Patents

Literature

52results about How to "Extend the antifouling period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

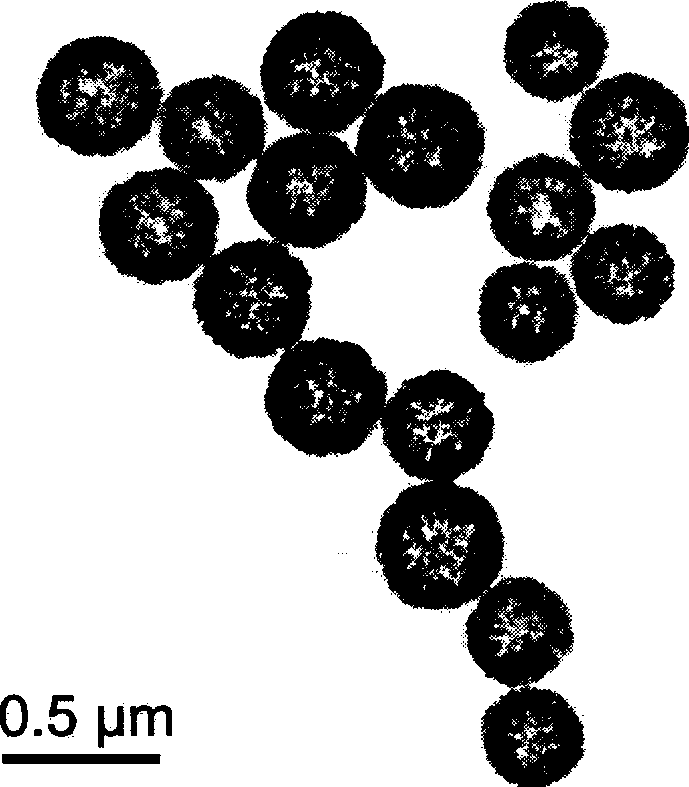

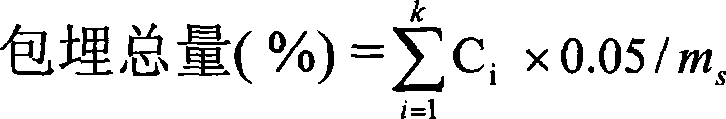

Method for preparing low-toxicity marine antifouling paint by applying Cu2O submicrospheres

InactiveCN101531841ALow densityEvenly dispersedRubber derivative coatingsAntifouling/underwater paintsMicrosphereSolvent

The invention discloses a method for preparing a low-toxicity marine antifouling paint by applying Cu2O hollow submicrospheres, and belongs to the fields of preparation and application of inorganic functional materials and marine antifouling paints. The method applies the Cu2O hollow submicrospheres singly or the Cu2O hollow submicrospheres embedded with a nontoxic organic antifouling composition as an antifouling composition to prepare the low-toxicity marine antifouling paint; and the antifouling composition, resin base stock, pigment (filler), and solvent are added to a ball mill for grinding to prepare the marine antifouling paint, wherein the antifouling composition consists of the Cu2O hollow submicrospheres with adjustable grain diameter (150-500nm), hollow structures and porous surfaces or the Cu2O hollow submicrospheres embedded with other antifouling compositions. The method has the characteristics that the Cu2O grain diameter reaches nano / micron grade, and grains in the paint are distributed uniformly; and the special appearance of the hollow structures and the porous surfaces can be used for embedding and slowly releasing other nontoxic organic antifouling compositions, reduces Cu2O dosage and has the function of cooperative antifouling so as to prolong the antifouling term, strengthen the antifouling effect and reduce the emission pollution.

Owner:JIANGNAN UNIV

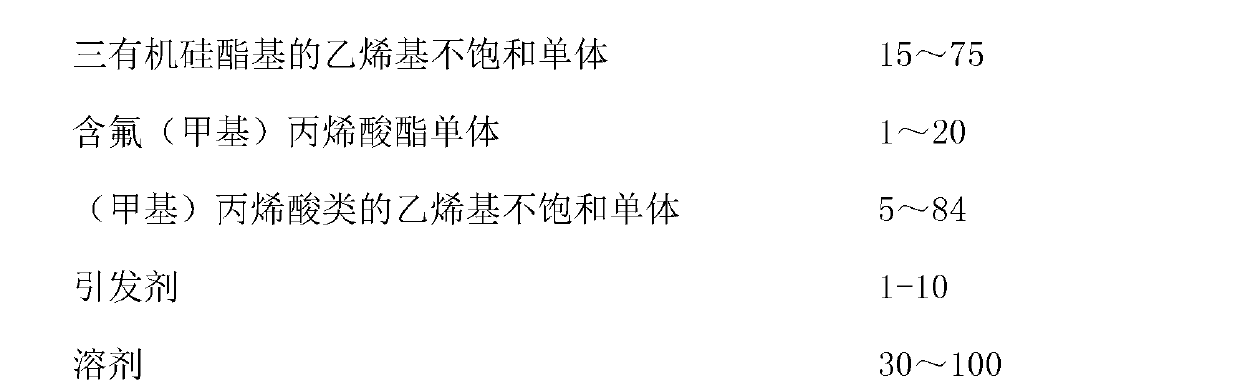

Preparation method of organic silicon self-repair antifouling material

ActiveCN108546337AOvercoming the problem of expiration dateExtend the antifouling periodAntifouling/underwater paintsPaints with biocidesWater bathsMechanical property

The invention belongs to the technical field of oceaneering antifouling paint preparation, and relates to a preparation method of an organic silicon self-repair antifouling material. According to themethod, firstly, melamine and a water solution containing a double aldehyde group or multi-aldehyde group compound are added into a three-neck flask; at 0 to 30 DEG C, magnetic stirring is performed for 0.5 to 3h; then, amino terminated polydimethylsiloxane and an organic solvent are added into the three-neck flask; finally, under the water bath condition and at 0 to 60 DEG C, magnetic stirring isperformed in the three-neck flask for 0.5 to 8h; the organic silicon self-repair antifouling material is obtained. The invention provides a method for preparing the self-repair antifouling material on the basis of amino terminated polydimethylsiloxane and melamine through double aldehyde group or multi-aldehyde group compound crosslinking; the antifouling period of an organic silicon fouling release material can be effectively prolonged. The preparation method solves the problems that the organic silicon antifouling material generally has poor mechanical property; in the use process, the damage caused by marine sediment, marine organisms and the like can easily occur, so that the use period of the organic silicon antifouling material is shortened. Wide application prospects are realized.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

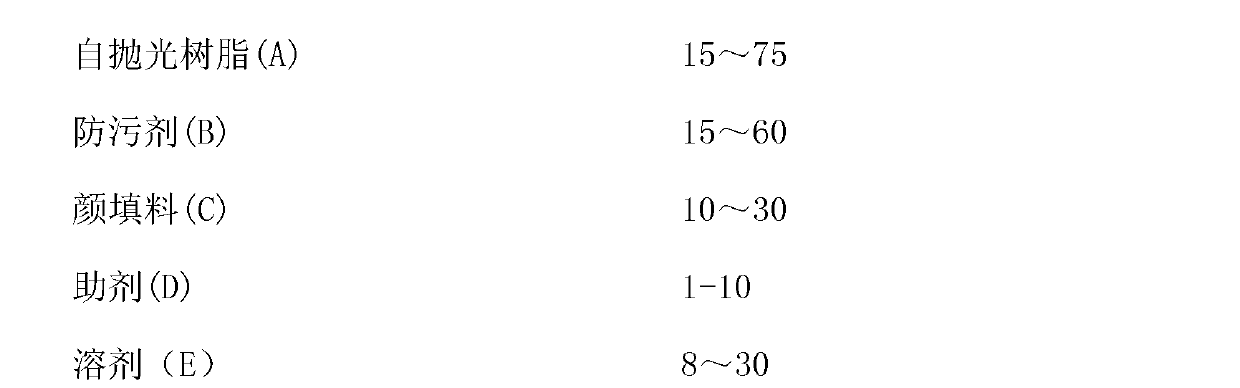

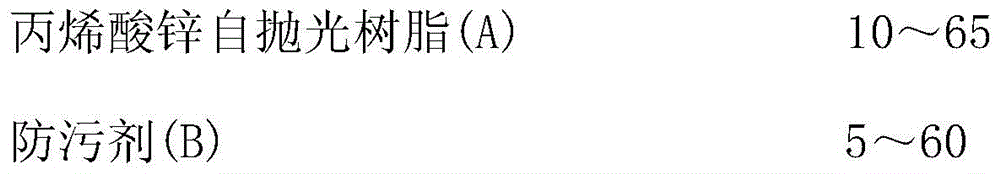

Preparation and application of self-polishing antifouling coating matrix resin

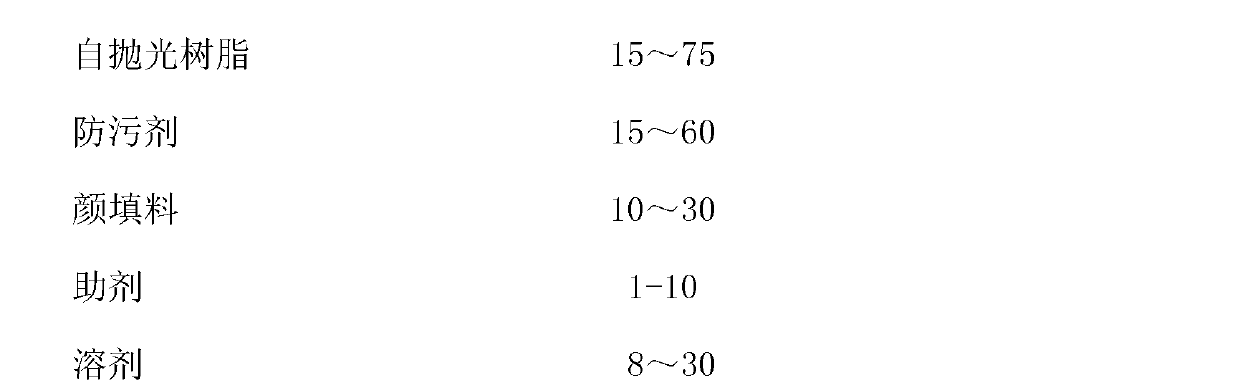

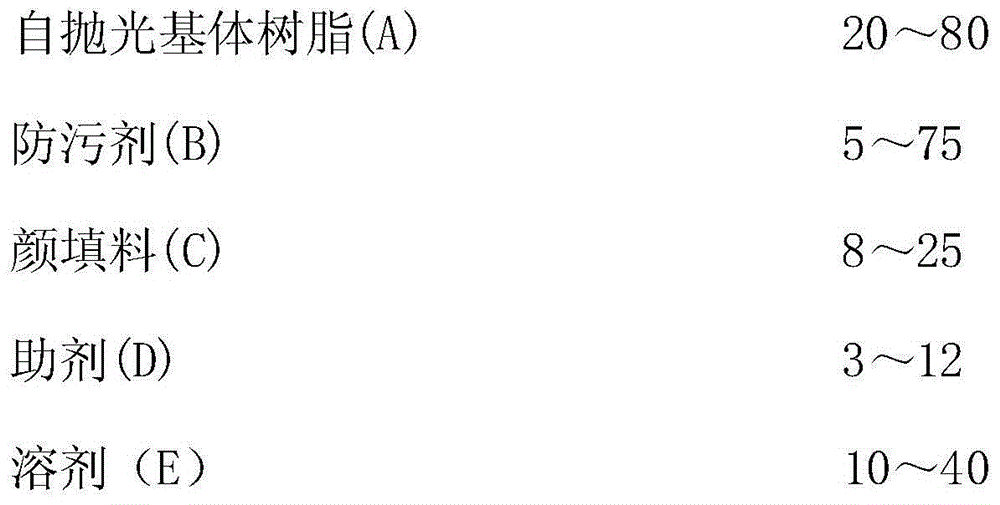

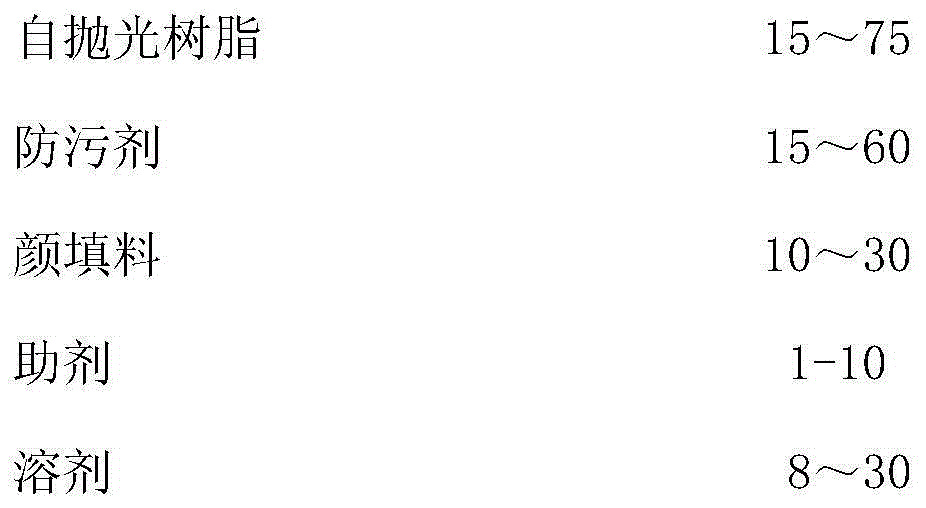

ActiveCN103131289AHas self-polishing propertiesReduce surface propertiesAntifouling/underwater paintsPaints with biocidesToxic materialSolvent

A self-polishing antifouling coating is characterized in that the self-polishing antifouling coating includes a fluorine-containing silyl acrylate matrix resin (A) having a self-polishing performance, an antifouling agent (B), a pigment filler (C), an assistant (D) and a solvent (E). The antifouling coating which has a good polishing performance and a low surface performance has the characteristics of long antifouling period, good antifouling performance, excellent polishing resistance reduction performance and the like. The antifouling coating which contains no toxic substances comprising tin, DDT or the like has the characteristics of friendliness to the sea environment, simple and convenient construction, easy maintenance and the like, and can satisfy the demands on the long-acting antifouling coating of subsea facilities.

Owner:MARINE CHEM RES INST CO LTD

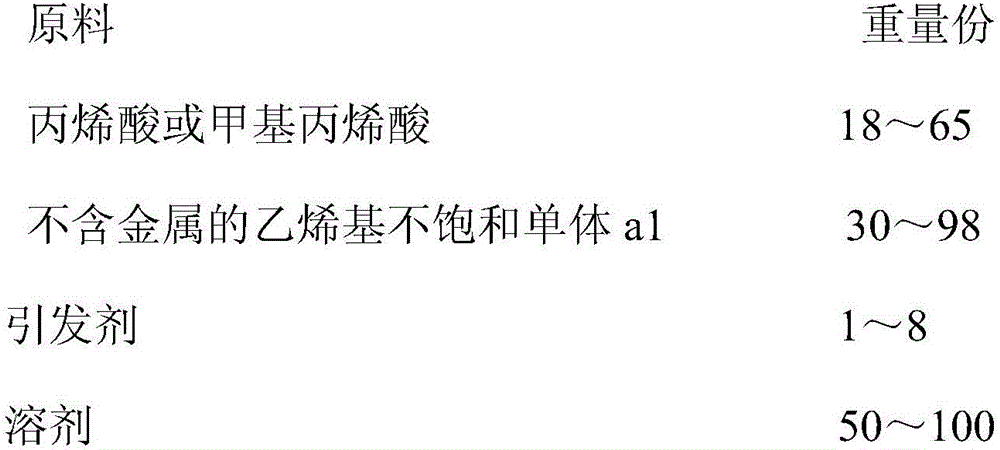

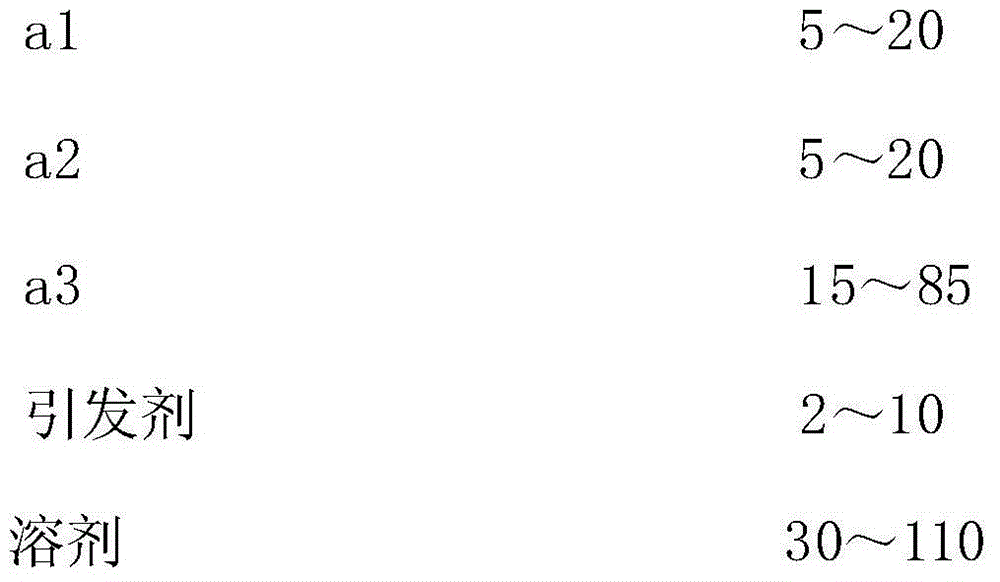

Copper-free and environment-friendly self-polishing ocean antifouling paint

ActiveCN106675294AEmission reductionSave resourcesAntifouling/underwater paintsPaints with biocidesSolventPolymer

The invention provides copper-free and environment-friendly self-polishing ocean antifouling paint. The copper-free environment-friendly and self-polishing ocean antifouling paint is prepared from matrix resin A with self-polishing property, an organic antifouling agent B without any copper type antifouling agent, pigment filling C, an auxiliary agent D and a solvent E. The matrix resin A is characterized in that a preparation process comprises two steps: step 1: carrying out free radical copolymerization on acrylic acid or methacrylic acid and an ethenyl unsaturated monomer a1 without metal in a certain amount of solvent at certain temperature under the action of an initiator, so as to prepare an acrylic acid or methacrylic acid pre-polymer; step 2: carrying out refluxing reaction on the pre-polymer prepared by the step 1, saturated organic acid and oxide or hydroxide of zinc or a zinc salt at certain temperature; stopping the reaction until obtained effluent reaches a pre-set value, so as to obtain the matrix resin A.

Owner:MARINE CHEM RES INST

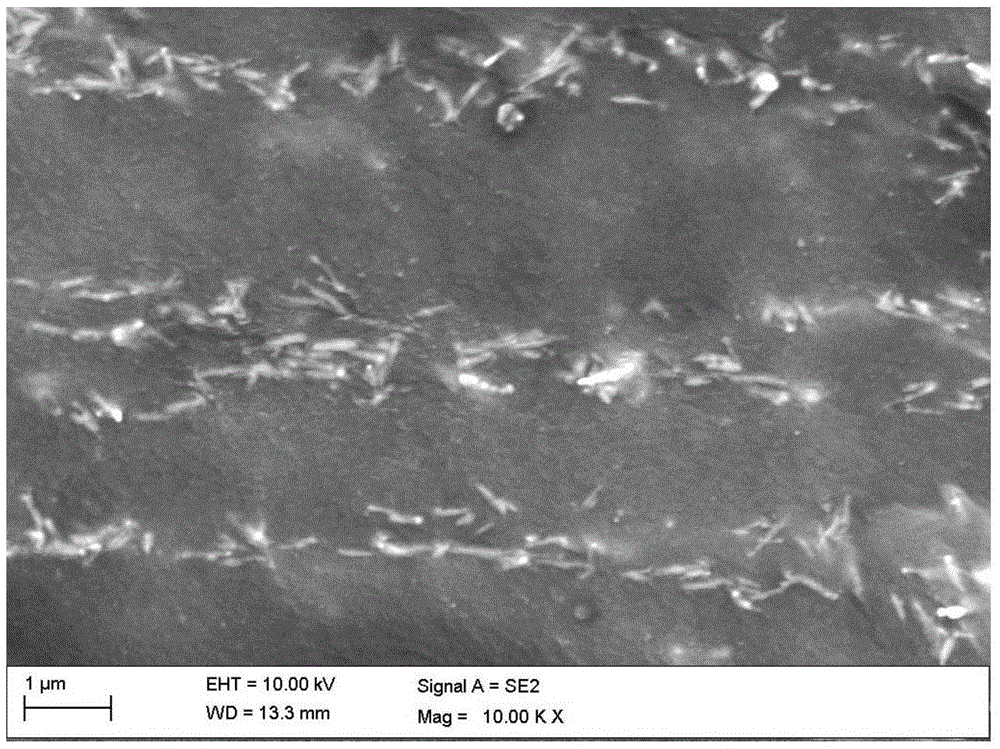

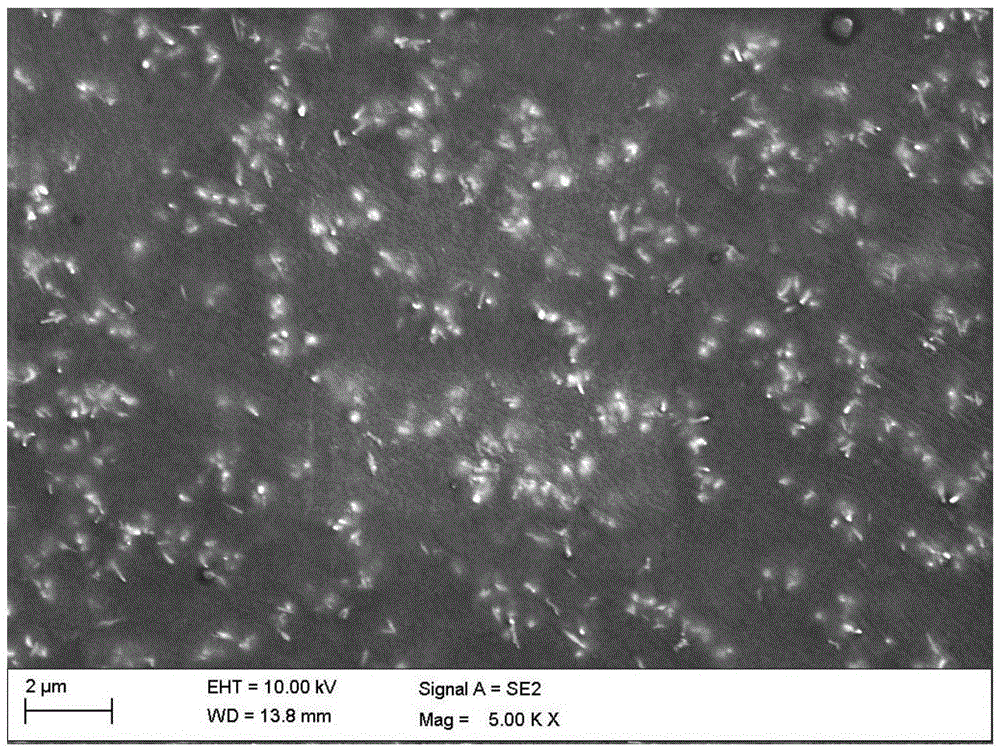

Antifouling material with directionally arranged acicular filler and preparation method thereof

ActiveCN105602380AReduce dosageReduced attachment sitesAntifouling/underwater paintsRosin coatingsSolventRosin

The invention belongs to the technical field of antifouling paint preparation, and relates to an antifouling material with a directionally arranged acicular filler and a preparation method thereof. The antifouling material is prepared from a self-polishing resin, rosin, a main antifouling compound, an auxiliary antifouling compound, a pigment, an acicular filler, a surfactant, an aid and a solvent. The preparation method comprises the following steps: sequentially adding the self-polishing resin, rosin, main antifouling compound, auxiliary antifouling compound, pigment, surfactant and solvent into a container according to the set parts by mass, carrying out ball milling or high-speed stirring, sequentially adding the aid and acicular filler according to the set parts by mass, stirring to obtain an antifouling paint, coating the antifouling paint onto a matrix surface, and curing the antifouling paint in a uniform magnetic field to form a film so that the acicular filler is directionally arranged along the magnetic field direction, thereby obtaining the antifouling material with the directionally arranged acicular filler. The antifouling compound coating and microstructure antifouling are combined to reduce the consumption of the antifouling compounds, and the antifouling material has favorable static antifouling property. The preparation method is simple and easy to implement; and the product has the advantages of energy saving, environment friendliness and long antifouling period, and is suitable for large-area application.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Comb type acrylic resin of lateral chain grafting polyester resin and preparation method and application thereof

InactiveCN102532559AEfficient releaseRelease stabilityAntifouling/underwater paintsPaints with biocidesPlasticizerAcrylic resin

The invention introduces comb type acrylic resin of lateral chain grafting polyester resin and a preparation method and application thereof. The value is homopolymer or copolymer with hydroxylated acrylic resin as a main chain, aliphatic polyester segmer as a lateral chain and polyester as inner ester and cyclic diester. The comb type acrylic resin of lateral chain grafting polyester resin can be used for preparing ocean antifouling paint. The antifouling paint is composed of the following components by weight 25 to 60 portions of comb type acrylic resin object solution of lateral chain grafting decomposable polyester resin, 1 to 20 portions of plasticizers, 1 to 30 portions of fillers and 1 to 40 portions of anti-fouling agents. The resin has the advantages of being high in mechanical b, having decomposable lateral chains and adjustable in decomposing speed, is applied to self-polishing anti-fouling coating, enables ships to have better polishing effect in traveling state and stopping state, achieves effective, stable and continuous releasing of anti-fouling agents, thereby prolonging anti-fouling efficacy, reducing dock repairing times and having potential economical and military benefits.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Matrix resin having self-polishing performance and self-polishing antifouling coating prepared by same

ActiveCN104974631AGood self-polishing performanceControllable self-polishing performanceAntifouling/underwater paintsPaints with biocidesCoated surfaceSurface layer

The invention relates to a matrix resin having self-polishing performance and an environmentally-friendly type self-polishing antifouling coating prepared by the same; the matrix resin contains a functional group, so that the matrix resin has good self-polishing performance; according to the antifouling coating prepared by the matrix resin, the functional group-containing matrix resin on the surface of an antifouling coating layer is subjected to a hydrolysis reaction with weak alkaline seawater to generate a hydrophilic resin and is gradually dissolved in the seawater, at the same time, a coated antifouling agent is released, denudation of a surface layer is achieved, a newly-exposed coating layer continues to undergo a hydrolysis reaction with the seawater, and finally, the self-polishing effect of layer-by-layer stripping of the coating layers is achieved. The antifouling coating prepared by the matrix resin has the characteristics of controllable self-polishing performance, long anti-fouling efficiency period, excellent antifouling performance and the like.

Owner:MARINE CHEM RES INST

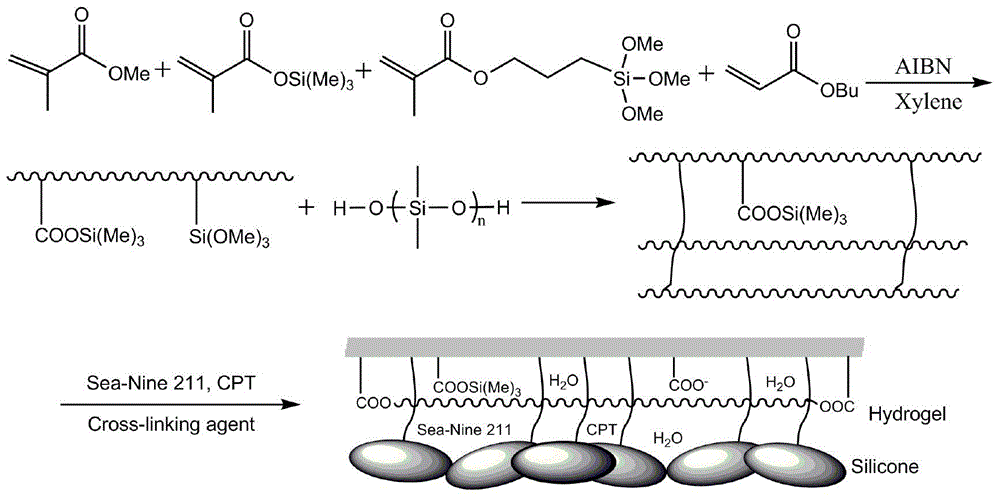

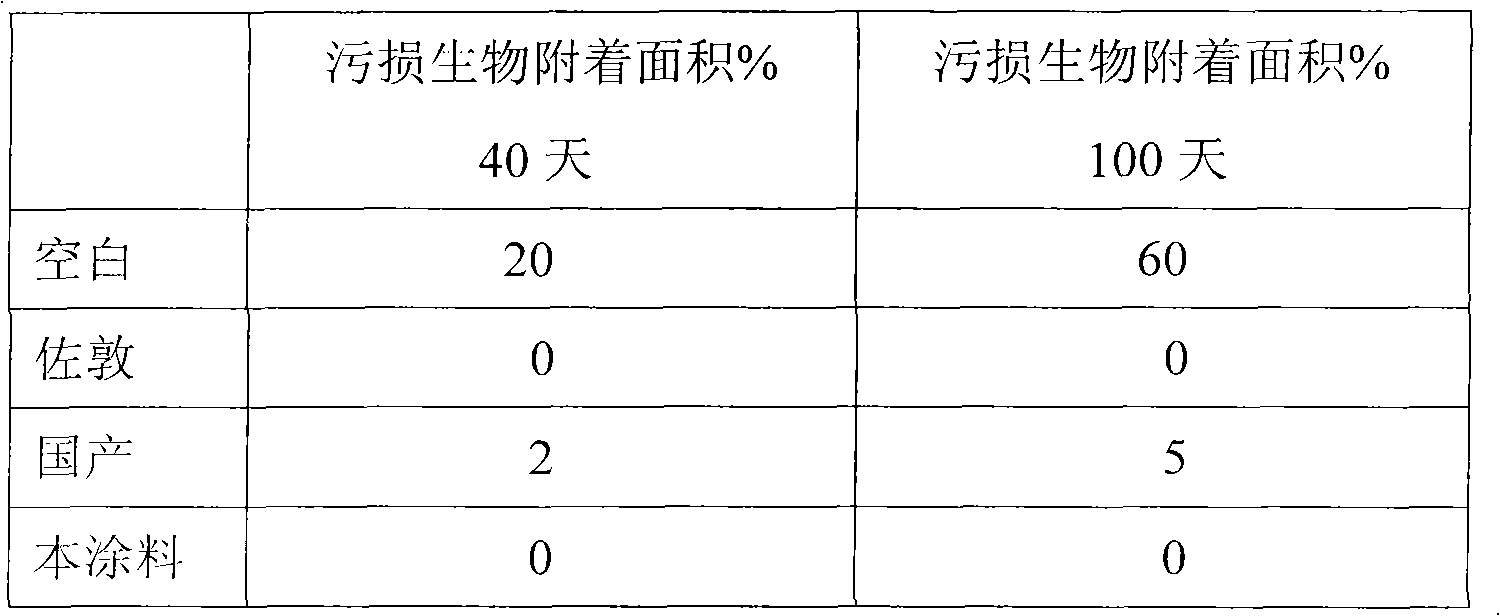

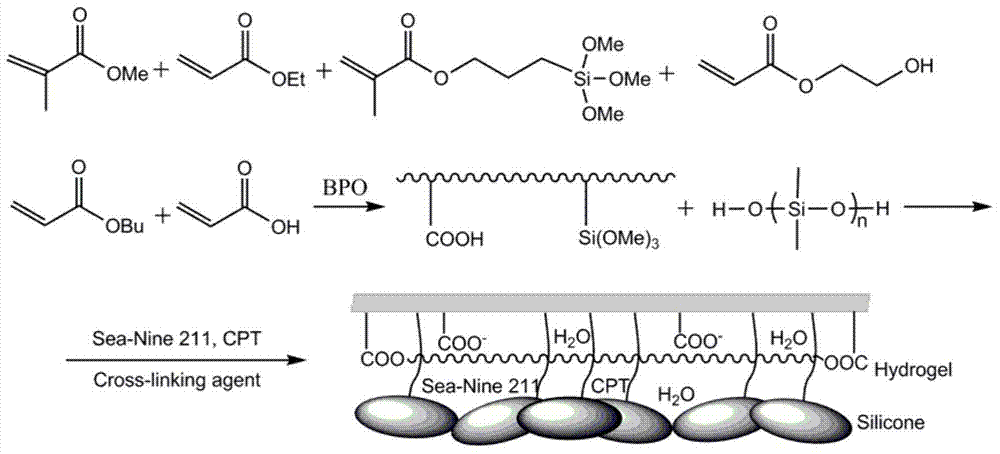

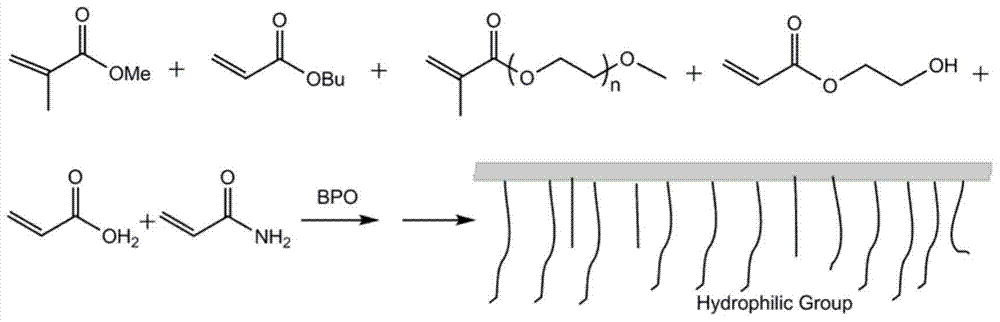

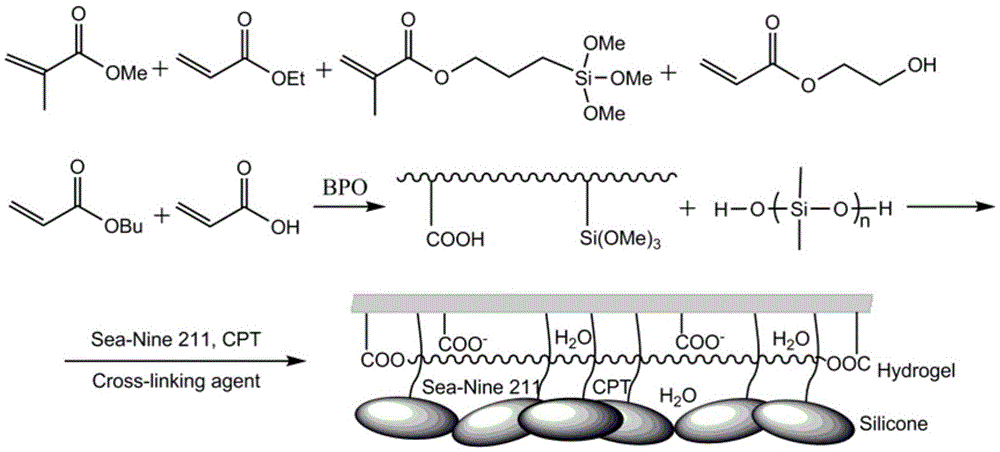

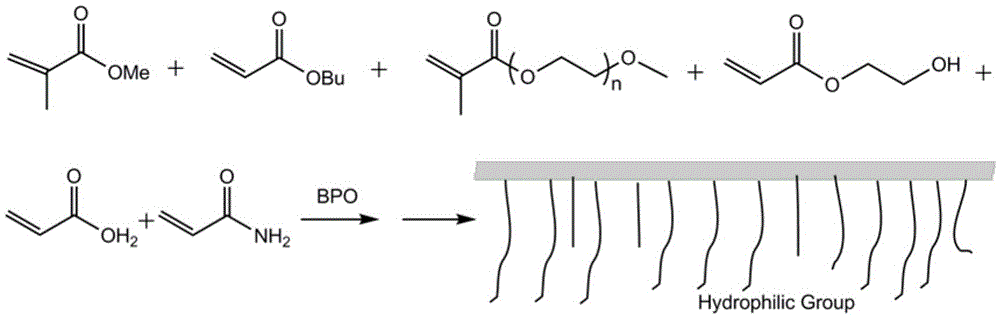

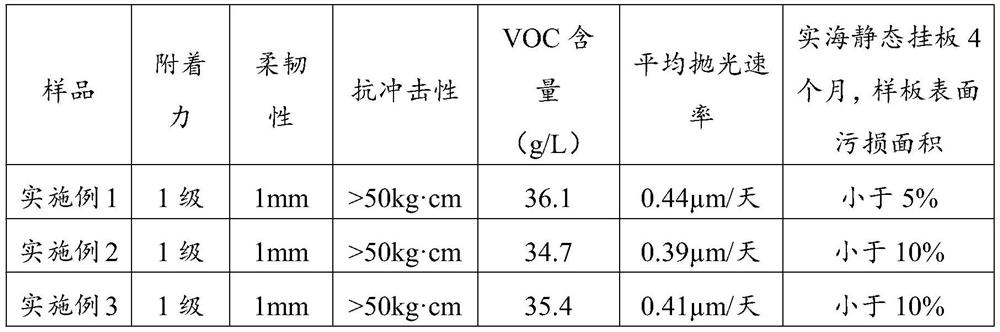

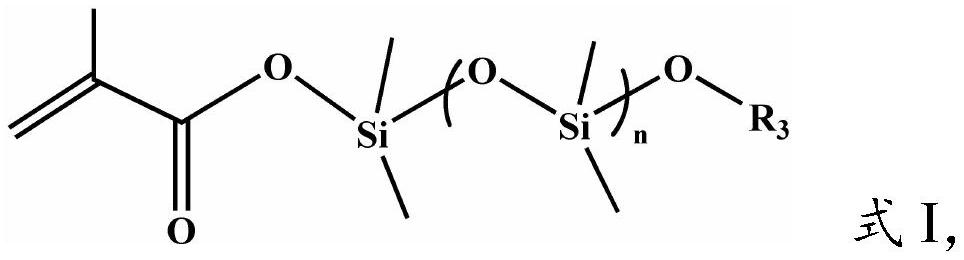

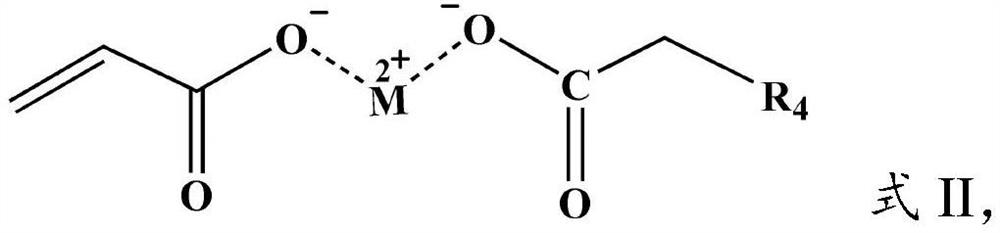

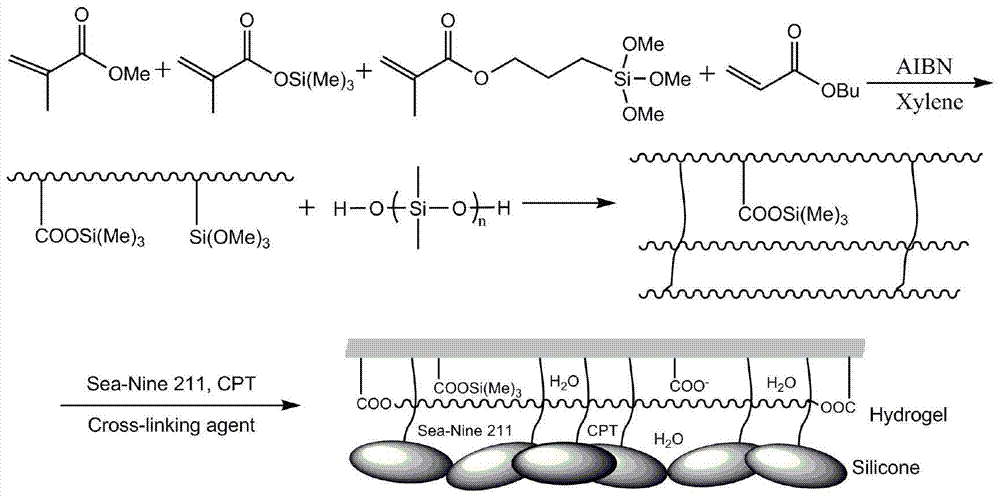

Preparation method of silicone modified acrylic hydrogel antifouling coating

ActiveCN105219206AImprove adhesionPrevent adhesionAntifouling/underwater paintsPaints with biocidesCross-linkAcrylic resin

A preparation method of a silicone modified acrylic hydrogel antifouling coating comprises the following steps: synthesizing silicone modified acrylic resin, and preparing the hydrogel antifouling coating. The antifouling coating is a double-component coating composed of a component A and a component B, and a mass ratio of the component A to the component B is 8:1, wherein the component A is a resin base material carrier, and comprises, by mass, 55-65 parts of the silicone modified acrylic resin, 4-6 parts of iron oxide red, 0.5-1.5 parts of organic bentonite, 4-6 parts of zinc oxide, 7-9 parts of copper pyrithione, 8-10 parts of a Sea-Nine211 antifouling agent and 10-12 parts of an organic solvent; and the component B is a cross-linking agent carrier, and comprises, by mass, 25-35 parts of an aziridine cross-linking agent, 60-70 parts of n-butanol and 4-6 parts of water. Silicone is introduced to the acrylic resin system through a chemical technology, and a proper assistant and the proper antifouling agent are matched to form a low-surface organosilicon antifouling barrier layer, so the coating has self-layering and self-restoration effects, simple process, good antifouling effect, small dosage of the antifouling agent, and effective prolongation of the antifouling time period.

Owner:舟山市知识产权促进会

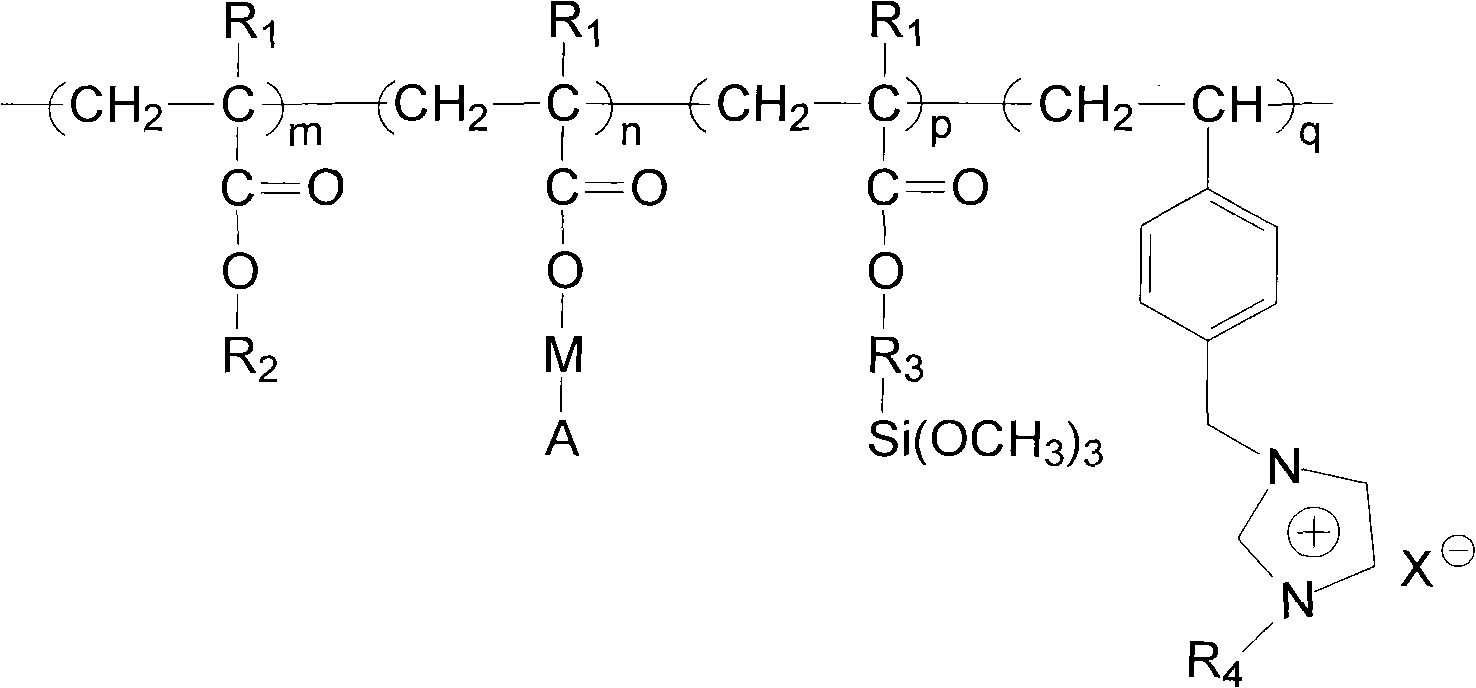

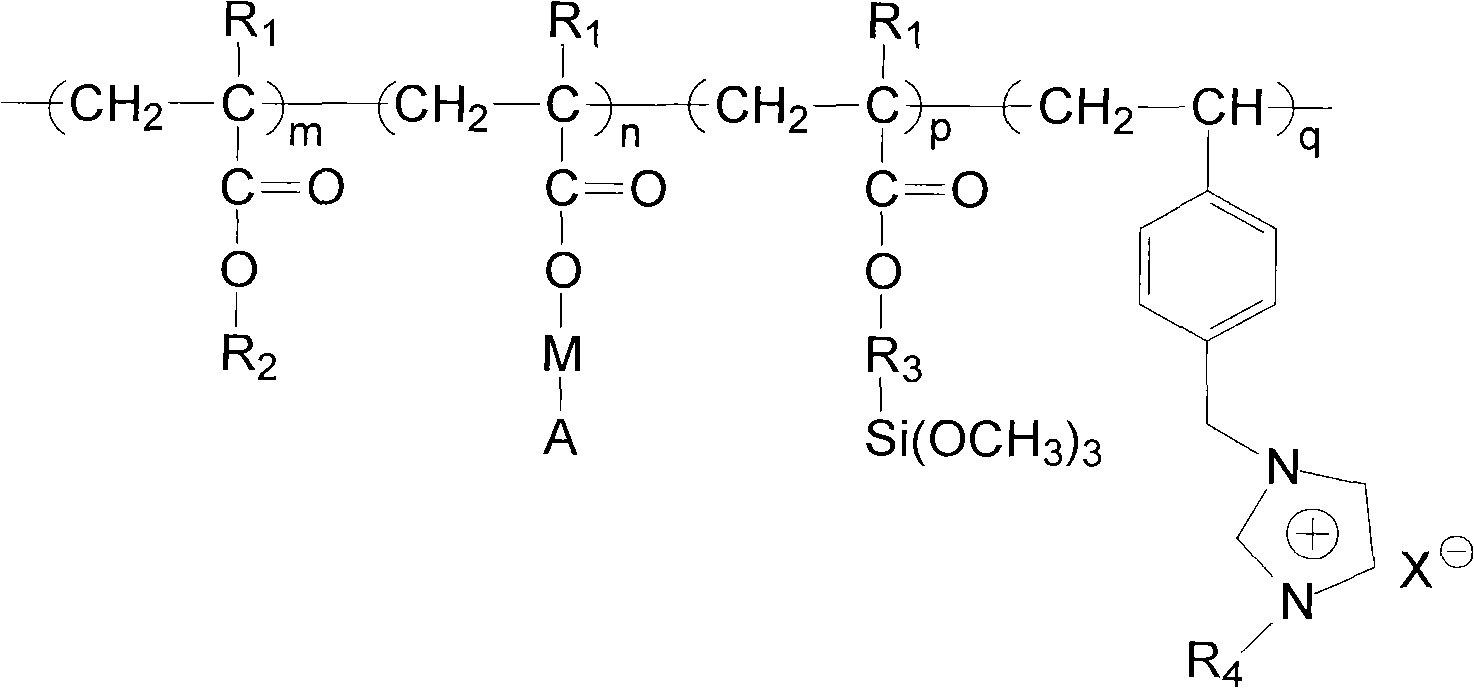

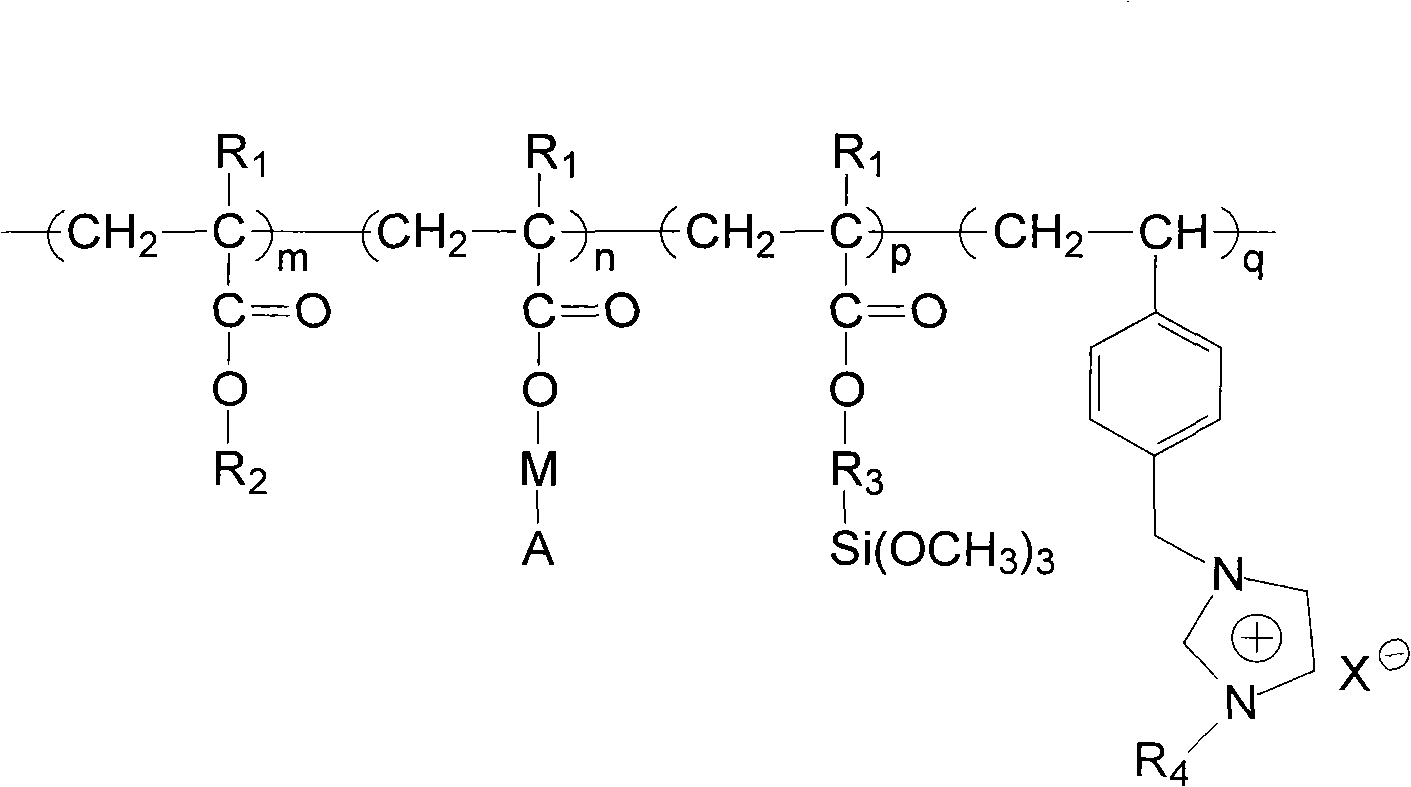

Ionic liquid modified marine antifouling paint

ActiveCN103122187AExtend the antifouling periodEnvironmentally friendlyAntifouling/underwater paintsPaints with biocidesSurface energyOrganic acid

The invention discloses ionic liquid marine antifouling paint, which comprises an antifouling paint matrix resin containing ionic liquid groups, an antifouling agent, a pigment filling material, an aiding agent and an organic solvent. The antifouling paint is mainly applied to the antifouling of a ship. In the ocean, based on the characteristic of the low surface energy of the paint, the adhering of marine organisms is effectively inhibited; an acrylic copolymer on the surface of the coating are hydrolyzed to release organic acid zinc or copper and the antifouling agent, so that the self polishing of the surface of the coating is realized; and the main chain of the hydrolyzed acrylic copolymer contains the ionic liquid groups with bactericidal activities, so that the efficient antifouling activity of the coating is maintained continuously, and the adhering of the marine organisms is prevented. Thus, the antifouling paint provided by the invention has the excellent long-term antifouling performance.

Owner:YANTAI ZHONGKE RES INST OF ADVANCED MATERIALS & GREEN CHEM ENG

Environmental-protection type multi-element collaborative marine anti-fouling coating

ActiveCN104761991ALower surface energySurface energy stabilizationAntifouling/underwater paintsPaints with biocidesOrganic solventMulti element

The invention discloses an environmental-protection type multi-element collaborative marine anti-fouling coating. The coating is composed of anti-fouling coating matrix resin containing an anti-fouling active group, a wetting and dispersing agent, a mixed organic solvent, a non-toxic anti-fouling agent, a pigment filler, a levelling agent, a defoaming agent and an anti-settling agent. The coating is non-toxic, does not pollute the environment, and is mainly applied in ship fouling resistance.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation and application of self-polishing antifouling coating matrix resin

ActiveCN103131289BHas self-polishing propertiesReduce surface propertiesAntifouling/underwater paintsPaints with biocidesPolymer scienceOrganic chemistry

A self-polishing antifouling coating is characterized in that the self-polishing antifouling coating includes a fluorine-containing silyl acrylate matrix resin (A) having a self-polishing performance, an antifouling agent (B), a pigment filler (C), an assistant (D) and a solvent (E). The antifouling coating which has a good polishing performance and a low surface performance has the characteristics of long antifouling period, good antifouling performance, excellent polishing resistance reduction performance and the like. The antifouling coating which contains no toxic substances comprising tin, DDT or the like has the characteristics of friendliness to the sea environment, simple and convenient construction, easy maintenance and the like, and can satisfy the demands on the long-acting antifouling coating of subsea facilities.

Owner:MARINE CHEM RES INST CO LTD

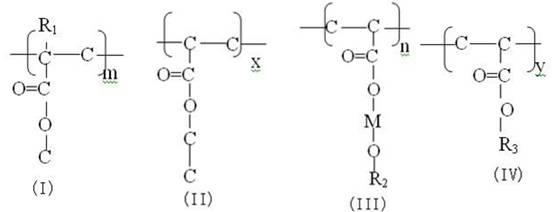

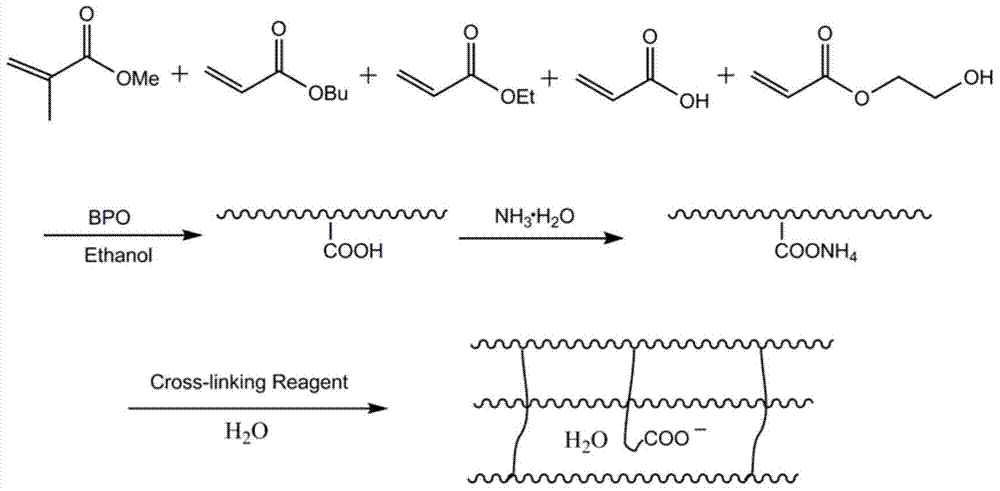

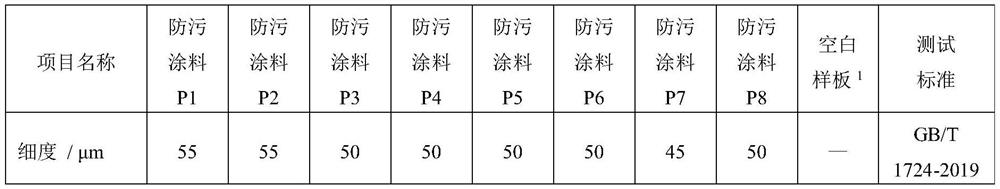

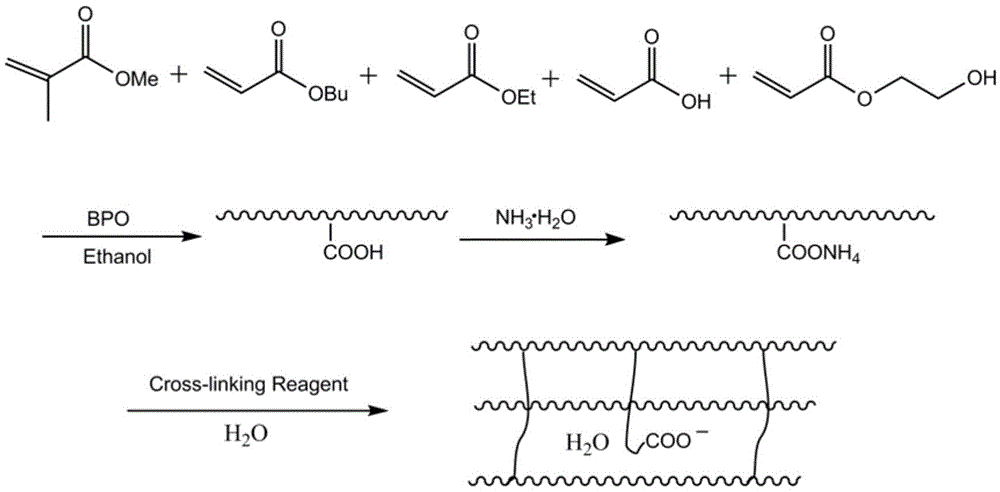

Aqueous self-polishing antifouling coating substrate resin and antifouling coating prepared from same

InactiveCN102617795ALow VOC contentEasy constructionAntifouling/underwater paintsPaints with biocidesMaterials scienceVolatile organic compound

The invention provides aqueous self-polishing antifouling coating substrate resin and an antifouling coating prepared from the same. The resin is prepared with a simple preparation method, and does not contain toxic agents such as DDT (Dichlorodiphenyltrichloroethane), organic tin and the like. The self-polishing antifouling coating is aqueous, has the characteristics of low VOC (Volatile Organic Compound) content, sea environmental friendliness, easiness and convenient for construction, easiness for maintaining and the like, and can be applied to a special substrate surface; and moreover, the substrate resin has self-polishing performance, so that the dissolution rate of an organic antifouling agent in seawater is controlled, the antifouling period can be prolonged, and the antifouling requirement is met.

Owner:MARINE CHEM RES INST CO LTD

Aqueous soft biomass anti-fouling paint and preparation method thereof

ActiveCN104293062AExtend the antifouling periodSave energyAntifouling/underwater paintsPaints with biocidesCross-linkSodium Pyrithione

The invention belongs to the technical field of marine protection and especially relates to an aqueous soft biomass anti-fouling paint and its preparation method. The aqueous soft biomass anti-fouling paint comprises dual components A and B, and mass ratio of the component A to the component B is 8-10: 1. The component A is a resin base-material carrier, and comprises the following ingredients, by weight, 60-66% of aqueous acrylic resin, 0-6% of iron oxide red, 5% of zinc oxide, 0-3% of active silica, 0-1% of organobentonite, 3-4% of zinc pyrithione, 3-4% of copper pyrithione, 9-10% of an antifouling agent, 5% of ethanol and 6% of water. The component B is a cross-linking agent. The formula adopted in the invention is nontoxic and harmless, and the anti-fouling paint obtained after mixing has a good antifouling effect.

Owner:舟山市知识产权促进会

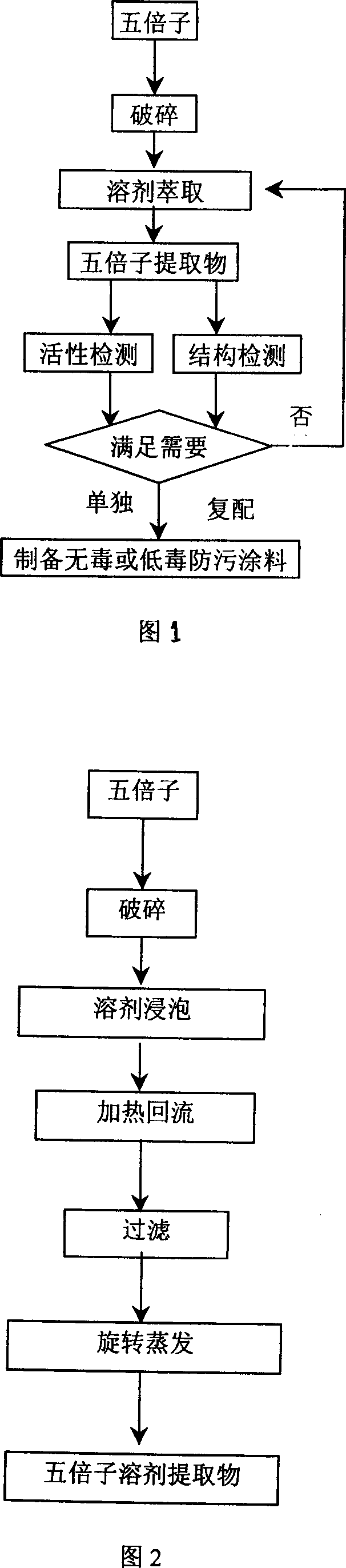

Non-toxic or low-toxicity anti-fouling coating prepared by utilizing Chinese medicinal crop gallnut solvent extract

InactiveCN1935907AReduce dosageReduce pollutionAntifouling/underwater paintsPaints with biocidesOxide compositeSolvent

The invention relates to nontoxic or low toxic anti-fouling paint made by Chinese gall solvent extract which includes resin base metal, dye, anti-fouling agent, and limed rosin, and various auxiliary agents. The anti-fouling agent is formed by Chinese gall extract, or Chinese gall extract and cuprous oxide composite. It is proved that the anti-fouling paint has obvious anti-fouling effect. The new type low toxic anti-fouling paint can effectively prevent marine life defiling, and reduce cuprous oxide use level to realize pollution abatement by properly adjusting the composite proportion of the Chinese solvent extract and cuprous oxide.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

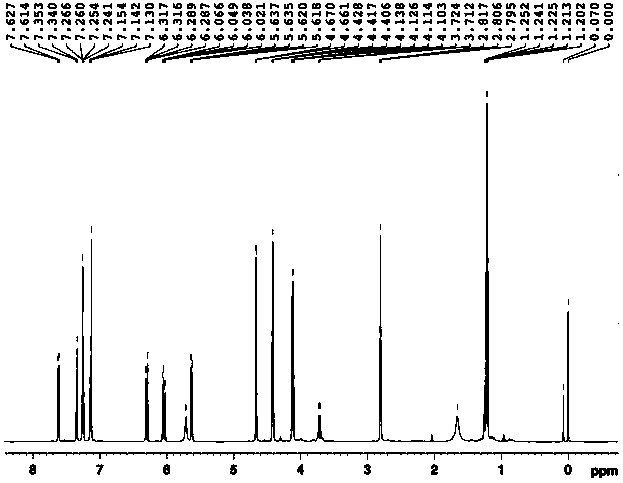

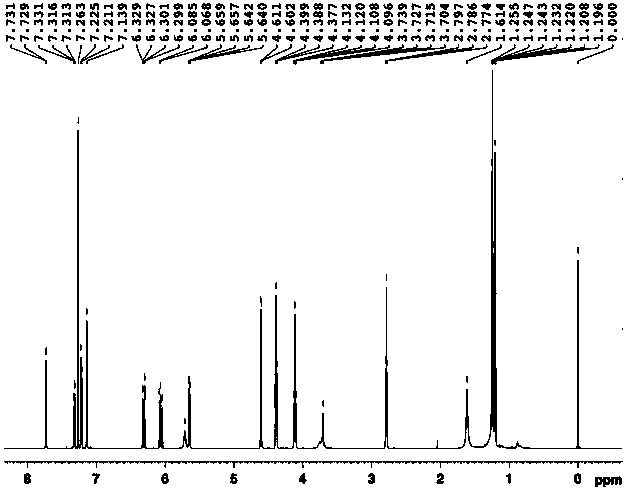

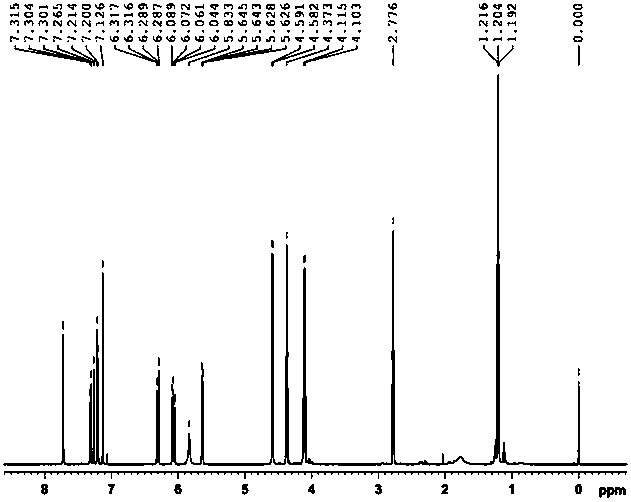

Ester derivative containing acrylamide indole, preparation method and application thereof

InactiveCN103664736AGood self-polishing performanceInhibition of attachmentOrganic chemistryAntifouling/underwater paintsGramineStructural formula

The invention relates to a formula (I) compound containing the structural formula (refer to the Specification), in the formula, X1 refers to H and Cl; X2 refers to H, Cl and Br; R refers to CH3, CH2CH3, CH2(CH3)2, CH2CH2CH2CH3 and CH2CH2CH2CH2CH2CH(CH3)2. The invention also relates to a preparation method for the formula (I) compound and an acyclic acid zinc / copper resin adopting the compound as a comonomer, and the invention further relates to application of the resin compound in marine antifouling paint. According to the formula (I) structure, the acyclic acid zinc / copper resin adopting an ester derivative containing acrylamide indole as the comonomer has a relatively good self-polishing property, can slowly release an antifouling gramine derived structure and can effectively prevent adhesion of marine fouling organisms.

Owner:OCEAN UNIV OF CHINA

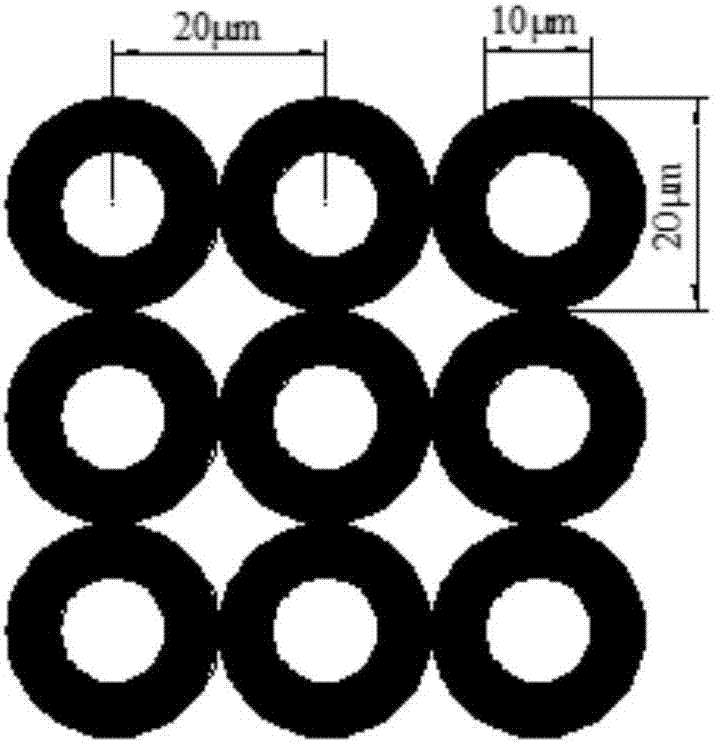

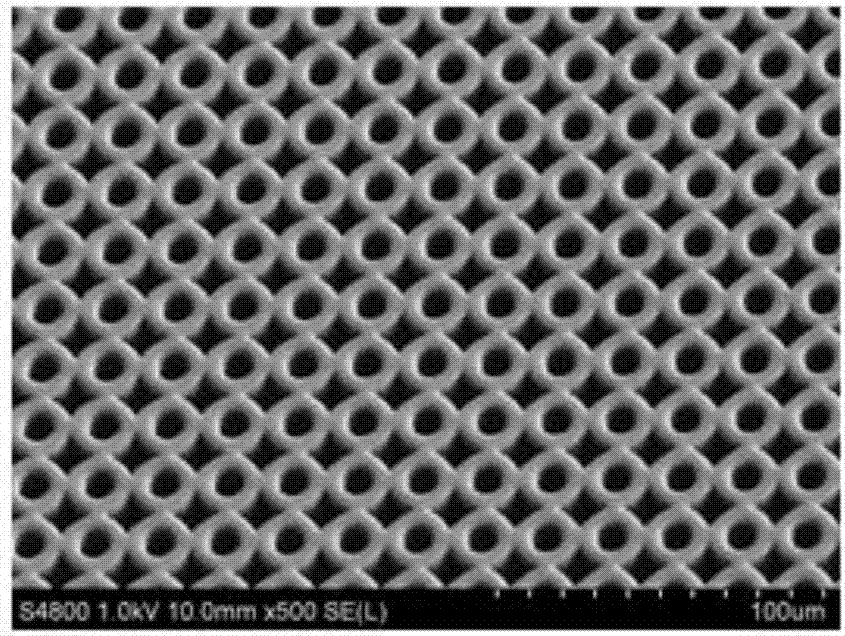

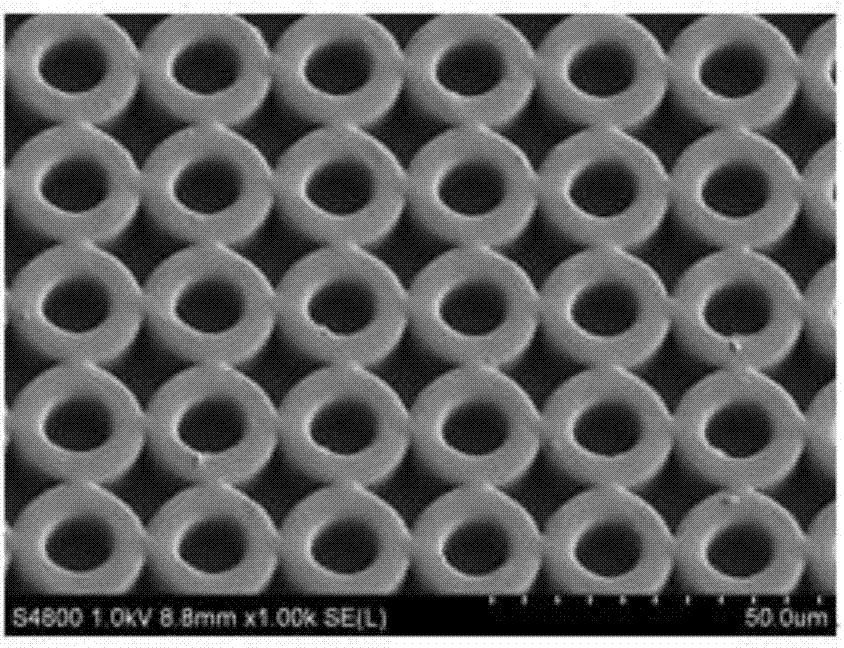

Synergistic antifouling material based on microstructures and antifouling active substances and preparation method thereof

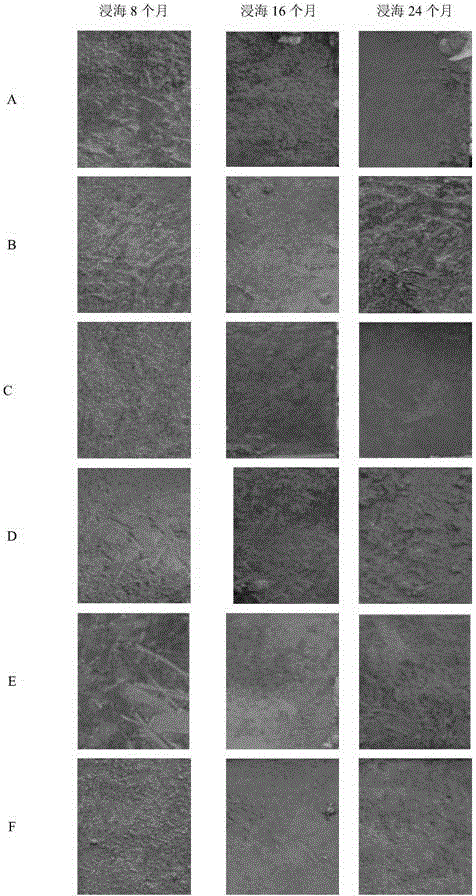

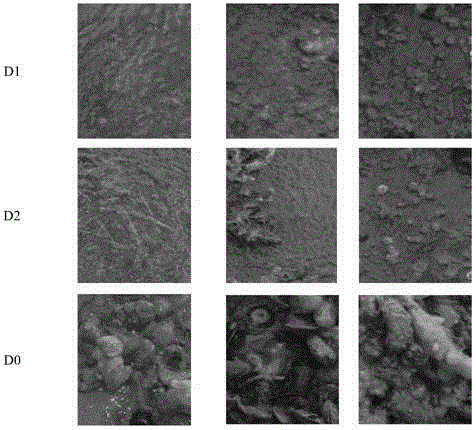

The invention belongs to the technical field of metal corrosion protection, and relates to a synergistic antifouling material based on microstructures and antifouling active substances and a preparation method thereof. The material is composed of matrixes formed by a plurality of microstructure base units with circular shaft structures, wherein the internal lower layer of each microstructure base unit is filled with an antifouling active substance, and the internal upper layer of the microstructure base unit is filled with a sealant. The process of the preparation method comprises steps of preparing microstructures, preparing the liquid antifouling active substances and preparing the synergistic antifouling material, and adhesion of fouling organisms is prevented through synergistic anti-fouling effect of the microstructures and the anti-fouling active substances. Components of the synergistic antifouling material are simple in structure, the material contains no nitrite, phosphate or heavy metals, and metal corrosion protection and inhibition effects on bacterial growth are good; the material is environment-friendly and safe, is a novel antifouling material based on new principles and new technologies because of adoption of surface microstructure properties and the anti-fouling active substances for synergistic fouling prevention, and has good promotion and application prospects.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Rosin organic acid metal salt resin with chemical structural characteristics and performances of acrylate metal salt resin and preparation method and application of rosin organic acid metal salt resin

ActiveCN104530986AThe synthesis method is simpleRaw materials are cheap and easy to getAntifouling/underwater paintsRosin coatingsBenzoic acidArginine

The invention relates to rosin organic acid metal salt resin with chemical structural characteristics and performances of acrylate metal salt resin and a preparation method and application of the rosin organic acid metal salt resin. The rosin organic acid metal salt resin disclosed by the invention has a structural formula of R-X-R1 (I), wherein R refers to acid radicals of benzoic acid, naphthenic acid, salicylic acid, furoic acid, parachlorobenzoic-acid, 2,4-dichlorobenzoic acid, proline, leucine, phenylalanine or arginine; and X refers to Zn<2+>, Cu<2+>, Mg<2+> or Ca<2+> metal ions; and R1 is selected from acid radicals of colopholic acid, ionated rosin acid or dimeric colopholic acid. The rosin organic acid metal salt resin disclosed by the invention is environment-friendly, has the similar chemical structural characteristics with the acrylate metal salt resin and is excellent in matching property with other components in the coating formula. The self-polishing antifouling paint taking the resin as a film forming matter is high in coating toughness, excellent in self-polishing performance and long in antifouling period, accords with the environment-friendly development trend of the antifouling coating and has wide application prospects.

Owner:OCEAN UNIV OF CHINA

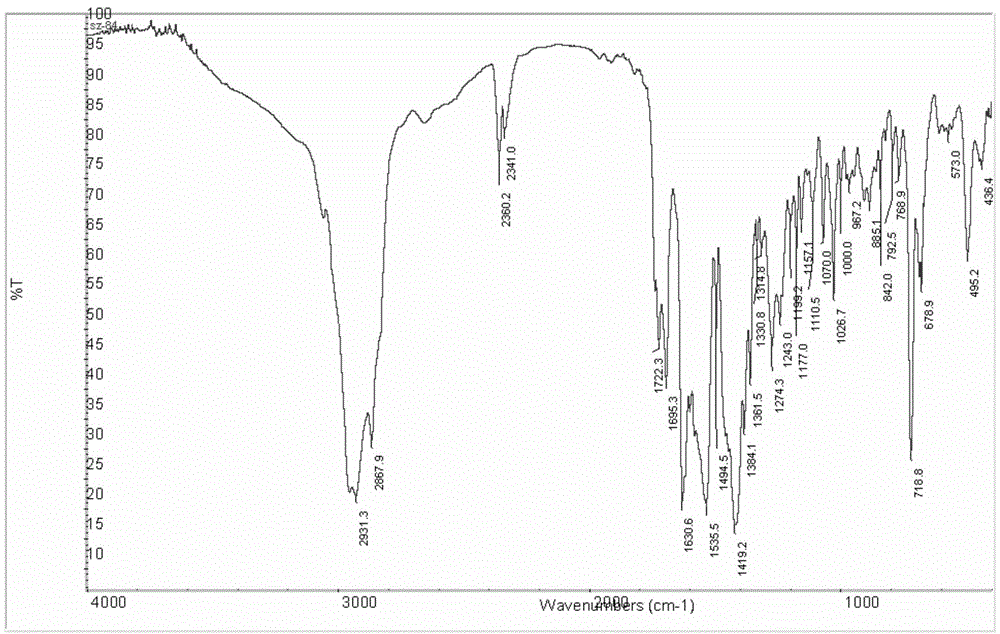

Preparation method for antifouling paint matrix resin containing ionic liquid perssads

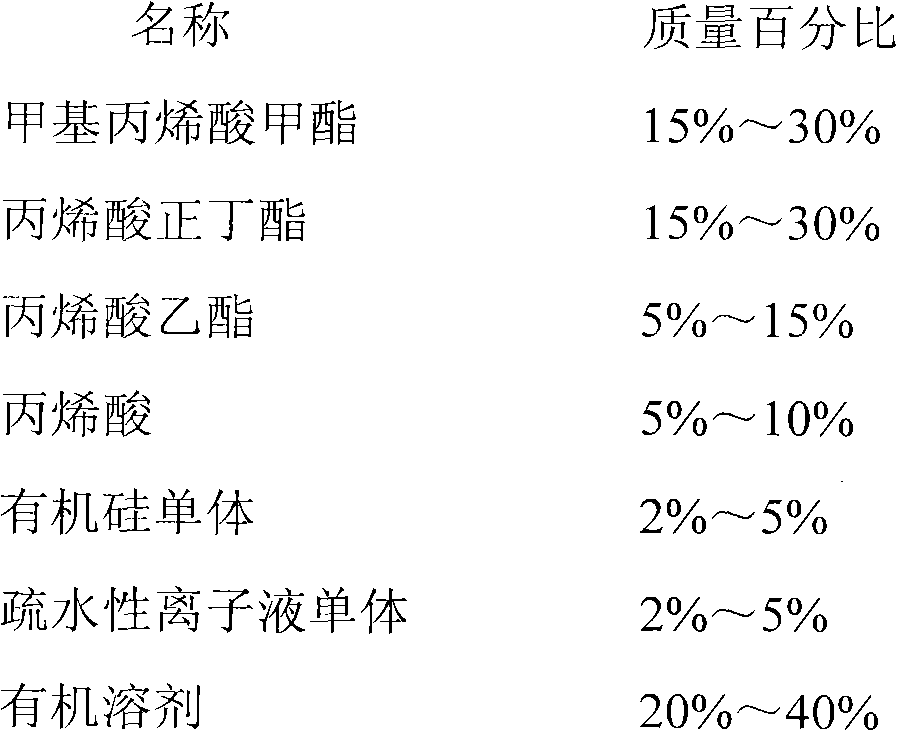

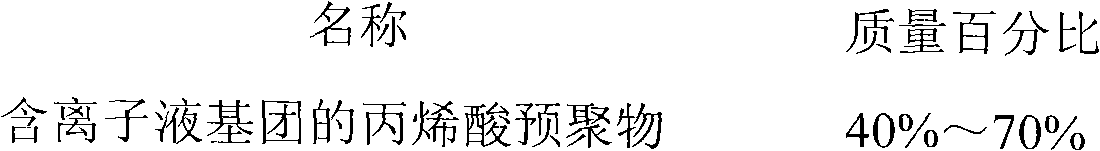

ActiveCN103122047AHigh activityGood eco-friendlinessAntifouling/underwater paintsPaints with biocidesZinc hydroxideSolvent

The invention discloses a preparation method for antifouling paint matrix resin containing ionic liquid perssads. The method comprises the following steps of: firstly synthetizing a hydrophobicity ionic liquid monomer, then polymerizing a crylic acid soft or hard monomer, a hydrophobicity ionic liquid monomer, crylic acid or methacrylic acid, and unsaturated organosilicone monomer in a solvent by an initiator through radical polymerization to obtain a crylic acid prepolymer containing ionic liquid perssads so as to be reacted with a mixture of zinc hydroxide (copper), perfluorinated organic acid and monovalence organic acid to obtain the antifouling paint matrix resin containing ionic liquid perssads. The resin also has a self polishing property and a low surface energy property.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Non-toxic marine ship antifouling coating material and preparation method thereof

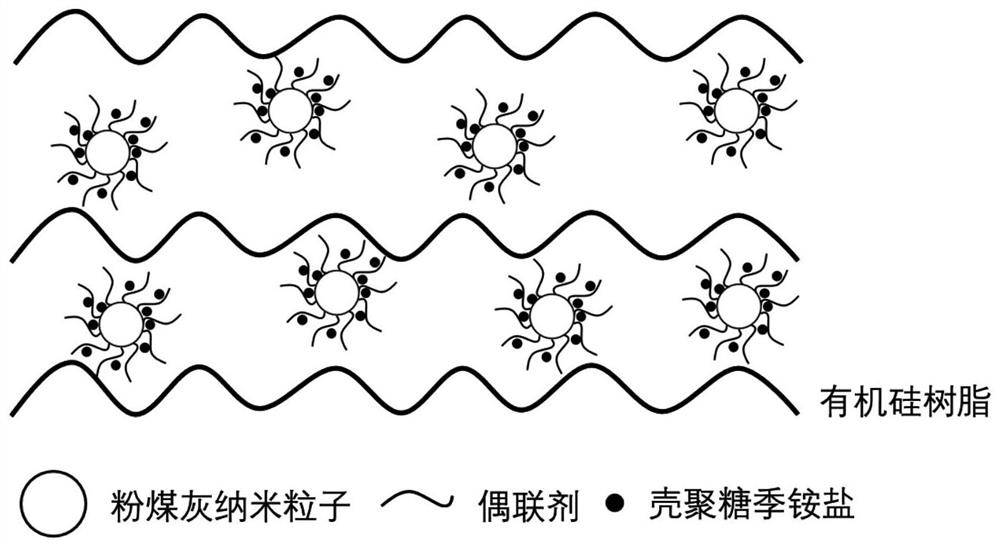

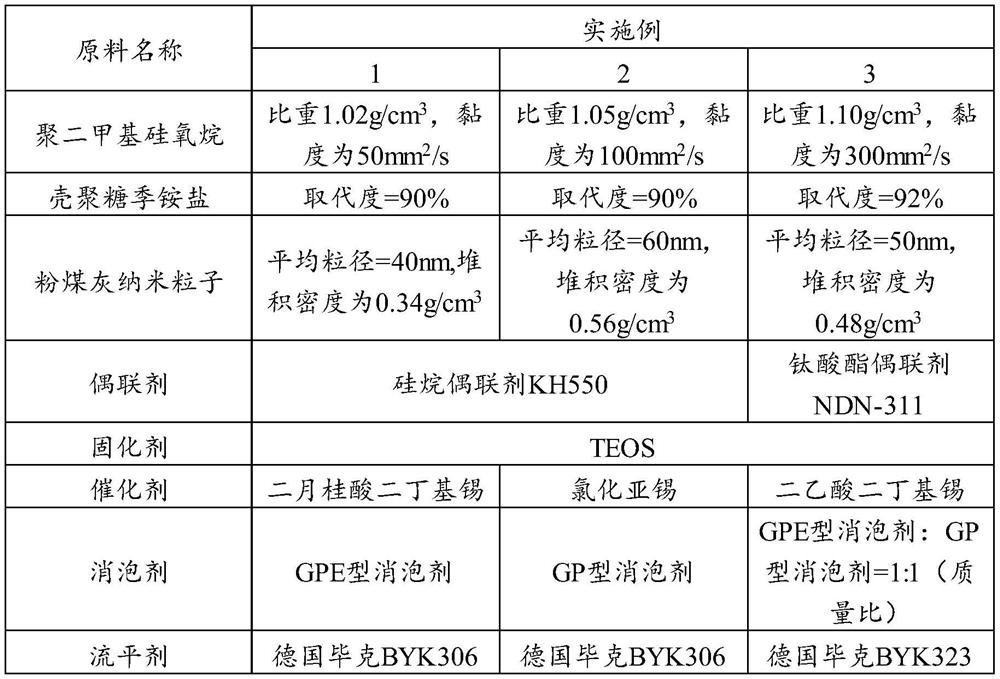

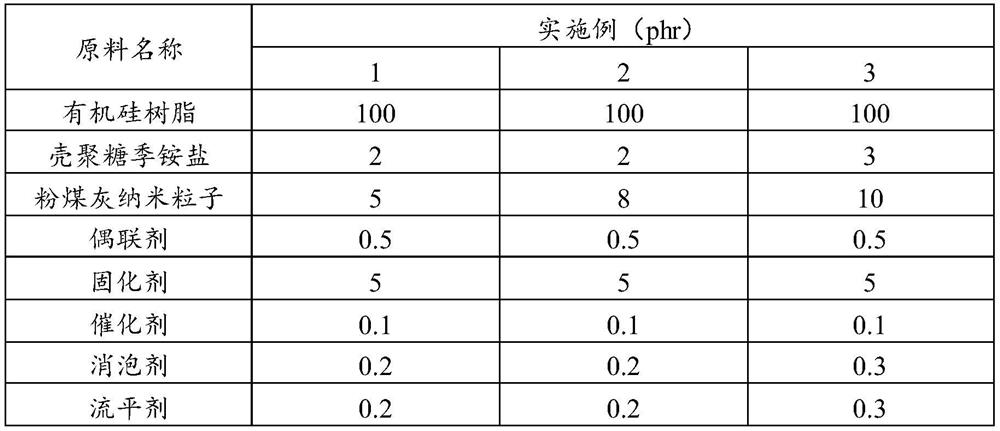

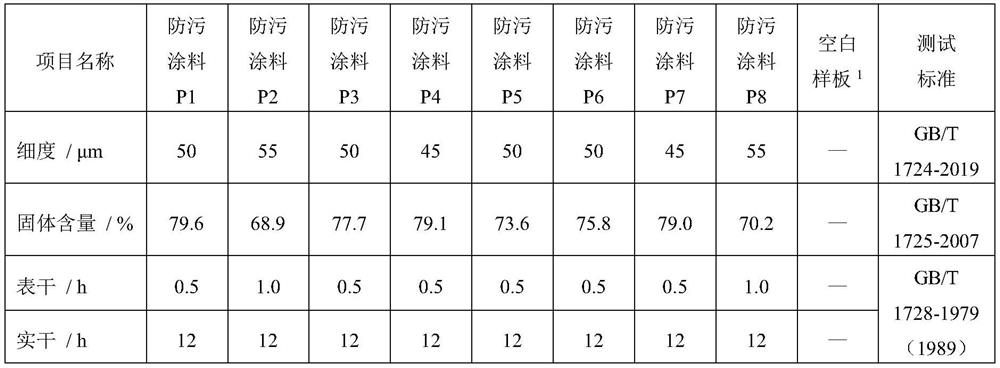

ActiveCN111793431AHigh strengthIncrease elasticityAntifouling/underwater paintsPaints with biocidesOrganosolvFirming agent

The invention provides a non-toxic marine ship antifouling coating material, which is prepared from the following raw materials in parts by mass: 100 parts of organic silicon resin, 1 to 3 parts of achitosan quaternary ammonium salt, 5 to 10 parts of fly ash nanoparticles, 0.5 to 1 part of a coupling agent, 3-5 parts of a curing agent, 0.01 to 0.1 part of a catalyst, 0.2 to 0.5 part of an antifoaming agent, and 0.2 to 0.5 part of a leveling agent. According to the invention, organic silicon resin is used as a matrix, nano fly ash is used as a carrier, and a chitosan quaternary ammonium salt loaded on the surface is used as a main antifouling agent, wherein the chitosan quaternary ammonium salt has good solubility and antibacterial property, has biocompatibility, and is safe and non-toxic,the fly ash nanoparticles have strong alkalinity, and the organic silicon is also a low surface energy material; by using a hydrophilic chitosan quaternary ammonium salt as a main antibacterial material, so that the use of a large amount of organic solvents is avoided, the cost is low, and less waste liquid is generated; and fly ash nanoparticles are activated to promote the self-polymerization of organic silicon resin molecules to form a layered structure with certain orientation so as to enhance the strength and elastic modulus of the coating material.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

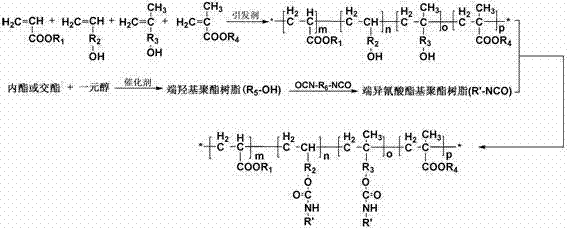

Zinc salt-containing acrylic polyurethane resin as well as preparation method and application thereof

InactiveCN112062921AGood physical and mechanical propertiesImprove mechanical propertiesAntifouling/underwater paintsPaints with biocidesFunctional monomerFresh water

The invention relates to zinc salt-containing acrylic polyurethane resin as well as a preparation method and application thereof. A hydroxyl acrylic functional monomer and organic zinc salt are introduced into an acrylate resin structure at the same time, and then isocyanate reacts with hydroxyl in the acrylate resin structure to form the zinc salt-containing acrylic polyurethane resin. The resinis used as a film forming matter, and an environment-friendly antifouling agent, a pigment filler, an auxiliary agent, a solvent and the like are added, so that environment-friendly antifouling paintcan be obtained. The antifouling paint has excellent physical and mechanical properties; the antifouling property of the paint is excellent, and the antifouling period of the paint is long; the paintdoes not contain organic tin, dichlorodiphenyl trichloroethane and other antifouling agents; an antifouling agent compounding system meeting the requirements of environmental protection laws and regulations is used, and marine environment friendliness is achieved; good fresh water soaking resistance is achieved, and the use requirement that a ship enters a fresh water river can be met; the single-component paint is low in VOC content, simple and convenient to construct and easy to maintain; and expensive acrylate monomers are not used, so that the paint has very high cost performance and is beneficial to popularization and application.

Owner:无锡市耀得信化工产品有限公司

Transparent anti-fouling membrane preparation method

ActiveCN106318060AHigh mechanical strengthReduce dissolution rateAntifouling/underwater paintsPaints with biocidesPolyvinyl alcoholUltrasonic dispersion

The invention belongs to the technical field of ocean engineering antifouling paint preparation, and particularly relates to a transparent anti-fouling membrane preparation method. The technological process comprises the steps that hydrotalcite nanosheets are dispersed in distilled water to obtain a hydrotalcite aqueous solution through ultrasound, polyvinyl alcohol is added into the hydrotalcite aqueous solution to be heated till polyvinyl alcohol is dissolved to form a mixed solution, standing is conducted on the mixed solution, the mixed solution is naturally cooled and then dispersed through ultrasound, phenolic amide antifoulant is added into the mixed solution, and an anti-fouling mixed solution is obtained through ultrasonic dispersion; the quartz surface is coated with the anti-fouling mixed solution through a spin-coating method or a coating method, and a transparent anti-fouling membrane is obtained after drying; the transparent anti-fouling membrane protects fouling of the parts such as detection shots, light sources and submarine windows of marine optical instruments. The molecular structure and preparation method of the transparent anti-fouling membrane are simple, the technology is scientific and reliable, the raw materials are low in cost and easy to obtain, the light transmittance is high, the antifouling activity is good, the effect is obvious, the application environment is friendly, and an important application prospect in the marine antifouling field is achieved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

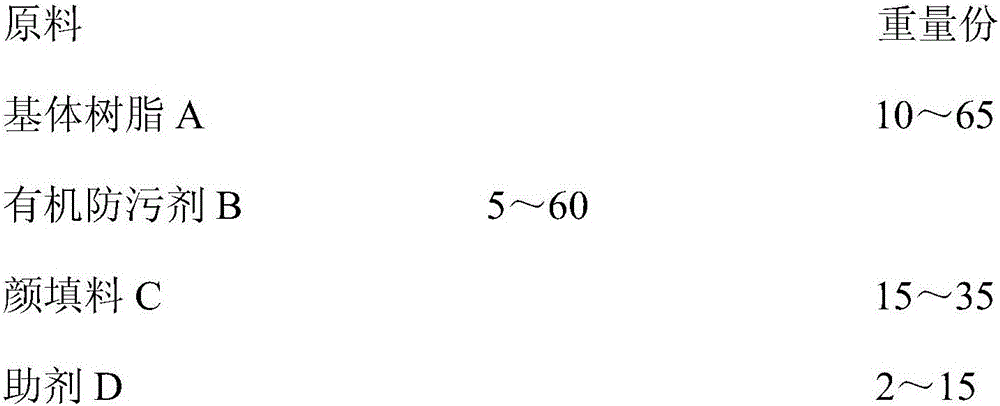

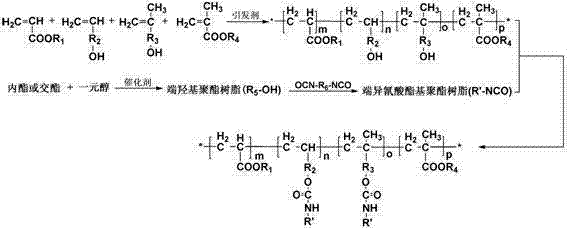

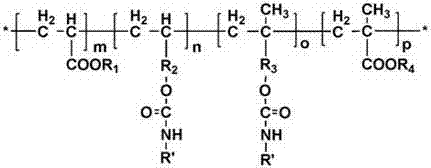

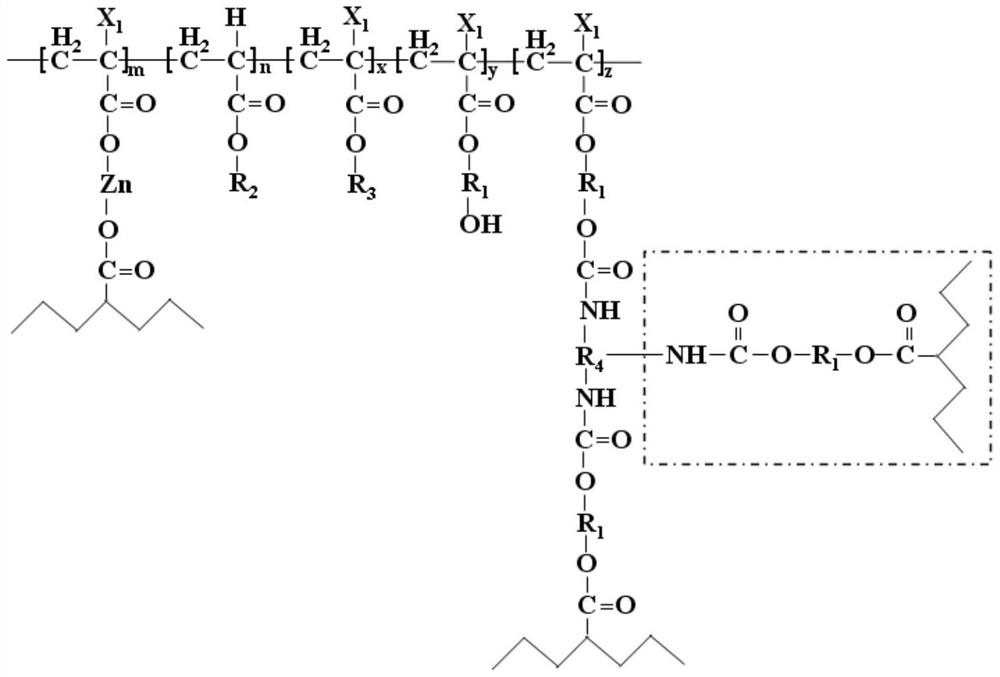

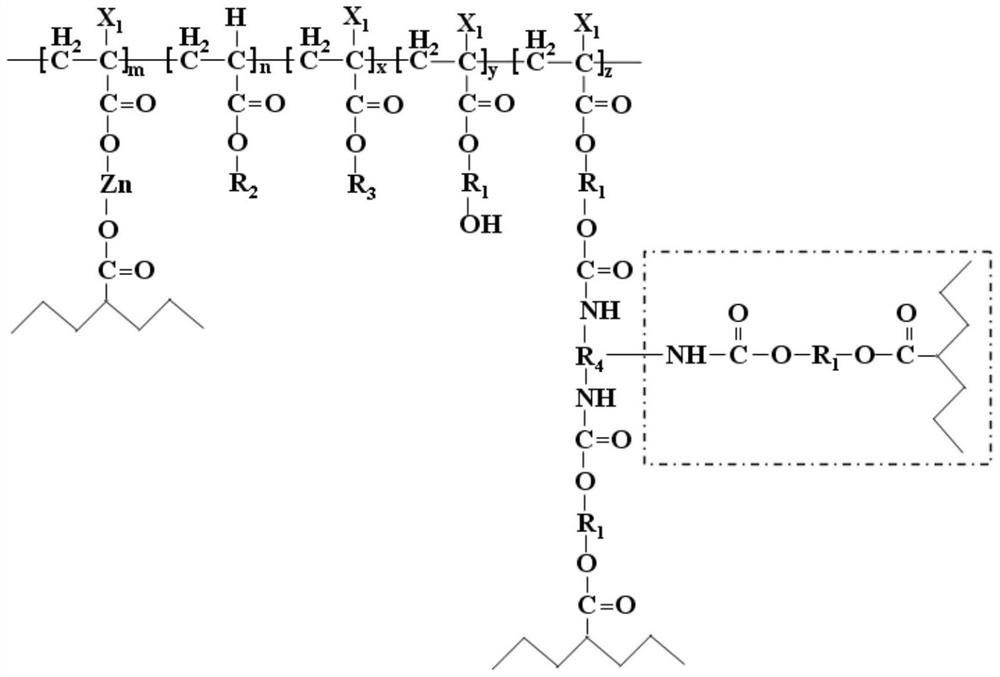

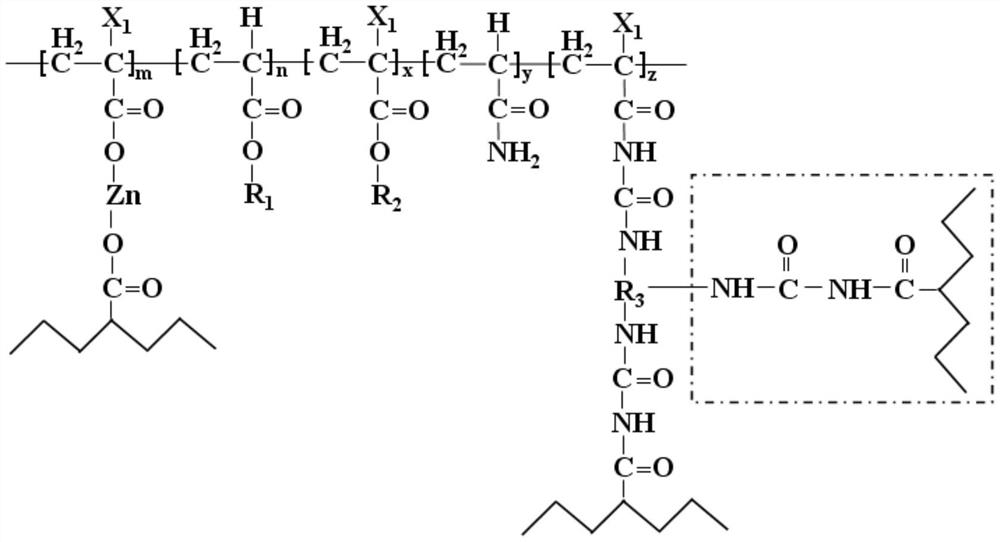

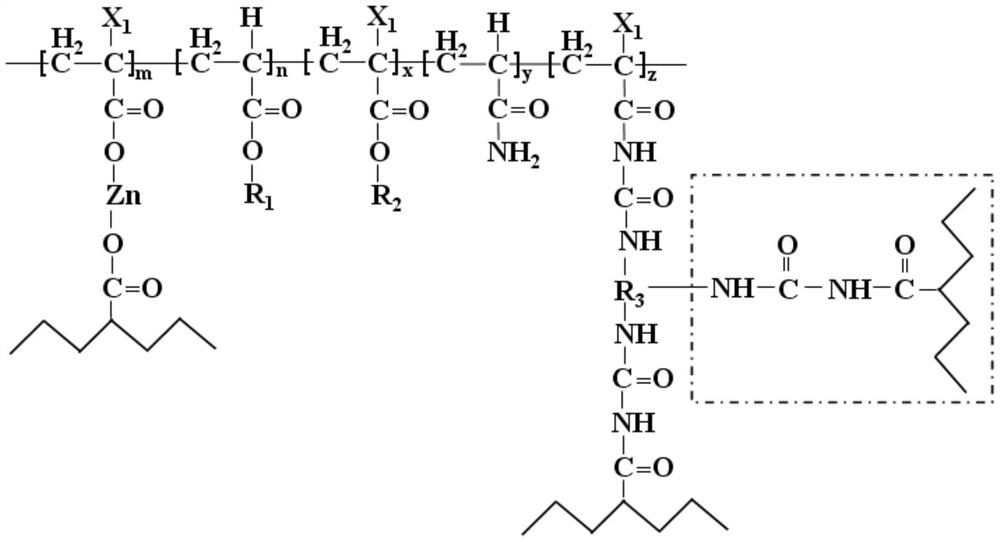

Polyurea modified organic zinc salt-containing acrylic resin as well as preparation method and application thereof

ActiveCN112062922AGood physical and mechanical propertiesExtend the antifouling periodAntifouling/underwater paintsPaints with biocidesAcrylic resinFresh water

The invention relates to polyurea-modified organic zinc salt-containing acrylic resin as well as a preparation method and application thereof. Acrylamide and organic zinc salt are introduced into an acrylate resin structure at the same time, and then isocyanate reacts with acylamino in the acrylate resin structure to form the polyurea-modified organic zinc salt-containing acrylic resin. With the resin used as a film forming matter, an environment-friendly antifouling agent, a pigment filler, an auxiliary agent, a solvent and the like are added, and therefore, environment-friendly antifouling paint can be obtained. The antifouling paint has excellent physical and mechanical properties; the antifouling property of the antifouling paint is excellent, and the antifouling period of the antifouling paint is long; the paint does not contain organic tin, dichlorodiphenyl trichloroethane and other antifouling agents, an antifouling agent compounding system meeting the requirements of environmental protection laws and regulations is used, so that marine environment friendliness is achieved; good fresh water soaking resistance is achieved, and the use requirement that a ship enters a fresh water river can be met; the single-component paint is low in VOC content, simple and convenient to construct and easy to maintain; and expensive acrylate monomers are not used, so that the paint has very high cost performance and is beneficial to popularization and application.

Owner:无锡市耀得信化工产品有限公司

Water-based soft bio-antifouling paint and preparation method thereof

ActiveCN104293062BExtend the antifouling periodSave energyAntifouling/underwater paintsPaints with biocidesAcrylic resinPyrithione

Owner:舟山市知识产权促进会

Fluorine-modified zinc acrylate antifouling coating material and preparation method thereof

InactiveCN105295631AHas self-polishing propertiesLower surface energyAntifouling/underwater paintsPaints with biocidesSurface layerSolvent

The present invention relates to a fluorine-modified zinc acrylate antifouling coating material and a preparation method thereof, wherein the base components comprise, by mass, 20-60 parts of a fluorine-modified zinc acrylate resin, 10-40 parts of an antifouling agent, 10-35 parts of a pigment filler, 1-10 parts of an auxiliary agent, and 10-35 parts of a solvent. According to the present invention, the prepared marine antifouling coating material has self-polishing property, wherein the coating gradually exposes the new surface layer so as to release the antifouling agent along with the new surface layer exposing; the coating material has low surface energy, such that marine microorganisms are difficult to adhere; and the required antifouling agent consumption is less than the antifouling agent consumption in other technologies, such that the harm on the environment is low.

Owner:SHANGHAI UNIV

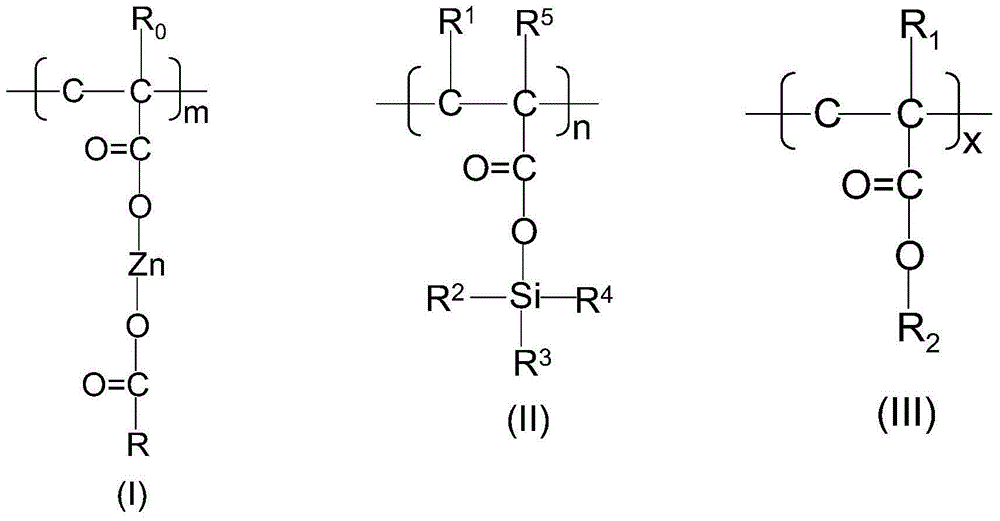

Preparation and Application of Matrix Resin for Zinc Acrylic Self-polishing Antifouling Coatings

ActiveCN103897092BGood self-polishing propertiesEasy to control dissolution rateAntifouling/underwater paintsPaints with biocidesToxic materialZinc

The invention relates to preparation and application of zinc acrylate-type self-polishing matrix resin for an antifouling coating. The matrix resin has good self-polishing property, and the antifouling coating prepared by using the matrix resin has the characteristics of being long in anti-fouling period, excellent in anti-fouling property, excellent in polishing and drag-reduction performances and the like. The invention provides the anti-fouling coating prepared from the zinc acrylate-type self-polishing matrix resin for the antifouling coating. The matrix resin has good self-polishing property, and the anti-fouling coating prepared by the matrix resin has the characteristics of being long in antifouling period, excellent in antifouling property, excellent in polishing and drag-reduction performances and the like. The anti-fouling coating does not contain toxic substances such as tin and dichloro-diphenyl-tricgloroethane (DDT), has the characteristics of being friendly to the marine environment, simple and convenient to construct, easy to maintain and the like, and can meet the requirements of underwater facilities on the long-term antifouling coating in the sea.

Owner:MARINE CHEM RES INST CO LTD

Environment-friendly antifouling paint as well as preparation method and application thereof

PendingCN114213930AExcellent antifouling activityGood surface self-renewalAntifouling/underwater paintsPaints with biocidesPolymer modifiedIonic polymerization

The invention provides environment-friendly antifouling paint as well as a preparation method and application thereof, and relates to the technical field of paint. The anionic polymerizable monomer, the cationic polymerizable monomer and the triisopropyl silicon acrylate are used as raw materials to prepare the anion-cation polymer modified emulsion, and the anion-cation polymer modified emulsion is used as a film-forming substance to endow the environment-friendly antifouling paint with excellent antifouling activity and good surface self-renewal and self-polishing capabilities; the antifouling period of the coating is obviously prolonged; meanwhile, the anion-cation polymer is used as an antifouling agent to replace a cuprous oxide heavy metal antifouling agent, so that the damage to the marine ecological environment caused by the release of heavy metal ions is effectively avoided. In addition, the environment-friendly antifouling coating provided by the invention is a water-based coating, takes water as a thinner, and is environment-friendly; the environment-friendly antifouling paint provided by the invention is good in film-forming property, strong in mechanical property of a paint film, stable in self-polishing rate, and excellent in water soaking resistance and antifouling property.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Novel marine antifouling coating

InactiveCN104830179AIncrease profitIncrease release speedAntifouling/underwater paintsRosin coatingsTemperature controlControlled release

The invention belongs to the technical field of preparation of ocean engineering antifouling coatings and in particular relates to a temperature-sensitive type intelligent marine antifouling coating. The novel marine antifouling coating comprises the following components in parts by weight: 20-60 parts of resin, 1-20 parts of titanium dioxide, 1-20 parts of rosin, 1-30 parts of iron oxide red, 1-10 parts of organobentonite, 1-30 parts of a solvent and 1-50 parts of a temperature-sensitive material. A chitosan material with thermo-response characteristics is adopted, so that the release speed of an antifouling composition in the antifouling coating is increased along with rise of the ambient temperature and is decreased along with reduction of the ambient temperature, intelligent temperature controlled release of the antifouling composition is realized, the antifouling period is prolonged to 1.5-4.5 years, the utilization rate of the antifouling coating is obviously improved, and the product is simple in components, environment-friendly, high-efficiency and low in price, has good application and development prospects and potential economic benefits and is used for antifouling treatment of ocean engineering such as ships, ports and wharfs.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

A kind of low-friction self-lubricating acrylic resin and its preparation method and application, low-friction self-lubricating marine antifouling coating

ActiveCN112480336BImprove adhesionExtend the antifouling periodAntifouling/underwater paintsPaints with biocidesOrganic acidPolymer science

The invention belongs to the technical field of lubricating functional materials, in particular to a low-friction self-lubricating acrylic resin, a preparation method and application thereof, and a low-friction self-lubricating marine antifouling coating. The structure of the low-friction self-lubricating acrylic resin provided by the present invention is grafted and introduced with silicone oil groups to construct a low-friction self-lubricating interface, which significantly improves the mechanical properties of the low-friction self-lubricating acrylic resin and is beneficial to improving the stability of the self-lubricating interface; Grafting introduces unsaturated organic acid divalent metal ion salt structure and sulfonic acid inner salt, which is beneficial to enhance the static antifouling performance of low-friction self-lubricating acrylic resin and prolong the antifouling effect; fluorine-containing acrylate structure and silicone oil structure are introduced together The main chain of the low-friction self-lubricating acrylic resin is beneficial to reduce the surface energy of the paint coating containing the low-friction self-lubricating acrylic resin and enhance the drag reduction performance.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Marine paint

InactiveCN106967320AGood self-polishing propertiesEasy to polishAntifouling/underwater paintsPaints with biocidesAcrylonitrilePolyethylene glycol

The invention provides a marine coating, which comprises the following raw materials in parts by weight: 250 parts of methyl methacrylate, 30 parts of polyethylene glycol diacrylate, 60 parts of acrylonitrile, 110 parts of tributyltin acrylate, and 140 parts of styrene 19 parts of polyethylene glycol, 220 parts of aluminum hydroxide, 110 parts of zinc oxide, 90 parts of titanium dioxide, and 190 parts of xylene. The invention has good self-polishing performance, and the antifouling coating does not contain toxic substances such as tin and DDT, and the antifouling coating prepared by using the matrix resin has the characteristics of long antifouling period, excellent antifouling performance, excellent polishing drag reduction performance, etc. .

Owner:施玉芳

Preparation method of silicone modified acrylic hydrogel antifouling coating

ActiveCN105219206BImprove adhesionPrevent adhesionAntifouling/underwater paintsPaints with biocidesSelf-healingAdjuvant

A preparation method of a silicone-modified acrylic hydrogel antifouling coating, the steps of: first synthesizing a silicone-modified acrylic resin, and then preparing a hydrogel antifouling coating: the antifouling coating is composed of A and B components For two-component coatings, the mass ratio of component A and component B is 8:1, and component A is the resin base material carrier, and the ingredients are: 55-65 parts of silicone modified acrylic resin, 4-4 parts of iron oxide red 6 parts, 0.5-1.5 parts of organic bentonite, 4-6 parts of zinc oxide, 7-9 parts of copper pyrithione, 8-10 parts of Sea‑Nine211 antifouling agent, 10-12 parts of organic solvent; component B is cross-linked agent carrier, the components are 25-35 parts of aziridine cross-linking agent, 60-70 parts of n-butanol, and 4-6 parts of water; the above-mentioned parts are parts by mass. The invention introduces silicone into the acrylic resin system by chemical method, and then cooperates with appropriate additives and antifouling agents to form a low-surface organic silicon antifouling barrier layer, so that the coating has the functions of self-layering and self-repairing, not only the process Simple, good anti-fouling effect, and the amount of anti-fouling agent is small, effectively prolonging the anti-fouling effect.

Owner:舟山市知识产权促进会

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com