Patents

Literature

363 results about "Trichloroethane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Trichloroethane can refer to either of two isomeric chemical compounds: 1,1,1-Trichloroethane 1,1,2-Trichloroethane

High-voltage insulator electrified cleaning agent

InactiveCN102559410AHigh insulation valueImprove insulation performanceNon-ionic surface-active compoundsDetergent compounding agentsActive agentOrganosolv

The invention relates to a high-voltage insulator surface electrified cleaning agent which comprises the following components in percentage by weight: 75-85% of detergent builder, 5-10% of nonionic surfactant, 1-5% of penetrating agent, 0.5-10% of organic solvent and 0.5-1% of protective agent, wherein the detergent builder is trichlorotrifluoroethane, and the protective agent is silicone oil. The cleaning agent has small surface tension, strong foul cleaning capacity on a high-voltage insulator, good permeability, insulation performance, high-voltage resistance, and good stability, is easy to volatilize and not easy to burn and non-toxic.

Owner:WUHAN UNIV

Fluorescent detection of proteins in polyacrylamide gels

ActiveUS7569130B2Laborious labelingLaborious staining stepElectrolysis componentsChemiluminescene/bioluminescenceSpectroscopyTryptophan

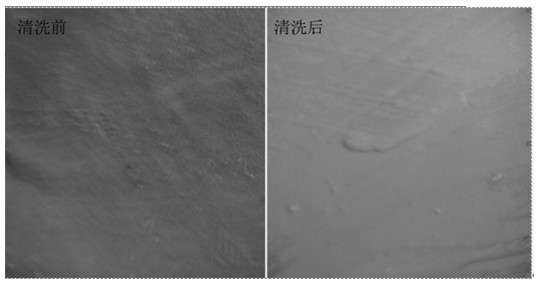

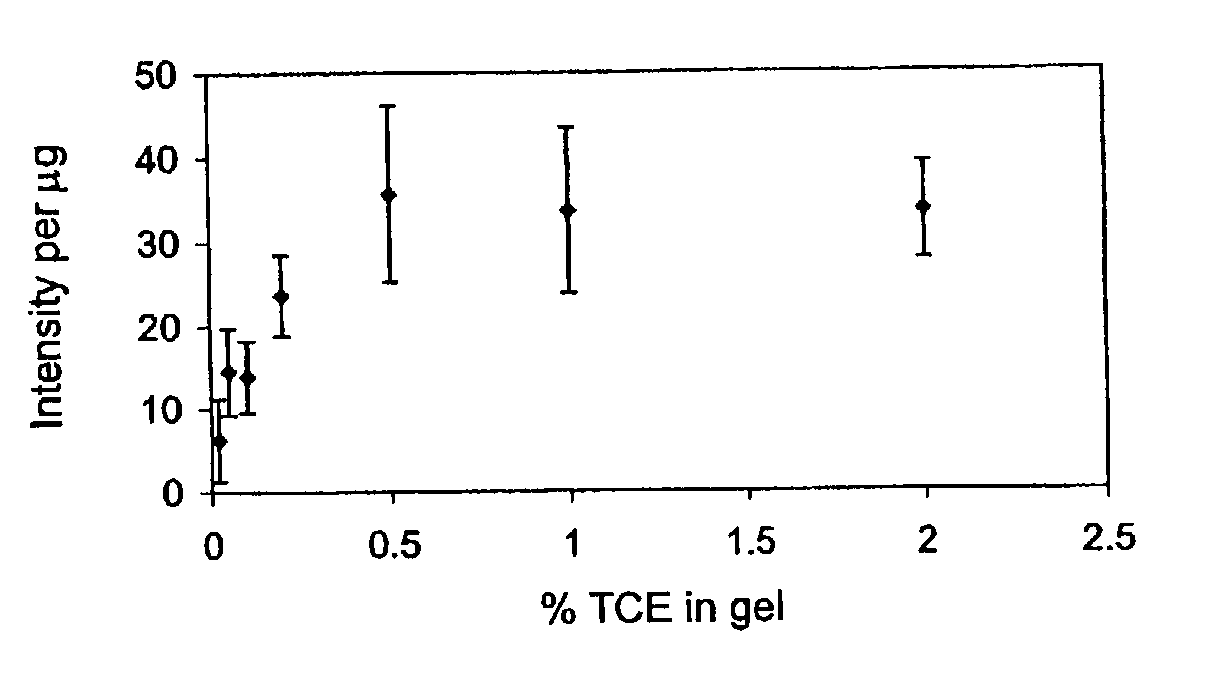

The mechanism of the UV light-induced reaction between the indole moiety of tryptophan and chloroform, and the structure of the modified tryptophan and polypeptides including such modified tryptophan residues. The excited indole moiety, which is formed upon UV light irradiation, emits a solvated electron which initiates a series of events that yield fluorescent derivatives that have CHO group covalently bound to the indole moiety. These derivatives are herein referred to as formyltryptophan, and are relatively stable. Similar reactions are observed when 5-hydroxytryptophan, 5-fluorotryptophan, or N-methylindolacetate are used in place of tryptophan, or when other haloalkanes, such as trichloracetic acid, trichlorethanol, trichlorethane, bromoform, and iodoactetate are used in place of chloroform. The derivatives can be used in a variety of applications in fluorescence spectroscopy, and for nuclear magnetic resonance, X-ray crystallography, infra-red spectroscopy, circular dicroism and mass spectroscopy. Additionally, the UV light-induced reaction between the indole moiety of tryptophan and haloalkanes can be used to prepare derivatives of tryptophan for chemical cross-linking studies of proteins and peptides.

Owner:UNIV TECH INT +1

Fluorescent detection of proteins in polyacrylamide gels

InactiveUS20100089753A1Without laborious labeling and staining stepElectrolysis componentsVolume/mass flow measurementSpectroscopyTryptophan

The mechanism of the UV light-induced reaction between the indole moiety of tryptophan and chloroform, and the structure of the modified tryptophan and polypeptides including such modified tryptophan residues. The excited indole moiety, which is formed upon UV light irradiation, emits a solvated electron which initiates a series of events that yield fluorescent derivatives that have CHO group covalently bound to the indole moiety. These derivatives are herein referred to as formyltryptophan, and are relatively stable. Similar reactions are observed when 5-hydroxytryptophan, 5-fluorotryptophan, or N-methylindolacetate are used in place of tryptophan, or when other haloalkanes, such as trichloracetic acid, trichlorethanol, trichlorethane, bromoform, and iodoactetate are used in place of chloroform. The derivatives can be used in a variety of applications in fluorescence spectroscopy, and for nuclear magnetic resonance, X-ray crystallography, infra-red spectroscopy, circular dicroism and mass spectroscopy. Additionally, the UV light-induced reaction between the indole moiety of tryptophan and haloalkanes can be used to prepare derivatives of tryptophan for chemical cross-linking studies of proteins and peptides.

Owner:UNIV TECH INT +1

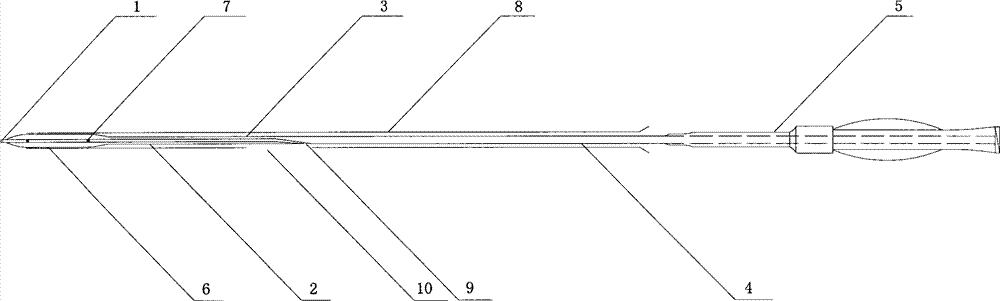

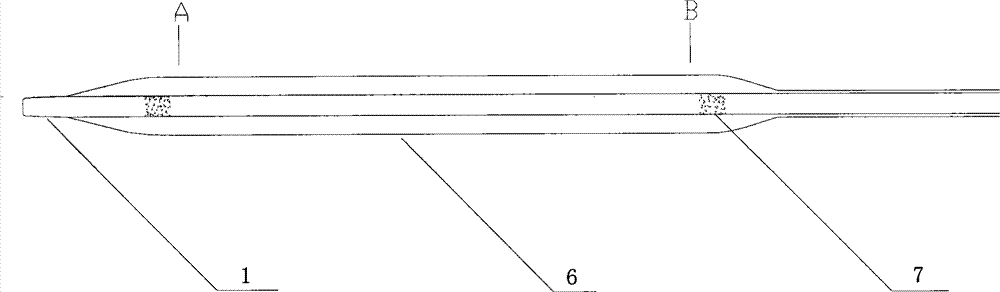

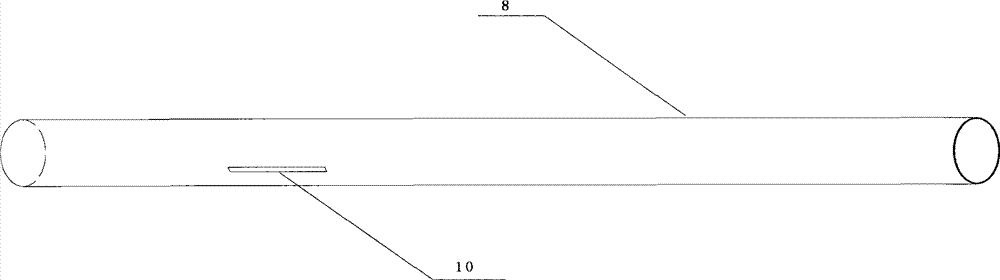

Protection-sleeve-carrying paclitaxel drug balloon and preparation method thereof

The invention relates to a protection-sleeve-carrying paclitaxel drug balloon and a preparation method thereof. The protection-sleeve-carrying paclitaxel drug balloon comprises a drug balloon and a paclitaxel-containing degradable drug coating which is coated on a balloon work section. The drug balloon can be used as a pre-expansion balloon, a conveying balloon and a post-expansion balloon and the drug balloon comprises a HUB protection-sleeve handle, a near-end push rod, a transition section, a far-end push rod and a head end. The coating, which is configured by the paclitaxel and a contrast agent, or which includes the paclitaxel, a degradable polymer and a solvent of trichloroethane, acetone or tetrahydrofuran, can be layeredly coated on the balloon work section. Through the arrangement of a protection sleeve, the drug balloon is, during conveying processes from entering blood vessels to reaching diseased regions, in a protection state, so that drugs on the drug balloon may not be scoured, ineffective loss is avoided, initial drug loading capacity of the drug balloon can be reduced, the treatment effect can be meet and at the same time safety of the drug balloon is greatly improved.

Owner:BIOVAS (WUHAN) MEDICAL TECH CO LTD

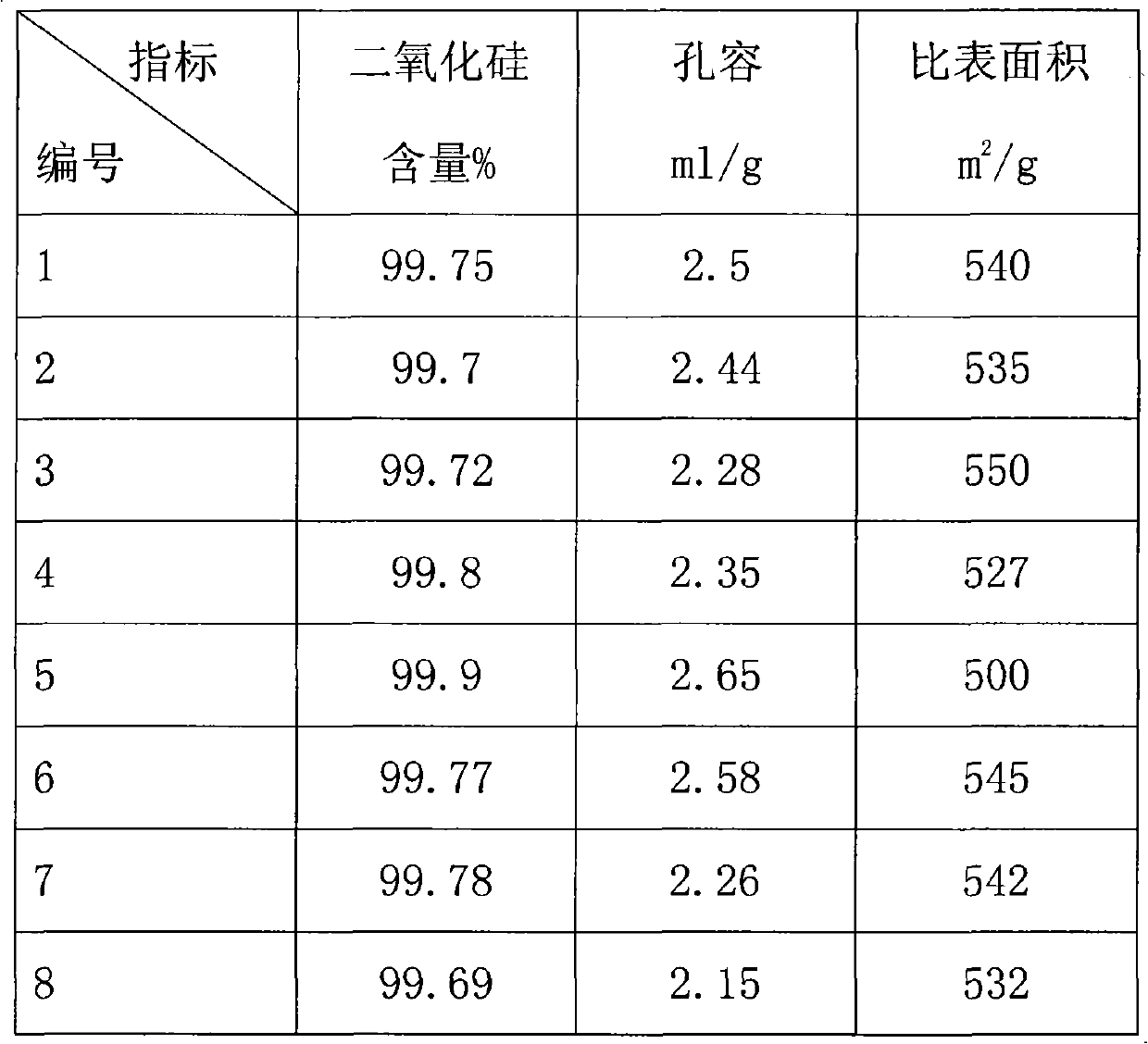

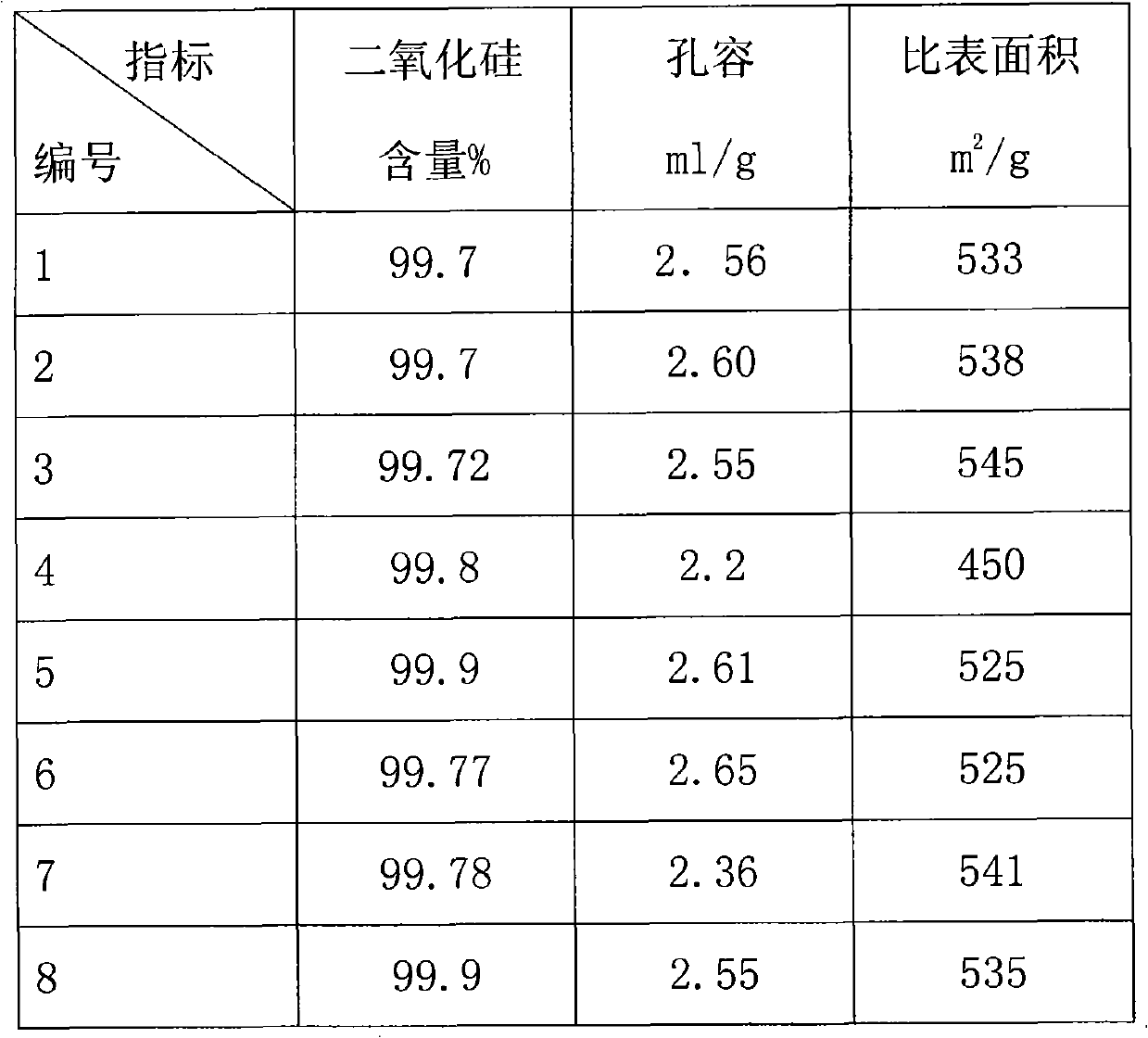

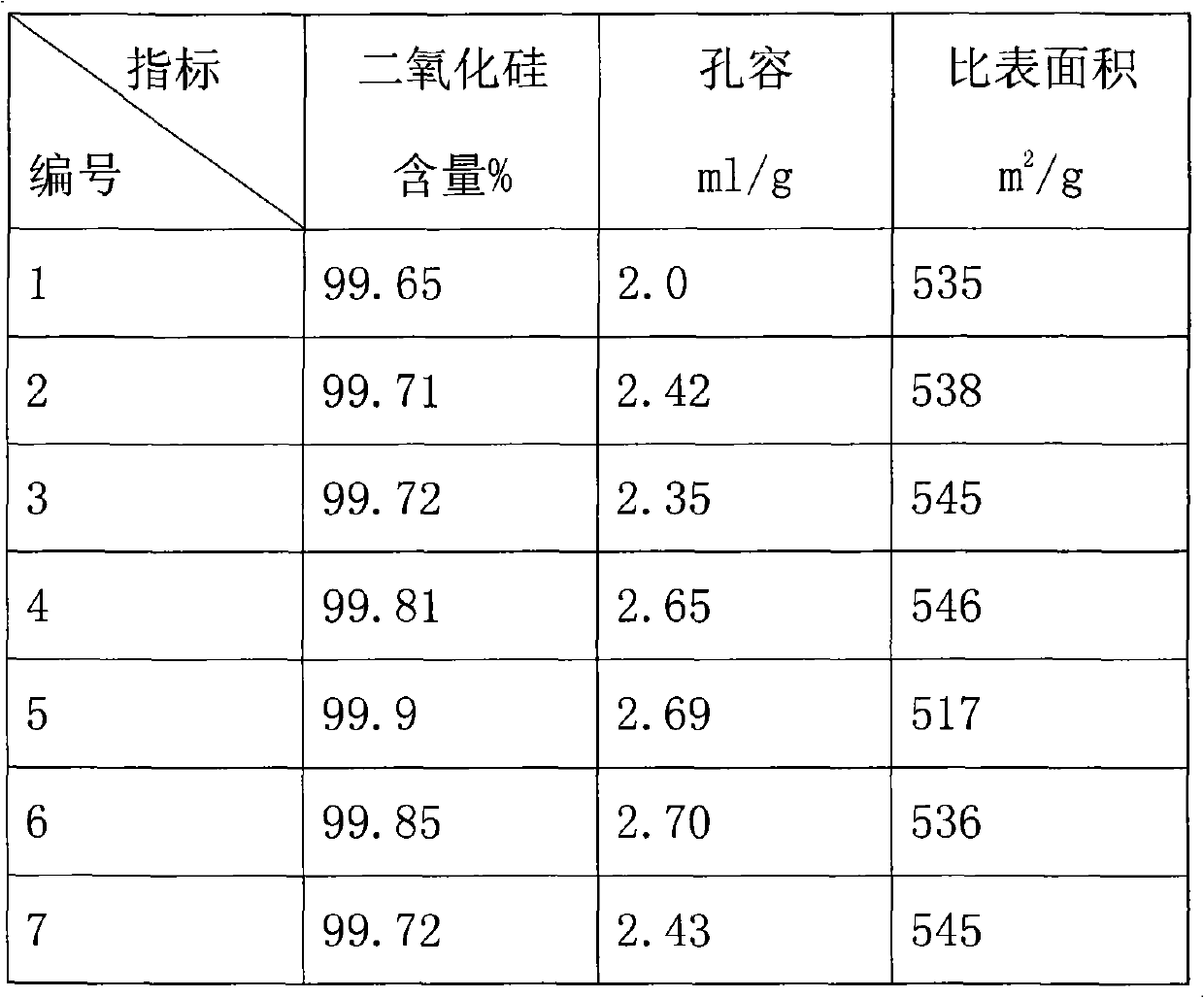

Method for preparing special silica gel carrier with large pore volume and large specific surface area

The invention relates to a method for preparing a special silica gel carrier with a large pore volume and a large specific surface area. The method is characterized by comprising the following process steps of: diluting industrial sodium silicate; adding inorganic acid solution dropwise at the initial temperature of between 20 and 40 DEG C, adjusting the pH value of a system to be 2 to 4, heating to the final temperature of between 80 and 100 DEG C and adding a specific surface control agent which may be one or more of glycol, ethyl acetate, glycerol, acetone and trichloroethane; preserving the heat for 2 to 4 hours and performing a hydro-thermal reaction; ageing for 1 to 2 hours; washing; drying; and performing particle size classification to obtain the final product.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Diffusion method for solace cell with polycrystalline silicon selective emitter

ActiveCN102593262AImprove efficiencyShallow dopingFinal product manufactureDiffusion/dopingDiffusionDopant

The invention discloses a diffusion method for a solar cell with a polycrystalline silicon selective emitter. The diffusion method includes the following steps: firstly, placing a silicon chip on which a doping agent grows into a diffusion furnace and raising the temperature to 750-800DEG C, wherein the environment in the furnace is N2 with the flow being 10-30slm; secondly, after the temperature is stabilized, uniformly raising the temperature in each temperature zone in the furnace to 850-900DEG C, introducing 0.2-2slm of N2 carrying trichloroethane, 1-5slm of O2 and 10-30slm of N2 while raising the temperature so as to realize heavy doping and controlling the heavily-doped sheet resistance between 30 and 60 omega / m<2>; thirdly, reducing the temperature of each temperature zone to the diffusion temperature of 820-840DEG C and introducing N2 carrying POCl3 for diffusing; fourthly, reducing the temperature of each temperature zone to 780-800DEG C, stopping introducing the N2 carrying the POCl3 so as to realize shallow doping, wherein the propulsion time is 10-25minutes and controlling the shallow-doped sheet resistance between 70-120 omega / m<2>; and fifthly, cooling the silicon chip, taking out the silicon chip and finishing the diffusion process. According to the diffusion method disclosed by the invention, the diffusion of a doping agent is realized at high temperature and the heavy doping and shallow doping of the selective emitter are realized; and meanwhile, the gettering of a polycrystalline silicon is realized, so that the conversion efficiency is greatly increased.

Owner:CSI CELLS CO LTD +1

Preparation of 3D rapid prototyping alumina-zirconia-carbon ceramic powder material

InactiveCN104725046ASmall median diameterNarrow particle size distributionAdditive manufacturing apparatusAdhesiveSilanes

The invention discloses a method for preparing a 3D rapid prototyping alumina-zirconia-carbon ceramic powder material. The method is characterized by comprising the following steps: firstly, pre-treating alumina-zirconia-carbon ceramic powder with N-(beta-aminoethyl)-gamma-amino propyl trimethoxy silane and stearic acid to obtain pre-treated alumina-zirconia-carbon ceramic powder; then, adding the following components in percentage by mass: 60-70 percent of trichloroethane and 2-5 percent of bisphenol A polycarbonate into a reactor, stirring and dissolving, and adding 26-36 percent of the pre-treated alumina-zirconia-carbon ceramic powder, uniformly stirring and mixing, intensively stirring at constant temperature of 50+ / -5 DEG C, refluxing to react for 5-7 hours, and drying by spraying to obtain the rapid prototyping alumina-zirconia-carbon ceramic powder material. The material does not need to spray adhesive, can be directly molded in a molding temperature range of 220-230 DEG C, has the advantages of simple preparation process, easily controlled condition and low production cost, and is easy for industrial production.

Owner:UNIV OF JINAN

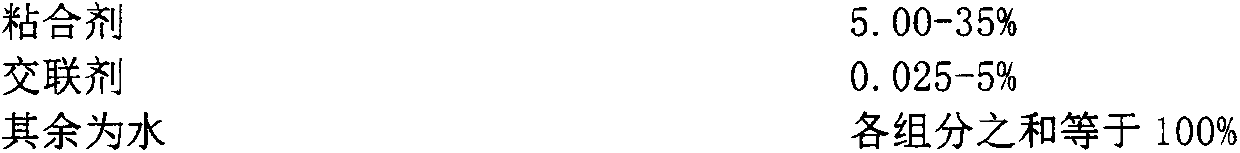

Fabric finishing liquid for insecticidal medium, and its use method and fabric product

InactiveCN1851109AImprove efficiencyHigh efficiency in repelling insect vectorsFibre treatmentLiquid/gas/vapor textile treatmentEpoxyCross-link

The invention relates to an insecticide -used fabric finishing liquid and the use method thereof as well as the fabric goods. And the formula of the fabric finishing liquid comprises: insecticide 0.5-40m% (mass percent); adhesive 5-40m%; cross- linking agent 0.025-1.50m%; water the rest, where the insecticide is 1-99% DDT (dichloro-diphenyl- trichloroethane) in any form; the adhesive is 30-50% adhesive in water aqua form; the cross-linking agent is epoxy polymer cross-linking agent, or methyl-etherized hexahydroxy-methyl-melamine resin primary contractor cross-linking agent, or other cross-linking agent. And the use method can select dip rolling process, or spraying process, or dipping process according to different fabric finishing materials. And the fabric goods is obtained by the fabric finishing liquid or / and the use method of the invention. And the fabric finishing liquid and the fabric goods have high effectiveness, strong adhesion, water washing resistance, etc.

Owner:TIANJIN YORKOOL INT TRADING

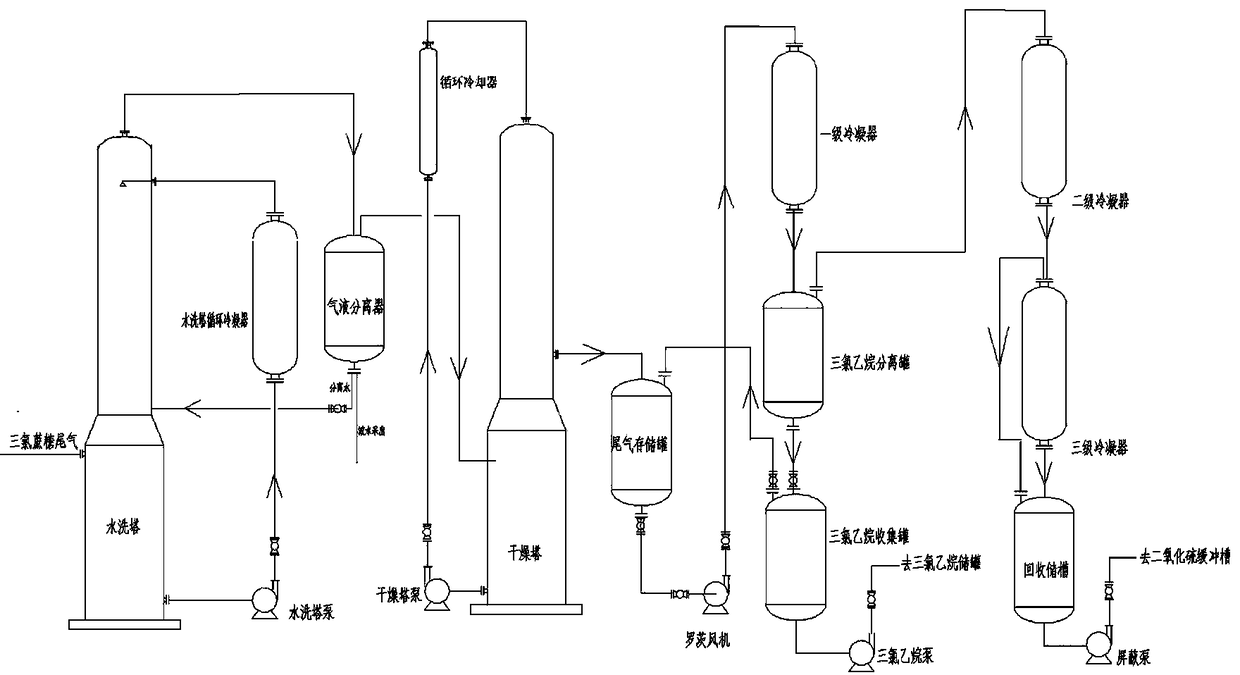

Recovery method and recovery device for sulfur dioxide in sucralose chlorination reaction

InactiveCN108373139AReduce consumptionReal-time control of the reaction cycleChlorine/hydrogen-chloride purificationSulfur compoundsWater chlorinationEnvironmental engineering

The invention relates to a recovery method for sulfur dioxide in sucralose chlorination reaction. The method includes steps: 1, adding concentrated sulfuric acid into a drying tower, removing moisturefrom tail gas of a gas-liquid separator, and allowing dried sulfur dioxide and trichloroethane tail gas to enter a primary condenser; 2, allowing residual tail gas and condensate flowing through theprimary condenser to enter a trichloroethane separation tank, allowing sulfur dioxide and trichloroethane condensate to enter a collection tank, and enabling tail gas sulfur dioxide to enter a secondary condenser; 3, enabling tail gas and sulfur dioxide condensate flowing through the secondary condenser to enter a tertiary condenser at a temperature ranging from -25 DEG C to -30 DEG C, condensinggaseous sulfur dioxide into liquid sulfur dioxide, and sending into a recovery storage tank. The recovery method has advantages that hydrogen chloride in the tail gas is subjected to three-stage waterabsorption to obtain high-concentration hydrochloric acid while sulfur dioxide and trichloroethane in the tail gas are separated out, and accordingly the product conversion rate is increased, raw material and energy consumption is reduced, and cost is saved to the maximum extent.

Owner:ANHUI JINGHE IND

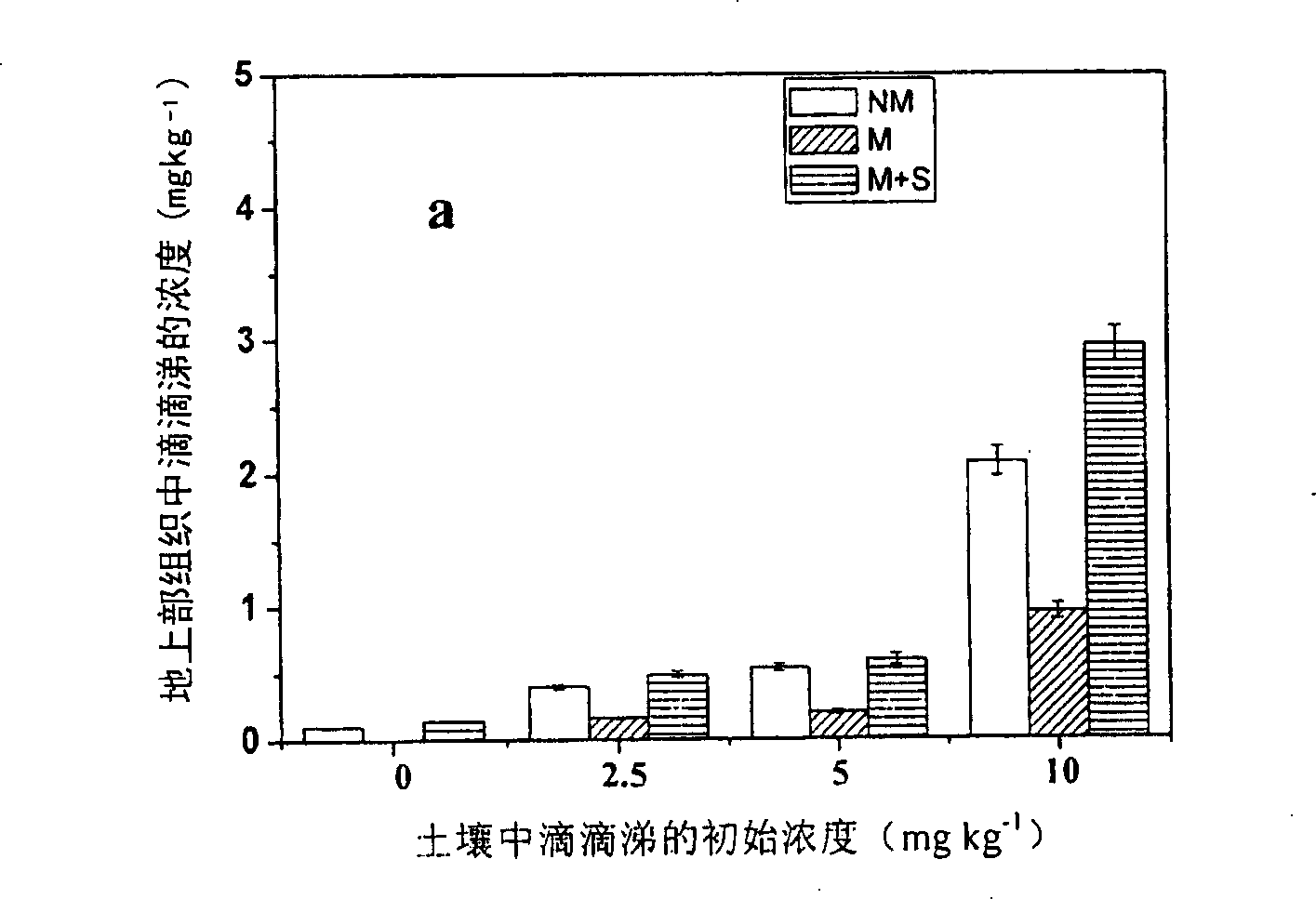

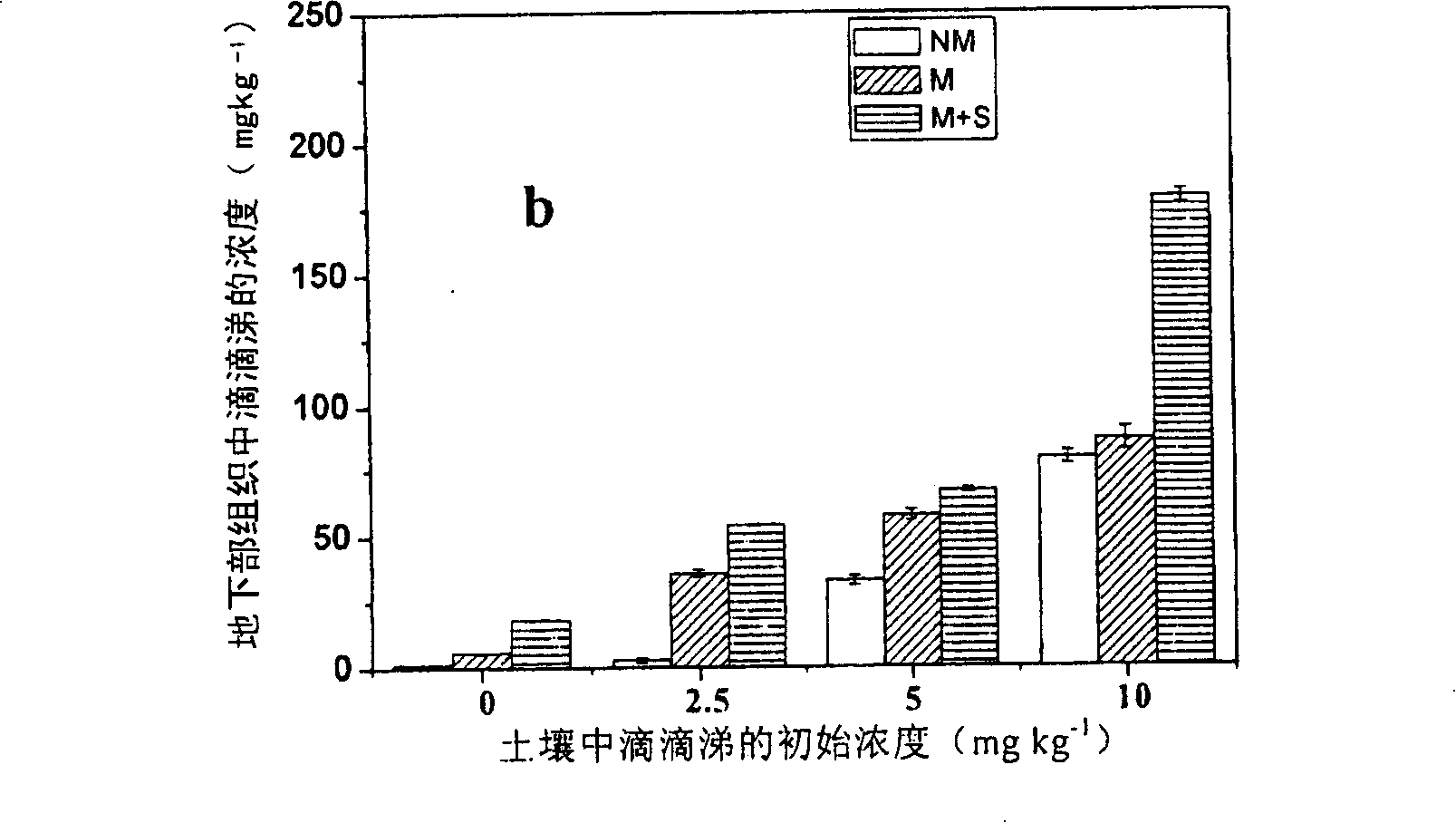

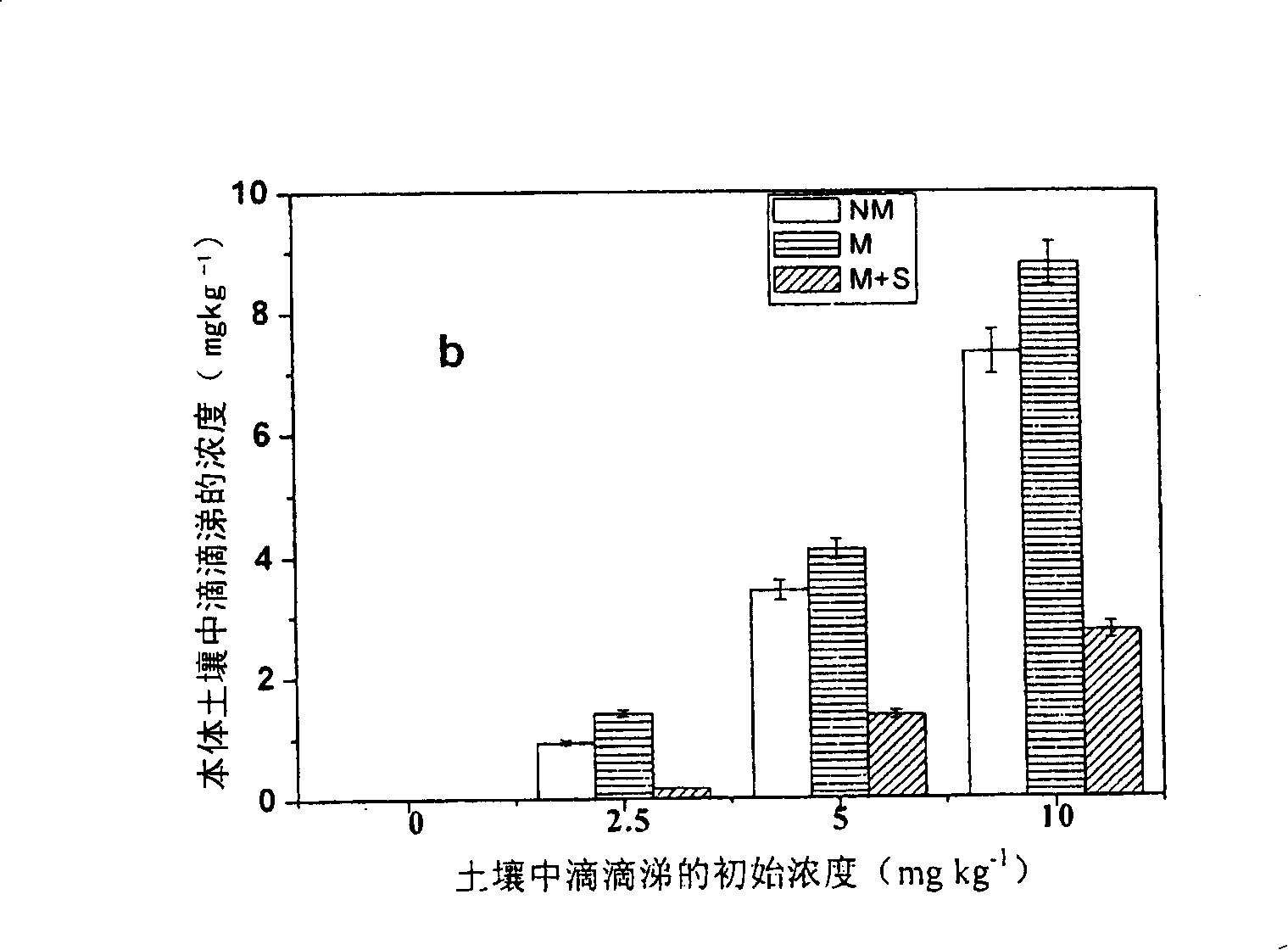

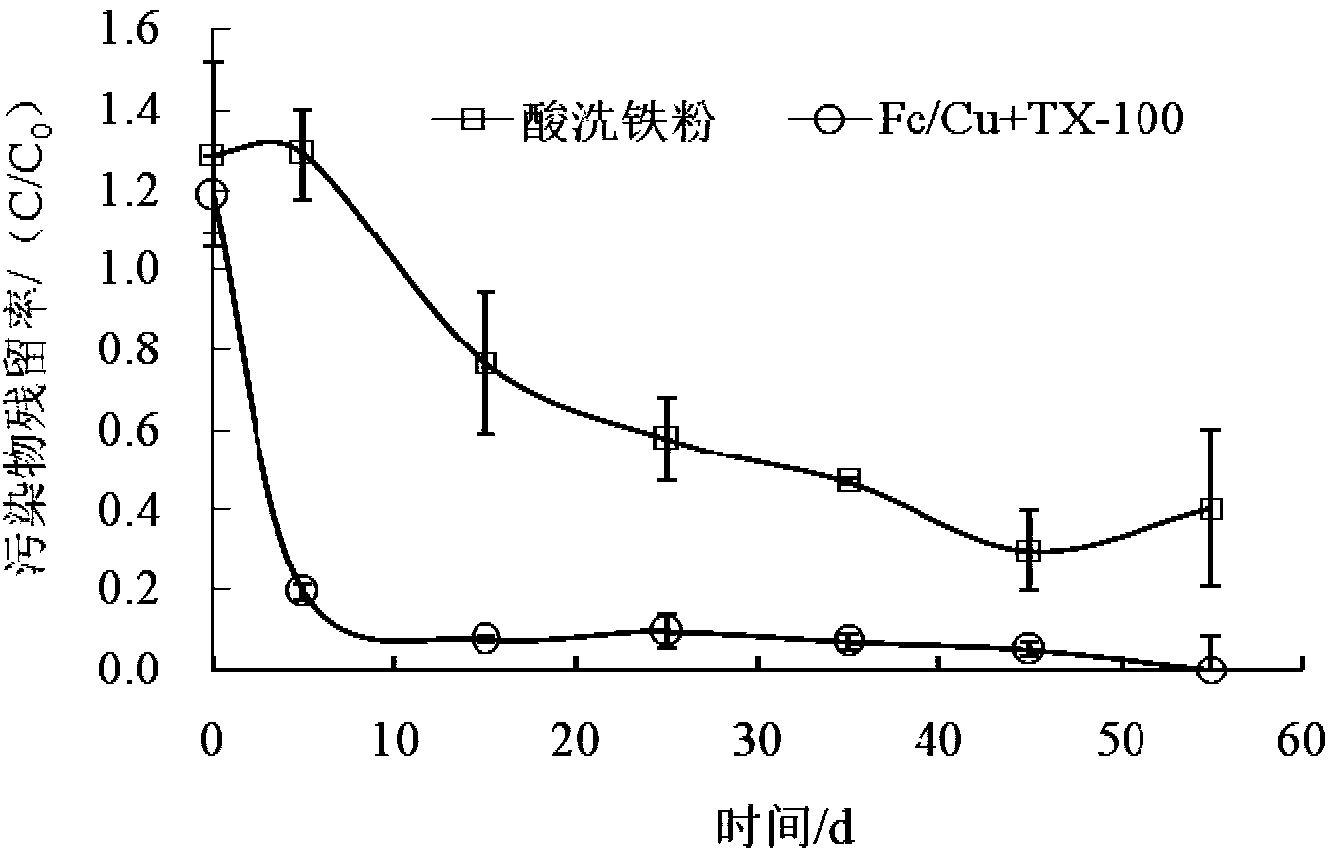

Method of increasing gesarex polluted soil phyto remediation efficiency

InactiveCN101229550APromote absorptionReduce DDT contentFungiContaminated soil reclamationBioremediationPhytoremediation

The invention provides a method for improving the plant-based recovery efficiency of dichlorodiphenyl trichloroethane (DDT)-polluted soil. The method is to promote mycorrhiza of clover and add chemical surfactant to recover the DDT-polluted soil with the joint function of uromyces striatus schroter and the surfactant. The steps of the method include that an inoculant layer is inoculated in a culture medium; mycorrhiza is carried out to the clover and that the sprouted clover is planted in the DDT-polluted soil and the surfactant TritonX-100 is added to the soil. The joint effect of the mycorrhiza and the surfactant can remarkably improve the resistance of plants to the DDT, reduce the concentration of the DDT in the soil and have evident plant-based recovery efficiency of the DDT-polluted soil. The method of the invention can be used for reference for the recovery of the soil polluted by other organic matters.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

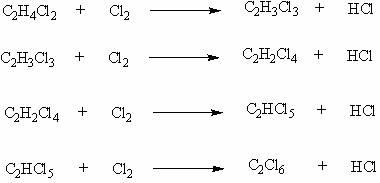

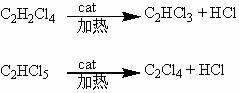

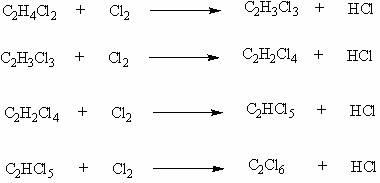

A kind of method that takes dichloroethane as raw material to produce trichloroethylene and tetrachloroethylene

InactiveCN102267863ATo satisfy the market's needsSimple processPreparation by hydrogen halide split-offTetrachloroethaneEthylene Dichloride

The invention relates to a method for preparing trichloroethylene and perchloroethylene from dichloroethane as a raw material. The existing method has the defects of difficult realization and large amount of investment. The method of the invention comprises the following steps that dichloroethane undergoes chlorination to produce a mixture of dichloroethane, trichloroethane, tetrachloroethane, pentachloroethane and hexachloroethane, and hydrogen chloride gas under a dichloroethane gaseous or liquid phase; the mixture is transferred into a rectifying tower to be rectified; a tetrachloroethane / pentachloroethane mixture fraction with a top temperature of 147 to 162 DEG C is collected; the collected tetrachloroethane / pentachloroethane mixture fraction is vaporized and then is fed into a fixedbed reactor to form a trichloroethylene / perchloroethylene gas mixture; the trichloroethylene / perchloroethylene gas mixture is condensed into a liquid mixture; the liquid mixture and hydroquinone are fed into a rectifying tower to be rectified; a fraction with a top temperature of 86 to 87.5 DEG C is collected to obtain trichloroethylene finished products; and a fraction with a top temperature of 120 to 121.5 DEG C is collected to obtain perchloroethylene finished products. The method has the advantages of simple process, good controllability, easy acquirement of raw materials, low cost and little or no process wastewater or waste residue.

Owner:内蒙古磐迅科技有限责任公司

Fiber/fabric/paper finishing liquid with effects of resisting mildew and repelling and killing mosquitoes as well as use method and product of fiber/fabric/paper finishing liquid

InactiveCN107780210AFix compatibility issuesSimple compositionBiochemical fibre treatmentPaper/cardboardCross-linkFiber

The invention relates to fiber / fabric / paper finishing liquid with the effects of resisting mildew and repelling and killing mosquitoes as well as a use method and a product of the fiber / fabric / paper finishing liquid. In the fiber / fabric / paper finishing liquid, an insecticide is water insecticide with the effective content of 0.1 to 99 percent or dichlorodiphenyl trichloroethane with various dosageforms and the effective content of 1 to 99 percent; a repellent is a water repellent with the effective content of 0.1 to 99.9 percent; an antibacterial agent is an inorganic, organic or natural antibacterial agent with various dosage forms and the effective content of 1 to 100 percent; an adhesive is a water adhesive with the solid content of 30 to 50 percent; a cross-linking agent is an epoxy polymer cross-linking agent, a methyl-etherified hexahydroxy methylmelamine resin early-shrinkage body cross-linking agent or the like. The use method of the fiber / fabric / paper finishing liquid, disclosed by the invention, can select one of a padding method, a spraying method or an impregnating method according to the difference of fabric / fiber materials. The fiber / fabric / paper finishing liquid andthe product thereof have the advantages of high efficacy, high adhesive force, washing resistance, low cost, good applicability, convenience in use and popularization and the like; the fiber / fabric / paper finishing liquid and the product thereof can reach the WTO standard.

Owner:张裕

Iron composite particles for purifying soil or ground water, purifying agent containing the iron composite particles, and method for purifying soil or ground water

InactiveUS20060081811A1Efficient and economicalMaterial nanotechnologyWater contaminantsPolychlorinated biphenylMaterials science

Iron composite particles for purifying soil or ground water, comprise an iron component, at least one noble metal selected from the group consisting of ruthenium, rhodium and palladium, and carbon or aluminum, and having a noble metal content of 0.01 to 5.00% by weight and a particle diameter of 0.01 to 1.0 μm. The iron composite particles and the purifying agent according to the present invention are capable of decomposing aliphatic organohalogen compounds such as dichloromethane, carbon tetrachloride, 1,2-dichloroethane, 1,1-dichloroethylene, cis-1,2-dichloroethylene, 1,1,1-trichloroethane, 1,1,2-trichloroethane, trichloroethylene, tetrachloroethylene, 1,3-dichloropropene or the like, and aromatic organohalogen compounds such as dioxins, PCB (polychlorinated biphenyl) or the like, which are contained in soil, ground water or waste water, at ordinary temperature in an efficient and economical manner.

Owner:TODA IND

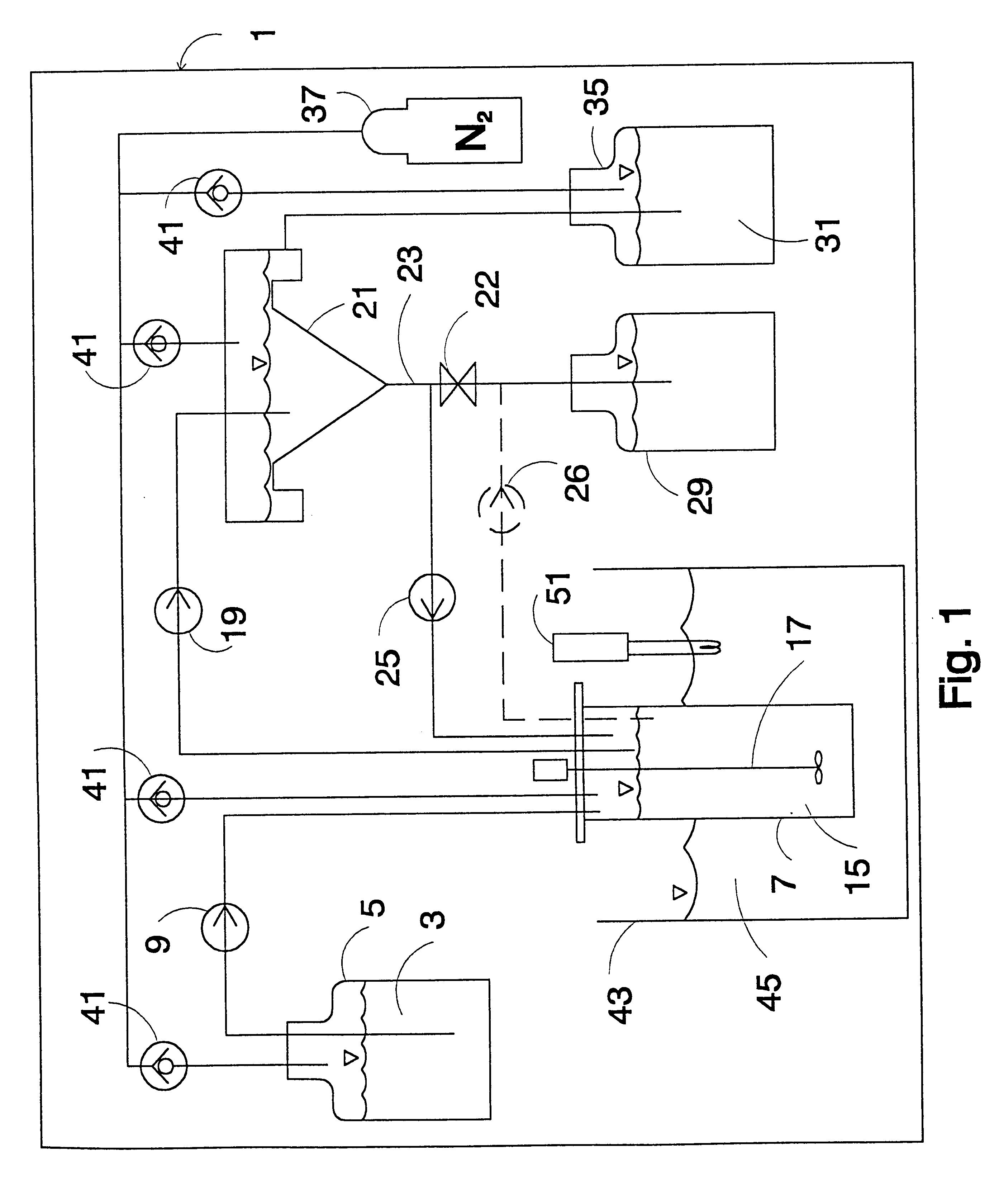

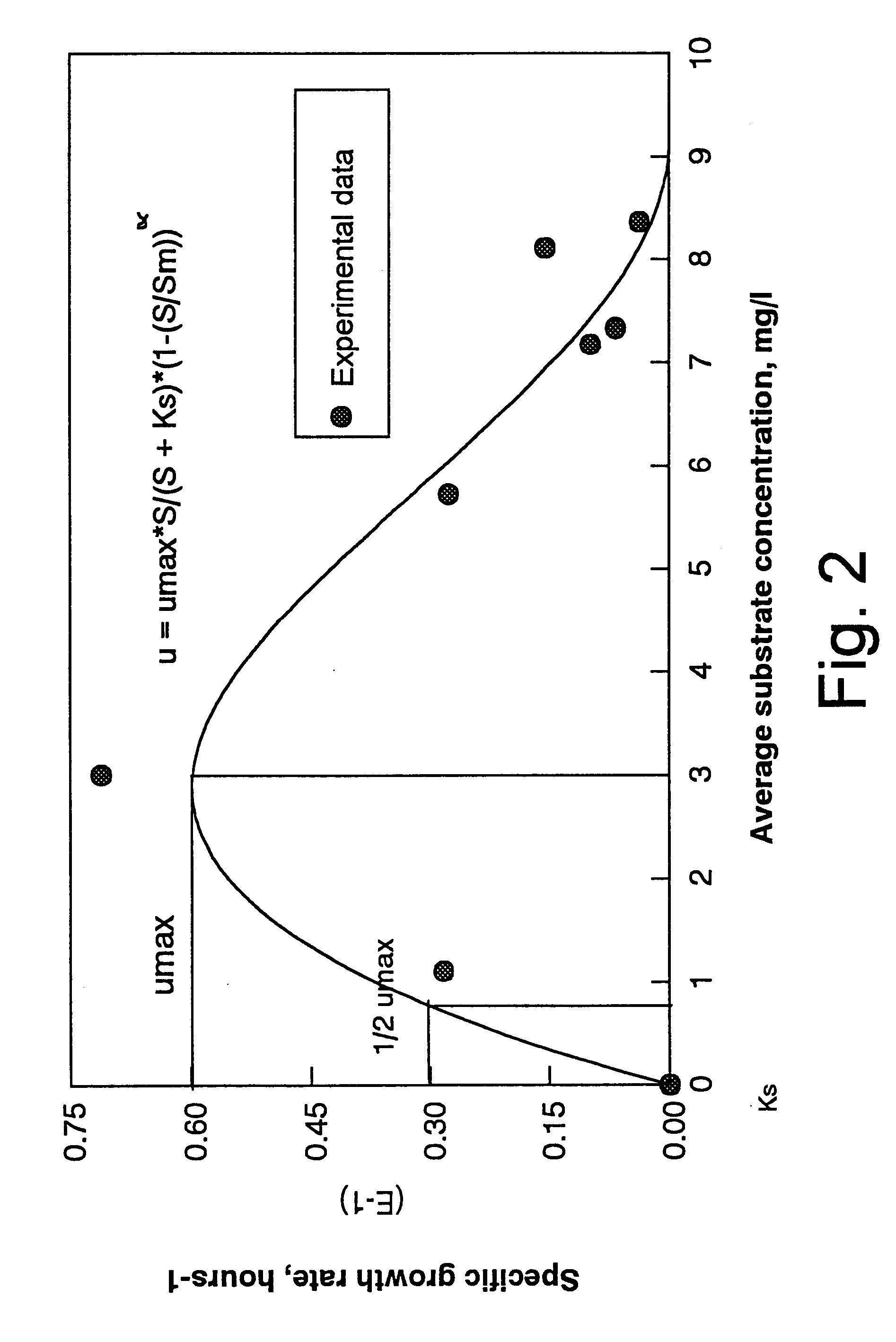

Anaerobic biodegradation of unsaturated, saturated, aromatic and halogenated hydrocarbons

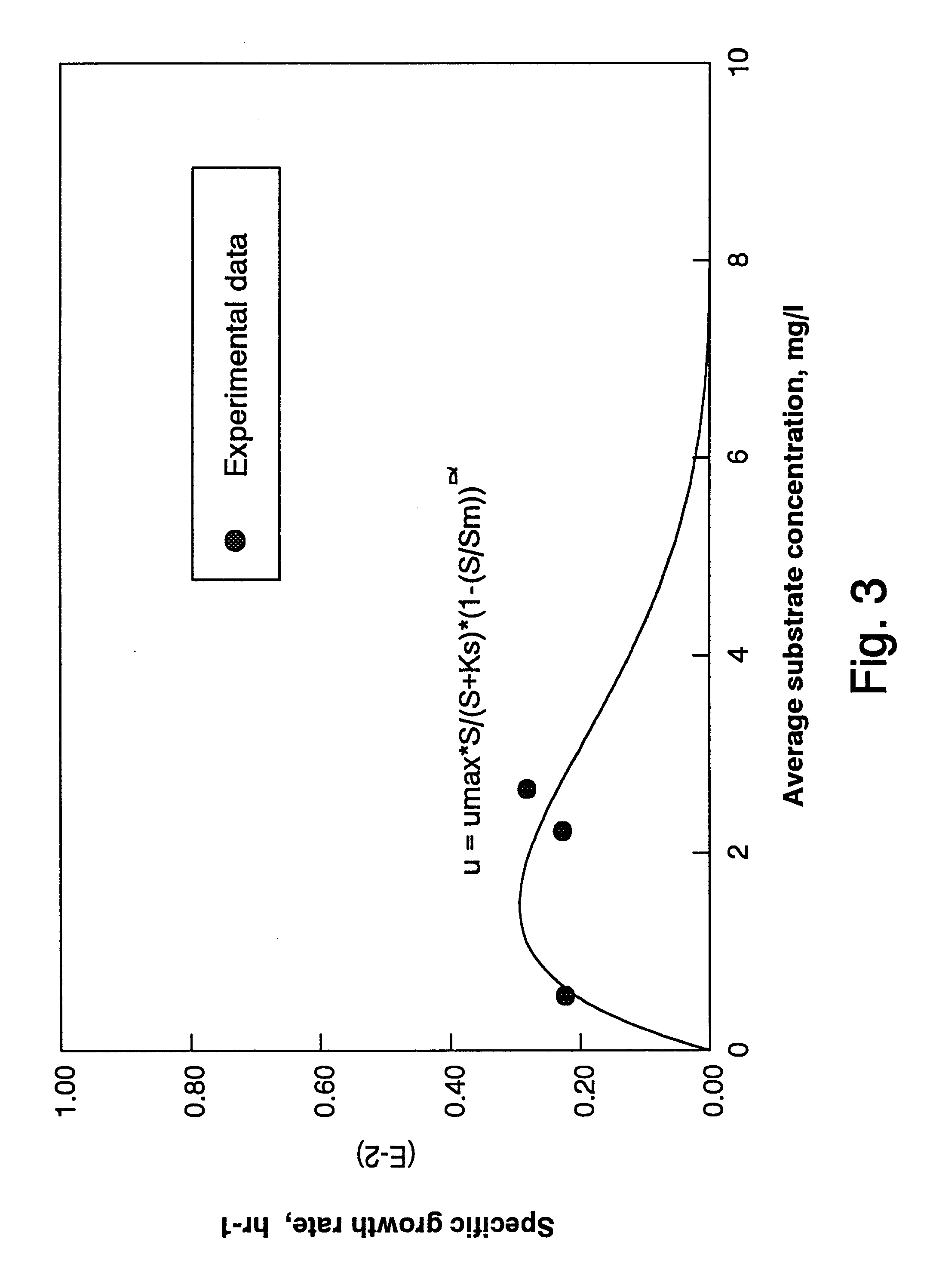

An apparatus and method for anaerobic biodegradation, bioremediation or bioprocessing of hydrocarbons dissolved in an aqueous matrix, such as wastewater, groundwater, or slurry. Dissolved alkanes (saturated hydrocarbons), alkenes (unsaturated hydrocarbons), aromatic hydrocarbons and / or halogenated hydrocarbons are metabolized or cometabolized. In one form, the invention involves introducing an aqueous stream comprising at least one dissolved aromatic hydrocarbon (such as benzene, toluene, ethylbenzene, o-xylene, m-xylene, p-xylene, phenol, o-cresol, m-cresol, or p-cresol) and a dissolved oxide of nitrogen [such as nitrate (NO3-), nitrite (NO2-), nitric oxide (NO) and nitrous oxide (N2O)] to a reactor, and operating said reactor under conditions that support denitrification of the aromatic hydrocarbon. Alternatively, the aqueous stream may comprise at least one alkane (such as ethane) and / or at least one alkene (such as ethene or ethylene) and biodegradation of these compounds is accomplished. In a preferred form, the aqueous stream also comprises at least one dissolved halogenated hydrocarbon (such as tetrachloroethylene, trichloroethylene, or 1,1,1-trichloroethane) and dehalogenation of the halogenated hydrocarbon is accomplished. The reactor may be a continuous stirred tank reactor, a batch (or sequencing batch) reactor, a plug-flow reactor, a fixed-film reactor, or a pore space in an underground aquifer in situ. The reactor is operated in such a way that molecular oxygen is excluded from the space or zone in which the biodegradation is occurring and the other requirements of denitrifying bacteria are met. In some implementations, kinetic control (control of mean cell residence time) is used to enrich a denitrifying culture in the reactor.

Owner:YESTECH

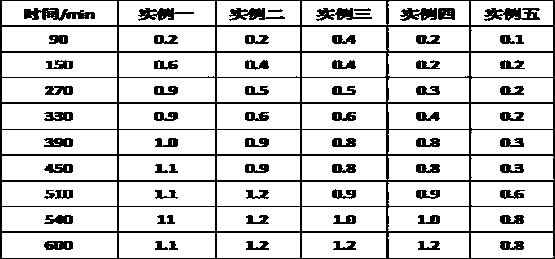

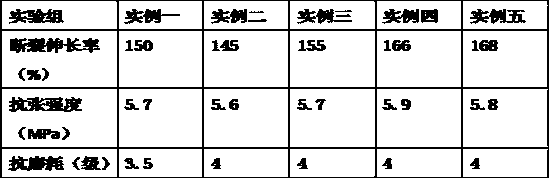

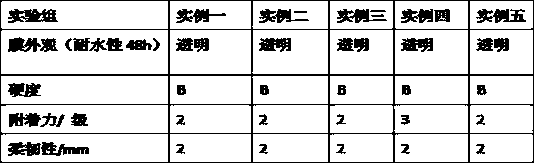

Preparation method of environment-friendly light-resistant and waterproof polyurethane coating and adhesive

ActiveCN103952071ALow toxicityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceAdhesive

The invention discloses a preparation method of an environment-friendly light-resistant and waterproof polyurethane coating and adhesive. The preparation method comprises the steps of mixing polytetramethylene ether glycol and isophorone diisocyanate in the existence of a dibutyltin dilaurate catalyst according to the NCO to OH molar ratio of 1.5:1 to 4.5:1, reacting at the temperature of 80-100 DEG C for 1-4h, adding lipidosome, and reacting at the temperature of 80 DEG C for 1h to obtain a polyurethane prepolymer A; adding a chain extender accounting for 1.2-3.2% of the weight of the prepolymer A and 1, 1, 2-trifluorotrichloroethane accounting for 12-25% of the weight of the prepolymer A into the prepolymer A, reacting at the temperature of 65-85 DEG C for 1.5-3.5h, adding a fluorine compound accounting for 0.5-1.2% of the weight of the prepolymer A, reacting at the temperature of 75-85 DEG C for 1-2h, adding triethylamine accounting for 10-15% of the weight of the prepolymer A to carry out neutral reaction for 30-50min, adding water to emulsify to obtain the environment-friendly light-resistant and waterproof polyurethane coating and adhesive. The prepared light-resistant polyurethane coating and adhesive is environment-friendly and low in price, can be widely applied to the surfaces of a wall, furniture and metal ware, and can be used as an adhesive for plastics, glass, papermaking and textiles.

Owner:广州富思德化工科技有限公司

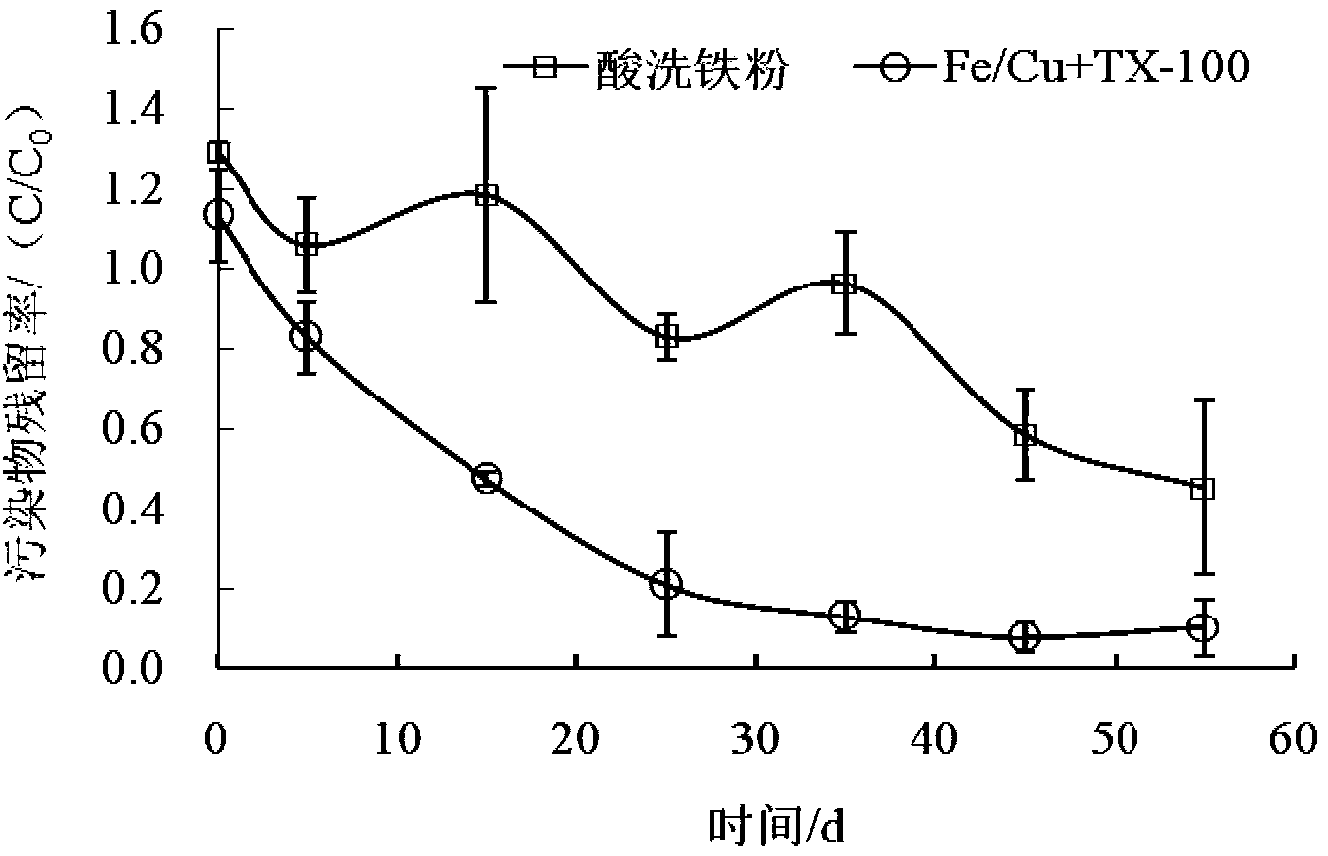

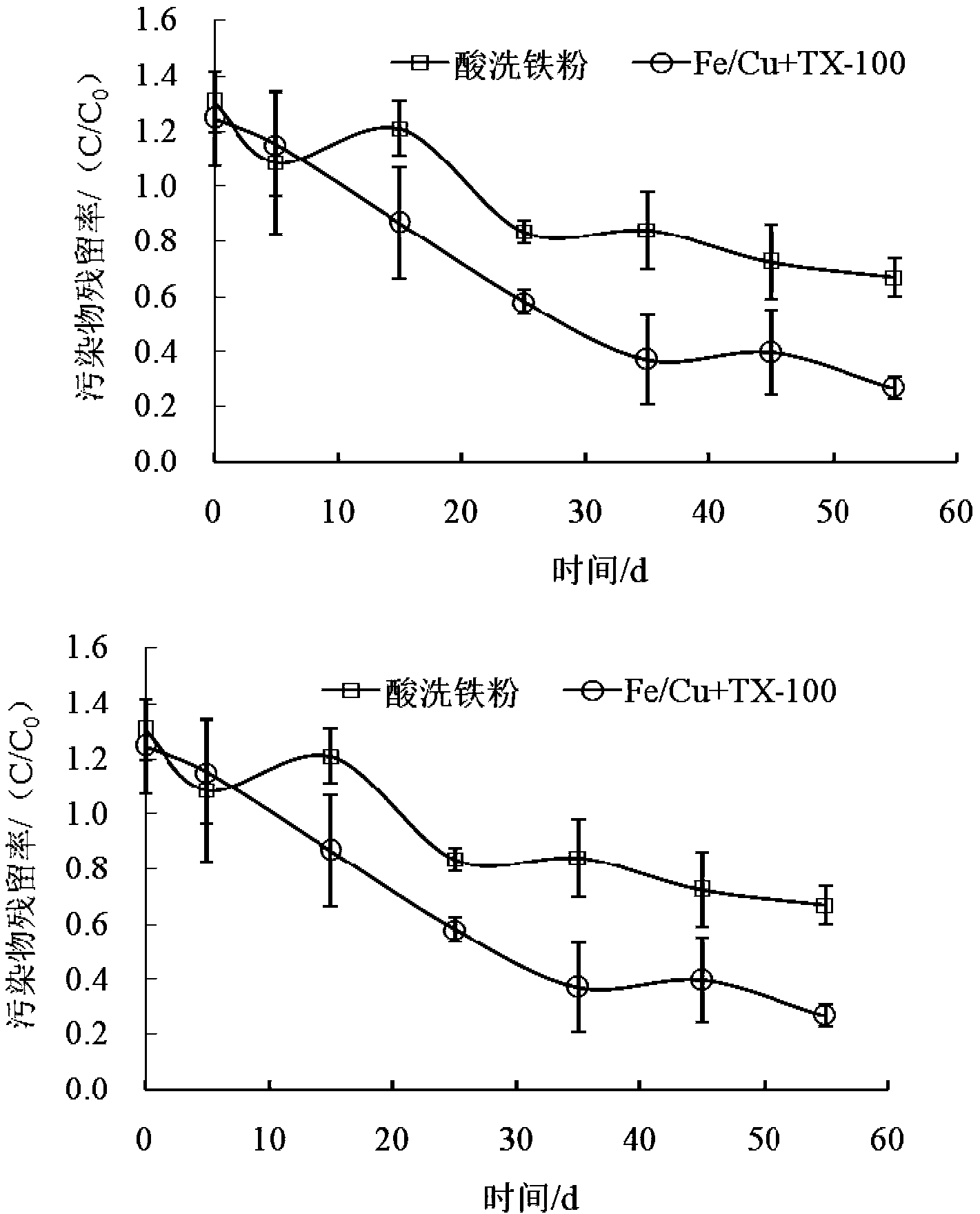

Method for intensively removing hexachloro-cyclohexane soprocide and dichlorodiphenyl trichloroethane in soil by zero-valent iron

InactiveCN104307869AEfficient degradationMild reaction conditionsContaminated soil reclamationIron powderMetallic materials

The invention relates to a method for intensively removing hexachloro-cyclohexane soprocide and dichlorodiphenyl trichloroethane in soil by zero-valent iron. The method comprises the following steps: immersing reduced iron powder into a copper solution to prepare a micron Fe / Cu duplex metal material, so that the load amount of Cu is 1%; sequentially adding duplex metal and triton X-100 into the soil according to the adding amounts of 5% and 0.1%; adjusting the initial pH value of the soil to 4-5 and adjusting the water content rate of the soil to 25%-30%; and isolating oxygen and piling to react for a certain time so as to degrade and remove hexachloro-cyclohexane soprocide and dichlorodiphenyl trichloroethane in the soil. The method does not need to use complicated equipment, is simple to operate and environment-friendly; the method has economical cost and has no secondary pollution; and the method has a relatively good application prospect in the remediation of the soil polluted by low-medium concentration hexachloro-cyclohexane soprocide and dichlorodiphenyl trichloroethane.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

Multifunctional polylactic acid (PLA) fiber and preparation method thereof

ActiveCN102936759AUV resistantAnti-mosquitoArtificial thread manufacturing machinesMonocomponent polyesters artificial filamentUltraviolet lightsDichloro diphenyl trichloroethane

The invention discloses a multifunctional polylactic acid (PLA) fiber and a preparation method thereof. The multifunctional PLA fiber comprises the following components in parts by weight: 87-98.5 of PLA, 0.5-3.0 of coupling agent modified ultraviolet resistant inorganic nanometer particle, 0.5-8 of organic ultraviolet light absorber and 0.5-8 of anti-mosquito agent dichloro diphenyl trichloroethane. The preparation method of the multifunctional PLA fiber comprises the steps of: (1) weighing the PLA, the ultraviolet resistant inorganic nanometer particle, the organic ultraviolet light absorber and the anti-mosquito agent according to the proportion, premixing and carrying out granulation via melt blending to obtain a functional master batch of the PLA, (2) carrying out spinning on the functional master batch of the PLA through a special-shape spinneret orifice on a melt spinning machine to obtain a PLA nascent fiber, and (3) drafting the nascent fiber to obtain the multifunctional PLA fiber. The obtained PLA fiber has the functions of resisting ultraviolet rays, preventing mosquitoes and guiding moisture, and can be used as a raw material for functional textiles.

Owner:JIANGNAN UNIV

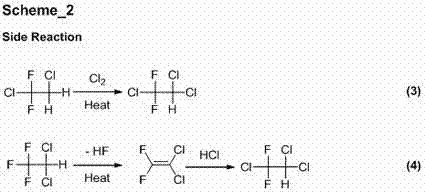

Preparation method of 2-bromo-2,2-difluoroacetyl chloride and 2-bromo-2,2-difluoro acetate and recycling method of waste difluoro trichloroethane

InactiveCN104761446AEnable recyclingIncrease added valuePreparation by hydrogen halide split-offPreparation from carboxylic acid halidesBromoethanePhenol

The invention relates to a preparation method of 2-bromo-2,2-difluoroacetyl chloride and 2-bromo-2,2-difluoro acetate and a recycling method of waste difluoro trichloroethane. The preparation method comprises the following steps: with waste difluoro trichloroethane produced in the production process of dichlorotrifluoroethane as a raw material, carrying out dehydrochlorination to obtain difluoro dichloroethylene, carrying out addition reaction on difluoro dichloroethylene and bromine to obtain difluoro dichlone dibromoethane; reacting difluoro dichlone dibromoethane with sulfur trioxide to obtain 2-bromo-2,2-difluoroacetyl chloride; and reacting 2-bromo-2,2-difluoroacetyl chloride with alcohol or phenol to obtain 2-bromo-2,2-difluoro acetate series products. According to the preparation method and the recycling method, recycling of waste difluoro trichloroethane is realized; 2-bromo-2,2-difluoroacetyl chloride and 2-bromo-2,2-difluoro acetate are prepared by a temperature oscillation method, so that the production cost is reduced; and meanwhile, the preparation method is an environment-friendly technique for producing products.

Owner:JIANGXI SUNWAY CHEM CO LTD

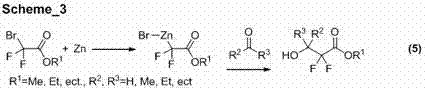

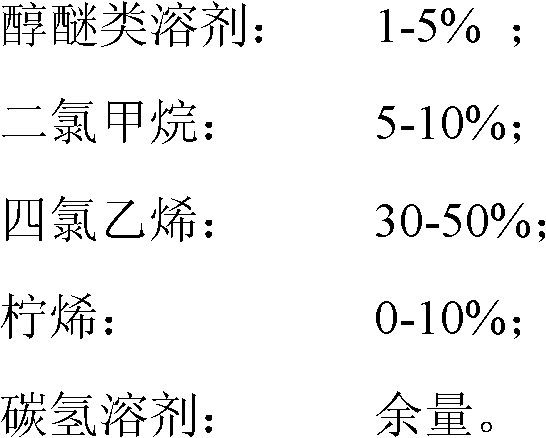

Electrical equipment cleaning agent and preparation method thereof

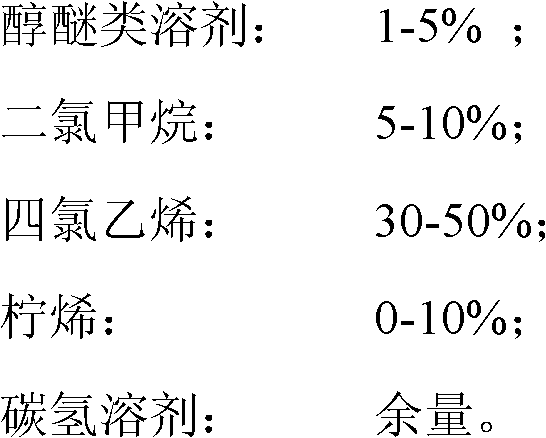

InactiveCN102660403AThe mechanism of action is simple and scientificSmall smellOrganic non-surface-active detergent compositionsNon-surface-active detergent solventsElectrical devicesLimonene

The invention relates to an electrical equipment cleaning agent and a preparation method thereof. The electrical equipment cleaning agent comprises 1 to 5% of one or more alcohol ether solvents, 5 to 10% of dichloromethane, 30 to 50% of tetrachloroethylene, 0 to 10% of limonene and the balance one or more hydrocarbon solvents. The preparation method comprises the following steps of standing the one or more hydrocarbon solvents in a storage tank having the cone-shaped bottom for more than 24 hours, adding the one or more hydrocarbon solvents into a stainless steel reactor according to a certain ratio, orderly adding the one or more alcohol ether solvents, dichloromethane, tetrachloroethylene and limonene into the stainless steel reactor, stirring for 20 to 30 minutes, drying by a dryer and filtering by a filter to obtain the electrical equipment cleaning agent. The electrical equipment cleaning agent does not contain ozone depleting substance (ODS) raw materials of trifluorotrichloroethane (F-113), 1,1,1-trichloroethane, trichloroethylene and carbon tetrachloride, is safe and environmentally friendly, has an ozone destruction coefficient of 0.00, strong detergency of 99.9% and a strong capacity of removing mineral oil stains, soldering and dust, allows on-line cleaning, has withstand voltage more than 25KV and stable chemical properties, does not produce corrosion on circuit boards and metal materials, and can be volatilized fully without residual.

Owner:华阳新兴科技(天津)集团有限公司

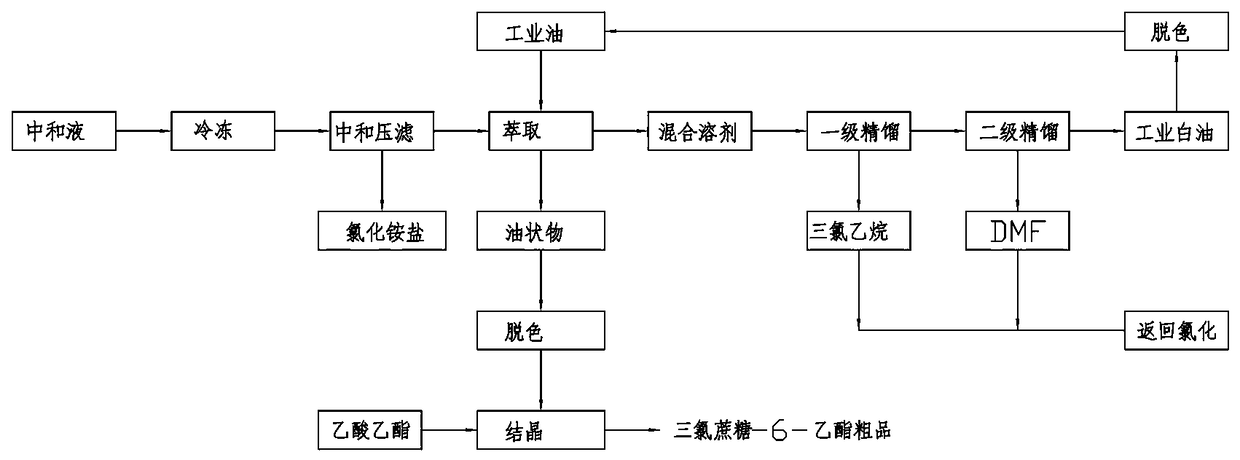

Method for separating solvents after chlorination and neutralization reaction of sucralose

ActiveCN109180748AAvoid lostEasy to separateEsterified saccharide compoundsSugar derivativesEthyl acetateSolvent

The invention relates to a method for separating solvents after a chlorination and neutralization reaction of sucralose. The method comprises the following steps: filtering a neutralized solution obtained after chlorination and neutralization, pumping the filtered neutralized solution into an extraction kettle, adding 10# industrial oil used as an extractant to extract the solvent trichloroethaneand DMF and make the solvents enter a supernatant, carrying out secondary reduced-pressure rectification on the supernatant, respectively separating the trichloroethane and DMF by using a boiling point difference, decolorizing high-boiling point industrial oil obtained after the secondary rectification with activated carbon to make the decolorized high-boiling point industrial oil directly reused,and directly reusing the trichloroethane and DMF obtained after the two-stage rectification in chlorination; and directly adding water to obtained lower oil to dissolve the lower oil, decolorizing and filtering the obtained solution, adding ethyl acetate, and performing freezing crystallization to obtain crude sucralose-6-acetate. The method has the advantages of simplicity, avoiding of the process of adding water to carry away the solvents during solvent recovery in traditional processes, reduction of the solvent recovery difficulty, improvement of the solvent recovery efficiency, energy consumption saving, great reduction of the production cost, and reduction of pollution.

Owner:ANHUI JINGHE IND

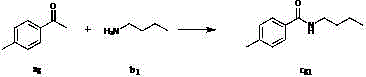

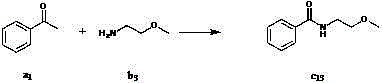

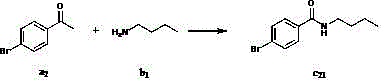

Method for preparing amide compound

InactiveCN102746077AMild reaction conditionsMeet the requirementsOrganic compound preparationSulfonic acid esters preparationSodium iodidePotassium iodine

The invention discloses a method for preparing an amide compound, which comprises the steps of configuration of reaction system. Methyl ketone, amine, catalyst, an oxidizing agent and solvent are use, wherein the general formula of the methyl ketone is RCOCH3, and R is selected from one kind of C6-C14 aryl group, C2-C8 alkenyl group, and five-or six-membered heterocyclic group; the amine is primary amine; the catalyst is selected from one kind of potassium iodide, iodine, tetramethyl ammonium iodide, tetrabutyl ammonium iodide, tetrahexyl ammonium iodide, bismuth iodide, lithium iodide, phenyl trimethyl ammonium iodide, benzyl trimethyl ammonium iodide or sodium iodide; the oxidizing agent is tert-butyl hydroperoxide; the solvent is selected from one kind of water, dichloromethane, ethyl acetate, toluene, 1,2-dichloroethane, 1,1,1-trichloroethane, acetonitrile, and isopropanol. The methyl ketone, the catalyst and the amine are added into the reaction system under the temperature of 0 DEG C and stirred for 5 minutes, and then the oxidizing agent is added to react for 2-48 hours to obtain the amide compound. The method provided by the invention is green, moderate, high in selectivity and wide in application range.

Owner:云梦星联物流有限公司

Method for removing hydrochloric ether contained in underground water and soil mud system through chemical reduction

InactiveCN103288200AEasy to operateGood processing effectWater contaminantsContaminated soil reclamationMud systemsEther

The invention relates to a method for removing hydrochloric ether contained in underground water and a soil mud system through chemical reduction, and belongs to the technical field of environmental management. The method mainly removes certain hydrochloric ether contaminants which exist in the underground water and the soil mud system through the reduction action of ZVI (Zero-Valent Iron). The method achieves the purpose of hydrochloric ether treatment by adding the zero-valent iron to the mud system which contains the hydrochloric ether contaminants in a treatment process. The method disclosed by the invention is simple, effective and outstanding in treatment effect. According to the invention, the zero-valent iron is rich in source, low in cost and higher in reducing capacity, and the hydrochloric ether can be fast dechlorinated and degraded and achieves high removal efficiency, for instance, the removal ratio of 1,1,1-trichloroethane can achieve 99.5%. The method disclosed by the invention can be used for simultaneously treating the hydrochloric ether contained in the underground water and the soil mud system and is less influenced by temperature and pH on reaction process and wide in application range.

Owner:EAST CHINA UNIV OF SCI & TECH

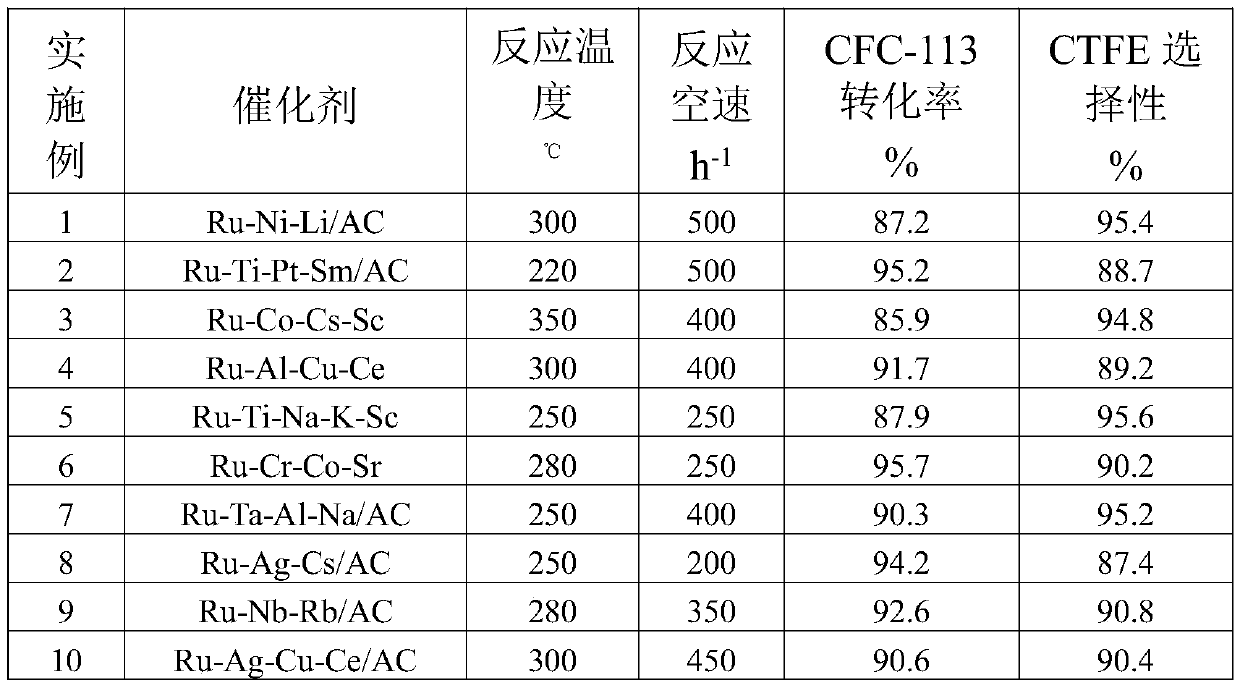

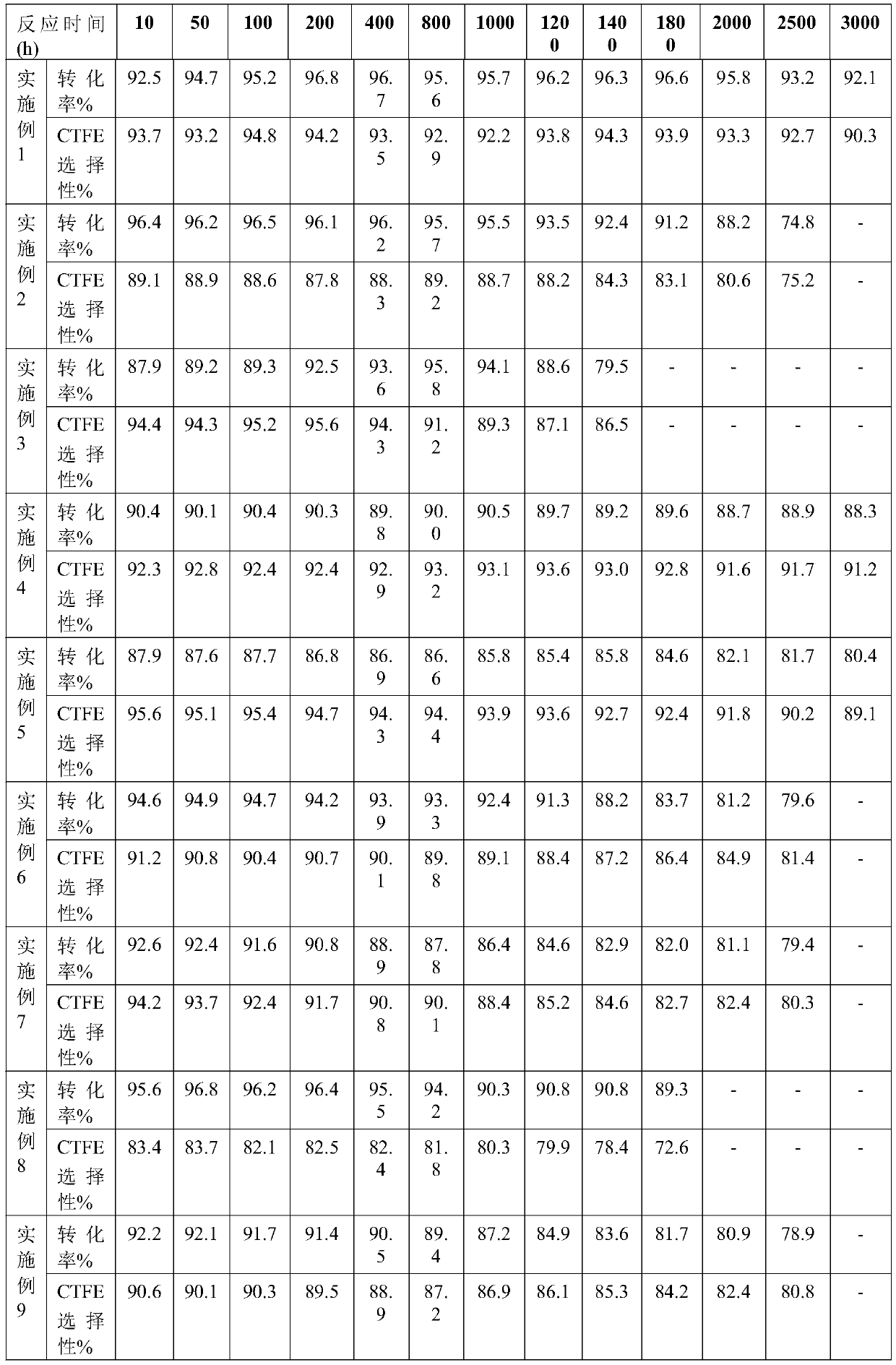

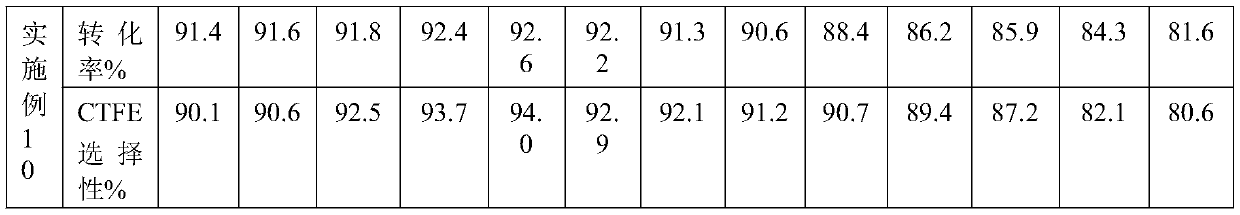

Catalyst for catalytic hydrodechlorination, and preparation method and application thereof

ActiveCN111013604AEasy to prepareLow costPreparation by dehalogenationMetal/metal-oxides/metal-hydroxide catalystsActivated carbonPtru catalyst

The invention discloses a catalyst for catalytic hydrodechlorination, and a preparation method and an application thereof. The catalyst for catalytic hydrodechlorination comprises an alloy catalyst, an auxiliary agent and a carrier, the alloy catalyst takes element Ru as a main body, and any one or more of specified alloy elements Re, Ti, Cr, Ni, Al, Co, Cu, Nb, Ta, Ru, Pt and Ag are selected to form an alloy with Ru; and the auxiliary agent is alkali metal or rare earth metal, and the carrier is an activated carbon carrier. The catalyst is simple in preparation method and convenient to operate, and has the advantages of low cost, high activity, high selectivity, good stability, mild reaction conditions and the like; the catalyst is applied to a reaction for preparing chlorotrifluoroethylene through catalytic hydrodechlorination of trichlorotrifluoroethane; and the catalyst is good in catalytic hydrodechlorination reaction temperature, instant in reaction at the temperature of 200-550DEG C, high in activity and high in chlorotrifluoroethylene selectivity, the activity of the catalyst reaches 85% or above, the maximum conversion rate of the catalyst reaches 95.7%, and the maximum selectivity of the catalyst reaches 95.6%.

Owner:ZHEJIANG UNIV OF TECH

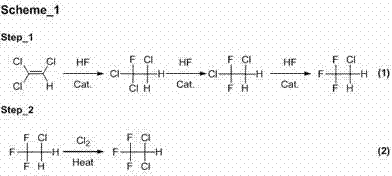

Method for producing 1,1,1-trifluoro-ethane

InactiveCN101028990AEasy to industrializePhysical/chemical process catalystsPreparation by halogen replacementAluminum fluorideHydrogen fluoride

A process for preparing 1,1,1-trifluoroethane (HFC-143a) features the gas-phase reaction between HF and 1,1,1-trichloroethane (HCC-140a) under the existence of fluorinating Cr-base catalyst at 150-280 deg.C. It has high output rate and selectivity.

Owner:江西百炼氟材料有限公司

Metallic antirust agent

InactiveCN101748417AStrong ability to degrease and decontaminateStrong rust resistanceHazardous substancePolyethylene glycol

The invention discloses a water-soluble metallic antirust cleaner, which is characterized in that the metallic antirust cleaner comprises the following raw materials in parts by weight: 4-8 parts of peregal, 2-6 parts of polyethylene glycol, 2-6 parts of oleic acid, 6-15 parts of triethanolamine, 2-3 parts of sodium nitrite, 0.5-1.2 parts of benzotriazole and 0.5-1.2 parts of silicone defoamer. The metallic antirust cleaner has the advantages of: 1. not containing harmful materials such as trichloroethane, carbon tetrachloride and the like, not damaging high-altitude ozone layer and not polluting the environment; 2. having strong degreasing and decontaminating abilities and having no bad effect on nonferrous metals; 3. having strong antirust capability; and 4. having strong anti-foaming property and generating no overflow phenomenon under high pressure.

Owner:TIANJIN SANNONGJIN TECH

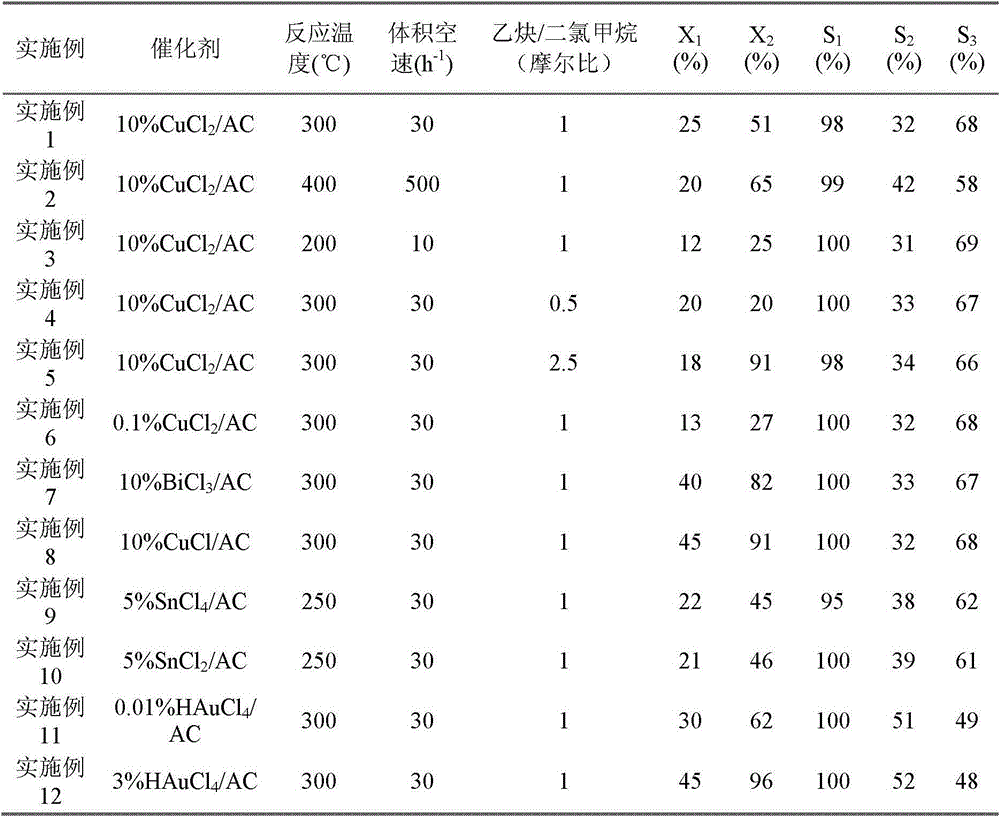

Method for preparing vinyl chloride and coproducing dichloroethylene and 1,1,2-trichloroethane by acetylene-dichloromethane coupled reaction

ActiveCN104672054ASolve pollutionReaction process with low energy consumptionPreparation by halogen halide addition1,1,2-TrichloroethaneReaction temperature

The invention relates to a method for preparing vinyl chloride and coproducing dichloroethylene and 1,1,2-trichloroethane by acetylene-dichloromethane coupled reaction, which is characterized by comprising the following steps: mixing acetylene and dichloromethane, and simultaneously carrying out dichloromethane coupled reaction and acetylene hydrochlorination on the acetylene and dichloromethane in a catalyst-filled reactor under the action of the catalyst, wherein the mole ratio of the acetylene to the dichloromethane is 0.5-2.5, the reaction temperature is 200-400 DEG C, the volumetric space velocity of the acetylene-dichloromethane gas mixture is 10-500 h<-1>, and the dichloromethane coupled reaction generates dichloroethylene, 1,1,2-trichloroethane and chlorine hydride; and further carrying out acetylene hydrochlorination on the generated chlorine hydride and acetylene to generate vinyl chloride. The method can simultaneously coproduce the dichloroethylene, 1,1,2-trichloroethane and other high-added-value products while producing vinyl chloride, and the process is more economical and has wider industrialization prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

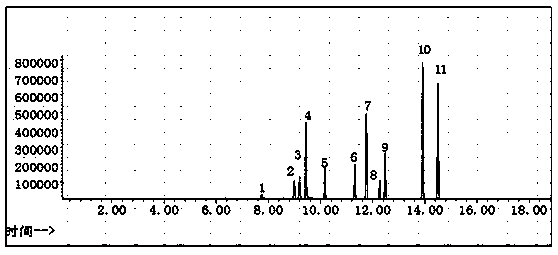

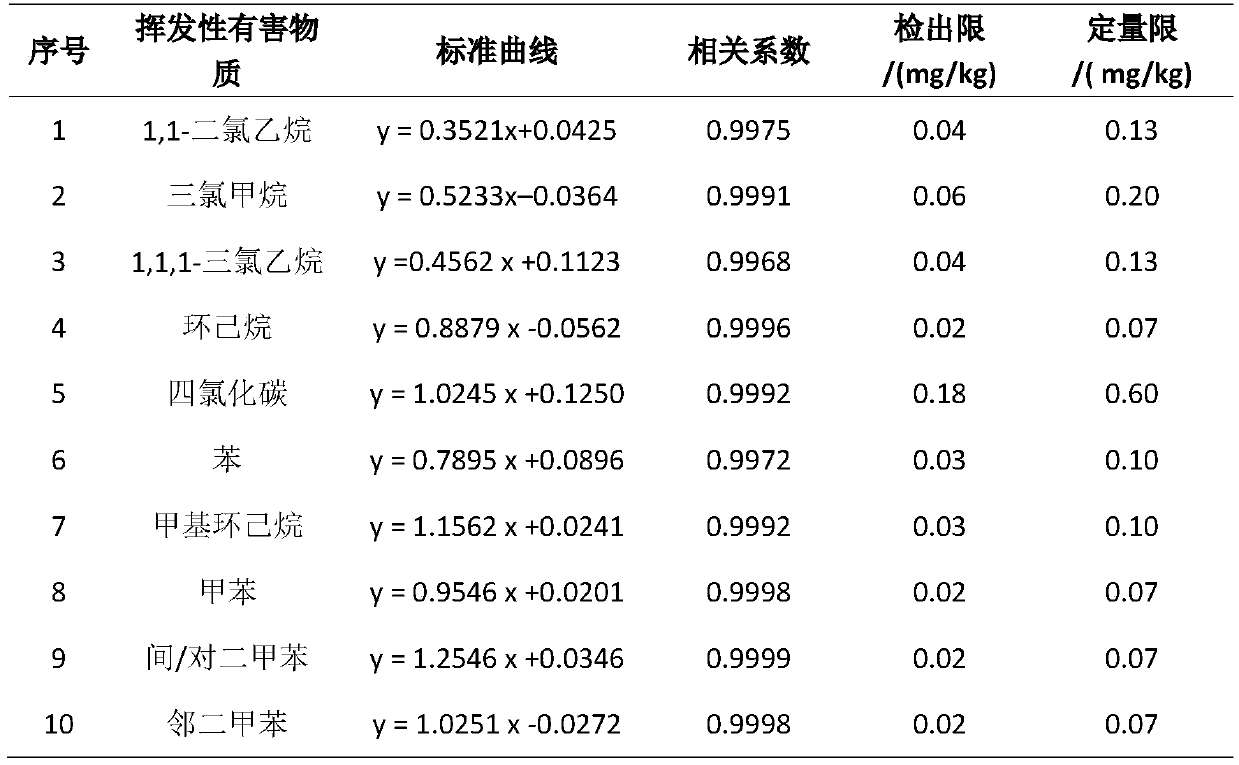

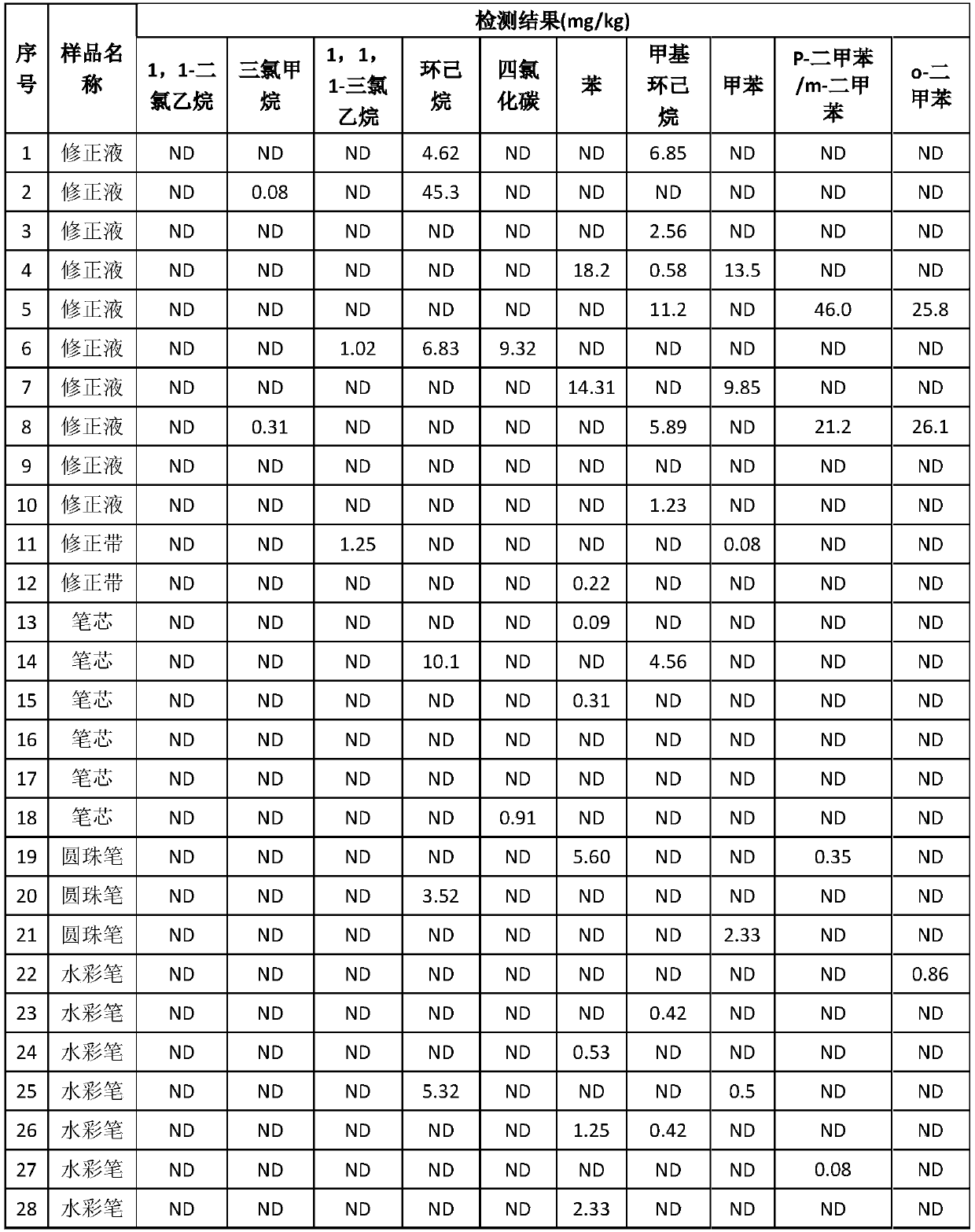

Headspace-gas chromatography/mass spectrometry (HS-GC/MS) measurement method of eleven types of volatile harmful substances in student supplies

ActiveCN110108816AEfficient detection methodImprove detection efficiencyComponent separationRelative standard deviationHazardous substance

The invention relates to a headspace-gas chromatography / mass spectrometry (HS-GC / MS) measurement method of eleven types of volatile harmful substances in student supplies, and belongs to the technicalfield of detection and risk assessment of the harmful substances in the student supplies. The HSGC-MS selection ion quantitative measurement method is established so as to measure the eleven types ofvolatile harmful substances such as 1,1-dichloroethane, trichloromethane, 1,1,1-trichloroethane, cyclohexane, carbon tetrachloride, benzene, methyl cyclohexane, toluene and xylene in the student supplies. After a sample is subjected to headspace at 70 DEG C for 30 min, toluene -d8 serves as the internal standard, then gas in a headspace sample injector is directly injected to a GC / MS system, andthe volatile harmful substances in the student supplies are qualitatively and quantitatively analyzed through the headspace sample injector and a gas chromatography-mass spectrometer. According to themethod, the detection limit is 0.02-0.18 mg / kg, the quantitative limit is 0.07-0.60 mg / kg, the standard recovery rate is 93.33-105.8%, and the relative standard deviation is smaller than 10%. The tedious step of solvent extraction is avoided, by selecting ion detection quantification, interference factors are few, operation is easy, and sensitivity and repeatability are good.

Owner:SHANDONG INST FOR PROD QUALITY INSPECTION

Water soluble metal anti-rust cleaning agent

InactiveCN1990913AStrong ability to degrease and decontaminateStrong rust resistanceOzone layerHazardous substance

The invention relates to a water soluble metallic antirust cleaner, which is characterized in that: it comprises following components with certain proportion by weight: peregal 4-8 units, polyethylene glycol 2-6 units, oleic acid 2-6 units, triethanolamine 6-15 units, sodium nitrite 2-3 units, benzotriazole 0.5-1.2 units, and Silicone defoaming agent 0.5-1.2 units. The advantages of this invention comprises: (1) containing no trichloroethane and carbon tetrachloride, which will destroy ozone layer and pollute environment; (2) strong ability to remove fat and dirty, no bad influence to color metal; (3) good performace of preventing rust; (4) strong ability to resist foam.

Owner:天津市怡佳商贸有限公司

Method for removing pesticide residue and heavy metal residue out of lentinan by using resin adsorption method

The invention relates to the technical field of environmental protection, and particularly relates to a method for removing pesticide residue and heavy metal residue out of lentinan by using a resin adsorption method. The method is characterized in that a process route is as follows: mushroom selection, cleaning, extraction, passing through a resin column, filtration, concentration, alcohol precipitation, recovery of ethanol, spray drying of precipitate, mixing and sub-packaging; the technical data of final products are as follows: moisture is less than or equal to 5.0%, polysaccharide content is more than or equal to 50.0%, lead is less than or equal to 0.1ppm, cadmium is less than or equal to 0.1ppm, and mercury is less than or equal to 0.1ppm; pesticide residues: hexachloro-cyclohexane soprocide is less than or equal to 0.01ppm, quintozene is less than or equal to 0.01ppm, Dichlorodiphenyl Trichloroethane is less than or equal to 0.01ppm, ash content is less than or equal to 4.0%, and mesh number is more than or equal to 100; microbiological indicators: total bacterial count is less than or equal to 1000 / g, saccharomycetes are less than or equal to 50 / g, mildew is less than or equal to 50 / g, and pathogenic bacteria cannot be detected. The resin column uses HPD500 type adsorption resin. The spray drying temperatures are as follows: the inlet temperature is 205 DEG C, and the outlet temperature is 80 DEG C. By adopting the adsorption resin for removing harmful ingredients out of mushroom, the polysaccharide content is increased, the color, aroma and taste of the mushroom cannot be destroyed, and the product quality of polysaccharides is improved.

Owner:FUSHUN HAOYUAN BIOLOGICAL SCI & TECH CO LTD

Low corresion fire retardant polyurethane composition material and its manufacturing method

The low corrosion fire retardant heat insulating polyurethane composition material includes two components, component A and component B. The component A consists of polyether polyol, cyclohexane, silicone oil, potassium acetate, dimethylethanolamine, 2, 4, 6-tri(dimethylaminomethyl) phenol, water, monofluoro trichloroethanone, trichloroethyl phosphate and silicate hydrate; and the component B is isocyanate. When the composition material is used, the component A and the component B are mixed to form the foamed heat insulating polyurethane material with low corrosion, high fire retarding performance and simple production process. The foamed heat insulating polyurethane material is used for oil and gas pipeline.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com