Fluoride-free waterproof finishing agent and preparation and application methods thereof

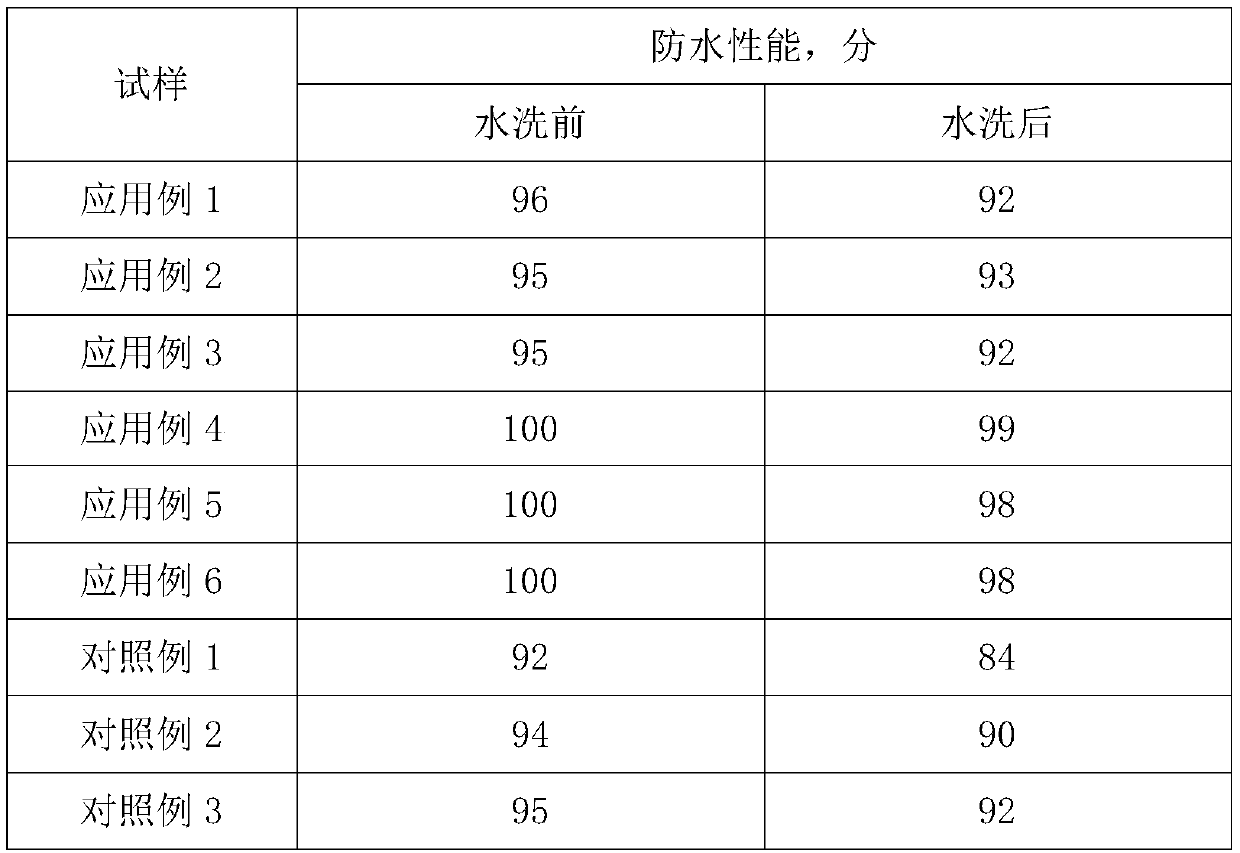

A fluorine-free waterproofing and application method technology, applied in fiber treatment, biochemical fiber treatment, textiles and papermaking, etc., can solve the problem that the waterproofness and washability of fluorine-free water repellent agent cannot meet people's requirements, and improve antibacterial properties. Antifungal properties, surface tension reduction, and the effect of reducing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 2

[0037] Preparation example 2 of crosslinking agent: take 5kg dimethylolpropionic acid, 5kg ethylene glycol and 35kg isophorone diisocyanate, heat up to 70°C, stir at 200r / min for 1.5h; then add 6.5kg butane Ketoxime was kept at a temperature of 70° C. for 2.5 hours, and after adding 2 kg of ethylenediamine, it was stirred at a speed of 6500 r / min for 30 minutes to obtain a crosslinking agent.

[0038]Preparation example 3 of crosslinking agent: take 6kg dimethylolpropionic acid, 6kg ethylene glycol and 40kg isophorone diisocyanate, heat up to 80°C, stir at 400r / min for 2h; then add 7kg butanone oxime , kept at a temperature of 75° C. for 3 h, added 3 kg of ethylenediamine, and stirred at a speed of 7000 r / min for 40 min to obtain a crosslinking agent.

[0039] 2. Preparation example of waterproof synergist The hydroxy silicone oil in the following preparation examples is selected from the hydroxy silicone oil of the model PMX-0156 provided by Dow Corning.

preparation example 1

[0040] Preparation example 1 of waterproof synergist: 10 kg of silicon dioxide, 2.25 kg of fatty alcohol polyoxyethylene ether, 0.75 kg of cetyl dimethyl ammonium chloride, 2 kg of stearyl methacrylate, oleic acid polyoxyethylene 2kg of ethylene glycol diester and 50kg of ethylene glycol were emulsified and dispersed for 5 minutes under the condition of ultrasonic frequency of 20KHz to obtain a pre-emulsion; after mixing 2kg of silane coupling agent KH560 and 30kg of hydroxyl silicone oil, add the pre-emulsion and heat to 80 ℃, stirring and dispersing at a speed of 1000r / min for 30 minutes; cooling down to 70 ℃, and keeping warm for 50 minutes to obtain a waterproof synergist.

[0041] Preparation example 2 of waterproof synergist: 15 kg of silicon dioxide, 3 kg of polyoxyethylene lauryl ether, 1 kg of lauryl dimethyl ammonium oxide, 3 g of stearyl methacrylate, polyethylene glycol oleate 3kg of diester and 55kg of ethylene glycol were emulsified and dispersed for 8min at an u...

preparation example 3

[0042] Preparation example 3 of waterproof synergist: 20 kg of silicon dioxide, 3.75 kg of sorbitan monostearate, 1.25 kg of lauryl dimethyl ammonium oxide, 4 kg of stearyl methacrylate, 4kg polyethylene glycol diester of oleic acid and 60kg ethylene glycol were emulsified and dispersed for 10min at an ultrasonic frequency of 30KHz to obtain a pre-emulsion; after mixing silane coupling agent KH5604kg and hydroxy silicone oil 40kg, add the pre-emulsion and heat to 90°C, stir and disperse at a speed of 2000r / min for 40 minutes; cool down to 75°C, and keep warm for 60 minutes to obtain a waterproof synergist.

[0043] 3. Examples The fluorine-free water repellent in the following examples includes fatty alcohol polyoxyethylene ether, and the CAS is 68002-97-1, which is selected from the product KW-802B provided by Guangzhou Hongyi Technology Co., Ltd.; the penetrating agent is α-isotridecyl-ω-hydroxyl-poly(oxy-1,2-ethylene), CAS 9043305; antifoaming agent is oleic acid polyethyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com