A kind of biodegradable marine antifouling paint and preparation method thereof

A marine antifouling and coating technology, applied in the application field of coating technology, can solve the problems of poor antifouling performance and mechanical performance, high energy, high price, etc., and achieve the effect of overcoming poor use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

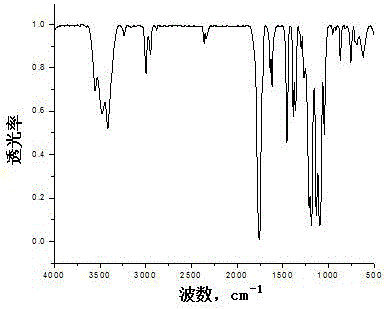

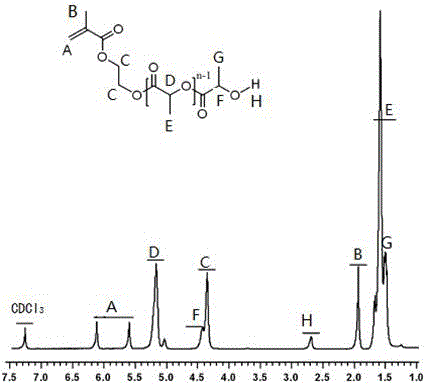

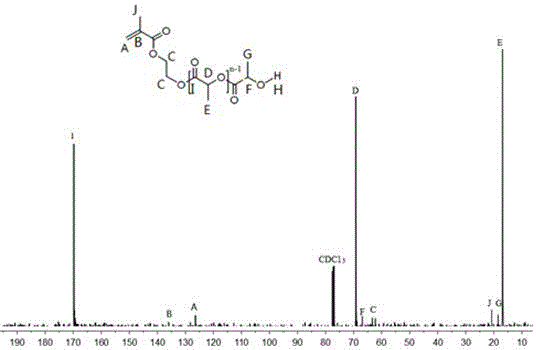

[0038] (1) Mix lactide and hydroxyethyl methacrylate with a molar ratio of 15:1, add 0.1% catalyst stannous octoate, and 2 Under protection, heat and melt first, then raise the temperature to 100° C., and react for 4 hours. Dissolved with chloroform, precipitated with methanol, and dried to obtain a white solid hydroxyethyl methacrylate-polylactic acid macromonomer. Its infrared spectrum is shown in figure 1 , 1759.1cm -1 The strong absorption peak that appears at is the characteristic absorption peak of ester carbonyl, 3446.8cm -1 is the O-H stretching vibration at one end of the PLLA chain, and the C-O stretching vibration peak appears at 1093.6cm -1 and 1186.2cm -1 , the group appears in HEMA, PLLA, and the connection between HEMA and PLLA is also C-O; at 1653cm -1 The absorption peak at shows that there is a -C=C-bond, and the double bond exists in HEMA; at 1384.9cm -1 and 1458.2cm -1 -CH- and -CH respectively 3 The bending vibration peak is at 3022-2900cm -1 -CH-...

Embodiment 2

[0042] Mix glycolide with hydroxyethyl methacrylate at a molar ratio of 10:1, add 0.08% catalyst stannous octoate, and 2 Under the protection, heat and melt first, then raise the temperature to 110° C., and react for 6 hours. Dissolve in chloroform, precipitate out with methanol, and dry to obtain a white solid hydroxyethyl methacrylate-polyglycolide macromonomer. use N 2 Replace the air in the device, and put the mixed solvent (mixture of ethyl acetate, ethanol, and toluene with a mass ratio of 1:4:6) and hydroxyethyl methacrylate-polyglycolide macromer in a four-necked flask, Add methyl methacrylate, styrene, ethyl acrylate, butyl acrylate, and hydroxyethyl acrylate monomers dropwise, rapidly raise the temperature to 45°C, then start to add azobisisobutyronitrile for 2 hours, drop 2 / 3. Then keep warm for 2 hours, then drip the remaining azobisisobutyronitrile, react for 2 hours, and finally keep warm for 1 hour to stop the reaction, and get a light yellow, uniform viscous...

Embodiment 3

[0044] Mix caprolactide and hydroxyethyl methacrylate with a molar ratio of 5:1, add 0.05% catalyst stannous octoate, in N 2 Under the protection, heat and melt first, then raise the temperature to 110° C., and react for 10 hours. Dissolved with chloroform, precipitated by methanol, and dried to obtain a white solid hydroxyethyl methacrylate-polycaprolactide macromonomer. use N 2 The air in the device was replaced, and the mixed solvent (a mixture of butyl acetate, ethanol, and toluene with a mass ratio of 1:3:5) and hydroxyethyl methacrylate-polycaprolactide macromonomers were placed in a four-necked flask, Add methyl methacrylate, styrene, ethyl acrylate, butyl acrylate, and hydroxyethyl acrylate monomers dropwise, rapidly raise the temperature to 75°C, then start to add azobisisobutyronitrile for 2 hours, and add 2 / 3 , then keep warm for 2 hours, then drop the remaining azobisisobutyronitrile, react for 2 hours, and finally keep warm for 1 hour to stop the reaction, and g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com