Fluorosilicone-modified acrylic resin hydrophobic anti-corrosion paint

A technology modified by acrylic resin and fluorosilicone, which is applied in the direction of anti-corrosion coatings and coatings to achieve the effects of stain resistance, chemical corrosion resistance, good hydrophobicity, and large-area painting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

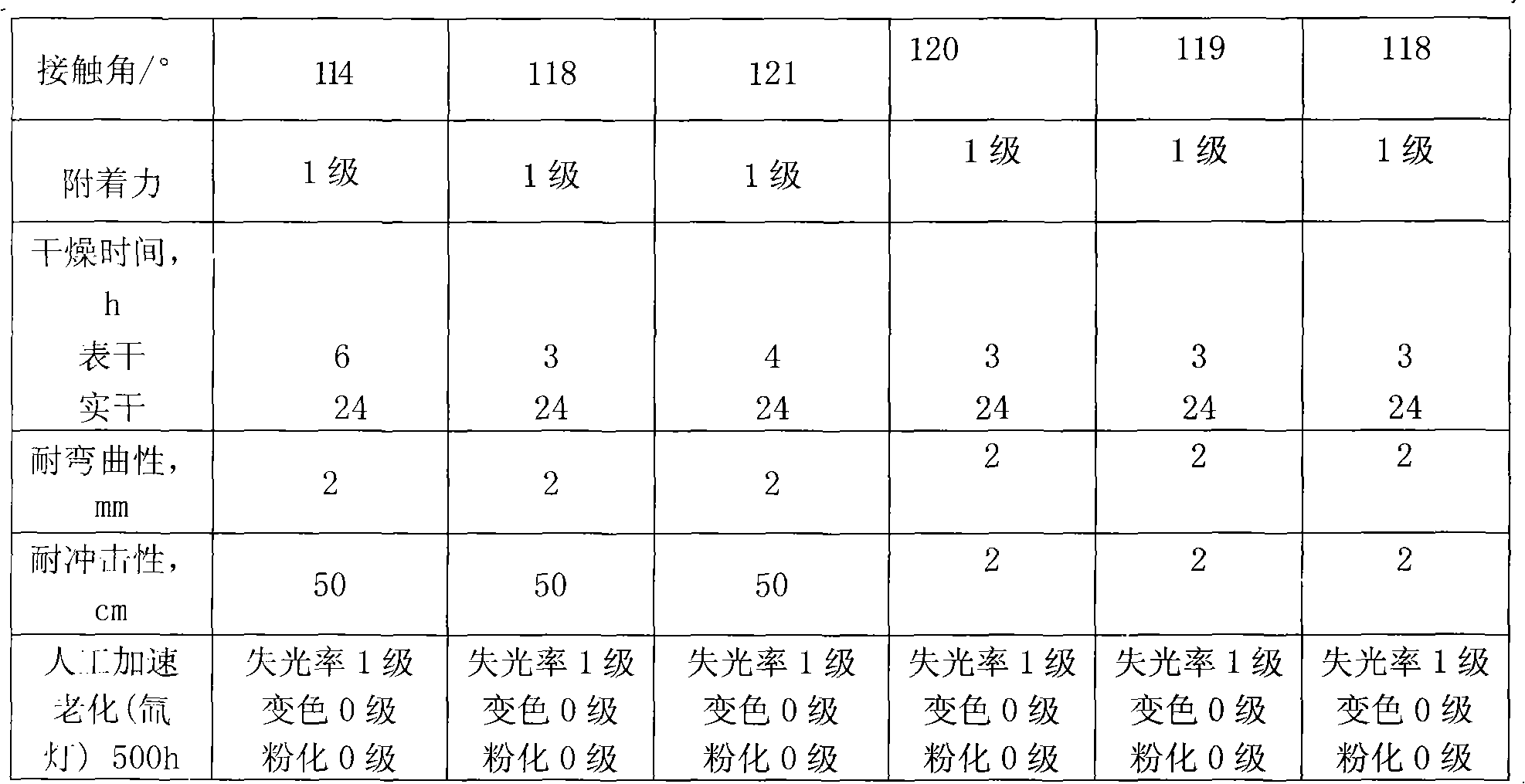

Embodiment 1

[0034] The hydrophobic anticorrosion coating of the fluorine silicon modified acrylic resin of the present embodiment, this coating is made of A component and B component by mass ratio;

[0035] Component A includes 70 parts of fluorosilicon modified acrylic resin; 5 parts of rutile titanium dioxide, zinc oxide, silicon dioxide; 8 parts of xylene, butanone, methyl isobutyl ketone; 3 parts of ultraviolet absorber UV- P, light stabilizer UV292; 5 parts of dispersant (BYK company) 104; 2 parts of organic bentonite, organic clay, modified hydrogenated castor oil prepared by mixing, grinding and stirring; B component is 7 parts of N90 of Bayer company ; Among them, the fluorine-silicon modified acrylic resin is: a mixture of ethyl acrylate and butyl acrylate, a copolymer of silicon-containing acrylate and fluorine-containing acrylate monomers.

[0036] Mix, grind and stir the raw materials of component A above to prepare a coating, and add component B and stir evenly to prepare a s...

Embodiment 2

[0039] The hydrophobic anticorrosion coating of the fluorine silicon modified acrylic resin of the present embodiment, this coating is made of A component and B component by mass ratio;

[0040] Component A includes 45 parts of fluorosilicon modified acrylic resin; 40 parts of rutile titanium dioxide, aluminum powder, zinc oxide, silicon dioxide, sericite and white carbon black; 6 parts of butyl acetate, ethyl acetate, butanone ; 2.5 parts of ultraviolet absorber UV-P, light stabilizer UV292; 1 part of dispersant (BYK company) 104S; 0.5 part of organobentonite, organoclay, modified hydrogenated castor oil prepared by mixing, grinding and stirring; group B It is divided into 5 parts of Bayer's N90; among them, the fluorosilicone modified acrylic resin is: a mixture of methacrylate, ethyl acrylate, butyl acrylate, isobutyl acrylate and silicon-containing acrylate, fluorine-containing acrylate monomer of copolymers.

[0041] Mix, grind and stir the raw materials of component A a...

Embodiment 3

[0044] The hydrophobic anticorrosion coating of the fluorine silicon modified acrylic resin of the present embodiment, this coating is made of A component and B component by mass ratio;

[0045] Component A includes 60 parts of fluorosilicon modified acrylic resin; 10 parts of rutile titanium dioxide, aluminum powder, zinc oxide, silicon dioxide, sericite and white carbon black; 14 parts of xylene, butyl acetate, propylene glycol ethyl ether acetate Ester; 2.5 parts of ultraviolet absorber UV-P, light stabilizer UV292; 4 parts of dispersant (AFCONA company) 4015; 1.5 parts of organobentonite, organoclay, modified hydrogenated castor oil are prepared by mixing, grinding and stirring; B The component is 8 parts of Bayer's N75; wherein, the fluorosilicon-modified acrylic resin is: a mixture of isopropyl acrylate, hydroxypropyl methacrylate, and acrylic monomers with silicon-containing acrylate and fluorine-containing acrylate monomers. copolymer.

[0046] Mix, grind and stir the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com