Self-crosslinked fluorosilicate acrylic resin and preparation method thereof

A technology of acrylic resin and perfluoroalkyl ethyl acrylate, applied in the field of self-crosslinking fluorosilicon modified acrylic resin and its preparation, can solve the problem of unsatisfactory heat resistance, poor substrate adhesion and poor mechanical properties and other problems, to achieve the effects of excellent mechanical properties, strong water and oil resistance, and low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Raw material distribution table

[0022] raw material name Mass percentage (g) Xylene 45 acrylic acid 0.6 Methyl methacrylate 32.0 ethyl acrylate 16.0 Hydroxyethyl Acrylate 3.4 Vinyltrimethoxysilane coupling agent 1.5 perfluorooctyl ethyl acrylate 0.5 tert-butyl hydroperoxide 1.0

[0023] in N 2 react under protection

[0024] (1) Add xylene into the reaction vessel according to the raw material dosage table, and raise the temperature to 100°C;

[0025] (2) Mix acrylic acid, methyl methacrylate, ethyl acrylate, hydroxyethyl acrylate, vinyltrimethoxysilane coupling agent, perfluorobutyl ethyl acrylate and tert-butyl hydroperoxide evenly, drop add 2 hours;

[0026] (3) Keep warm for 3.5 hours;

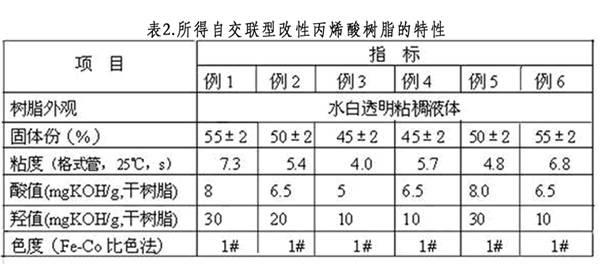

[0027] (4) Then cool down to 40°C and discharge to obtain a self-crosslinking fluorosilicon-modified acrylic resin with a molecular weight of 79,000. The properties of the obtained self-crosslinking fluorosilicon-m...

Embodiment 2

[0030] Raw material distribution table

[0031] raw material name Mass percentage (g) Xylene 50 acrylic acid 0.4 Methyl methacrylate 27.4 ethyl acrylate 13.7 Hydroxyethyl Acrylate 2.1 Vinyltrimethoxysilane coupling agent 3.2 perfluorooctyl ethyl acrylate 2.5 tert-butyl hydroperoxide 0.7

[0032] in N 2 react under protection

[0033] (1) Add xylene into the reaction vessel according to the raw material dosage table, and raise the temperature to 95°C;

[0034] (2) Mix acrylic acid, methyl methacrylate, ethyl acrylate, hydroxyethyl acrylate, vinyltrimethoxysilane coupling agent, perfluorobutyl ethyl acrylate and tert-butyl hydroperoxide evenly, drop Add 2.5 hours;

[0035] (3) keep warm for 4 hours;

[0036] (4) Then cool down to 50°C and discharge to obtain a self-crosslinking fluorosilicon-modified acrylic resin with a molecular weight of 70,000. The properties of the obtained self-crosslinking fluorosilicon-mo...

Embodiment 3

[0039] Raw material distribution table

[0040] raw material name Mass percentage (g) Xylene 55 acrylic acid 0.3 Methyl methacrylate 22.5 ethyl acrylate 11.3 Hydroxyethyl Acrylate 0.9 Vinyltrimethoxysilane coupling agent 5.0 perfluorooctyl ethyl acrylate 4.5 tert-butyl hydroperoxide 0.5

[0041] in N 2 react under protection

[0042] (1) Add xylene into the reaction vessel according to the raw material dosage table, and raise the temperature to 90°C;

[0043] (2) Mix acrylic acid, methyl methacrylate, ethyl acrylate, hydroxyethyl acrylate, vinyltrimethoxysilane coupling agent, perfluorobutyl ethyl acrylate and tert-butyl hydroperoxide evenly, drop add 3 hours;

[0044] (3) keep warm for 3 hours;

[0045] (4) Then cool down to 60°C and discharge to obtain a self-crosslinking fluorosilicon-modified acrylic resin with a molecular weight of 62,000. The properties of the obtained self-crosslinking fluorosilicon-modi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com