Patents

Literature

315results about How to "Achieve finishing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

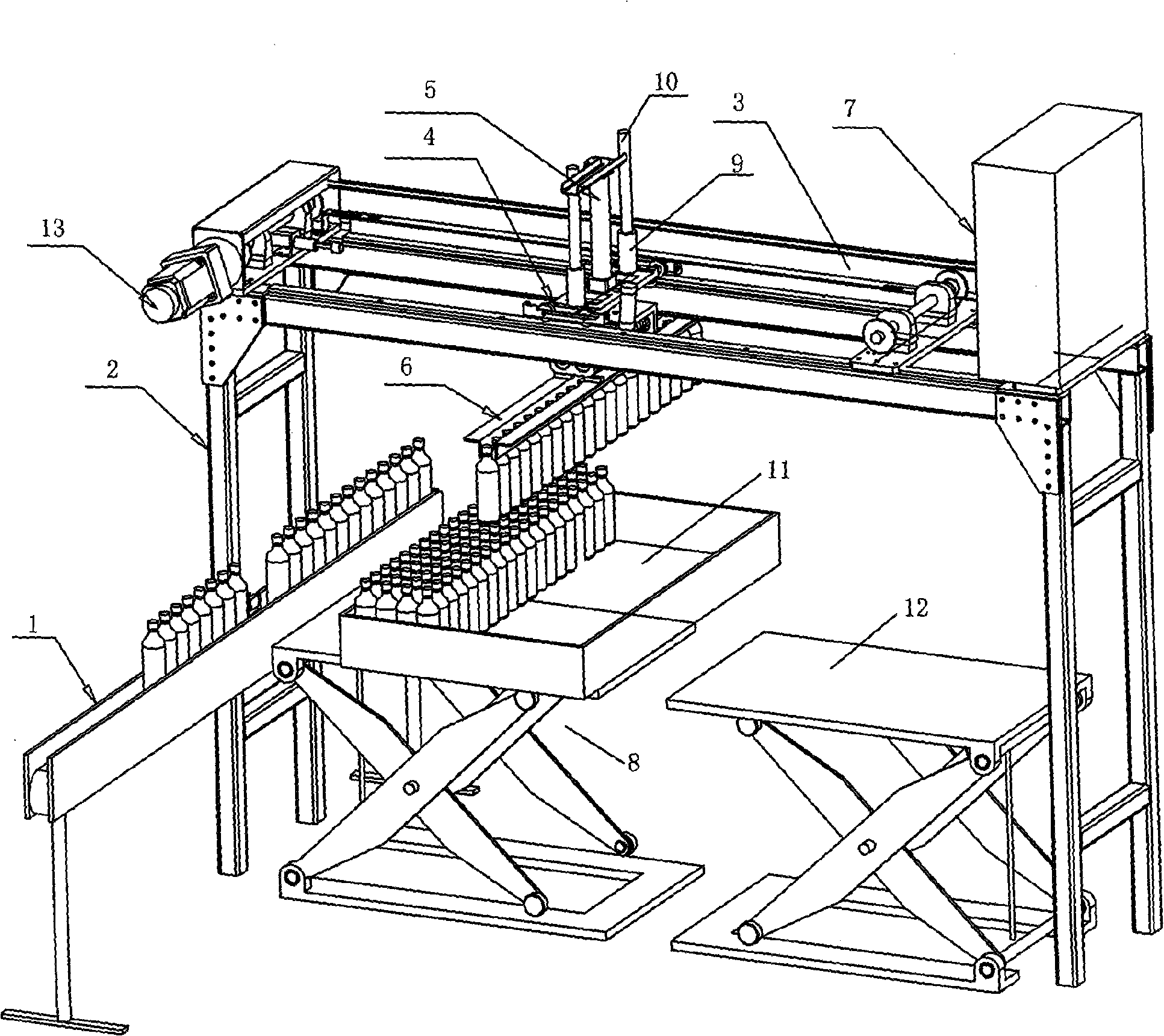

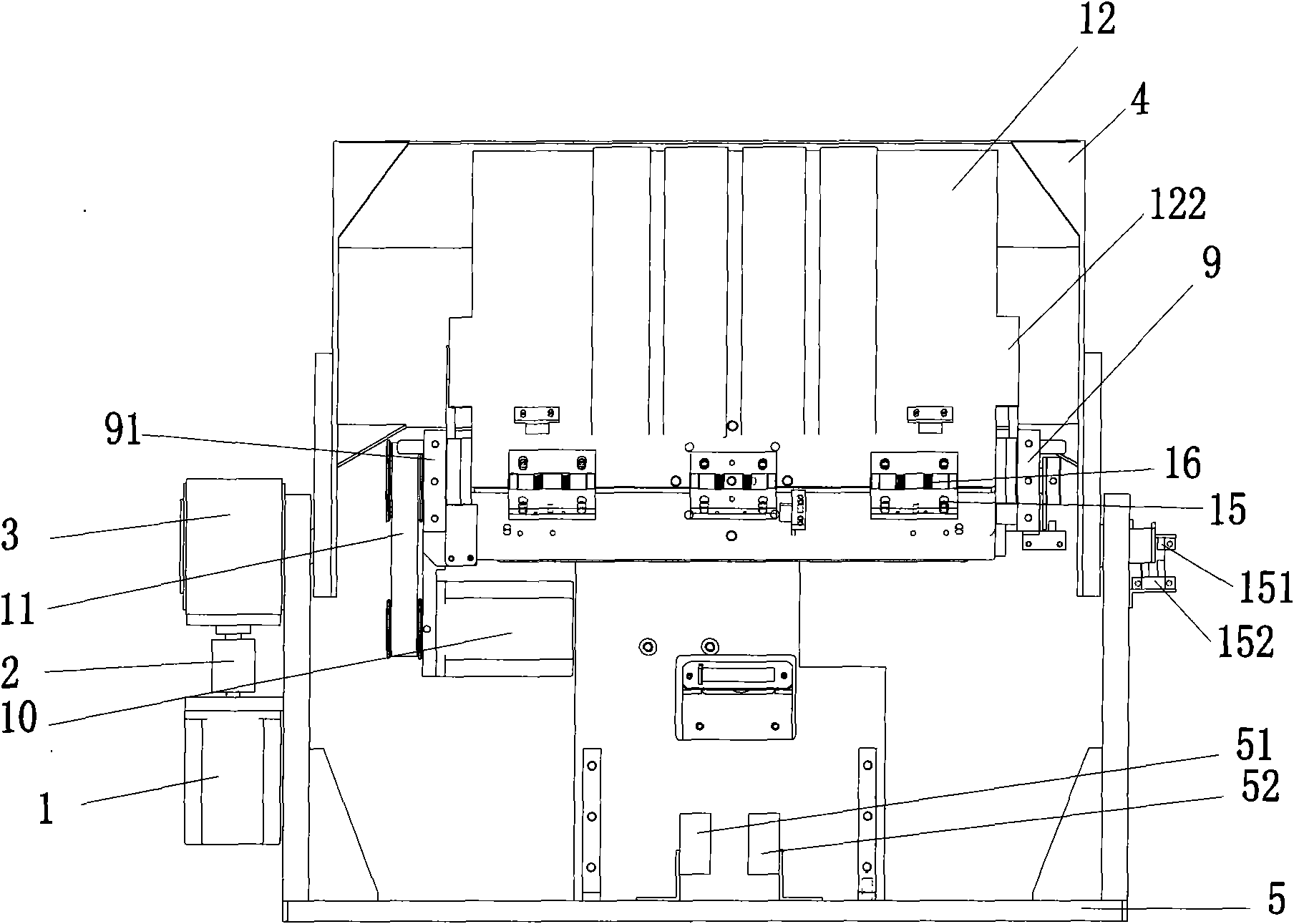

Automatic collecting and arranging machine for plastic soft bottle

ActiveCN101327851AImprove processing progressRealize the collectionProgramme-controlled manipulatorGripping headsAutomatic controlEngineering

The invention discloses an automatic machine for collecting and sorting plastic soft bottles. The device comprises a conveyor for plastic bottles, soft bottles or soft bags, as well as a machine frame, wherein a traction device moving horizontally is arranged above the machine frame; a bottle clamping device connected via a lifting cylinder is arranged on a moving trolley of the traction device; the traction device, the lifting cylinder and the bottle clamping device are connected with an electric control device with electrical automatic control; a product collecting device is arranged below the machine frame beside the conveyor; and the electric control device controls the bottle clamping device to make vertical up-down lifting movement under the drive of the lifting cylinder and to make horizontal translating movement under the drive of the traction device, and controls the bottle clamping device to clamp a product input by the conveyor, to transfer the product to the product collecting device through the lifting cylinder and the traction device and then to unclamp the product. The machine can clamp, lift and translate plastic bottles, soft bottles or soft bags input by the conveyor to a preset distance, drop and put the bottles or bags into the product collecting device.

Owner:SICHUAN KELUN PHARMA CO LTD

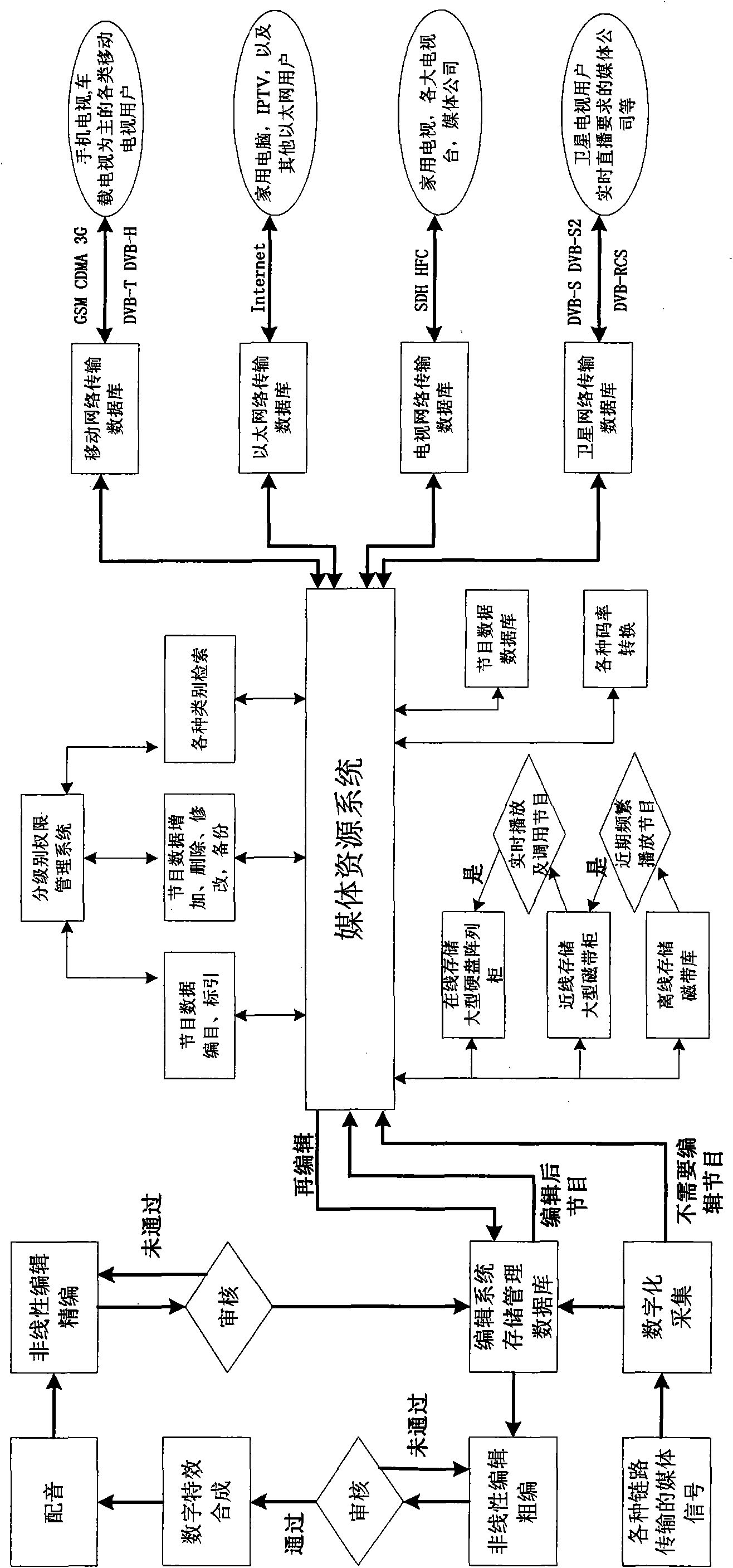

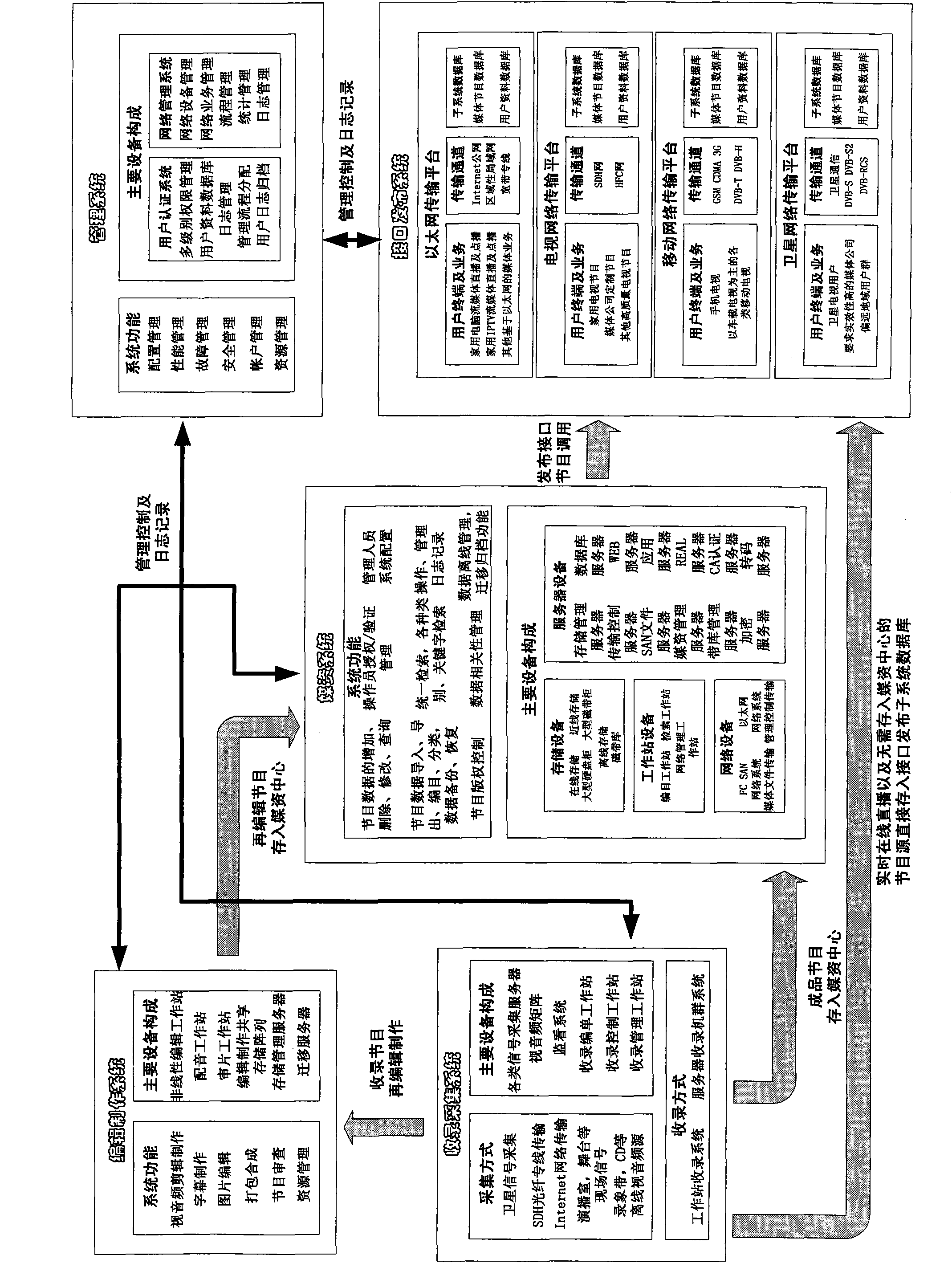

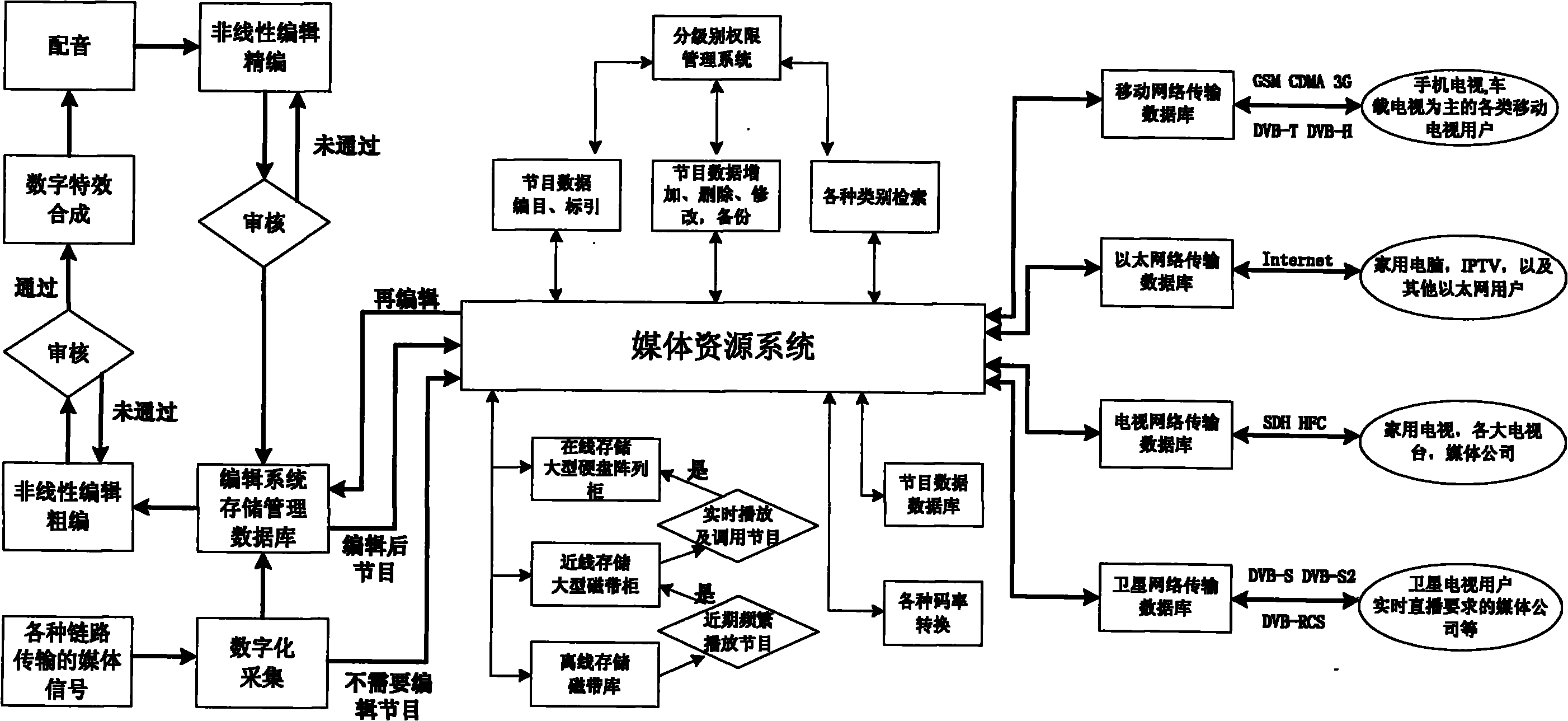

Digital multimedia information transmission platform

InactiveCN101783873ASupport automatic technical review functionImprove review efficiencyTelevision system detailsColor television detailsSystems managementCataloging

The invention discloses a digital multimedia information transmission platform, which comprises an acquisition system, a manufacturing system, a media resource system, a management system and a release system, wherein the acquisition system consists of control equipment, outside network material receiving server and an foreign signal, studio signal and magnet tape material acquisition and collection subsystem; the manufacturing system consists of a program editing system, a program examination system, a background packing and synthesizing system and a resource manager; the media resource system consists of a media resource cataloging and searching work station, a transcoding server, a database server, a storage management and migration server and a system management working station; the management system consists of a uniform user identification system and a network management system; the release system serving as an external interface module of a multimedia center encrypts finished products in multiple formats and executes related release according to outside service demands; and the platform is an integrated production line of digital media contents and also a digital media resource comprehensive service system platform and can realize overall media resource sharing.

Owner:BEIJING INFV MEDIA TECH

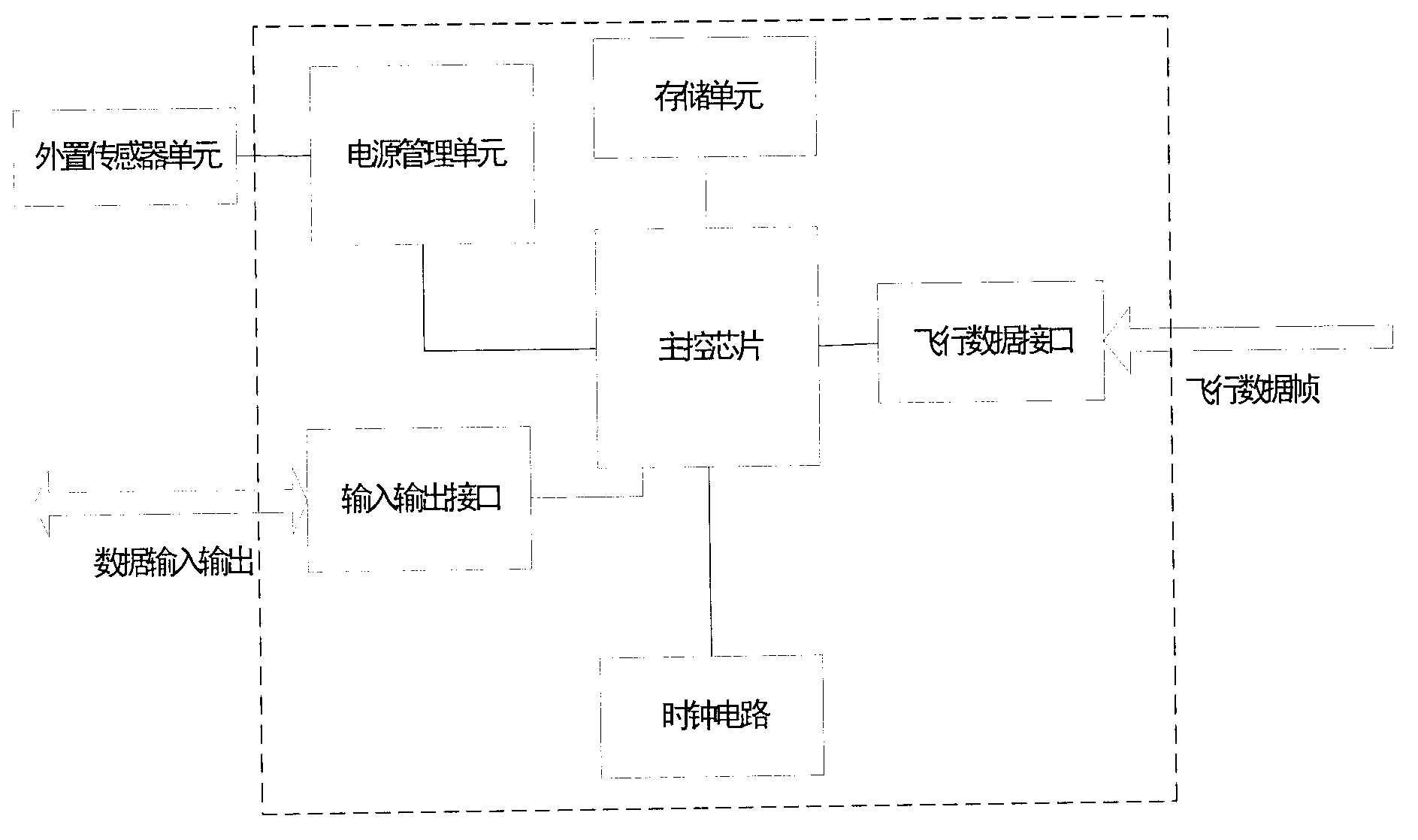

Electronic resume recording device of unmanned aerial vehicle

ActiveCN102915576ARealize simultaneous recordingAchieve finishingRegistering/indicating working of machinesUncrewed vehicleWork status

The invention discloses an electronic resume recording device of an unmanned aerial vehicle, which comprises a main control chip, a flight data receiving interface, a clock circuit, a storage unit and a power management chip, wherein the main control chip reads flight data frames through the flight data receiving interface, and extracts a status bit and UTC (universal time coordinated) time in the flight data frames; the flight data frames are added with time stamps output by the clock circuit and output to the flight data region in the storage unit; the status bit is output to the resume use region of the storage unit; the UTC time is output to the clock circuit to carry out time correction on the clock circuit; the status bit is used for identifying the flight operation condition of the unmanned aerial vehicle; and the main control chip periodically queries the power supplying state of the power management chip and outputs the power supplying state to the resume use region of the storage unit. The electronic records such as device working conditions, storage environment, mounted equipment configuration information, flight and task data of the unmanned aerial vehicle are recorded.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

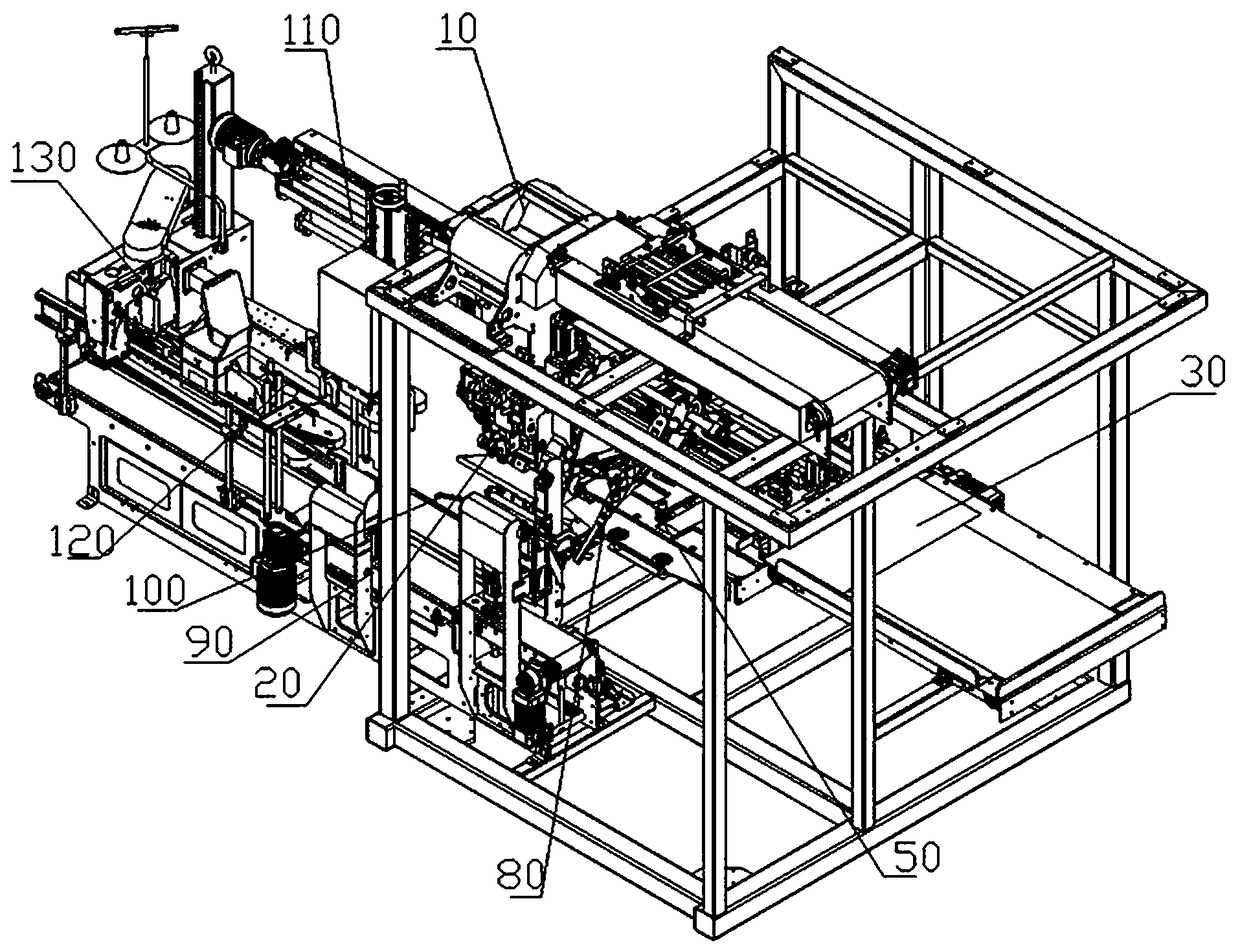

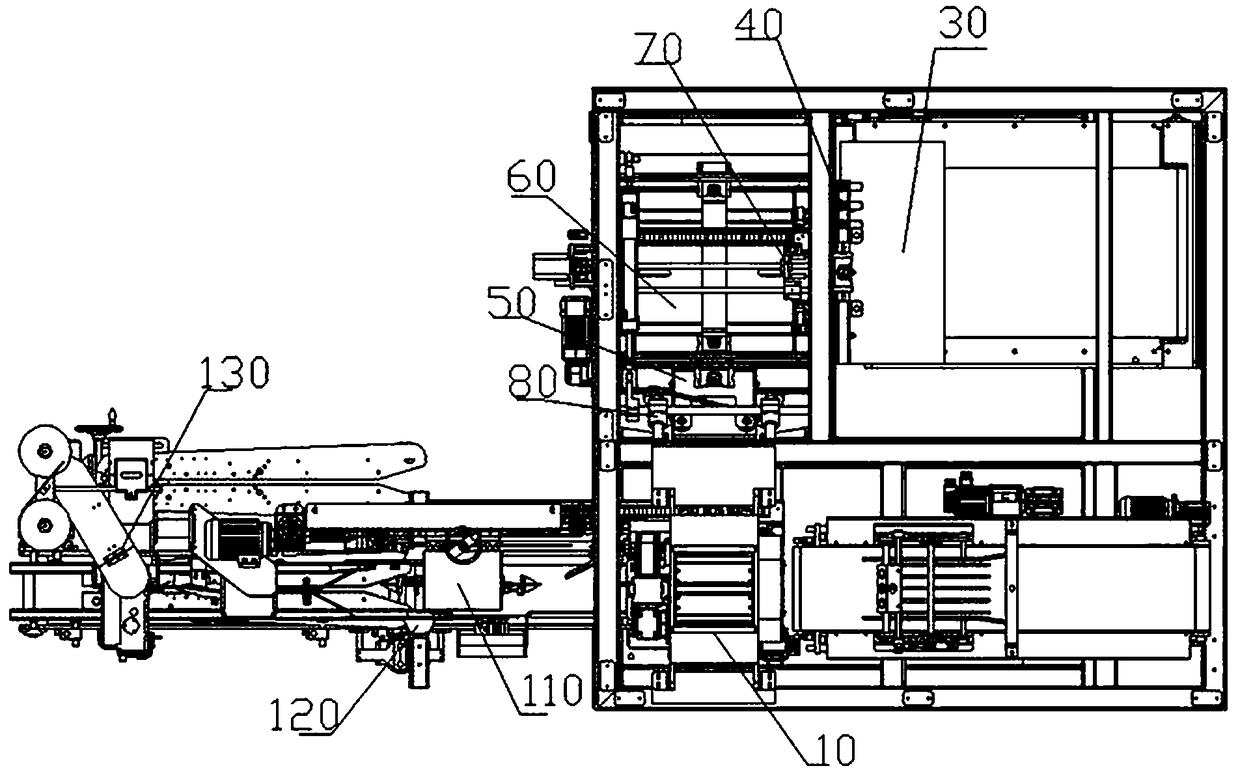

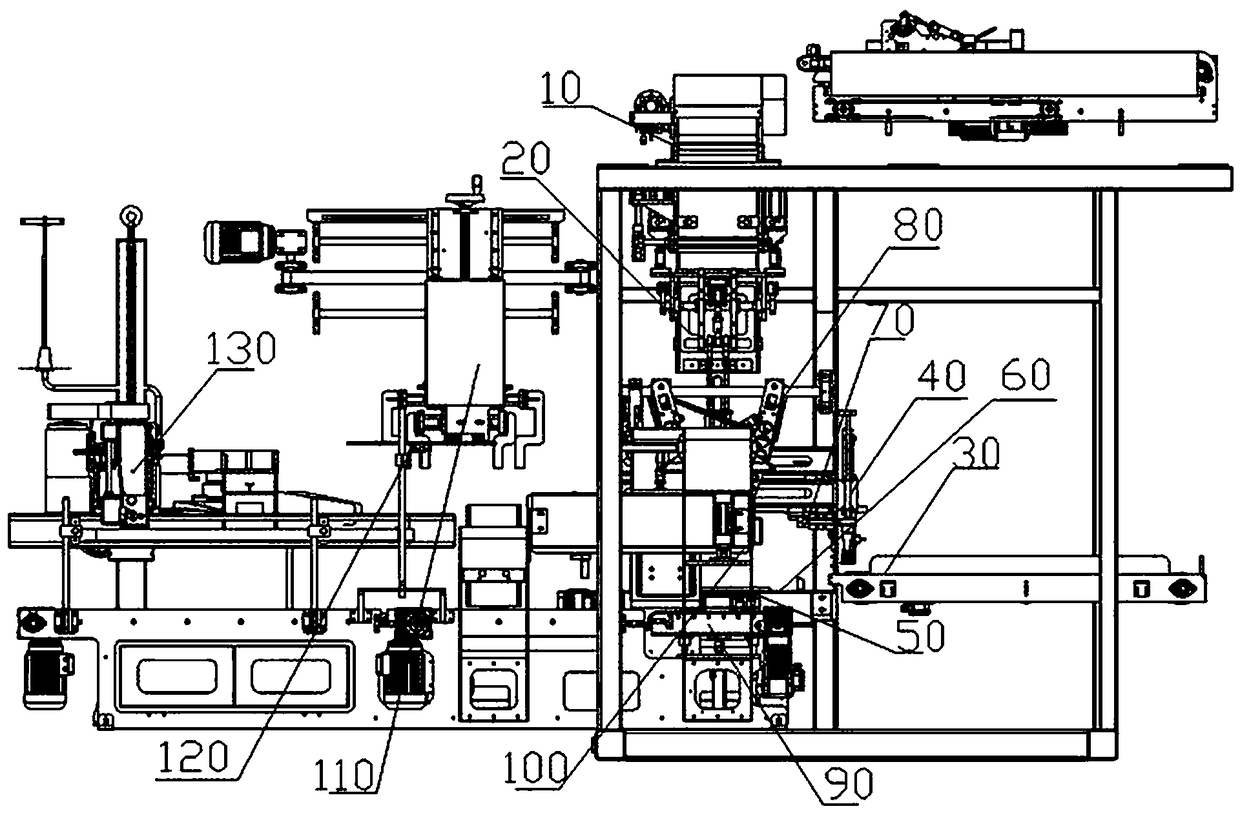

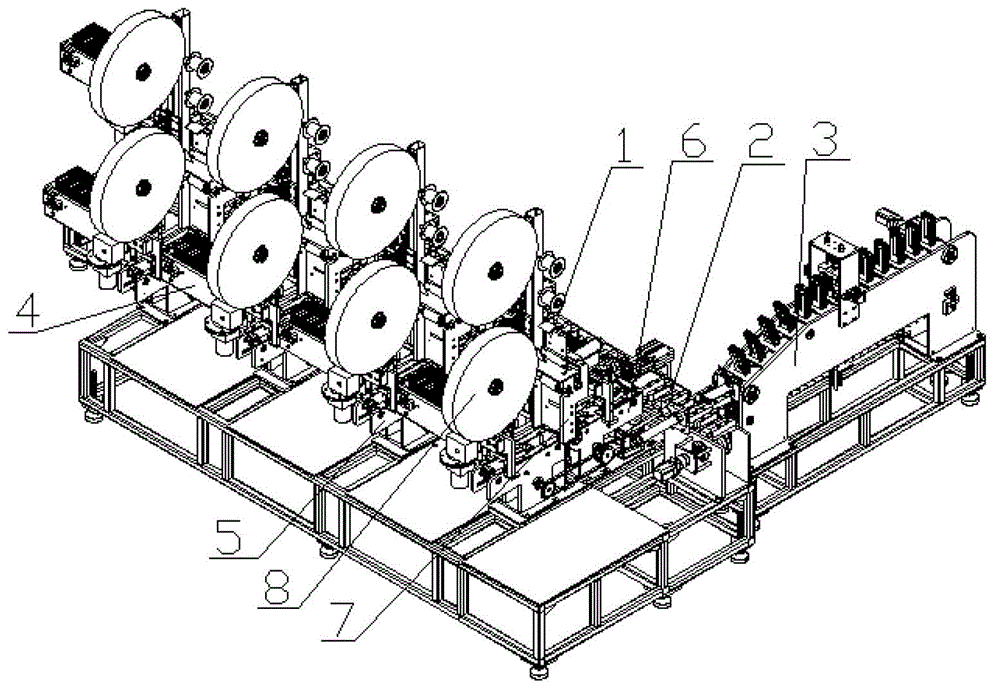

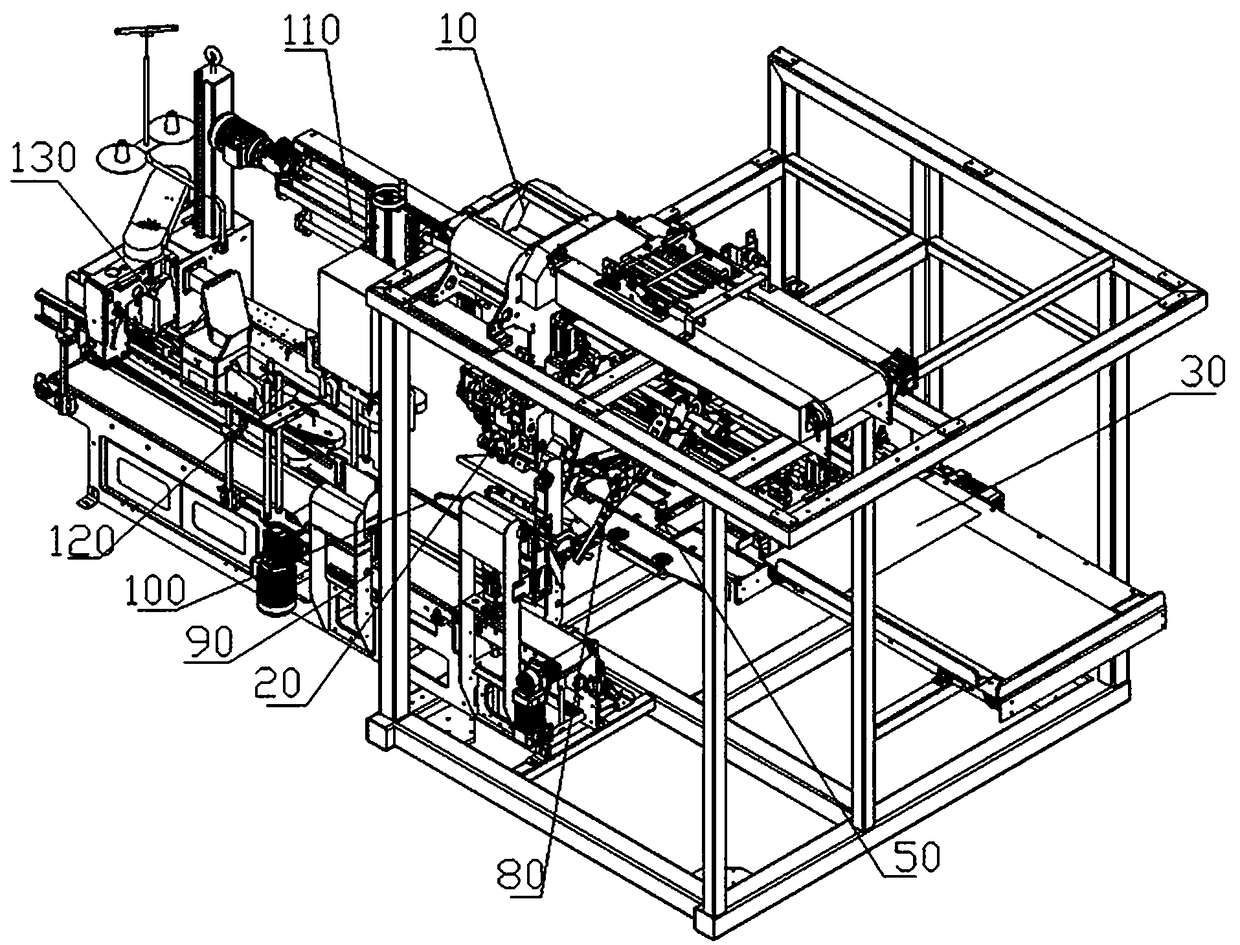

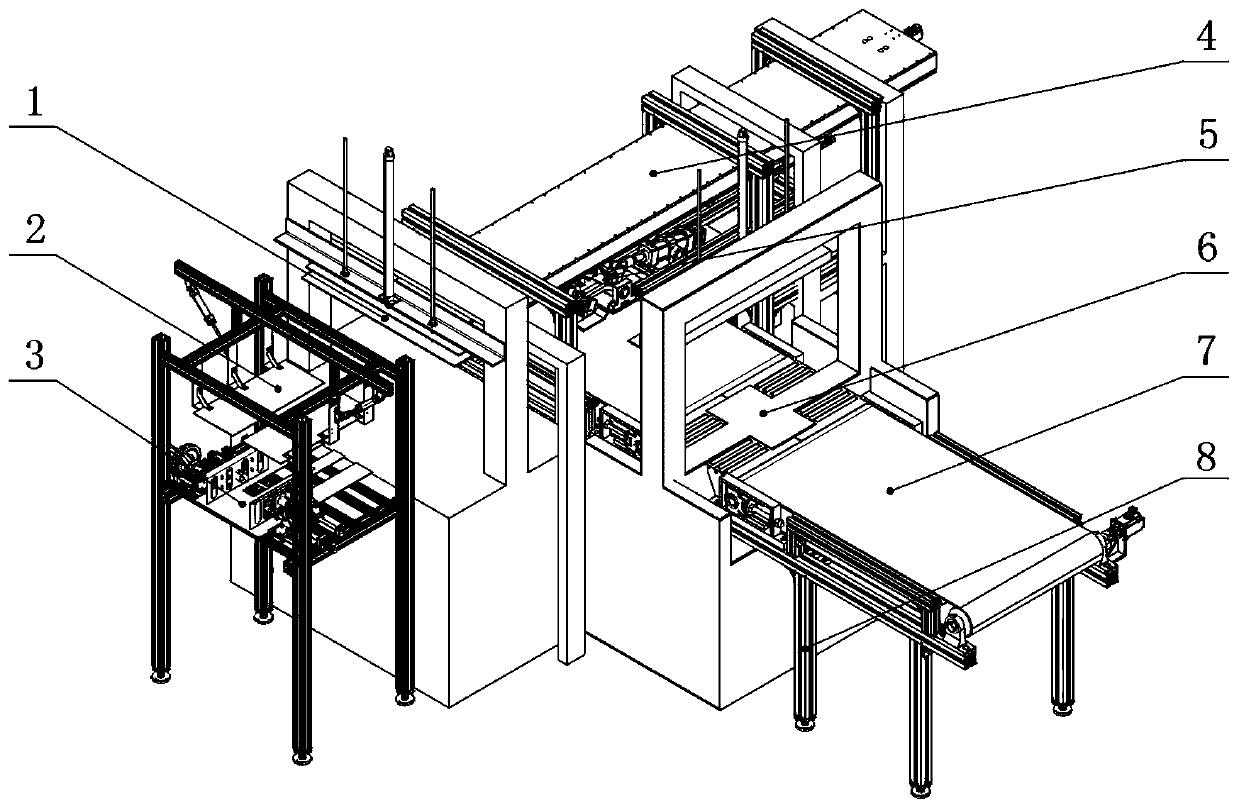

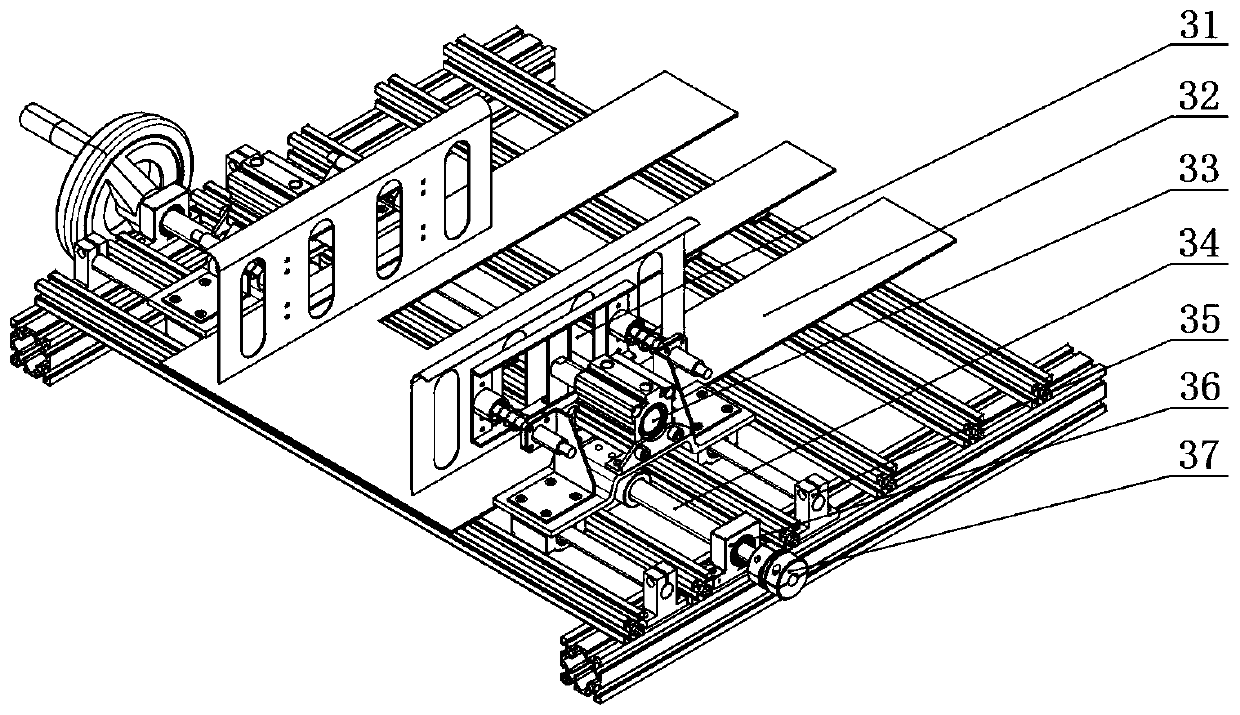

Automatic bagging machine

PendingCN108820273APrevent the bag from fallingEasy to stackWrapper twisting/gatheringSolid materialEngineeringMechanical engineering

The invention discloses an automatic bagging machine, and relates to the technical field of packaging machinery. The automatic bagging machine comprises a bag receiving bin mechanism, a bag clamping mechanism, a bag storage, a bag taking mechanism, a bag opening mechanism, a bagging mechanism, a bag shaking mechanism, a bag holding mechanism, a bag opening arranging mechanism, a bag opening guidemechanism and a bag sewing mechanism, wherein the bag shaking mechanism comprise a bag shaking platform which moves up and down in a reciprocating manner and flaps the bottoms of packaging bags sleeving on the bag clamping mechanism, the bag holding mechanism is arranged on one side of the bag shaking mechanism, the bag opening arranging mechanism is used for sorting the bag opening of each packaging bag, and the bag opening of each packaging bag enters the bag sewing mechanism under the guide of the bag opening guide mechanism to be sealed. According to the automatic bagging machine, in the bagging process, bag pouring of the packaging bags can be effectively prevented, the bag opening of each packaging bag is folded into an M shape through the bag opening arranging mechanism when the packaging bag is sealed, so that the opening of the sealing bag forms an end surface, and therefore material loosening of salt bags in the packaging bags cannot be caused in the transportation process.

Owner:SHANGHAI SOONTRUE MACHINERY EQUIP

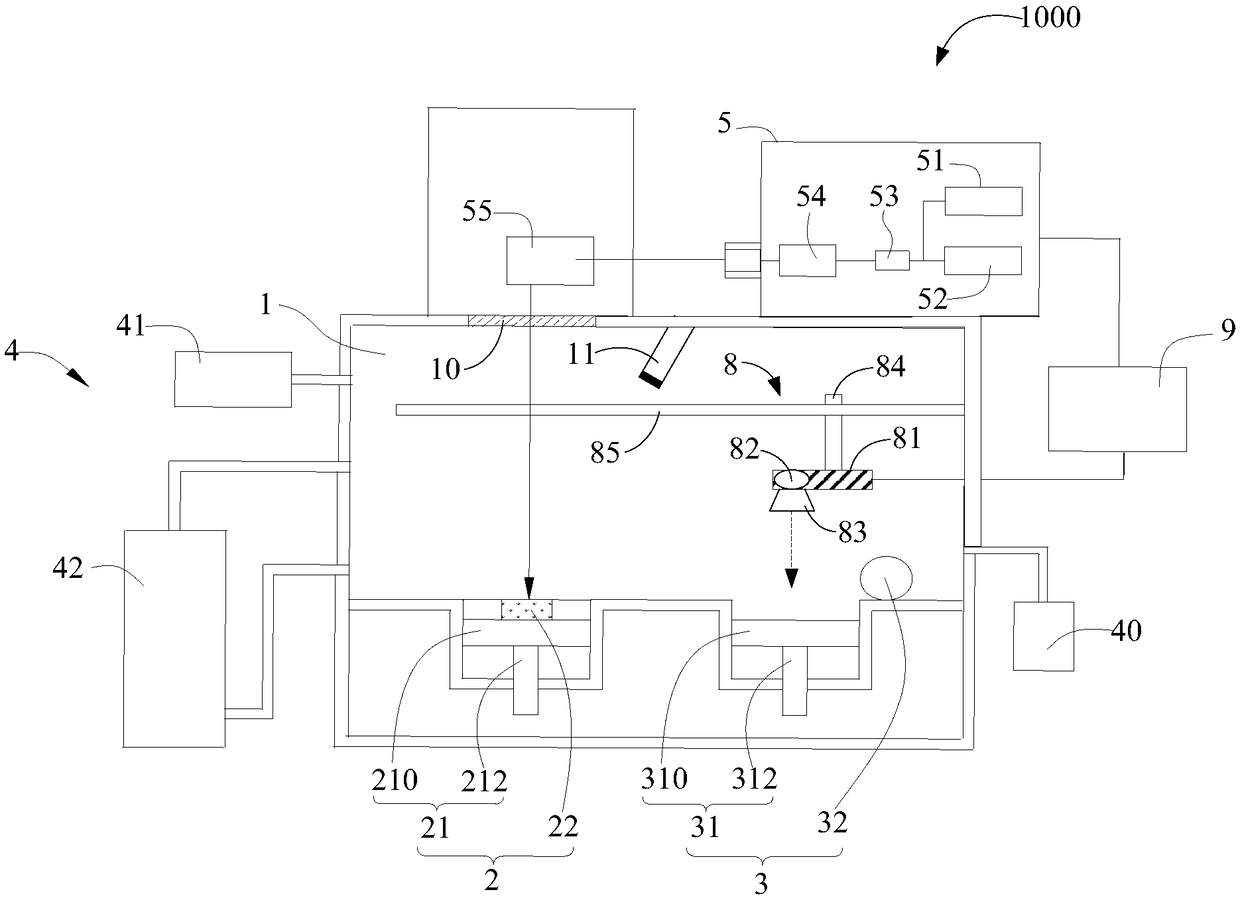

3D printing device and printing method for hard alloy part

PendingCN108176856AImprove printing accuracyComplex structureAdditive manufacturing apparatusIncreasing energy efficiencyAlloyOptoelectronics

The invention discloses a 3D printing device and printing method for a hard alloy part. The printing device comprises a forming workbench, a powder spreading device, a first laser module, a second laser module and a laser control module, wherein the laser control module is used for controlling a first laser to carry out scanning and forming and outputting pulse laser to carry out precision processing on a printing layer, and used for controlling a second laser to carry out microstructure reduction processing on the printing layer after the printing layer is subjected to precision processing. According to the 3D printing device and printing method for the hard alloy part, the high-stability first laser module is adopted to correspondingly send out continuous laser and the pulse laser, scanning and forming are carried out by the first laser module, furthermore, the pulse laser is used for carrying out precision processing on the printing layer, and the second laser module is used for carrying out microstructure reduction processing, and therefore, two kinds of layered structures with different materials can be printed, the requirement for the complex structure of the composite structure hard alloy part is met, secondary grinding treatment is not need to be carried out on the 3D printing hard alloy part, printing precision is high, size, shape and appearance can be completely controlled.

Owner:GUANGDONG HANBANG 3D TECH CO LTD

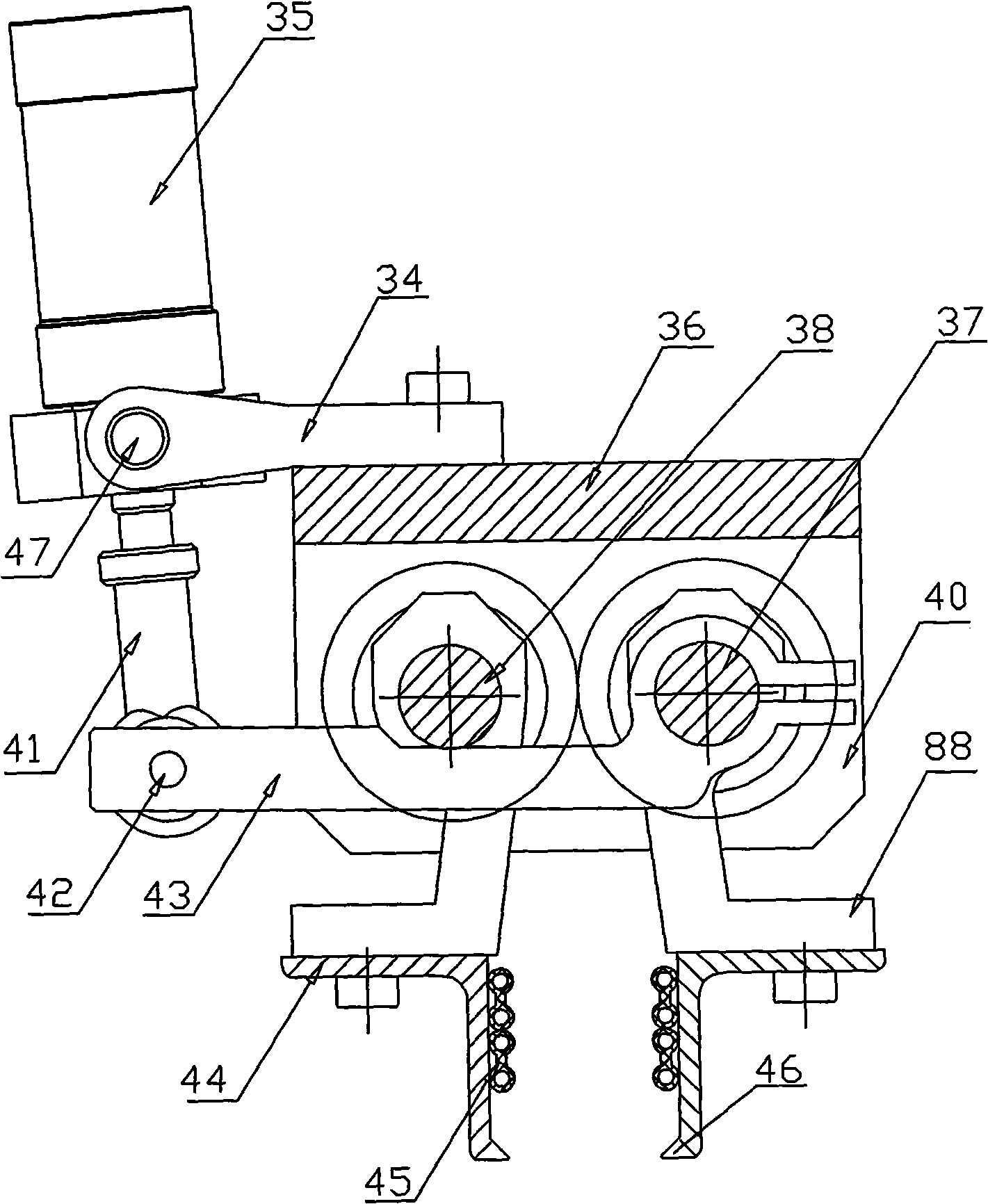

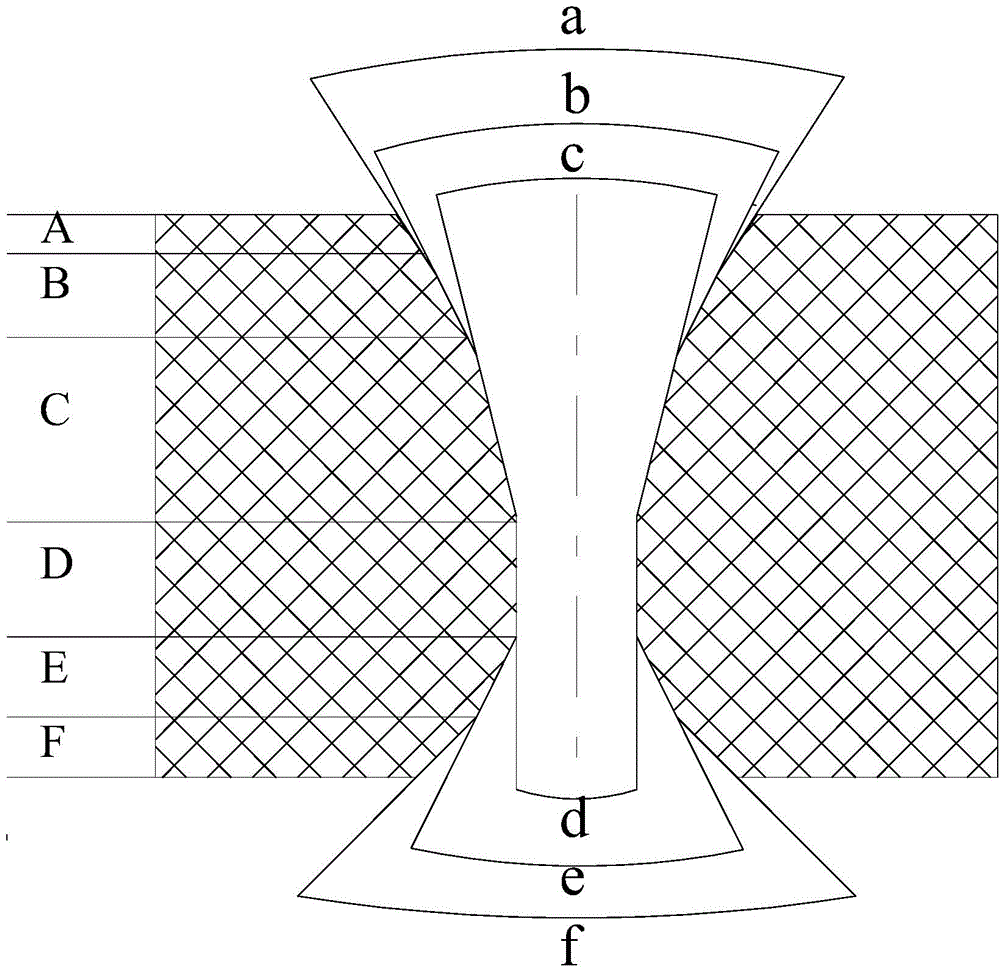

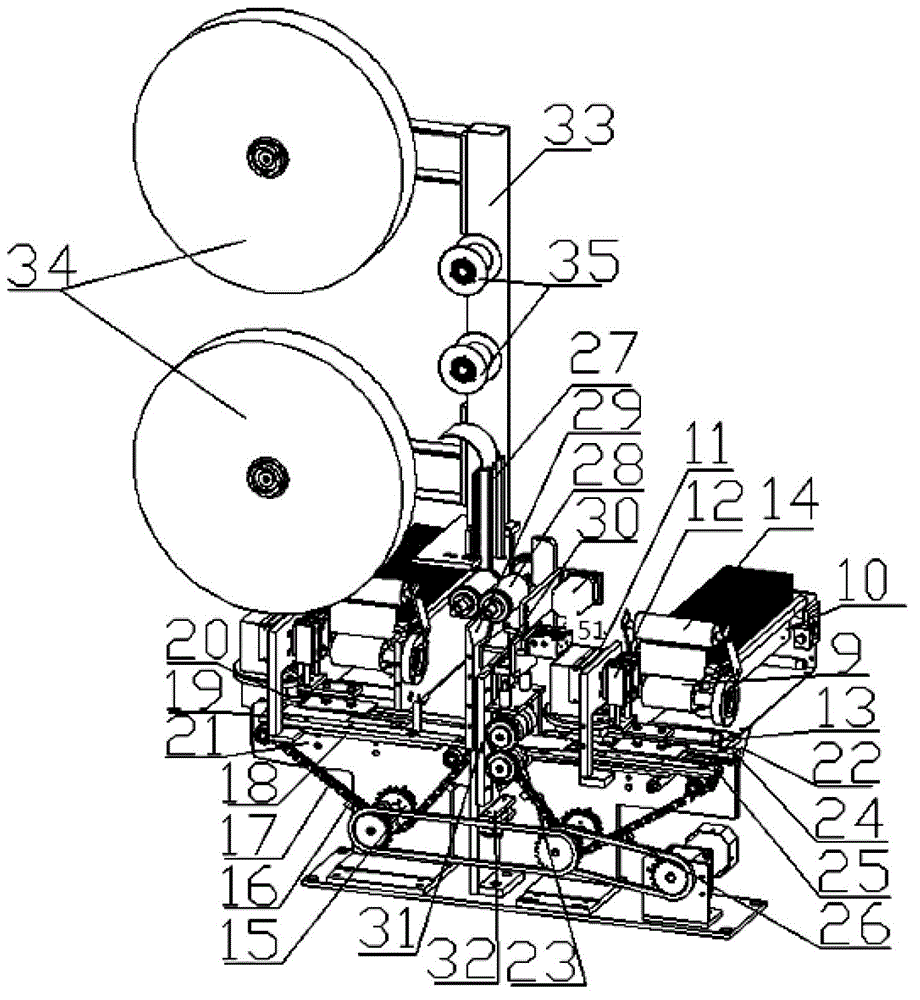

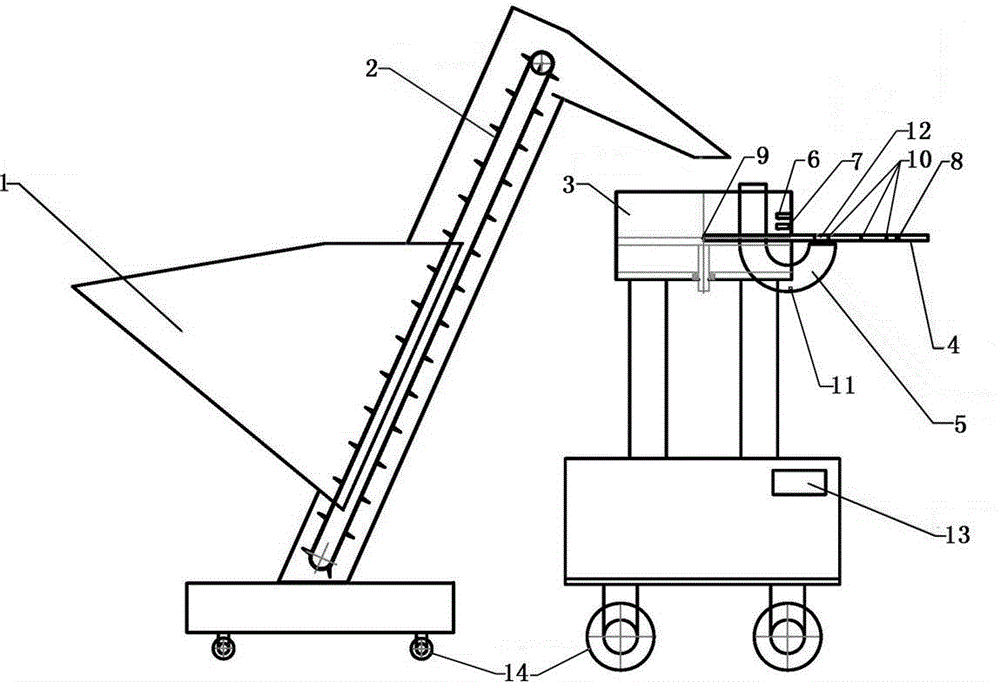

Finish machining device for wire-drawing die

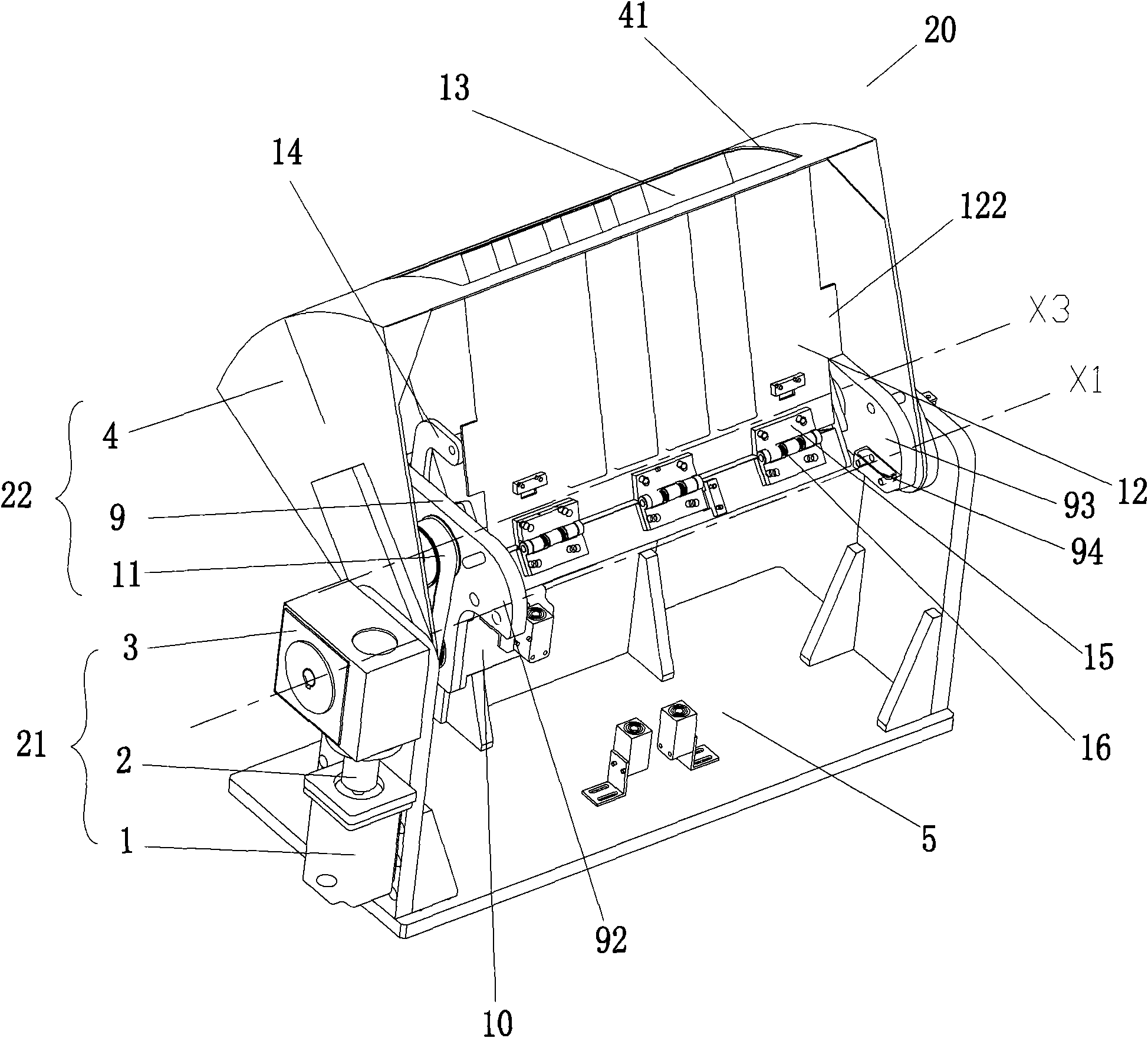

InactiveCN104551890AEasy to polishMeet finishing requirementsRevolution surface grinding machinesGrinding drivesYarnEngineering

The invention provides a finish machining device for a wire-drawing die. The finish machining device for the wire-drawing die comprises a first sliding rod, a second sliding rod, a sliding support, a bearing tray, a first screw, a second screw, a fixture, a first wire winder, a first wire leading tray, a second wire leading tray, a second wire winder, a bracket, a silk yarn, a first driving mechanism and a second driving mechanism, wherein the first driving mechanism controls the sliding support to vertically slide along the first sliding rod and the second sliding rod; the wire-drawing die vertically slides along with the sliding support; the second driving mechanism drives the fixture to rotate and drives the wire-drawing die to rotate, i.e., the second driving mechanism drives the wire-drawing die to be processed to vertically slide and rotate, so that the silk yarn fully polishes a functional surface of the contacted wire-drawing die to realize the finish machining of a wire-drawing hole in the wire-drawing die. The wire-drawing die disclosed by the invention has the advantages of simple structure, high processing efficiency and good finish processing effect, and requirements on the finish machining of the multifunctional surface of the wire-drawing hole in the wire-drawing die is realized.

Owner:天长市天屹模具科技发展有限公司

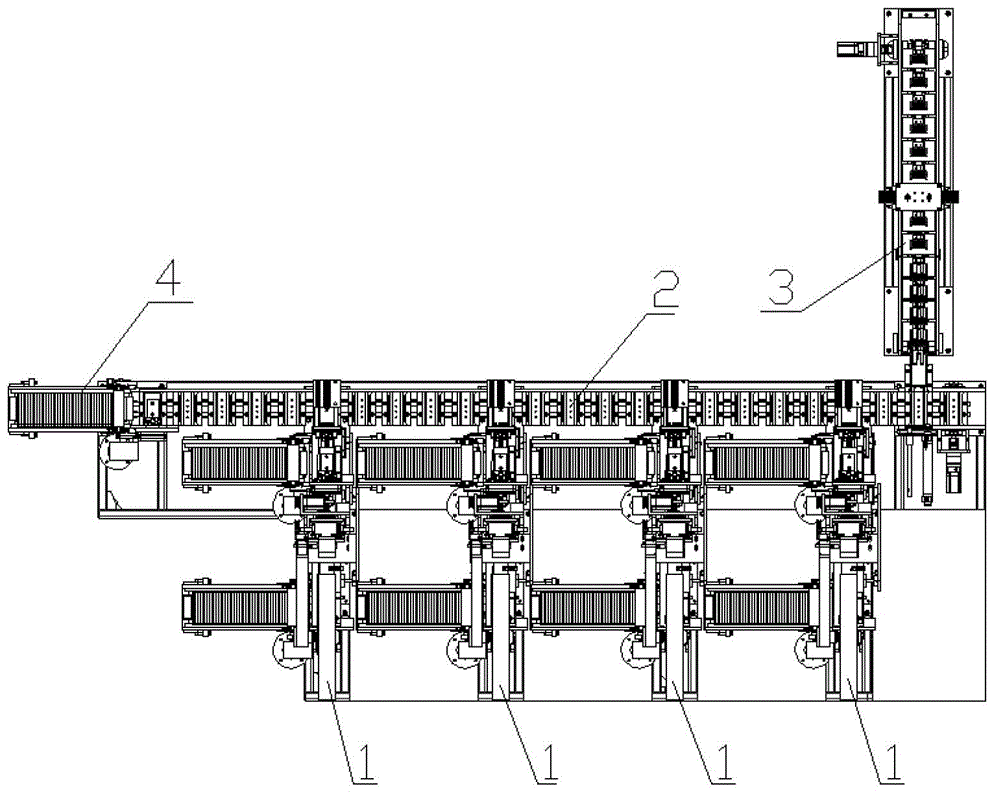

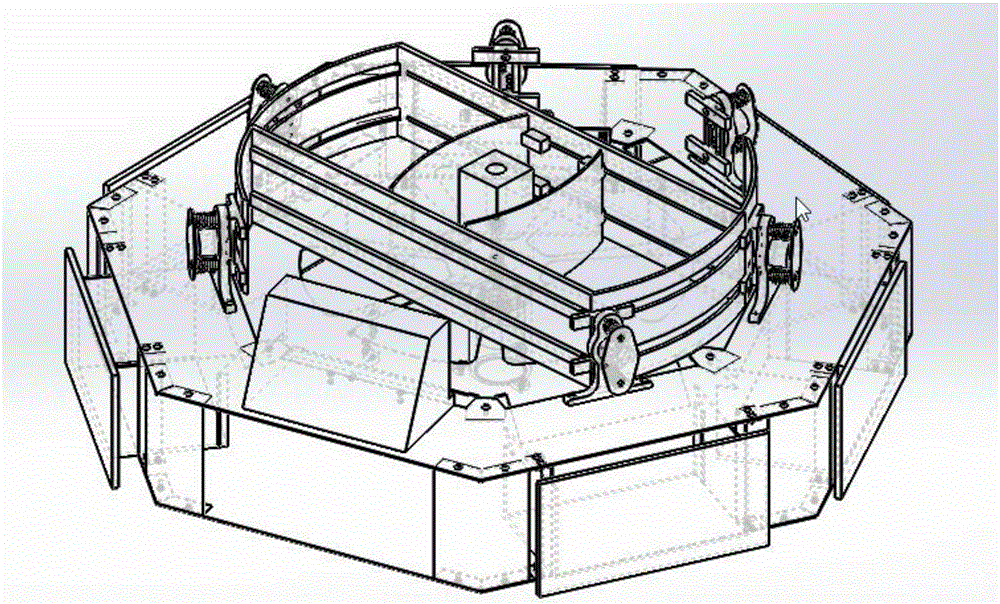

Parallel connection plate wrapping mechanism of storage battery pole plate

InactiveCN102945984ARealize automatic feedingRealize automatic assemblyFinal product manufactureLead-acid accumulators constructionEngineeringMechanical engineering

The invention provides a parallel connection plate wrapping mechanism of a storage battery pole plate. The parallel connection plate wrapping mechanism comprises a pole plate feed mechanism for providing a first pole plate, an independent conveying mechanism, a lamination mechanism and an erecting mechanism, the first pole plate and a second pole plate which are subjected to plate wrapping are stacked at intervals to form a plate wrapping group by the independent conveying mechanism, the clustering is achieved by the lamination mechanism, and the erecting mechanism erects and arranges a cluster. The parallel connection plate wrapping mechanism of the storage battery pole plate has the advantages that the structure is compact and reasonable, the operation is convenient, pole plate automatic feeding, automatic plate wrapping, pole plate automatic assembly after plate wrapping and cluster erecting and arranging are achieved, the production efficiency is greatly improved, the labor intensity of workers is reduced, and harm of lead dust is reduced.

Owner:SHANGHAI RUNTECH ELECTRONICS TECH

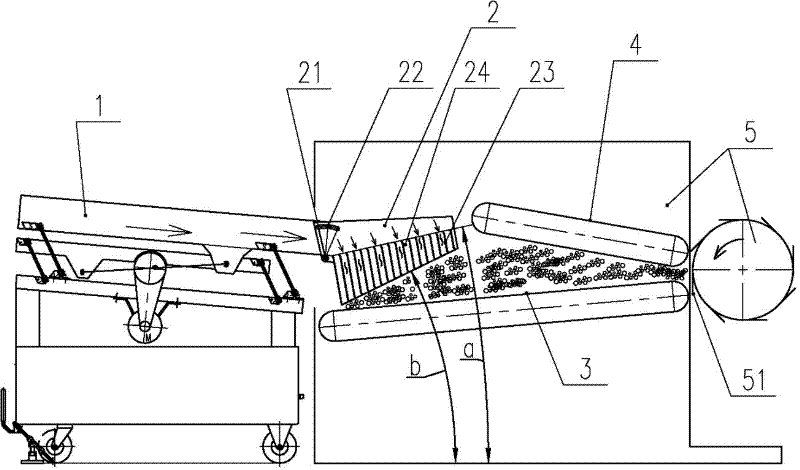

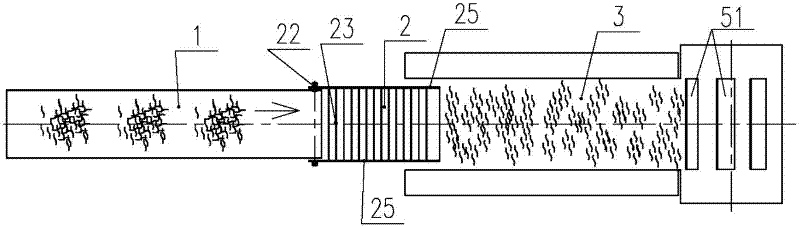

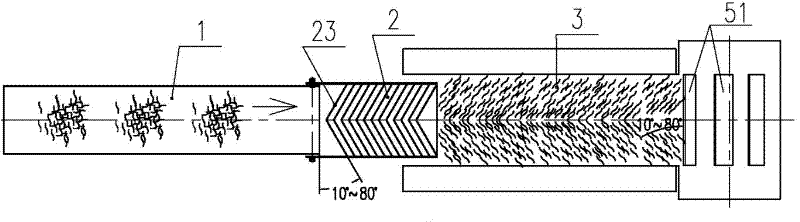

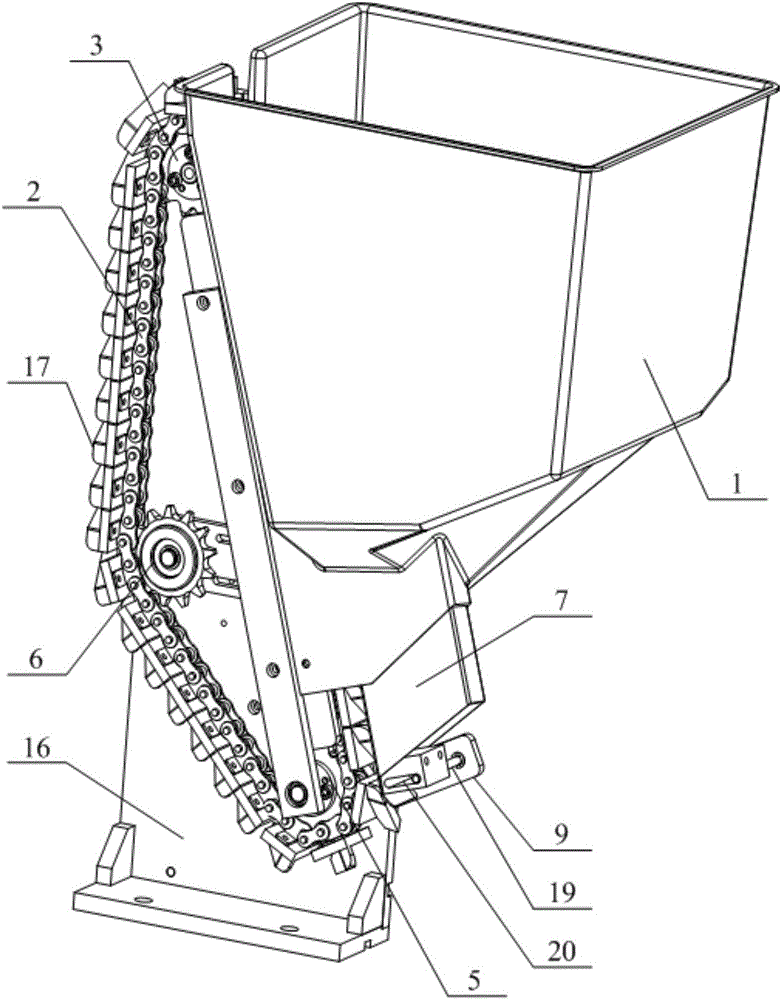

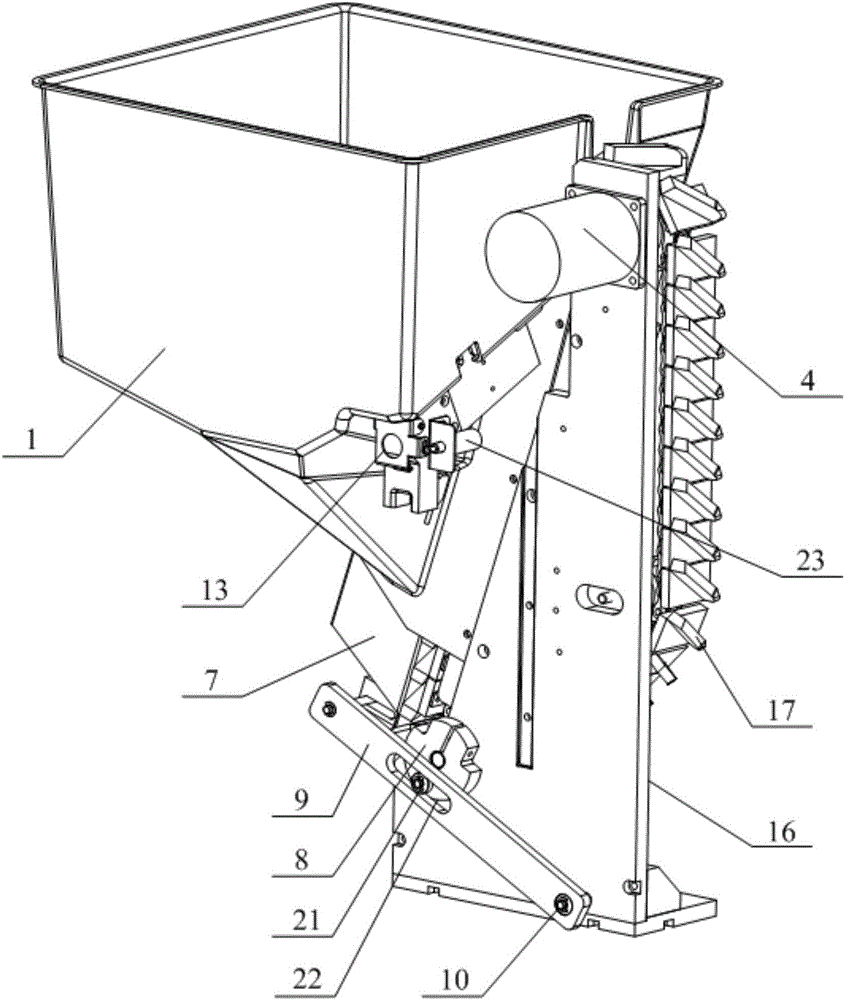

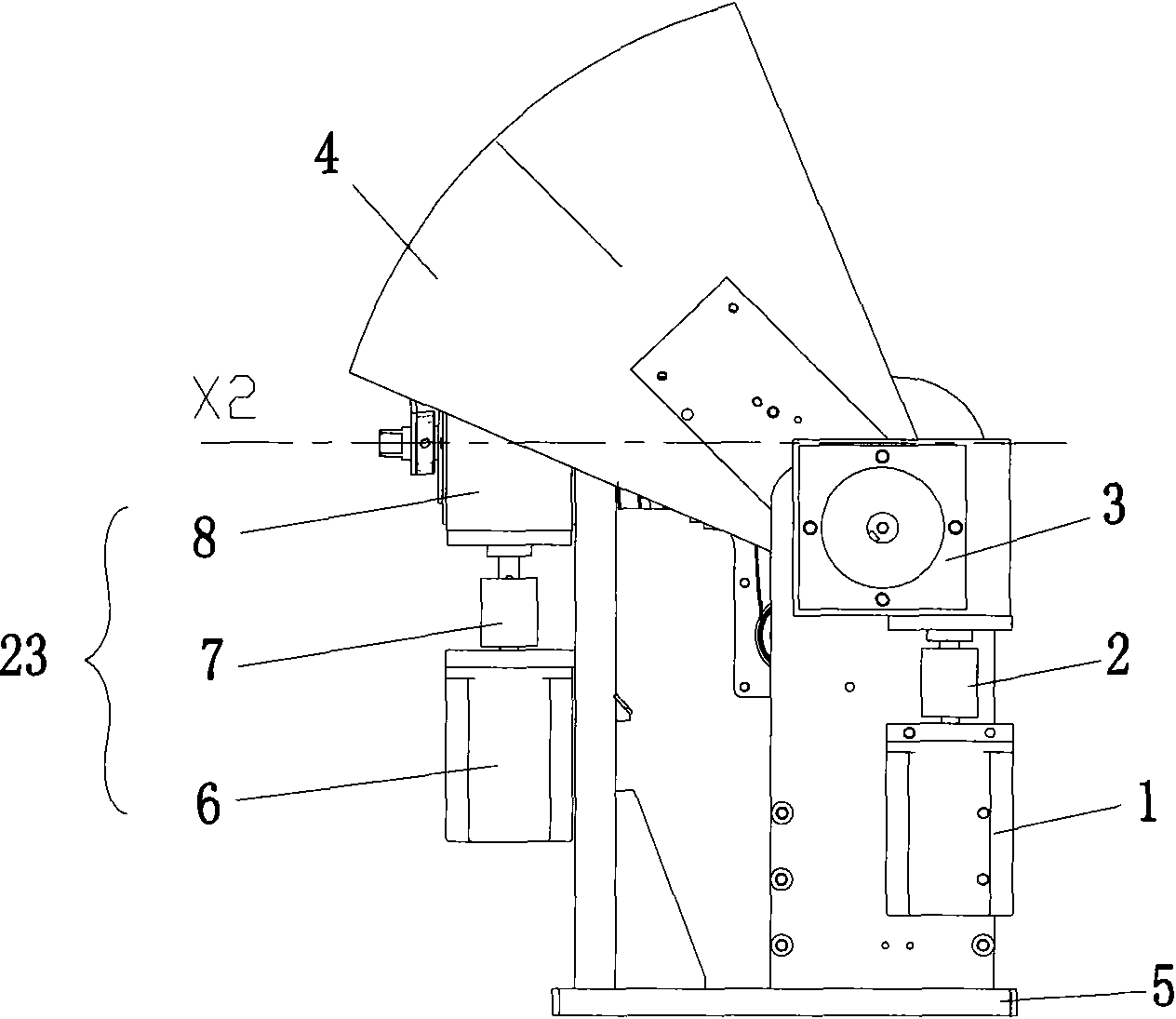

Vibration tobacco stem sorting machine

InactiveCN102406229AAchieve finishingEasy dischargeTobacco treatmentConveyor partsEngineeringMechanical engineering

A vibration tobacco stem sorting machine comprises a vibration conveying groove body (1) and a vibration grid type leakage groove (2) which are connected in turn. The vibration grid type leakage groove (2) is located between the feeding ends of an upper chain (4) and a lower chain (3) used for conveying the tobacco stems to a stem cutting machine (5). The vibration grid type leakage groove (2) is formed by horizontally connecting separation plates (23) which are continuously arranged in equal spaces or along the flow direction of the material in a widening meaner to lateral plates (25) at the two sides. The separation plates (23) and the lateral plates (25) are separated from each to form a continuous grid leaking groove (24). The invention can sort the tobacco stems as that the stem cutting angle is any one pre-set angle smaller than 90 degrees. The tobacco stems can enter a steam cutting machine according to the sorted postures. The structure is simple and reliable, and the sorting effect is good.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

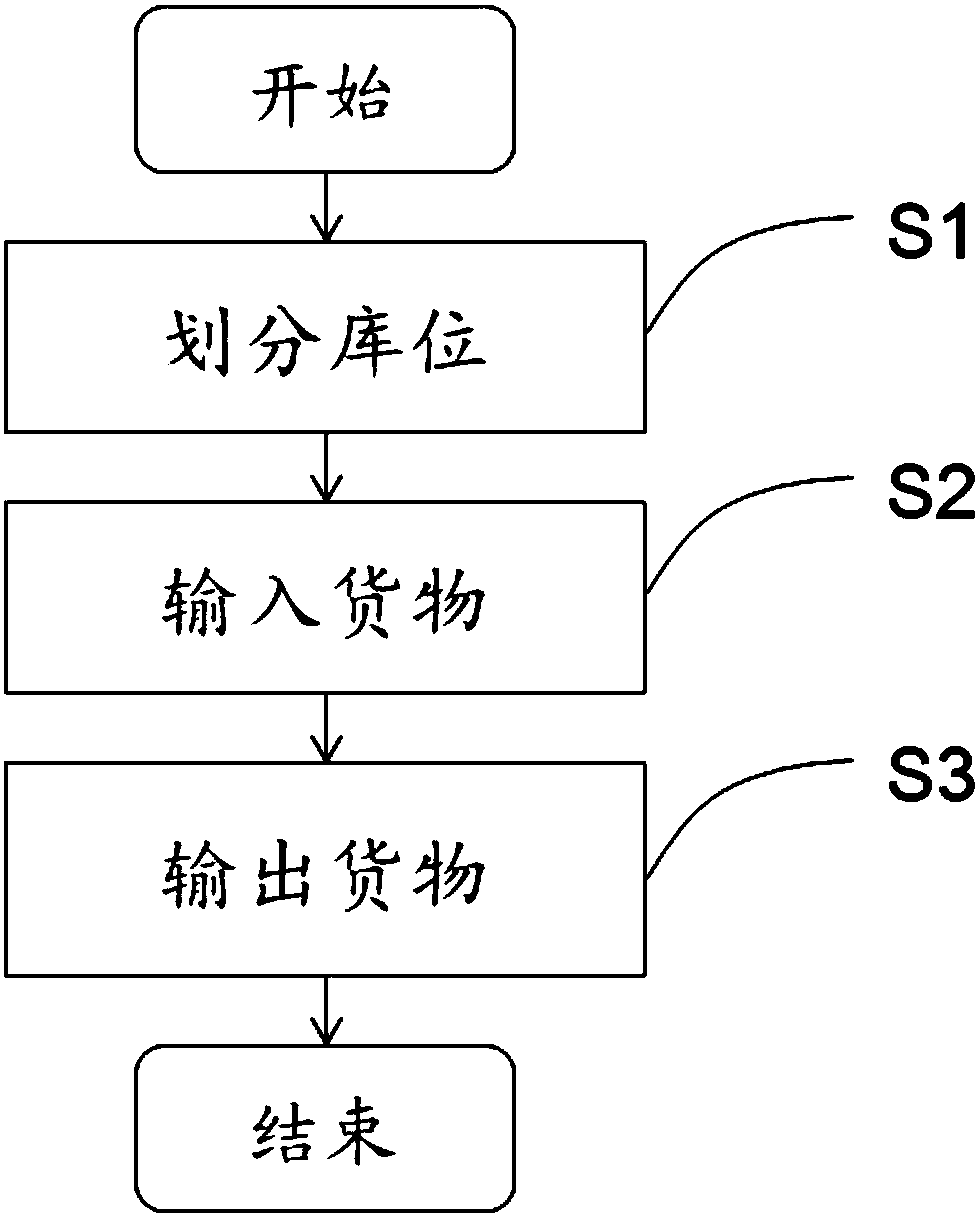

A warehouse layout management method and system

The invention discloses a warehouse layout management method and system. The method comprises the following steps: dividing storage locations: the warehouse is divided into a plurality of sub-warehouses, each sub-warehouse comprises a plurality of warehouse areas, wherein each warehouse area corresponds to one commodity type; each storage area is provided with a plurality of storage locations; inputting goods; identifying a to-be-input cargo identification code; wherein the bar code is matched with the commodity type of the warehouse area, if matching succeeds, a first judgment program is executed, if matching fails, library building is conducted, goods are output, specifically, demand information is obtained and matched with inventory information, if matching succeeds, the goods are output, and if matching fails, the demand information is recorded, and library building and filing are conducted. The system comprises a storage location division module, a goods input module and a goods output module. Through the scheme, the storage location can be flexibly managed, and the quality and efficiency of warehousing and warehouse management are improved.

Owner:上海德启信息科技有限公司

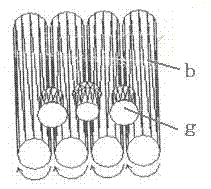

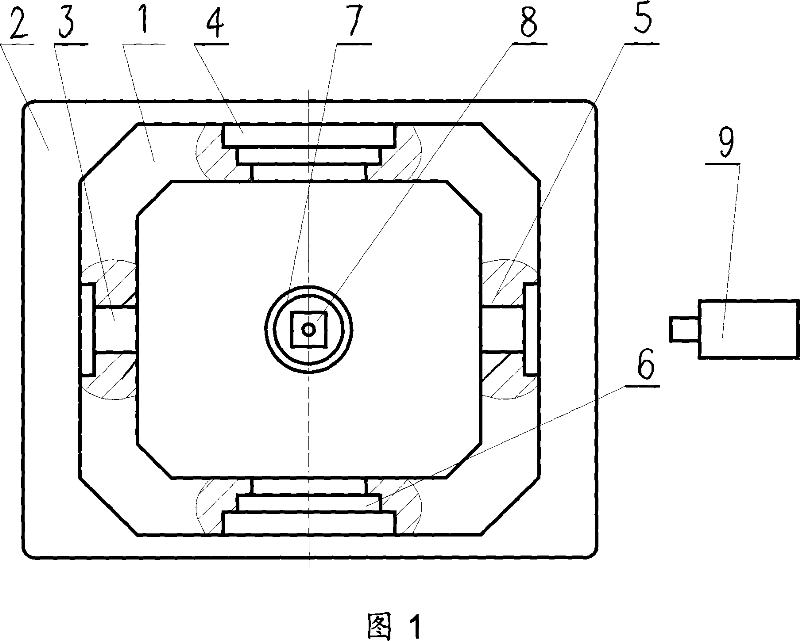

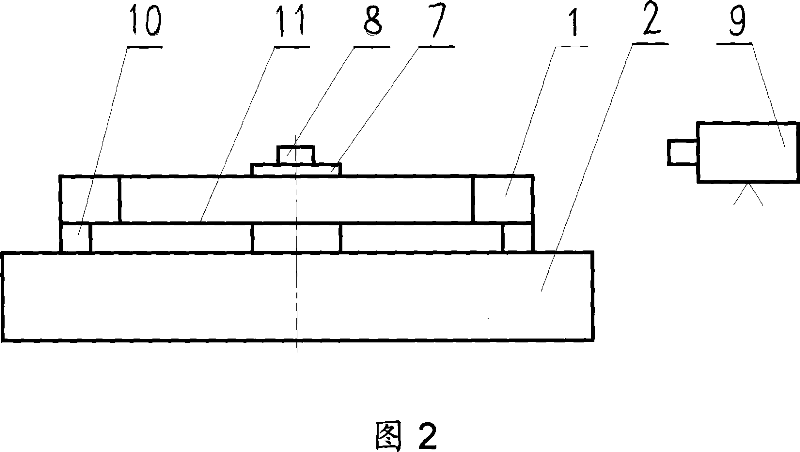

Bottle cap automatic cap-arranging device

InactiveCN103086142AAchieve finishingRealize functionLoading/unloadingConveyor partsBiochemical engineeringBottle cap

The invention discloses a bottle cap automatic cap-arranging device which comprises a feeding platform, a rotation arranging rod array, an anti-rotation plectrum array, a workpiece gesture photoelectric detection head, a workpiece baffle and a turnable grabbing mechanical arm, wherein the rotation arranging rod array comprises a plurality of rotary rods which are arranged side by side, the axes direction of the rotation arranging rod array is lower in the front and higher in the back and tilts downwards, the feeding platform is correspondingly arranged at the back end of the rotation arranging rod array, the workpiece baffle is correspondingly arranged at the front end of the rotation arranging rod array, the anti-rotation plectrum array is arranged above the middle portion of the rotation arranging rod array, and the workpiece gesture photoelectric detection head and the turnable grabbing mechanical arm are arranged between the anti-rotation plectrum array and the workpiece baffle above the rotation arranging rod array in sequence. The bottle cap automatic cap-arranging device has the advantages of being simple in structure, high in degree of automation, convenient to use, accurate in cap arranging, high in efficiency, capable of achieving the functions of automatic charging and automatic arranging, and capable of effectively saving manpower resource, lowering production cost and greatly improving sanitary level of products.

Owner:范自鲁

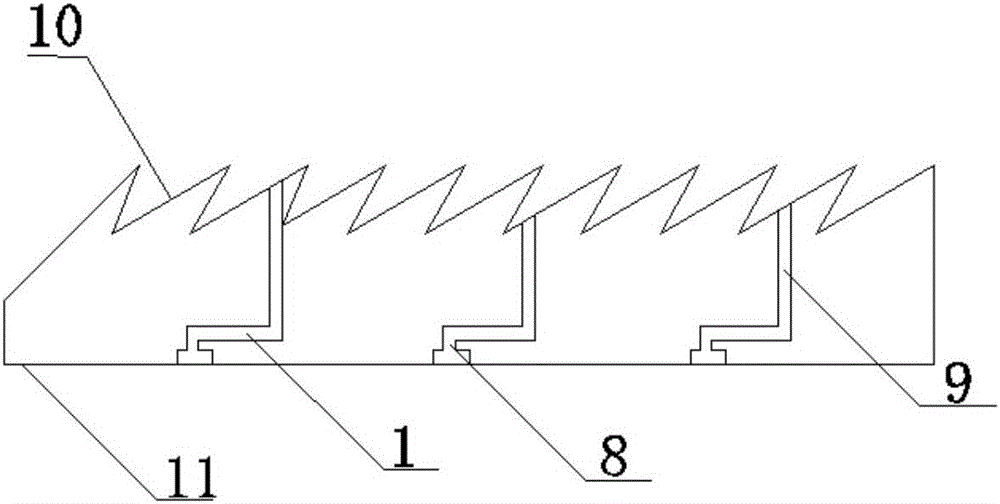

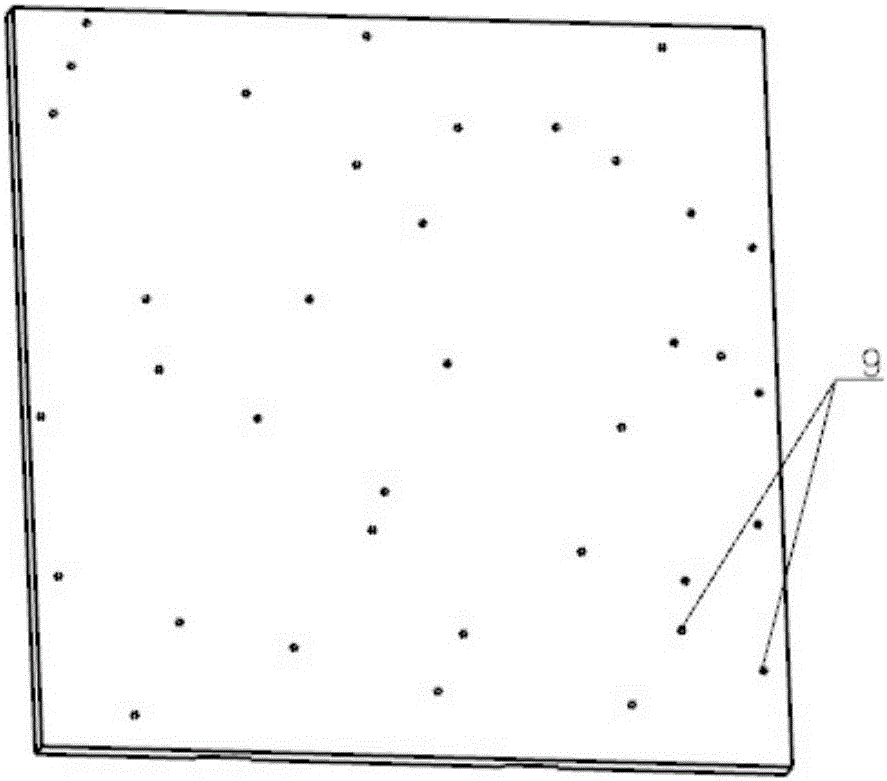

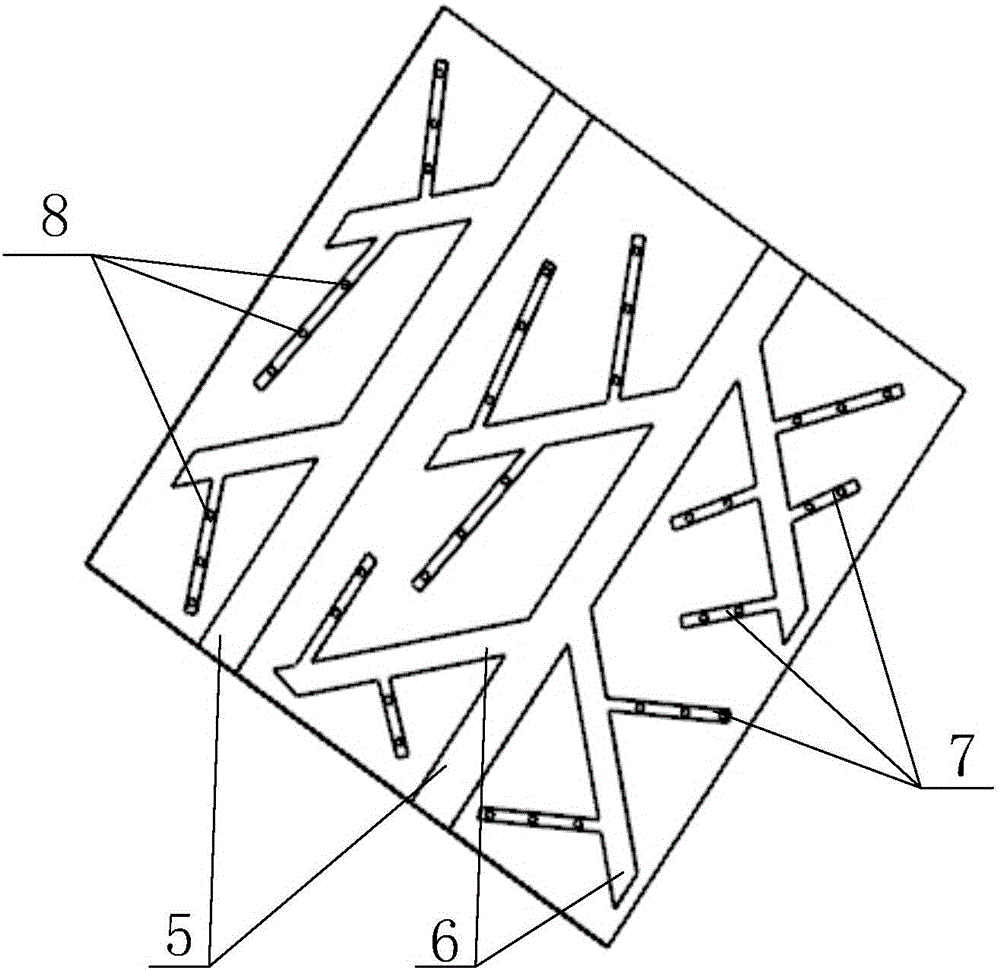

Drag reduction device used for water surface and underwater vehicle and manufacturing method of drag reduction device

InactiveCN106043591AEfficient coupling drag reduction effectReach a high degree of biomimicryWatercraft hull designGlass shaping apparatusViscous liquidManufacturing technology

The invention discloses a drag reduction device used for a water surface and underwater vehicle and a manufacturing method of the drag reduction device, and belongs to the technical field of ship manufacturing. The drag reduction device provided by the invention comprises a placoid layer, a supporting layer and a slow release layer, wherein the placoid layer and the supporting layer are arranged in parallel; the slow release layer is located between the placoid layer and the supporting layer; a channel layer is machined on the supporting layer; overflowing holes communicating with the slow release layer are formed in the surface of the placoid layer; the slow release layer communicates with the channel layer through communicating holes and comprises a plurality of sawtooth-shaped maze flow channels; the channel layer is composed of multi-stage channels with different widths, and the multi-stage channels are distributed dendritically; and the channel with the smallest width communicates with the slow release layer through the communicating holes. Meanwhile, the invention provides the method for manufacturing the drag reduction device. The highly lifelike shark-imitated drag reduction structure manufactured through the manufacturing method is in highly lifelike shark-imitated scale groove shapes and can slowly release a drag reducer, so that the efficient coupling and drag reducing effects of the scale grooves and self-lubricating viscous liquid are achieved.

Owner:SHANDONG UNIV OF TECH

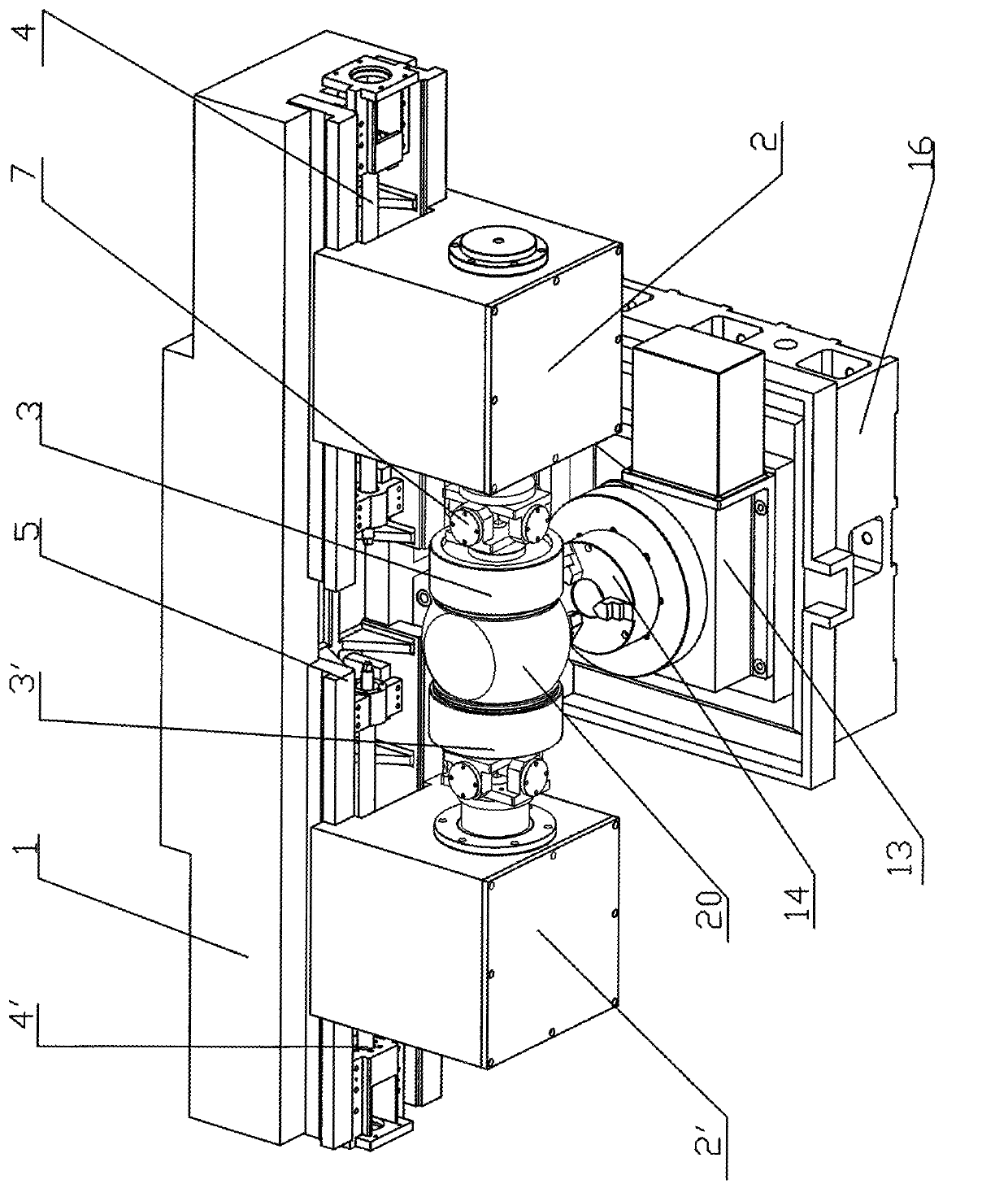

Finish machining method of the frame of the rotating table

ActiveCN101036948AAchieve finishingHigh precisionPrecision positioning equipmentMeasurement/indication equipmentsStanding frameAutocollimation

A fine machining method of the rolling stand frame belongs to machine finishing technology field. At first determining center of turning circle position of the fine boring machine table and mounting end face multiple tooth circular dividing table thereon, the tetrahedron is mounted on the end face multiple tooth circular dividing table, and adjusting it to collimate with the photoelectricity autocollimation to determine machineable machine zero position point; the rolling stand frame is mounted on the worktable, and adjusting it to symmetry with the center of gyration; boring the frame side face of each axle hole for the rolling stand frame and the axle hole until achieving to the required precise size, when the frame rotates from one side to another side, rotating relevant angle of the worktable contrasting to graduation value of the end face multiple tooth circular dividing table, the tetrahedron is measured by the photoelectricity autocollimation, fine tuning the worktable to collimate the corresponding face of the tetrahedron with the sending beam of the photoelectricity autocollimation, at this point, the rotating angle is exact value, then processing. The invention operates conveniently and audio-visually, with reliable processing manufacturability, and reducing accumulation of error and improving process precision of the frame.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

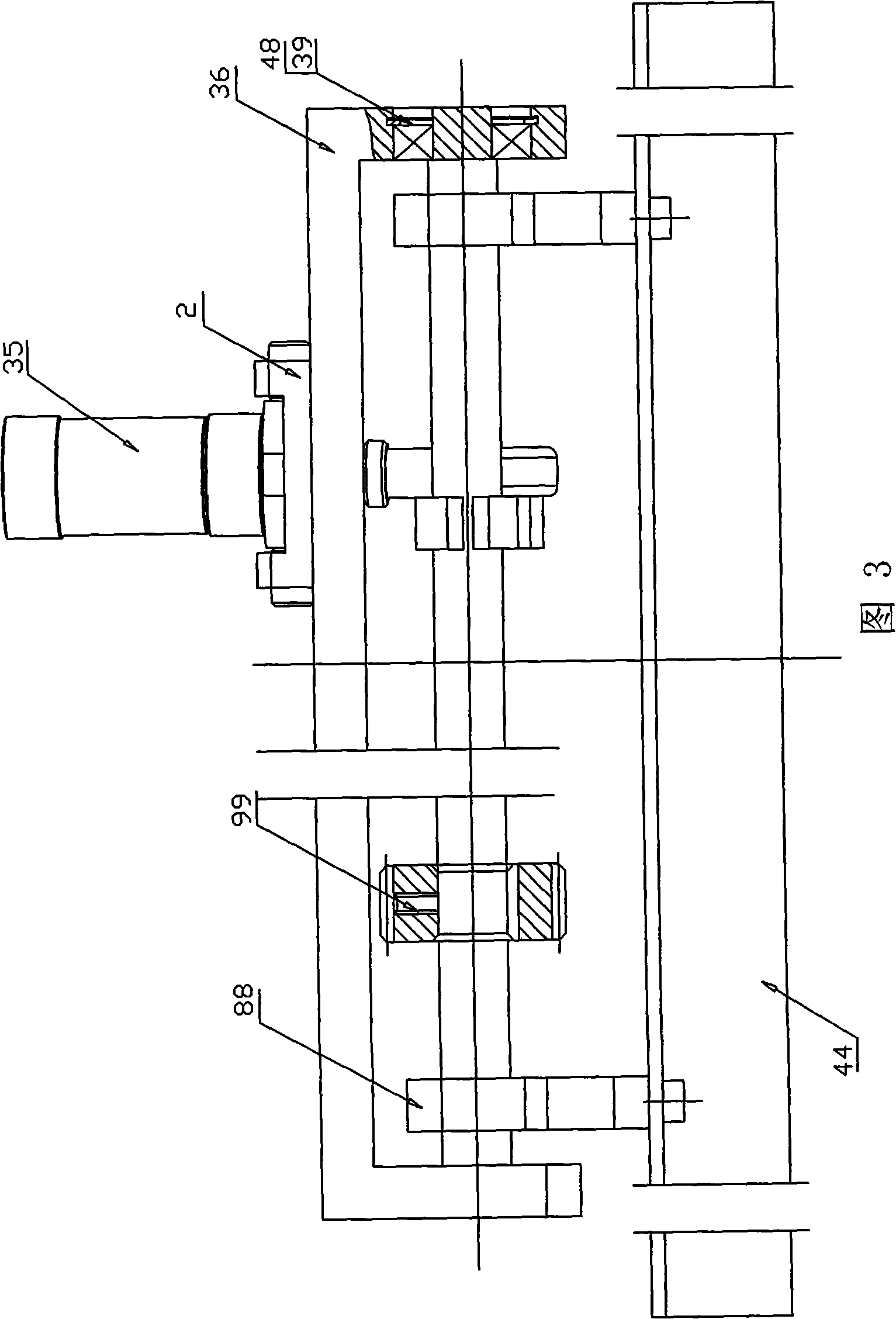

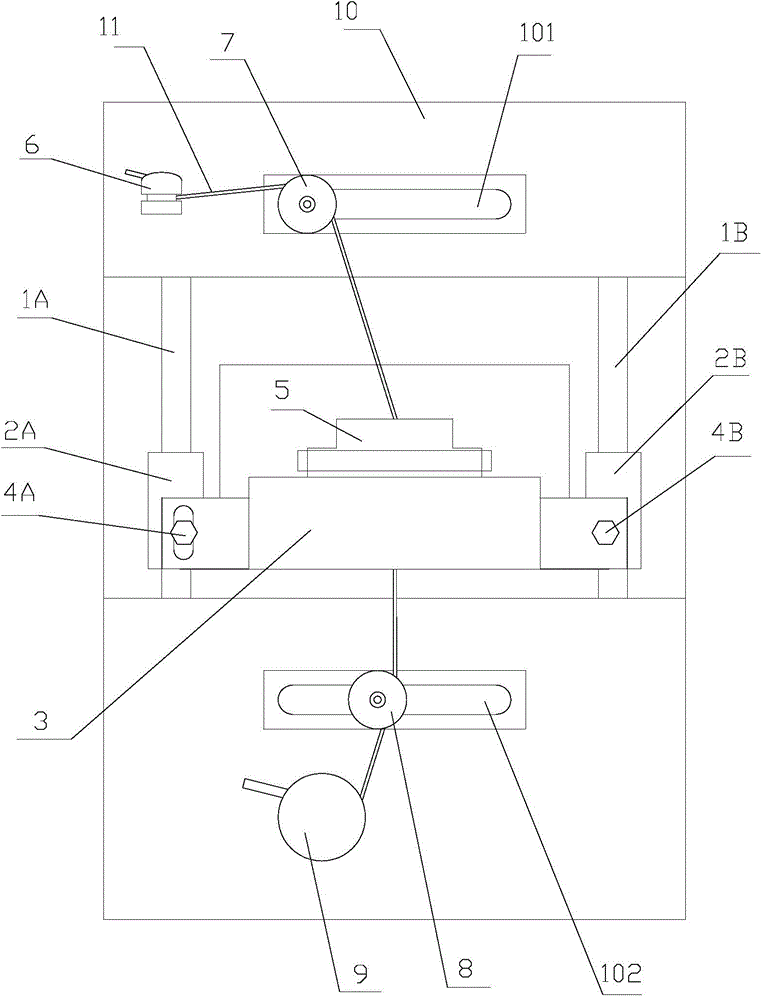

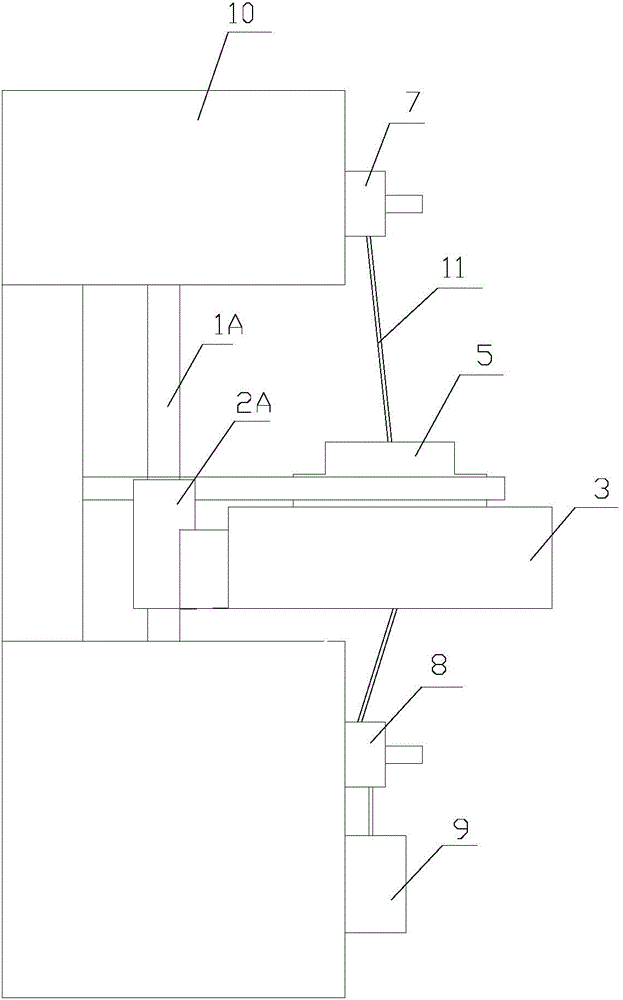

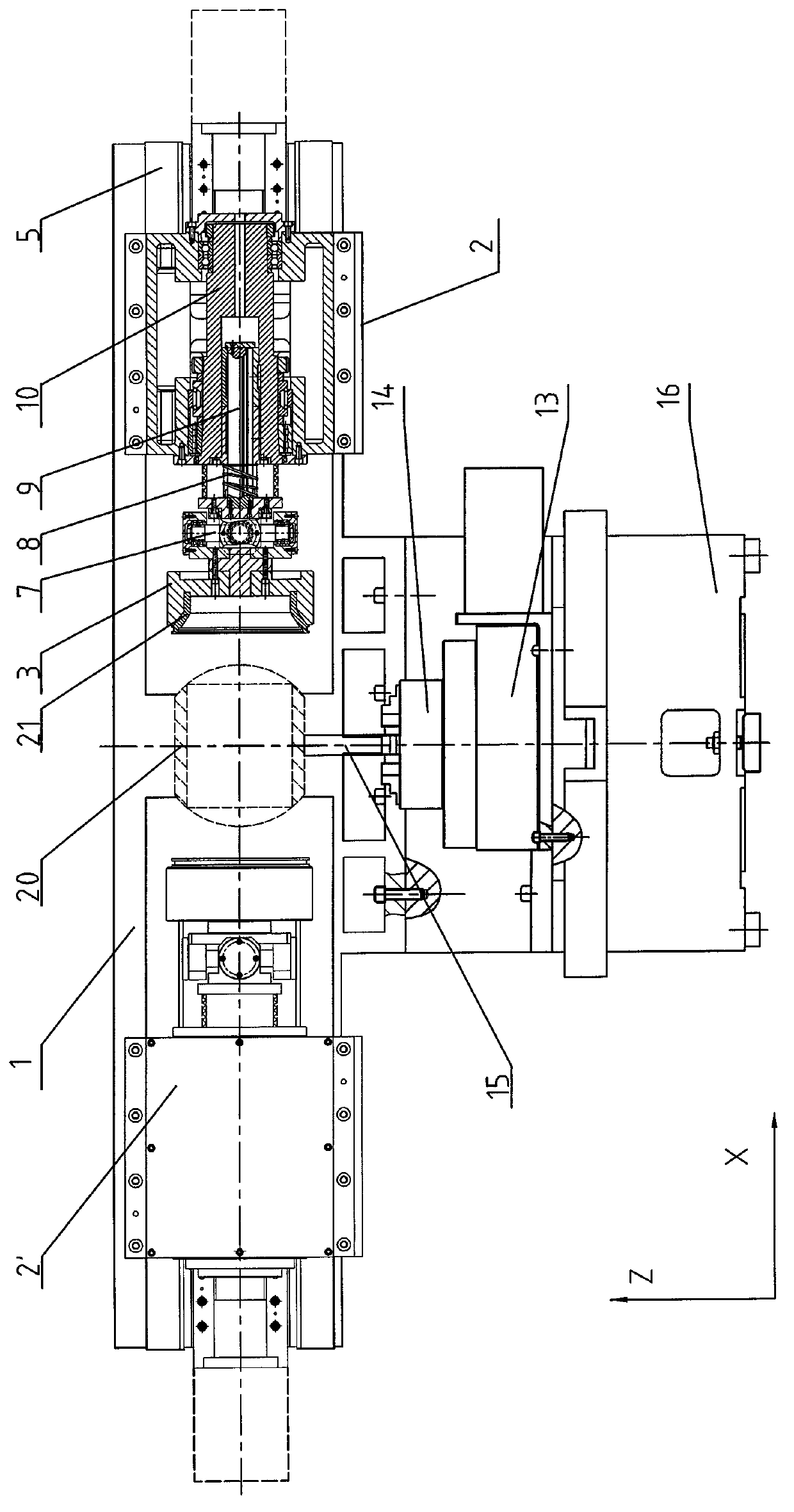

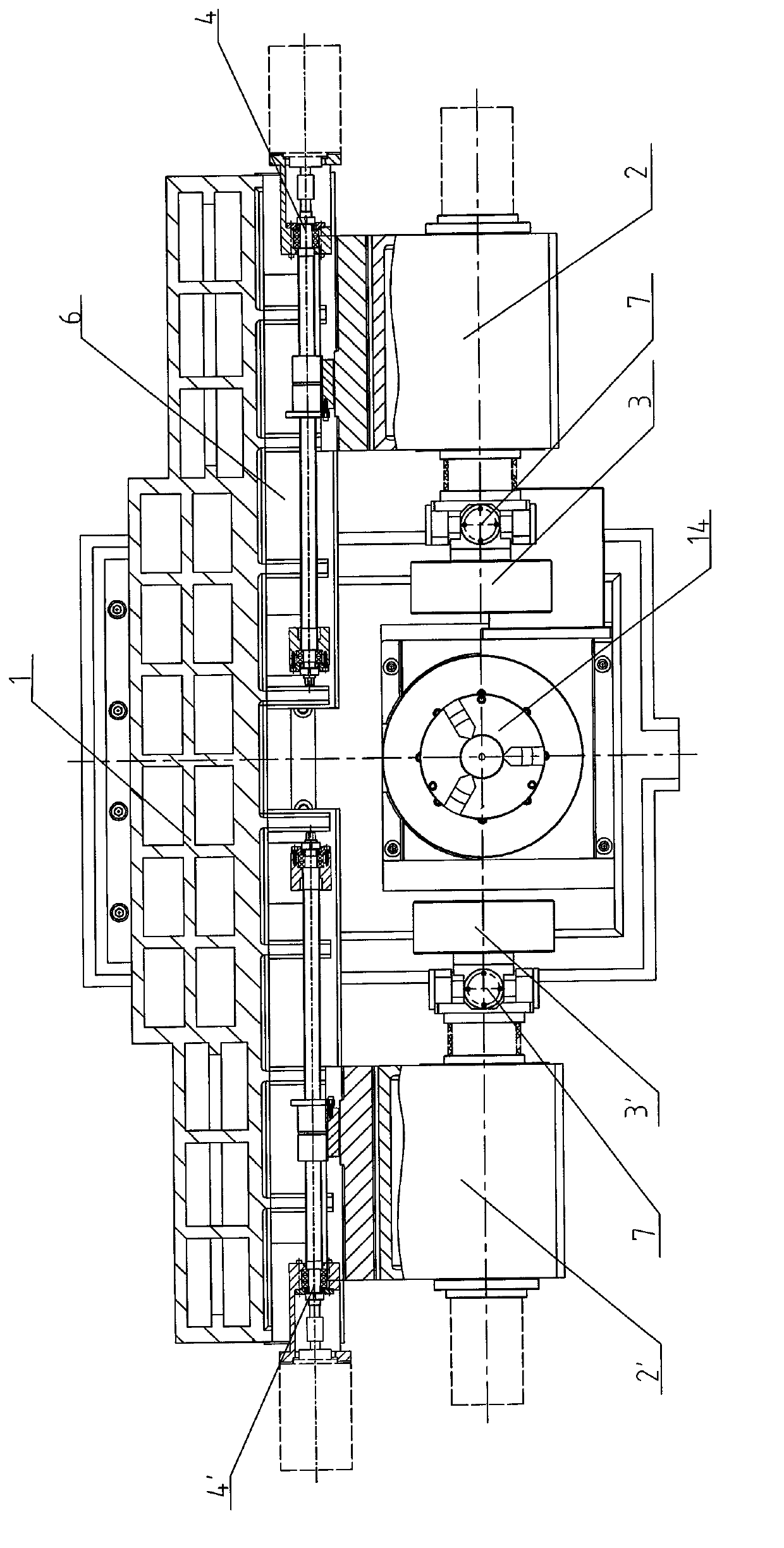

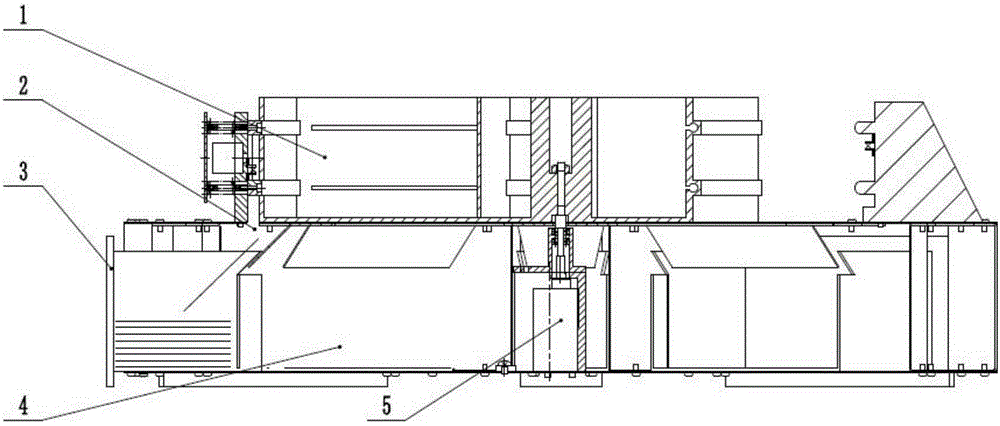

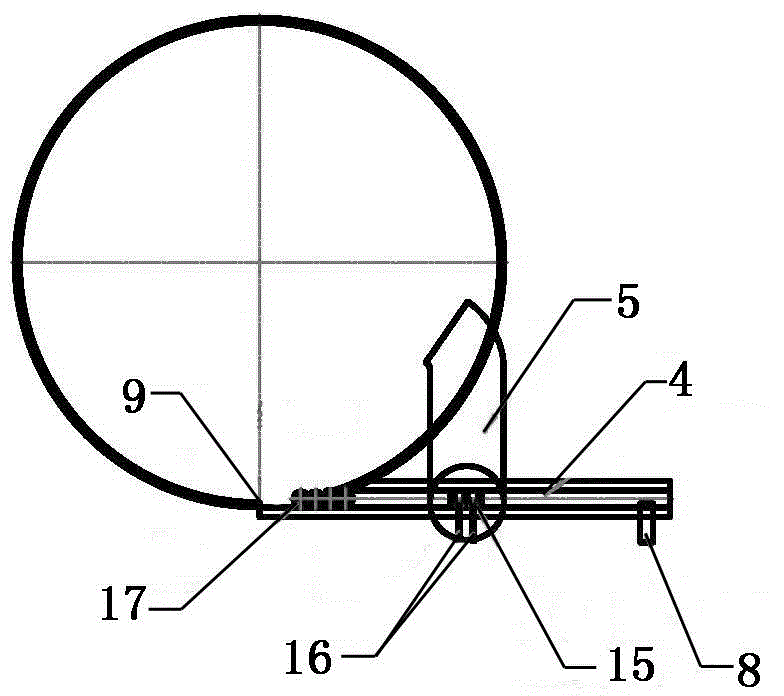

Machine tool for running-in process of ball and valve seat of ball valve

InactiveCN103128647AControl grinding amountControl grinding precisionLapping machinesWork carriersBall screw driveEngineering

The invention relates to a machine tool for the running-in process of a ball and a valve seat of a ball valve. The machine tool comprises a beam, a left grinding head spindle assembly, a right grinding head spindle assembly, a left spindle feed and ball screw drive system, a right spindle feed and ball screw drive system, a ball motion control device and a valve seat clamping fixture, wherein the beam is provided with a guide rail, the left and the right grinding head spindle assemblies are arranged on the guide rail, the output ends of the spindle feed and ball screw drive systems are respectively connected with the grinding head spindle assemblies, the ball motion control device is arranged in the interspace between the left and the right grinding head spindle assemblies, and the valve seat clamping fixture is arranged on a cardan joint which is arranged on the output ends of the left and the right grinding head spindle assemblies. The invention aims at designing a machine tool which can run in and process the ball and the valve seat of the ball valve and achieve a high grinding precision and high efficiency. Compared with the prior art, the machine tool for the running-in process of the ball and the valve seat of the ball valve has the advantages that the grinding degrees and the grinding precision are controllable, the processing efficiency is high, and the cooperation between the ball and the valve seat can completely meet the hard seal requirements.

Owner:温州市木野数控设备有限公司

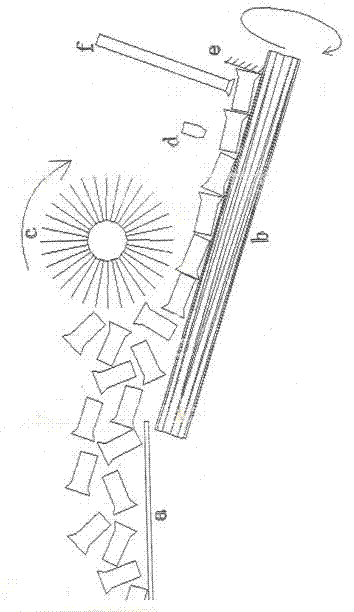

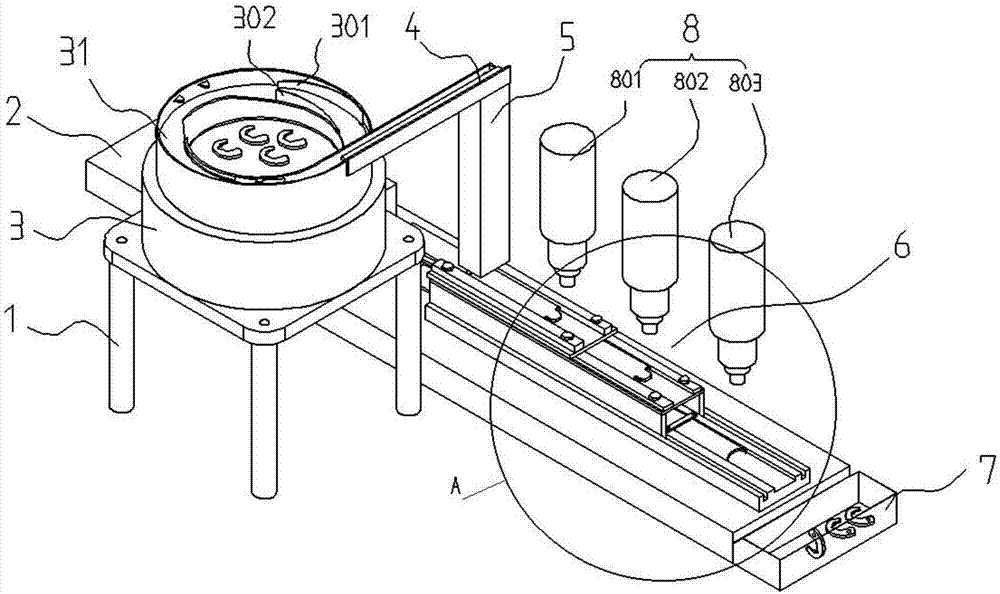

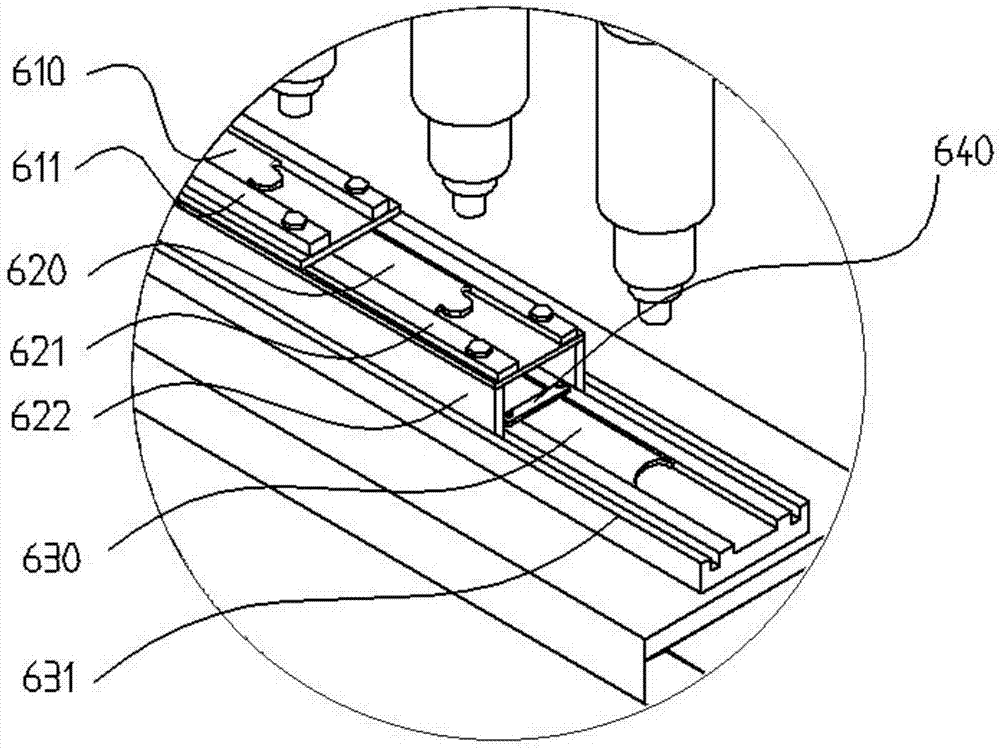

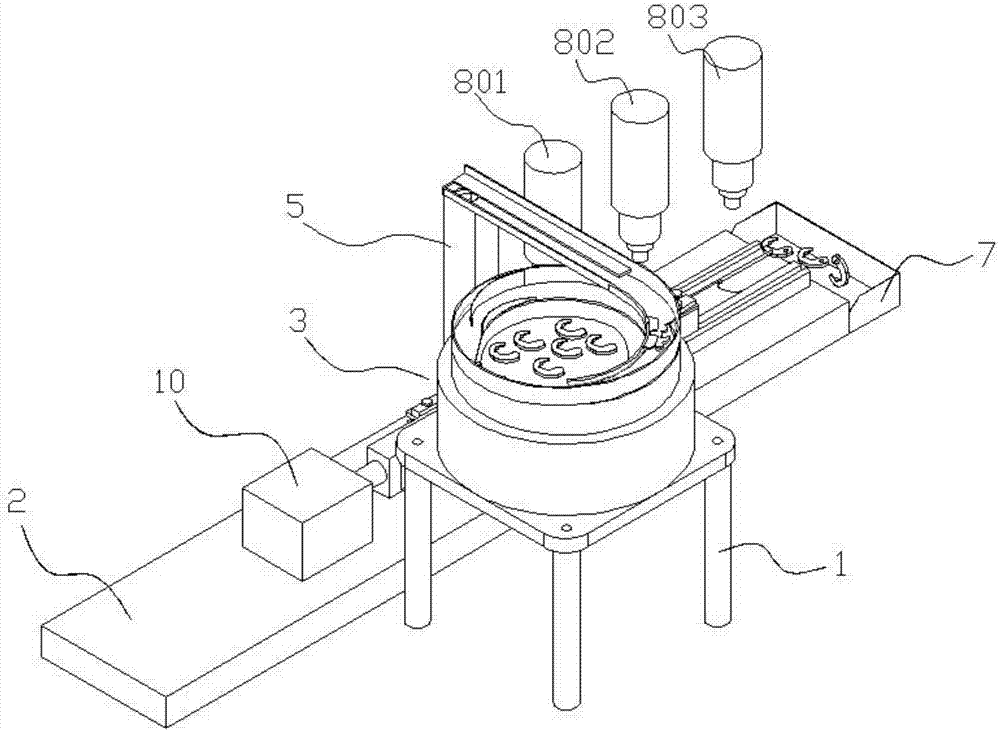

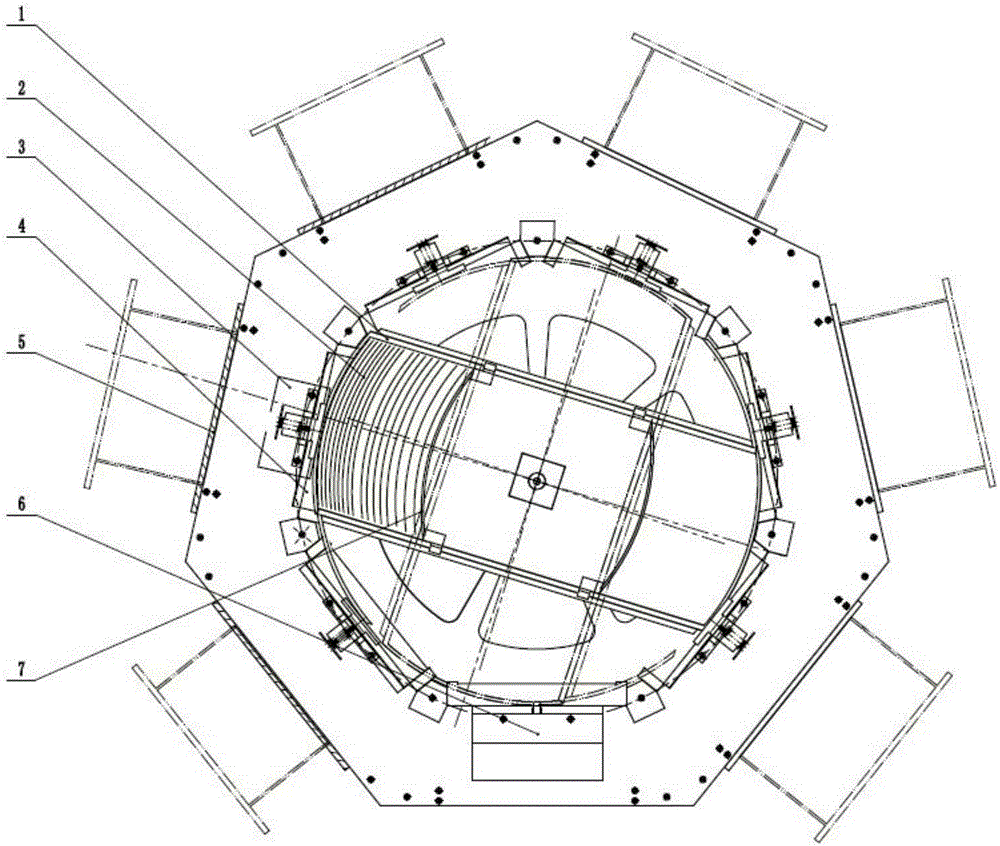

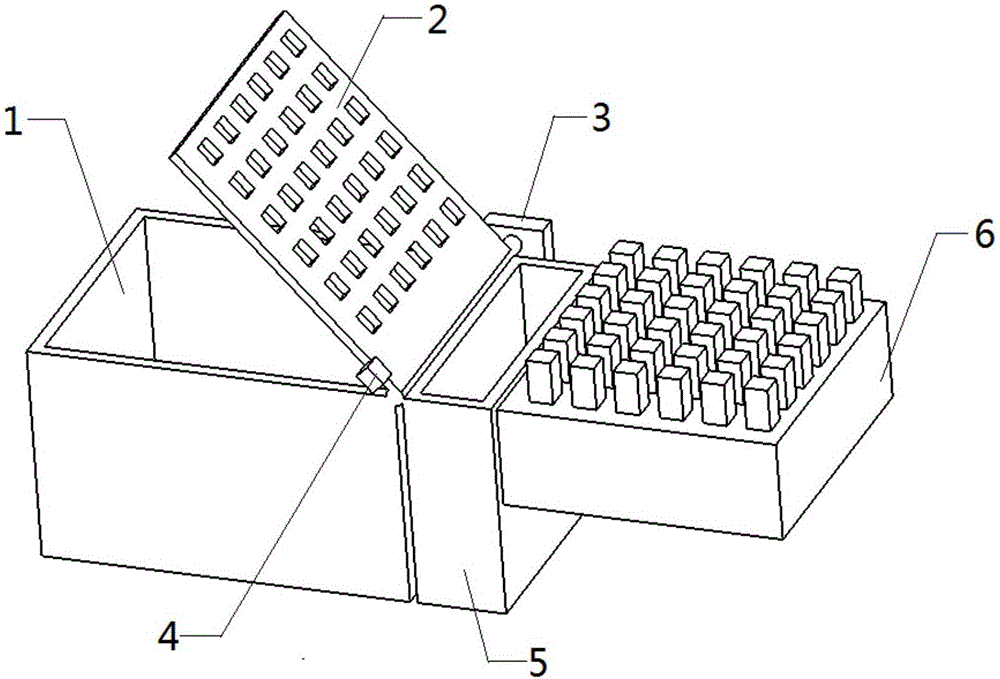

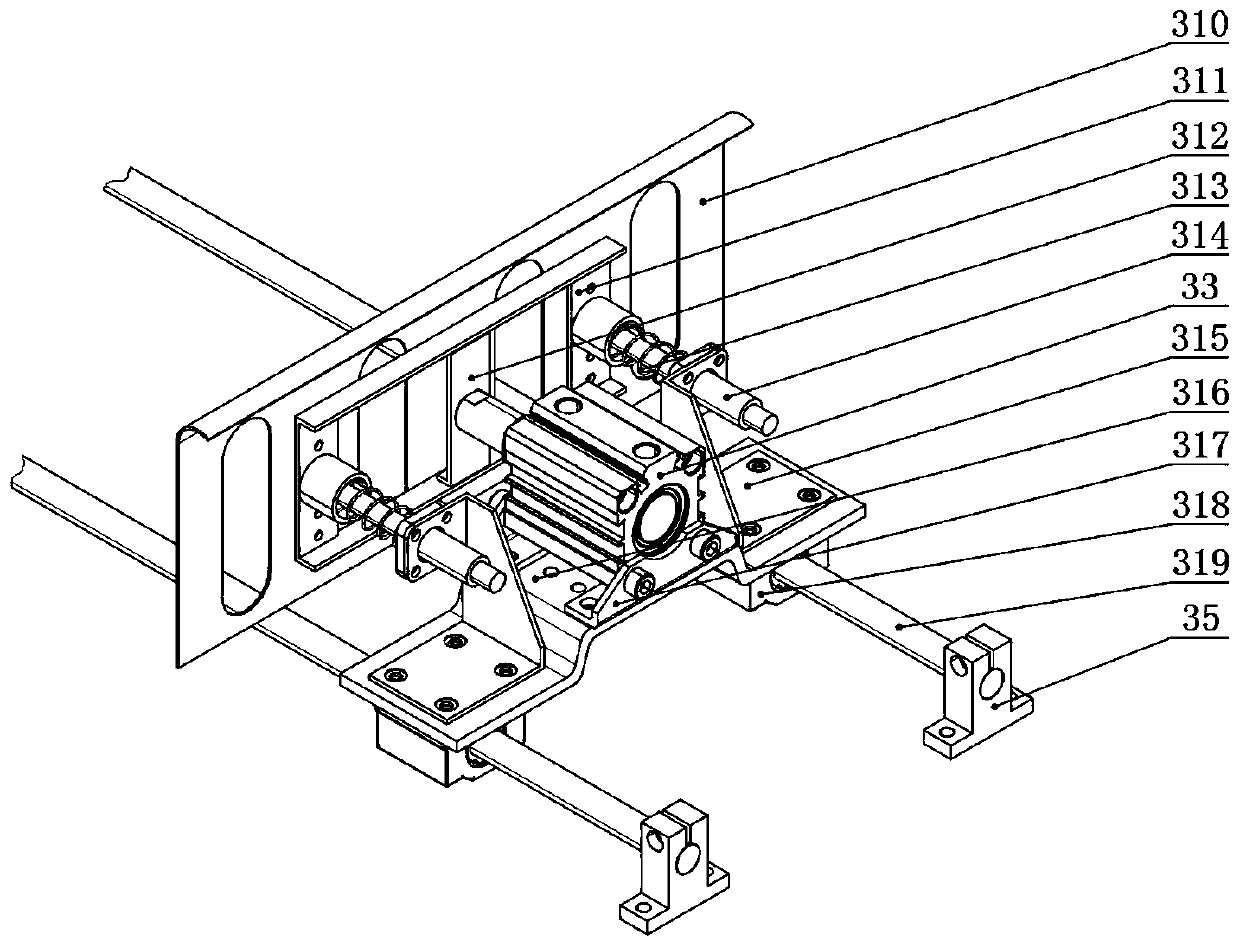

Automatic production device for precise machining of rotating pin holes of ratchet wrench heads

PendingCN107309465AReduce manual operationsIncrease productivityMetal working apparatusBoring/drilling machinesWrenchEngineering

The invention discloses an automatic production device for precise machining of rotating pin holes of ratchet wrench heads. The automatic production device comprises a vibration feeding disc and a drilling machine device; a spiral surrounding type feeding plate is arranged in the vibration feeding disc; a layer-limited guide plate, a material discharging groove and a material sorting groove are sequentially arranged on the spiral surrounding type feeding plate in the moving direction of parts; a matching baffle is arranged opposite to the layer-limited guide plate, and the spiral surrounding type feeding plate is connected to a discharging rail; the discharging rail is connected to a guide bin; a pushing device is arranged at the lower end of the guide bin and comprises an upper-layer feeding sliding groove and a lower-layer feeding sliding groove which are stacked mutually; a first pushing plate is arranged on the upper-layer feeding sliding groove; a second pushing plate is arranged on the lower-layer feeding sliding groove; the tail end of the first pushing plate and the tail end of the second pushing plate are connected to a telescopic device; and the drilling machine device is positioned right above the pushing device. According to the automatic production device, orientation sorting can be carried out rapidly on the ratchet wrench heads in batches, drilling and reaming machining can be carried out on the ratchet wrench heads, the production efficiency is high, machining is stable and reliable, the precision is high, the potential safety hazard is avoided, and the production efficiency is improved.

Owner:湖南精专自动化技术有限公司

Small-sized rotary paper currency sorter

The invention discloses a brand-new small-sized rotary paper currency sorter, which can be used for sorting six kinds of paper currency at single time by changing an identification control module and has the advantages of small size, high efficiency, simple structure and strong expandability. The paper currency sorter is in a septimal prism flat shape; by adopting a brand-new paper currency delivery mode, namely a rotating money slot substitutes a traditional rubber roller to deliver paper currency, so that the sorter is smaller and higher in efficiency; and different denominations of paper currency are sorted at different money outlets by six electromagnetic controlled frictional grabbing devices on a base, so that the sorter is simple in control and fast in response. Meanwhile, the sorter realizes acceptance and arrangement of paper currency through an impeller-free paper currency receiving device by means of the gravity of the paper currency.

Owner:CHONGQING UNIV

Feeding and finishing system and process of aluminum and plastic caps

ActiveCN104444292AAchieve the purpose of organizingReduce mutual frictionConveyor partsEngineeringHigh pressure

The invention discloses a feeding and finishing system of aluminum and plastic caps. The system comprises an aluminum cap feeding and finishing portion, a plastic cap feeding and finishing portion, a pneumatic control portion, a photoelectric control portion and an automatic controller. The invention further discloses a feeding and finishing process of aluminum and plastic caps employing the system. By the use of the centrifugal separation mode with a unique tray structure, friction of the aluminum or plastic caps is greatly reduced, and loss is reduced; by the use of a pneumatic mode with a unique screening rail and the use of high-pressure air as power to finish the caps, the caps run faster on the rail, the cap finishing process is stable and is better than mechanical finishing, product yield can be evidently increased, the surfaces of the caps have no scratch or deformation after finishing, and fewer caps are jammed or deformed; the fishing and moving speeds are higher, above 900 caps per minute; finishing and arrangement of the aluminum and plastic caps is achieved, and feeding for a next procedure is achieved.

Owner:HEBEI JINHUAN PACKAGING

Automatic cleaning device for screen

ActiveCN107175201AAchieve cleaning effectAchieve finishingSievingScreeningElectric machineryEngineering

Owner:JIANGSU KANG CHENG NEW MATERIAL TECH CO LTD

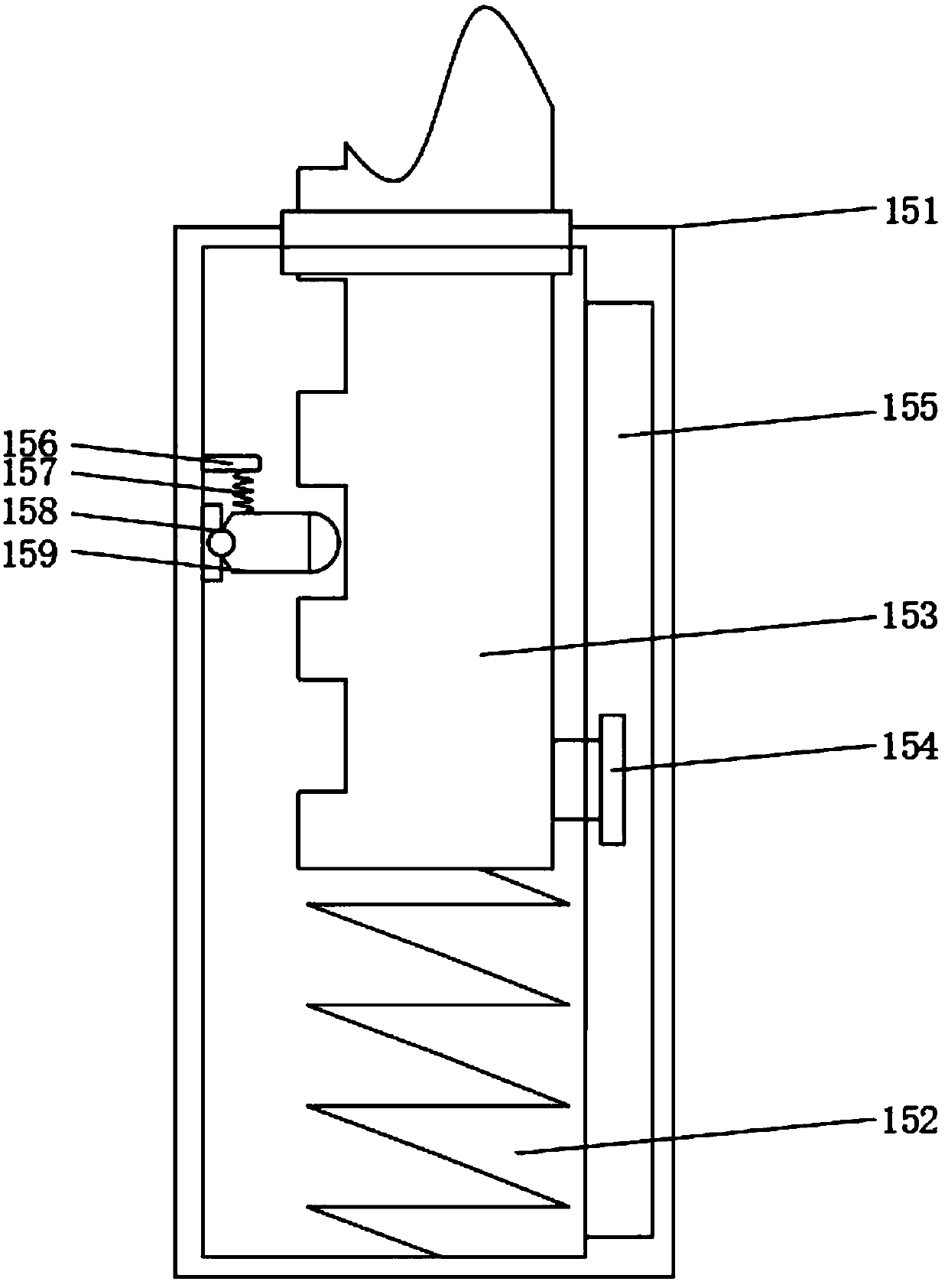

Reaction cup loading device

The invention discloses a reaction cup loading device which comprises a base, a hopper arranged on the base, a direction adjusting structure arranged in the hopper, and a lifting mechanism arranged on the base and lifting a reaction cup from the bottom of the hopper to the direction adjusting structure. The direction adjusting structure comprises a direction adjusting groove and a direction adjusting groove cover detachably connected with the direction adjusting groove and covering an opening of the direction adjusting groove, width of the direction adjusting groove is greater than outer diameter of a cup body of the reaction cup and less than outer diameter of a flange of the reaction cup, the direction adjusting groove inclines from one end close to the lifting mechanism to one end away from the lifting mechanism towards the bottom end of the hopper, an outlet for the reaction cup to pass is arranged at one end, away from the lifting mechanism, of the bottom of the direction adjusting groove, the lifting mechanism comprises a lifting groove containing the reaction cup and capable of being communicated with the direction adjusting groove in the hopper, and the lifting groove inclines from one end away from the direction adjusting groove to one end close to the direction adjusting groove towards the bottom end of the hopper. By using the reaction cup loading device, convenience is brought to solve the fault of pipe jamming, and lowering of using efficiency of a detection instrument due to solving of the fault of pipe jamming is avoided.

Owner:MACCURA MEDICAL INSTR CO LTD

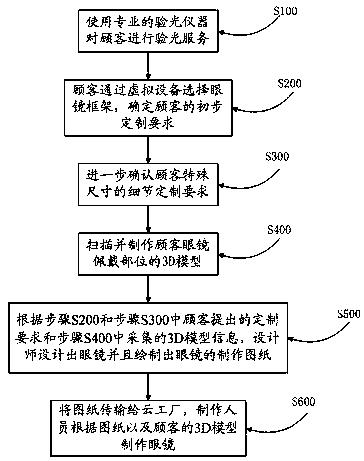

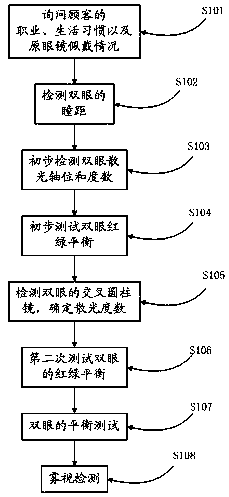

Glasses customizing method

InactiveCN107589562AFacilitate decision-makingGood choiceSpectales/gogglesUses eyeglassesComputer graphics (images)

The invention discloses a glasses customizing method. The glasses customizing method comprises the following steps: S100, optometry is performed on a customer by a professional optometric instrument;S200, the customer selects a glasses frame through a virtual device, and preliminary customizing requirements of the customer are determined; S300, detail customizing requirements of the customer forspecial dimensions are further determined; S400, a 3D model of a glasses wearing part of the customer is made; S500, a designer designs glasses and draws a making drawing of the glasses according to the customizing requirements proposed by the customer in S200 and S300 and 3D model information acquired in S400; S600, the drawing is transmitted to a cloud factory, a maker makes the glasses according to the drawing and the 3D model of the customer. With adoption of the glasses customizing method, the customer can select appropriate glasses pattern with application of an AR technology, the glasses meeting actual conditions of the customer can be made by comprehensive application of a 3D printing technology, the user experience is good, and the matching degree of the customized glasses with the customer is high.

Owner:厦门云镜视界设计有限公司

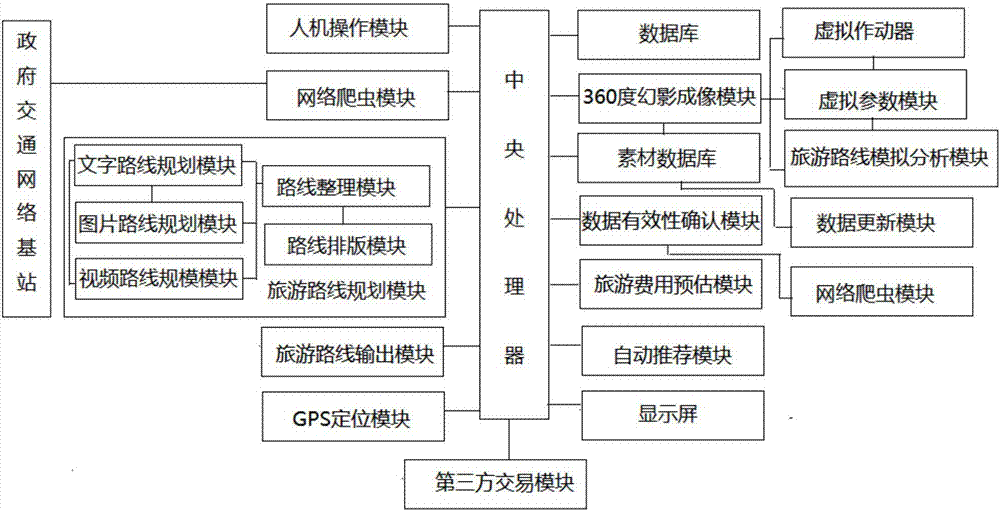

Management system for rural tourism

InactiveCN106990845AAchieve finishingAchieve sharingInput/output for user-computer interactionForecastingPersonalizationThird party

The invention discloses a management system of rural tourism. The system includes a human-computer interaction module, a tourism route planning module, a tourism route output module, a traveling expense estimation module, a GPS positioning module, a third party transaction module, an automatic recommendation module, a data validity confirmation module, a 360-degree phantom imaging module, a virtual actuator, a virtual parameter module, a travel route simulation analysis module and a central processor. The system achieves collection and sharing of rural tourism resources, map information can be acquired from a real environment and can be updated in real time, and the feasibility of implementation of the route planning is improved; through the arrangement of the 360-degree phantom imaging module, the travel route simulation analysis module and the like, users can be personally on each tourism route, and a final personalized tourism scheme is thus formed.

Owner:HENAN UNIV OF URBAN CONSTR

Method for bagging of materials

ActiveCN108839828AConvenient reverseInhibit sheddingWrapper twisting/gatheringSolid materialEngineering

Owner:SHANGHAI SOONTRUE MACHINERY EQUIP

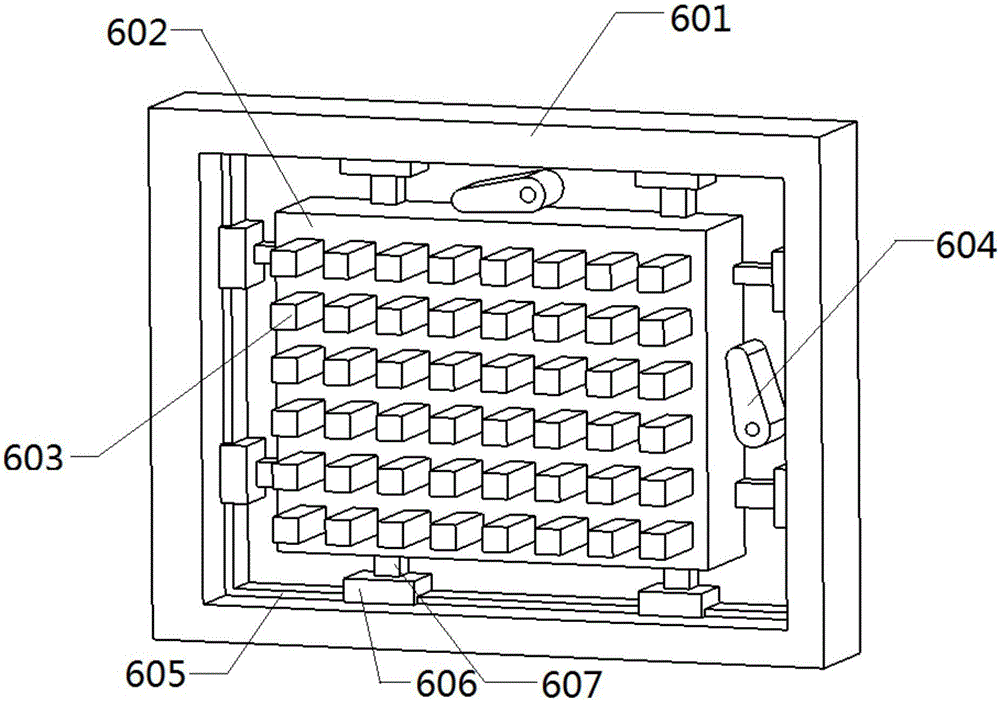

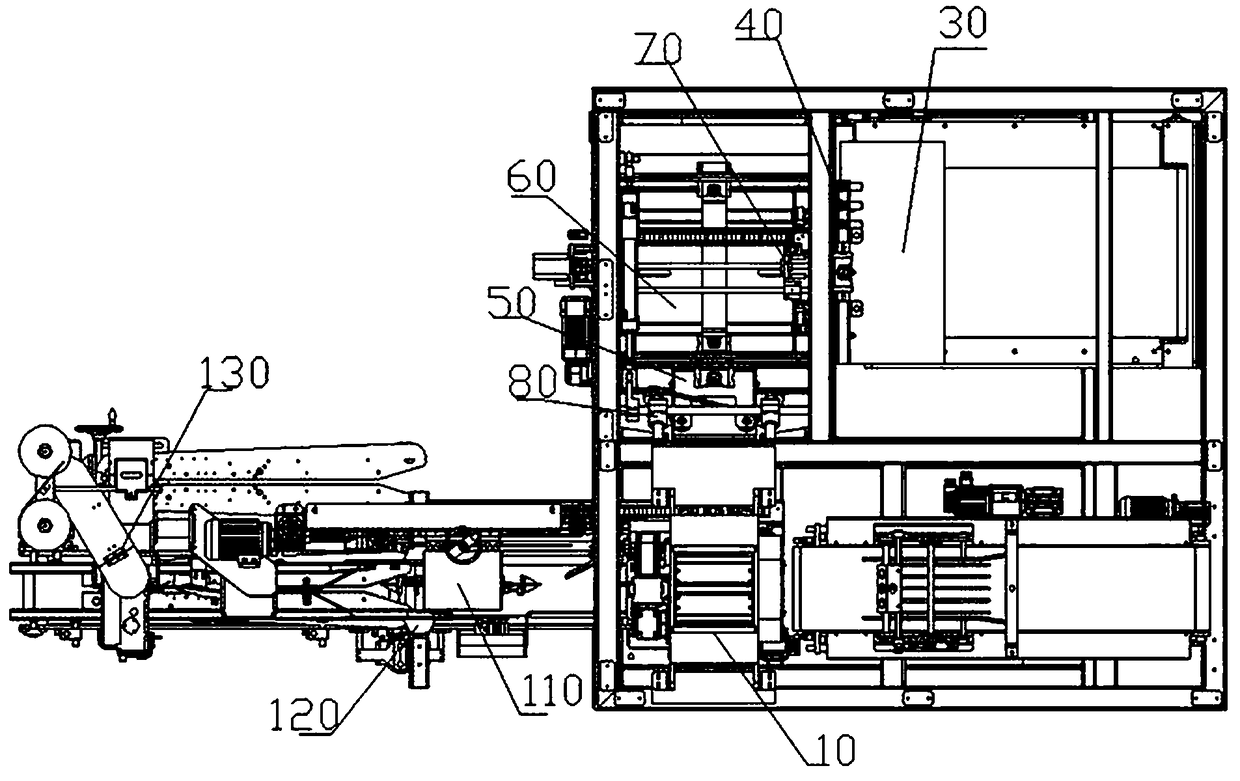

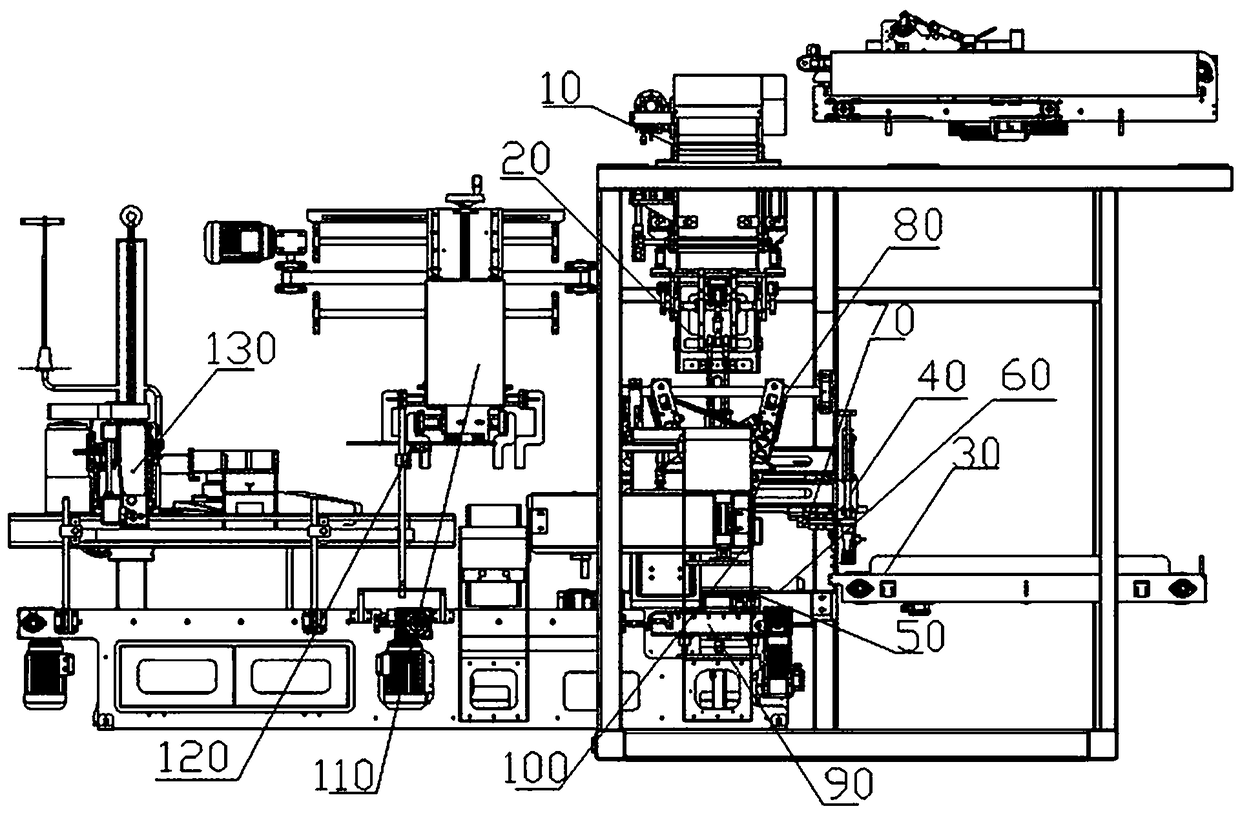

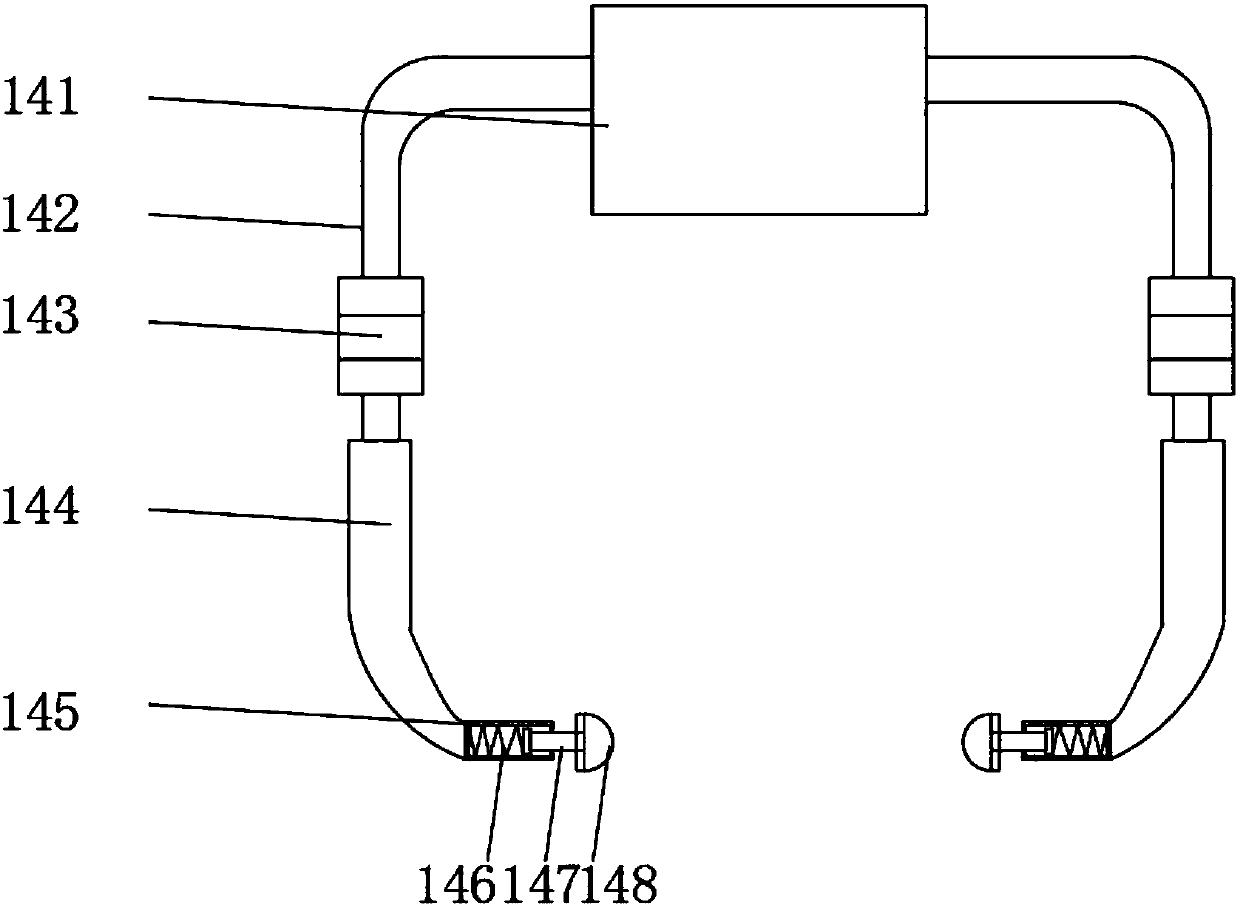

Automatic collecting and bundling device for packaging bags

ActiveCN110182403ARealize the collectionAchieve finishingPaper article packagingBag making operationsEnvironmental resistanceElectric machinery

The invention provides an automatic collecting and bundling device for packaging bags. The device comprises a pressing device, a bag stopping baffle device, a collecting and arranging device, a conveying positioning device, a clamping device, an automatic bundling device, a conveyor and a rack. The bag stopping baffle device comprises a third air cylinder, an L-shaped swing arm, a baffle, a hingeand a connecting support plate. The collecting and arranging device comprises an arranging mechanism, a large flat plate and a bag beating plate positioning device, and the large flat plate is fixed on the rack. The conveying positioning device comprises a linear sliding table mechanism, a lead screw nut, a lead screw and a motor. The clamping device comprises a mechanical claw device, a second air cylinder, a first connecting rod and a pressure head device. The mechanical claw device drives the first connecting rod to move through the second air cylinder. By means of the automatic collectingand bundling device, full automation of the collection, arrangement, bundling and transfer processes of the plastic bags is realized, a motor is adopted for driving, work is stable, cleanliness and environmental protection are achieved, the structure is safe and reliable, the labor cost is reduced, and the production efficiency is improved.

Owner:ZHEJIANG UNIV OF TECH +1

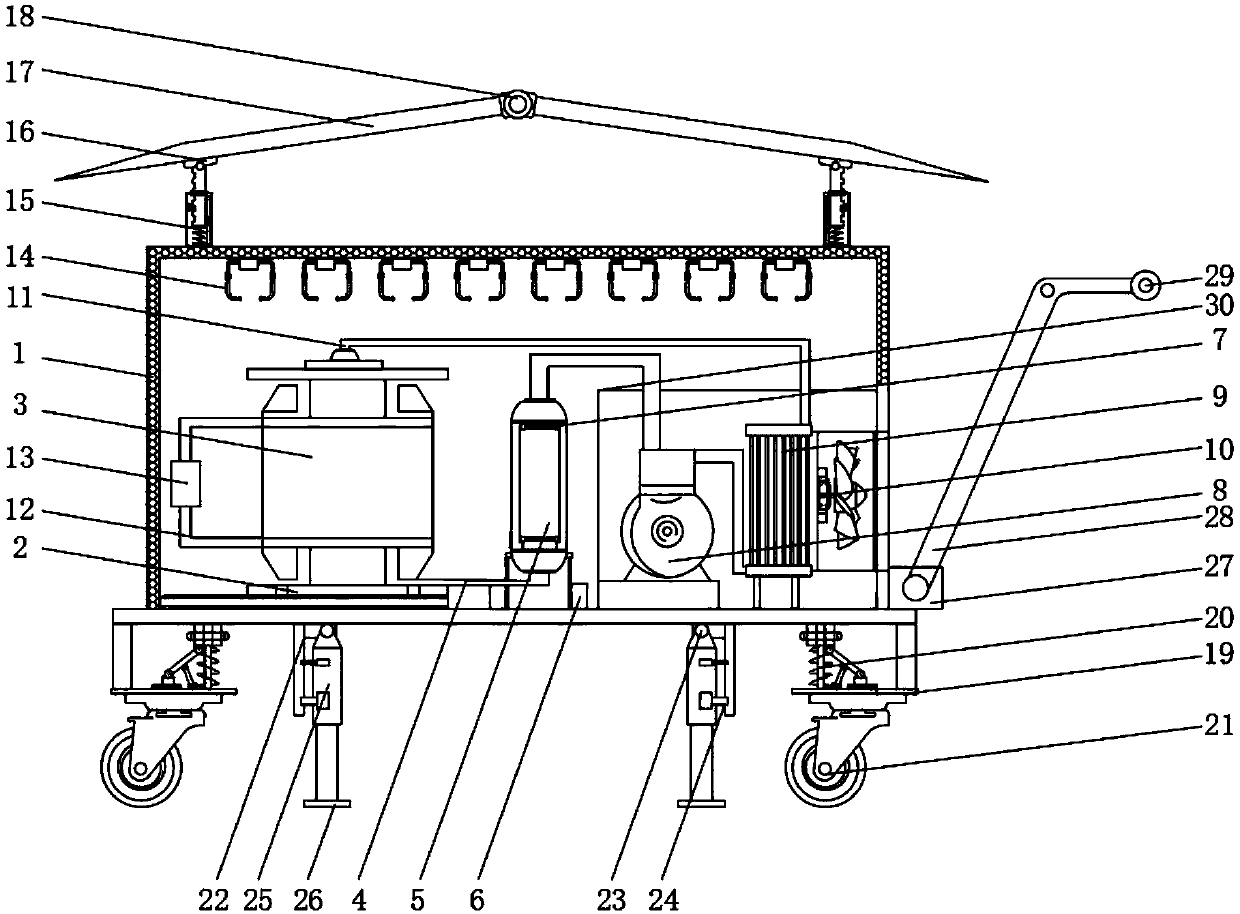

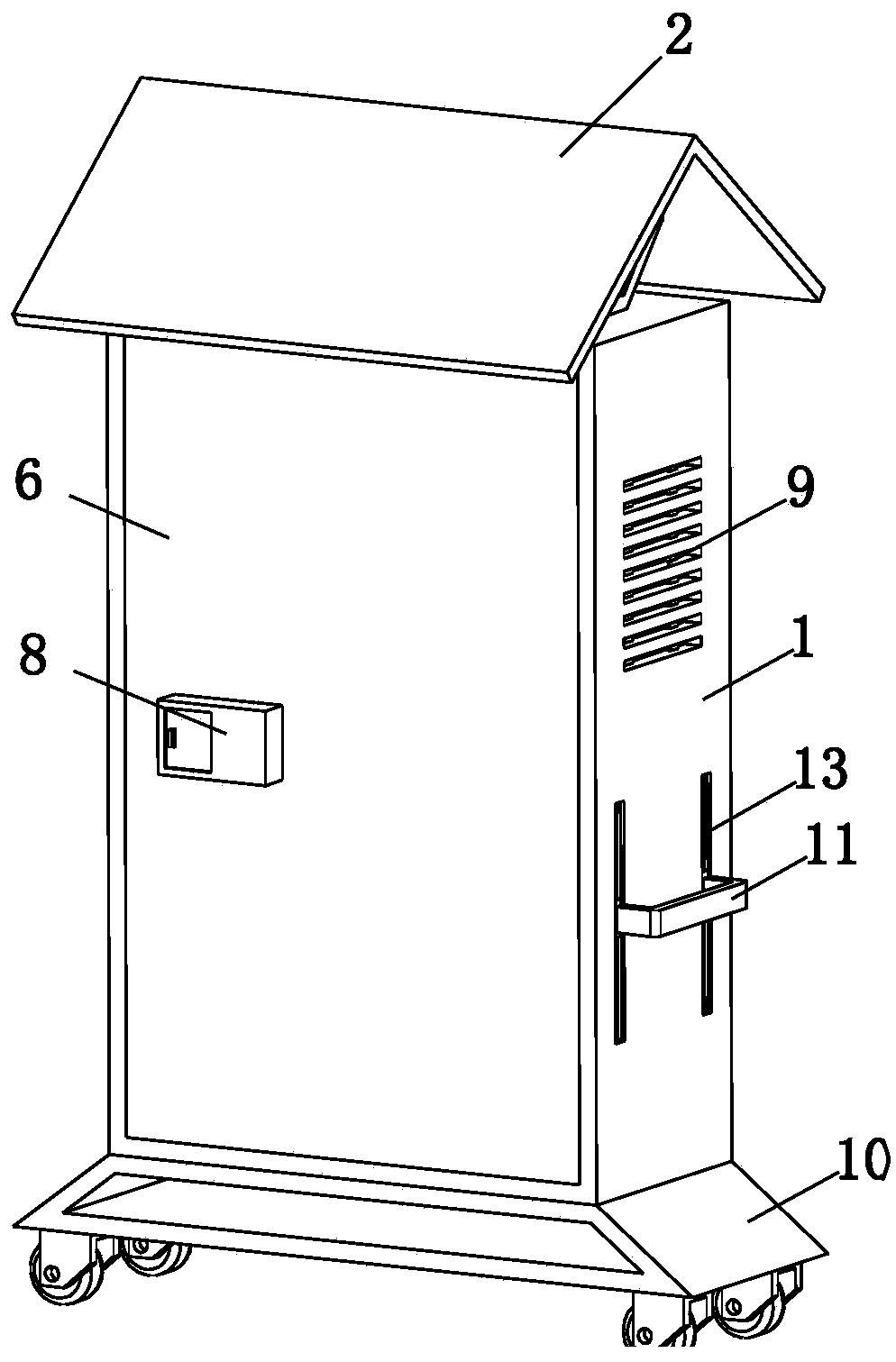

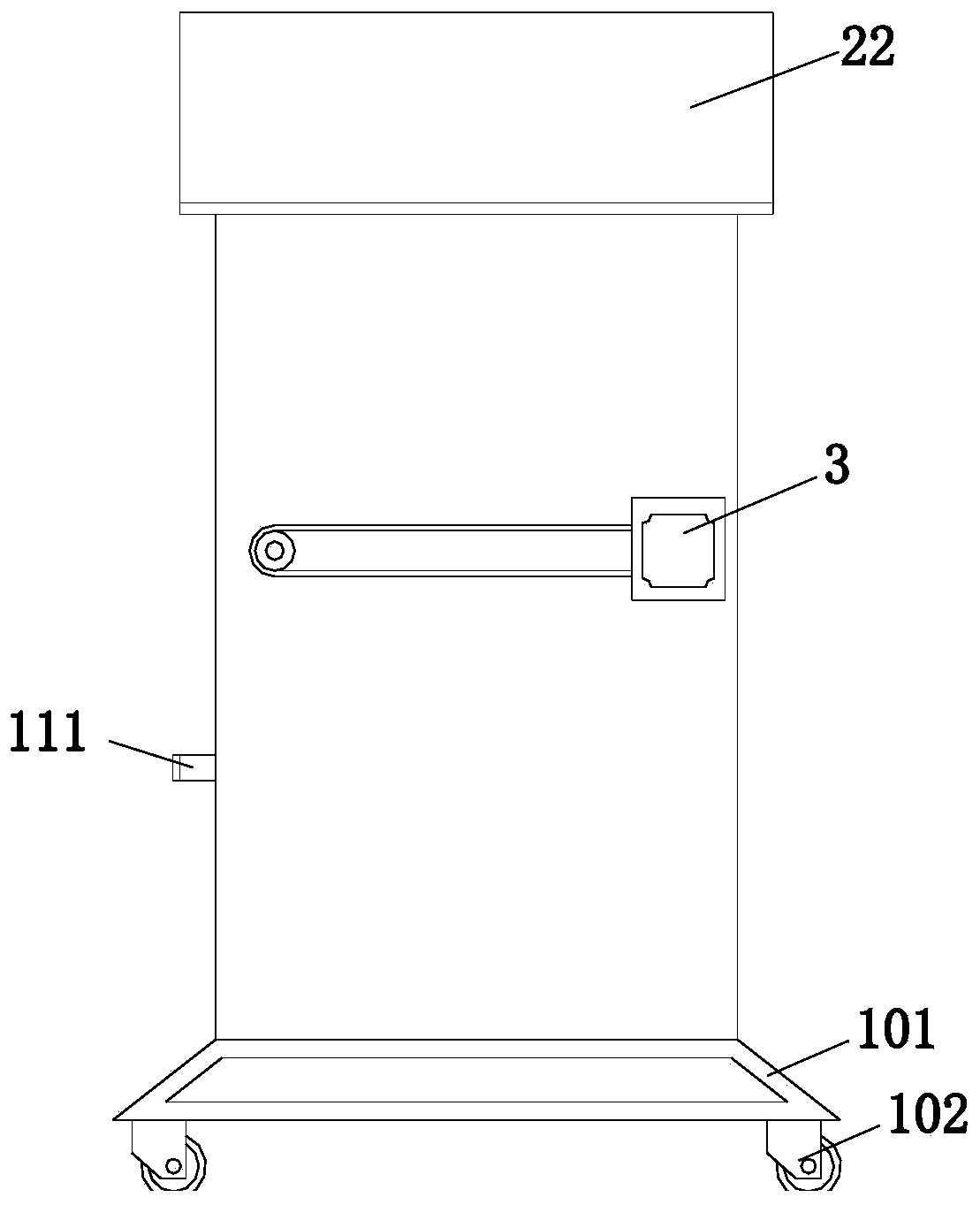

Transformer capable of being conveniently moved and fixed and achieving cooling function

InactiveCN107731470AEasy to moveEasy to fixTransformers/reacts mounting/support/suspensionTransformers/inductances coolingEngineeringTransformer oil

The invention discloses a transformer capable of being conveniently moved and fixed and achieving a cooling function. The transformer comprises a work box, wherein one side of the bottom of the innerwall of the work box is fixedly connected with a transformer through a transformer fixed installing frame; the bottom of the transformer communicates with a transformer oil storage tank through a first cooling pipe; one side, far away from the transformer, of the bottom of the inner wall of the work box is fixedly connected with a cooling machine case; one side of the bottom of the inner wall of the cooling machine case is fixedly connected with a circulation pump; the transformer oil storage tank communicates with the circulation pump through a liquid guide pipe; a transformer oil cooling baris fixedly connected in the middle position of the bottom of the inner wall of the cooling machine case. The transformer relates to the technical field of electric equipment. The transformer capableof being conveniently moved and fixed and achieving the cooling function solves the problem to achieve the stable cooling and temperature reduction on the transformer, the cable sorting and the rain shielding; the moving stability and the fixation of the integral equipment can be ensured; the work stability and the work efficiency of the transformer are ensured; the high-efficiency work is realized; the damage probability is reduced.

Owner:佛山杰致信息科技有限公司

High-speed bogie wheel maintenance virtual simulation training system

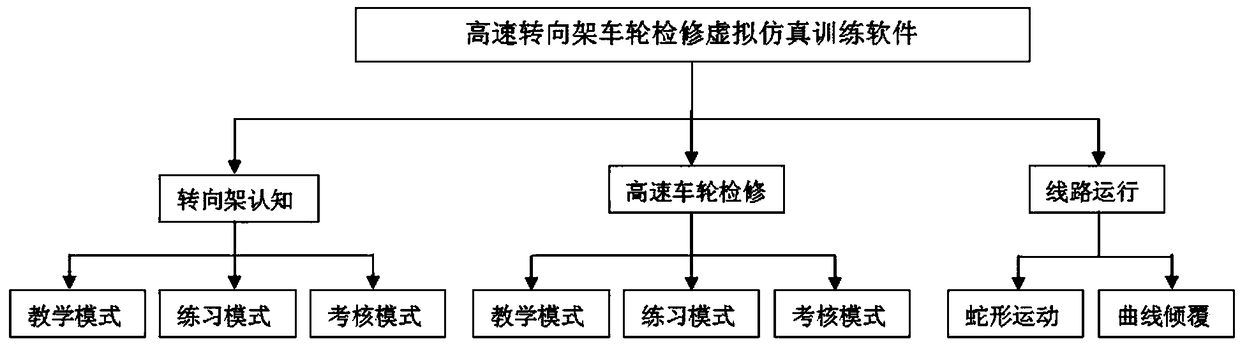

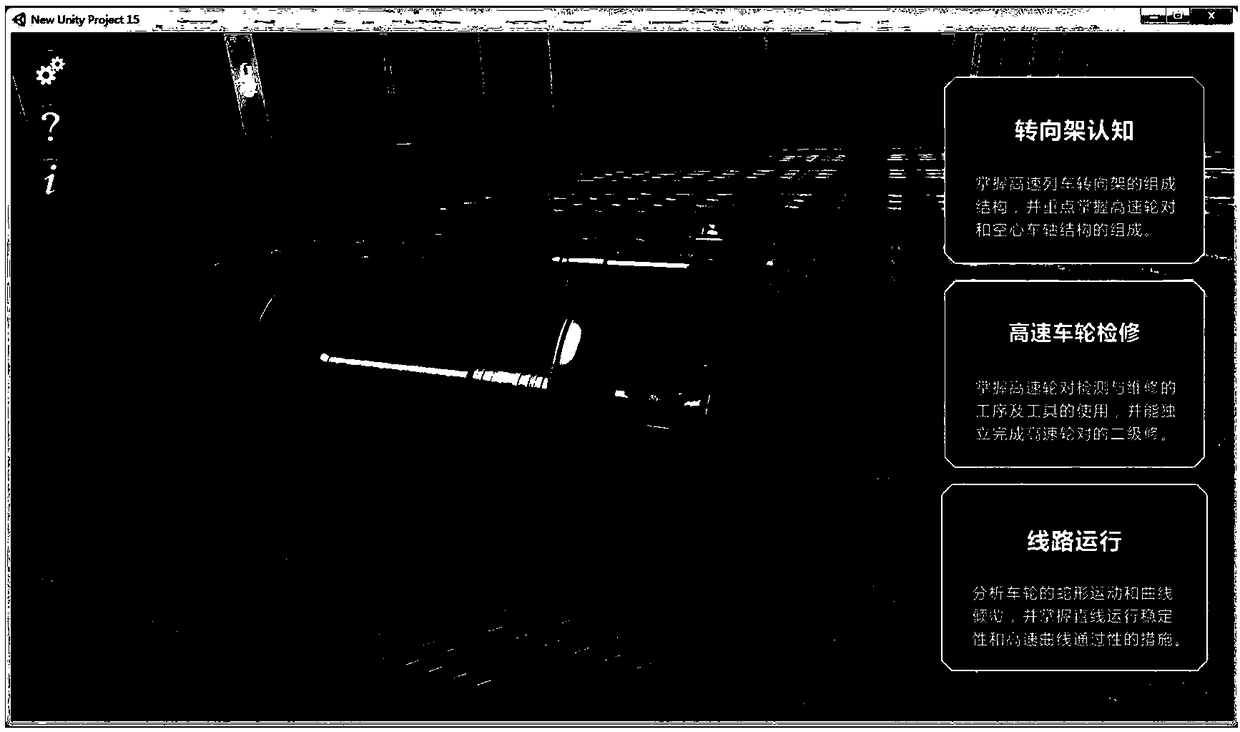

The invention relates to a high-speed bogie wheel maintenance virtual simulation training system. The system comprises a bogie cognition module, a high-speed wheel maintenance module and a line running module. By means of the virtual reality technology, the rail industry standard serves as a basis, and high-speed bogie wheel maintenance virtual simulation training software developed through careerplanning is also used so that the three problems that rail vehicle experiments are difficult, practical training is difficult and practice is difficult can be solved; the practical problem that railvehicle equipment is expensive and accordingly multi-people repeated training cannot be conducted can be solved; the problems that the fault phenomenon coverage is not complete, the identification degree is low, and measurement and control points are difficult to master during maintenance can be solved; digital simulation of complex, core and high-precision part practical training of rail vehiclesis achieved; the method is applied to teaching, training and examining links of vehicle structural design, mechanical analysis, virtual assembly and maintenance.

Owner:CHANGCHUN NORMAL UNIVERSITY

Book collating device

Owner:INVENGO INFORMATION TECH

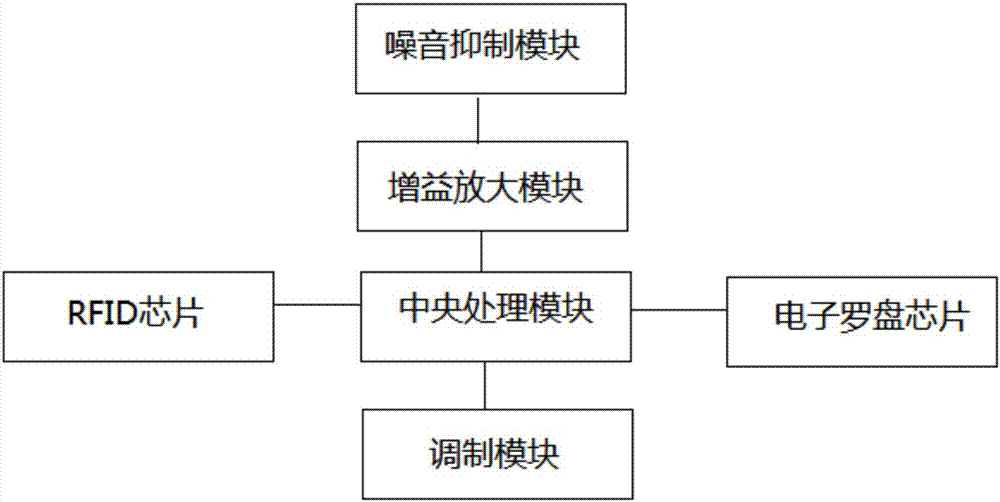

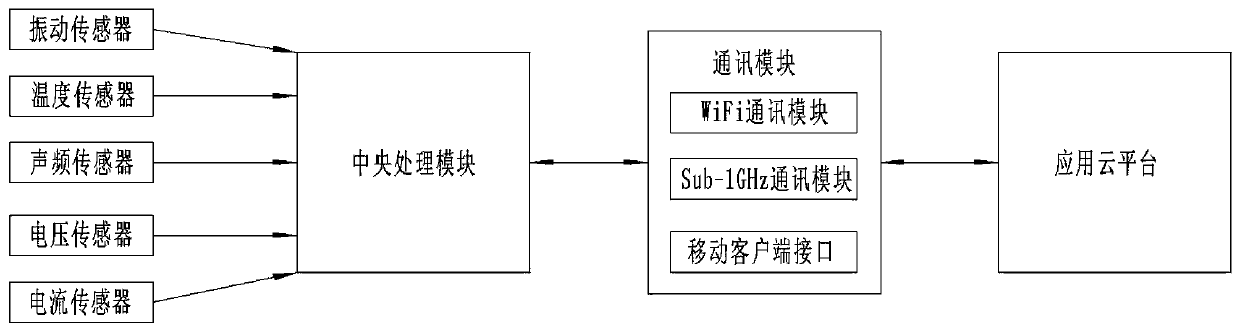

Motor monitoring method

InactiveCN110703094AEffective monitoringEffective data collectionDynamo-electric machine testingElectric machineData acquisition

The invention discloses a motor monitoring method. The motor monitoring method comprises the following steps: S1: establishing identity information for a tested motor; S2: integrating a data collection module for the tested motor; S3: integrating the data collection module with a central processing module; S4: encoding, by the central processing module, the collected data; S5: electrically connecting the central processing module with a communication module; S6: establishing a communication channel between the communication module and an application cloud platform; and S7: decoding and analyzing, by the application cloud platform, the received data. Fast and effective monitoring is performed on large-scale motors, the application cloud platform monitors different types of motors produced by different manufacturers, and build a database based on the same type of motors. The monitoring object can be set as a motor bearing, so a lot of work is reduced, feature monitoring can be performedmore easily, and qualitative analysis can be performed on the motor bearing very easily according to multi-dimensional data collection, so that the running health state and the service of the bearingare judged.

Owner:联桥网云信息科技(长沙)有限公司

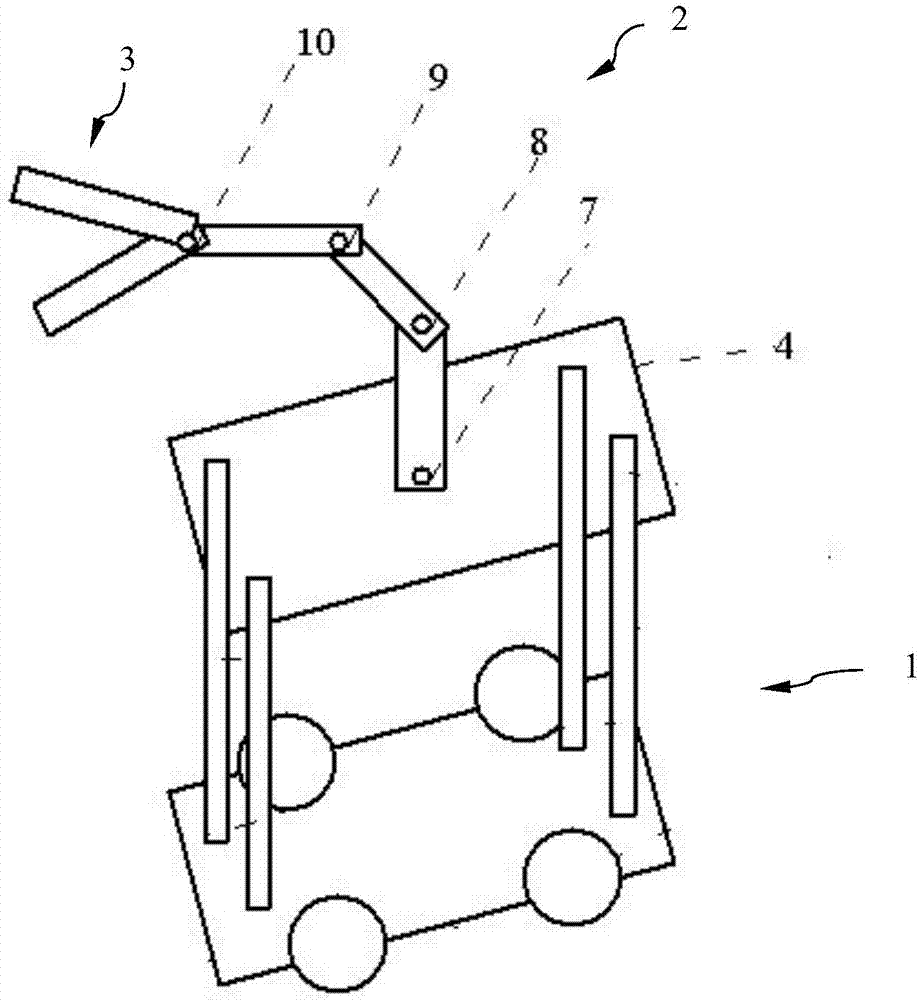

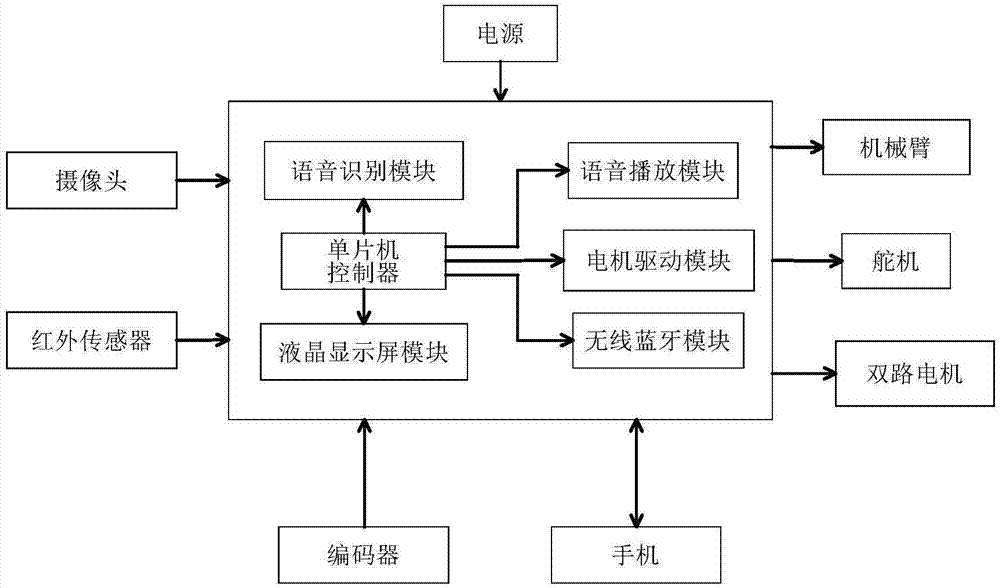

Multi-mode intelligent toy-collecting robot

InactiveCN107253203ASolve handling and grabbing problemsReduce volumeManipulatorImaging processingMotor drive

A multi-mode intelligent toy-collecting robot comprises a four-wheeler, a mechanical arm and a control system, wherein a plurality of infrared sensors, motors provided with small-sized encoders and located on the inner sides of rear wheels of the four-wheeler, motor driving modules connected with the motors and arranged on the motors and a steering engine located between two front wheels of the four-wheeler and connected with the two front wheels are fixed on the four-wheeler; the mechanical arm is carried on an intelligent vehicle device, comprises a mechanical jaw, a camera and a mechanical arm controller, and is used for grabbing toys; the control system is connected with the intelligent vehicle device and the mechanical arm, and comprises a display screen, a power source, a voice device and a main controller; the main controller comprises a system board and a main board, and the main board comprises an infrared induction interface, a camera interface, an encoder interface, a power source interface, a motor interface, a display screen interface and a voice interface; and the main board is further provided with a voice recognition module, a voice playing module, an encoder speed-measuring module, a mechanical arm controller module, an image processing module and a bluetooth communication module.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

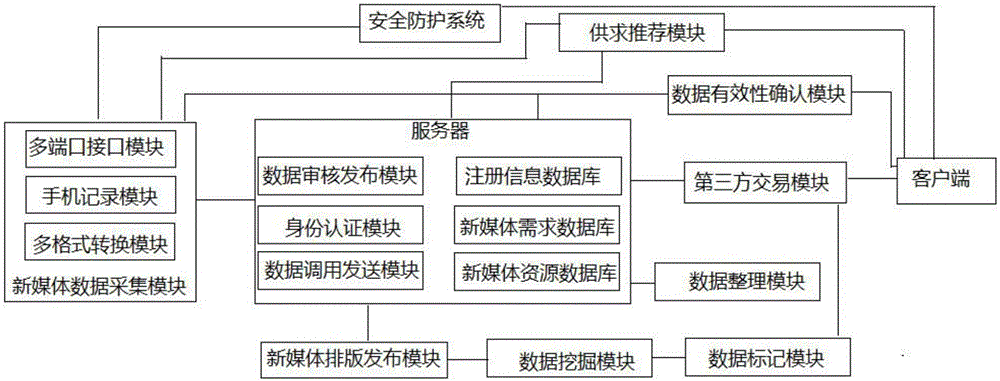

Public service platform of new media

InactiveCN106339925AEasy to manageRealize automatic calculationBuying/selling/leasing transactionsClient-sideThird party

The invention discloses a public service platform of new media. The platform comprises a new media data acquisition module, a client, a third-party transaction module, a server for data checking, a supply and demand recommendation module, a data validity confirmation module, a data arrangement module, a data mining module, a data marking module and a new media typesetting and publishing module. According to the public service platform of new media, resource data of new media is arranged and gathered, and convenience is provided for management; and the supply and demand matching degree is calculated automatically while demand information and new media resources are published, automatic recommendation is completed, the success rate of transaction is improved greatly, user time is saved, and published information is updated timely.

Owner:BOHAI UNIV

Constant temperature fireproof power distribution cabinet

InactiveCN110311313AImprove cooling and heat dissipationSimple structureBus-bar/wiring layoutsSubstation/switching arrangement cooling/ventilationEngineeringRadiation

The invention discloses a constant temperature fireproof power distribution cabinet and belongs to the technical field of a power distribution cabinet. The constant temperature fireproof power distribution cabinet includes a cabinet body, a rotating mechanism, a heat radiation mechanism, a monitoring control mechanism and a wire harness mechanism, wherein a front side wall of the cabinet body is provided with a door plate matched with the cabinet body, the door plate is provided with a lock capable of being locked with the cabinet body, the door plate is provided with a protection assembly, the rotating mechanism is arranged at the top of the cabinet body, two side walls of the cabinet body are provided with multiple vent holes, the monitoring control cabinet is arranged at an upper portion in the cabinet body, the wire harness mechanism is vertically movably mounted in the cabinet body, a bottom wall and a side wall of the cabinet body are provided with a moving assembly and a handleassembly respectively, a top portion in the cabinet body is provided with an illumination lamp, and the rotating mechanism, the heat radiation mechanism and the illumination lamp are electrically connected with the monitoring control mechanism. The constant temperature fireproof power distribution cabinet is advantaged in that the structure is simple, rapid heat radiation operation of the whole cabinet can be realized, efficiency is relatively high, functions are various, and practicality is relatively strong.

Owner:常德三欣电力电子科技有限公司

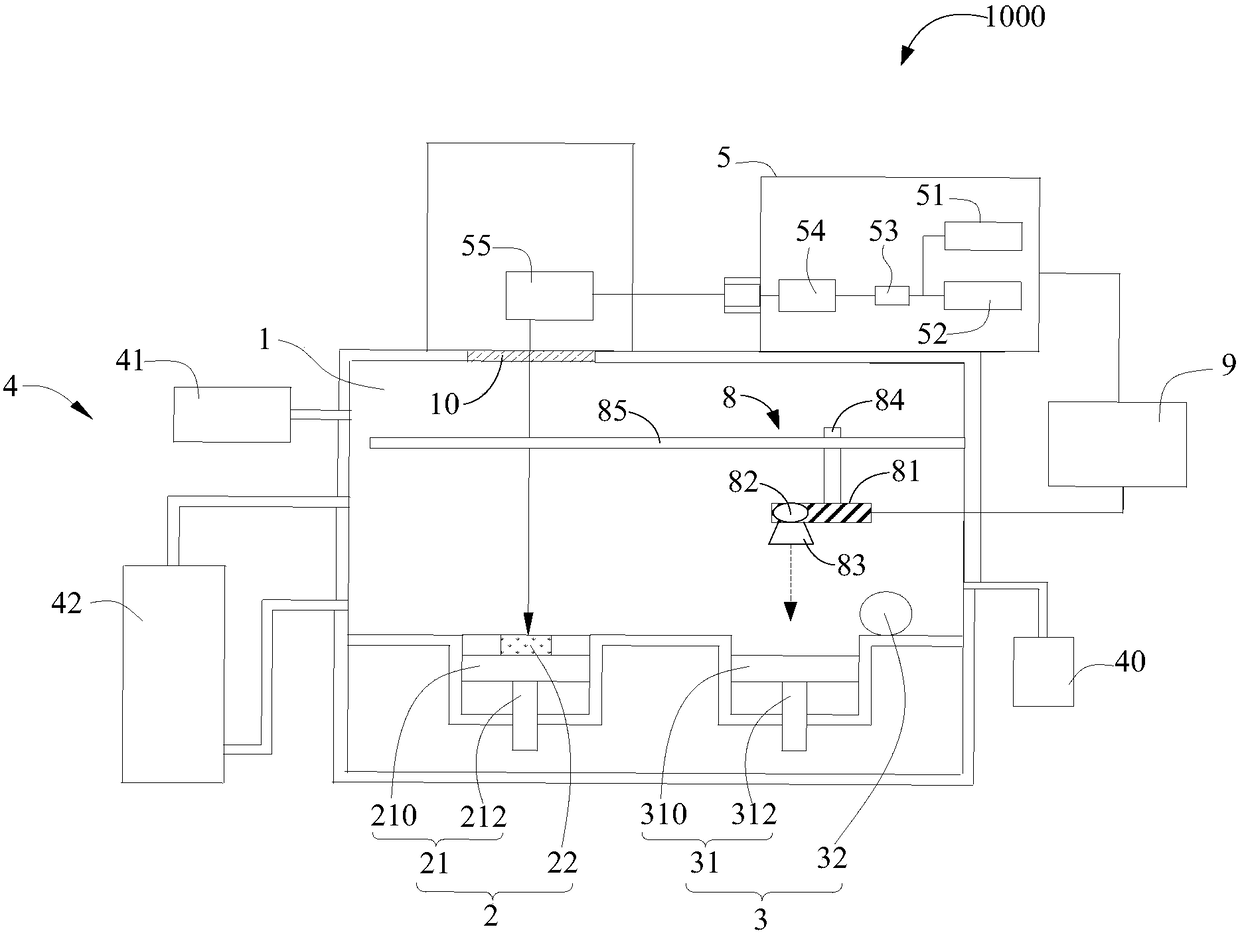

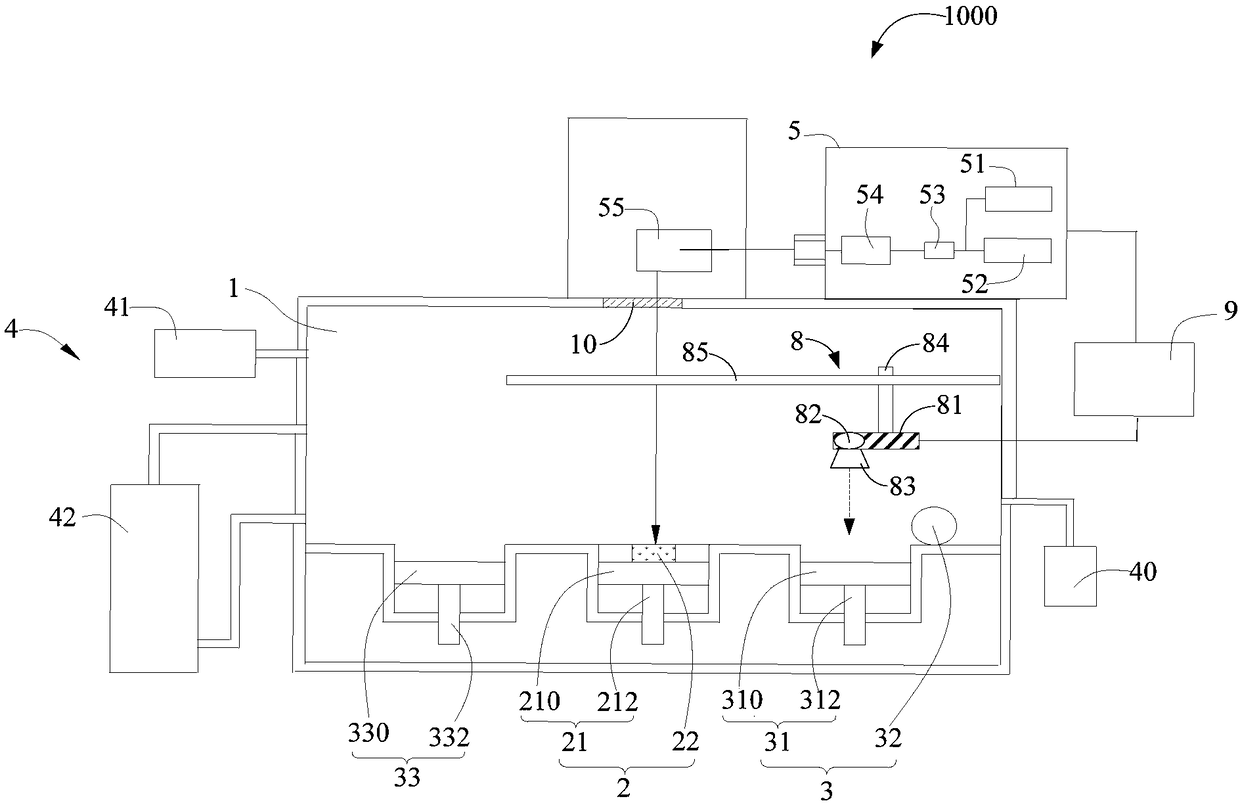

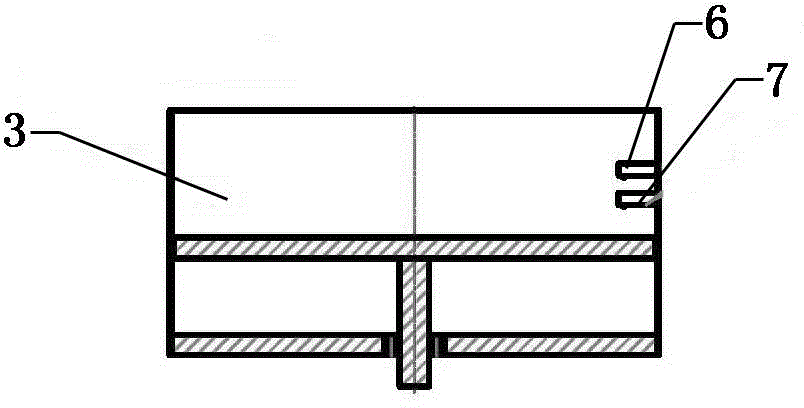

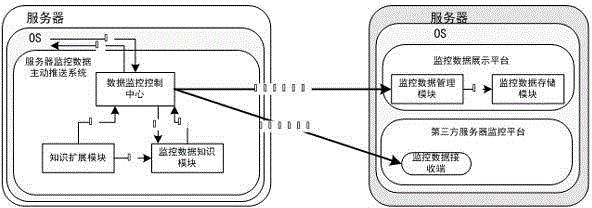

Active monitoring data pushing method of server

InactiveCN103984617ARealize acquisitionAchieve finishingHardware monitoringTransmissionActive monitoringStructure of Management Information

The invention provides an active monitoring data pushing method of a server. The active monitoring data pushing method of the server is characterized in that a data active pushing agent system is installed on an operation system of the server so as to combine monitoring methods of various servers, unify monitoring data formats and send completed and readable monitoring data to a monitoring service end, the data active pushing agent system structurally comprises a data monitoring control center (1), a knowledge expansion module (2), a monitoring data management module (3), a monitoring data knowledge module (4) and a monitoring data memory module (5), the data active pushing agent system performs modularization processing on collection, collation, analysis and transmission of the monitoring data and performs expansion of monitoring modes, and the whole collection process of the monitoring data is completed by being globally controlled through the data monitoring control center. Furthermore, a user can install an agent program of the data active pushing agent system on the operation system of the server, and then collection, collation, analysis and display of complex monitoring data can be achieved.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com