Recovery method and recovery device for sulfur dioxide in sucralose chlorination reaction

A technology of sulfur dioxide and sucralose, which is applied to the recovery of sulfur dioxide in the chlorination of sucralose, the production of sucralose, and the recovery of sulfur dioxide in the chlorination of sucralose, can solve the problem of shortening the service life of cooling devices, The cooling device is highly corrosive and the water content of trichloroethane is high, so as to reduce the loss of equipment, save cost and consumption, and shorten the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

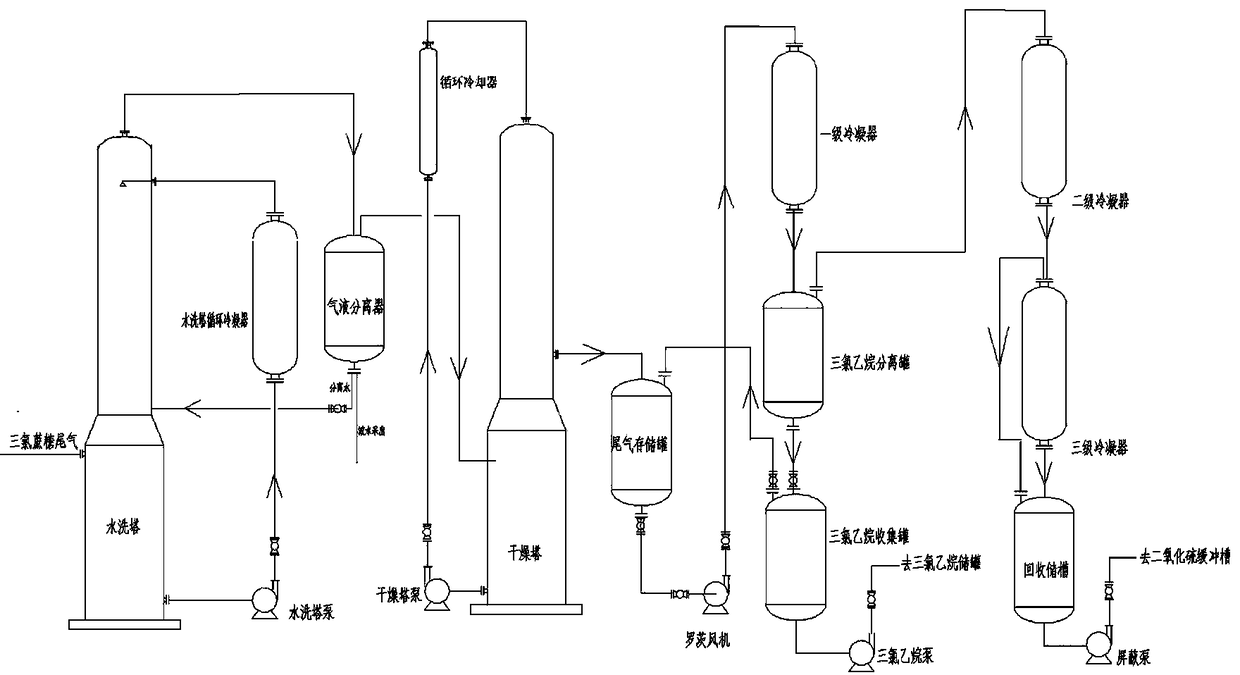

[0019] like figure 1 As shown, a recovery device for sulfur dioxide in the chlorination reaction of sucralose adopts the following equipment in the existing process: water washing tower, water washing tower circulation condenser, water washing tower pump, gas-liquid separator, Roots blower, primary condensation Condenser, secondary condenser, recovery storage tank, canned pump;

[0020] The sucralose tail gas enters from the bottom of the washing tower through a pipeline and absorbs the washing liquid from the top of the washing tower. Another outlet at the bottom of the washing tower connects the pump of the washing tower and the circulating condenser of the washing tower to the top of the washing tower through a pipeline. Under the action of the water washing tower pump, it is condensed by the circulating condenser of the water washing tower and then participates in circular absorption; the tail gas absorbed by the water washing tower enters the gas-liquid separator through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com