Tea fixation automatic control device and fixation method

An automatic control device and tea technology, applied in the direction of non-electric variable control, control/regulation system, and simultaneous control of multiple variables, etc., can solve the problems of poor greening effect, influence of tea quality, uneven greening effect, etc., and achieve cost Low, improve the effect of finishing, solve the judgment error and the effect of poor uniformity of finishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

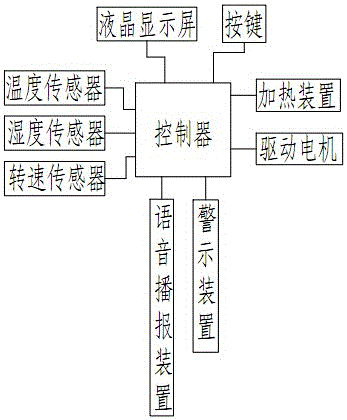

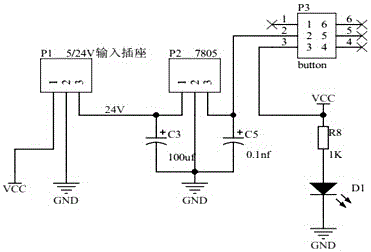

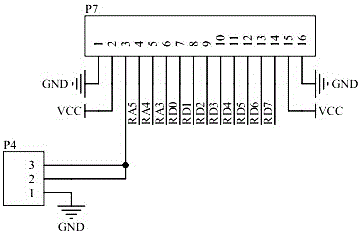

[0026] Embodiment 1: as Figure 1-Figure 5 As shown, an automatic control device for tea greening includes a controller, which is connected with a power module, a temperature sensor, a humidity sensor, a speed sensor, a driving motor for a baking drum, and a heating device, and is connected to the controller through an RS-232 serial port communication module. Connected to the monitoring terminal, the temperature sensor and the humidity sensor are used to detect the temperature of the drum surface and the humidity in the drum respectively, and the speed sensor is used to detect the rotation speed of the drum.

[0027] Preferably, the above-mentioned heating device adopts a thyristor to adjust the heating resistance wire.

[0028] Preferably, the above-mentioned controller is connected with a human-computer interaction module, and the human-computer interaction module adopts a 1602 LCD liquid crystal display screen and buttons, and the 1602 can simultaneously display 16×02 chara...

Embodiment 2

[0034] Embodiment 2: as Figure 1-Figure 5 Shown, a kind of finishing method of tealeaves greening automatic control device, this method comprises the following steps:

[0035] (1) The pitch of the spiral deflector 2 of the drum 1 is set to be 1 / 5-1 / 8 of the diameter of the drum 1, and the deflector (2) The baffle plate 3 spirally installed on the drum 1 within one spiral is 6- 8 pieces, the height of the baffle (3) is 2 / 3 of the height of the deflector (2);

[0036] (2) Install the heating pipe 5 and the temperature sensor 4 of the heating device according to the installation method of claim 8, and install the three sets of humidity sensors 6 at the center of the drum 1 and on the same neutral plane as the temperature sensor 4;

[0037] (3) Set the temperature of the first heating device from left to right to 220°C and humidity of 20%, the temperature of the second heating device to 200°C and humidity of 15%, and the temperature of the third heating device to 180°C and humid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com