Feeding and finishing system and process of aluminum and plastic caps

A technology of aluminum caps and plastic caps, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of high damage rate of aluminum caps, wear and tear of raw material caps, and high noise, so as to improve yield, reduce deformation caps, and reduce loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The aluminum cap and plastic cap feeding and sorting system of the present invention is composed of an aluminum cap feeding and sorting part, a plastic cap feeding and sorting part, a pneumatic control part, a photoelectric control part and an automatic controller.

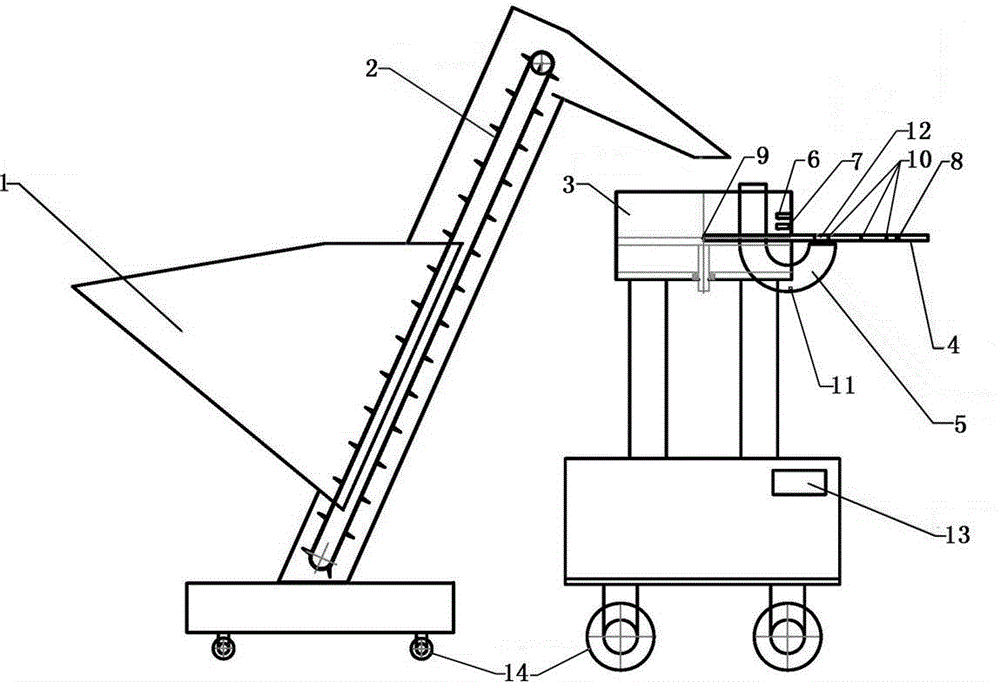

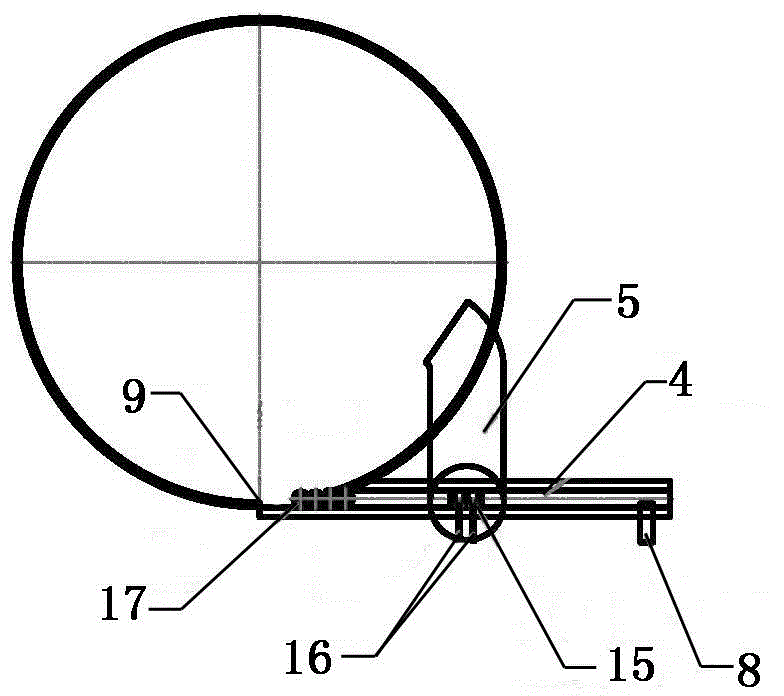

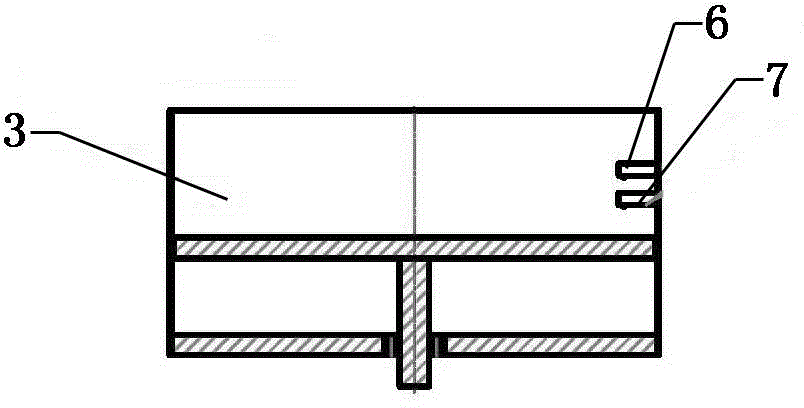

[0036] Such as figure 1 As shown, the aluminum cap feeding and sorting part is composed of an aluminum cap feeding mechanism and an aluminum cap finishing mechanism: the aluminum cap feeding mechanism is composed of a first raw material hopper 1 and a first baffle conveyor belt 2; figure 2 As shown, the aluminum cover sorting mechanism is composed of the first rotating centrifugal bin 3 and the first screening track 4: the first rotating centrifugal bin 3 is composed of a rotatable bottom aluminum cover sorting tray and a surrounding enclosure around the aluminum cover sorting tray. barriers, such as Figure 7 As shown, the central area of the aluminum cover sorting tray is the aluminum cover stacking a...

Embodiment 2

[0046] a, the aluminum cover 17 in the first raw material hopper 1 is transported to the aluminum cover stacking area 25 of the first rotary centrifugal bin 3 through the first baffle conveyor belt 2, and the centrifugal force produced when the aluminum cover sorting tray rotates The cover 17 is thrown to the edge, and due to the effect of the dot-shaped protrusion 33, the aluminum cover 17 is distributed between the protrusions 34 with a slope surface with the cover opening facing up or down, and then between the first rotating centrifugal bin 3 and the The interface of the first screening track 4 enters the first screening track 4 under the impetus of the high-pressure air blown by the first blowing pipe 9, and some second blowing pipes 10 arranged along the first screening track 4 blow out high-pressure air to push the aluminum The cover continues to move along the first screening track 4 to the first penetrating section 12; when the aluminum cover 17 moves to the rectangula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com