Sub-compartment vacuum insulation board continuous packaging production line and production method

A technology of vacuum insulation panels and production lines, which is applied in the direction of thermal insulation protection of pipelines, heat exchange equipment, heat preservation, etc., can solve the problems of low packaging efficiency and inability to achieve continuous packaging, and achieves improved packaging efficiency and continuous packaging vacuum insulation. board, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

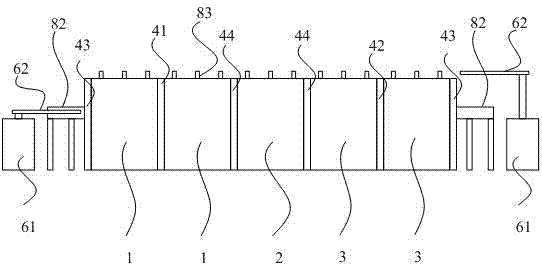

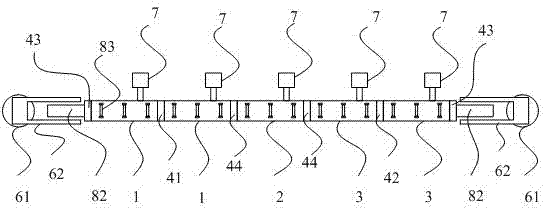

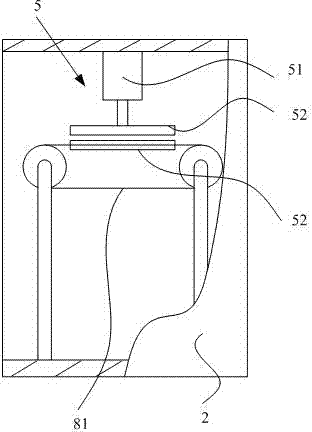

[0019] Such as Figure 1-Figure 3 As shown, the sub-chamber continuous packaging production line for vacuum insulation panels in this embodiment includes: a vacuum line warehouse and a sealing machine 5; Two outgoing line buffer warehouses 3 connected together; a first openable and closable airtight door 41 is arranged between two adjacent incoming line buffer warehouses 1, and an openable and closable first airtight door 41 is arranged between two adjacent outgoing line buffer warehouses 3 Two sealed doors 42, the warehouse mouth of the incoming line buffer warehouse 1 and the warehouse outlet of the outlet buffer warehouse 3 at the end are respectively provided with a third airtight door 43 that can be opened and closed, and the warehouse mouths at the two ends of the sealed warehouse 2 can be opened and closed respectively. The fourth airtight door 44 is connected with the adjacent incoming line buffer warehouse 1 and the outgoing line buffer warehouse 3; the incoming line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com