Preparation and application of self-polishing antifouling coating matrix resin

A technology of self-polishing resin and antifouling paint, applied in antifouling/underwater paints, coatings, paints containing biocides, etc. The effect of prolonging the antifouling period, simple and convenient construction and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

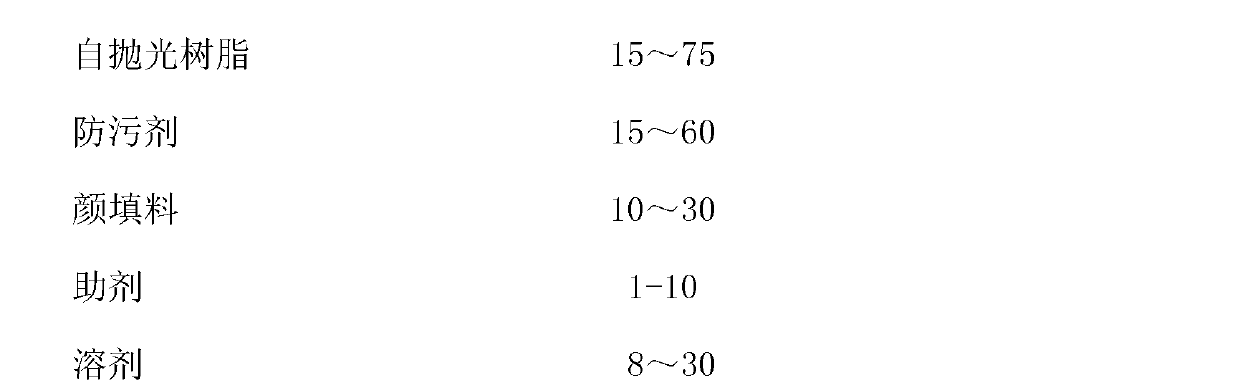

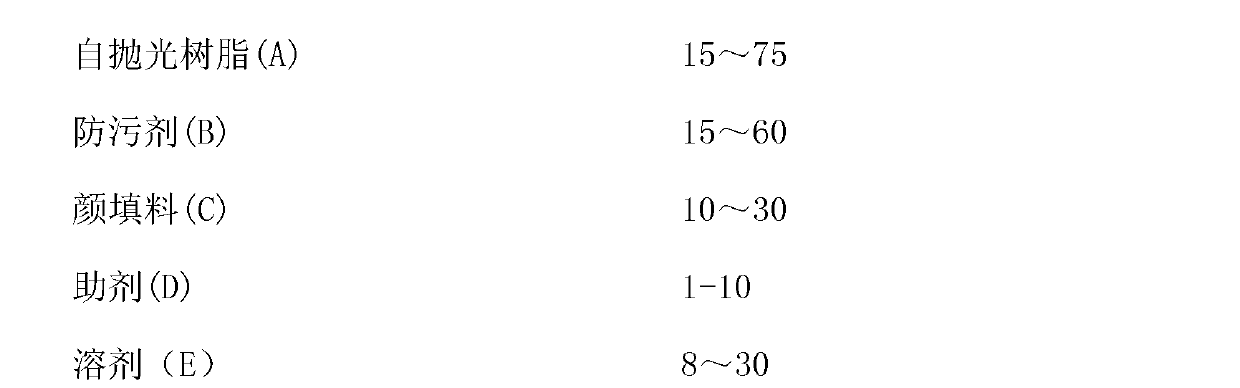

Method used

Image

Examples

preparation example Construction

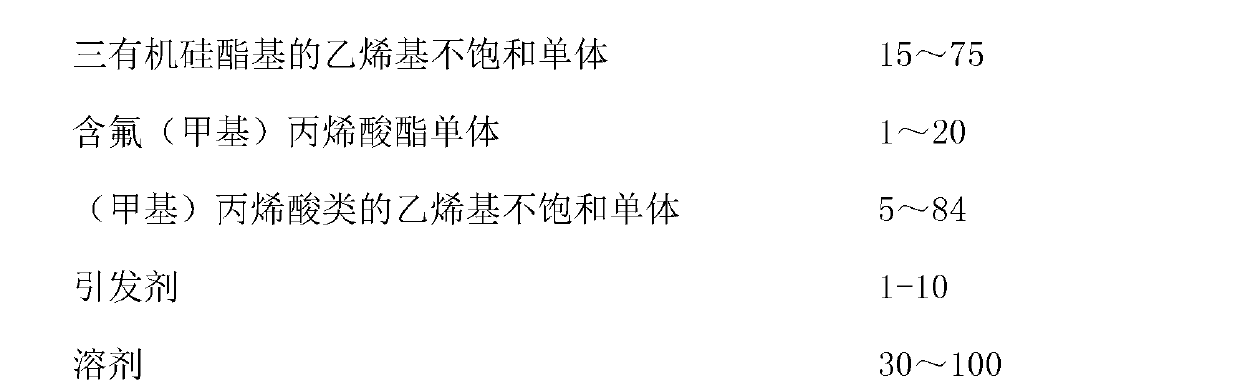

[0031] Preparation of self-polishing resin (A)

[0032] Add a stoichiometric organic mixed solvent and part of a3 monomer into a four-necked flask equipped with a stirring device, condenser, dropping funnel, and thermometer. The temperature is raised to 100℃, and the a1 monomer, a2 monomer and the remaining a3 The monomers and initiators are mixed evenly according to the metering ratio, and they are added dropwise to a four-necked bottle. Add dropwise for 3 to 4 hours, keep it for 2 hours, then add initiator and solvent, and keep it for 2 hours after the addition is complete. The material is discharged to obtain the self-polishing resin of the present invention.

[0033] In the process of preparing the self-polishing resin, the amount ratio of the two initiators added is 2-5:1.

[0034] In the process of preparing the self-polishing resin, the amount ratio of the two added solvents is 5-10:1.

[0035] In the process of preparing the self-polishing resin, the amount ratio of the a3 mo...

Embodiment 1

[0044] Example 1 (Resin A-1)

[0045] In a four-neck flask equipped with a stirring device, a condenser, a dropping funnel, and a thermometer, add 25 parts of propylene glycol methyl ether, 70 parts of xylene and 5 parts of ethyl acrylate under stirring, and heat to 100°C. From the dropping funnel, drop a mixture consisting of 35 parts of methyl methacrylate, 25 parts of ethyl acrylate, 5 parts of trifluoroethyl acrylate, 30 parts of trimethylsilyl acrylate, and 2.5 parts of azobisisobutyronitrile. Liquid for 4 hours. After the dripping is completed, keep it warm for 2 hours, then add 0.5 parts of azobisisobutyronitrile and 5 parts of xylene. After keeping the temperature for another 2 hours, cool down and discharge. The fluorine-containing silyl acrylate resin A-1 with self-polishing properties was prepared.

Embodiment 2

[0046] Example 2 (Resin A-2)

[0047] In a four-neck flask equipped with a stirring device, a condenser, a dropping funnel, and a thermometer, add 25 parts of propylene glycol methyl ether, 70 parts of xylene and 5 parts of ethyl acrylate under stirring, and heat to 100°C. Add 35 parts methyl methacrylate, 20 parts ethyl acrylate, 10 parts trifluoroethyl acrylate, 30 parts triisopropylsilyl acrylate, 2.5 parts azobisisobutyronitrile from the dropping funnel. Mix the liquid for 4 hours. After the dripping is completed, keep the temperature for 2 hours, add 0.5 parts of azobisisobutyronitrile and 5 parts of xylene, and keep the temperature for another 2 hours, then cool and discharge. A fluorine-containing silyl acrylate resin A-2 with self-polishing properties was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com