Patents

Literature

60results about How to "Reduce surface properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

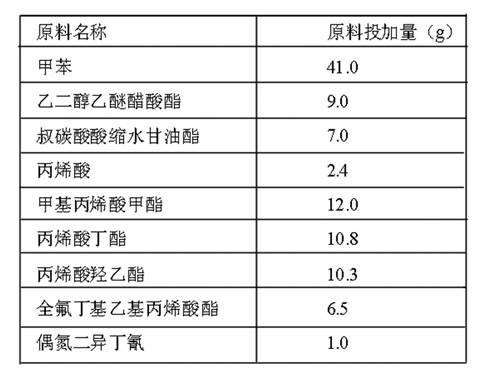

Perfluoro alkyl ethyl acrylic ester-modified single-component acrylic resin and preparation method as well as application thereof

ActiveCN102250280AReduce surface propertiesAccelerated corrosionCoatingsPolymer scienceAcrylic resin

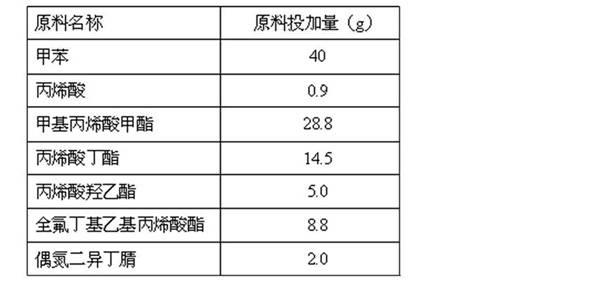

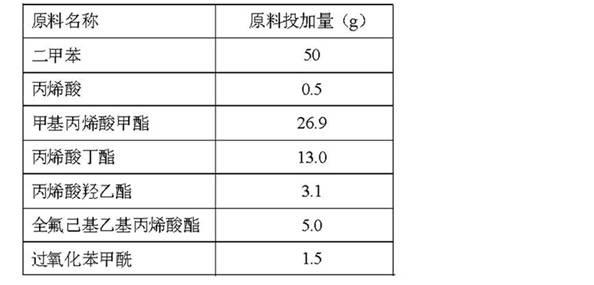

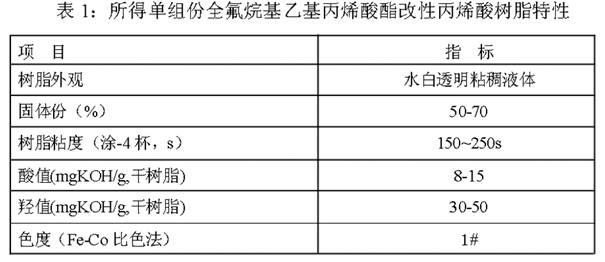

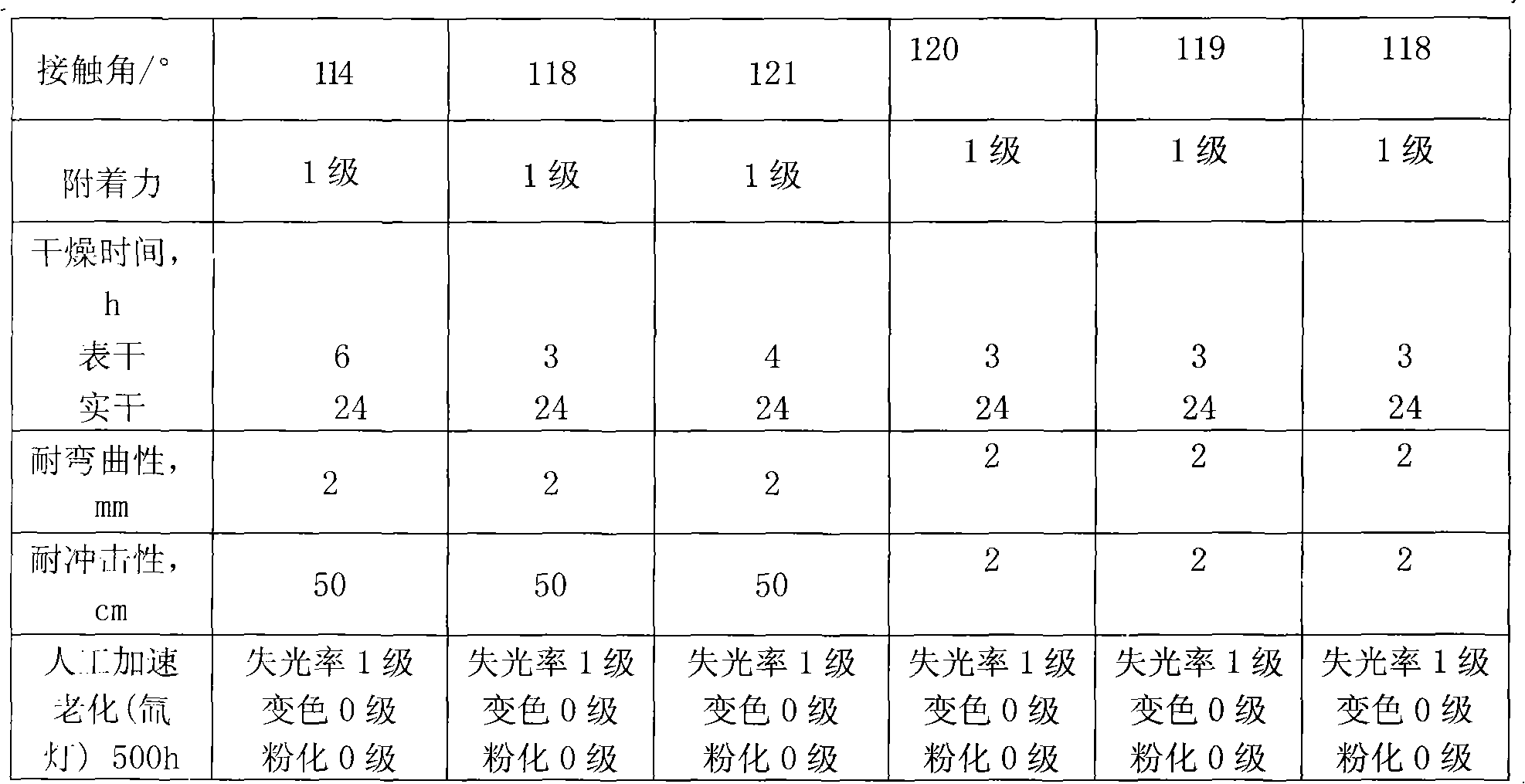

The invention relates to a perfluoro alkyl ethyl acrylic ester-modified single-component acrylic resin and a preparation method as well as application thereof. The perfluoro alkyl ethyl acrylic ester-modified single-component acrylic resin has the structural formula which is shown in the specification, wherein n is equal to 4, 6 or 8; and the molecular weight is 40,000-55,000. The preparation method comprises the following steps of: adding a solvent into a reaction vessel and heating to 60-80 DEG C; uniformly mixing methyl methacrylate, acrylic acid, butyl acrylate, hydroxyethyl acrylate and perfluoro alkyl ethyl acrylic ester type monomer with an initiator and dropwise adding for 2-3 hours; preserving heat for 0.5-1 hour; and cooling to 40-70 DEG C and discharging. The resin prepared by the invention has high thermal stability and chemical resistance stability and low surface energy and is used as a main raw material of a paint; and a coating also has low surface energy, strong water-proof and oil-proof capacities and high weather resistance, corrosion resistance and aging resistance, has superior mechanical performance and high glossiness of an acrylic ester paint, can be cured at normal temperature and is easy and convenient to use.

Owner:JINZHOU DPF TH CHEM CO LTD

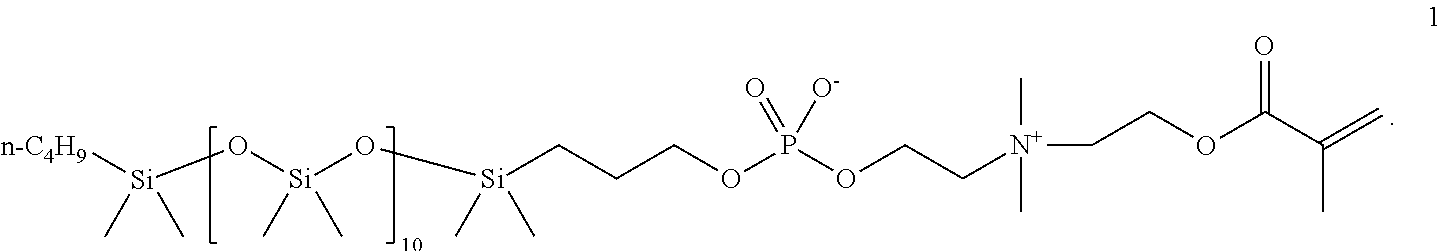

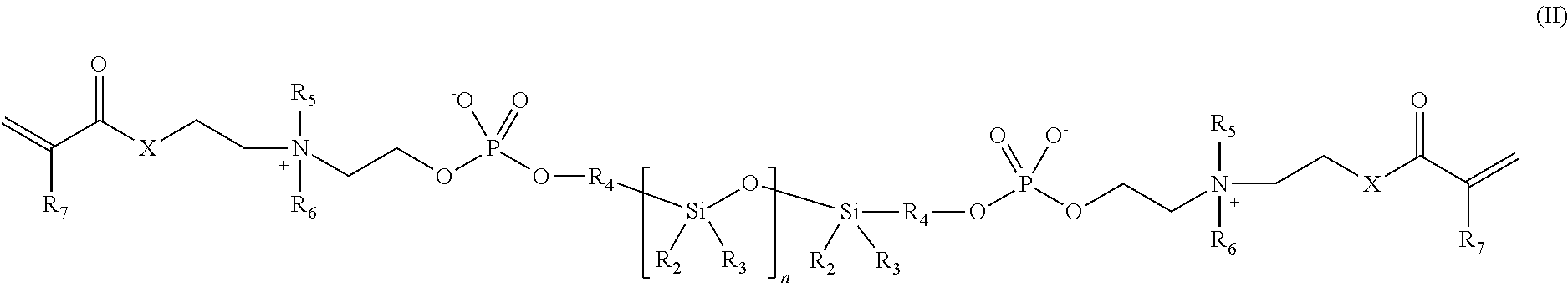

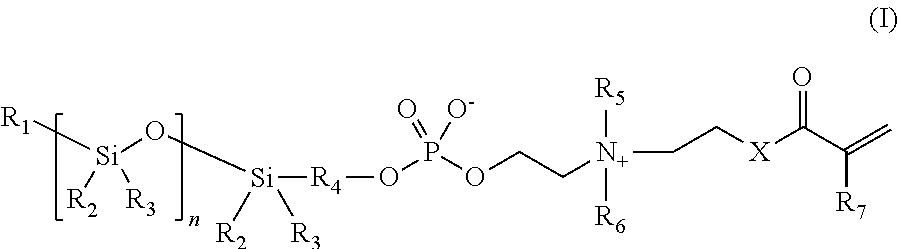

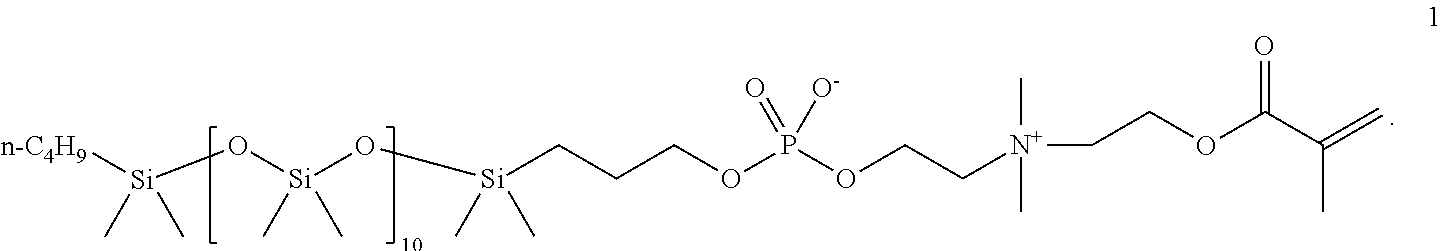

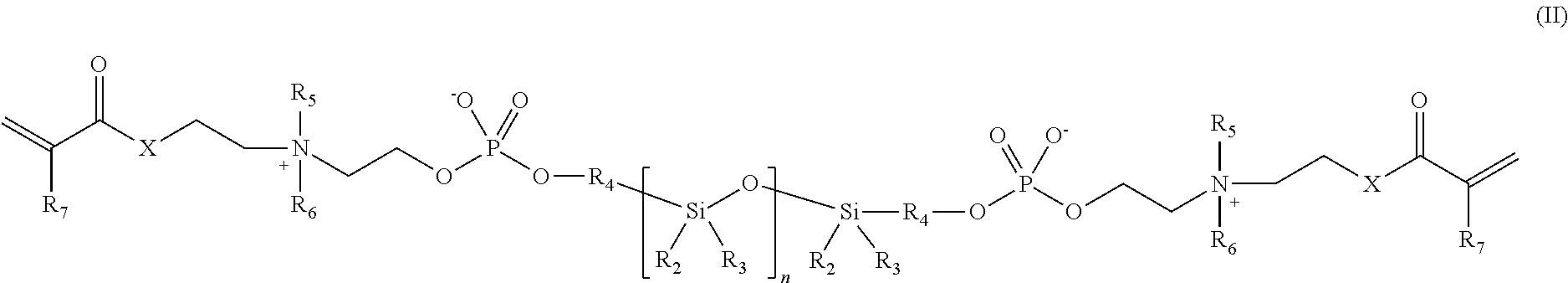

Phosphorylcholine-based amphiphilic silicones for medical applications

InactiveUS20120136087A1High oxygen permeabilityReduce protein and lipid adsorptionSilicon organic compoundsCosmetic preparationsPhosphoric acidPhosphorylcholine

Amphiphilic biomimetic phosphorylcholine-containing silicone compounds for use in both topical and internal applications as components in biomedical devices. The silicone compounds, which include zwitterionic phosphorylcholine groups, may be polymerizable or non-polymerizable. Specific examples of applications include use as active functional components in ophthalmic lenses, ophthalmic lens care solutions, liquid bandages, wound dressings, and lubricious and anti-thrombogenic coatings.

Owner:DSM IP ASSETS BV

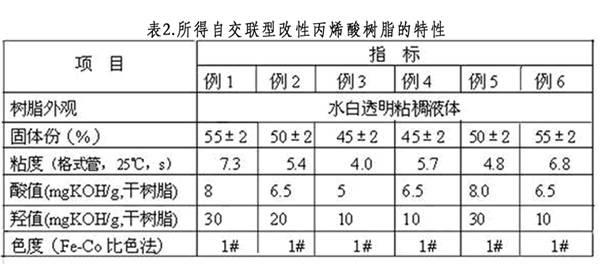

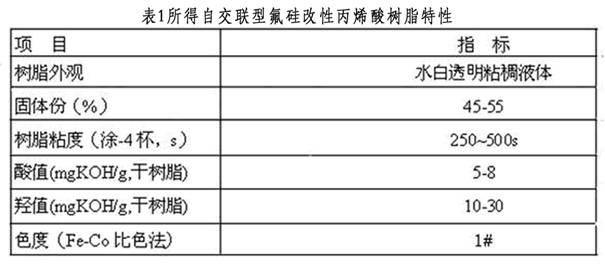

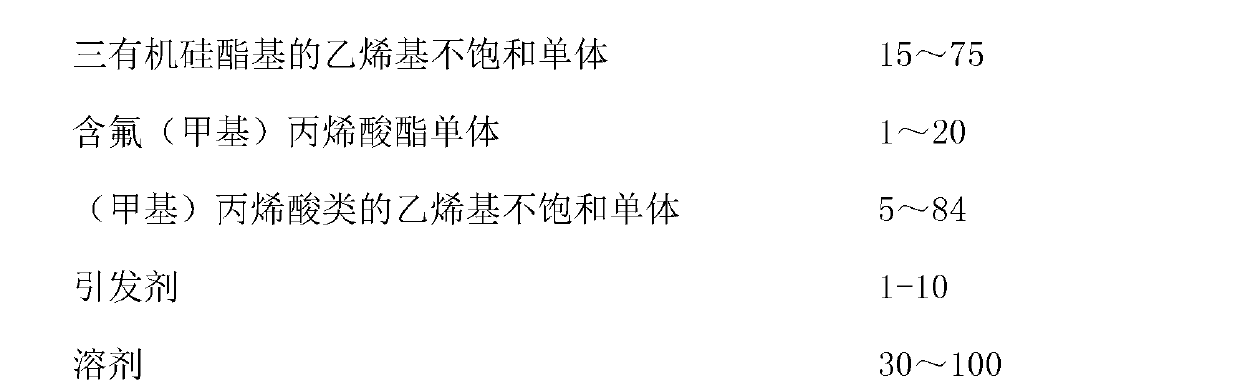

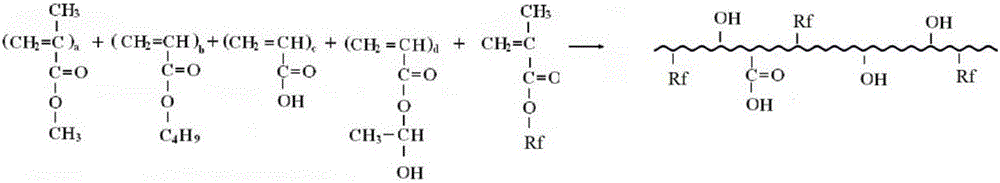

Self-crosslinked fluorosilicate acrylic resin and preparation method thereof

The invention discloses self-crosslinked fluorosilicate acrylic resin and a preparation method thereof. The self-crosslinked fluorosilicate modified acrylic resin has the structural formula shown in the specifications, wherein n=4, 6 and 8, and the molecular weight is 60,000-80,000; X refers to a (meth)acryloxy functional group or an alkenyl-containing silane coupling agent; and X has the structural formula shown in the specifications, wherein R is -CH3 or -CH2CH3. The preparation method comprises the following steps of: adding a solvent into a reaction container, and heating to the temperature of between 90 and 100DEG C; uniformly mixing methyl methacrylate, acrylic acid, ethyl acrylate, hydroxyethyl acrylate, a silane coupling agent, perfluoroalkylethyl acrylate and tert-butyl hydroperoxide, and dripping for 2 to 3 hours; keeping the temperature for 3 to 4 hours; and reducing the temperature to 40-60DEG C and discharging. The prepared resin has high weatherability, high chemical resistance, high-temperature resistance, good mechanical properties and glossiness, and high insulativity; and the preparation method has simple process steps and is easy to implement.

Owner:JINZHOU DPF TH CHEM CO LTD

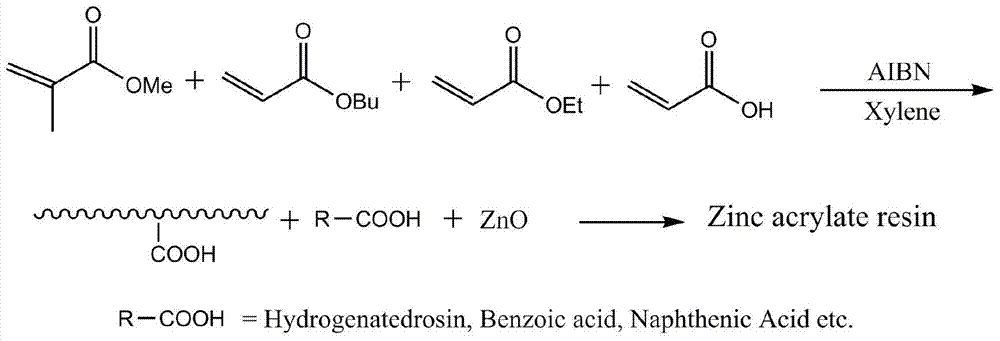

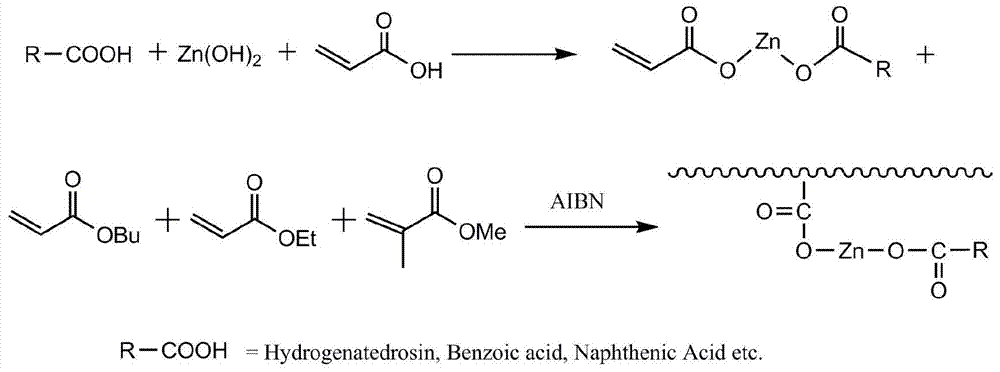

Preparation and application of self-polishing antifouling coating matrix resin

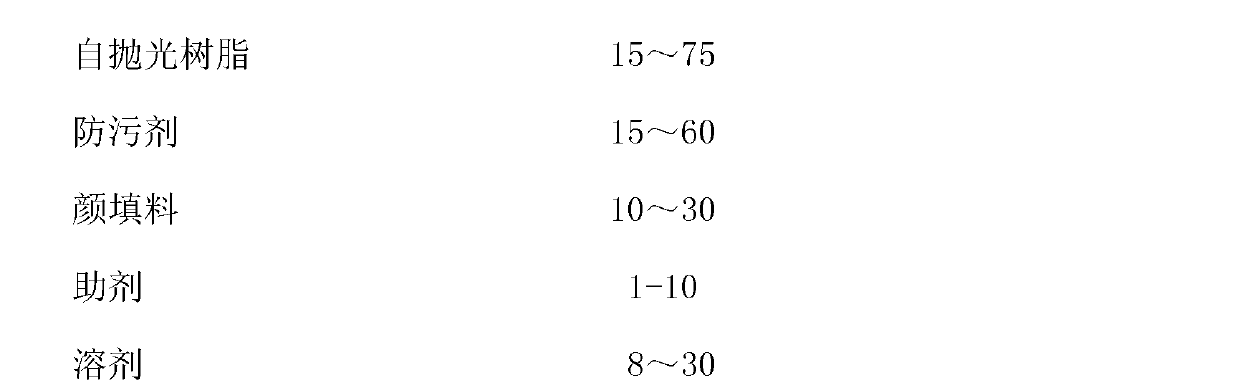

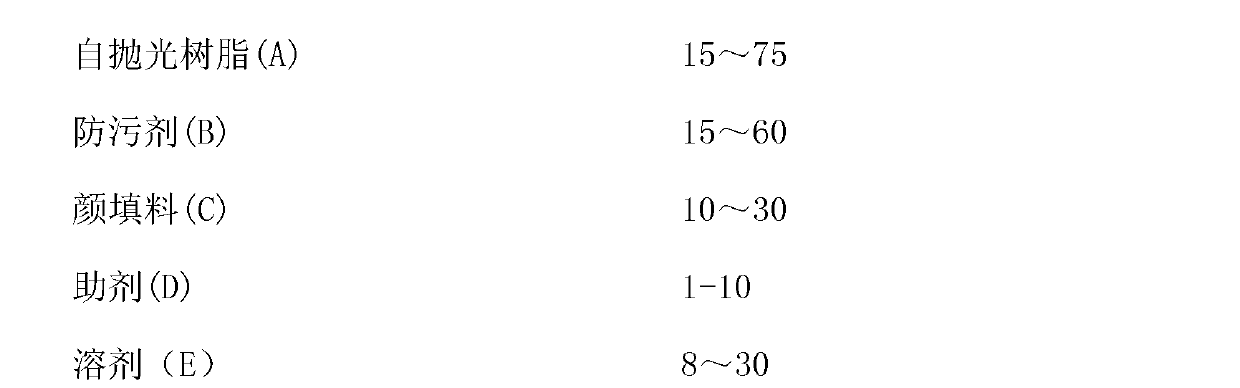

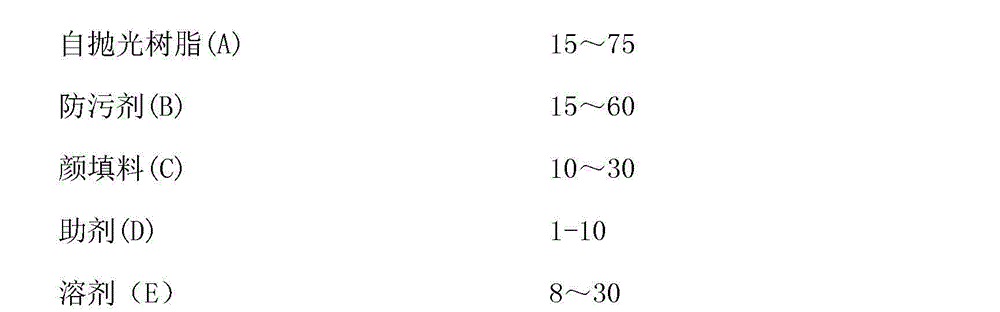

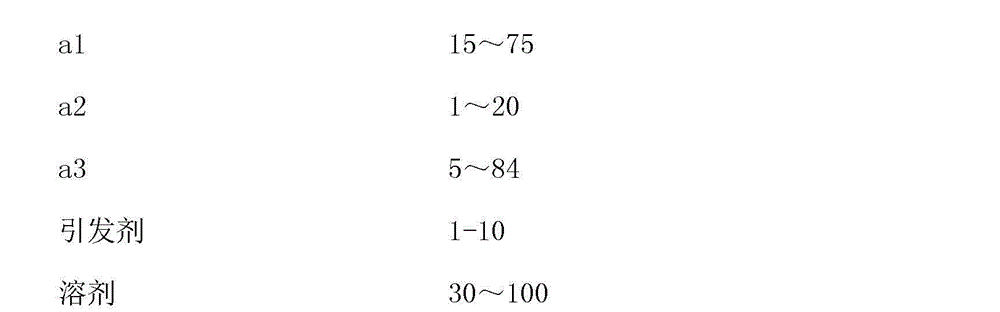

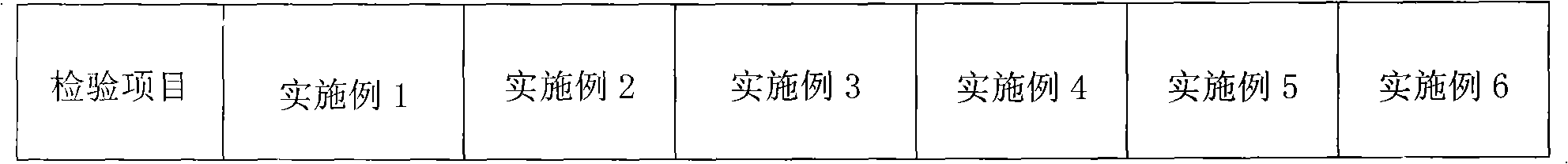

ActiveCN103131289AHas self-polishing propertiesReduce surface propertiesAntifouling/underwater paintsPaints with biocidesToxic materialSolvent

A self-polishing antifouling coating is characterized in that the self-polishing antifouling coating includes a fluorine-containing silyl acrylate matrix resin (A) having a self-polishing performance, an antifouling agent (B), a pigment filler (C), an assistant (D) and a solvent (E). The antifouling coating which has a good polishing performance and a low surface performance has the characteristics of long antifouling period, good antifouling performance, excellent polishing resistance reduction performance and the like. The antifouling coating which contains no toxic substances comprising tin, DDT or the like has the characteristics of friendliness to the sea environment, simple and convenient construction, easy maintenance and the like, and can satisfy the demands on the long-acting antifouling coating of subsea facilities.

Owner:MARINE CHEM RES INST CO LTD

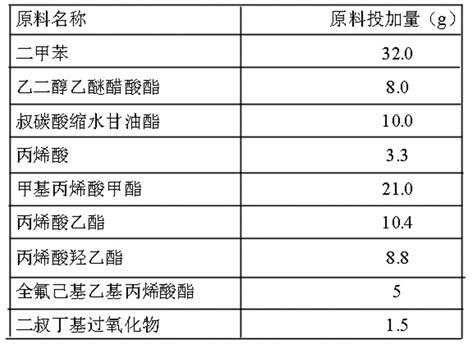

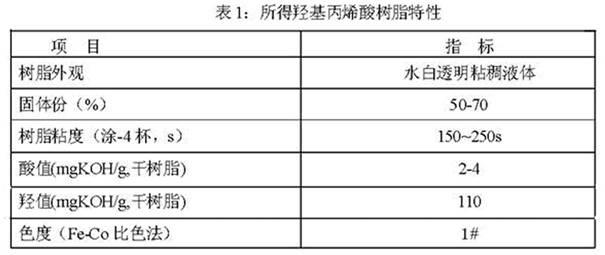

Hydroxylated acrylic resin as well as preparation method and application thereof

The invention relates to hydroxylated acrylic resin as well as preparation method and application thereof. The hydroxylated acrylic resin has a structural formula, wherein n is equal to 4, the sum of C number in 6, 8, R1 and R2 is 9, and the molecular weight is 10,000-20,000; the preparation method comprises the steps of: adding solvent and reactive solvent into a reaction vessel under protectionof nitrogen gas environment, and increasing temperature to 150-160 DEG C; evenly mixing acrylic acid, methyl methacrylate, ethyl acrylate, hydroxyethyl acrylate and perfluoroalkylethyl acrylate monomer with initiator, and carrying out dropwise addition for 3-4 hours; carrying out heat insulation for 1.5-2 hours; and reducing temperature to 40-70 DEG C for discharging, thus obtaining hydroxylated acrylic resin. A paint film formed by the hydroxylated acrylic resin and a curing agent has properties of both acrylic polyurethane and fluorocarbon coating. The prepared hydroxylated acrylic resin can carry out reaction smoothly at normal temperature and normal pressure, has low production cost, can be cured at normal temperature and be applied in the fields of ships, containers, drilling platforms, anticorrosion of steel structures, outer wall coating of high-rise buildings and the like.

Owner:JINZHOU DPF TH CHEM CO LTD

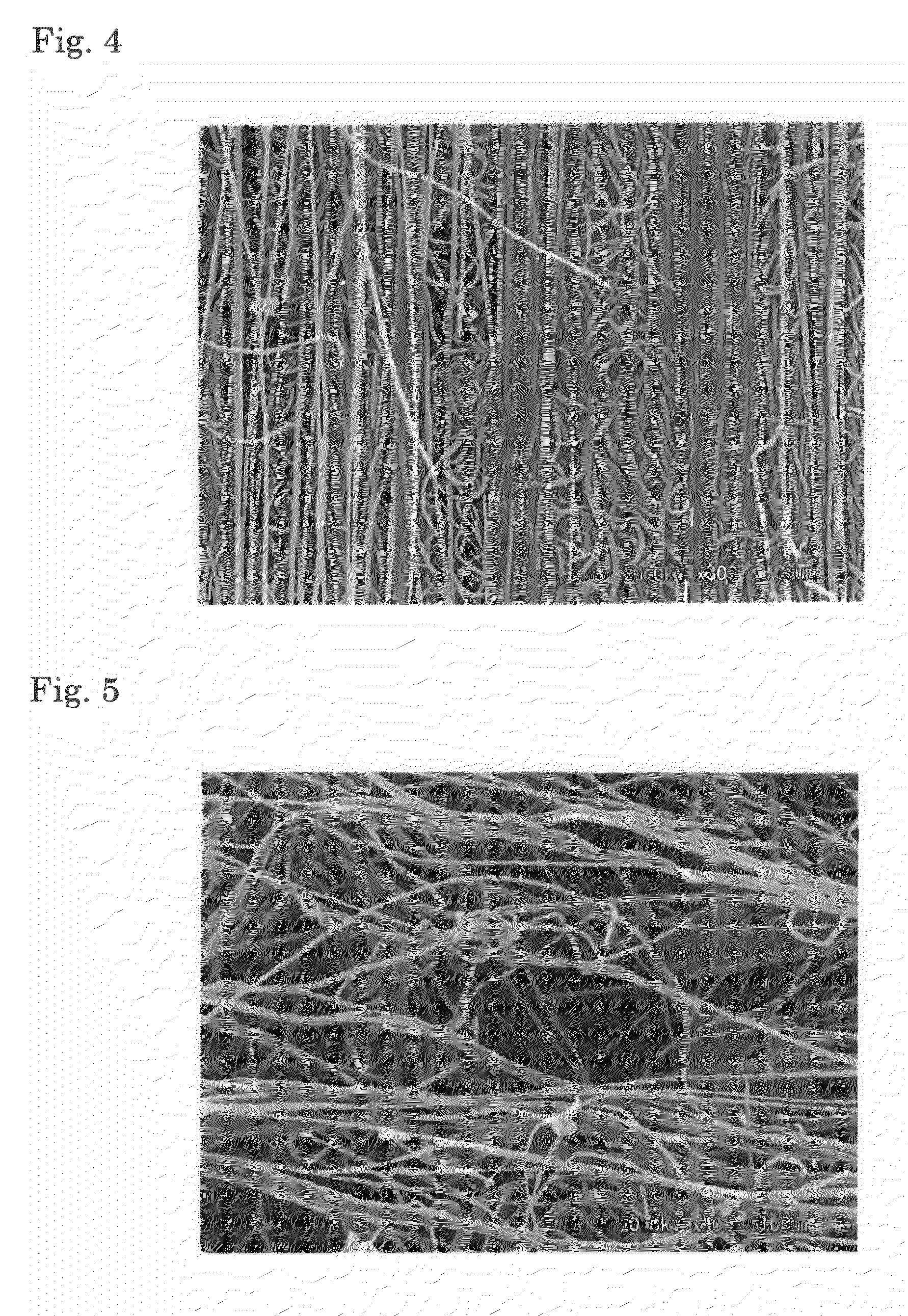

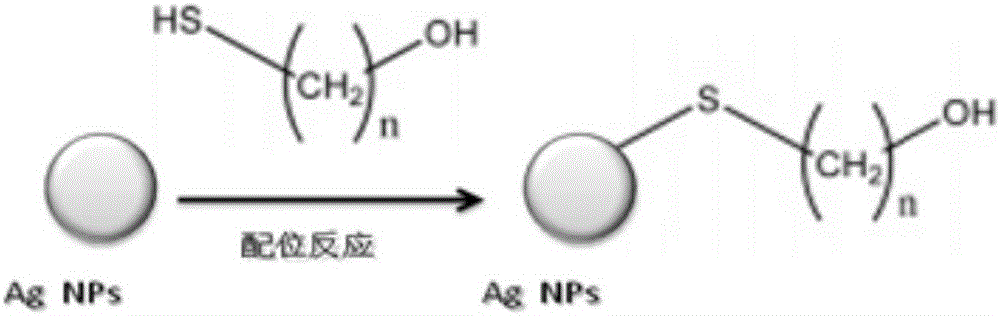

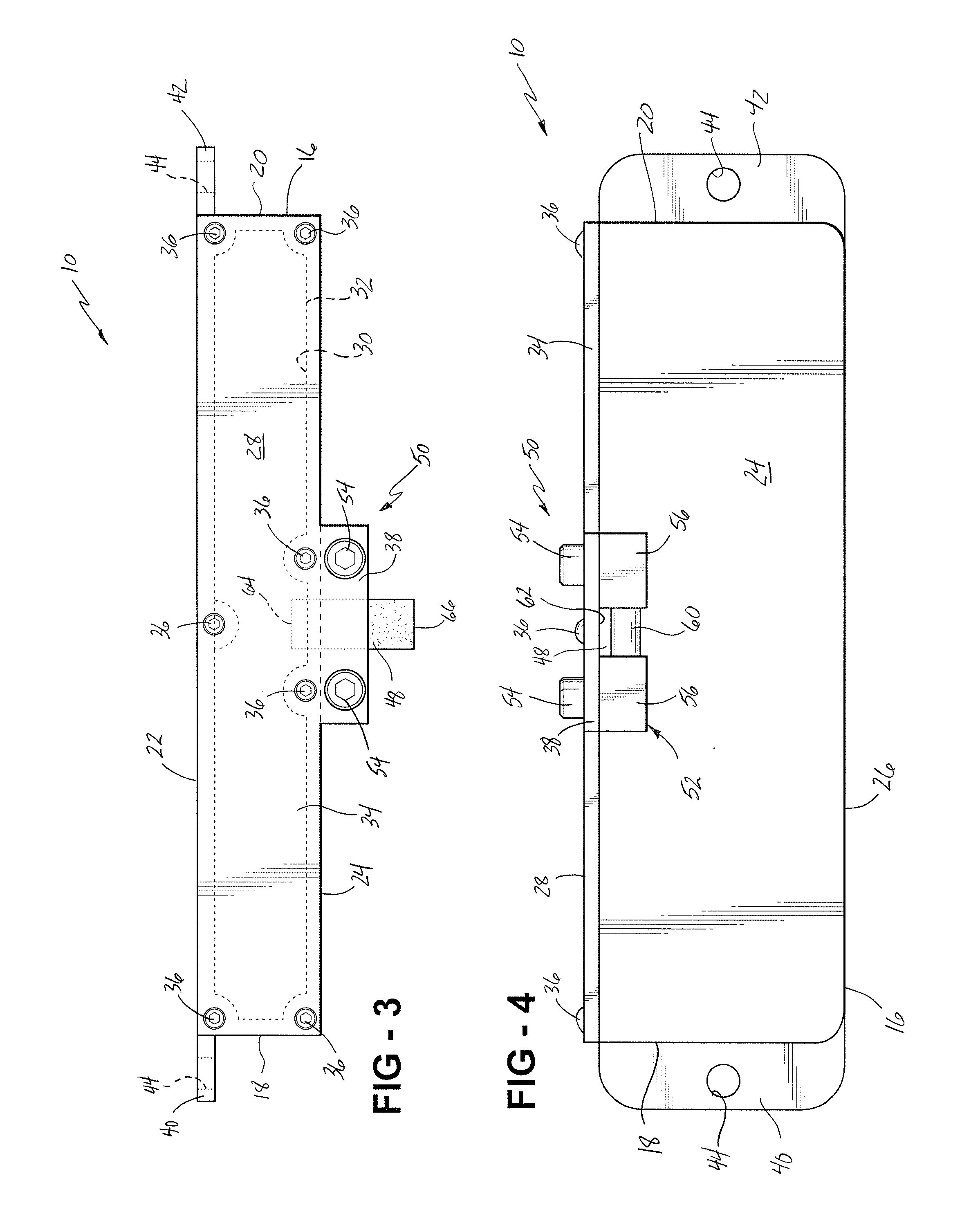

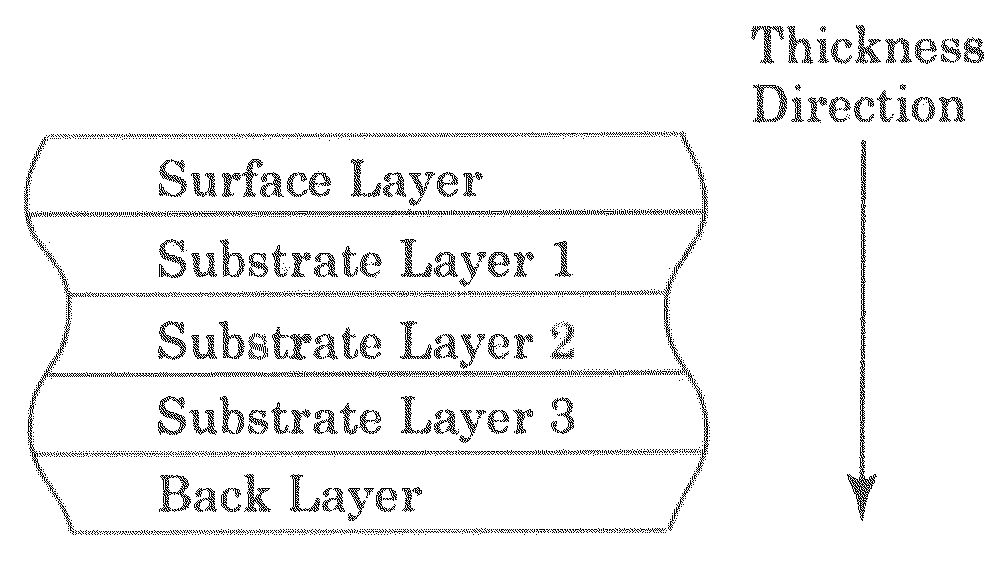

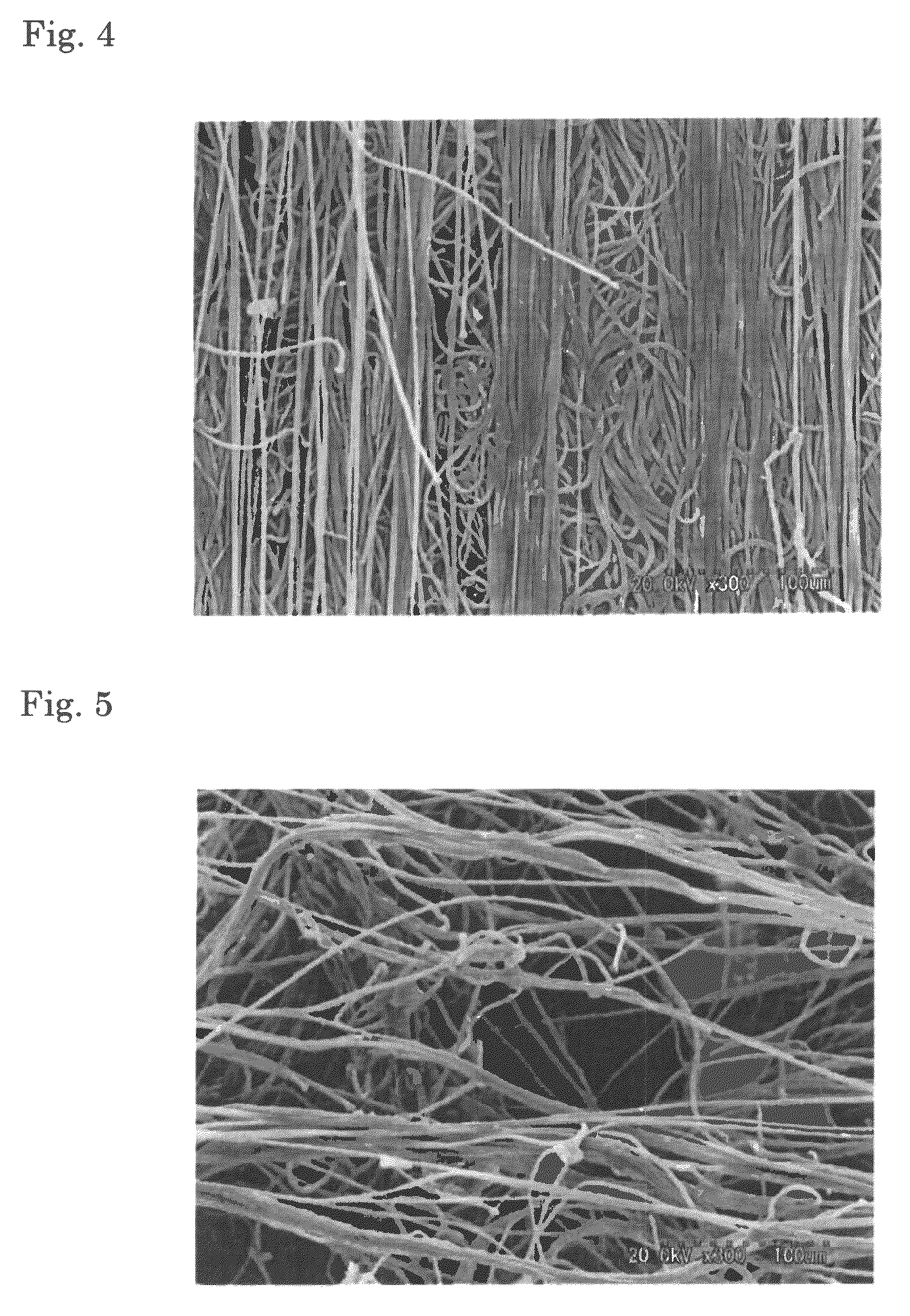

Leather-like sheet bearing grain finish and process for producing the same

ActiveUS20100086738A1Readily apparentImprove surface propertiesHollow inflatable ballsHollow non-inflatable ballsSurface layerFiber bundle

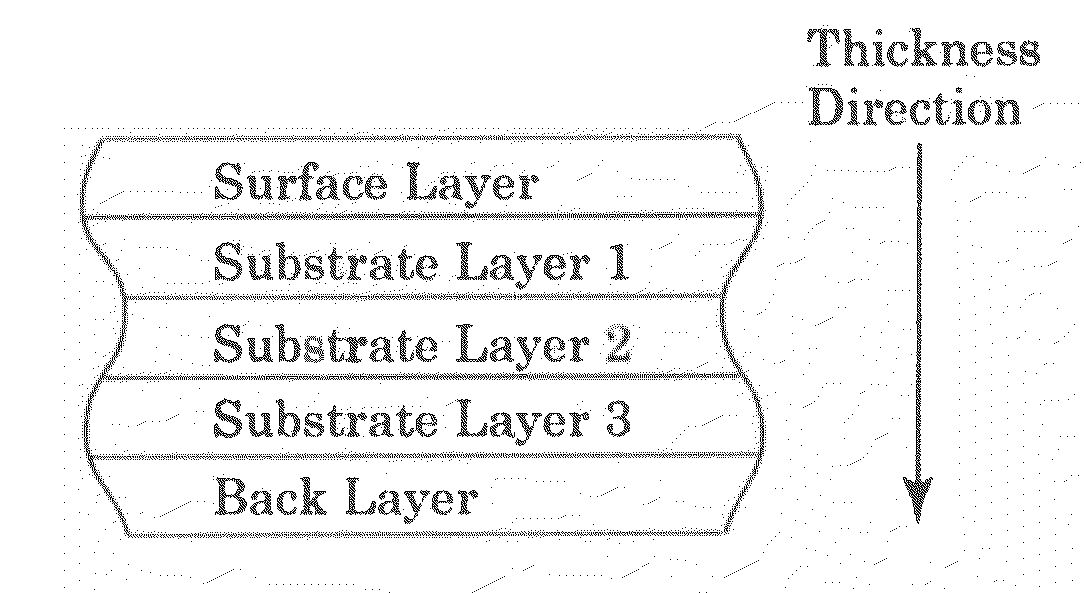

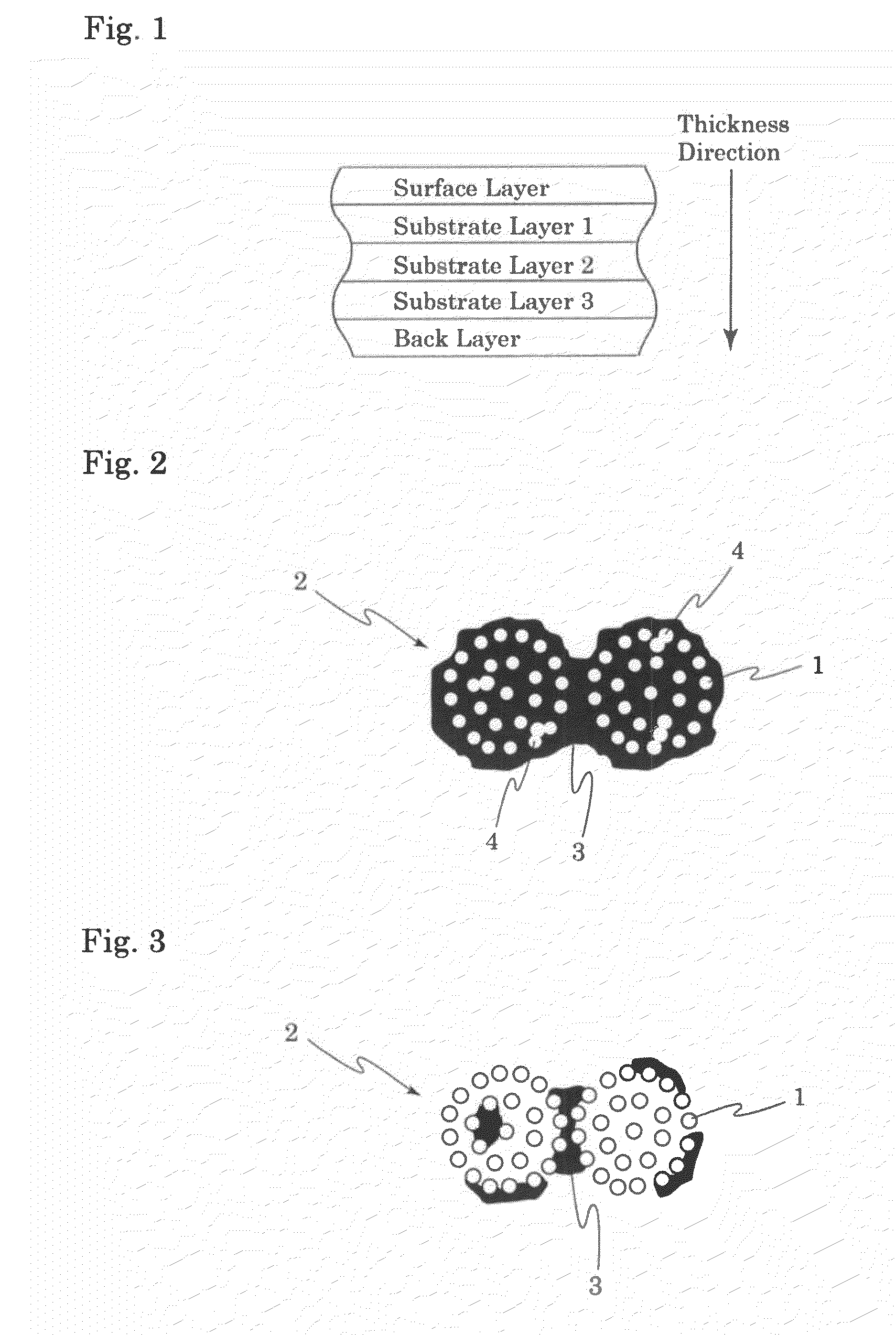

A (semi)grain-finished leather-like sheet composed of an entangled nonwoven fabric of three-dimensionally entangled fiber bundles containing microfine long fibers and an elastic polymer contained in the entangled nonwoven fabric. When dividing the (semi)grain-finished leather-like sheet to five layers with equal thickness, i.e., surface layer, substrate layer 1, substrate layer 2, substrate layer 3 and back layer in this order along the thickness direction, part of the microfine long fibers forming the surface layer and / or the back layer are fuse-bonded to each other and the microfine long fibers forming the intermediate layer are not fuse-bonded. With such a fuse-bonding state of the microfine long fibers, the (semi)grain-finished leather-like sheet combines a low compression resistance and a dense feel each comparable to natural leathers, has a sufficient practical strength, and are excellent in properties which are required according to its use.

Owner:KURARAY CO LTD

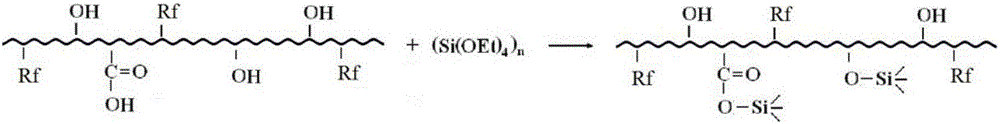

High-adhesion, low-surface-energy silver-loaded antifouling paint and preparation method thereof

ActiveCN106085187AGood adhesionGood dispersionAntifouling/underwater paintsPaints with biocidesCross-linkAcrylic resin

The invention discloses high-adhesion, low-surface-energy silver-loaded antifouling paint and a preparation method thereof. The preparation method comprises the following steps: 1, preparing organic fluorine modified acrylic resin; 2, mixing ethyl orthosilicate, absolute ethyl alcohol, hydrochloric acid and deionized water, and conducting hydrolytic polycondensation reaction to prepare organic silicone resin; 3, blending the organic fluorine modified acrylic resin and the organic silicone resin, and enabling dealcoholization reaction to synthesize organic fluorine-silicon modified acrylic resin; 4, enabling coordination reaction of nano silver particles, methanol, acetic acid and sulfydryl and hydroxyl containing organic ligand to prepare hydroxyl containing mercaptan nano-silver organic coordinated particles; 5, mixing the organic fluorine-silicon modified acrylic resin, the hydroxyl containing mercaptan nano-silver organic coordinated particles and a catalyst, dropwise adding isophorone diisocyanate, and enabling cross-linking reaction to prepare the high-adhesion, low-surface-energy silver-loaded antifouling paint. The high-adhesion, low-surface-energy silver-loaded antifouling paint has the high-adhesion property of acrylic acid and polyurethane, has the low-surface-energy property of organic fluorine and organic silicone, and has the significant antifouling effect.

Owner:SHANGHAI MARITIME UNIVERSITY

Heat reflecting paint, and preparation method and application thereof

ActiveCN103666174ALow polarizabilityGood acid and alkali resistanceClimate change adaptationReflecting/signal paintsWeather resistanceEmulsion

The invention discloses a heat reflecting paint, and a preparation method and an application thereof. The heat reflecting paint comprises the following components in parts by weight: 100 parts of fluorine-containing (methyl) acrylate polymer emulsion, 2-30 parts of reflecting pigment, 0.1-4 parts of filler, 2-40 parts of flatting agent, 1-20 parts of coalescing agent, 0.01-1 part of thickening agent, 0.01-2 parts of dispersant, 0.001-1 part of wetting agent, 0.1-60 parts of distilled water and 0.5-5 parts of cross-linking agent. The heat reflecting paint provided by the invention is high in heat reflection performance, and excellent in acid and alkali resistance, weather fastness and stain resistance. The heat reflecting paint provided by the invention is applied to a bituminous pavement; the heat reflecting paint is capable of relieving the urban heat island effect by reducing the road surface temperature, and reducing the environmental pollution generated in the use process of the coating, and also capable of improving the stain resistance of the coating and ensuring persistent cooling effect of the heat reflecting coating.

Owner:唐伯明

Fluorine-containing paper oil-proof agent and its preparation method

A fluorine-containing paper oil-proof agent is an acrylate polymer solution containing a perfluoroalkyl side chain, wherein the polymer is prepared from 55.0-85.0% of a fluorine-containing monomer, 5.0-35.0% of a fluorine-free monomer, 3.0-10.0% of a functional monomer, 2.0-10.0% of an adhesion reinforcing monomer, 0.5-2.0% of an initiator, 0.1-0.4% of a chain transfer agent, and acetone and isopropanol mixed solution by copolymerization. The polymer solution has the characteristics of strong adhesion, low consumption, good oil resistance and good water resistance. By adding the adhesion reinforcing monomer, a fluorine-containing activator can be adhered to paper fiber, and the surface property of the paper fiber is reduced, therefore, the oil proofness of the paper is improved, and the strength and stiffness of the paper are increased at the same time.

Owner:QUANZHOU SICONG NEW MATERIAL DEV

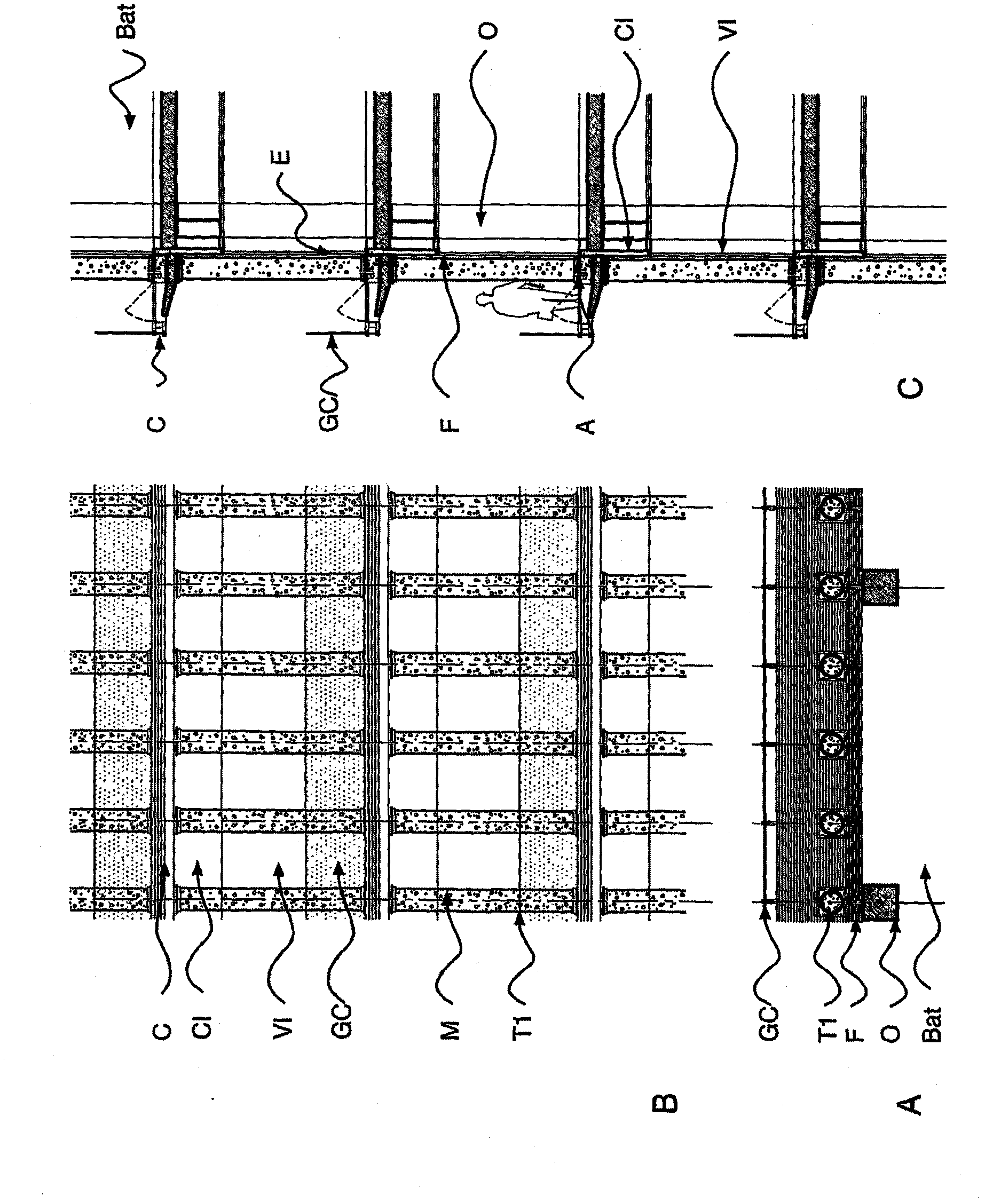

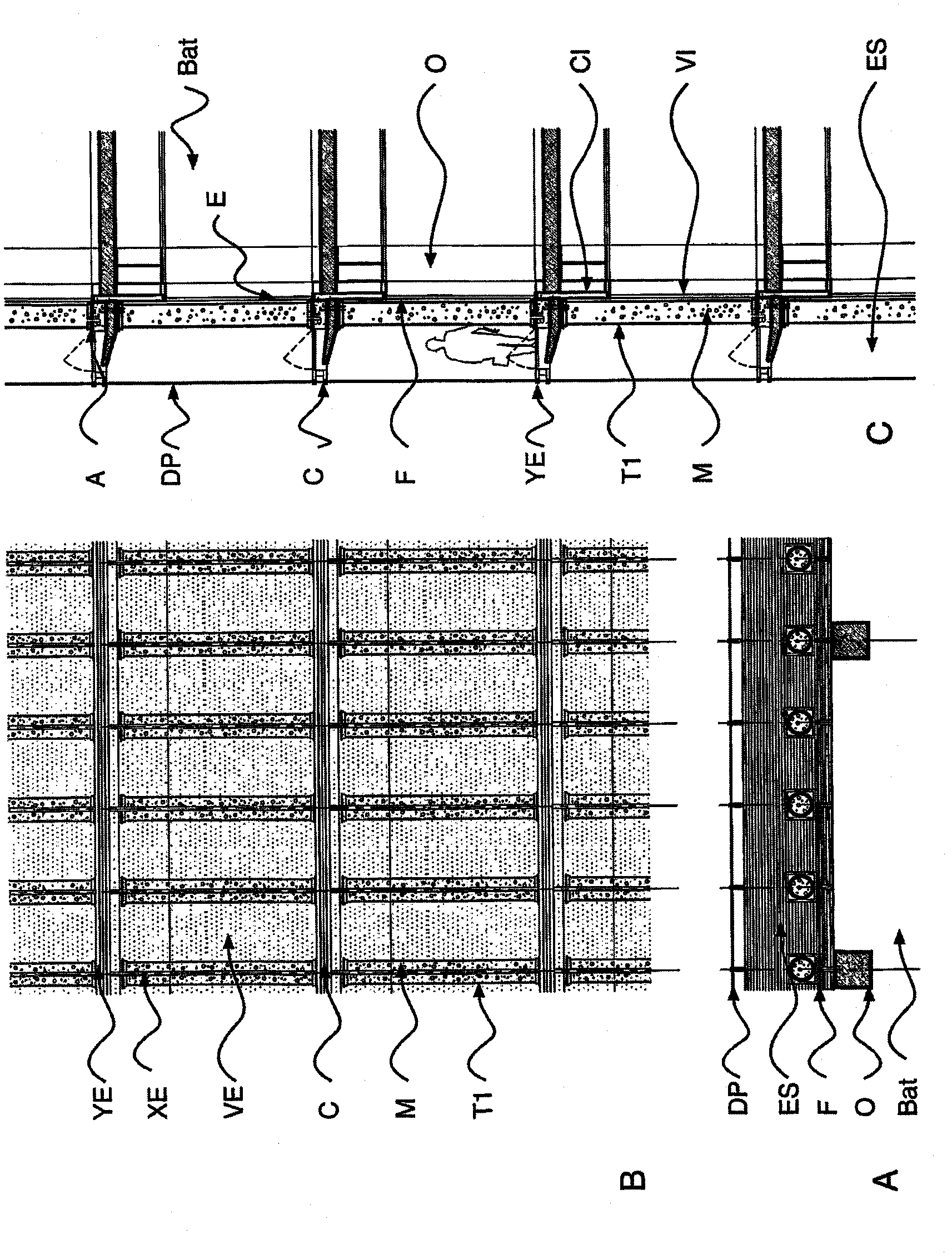

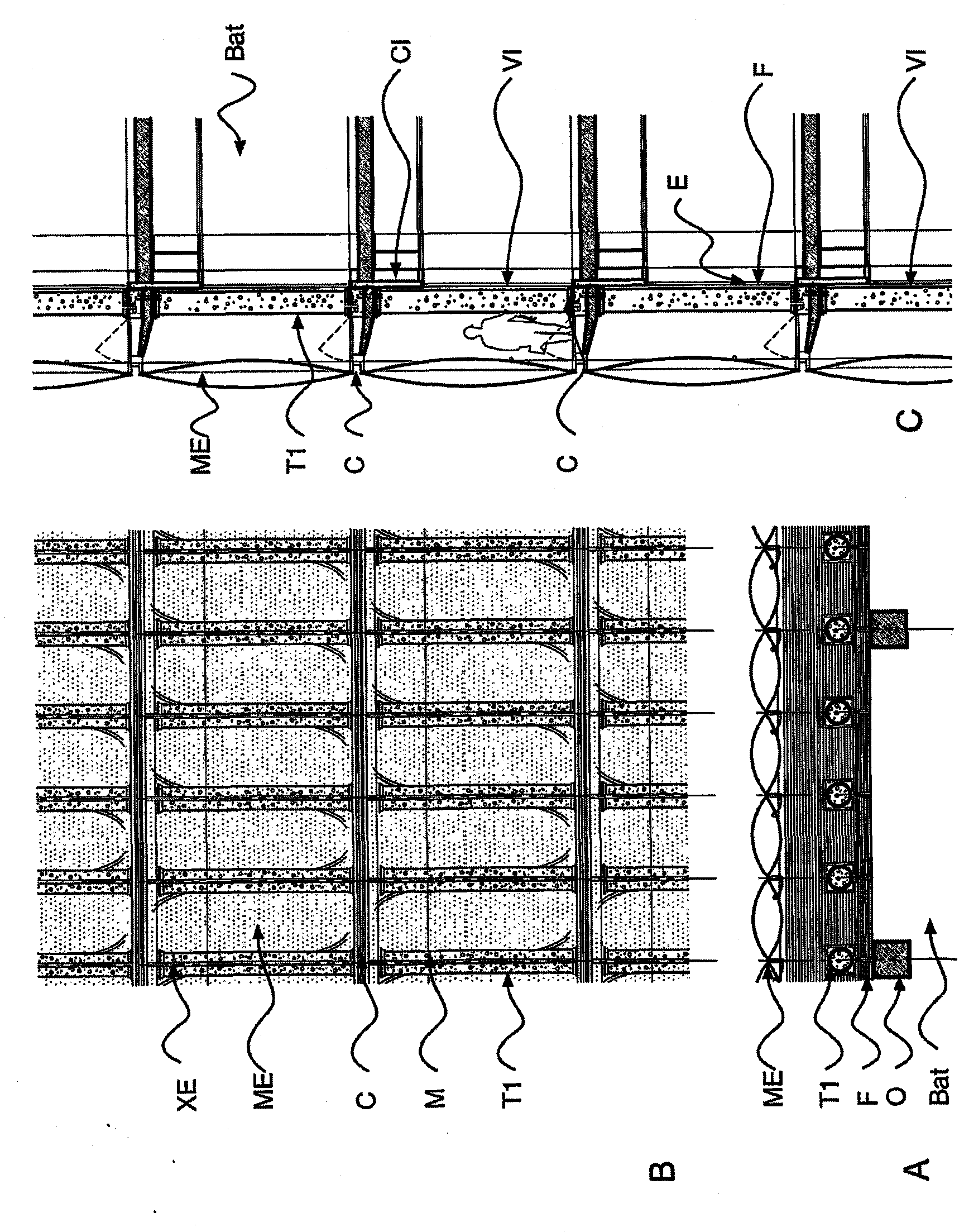

Device for cultivating algae and/or microorganisms for treating an effluent, and biological frontage

InactiveCN102325868AGet rid of pollutionImprove efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsBiofuelBuilding under construction

The invention relates to a device for processing effluents and / or, for example, making a building frontage capable of producing biochemical primary energy obtained by photosynthesis. The invention more particularly relates to a device that includes: a container for cultivating algae and / or microorganisms in an aqueous medium; supply means for the algae and / or microorganism culture; means for injecting an effluent into said algae and / or microorganisms, said effluent coming from a building; means for adjusting the temperature of the algae and / or microorganism culture; effluent recovery means for recovering the effluent from a building and for injecting the same into the algae and / or microorganism culture; and optionally a lighting system for promoting the growth of the algae and / or microorganism culture.; The device of the invention can be used for producing biofuel, organic molecules, chemical compounds and proteins. The biofuel thus obtained may consist of oleaginous biomass, for example, which can directly be used in a thermal power plant or be converted by pyrolysis into coal or biopetroleum. The present invention also makes it possible to implement a new biological frontage and biological reactors integrated in the frontages of modern or old buildings under construction or already existing.

Owner:XTU

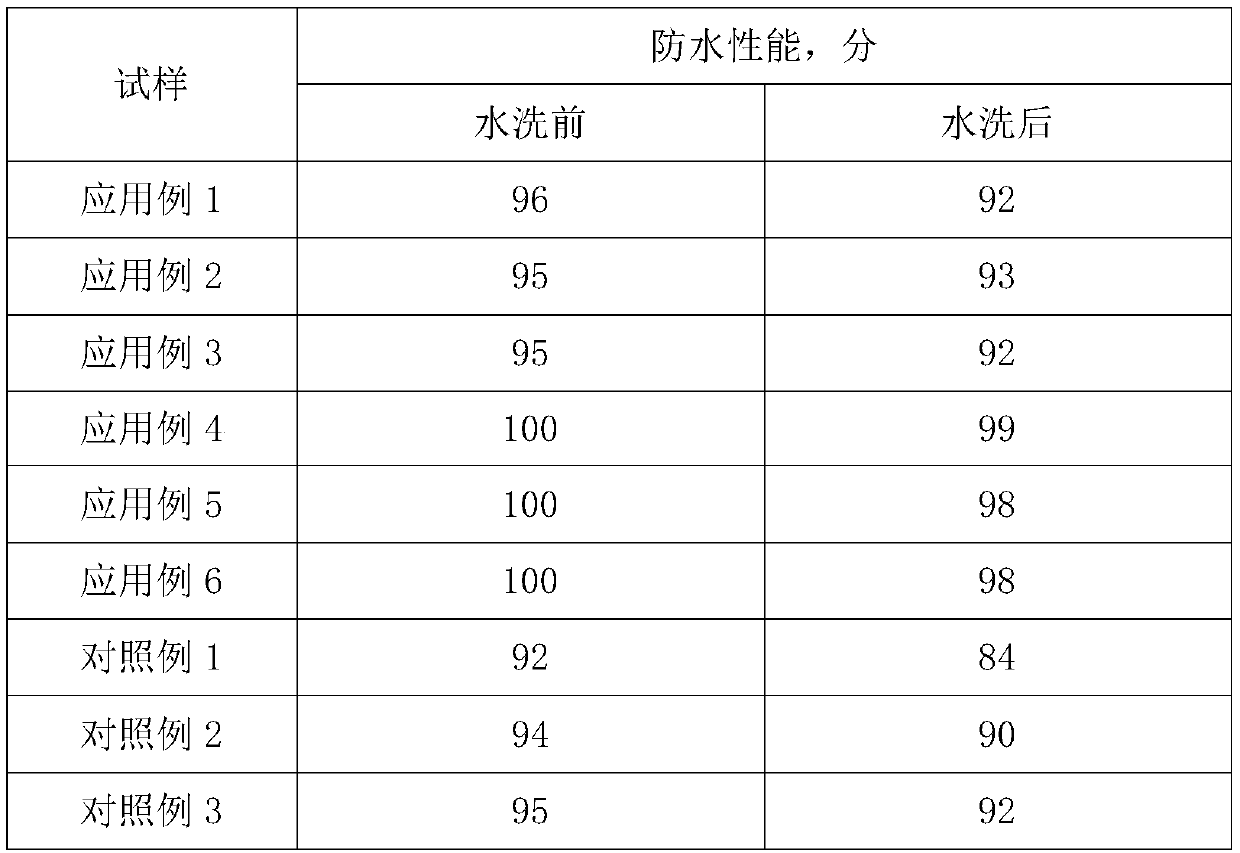

Fluoride-free waterproof finishing agent and preparation and application methods thereof

InactiveCN110409183AReduce surface propertiesExcellent water repellencyBiochemical fibre treatmentLiquid repellent fibresCross-linkFiber

The invention discloses a fluoride-free waterproof finishing agent and preparation and application methods thereof, and relates to the technical field of fabric finishing. According to the technical scheme, the fluoride-free waterproof finishing agent is characterized by being prepared from, by weight, 2-4 parts of a fluoride-free water repellency agent, 0.1-0.3 part of a cross-linking agent, 1-2parts of a penetrating agent, 1-2 parts of a defoaming agent and 45-55 parts of water; the fluoride-free water repellency agent comprises fatty alcohol polyoxyethylene ether. According to the fluoride-free waterproof finishing agent, the characteristic of low-surface performance of the fluoride-free water repellency agent is utilized, excellent water repellency performance is achieved, the fluoride-free waterproof finishing agent prepared through cooperation of the fluoride-free water repellency agent, the cross-linking agent, the penetrating agent and the defoaming agent can be quickly spreadout to form a film on the fiber surface, the friction coefficient of the fiber surface is effectively reduced, and the waterproof performance of fiber fabrics is improved.

Owner:三赢家居用品(河源)有限公司

Preparation and application of self-polishing antifouling coating matrix resin

ActiveCN103131289BHas self-polishing propertiesReduce surface propertiesAntifouling/underwater paintsPaints with biocidesPolymer scienceOrganic chemistry

A self-polishing antifouling coating is characterized in that the self-polishing antifouling coating includes a fluorine-containing silyl acrylate matrix resin (A) having a self-polishing performance, an antifouling agent (B), a pigment filler (C), an assistant (D) and a solvent (E). The antifouling coating which has a good polishing performance and a low surface performance has the characteristics of long antifouling period, good antifouling performance, excellent polishing resistance reduction performance and the like. The antifouling coating which contains no toxic substances comprising tin, DDT or the like has the characteristics of friendliness to the sea environment, simple and convenient construction, easy maintenance and the like, and can satisfy the demands on the long-acting antifouling coating of subsea facilities.

Owner:MARINE CHEM RES INST CO LTD

Cationic fluorine-containing paper oil-proofing agent

InactiveCN103396510AGood water repellencyGood oil repellencyNon-fibrous pulp additionFiberFunctional monomer

The invention relates to a cationic fluorine-containing paper oil-proofing agent which is an acrylate high molecular polymer solution containing perfluorohexylethyl on a side chain, wherein the high molecular polymer solution is prepared from 55.0-85.0% of fluorine-containing monomer, 5.0-35.0% of methyl / acrylate monomer, 3.0-10.0% of cationic monomer, 3.0-10.0% of functional monomer and 2.0-10.0% of adhesion reinforcement monomer through copolymerization reaction. The oil-proofing agent provided by the invention has the characteristics of high adhesion, low consumption, favorable oil / water resistance and the like; and by adding the adhesion reinforcement monomer, the fluorine-containing activating agent can be adsorbed on fiber of paper, so that the surface property of the paper fiber is reduced, thereby improving the oil-proofing property of the paper and simultaneously increasing the strength and stiffness of the paper.

Owner:XIAMEN AISIKANG NEW MATERIAL

Anti-pollution flashover coating for electrical device and preparation method thereof

InactiveCN107652885ABoth hydrophobicHydrophobicAntifouling/underwater paintsPaints with biocidesSilanesSolvent

The invention relates to the field of coatings, and specifically relates to an anti-pollution flashover coating for an electrical device and a preparation method thereof. The coating is hydrophobic, insulated and self-cleaning coating developed based on pollution flashover occurring principle and is applicable to the surface treatment of an outdoor electrical device, in particular an insulator. The anti-pollution flashover coating comprises 5-20 parts of organic silicon resin, 2-12 parts of fluoridized titanium dioxide powder, 1-10 parts of fumed silica powder, 0.1-0.5 part of silane couplingagent, 0.2-3 parts of auxiliary, 0.3-2 parts of carbon black, 50-80 parts of mixed solvent, and 8-15 parts of a curing agent. The anti-pollution flashover coating has the beneficial effects of being hydrophobic, anti-pollution, self-cleaning, and insulated, and is applicable to an outer coating layer of the outdoor electrical device; nano silica and the silane coupling agent are compounded, so that the superficiality of the coating layer is greatly reduced, and the hydrophobic and oleophobic performances of the coating layer are improved; nano fluoridized titanium dioxide is added, so that thecoating is capable of self-cleaning; the coating has a good adhering performance relative to a base material, and is high in weather resistance, resistant to high- and low-temperature, resistance toillumination, and resistance to radiativity.

Owner:湖南创研工业技术研究院有限公司

Fluorosilicone-modified acrylic resin hydrophobic anti-corrosion paint

The invention relates to a fluorosilicone-modified acrylic resin hydrophobic anti-corrosion paint which is characterized in that the paint comprises a component A and a component B in parts by weight, wherein the component A comprises 45-70 parts of hydrophobic resin, 5-40 parts of pigments and fillers, 6-30 parts of solvent, 1-3 parts of anti-aging agent, 1-5 parts of dispersant, and 0.5-2 parts of anti-settling agent, and the component A is prepared by mixing, grinding and stirring; and the component B comprises 5-8 parts of curing agent. The paint has the characteristics of good hydrophobic property, good adhesion, strong anti-photoaging property, strong flexibility, self-cleaning property, good corrosion resistance, excellent performances and the like, is convenient for construction and can be coated for a large area.

Owner:CHINA ELECTRIC POWER RES INST +1

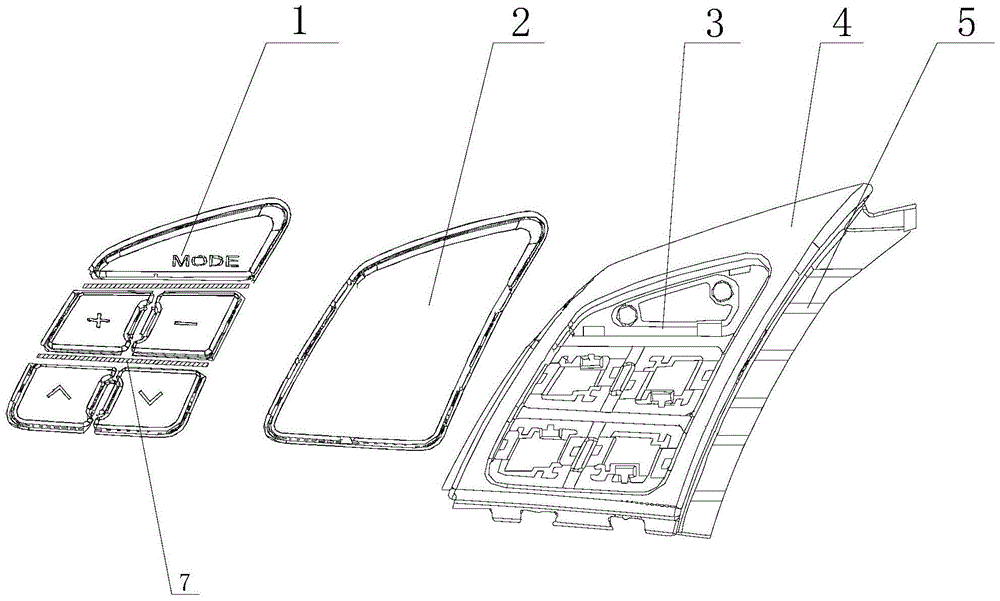

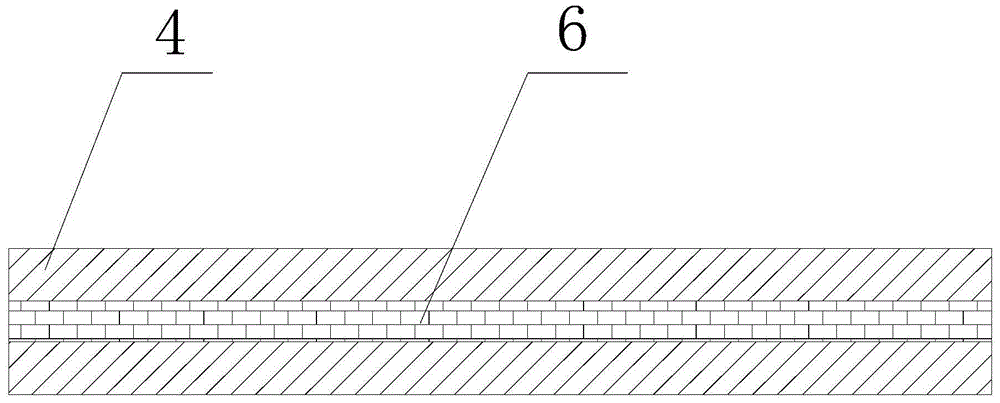

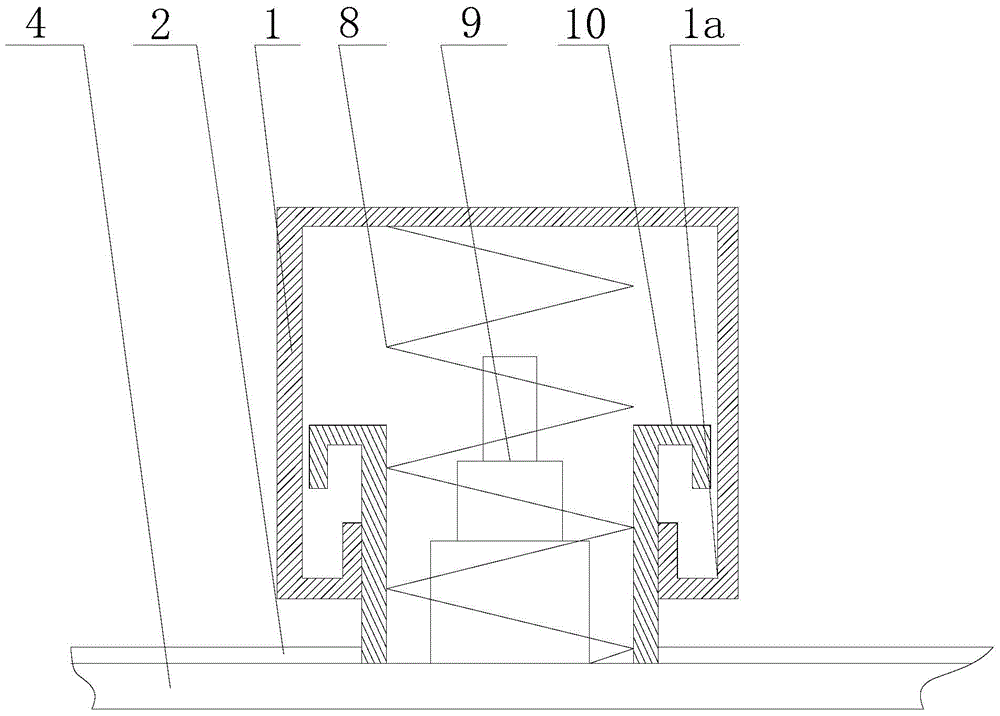

Waterproof dustproof steering wheel switch

ActiveCN105679582AExtended service lifeImprove heat resistanceElectric switchesSteering wheelEngineering

The invention relates to a waterproof dustproof steering wheel switch. The waterproof dustproof steering wheel switch comprises a substrate, an insulating thin film and keys, wherein heating sheets are embedded in the substrate; a control circuit board is mounted on the upper surface of the substrate; the control circuit board is connected with at least a microswitch; the control circuit board is covered with the insulating thin film; the keys are mounted above the insulating thin film close to the microswitches; the lower ends of the keys are close to the upper ends of the microswitches; parting strips are arranged between the keys; a compression spring is arranged between the keys and the substrate; clamping hooks are arranged at the lower ends of the keys; limiting clamping boards matched with the clamping hooks are fabricated on the substrate; and limiting clamping hooks are arranged at the upper ends of the limiting clamping boards. According to the waterproof dustproof steering wheel switch, the control circuit board is covered with the insulating thin film, so that the waterproof performance of the waterproof dustproof steering wheel switch is effectively improved, the switch failure caused by water in the control circuit board can be effectively prevented, and the service life of the steering wheel switch is prolonged.

Owner:乐星汽车技术(无锡)有限公司

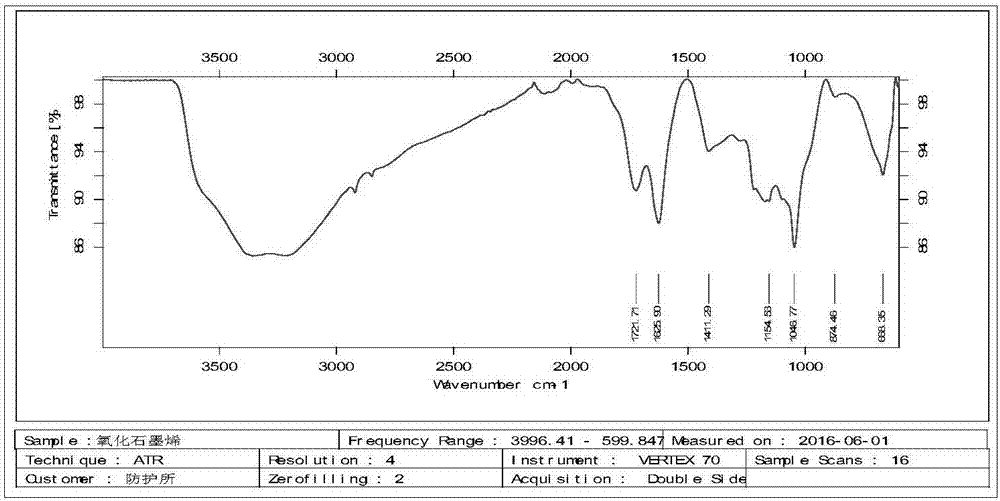

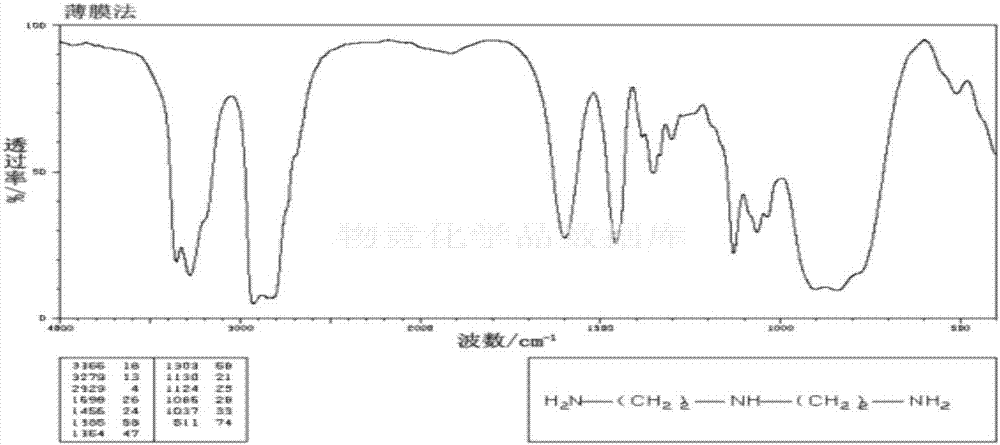

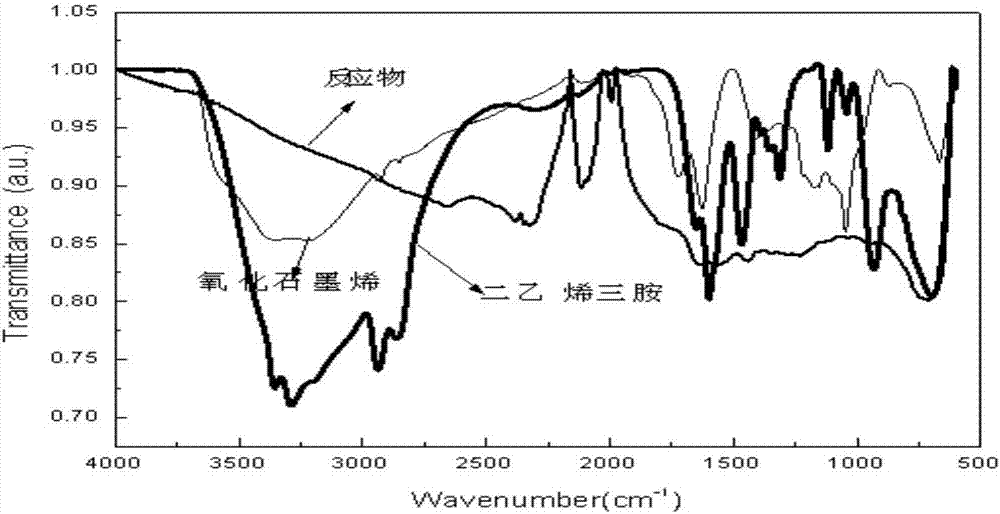

Method for preparing large-area graphene material by adopting suturing method

The invention relates to a method for preparing a large-area graphene material by adopting a suturing method. The preparation method comprises the following steps: adding graphene oxide into a conicalflask filled with one of ethylenediamine, diethylenetriamine, triethylenetetramine and paraphenylenediamine according to a mass ratio of 1 to (100 to 600); then performing dispersion for 30 to 60 minutes by using an ultrasonic dispersing machine, uniformly dispersing the solutions and instantly transferring the solutions into a three-neck flask; heating the flask while stirring, controlling a reaction temperature to be between 100 and 200 DEG C, and performing reaction for 20 to 24 hours; taking reaction solutions after the reaction is finished and uniformly coating a steel plate which is ground and smoothed in advance and is cleaned and dried by using absolute ethyl alcohol with the reaction solutions, and putting the steel plate in a baking oven to be dried for 3 hours at 120 DEG C so as to obtain a graphene film with a sutured continuous structure. According to the method disclosed by the invention, the method for suturing the micron-scale graphene oxide into the graphene film withlarge area, high heat conduction and capability of being firmly adhered on the surface of metal by utilizing a suture agent is innovatively provided.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Silicon rubber with temperature self-control performance

InactiveCN103214857ALittle temperature dependenceGood heat stabilityUltrasound attenuationOrganic Oxide

The invention aims at providing temperature self-control silicon rubber which is used for solving the problem that the existing temperature self-control material is improved polyethylene and conductive particles are difficult to uniformly fill due to polymerization-adhesion trend of conductive particles under a base molten state. During a processing and using process of the product, the polymerization-adhesion trend can continue, so that the function attenuation of the product is accelerated; and the product is short in service life and poor in safety due to heat insulation or spontaneous combustion. The highest temperature maintaining range of the product is narrow due to the limit of the characteristics of the base material. The technical key point of the invention is that the silicon rubber comprises the following components in parts by weight: 100 parts of raw silicon rubber, 30-60 parts of reinforcing agent, 6-35 parts of conductive medium, 5.5-16 parts of constitution controller and 0.5-2 parts of vulcanizing agent organic oxide. The silicon rubber with the temperature self-control performance has the positive effect that the highest temperature maintaining range ranges from a certain DEG C to 200 DEC or higher. The silicon rubber with the temperature self-control performance can be used within a wider environment temperature range. Moreover, an open circuit due to sparse conductive particles is avoided and a short circuit due to gathering of conductive particles is also avoided, so that the self rubber with the temperature self-control performance is high in safety, longer in service life and strong in practicability.

Owner:肖万军

High-effective drought-resisting fertilizer

InactiveCN1460665AReduce surface propertiesReduce dosageOrganic fertilisersFertilizer mixturesChemistryCoal

The present invention relates to a high-effective drought-resisting fertilizer and its preparation process. It is made up by mixing fulvic acid extracted from danty, cupric sulfate, ferrous sulfate, manganese sulfate and zinc sulfate according to a certain proportion, and is characterized by that in the process of extracting fulvic acid firstly, a certain quantity of concentrated nitric acid is added so as to make the ulmic acid and humic acid be converted into the fulvic acid to raise extracting rate of fulvic acid. Its main preparation process includes the steps of extracting fulvic acid and adding trace elements. Besides, it also provides application method.

Owner:李琴

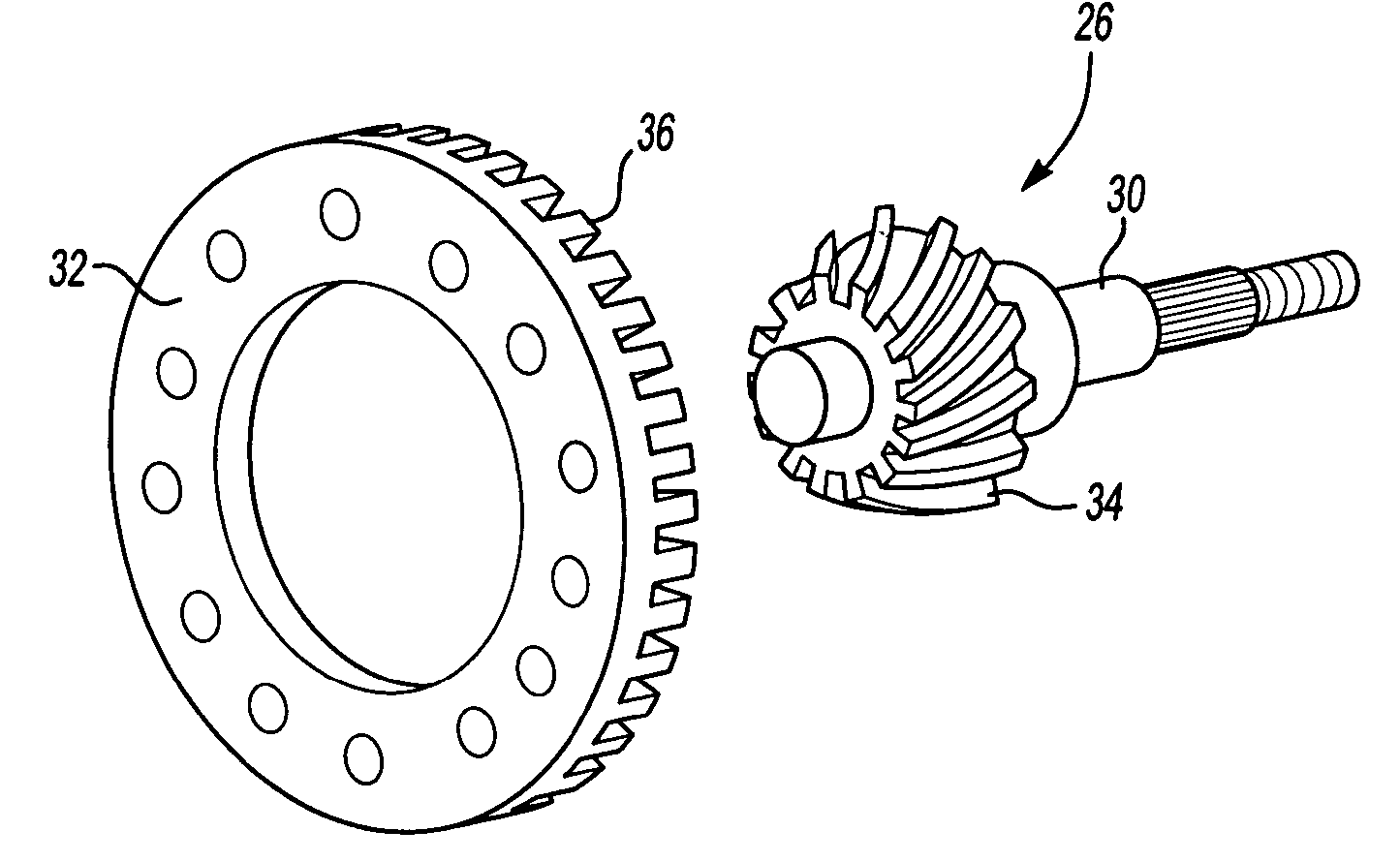

Low manganese carbon steel

InactiveUS20060048863A1Improve mechanical propertiesReduce materialSolid state diffusion coatingDrivetrainManganese

An alloy composition forms a steel having low manganese content, low silicon content, and medium carbon content. The alloy composition comprises in combination, by weight, about 0.3 to 0.5% carbon (C) and 0.15 to 0.40% manganese (Mn), with the balance being essentially iron (Fe). Further, the alloy composition has no more than about 0.04% aluminum (Al), no more than about 0.035% phosphorous (P), no more than about 0.025% sulfur (S), no more than about 0.15% chromium (Cr), no more than about 0.18% silicon (Si), and no more than about 0.08% molybdenum (Mo). The use of an alloy composition with lower silicon and manganese contents eliminates the need for prolonged carbuization. Instead, shorter carbonitriding cycles can be used, which results in improved residual stress, bending fatigue, and surface characteristics for driveline components.

Owner:ARVINMERITOR TECH

Antifouling coating material and preparation method thereof

ActiveCN104177970AReduce surface propertiesImprove surface propertiesAntifouling/underwater paintsPaints with biocidesMethacrylateMicro nano

The invention provides an antifouling coating material and a preparation method thereof. The preparation method comprises the following steps: (A) mixing a thermoplastic butylbenzene segmented copolymer, dodecafluoroheptyl methacrylate and an initiator, and reacting so as to obtain a reaction product; and (B) mixing the reaction product with a mesoporous molecular sieve, thereby obtaining the antifouling coating material. As the thermoplastic butylbenzene segmented copolymer, the dodecafluoroheptyl methacrylate and the initiator are mixed and reacted to obtain a fluorinated copolymer, due to addition of a dodecafluoroheptyl methacrylate fluorine-containing monomer, the surface property of a copolymer coating is effectively degraded, so that the coating has certain anti-wettability, can prevent the surface of the coating from being moistened by microorganism secretion mucus, thereby inhibiting adhesion of microorganisms. As the fluorinated copolymer is mixed with the mesoporous molecular sieve, special micro-nano morphology is formed on the surface of the coating because of the dopant; because of the morphology, the surface anti-wettability of the polymer coating is further improved, and the antifouling effect on the fluorine-containing coating is well improved.

Owner:HAINAN UNIVERSITY

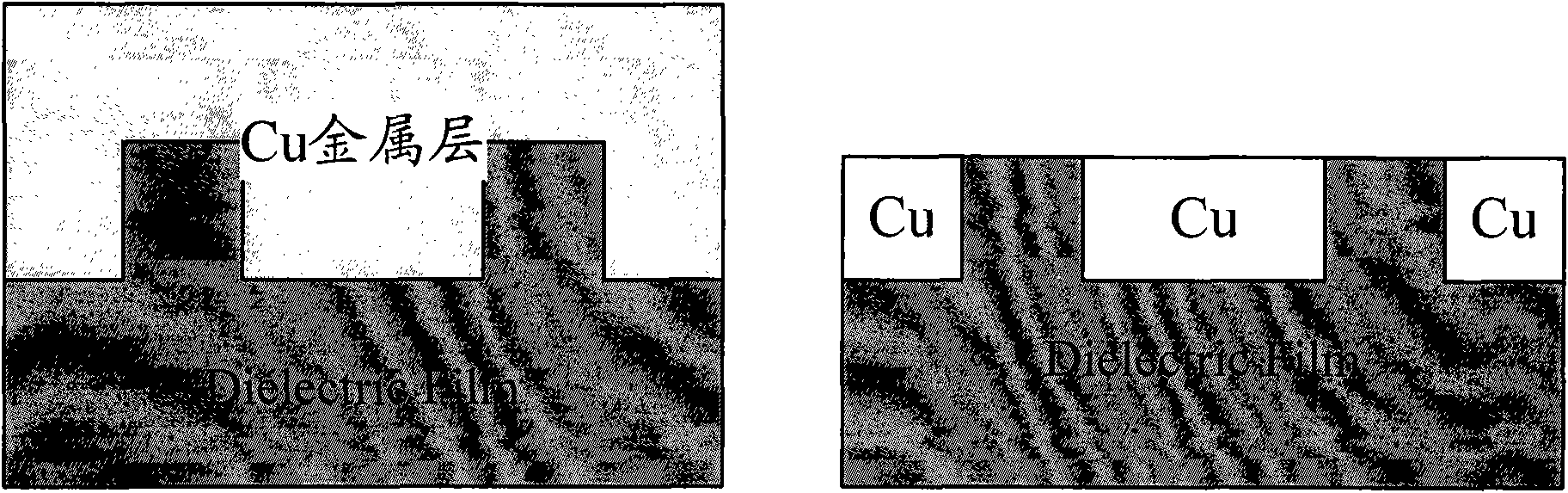

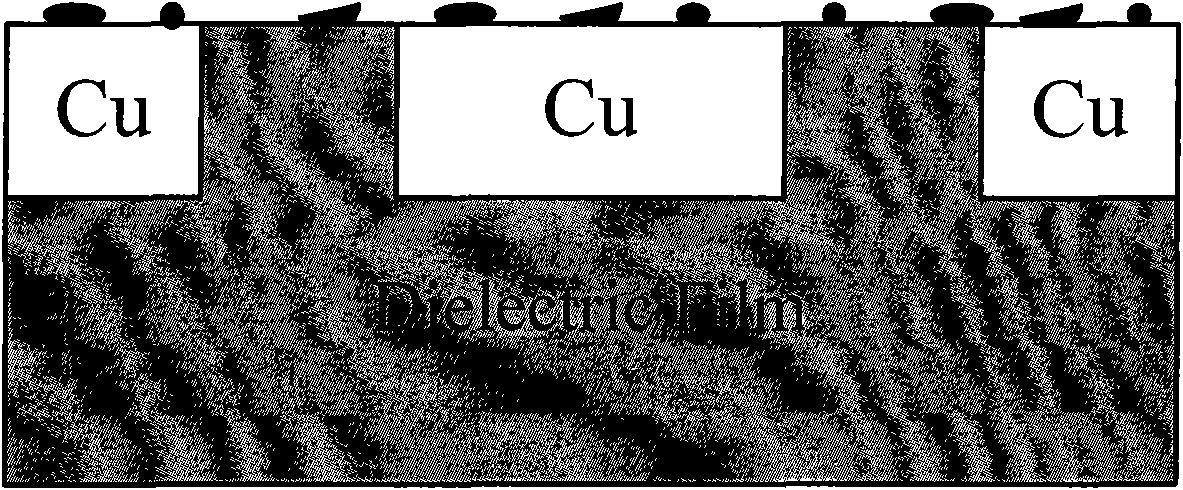

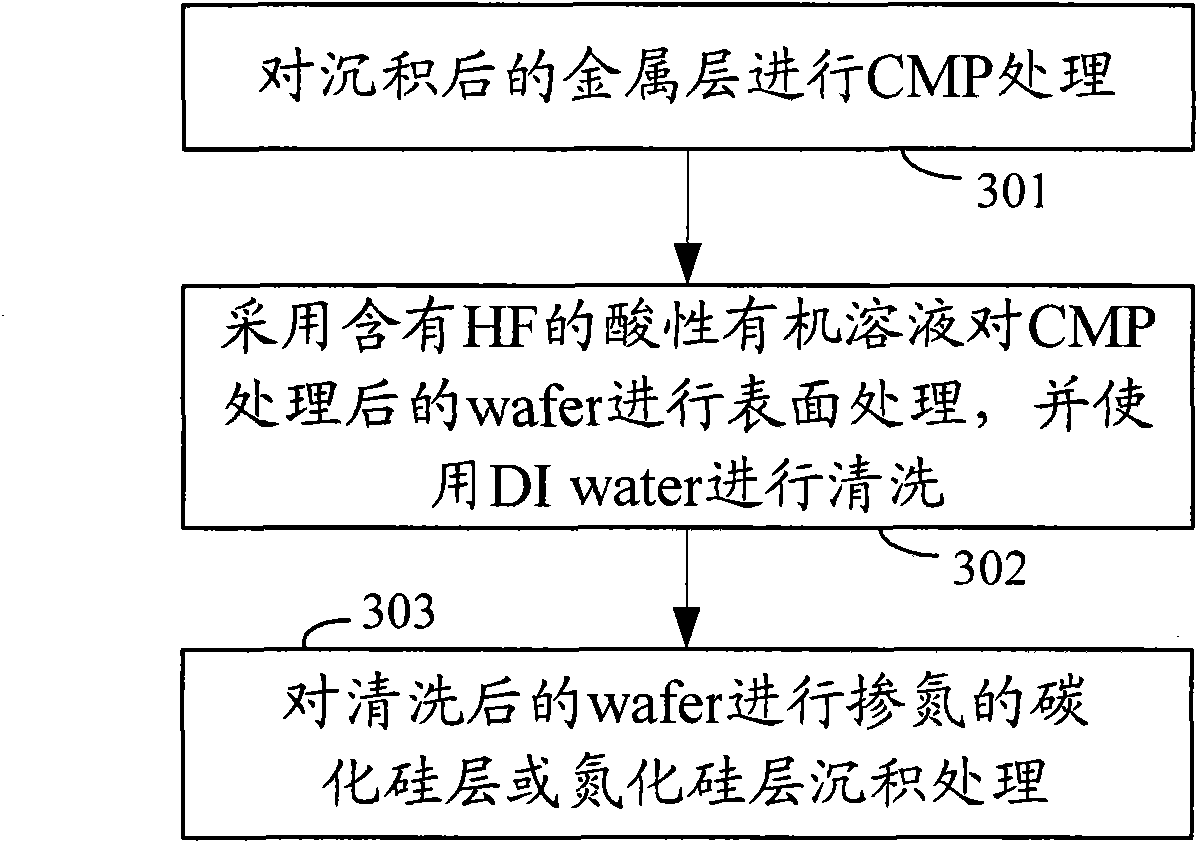

Method for improving surface performance

InactiveCN101789373AImprove surface propertiesReduce surface propertiesSemiconductor/solid-state device manufacturingMetallic material coating processesHydrofluoric acidMachining process

The invention discloses a method for improving surface performance. After a deposited metal layer is subjected to chemically mechanical polishing and before a silicon carbide layer or a silicon nitride layer for performing nitrogen doping on wafers is deposited, the method further comprises the steps of: performing surface treatment on the wafers after the chemically mechanical polishing by adopting acidic organic solution containing hydrofluoric acid, and washing the wafers by using deionized water. In the method for improving the surface performance, by using the acidic organic solution containing HF, free metal ions on the surfaces of the wafers can be reduced, metallic oxides can be eliminated and organic particles causing surface contamination can be dissolved; the reduction of the surface performance of the wafers during Q time is effectively repaired; and compared with the prior art, the method effectively improves the surface performance of the wafers, and an improved machining process applied cannot cause cost increase.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Phosphorylcholine-based amphiphilic silicones for medical applications

InactiveUS9181401B2Improve wettabilityImprove the lubrication effectSilicon organic compoundsNon-adhesive dressingsWound dressingPhosphorylcholine

Amphiphilic biomimetic phosphorylcholine-containing silicone compounds for use in both topical and internal applications as components in biomedical devices. The silicone compounds, which include zwitterionic phosphorylcholine groups, may be polymerizable or non-polymerizable. Specific examples of applications include use as active functional components in ophthalmic lenses, ophthalmic lens care solutions, liquid bandages, wound dressings, and lubricious and anti-thrombogenic coatings.

Owner:DSM IP ASSETS BV

PVC (polyvinyl chloride)-used bi-component waterborne coating as well as preparation method and application thereof

InactiveCN106752832AReduce surface propertiesReduce performancePolyurea/polyurethane coatingsPolyvinyl chlorideDefoaming Agents

The invention relates to the technical field of coating and particularly relates to PVC (polyvinyl chloride)-used bi-component waterborne coating as well as a preparation method and application thereof. The PVC-used bi-component waterborne coating comprises a main agent and a curing agent, wherein the curing agent is a waterborne polyurethane curing agent; the main agent comprises the following raw materials by mass percentage: 40-60% of waterborne hydroxyl acrylate, 8-18% of waterborne vinyl chloride-vinyl acetate resin, 0.5-1.5% of a defoaming agent, 0.2-2% of a dispersing agent, 0.2-0.5% of a lubricating agent, 0.2-0.5% of a flatting agent, 18-25% of titanium dioxide, 0.4-2% of a rheological agent, 4.1-10.5% of a coalescing agent, 0.1-0.5% of a pH regulator and the balance of water. Compared with the existing oil-based PVC product, the PVC-used bi-component waterborne coating conforms to the environment-friendly requirement, is simple in construction, is directly sprayed on most PVC substrates after raw materials are configured in construction proportion and still has excellent adhesion under a condition of no polishing.

Owner:CHENGDU ZHANCHEN PAINT

Drought-resistance biological fertilizer for pears

InactiveCN104710246APromote absorptionIncrease productionBioloigcal waste fertilisersFertilizer mixturesIron sulphatePesticide residue

The invention relates to the technical field of fertilizer, and more specifically relates to a drought-resistance biological fertilizer for pears, the dought-resistance biological fertilizer for pears comprises the following components by weight part: 20-30 parts of weathered coal, 10-15 parts of soybean meal, 9-11 parts of peanut cake, 9-11 parts of bran, 3-5 parts of microzyme, 5-7 parts of starch, 3-5 parts of brown sugar, 2-4 parts of copper sulphate, 1-3 parts of manganese sulfate, 1-3 parts of zinc phosphate, 3-5 parts of ferrous sulphate, 1.5-3.5 parts of borax, 7-9 parts of sweet potato powder, 15-25 parts of grass carbon, and 4-6 parts of fish meal. The biological fertilizer can satisfy various nutrition components required by pear growth, has advantages of no toxicity, no flavor, safety and reliability, can enhancing the anti adversity capability such as drought resistance, illness resistance and lodging resistance of crops, and is capable of reducing pesticide residues, eliminating soil hardening, improving saline land, prolonging fertilizer efficiency, improving quality and increasing output.

Owner:张元宝

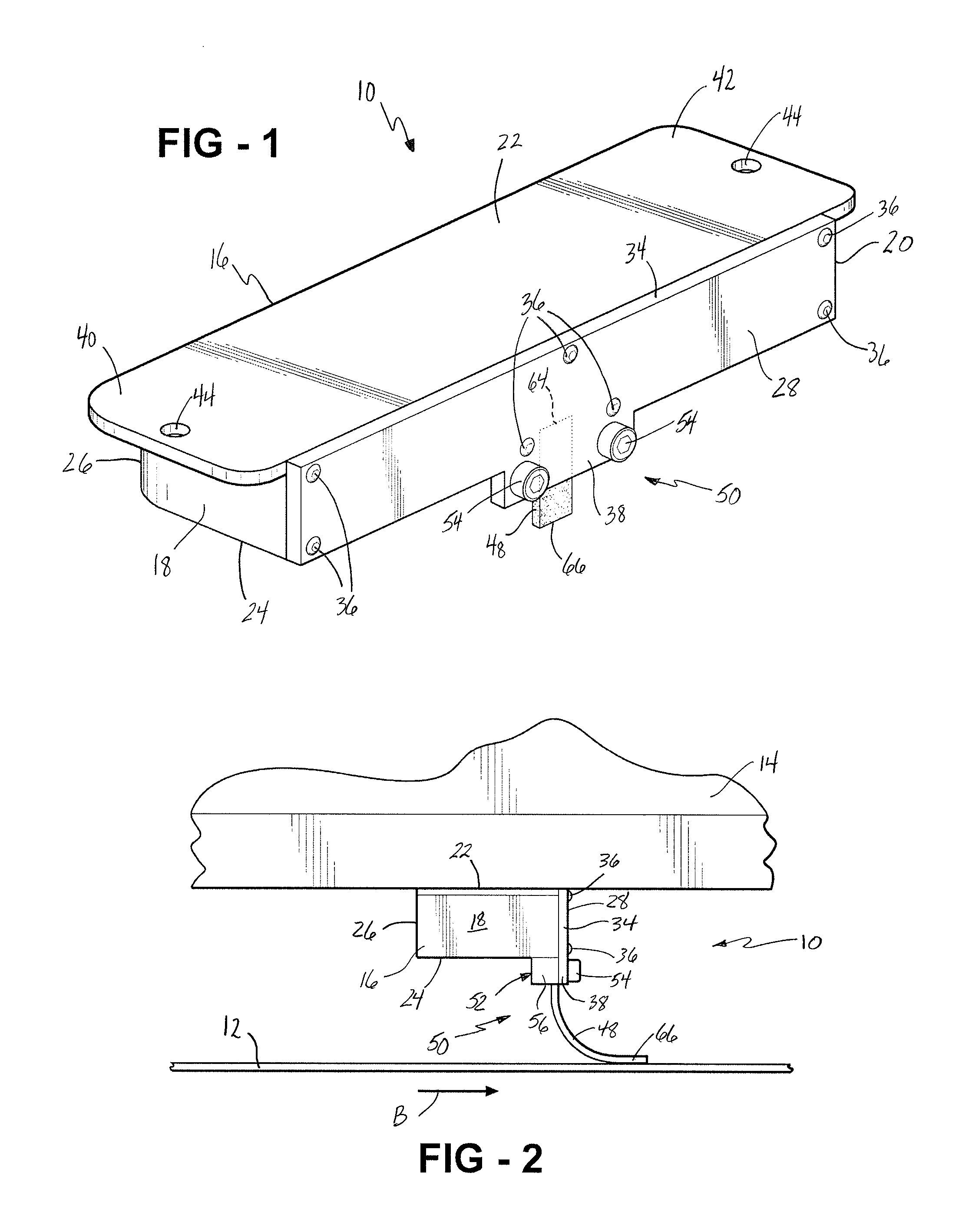

Lubrication Device

InactiveUS20070227822A1Reduce frictional propertyReduce frictionBowling gamesCleaningLubricationEngineering

A lubrication assembly is provided for lubricating a surface with a lubricant. The lubrication assembly includes a tube adapted to be coupled to the surface. The tube defines a reservoir for storing the lubricant thereon. The lubrication assembly also includes a wiper that is coupled to the tube. The wiper includes a first portion in fluid communication with the lubricant and a second portion disposed for continuous contact with the surface for automatically transferring and supplying the lubricant from the reservoir to the surface. The lubricant reduces frictional properties of the surface.

Owner:PERMAWICK

Leather-like sheet bearing grain finish and process for producing the same

ActiveUS8883662B2Improve surface propertiesGood lookingHollow inflatable ballsHollow non-inflatable ballsFiber bundleSurface layer

A (semi)grain-finished leather-like sheet composed of an entangled nonwoven fabric of three-dimensionally entangled fiber bundles containing microfine long fibers and an elastic polymer contained in the entangled nonwoven fabric. When dividing the (semi)grain-finished leather-like sheet to five layers with equal thickness, i.e., surface layer, substrate layer 1, substrate layer 2, substrate layer 3 and back layer in this order along the thickness direction, part of the microfine long fibers forming the surface layer and / or the back layer are fuse-bonded to each other and the microfine long fibers forming the intermediate layer are not fuse-bonded. With such a fuse-bonding state of the microfine long fibers, the (semi)grain-finished leather-like sheet combines a low compression resistance and a dense feel each comparable to natural leathers, has a sufficient practical strength, and are excellent in properties which are required according to its use.

Owner:KURARAY CO LTD

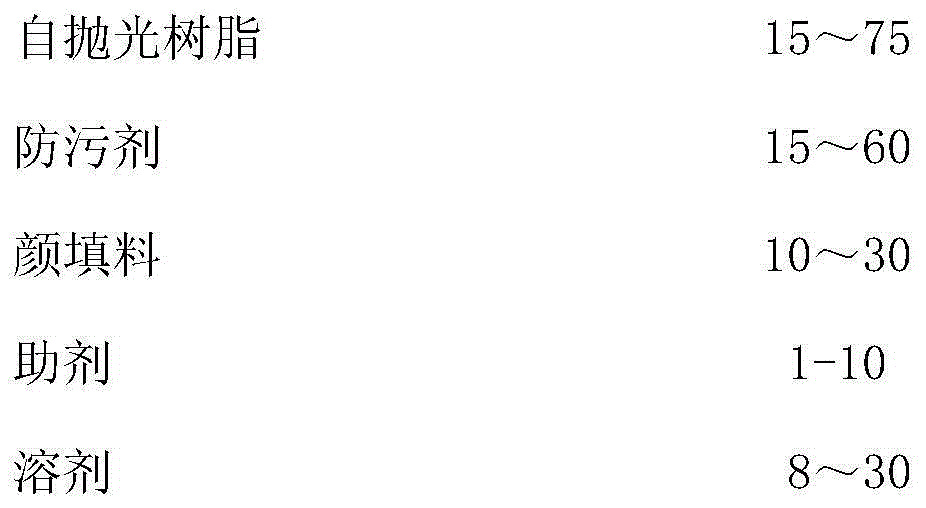

A copper-free and tin-free low-surface antifouling paint

ActiveCN105255297BReduce surface propertiesEasy to useAntifouling/underwater paintsPaints with biocidesAdjuvantCoating system

The invention relates to an antifouling paint, in particular to a copper-free and tin-free low-surface antifouling paint. A copper-free and tin-free low-surface antifouling paint, the antifouling paint is formed by mixing component A and component B by weight: component A is mainly composed of 30-55% of film-forming substances and 3-6% of antifouling agent %, filler 15-35%, solvent 5-15% and additive 1-15%, mixed evenly and then ground to a fineness below 70μm; component B is composed of crosslinking agent, catalyst and solvent; component A and The weight ratio of component B is 9:1. The invention has the following advantages: (1) tin-free and copper-free, which effectively reduces the impact on the environment, and at the same time has excellent compatibility and short curing time; (2) the coating system can play a role in the roughness of underwater metals to a smooth effect.

Owner:ZHEJIANG MARINE DEV RES INST

Large 3D printing support material and preparation method thereof

ActiveCN109233318AReduce intensityReduce toughnessAdditive manufacturing apparatusAntioxidantSupport surface

The invention discloses a large 3D printing support material and a preparation method thereof. The large 3D printing support material comprises the following main materials: calcium carbonate fillingmaster batch, a thermoplastic elastomer, a foaming agent, a surface modifier, a plasticizer and an antioxidant, wherein the calcium carbonate filling master batch is taken as a main ingredient, and the thermoplastic elastomer is a binding agent. The main materials such as the calcium carbonate filling master batch and the thermoplastic elastomer are cheap in materials and environmentally friendly;through the addition of the foaming agent, the strength and tenacity of the material are reduced, the material is convenient to disassemble, and through the surface modifier, the adhesiveness of a supporting surface with the main body material is increased; in the application of 3D printing, the support material is high in plasticity, the support material can be completely separated from the mainbody material, the support material can be directly dismantled without the use of a tool due to low strength and tenacity, and the shape of a molding part cannot be damaged due to the stripping of the support material; and compared with a water-soluble support material, the support material is more environmentally friendly and economical since water is not needed, and the support material is moreapplicable for 3D printers using screw extrusion.

Owner:广东华领智能制造有限公司 +1

Heat reflective coating and its preparation method and application

ActiveCN103666174BReduce polarizabilityGood acid and alkali resistanceClimate change adaptationReflecting/signal paintsCooling effectAcrylate polymer

The invention discloses a heat reflecting paint, and a preparation method and an application thereof. The heat reflecting paint comprises the following components in parts by weight: 100 parts of fluorine-containing (methyl) acrylate polymer emulsion, 2-30 parts of reflecting pigment, 0.1-4 parts of filler, 2-40 parts of flatting agent, 1-20 parts of coalescing agent, 0.01-1 part of thickening agent, 0.01-2 parts of dispersant, 0.001-1 part of wetting agent, 0.1-60 parts of distilled water and 0.5-5 parts of cross-linking agent. The heat reflecting paint provided by the invention is high in heat reflection performance, and excellent in acid and alkali resistance, weather fastness and stain resistance. The heat reflecting paint provided by the invention is applied to a bituminous pavement; the heat reflecting paint is capable of relieving the urban heat island effect by reducing the road surface temperature, and reducing the environmental pollution generated in the use process of the coating, and also capable of improving the stain resistance of the coating and ensuring persistent cooling effect of the heat reflecting coating.

Owner:唐伯明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com