Patents

Literature

447results about How to "Improve finishing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

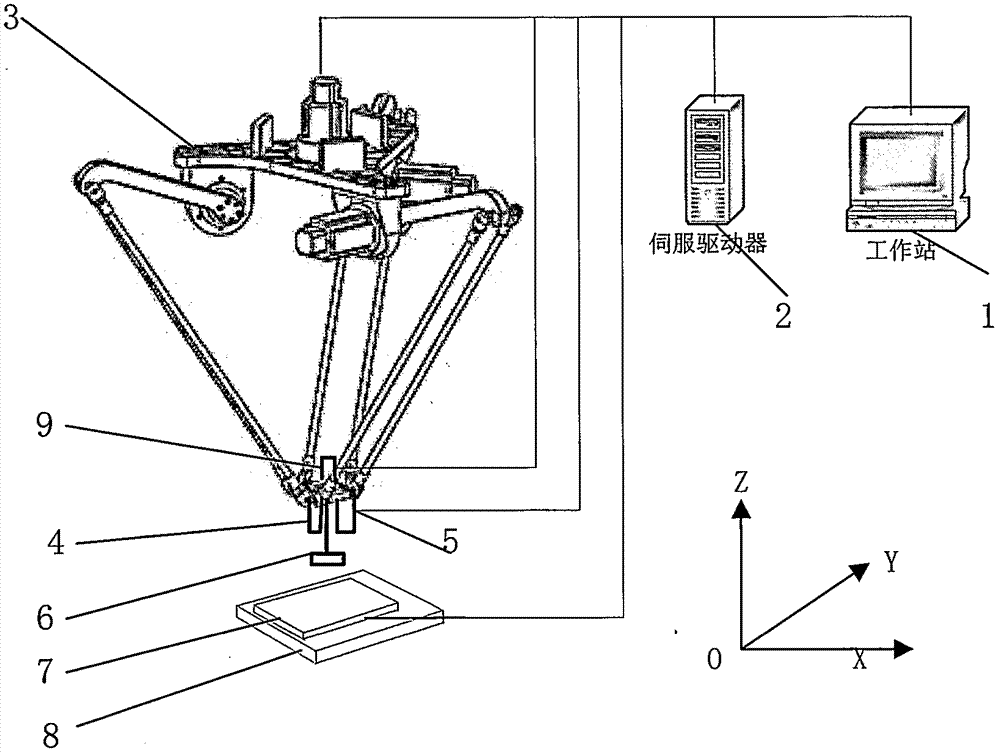

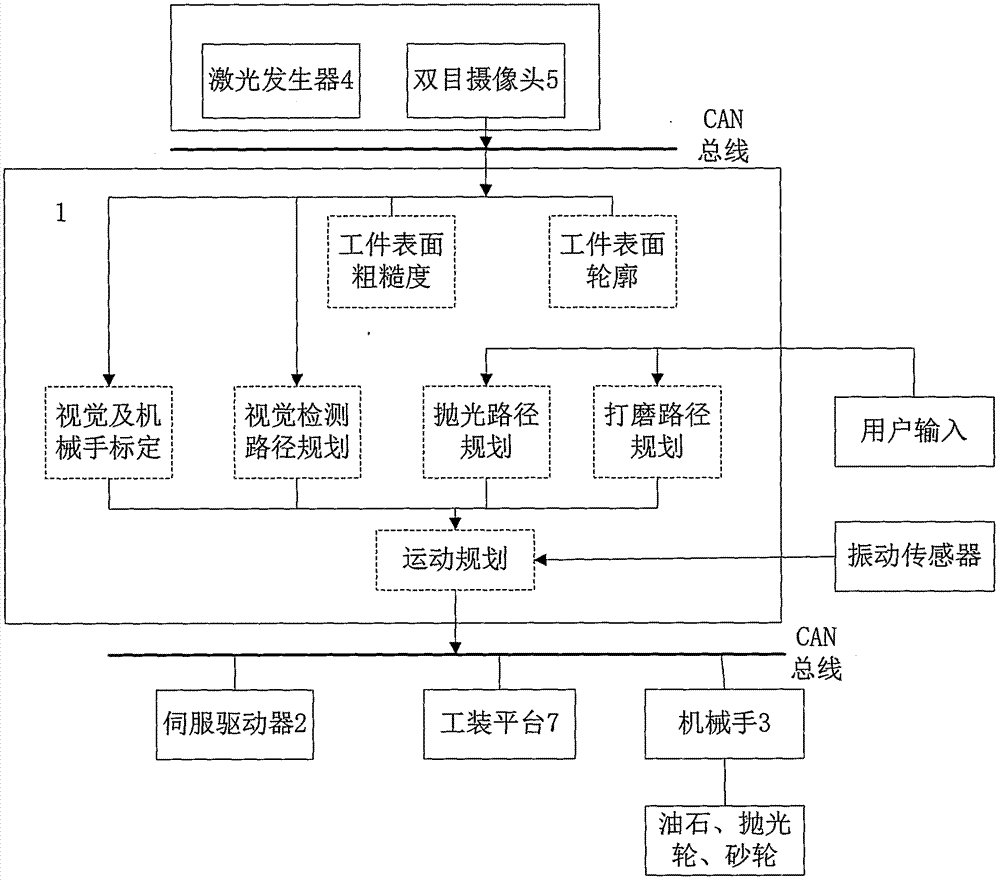

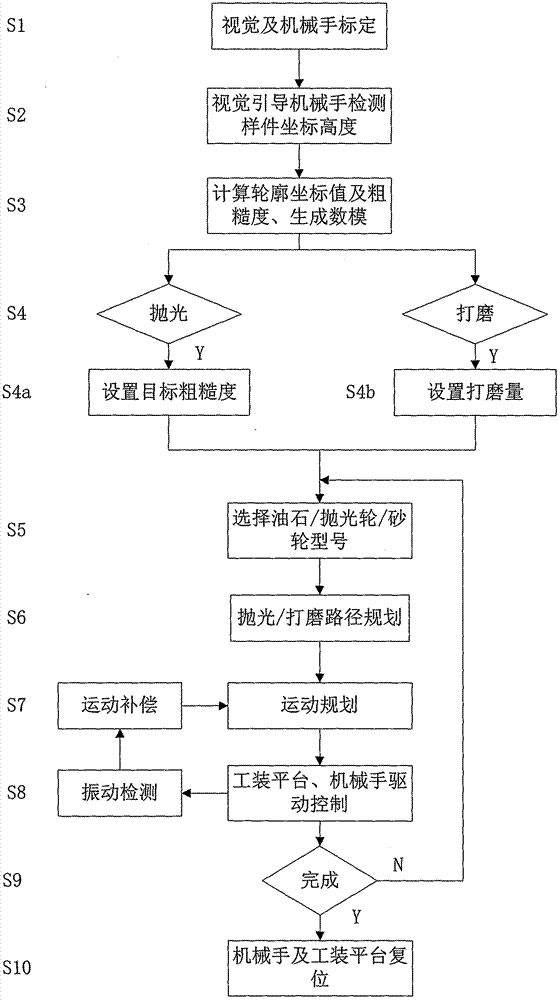

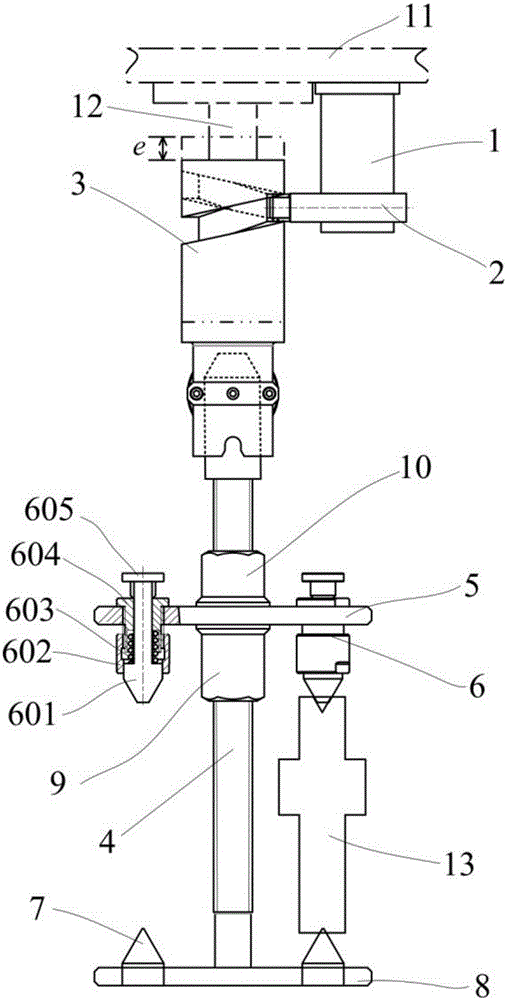

Complex curved face grinding and polishing system and method

InactiveCN107052950AFlexible setting methodHigh speedProgramme-controlled manipulatorGrinding feed controlThree degrees of freedomEngineering

The invention relates to a complex curved face grinding and polishing system and method. The system comprises a three-degree-of-freedom manipulator, a visual detection device, a vibrating sensor and a three-degree-of-freedom tool platform. An installation clamp is arranged at the tail end of the manipulator and can install an oilstone, a polishing wheel and a grinding wheel. The visual detection device comprises a laser generating device and a binocular camera, is installed on the manipulator, and detects the outline and roughness of a workpiece. During working, the workpiece is installed on the three-degree-of-freedom tool platform. The visual detection device guides the manipulator to scan the outline of the workpiece, a three-dimensional outline data model is generated, and the roughness is analyzed. Polishing or grinding setting can be conducted on a work station. During grinding, setting can be conducted in three modes that a referential three-dimensional data model is compared with an actually measured workpiece three-dimensional data model, modification is conducted on the actually measured three-dimensional data model with a drawing tool, and grinding data are directly set on the actually measured three-dimensional data model.

Owner:上海莫亭机器人科技有限公司

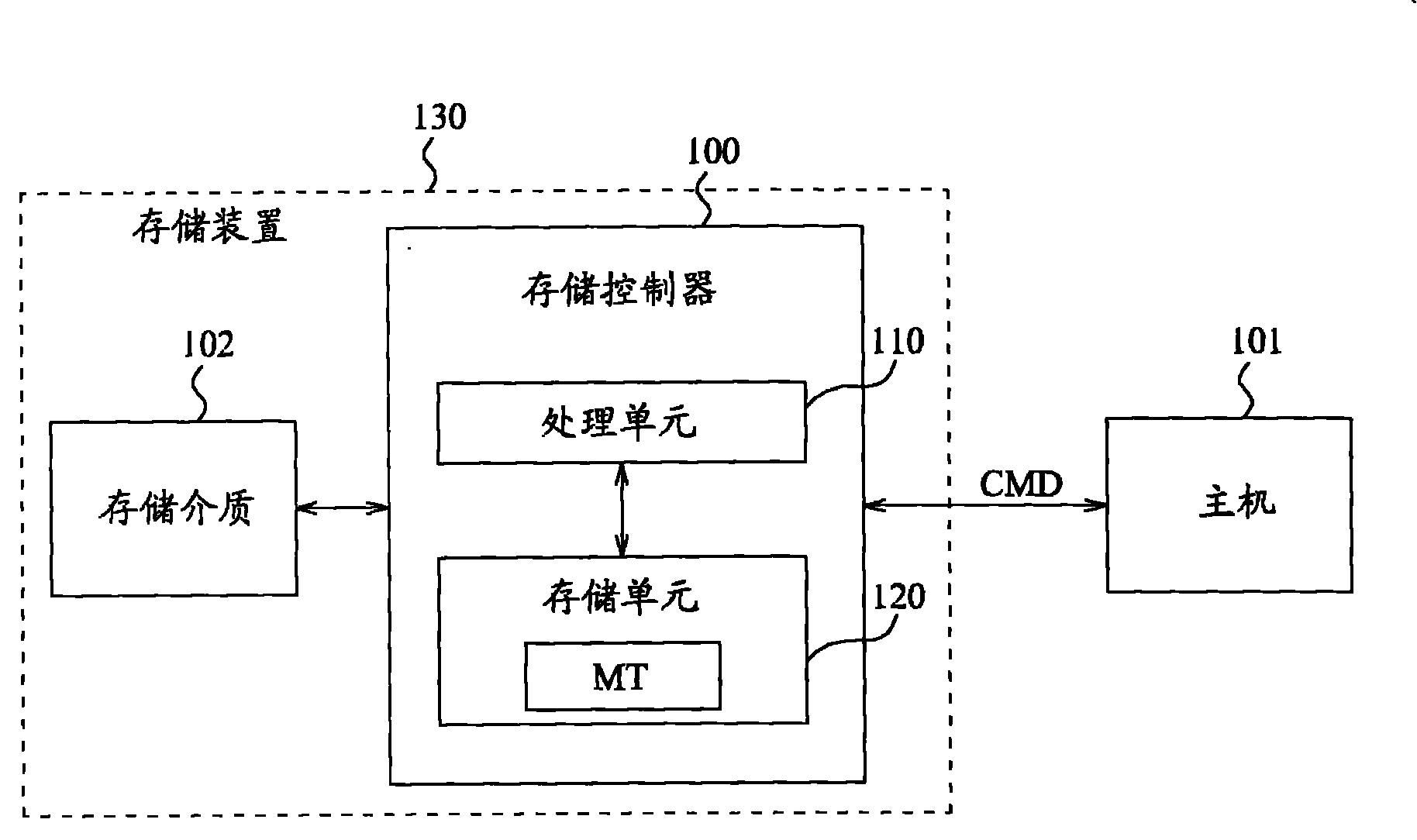

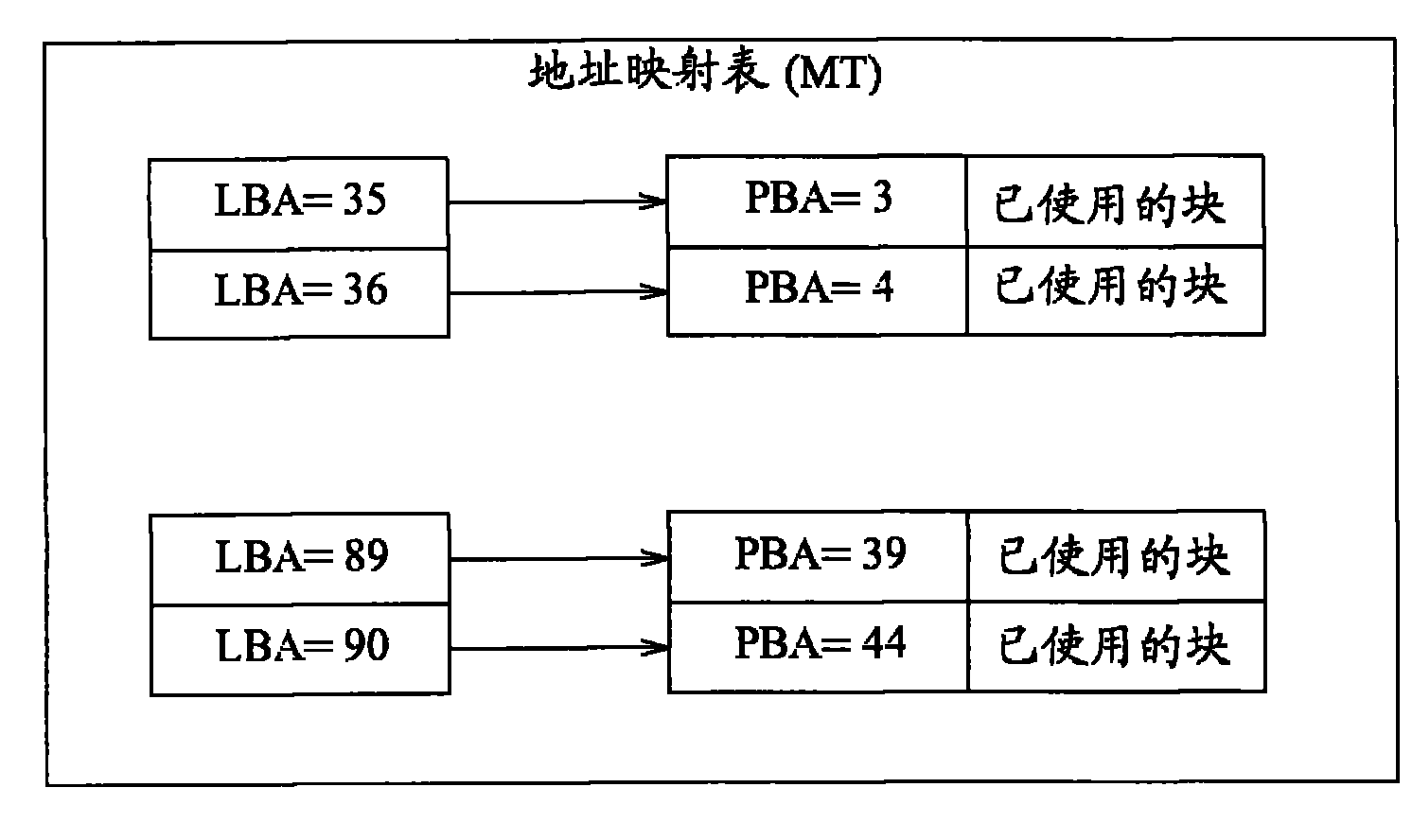

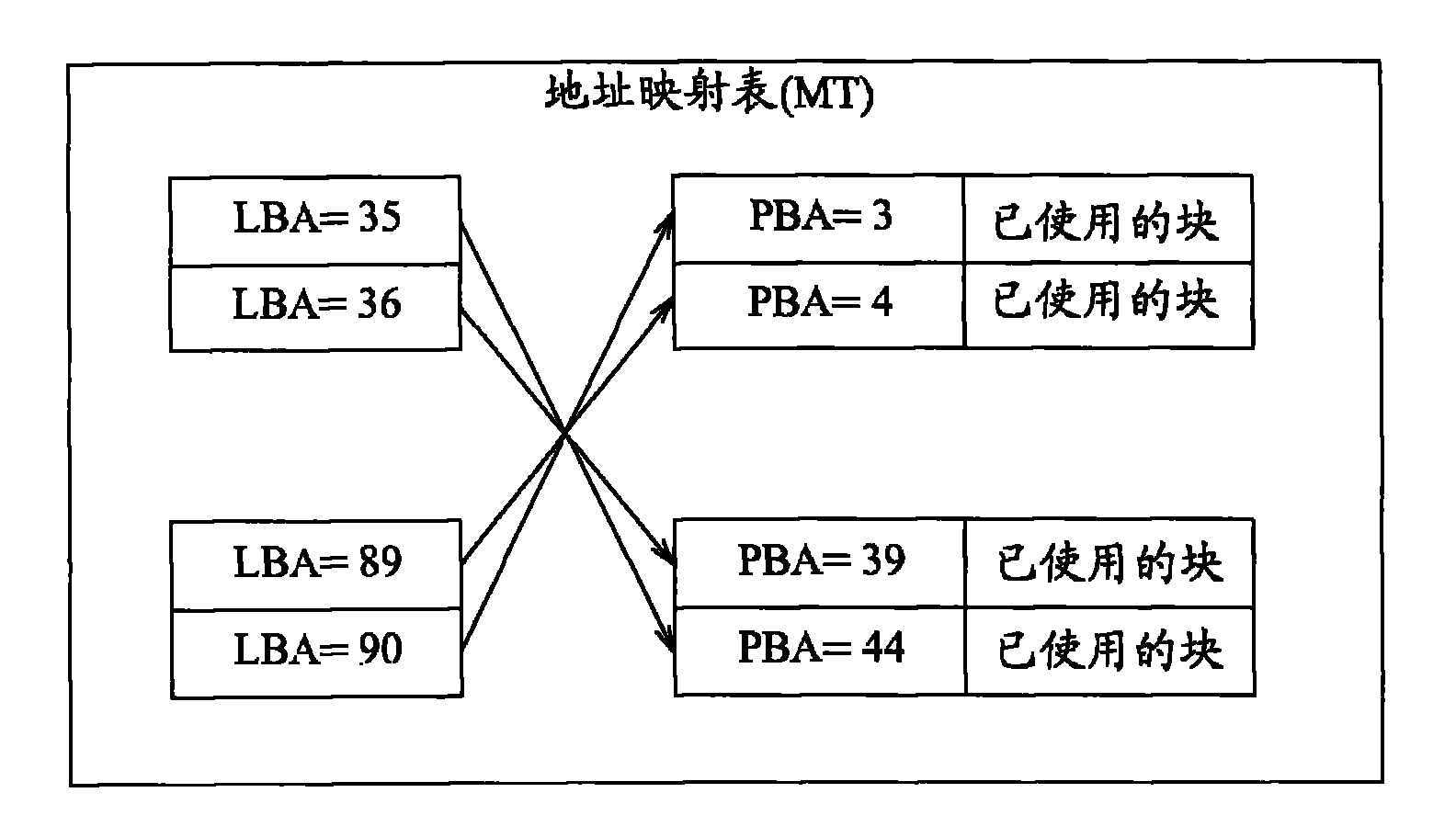

Method of managing data access of a storage medium and storage controller

ActiveCN102063377AImprove finishing effectMemory architecture accessing/allocationInput/output to record carriersControl storeData access

The invention relates to a method of managing data access of a storage medium and a storage controller. The storage controller for managing data access of the storage medium comprises: a storage unit, storing an address mapping table to record at least a physical address of a first data stored in the storage medium, where the physical address of the first data is mapped to a logical address of the first data; and a processing unit, coupled to the storage unit, wherein when receiving a command for handling at least the first data in the storage medium internally, the processing unit processes the address mapping table to serve the command without controlling the storage medium to physically accessing at least the first data stored therein; a plurality of command sets are sent through effective load data of the single command; and the processing unit searches the plurality of command sets sent by the single command for subsequently updating the address mapping table so as to respond the single command. One advantage of the invention is to improve the performance for collating the paper fragmentation.

Owner:MEDIATEK INC

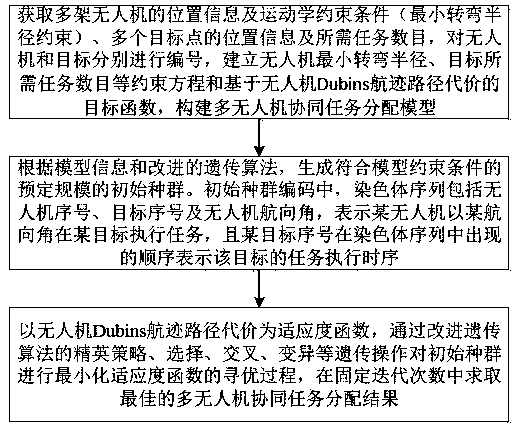

Multi-unmanned aerial vehicle cooperative task allocation method based on improved genetic algorithm

InactiveCN110766254AImprove collaborationSolving the Problem of Efficient Resource AllocationResourcesPosition/course control in three dimensionsSimulationGenetics algorithms

The invention provides a multi-unmanned aerial vehicle cooperative task allocation method based on an improved genetic algorithm. The method comprises the following three steps: establishing constraint equations such as the minimum turning radius of an unmanned aerial vehicle and the number of tasks required by a target, and a multi-unmanned aerial vehicle cooperative task allocation model based on Dubins flight path cost; generating an initial population of a predetermined scale conforming to model constraint conditions; taking the Dubins track path cost of the unmanned aerial vehicle as a fitness function, and iteratively updating the initial population by using genetic operations such as elite strategy, selection, crossover, variation and the like of an improved genetic algorithm to generate a feasible solution which minimizes the target function in fixed iteration times, and taking the feasible solution as a result of multi-unmanned aerial vehicle cooperative task allocation and route planning. The method has wide application value in multi-unmanned aerial vehicle cooperative task combat, is beneficial to implementation of multi-unmanned aerial vehicle multi-target cooperativetask execution, and improves the task completion efficiency. The method has important significance in the field of multi-unmanned aerial vehicle cooperative control.

Owner:深圳市白麓嵩天科技有限责任公司

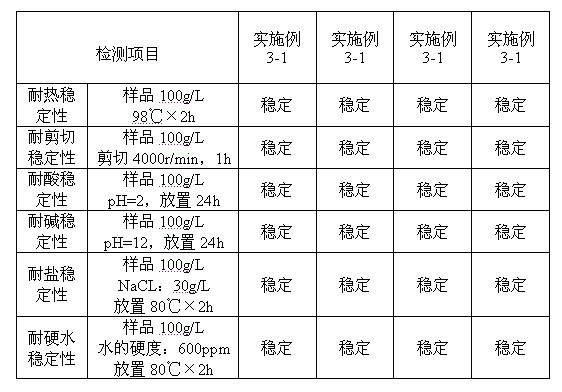

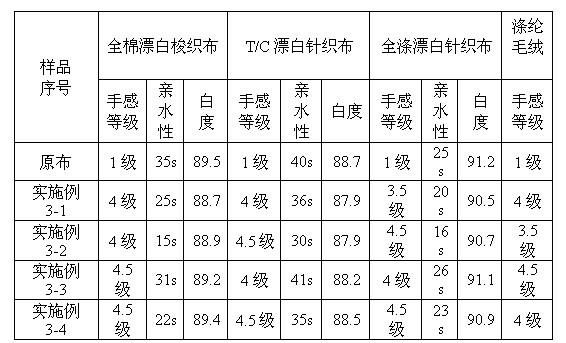

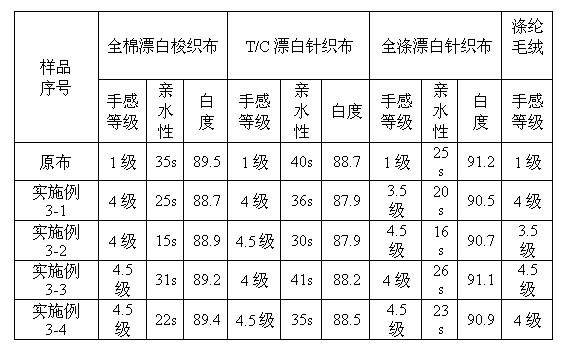

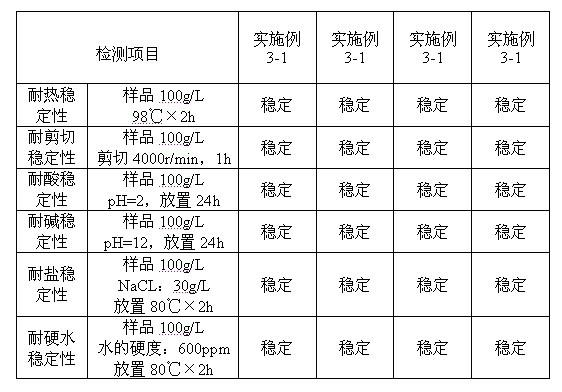

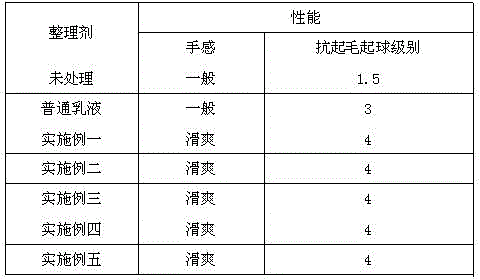

Supersoft hydrophilic block silicone oil compound and preparation method thereof

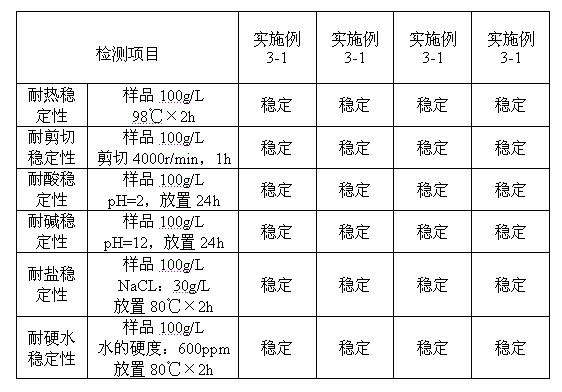

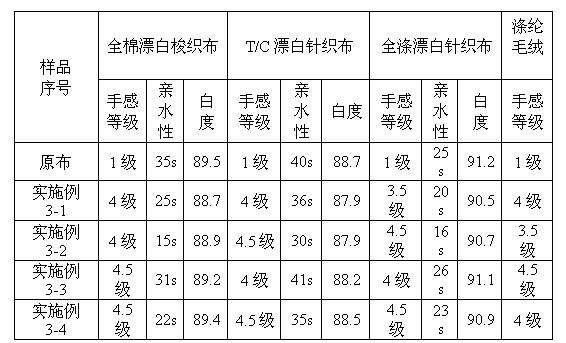

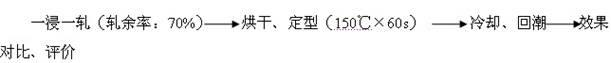

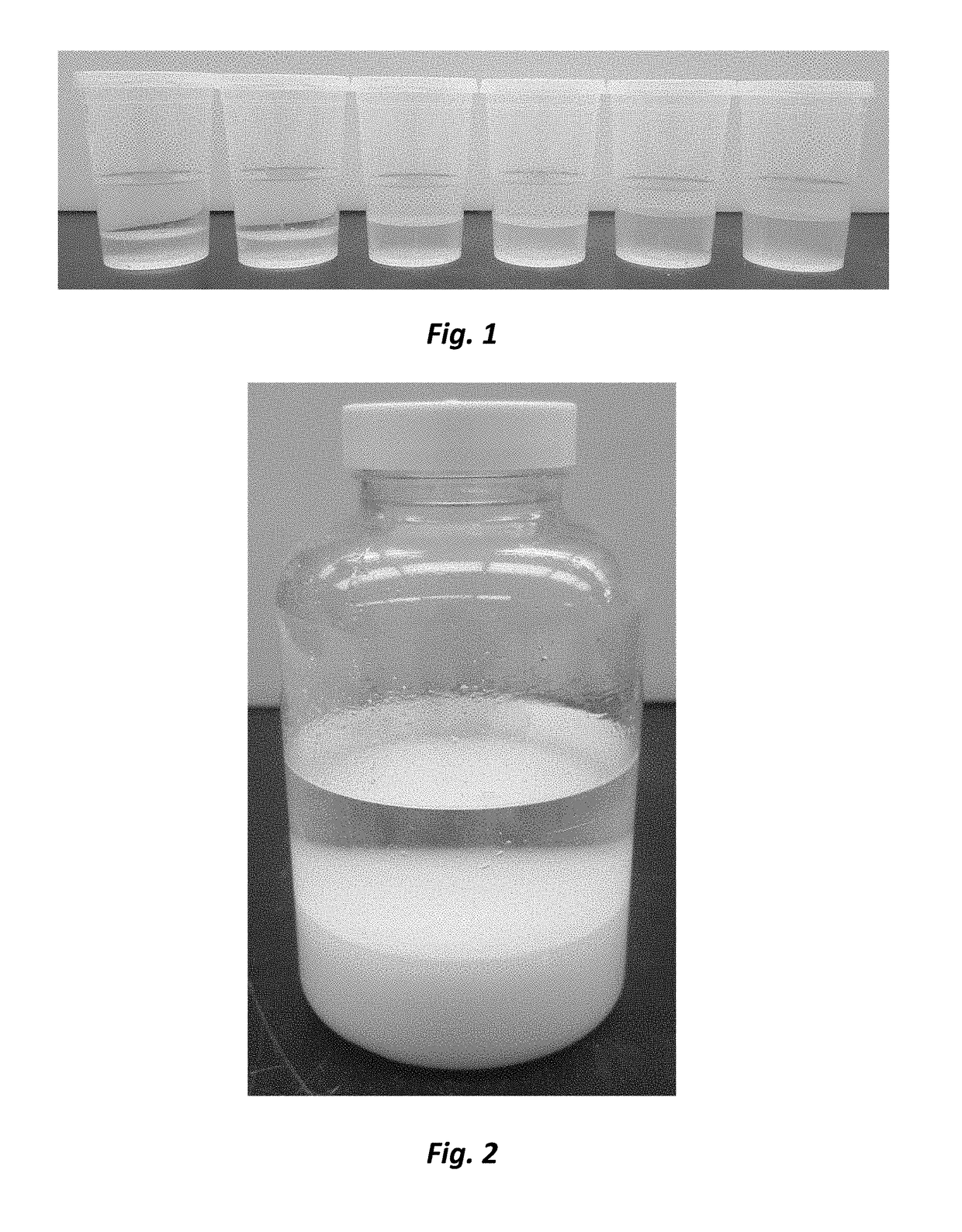

The invention relates to the field of textile finishing agent, in particular to supersoft hydrophilic block silicone oil compound and a preparation method thereof. The supersoft hydrophilic block silicone oil compound is composed of cations of the structural formula, wherein the n1 is the number of 5 to 10, the R is polyether group, and the degree of polymerization ranges from 3 to 50. The supersoft hydrophilic block silicone oil compound is applicable to handle finishing of fabric knitted by one or multiple fibers of cotton, dacron, chinlon and acrylic fibers and has softness, smoothness and looseness effects superior to those of amino-modified silicone oil, has excellent stability in acid and alkali resistance, electrolyte resistance, high temperature resistance, shearing resistance and the like and thoroughly solves the problems of easy demulsification, floating oil, roll banding, difficulty in refinishing and the like.

Owner:RUNHE ORGANICSILICONE NEW MATERIAL

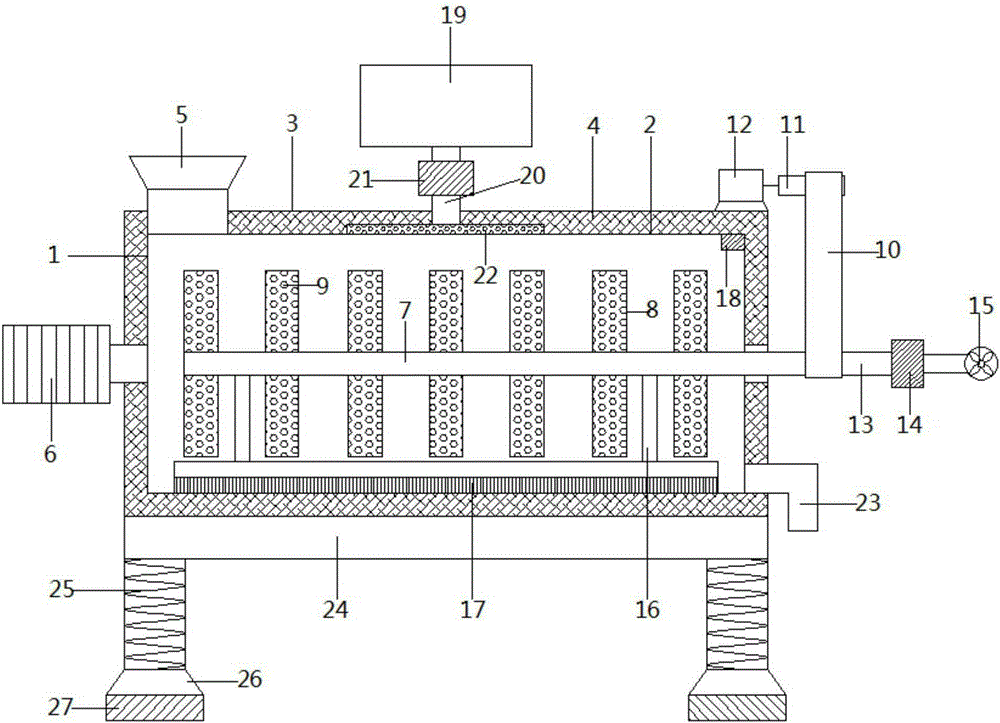

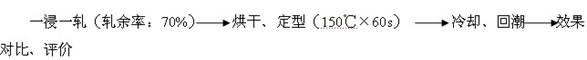

Novel pilot test setter

InactiveCN101660253AReach the gram weight requirementRequirements for Achieving Buffer ExpansionHeating/cooling textile fabricsStretchingEngineeringFar infrared

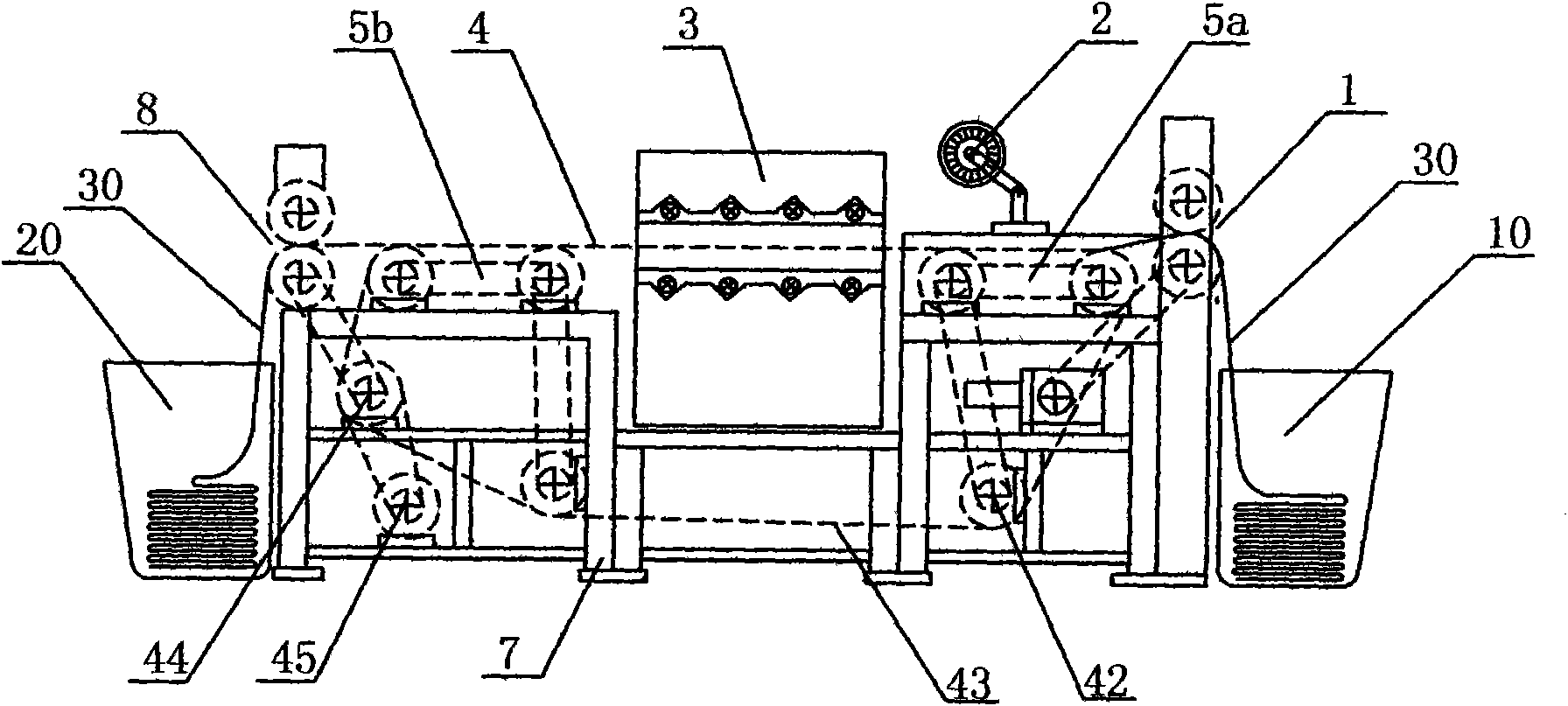

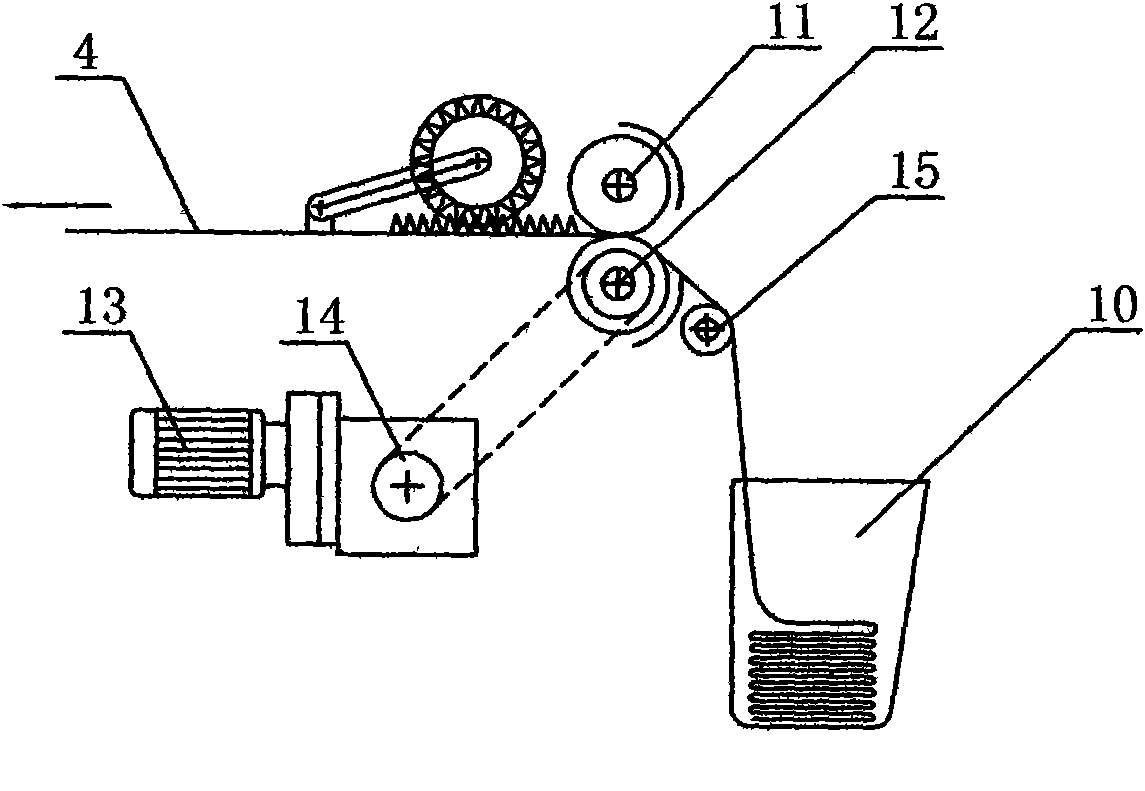

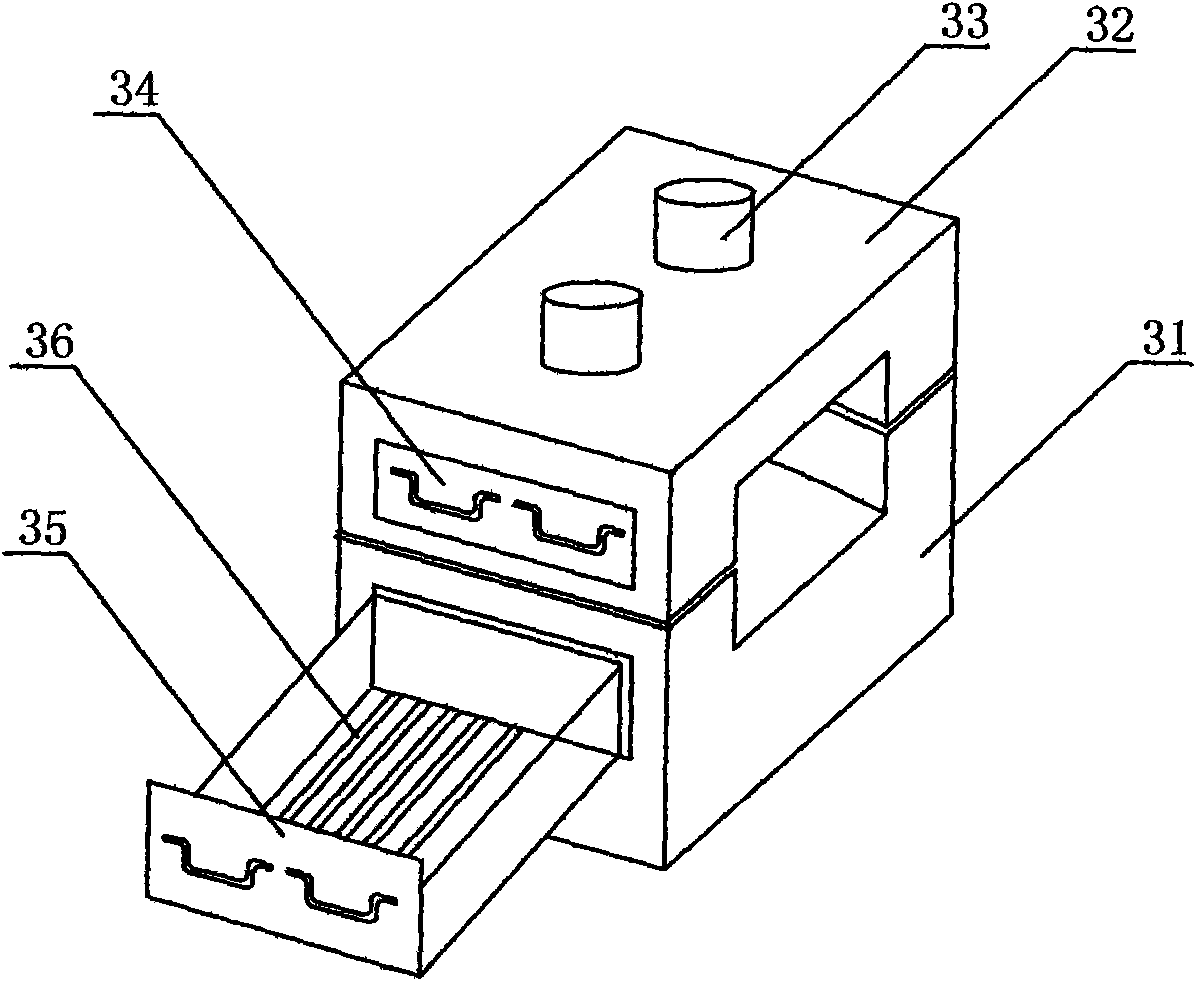

The invention discloses a novel pilot test setter which belongs to the technical field of pilot test dyeing equipment and is characterized by comprising a rack, cloth over-feeding actuating devices, sectional type stretch expanders, an infrared oven and a cloth discharge cooling device, wherein a cloth feeding barrel and a cloth discharging barrel are installed at two ends of the rack so as to beused for arranging cloth samples, an actuating device is installed on the rack and used for connecting a cloth feeding end with a cloth discharging end so as to complete the delivery of the cloth samples; the cloth over-feeding actuating devices are sequentially installed along the actuating device from the cloth feeding end to the cloth discharging end, and installed at the cloth feeding end, adjust the linear velocity when the cloth samples enter and realize over-feeding function; the sectional type stretch expanders are installed at two sides of the infrared oven and realize buffering expansion; and the infrared oven is arranged in way of double layer (an upper layer and a lower layer), and conducts infrared drying and setting. The novel pilot test setter integrates the technologies ofheating by far infrared radiation, overfeeding and sectional expansion into a whole, and has the advantages of quick heating rate, short processing time, low energy consumption, high processing efficiency and good finishing effect.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH +1

Method for synthesizing novel reactive ultraviolet absorbent and application thereof

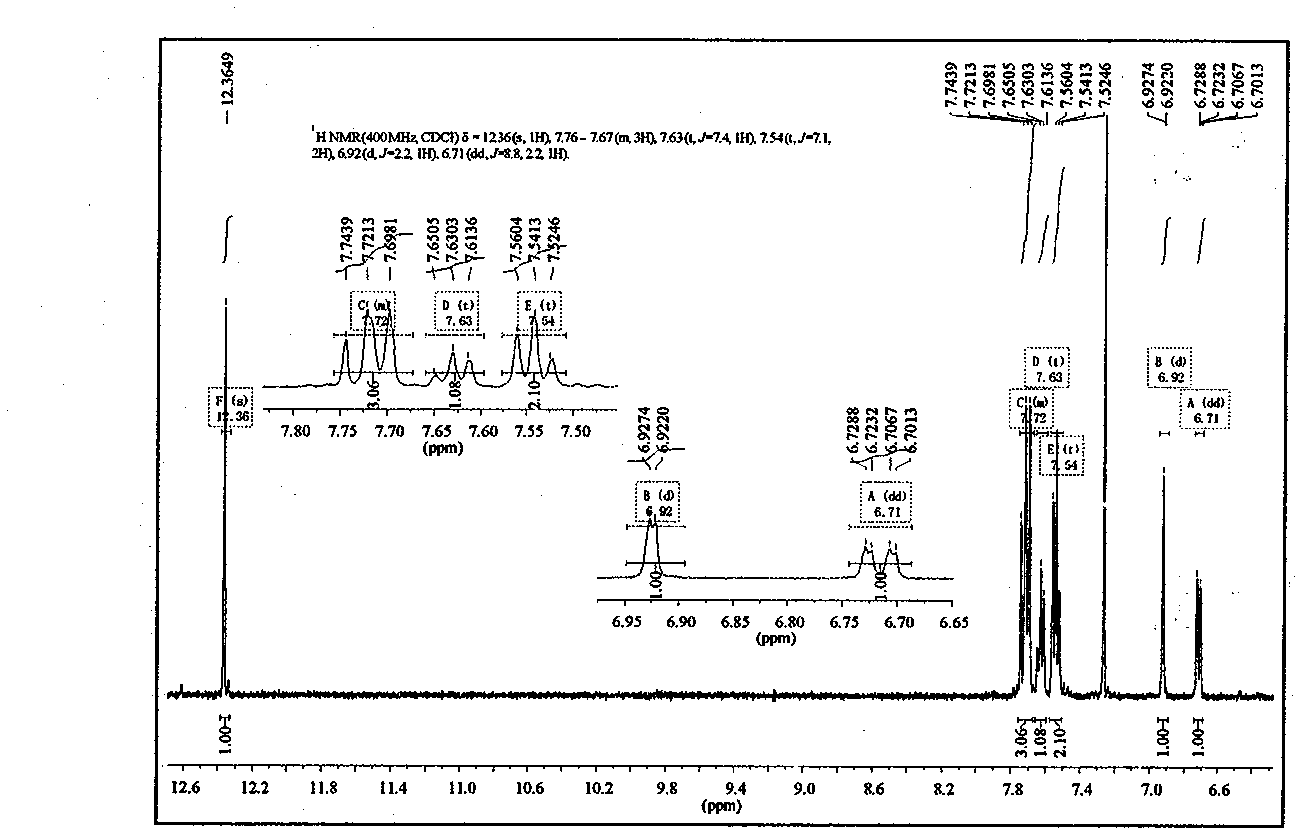

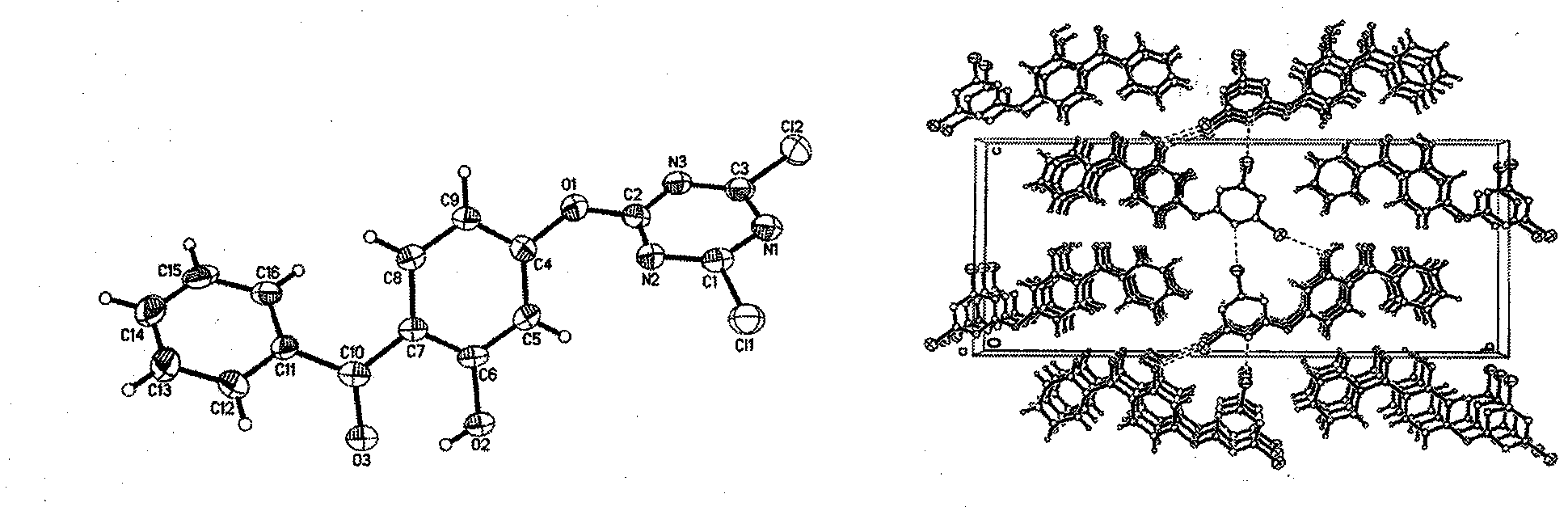

InactiveCN102584727AStructure determinationStrong UV Absorbing PropertiesOrganic chemistryVegetal fibresUv absorbanceBenzophenone

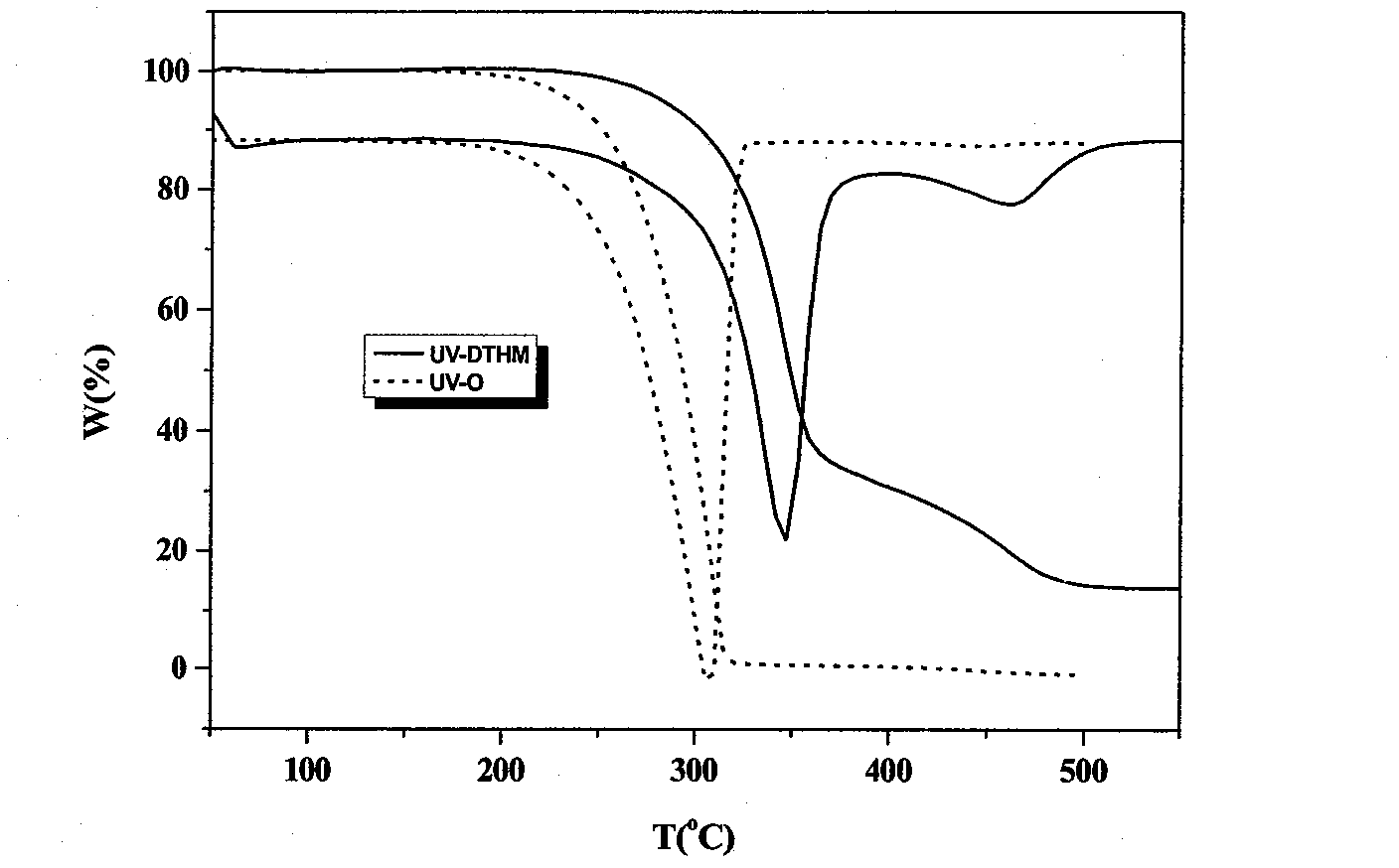

The invention relates to a method for synthesizing 4-(4,6-dichloro-1,3,5-triazine-2-oxo)-2-hydroxyl phenyl benzophenone serving as a novel reactive ultraviolet absorbent (UV-DTHM) and application of the UV-DTHM to the uvioresistant arrangement of cotton fabrics, and belongs to the technical field of functional aids. The method comprises the following steps of: performing etherification reaction of diphenyl ketone (UV-O) and trichloro-s-triazine (CYC) which serve as raw materials under the catalysis of sodium hydroxide, wherein a ratio of UV-O to CYC to NaOH is 1:2.0:1.5; reacting in a mixed solvent of acetone and water at the temperature of 0 DEG C for 5 hours to obtain the UV-DTHM, and the yield of the UV-DTHM is 82.5 percent. The UV-DTHM has the excellent ultraviolet absorption performance, and is high in heat stability; and active groups are contained in a molecular structure and can be reacted with substances containing groups such as animo, hydroxyl and the like. The UV-DTHM is applied to the uvioresistant arrangement of white cotton fabrics to achieve an excellent uvioresistant effect (the value of an ultraviolet protective factor (UPF) reaches 67), and the UPF value is kept at 43+ / -3 basically after the cotton fabrics are soaped for 30 times, so the UV-DTHM has an excellent soaping-resistant effect.

Owner:JIANGNAN UNIV

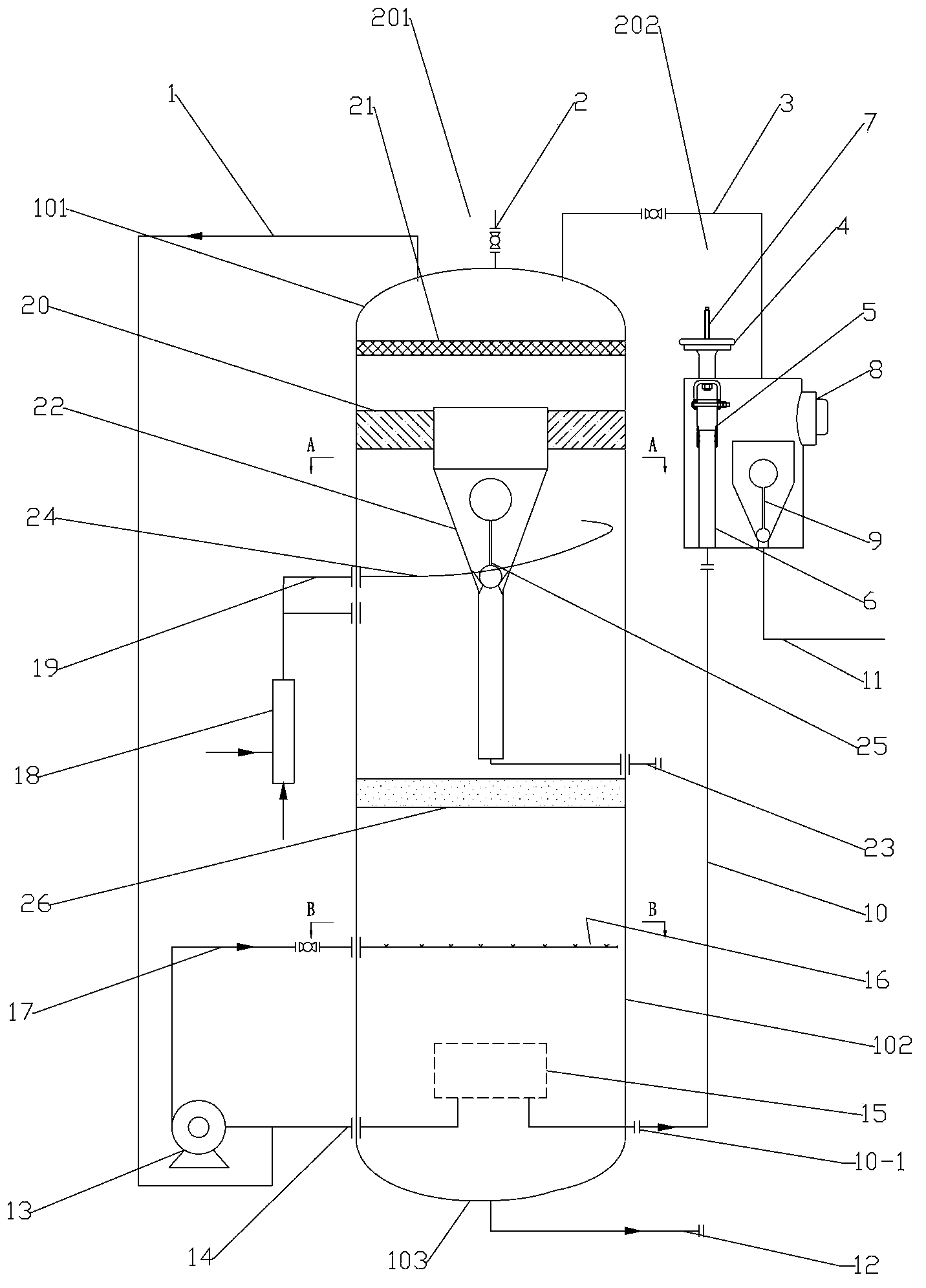

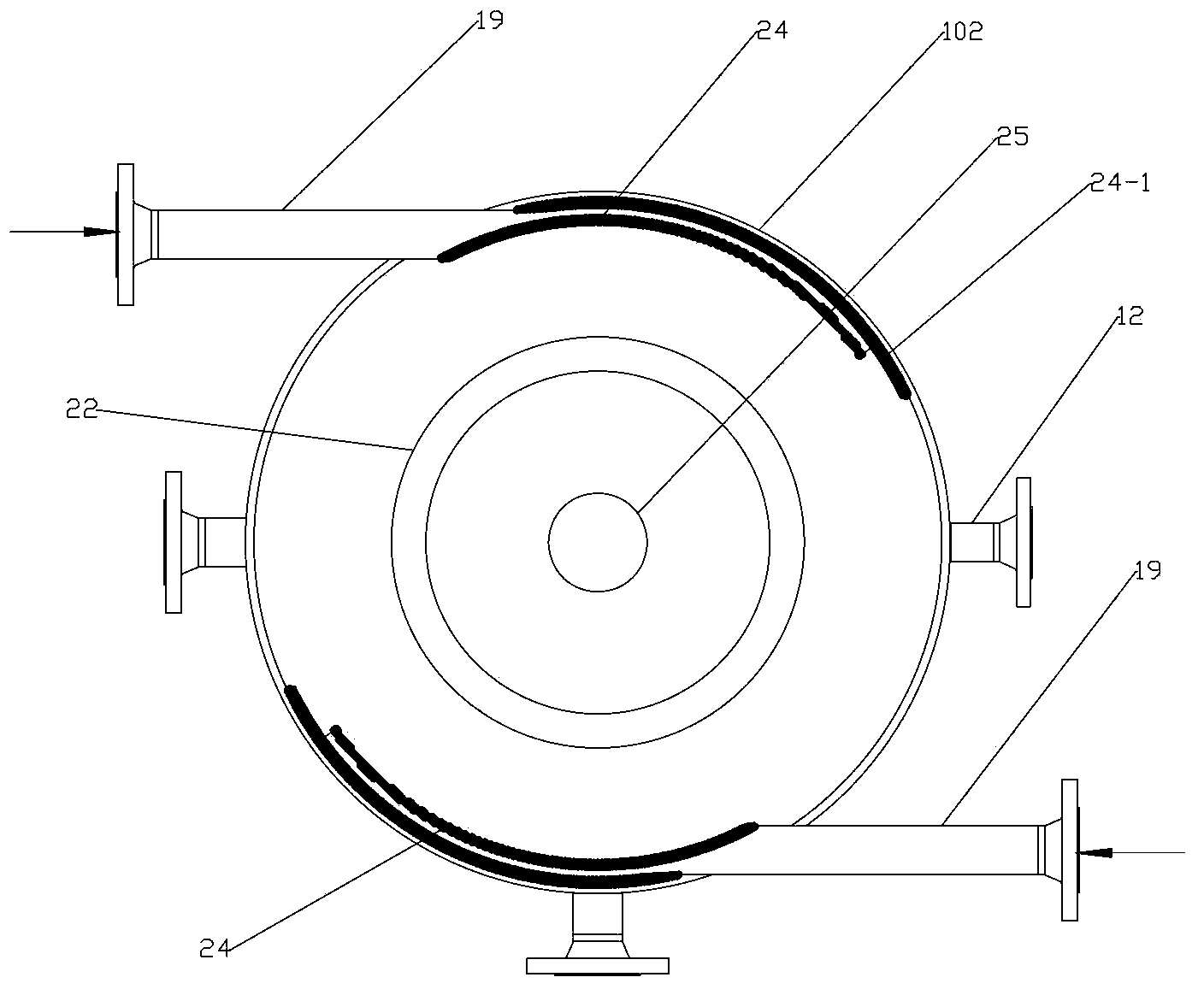

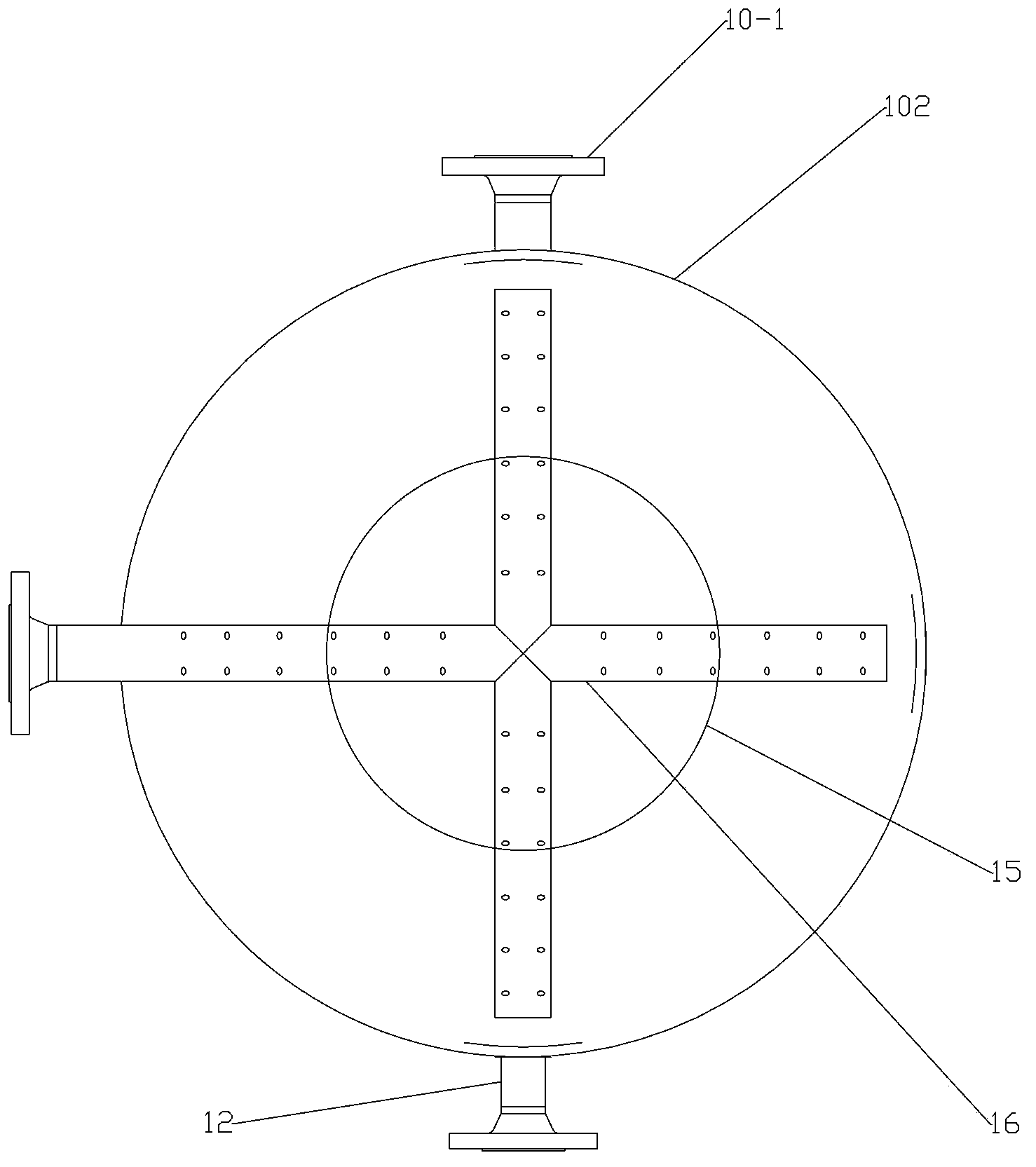

Gas-floatation rotational-flow coalescence composite type sewage oil-removing device

InactiveCN103351038AIncreased chance of coalescence growthImprove utilization efficiencyWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesWater solubleRotational flow

The invention discloses a gas-floatation rotational-flow coalescence composite type sewage oil-removing device. The gas-floatation rotational-flow coalescence composite type sewage oil-removing device mainly comprises a multifunctional separating tank, a two-stage gas-water mixing device and an adjusting and control box, wherein liquid inlets are formed in the middle-upper part of the multifunctional separating tank, an oil outlet is formed in the middle part of the multifunctional separating tank, a water-soluble gas circulation device, a sewage discharging port is formed in the bottom of the multifunctional separating tank, and an gas exhaust port is formed in and a communicating pipe is arranged at the top part of the multifunctional separating tank. The multifunctional separating tank is internally provided with an inner rotational-flow drum, and the bottom of the multifunctional separating tank is connected with an oil outlet pipe. A gas mist catcher is arranged above the inner rotational-flow drum; a water collector at the lower part of the multifunctional separating tank is respectively connected with a water outlet and a circulatign water outlet of the multifunctional separating tank; a gas exhaust port in the top part of the separating tank is connected with an inlet of the two-stage gas-water mixing device by a pipeline. The water outlet of the separating tank is connected with a water inlet of the adjusting and control box at the side, and the top part of the adjusting and control box is communicated with the top part of the separating tank. The gas-floatation rotational-flow coalescence composite type sewage oil-removing device disclosed by the invention has the advantage that the technical problems of low efficiency, poor intensiveness, unstable operation and the like in the rotational-flow gas-floatation integration combined oil-removing technical equipment can be solved.

Owner:CHINA OIL HBP SCI & TECH CO LTD +1

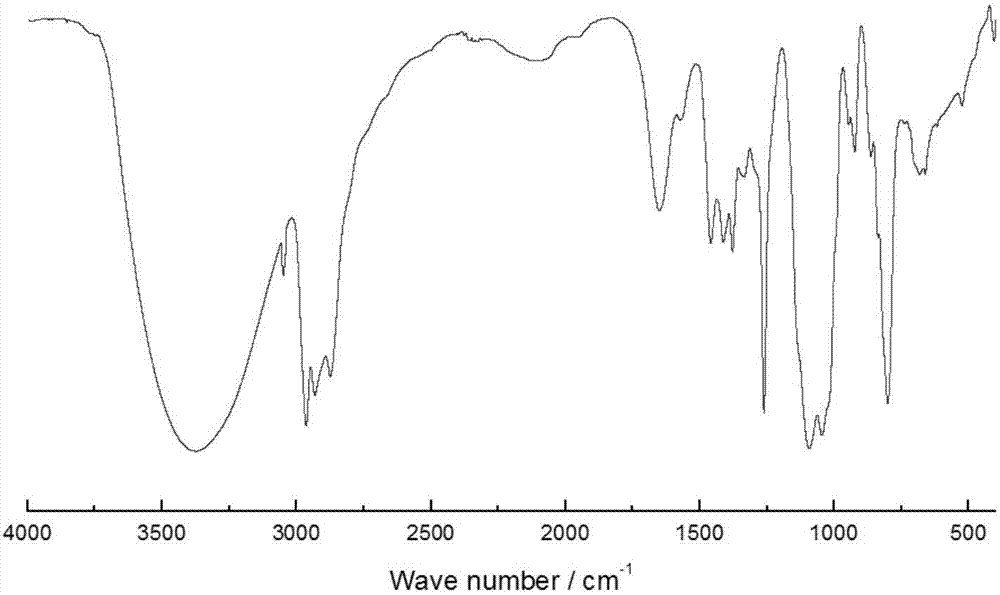

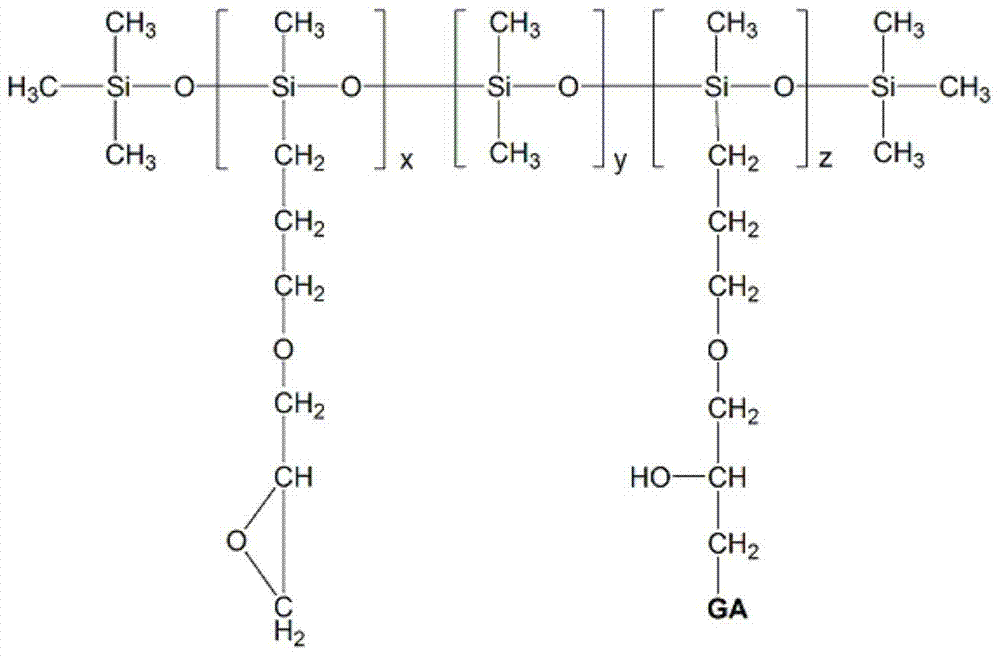

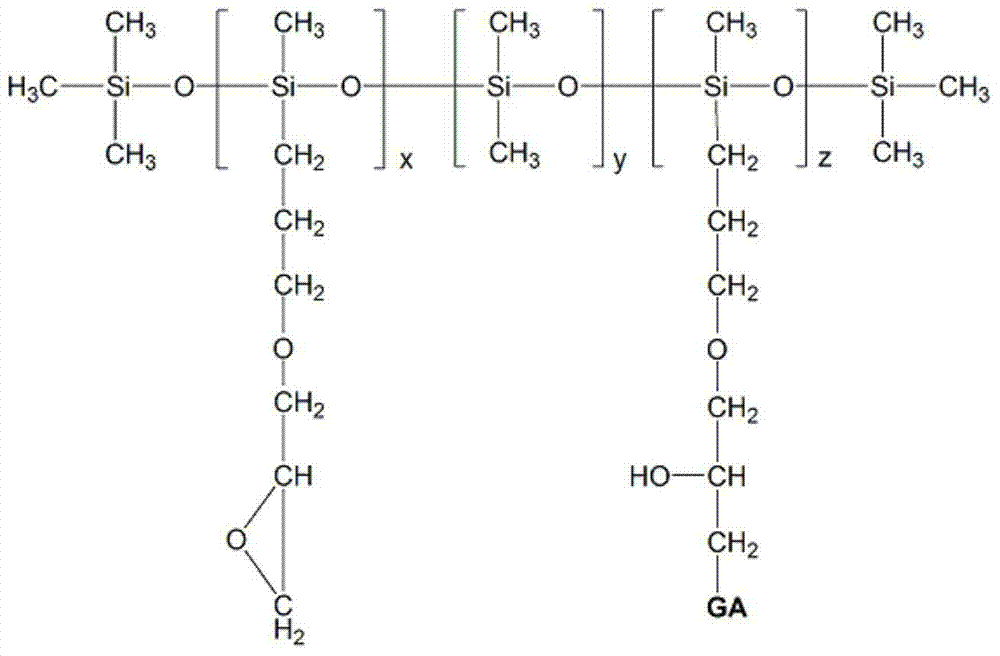

Glycosyl modified polysiloxane organic silicone softener and preparation method thereof

The invention discloses a glycosyl modified polysiloxane organic silicone softener and a preparation method thereof. The preparation method comprises the steps of enabling gamma-glycidoxy propyl methyl dialkoxy silane and octamethyl cyclotetrasiloxane with the mole rate of 1: (2.5-50) to react in an alkyl polyglucoside surfactant and basic catalyst water solution at the temperature of 60-100 DEG C to obtain a semitransparent alkoxy modified polysiloxane intermediate emulsion; regulating the pH value of the alkoxy modified polysiloxane intermediate emulsion in the step (1) to 0.5-6, adding N, N-dimethyl-N'-glycosylacyl-1, 3-propane diamine, and enabling N, N-dimethyl-N'-glycosylacyl-1, 3-propane diamine and gamma-glycidoxy propyl methyl dialkoxy silane in the step (1) to react at the temperature of 70-95 DEG C to obtain a semitransparent glycosyl modified polysiloxane emulsion, wherein the mole ratio of N, N-dimethyl-N'-glycosylacyl-1, 3-propane diamine to gamma-glycidoxy propyl methyl dialkoxy silane is (0.3-0.8):1. The softener disclosed by the invention has the super softness of amino silicon oil and the solidifying and finishing effects of epoxy modified silicon oil, and can be used for effectively improving the washing fastness and the smoothness.

Owner:SHANGHAI FINE CHEM CO LTD

Laundry detergent tablets

InactiveUS20020058604A1Improve finishing effectInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsCationic polymerizationSURFACTANT BLEND

Laundry detergent tablets are proposed comprising (a) anionic, nonionic and / or amphoteric surfactants, (b) cationic polymers, (c) zeolites, (d) disintegrants, and if desired (e) phyllosilicates.

Owner:KISCHKEL DITMAR +2

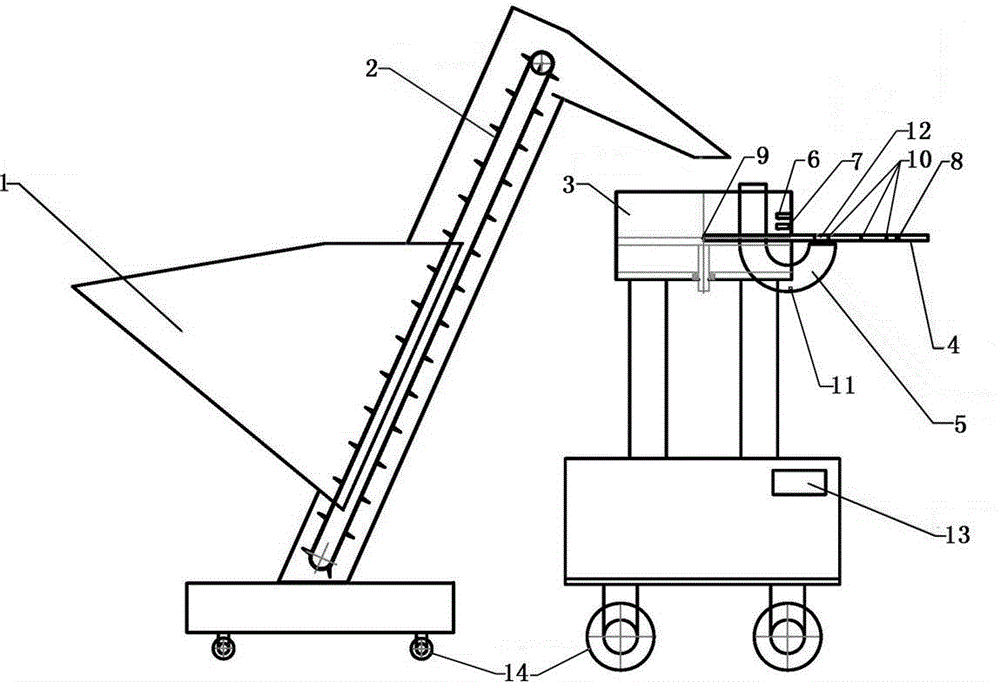

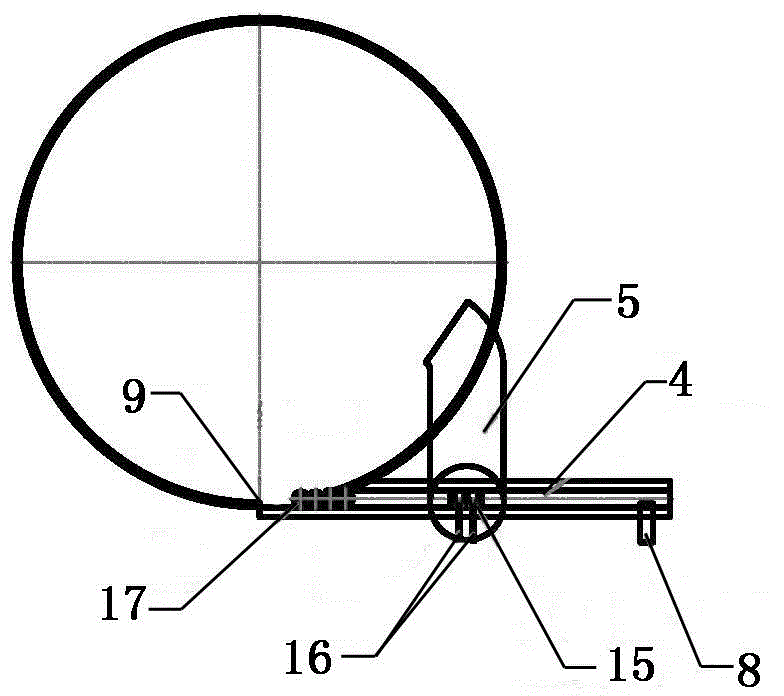

Efficient tea leaf de-enzyming machine with humidifying device

InactiveCN105192119AFully heatedImprove the killing effect and efficiencyPre-extraction tea treatmentDrive motorEnzyme

The invention discloses an efficient tea leaf de-enzyming machine with a humidifying device. The de-enzyming machine comprises a de-enzyming cylinder, an inner cylinder and an outer cylinder. The de-enzyming cylinder is of a double-layer structure and comprises the inner cylinder and the outer cylinder. The inner cylinder and the outer cylinder are coaxially arranged, an electric heating layer is arranged between the inner cylinder and the outer cylinder, a feeding hopper is connected with the left end of the upper side of the inner cylinder, the left end of the inner cylinder is connected with a drive motor through a rotary shaft, and the rotary shaft is horizontally arranged in the center of the interior of the inner cylinder. According to the efficient tea leaf de-enzyming machine with the humidifying device, the inner cylinder and the rotary shaft rotate in opposite directions, and tea leaves in the inner cylinder are stirred and overturned. Meanwhile, the electric heating layer and hot air are matched to de-enzyme the tea leaves, the tea leaves are fully and evenly heated, the de-enzyming effect is good, efficiency is high, the tea leaves attached to the inner wall of the inner cylinder can be scraped off, and waste of raw materials is avoided. Besides, the tea leaves can be humidified, the situation that quality is affected because the tea leaves are excessively dehydrated is avoided, effective shock absorption can be achieved through a shock-absorbing spring and a shock-absorbing pad, noise is lowered, and the service life of the de-enzyming machine is also prolonged.

Owner:成都米戈科技有限公司

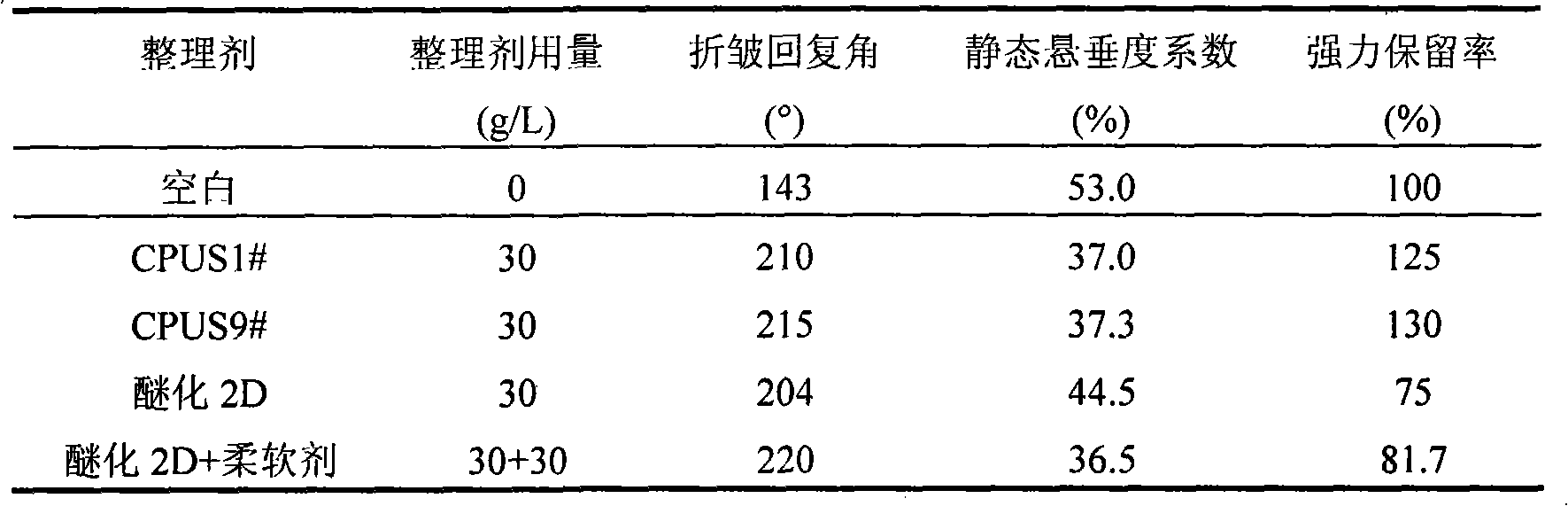

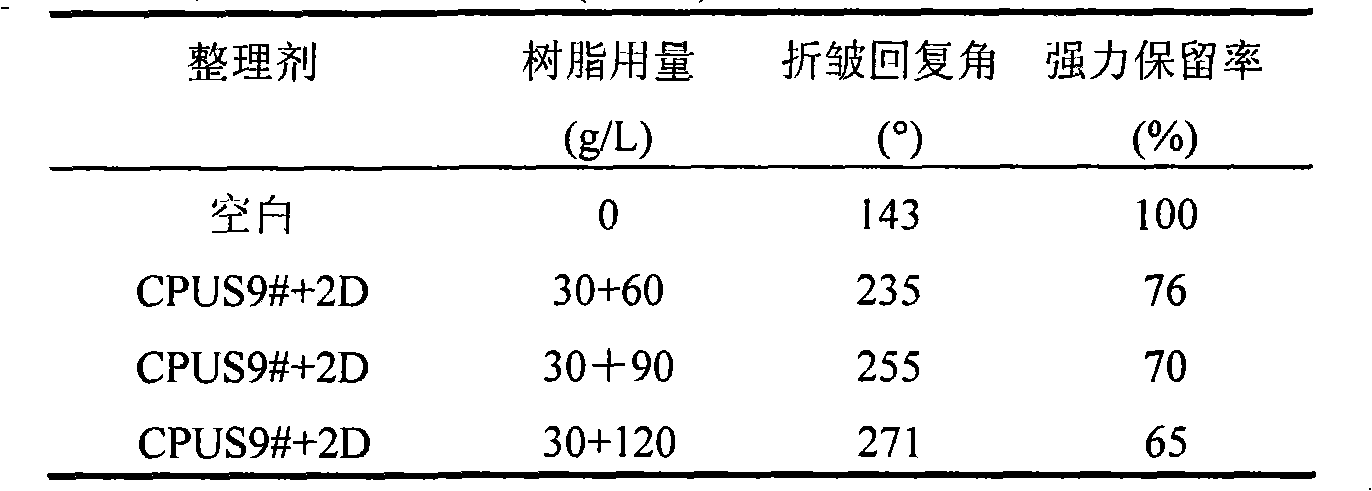

Cationoid polyurethane and modified silicon oil composite water dispersion, preparation and applications

The invention relates to a cationic polyurethane and modified silicone oil composite nano aqueous dispersion and a preparation method and an application thereof. The dispersion particles of the dispersion are compounded with cationic polyurethane and modified silicone oil, the diameters of the dispersion particles are less than 100nm. The mass composition of the modified silicone oil in the dispersion particles is 10 to 50 percent. High molecular weight polyether glycol and cationic diol chain extender react with isophorone diisocyanate(IPDI) to form ionic polyurethane after end capping and neutralization. The ionic polyurethane and the modified silicone oil are compounded and added with water to conduct self-emulsification at the room temperature to form the polyurethane and modified silicone oil composite nano aqueous dispersion. The nano aqueous dispersion can be used as a multifunction finishing material cotton cloth and can effectively improve the crease resistant, draping property and strength conservation rate and improve the hand feeling of fabrics and hydrophilcity and hydrophobicity of the surfaces of the fabrics.

Owner:TIANJIN UNIV

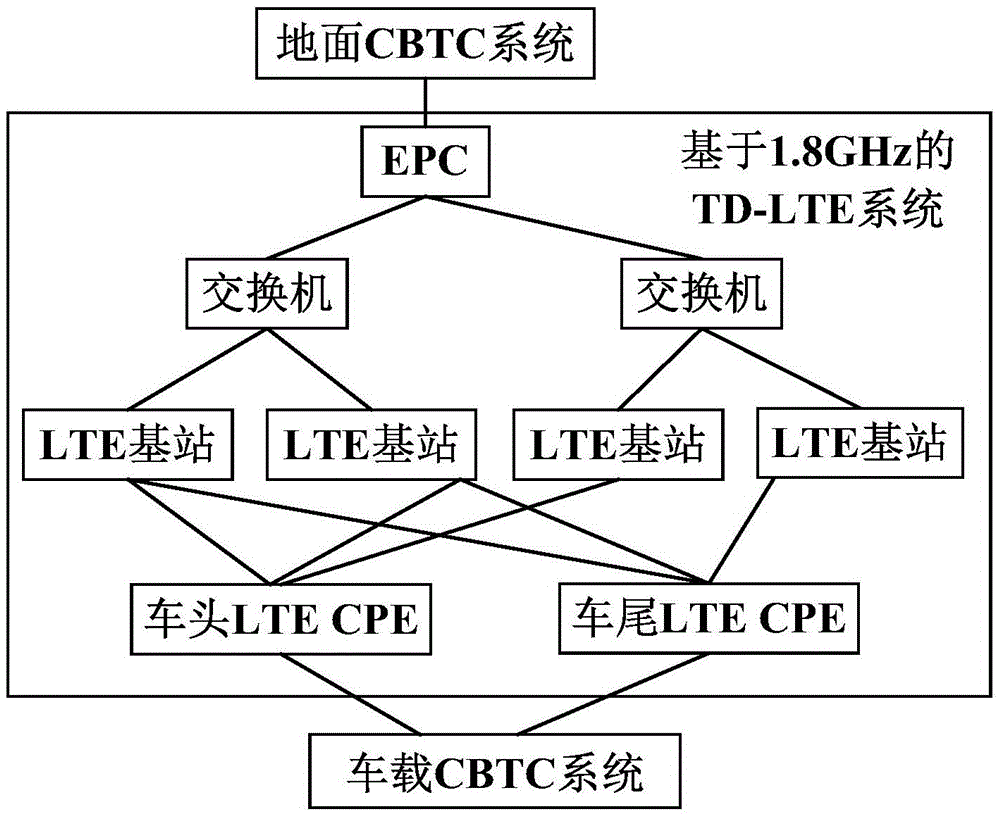

1.8GHz-based TD-LTE (Time Division Long Term Evolution) system used for subway rail communication

InactiveCN105636145AImprove versatilityHigh market fundamentalsRailway traffic control systemsWireless communicationFrequency bandEngineering

The invention discloses a 1.8GHz-based TD-LTE (Time Division Long Term Evolution) system used for subway rail communication, relating to the field of subway rail communication. The TD-LTE system comprises an EPC (Evolved Packet Core), vehicle-mounted terminal equipment and a plurality of LTE base stations, wherein the TD-LTE system works in a 1.8GHz frequency band; the EPC is connected to a CBTC (Communication Based Train Control) system on the ground; the LTE base stations are distributed along a subway rail line and are connected to the EPC through optical fibers after passing through switches; the vehicle-mounted terminal equipment comprises front LTE CPE (Customer Premise Equipment) and rear LTE CPE, wherein the front LTE CPE and the rear LTE CPE are both connected to the vehicle-mounted CBTC system and are connected to the LTE base stations through a wireless network. The TD-LTE system utilizes the special 1.8GHz frequency band, so that a problem of radio interference is avoided from the source, the driving operation safety is guaranteed to the greatest extent, and meanwhile, the future rail transit development trend and the long-term benefit of the operating unit are both considered.

Owner:WUHAN FIBERHOME INFORMATION INTEGRATION TECH CO LTD

Purpleblow maple health-care tea and its prepn. method

InactiveCN1537443ATreatment and prevention of cardiovascular and cerebrovascular diseasesEliminate free radicals in the human bodyTea substituesCoronary heart diseaseNutrient content

A health-care purpleblow maple tea for auxiliary therapy to coronary heat disease, angina pectoris and blood circulation disfunction is prepared from the tenden leaves of pterocarya stenoptera through washing, drying in air, steaming at 180-200 deg. for 5-6 min, kneading, shaping and baking at 90-100 deg.C for 20-25 min.

Owner:云南威达元宝枫产业开发有限公司

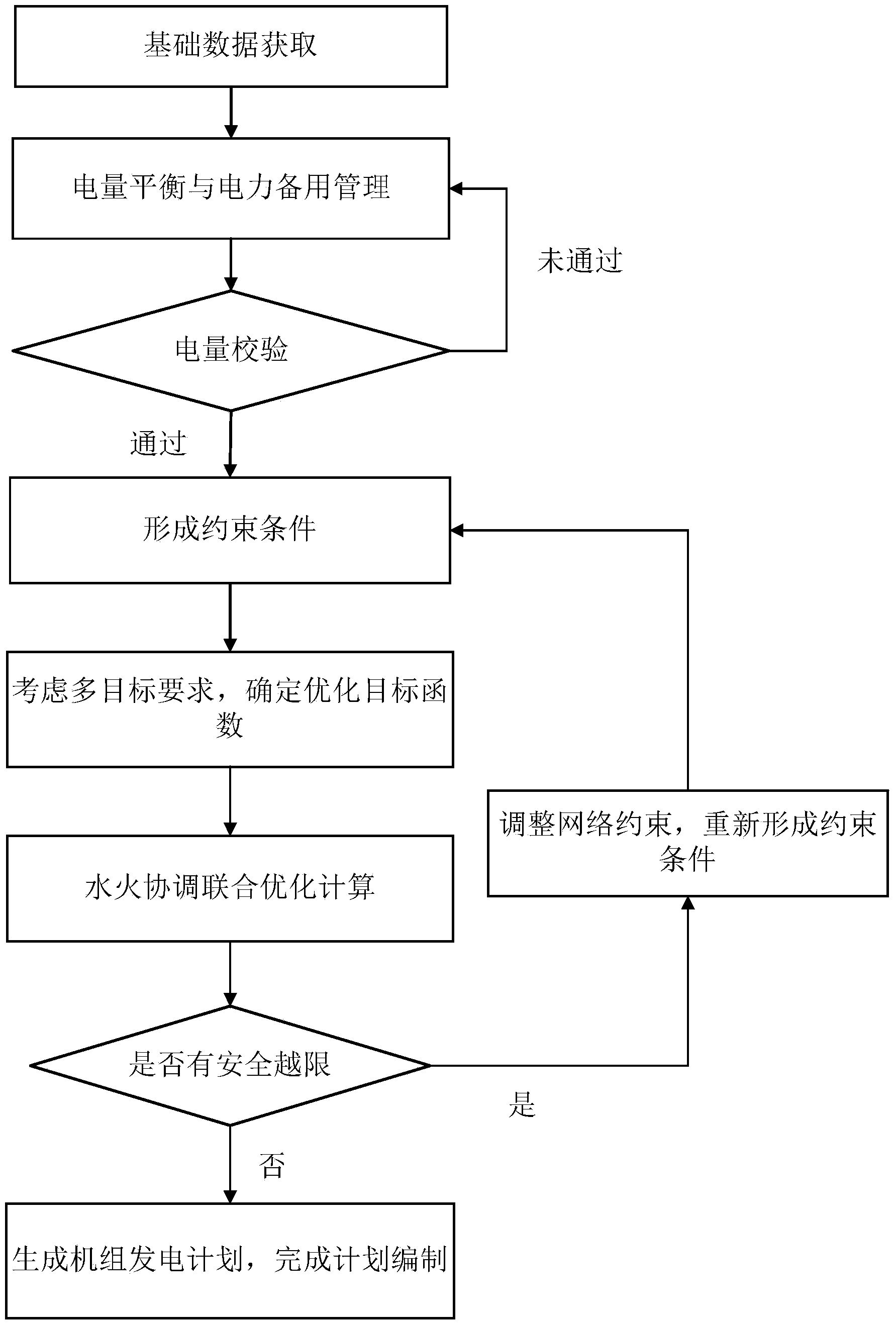

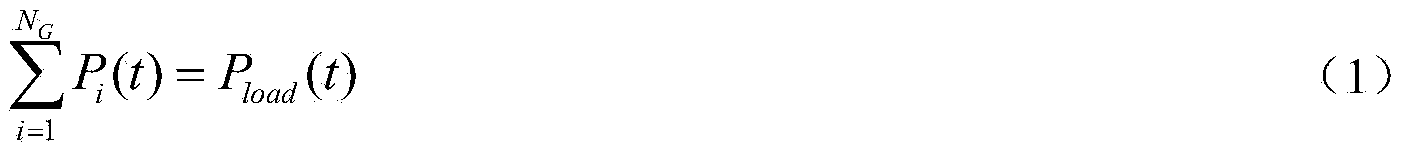

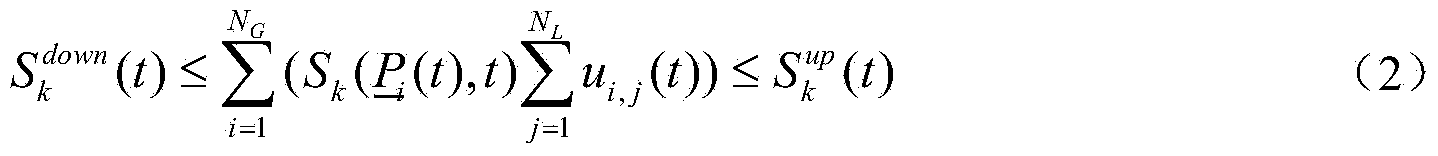

Security constraint generation schedule planning method based on water and fire coordination

ActiveCN104299072AReduce the total adjustment range of outputReduce power regulation lossesForecastingResourcesElectricityPower grid

The invention provides a security constraint generation schedule planning method based on water and fire coordination. The method comprises the following steps that power grid basic data are acquired, and electricity demands are determined; based on 'just, fair and open' dispatching and energy-saving dispatching, the electric quantity is balanced, and electric power is adjusted; according to the water and fire coordination constraint demand, the constraint condition of a water and fire coordination joint optimization model is determined; an optimization objective is determined; water and fire coordination joint optimization computing is carried out, and the generation schedule is determined. According to the method, based on the running and planning characteristic of a power grid including a large-scale water and electricity access dispatching mechanism, the water and electricity running and water and fire coordination optimizing characteristics are combined, the optimization objective includes the running cost of a thermal power unit and a hydropower unit and a unit output force adjusting penalty function, peak elimination and valley filling are carried out through coordination of the hydropower unit and the thermal power unit, so that the total adjusting amplitude of output force of the units in the system is reduced, and therefore power adjustment losses of the units in the system are reduced.

Owner:STATE GRID CORP OF CHINA +2

Vibration tobacco stem sorting machine

InactiveCN102406229AAchieve finishingEasy dischargeTobacco treatmentConveyor partsEngineeringMechanical engineering

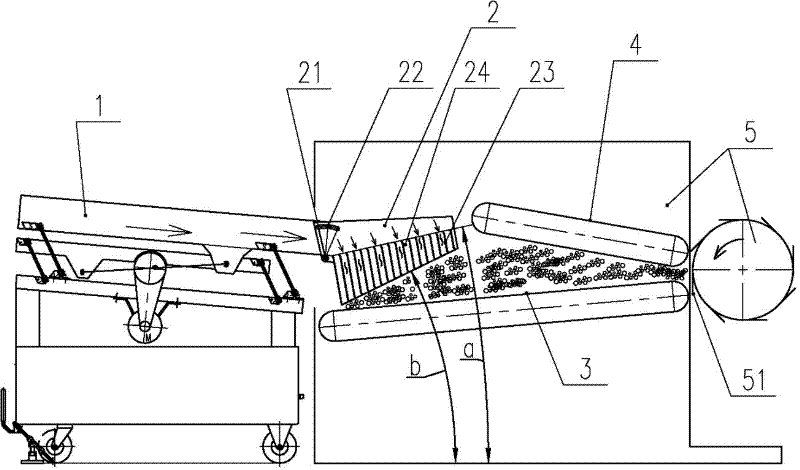

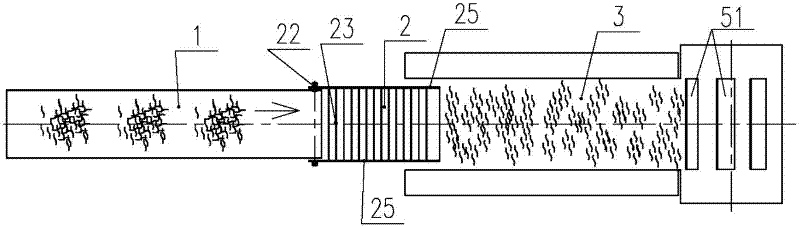

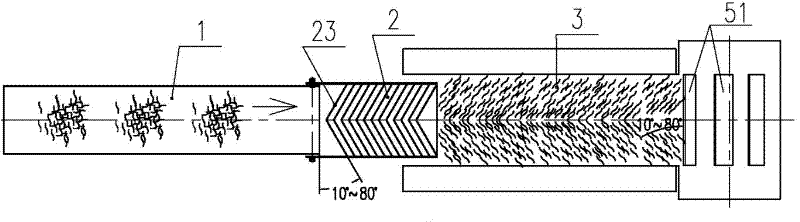

A vibration tobacco stem sorting machine comprises a vibration conveying groove body (1) and a vibration grid type leakage groove (2) which are connected in turn. The vibration grid type leakage groove (2) is located between the feeding ends of an upper chain (4) and a lower chain (3) used for conveying the tobacco stems to a stem cutting machine (5). The vibration grid type leakage groove (2) is formed by horizontally connecting separation plates (23) which are continuously arranged in equal spaces or along the flow direction of the material in a widening meaner to lateral plates (25) at the two sides. The separation plates (23) and the lateral plates (25) are separated from each to form a continuous grid leaking groove (24). The invention can sort the tobacco stems as that the stem cutting angle is any one pre-set angle smaller than 90 degrees. The tobacco stems can enter a steam cutting machine according to the sorted postures. The structure is simple and reliable, and the sorting effect is good.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

Single-component emulsion organic silicon performed polymer self-cross-linked water-proof finishing agent and its preparation

This invention publics a monocomponent emulsion preorganosilicon aggressiveness self crosslinking waterproof finish acidifier,of which the constituent includes silicon dioxide, hydrogen -silicone oil, functional organosilicon and surface modifier. The invention also publics the method preparing waterproof finish agent, which includes: first surface modify silicon dioxide, make silicon dioxide and hydrogen -silicone oil into performed polymer, then functional graft, in the end add emulsifying agent for emulsification. Waterproof finish produced by the this method equals fluor-finishing agent in waterproof effect, and is of low cost, so it's prospect application is good.

Owner:上海汉宇理化研究所

Supersoft hydrophilic block silicone oil intermediate compound and preparation method thereof

The invention relates to the field of textile finishing agent, in particular to supersoft hydrophilic block silicone oil intermediate compound and a preparation method thereof. The supersoft hydrophilic block silicone oil intermediate compound is composed of cations of the structural formula, wherein the n1 is the number of 5 to 10, and the degree of polymerization ranges from 3 to 50. Supersoft hydrophilic block silicone oil prepared by the intermediate compound synthetized is applicable to handle finishing of fabric knitted with one or multiple fibers of cotton, dacron, chinlon and acrylic fibers and has softness, smoothness and looseness effects superior to those of amino-modified silicone oil, has excellent stability in acid and alkali resistance, electrolyte resistance, high temperature resistance, shearing resistance and the like and thoroughly solves the problems of easy demulsification, floating oil, roll banding, difficulty in refinishing and the like.

Owner:RUNHE ORGANICSILICONE NEW MATERIAL

Microwave enzyme-deactivating process for green tea

ActiveCN103380829AStop metabolismNot easy to crushPre-extraction tea treatmentGreen teasMicrowave power

The invention discloses a microwave enzyme-deactivating process for green tea. The process comprises the following steps: setting the temperature of a microwave warehouse to be more than 200 DEG C and preheating the microwave warehouse; placing 1.5 to 2 kg of fresh tea leaves into the microwave warehouse, adjusting microwave power to be 1500 to 1800 W, stirring the fresh tea leaves, allowing leaf temperature to rapidly rise to more than 80 DEG C and maintaining the temperature for 5 min; shaking the leaves, throwing the enzyme-deactivated leaves upwardly to allow the leaves to scatter in the air and then to naturally fall into the microwave warehouse and repeatedly throwing the leaves until leaf temperature drops to less than 42 DEG C; adjusting the microwave power to be 2000 to 2200 W and stewing the leaves; and taking the enzyme-deactivated leaves out of the microwave warehouse when water content in the leaves is in a range of 55 to 60%. The process provided by the invention terminates metabolism of the tea leaves, allows substances related to tea quality to maintain optimal, removes grassy smell and retains original tea fragrance of the green tea; the prepared green tea has a good color, almost being dark blue, and has no burnt leaves; moisture in the leaves gradually decreases, the tea is soft and is difficult to triturate during rolling, and the tea naturally curls to form cords.

Owner:绍兴健茗茶业有限公司

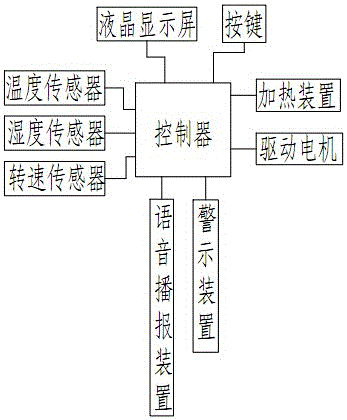

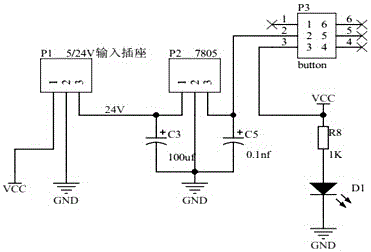

Tea fixation automatic control device and fixation method

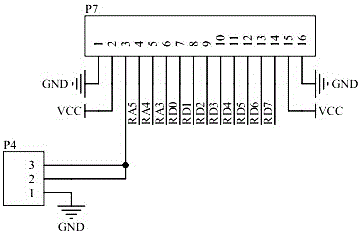

ActiveCN105786064AGood killing effectImprove qualityPre-extraction tea treatmentSimultaneous control of multiple variablesAutomatic controlComputer module

The invention discloses a tea fixation automatic control device and a fixation method. The tea fixation automatic control device comprises a controller; the controller is connected with a power source module, a temperature sensor, a humidity sensor, a rotation speed sensor, a driving motor of a baking roller and a heating device; the controller is connected with a monitoring terminal through an RS-232 serial communication module; the temperature sensor and the humidity sensor are used for detecting the temperature of the surface of the roller and detecting humidity in the roller respectively; and the rotation speed sensor is used for detecting the rotation speed of the roller. According to the tea fixation automatic control device and the fixation method of the invention, the temperature sensor, the humidity sensor and automatic control on rotation speed are adopted, so that fixation is more uniform, a fixation effect is greatly improved, and the problems of judgment error, poor fixation uniformity, poor fixation effect and low tea quality caused by manual control in the prior art can be solved effectively. The tea fixation automatic control device and the fixation method have the advantages of simple structure, low cost and quick and convenient operation and use.

Owner:GUIZHOU UNIV

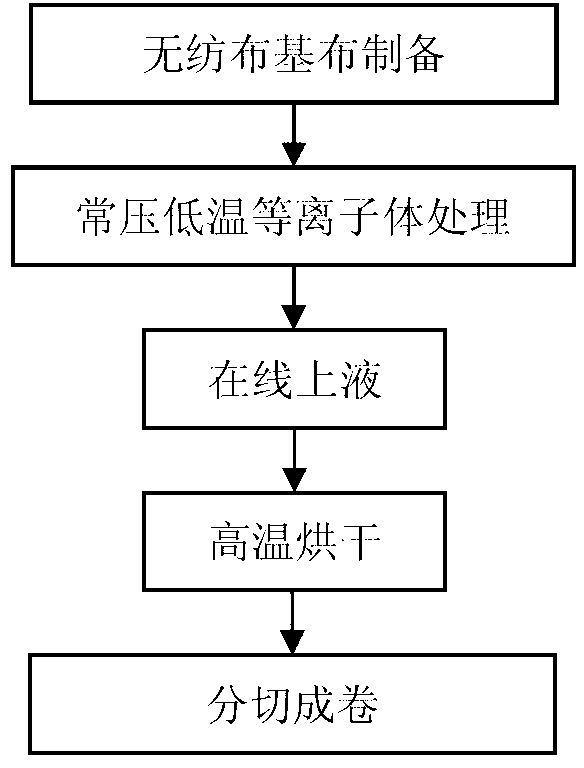

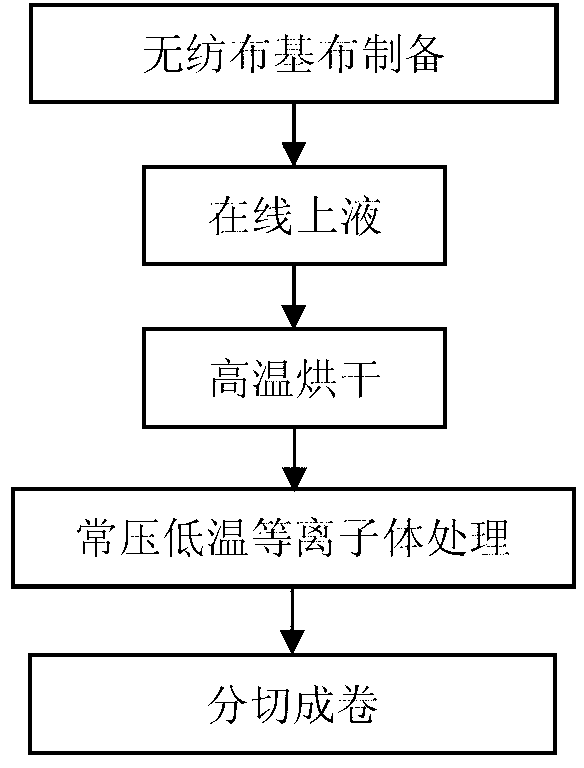

Finishing method for non-woven fabrics with high isolation performance and materials of non-woven fabrics with high isolation performance

ActiveCN102995400ALittle impact on air permeabilityReduce consumptionFibre treatmentAlcoholEngineering

The invention relates to a finishing method for non-woven fabrics with high isolation performance and materials of the non-woven fabrics with the high isolation performance. The finishing method combines on-line liquid feeding and normal-pressure low-temperature plasma processing, carries out normal-pressure low-temperature plasma processing before or after on-line liquid feeding, and forms a fluorine-containing polymer layer on the surface of the non-woven fabrics, so as to realize high isolation performance. The invention provides the finishing method for the non-woven fabrics which is novel, simple in process and good in finishing effect. Compared with the traditional saturated steeping, the finishing method has small influences on the non-woven fabrics, is high in production efficiency and has low energy consumption; compared with the existing plasma processing method, vacuum conditions are not needed, on-line liquid feeding is directly carried out, and low-temperature plasma processing is directly carried out under normal pressure, and other additional equipment conditions are not needed; and the contact angle between the prepared non-woven fabrics with high isolation performance and water can reach 120-160 degrees, and the prepared non-woven fabrics with high isolation performance has good air permeability and soft and comfortable feel, can reach requirements for resisting alcohol, oil and blood of each industry, and can well meet the large-scale industrial production.

Owner:SHANDONG JUNFU NONWOVEN MATERIALS

Super-soft finishing agent of silicone oil

ActiveCN102644200ASolve the problem of easy demulsificationSolve floating oilVegetal fibresPolymer scienceSilicone oil

The invention relates to the textile finishing agent field, in particular to a super-soft finishing agent of silicone oil. The super soft finishing agent of the silicone oil comprises a silicone oil compound with the following cation structural formula as followed. The silicone oil compound occupies a weight percentage of 2%-60% in the finishing agent, the n1 is 5-10, the R is a polyether group, and a polymerization degree is 3-50. The super soft finishing agent of the silicone oil is suitable for feel finishing of one or more fiber constituted fabric such as cotton, Dacron, chinlon and acrylic fibers, and provided with better soft, smooth and fluffy effects than amino-modified silicone oil and excellent stability in resistance to acid and alkali, electrolyte, high temperature, shearing and the like; and problems of easy demulsification, floating oil, roll banding, difficult rework and the like in the existing amino-modified silicone oil are completely solved.

Owner:NINGBO RUNHE HIGH TECH MATERIAL CO LTD

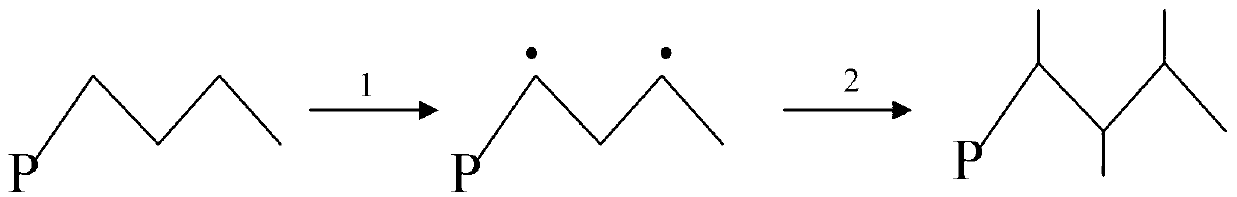

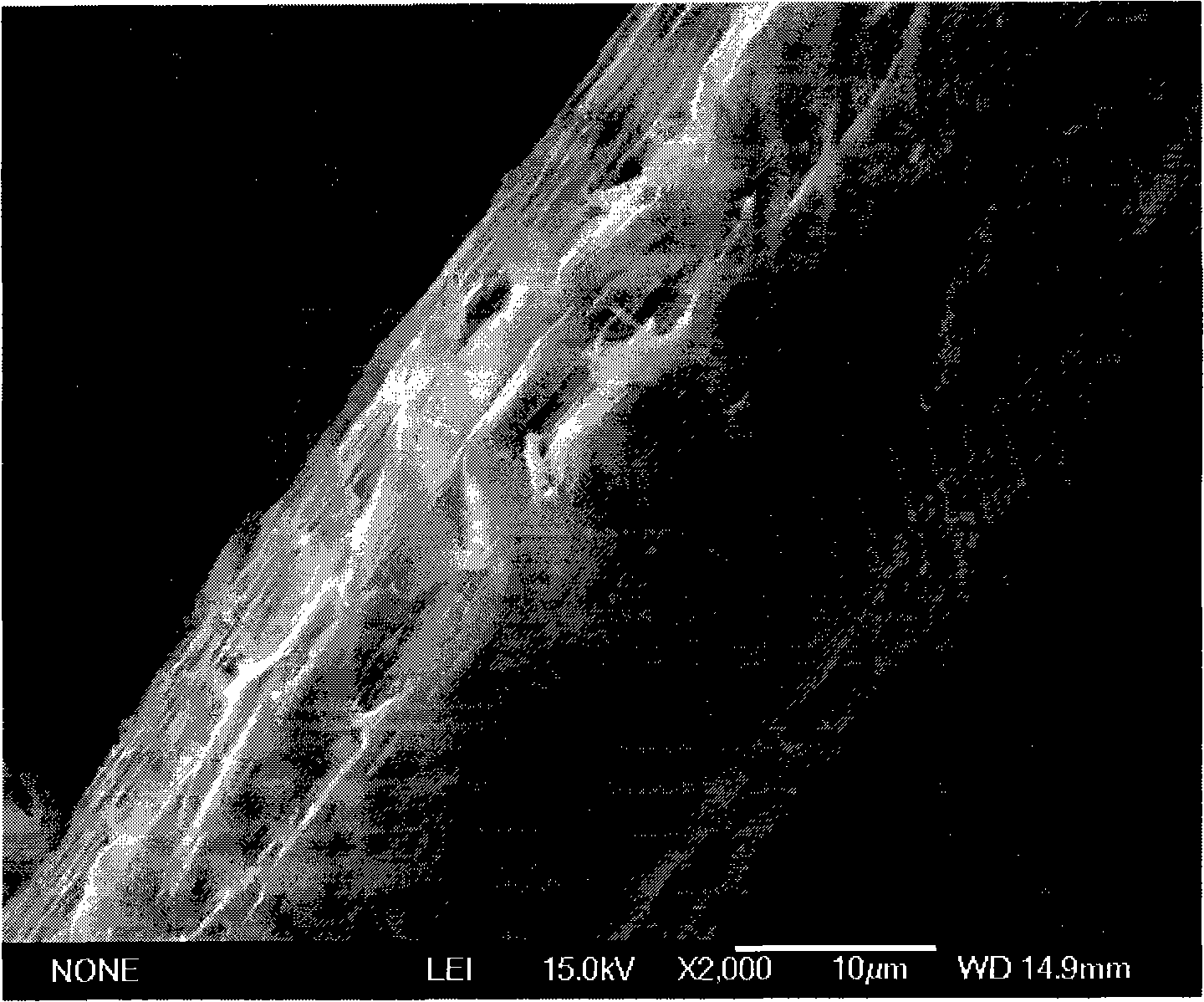

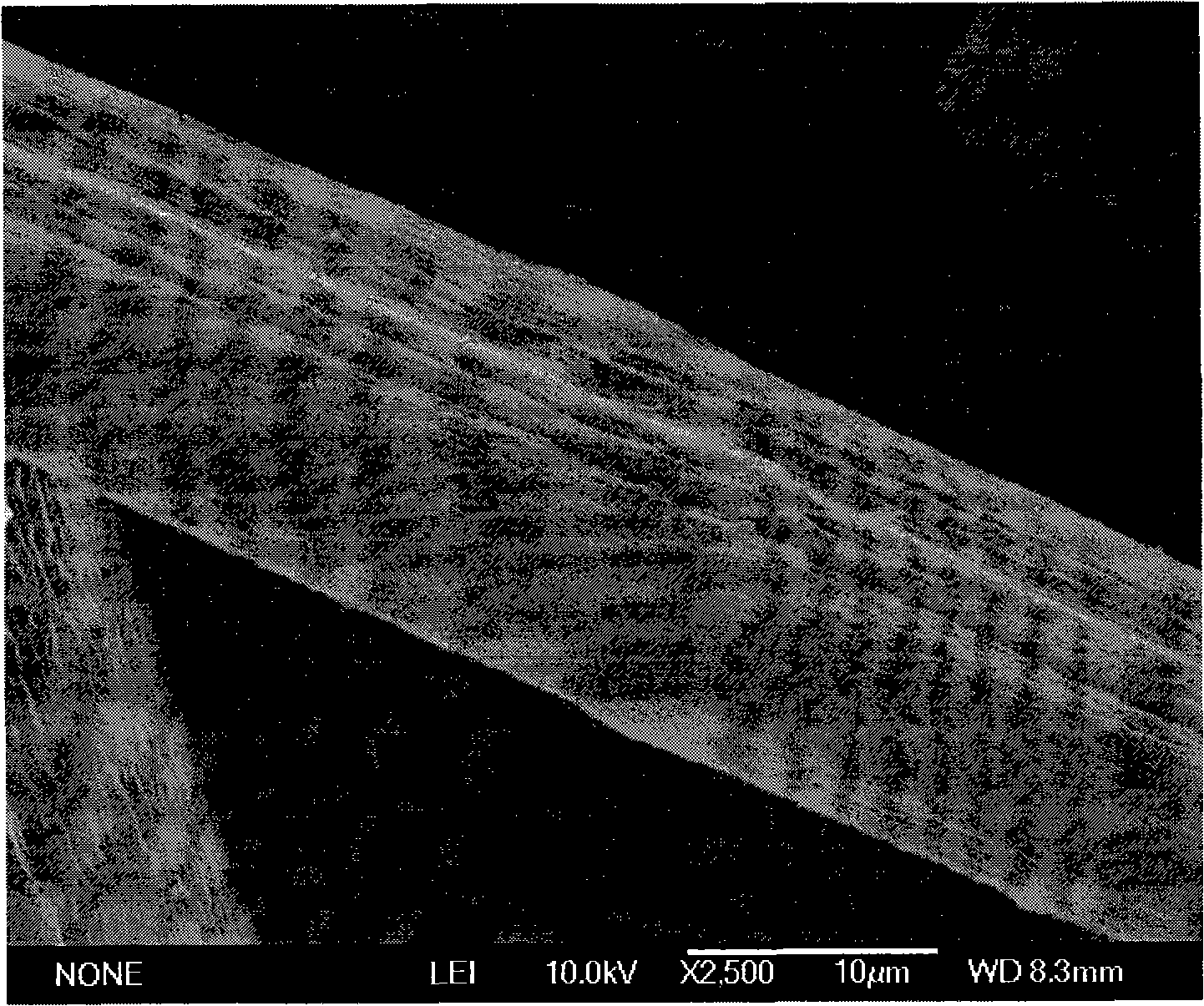

Biological enzyme method for water repellent finish of real silk fabric

The invention discloses a biological enzyme method for water repellent finish of real silk fabric. Tyrosine residues in fibroin of the real silk fabric are catalyzed by the aid of a horseradish peroxidase / hydrogen peroxide / diacetone system to generate phenoxy radicals, the phenoxy radicals and fluorinated acrylate monomers are subjected to graft copolymerization, the water repellent property of the real silk fabric is improved, and water repellent finish of the real silk fabric is realized with the biological enzyme method. The biological enzyme method comprises specific steps as follows: (1) preparation of a fluorinated acrylate emulsion; (2) treatment of the real silk fabric with horseradish peroxidase; (3) graft copolymerization of real silk and fluorinated acrylate; (4) after-treatment of the real silk fabric. Compared with a high-temperature padding and baking method and a traditional graft copolymerization method adopting ultraviolet light or microwave radiation, the method has higher graft copolymerization efficiency, the enzyme treatment condition is mild, the water repellent finish effect of the fabric is better, and the problems of reduction of strength of the fabric and yellowing of the surface of the fabric are solved.

Owner:JIANGNAN UNIV

Green tea processing technology

InactiveCN103652005ASimple and fast operationEasy to operatePre-extraction tea treatmentGreen teaCold storage

The invention discloses a green tea processing technology which comprises the following steps: in the process of de-enzyming, a roll miller is adopted for de-enzyming, then a caldron type de-enzyming machine is adopted for de-enzyming, and then rolling, drying, classification and cold storage are performed. The green tea produced through the green tea processing technology is jade green in color and unique in fragrance.

Owner:ANHUI TIANSI FOOD

Early strength enhancing concrete admixture

The present invention provides an admixture composition comprising a liquid suspension of colloidal silica, siloxane, and polycarboxylate polymer cement dispersant for enhancing early age strength, finishability, and other properties in hydratable cementitious compositions such as concrete (e.g., shotcrete). An inventive method involves mixing the components together in a specific sequence, thereby to obtain a stable liquid suspension. This attainment of a stable liquid suspension is surprising and unexpected because (i) the polycarboxylate polymer cement dispersant and siloxane components are incompatible and immiscible with one another; and (ii) that colloidal silica and siloxane compound are incompatible and immiscible with one another. Yet, the present inventors achieved an additive in the form of a stable liquid suspension which can be conveniently dosed into concretes and shotcrete mixtures, to enhance early age strength, and to improve workability and rheology in terms of finishability of concrete surfaces and improved rebound performance in shotcrete applications.

Owner:GCP APPL TECH INC

Feeding and finishing system and process of aluminum and plastic caps

ActiveCN104444292AAchieve the purpose of organizingReduce mutual frictionConveyor partsEngineeringHigh pressure

The invention discloses a feeding and finishing system of aluminum and plastic caps. The system comprises an aluminum cap feeding and finishing portion, a plastic cap feeding and finishing portion, a pneumatic control portion, a photoelectric control portion and an automatic controller. The invention further discloses a feeding and finishing process of aluminum and plastic caps employing the system. By the use of the centrifugal separation mode with a unique tray structure, friction of the aluminum or plastic caps is greatly reduced, and loss is reduced; by the use of a pneumatic mode with a unique screening rail and the use of high-pressure air as power to finish the caps, the caps run faster on the rail, the cap finishing process is stable and is better than mechanical finishing, product yield can be evidently increased, the surfaces of the caps have no scratch or deformation after finishing, and fewer caps are jammed or deformed; the fishing and moving speeds are higher, above 900 caps per minute; finishing and arrangement of the aluminum and plastic caps is achieved, and feeding for a next procedure is achieved.

Owner:HEBEI JINHUAN PACKAGING

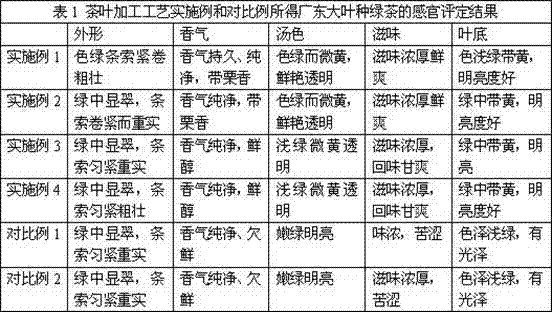

Processing technology for reducing Guangdong big-leaf green tea bitterness

InactiveCN107047835AShorten the time for finishingShorten the timePre-extraction tea treatmentTanninCaffeine

The invention belongs to the field of tea processing, and particularly relates to a processing technology for reducing Guangdong big-leaf green tea bitterness. The technology comprises the steps that fresh picked tea leaves are spread for 4-6 h till the water content of the tea-green color is 70-80%, the tea leaves are put into a fixation machine with the temperature increased to 230-260 DEG C to perform fixation; the tea leaves are spread and aired for 1-2 h after fixation is performed for 1-2 h, non-pressure empty rolling and light rolling are adopted, non-pressure light sequential rolling is performed for 20-30 min, and deblocking is performed; the tea leaves obtained after rolling need to be stacked for 1-2 h, and the stacking thickness is 10-20 cm; initial drying is performed, and the tea leaves are taken out and spread till the water content of the tea leaves is 20-30%, the water inside the tea leaves is distributed again, the stacking thickness is 2-4 cm, and drying is performed after stacking is performed for 20-40 min till the water content is not larger than 6%. According to the processing procedures, the probability that extra bitterness of the tea leaves is generated is lowered, the tea leaves are instantly in contact at high temperature during fixation, spreading is performed after fixation, and stacking is performed after rolling is performed, so that the content of caffeine and tea tannin in tea leaves is lowered, and therefore the bitterness of the tea leaves and tea soup is lowered.

Owner:TEA RES INST GUANGDONG ACAD OF AGRI SCI

Degumming flame-proof process technique for Han fibrilia

The invention discloses a Chinese bast fiber degumming flame retardant treatment technique. The technique carries out ultraviolet radiation, quencher and heating treatments after hot water bath, pre-pickling and pre-chlorination treatments; then carries out alkali oxygen-machine combined degumming treatment and finally carries out flame retardant treatment for twice repeatedly. The surface of the Chinese bast fiber treated by the technique has excellent degumming effect and is better than degumming with a normal alkali oxygen method and a mechanical method; the flame retardant effect is better than the effect of flame retardant post treatment aimed at a Chinese bast fabric and a better white content is obtained; a special blanching working procedure and a flame retardant working procedure are not needed to be arranged in post finishing, thus shortening the flow and saving the cost; the length and the fineness of the fiber are also improved after treatment; less polluting waste water is discharged. The invention is a green and environment protective technical method.

Owner:TAIYUAN UNIV OF TECH

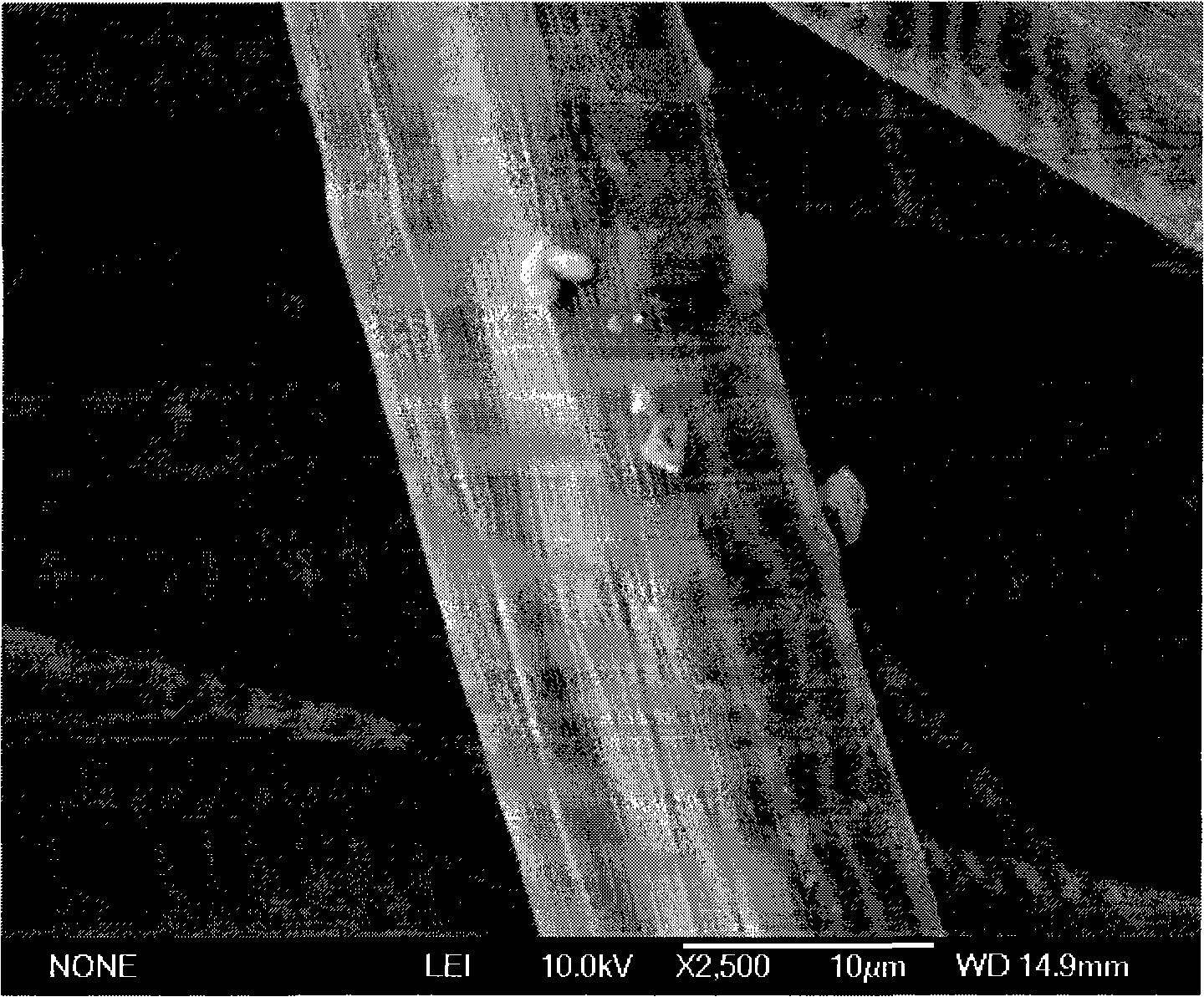

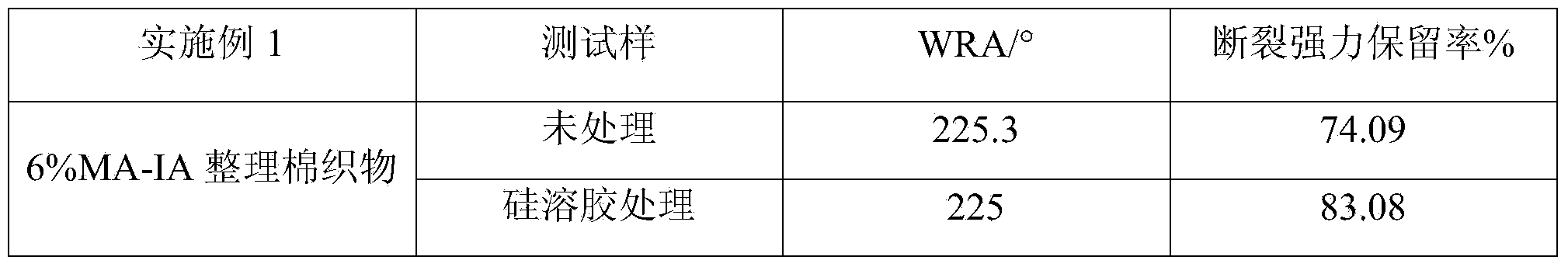

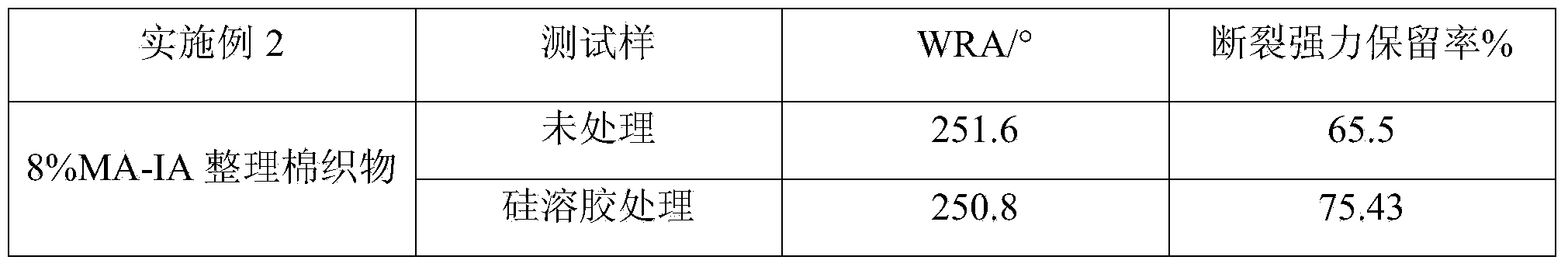

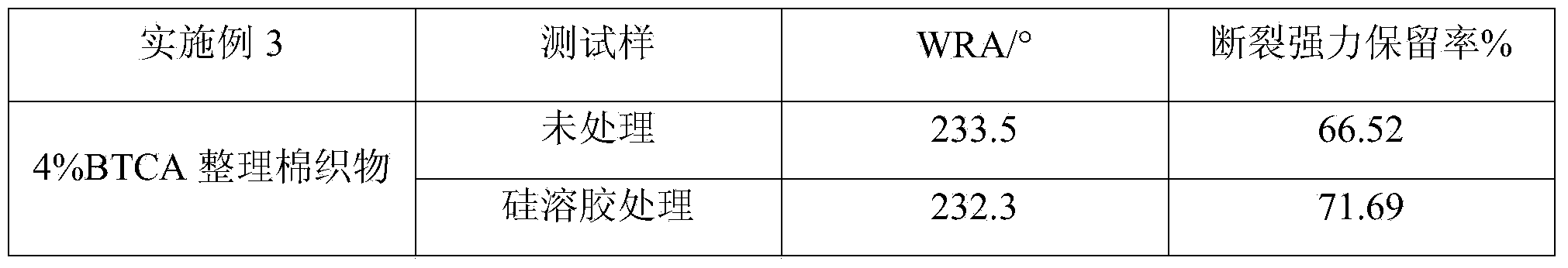

Method for preparing crease-resistant cotton fabric from silica sol

InactiveCN103643526AEnhanced tensile breaking strengthHigh strengthVegetal fibresBreaking strengthPolymer science

The invention relates to a method for preparing a crease-resistant cotton fabric from silica sol. The method comprises the steps of (1) sequentially dissolving catalysts and silicate in de-ionized water, adding an acid thinner to a solution, stirring for dissolving, immersing a cotton fabric in the solution, controlling the temperature at 10-30 DEG C for 1-48 hours, immersing and rolling twice till the liquid rate is 80%-85%, drying, washing, and drying again; and (2) immersing the cotton fabric in a crease-resistant finishing solution for 3-5 minutes, immersing and rolling twice till the liquid rate is 80%-85%, and finally, drying and baking. The tensile breaking strength of the fabric prepared by the preparation method is obviously improved, a problem of decrease in strength of an existing crease-resistant finishing fabric is obviously solved, and the fabric has wide application prospect and market prospect.

Owner:DONGHUA UNIV +1

Cationic organosilicon-modified polyurethane emulsion and preparation method thereof

InactiveCN104130376AStrong cation chargeEasy to manufactureFibre treatmentSilanesPotassium hydroxide

The invention relates to a cationic organosilicon-modified polyurethane emulsion and a preparation method. The method comprises the following steps: 1)synthesizing amino silicone oil, placing octamethylcyclotetrasiloxane, N-beta-(aminoethyl)-gamma- aminopropyl methyl dimethoxyl silane, hexamethyldisiloxane, potassium hydroxide and deionized water in a reaction container under the temperature of 100-110 DEG C to prepare the amino silicone oil; 2)adding haloalkane or epoxy alkyl halide, performing quaternization under 50-90 DEG C, removing micromolecule matter to obtained quaternized modified amino silicone oil; and 3)adding the quaternized modified amino silicone oil in the step 2) drop by drop in high molecular weight polyether polyalcohol, cationic glycol chain extender and isophorone diisocyanate prepolymer and reacting under 60-90 DEG C to obtain cationic organosilicon-modified, then adding deionized water to obtain the cationic organosilicon-modified polyurethane emulsion. The product can be used for textile arrangement, and is especially suitable for acrylic fibers fabric, and has good pilling resistance and hand feel.

Owner:SHANGHAI UNIV

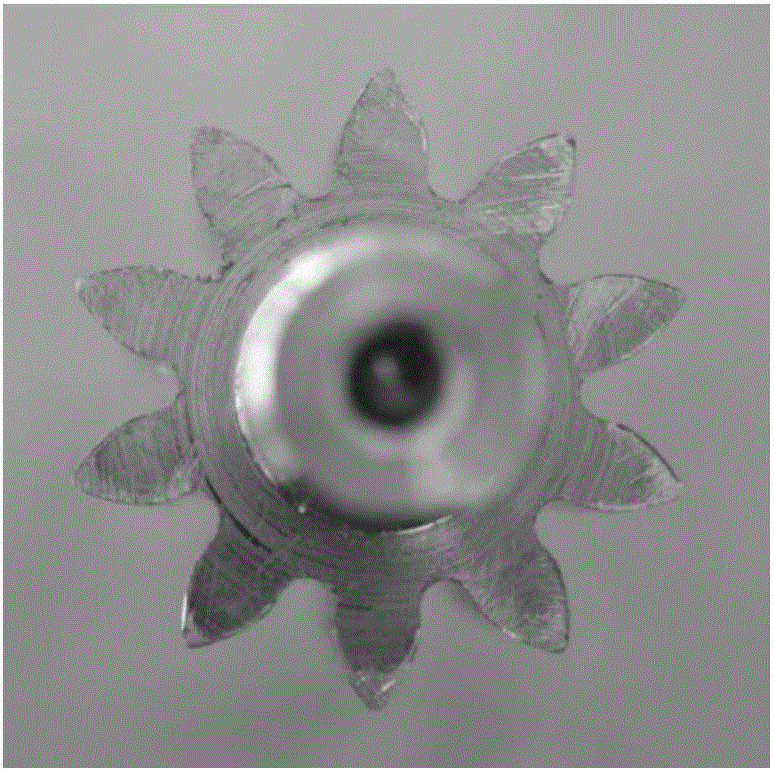

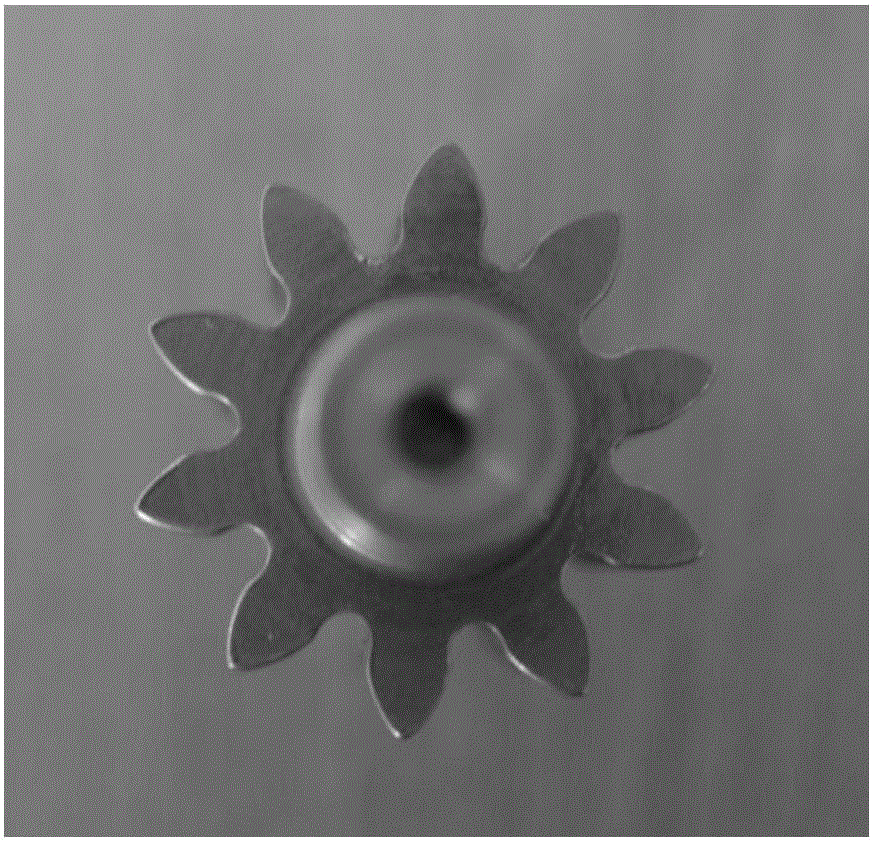

Oil pump gear shaft spiral flow type barrel finishing jig device and method

ActiveCN106141889AImprove finish processing efficiencySuitable for mass productionEdge grinding machinesGrinding carriagesReciprocating motionGear wheel

The invention discloses an oil pump gear shaft spiral flow type barrel finishing jig device and method. The oil pump gear shaft spiral flow type barrel finishing jig device comprises a cam mechanism and a jig body. With the cam mechanism, it is achieved that the whole jig body can carry out perpendicular reciprocating motion additionally while carrying out rotation motion, and therefore, the effect of finishing carried out on the upper end face and the lower end face of a gear can be remarkably improved. The jig body comprises a jig shaft, an upper center disk, clamping adjustment mechanisms, lower centers and a lower center disk. More than one part can be clamped between the upper center disk and the lower center disk, and therefore, the production efficiency is high. Through two steps of adjustment, including coarse adjustment and fine adjustment, carried out on the distance between the upper center disk and the lower center disk, the parts can be controlled to rotate or not in the machining process, and the technological performance of finishing is greatly improved. After the oil pump gear shaft spiral flow type barrel finishing jig device is used for machining gear shafts, tooth surfaces, especially the upper end faces and the lower end faces of gears are good in machining effect.

Owner:LANGFANG NORTH TIANYU ELECTROMECHANICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com