Method for preparing vinyl chloride and coproducing dichloroethylene and 1,1,2-trichloroethane by acetylene-dichloromethane coupled reaction

A technology of dichloromethane and dichloroethylene, applied in the field of vinyl chloride monomer preparation, can solve the problem of low conversion rate of vinyl chloride selectivity, and achieve the effects of avoiding pollution, easy operation and control, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Catalyst preparation:

[0036] 1.27g CUCl 2 2H 2 0 was dissolved in 13.73g of deionized water to make a solution, and 10g of HNO3 Activated carbon after treatment, make the activated carbon completely absorb the above solution, let it stand at room temperature for 10 hours, and then dry it at 100°C to get 10% CuCl 2 / AC Catalyst.

[0037] Other supported catalysts in the present invention can be prepared similarly to the above method.

Embodiment 1 to 12

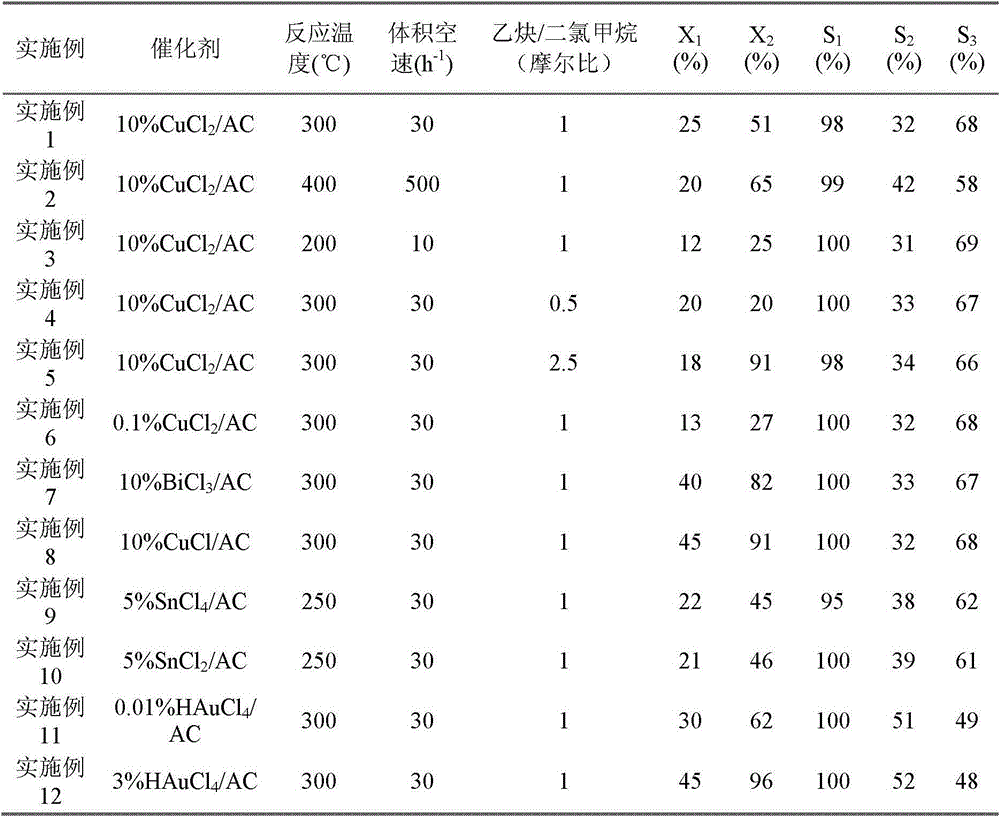

[0039] The dichloromethane is transported to the gasifier by a metering pump for gasification. The temperature of the gasifier is 100°C. The gasified dichloromethane is mixed with acetylene and preheated by a preheater. The preheating temperature is the same as the reaction temperature. Adjust the dichloromethane metering pump and acetylene flowmeter so that acetylene and gasified dichloromethane are mixed in a certain molar ratio through a mixer and then passed into a fixed-bed reactor equipped with a catalyst to control the reaction volume space velocity and reaction temperature The reaction is carried out at a certain value, and the product after the reaction is analyzed by gas chromatography. Catalyst, reaction temperature, volume space velocity, acetylene / methylene chloride molar ratio that concrete use among the embodiment 1 to 12 refer to following table 1, and calculate acetylene conversion rate, methylene chloride conversion rate, vinyl chloride selectivity, Dichloroe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com