Biodegradable antifouling marine coating and preparation method thereof

A marine antifouling and coating technology, applied in the field of coating technology application, can solve the problems of poor antifouling performance and mechanical properties, high price, high energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

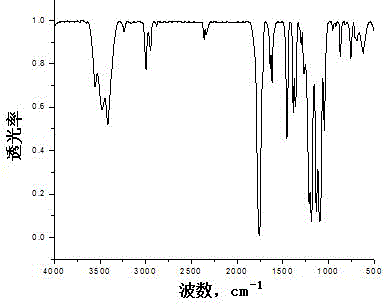

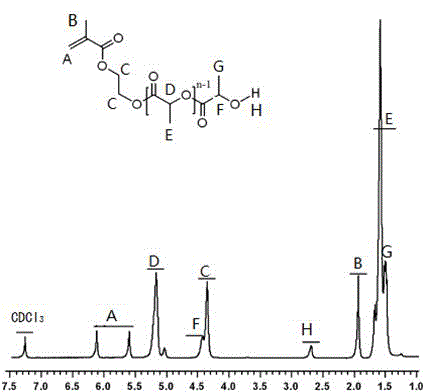

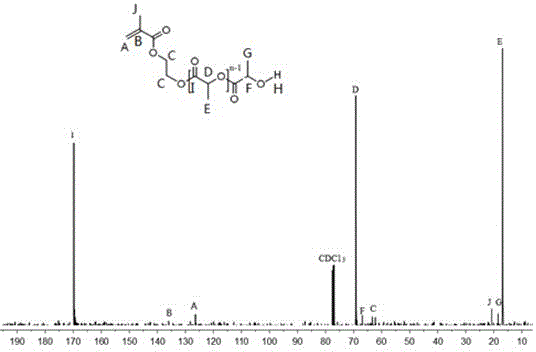

[0037] (1) Mix lactide and hydroxyethyl methacrylate with a molar ratio of 15:1, add 0.1% catalyst stannous octoate, and 2 Under protection, heat and melt first, then raise the temperature to 100° C., and react for 4 hours. Dissolved with chloroform, precipitated with methanol, and dried to obtain a white solid hydroxyethyl methacrylate-polylactic acid macromonomer. Its infrared spectrum is shown in figure 1 , 1759.1cm -1 The strong absorption peak that appears at is the characteristic absorption peak of ester carbonyl, 3446.8cm -1 is the O-H stretching vibration at one end of the PLLA chain, and the C-O stretching vibration peak appears at 1093.6cm -1 and 1186.2cm -1 , the group appears in HEMA, PLLA, and the connection between HEMA and PLLA is also C-O; at 1653cm -1 The absorption peak at shows that there is a -C=C-bond, and the double bond exists in HEMA; at 1384.9cm -1 and 1458.2cm -1 -CH- and -CH respectively 3 The bending vibration peak is at 3022-2900cm -1 -CH-...

Embodiment 2

[0041] Mix glycolide with hydroxyethyl methacrylate at a molar ratio of 10:1, add 0.08% catalyst stannous octoate, and 2 Under the protection, heat and melt first, then raise the temperature to 110° C., and react for 6 hours. Dissolve in chloroform, precipitate out with methanol, and dry to obtain a white solid hydroxyethyl methacrylate-polyglycolide macromonomer. use N 2 Replace the air in the device, and put the mixed solvent (mixture of ethyl acetate, ethanol, and toluene with a mass ratio of 1:4:6) and hydroxyethyl methacrylate-polyglycolide macromer in a four-necked flask, Add methyl methacrylate, styrene, ethyl acrylate, butyl acrylate, and hydroxyethyl acrylate monomers dropwise, rapidly raise the temperature to 45°C, then start to add azobisisobutyronitrile for 2 hours, drop 2 / 3. Then keep warm for 2 hours, then drip the remaining azobisisobutyronitrile, react for 2 hours, and finally keep warm for 1 hour to stop the reaction, and get a light yellow, uniform viscous...

Embodiment 3

[0043] Mix caprolactide and hydroxyethyl methacrylate with a molar ratio of 5:1, add 0.05% catalyst stannous octoate, in N 2 Under the protection, heat and melt first, then raise the temperature to 110° C., and react for 10 hours. Dissolved with chloroform, precipitated by methanol, and dried to obtain a white solid hydroxyethyl methacrylate-polycaprolactide macromonomer. use N 2 The air in the device was replaced, and the mixed solvent (a mixture of butyl acetate, ethanol, and toluene with a mass ratio of 1:3:5) and hydroxyethyl methacrylate-polycaprolactide macromonomers were placed in a four-necked flask, Add methyl methacrylate, styrene, ethyl acrylate, butyl acrylate, and hydroxyethyl acrylate monomers dropwise, rapidly raise the temperature to 75°C, then start to add azobisisobutyronitrile for 2 hours, and add 2 / 3 , then keep warm for 2 hours, then drop the remaining azobisisobutyronitrile, react for 2 hours, and finally keep warm for 1 hour to stop the reaction, and g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com