A copper-free and tin-free low-surface antifouling paint

An antifouling paint, low surface technology, applied in antifouling/underwater paints, biocide-containing paints, coatings, etc., can solve problems such as food chain enrichment, marine pollution, etc., to reduce environmental impact, curing time Short, good matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

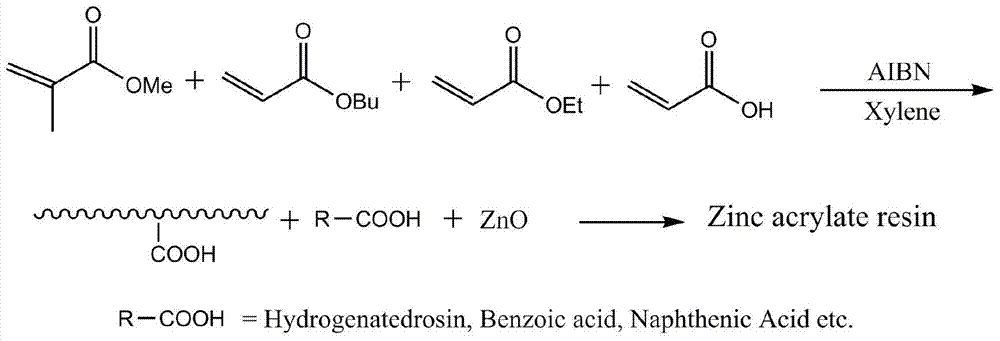

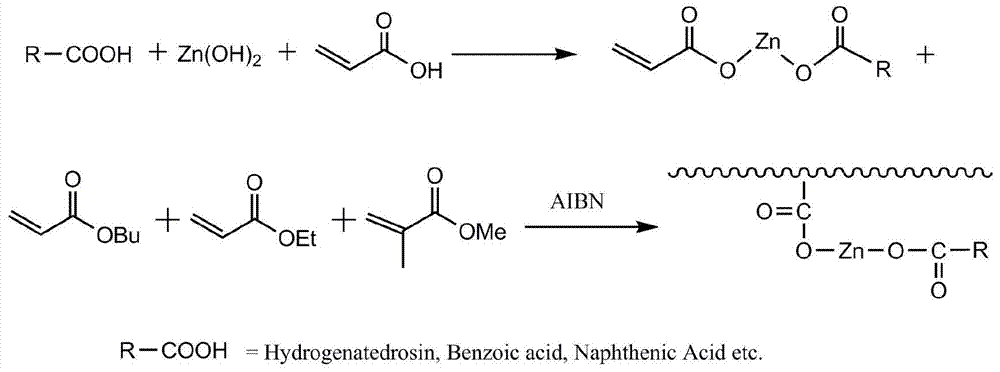

[0017] Embodiment one: the preparation of zinc acrylate resin (prepolymer method)

[0018] Add 50g of n-butanol and 150g of xylene into a four-neck flask equipped with a stirrer, reflux condenser, constant pressure dropping funnel, and thermometer, raise the temperature to 100°C, and then weigh 26g of acrylic acid and 50g of methyl methacrylate , 62g of ethyl acrylate, 62g of n-butyl acrylate, and 5g of azobisisobutyronitrile were added dropwise at a constant speed for 3 hours with a constant pressure dropping funnel, and the acrylic resin prepolymer was obtained after continuing to react for 3 hours . Then cool to 60°C, add 34g of hydrogenated rosin, 7.4g of zinc oxide, 20g of xylene, 40g of n-butanol, mix well and heat up to 120°C, react for 3 hours, cool to 60°C, add 3.5g of calcium hydroxide, After stirring for 1 hour, add an oil-water separator to separate the water produced in the reaction process by azeotropic separation, and obtain the hydrogenated abietic acid type z...

Embodiment 2

[0020] Embodiment two: the preparation of zinc acrylate resin (direct reaction method)

[0021] Acrylic acid zinc resin preparation reaction example one:

[0022] Add 7.4g of zinc oxide, 34g of hydrogenated rosin, 120g of xylene, and 30g of n-butanol into a 1L four-neck flask equipped with a stirrer, reflux condenser, constant pressure dropping funnel, and thermometer and raise the temperature to 120°C. After 5 hours of reaction Add 26g of acrylic acid, take out the mixture after reacting for 2h and put it in a 1L round bottom flask, add 50g of methyl methacrylate, 62g of ethyl acrylate, 62g of n-butyl acrylate, 5g of azobisisobutyronitrile, mix well, and use The constant pressure dropping funnel was used to drop the mixed solution at a constant speed for 3-4 hours into a 1L four-necked flask (containing 150g xylene) equipped with a stirrer, a reflux condenser, a constant pressure dropping funnel and a thermometer. After heat preservation for 3 hours, cool to 60°C, add 3.5g o...

Embodiment 3

[0037] Embodiment three: the preparation of plasticizer acrylic resin

[0038] Add 50g of n-butanol and 150g of xylene into a four-necked flask equipped with a stirrer, reflux condenser, constant pressure dropping funnel, and thermometer, raise the temperature to 100°C, then weigh 26g of acrylic acid, 102g of ethyl acrylate, 72g The mixed solution of n-butyl acrylate and 5g of azobisisobutyronitrile was added dropwise at a constant speed for 3 hours with a constant pressure dropping funnel, and the acrylic resin prepolymer was prepared after 3 hours of heat preservation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com