Preparation method of organic zinc or copper acrylic resin

A kind of technology of acrylic resin and acrylic acid, which is applied in paints, coatings, anti-fouling/underwater coatings containing biocide, etc. It can solve the problems of synthesis, high reaction temperature and complex synthesis process, and achieve low energy consumption and high reaction temperature The effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

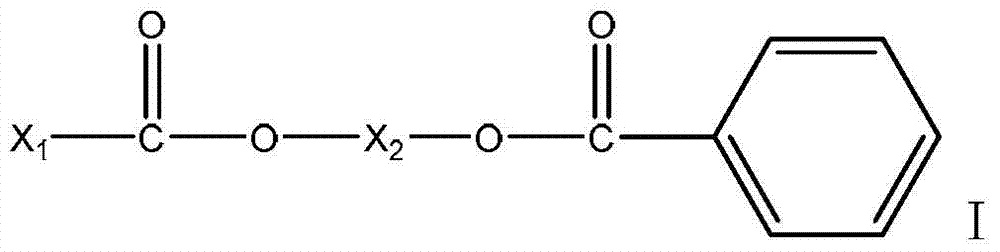

[0022] (1) Add 72g of acrylic acid, 99g of zinc hydroxide, 124g of sodium benzoate and 600g of solvent into a three-neck round bottom flask equipped with a stirrer, a thermometer, and an oil-water separator, stir, react at 80°C for 1.5h, and heat up to 110°C , after dehydration until no water is distilled off, the reaction obtains solution A containing organic zinc acrylate shown in structural formula I, X 2 is a zinc atom, the solvent is a mixture of xylene and n-butanol with a mass ratio of 4.9:1, and the total amount of distilled water is 18g;

[0023] (2) 84g methyl methacrylate, 62g butyl acrylate, 6.14g azobisisobutyronitrile and 2.05g tert-dodecyl mercaptan are mixed uniformly to obtain solution B, which is added to a constant pressure dropping funnel, and the step (1) The temperature of the obtained solution A is raised to 75°C, and the solution B in the constant pressure dropping funnel is dropped drop by drop within 2 hours under stirring at a rotating speed of 100r / ...

Embodiment 2

[0025] (1) Add 72g of acrylic acid, 98g of copper hydroxide, 122g of sodium benzoate and 600g of solvent into a three-neck round bottom flask equipped with a stirrer, a thermometer, and an oil-water separator, stir, react at 81°C for 1.4h, and heat up to 110°C , after dehydration until no water is distilled off, the reaction obtains solution A containing organic zinc acrylate shown in structural formula I, X 2 is a copper atom, the solvent is a mixture of xylene and n-butanol with a mass ratio of 5:1, and the total amount of distilled water is 18g;

[0026] (2) 83g methyl methacrylate, 63g butyl acrylate, 6.12g azobisisobutyronitrile and 2.04g tert-dodecyl mercaptan are mixed uniformly to obtain solution B, which is added to a constant pressure dropping funnel, and the step (1) The temperature of the obtained solution A was raised to 75°C, and under stirring at 100r / min, the solution B in the constant pressure dropping funnel was dropped drop by drop within 2 hours, kept warm,...

Embodiment 3

[0028] (1) Add 72g of acrylic acid, 98g of copper hydroxide, 117g of sodium benzoate and 600g of solvent into a three-necked round-bottomed flask equipped with a stirrer, a thermometer, and an oil-water separator, stir, react at 79°C for 1.6h, and heat up to 110°C , after dehydration until no water is distilled off, the reaction obtains solution A containing organic zinc acrylate shown in structural formula I, X 2 is a copper atom, the solvent is a mixture of xylene and n-butanol with a mass ratio of 5:1, and the total amount of distilled water is 18g;

[0029] (2) 85g methyl methacrylate, 68.2g butyl acrylate, 6.13g azobisisobutyronitrile and 2.04g tert-dodecyl mercaptan are mixed uniformly to obtain solution B, add a constant pressure dropping funnel, and Solution A obtained in step (1) was heated to 75°C, and under stirring at a speed of 100r / min, the solution B in the constant pressure dropping funnel was dropped dropwise within 2 hours, kept warm, and polymerized for 1 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com