Device and method for removing sulfur trioxide from smoke

A sulfur trioxide and flue gas technology, applied in chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve the problems of flue corrosion at the denitrification inlet, front-end denitrification device, air preheater hazards, and more pollutant emissions. , to achieve the effect of reducing SO3 content, reducing clean emissions and high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Alkaline absorbent choose magnesium hydroxide Mg(OH) 2 Particles with an average particle size of 40 μm.

[0029] The flue gas temperature at the denitrification inlet is 350°C, SO 3 Content 20ppm, according to flue gas conditions and magnesium oxide composition, determine the chemical reaction equivalent ratio SO 3 : Mg(OH) 2 =1:3, through a higher stoichiometric ratio to ensure SO 3 removal efficiency.

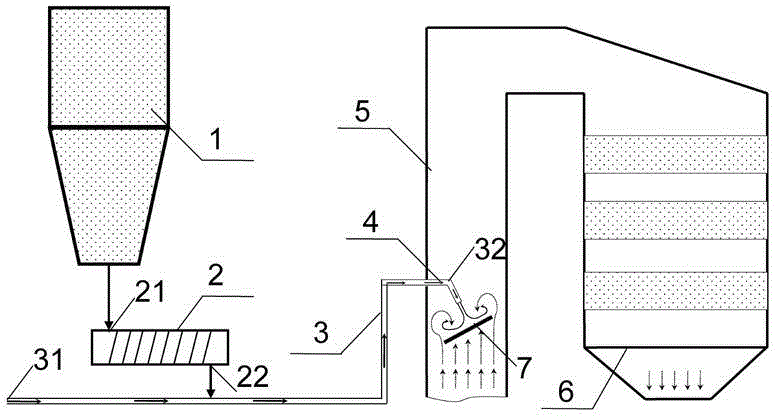

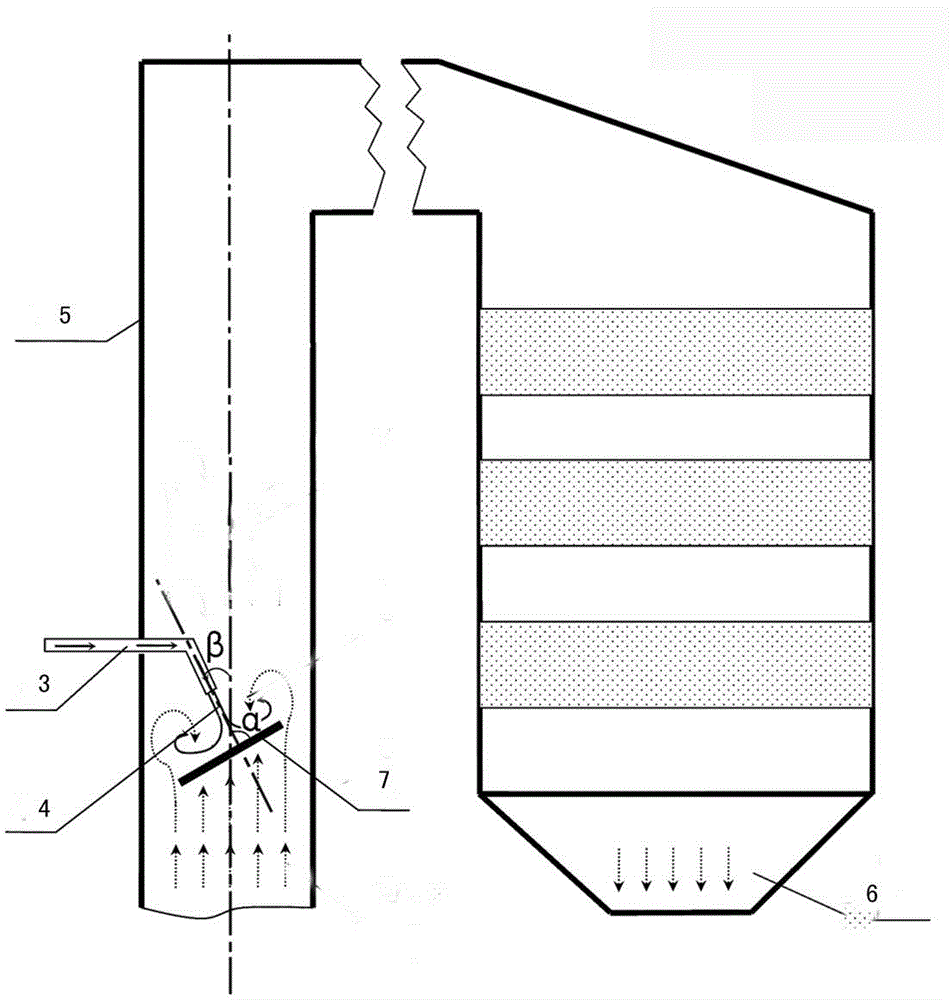

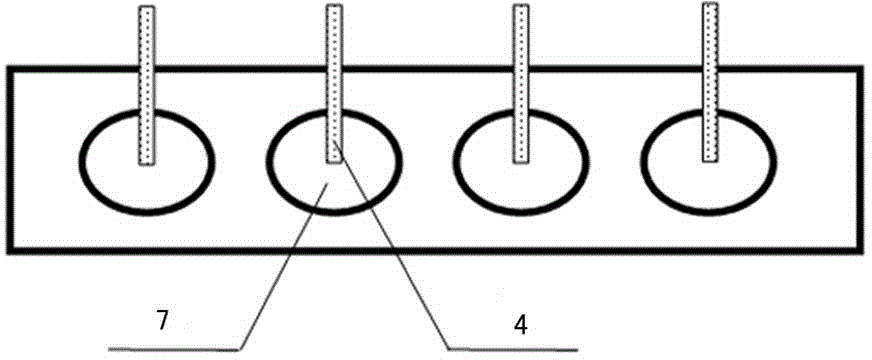

[0030] Such as figure 1 As shown, a method for removing SO from flue gas 3 In the process system, the magnesium hydroxide absorbent is stored in the silo 1 in the form of powder, and the feeding rate of the absorbent is controlled by the screw feeder 2, and the pneumatic conveying system 3 uses compressed air to transport magnesium hydroxide particles to the injection device 4. Spray magnesium hydroxide particles into the denitrification inlet flue 5 . Magnesium hydroxide is uniformly mixed with the flue gas in the denitrification flue, and part of the SO in t...

Embodiment 2

[0034] The difference between this embodiment and embodiment 1 is that sodium bicarbonate is used as the alkaline absorbent, and the particle size of the absorbent is 60 μm.

[0035] The alkalinity of sodium bicarbonate alkaline absorbent is higher than that of magnesium hydroxide, so the chemical equivalent ratio SO3:NaHCO3=1:5, under the design conditions, the removal efficiency of SO3 is 90%.

Embodiment 3

[0037] The difference between this example and Example 1 is that calcium hydroxide (Ca(OH)2) is used as the alkaline absorbent, and the particle size of the absorbent is 40 μm.

[0038] The alkalinity of calcium hydroxide is slightly weaker, so the chemical equivalent ratio of SO3:Ca(OH)2=1:8, under the design conditions, the removal efficiency of SO3 is 65%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com