Patents

Literature

2081 results about "Sulfur oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sulfur oxide refers to many types of sulfur and oxygen containing compounds such as SO, SO₂, SO₃, S₇O₂, S₆O₂, S₂O₂, etc.

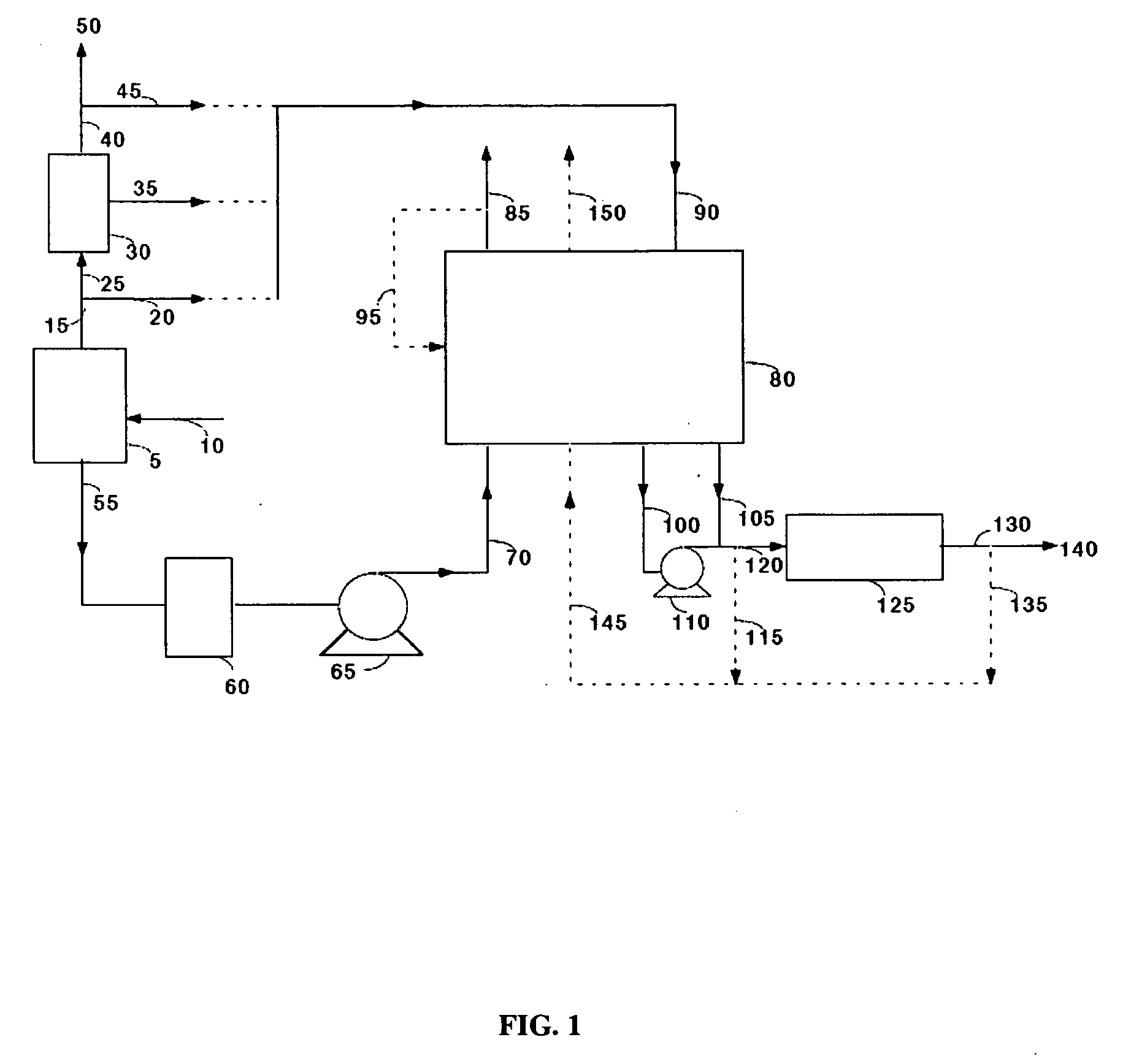

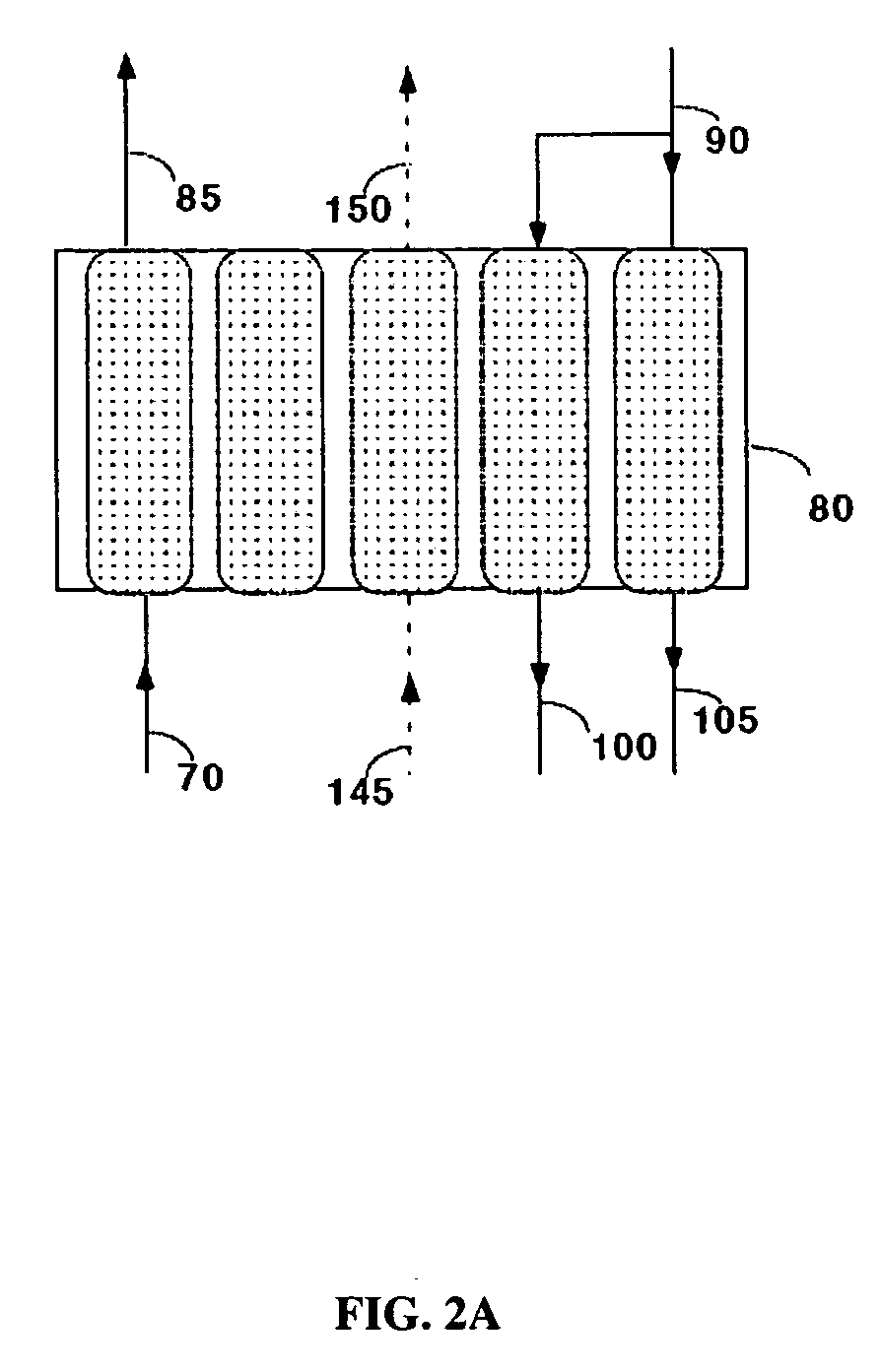

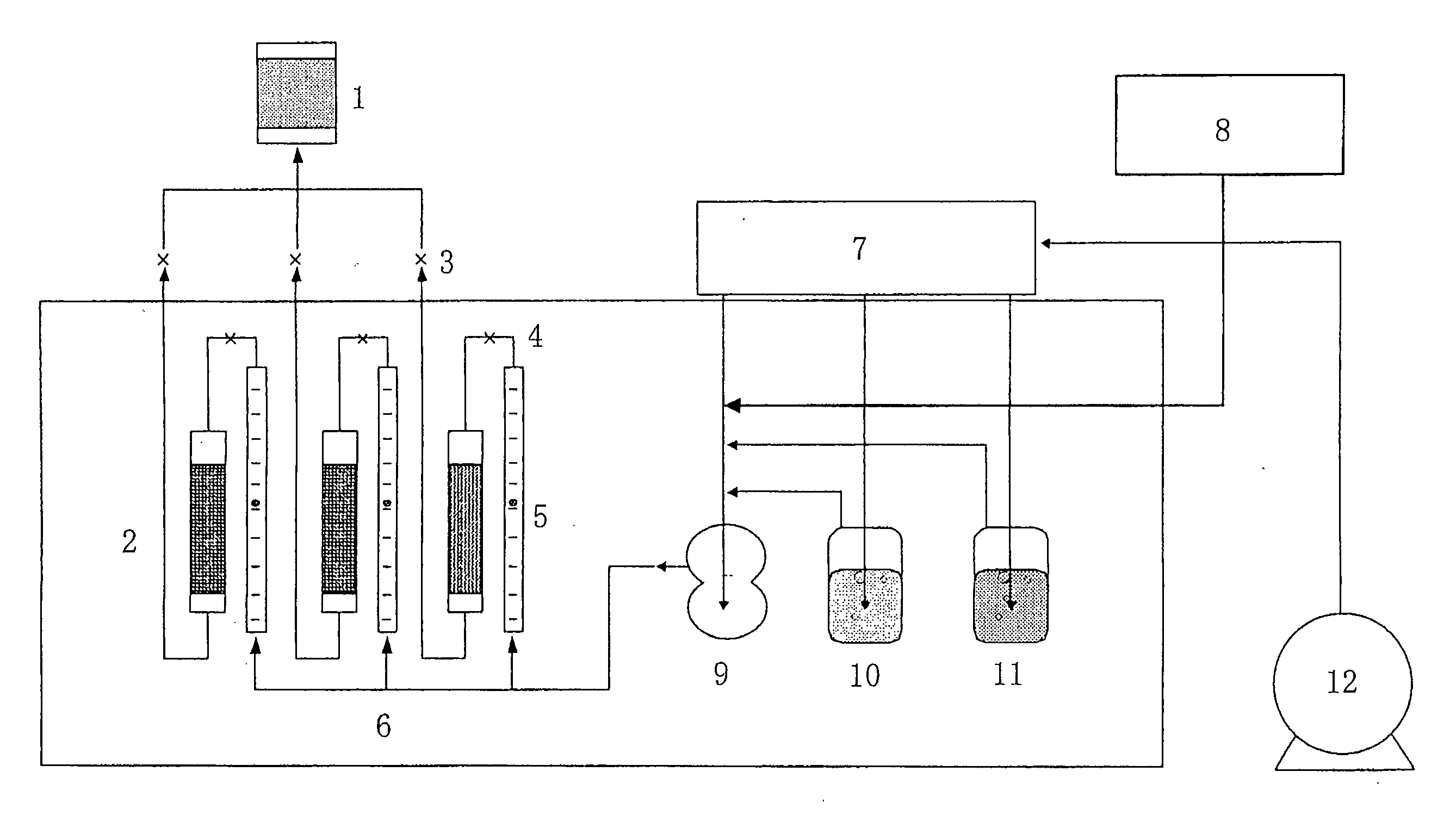

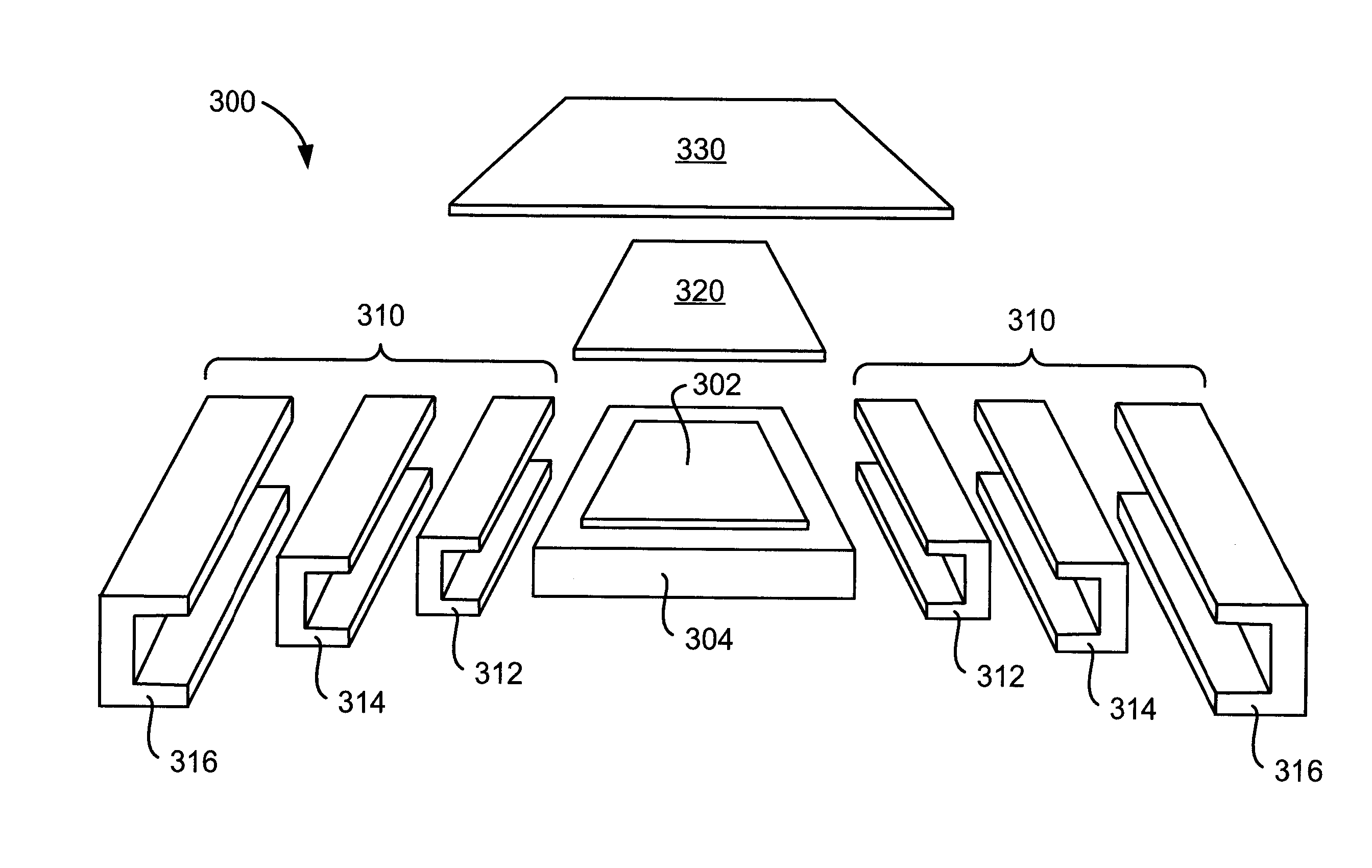

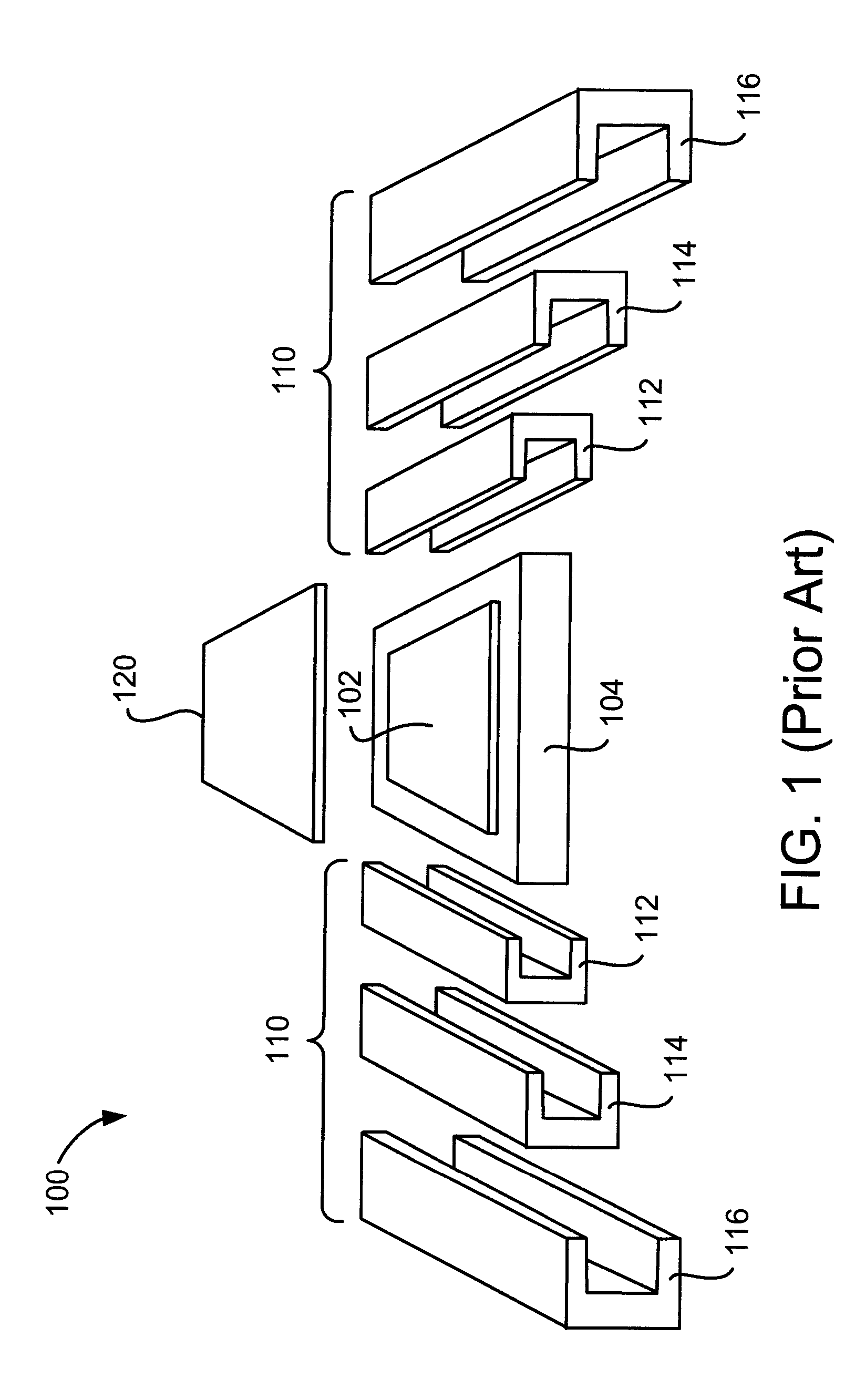

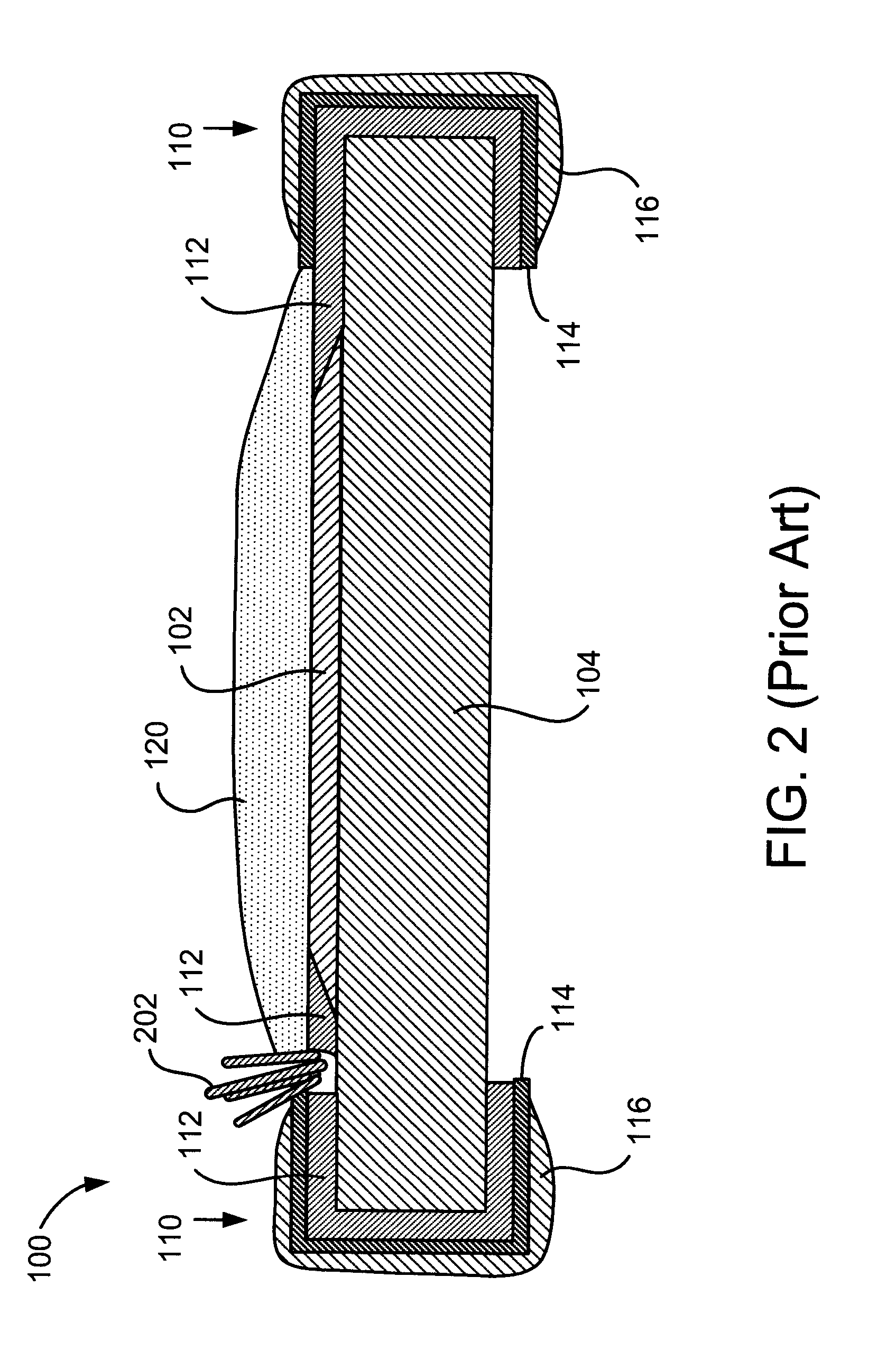

Effluent gas stream treatment system having utility for oxidation treatment of semiconductor manufacturing effluent gases

InactiveUS6322756B1Reduce sensitivityReduces water requiredCombination devicesExhaust apparatusOxygenOxidative treatment

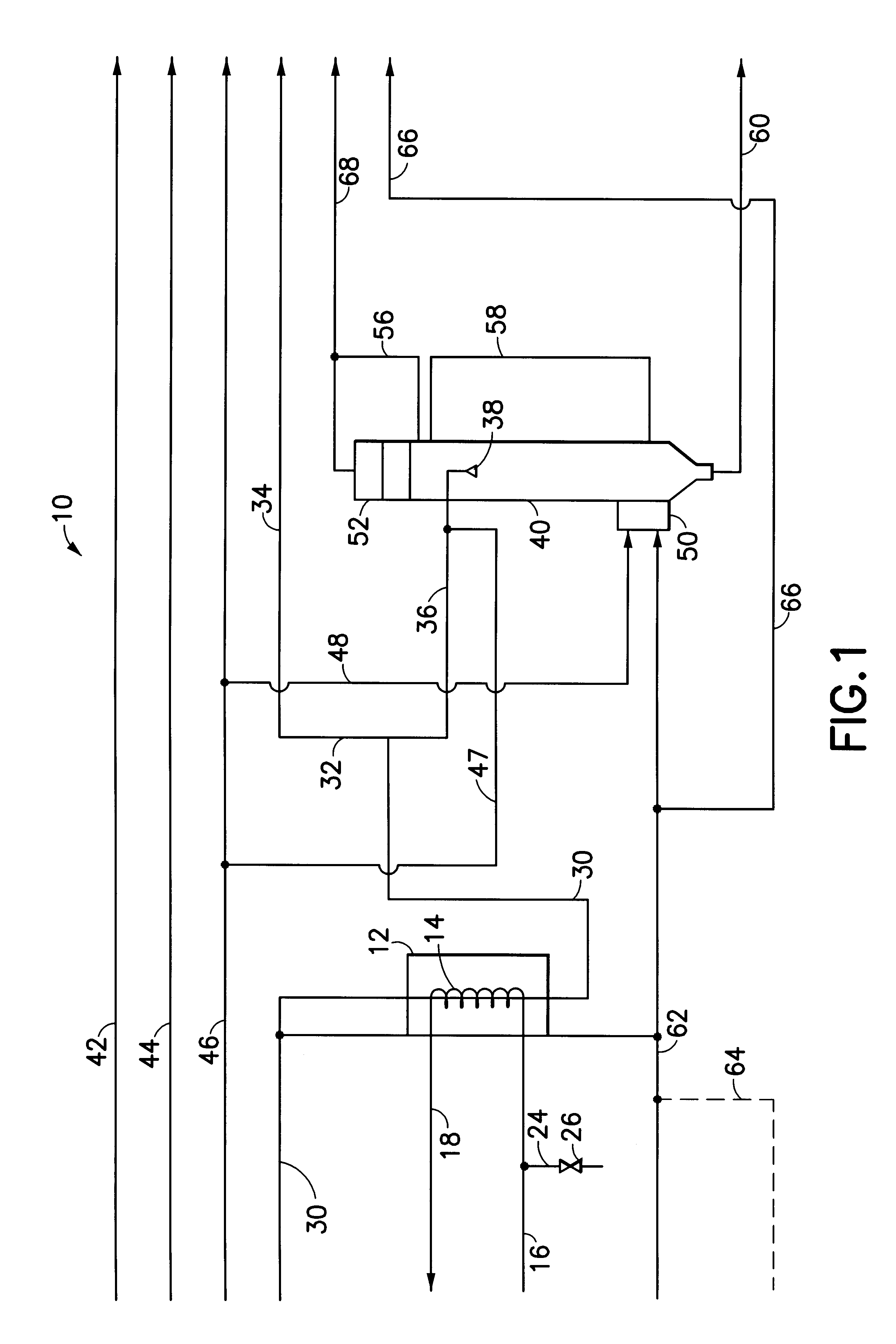

An effluent gas stream treatment system for treatment of gaseous effluents such as waste gases from semiconductor manufacturing operations. The effluent gas stream treatment system comprises an oxidation unit to which an oxygen-containing gas such as ozone may be added, with input of energy (e.g., thermal, radio frequency, electrical, microwave, etc.), to effect oxidation of oxidizable species in the effluent, such as halocompounds (e.g., chlorofluorocarbons, perfluorocarbons), CO, NF3, nitrogen oxides, and sulfur oxides). The effluent gas stream treatment system may include a wet scrubber associated with the oxygen-containing gas source, so that the gas stream is contacted with the oxygen-containing gas during the wet scrubbing operation, to enhance removal of oxidizable species in the gas stream during treatment.

Owner:BHT SERVICES PTE LTD

Carbon Dioxide Recovery

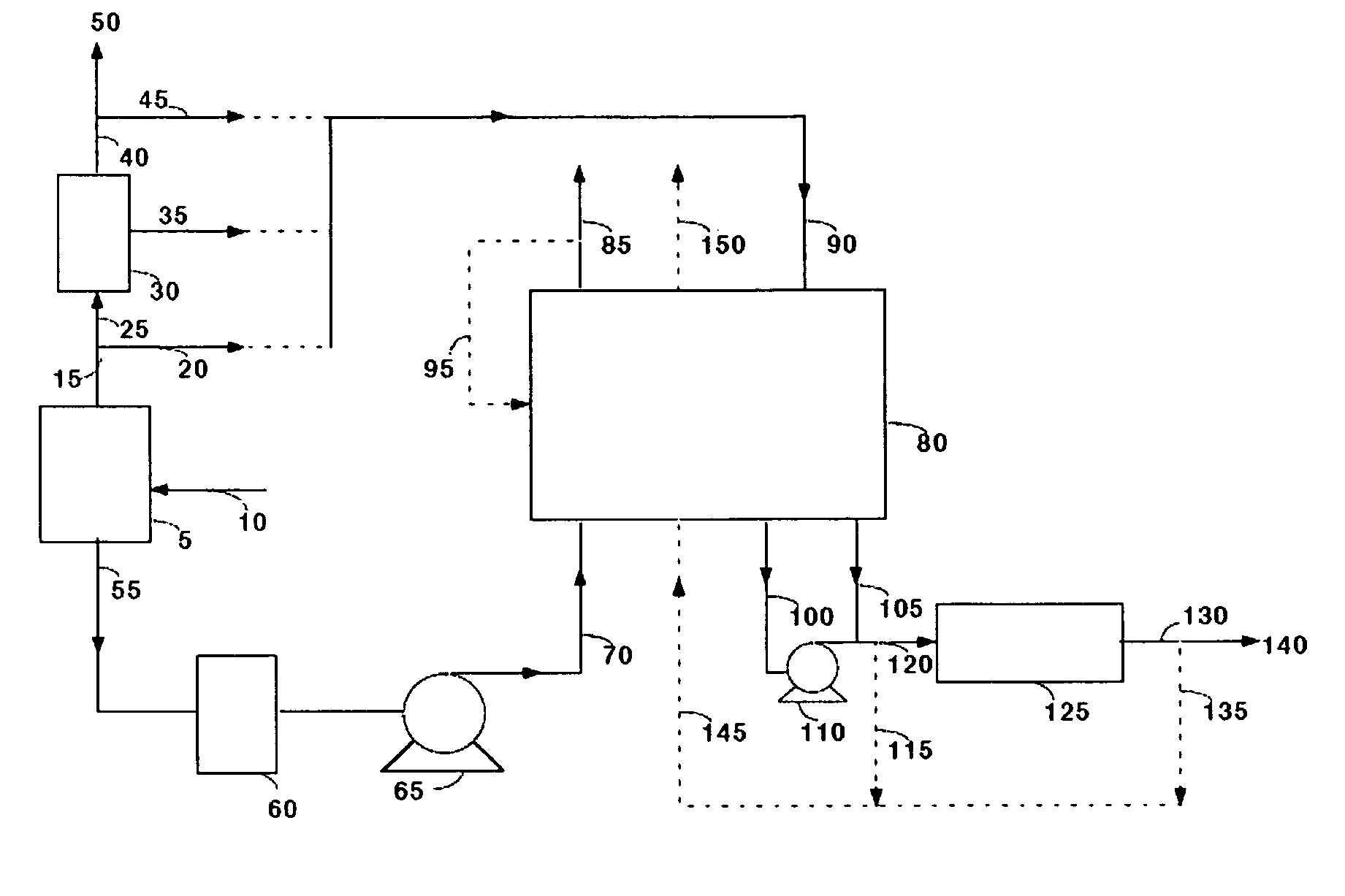

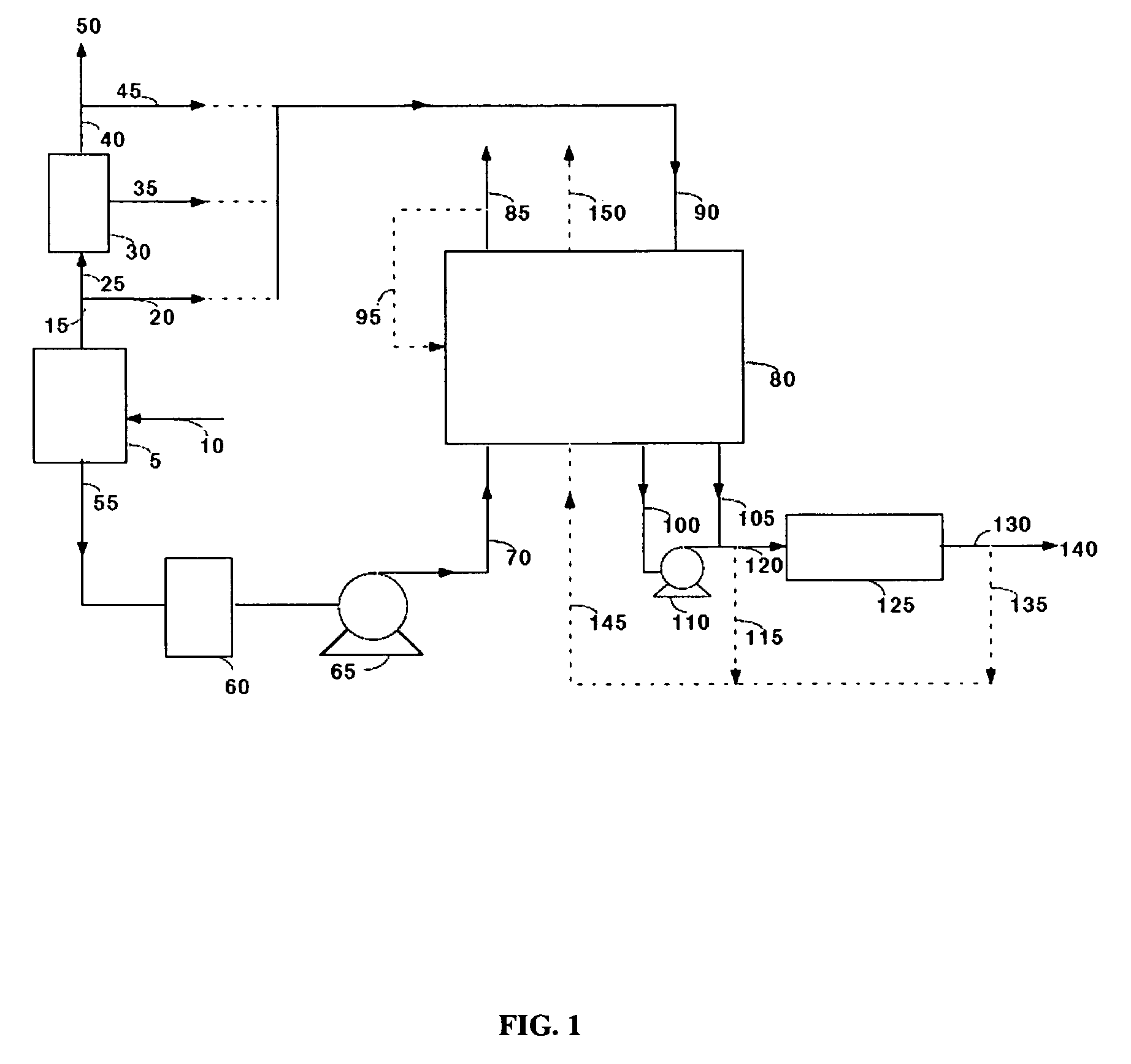

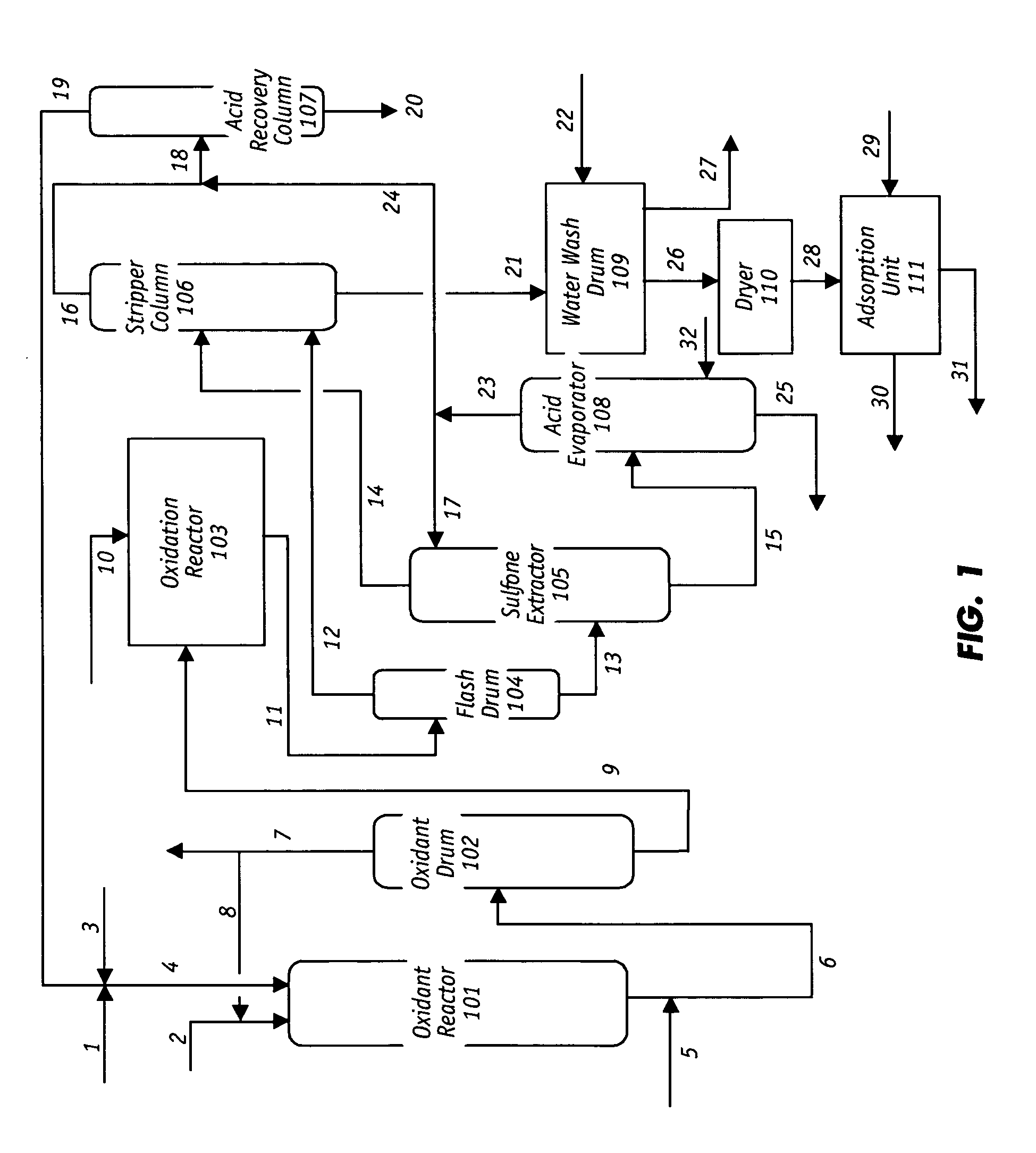

Disclosed herein is a method and system for separating carbon dioxide (CO2) from a CO2 containing gas stream containing water vapor and additional impurities, for example, nitrogen, oxygen, sulfur oxides, nitrogen oxides, and mercury. The CO2 is captured by subjecting the CO2 gas feed stream to a temperature swing adsorption step. The temperature swing adsorption step comprises an adsorption step for producing a substantially dry carbon dioxide-depleted stream, and an adsorbent regeneration step comprising heating the adsorbent bed to produce a substantially water vapor-free carbon dioxide stream. Moisture from the gas stream containing CO2 is optionally removed by pressure swing adsorption, temperature swing adsorption, membrane separation, or absorption prior to CO2 capture.

Owner:INNOSEPRA LLC

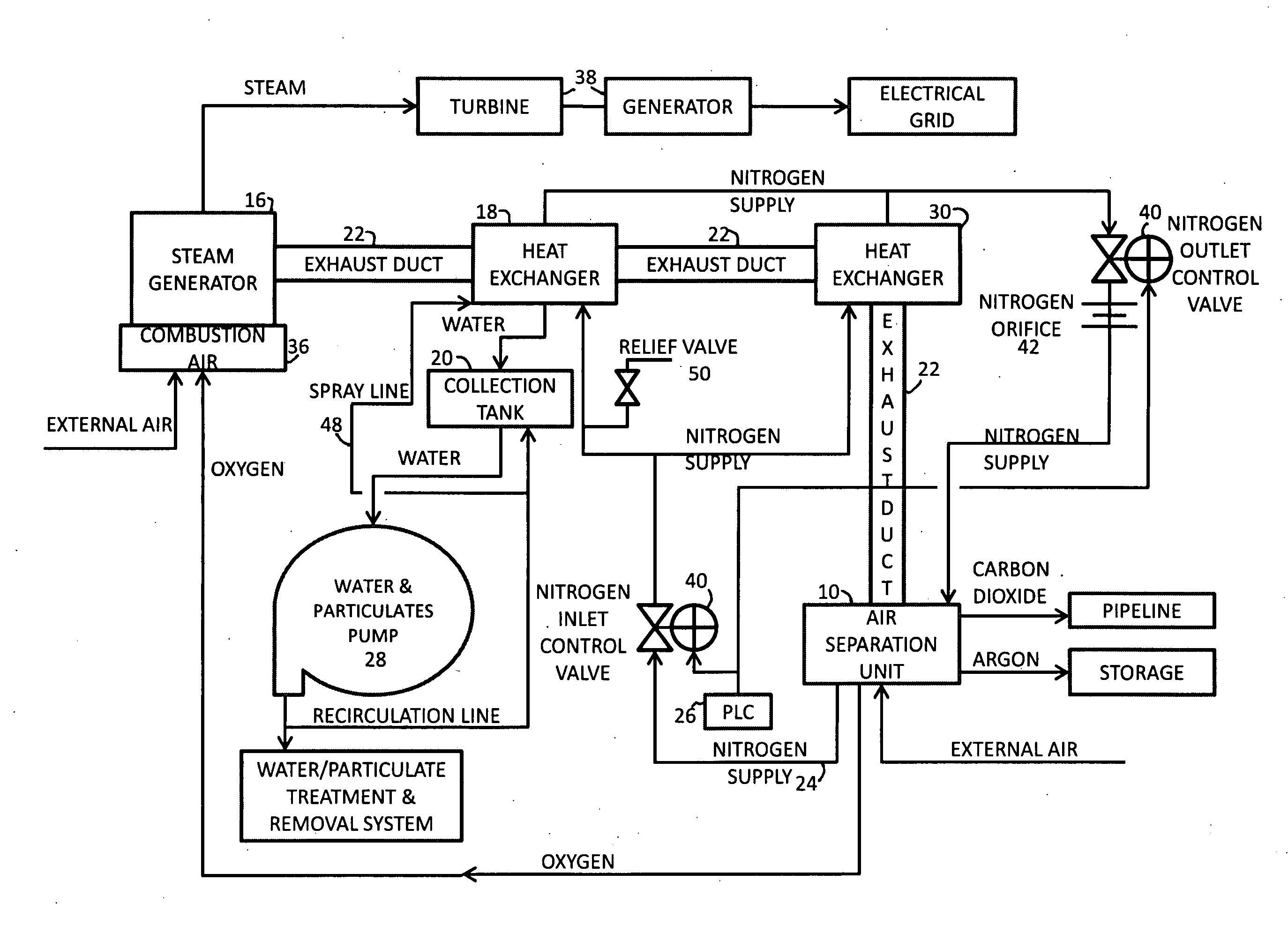

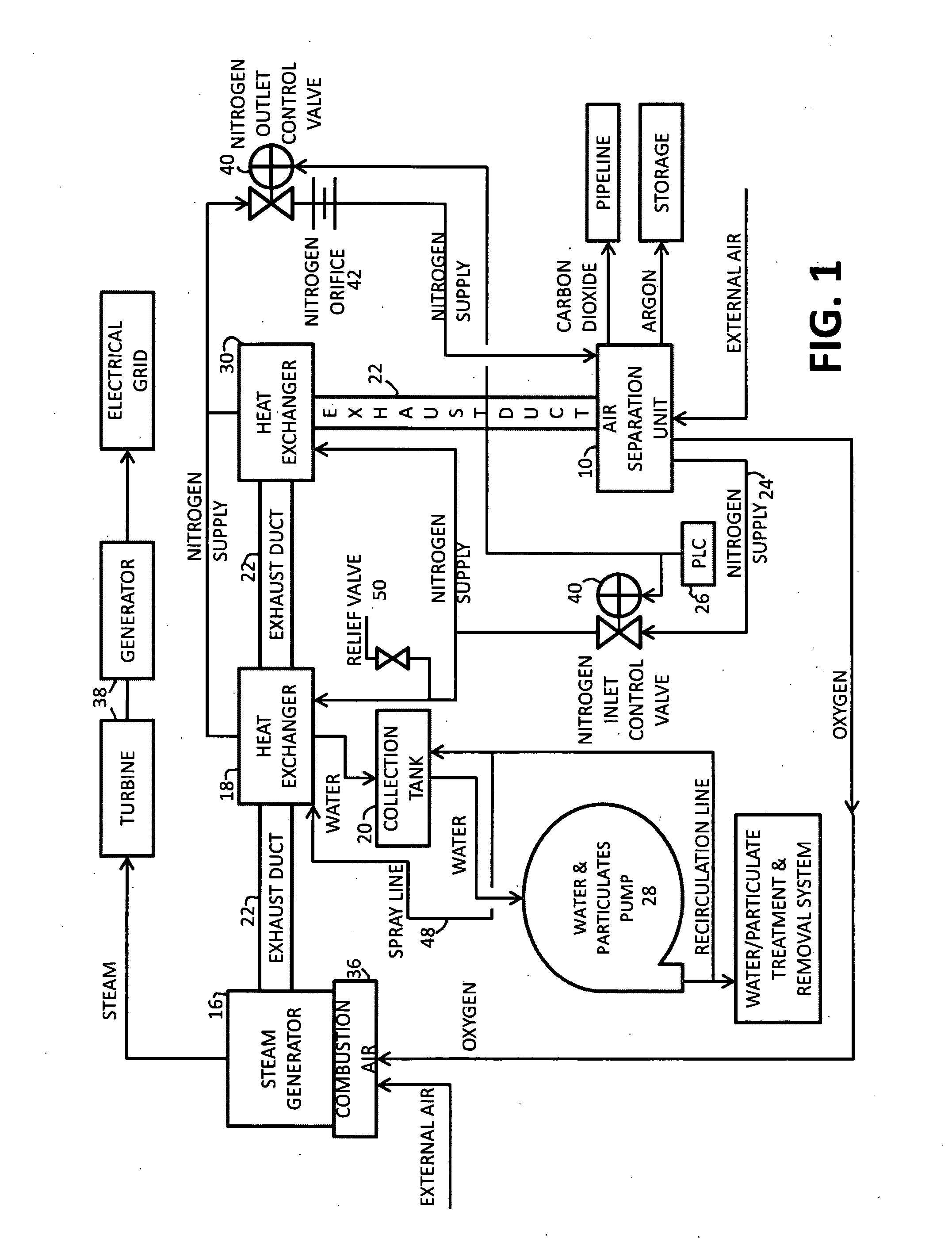

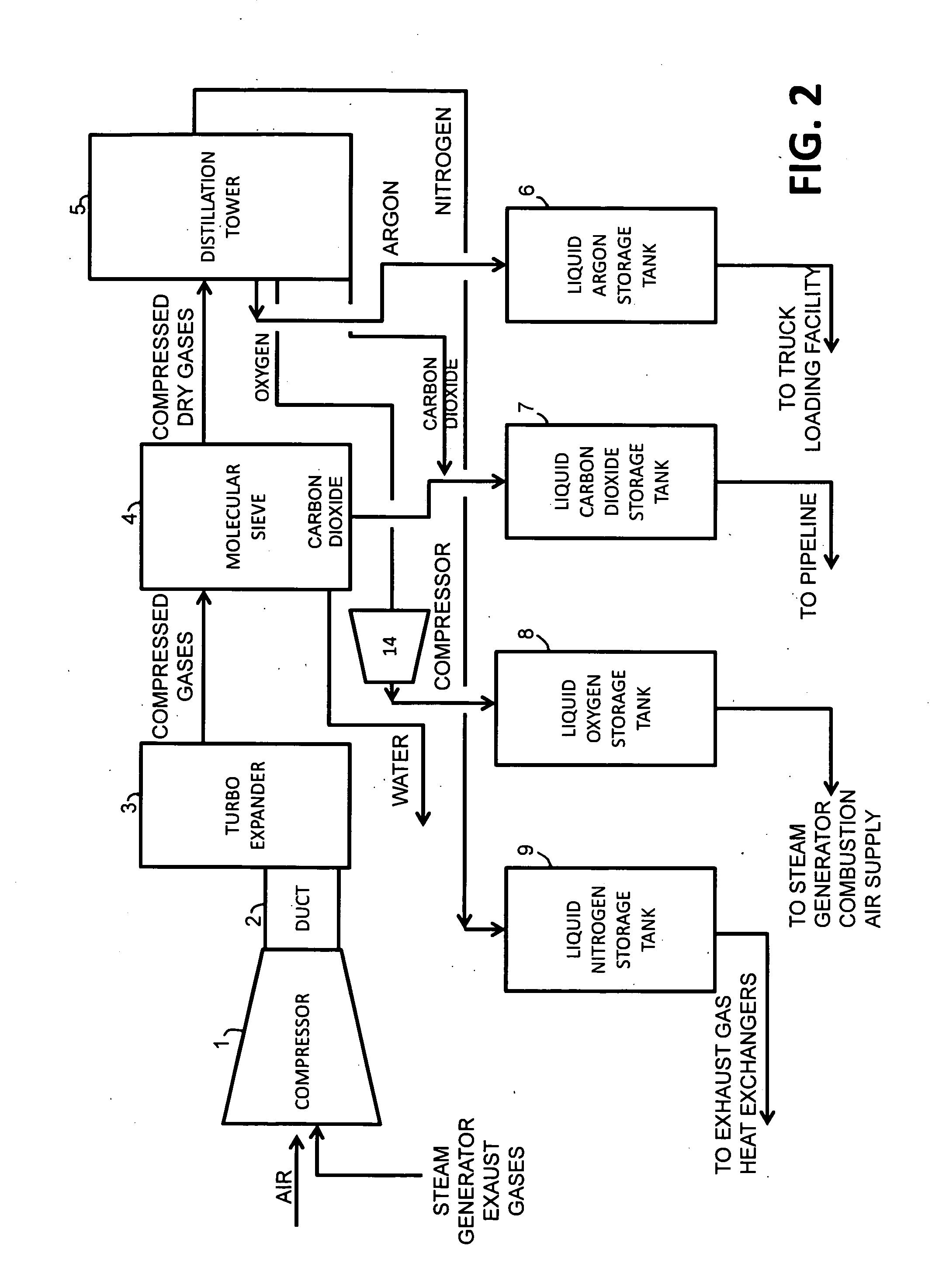

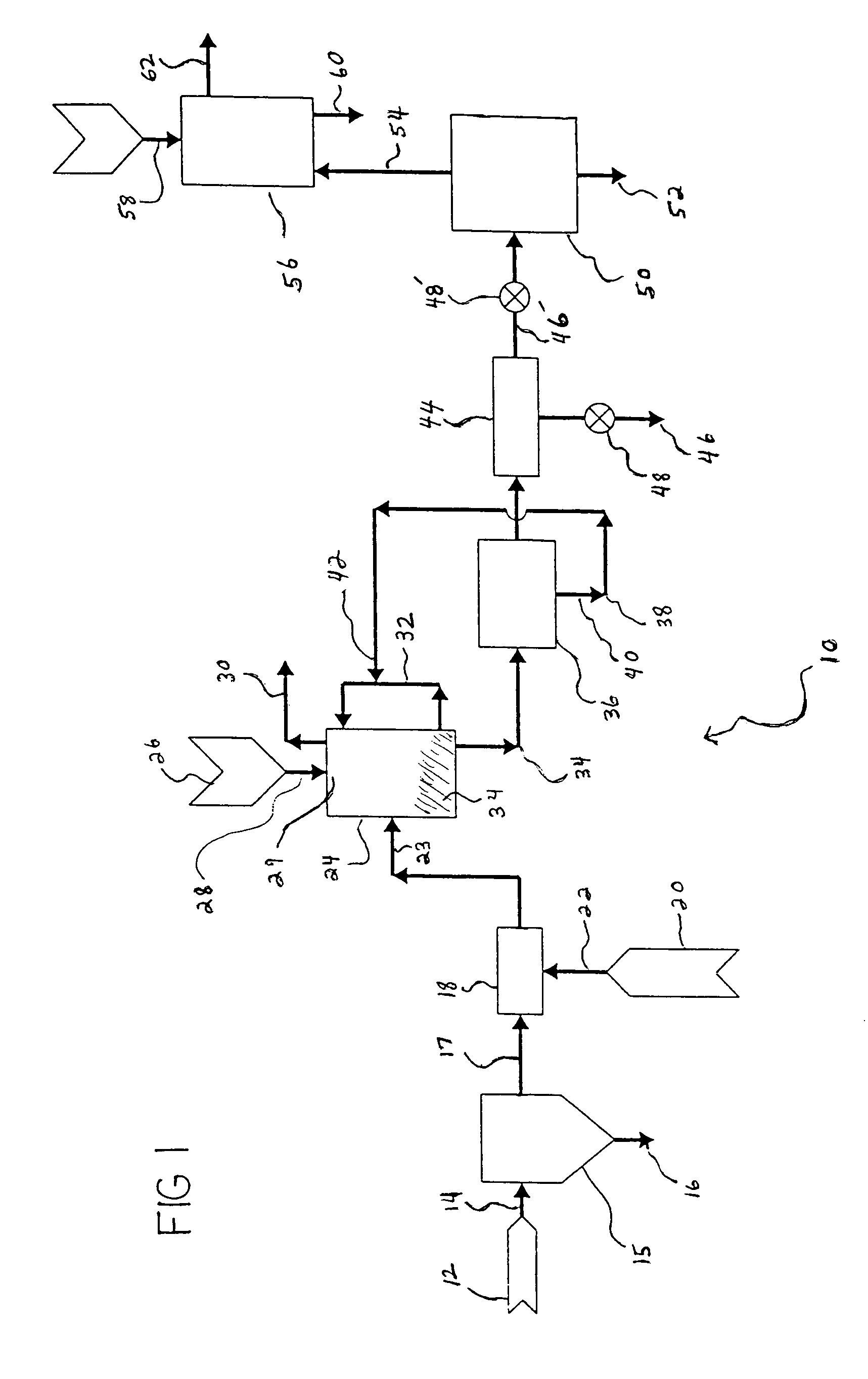

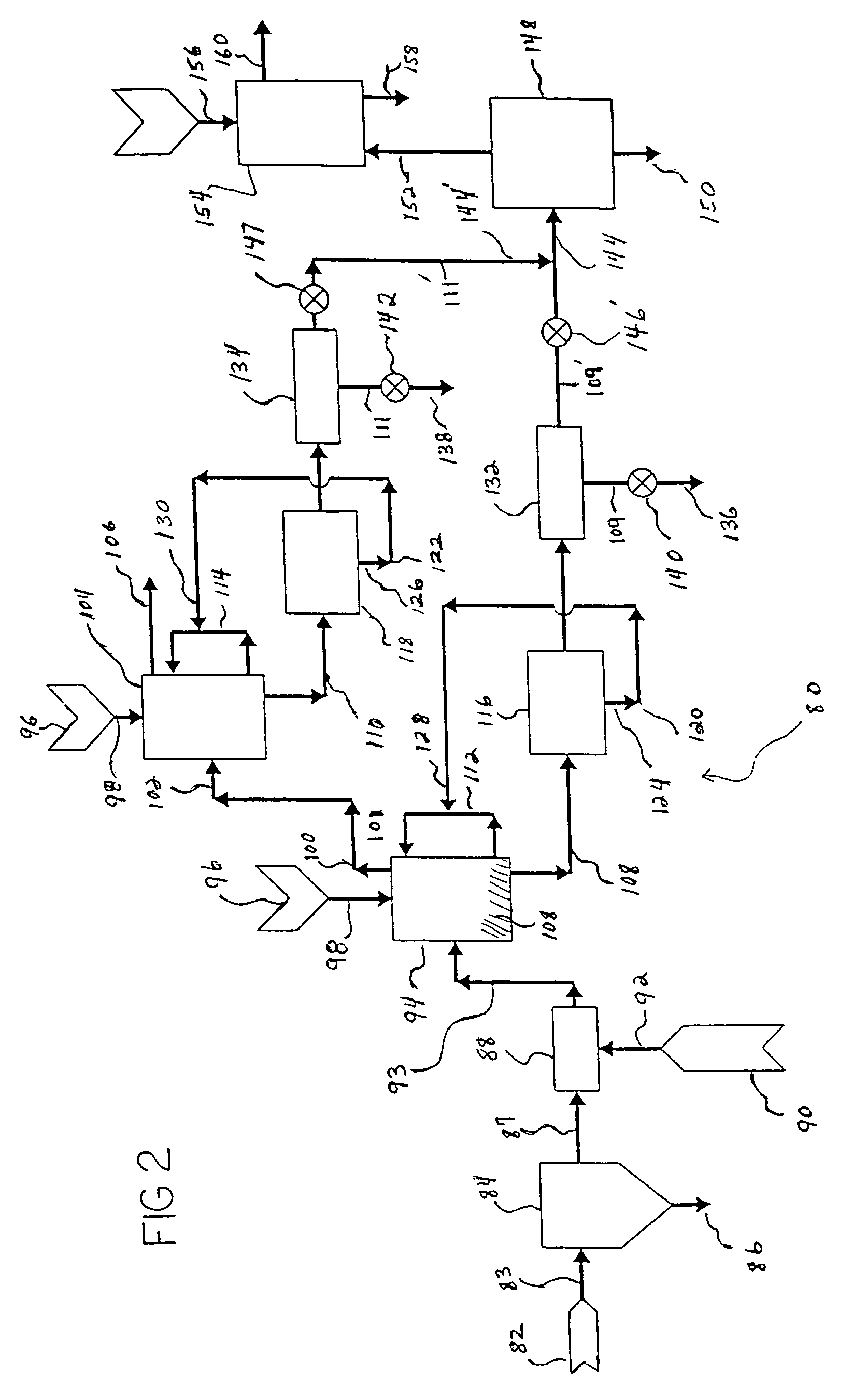

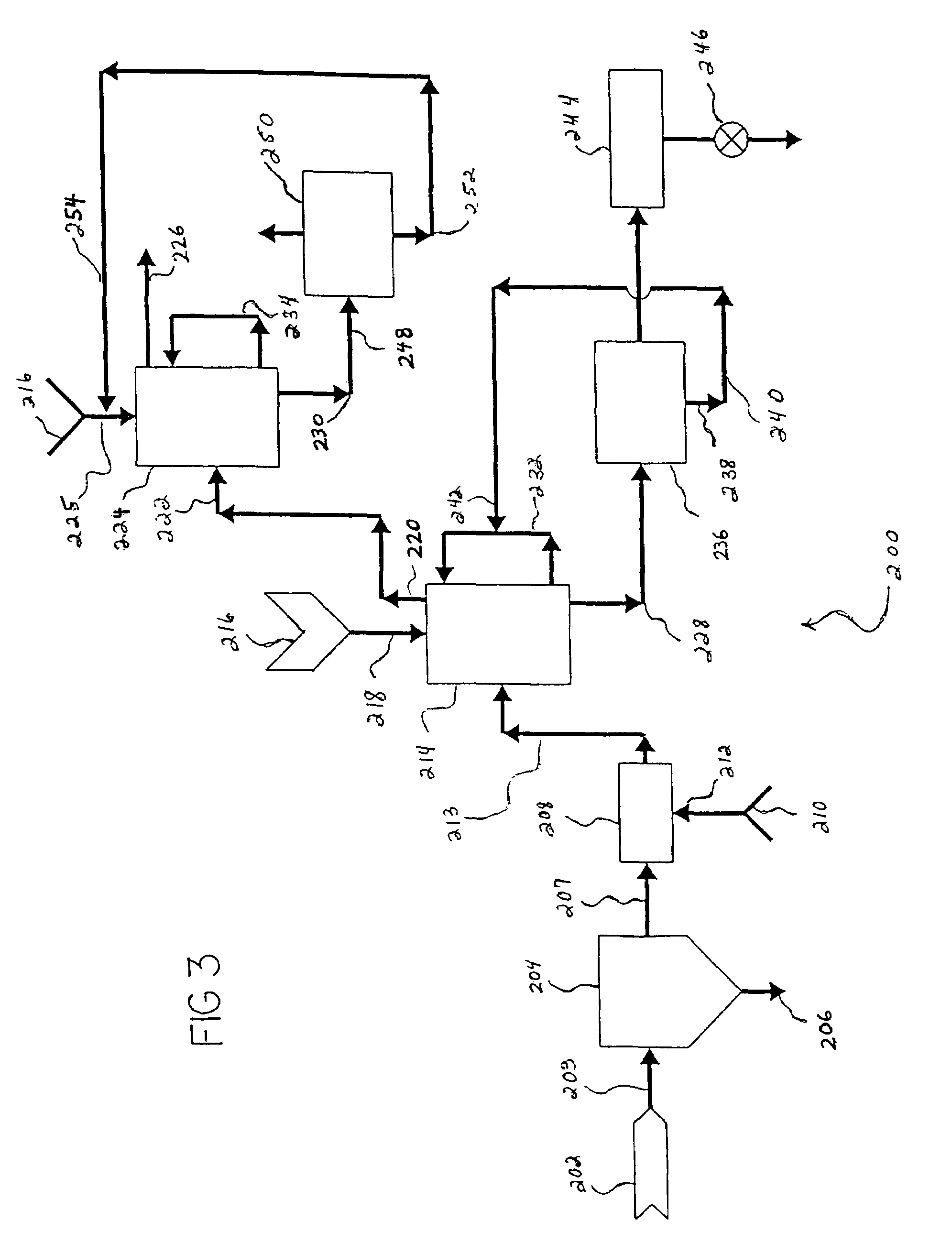

Power plant with emissions recovery

InactiveUS20100018218A1Reduce deliveryEnvironment safetySolidificationLiquefactionParticulatesNitrogen gas

A power plant including an air separation unit (ASU) arranged to separate nitrogen, oxygen, carbon dioxide and argon from air and produce a stream of substantially pure liquid oxygen, nitrogen, carbon dioxide and argon; a steam generator, fired or unfired, arranged to combust a fuel, e.g., natural gas, liquefied natural gas, synthesis gas, coal, petroleum coke, biomass, municipal solid waste or any other gaseous, liquid or solid fuel in the presence of air and a quantity of substantially pure oxygen gas to produce an exhaust gas comprising water, carbon dioxide, carbon monoxide, nitrogen oxides, nitrogen, sulfur oxides and other trace gases, and a steam-turbine-generator to produce electricity, a primary gas heat exchanger unit for particulate / acid gas / moisture removal and a secondary heat exchanger arranged to cool the remainder of the exhaust gases from the steam generator. Exhaust gases are liquefied in the ASU thereby recovering carbon dioxide, nitrogen oxides, nitrogen, sulfur oxides, oxygen, and all other trace gases from the steam generator exhaust gas stream. The cooled gases are liquefied in the ASU and separated for sale or re-use in the power plant. Carbon dioxide liquid is transported from the plant for use in enhanced oil recovery or for other commercial use. Carbon dioxide removal is accomplished in the ASU by cryogenic separation of the gases, after directing the stream of liquid nitrogen from the air separation unit to the exhaust gas heat exchanger units to cool all of the exhaust gases including carbon dioxide, carbon monoxide, nitrogen oxides, nitrogen, oxygen, sulfur oxides, and other trace gases.

Owner:TRIENCON SERVICES

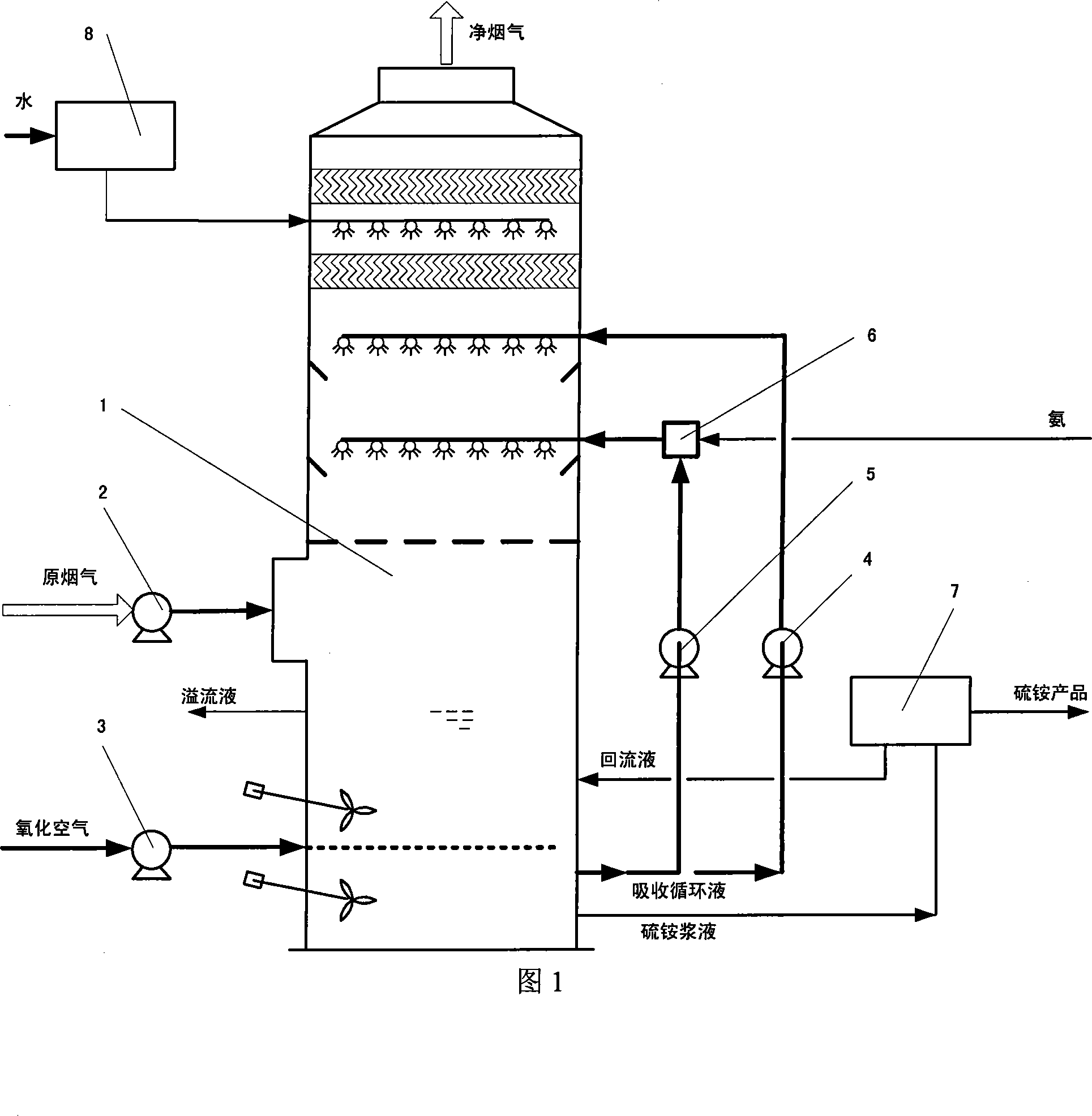

Multi-component removal in flue gas by aqua ammonia

InactiveUS7255842B1Regeneration process is less-costlyIncrease load capacityGas treatmentNitrogen compoundsNitric oxideSlurry

A new method for the removal of environmental compounds from gaseous streams, in particular, flue gas streams. The new method involves first oxidizing some or all of the acid anhydrides contained in the gas stream such as sulfur dioxide (SO2) and nitric oxide (NO) and nitrous oxide (N2O) to sulfur trioxide (SO3) and nitrogen dioxide (NO2). The gas stream is subsequently treated with aqua ammonia or ammonium hydroxide which captures the compounds via chemical absorption through acid-base or neutralization reactions. The products of the reactions can be collected as slurries, dewatered, and dried for use as fertilizers, or once the slurries have been dewatered, used directly as fertilizers. The ammonium hydroxide can be regenerated and recycled for use via thermal decomposition of ammonium bicarbonate, one of the products formed. There are alternative embodiments which entail stoichiometric scrubbing of nitrogen oxides and sulfur oxides with subsequent separate scrubbing of carbon dioxide.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Process for mitigation of wellbore contaminants

InactiveUS6942037B1Lessened potential hazardSimple treatmentCleaning apparatusFluid removalFoaming agentWater flow

A method is disclosed for intermittently mitigating hazardous sulfur compounds, such as hydrogen sulfide, mercaptans and sulfur oxides, from a fluid in the head space of a wellbore. The method comprises contacting the fluid with a foamed aqueous stream comprising an active scavenging agent, such as a triazine, and a stiff foaming agent. The scavenging agent reacts with hazardous sulfur compounds to eliminate the compounds from the fluid stream in the vapor space of the wellbore without withdrawing the hydrocarbon from the wellbore and without releasing hazardous sulfur compounds to the environment.

Owner:CLARIANT INT LTD

Method for removing mercury vapor in gas

When sulfur oxides are present in mercury vapor-containing gas, the adsorption of mercury vapor by activated carbon is inhibited. Therefore, there has been demand for development of a method for effective adsorption removal of mercury vapor even in the coexistence of sulfur oxides.Efficient and long-term removal of mercury vapor was made successful by contacting an activated carbon adsorbent consisting of 100 parts by weight of activated carbon impregnated with 5 to 70 parts by weight of only an alkali metal halide, with mercury vapor in sulfur oxide-containing gas.

Owner:JAPAN ENVIROCHEM

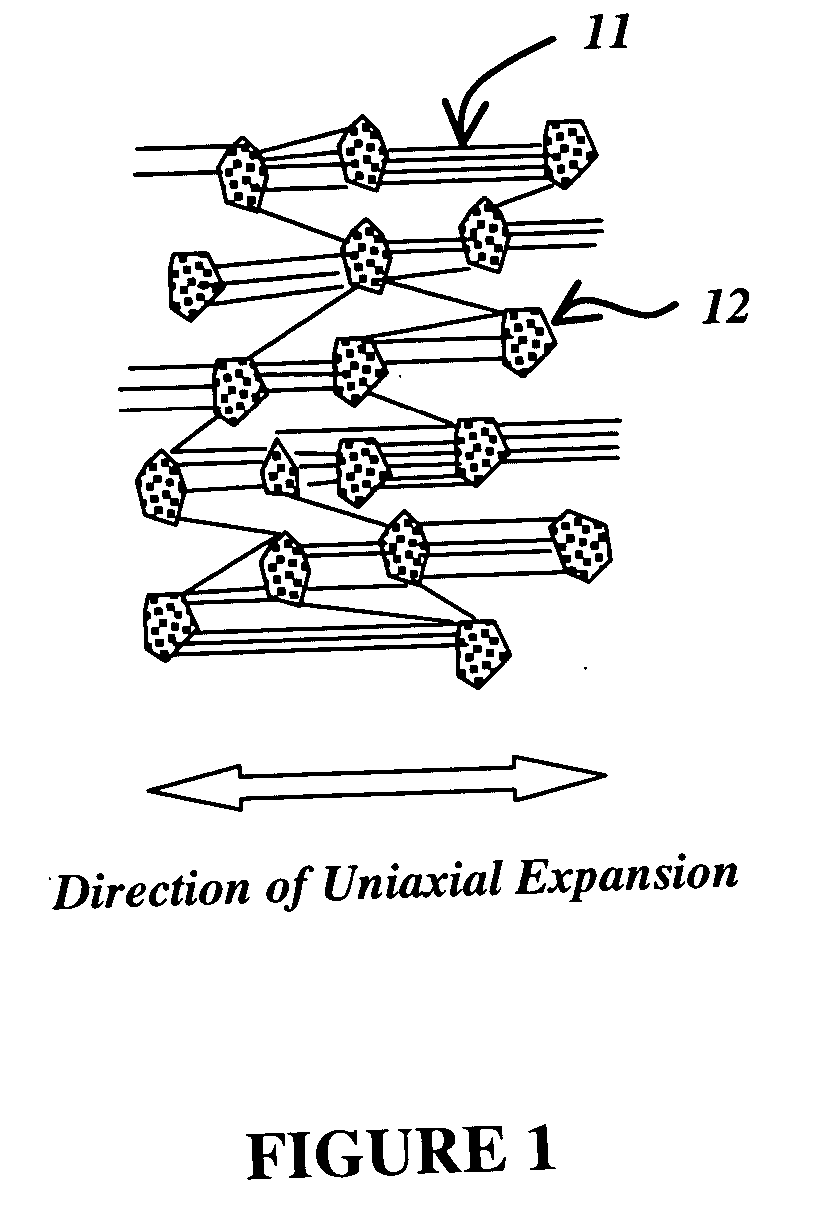

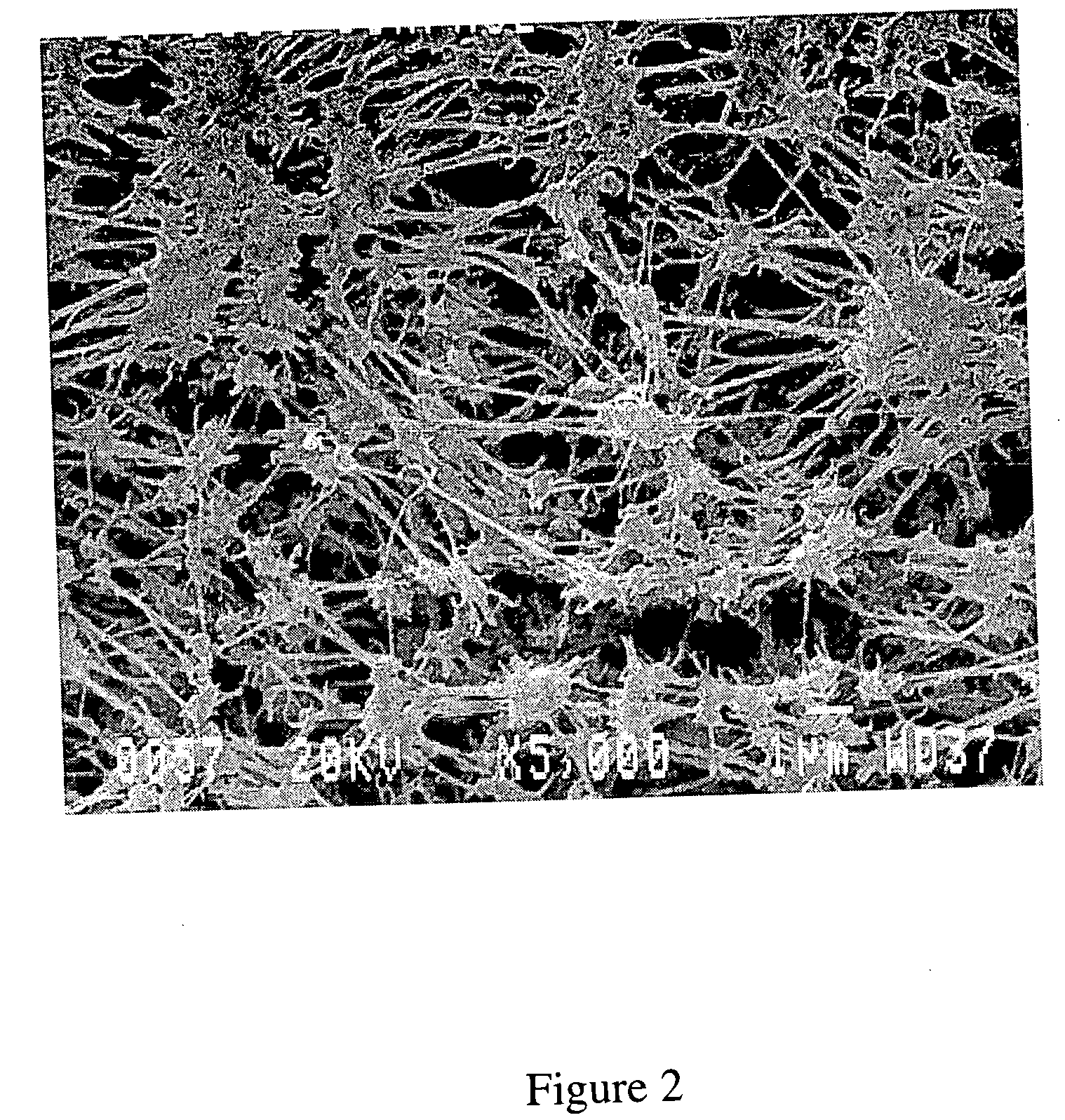

Flue gas purification process using a sorbent polymer composite material

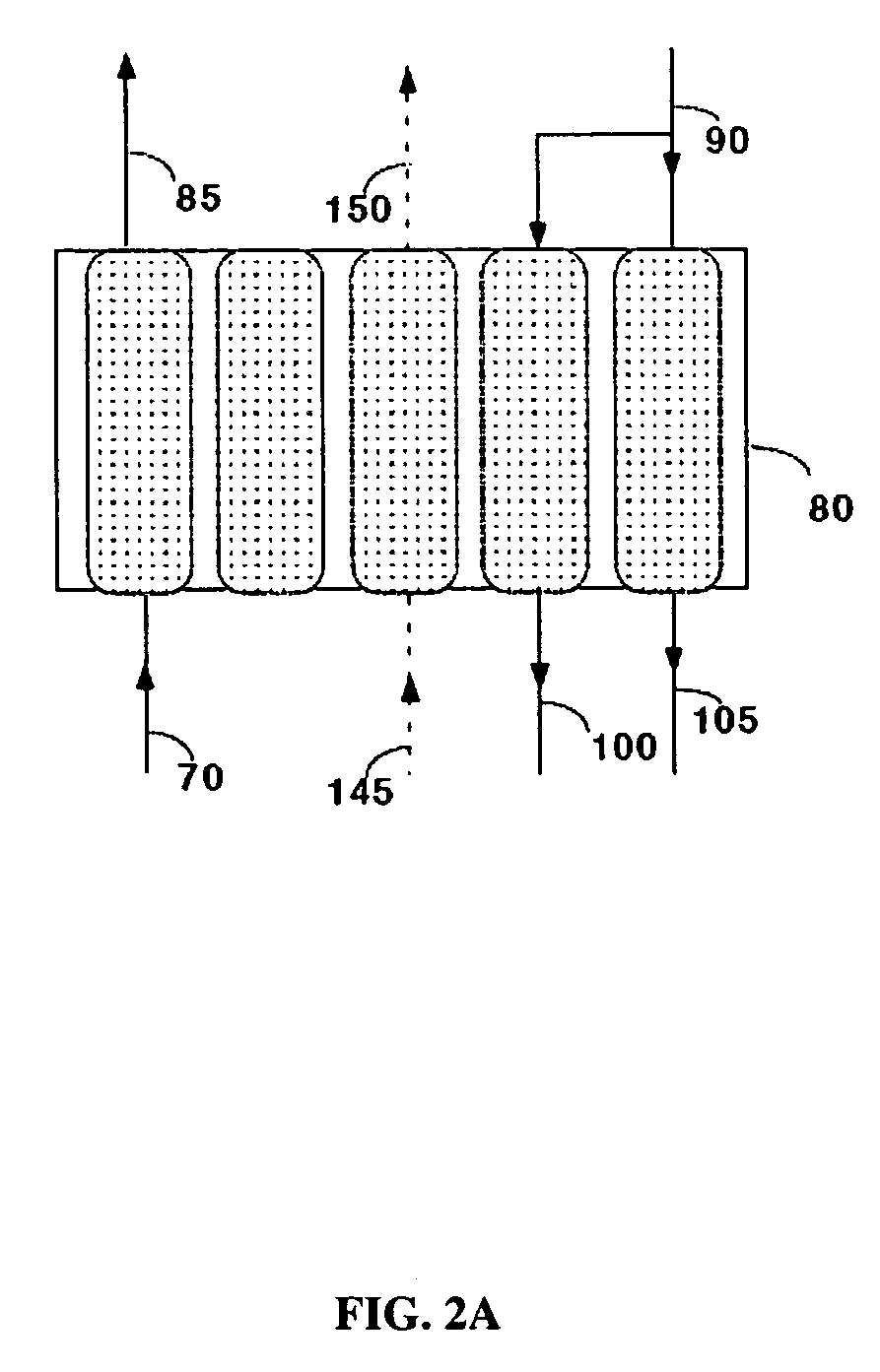

ActiveUS20050019240A1Easy to fixImprove removal efficiencyGas treatmentNitrogen compoundsSorbentFluoropolymer

This invention provides a process of removing sulfur oxides, mercury vapor, and fine particulate matters from industrial flue gases that contain such pollutants. The pollutants are removed by modules, which contain microporous adsorbent (i.e., sorbent) material that is held within a polymer matrix. The preferred polymers are fluoropolymers. The composite material that contains the microporous absorbent material held within a polymer matrix removes sulfur oxides by converting them into high concentration sulfuric acids. It also removes mercury vapor by chemically adsorbing the mercury into the matrix. It also removes fine particulate matters by surface filtration. The sulfuric acid that is produced inside the composite material is automatically expelled onto the external surfaces of the composite material and is drained into an acid reservoir together with the fine particulate matters which are washed from the external surfaces of the composite material by the constant dripping of the sulfuric acid along the external surfaces of the composite material.

Owner:WL GORE & ASSOC INC

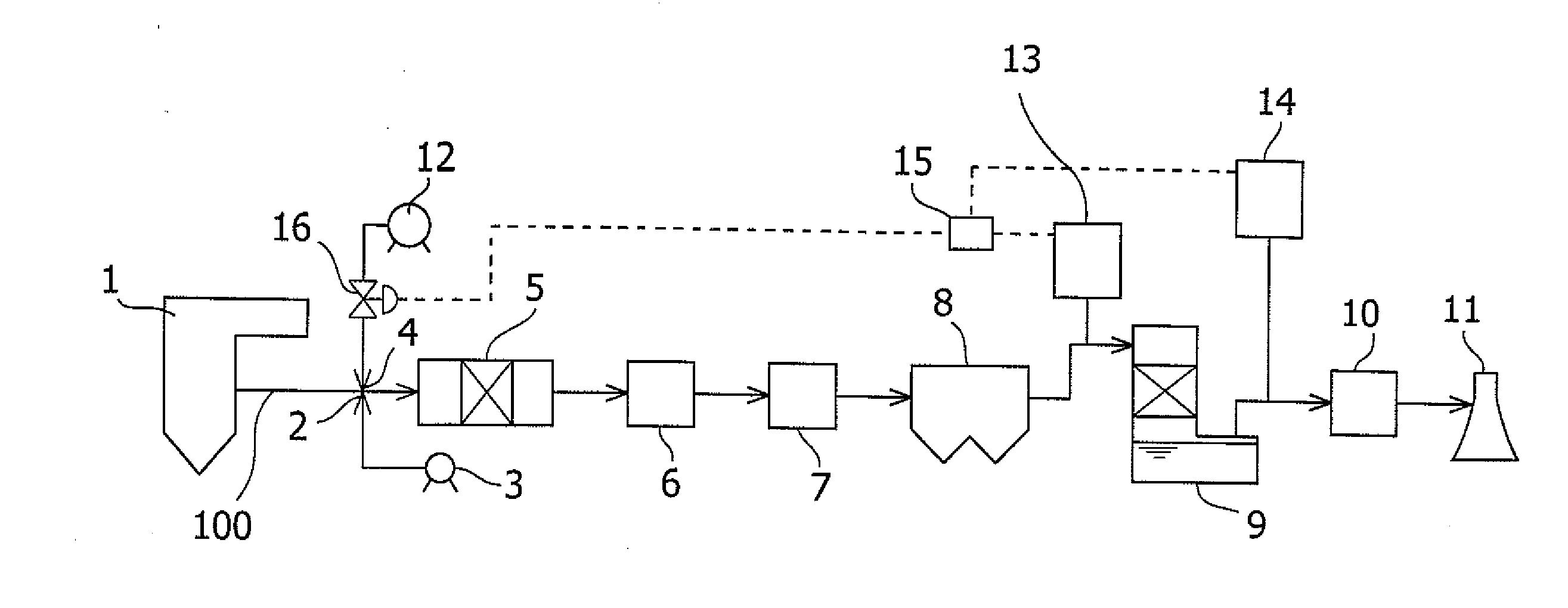

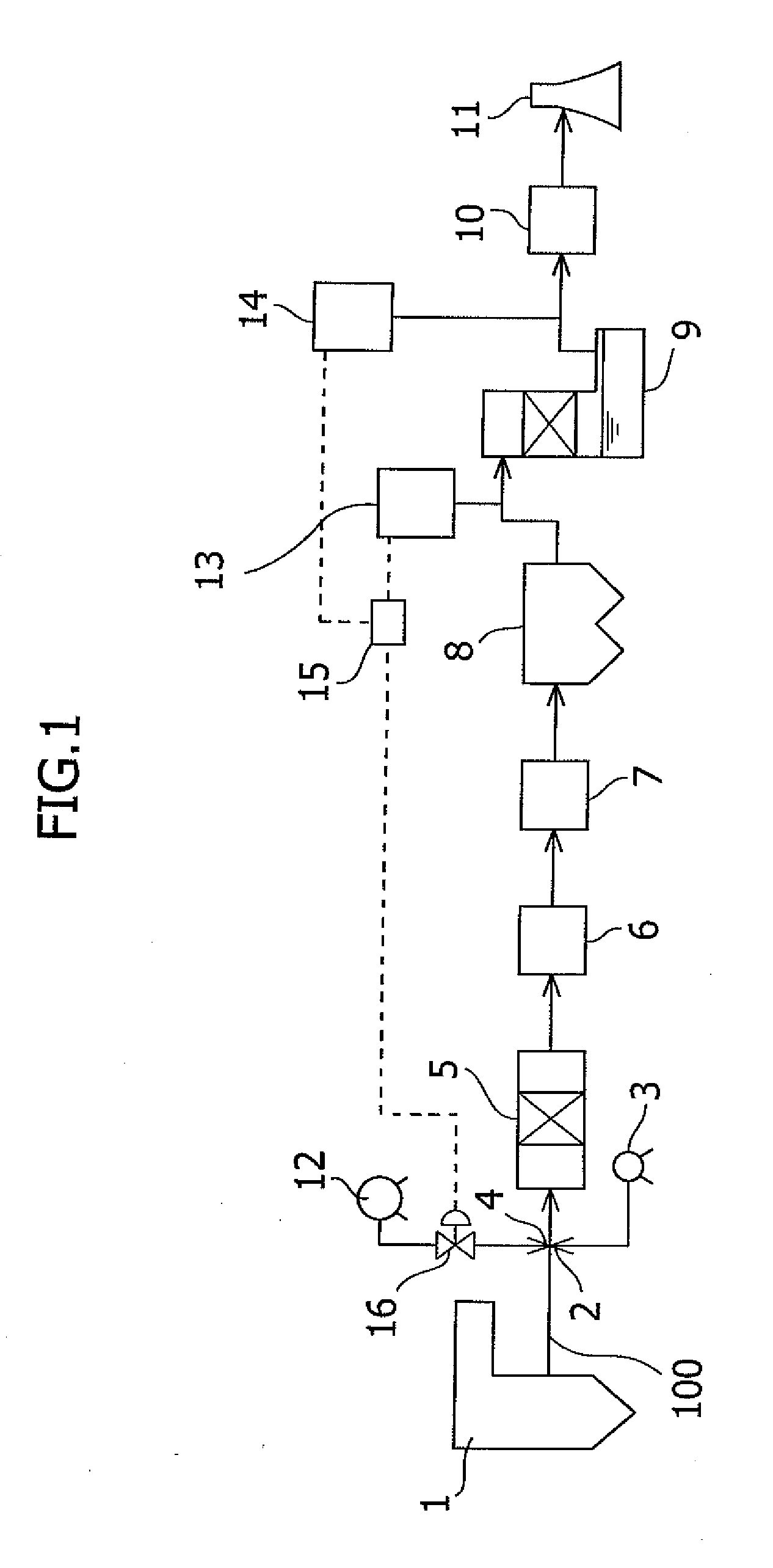

Flue gas control system of coal combustion boiler and operating method thereof

ActiveUS8071060B2Reduce operating costsCombination devicesNitrogen compoundsAir preheaterParticulates

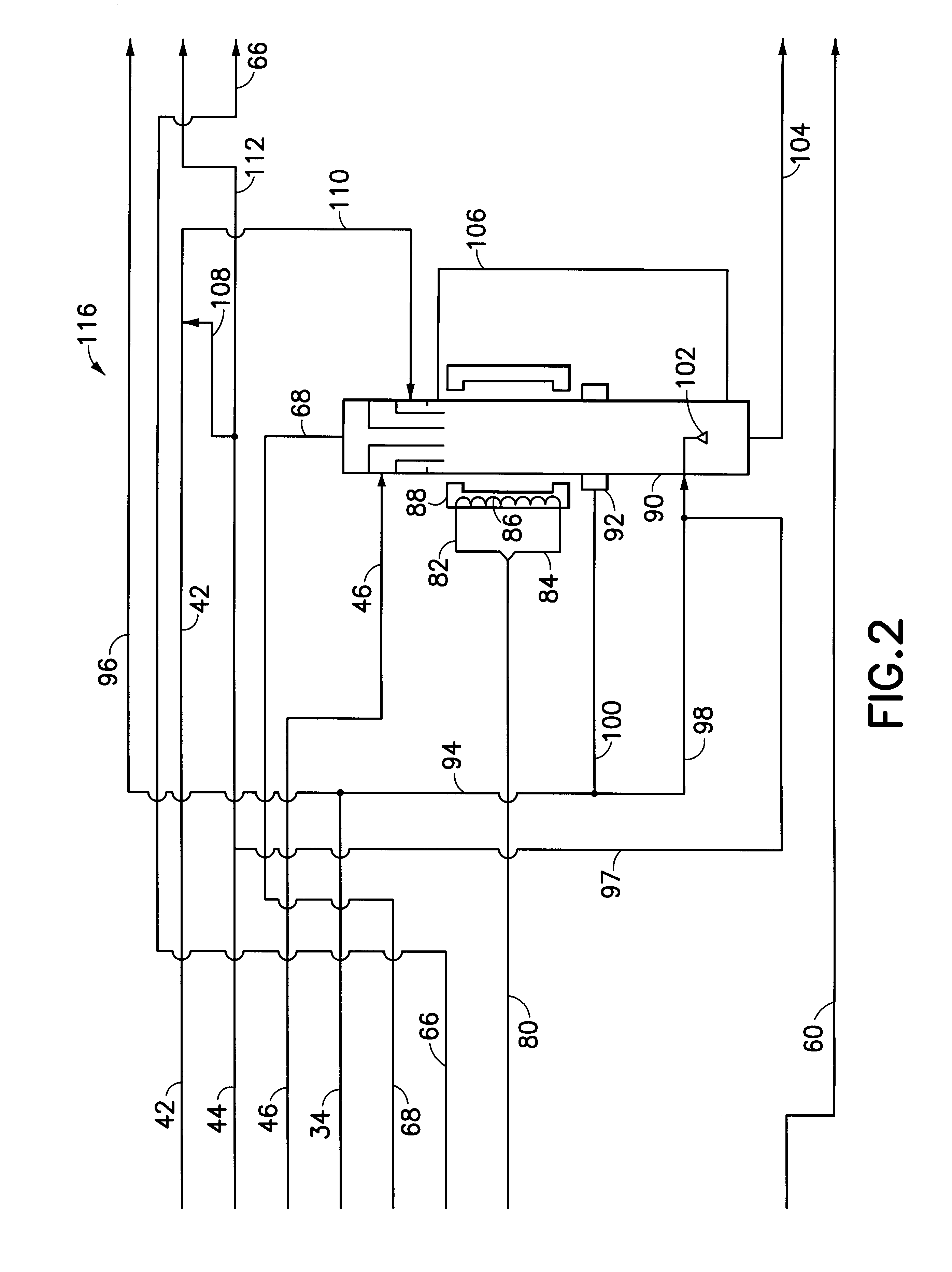

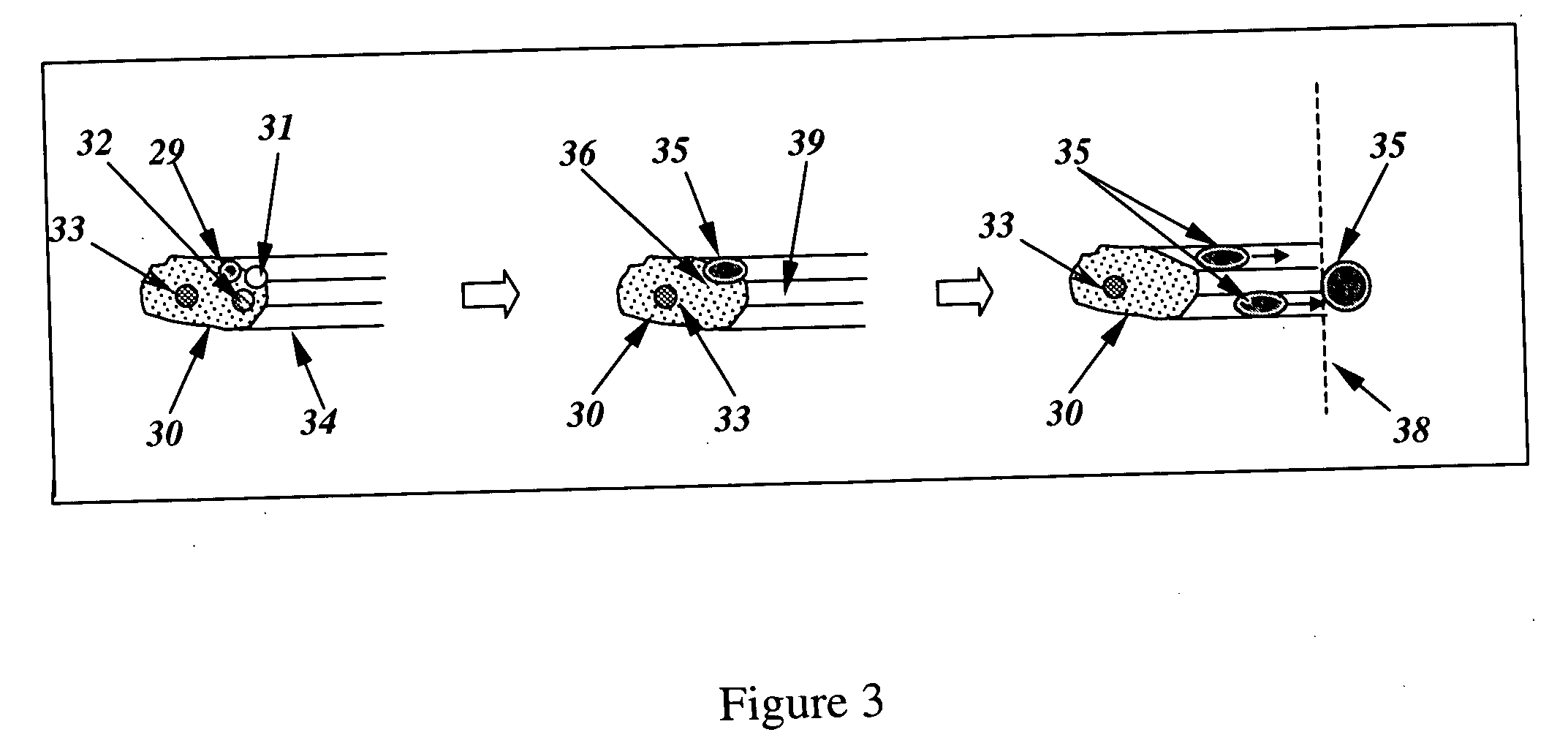

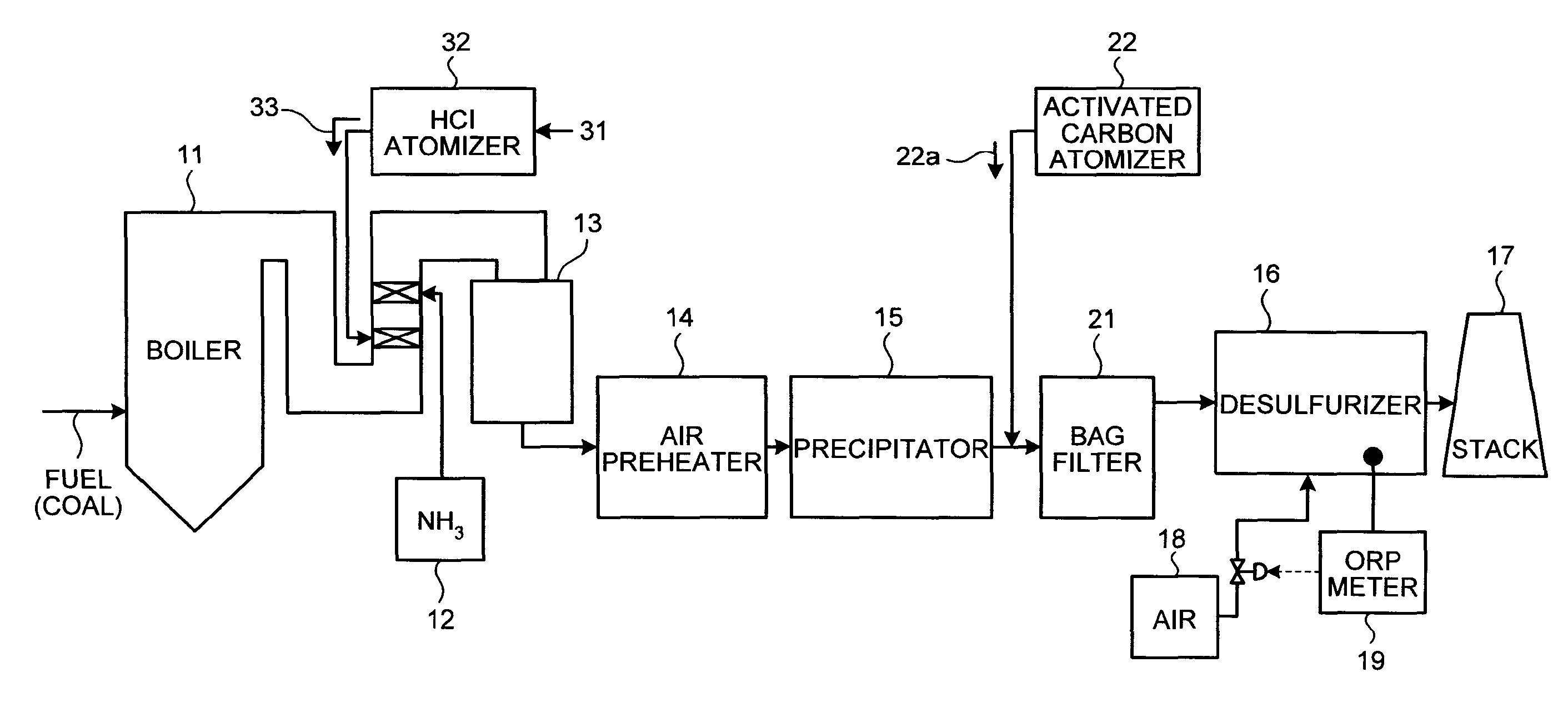

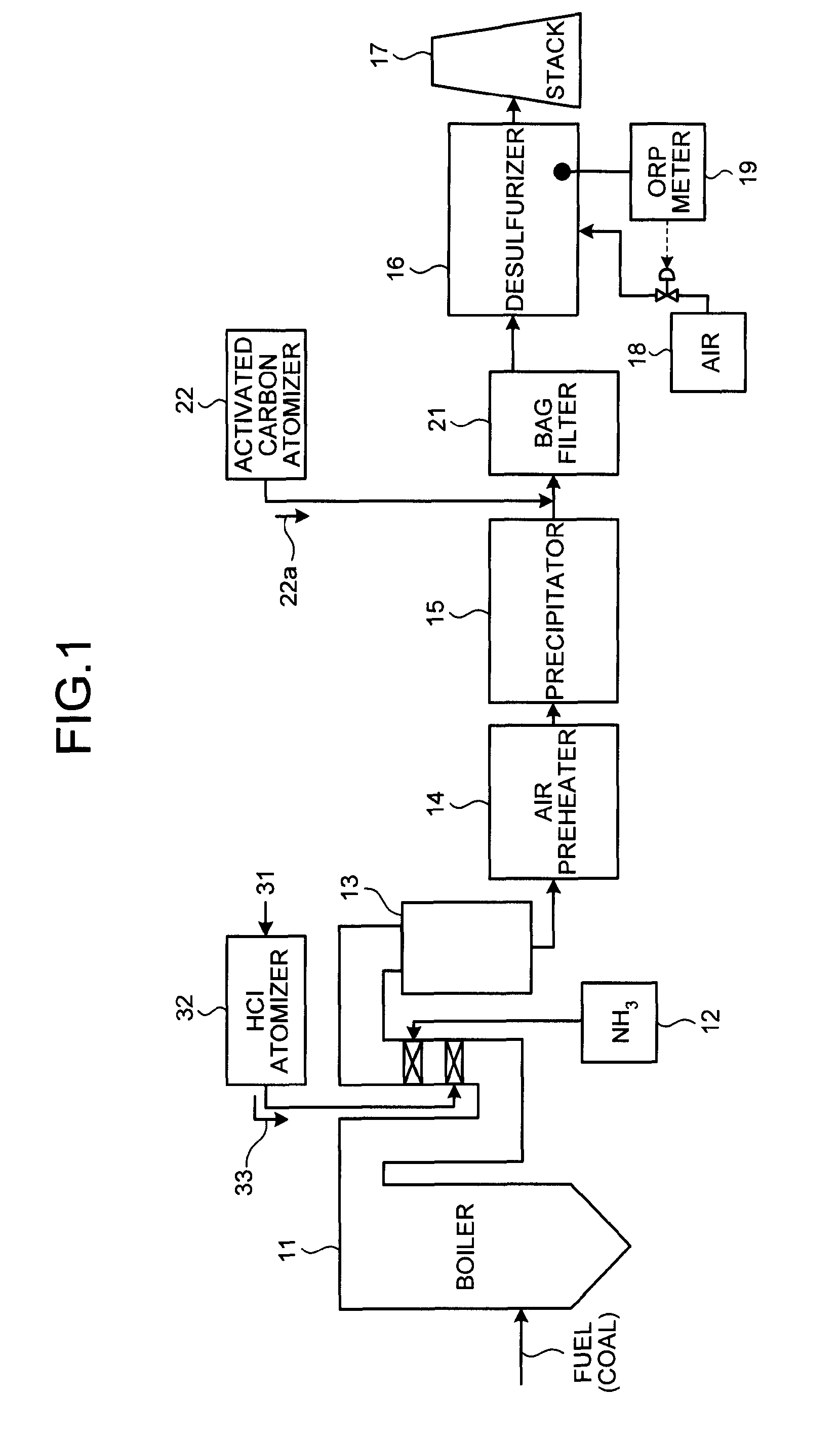

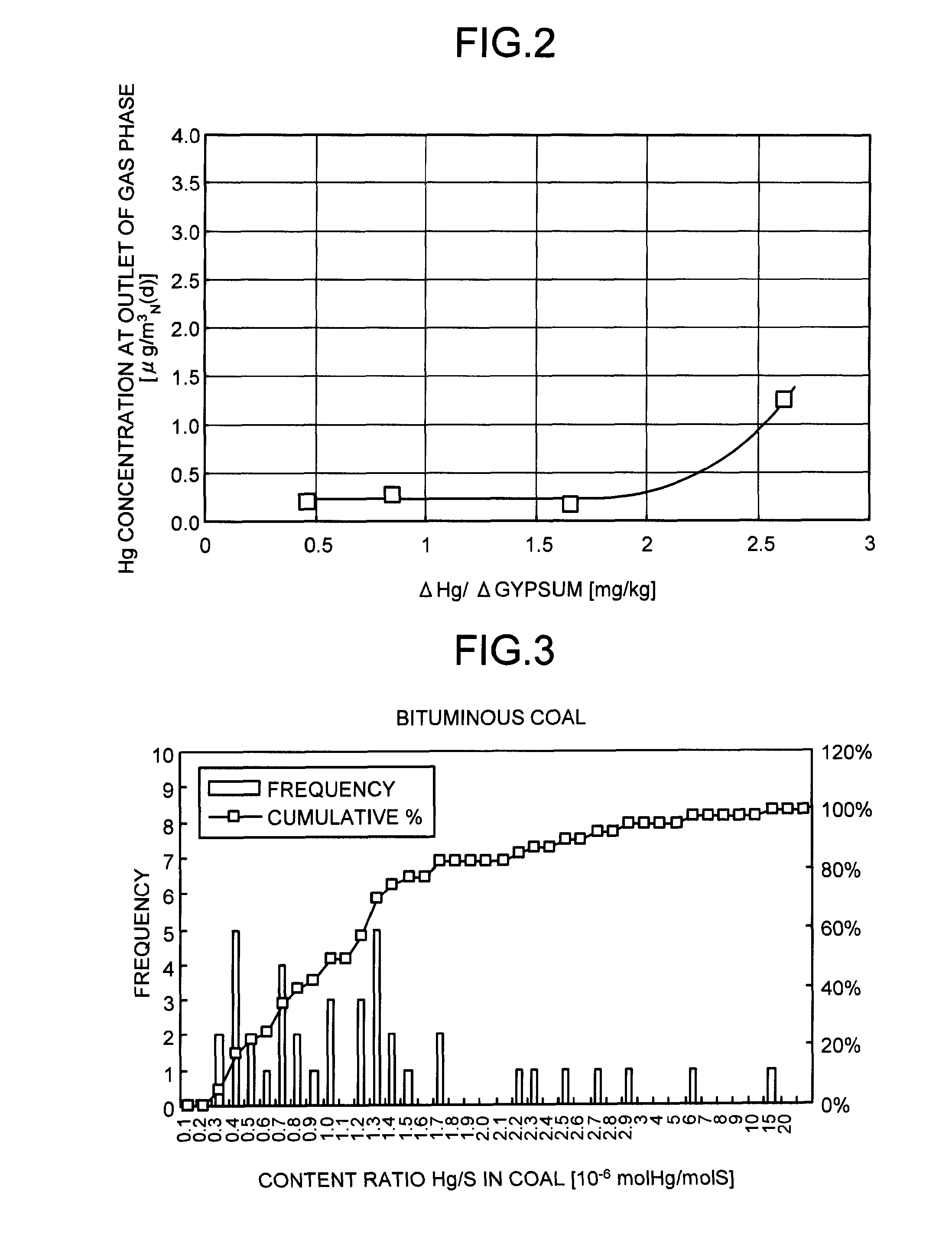

A flue gas control system of a coal combustion boiler comprises an HCl atomizer that sprays hydrogen chloride to flue gas from a coal combustion boiler that uses coal as a fuel; NOx removing apparatus that removes nitrogen oxides by ammonia denitration by adding ammonia to the flue gas after spraying hydrogen chloride and oxidizes mercury; an air preheater that recovers heat in the gas after removal of nitrogen oxides; a precipitator that removes particulates in the gas; an activated carbon atomizer that sprays activated carbon into the gas after particulate collection; a bag filter that collects activated carbon having adsorbed mercury; a desulfurizer that removes sulfur oxides in the flue gas after removal of activated carbon; a stack that discharges the gas which has undergone desulfurization to outside; and an ORP meter that measures an oxidation reduction potential for feeding air to a slurry absorbent in the desulfurizer.

Owner:MITSUBISHI HEAVY IND LTD

Amino acid ion liquid for acidic gas absorption

The present invention relates to amino acid ion liquid for absorbing acidic gas. The anion of ion liquid is amino acid, amino acid ramification, similar to amino acid ion, imidazole cation, phosphoric cation, amine cation, ammoniumate cation and etc. After dipping craft, all ions can adhere to poriferous solid to absorb acidic gas such as carbon dioxide, sulfur dioxide emitted by flue and motor vehicles.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

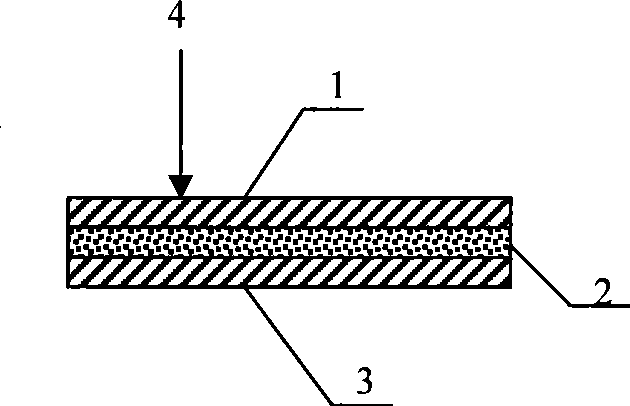

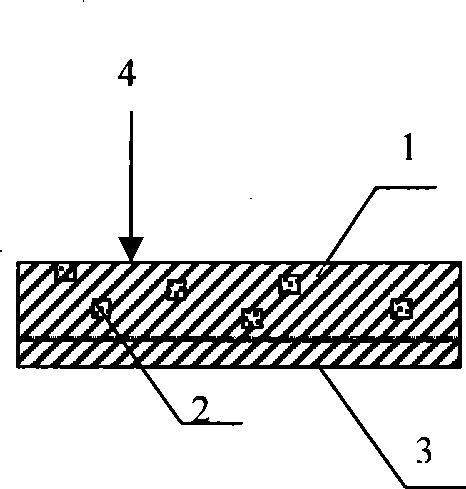

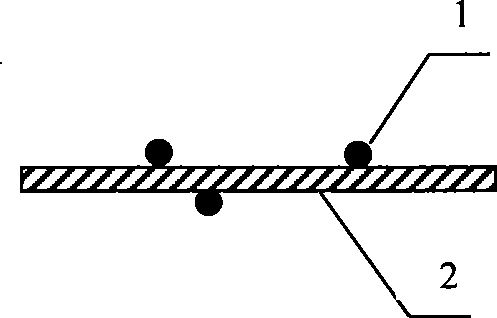

Functional filter felt for eliminating harmful constituents of fume, preparation method and application method thereof

ActiveCN101518718AExtended service lifePrevent penetrationPhysical/chemical process catalystsDispersed particle separationNonwoven fabricHigh heat

The invention pertains to the technical field of fume purification. The provided functional filter felt for eliminating harmful constituents of fume can realize the desulfurization or denitration of fume when removing dust; the filter felt is made from fiber materials and a functional catalyst in a compound manner; when purifying the harmful constituents of fume, the filter felt filters the dusts in the fume with nonwoven fabrics made from high temperature-resistant fiber material and carries out a catalytic reaction to eliminate nitrogen oxides (NOX) and / or sulfur oxides (SOX) through the functional catalyst contained in the filter felt. The provided filter felt is applicable to fume dedusting devices, fume desulfurization devices and fume denitration devices in power plants, metallurgical plants and chemical plants, in particular to the manufacturing of bag type fume filter. Compared with the prior art, the invention simplifies the fume purifying processes, improves processing efficiency, effectively saves the investment and reduces operational expenses, thus being suitable for the modification of the existing fume dedusting device.

Owner:CHINESE TEXTILE ACAD

Methods and devices for reducing hazardous air pollutants

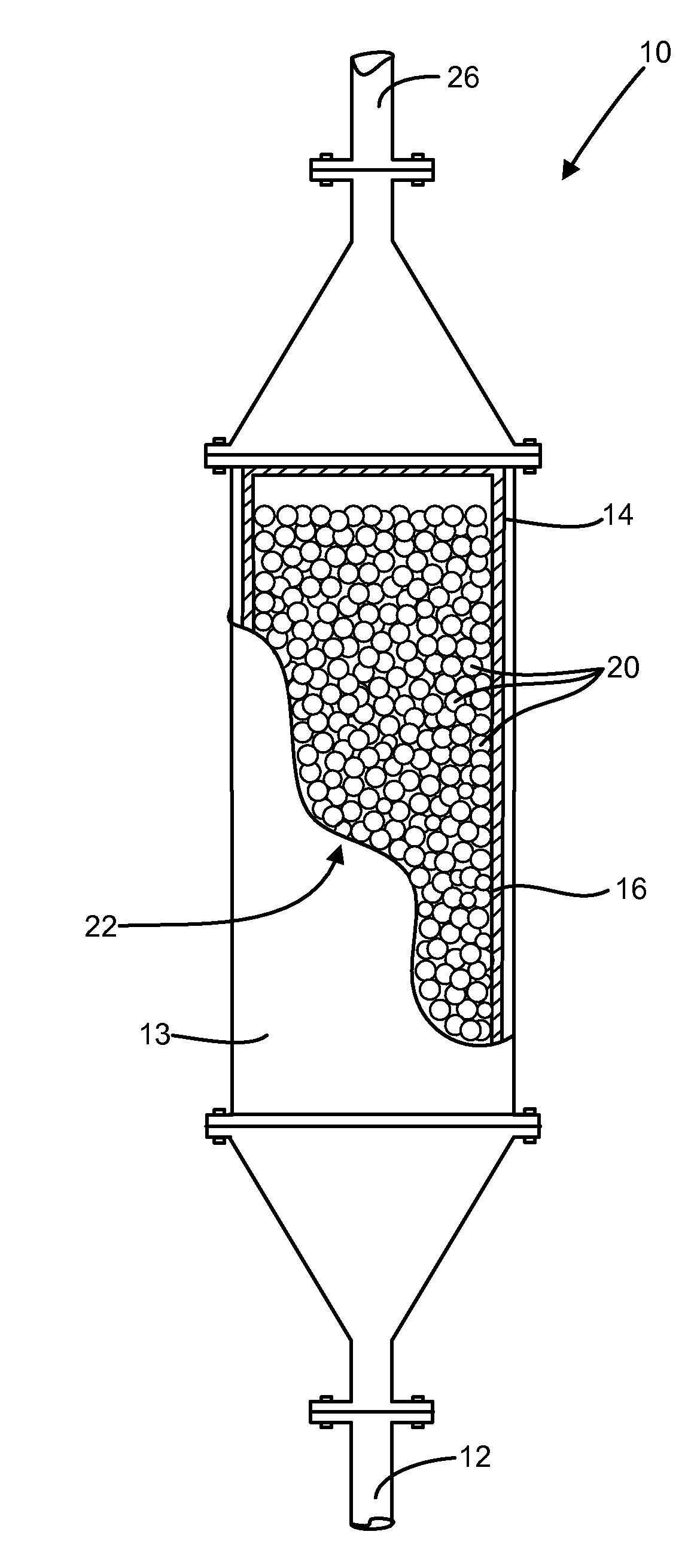

ActiveUS20090081093A1Reduce pollutionReduce the amount requiredCombination devicesCyanogen compoundsSlagSolid particle

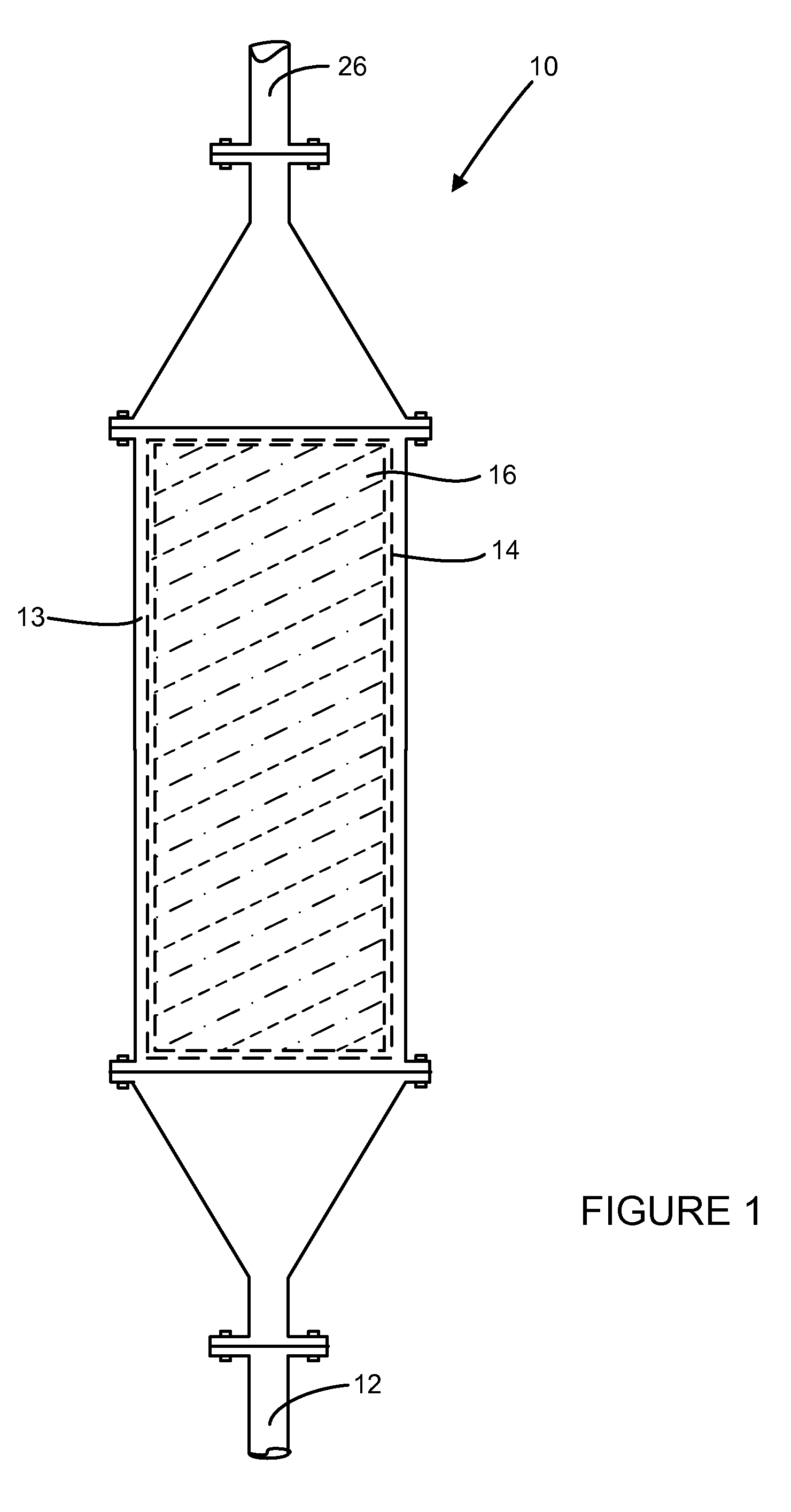

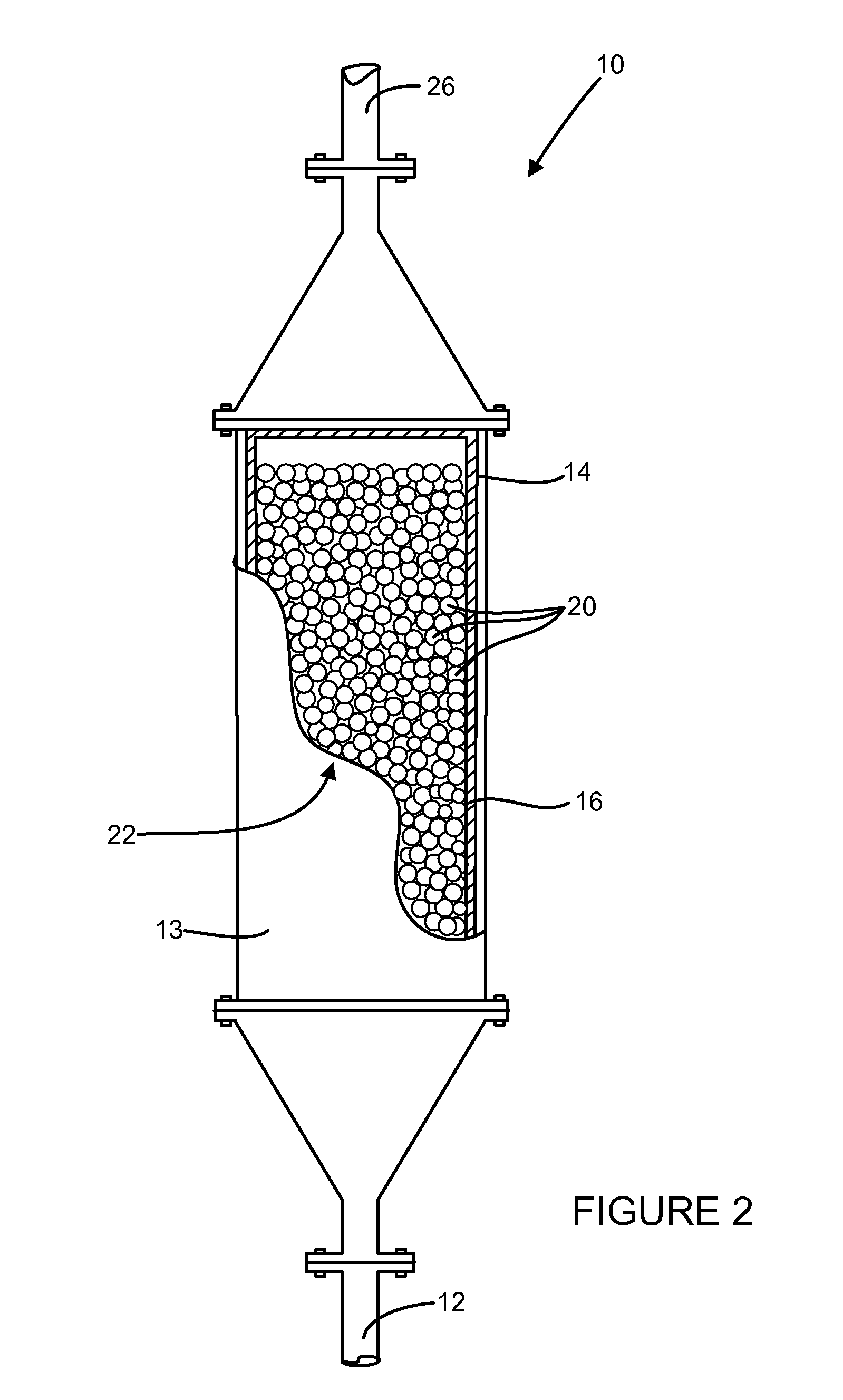

The disclosure provides methods and systems for sequestering and / or reducing sulfur oxides, nitrogen oxides and / or carbon dioxide present in industrial effluent fluid streams. A solid particulate material comprising a slag component, a binder component (distinct from the slag component), and optionally water is formed and then contacted with the effluent fluid stream to reduce at least one of the sulfur oxides, nitrogen oxides, and / or carbon dioxide. The contacting of the effluent stream may occur in a packed bed reactor with the solid dry particulate material. Methods of reducing pollutants from exhaust generated by combustion sources, lime and / or cement kilns, iron and / or steel furnaces, and the like are provided.

Owner:C QUEST TECH

Carbon dioxide recovery

Disclosed herein is a method and system for separating carbon dioxide (CO2) from a CO2 containing gas stream containing water vapor and additional impurities, for example, nitrogen, oxygen, sulfur oxides, nitrogen oxides, and mercury. The CO2 is captured by subjecting the CO2 gas feed stream to a temperature swing adsorption step. The temperature swing adsorption step comprises an adsorption step for producing a substantially dry carbon dioxide-depleted stream, and an adsorbent regeneration step comprising heating the adsorbent bed to produce a substantially water vapor-free carbon dioxide stream. Moisture from the gas stream containing CO2 is optionally removed by pressure swing adsorption, temperature swing adsorption, membrane separation, or absorption prior to CO2 capture.

Owner:INNOSEPRA LLC

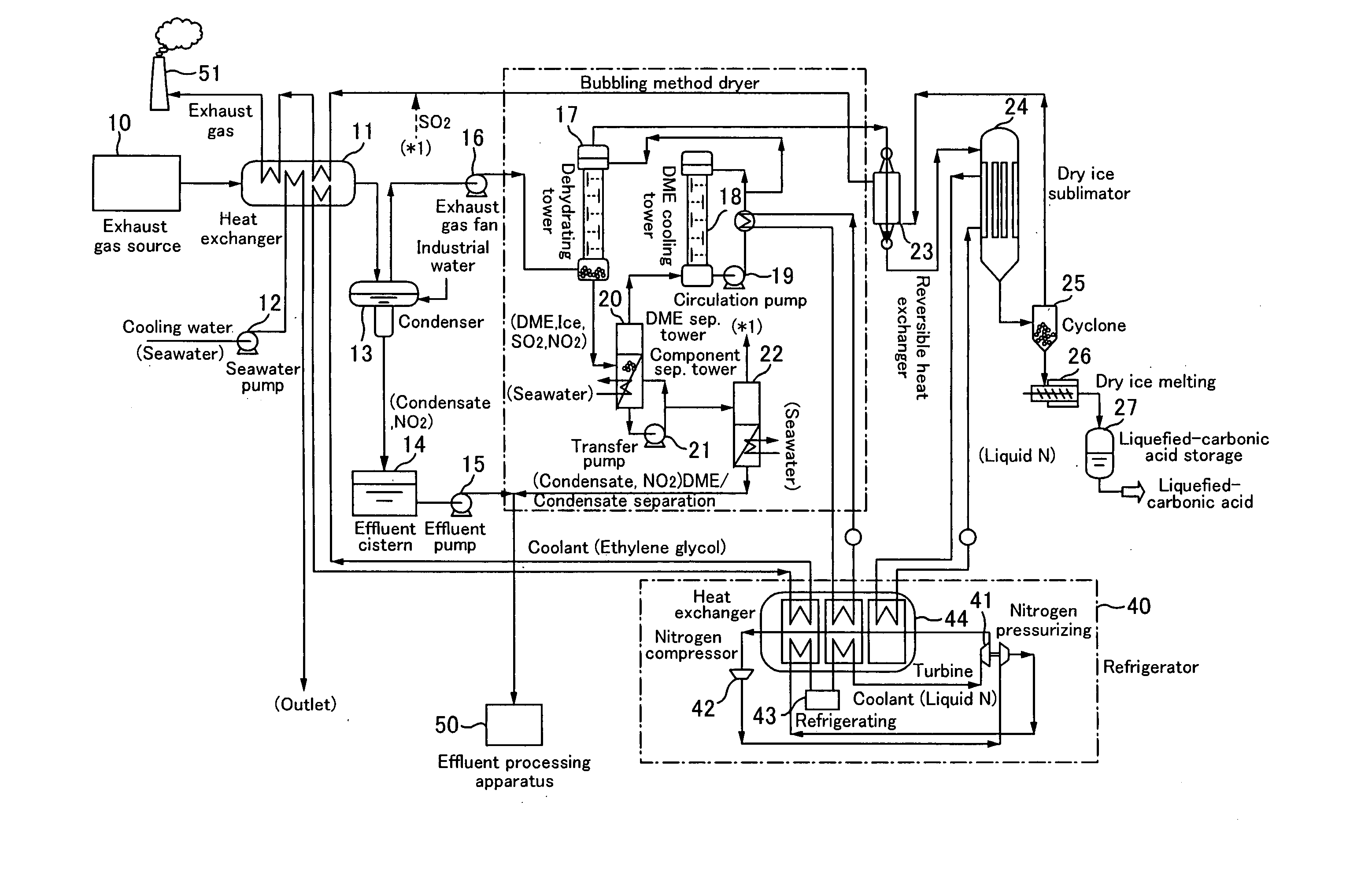

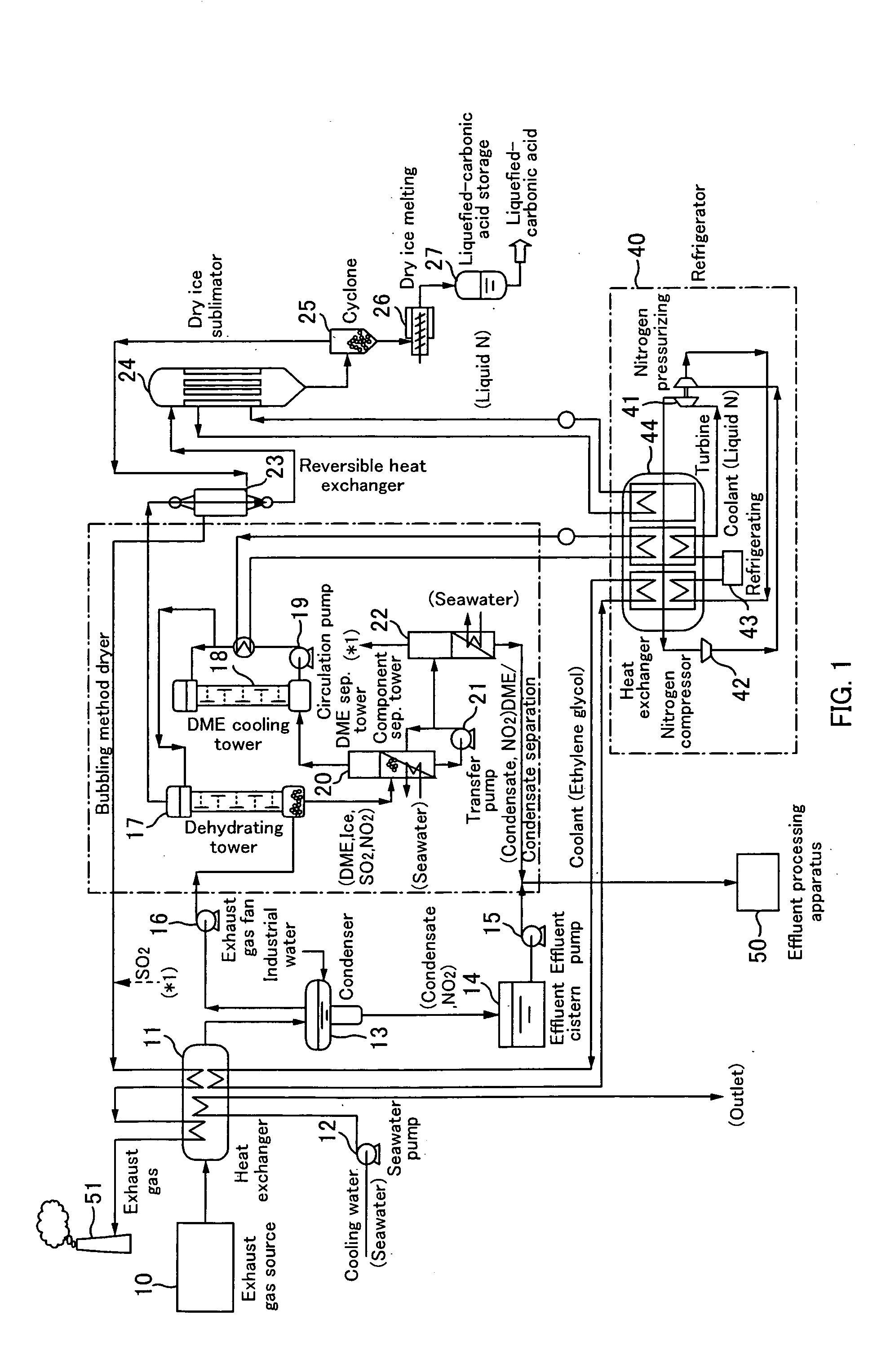

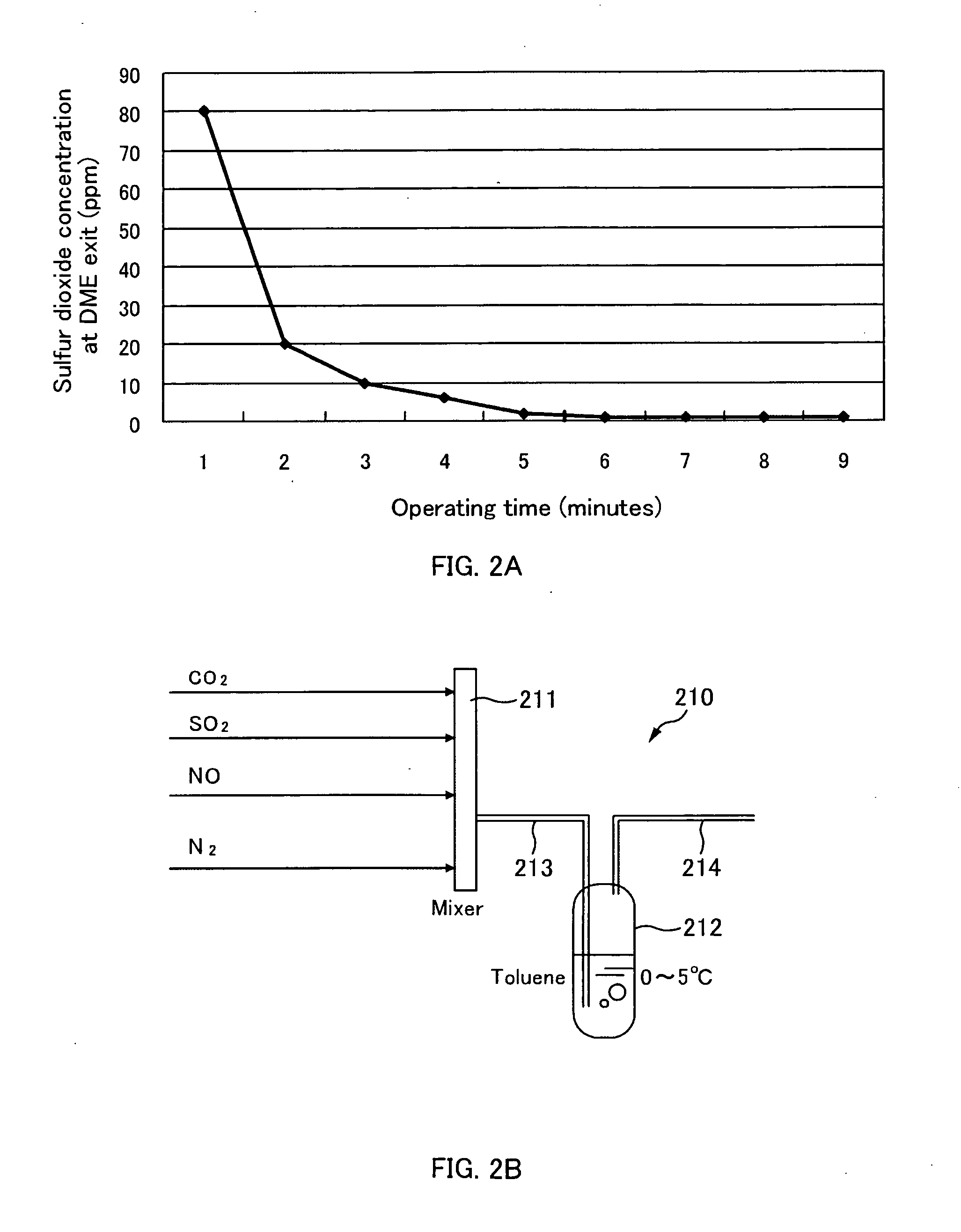

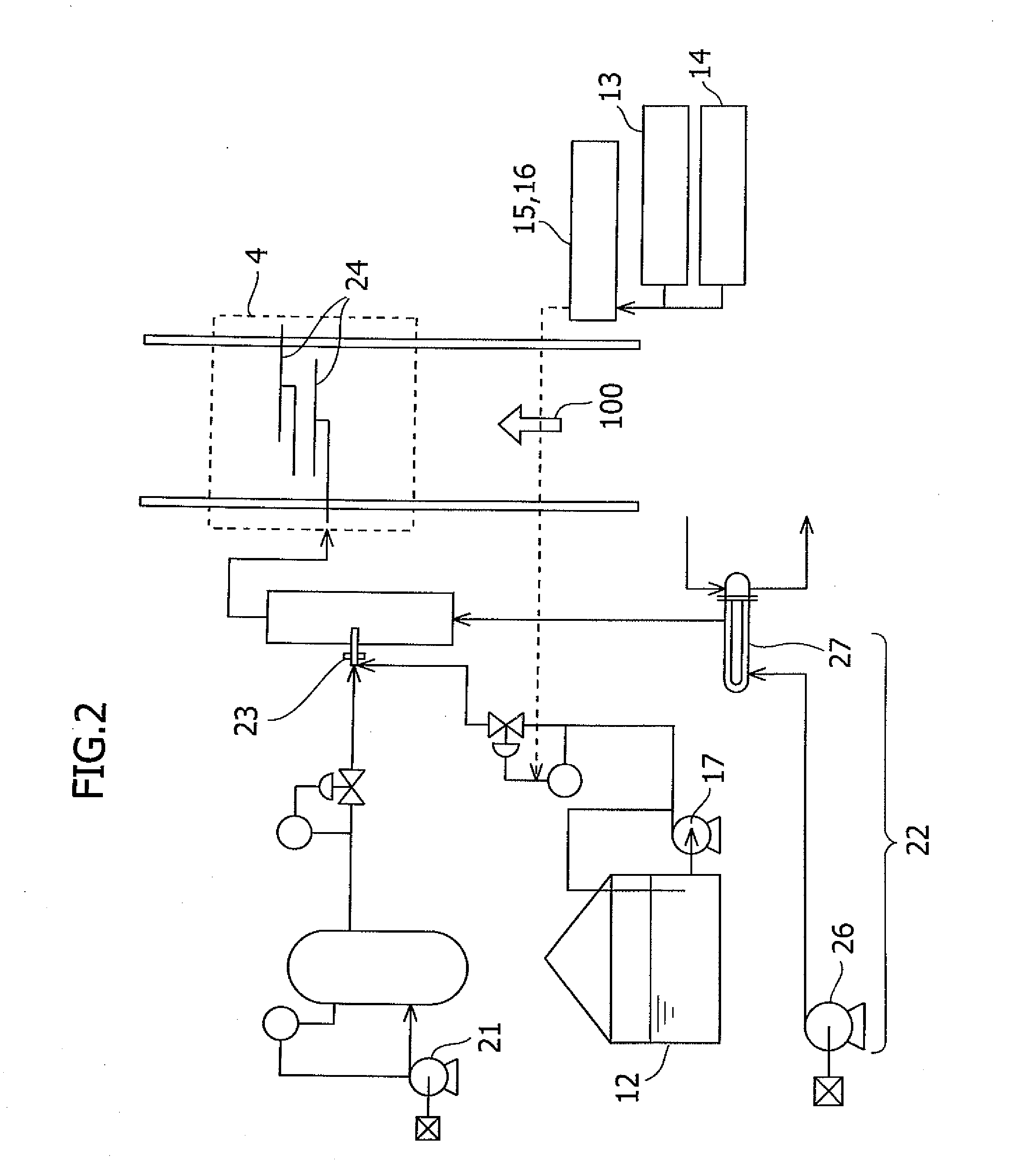

Method And System Of Processing Exhaust Gas, And Method And Apparatus Of Separating Carbon Dioxide

An exhaust gas processing method comprises making exhaust gas, exhausted from a coal burning boiler or an LNG burning boiler, flow through coolant to cool it to such a first temperature as to liquefy or solidify nitrogen oxides or sulfur oxides without solidifying carbon dioxide, thereby liquefying or solidifying nitrogen oxides or sulfur oxides as toxic gas components contained in the exhaust gas to separate them from the exhaust gas; removing moisture contained in the exhaust gas; and cooling the exhaust gas to such a second temperature as to solidify carbon dioxide, thereby solidifying carbon dioxide contained in the exhaust gas to separate it from the exhaust gas.

Owner:THE CHUGOKU ELECTRIC POWER CO INC +1

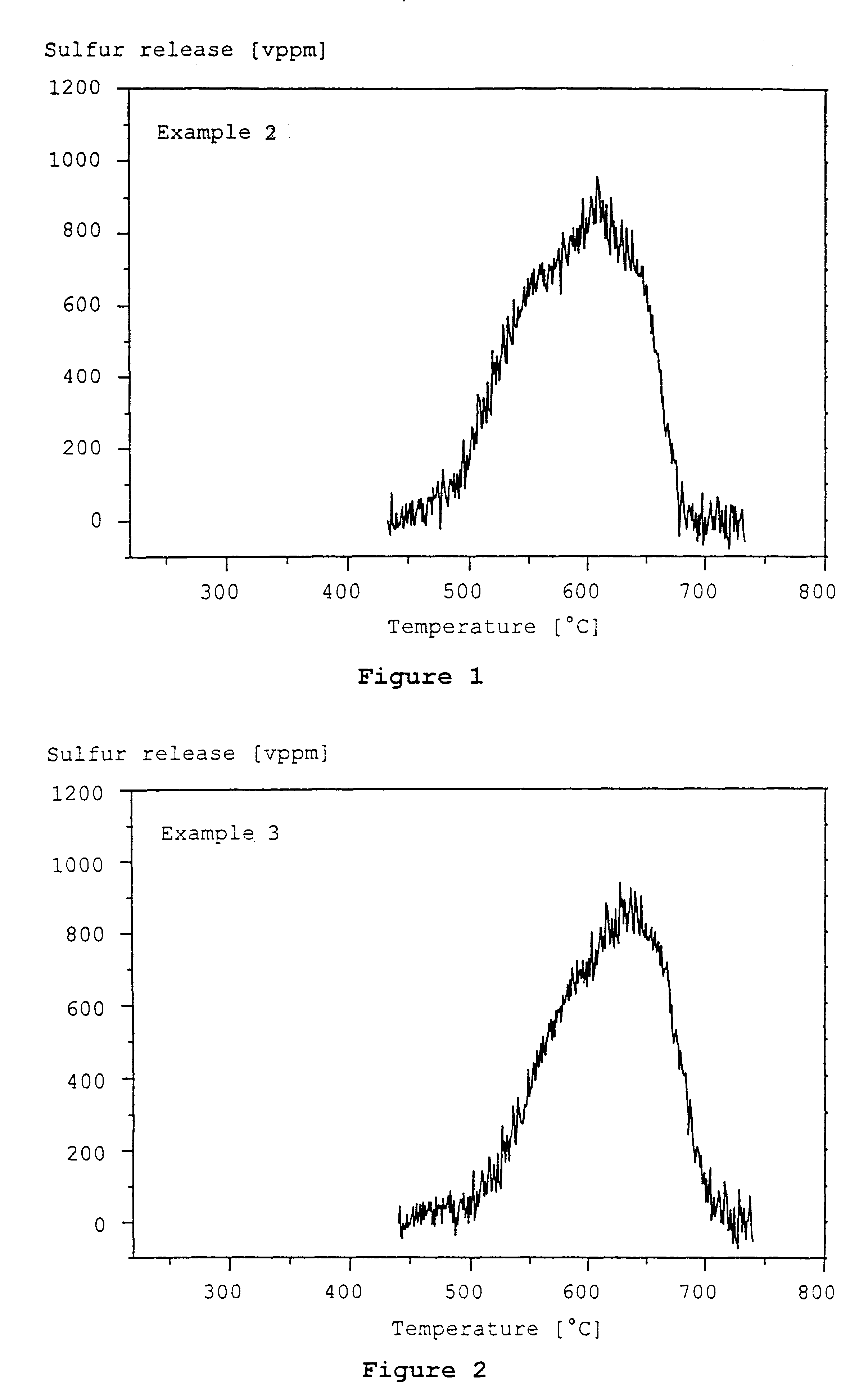

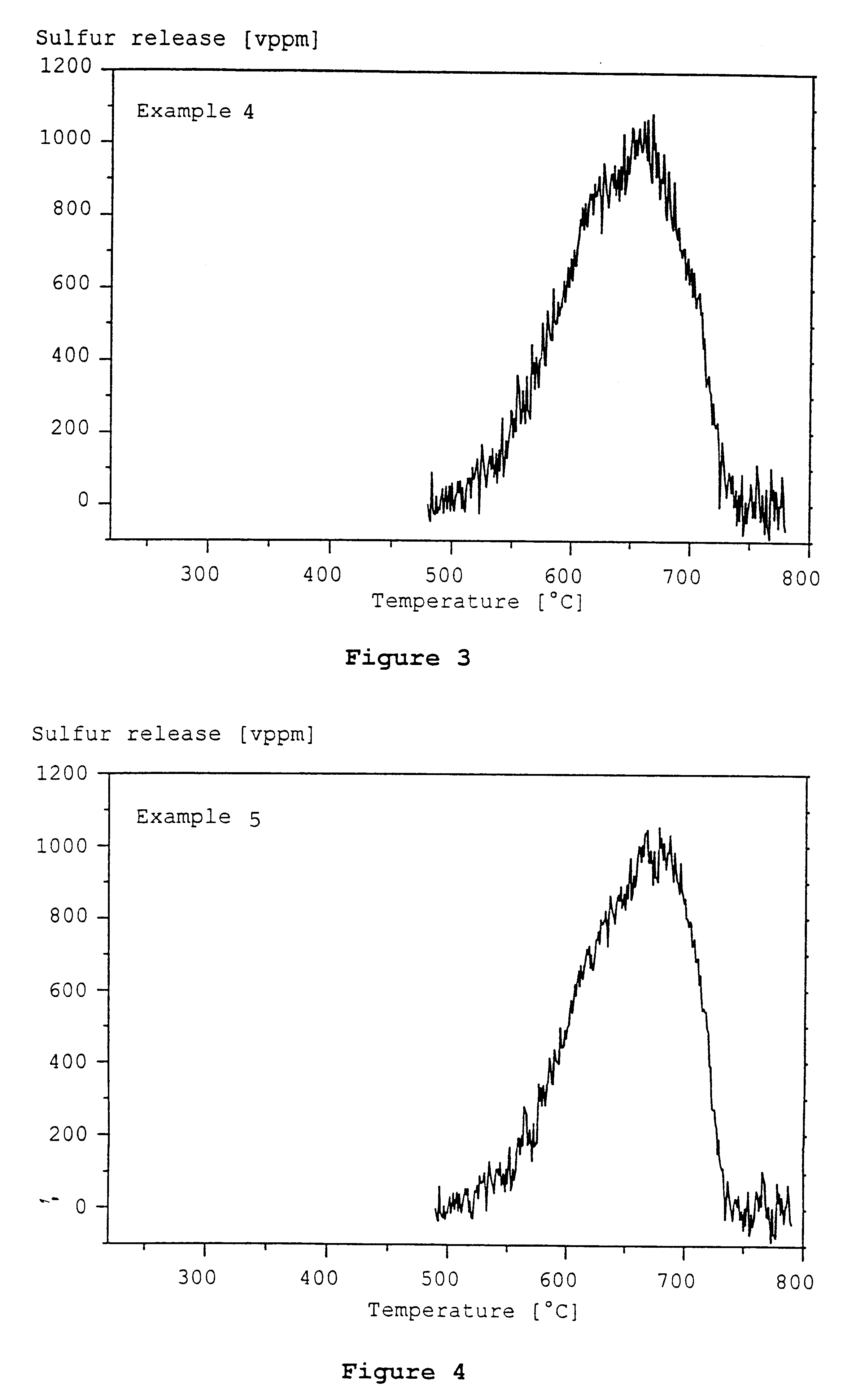

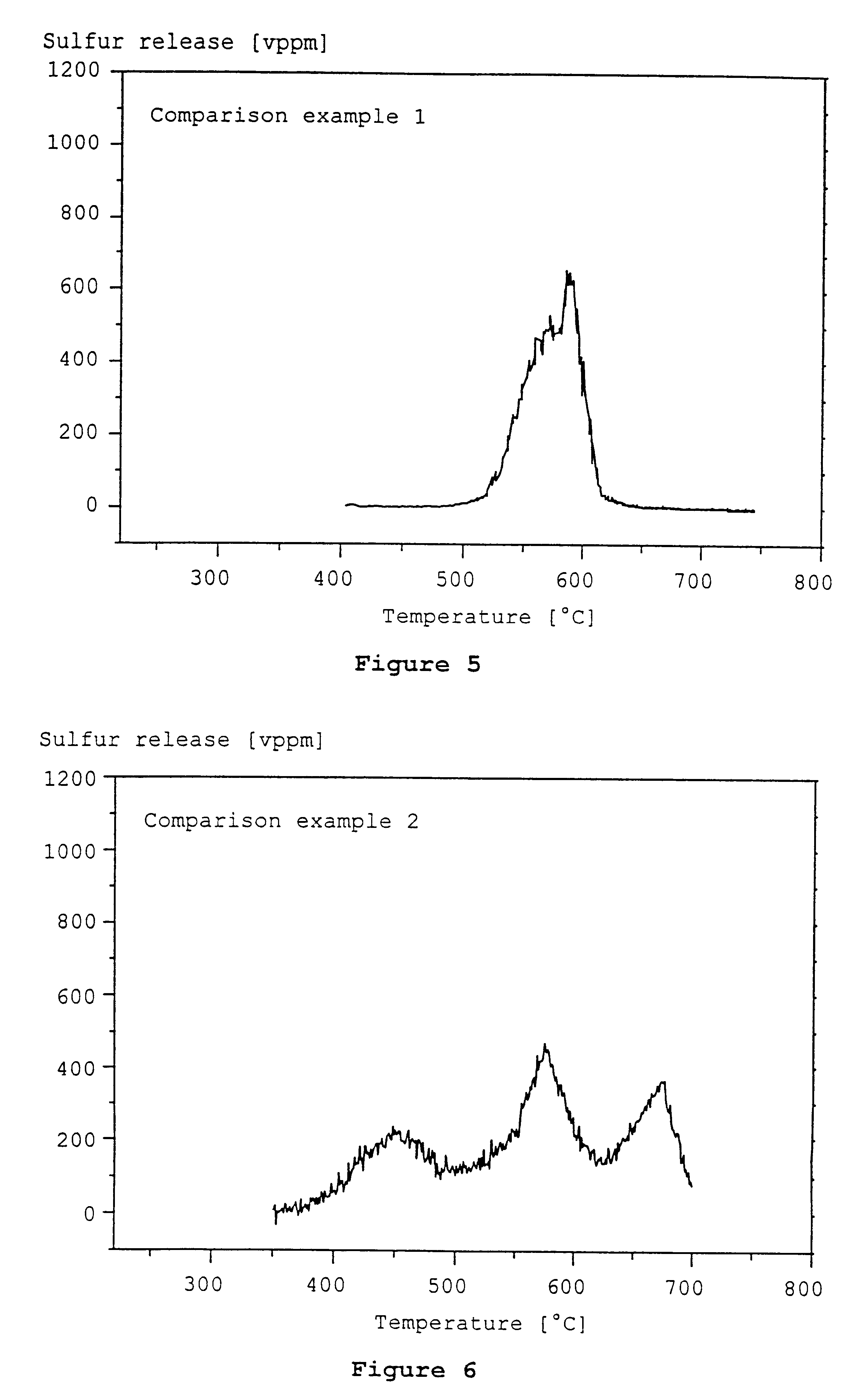

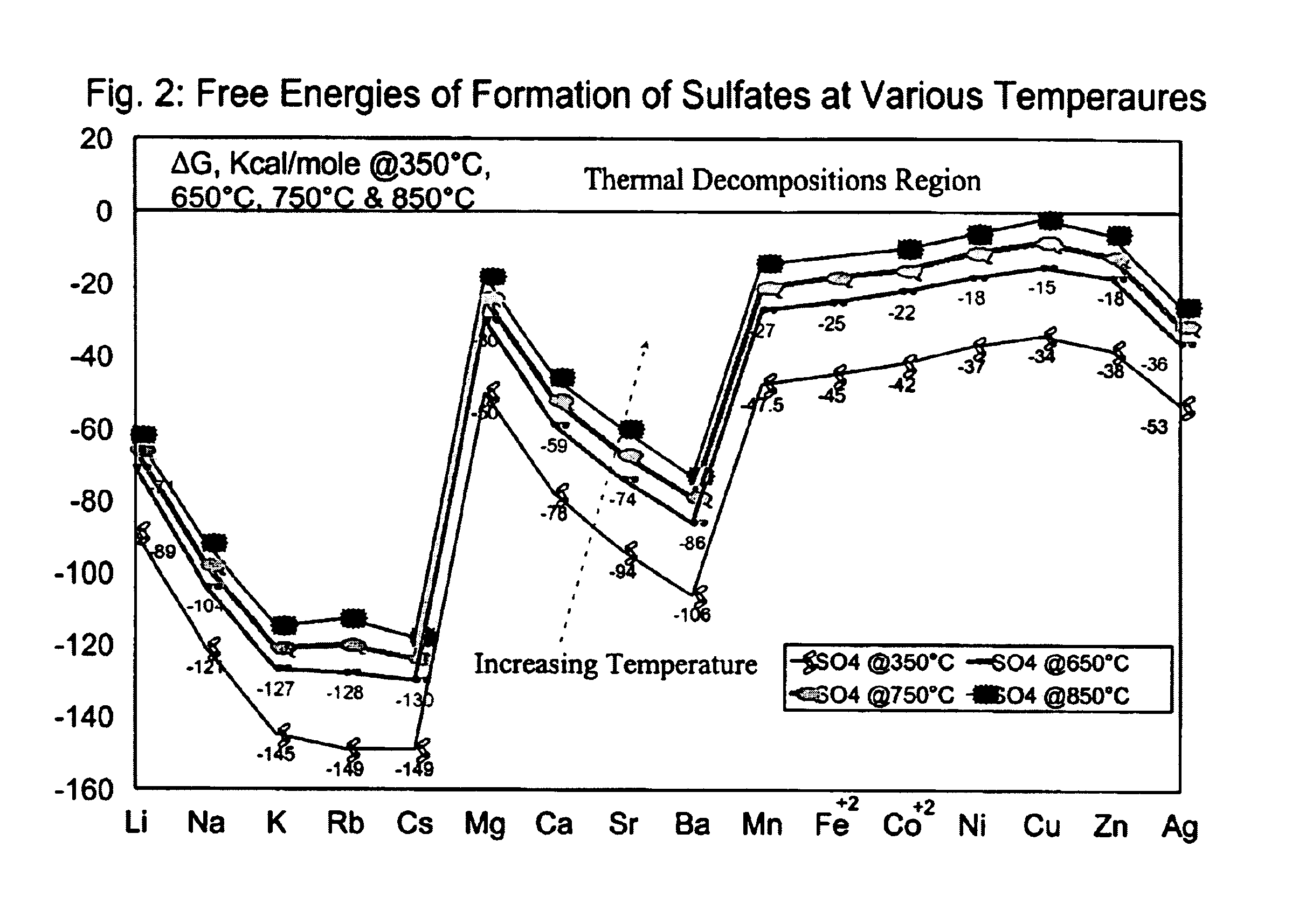

Storage material for sulfur oxides

InactiveUS6338831B1Improve the immunityRestores original storage capacityNitrogen compoundsExhaust apparatusOxygenInternal combustion engine

A sulfur oxide storage material contains a magnesium-aluminum spinel (MgO.Al2O3) and can be used as a so-called "sulfur trap" to remove sulfur oxides from oxygen-containing exhaust gases of industrial processes. In particular, it can be used for the catalytic purification of exhaust gas from internal-combustion engines to remove the sulfur oxides from the exhaust gas in order to protect the exhaust gas catalysts from sulfur poisoning. The material displays a molar ratio of magnesium oxide to aluminum oxide in the range of over 1.1:1, and the magnesium oxide present in stoichiometric excess is homogeneously distributed in a highly disperse form in the storage material.

Owner:DMC2 DEGUSSA METALS +1

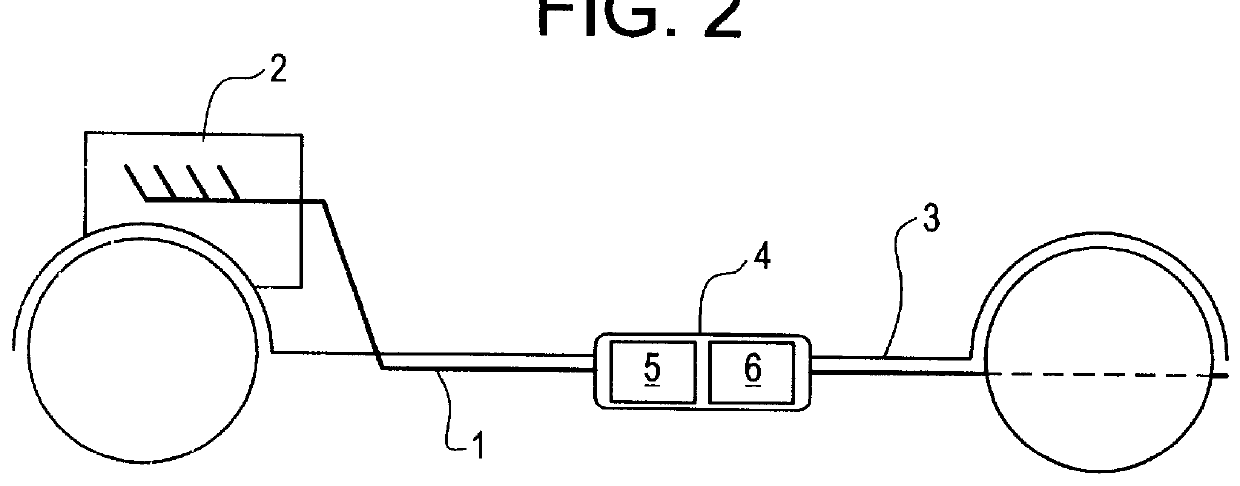

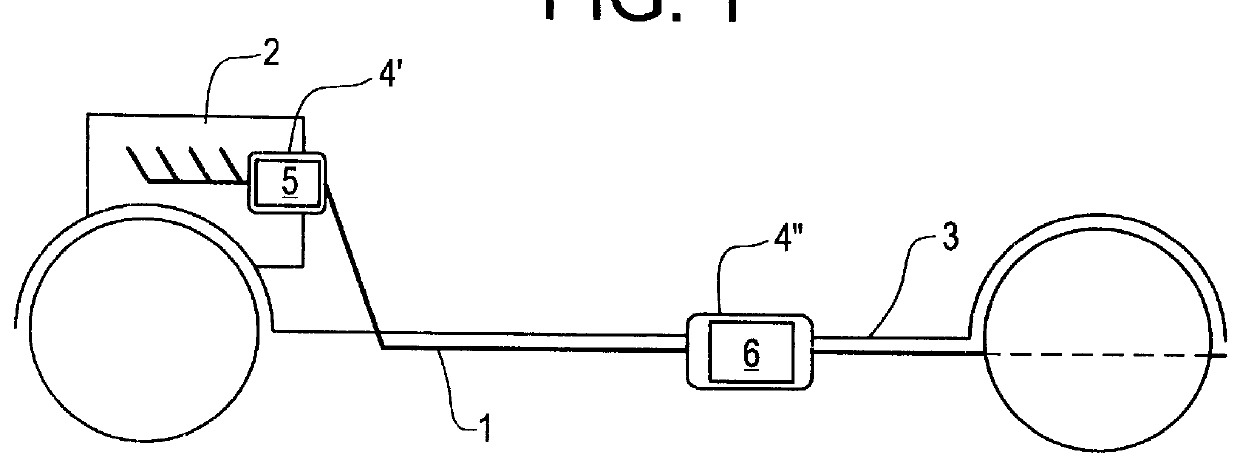

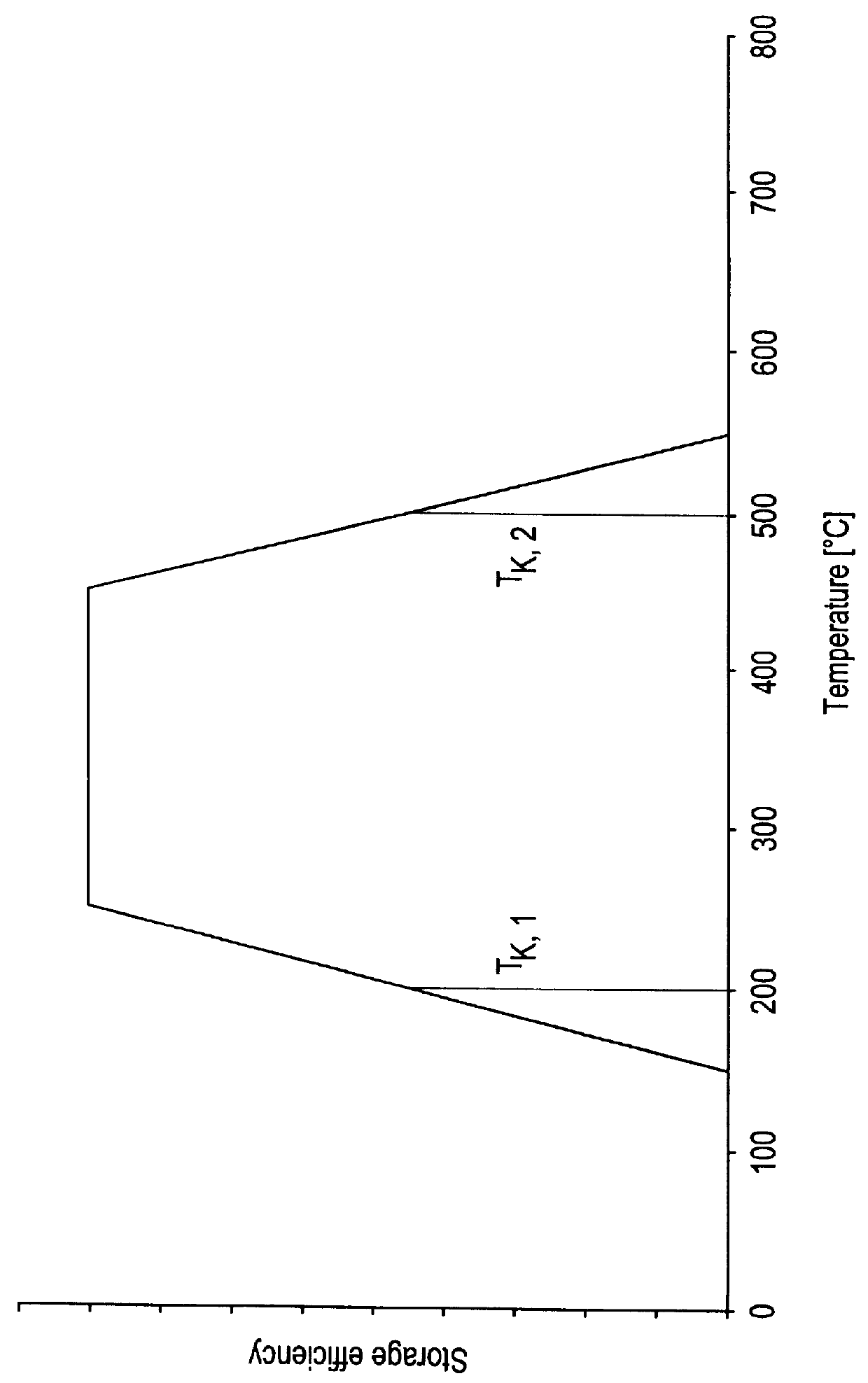

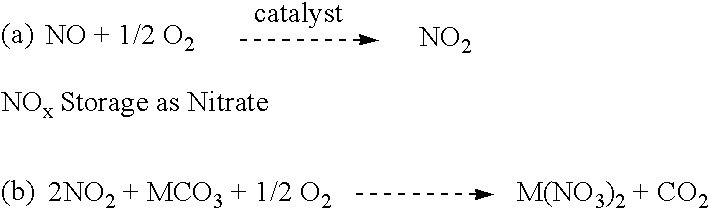

Process for operating an exhaust gas treatment unit containing a sulfur trap and a nitrogen oxides storage catalyst

A process is disclosed for operating an exhaust gas treatment unit for an internal combustion engine which is operated with lean normalized air / fuel ratios over most of the operating period. The exhaust gas treatment unit contains a nitrogen oxides storage catalyst with an activity window DELTA TNOX for the storage of nitrogen oxides at normalized air / fuel ratios of greater than 1 and release of the nitrogen oxides at normalized air / fuel ratios of less than or equal to 1 and a sulfur trap, located upstream of the nitrogen oxides storage catalyst, with a sulfur desorption temperature TS,DeSOx above which the sulfates stored on the sulfur trap are decomposed at normalized air / fuel ratios of less than or equal to 1. The nitrogen oxides contained in the exhaust gas are stored on the nitrogen oxides storage catalyst and the sulfur oxides are stored on the sulfur trap at normalized air / fuel ratios greater than 1 and exhaust gas temperatures TK within the activity window TNOX, wherein at the same time the exhaust gas temperature just upstream of the sulfur trap is lower than its sulfur desorption temperature TS,DeSOx. By cyclic lowering of the normalized air / fuel ratio in the exhaust gas to less than 1 the stored nitrogen oxides are released again from the storage catalyst. After each predetermined number N1 of nitrogen oxides storage cycles, sulfur is removed from the sulfur trap. This takes place by raising the exhaust gas temperature just upstream of the sulfur trap to above its sulfur desorption temperature TS,DeSOx and also lowering the normalized air / fuel ratio in the exhaust gas to less than 1.

Owner:UMICORE AG & CO KG +1

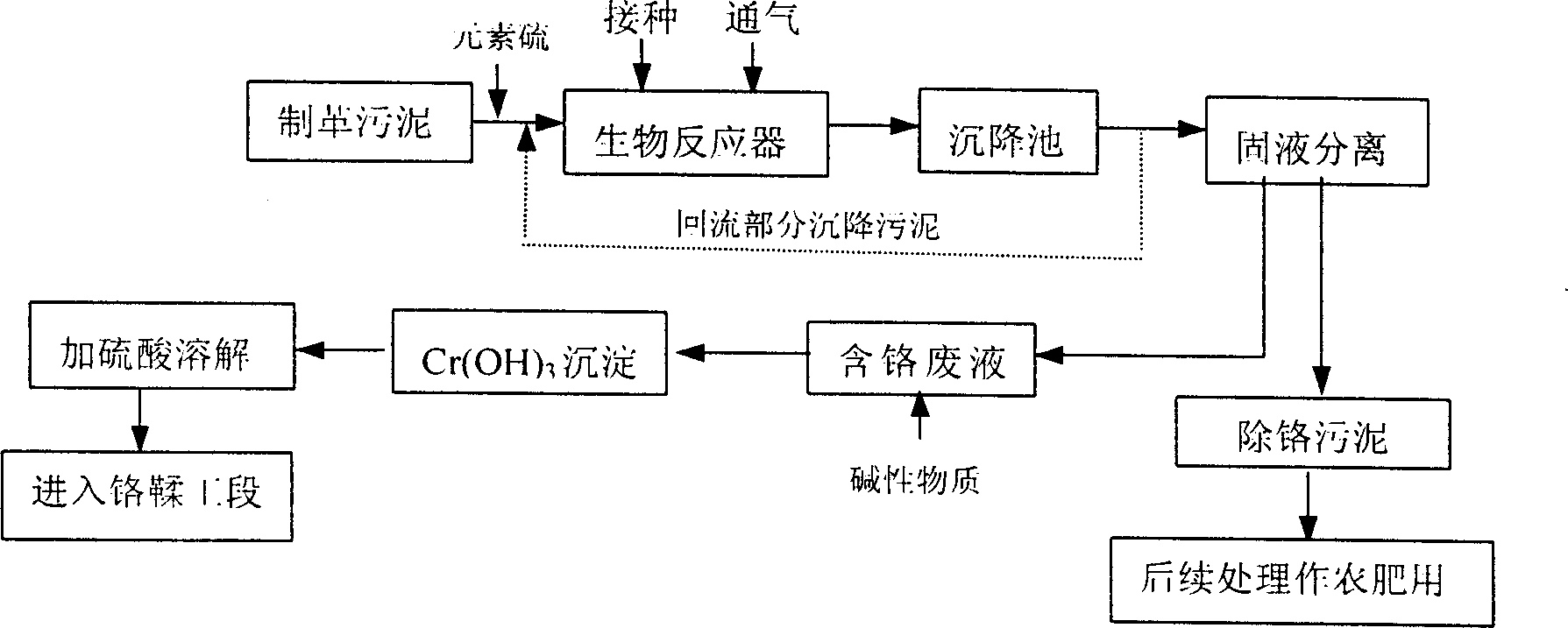

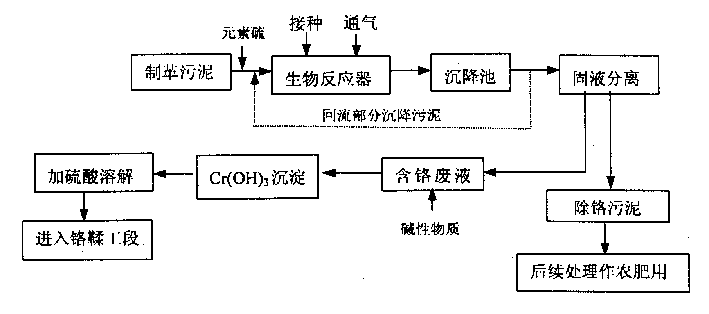

Thiobacillus thiooxidans and biological eliminating method of chromium in tanning sludge

InactiveCN1389564ALess value lossAchieve recyclingBacteriaSludge processingThiobacillus ferrooxidansSludge

The invention relates to sulfur oxide sulfur bacilli and biological eliminating method of chromium in tanning mud. Bacterial strain is named as TS6, preserve mark is CGMCCNO.0759. The method of eliminate chromium in tanning mud by above mentioned sulfur oxide sulfur bacilli is adding 1-3 g / L sulfur into tanning mud in biology reactor, inocualting 10-15% (v / v, the same below) TS6 bacteria strain, stirring, ventilating and subsiding; that 10-20% of subsiding mud backflow to reactor; dehydrating suprplus subsiding mud; adding basic material into liquid part to turn Cr3+ into Cr(OH)3 and subside, sediment is dissolved by sulfuric acid, then there is the tannage stage; solid part is neutralized to agriculture. The elimianting rate of Cr in mud is 95%-100%, reserving rate of nutrient in mud is above 80%.

Owner:周立祥 +1

Method and device for reclaiming sulfur dioxide from countercurrent flue gas

InactiveCN101085410AAvoid short circuitImprove efficiencyDispersed particle separationSulfur compoundsSulfur dioxideFlue gas

The invention relates to the new SO2 absorption device with three function areas, namely deamination zone, desulfuration zone and oxidization zone. It has purification air exhaust at the top of the SO2 absorption device, top of the inside of the tower composed of water and liquid separator of the flush water distributor, deamination circulation absorbing distributor connected to its inlet under the air and liquid separation component, under the deamination zone set with desulfuration circulation absorbing outlet connected liquid absorbing distributor, under which set the desulfuration zone, with absorbent liquid overflow outlet on the tower, and oxidization crystallization zone under the overflow outlet. It is low in investment, small in energy consumption, strong in gas treatment ability, high in efficiency, applicable for mass mode industrial application.

Owner:娄爱娟

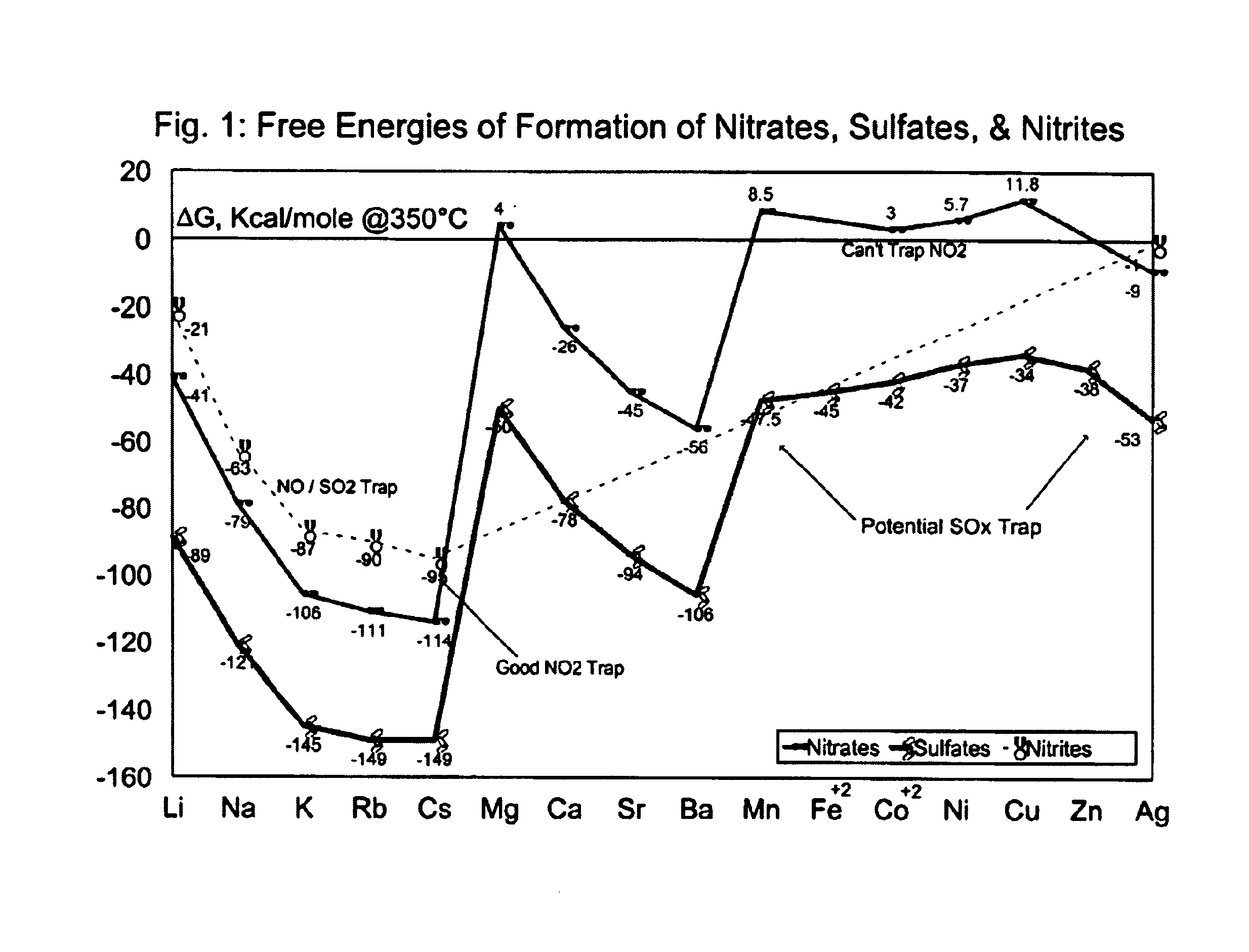

Layered SOX tolerant NOX trap catalysts and methods of making and using the same

InactiveUS6923945B2Alleviates sulfur oxide poisoningMaintain long-term activityNitrogen compoundsInternal combustion piston enginesPlatinumFree energies

The present invention relates to a layered catalyst composite useful for reducing contaminants in exhaust gas streams, especially gaseous streams containing sulfur oxide contaminants. More specifically, the present invention is concerned with improved catalysts of the type generally referred to as “three-way conversion” catalysts. The layered catalysts trap sulfur oxide contaminants which tend to poison three-way conversion catalysts used to abate other pollutants in the stream. The layered catalyst composites of the present invention have a sulfur oxide absorbing layer before or above a nitrogen oxide absorbing layer. The layered catalyst composite comprises a first layer and a second layer. The first layer comprises a first support and at least one first platinum component. The second layer comprises a second support and a SOx sorbent component having a free energy of formation from about 0 to about −90 Kcal / mole at 350° C. The sulfur oxide absorbing layer selectively and reversibly absorbs sulfur oxides over nitrogen oxides and prevents or alleviates sulfur oxide poisoning of the nitrogen oxide trap.

Owner:ENGELHARD CORP

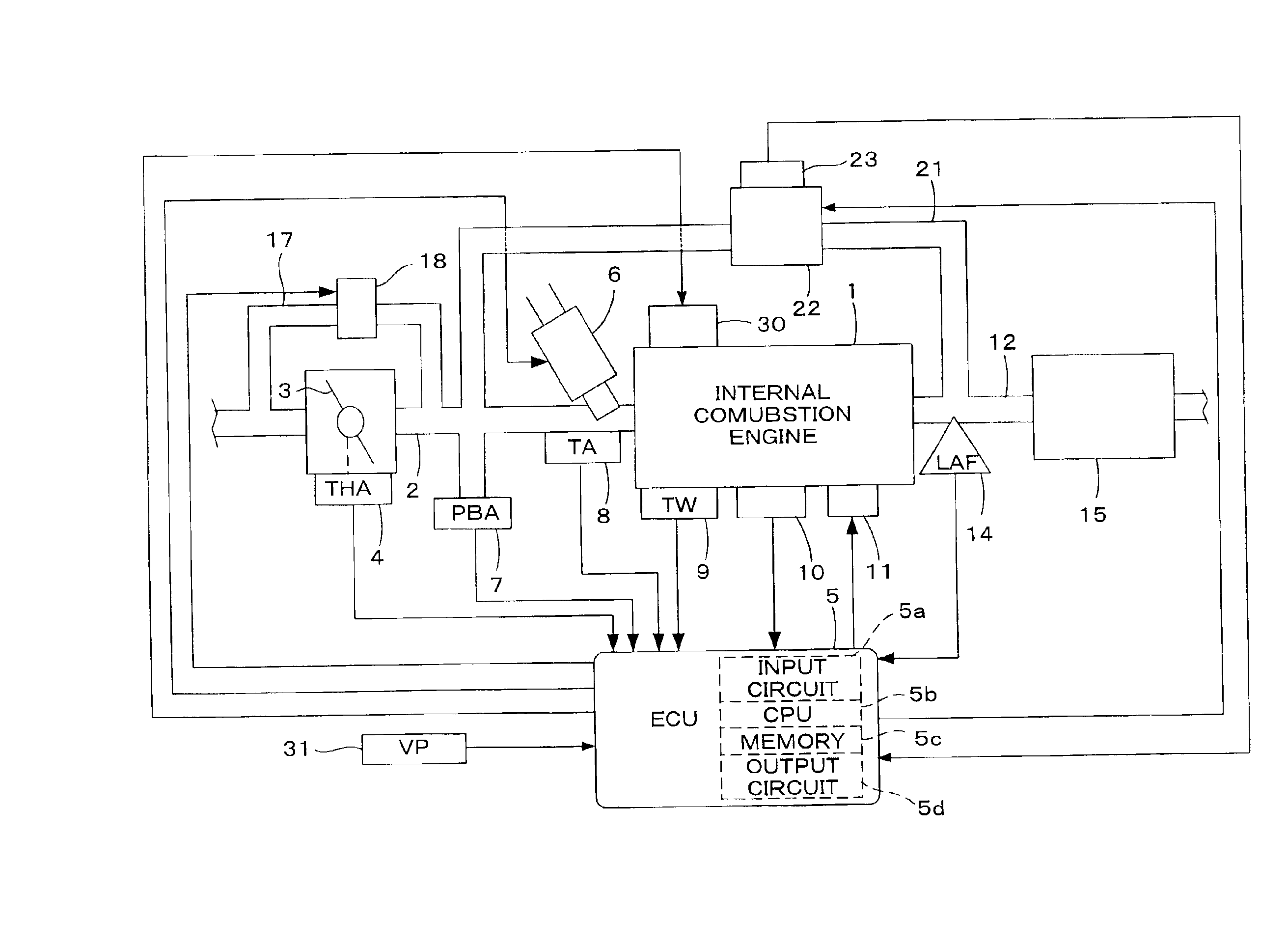

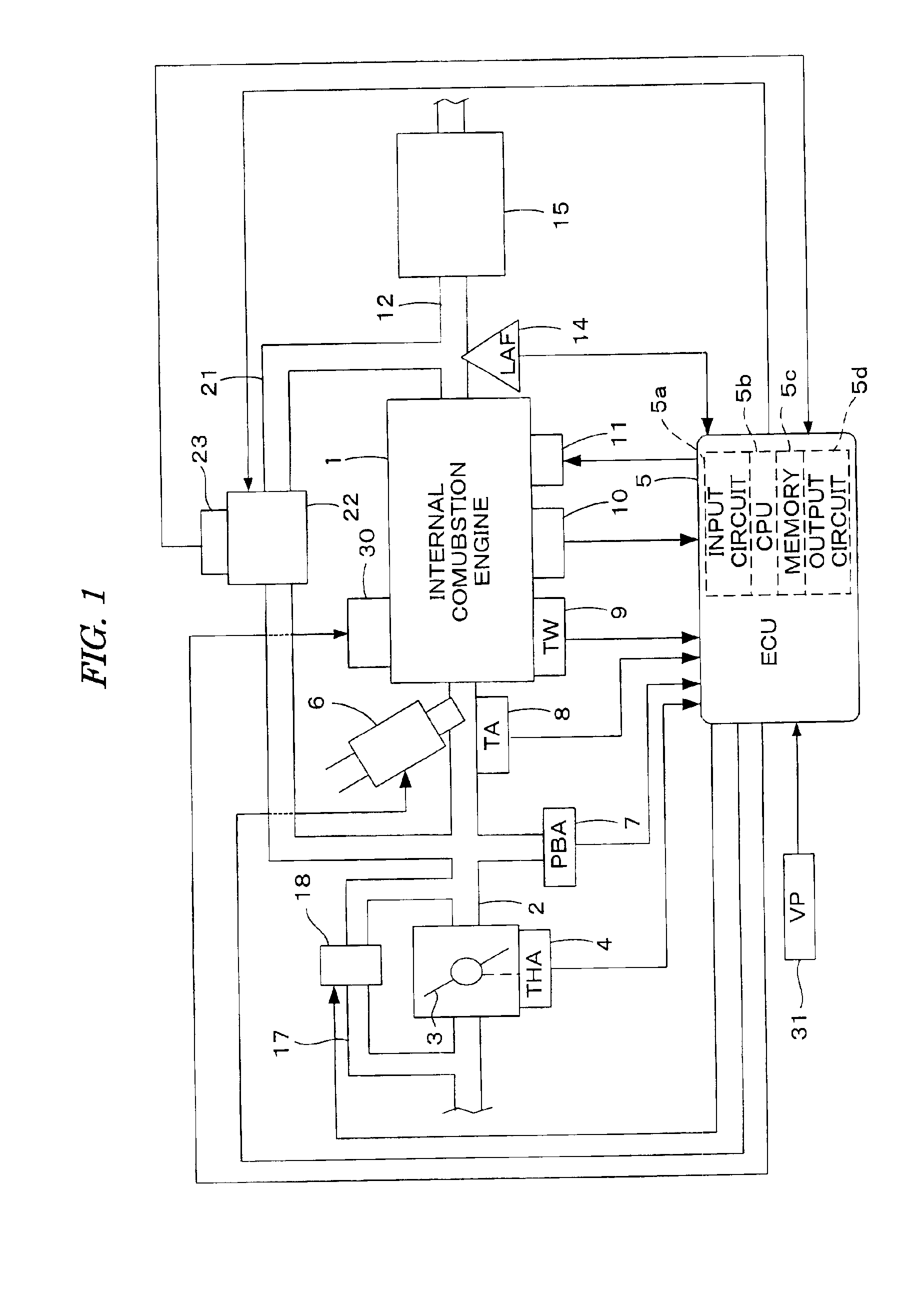

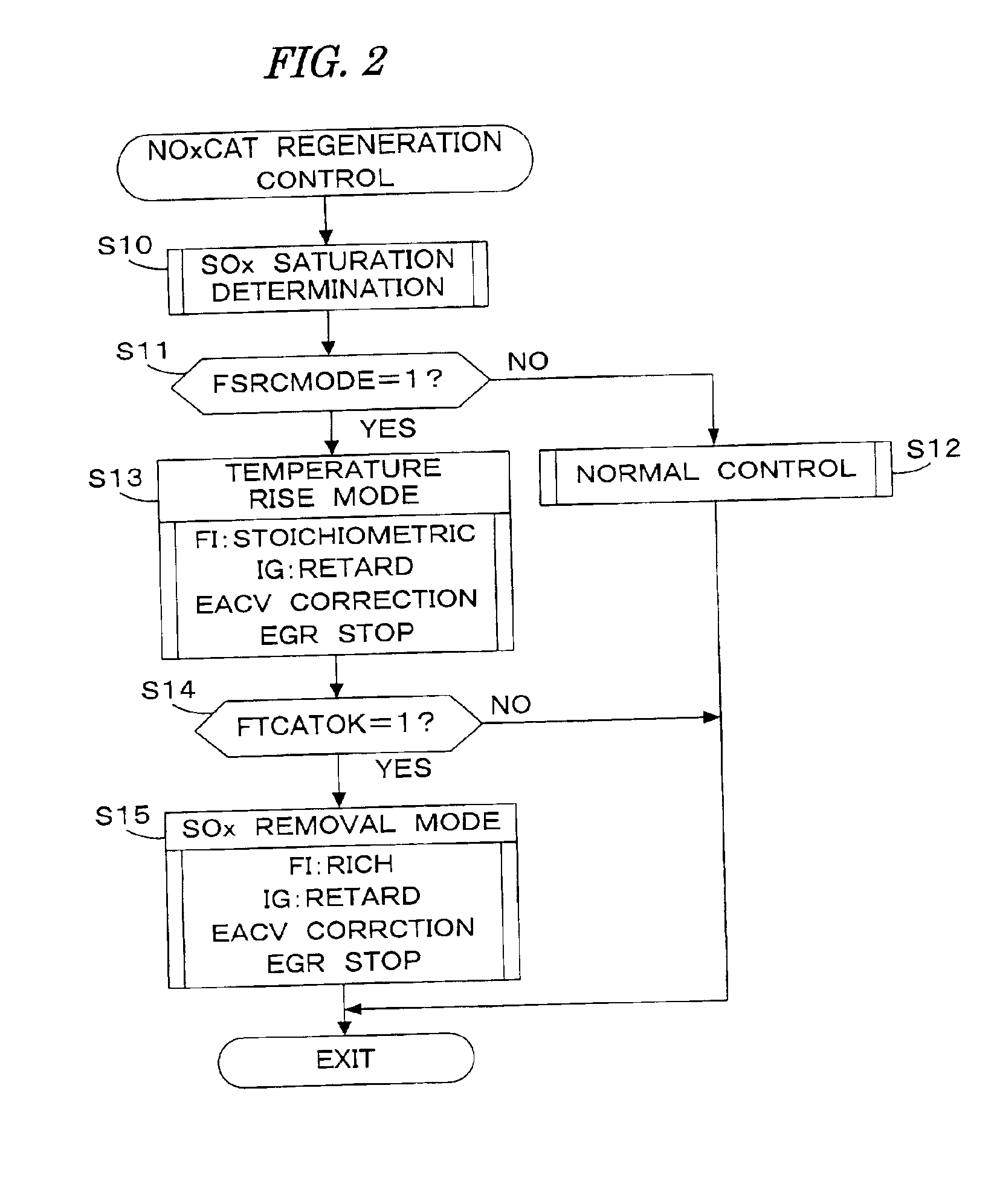

Exhaust emission control system for internal combustion engine

InactiveUS6901749B2Shorten ignition timeAccurate estimateCombination devicesElectrical controlControl systemEnvironmental engineering

An exhaust emission control system for an internal combustion engine, having a nitrogen oxide removing device provided in an exhaust system of said engine for absorbing nitrogen oxide contained in exhaust gases in an exhaust lean condition. An amount of change per unit time in the sulfur oxide amount absorbed in the nitrogen oxide removing device is estimated according to the air-fuel ratio of an air-fuel mixture supplied to said engine and the operating condition of said engine. The estimated amount of change is accumulated to thereby estimate the sulfur oxide amount absorbed in the nitrogen oxide removing device. The sulfur oxide is removed from the nitrogen oxide removing device when the estimated sulfur oxide amount has reached a set value.

Owner:HONDA MOTOR CO LTD

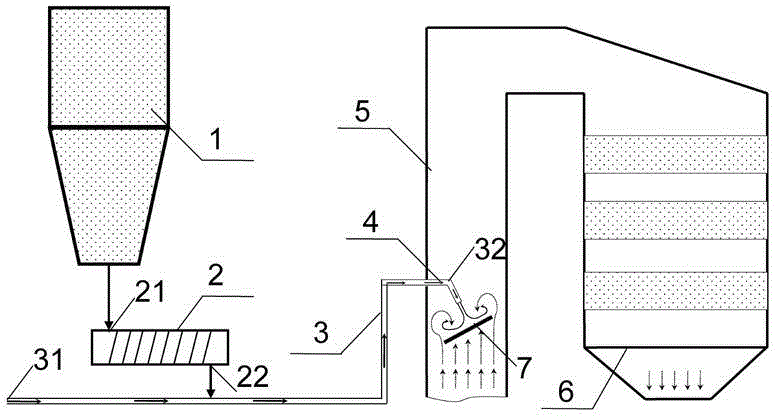

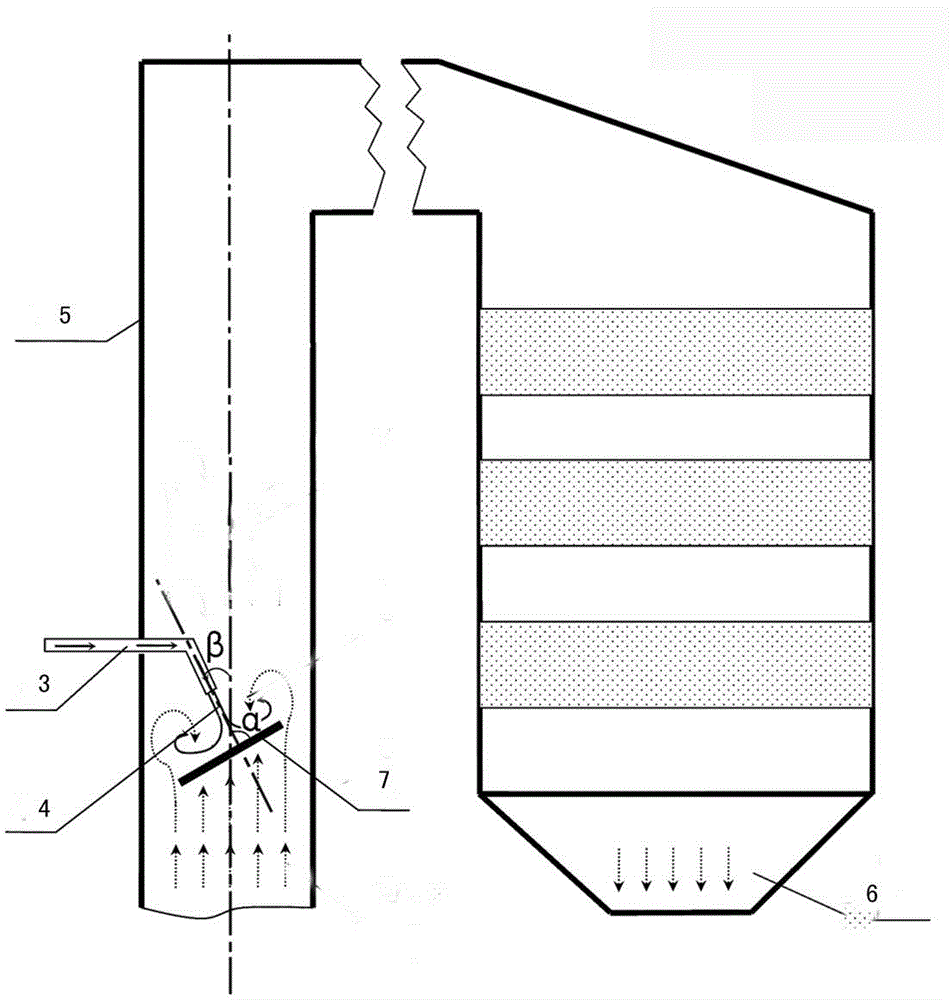

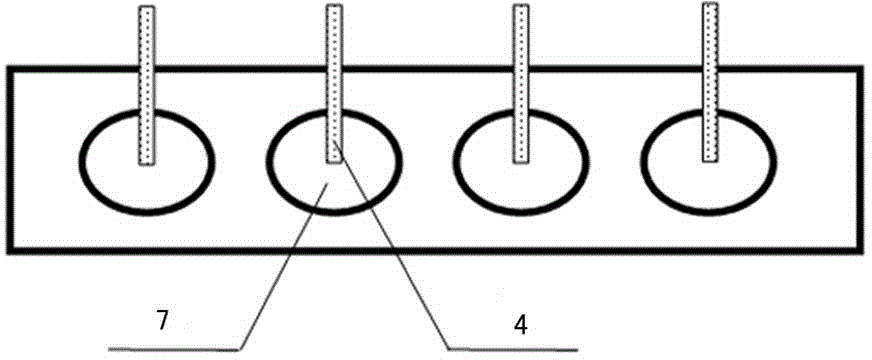

Device and method for removing sulfur trioxide from smoke

InactiveCN104857841AReduce contentReduce the impactDispersed particle separationSulfur trioxideDischarge rate

The invention discloses a device for removing sulfur trioxide from smoke. The device comprises a bin, a screw feeder, a smoke delivery pipe, a spray gun, a denitration inlet flue, a denitration reactor and a spoiler, wherein the screw feeder is provided with a feeding opening and a discharging opening, and the feeding opening is connected with the bin and used for controlling the discharging rate of an absorbent; the smoke delivery pipe is provided with a smoke inlet and a smoke outlet, and the discharging opening is connected with the smoke delivery pipe; the smoke outlet is connected with the spray gun, and the spray gun is used for spraying the absorbent for strong alkaline particles; the denitration inlet flue is used for mixing the absorbent with smoke, and the smoke outlet and the spray gun are positioned in the flue; the denitration reactor is connected with the denitration inlet flue. The device can be applied to a coal firing unit of a thermal power plant, effectively reduce the SO3 content, reduce the influence of the sulfur trioxide on the denitration device and an air pre-heater, and reduce pollutants to realize smoke clean emission.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

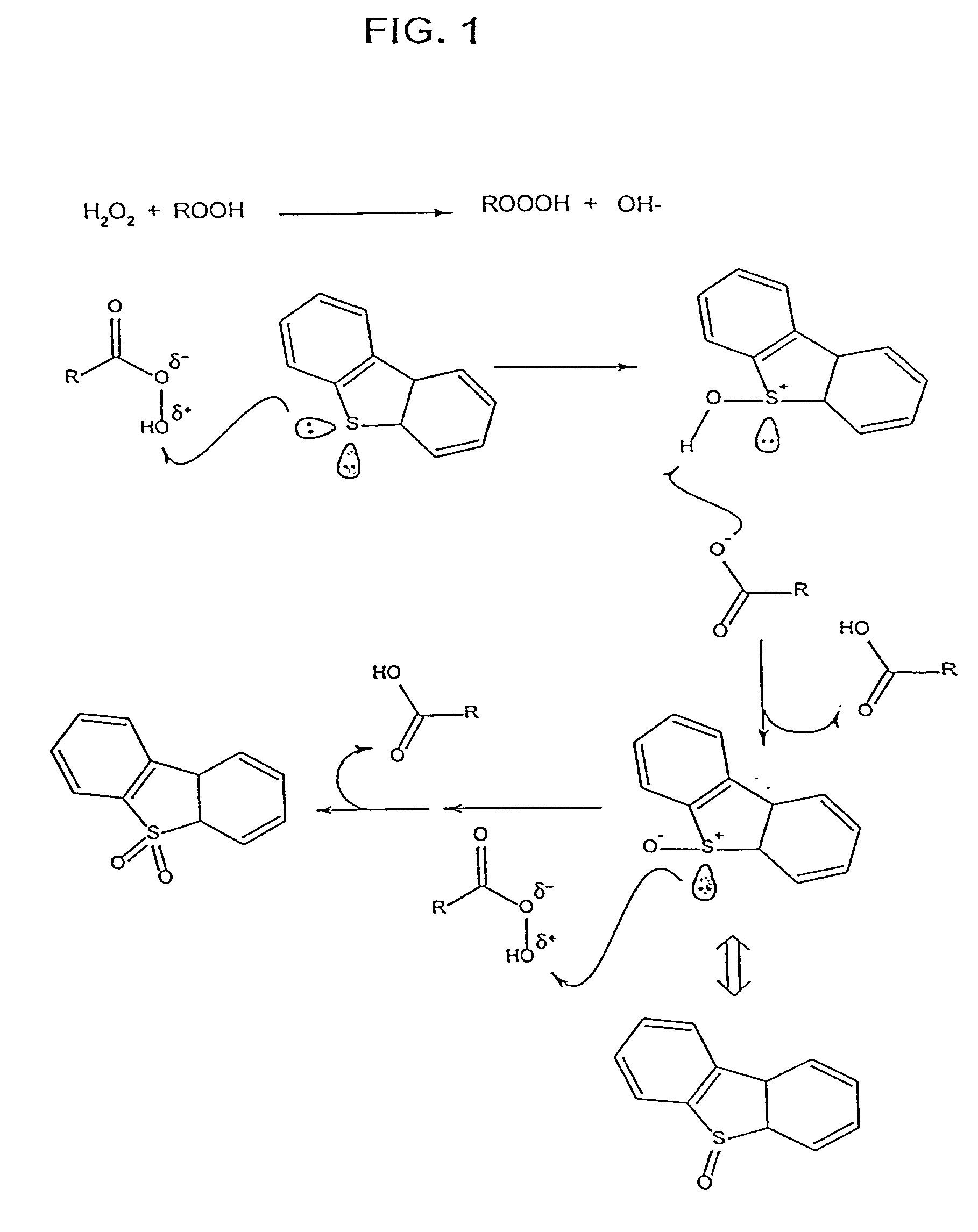

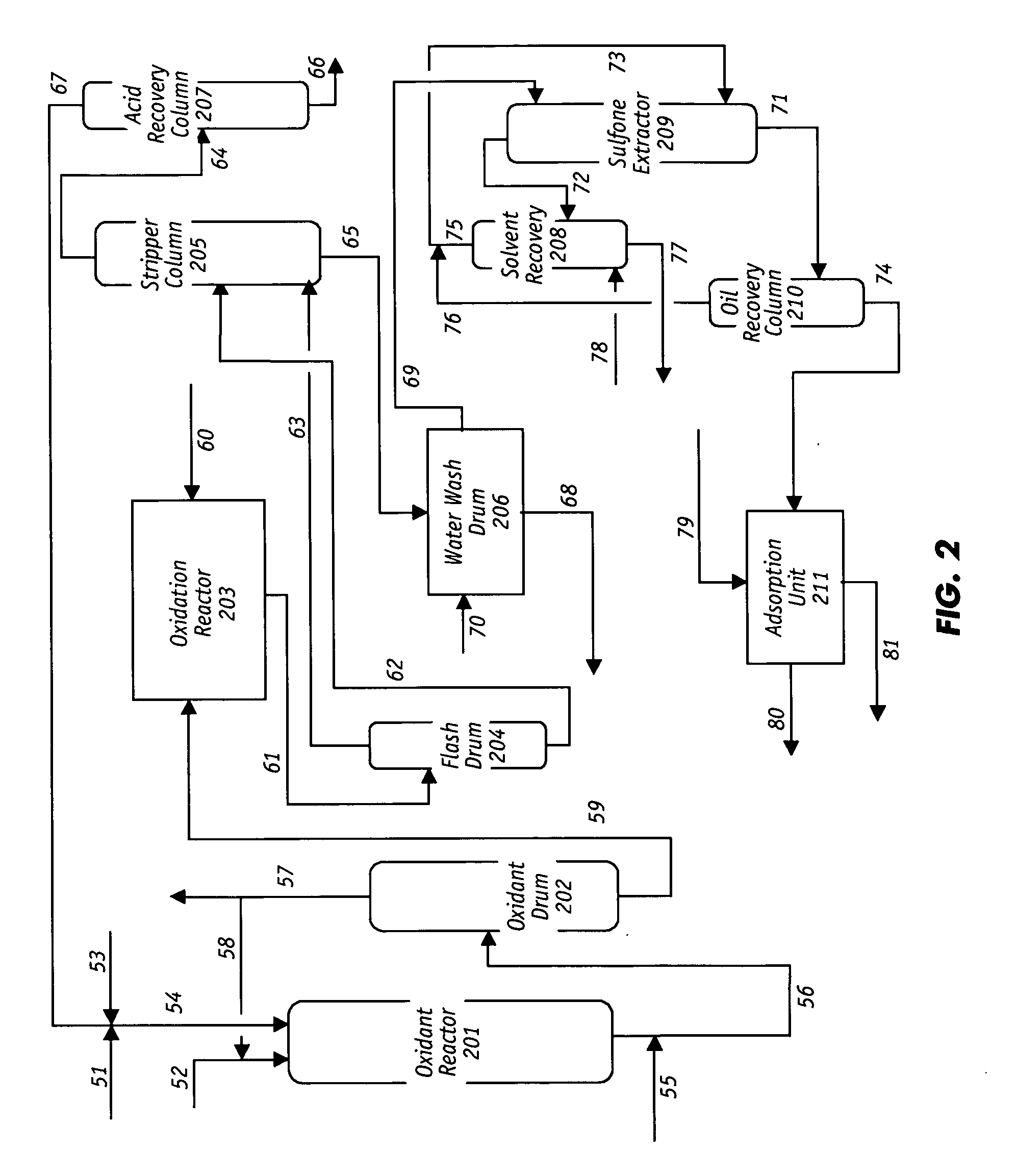

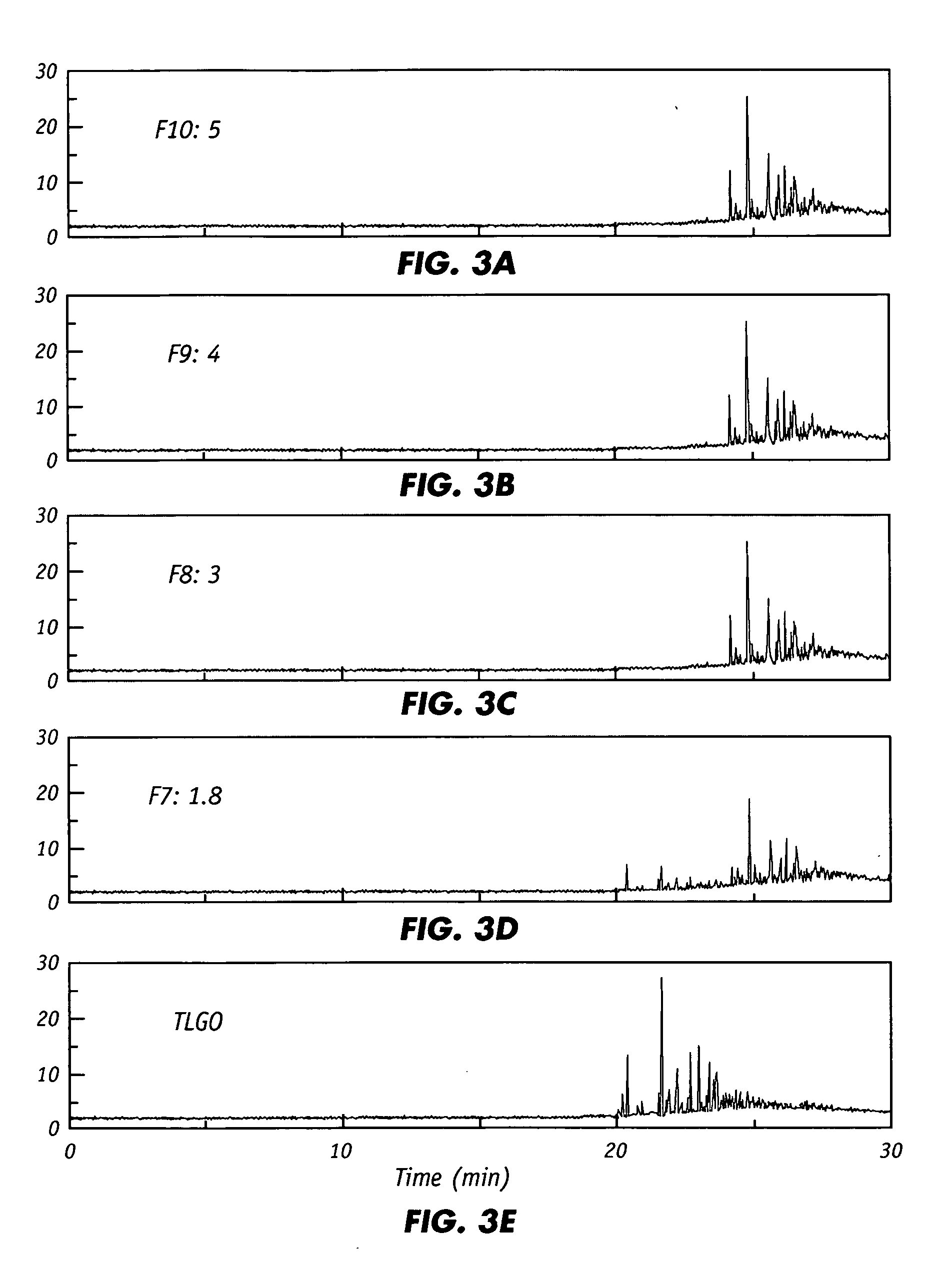

Process for the catalytic oxidation of sulfur, nitrogen and unsaturated compounds from hydrocarbon streams

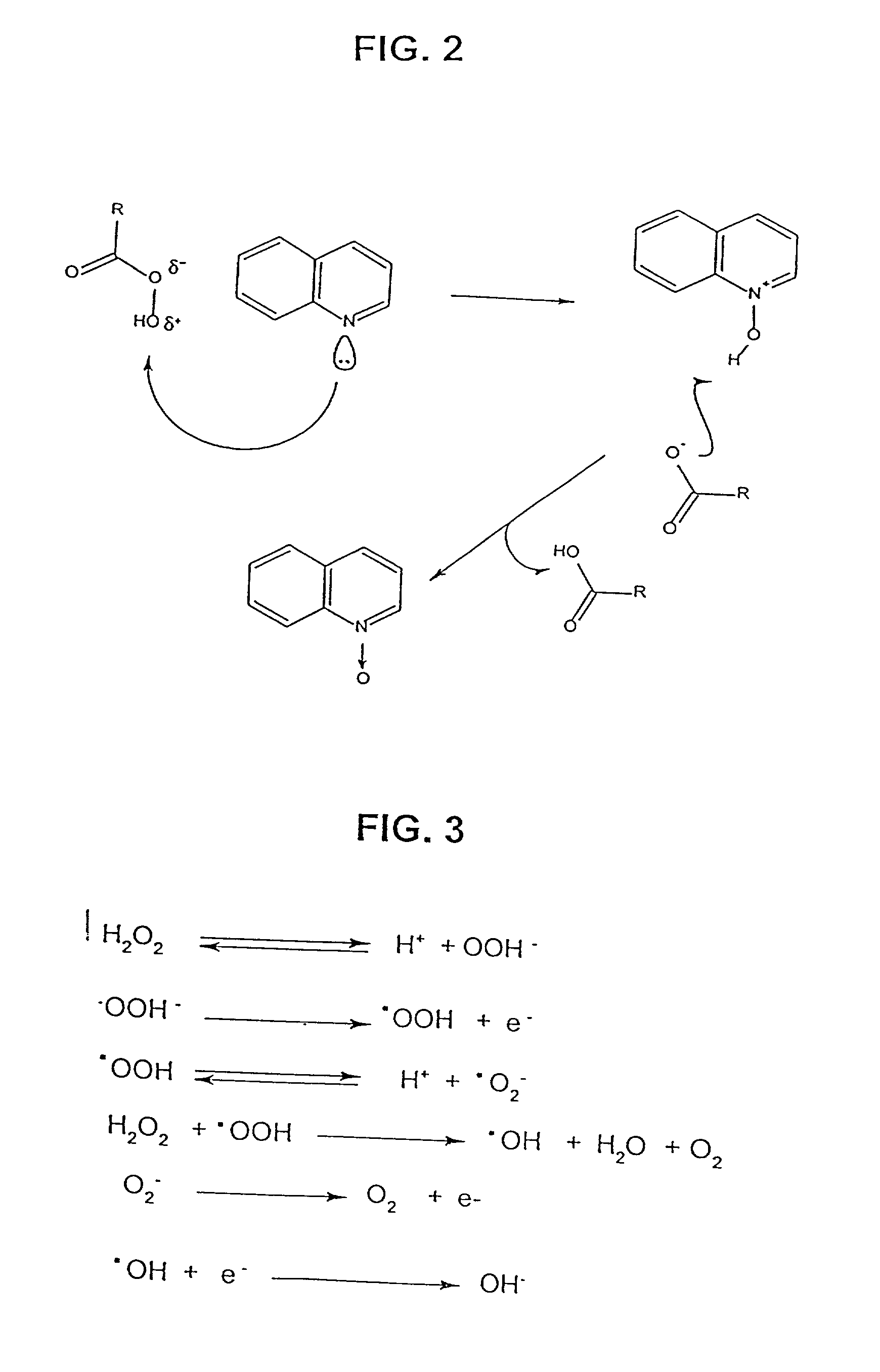

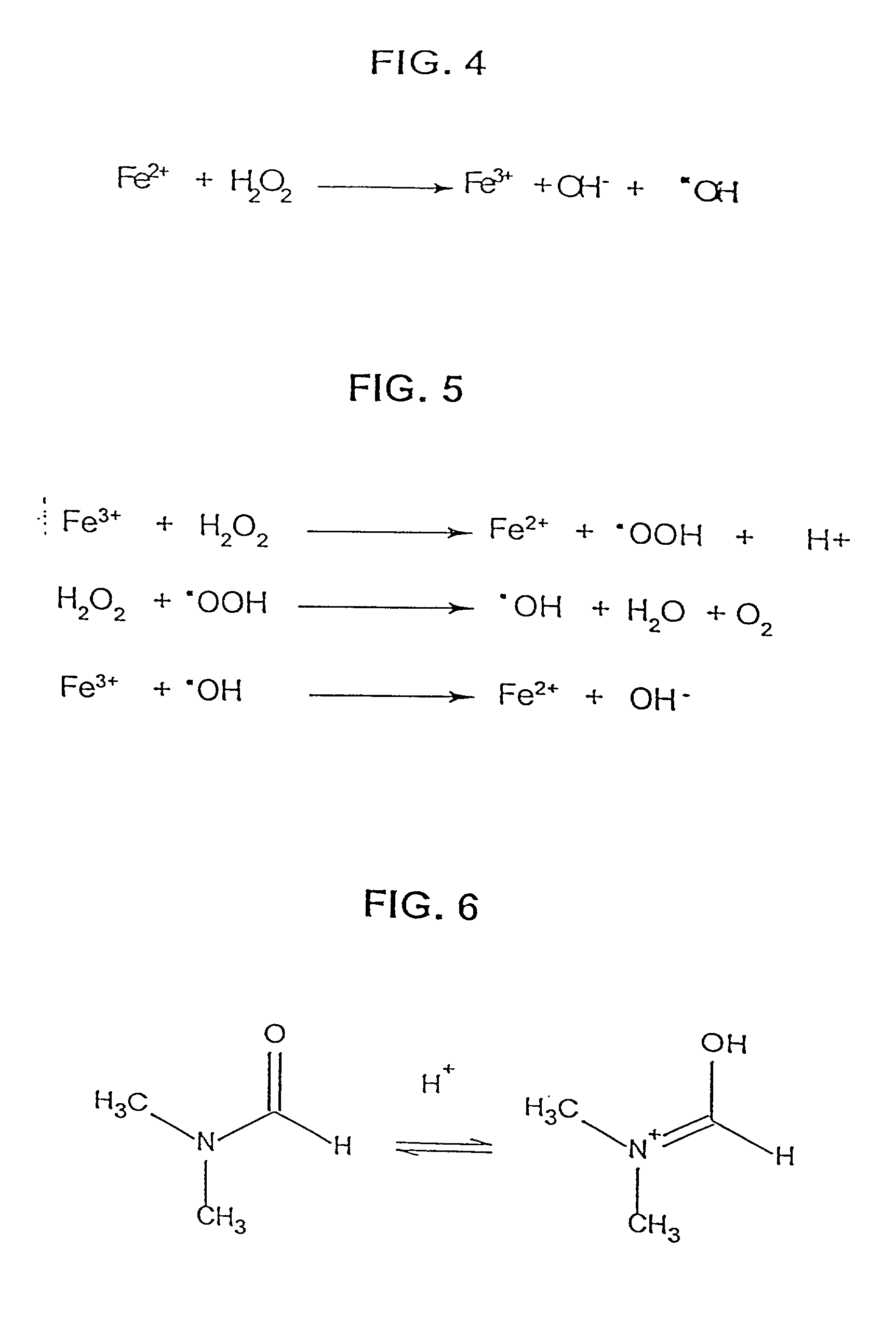

InactiveUS20020189975A1Refining with metalsRefining with oxygen compoundsCatalytic oxidationPeroxy acid

A process for the catalytic oxidation of sulfur and nitrogen contaminants as well as unsaturated compounds present in a hydrocarbon fossil oil medium is described, the process comprising effecting the oxidation in the presence of at least one peroxide, at least one acid and a pulverized raw iron oxide. The process shows an improved oxidation power towards the contaminants typically present in a fossil oil medium, this deriving from the combination of the peroxy-acid and the hydroxyl radical generated in the reaction medium due to the presence of an iron oxyhydroxide such as a limonite clay, which bears a particular affinity for the oil medium. The process finds use in various applications, from a feedstock for refining until the preparation of deeply desulfurized and deeply denitrified products.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

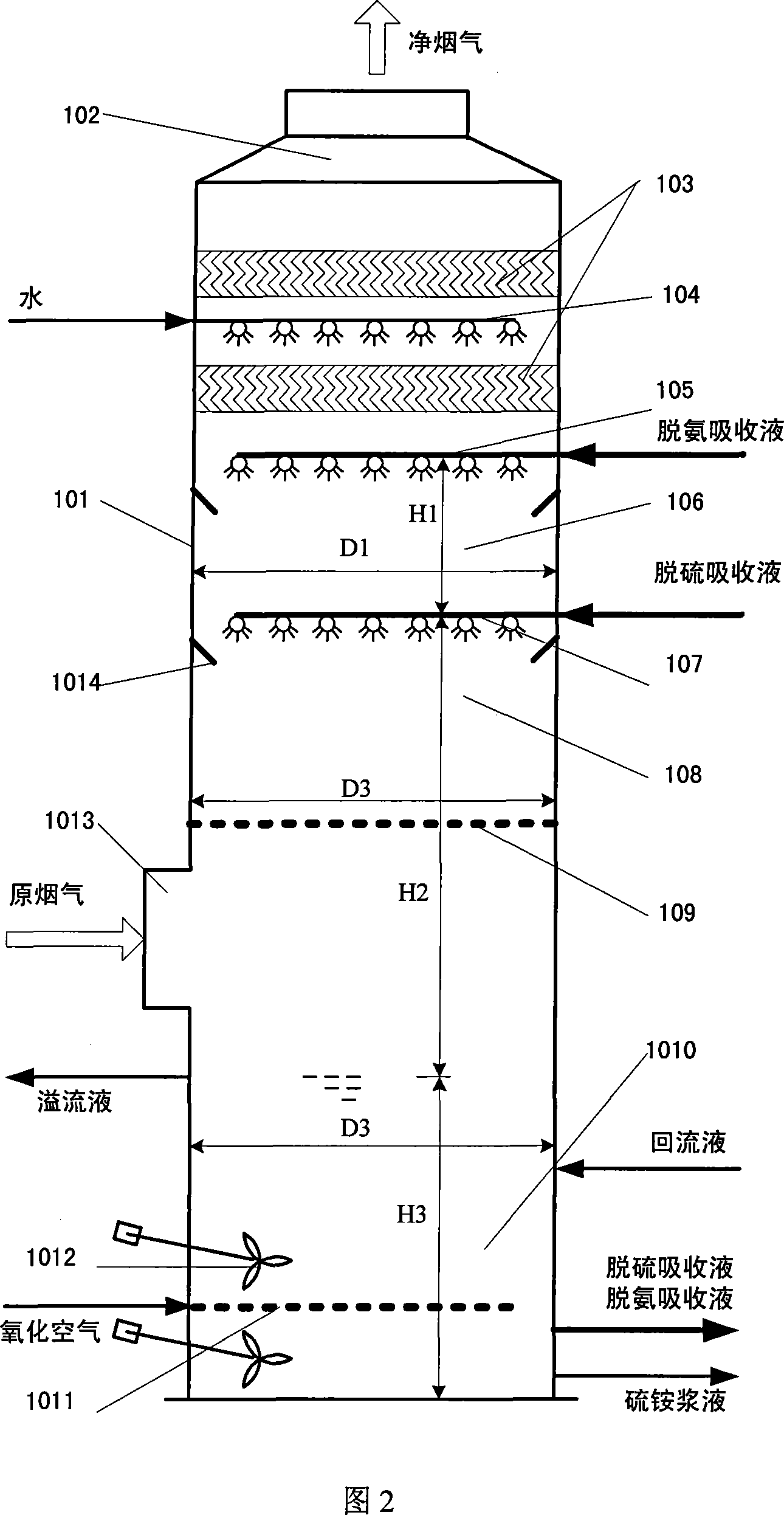

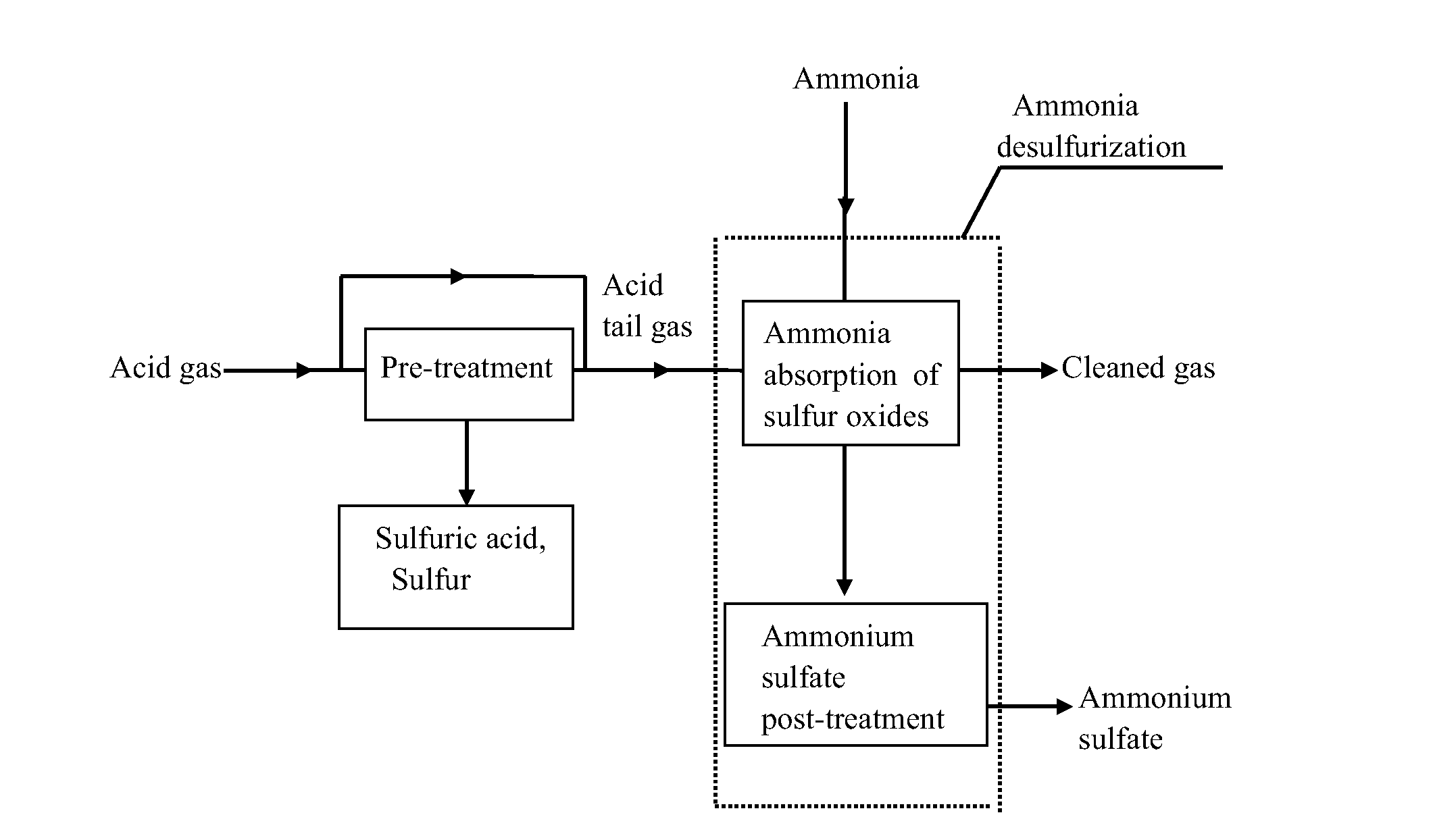

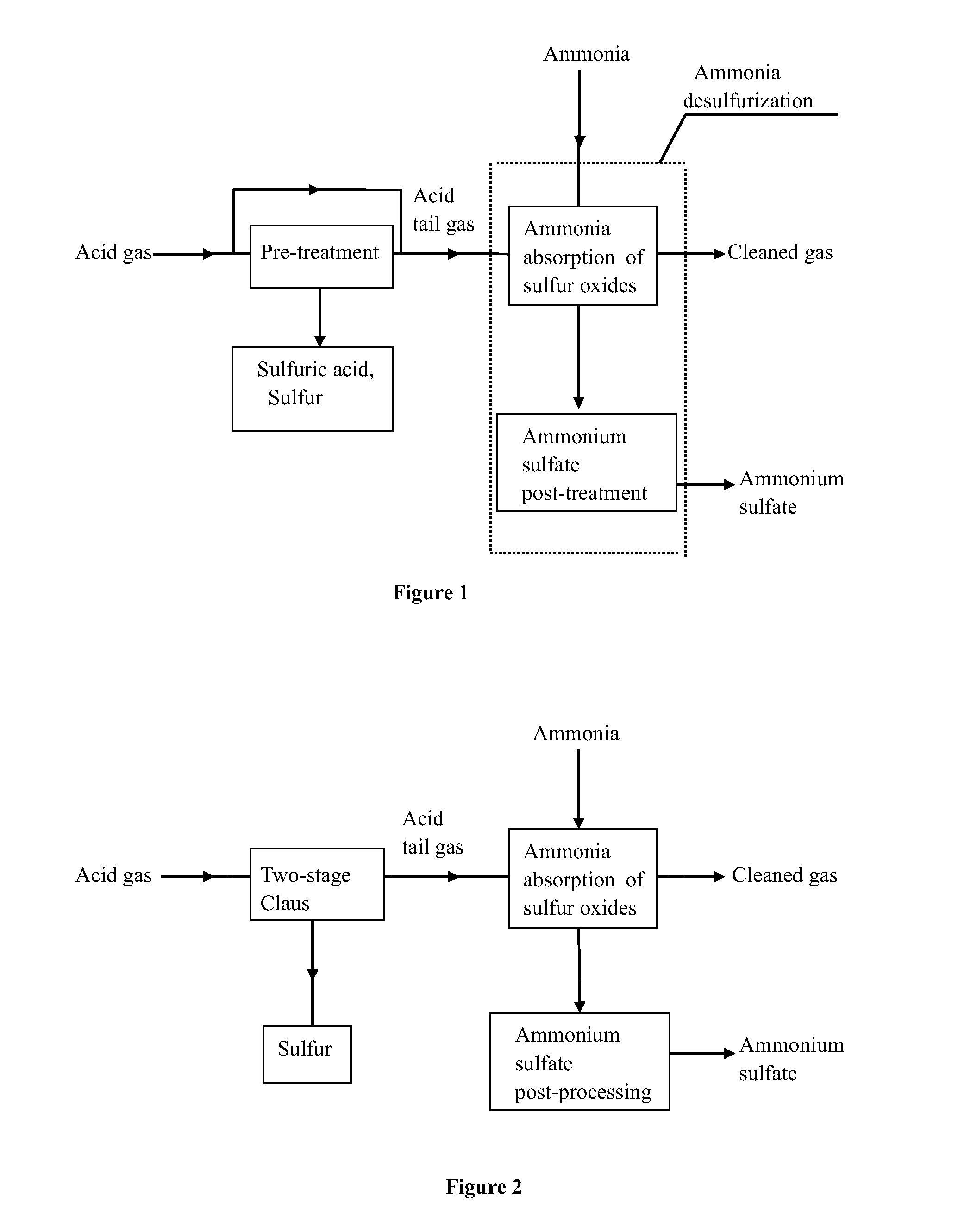

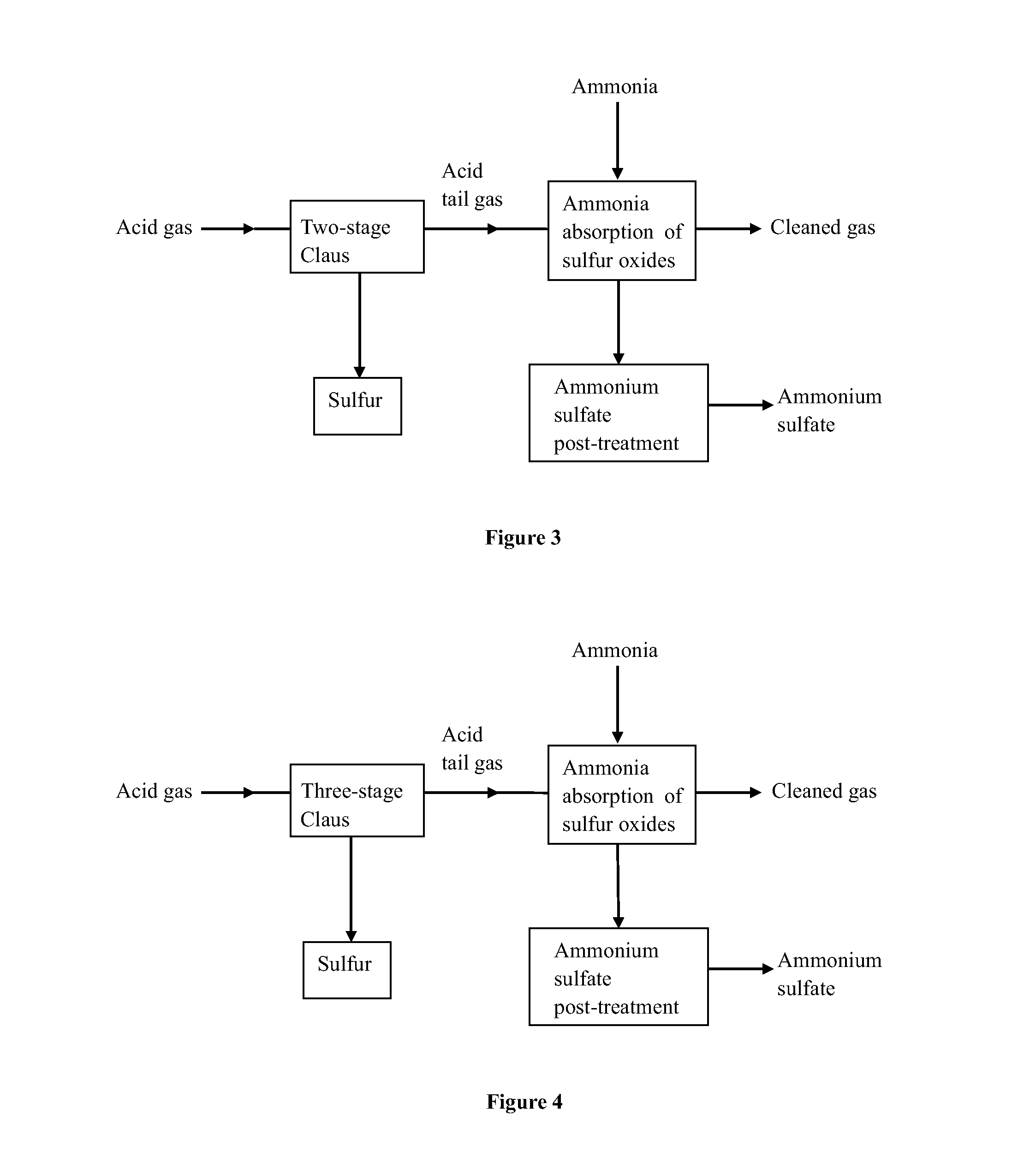

Effective removal of acidic sulfide gas using ammonia-based desulfurization

InactiveUS20150352489A1Efficient removalPromote recoveryGas treatmentDispersed particle separationChemical industryPretreatment method

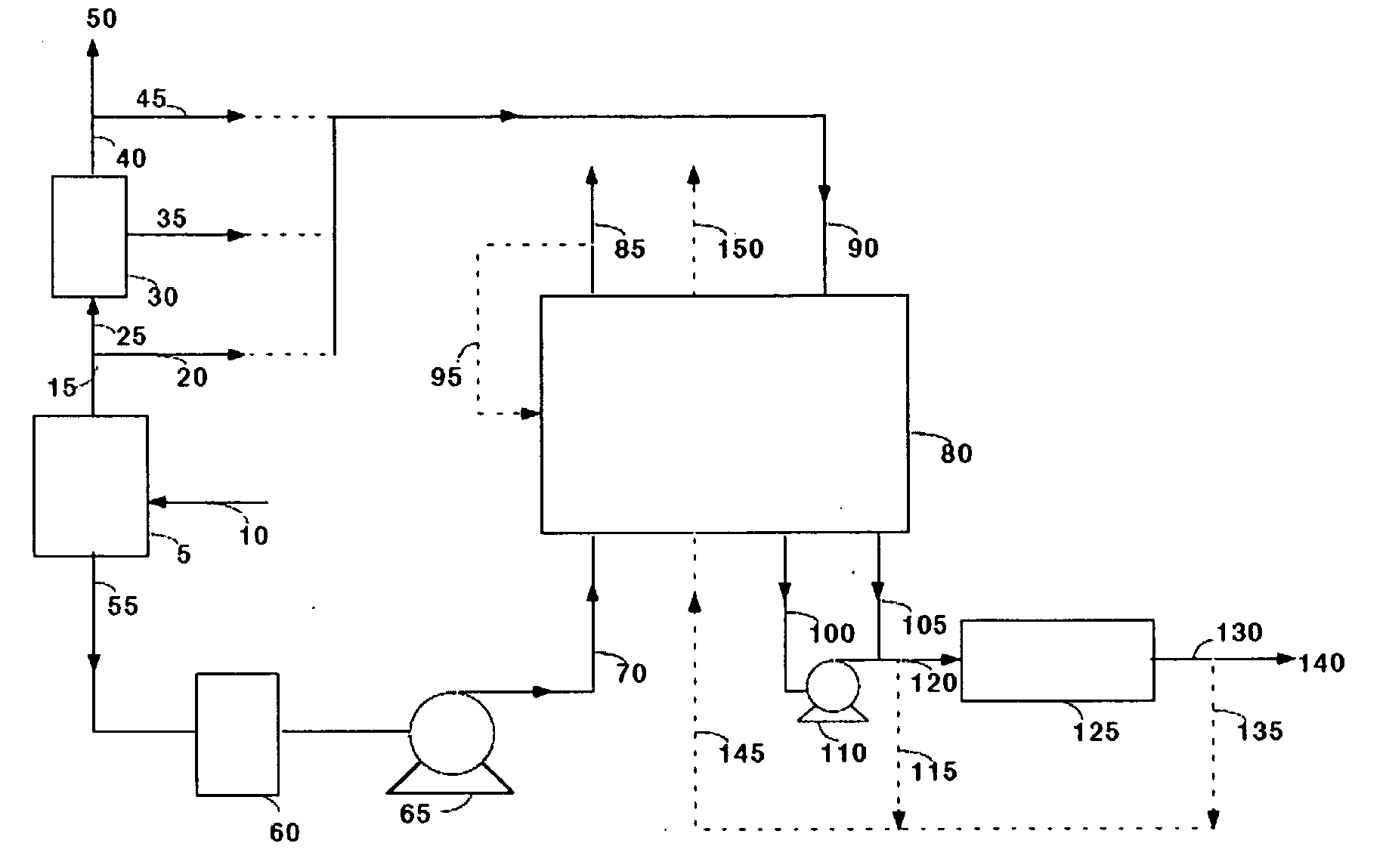

A method for effectively removing acidic sulfide gas using ammonia-based desulfurization includes the following steps of: 1) pre-treatment, wherein sulfide in acid gas undergoes through pre-treatment methods of sulfur recovery, acid making or / and incineration to convert remaining sulfur in the acid gas into sulfur oxides, and the acid tail gas with sulfur oxides is obtained; and the acid gas is derived from petrochemical industry, natural gas chemical industry, coal chemical industry, etc.; 2) ammonia absorption of sulfur oxides, wherein the acid tail gas with sulfur oxides is allowed to flow into an ammonia absorption apparatus, and a cyclic absorption solution is used to absorb sulfur oxides; and 3) post-treatment of ammonium sulfate, wherein a saturated or nearly saturated absorption solution undergoes concentration, crystallization, solid-liquid separation, and drying to obtain a solid product of ammonium sulfate. Sulfur oxides (including sulfur dioxide, sulfur trioxide and hydrates thereof) in the acid tail gas are removed and sulfuric acid, sulfur and ammonium sulfate are byproduced, and the cleaned gas is discharged upon meeting the emission standard.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

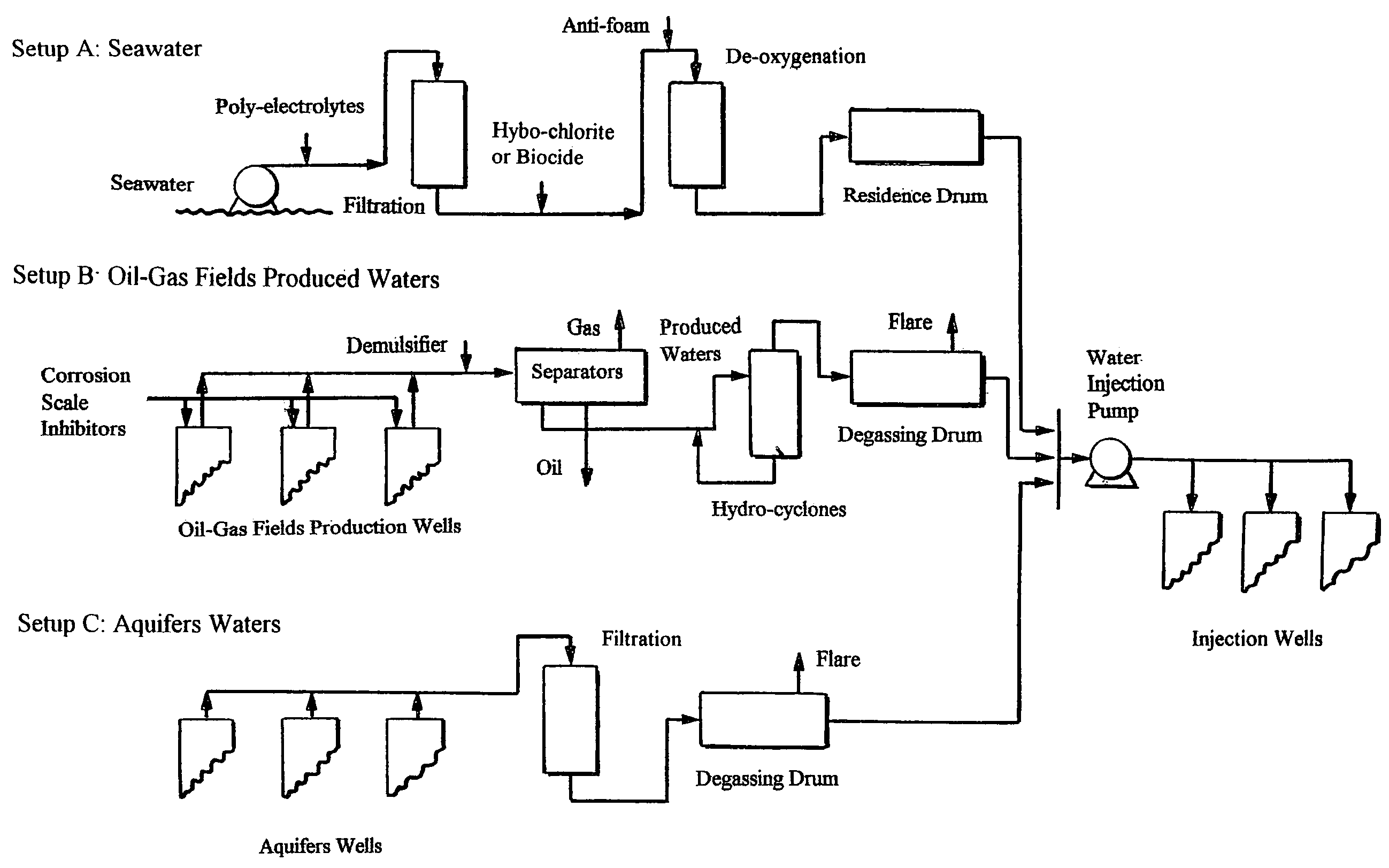

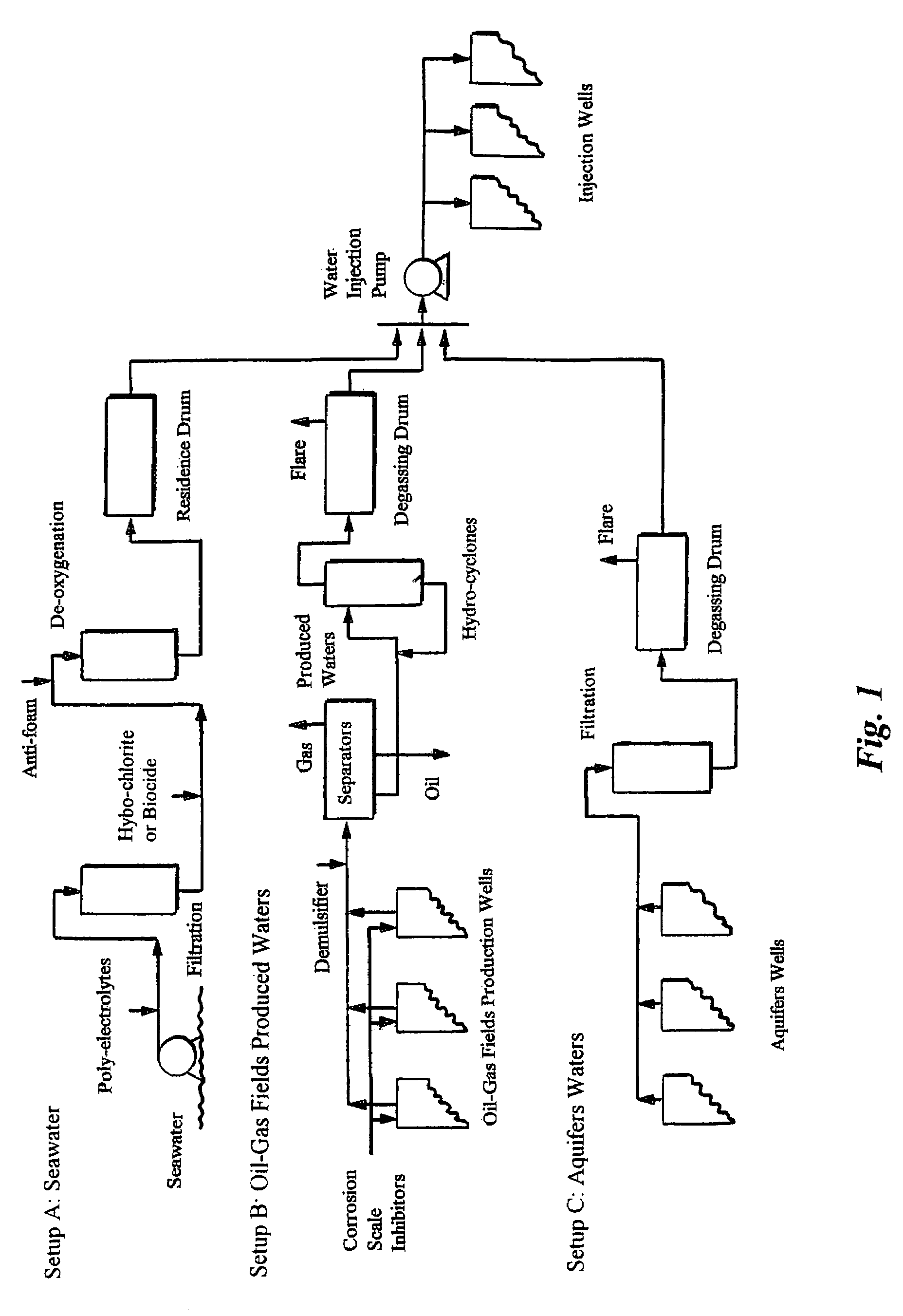

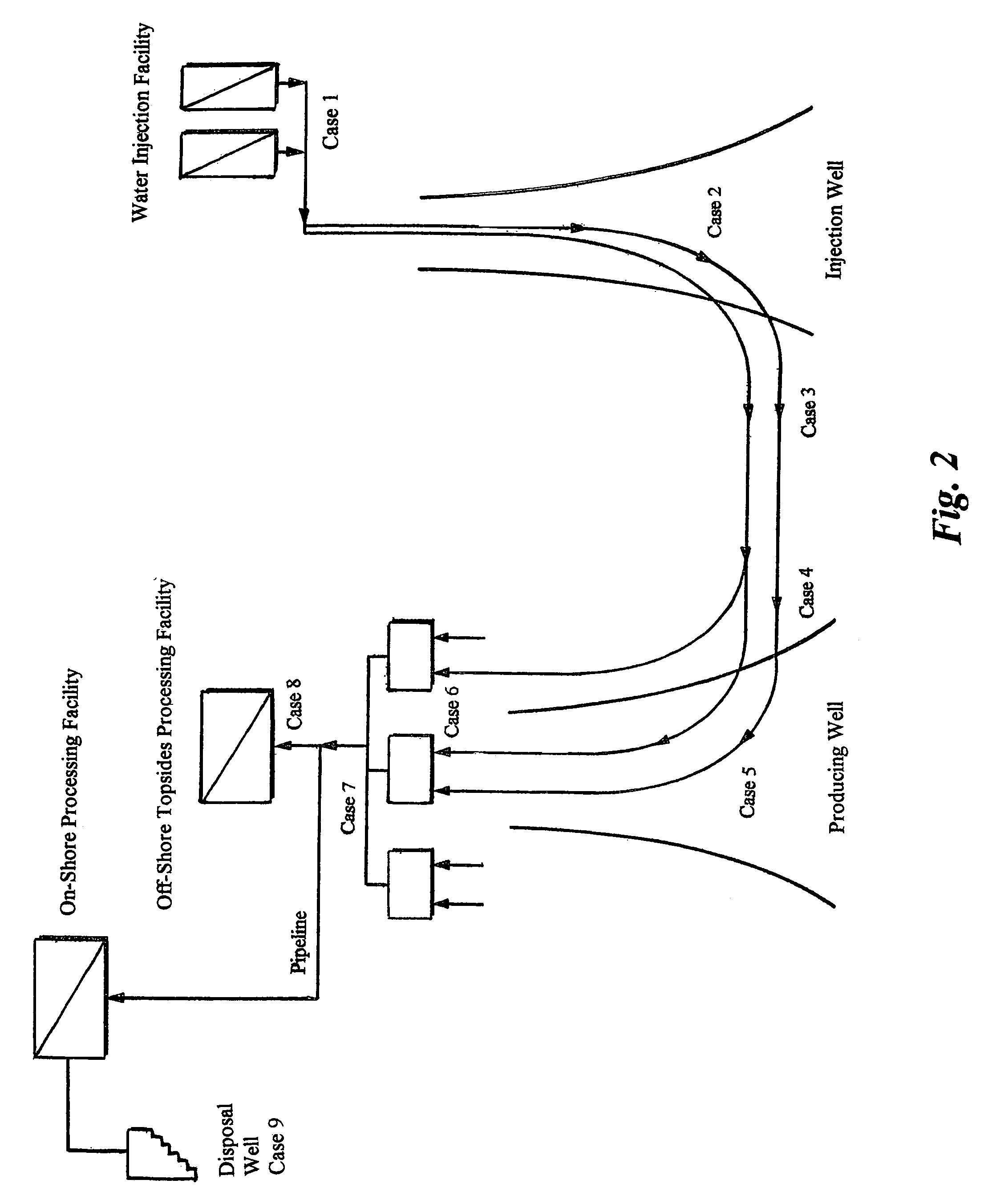

Methods to solve alkaline-sulfate scales and related-gases problems

InactiveUS7093663B1Sufficient absorption capacityLimited aqueous solubilitySeparation devicesFluid removalRadonProduced water

Methods for the removal of alkaline and sulfate scales from aqueous saline streams such as seawater, oil-gas fields produced waters, formation waters, and the like. Such processing methods can also be extended for the simultaneous removal of hydrogen sulfide, and / or sulfur dioxide, and / or oxides of nitrogen, and / or carbon dioxide from gaseous streams. The same processing concept with modified methods can further be employed for the removal of gases such as radon, hydrogen sulfide, sulfur dioxide, oxides of nitrogen, and carbon dioxide from gaseous streams.

Owner:BADER MANSOUR S

Sulfur oxide/nitrogen oxide trap system and method for the protection of nitrogen oxide storage reduction catalyst from sulfur poisoning

ActiveUS20070012028A1Improved NOx adsorption efficiencyIncreased durabilitySilencing apparatusMachines/enginesEmission standardNitrogen gas

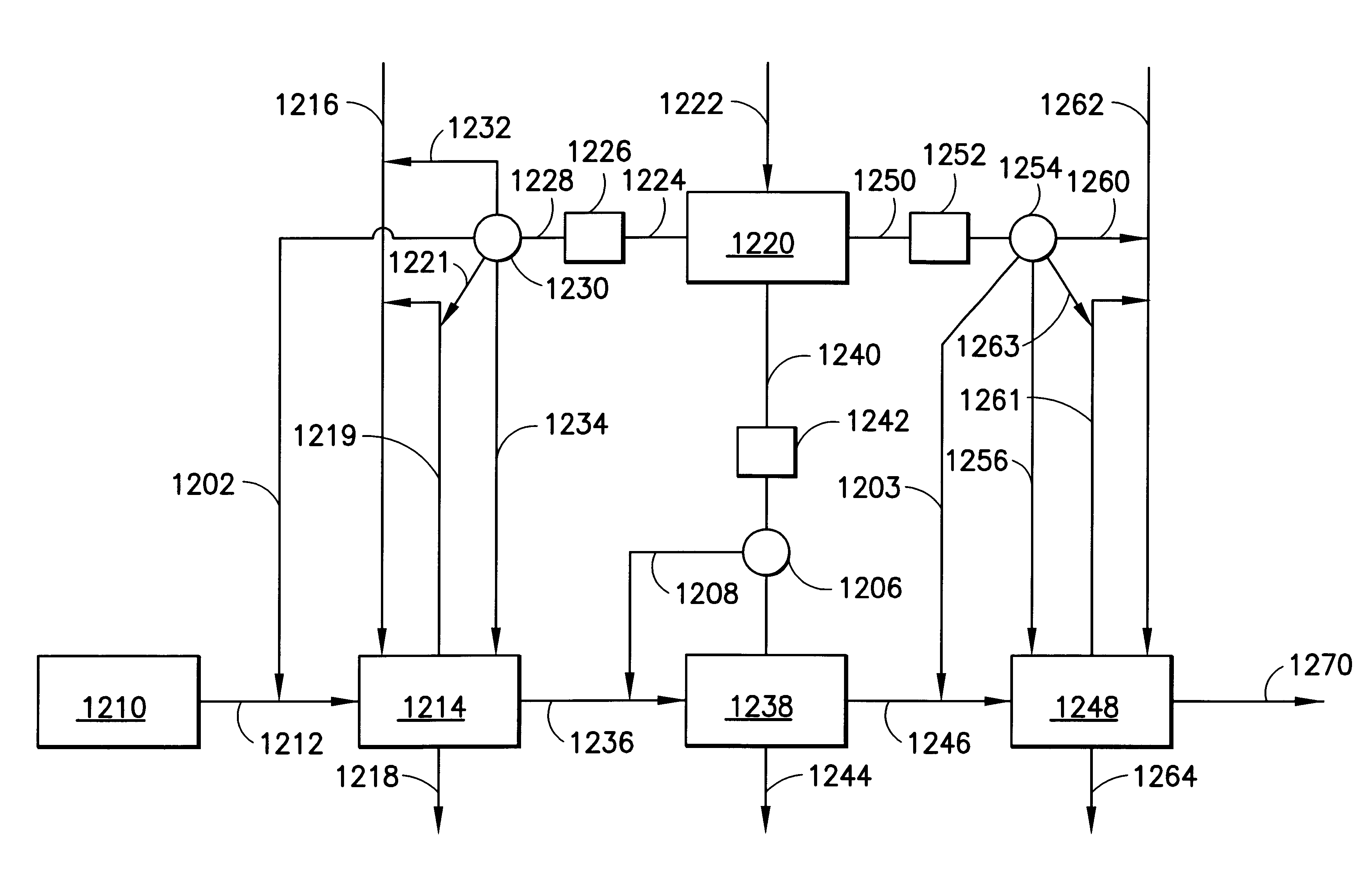

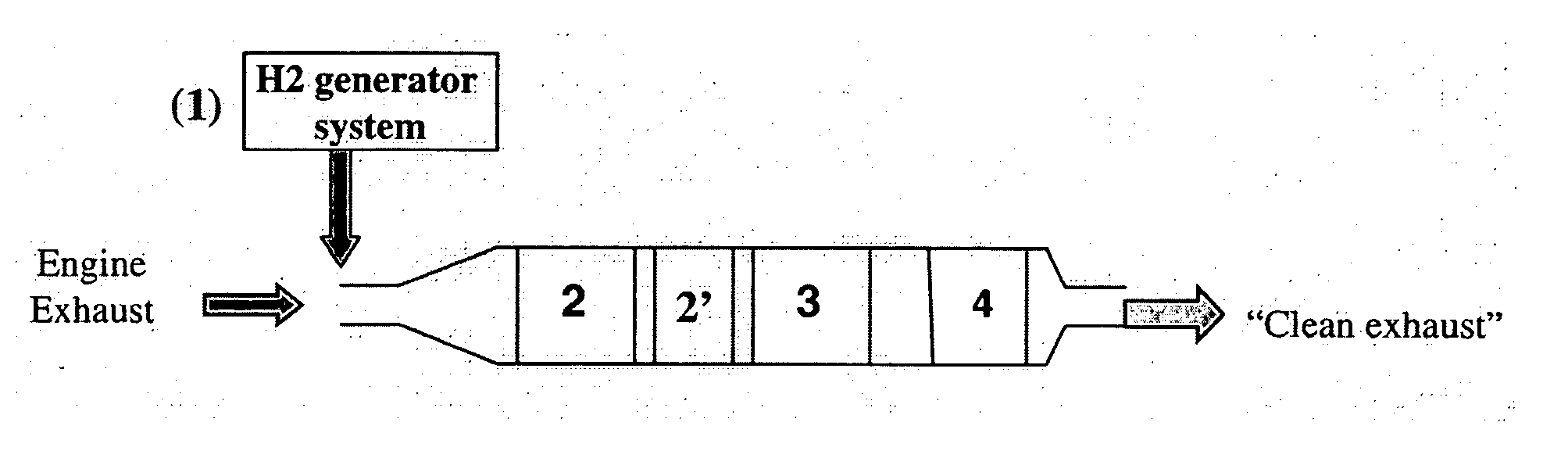

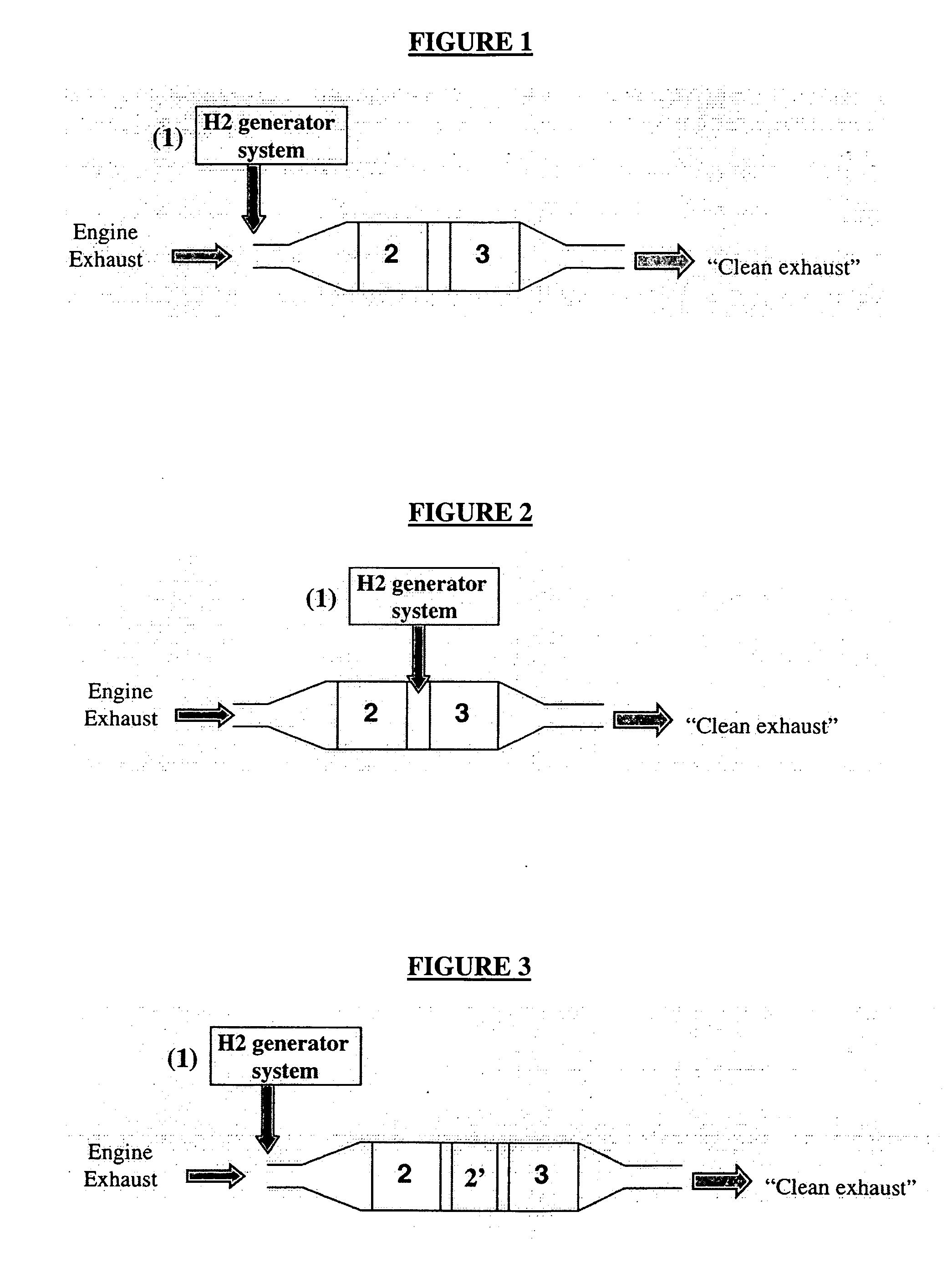

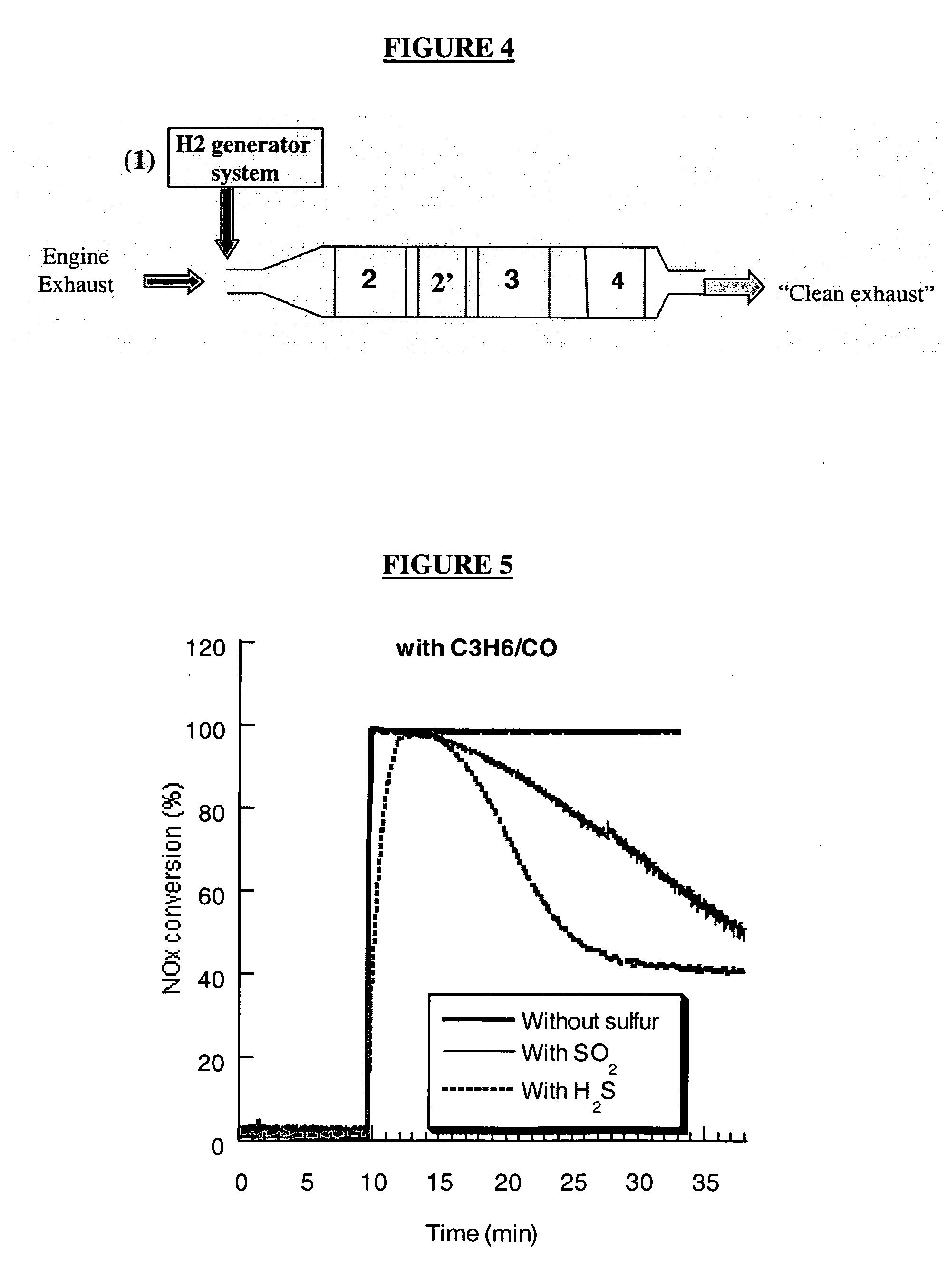

The present invention relates to an improved exhaust gas cleaning system and method for a combustion source comprising a hydrogen generation system, a sulfur oxides trap, and a nitrogen storage reduction (NSR) catalyst trap. The improved exhaust gas cleaning system and method of the present invention also provides for a water-gas-shift catalyst between the sulfur oxides trap and the NSR catalyst trap, and a clean-up catalyst downstream of the NSR catalyst trap. The invention provides also a sulfur trap regenerable at moderate temperatures with rich pulses, rather than at high temperatures. The improved exhaust gas cleaning system of the present invention provides for the sulfur released from the sulfur trap to pass through the nitrogen oxide trap with no or little poisoning of NOx storage and reduction sites, which significantly improves NSR catalyst trap lifetime and performance to meet future emissions standards. The disclosed exhaust gas cleaning systems are suitable for use in internal combustion engines (e.g., diesel, gasoline, CNG) which operate with lean air / fuel ratios over most of the operating period.

Owner:EXXON RES & ENG CO

Oxidative desulfurization and denitrogenation of petroleum oils

InactiveUS20060108263A1Active and fast in oxidizing the sulfurReduce the temperatureOrganic chemistryRefining with oxygen compoundsPtru catalystEnvironmental engineering

A robust, non-aqueous, and oil-soluble organic peroxide oxidant is employed for oxidative desulfurization and denitrogenation of hydrocarbon feedstocks including petroleum fuels. Even at low concentrations, the non-aqueous organic peroxide oxidant is extremely active and fast in oxidizing the sulfur and nitrogen compounds in the hydrocarbon feedstocks without catalyst. Consequently, the oxidation reactions that employ the non-aqueous organic peroxide oxidant take place at substantially lower temperatures and shorter residence times than reactions in other oxidative desulfurization and denitrogenation processes. As a result, a higher percentage of the valuable non-sulfur and non-nitrogen containing components in the hydrocarbon feedstock are more likely preserved with the inventive process. Desulfurization and denitrogenation occur in a single phase non-aqueous environment so that no phase transfer of the oxidant is required.

Owner:CPC CORPORATION

Combustion catalyst of hydrogen sulfide in gas and its preparation and use method

InactiveCN1410149AHigh selectivityImprove conversion rateDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystSilicon oxide

A combustion catalyst for the hydrogen sulfide in gas is composed of silicon oxide as carrier (75-96 wt.%), vanadium oxide (0.5-15) and iron oxide (0.2-10). Its advantages are high selectivity to hydrogen sulfide, high conversion rate of SO2 and catalytic activity, low operation temp. (250-350 deg.C), and high specific surface area and strength.

Owner:CHINA PETROLEUM & CHEM CORP

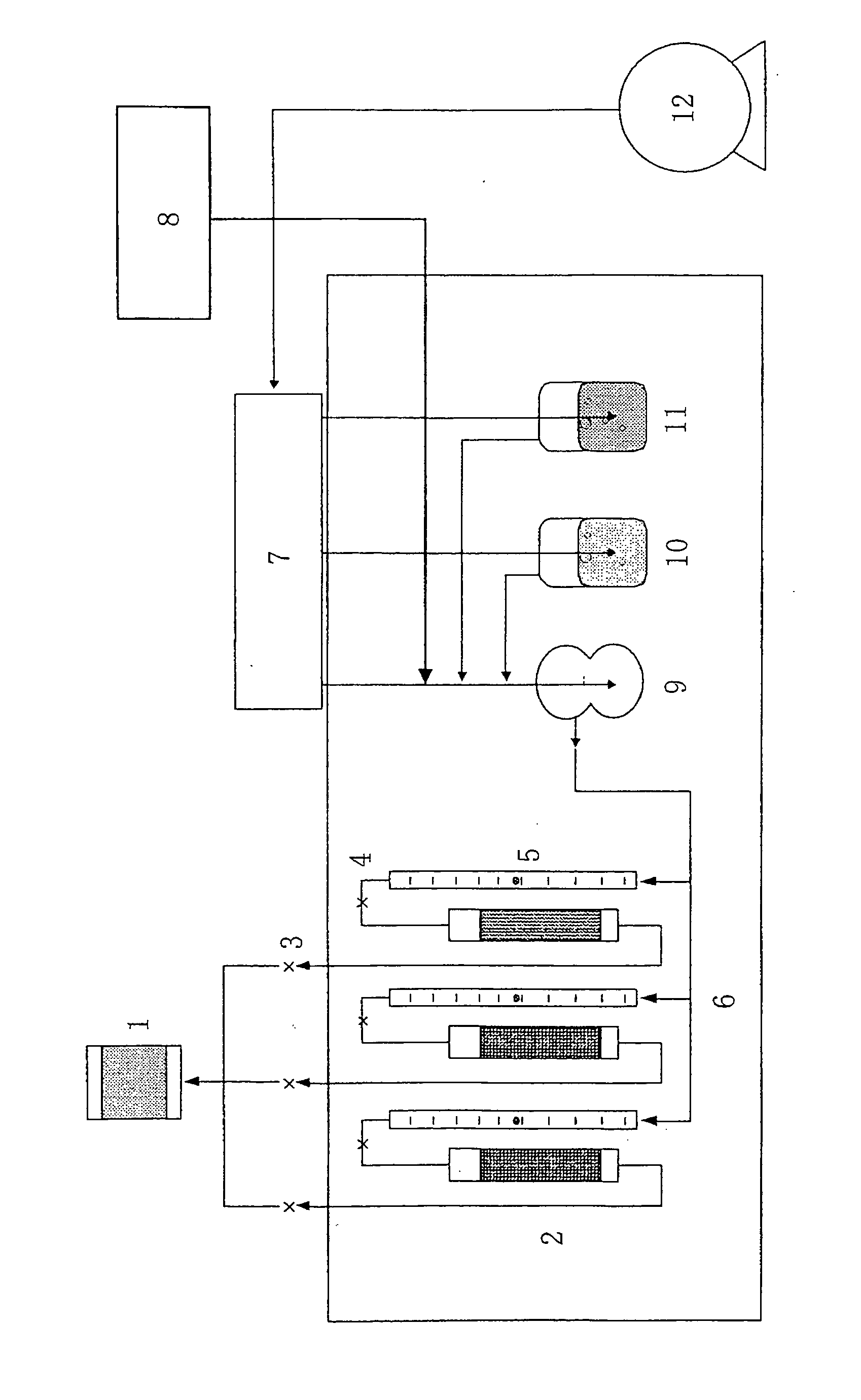

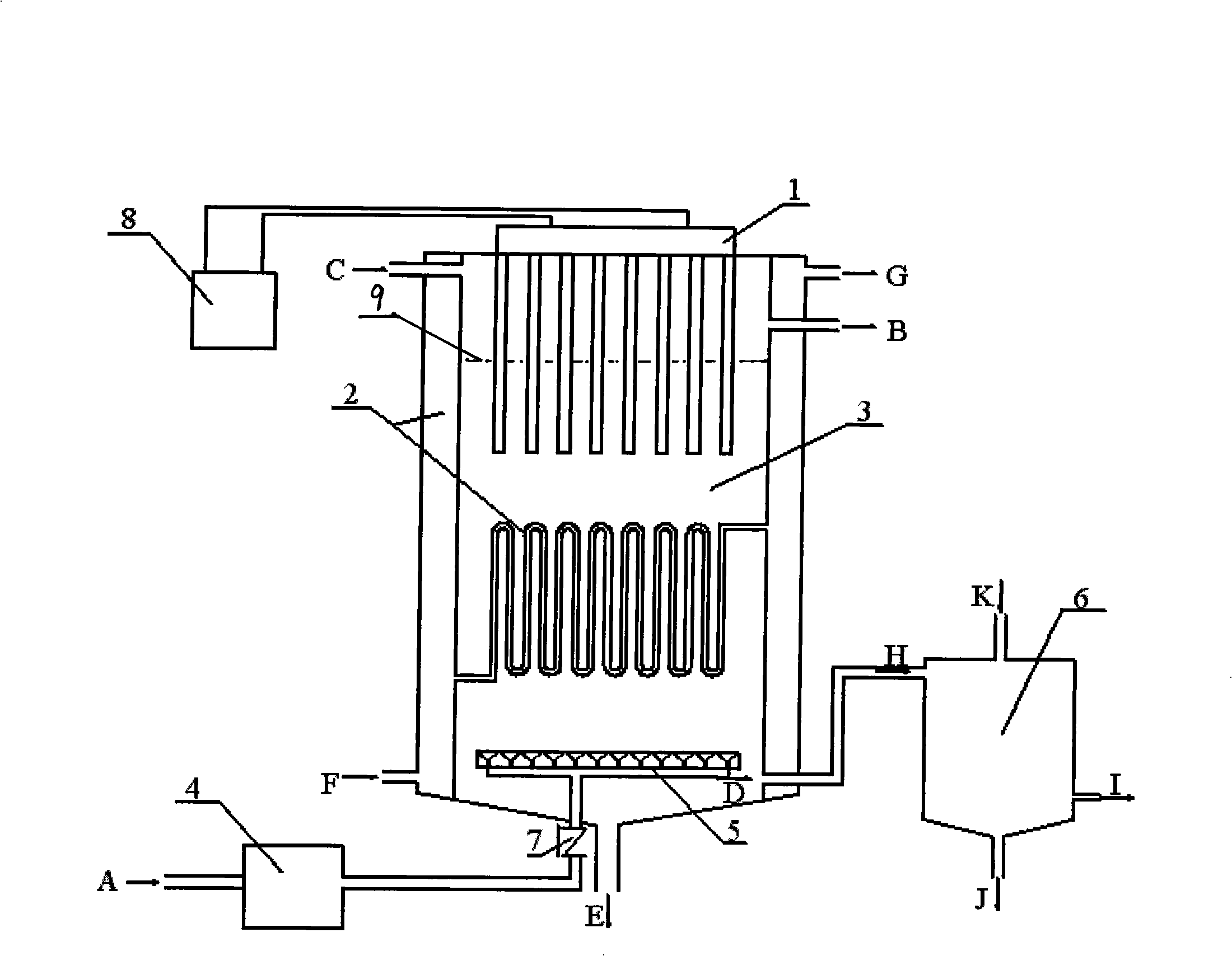

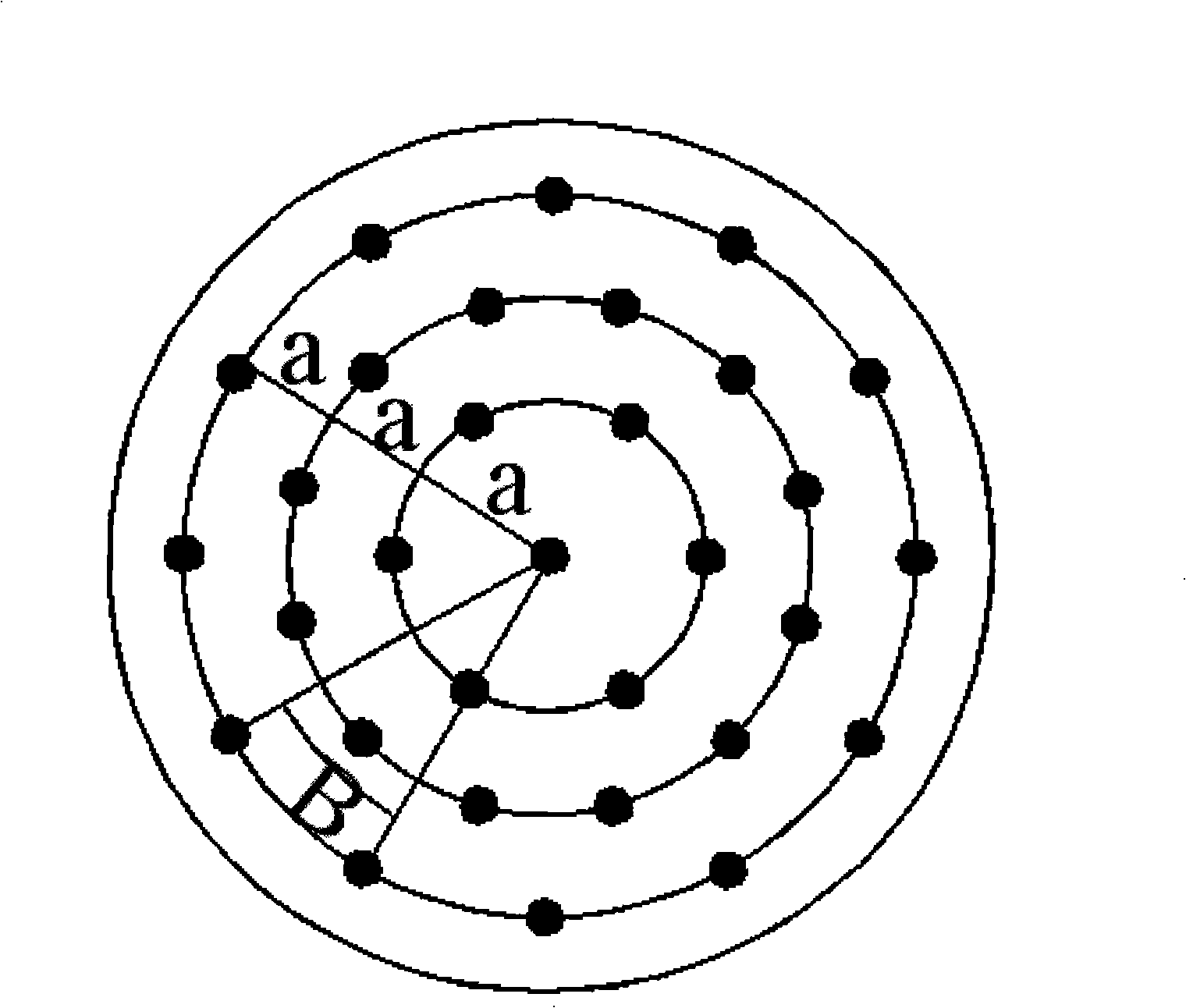

Ultrasonic integration desulfurization denitration demercuration method and device thereof

InactiveCN101337153ACost savingsSave operation and maintenance costsDispersed particle separationEnergy based chemical/physical/physico-chemical processesCavitationAtmospheric air

The invention provides a method for integrally desulfurizing, denitrating and removing mercury under the ultrasonic action. Hydroxyl free radicals OH* with strong oxidizability are released when a cavitation effect is generated in a reaction solution under the ultrasonic action and subjected to the oxidization removal reaction with sulfur oxides, nitrogen oxides and Hg<0> in fume; the cleaned fume is exhausted to the atmosphere; the separated mixed acid solution is applied for producing fertilizers after being absorbed by ammonia water; and the heavy metal precipitate is extracted for the recovery. An ultrasonic generator, an ultrasonic transmitter, a cooling water system, a bubbling bed reactor, an electrostatic dust collector, a fume diffuser, a separating column and a check valve are provided. The ultrasonic transmitter is disposed in the bubbling bed reactor. The fume is introduced into a pipe, sequentially passes through the electrostatic dust collector and the check valve and is introduced into the fume diffuser from the bottom of the bubbling bed reactor. A fume outlet is positioned at the upper part of the bubbling bed reactor. A residue discharge port is formed at the bottom of the bubbling bed reactor. The inlet of the separating column is connected with the outlet of the reaction products of the bubbling bed reactor. The separating columns are respectively provided with an insoluble substance outlet, a chemical feed port and a soluble substance outlet.

Owner:SOUTHEAST UNIV

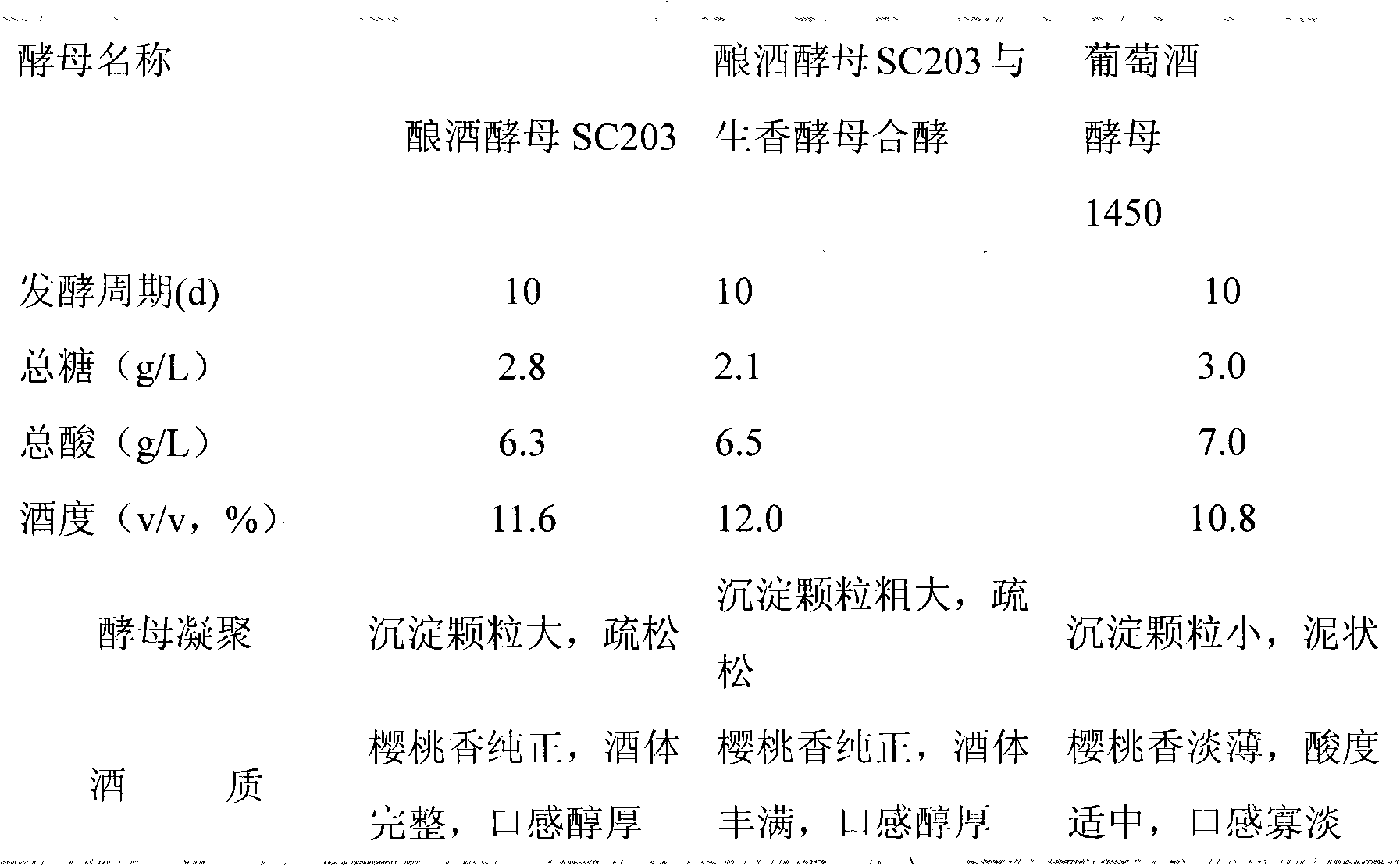

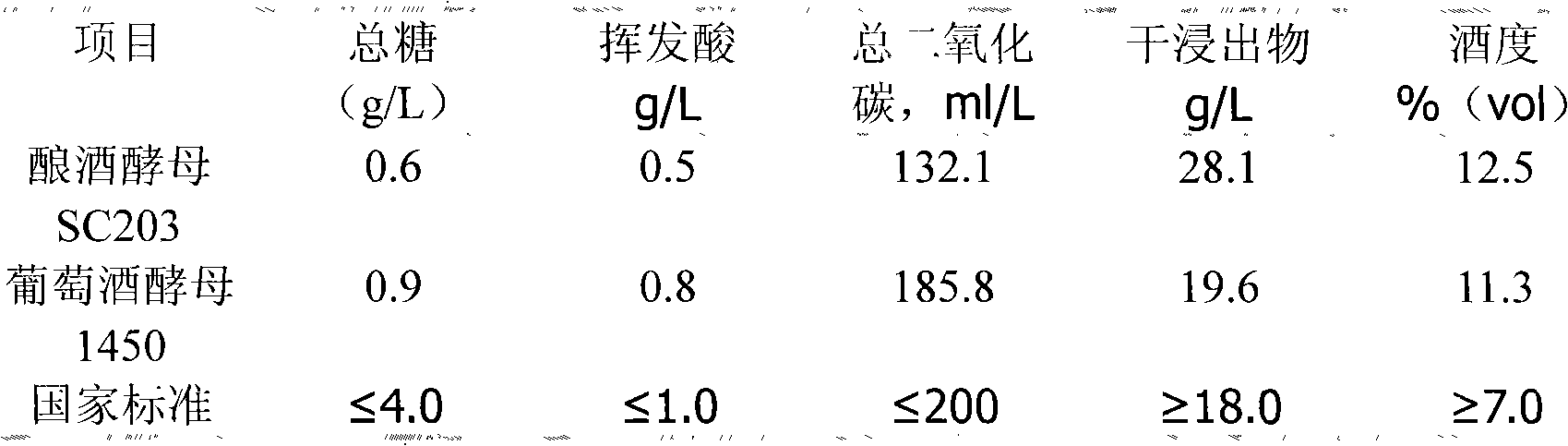

Saccharomyces cerevisiae and screening method and application thereof

ActiveCN101550400AShorten the fermentation cycleStrong low temperature fermentation abilityFungiBeer fermentationMicroorganismAlcohol

The invention relates to screening and application of saccharomyces cerevisiae suitable for the brewing of a series of kirschwasser, pertaining to the technical field of biological engineering. SC203 strain of the saccharomyces cerevisiae has been preserved in Center of General Microbiology of China Committee for Culture Collection of Microorganisms, with a registration number of CGMCC No. 2786. The strain is characterized by rapid growth, early fermentation, short fermentation cycle, strong tolerance against low temperature, acid, alcohol, sulfur dioxide and the like and is applicable to the brewing of such a series of kirschwasser as kirschwasser, ice kirschwasser, kirschwasser liqueur, kirschwasser ratafee and the like. In addition, the strain can also be used for the brewing of grape wine and other common ratafee and icewine.

Owner:山东九道生物科技有限公司

Anti-Corrosion Conformal Coating for Metal Conductors Electrically Connecting an Electronic Component

InactiveUS20110189381A1Prolong lifeFinal product manufacturePretreated surfacesElectrical conductorPhosphine

An apparatus includes an electronic component mounted on a substrate and metal conductors electrically connecting the electronic component. A conformal coating overlies the metal conductors and comprises a polymer into which a phosphine compound is impregnated and / or covalently bonded. Accordingly, the conformal coating is able to protect the metal conductors from corrosion caused by sulfur components (e.g., elemental sulfur, hydrogen sulfide, and / or sulfur oxides) in the air. That is, the phosphine compound in the polymer reacts with any corrosion inducing sulfur component in the air and prevents the sulfur component from reacting with the underlying metal conductors. Preferably, the phosphine compound in the polymer does not react with other components in the air (e.g., carbon dioxide) which would otherwise deplete its availability for the target reaction. The phosphine compound may be rendered completely non-volatile by covalently bonding it directly into the polymer backbone.

Owner:IBM CORP

Mercury removal system and mercury removal process

ActiveUS20070202020A1Improve reliabilityReduce operating costsCombination devicesNitrogen compoundsFlueSulfur oxide

Provided is a system for removing mercury from a mercury-containing exhaust gas, which contains a mercury chlorinating agent feed unit for feeding a mercury chlorinating agent to an flue exhaust gas containing nitrogen oxide, sulfur oxide and mercury, a reductive denitration unit for reducing the nitrogen oxide, and a desulfurization unit for removing the sulfur oxide, characterized in that the mercury chlorinating agent feed unit further comprises a heating unit for heating a non-gaseous agent for mercury chlorination which is in the non-gaseous form under normal temperature and normal pressure or a gasifying unit for obtaining a gaseous agent for mercury chlorination from the non-gaseous agent for mercury chlorination. The present invention makes it possible to provide a mercury removal process and system which have high reliability and can be operated at a low cost.

Owner:MITSUBISHI POWER LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com