Method for preparing low-toxicity marine antifouling paint by applying Cu2O submicrospheres

A marine antifouling and submicrosphere technology, which is applied in antifouling/underwater coatings, rubber derivative coatings, coatings, etc., can solve the problems of high particle density, uneven mixing, and affecting the killing effect, so that it is not easy to deposit , Prolong anti-fouling effect, reduce the effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

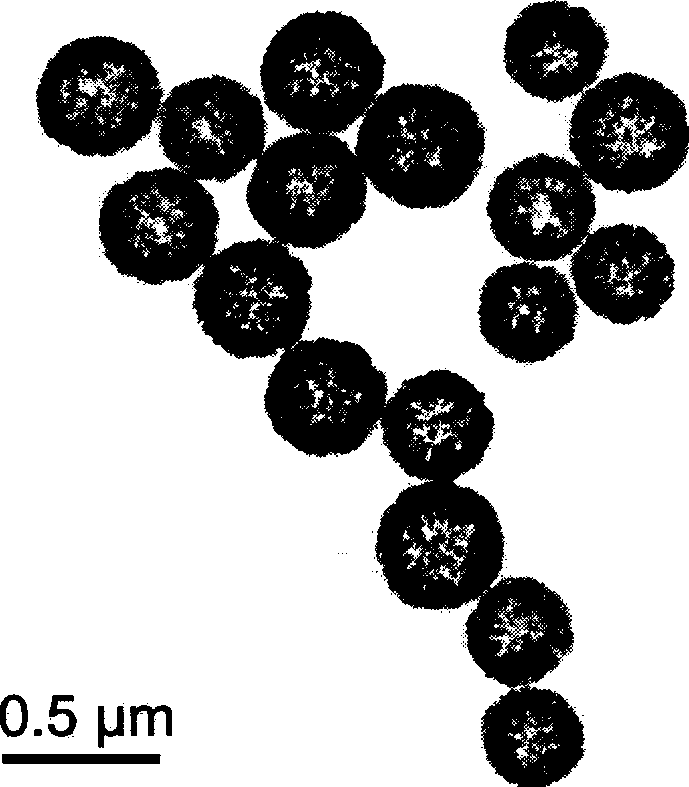

[0025] Example 1: Cu 2 O hollow submicrospheres alone as antifouling agent

[0026] The average particle size is 290nm, the specific surface area is 88.6m 2 / g Cu 2 20g of O hollow submicrospheres, 40g of acrylic resin, 15g of zinc oxide, 10g of red iron oxide, 5g of talcum powder, and 10g of xylene were put into a ball mill and ground for 4 hours at 2000r / min to prepare 100g of low-toxic marine antifouling paint.

[0027] The low-toxic antifouling paint was painted on the sandblasting sample plate required by the national standard GB6824-86, and the paint at the section was observed with a scanning electron microscope (SEM). The results showed that Cu 2 O hollow submicrospheres are uniformly dispersed in the coating; according to the national standard GB6824-86, the copper ion exudation rate is measured at 10 μg / (cm 2 d) above, and the downward trend is slow with time, and the antifouling period is long.

Embodiment 2

[0028] Example 2: Cu 2 O hollow submicrospheres alone as antifouling agent

[0029] The average particle size is 500nm, the specific surface area is 81.6m 2 / g Cu 210g of hollow submicrospheres, 50g of vinyl resin, 10g of zinc oxide, 10g of red iron oxide, 5g of talcum powder, and 15g of mixed xylene were put into a ball mill and ground for 2 hours at 2000r / min to prepare 100g of low-toxic marine antifouling paint.

Embodiment 3

[0030] Example 3: Cu 2 O hollow submicrospheres alone as antifouling agent

[0031] The average particle size is 150nm, the specific surface area is 89.4m 2 / g Cu 2 70g of O hollow submicrospheres, 10g of chlorinated rubber, 5g of zinc oxide, 10g of talcum powder, and 5g of mixed xylene were put into a ball mill and ground for 2 hours at 2000r / min to prepare a low-toxic marine antifouling coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com