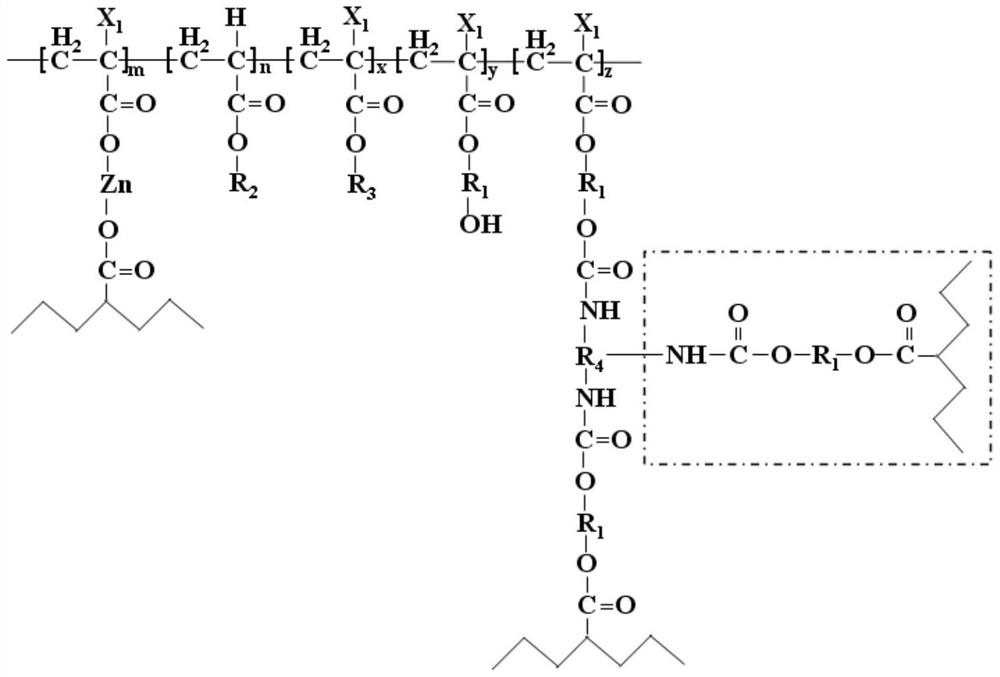

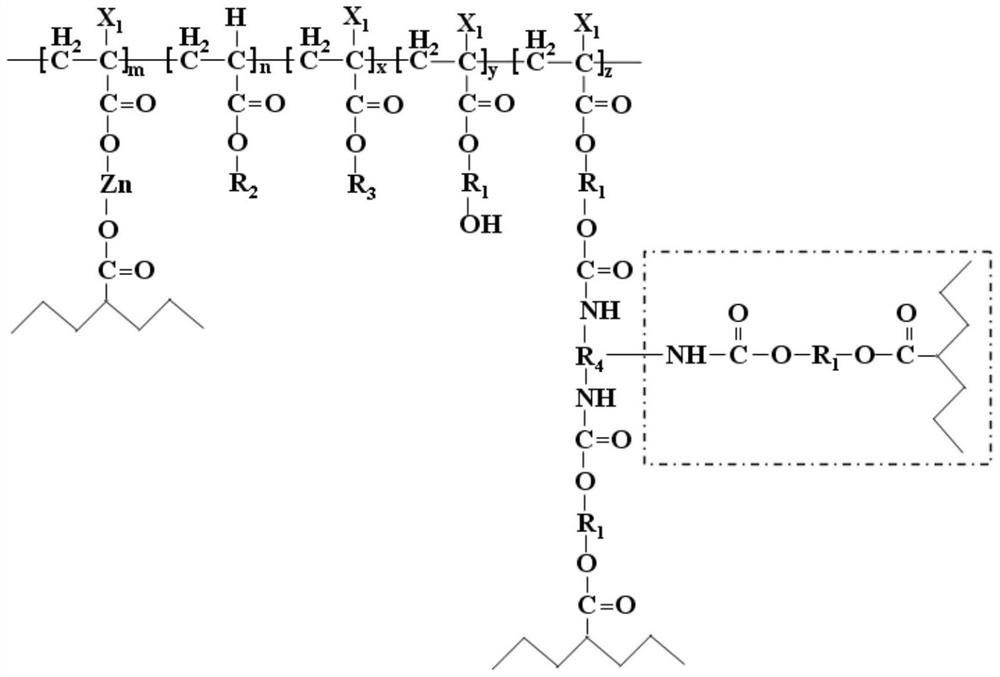

Zinc salt-containing acrylic polyurethane resin as well as preparation method and application thereof

An acrylic polyurethane, acrylate technology, applied in polyurea/polyurethane coatings, biocide-containing paints, coatings, etc., can solve the role of enhancing the physical and mechanical strength of coatings and resistance to fresh water immersion, alicyclic hydrocarbon resins Problems such as small molecular weight and limited

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

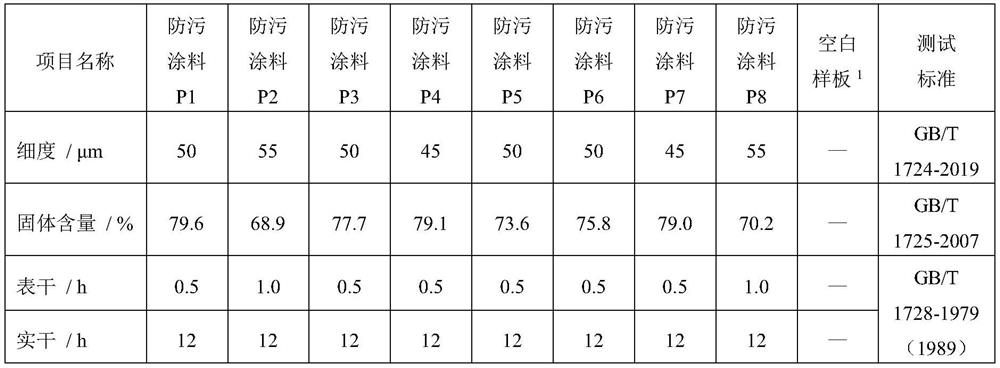

Examples

Embodiment 1

[0055] Embodiment 1 (resin R-1)

[0056] Dissolve 17 parts of zinc acrylate (ZDAA) in 17 parts of propylene glycol methyl ether acetate in a mixing vessel, then add 8 parts of 2-hydroxyethyl acrylate, 56 parts of ethyl acrylate, 19 parts of methyl methacrylate, 8 parts of xylene and 7 parts of azobisisoheptanonitrile were stirred evenly to form a mixed monomer solution. Add 60 parts of xylene and 20 parts of propylene glycol methyl ether acetate into a reaction vessel equipped with a stirring device, a condenser, a dropping device and a thermometer, and heat to 100°C. Maintaining the reaction temperature at 100°C, the mixed monomer solution was added dropwise to the reaction vessel at a constant speed within 5 hours, and then the reaction temperature was maintained for 1 hour. Dissolve 0.5 parts of azobisisovaleronitrile in 10 parts of xylene, and drop them into the reaction vessel at a constant speed within 0.5 h. Keep the reaction temperature for 2h and cool down to room t...

Embodiment 2

[0057] Embodiment 2 (resin R-2)

[0058] Dissolve 28 parts of zinc acrylate (ZDAA) in 28 parts of propylene glycol methyl ether acetate in a mixing vessel, then add 10 parts of 2-hydroxyethyl acrylate, 32 parts of n-butyl acrylate, 30 parts of methyl methacrylate , 8 parts of xylene and 9 parts of azobisisoheptanonitrile were stirred evenly to form a mixed monomer solution. Add 50 parts of xylene and 20 parts of propylene glycol methyl ether acetate into a reaction vessel equipped with a stirring device, a condenser, a dropping device and a thermometer, and heat to 90°C. Maintaining the reaction temperature at 90° C., the mixed monomer solution was added dropwise into the reaction vessel at a constant speed within 5 hours, and then the reaction temperature was maintained for 1 hour. Dissolve 0.5 parts of tert-butyl peroxy-2-ethylhexanoate in 6 parts of xylene, and drop them into the reaction vessel at a constant speed within 0.5 h. Keep the reaction temperature for 2h and co...

Embodiment 3

[0059] Embodiment 3 (resin R-3)

[0060] Dissolve 23 parts of zinc methacrylate (ZDMA) in 23 parts of propylene glycol methyl ether acetate in a mixing vessel, then add 10 parts of 2-hydroxyethyl acrylate, 59 parts of ethyl acrylate, 8 parts of methyl methacrylate Esters, 8 parts of xylene and 7 parts of azobisisoheptanonitrile were stirred evenly to form a mixed monomer solution. Add 55 parts of xylene and 20 parts of propylene glycol methyl ether acetate into a reaction vessel equipped with a stirring device, a condenser, a dropping device and a thermometer, and heat to 100°C. Maintaining the reaction temperature at 100° C., the mixed monomer solution was added dropwise into the reaction vessel at a constant speed within 5 hours, and then the reaction temperature was maintained for 1 hour. Dissolve 0.5 parts of tert-butyl peroxy-2-ethylhexanoate in 6 parts of xylene, and drop them into the reaction vessel at a constant speed within 0.5 h. Keep the reaction temperature for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com