Patents

Literature

53results about How to "Continuous uninterrupted operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

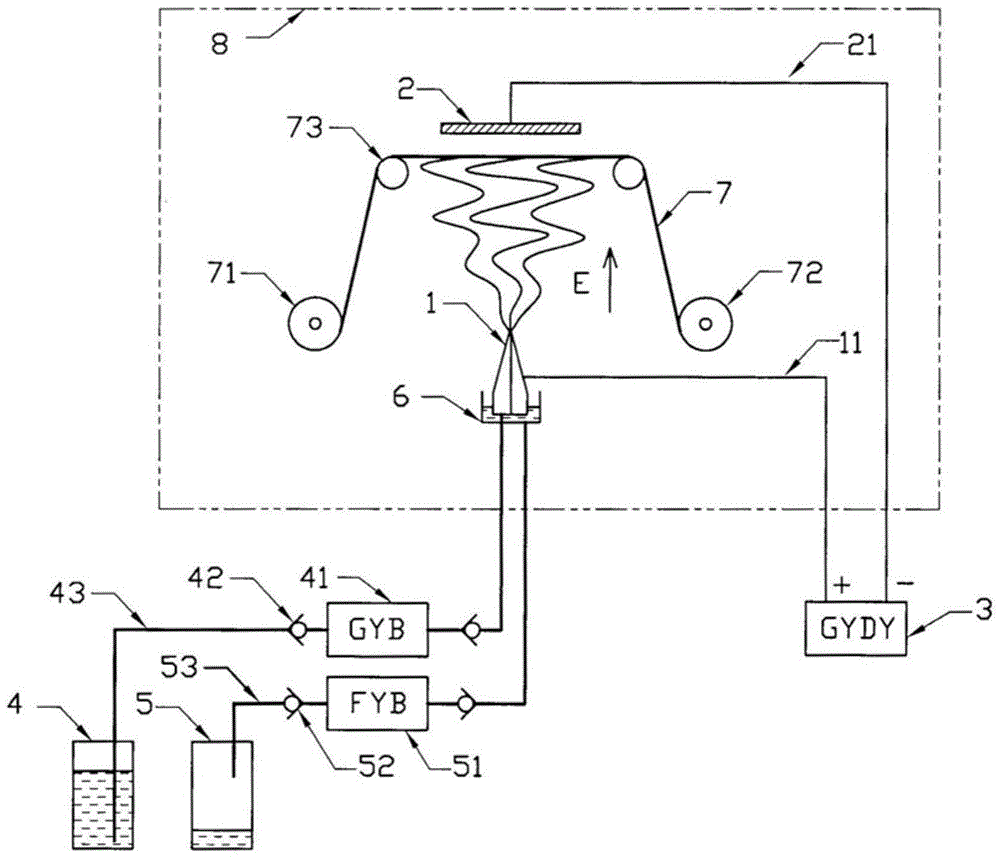

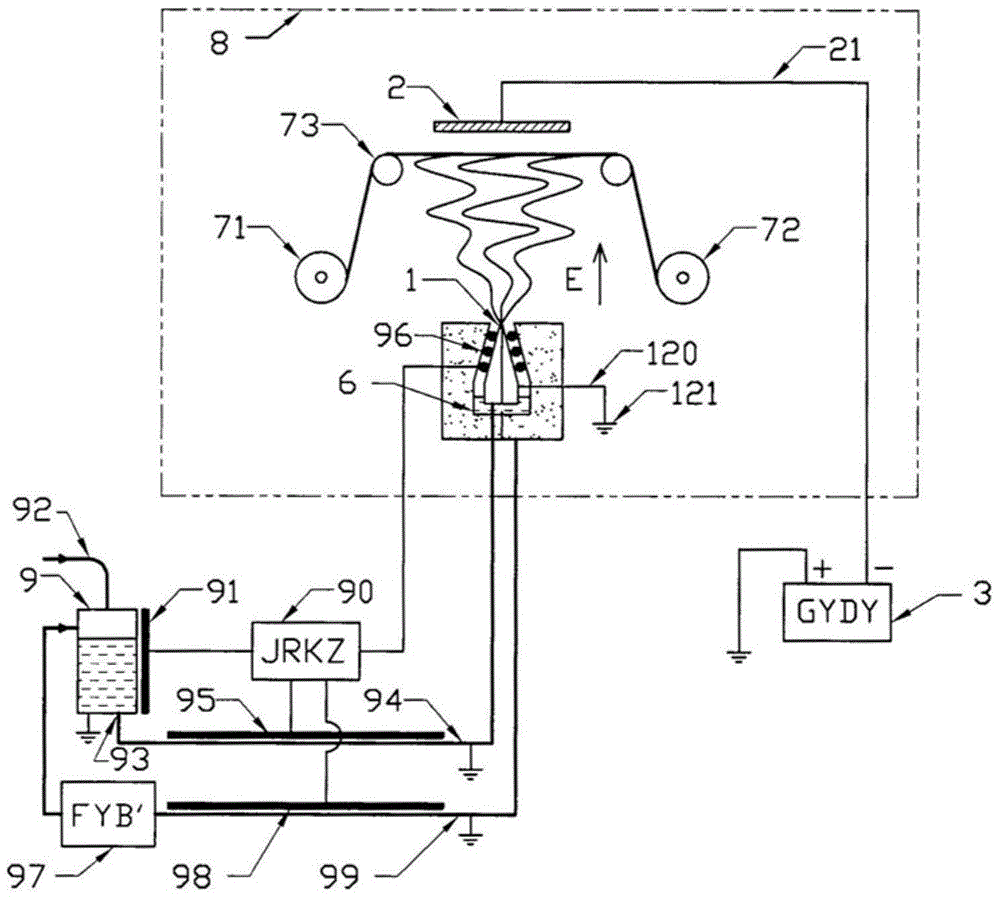

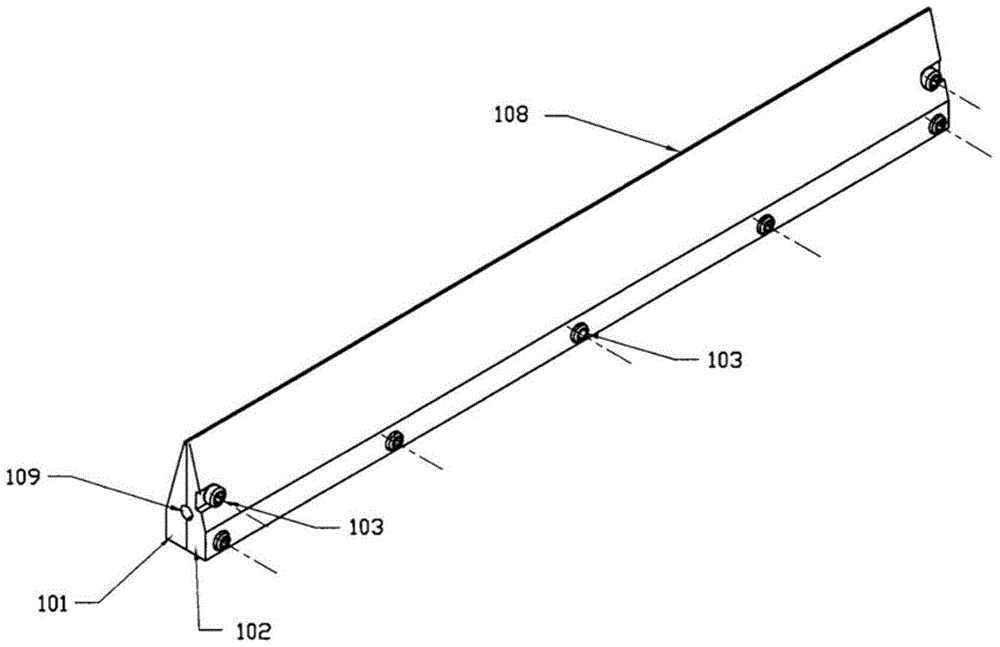

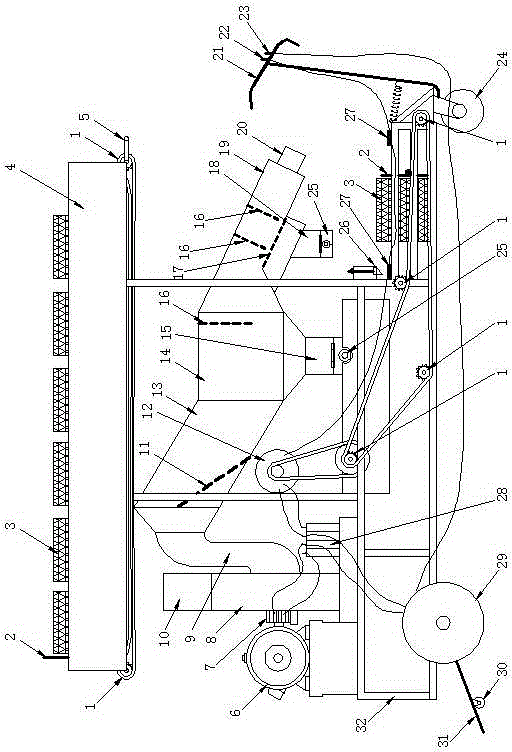

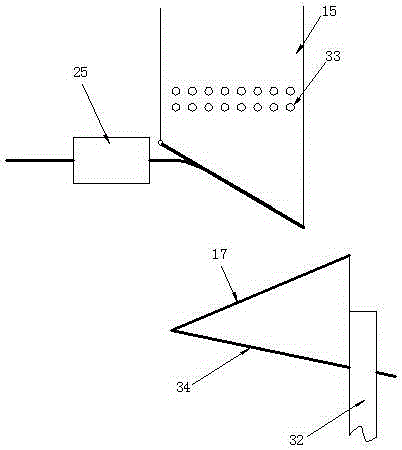

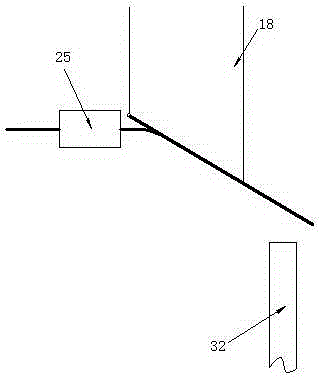

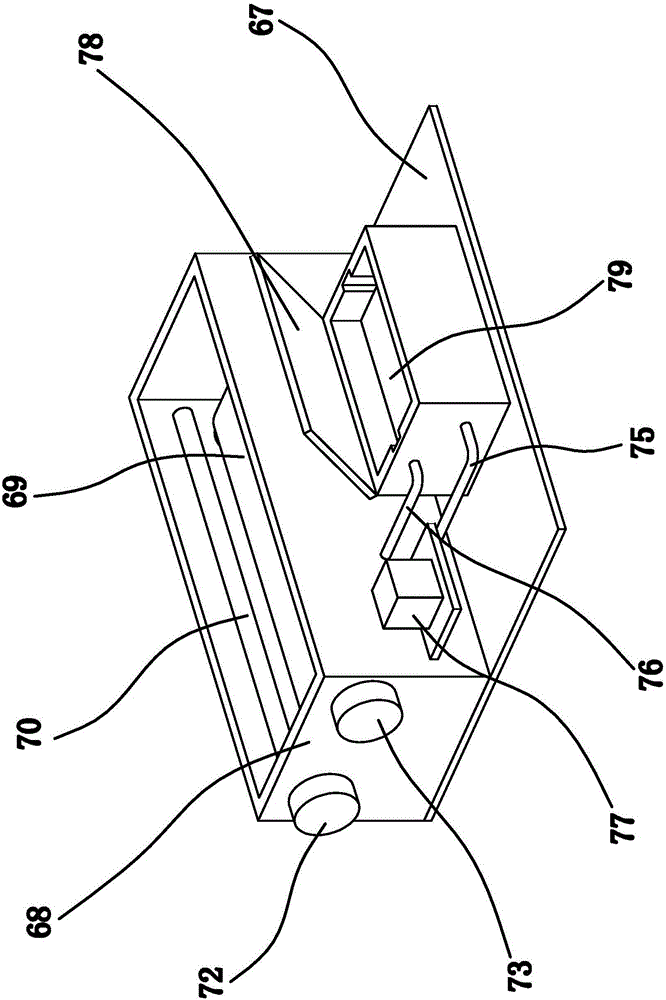

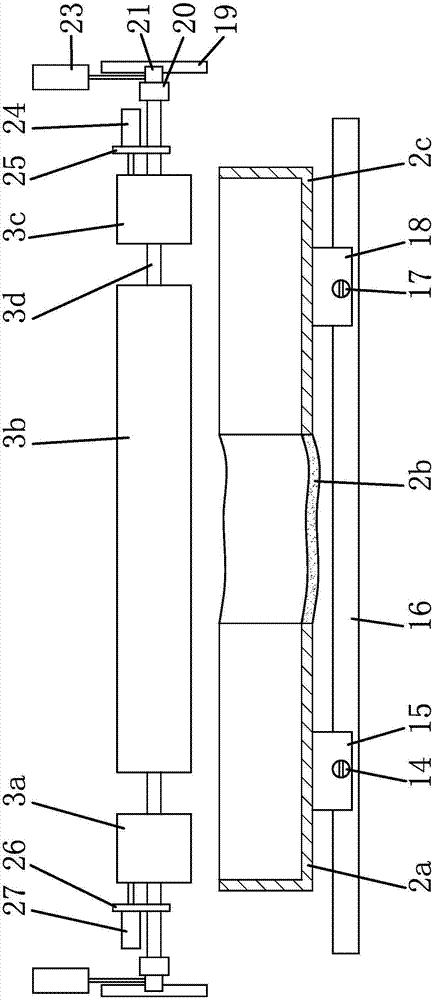

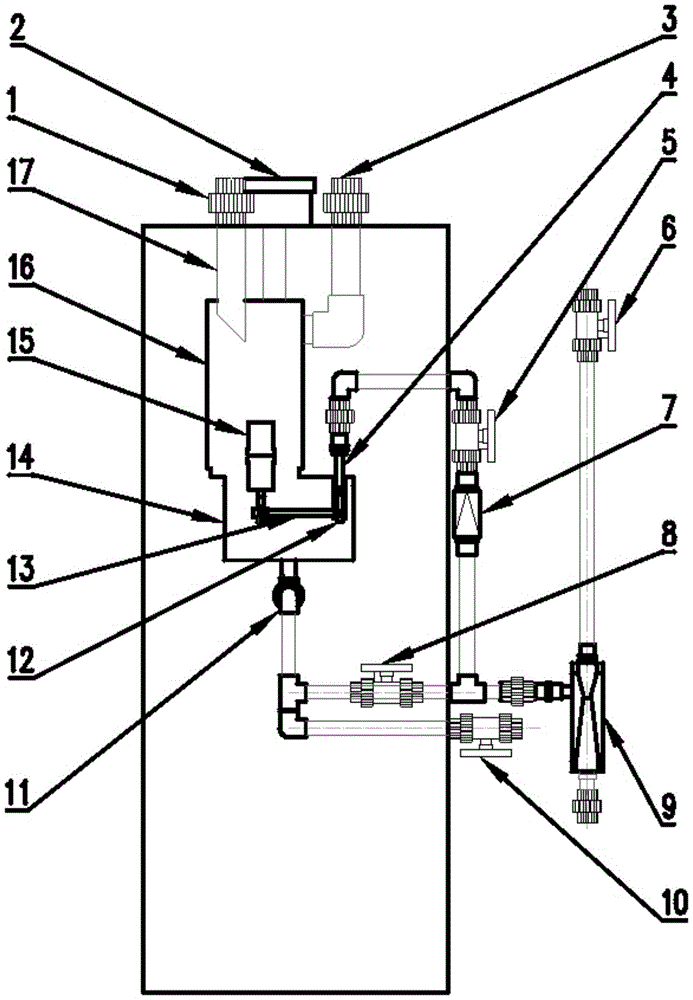

Needleless electrostatic spinning device

ActiveCN104790048AEasy to disassembleEasy to cleanArtificial thread manufacturing machinesElectro-spinningFiberElectrospinning

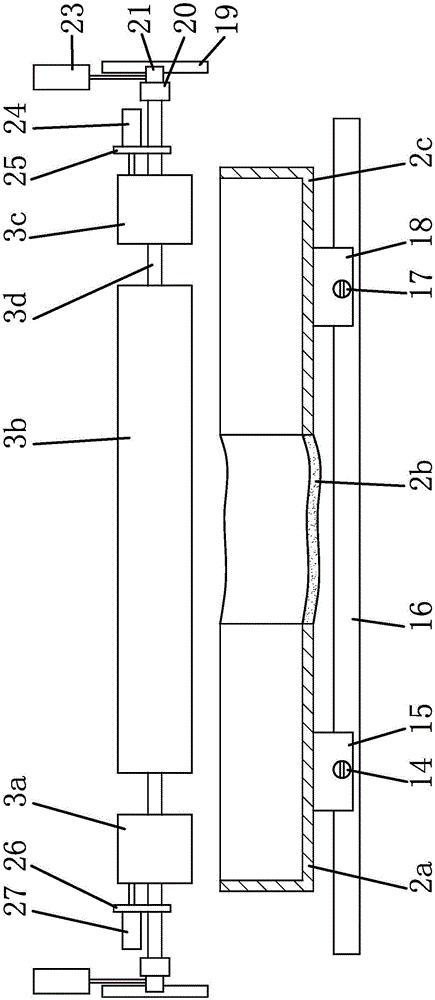

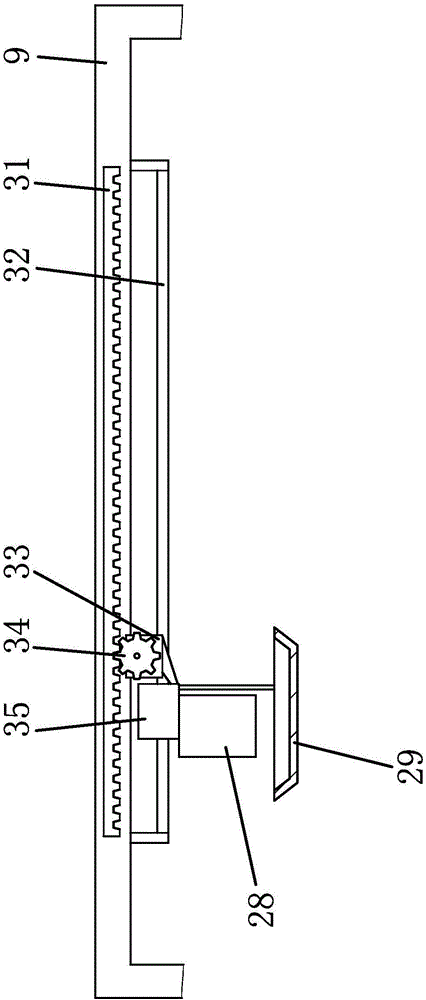

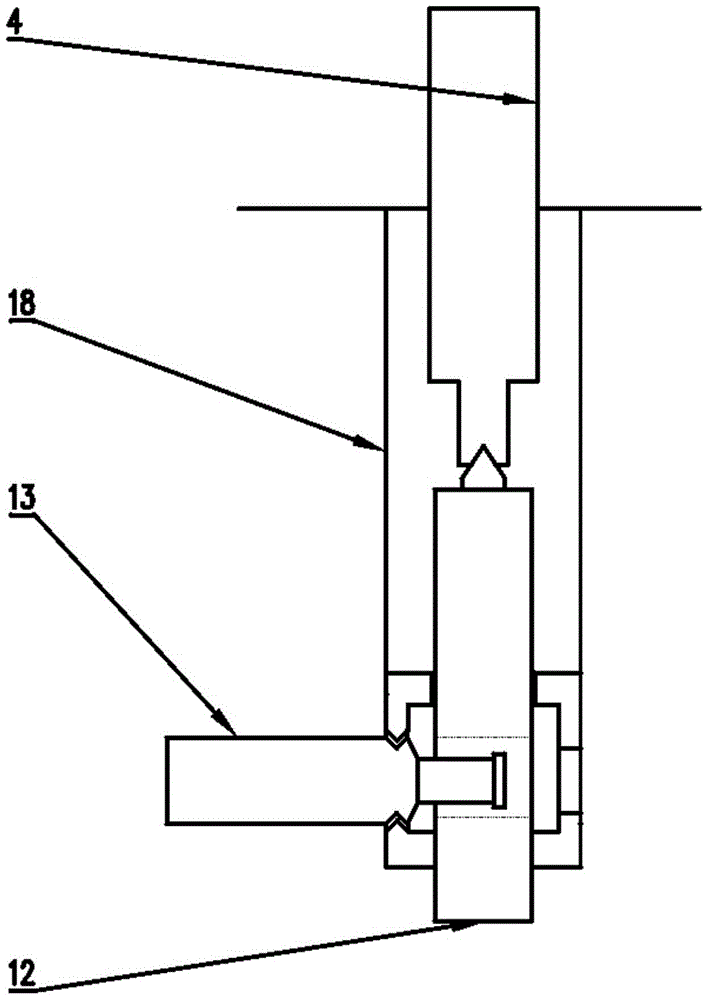

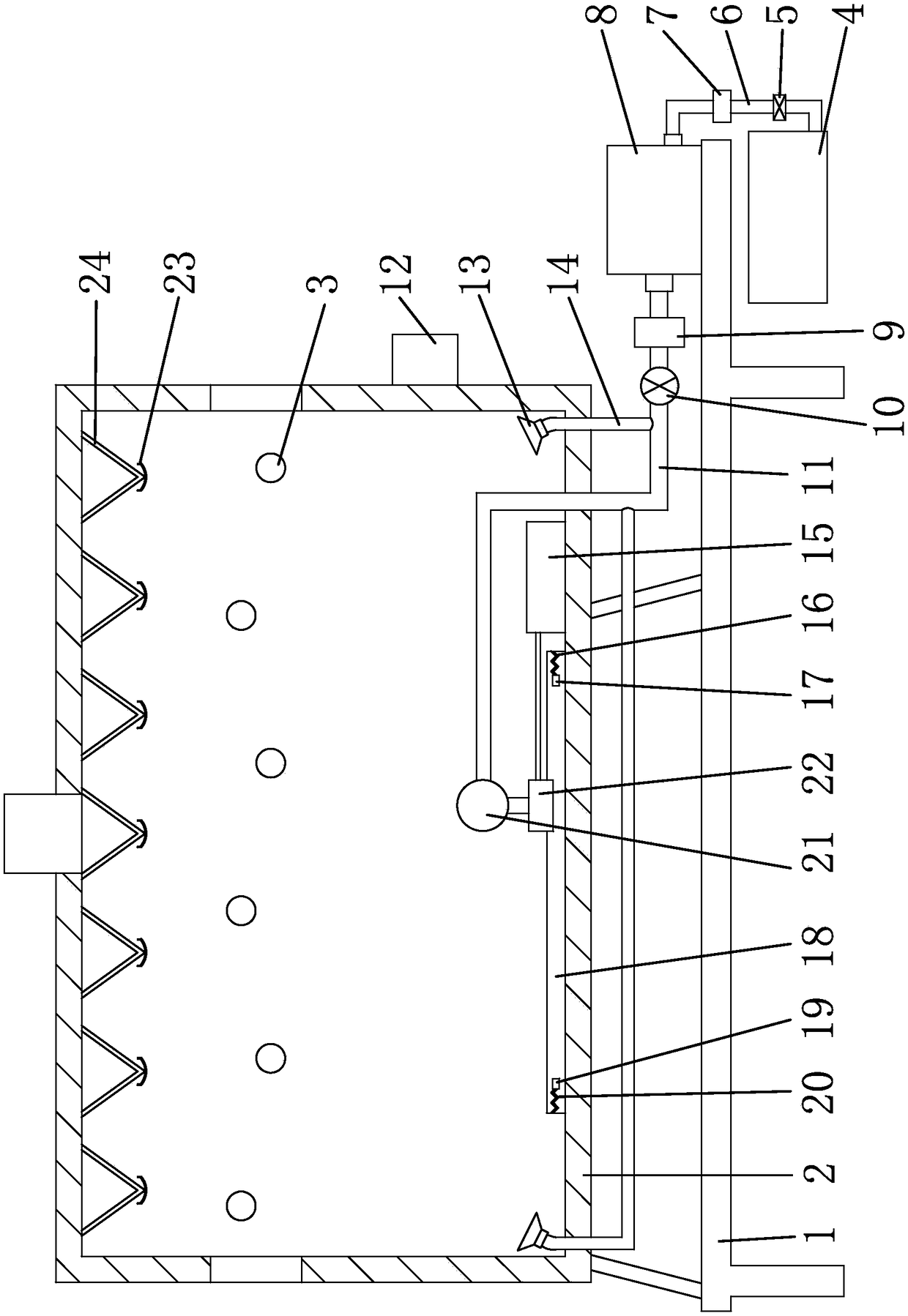

The invention relates to a needless electrostatic spinning device. The needless electrostatic spinning device is composed of a spinning jet, a reception electrode, a high voltage power supply, a solution tank used for storing polymer solution, a waste fluid slot, base materials, a winding system of the base materials and the like, or the needless electrostatic spinning device is composed of the spinning jet, the reception electrode, the high voltage power supply, the solution tank used for storing polymer solution, the waste fluid slot, base materials, the winding system of the base materials, a heating device, an electric heating control device thereof and the like. The spinning jet adopts a slit-type spinning jet. The spinning jet is integrally constituted through the tight fitting of a left semi-spinning jet and a right semi-spinning jet, and the left semi-spinning jet and the right semi-spinning jet are fastened through a threaded connector, or the spinning jet is constituted by a left spinning jet component, a right spinning jet component and a flow-equalizing grid plate clamping piece arranged between the left spinning jet component and the right left spinning jet component. According to the needless electrostatic spinning device, the slit-type spinning jet is adopted, assembly, disassembly and cleaning are convenient, nano fibers can be produced continuously and effectively, and the spinning efficiency is improved greatly; the needless electrostatic spinning device can be applied both to the electrostatic spinning of the polymer solution and to the electrostatic spinning of the polymer molten mass.

Owner:QINGDAO HSJ ENVIRONMENTAL PROTECTION TECH CO LTD

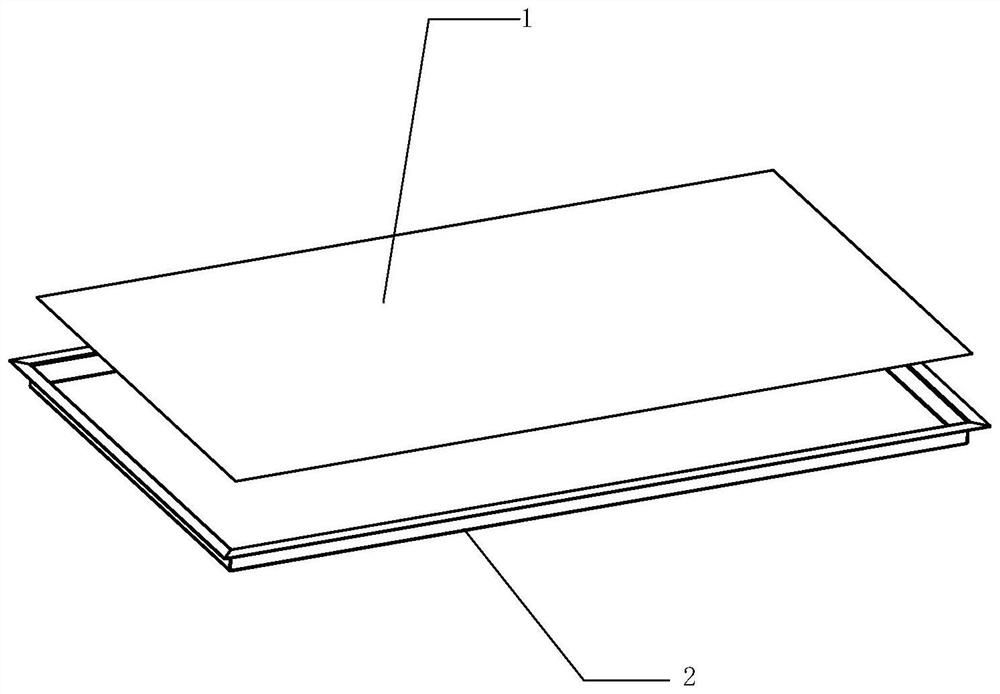

Waterproof anti-aging military ground cloth coated with PVC (polyvinyl chloride) at two sides and preparation method thereof

The invention relates to military ground cloth, in particular to waterproof anti-aging military ground cloth coated with PVC (polyvinyl chloride) at two sides and a preparation method thereof. The waterproof anti-aging military ground cloth coated with PVC at two sides comprises a base cloth layer, wherein PVC coatings are arranged at two side surfaces of the base cloth layer; the PVC coating layer is mainly prepared from the following raw materials in parts by weight: 68 to 84 parts of PVC paste resin, 30 to 40 parts of plasticizers DINP, 6 to 10 parts of calcium carbonate, 2 to 8 parts of chlorinated paraffin, 1 to 6 parts of stabilizing agents, 12 to 18 parts of fire retardants, 4 to 10 parts of bonding agents, 20 to 25 parts of compound additives and 0.1 to 0.5 parts of anti-UV adsorbents. The product of the military ground cloth has the advantages that the anti-aging performance is better; the adhesion fastness is better; after paint coating, the military ground cloth can still maintain good mechanical property, so that the military ground cloth has a longer service life.

Owner:ZHEJIANG SHANGCHENG SCI&TECH

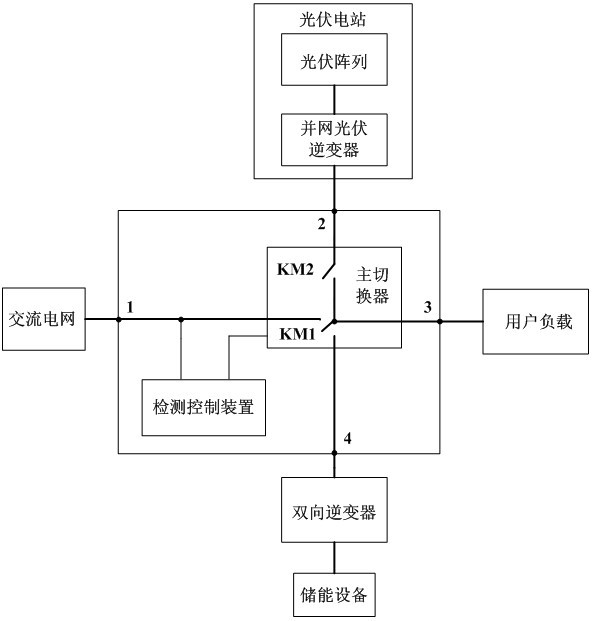

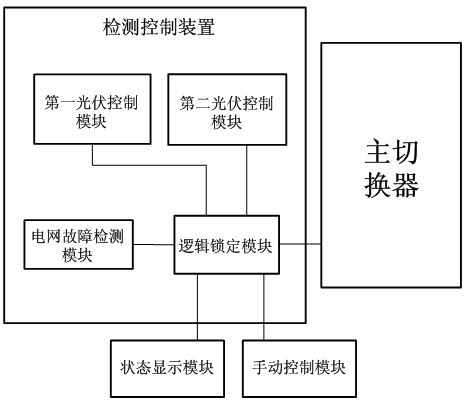

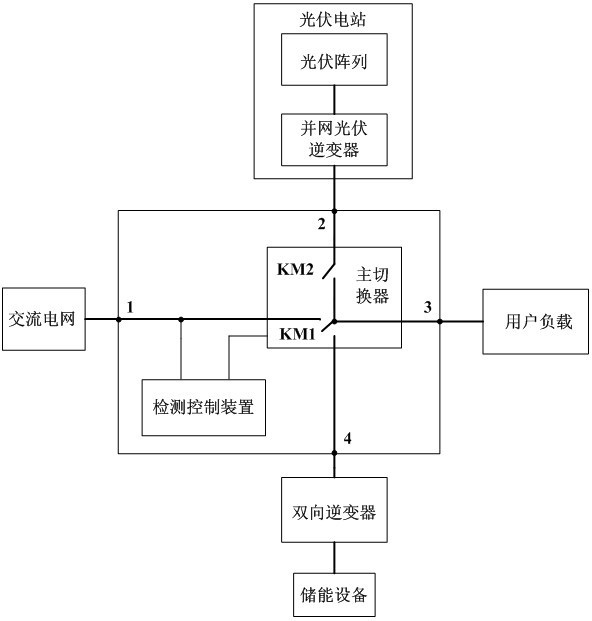

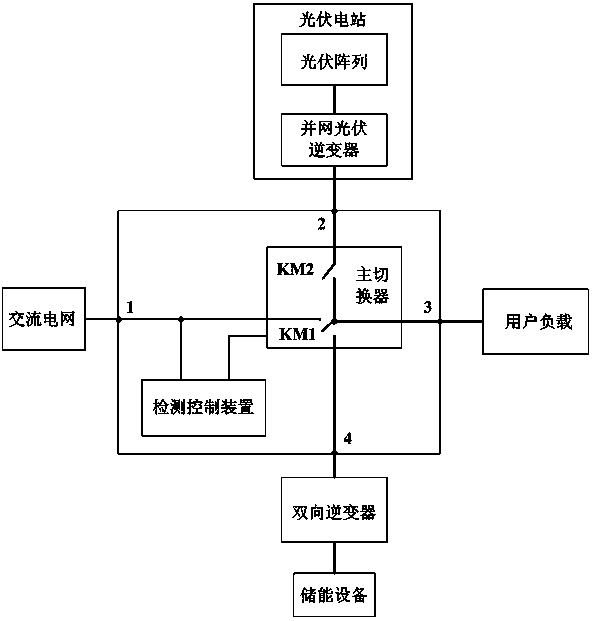

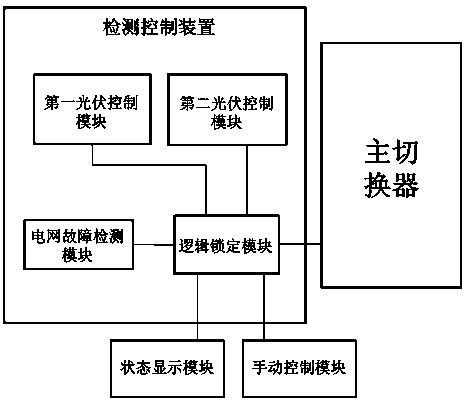

Controller for switching grid connection photovoltaic power generation system and off-grid photovoltaic power generation system

ActiveCN102694393AFusion wellContinuous uninterrupted operationSingle network parallel feeding arrangementsPhotovoltaic energy generationElectricityGrid fault

The invention relates to a controller for switching a grid connection photovoltaic power generation system and an off-grid photovoltaic power generation system, which comprises a detection control device, a main switcher and four wiring terminals; the detection control device comprises a logic locking module, and a grid fault detection module, a first photovoltaic control module and a second photovoltaic control module which are respectively connected with the logic locking module; and the logic locking unit is connected with the main switcher, and is used for controlling the main switcher to switch the grid connection photovoltaic power generation system and the off-grid photovoltaic power generation system according to the detection information of the grid fault detection module, the first photovoltaic control module and the second photovoltaic control module. According to the controller for switching the grid connection photovoltaic power generation system and the off-grid photovoltaic power generation system, the logic locking module controls the main switcher to quickly switch a grid connection photovoltaic power generation method or an off-grid photovoltaic power generation method, so that the load of a user or important loads can continue to work uninterruptedly without being affected by the faults of utility power or power-off, and the grid connection photovoltaic power generation system and the off-grid photovoltaic power generation system are effectively integrated.

Owner:广东永光新能源设计咨询有限公司

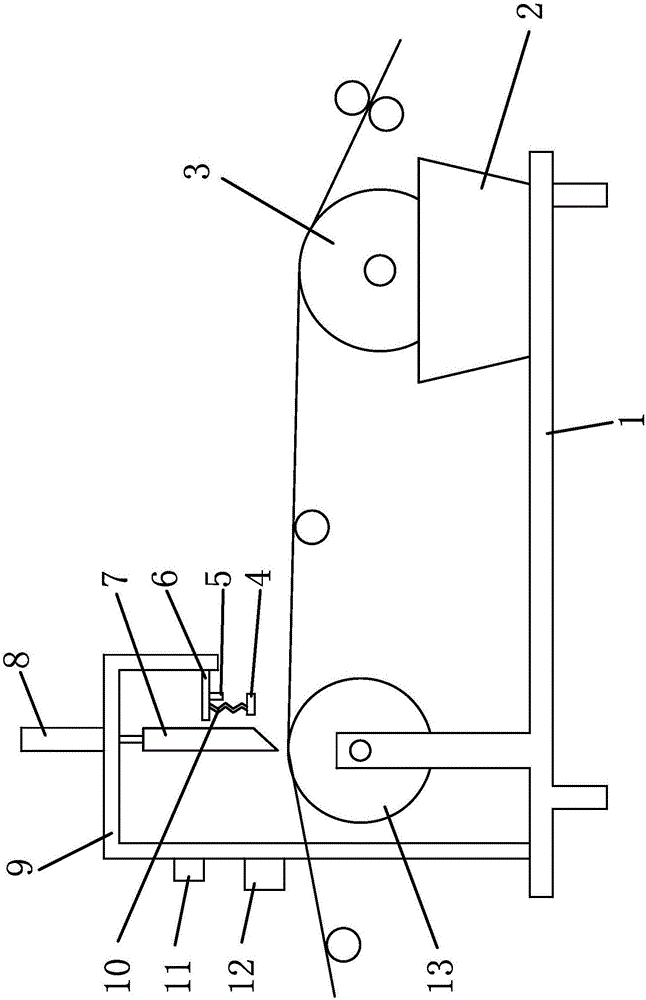

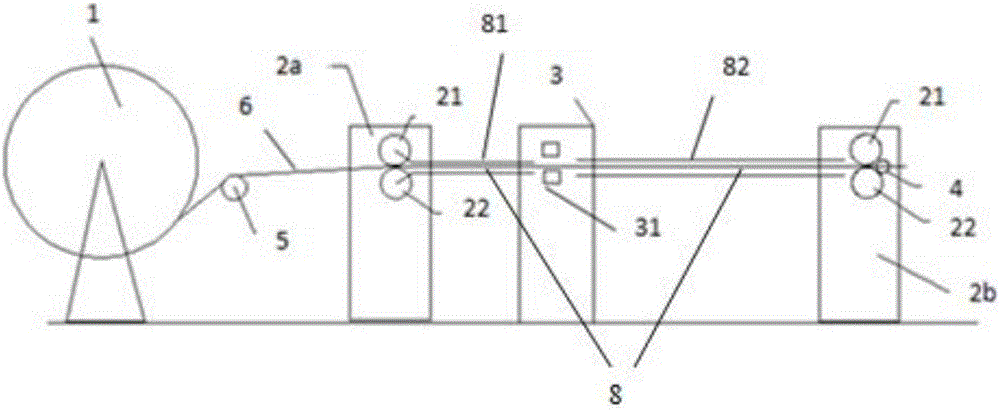

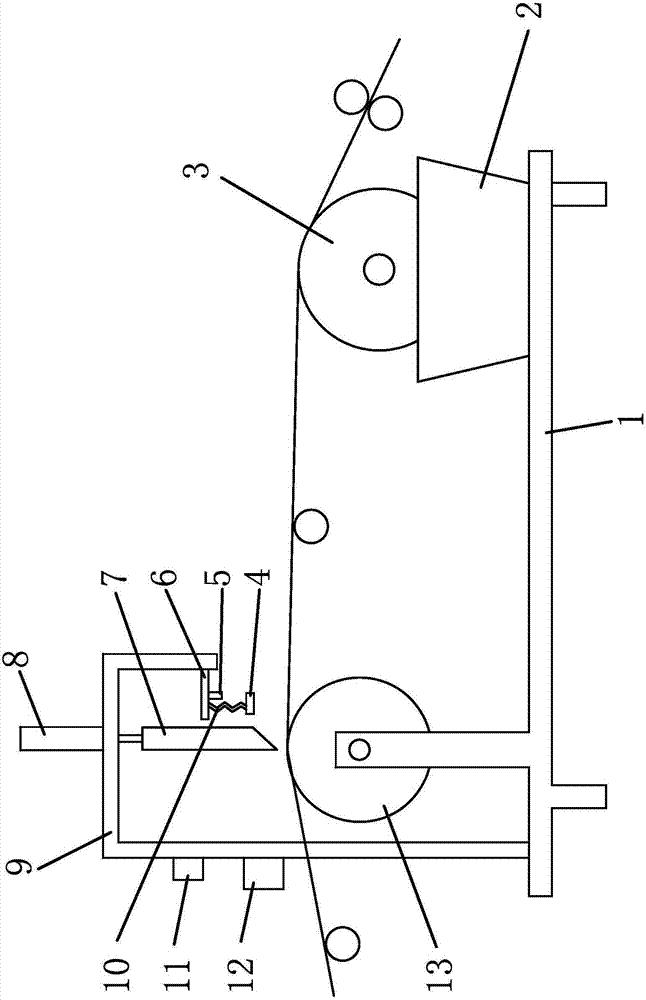

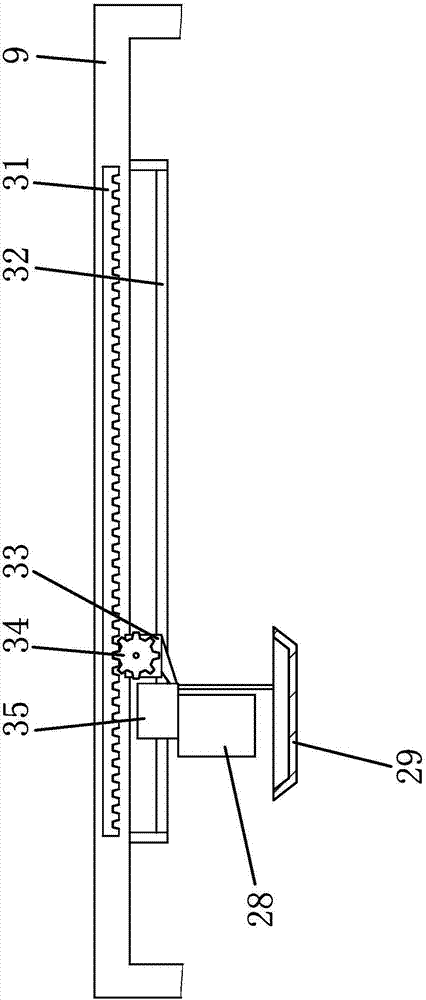

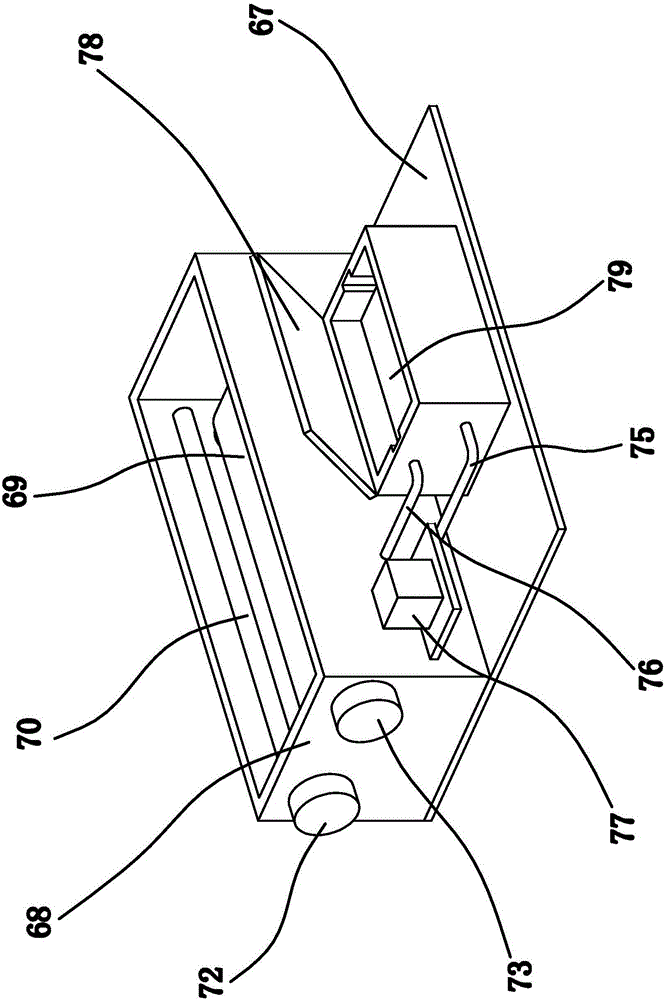

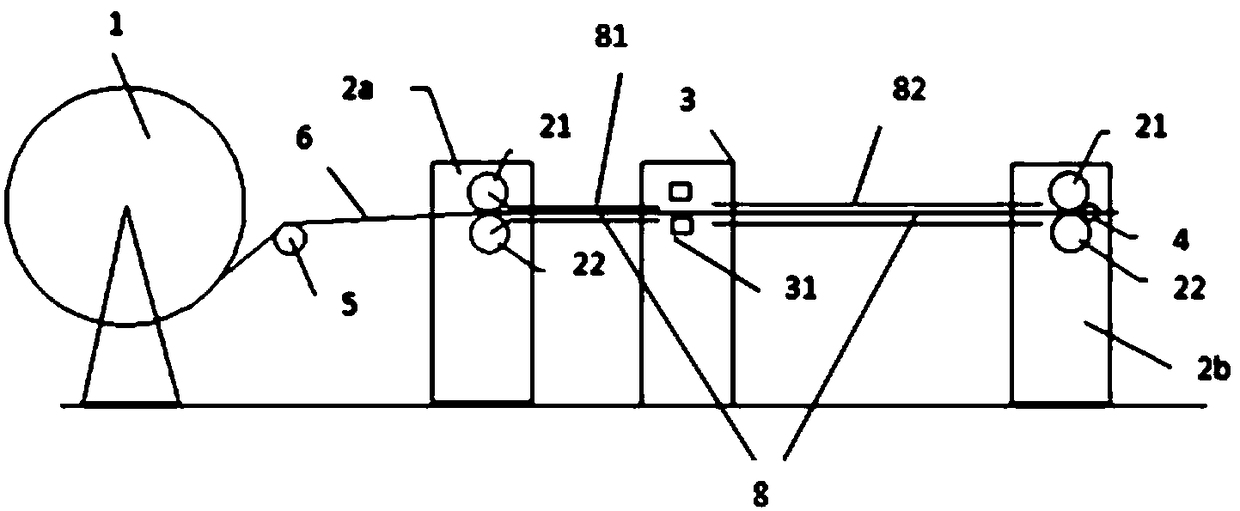

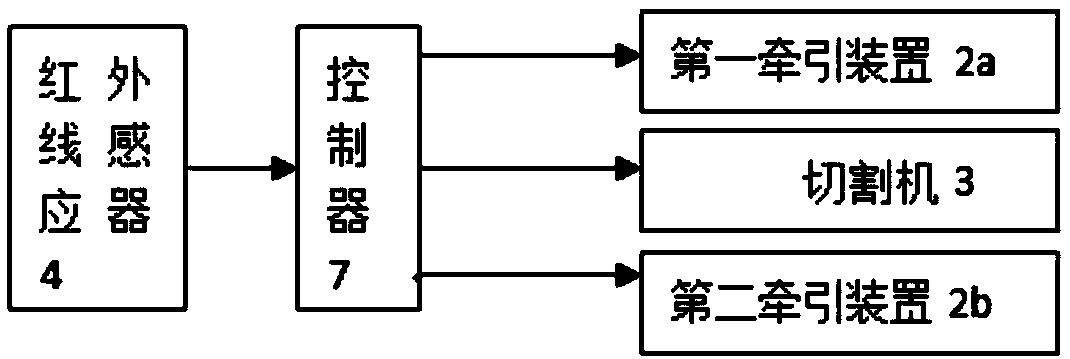

Fixed-length steel strand blanking machine and steel strand machining method

ActiveCN107175301AContinuously workingNo staggerMetal working apparatusEngineeringContinuous operation

The invention discloses a fixed-length steel strand blanking machine comprising a steel strand tray and a cutting machine used for cutting out steel strands. A first traction device is arranged between the steel strand tray and the cutting machine of which the rear part is also provided with a second traction device, and both sides of the cutting machine are provided with tubes; and the second traction device is located at the construction station side. The two traction devices are used for respectively pulling the steel strands cut and the steel strands on the steel strand tray to move forward, and the continuous operation of the fixed-length steel strand blanking machine is ensured.

Owner:CHINA RAILWAY 16TH BUREAU GRP RAIL TRANSPORT ENG CO LTD

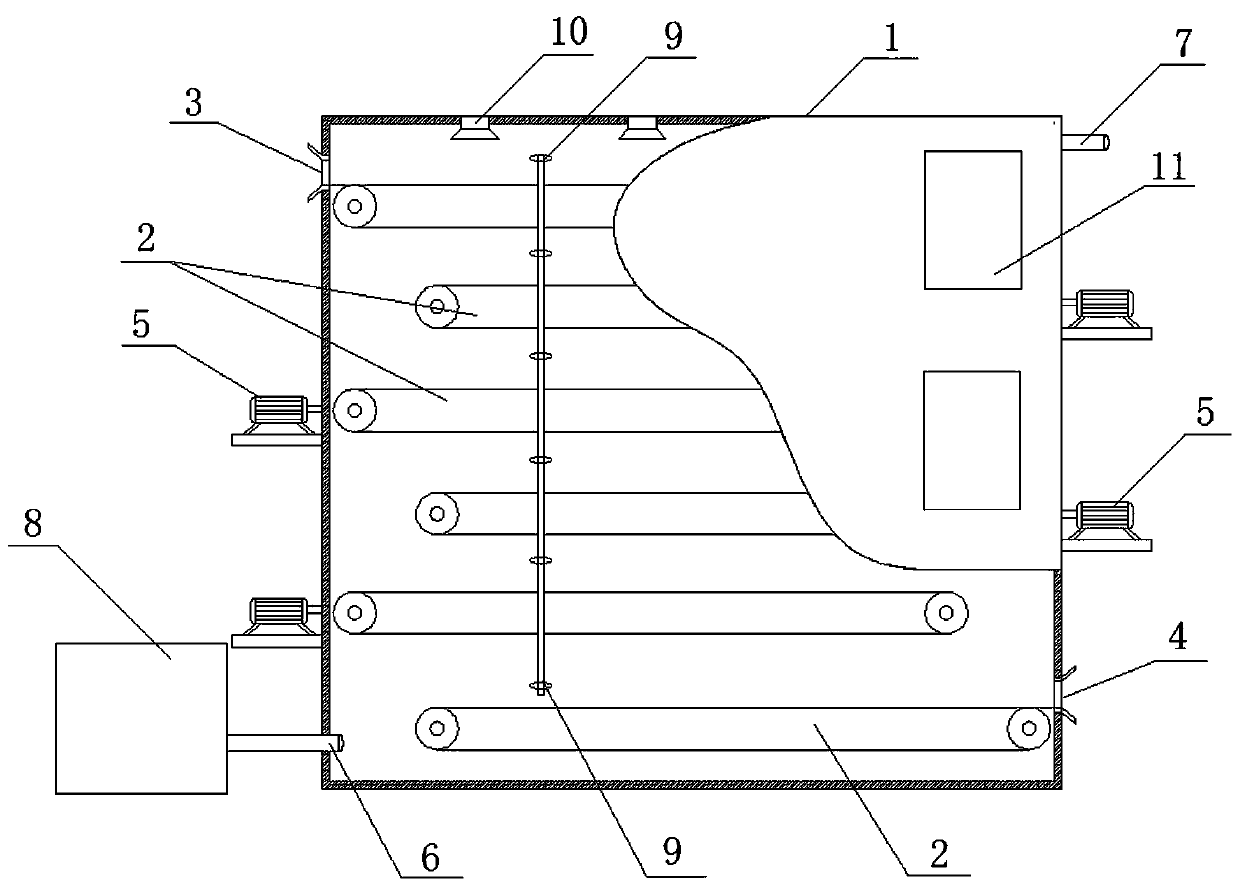

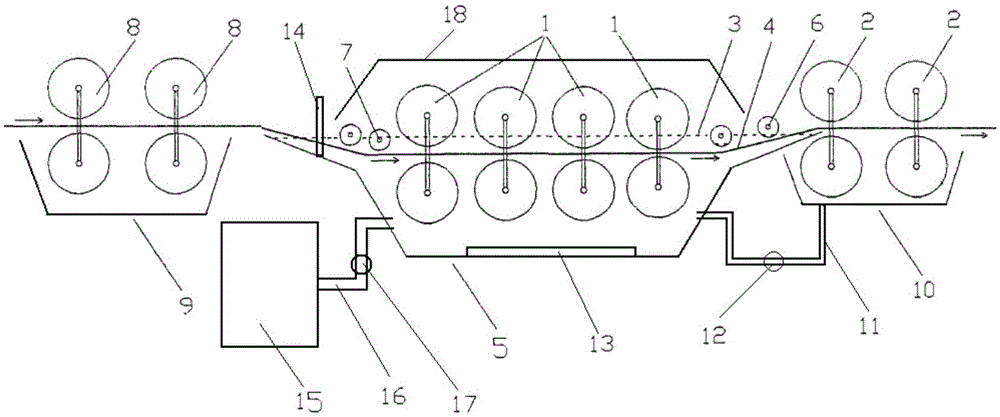

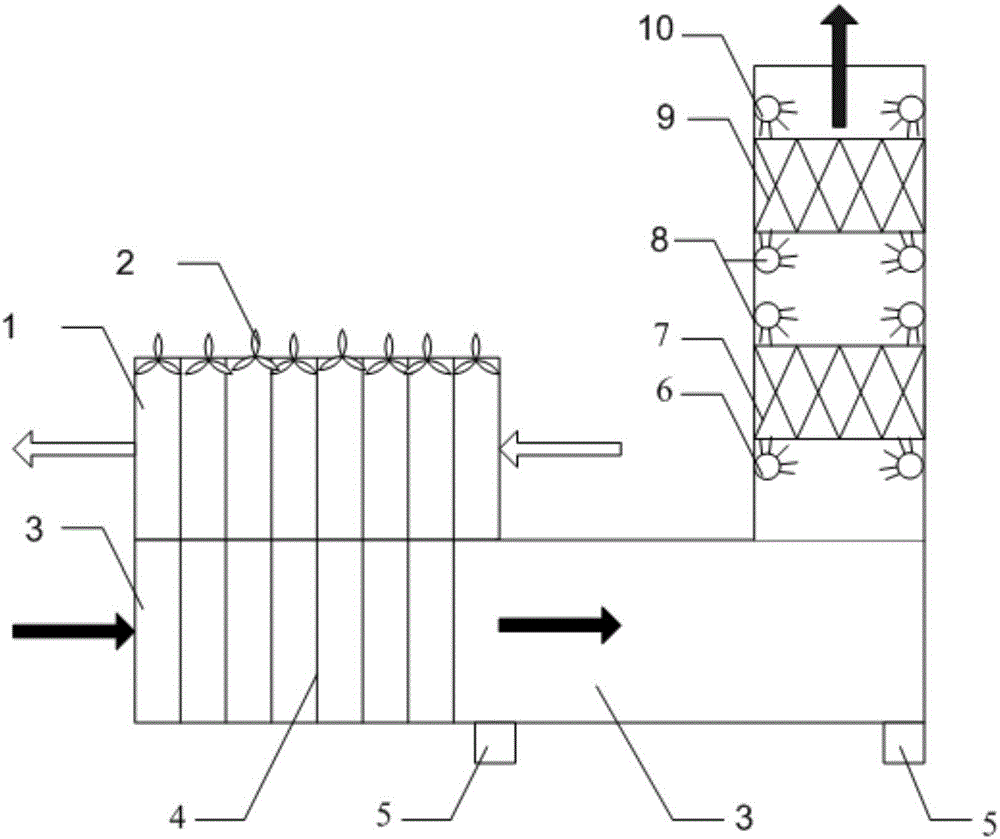

Continuously running layered grass drying device

PendingCN107764022AFully dryDry thoroughlyDrying gas arrangementsDrying chambers/containersHot air ovenAgricultural engineering

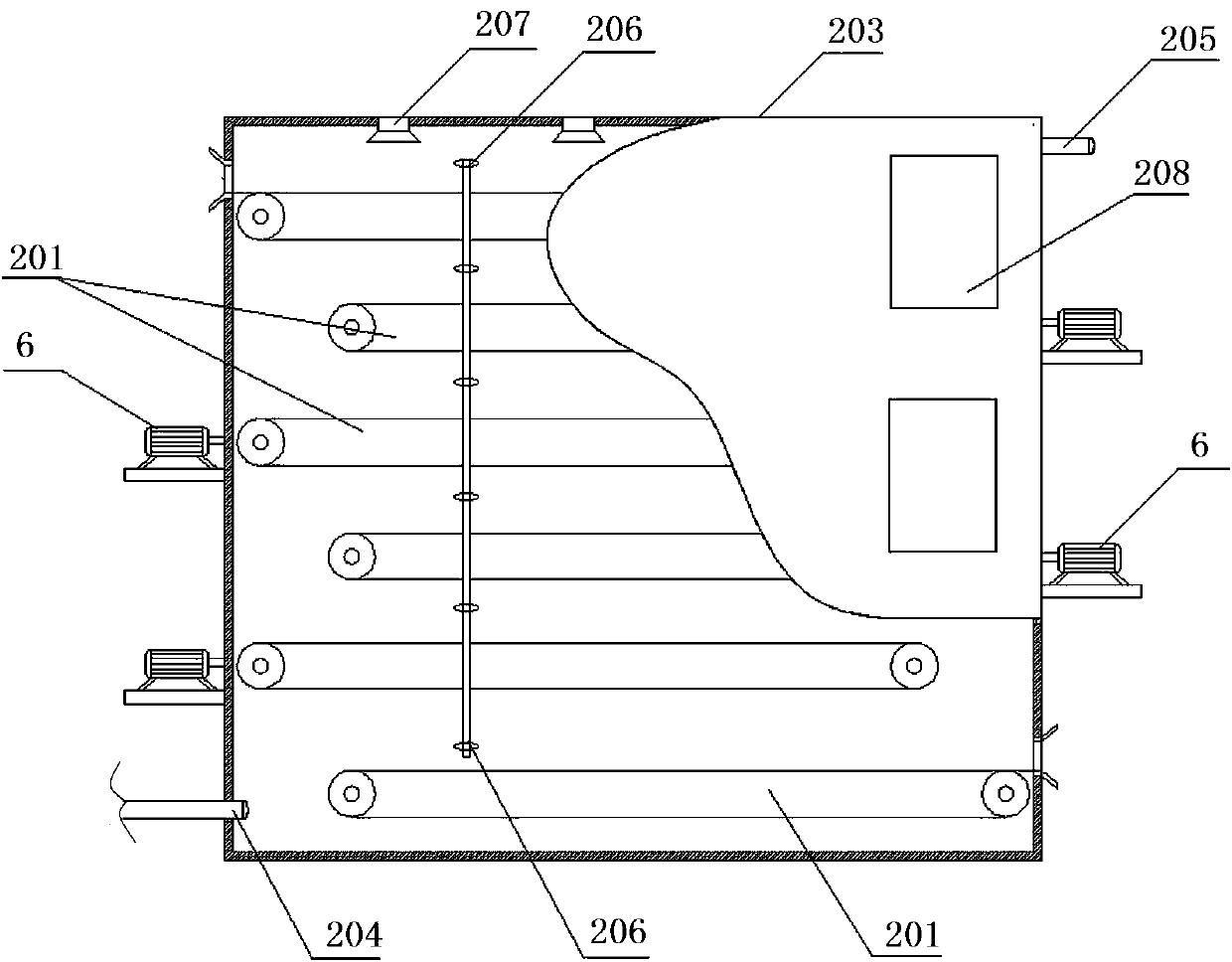

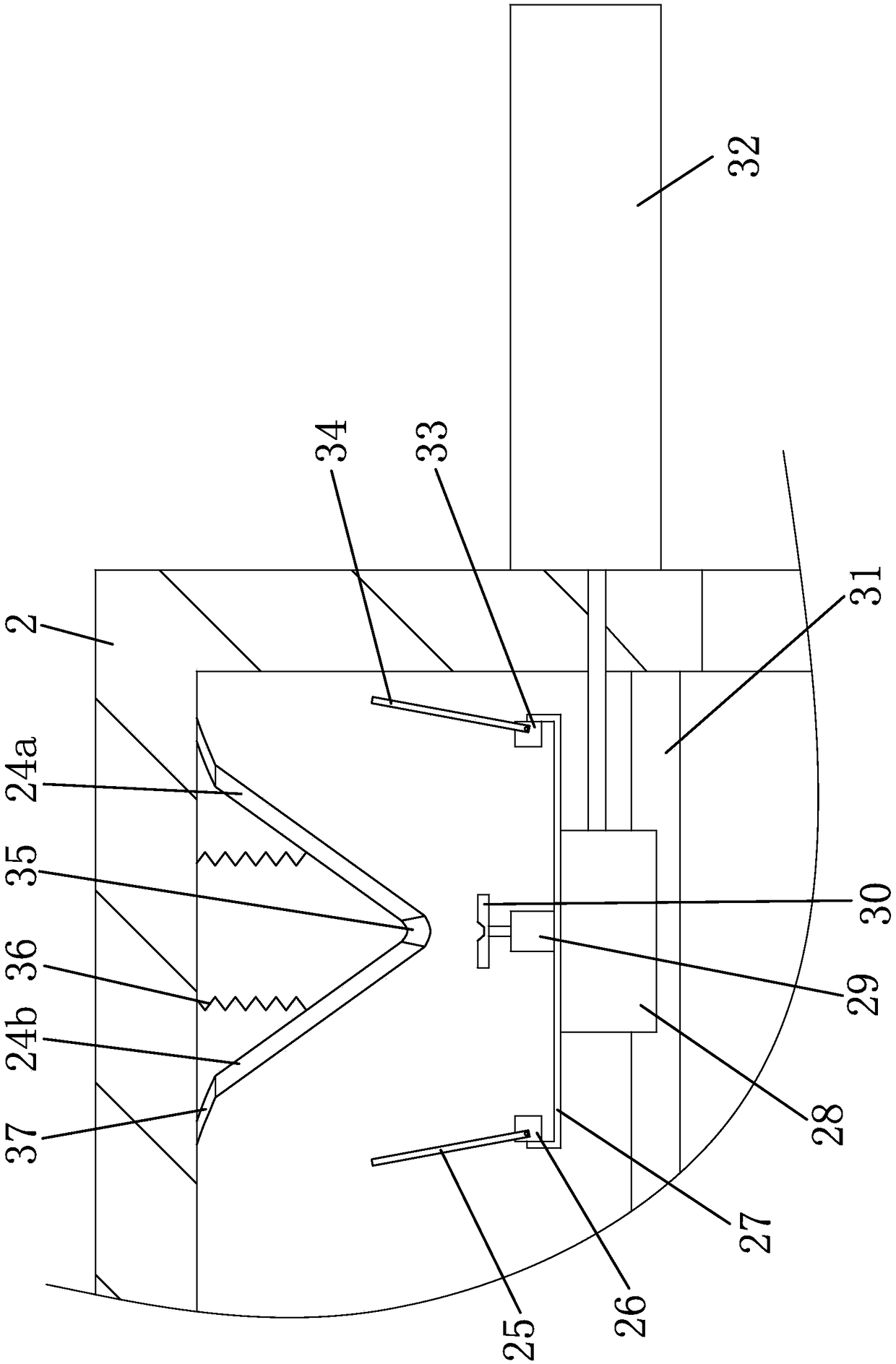

The invention discloses a continuously running layered grass drying device which comprises a shell. The shell is provided with a grass inlet and a grass outlet. Multiple layers of belt conveyors usedfor conveying grass are horizontally arranged in the shell. Conveying belts of the conveyors are of ventilating grid type structures, and the conveyors are sequentially arranged in a staggered mannerfrom top to bottom. The conveying directions of every two adjacent conveyors are opposite. The conveyor on the topmost layer is connected with the grass inlet in the upper end, and the conveyor on thelowermost layer is connected with the grass outlet in the lower end. Grass of the conveyors of the upper layers can downwards fall into the conveying belts of the lower layers of conveyors when conveyed to the tail ends in the conveying directions of the conveyors, and the conveyors on different layers are independently driven by motors which are arranged on the outer wall of the shell correspondingly. The bottom of the shell is provided with a hot air inlet externally connected with a hot blast heater, and a hot air outlet is formed in the top of the shell. Continuous and sufficient drying of grass can be achieved through the layered structure, and the technical problems that drying is not even and not thorough and the drying efficiency is low of an existing drying device are solved, wherein the technical problems are caused by structural defects.

Owner:山丹县天泽农牧科技开发有限责任公司

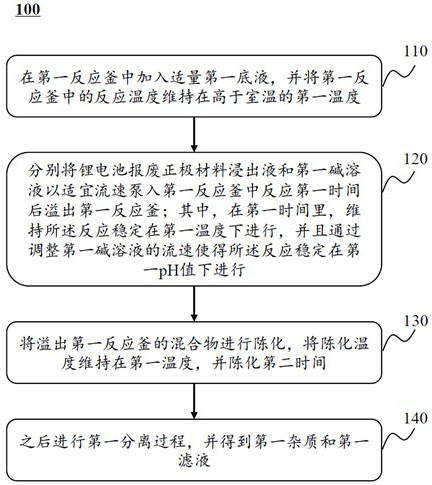

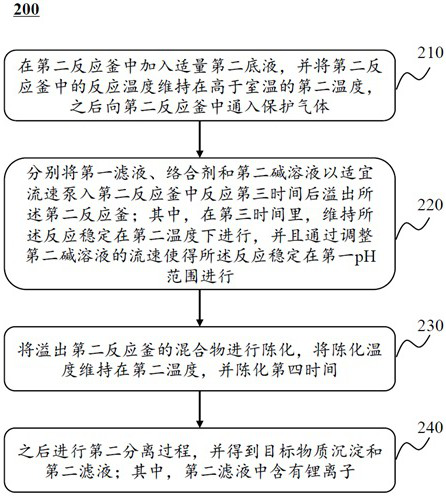

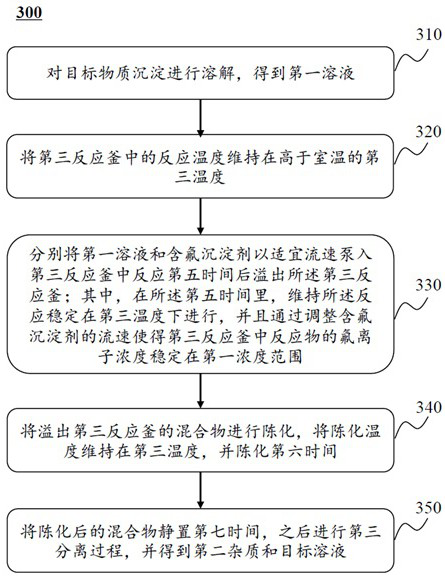

Impurity removal and treatment method in lithium battery scrapped positive electrode material recovery process

ActiveCN112151903AThe reaction environment is stableContinuous uninterrupted operationNon-aqueous electrolyte cellsReclaiming serviceable partsAluminum IonElectrode material

The embodiment of the invention discloses an impurity removal and treatment method in a lithium battery scrapped positive electrode material recovery process. The method comprises the following steps:at a first temperature higher than room temperature and a fixed first pH value, controlling the flow flows of a lithium battery scrapped positive electrode material leaching solution and a first alkaline solution to precipitate and remove iron ions, aluminum ions and at least part of copper ions to obtain a first filtrate; controlling the flow rates of the first filtrate, a complexing agent and asecond alkaline solution at a second temperature higher than room temperature and a fixed first pH range to separate out a second filtrate containing lithium ions to obtain a target substance precipitate; dissolving the target substance precipitate to obtain a first solution; and controlling the flow rates of the first solution and a fluorine-containing precipitant to precipitate and remove calcium ions, magnesium ions and at least part of lead ions at a third temperature higher than room temperature and a fixed fluorine ion concentration to obtain a target solution. According to the method,the precipitate with large particle size, high crystallinity and low water content can be obtained, washing is convenient, and the recovery rate of the lithium battery scrapped positive electrode material nickel-cobalt-manganese is increased.

Owner:SICHUAN ENERGY INTERNET RES INST TSINGHUA UNIV

Method for producing hollowed water-soluble embroidery

InactiveCN105648677AFlexible useUnique styleSucessive textile treatmentsIroning machinesViscosePulp and paper industry

The invention provides a method for producing a hollowed water-soluble embroidery. The technical problem that the water-soluble embroidery in the existing production method can only be used on clothes is solved. The method for producing the hollowed water-soluble embroidery comprises the following steps: a, taking a piece of water-soluble paper as a base fabric, and viscose fiber as an embroidery thread; b, putting the water-soluble paper on an embroidery machine, embroidering the viscose fiber on the water-soluble paper by the embroidery machine to form the required pattern; c, putting the embroidered water-soluble paper into a cleaner to be cleaned for 2 to 3 min at a water temperature of 70 to 90 DEG C, and obtaining a hollowed water-soluble embroidery after dissolving away the water-soluble paper. The method provided by the invention has the advantage of high practicality.

Owner:绍兴恒阳制线有限公司

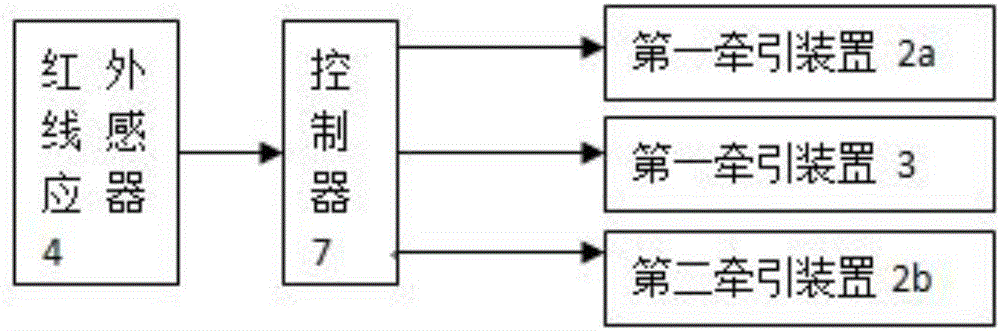

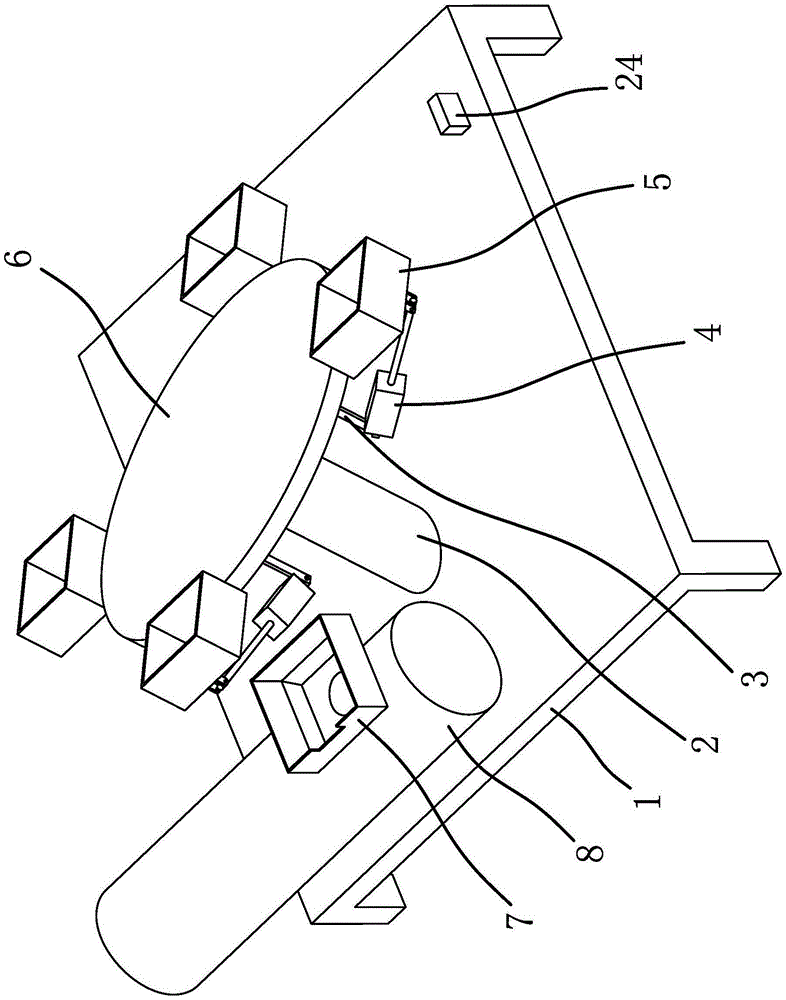

Red jujube pick-up machine

InactiveCN105165260AReduce consumptionContinuous uninterrupted operationHarvestersSuction forceEngineering

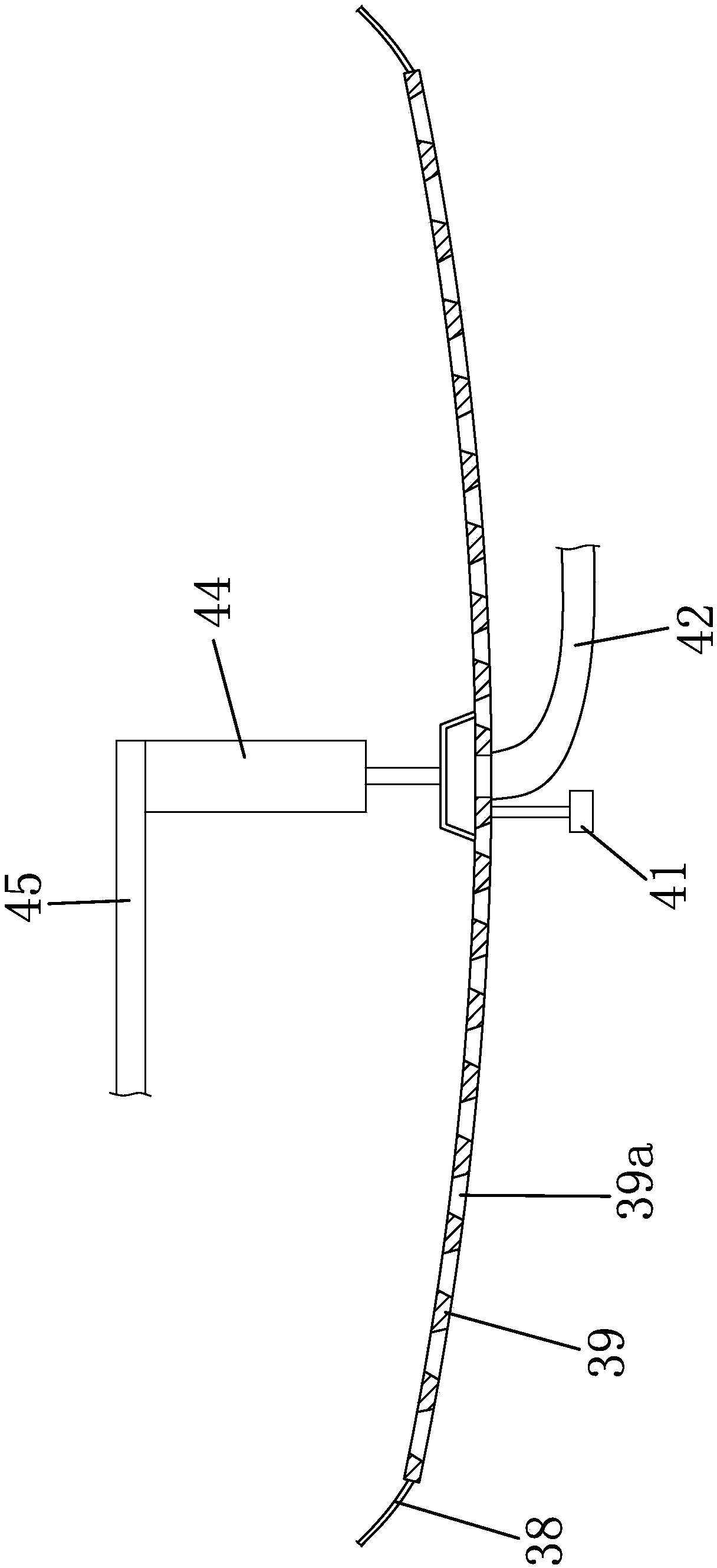

The invention relates to a red jujube pick-up machine which comprises a machine frame, wherein a direction wheel and operating handles are arranged at the front end of the machine frame; travelling wheels driven by a motor is arranged at the rear bottom end of the machine frame; a travelling control button is arranged on one operating handle; a storage battery for supplying power to the travelling wheel motor is arranged on the machine frame; a bracket for placing of collecting baskets is arranged at the lower part of the machine frame; a red jujube suction container is arranged above the machine frame, and divided into a front cavity, a middle cavity and a rear cavity; the caliber of the front cavity is relatively small, the front cavity is inclined backwards and upwards, and a red jujube suction pipe connecting part is arranged in the front cavity; the caliber of the middle cavity is relatively large, a red jujube dropping cavity is arranged at the lower part of the middle cavity, an inclined red jujube dropping hole is formed in the red jujube dropping cavity, a weigh balancing door is arranged in the red jujube dropping hole, and the distance between the red jujube dropping hole and the bracket is greater than the height of each collecting basket; the rear cavity is inclined backwards and upwards, and connected with a suction fan through an air duct; the suction fan is driven by an engine. Through adoption of the red jujube pick-up machine, stable negative pressure can be kept, and thus continuous suction force is formed to pick up red jujubes.

Owner:徐广建

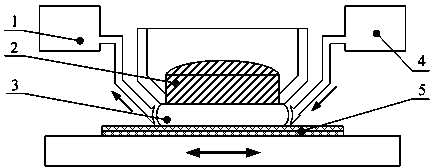

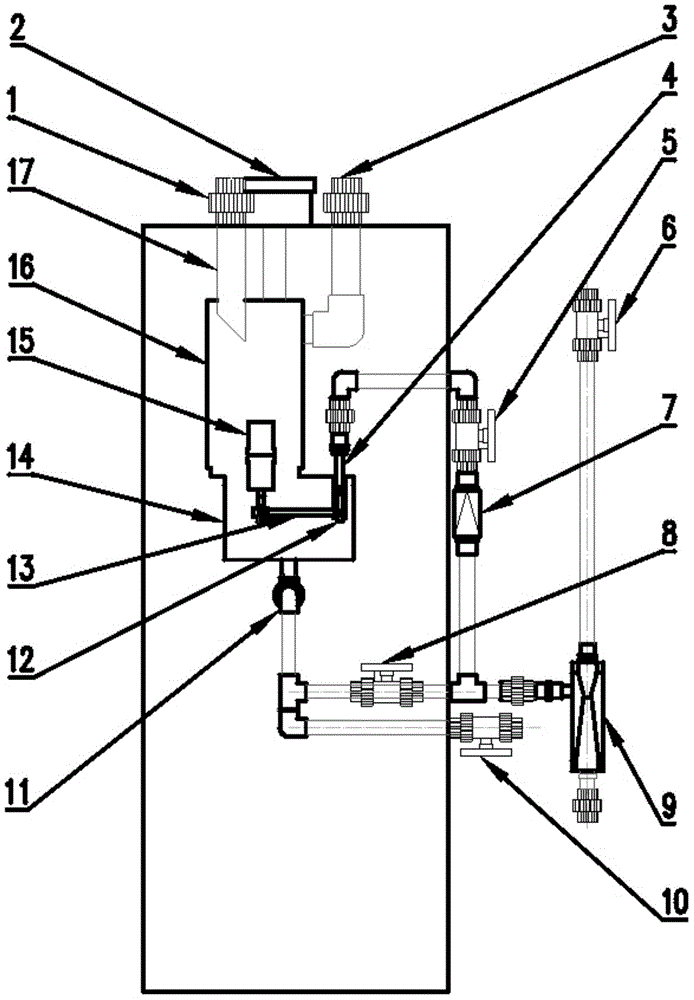

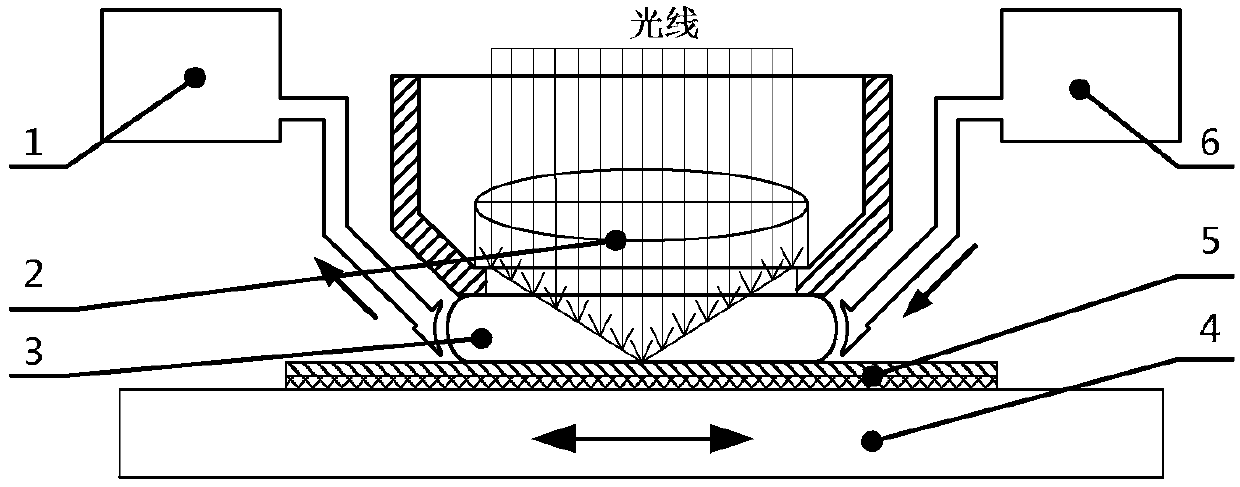

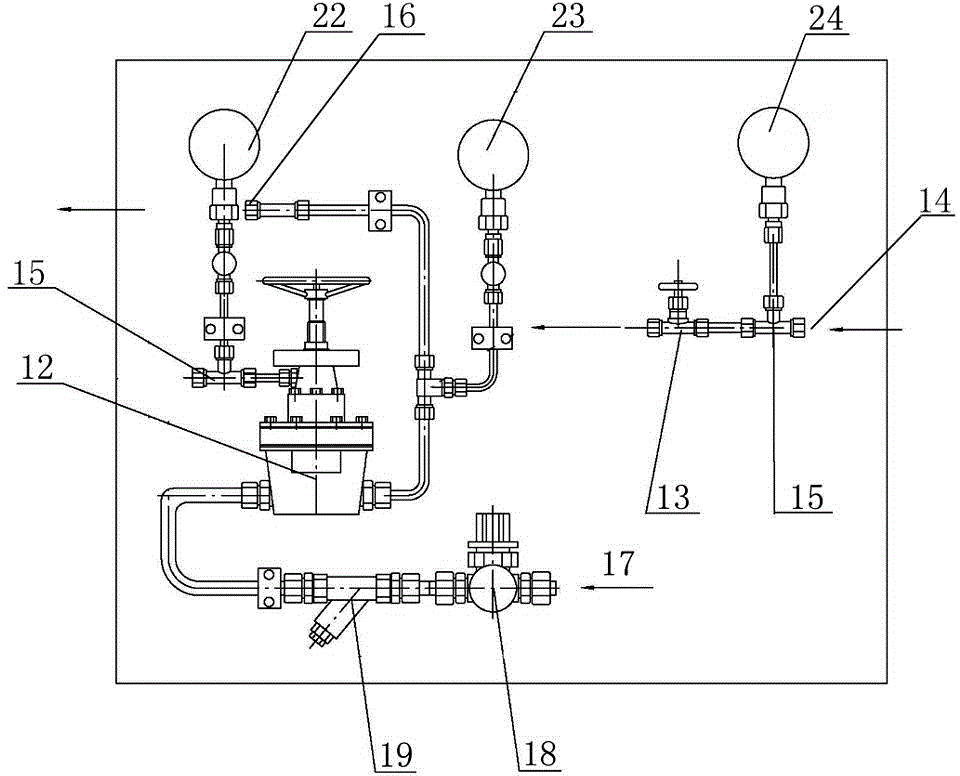

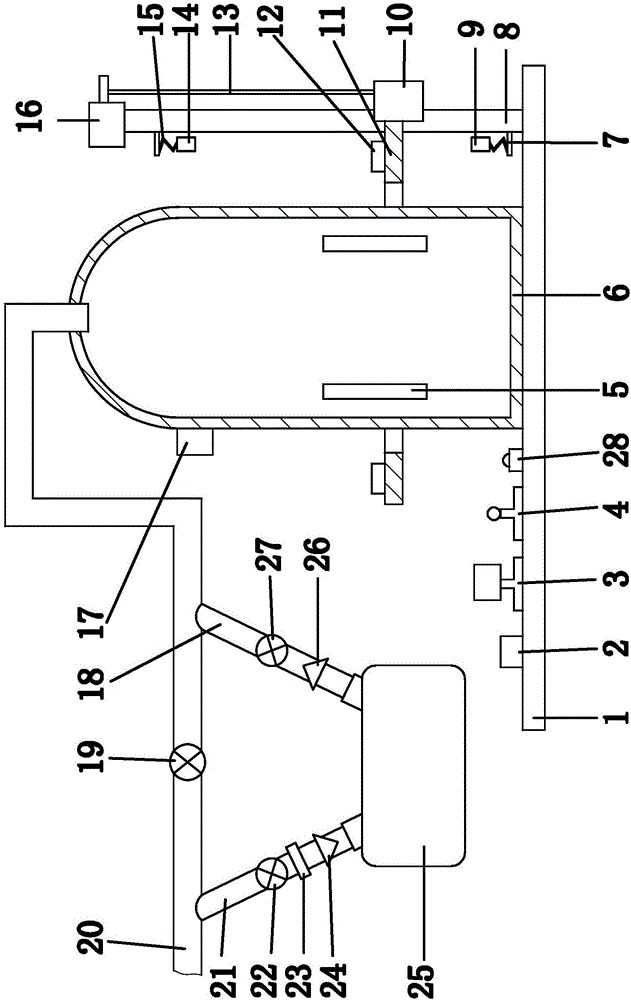

Continuous gas-liquid separation device used for immersion type photoetching machine under negative-pressure environment

InactiveCN104035288AContinuous uninterrupted operationNot affected by injectionPhotomechanical exposure apparatusMicrolithography exposure apparatusVacuum pressureElectricity

The invention discloses a continuous gas-liquid separation device used for an immersion type photoetching machine under a negative-pressure environment. The continuous gas-liquid separation device comprises a gas-liquid separation and storage containing cavity containing a liquid level detection element, a vacuum loop and a water discharging loop, wherein a gas-liquid mixture in the vacuum loop is connected with an inlet in the upper part of the gas-liquid separation and storage containing cavity; the inlet of a vacuum pressure transmitter is connected with an outlet in the upper part of the gas-liquid separation and storage containing cavity; the outlet of the vacuum pressure transmitter is connected with a gas recycling point through a vacuum proportional valve, a switching valve, a vacuum pump and a gas-liquid separator sequentially; the vacuum pressure transmitter and the vacuum proportional valve are electrically connected with a controller; the outlet in the bottom of the gas-liquid separation and storage containing cavity in the water discharging loop is divided into two paths, one path is connected with the inlet of a self suction pump through a flow adjusting valve and the other path is connected with the inlet of an unloading valve; the outlet of the self suction pump and the outlet of the unloading valve are connected with a liquid outlet point. According to the continuous gas-liquid separation device, the separation of a gas phase and a liquid phase can be continuously carried out; the separation of the gas phase and the liquid phase under the negative-pressure environment can be realized.

Owner:ZHEJIANG UNIV

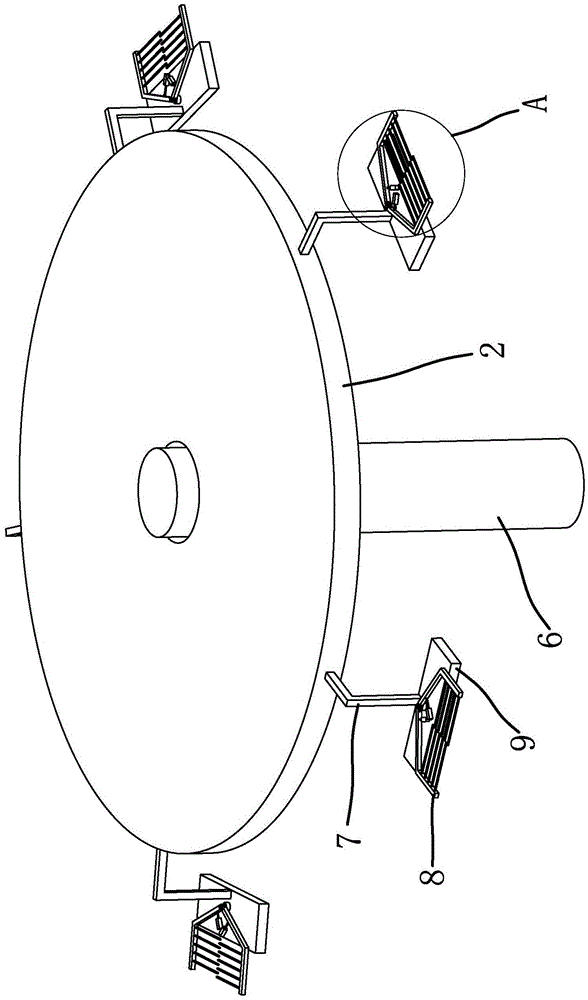

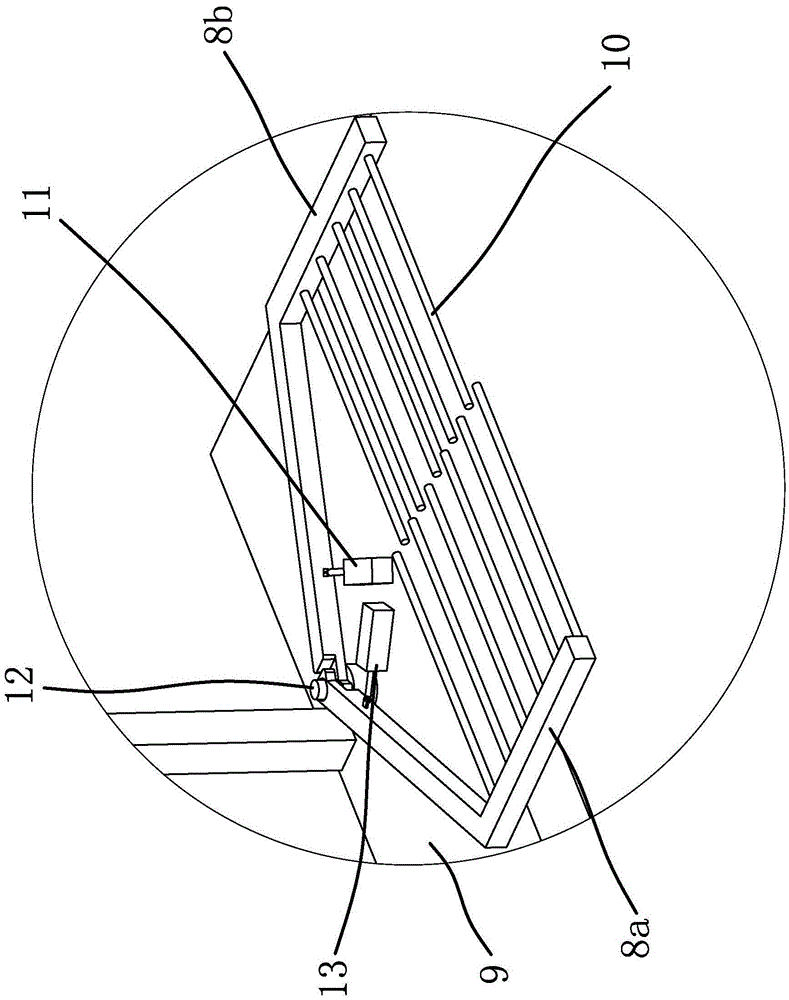

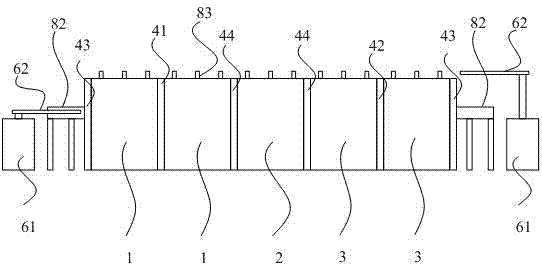

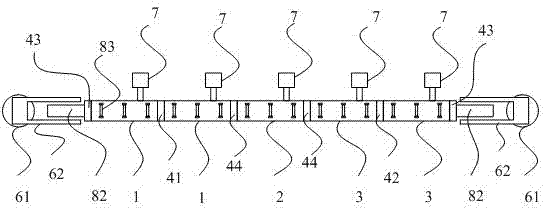

Machining device for rolling impregnation of wood and bamboo materials

InactiveCN105522626AReduce wasteReduce manufacturing costWood treatment detailsWood impregnation detailsExtrusionStorage tank

The invention relates to a machining device for rolling impregnation of wood and bamboo materials. The machining device comprises an impregnation roller set, a cleaning roller set and an impregnation tank; the impregnation tank is positioned below the impregnation roller set; the cleaning roller set is positioned on the right side of the impregnation roller set; a water extrusion roller set is additionally arranged on the left side of the impregnation roller set; one or more first guide rollers are arranged between the water extrusion roller set and the impregnation roller set; one or more second guide rollers are arranged between the impregnation roller set and the cleaning roller set; a modifying agent recovery device is arranged below the cleaning roller set; a heating device is arranged at the bottom of the impregnation tank; a temperature meter is arranged at the upper part of the impregnation tank; and a modifying agent storage tank is arranged on the left side of the impregnation tank. The machining device for rolling impregnation of the wood and bamboo materials has the following beneficial effects: the device can obtain the wood and bamboo materials uniformly impregnated by a modifying agent and with clean surfaces, can realize the assembly operation, and improves the working efficiency; and the assembly operation can reduce damage of the materials in the loading and unloading process.

Owner:BEIJING JMB SCI & TECH DEV LTD

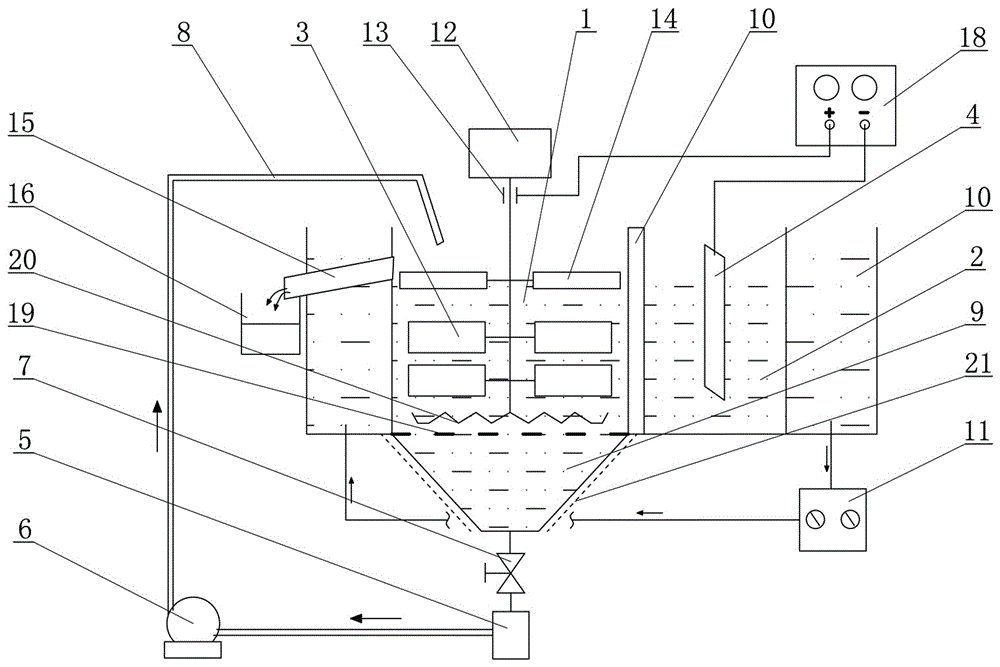

Continuous electrolytic cell for potassium ferrate

InactiveCN105696016AFor automatic dischargeIncrease productivityCellsTemperature controlContinuous/uninterrupted

The invention provides a continuous electrolytic cell for potassium ferrate. The continuous electrolytic cell for potassium ferrate comprises an electrolytic cell body and an electrolytic electrode. The lower end of the electrolytic cell body communicates with a silt collecting chamber which is connected with a silt bin through a valve; the high position of the silt bin communicates with the electrolytic cell body through a backflow pipe; backflow power is supplied to the backflow pipe by a circulating pump; the electrolytic cell body comprises an anode chamber, a cathode chamber, a diaphragm assembly and a temperature control device; a stirrer is vertically mounted in the anode chamber; an electric brush, helical blades and iron electrodes are sequentially arranged on a stirring shaft of the stirrer; a potassium ferrate discharge opening is formed in the upper side portion of the anode chamber; the helical blades are arranged corresponding to the potassium ferrate discharge opening; the electric brush is connected with the positive pole of a direct current power source; and the negative pole of the direct current power source is connected with a graphite electrode in the cathode chamber. The continuous electrolytic cell for potassium ferrate has the advantages of being scientific in design, capable of enabling electrolyte to be recycled and automatically collecting potassium ferrate coarse materials, capable of achieving continuous uninterrupted production and high in electrolytic efficiency.

Owner:HENAN VOCATIONAL COLLEGE OF APPLIED TECH

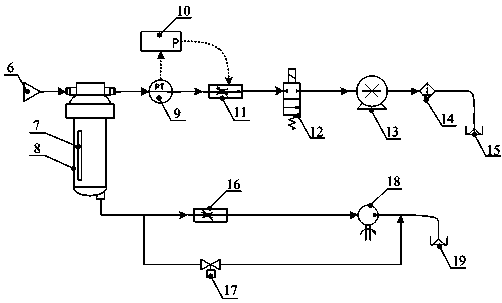

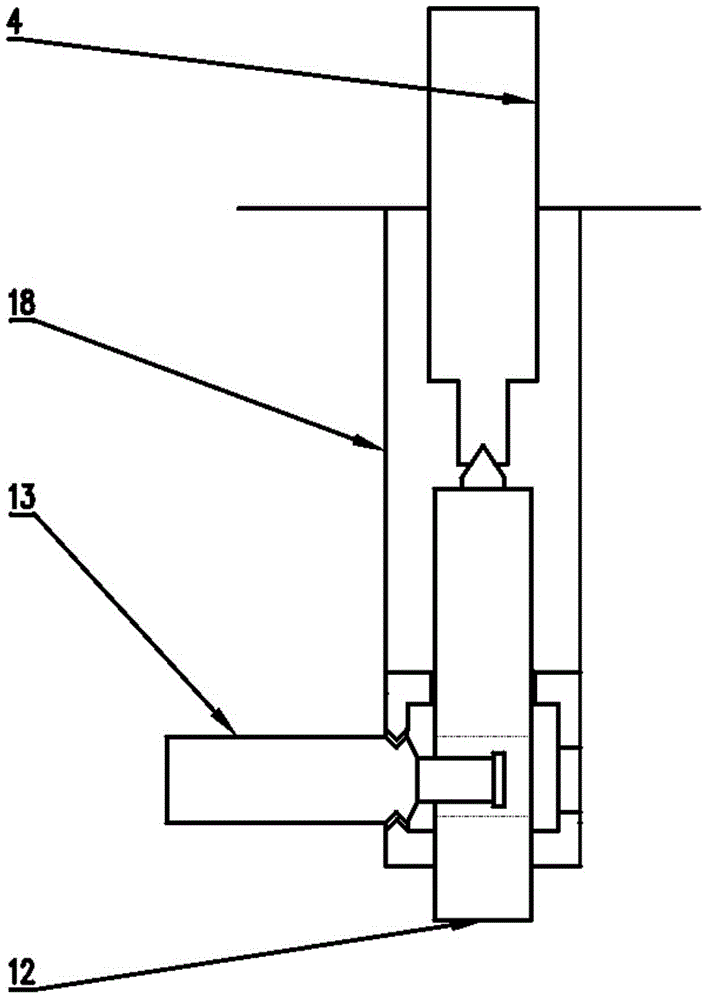

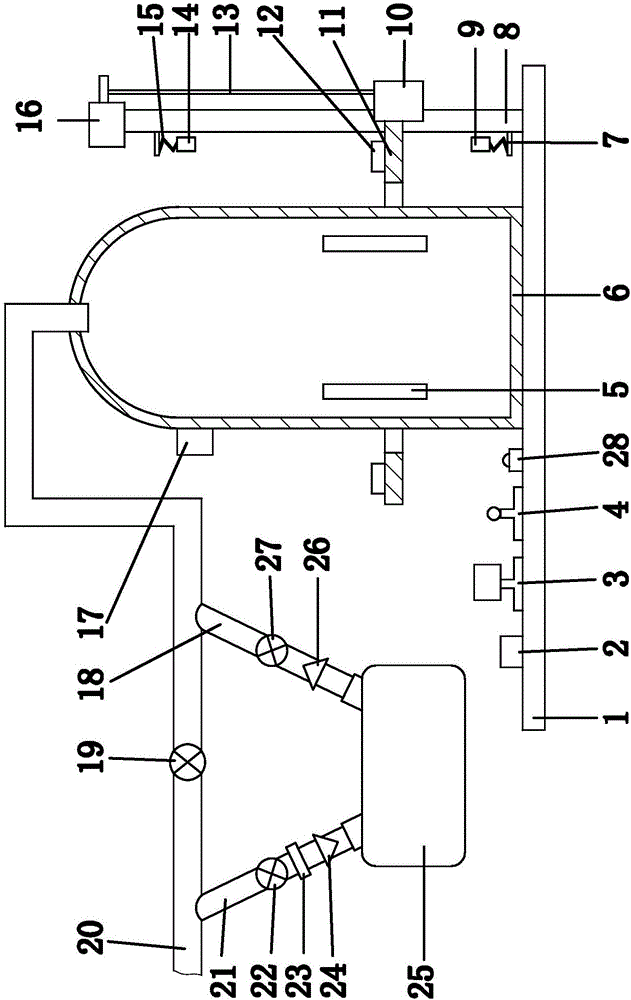

Automatic gas-liquid separation device and method for chlorine dioxide generator under high negative pressure environment

ActiveCN104906874AContinuous uninterrupted operationOvercome the situation that cannot be automatically flowed outChlorine oxidesDispersed particle separationProcess engineeringWater jet

The invention discloses an automatic gas-liquid separation device and method for a chlorine dioxide generator under a high negative pressure environment. The device comprises a shell, an automatic gas-liquid separation system and a residual liquid exhaust system, wherein the automatic gas-liquid separation system comprises a gas-liquid mixture inlet, an internal insertion pipe, a gas outlet, a separation box, a liquid collection box, a floater, a linkage rod, a sealing cone and a liquid outlet pipe, and the residual exhaust system comprises a residual liquid valve, a check valve, a water jet and a power water valve; the gas-liquid mixture of chlorine dioxide generated by the generator, chlorine and a reaction liquid enters the separation tank through the mixture inlet and the internal insertion pipe; chlorine dioxide and chlorine are output through the gas outlet; the reaction liquid enters the liquid collection tank; the liquid level gradually rises; the floater floats to drive the sealing cone to leave the opening of the liquid outlet pipe; a solution enters the liquid outlet pipe and is discharged by virtue of negative pressure. According to the automatic gas-liquid separation device, gas-liquid separation can be automatically carried out so as to achieve the gas-liquid separation under high negative pressure environment; meanwhile, the difficulty that chlorine dioxide is limited by acidity when applied to the fields of bleaching and the like is solved.

Owner:SHANDONG SHANDA WIT ENVIRONMENTAL ENGINEERING CO LTD

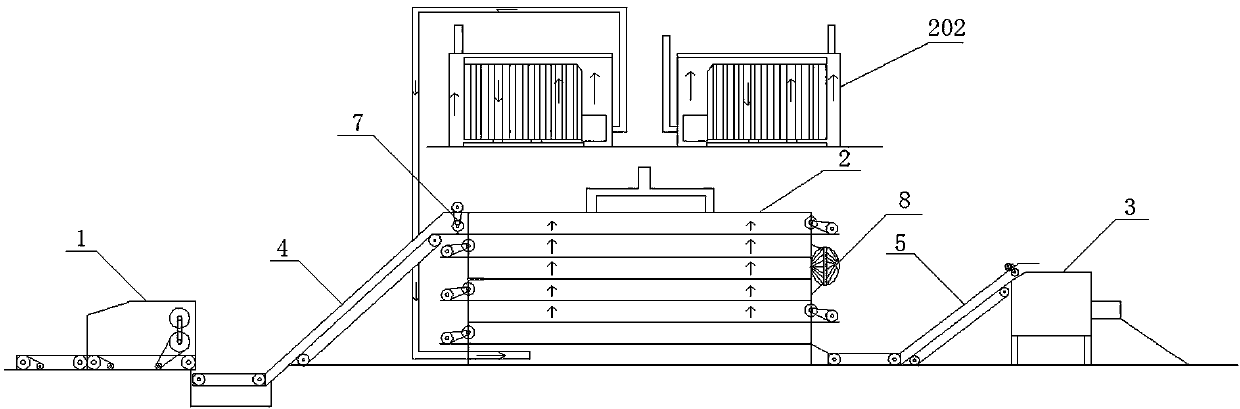

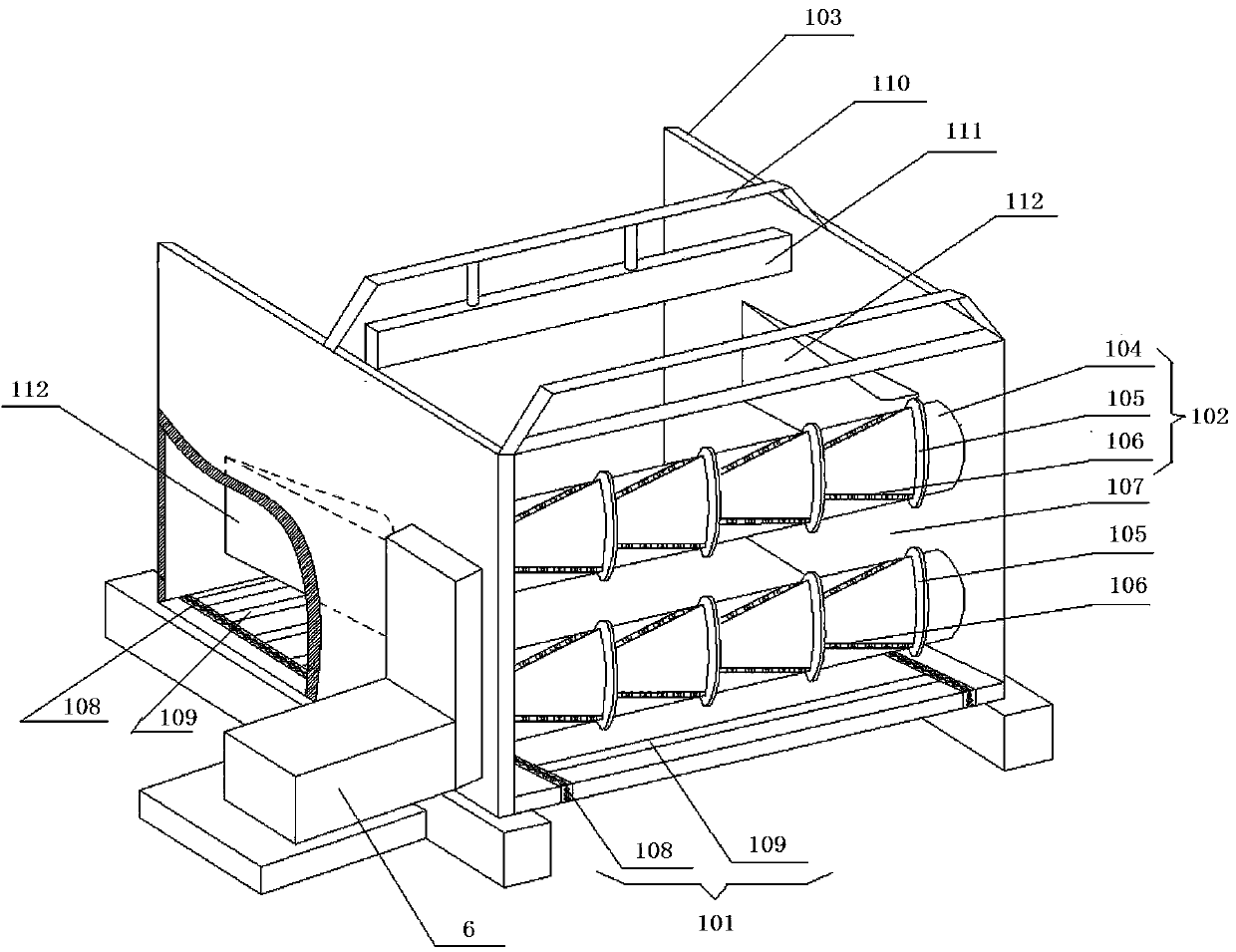

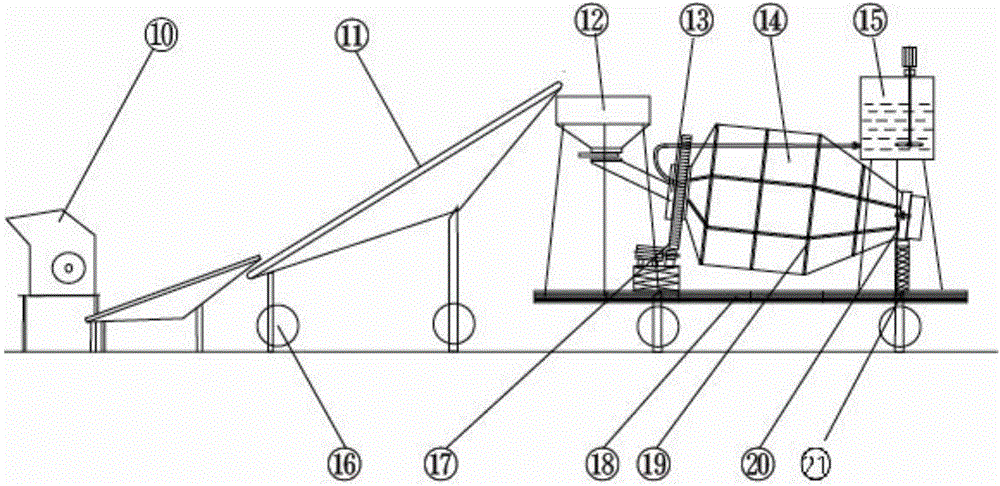

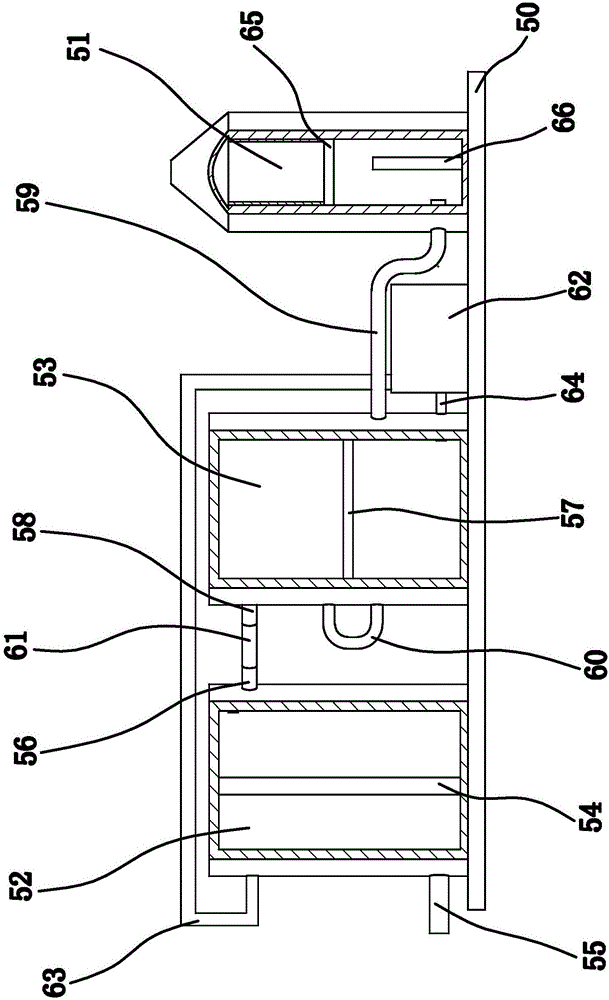

Large-scale automatic pasture processing device system

PendingCN107751579ARealize large-scaleImprove processing qualityBalingAnimal fodder preservationAgricultural scienceHot air oven

The invention discloses a large-scale automatic pasture processing device system. The large-scale automatic pasture processing device system comprises a bundle breaking and feeding device, a layered drying device and a forming and binding device, wherein a pushing mechanism is arranged at one end of the body of the bundle breaking and feeding device, a bundle breaking and feeding mechanism is arranged closely to the pushing mechanism, a discharge port of the bundle breaking and feeding device is connected with a feed port of a forage conveying belt I device, multiple layers of belt-type conveyors used for conveying pasture are arranged horizontally in a shell of the layered drying device, the conveying belts of the conveyors are of a ventilated mesh type structure, dry high-temperature airis introduced into the shell by a hot-blast stove for drying the pasture in the process that the pasture is conveyed layer by layer, a discharge port of the layered drying device is connected with afeed port of the forming and binding device through a forage conveying belt II, and the devices are powered by a variable frequency motor. The large-scale automatic pasture processing device system can realize large-scale, mechanical and automatic processing and production of pasture, obviously improve the processing quality of the pasture, shorten the processing cycle of the pasture, improve theproduction efficiency and reduce the production cost.

Owner:山丹县天泽农牧科技开发有限责任公司

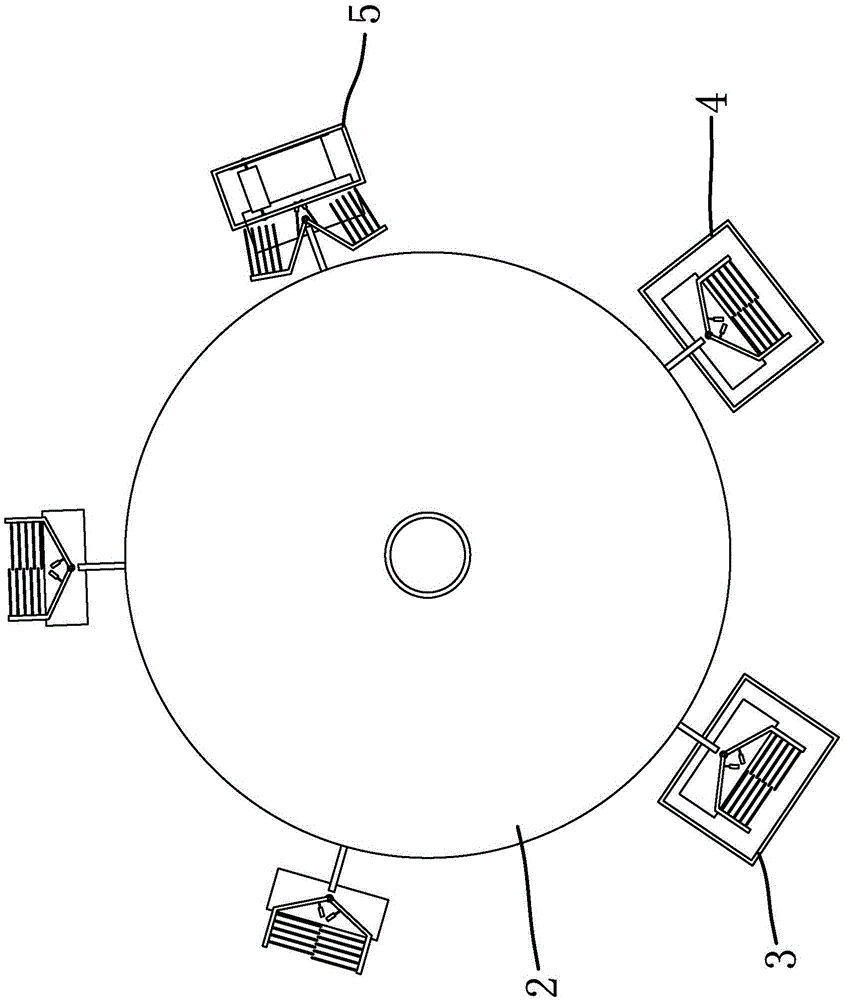

Harmless remediation method and device of electrolytic aluminum waste slag and contaminated soil of electrolytic aluminum waste slag

The invention belongs to the field of environment protection, and relates to a soil remediation technology and device, in particular to a harmless remediation treatment technology and device of electrolytic aluminum waste slag and contaminated soil of the electrolytic aluminum waste slag. According to a harmless treatment method of the electrolytic aluminum waste slag and the contaminated soil of the electrolytic aluminum waste slag, cyanide, soluble fluoride and other harmful substances can be removed simply, economically and efficiently, and green harmless treatment of the electrolytic aluminum waste slag and contamination therefore is achieved. According to the harmless treatment device of the electrolytic aluminum waste slag and the contaminated soil of the electrolytic aluminum waste slag, a rotary stirring tank is used as a stirring system for the first time to carry out harmless treatment of the electrolytic aluminum waste slag and the contaminated soil thereof, the walking speed of materials is adjusted by adjusting the tilt angle of the rotary stirring tank, and therefore the mixing effect is adjusted, the design length of the rotary stirring tank is reduced, the device is simple, and the equipment manufacturing cost is greatly reduced.

Owner:XINZHONGTIAN ENVIRONMENTAL PROTECTION

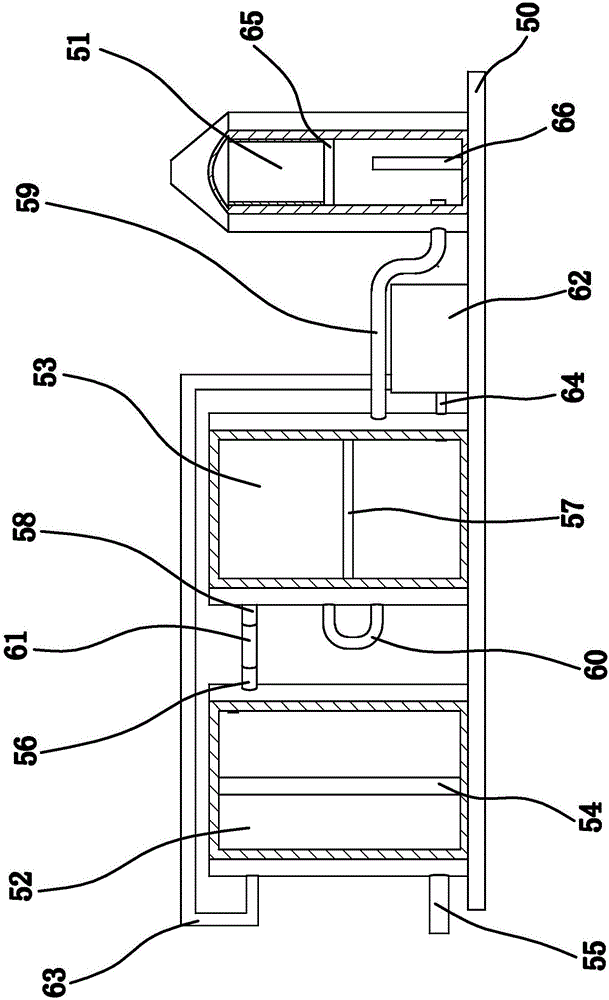

Two-stage gas-liquid separation and recovery device for immersion type lithography machine

PendingCN107861339AImprove efficiency and effectivenessGuarantee the effect of coordinationDispersed particle separationPhotomechanical exposure apparatusPhysicsSeparation process

The invention relates to a two-stage gas-liquid separation and recovery device for an immersion type lithography machine. The device comprises a gas-liquid separator, a gas-liquid separation tank, a liquid flow controller, a two-phase flow loop before gas-liquid separation, an exhaust loop after gas-liquid separation, and a drainage loop after gas-liquid separation. The gas-liquid separator is connected with the two-phase flow loop before gas-liquid separation and an upper inlet of the gas-liquid separation tank; the gas-liquid separation tank is connected with the exhaust loop after gas-liquid separation and an inlet of the liquid flow controller; the liquid flow controller and the gas-liquid separator are connected with the drainage loop after gas-liquid separation. By means of the device, continuous separation process of a gaseous phase and a liquid phase can be achieved under the action of negative-pressure suction, and the separation and recovery efficiency and effects are obviously improved compared with those of solutions in the prior art. Meanwhile, interference on negative pressure of a system is avoided, and gas and liquid in the system can be discharged in time under a fault condition to achieve timely decompression.

Owner:ZHEJIANG CHEER TECH CO LTD

Device for collecting vapor in flue gas

InactiveCN106287646AGood recovery of flue gasFull recoverySteam separation arrangementsIndirect heat exchangersContinuous/uninterruptedEnvironmental resistance

The invention relates to a device for collecting vapor in flue gas. The device comprises a heat exchange unit and a vapor collecting unit, an air channel is arranged on the upper portion of the heat exchange unit, a flue gas channel is arranged on the lower portion of the heat exchange unit, the heat exchange unit is connected with the vapor collecting unit through the flue gas channel, the bottom of the flue gas channel is provided with a plurality of drain pipes, and the vapor collecting unit comprises a plurality of cold water sprayers and a vapor collector. Air exchanges heat with the flue gas through the heat exchange unit, part of the vapor in the flue gas is condensed, the flue gas flows to the vapor collecting unit and is further cooled, the vapor in the flue gas is further collected, and the low-temperature flue gas is discharged. Compared with the prior art, the device is simple, low in cost, capable of continuously running, good in flue gas recovery effect and high in universality, running cost can be greatly reduced, economical efficiency is improved, the emission problem of the vapor is effectively solved, and environmental protection level can be improved.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Production system of polycrystalline solar cell

ActiveCN105932102AEasy to cleanAvoid Oil BackflowFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringSolar cell

The invention provides a production system of a polycrystalline solar cell, and aims at solving the technical problems that an existing production system is too simple in structure, texturing, diffusion, coating and sintering cannot be continuously carried out, the production speed is low and the like. The production system of the polycrystalline solar cell comprises a mounting frame, wherein the mounting frame is sequentially provided with a texturing device, a diffusion device, a coating device and a sintering device. The production system has the advantage of high production efficiency.

Owner:ZHEJIANG GUANGLONG ENERGY TECH

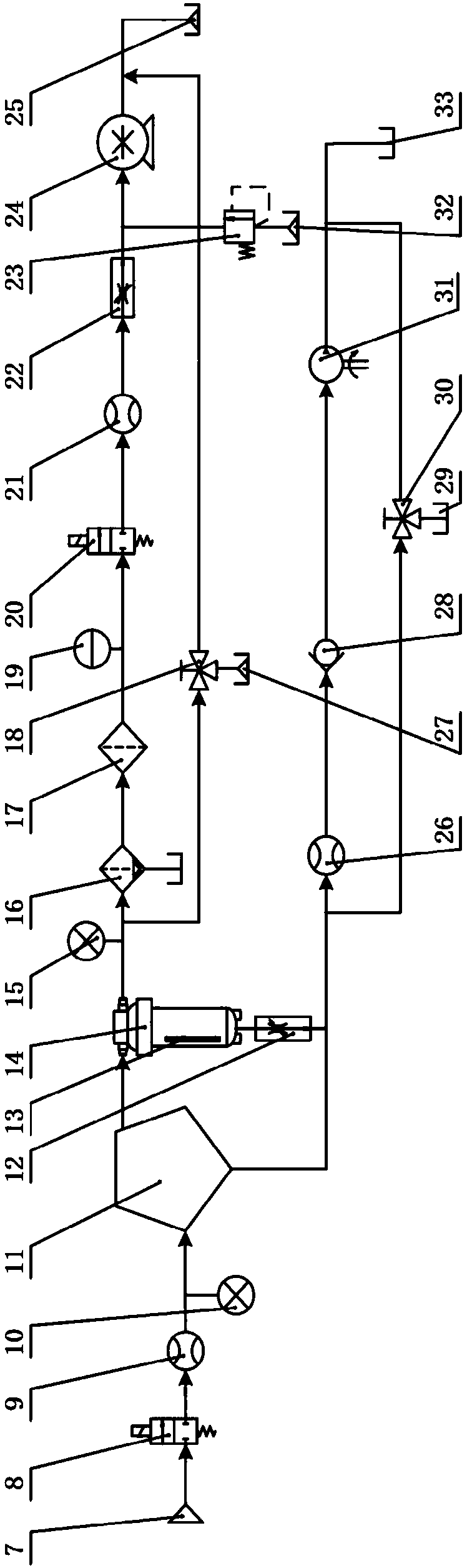

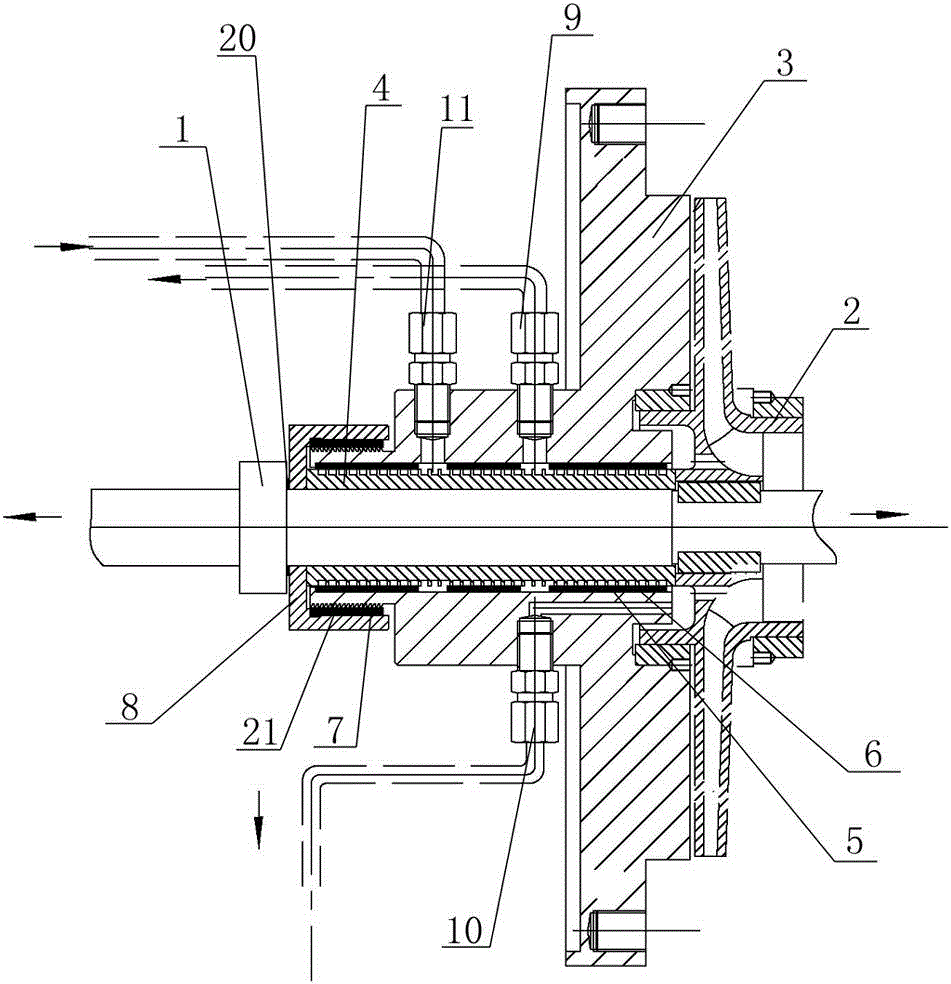

Shaft seal structure of low temperature pump and sealing gas control system of shaft seal

ActiveCN103953574AReasonable structureEasy to usePump componentsPumpsEngineeringContinuous/uninterrupted

The invention discloses a shaft seal structure of a low temperature pump and a sealing gas control system of a shaft seal. The shaft seal structure of the low temperature pump comprises a sealing seat, wherein a labyrinth sleeve and a first sealing liner are arranged between the sealing seat and a pump shaft, the first sealing liner is positioned outside the labyrinth sleeve and is embedded in a shaft hole of the sealing seat, and a labyrinth type sealing pair is formed in a way that a comb-tooth structure arranged on the labyrinth sleeve is matched with a sealing groove, which runs out of the first sealing liner, on the first sealing liner due to mutual rotational running of the comb-tooth structure and the first sealing liner; the outer end of the sealing seat is provided with a shaft sleeve type check ring with a second sealing liner; the sealing seat is respectively provided with three air source connectors which are communicated with the labyrinth type sealing pair. According to the shaft seal structure disclosed by the invention, the low temperature pump can be used in a process technology which is capable of meeting continuous running and does not affect the medium purity, and the reliable running of the low temperature pump cannot be affected by the pressure fluctuation at an inlet of the low temperature pump.

Owner:HANGZHOU HANGYANG KOSO PUMP & VALVE

Antistatic fiber fabric and production method thereof

ActiveCN105563980AHigh mechanical strengthImprove antioxidant capacitySynthetic resin layered productsLaminationFiberAntistatic agent

The invention provides an antistatic fiber fabric and a production method thereof. The technical problems of no antistatic or anti-oxidative characteristics, only use in single welding environment, simple use and no production methods of present composite fabrics are solved in the invention. The antistatic fiber fabric comprises a base cloth layer, a protection layer is arranged on the base cloth layer, and the protection layer comprises, by weight, 30-50 parts of polyvinyl chloride resin, 1.8-3.6 parts of azodicarbonamide, 7-8 parts of talcum powder, 1.6-4.8 parts of white oil, 6-12 parts of an antistatic agent, 2-4 parts of a light stabilizer, 1-3 parts of an antioxidant and 0.8-2.4 parts of a plasticizer. The antistatic fiber fabric has the advantages of strong practicality and stable quality.

Owner:南通汇优洁医用材料有限公司

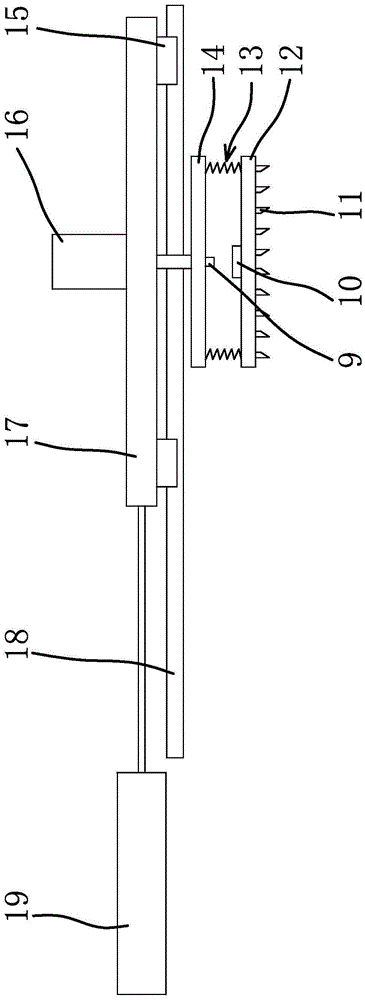

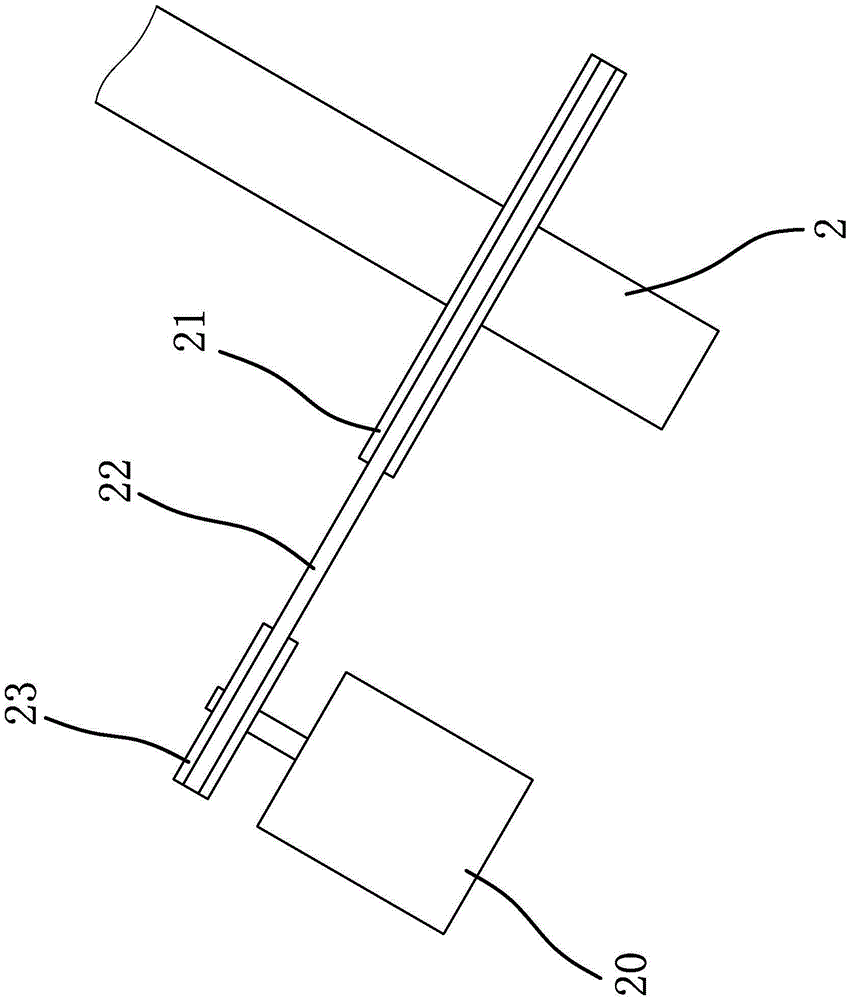

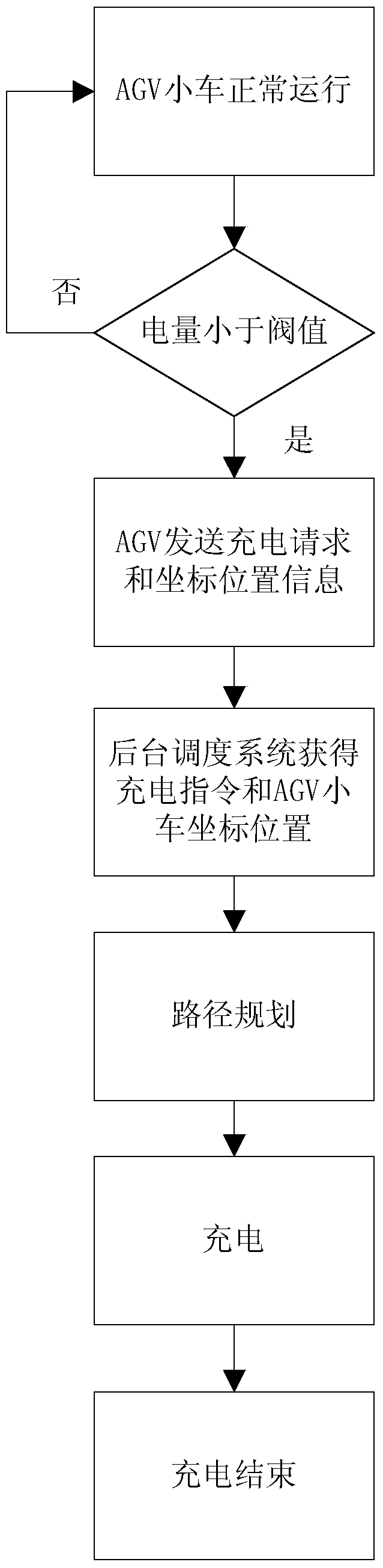

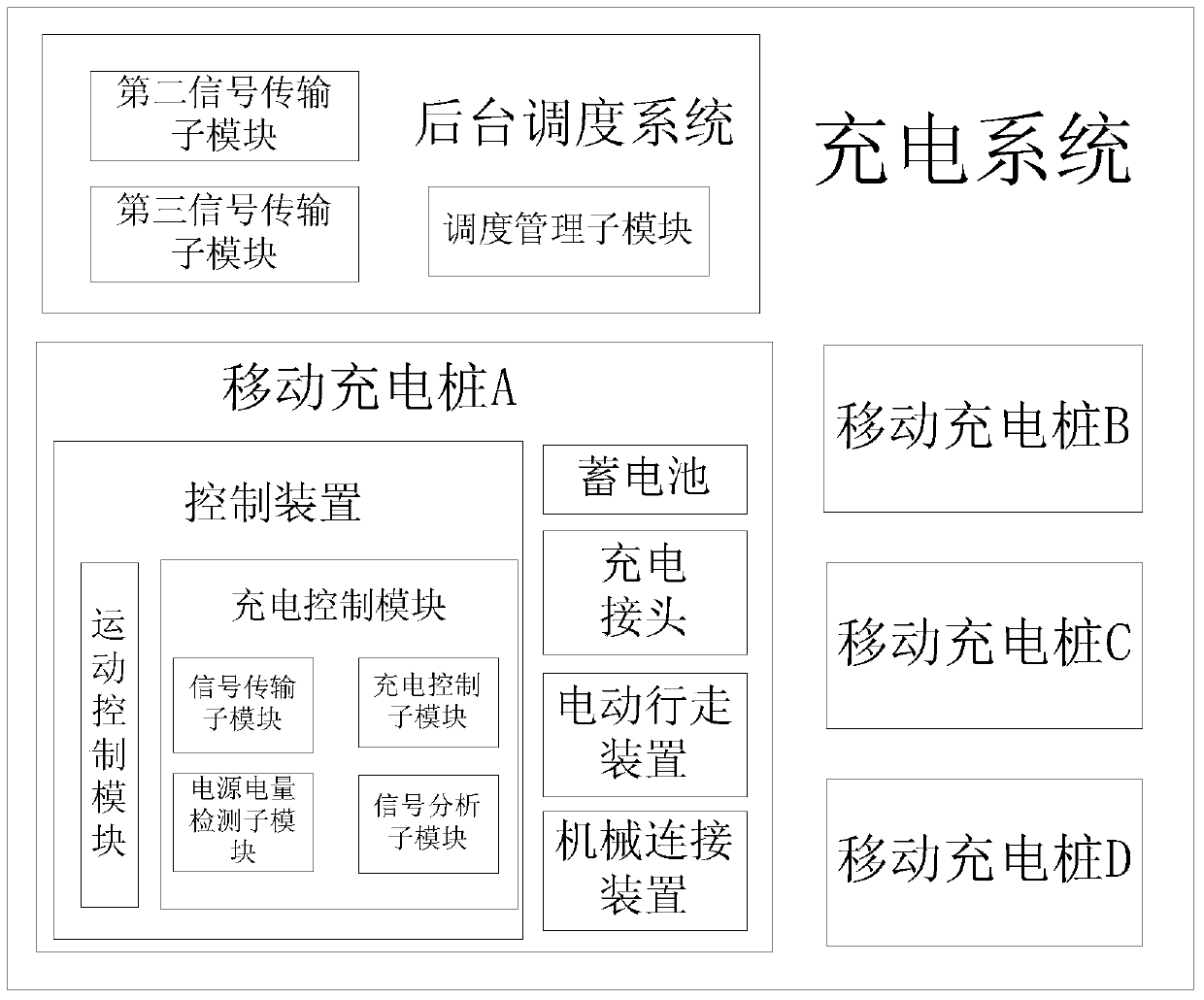

Automatic guided vehicle (agv) charging method, mobile charging pile, and charging system

ActiveCN104836293BTimely chargingContinuous operationSecondary cells charging/dischargingElectric powerControl engineeringCharging station

The invention provides a charging method of an automatic guided vehicle (AGV), a movable charging pile according to the charging method, and an AGV charging system. A moving path is independently planned through the movable charging pile, and the AGV is actively charged when the movable charging pile arrives at the AGV. Not only are AGV moving to a charging station for charging and working time occupation prevented, but also no interference and obstruction among different movable charging piles in a movement path are prevented. Furthermore high equipment utilization rate and in-time charging to the AGV are realized. The movable charging pile of the invention can move simultaneously with charged equipment for ensuring connection of charging interfaces, realizing continuous charging and ensuring continuous and non-stopped operation of the AGV. Furthermore, through scheduling by a background scheduling system, not only can charging timeliness be ensured, but also beforehand time arrangement for the movable charging pile can be realized, thereby ensuring most timely and most reasonable charging opportunity for the AGV in a busy charging task.

Owner:HANGZHOU JIAZHI TECH CO LTD

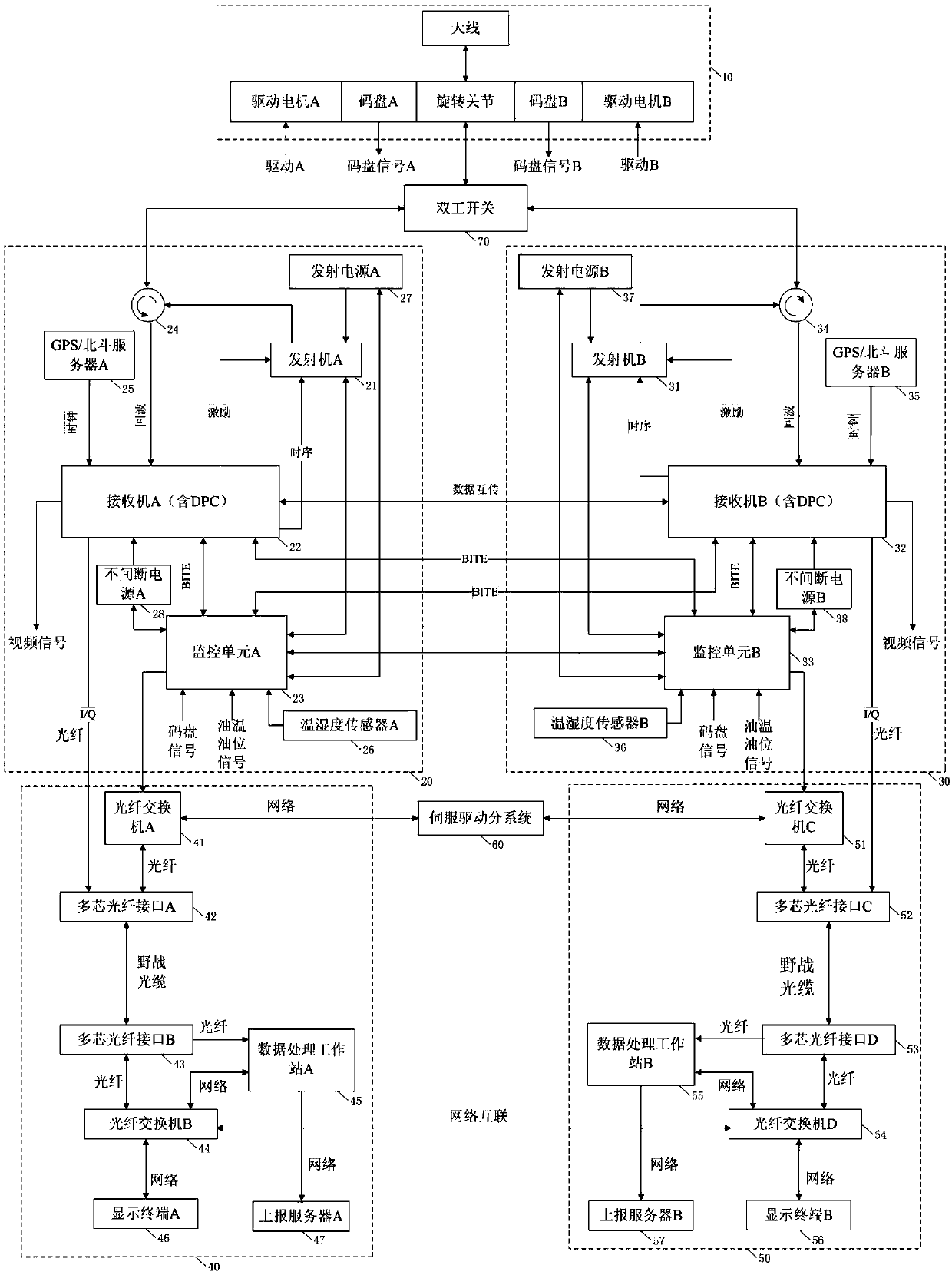

All-solid-state X-band airport surface detection radar and working method thereof

InactiveCN107807348AEffective surveillanceContinuous uninterrupted operationWave based measurement systemsRadar systemsSolid state amplifiers

The invention belongs to the technical field of a radar system and especially relates to an all-solid-state X-band airport surface detection radar and a working method thereof. The airport surface detection radar adopts a dual-redundancy system structure; a servo drive subsystem realizes dual-redundancy connection under control of a monitoring unit A and a monitoring unit B; each transmitter adopts a high-power solid-state amplifier; and each receiver adopts a large dynamic modularized digital receiver, and supports single-channel frequency agility and frequency diversity working modes. A transmit-receive subsystem A and a transmit-receive subsystem B realize dual-redundancy connection under the control of the monitoring unit A and the monitoring unit B. A signal processing subsystem A anda signal processing subsystem B realize dual-redundancy connection under the control of the monitoring unit A and the monitoring unit B. The radar system has a function of whole-course supervision offixed and moving targets and rainfall distribution, and supports all-weather and all-day uninterrupted unattended operation.

Owner:ANHUI SUN CREATE ELECTRONICS

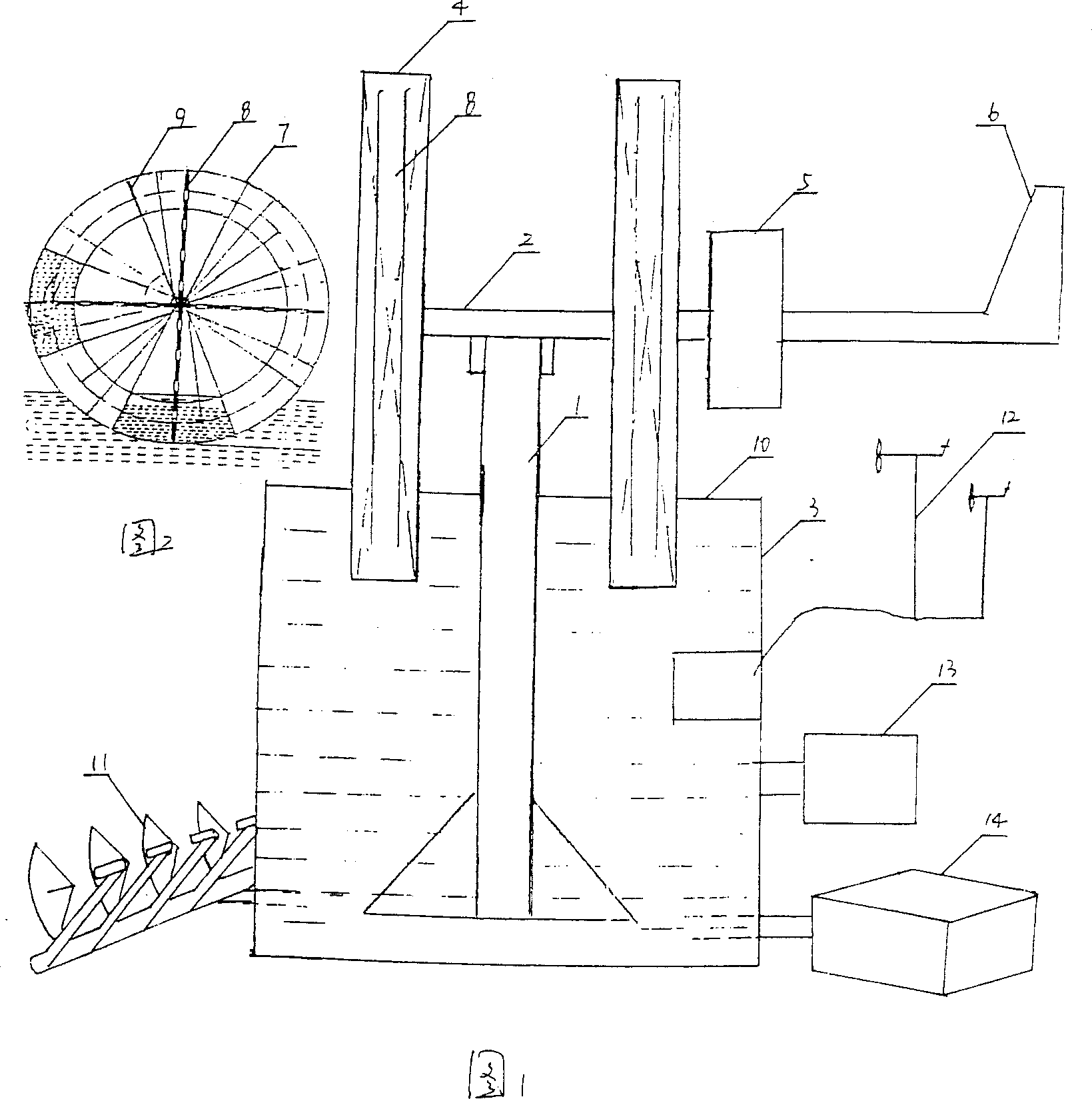

Multiple energy power machine with combined horizotal shaft

InactiveCN1847648AIncrease temperatureImprove efficiencyMachines/enginesMechanical power devicesEngineeringMechanical engineering

The multiple energy power machine with combined horizontal shaft consists of heat accumulating pond, upright, horizontal shaft, rotating wheel and generator. The upright is installed inside the heat accumulating pond and has horizontal shaft installed on its top, at least one rotating wheel is installed operate horizontal shaft and has its lower part soaked inside the heat accumulating pond, the generator is installed on the horizontal shaft. The rotating shaft consists of rotating wheel stand on the horizontal shaft, closed heat pipes and vanes on the rotating wheel stand. The power machine of the present invention has simultaneous utilization of multiple kinds of energy sources for continuous running in low cost and high efficiency.

Owner:李士明

A kind of military ground cloth and preparation method thereof

ActiveCN105951469BWaterproofAging resistantLiquid surface applicatorsCoatingsPolyvinyl chlorideUltraviolet lights

The invention provides military ground cloth and a preparation method of the military ground cloth, and solves the technical problems that the existing tent cloth is too simple in structure, has no features of resisting flame and ultraviolet light, is poor in functionality, and has no preparation method. The military ground cloth comprises a base cloth layer, wherein each of the upper side and the lower side of the base cloth layer is provided with a PVC (polyvinyl chloride) coating; the PVC coating is prepared from the following components in parts by weight: 68 to 84 parts of PVC paste resin, 30 to 40 parts of plasticizer DINP (Diisononyl phthalate), 6 to 10 parts of calcium carbonate, 2 to 8 parts of chlorinated paraffin, 1 to 6 parts of stabilizing agent, 12 to 18 parts of flame retardant, 4 to 10 parts of bonding agent and 0.1 to 0.5 part of anti-UV (anti-ultraviolet) agent. The military ground cloth has the advantage of strong functionality.

Owner:ZHEJIANG SHANGCHENG SCI&TECH

Controller for switching grid connection photovoltaic power generation system and off-grid photovoltaic power generation system

ActiveCN102694393BFusion wellContinuous uninterrupted operationSingle network parallel feeding arrangementsPhotovoltaic energy generationElectricityGrid fault

Owner:广东永光新能源设计咨询有限公司

An automatic gas-liquid separation device and method for chlorine dioxide generator

ActiveCN104906874BContinuous uninterrupted operationOvercome the situation that cannot be automatically flowed outChlorine oxidesDispersed particle separationChlorine dioxideVapor–liquid separator

The invention discloses an automatic gas-liquid separation device and method for a chlorine dioxide generator under a high negative pressure environment. The device comprises a shell, an automatic gas-liquid separation system and a residual liquid exhaust system, wherein the automatic gas-liquid separation system comprises a gas-liquid mixture inlet, an internal insertion pipe, a gas outlet, a separation box, a liquid collection box, a floater, a linkage rod, a sealing cone and a liquid outlet pipe, and the residual exhaust system comprises a residual liquid valve, a check valve, a water jet and a power water valve; the gas-liquid mixture of chlorine dioxide generated by the generator, chlorine and a reaction liquid enters the separation tank through the mixture inlet and the internal insertion pipe; chlorine dioxide and chlorine are output through the gas outlet; the reaction liquid enters the liquid collection tank; the liquid level gradually rises; the floater floats to drive the sealing cone to leave the opening of the liquid outlet pipe; a solution enters the liquid outlet pipe and is discharged by virtue of negative pressure. According to the automatic gas-liquid separation device, gas-liquid separation can be automatically carried out so as to achieve the gas-liquid separation under high negative pressure environment; meanwhile, the difficulty that chlorine dioxide is limited by acidity when applied to the fields of bleaching and the like is solved.

Owner:SHANDONG SHANDA WIT ENVIRONMENTAL ENGINEERING CO LTD

Improved finishing process for fabric

ActiveCN108729077ARealize rational utilizationAchieve finishingSucessive textile treatmentsBiochemical fibre treatmentEngineeringDrying time

Owner:金伦(苏州)织造有限公司

A production system for polycrystalline solar cells

ActiveCN105932102BContinuous uninterrupted operationIncrease productivityFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringSolar cell

Owner:ZHEJIANG GUANGLONG ENERGY TECH

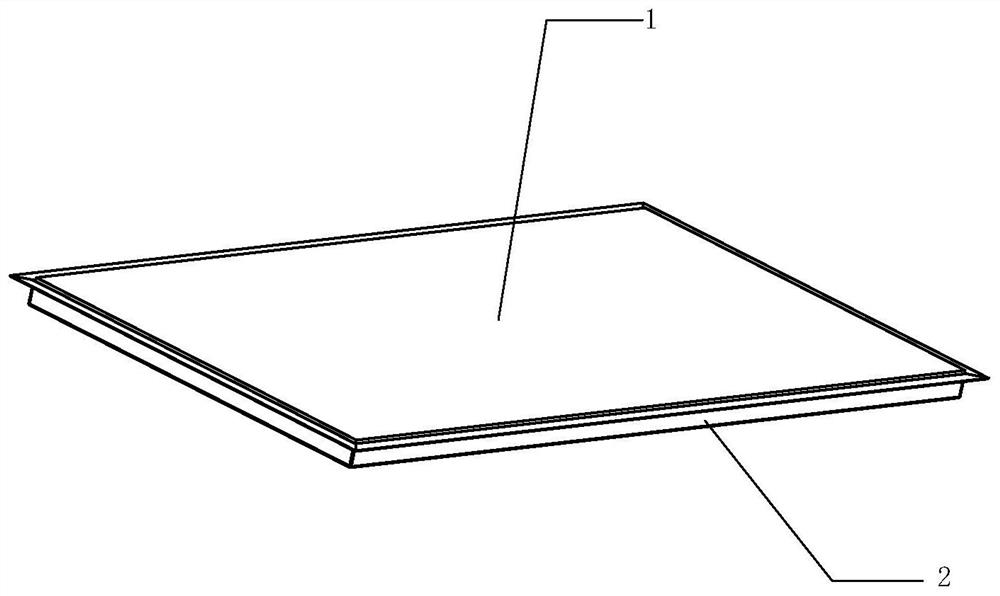

Production method and production device of vacuum insulated panel

PendingCN114148001AImprove efficiencyEasy to cutThermal insulationPipe protection by thermal insulationVacuum pumpingRoll film

The invention provides a production method of a vacuum insulated panel, which comprises the following steps of: 1) manufacturing a lower film of the vacuum insulated panel: pressing a barrier film through a mold so as to form an accommodating cavity which is concave downwards along the thickness direction on the surface of the barrier film; (2) the filling core material is placed in the containing cavity, a rolled film serves as an upper film and is conveyed to an external two-edge sealing device, and two edges of the lower film and the upper film are subjected to hot-pressing sealing; openings for vacuum pumping are formed in the other two edges of the upper film and the other two edges of the lower film. And (3) air is pumped out through the opening under the vacuum condition, the inner vacuum state of the filling core material is kept, and the opening is subjected to hot-pressing sealing. The invention further provides a production device of the vacuum insulated panel, and the production device is used for achieving the production method.

Owner:福建建壹真空科技有限公司

A fixed-length steel strand cutting machine and its processing method

The invention discloses a fixed-length steel strand blanking machine comprising a steel strand tray and a cutting machine used for cutting out steel strands. A first traction device is arranged between the steel strand tray and the cutting machine of which the rear part is also provided with a second traction device, and both sides of the cutting machine are provided with tubes; and the second traction device is located at the construction station side. The two traction devices are used for respectively pulling the steel strands cut and the steel strands on the steel strand tray to move forward, and the continuous operation of the fixed-length steel strand blanking machine is ensured.

Owner:CHINA RAILWAY 16TH BUREAU GRP RAIL TRANSPORT ENG CO LTD

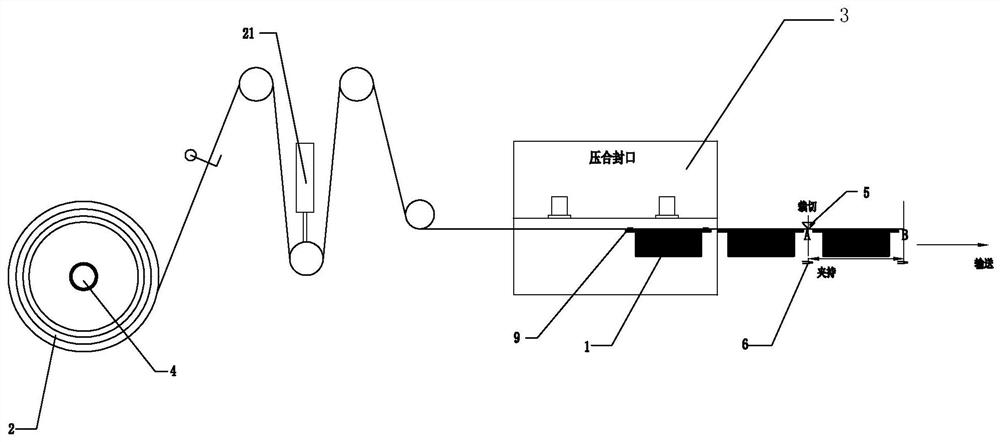

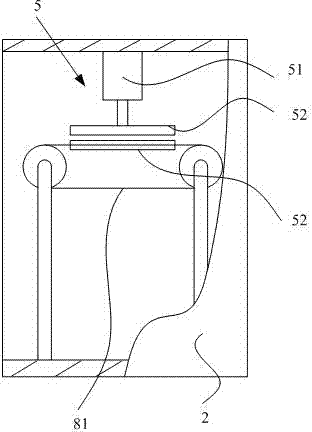

Sub-compartment vacuum insulation board continuous packaging production line and production method

InactiveCN102853212BContinuous uninterrupted operationReduce labor intensityThermal insulationPipe protection by thermal insulationVacuum pumpingProduction line

The invention provides a split chamber type production line for continuously encapsulating vacuum insulation panels and a production method thereof. The split chamber type production line for continuously encapsulating vacuum insulation panels comprises a vacuum line chamber and a sealing machine; the vacuum line camber comprises feeding surge chambers, a sealing chamber and outlet surge chambers; a first sealing door is arranged between two adjacent feeding surge chambers, a second sealing door is arranged between two adjacent outlet surge chambers, each of chamber ports of the feeding surge chambers and the outlet surge chambers positioned at the end part is provided a third sealing door, and chamber ports at two ends of the sealing chamber are connected with the feeding surge chambers and the outlet surge chambers through a forth sealing door; a first conveying line is arranged in each of the feeding surge chambers, the sealing chamber and the outlet surge chambers; and the feeding surge chambers, the sealing chamber and the outlet surge chambers are connected with a vacuum pumping device respectively, and the sealing machine is arranged at one side of the first conveying line positioned in the sealing chamber. The split chamber type production line for continuously encapsulating vacuum insulation panels realizes continuous encapsulation of vacuum insulation panels, and the encapsulation efficiency is improved.

Owner:QINGDAO YICHEN NEW ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com