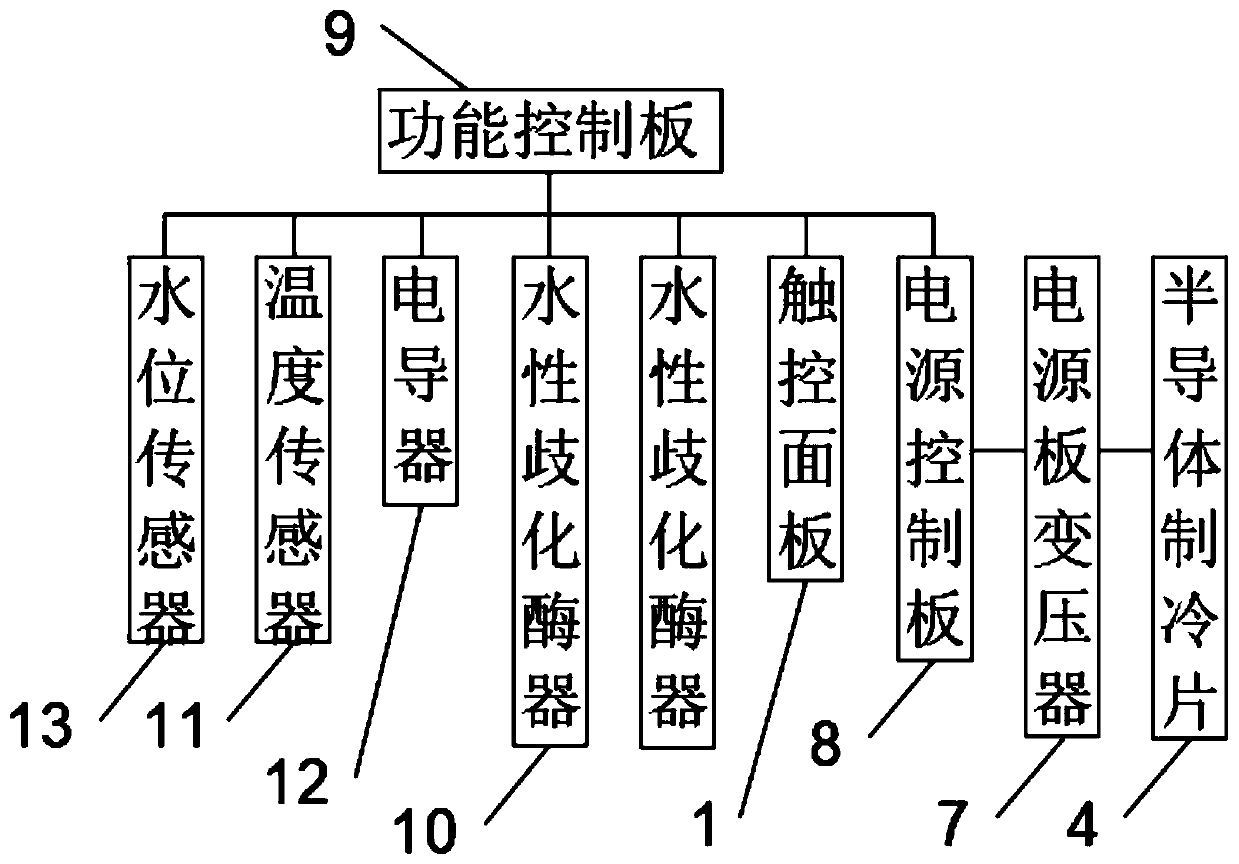

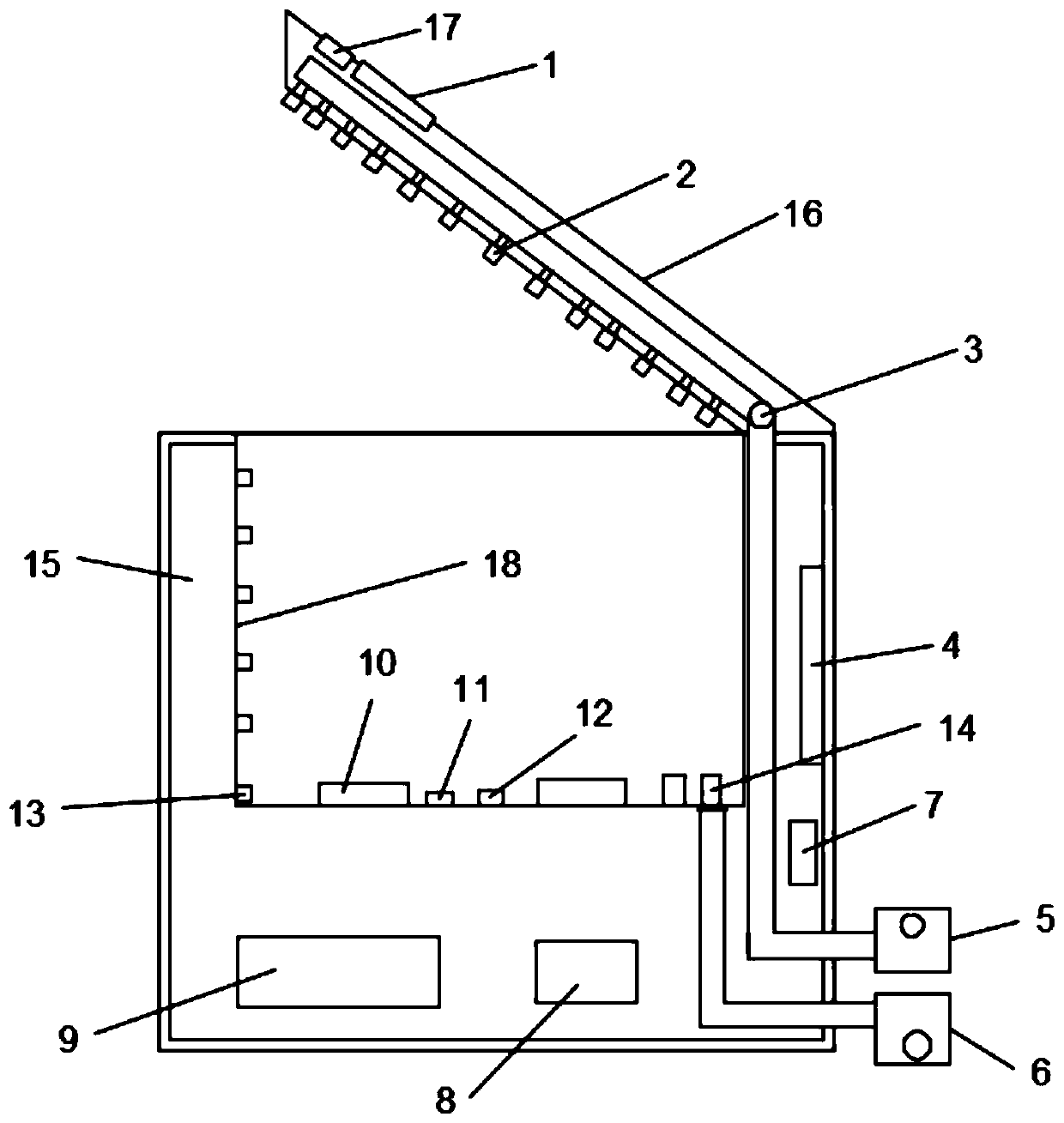

Cooling system of hydrogen energy tramcar fuel cell

ActiveCN106328971AThe reaction environment is stableImprove reaction efficiencyFuel cell heat exchangeMotive system fuel cellsNuclear engineeringHydrogen fuel cell

The invention discloses a cooling system of a hydrogen energy tramcar fuel cell. The cooling system comprises a hydrogen fuel cell, a circulating device, a cooling device and an electric heating pipe, wherein the hydrogen fuel cell, the circulating device and the cooling device are sequentially connected to form a cooling circulating loop; one end of the electric heating pipe I communicates with the circulating device through a pipeline, the other end communicates with the hydrogen fuel cell through a pipeline, and a heating circulating loop is formed. The temperature of a coolant entering the hydrogen fuel cell can be controlled within the best reaction temperature range accurately and more stably, so that the hydrogen fuel cell is located in a proper reaction temperature environment, and the reaction efficiency of the hydrogen fuel cell is improved; the cooling system is simple in structure, has an obvious effect and saves energy.

Owner:CRRC QINGDAO SIFANG CO LTD

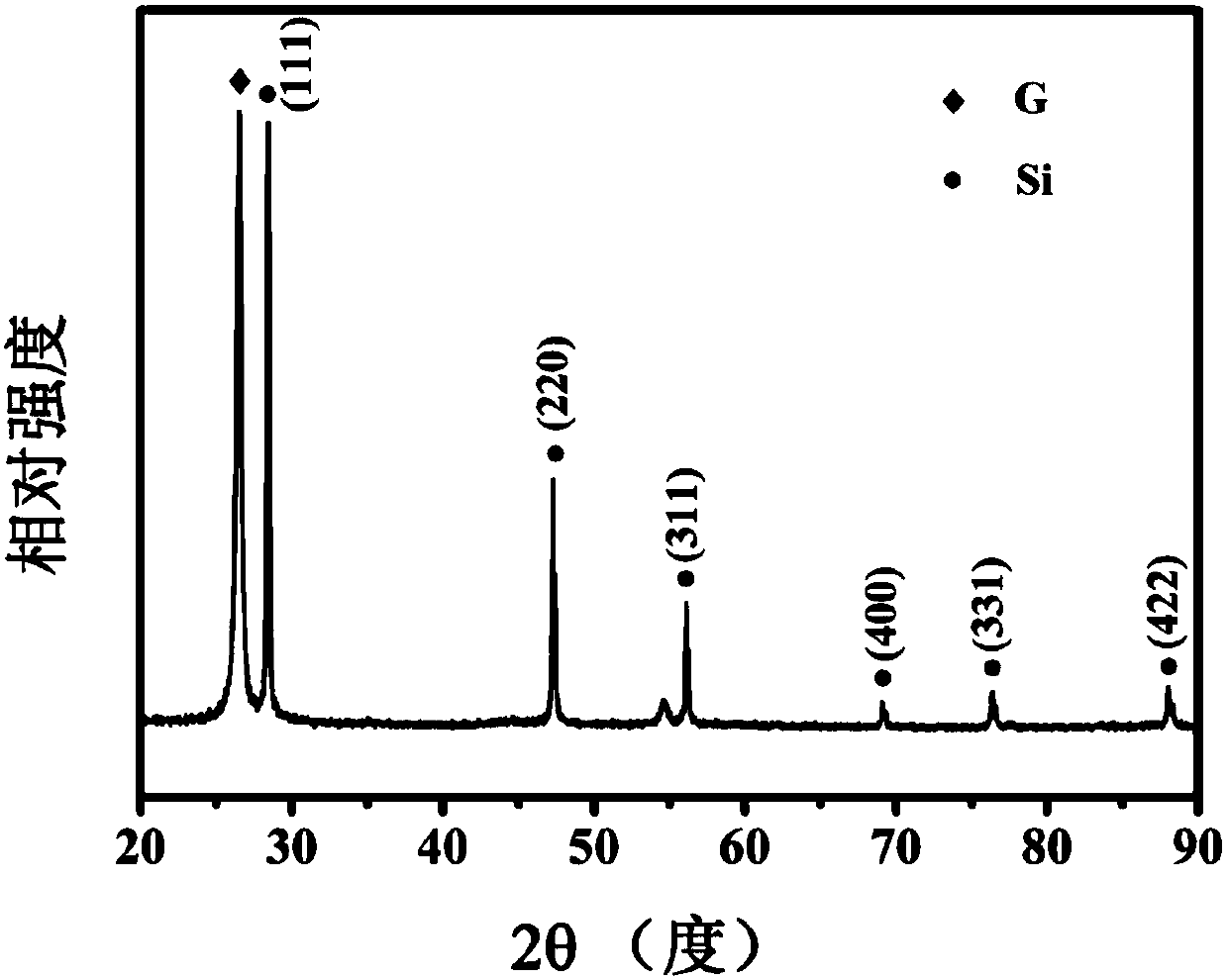

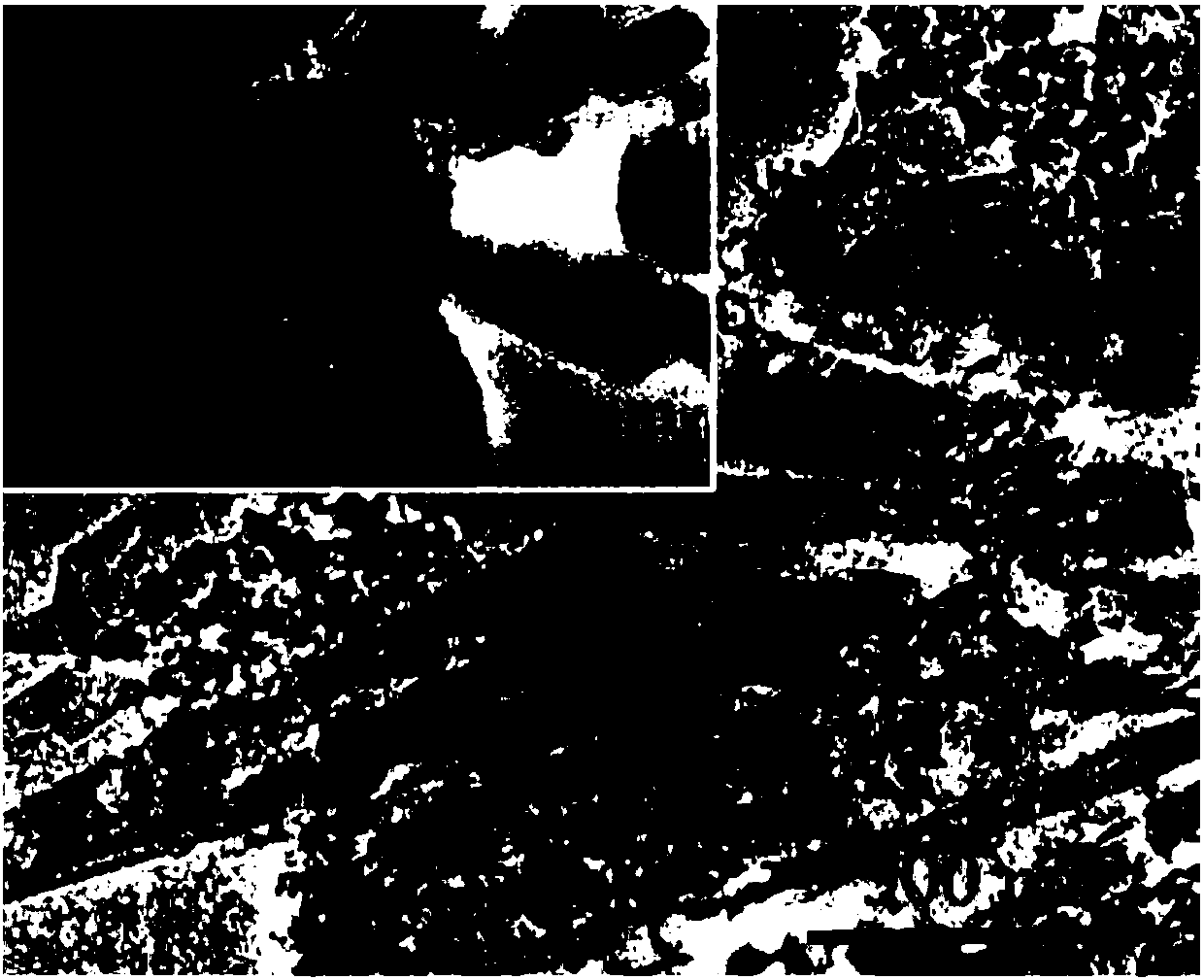

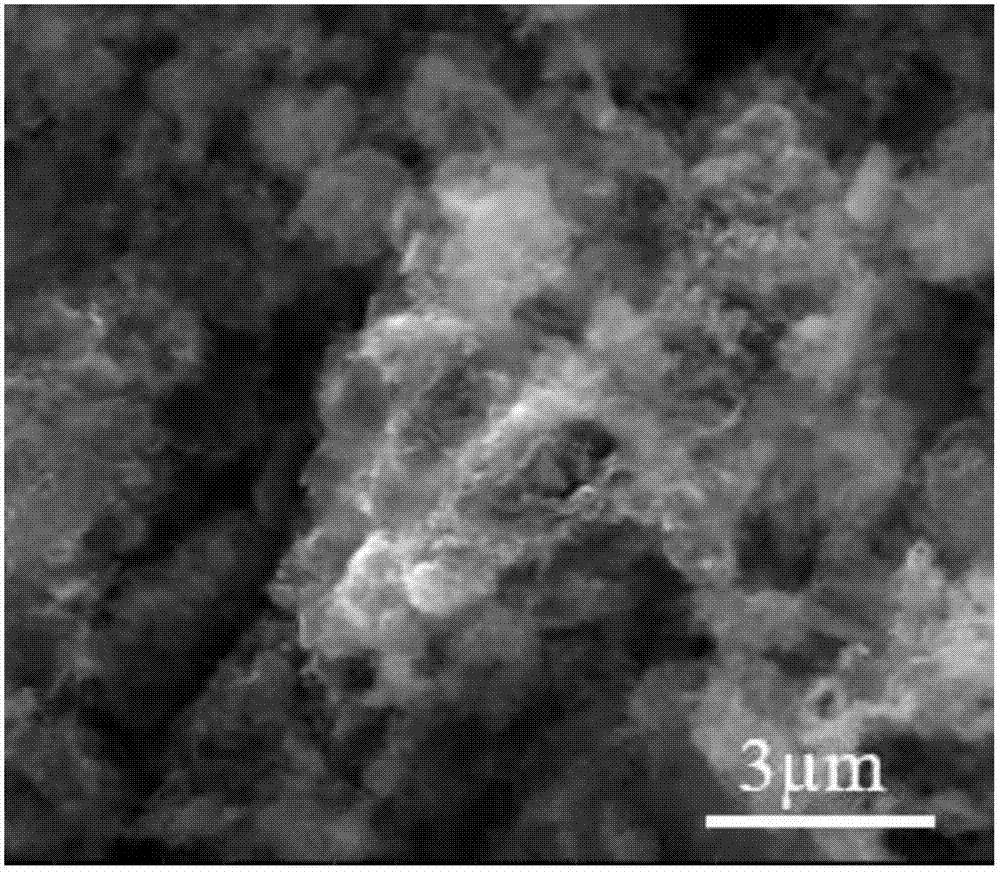

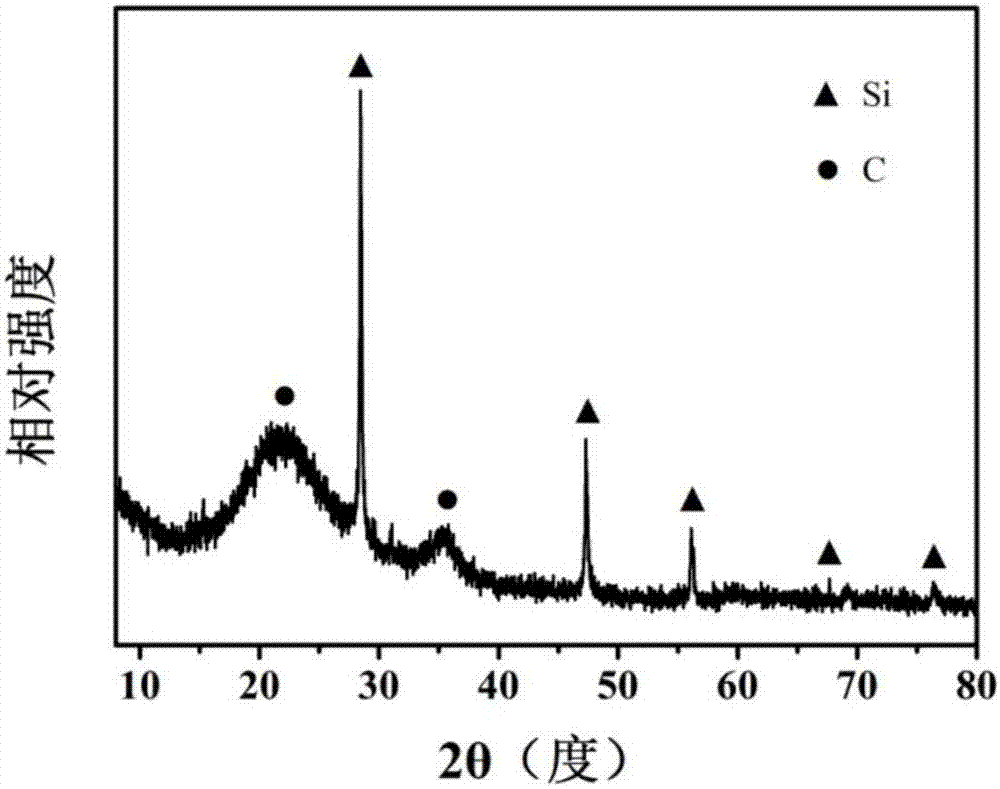

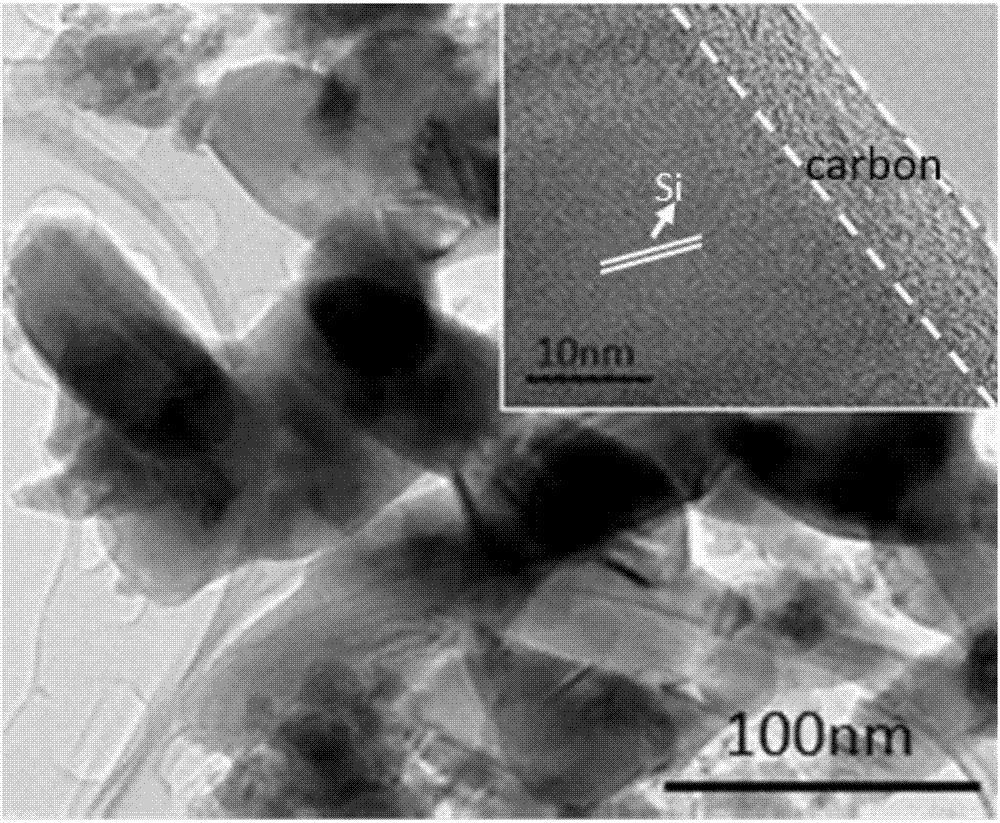

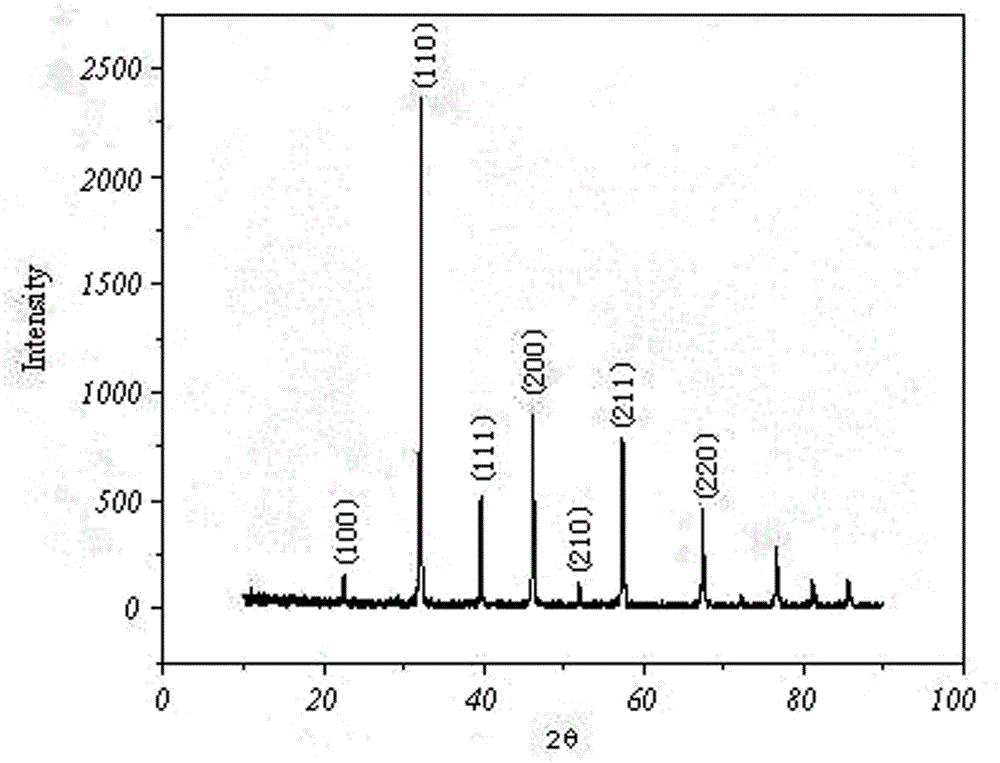

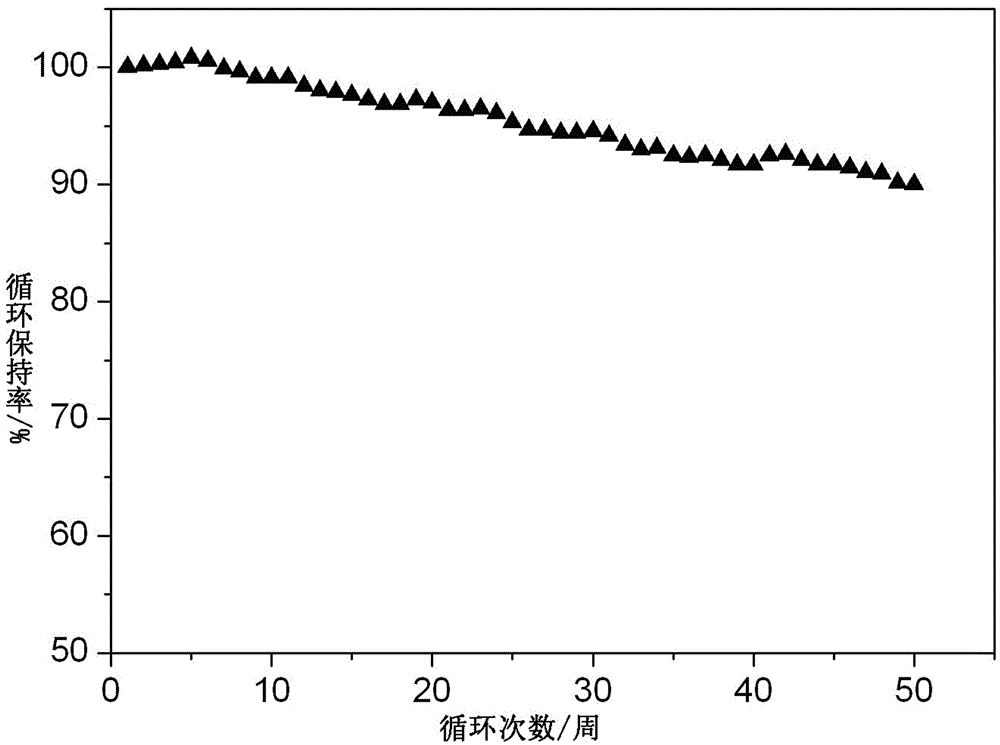

Silicon carbon composite material, and preparation method and application thereof

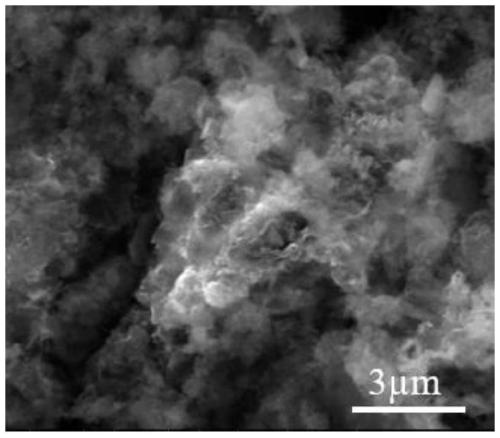

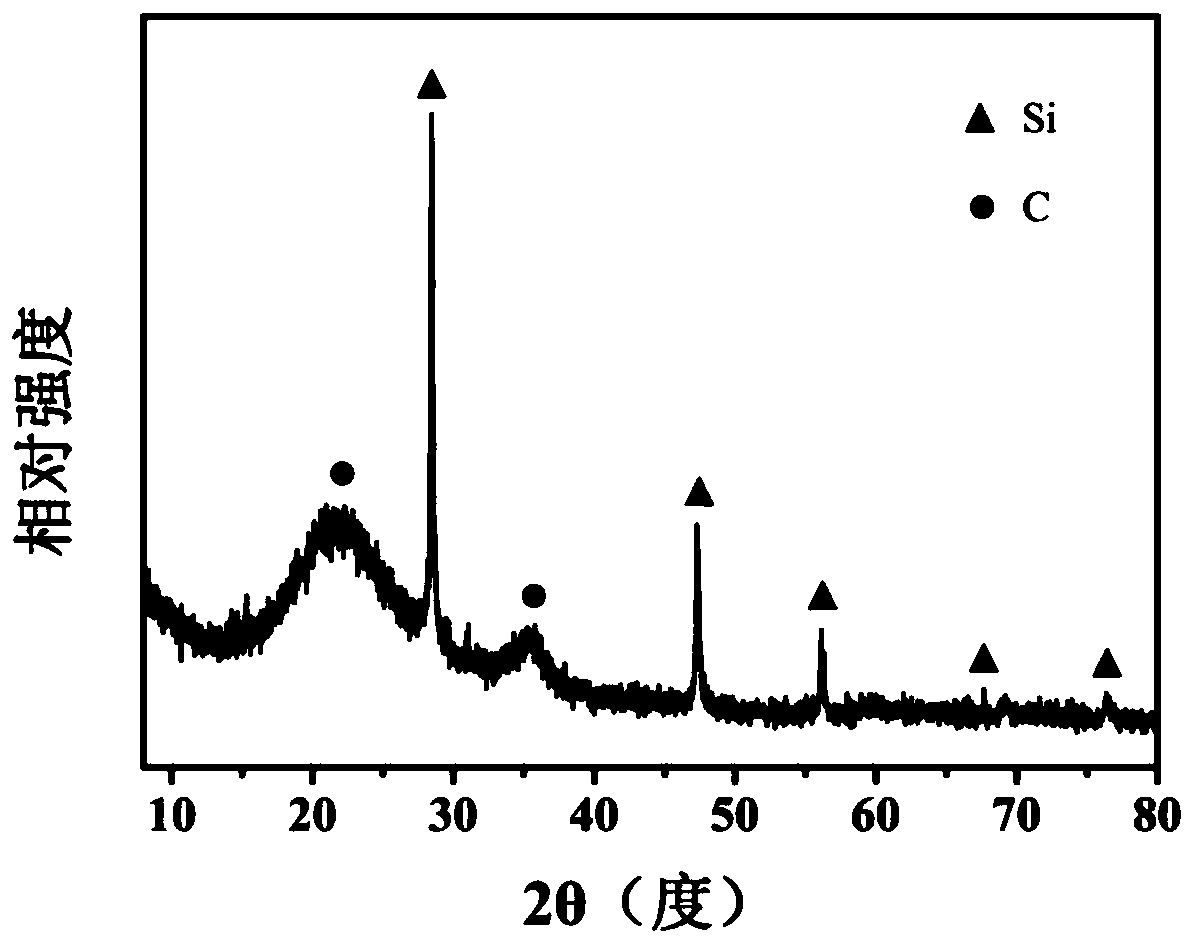

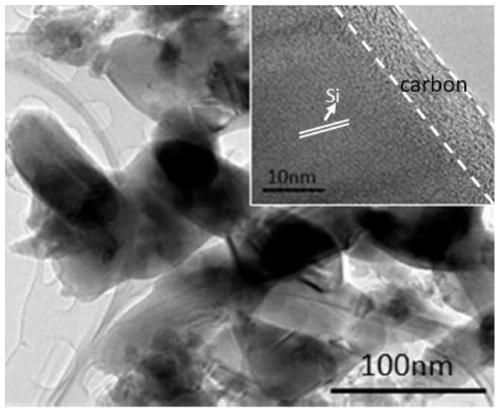

ActiveCN107611416AHigh tap densityIncrease compaction densityCell electrodesSandwich likeCarbon composites

The invention discloses a silicon carbon composite material, and a preparation method and an application thereof. The preparation method comprises the following steps of performing wet process ball milling on glass powder and a laminated layer carbon material to obtain a uniform mixed product of glass and the carbon material; next, performing uniform mixing and compacting on the product and magnesium powder and fused salt to form an ingot; and then performing a magnesium thermal reaction, and carrying out acid washing on the reaction product to obtain a sandwich layer-shaped porous silicon / graphene-like structured composite material. The preparation method are simple in steps and easy to implement, and the raw materials are wide in resource; more importantly, the mixture is made into the ingot through the compacting process, and then the magnesium thermal reaction is performed, so that the tap density of the silicon carbon negative electrode material is greatly improved, and the volumetric specific capacity of the negative electrode material is improved; meanwhile, by compounding with the graphite and other carbon material to form the sandwich-like structure, the electronic conductivity of the material is improved effectively, and the compatibility between the silicon base material and an electrolyte can be improved, thereby improving cycle performance and rate capability of the material; and therefore, the silicon carbon composite material can be applied to the negative electrode material with high power density and high energy density of the lithium ion battery.

Owner:WUHAN UNIV OF SCI & TECH

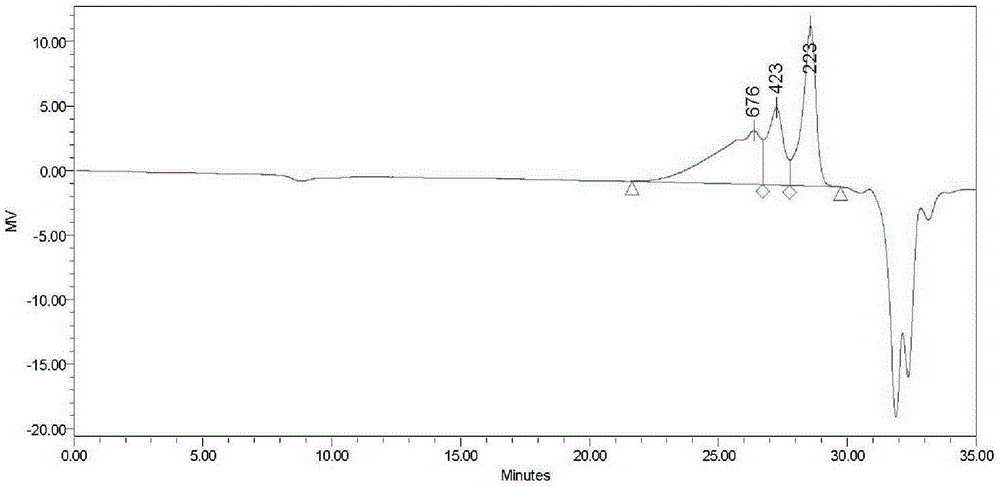

Method for preparing silicon carbon composite material by taking silicate glass as raw material, product thereof and application

ActiveCN107579214AHigh crystallinityImprove conductivityMaterial nanotechnologyCell electrodesMagnesiumLithium electrode

The invention discloses a method for preparing a silicon carbon composite material by taking silicate glass as a raw material, a product thereof and application. The method comprises the following steps: performing wet ball milling on glass powder and a carbon material to obtain a uniformly mixed product of the glass and the carbon material, uniformly mixing the uniformly mixed product, magnesiumpowder and molten salt, pressing into an ingot, performing magnesium thermal reaction, and performing acid-washing treatment on the reaction product to obtain the carbon and silicon composite materials with different structures. According to the method, the steps are simple and practical, the raw material source is wide, most importantly, the magnesium thermal reaction is conducted after the mixture is made into the ingot, so that the ramming density of the silicon carbon negative electrode material is greatly increased and the volume specific capacity of the negative electrode material is increased; meanwhile, the electronic conductivity of the silicon carbon composite material formed by compounding the negative electrode material and a graphited carbon material is effectively improved, and the compatibility of the silicon based material and electrolyte is improved, so that the circulating performance and the rate performance of the material are improved, and the material can be applied to a lithium ion battery negative electrode material with high power density and high energy density.

Owner:WUHAN UNIV OF SCI & TECH

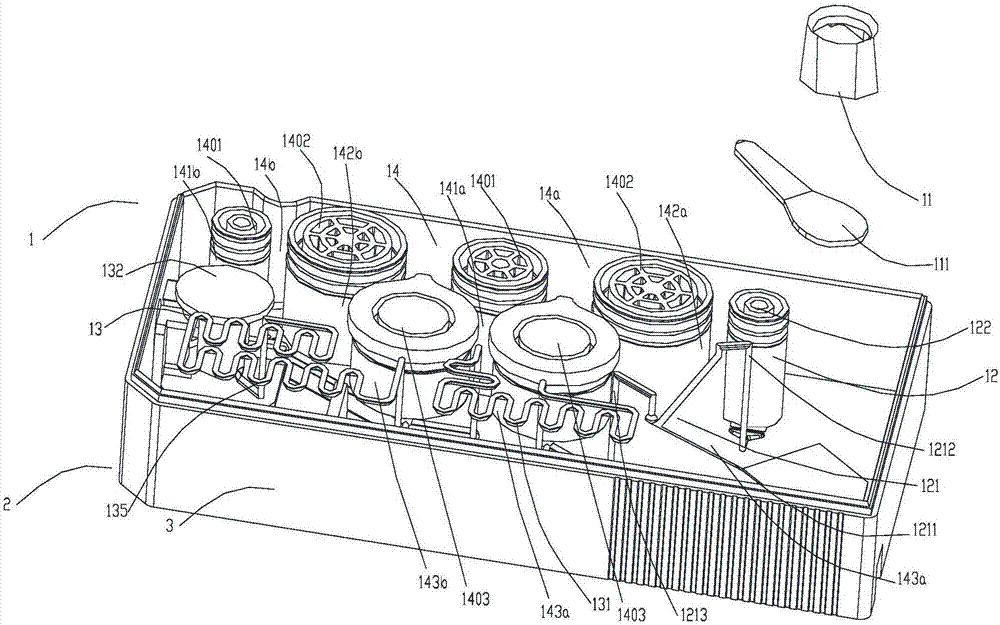

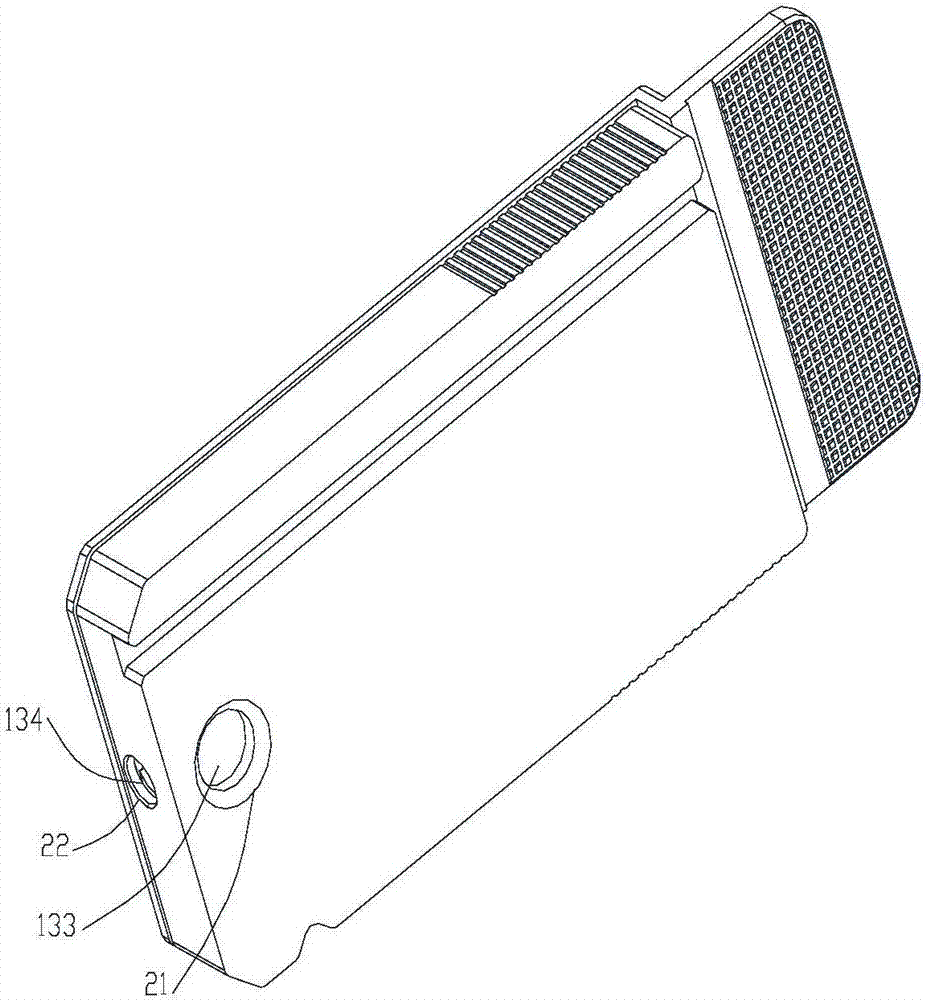

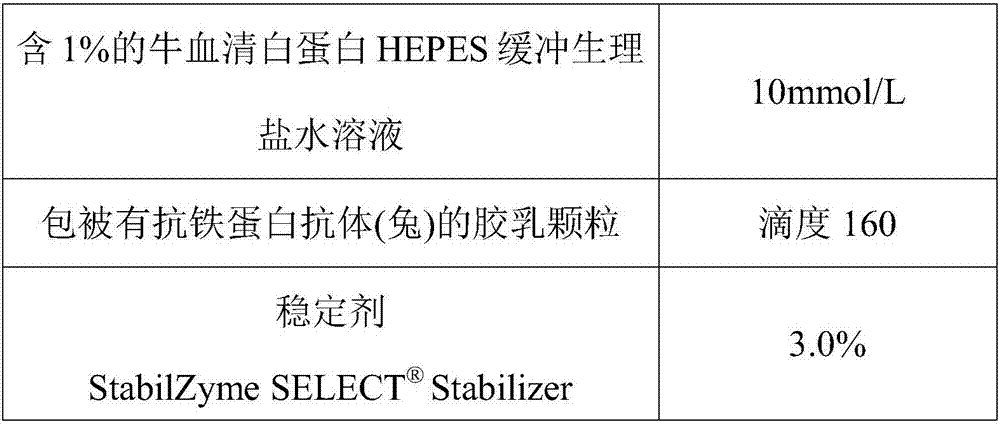

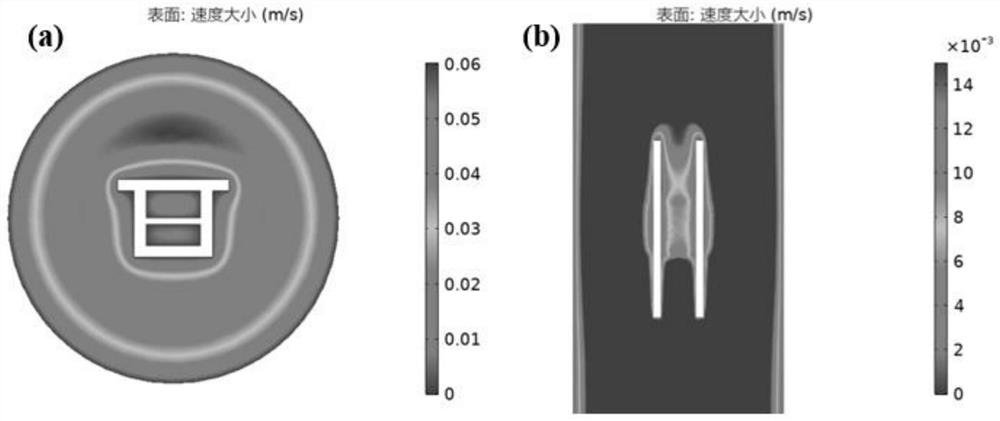

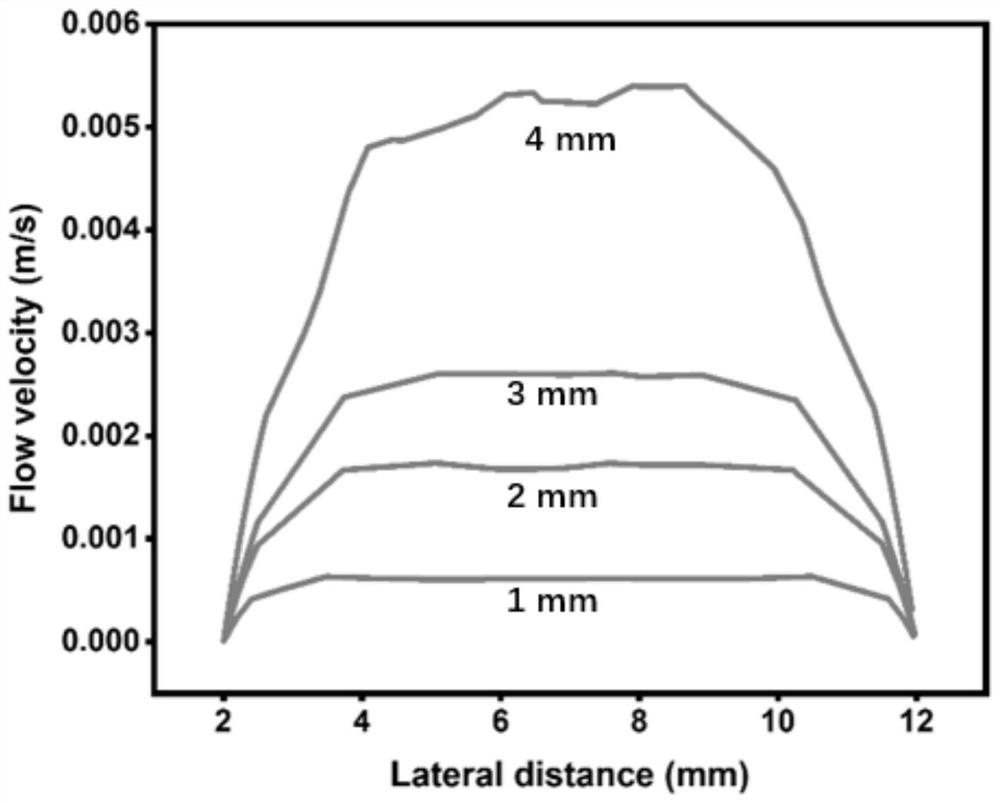

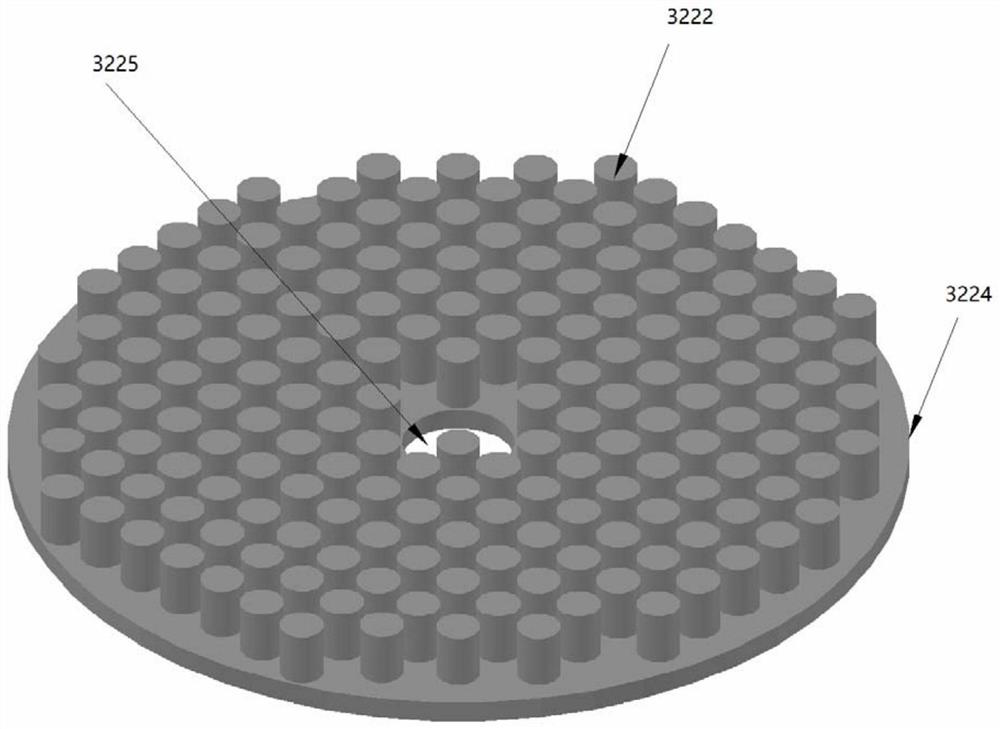

Microfluidic chip and application thereof

ActiveCN107321397AReduce the risk of contaminationImprove detection accuracyLaboratory glasswaresMaterial analysisEngineeringContamination

The invention discloses a microfluidic chip. The microfluidic chip comprises a substrate and a bottom cover, wherein a sample inlet, a diluent chamber, a detection chamber and a mixing area are arranged on the substrate; the mixing area comprises a reagent chamber, an air chamber and a uniform mixing chamber; the sample inlet, the diluent chamber and the uniform mixing area are communicated through a first flow passage; the detection chamber is communicated with the uniform mixing chamber through a second flow passage; the reagent chamber is communicated with the uniform mixing chamber through a reagent flow channel; the air chamber is communicated with the uniform mixing chamber through an air channel; a light transmitting panel is arranged on the upper surface of the detection chamber, a light transmitting bottom plate is arranged on the lower surface, and a light transmitting side plate is arranged on the side surface. By means of the microfluidic chip, all reagent components required for a reaction can be integrated onto the chip and do not contact with the outside during the reaction, so that the risk of contamination is greatly reduced; the microfluidic chip is used for detecting the content of to-be-detected components in a sample; reaction time is short, sensitivity is quite high and quantitation is accurate.

Owner:深圳市海拓华擎生物科技有限公司

Resin composition and presoaking material and laminated board using same

ActiveCN105419348ALess cross-linking pointsReduce intensitySynthetic resin layered productsLaminationEpoxyGlass fiber

The invention provides a resin composition and a presoaking material and laminated board using the same. The resin composition comprises a prepolymer of epoxy-resin-modified polyphenylene oxide resin and benzoxazine resin. According to the resin composition and the presoaking material and laminated board using the same, the prepolymer of the epoxy-resin-modified polyphenylene oxide resin is used for the resin composition of a printed circuit board, the dielectric property of a copper-clad plate can be improved, the wettability of glass fibre cloth made of the resin composition containing the prepolymer of the epoxy-resin-modified polyphenylene oxide resin can be improved, and the obtained resin composition can have excellent appearance, heat resistance, dielectric property and peeling strength.

Owner:GUANGDONG SHENGYI SCI TECH

Technology for preparing metal sodium with molten electrolysis of sodium hydroxide and electrolytic system of technology

The invention discloses a technology for preparing metal sodium with molten electrolysis of sodium hydroxide and an electrolytic system of the technology and belongs to the technical field of molten electrolysis technologies and equipment. By adopting the electrolytic system, under regulation and control of protective gas, the pressures of a fine sodium temporary storage cavity, a fine sodium groove and a fine sodium storage tank keep constant and are changed, and then generation and transferring of fine sodium are finished through heating, thermal insulation and current regulation. By adopting the preparation technology, through an electrochemical method, by utilizing the principle of diaphragm ceramic pipe ion permselectivity, impurities are blocked out of a diaphragm, and thus the purity of a metal sodium product is improved; and in addition, the preparation technology is liable to realize quantity production and low in energy consumption and is simple. The electrolytic system is simple in structure, convenient to install, good in sealing performance and convenient and complete in sodium discharge, can prevent pollution of air and pipeline parts and provides a favorable and stable environment to preparation of the fine sodium.

Owner:中国东方电气集团有限公司 +1

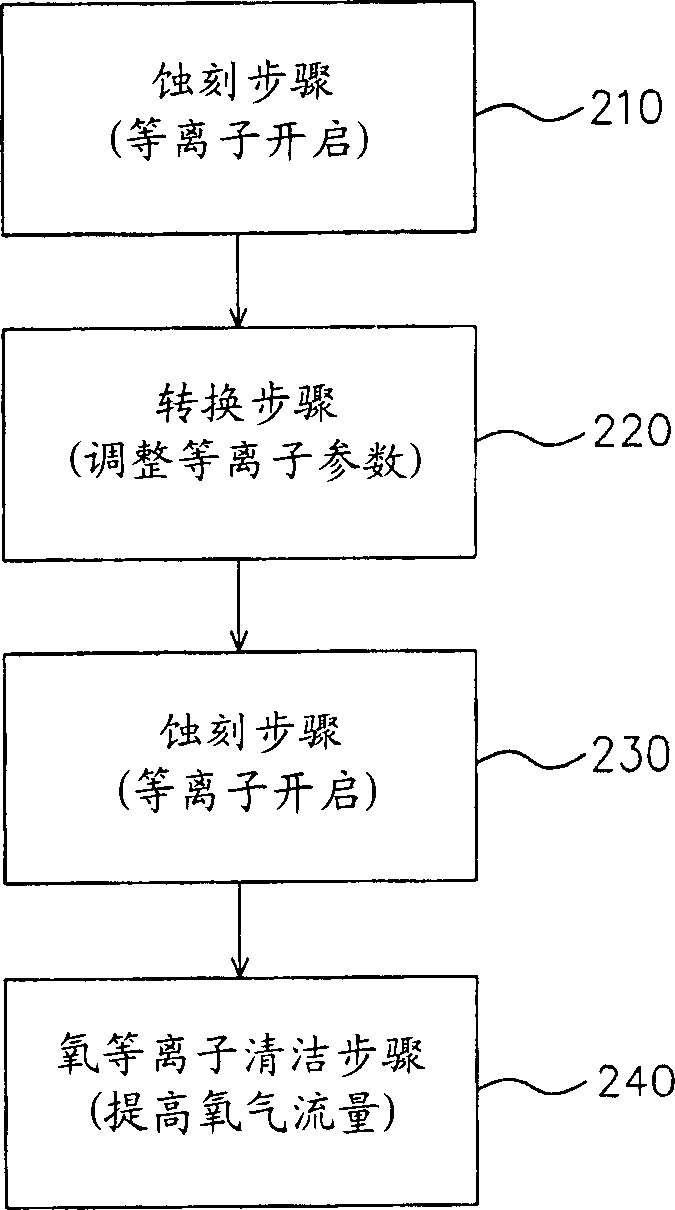

Plasma etching method of reducing generation of fine dust

InactiveCN1797716ATo avoidThe reaction environment is stableSemiconductor/solid-state device manufacturingOxygen plasmaPhysical chemistry

Being suitable for forming trench in substrate, the method includes steps: carrying out first etching step for the substrate under first etching condition; carrying out second etching step for the substrate under second etching condition; carrying out a conversion step between the first etching step and second etching step in order to adjust one of environmental parameters such as pressure condition in reaction chamber, gas flow, source power of plasma or temperature of reaction chamber; moreover, making variance of environmental parameters between etching step and conversion step be les than 15úÑ in order to maintain stabilized environment for reaction, and to avoid dropping off fine dust. Afterwards, when cleaning step of oxygen plasma is carried out, pressure in reaction chamber is raised to 40mTorr -80mTorr so as to prevent generation of spheroidal defect.

Owner:UNITED MICROELECTRONICS CORP

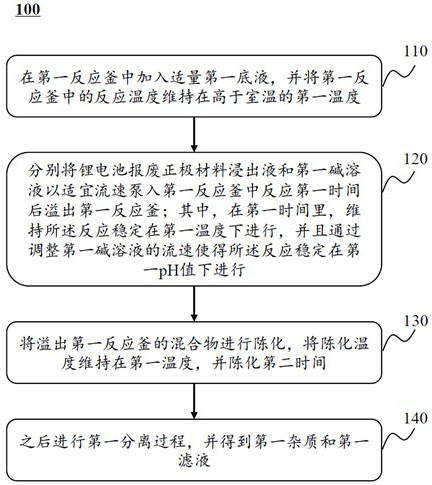

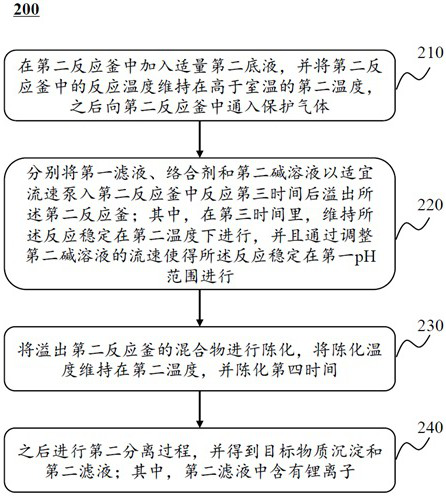

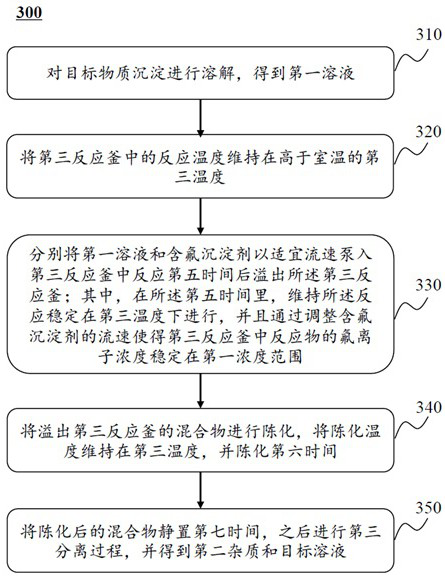

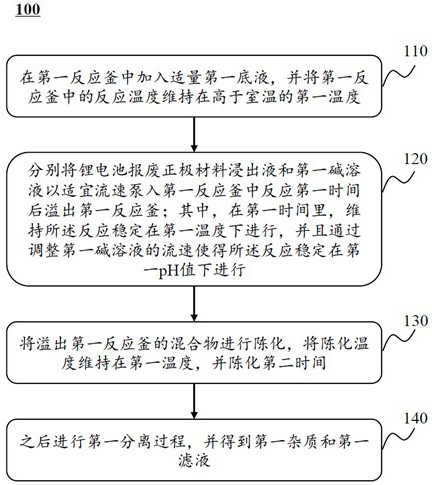

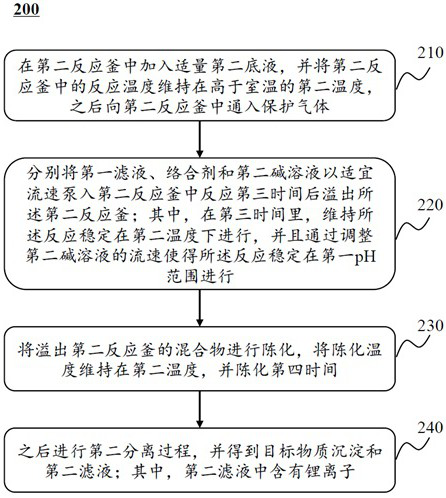

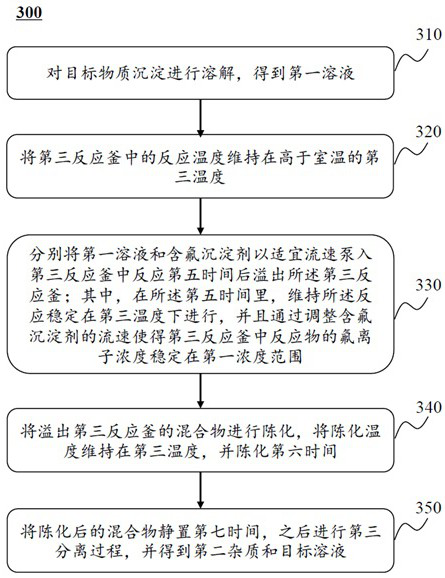

Impurity removal and treatment method in lithium battery scrapped positive electrode material recovery process

ActiveCN112151903AThe reaction environment is stableContinuous uninterrupted operationNon-aqueous electrolyte cellsReclaiming serviceable partsAluminum IonElectrode material

The embodiment of the invention discloses an impurity removal and treatment method in a lithium battery scrapped positive electrode material recovery process. The method comprises the following steps:at a first temperature higher than room temperature and a fixed first pH value, controlling the flow flows of a lithium battery scrapped positive electrode material leaching solution and a first alkaline solution to precipitate and remove iron ions, aluminum ions and at least part of copper ions to obtain a first filtrate; controlling the flow rates of the first filtrate, a complexing agent and asecond alkaline solution at a second temperature higher than room temperature and a fixed first pH range to separate out a second filtrate containing lithium ions to obtain a target substance precipitate; dissolving the target substance precipitate to obtain a first solution; and controlling the flow rates of the first solution and a fluorine-containing precipitant to precipitate and remove calcium ions, magnesium ions and at least part of lead ions at a third temperature higher than room temperature and a fixed fluorine ion concentration to obtain a target solution. According to the method,the precipitate with large particle size, high crystallinity and low water content can be obtained, washing is convenient, and the recovery rate of the lithium battery scrapped positive electrode material nickel-cobalt-manganese is increased.

Owner:SICHUAN ENERGY INTERNET RES INST TSINGHUA UNIV

Ionic liquid electrolyte for magnesium alloy surface treatment and method for electroplating aluminum on surface of magnesium alloy

The invention provides ionic liquid electrolyte for magnesium alloy surface treatment and a method for electroplating aluminum on the surface of magnesium alloy and relates to the technical field of protection of magnesium alloy surfaces. The ionic liquid electrolyte for magnesium alloy surface treatment comprises ionic liquid mixed liquid of aluminum chloride and organic salt, wherein the organicsalt is one of halogenated alkyl pyridine, halogenated alkyl imidazole or chlorinated aryl ammonium salt. The method for electroplating aluminum on the surface of the magnesium alloy comprises the following steps: magnesium alloy pre-treatment: mechanically grinding the magnesium alloy, alkali washing to remove oil liquor, dipping the magnesium alloy with galvanizing zinc and drying the magnesiumalloy successively for later use; electrolyte preparation: electroplating aluminum to the surface of the magnesium alloy, putting an anode material which is made from a high purity aluminum plate anda cathode material which is the pre-treated magnesium alloy in the electrolyte, and carrying out pulse electroplating mode or a direct current electroplating mode; and cleaning: flushing the electroplated magnesium alloy to obtain the aluminized magnesium alloy. According to the technical scheme, the ionic liquid electrolyte is novel and environment-friendly, a tight and uniform aluminized layeris obtained on the surface of the magnesium alloy, and the corrosion resistance of the magnesium alloy is improved.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

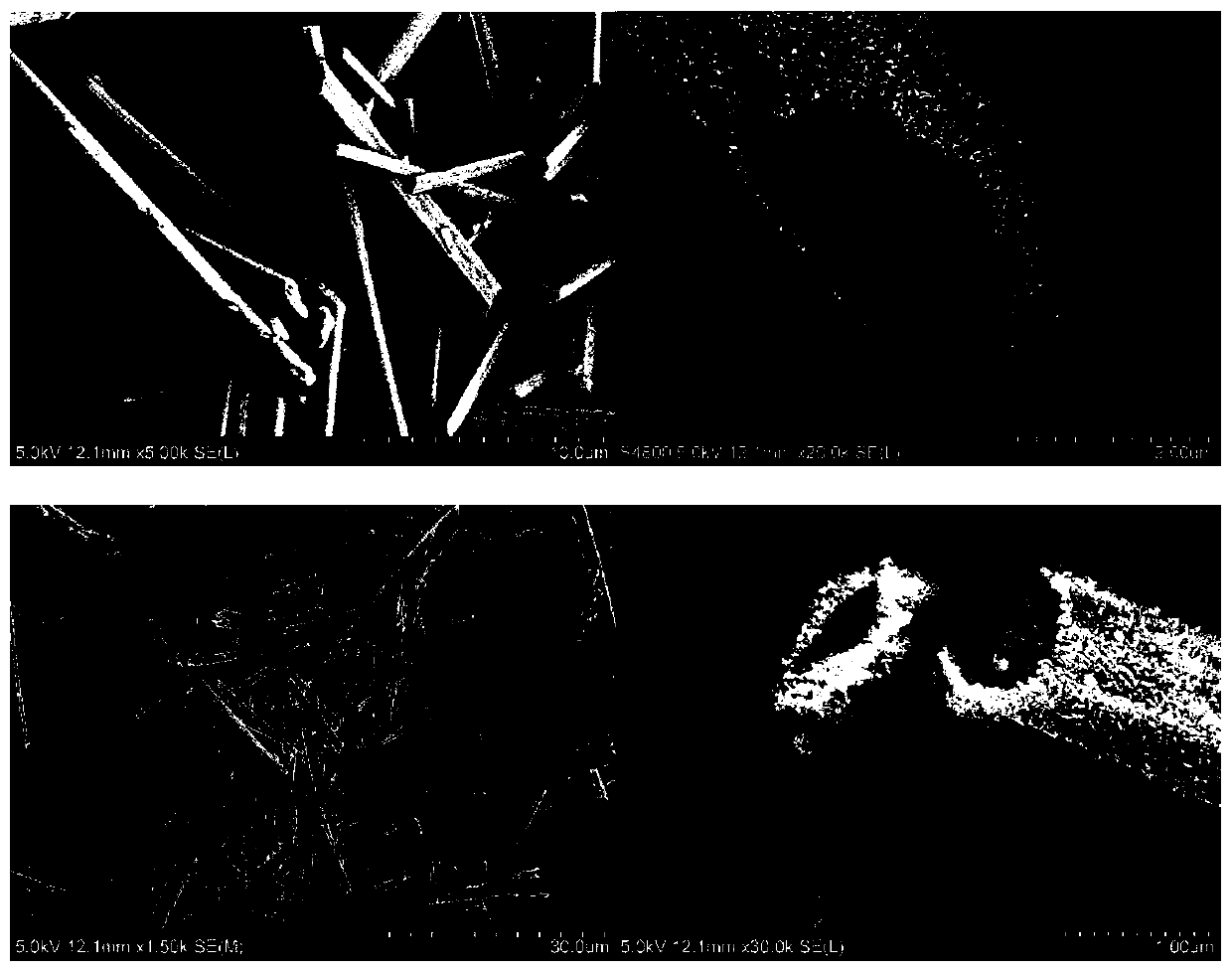

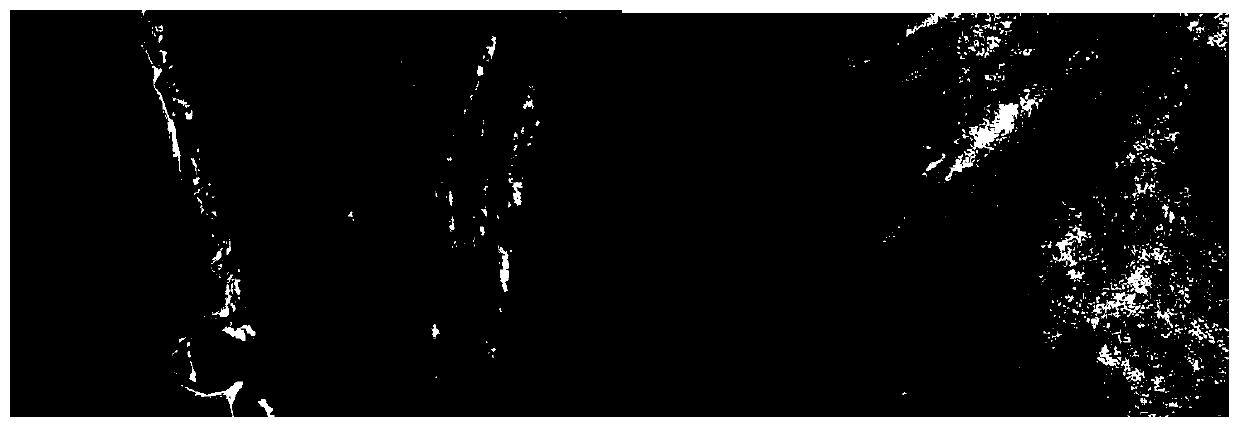

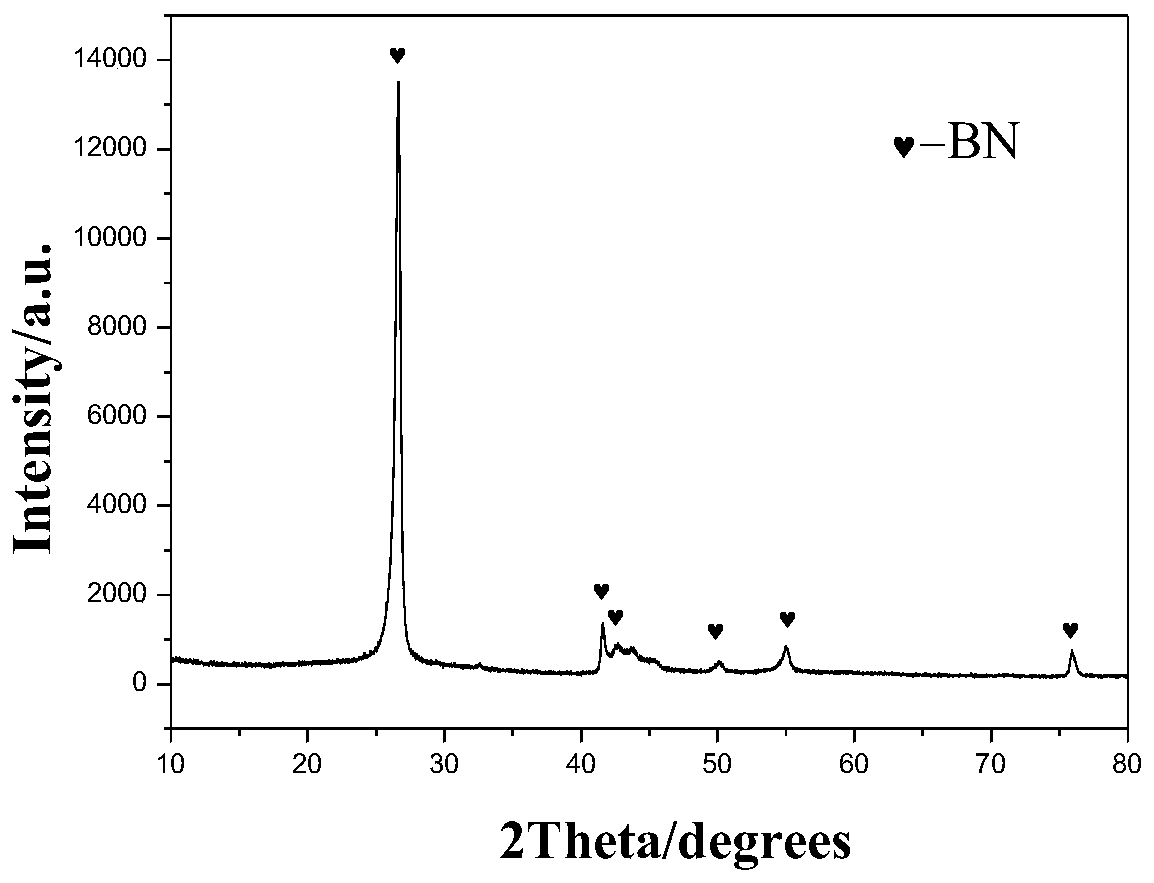

Preparation method of one-dimensional hierarchical-structure thin-wall BN microtube, and product thereof

ActiveCN110817814AHigh purityFacilitate large-scale industrial productionMaterial nanotechnologyPhysical/chemical process catalystsTube furnaceBoron containing

The invention relates to a preparation method of a hierarchical-structure thin-wall BN microtube. The preparation method mainly comprises the following steps: putting a boron-containing precursor intoa tube furnace, introducing nitriding reaction gas, carrying out heating to 1000-1200 DEG C, and keeping the temperature for 2 hours or more to obtain a large batch of high-quality one-dimensional boron nitride hierarchical-structure materials. According to the method, a substrate is not needed; the preparation method is simple and effective in process and low in energy consumption and uses cheapand non-toxic raw materials; and the purity of a purified target product is high, which is favorable for batch production of the boron nitride micro-nano hierarchical structure materials.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

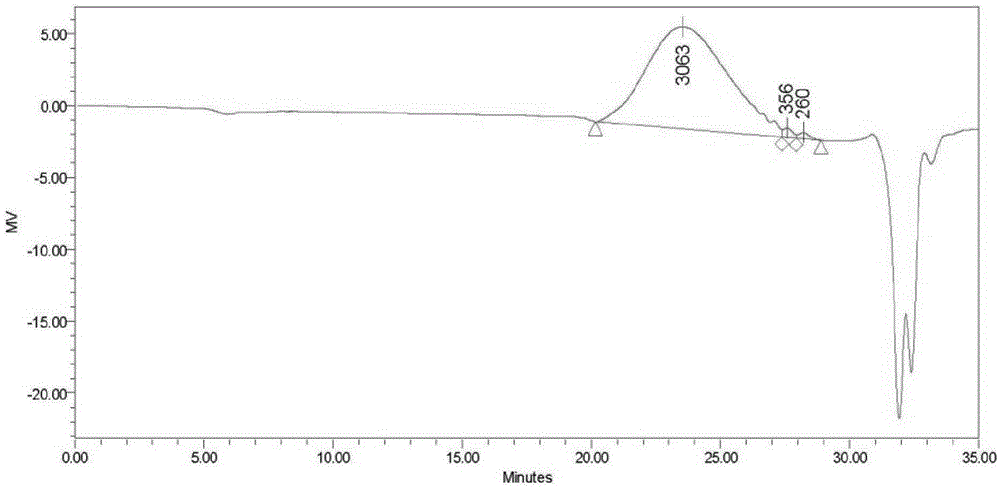

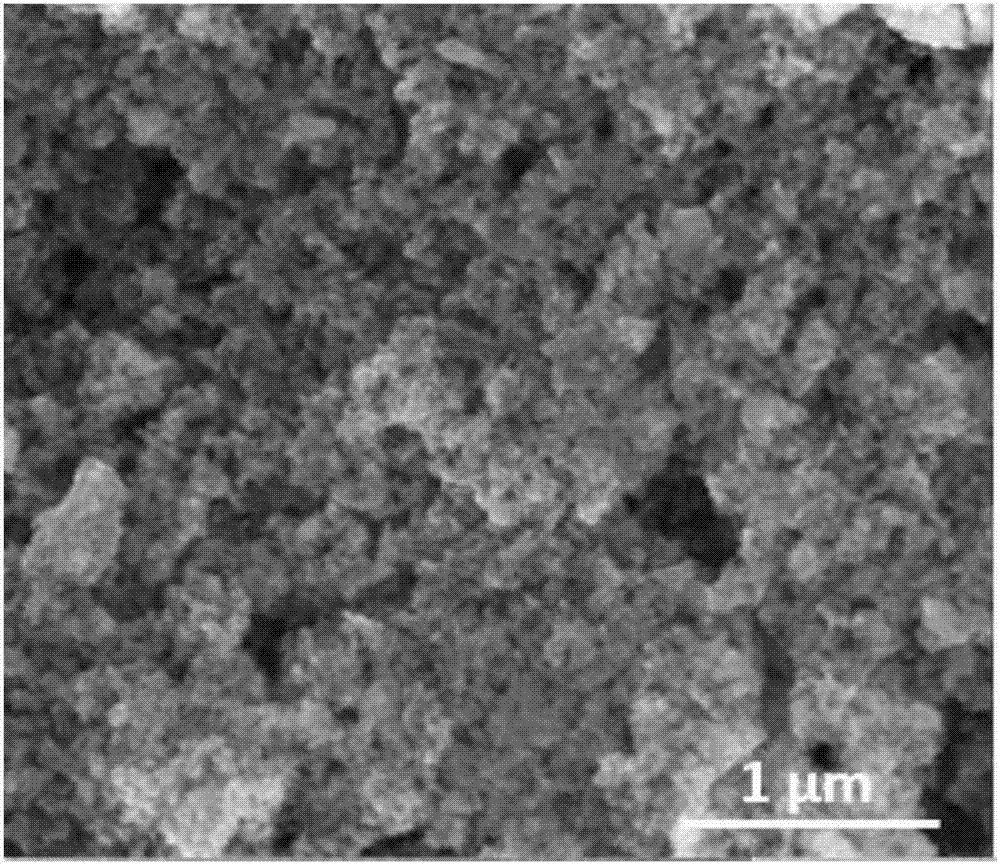

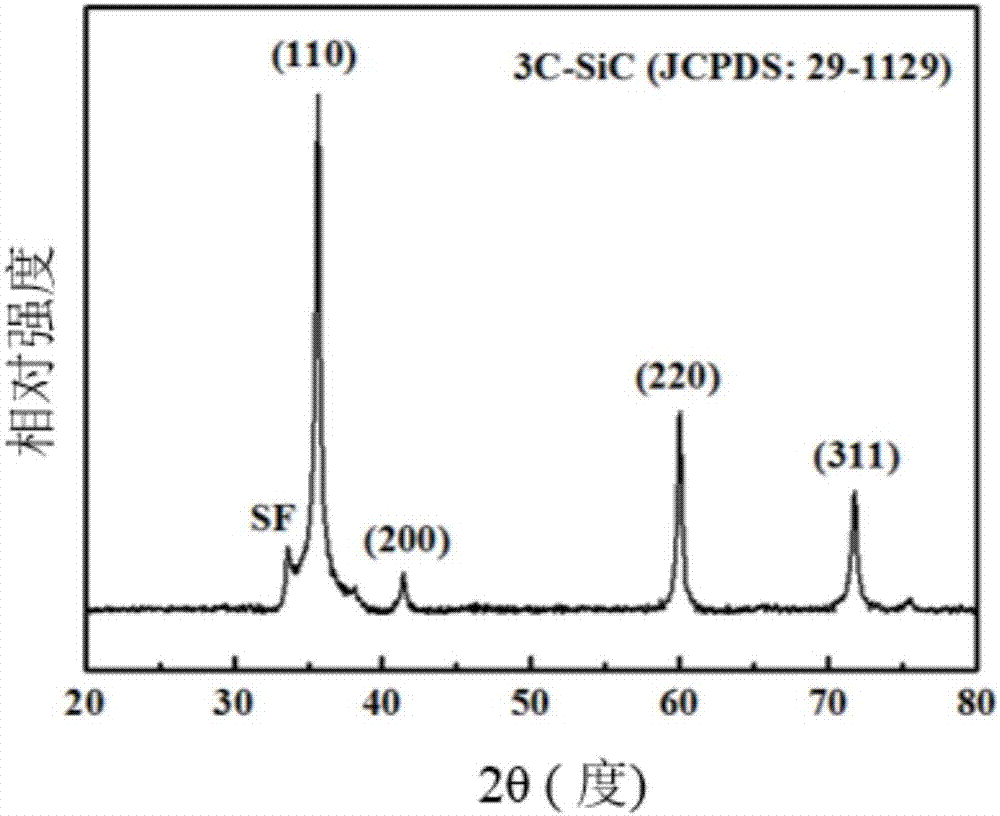

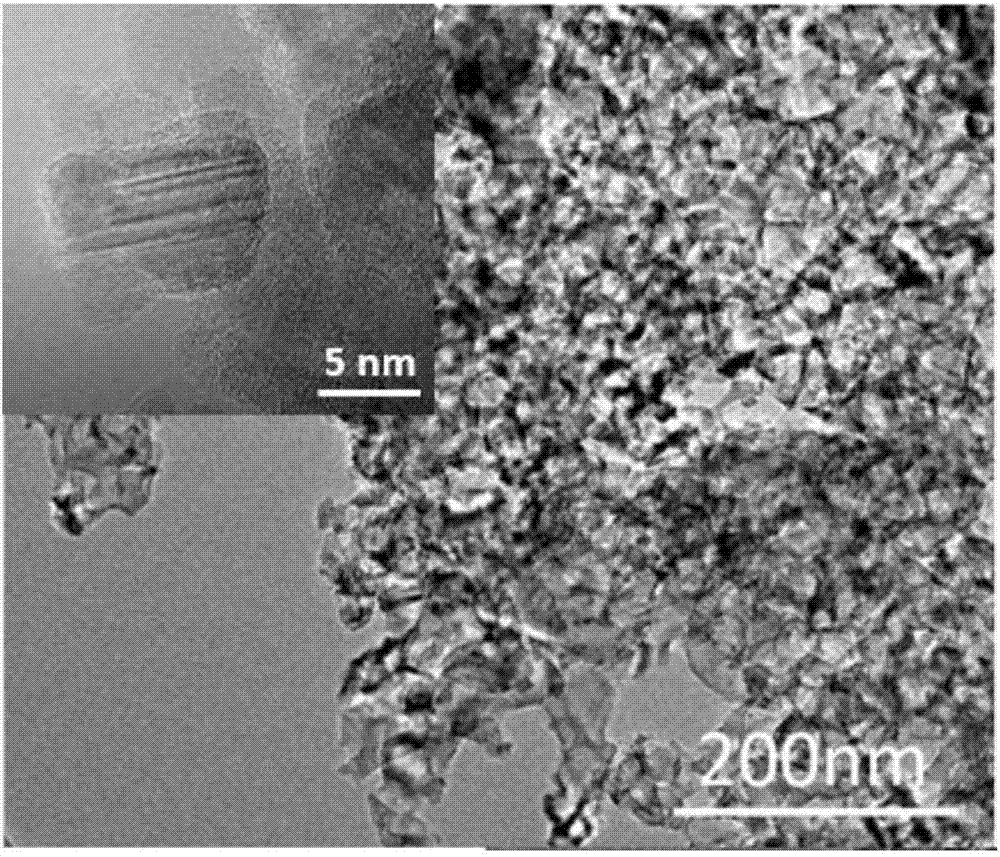

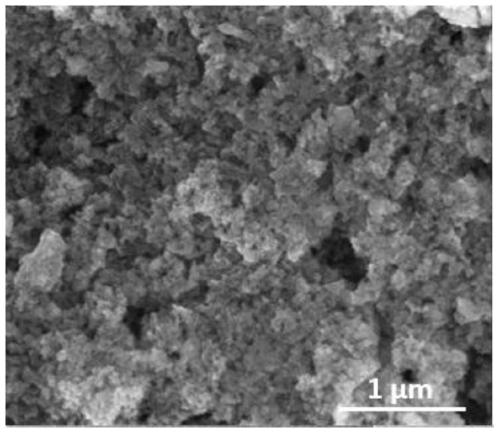

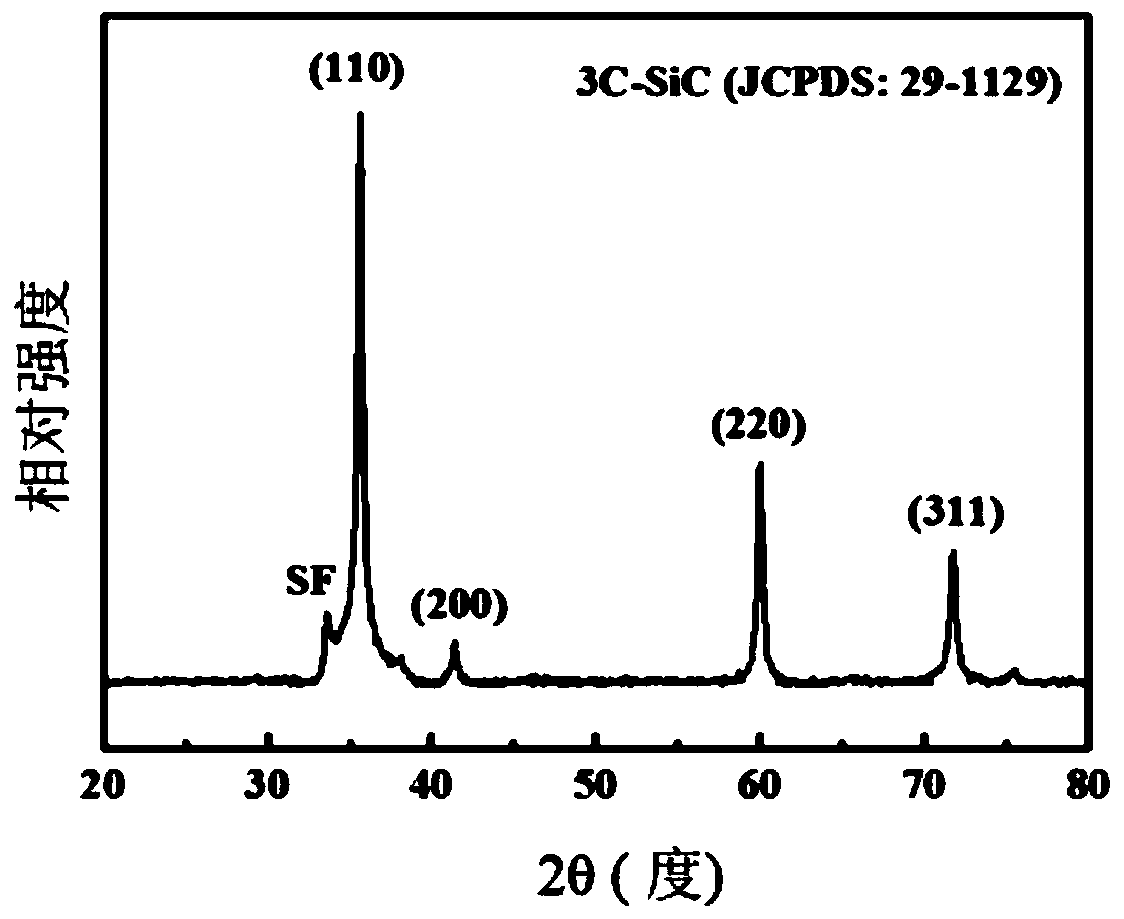

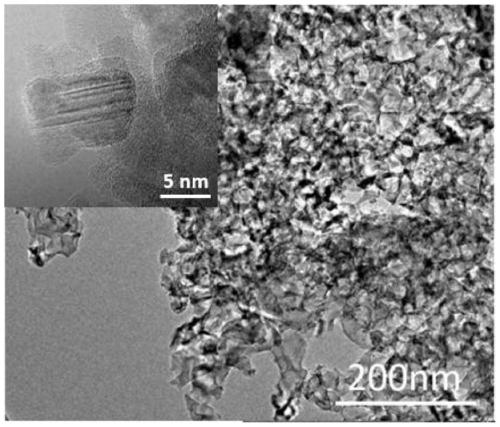

Method for preparing porous nano-silicon carbide by using silicate glass as raw material

ActiveCN107416837ALow costExcellent heat responseMaterial nanotechnologyCarbon compoundsSolubilityReaction temperature

The invention discloses a method for preparing nano-silicon carbide by using silicate-based glass as a raw material. The method comprises the following steps: carrying out mechanical ball milling on glass; carrying out uniform ball milling and mixing on the ball-milled powdery glass, magnesium powder, coal tar and molten salt according to a certain proportion, and placing into a container for reaction under inert gas; then pickling the reaction product to obtain nano-silicon carbide. The method disclosed by the invention has the advantages that steps are simple and easy and the source of raw materials is wide; further, the Mg-containing molten salt is added as a heat absorbent to control the reaction temperature and increase the solubility and wettability of magnesium so as to enable the reaction to be more sufficient and the reactants not to agglomerate easily. The three-dimensional porous silicon carbide prepared by the method has the advantages of relatively high purity, uniform particle, high specific surface area (180-260m<2> / g), rich mesoporous structure and the like, and has wide application prospects in the aspects of radiation resistance, radiation resistance and wave absorption.

Owner:WUHAN UNIV OF SCI & TECH

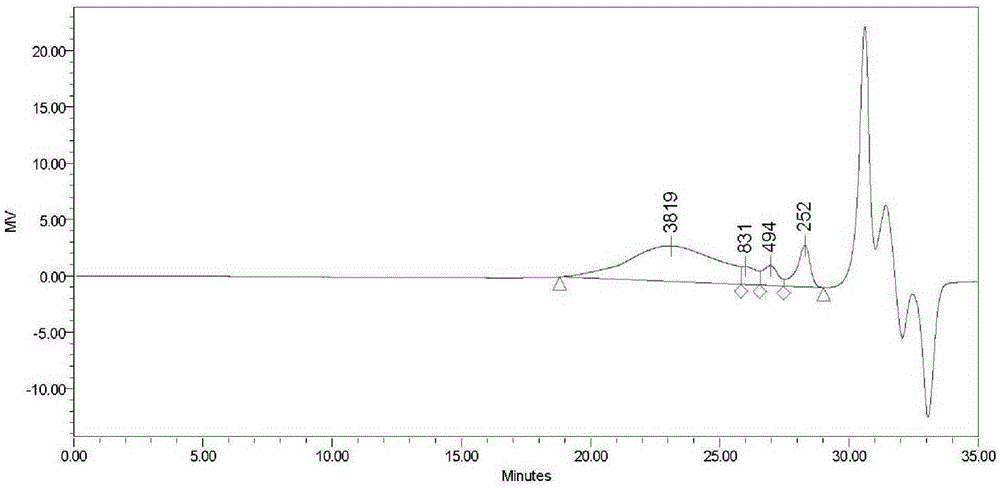

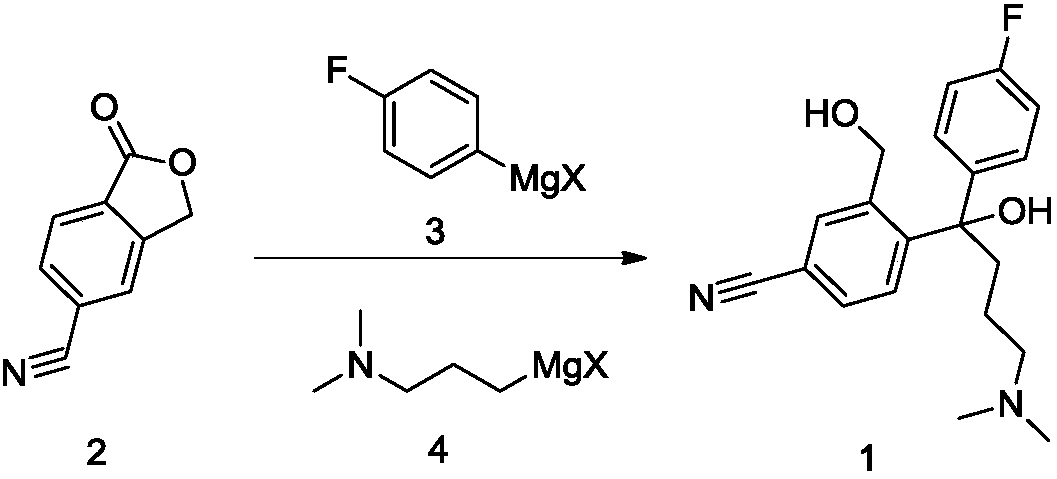

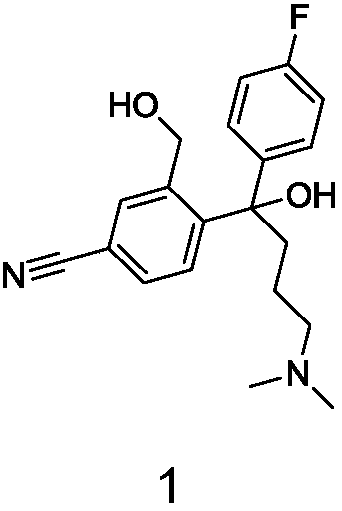

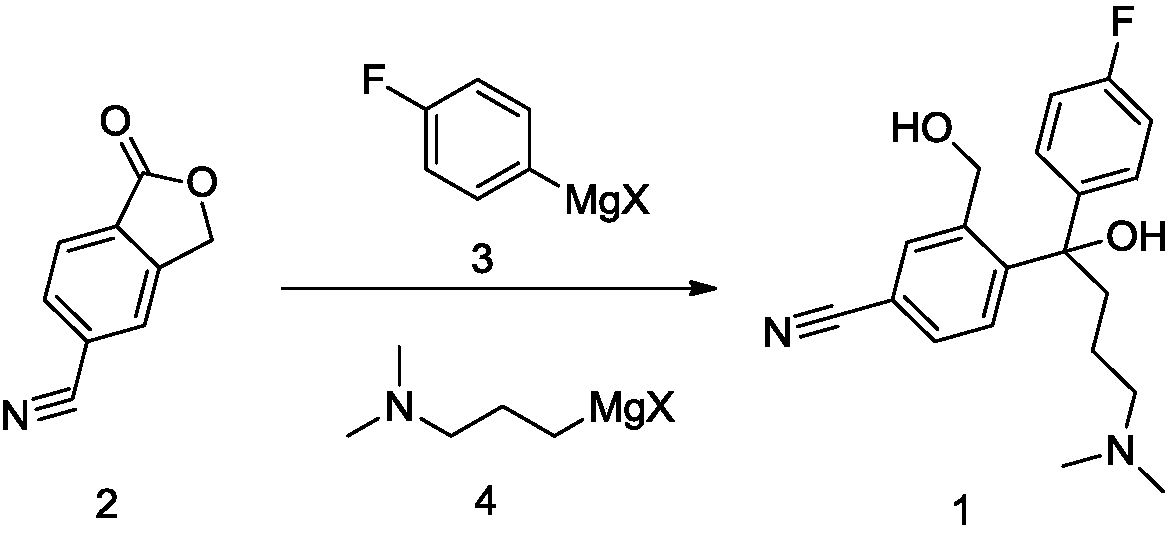

Method for continuously preparing citalopram diol

ActiveCN111302971AControl generationHigh selectivityCarboxylic acid nitrile preparationOrganic compound preparationGrignard reagentCombinatorial chemistry

The invention provides a method for continuously preparing a citalopram intermediate citalopram diol. The method comprises the following steps: preferentially mixing two Grignard reagents required bya reaction, mixing the mixed Grignard reagent with a raw material 5-cyanophthalide in a micro-mixer to obtain a reaction solution, completing the reaction of the reaction solution through a reactor toobtain a citalopram diol reaction solution, quenching, concentrating, extracting, acidifying, crystallizing, and carrying out other operations to obtain a qualified product. The citalopram diol provided by the invention is good in selectivity, high in yield, high in safety, safe, reliable, less in pollution discharge and suitable for industrial production.

Owner:SHANGHAI AOBO PHARMTECH INC LTD +1

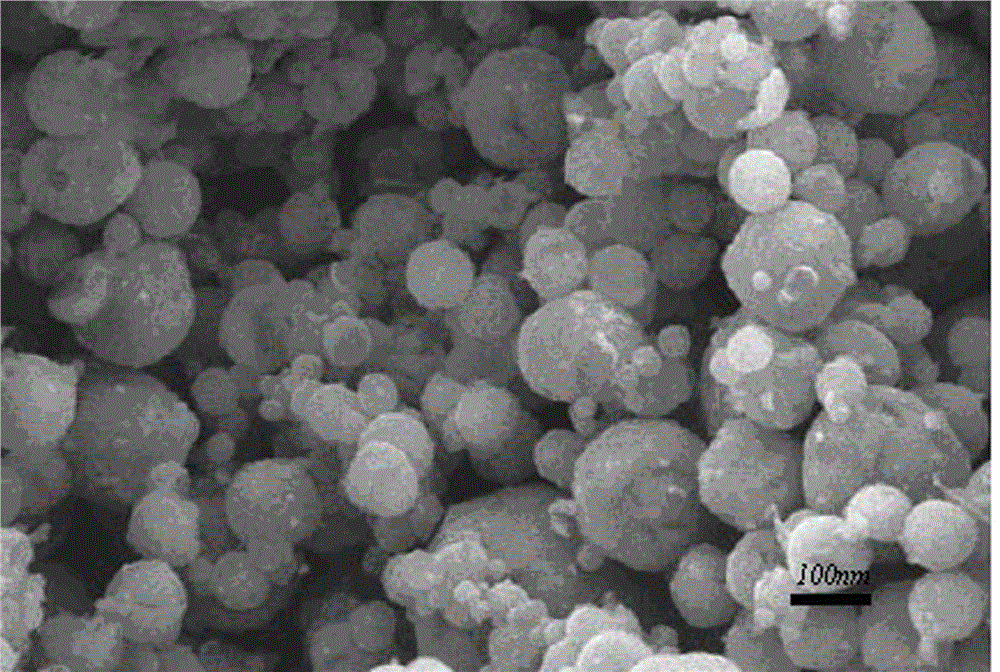

Preparation method of novel nano manganese lithium titanate LiMnxTiO4 cathode material

InactiveCN105576199AEasy reunionEasy to manufactureMaterial nanotechnologyCell electrodesPhysical chemistryManganese

The invention relates to a preparation method of a novel nano manganese lithium titanate cathode material. The preparation method comprises: firstly, preparing a manganese lithium titanate precursor by combining a solvothermal method with a solid phase method; then preparing the carbon coated nano manganese lithium titanate cathode material by utilizing a high-temperature calcination method. By testing, the material is relatively structured in morphology, has a size of about 50 to 200 nanometers, and has a high crystallinity degree and excellent electrochemical performance. Meanwhile, the material is relatively simple in steps of a synthetic process, is easy for controlling the process, and is suitable for large-scale industrial production.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

Mixing kettle for preparing light-color disproportionated rosin potassium soap rubber auxiliary agent and application method

InactiveCN108816176AEasy to useThe reaction environment is stableRotary stirring mixersTransportation and packagingPotassium soapRosin

The invention discloses a mixing kettle for preparing a light-color disproportionated rosin potassium soap rubber auxiliary agent and an application method and provides the mixing kettle for preparingthe light-color disproportionated rosin potassium soap rubber auxiliary agent. According to the mixing kettle, steam is used for heating and the temperature is easier to control; meanwhile, the mixing kettle is provided with a cooling water circulating system and can be used for cooling more rapidly. Meanwhile, the application method of the mixing kettle is simple and is easy to operate.

Owner:NANJING WUSONG FORESTRY CHEM

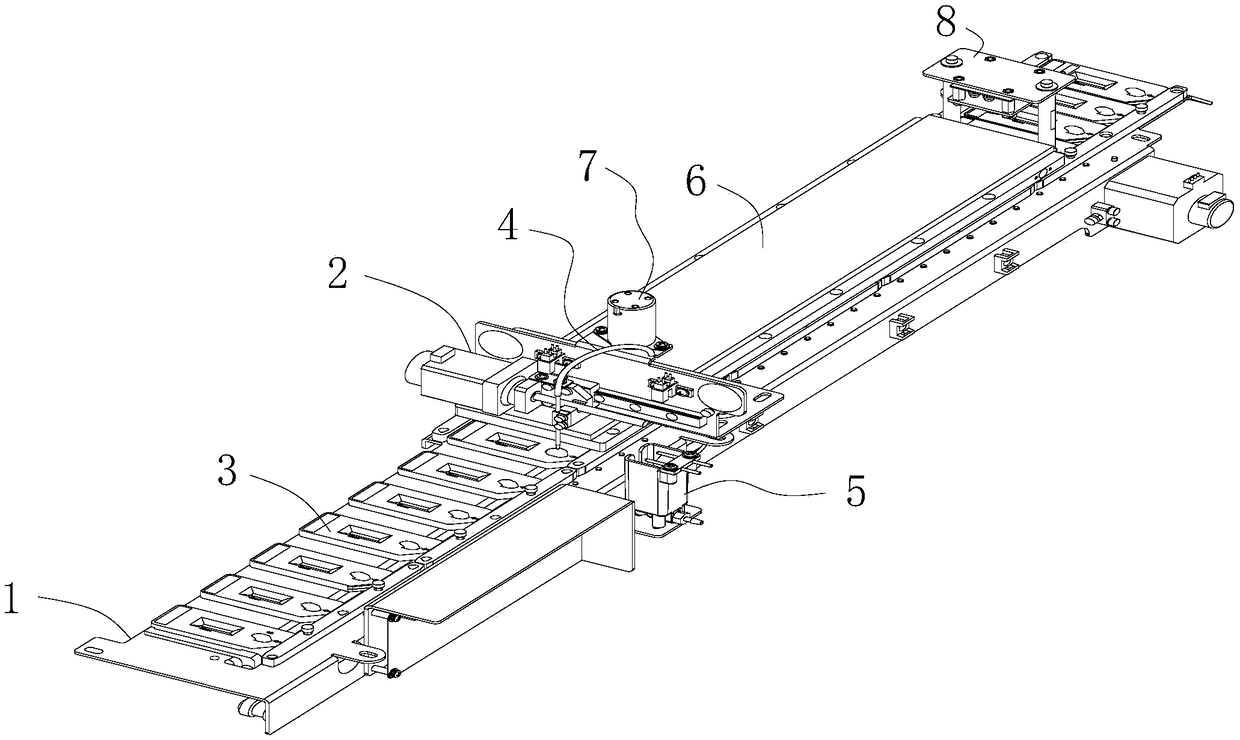

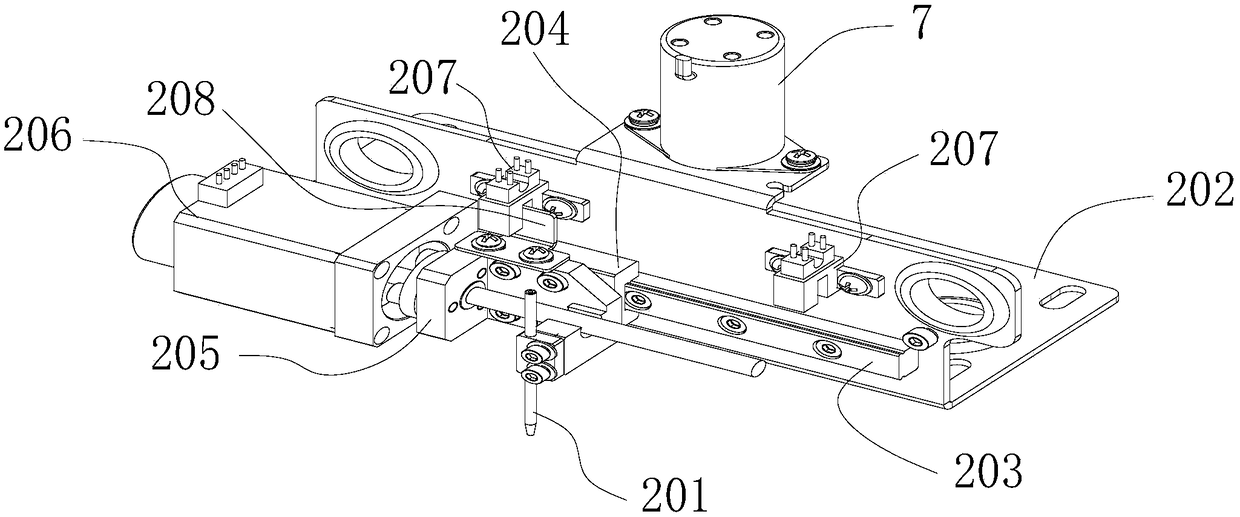

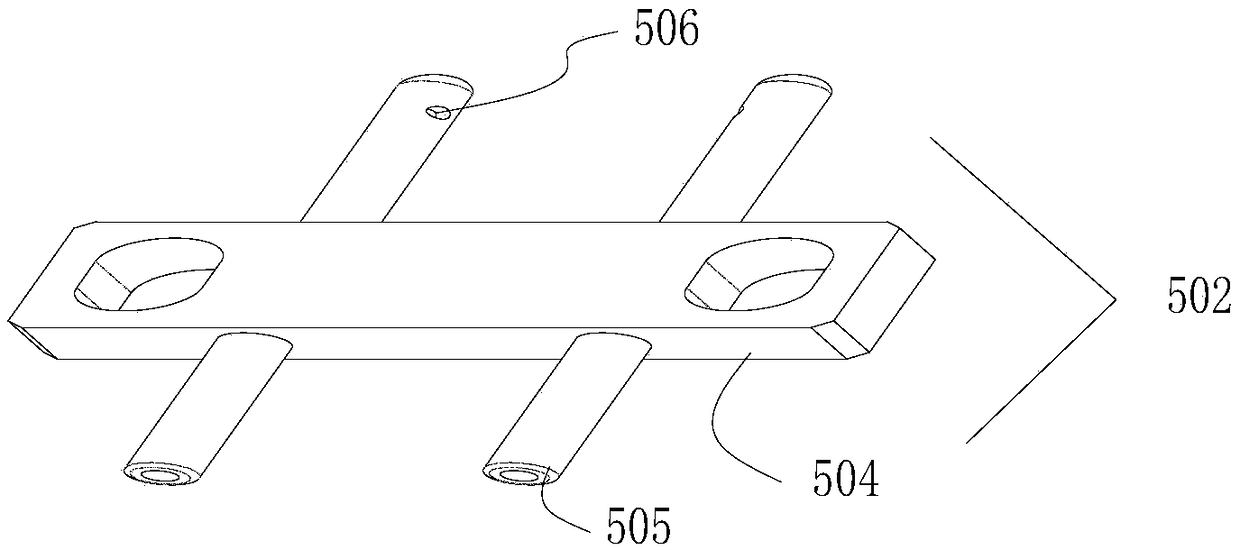

Liquid adding device

The invention discloses a liquid adding device. The liquid adding device comprises a card pushing assembly and a liquid adding assembly; the card pushing assembly comprises a positioning base plate and a pushing mechanism, and a plurality of gold sample cards are distributed on the positioning base plate in an axial direction; the pushing mechanism automatically pushes the gold sample cards to axially move along the positioning base plate; the liquid adding assembly comprises a liquid adding needle arranged above the positioning base plate; and one end of the liquid adding needle is connectedwith a liquid inlet pipe, and the other end is used for adding liquid to the gold sample card which is moved to the space just below the liquid adding needle. The invention provides the automatic liquid adding device which can realize rapid and accurate liquid adding as well as can realize isolation of an operator and a sample.

Owner:SICHUAN ORIENTER BIOLOGICAL TECH

Oil field acidification plug removal system based on deep eutectic solvent

InactiveCN113234427AStable generationThe reaction environment is stableDrilling compositionHexamethylenetetramineSuccinic acid

The invention provides an acidification plug removal system based on a deep eutectic solvent. Specifically, the scale inhibitor is obtained by mixing the following raw materials in parts by mole: 9 to 11 parts of hexamethylenetetramine, 9 to 11 parts of D-sodium gluconate, 9 to 11 parts of sodium polyepoxysuccinate, 9 to 11 parts of polyaspartic acid, 7 to 9 parts of sodium ethylenediamine tetramethylene phosphonate, 6 to 9 parts of ethanol, 4 to 6 parts of rhamnolipid, 4 to 6 parts of benzotriazole and 4 to 7 parts of MA-AA polymer. The scale inhibitor, hydrochloric acid and villiaumite are mixed according to the total mole number ratio of 1: (2-4): (1-2) to form a solute, then the solute formed by mixing the scale inhibitor and the villiaumite is dissolved in a deep eutectic solvent, the novel plug removal system is obtained, and the total mole number ratio of the deep eutectic solvent to the solute formed by the villiaumite, the hydrochloric acid and the scale inhibitor is (0.01-0.5): 1. The deep eutectic solvent can control the strong acidity of hydrochloric acid, delay the intense reaction effect of a rock stratum and an acid liquid system, fully exert the solvent effect of the deep eutectic solvent, reduce the generation of precipitates and improve the plug removal efficiency.

Owner:DONGGUAN UNIV OF TECH

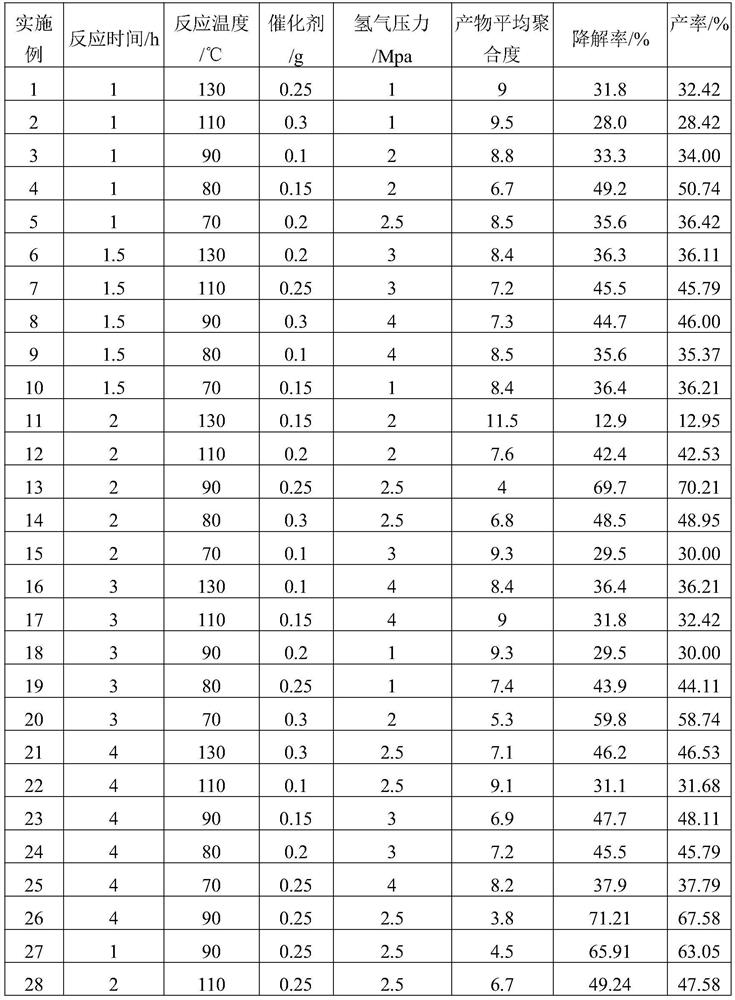

Hydrolysis method of polymeric proanthocyanidins and product and application thereof

PendingCN113321635ALow priceUniform degree of polymerizationCosmetic preparationsOrganic chemistryPolymer scienceProanthocyanidin

The invention discloses a hydrogenolysis method of polymeric proanthocyanidins as well as a product and application of the polymeric proanthocyanidins. The hydrogenolysis method provided by the invention comprises the step of carrying out hydrogenolysis reaction on polymeric proanthocyanidins in the presence of an ionic liquid and a hydrogenolysis catalyst. According to the method, the proanthocyanidins is subjected to concerted catalytic hydrogenolysis by adopting the ionic liquid, a safe and stable reaction environment is provided for hydrogenolysis of the proanthocyanidins, and the polymerization degree of the obtained oligomeric proanthocyanidins product is more uniform.

Owner:NORTHEAST FORESTRY UNIVERSITY

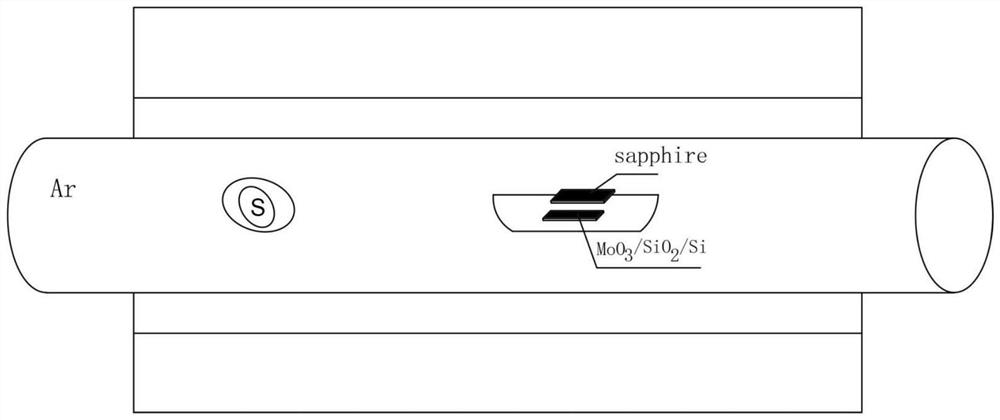

Two-dimensional material, two-dimensional material alloy and two-dimensional material heterojunction preparation method

PendingCN114411148AEvenly distributedImprove controllabilityVacuum evaporation coatingSputtering coatingHeterojunctionEvaporation (deposition)

The invention provides a two-dimensional material, a two-dimensional material alloy and a two-dimensional material heterojunction preparation method, and belongs to the technical field of two-dimensional material preparation. A metal film or a metal oxide film is prepared on a silicon wafer through a thermal evaporation coating method to serve as a precursor film, the silicon wafer plated with the precursor film and a substrate are placed in an evaporation boat in a face-to-face mode, the precursor film is vulcanized through a chemical vapor deposition method, and the two-dimensional transition metal chalcogenide grows on the substrate. The two-dimensional material with controllable thickness and size can be obtained by changing the thickness of the precursor film and the face-to-face distance between the silicon wafer and the substrate. The preparation method provided by the invention is universally suitable for growth of two-dimensional materials including two-dimensional transition metal selenium compounds and two-dimensional transition metal tellurium compounds, can be used for preparation of two-dimensional material alloys and heterostructure materials, and is simple in preparation process, high in repeatability and suitable for industrial production. The controllability and the stability of the two-dimensional material in the growth process can be effectively improved.

Owner:ZHEJIANG UNIV HANGZHOU GLOBAL SCI & TECH INNOVATION CENT

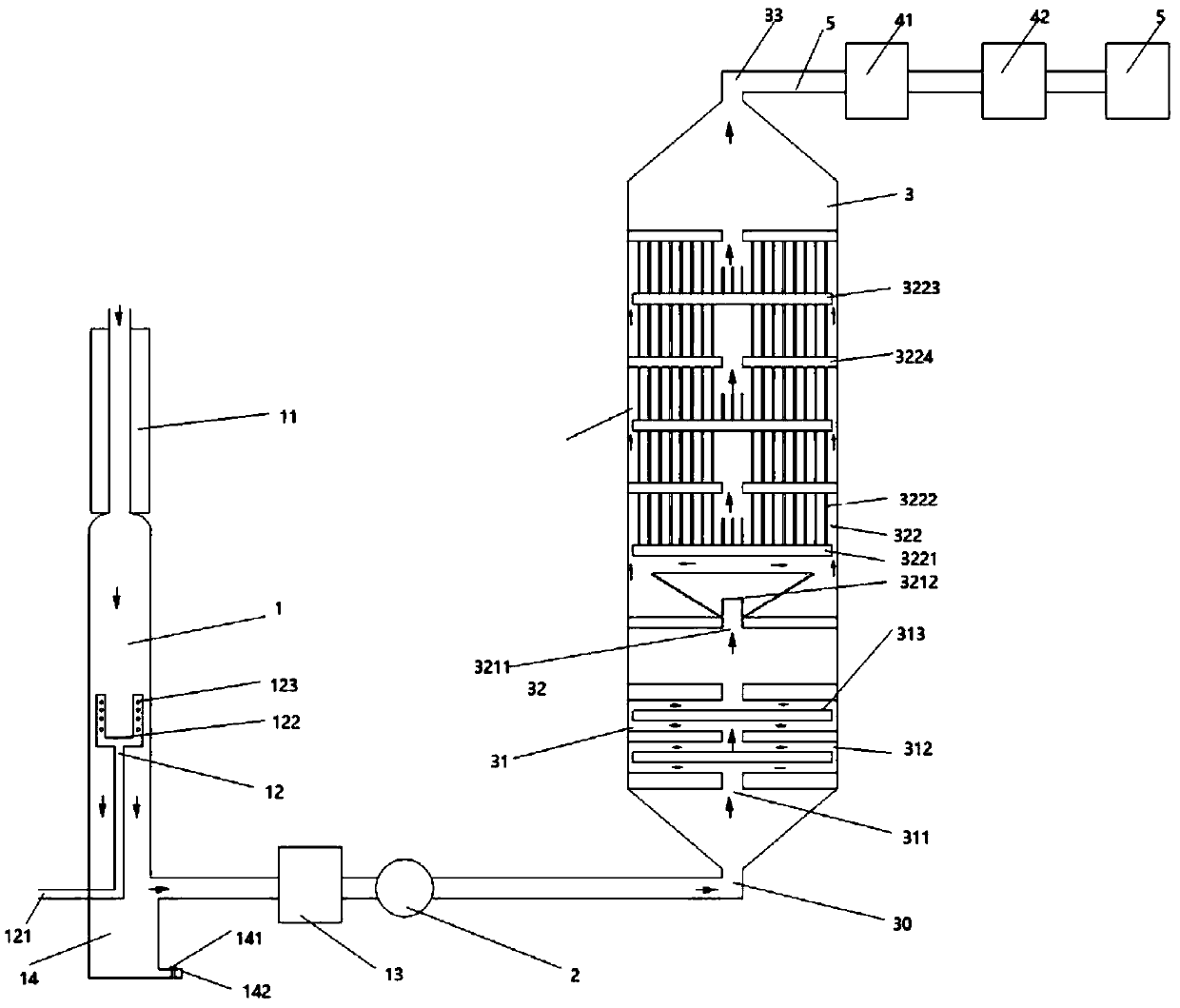

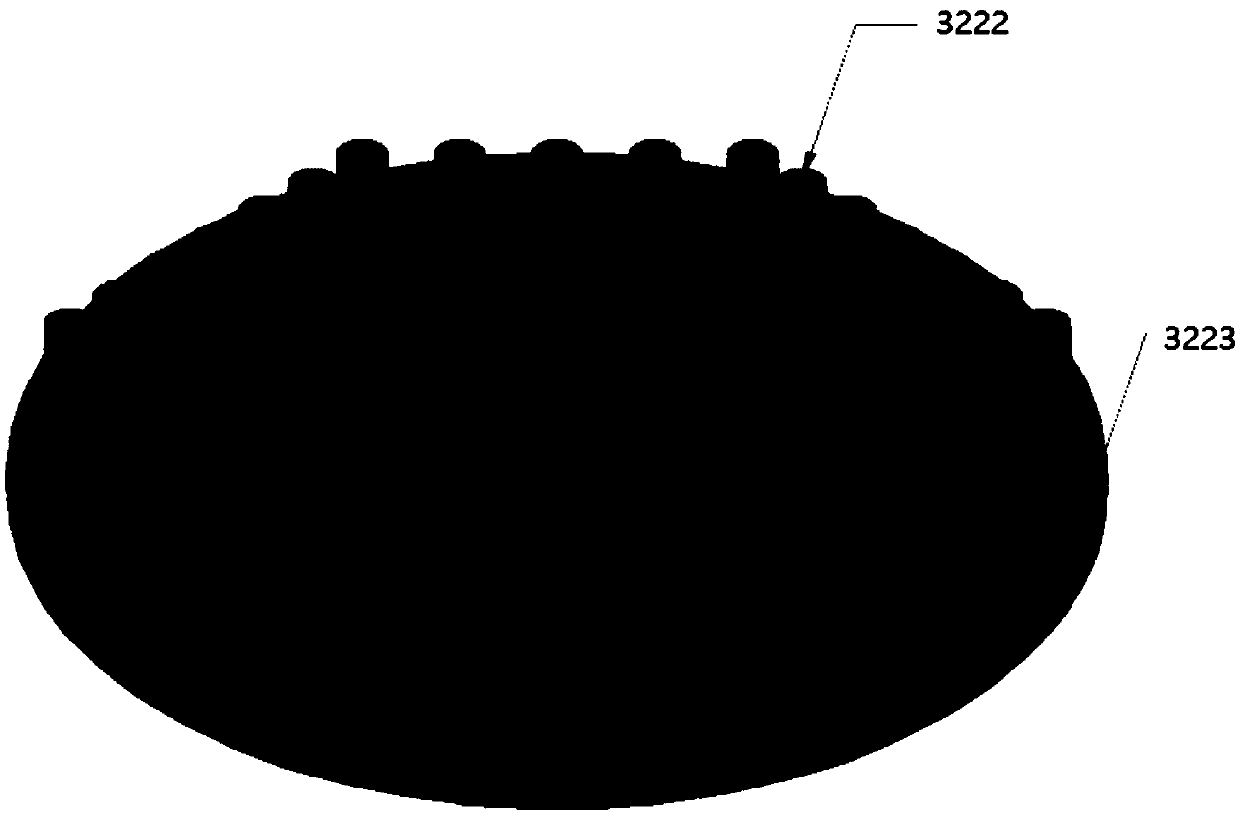

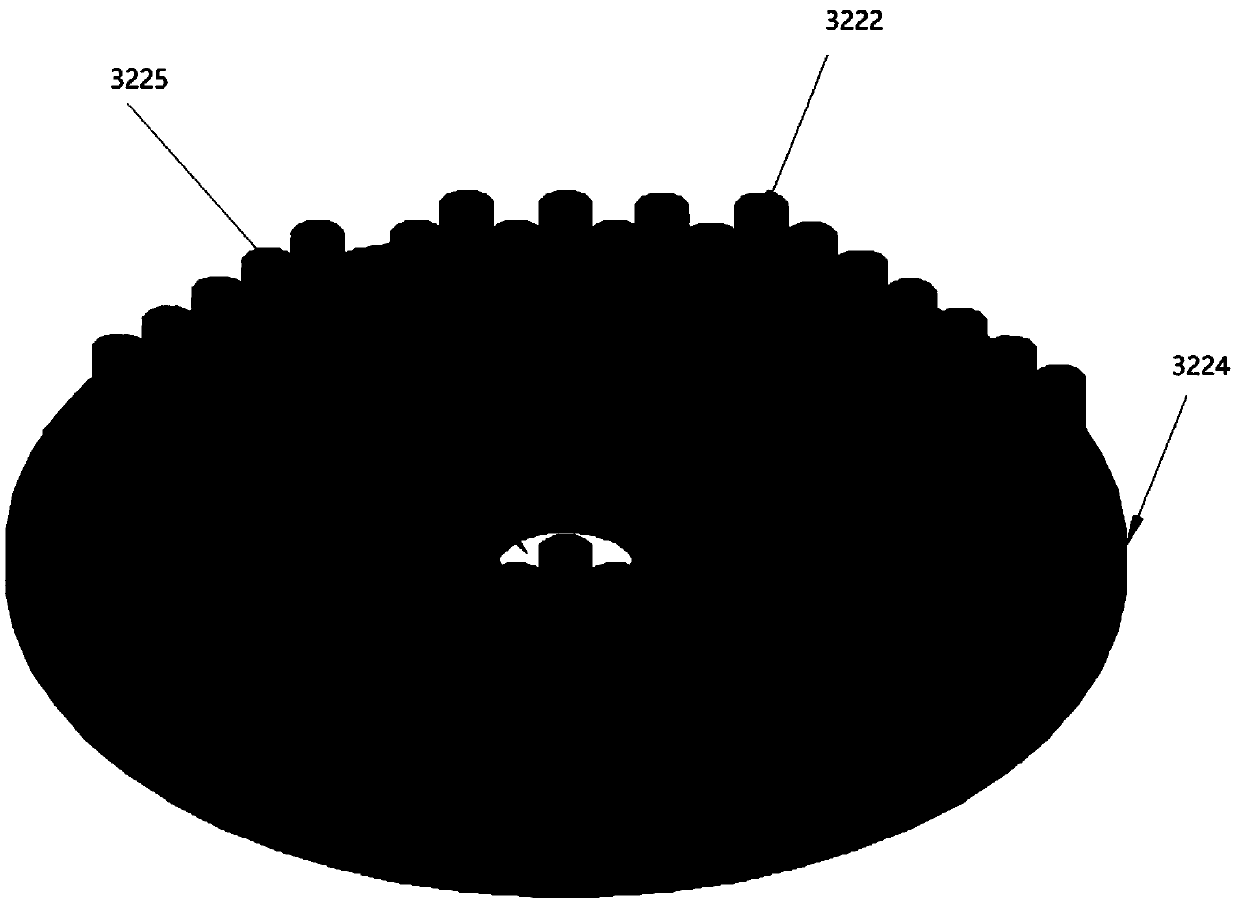

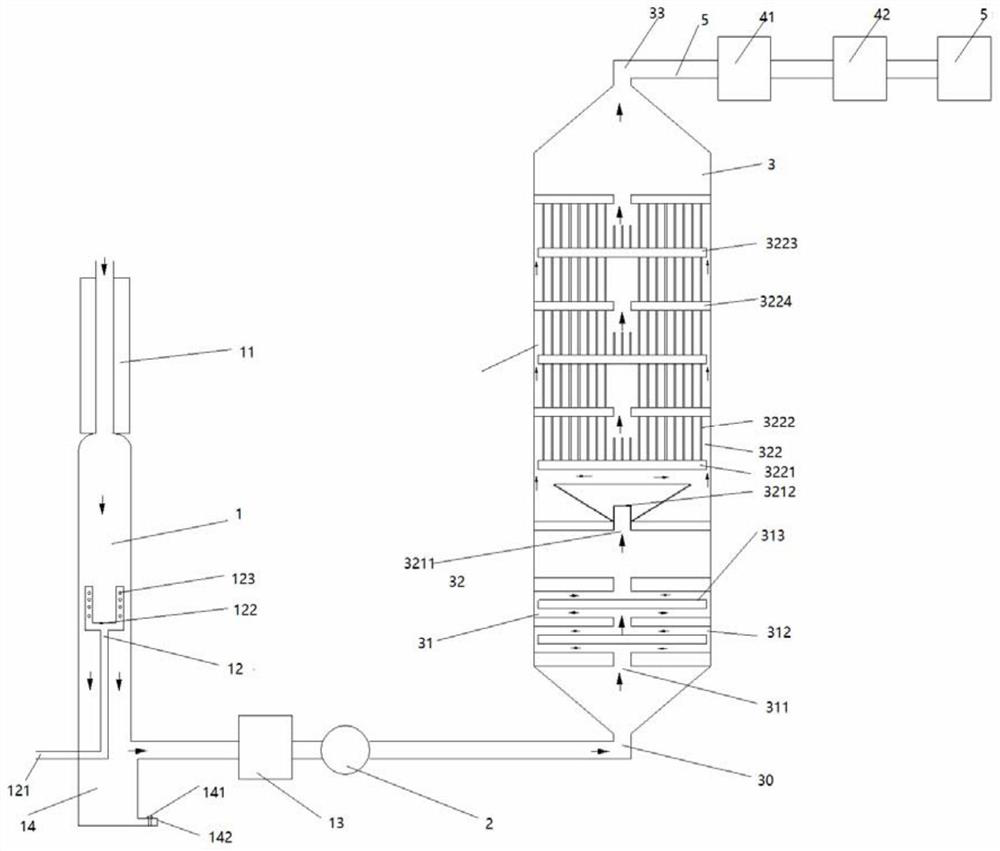

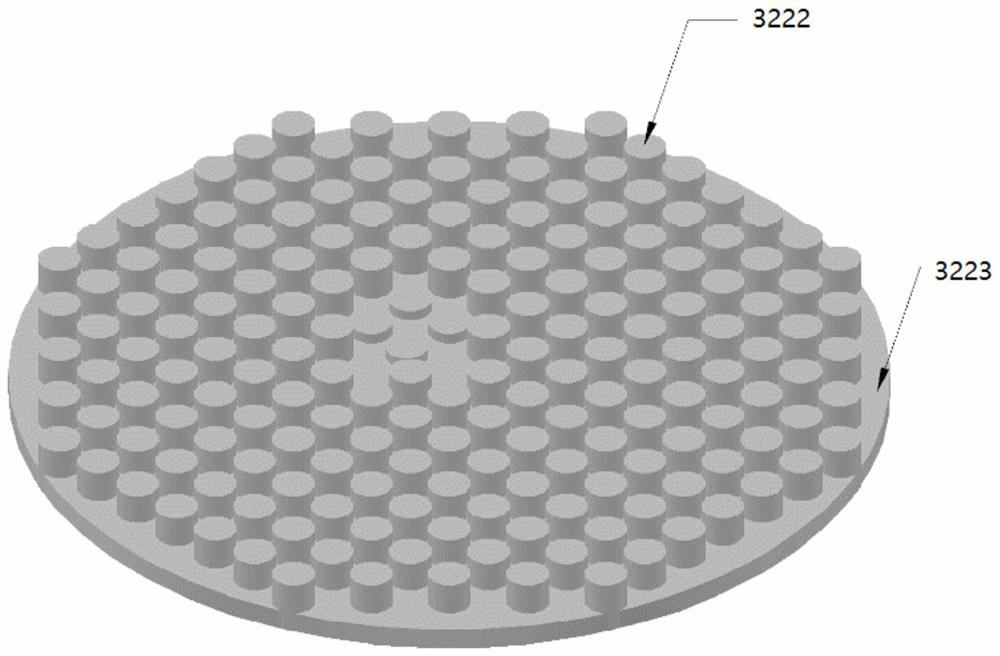

CVI/CVD process tail gas recovery device and method

The invention discloses a CVI / CVD process tail gas recovery device and method, wherein the device includes a cooling filter device, a vacuum pump, an isothermal cracking furnace and a post comprehensive treatment device; the cooling filter device comprises a circulating liquid cooling module, an oil filter and a drying filter; a preheating zone module is arranged at the bottom of the interior of the isothermal cracking furnace, and an isothermal zone module is arranged above the preheating zone module. The preheating zone module is a multilayer labyrinth graphite plate. The lower part of the isothermal zone module is a delay buffer zone, the upper part of the isothermal zone module is an upper cavity of the isothermal zone, and the upper cavity of the isothermal zone is provided with a multilayer graphite plate structure; the graphite plate is provided with an active carbon growth structure, and the surface of the active carbon growth structure is provided with a carbon black catalyst.The top of the isothermal cracking furnace is provided with a gas outlet, and the gas outlet is connected with the post comprehensive treatment device through a pipeline. The later comprehensive treatment device includes a pressure swing separator and a solid filter. The invention provides the CVI / CVD process tail gas recovery device and method with high treatment efficiency, good safety performance and high ecological environment friendliness.

Owner:上海康碳复合材料科技有限公司 +1

Resin composition and prepreg and laminate using the same

ActiveCN105419348BLess cross-linking pointsReduce intensitySynthetic resin layered productsLaminationGlass fiberHeat resistance

The present invention provides a resin composition, and a prepreg and a laminated board using the same. The resin composition comprises an epoxy resin-modified polyphenylene oxide resin prepolymer and a benzoxazine resin. The present invention applies the epoxy resin-modified polyphenylene oxide resin prepolymer in a resin composition for a printed circuit board, improving a dielectric performance of a copper clad laminate and increasing a glass fabric impregnation of the resin composition comprising the epoxy resin-modified polyphenylene oxide resin prepolymer. The resulting resin composition thereby provides excellent appearance, heat resistance, dielectric performance and peeling strength.

Owner:GUANGDONG SHENGYI SCI TECH

A method for preparing titanium dioxide/hollow microsphere composite reflective heat insulation filler

ActiveCN109988449BUniform hydrolysisImprove the wrapping effectReflecting/signal paintsPolymer scienceHydrolysis

The invention discloses a preparation method of titanium dioxide / hollow microsphere composite particles. In this method, a hydrophilic alkaline ionic liquid is used to replace the water+alkali system, so that the reaction has a more stable hydrolysis rate. Bead dispersion and surface titania adsorption film formation. The composite particle filler prepared by the above method has good titanium dioxide dispersion and film-forming properties, improves coating uniformity, and has obvious heat insulation effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of fluoride ceramic crucible and its manufacturing method

The invention discloses a fluoride ceramic crucible and a preparation method thereof. The base material of the crucible is composed of fluoride ceramic powder. The fluoride ceramic powder is heat-treated, and then the treated fluoride ceramic powder is crushed and sieved; Add sintering aids to the final fluoride ceramic powder, mix evenly, and sieve; put the under-sieve powder into the designed crucible mold for preforming; sinter the formed fluoride crucible, and finally machine it to meet the product requirements Specification. The invention is mainly used in the equipment of the fluorination and volatilization process in the dry method. The crucible can provide a stable reaction environment in the process of post-treatment of spent fuel by the fluorination and volatilization method, and prevent fluorine gas and fluorination volatiles from affecting the equipment. Corrosion to ensure safe production.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

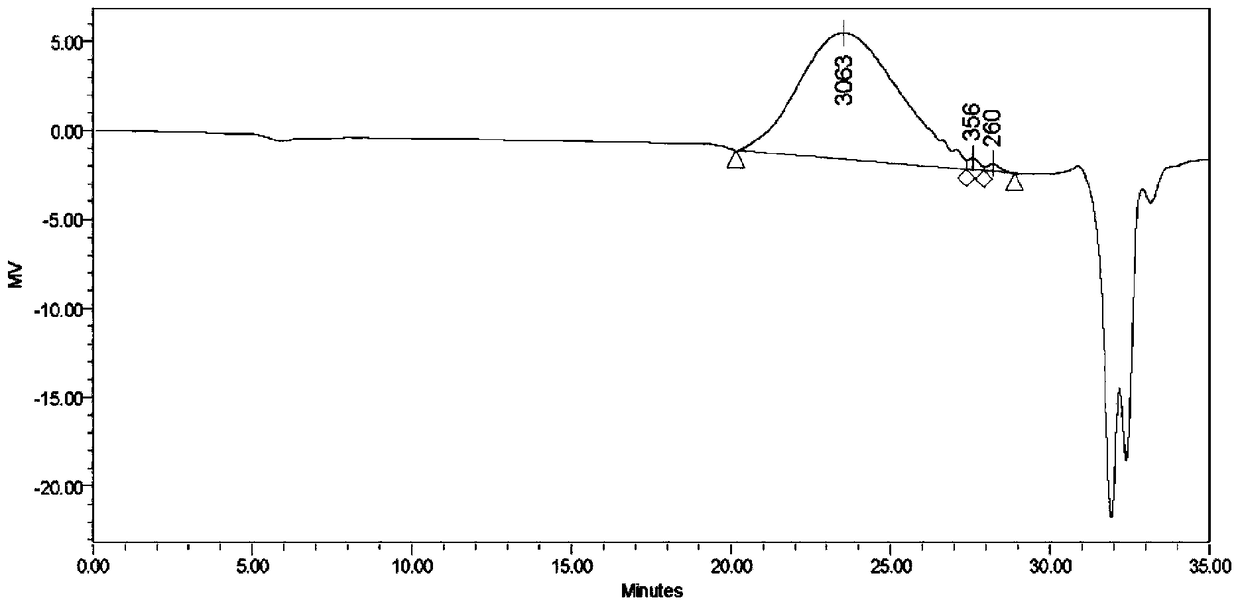

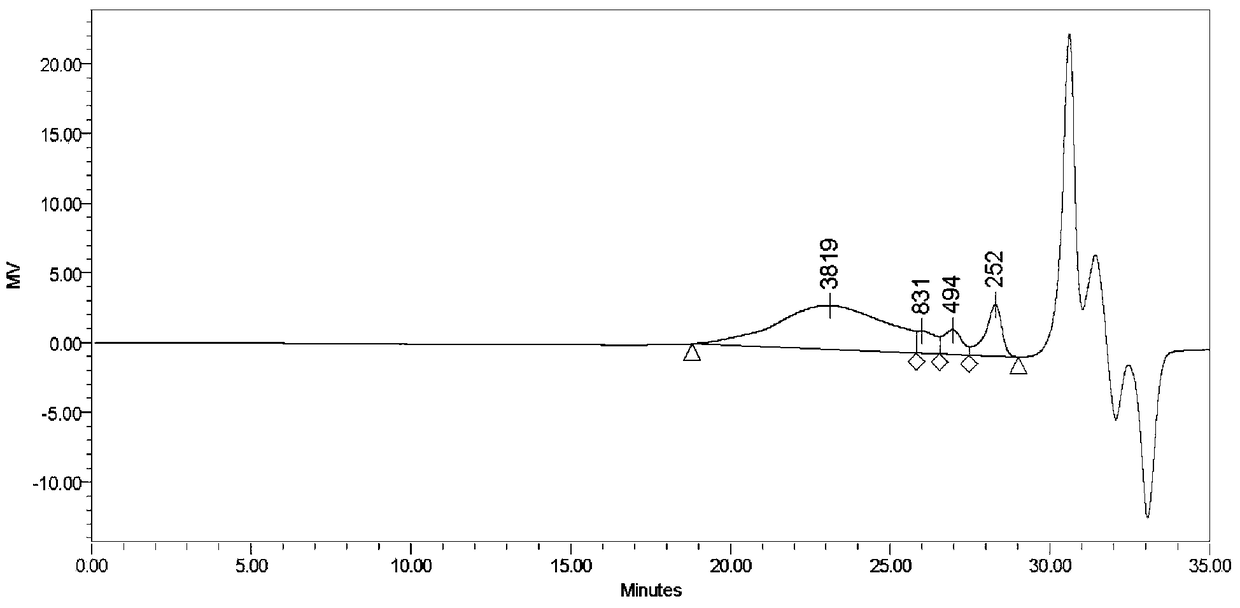

Micro NOx purification reaction activity evaluation system

PendingCN114324729AThe reaction environment is stableHigh accuracy of reactivity evaluationChemical analysis using catalysisExhaust gasChemistry

The invention discloses a micro NOx purification reaction activity evaluation system which comprises a gas distribution system which comprises a sample gas bottle, a gas mixing system and a stainless steel pipe, and the sample gas bottle is communicated with the gas mixing system through the stainless steel pipe; the feeding system comprises a stock bin, a screw blanking machine and a conveying pipe, a discharge port of the stock bin is communicated with a feed port of the screw blanking machine, a blanking screw is arranged in the screw blanking machine, the blanking screw is connected with a variable frequency motor, and the variable frequency motor is connected with a speed regulator; the catalytic reaction system comprises a reactor, a plurality of layers of partition reaction furnaces which are arranged up and down and communicated are arranged in the reactor, an air inlet is formed in the lower end of the partition reaction furnace on the lowermost layer, and a catalytic feeding hole and an air outlet are formed in the upper end of the partition reaction furnace on the uppermost layer; the gas mixing system is communicated with the gas inlet through a stainless steel pipe, and the conveying pipe is communicated with the catalytic feeding hole; the flue gas analysis system comprises a flue gas analyzer which is communicated with a gas outlet of the partition reaction furnace through a stainless steel pipe; and the tail gas collection and treatment system comprises a tail gas treatment chamber which is communicated with the flue gas analyzer through a stainless steel pipe.

Owner:江苏海默环保科技有限公司

A cooling system for hydrogen energy tram fuel cell

ActiveCN106328971BThe reaction environment is stableImprove reaction efficiencyFuel cell heat exchangeMotive system fuel cellsThermodynamicsHydrogen fuel cell

The invention discloses a cooling system for a fuel cell of a hydrogen energy tram, which comprises a hydrogen fuel cell, a circulation device, a cooling device and an electric heating tube, wherein the hydrogen fuel cell, the circulation device and the cooling device are sequentially connected through pipelines, and A cooling circulation loop is formed; one end of the electric heating tube communicates with the circulation device through a pipeline, and the other end communicates with the hydrogen fuel cell through a pipeline to form a heating circulation loop. The invention can accurately and relatively stably control the temperature of the cooling liquid when it enters the hydrogen fuel cell within the optimum reaction temperature range, so that the hydrogen fuel cell is in a suitable reaction temperature environment and improves the reaction efficiency of the hydrogen fuel cell; and the invention has a simple structure , the effect is obvious and saves energy.

Owner:CRRC QINGDAO SIFANG CO LTD

A recovery device for cvi/cvd process tail gas

The invention discloses a recovery device for CVI / CVD process tail gas, which comprises cooling filter equipment, a vacuum pump, an isothermal cracking furnace and later comprehensive treatment equipment. The cooling filter equipment includes a circulating liquid cooling module, an oil filter and a dry filter; isothermal cracking A preheating zone module is placed at the bottom of the furnace, and an isothermal zone module is set above the preheating zone module. The preheating zone module is a multi-layer labyrinth graphite plate. The lower part of the isothermal zone module is the delay buffer zone, and the upper part of the isothermal zone module is the upper cavity of the isothermal zone. The upper cavity of the isothermal zone is equipped with a multi-layer graphite plate structure. The graphite plate is equipped with an activated carbon growth structure, and the surface of the activated carbon growth structure is loaded with carbon black catalyst. . The top of the isothermal cracking furnace is a gas outlet, and the gas outlet is connected to the later comprehensive processing equipment through pipelines. The post-comprehensive treatment equipment includes a pressure change separator and a solid filter. The invention is a recovery device and method of CVI / CVD process tail gas with high treatment efficiency, good safety performance and high eco-environmental friendliness.

Owner:上海康碳复合材料科技有限公司 +1

A method for preparing porous nano-silicon carbide using silicate glass as raw material

ActiveCN107416837BLow costExcellent heat responseMaterial nanotechnologyCarbon compoundsReaction temperatureMaterials science

The invention discloses a method for preparing nano-silicon carbide by using silicate-based glass as a raw material. A certain proportion is uniformly ball-milled and mixed, put into a container and reacted under an inert gas, and then the reaction product is pickled to obtain nano-silicon carbide. The steps of the invention are simple and easy, and the sources of raw materials are extensive. Adding molten salt containing Mg can be used as an endothermic agent to control the reaction temperature and increase the solubility and wettability of magnesium, so that the reaction can be more complete, and the reactants are not easy to agglomerate. The three-dimensional porous silicon carbide prepared by this method has high purity, uniform particles, and high specific surface area (180-260m 2 / g), rich mesoporous structure and other advantages, it has broad application prospects in radiation resistance, radioactivity resistance and wave absorption.

Owner:WUHAN UNIV OF SCI & TECH

A method for preparing silicon-carbon composite materials using silicate glass as raw material, its products and applications

ActiveCN107579214BImprove conductivityHigh bulk densityMaterial nanotechnologyCell electrodesCarbon compositesElectrolytic agent

The invention discloses a method for preparing a silicon-carbon composite material using silicate glass as a raw material, its product and application. The method comprises the following steps: wet ball milling glass powder and carbon material to obtain a uniform mixture of glass and carbon material The product is uniformly mixed with magnesium powder and molten salt, pressed into an ingot, and undergoes magnesium thermal reaction, and then the reaction product is pickled to obtain carbon and silicon composite materials with different structures. The steps of the invention are simple and easy, and the source of raw materials is wide. The most important thing is that the tap density of the silicon-carbon negative electrode material is greatly increased by making the mixture into an ingot, and then the magnesia thermal reaction is carried out, and the volume specific capacity of the negative electrode material is improved. At the same time, the electronic conductivity of the silicon-carbon composite material formed by compositing with graphitized carbon materials is also effectively improved, which improves the compatibility between silicon-based materials and electrolytes, thereby improving the cycle performance and rate performance of the material, which can be applied Anode materials for lithium-ion batteries with high power density and high energy density.

Owner:WUHAN UNIV OF SCI & TECH

A kind of impurity removal and treatment method in the recycling process of lithium battery scrap positive electrode materials

ActiveCN112151903BThe reaction environment is stableContinuous uninterrupted operationNon-aqueous electrolyte cellsReclaiming serviceable partsAluminum IonManganese

The embodiment of the present application discloses a method for removing impurities and treating waste positive electrode materials of lithium batteries during the recovery process. Including at a first temperature higher than room temperature and a fixed first pH value, controlling the flow rate of the lithium battery scrap positive electrode material leaching solution and the first alkaline solution to precipitate and remove iron ions, aluminum ions and at least part of the copper ions to obtain the first filtrate; Under the second temperature higher than room temperature and the fixed first pH range, control the flow velocity of the first filtrate, complexing agent and the second alkaline solution to separate the second filtrate containing lithium ions to obtain the precipitation of the target substance; carry out the precipitation of the target substance Dissolving to obtain a first solution; at a third temperature higher than room temperature and a fixed fluoride ion concentration, controlling the flow rate of the first solution and a fluorine-containing precipitant to precipitate and remove calcium ions, magnesium ions and at least part of lead ions to obtain a target solution. Through the method of the present application, a precipitate with large particle size, high crystallinity and low water content can be obtained, which is convenient for washing and improves the recovery rate of nickel-cobalt-manganese, the scrap positive electrode material of lithium batteries.

Owner:SICHUAN ENERGY INTERNET RES INST TSINGHUA UNIV

Aqueous dismutase generating device

PendingCN111154643AStable outputUniform rateBioreactor/fermenter combinationsBiological substance pretreatmentsInlet valveMechanical engineering

The invention discloses an aqueous dismutase generating device. The aqueous dismutase generating device comprises a touch panel fixedly mounted on one edge of the outer side surface of a cover body, wherein a wireless charger is arranged on the edge, on which the touch panel is located, of the cover body, and a plurality of rotary flushing heads are fixedly mounted on one side surface, far from the wireless charger, of the cover body and are connected with an automatic water inlet valve through a rotary water inlet pipe; one end, far from the rotary flushing heads, of the rotary water inlet pipe penetrates through a heat-preservation tank body; the automatic water inlet valve is arranged outside the heat-preservation tank body; and a semiconductor chilling plate is fixedly mounted on one side of the rotary water inlet pipe located in the heat-preservation tank body. A water-level sensor and the rotary flushing heads are additionally arranged to precisely control the water amount in a reaction bin, so that an aqueous dismutation process is stabilized, the uniform speed is guaranteed, and the yield is stable.

Owner:瑞德咖谱(厦门)生命科学技术有限公司

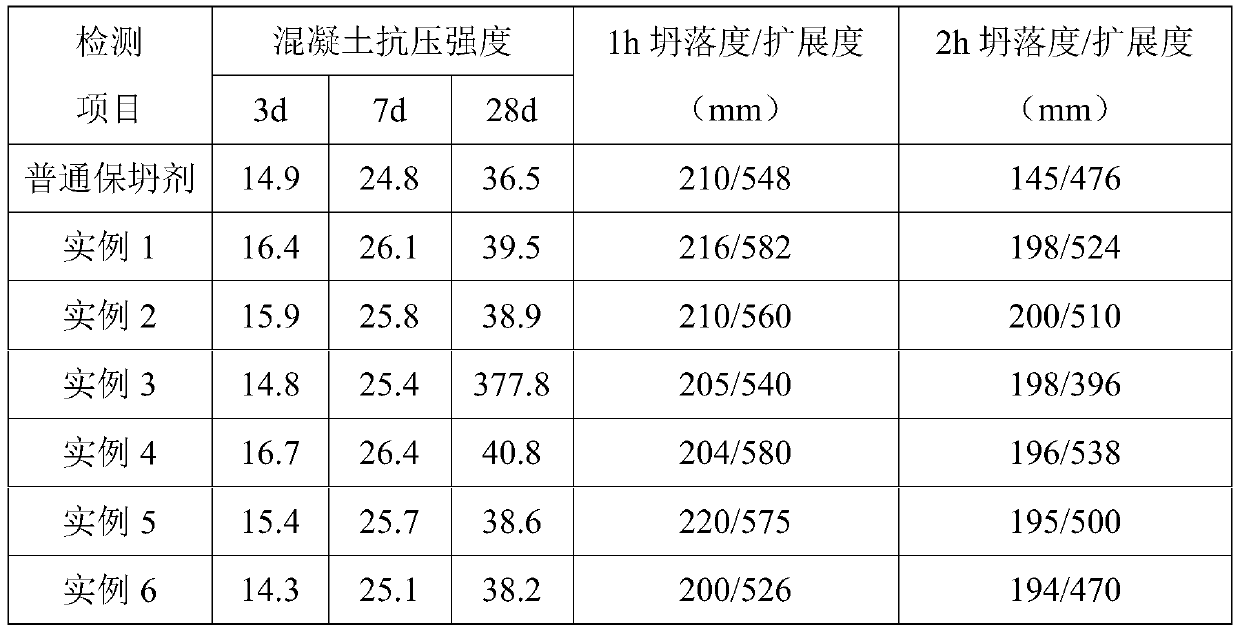

Polycarboxylic acid slump retaining agent modified by phenyl hydroxyl composite ATRP method and preparation method thereof

The invention discloses a polycarboxylic acid slump retaining agent modified by a phenyl hydroxyl composite ATRP method and a preparation method thereof. In the preparation process, firstly 5-10 partsof benzene rings, 7-16 parts of hydroxyl monomers, 0.7-1.6 parts of ligands, 0.02-0.1 part of a catalyst, 3-5 parts of an emulsifier and 300 parts of water are added into a first reaction kettle, and1.1-2.2 parts of an initiator is dropwise added protectively at the inert atmosphere of 80-95 DEG C to prepare a block polymer I; a polyether macromonomer and alkyl acrylate are dropwise added into the block polymer I to react at 55-70 DEG C and keep the temperature to prepare a polymer II; and liquid caustic soda with the mass fraction of 30% is added into the polymer II until the pH value of the reaction system is about 10 and the temperature is kept at 60 DEG C until the pH value of the system is stable to obtain the polycarboxylic acid slump retaining agent. The prepared polycarboxylic acid slump retaining agent is narrow in molecular mass distribution gradient, high in effective component content and excellent in performance and has high dispersity and slump retaining property, and the slump retaining agent is endowed with additional water reducing capacity due to the hydration inhibition capacity of hydroxyl.

Owner:HUBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com