High-adhesion, low-surface-energy silver-loaded antifouling paint and preparation method thereof

A low surface energy, antifouling coating technology, applied in antifouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc. Focus on other issues to achieve the effect of significant antifouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

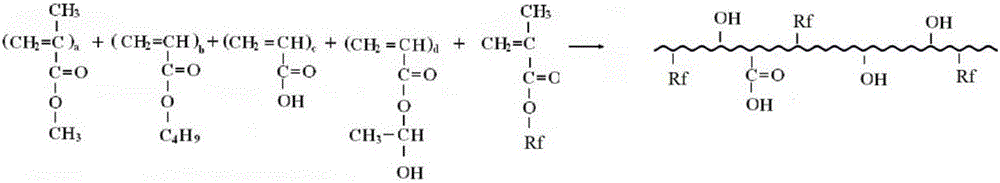

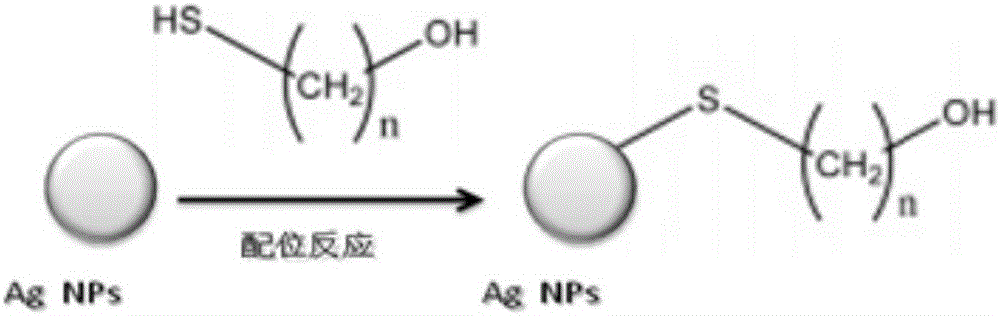

[0034] Step 1: Preparation of organic fluorine modified acrylic resin

[0035] First, MMA, BA, β-HEA, AA, and FMA are mixed in proportions, and uniformly stirred at room temperature to obtain a pre-mixed monomer. The mass fractions of the monomers are respectively: 30-35%, 22-28%, 10-16%, 15-19%, 3-12%; secondly, the initiator AIBN is mixed with the solvent xylene to obtain a mixed solvent, the mass of AIBN The fraction is 1.2-5.5%; finally, under the protection of N2, the pre-mixed monomers and mixed solvents prepared above are added to the reaction vessel at a uniform speed and dropwise at a mass ratio of 7:3 to 6:4. The entire reaction temperature is controlled at 55°C to 85°C, the reaction time is 2 to 5 hours, the reaction is completed, and the temperature is naturally lowered to obtain the organic fluorine modified acrylic resin.

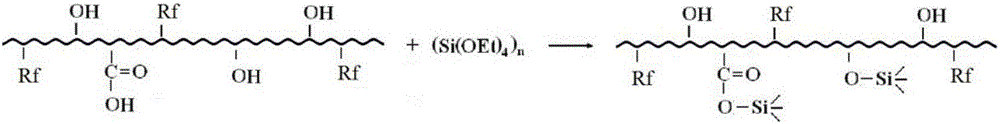

[0036] Step 2: Preparation of silicone

[0037] First, ethyl orthosilicate (TEOS), absolute ethanol, hydrochloric acid, and deionized water are mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com