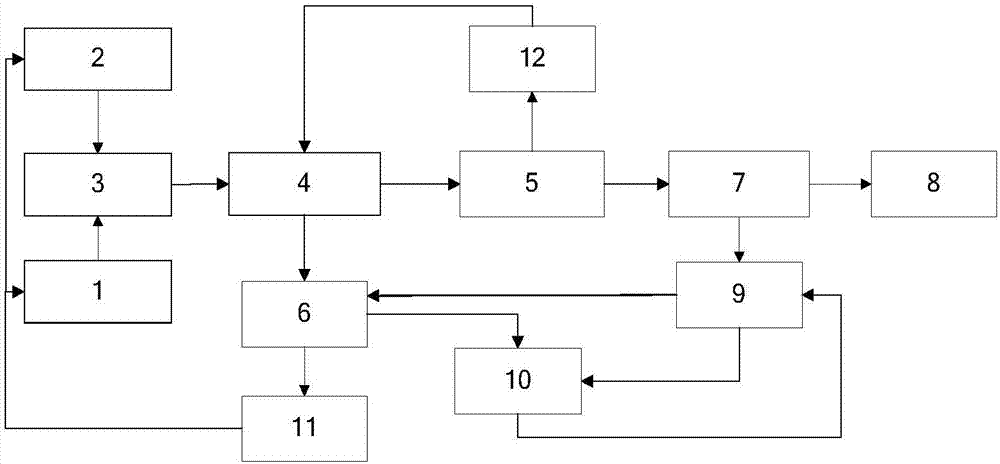

Patents

Literature

63results about How to "Achieve clean emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

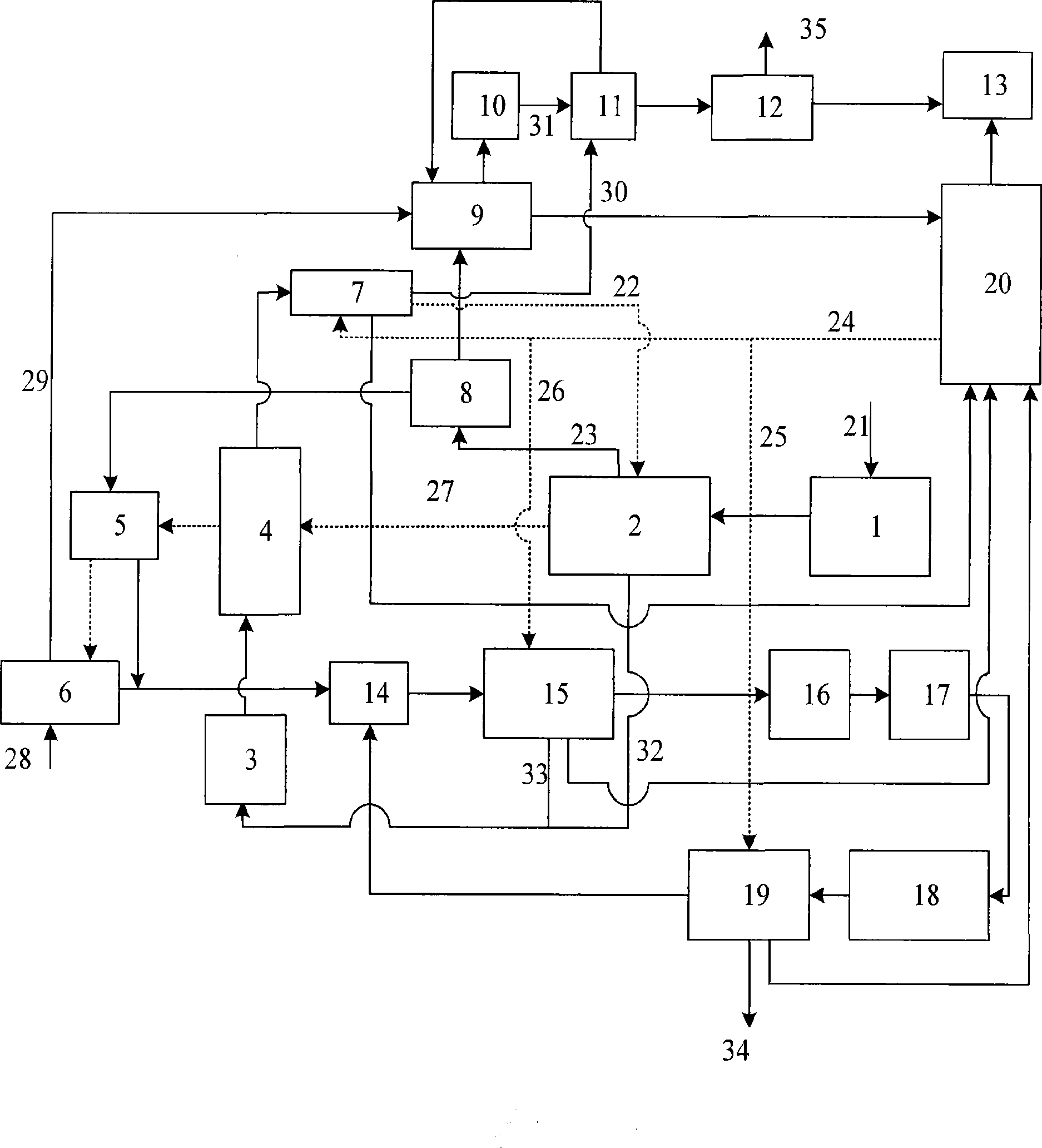

Integrated process of furfural production as well as wastewater, waste slag and waste gas treatment

InactiveCN101481189ACurb emissionsPollution suppressionOrganic chemistryEnergy inputWater vaporDistillation

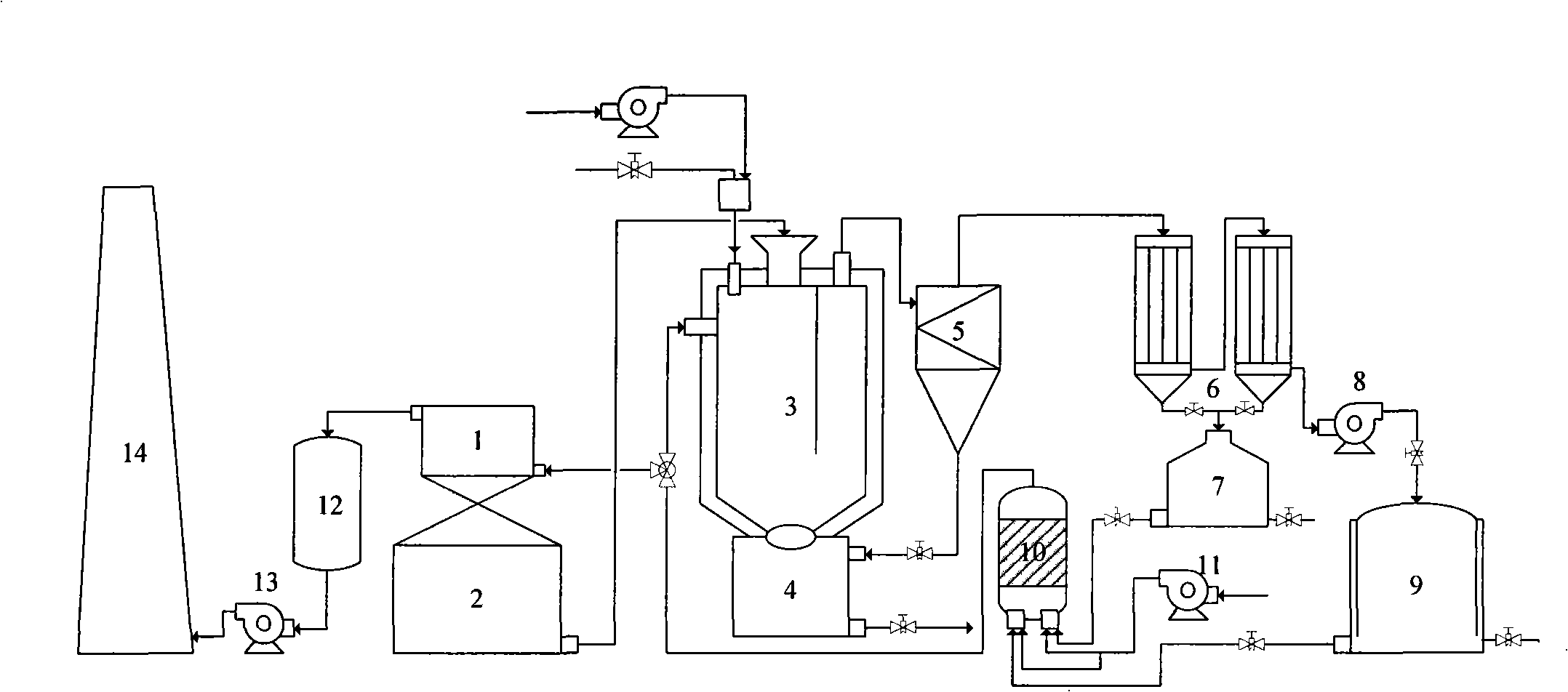

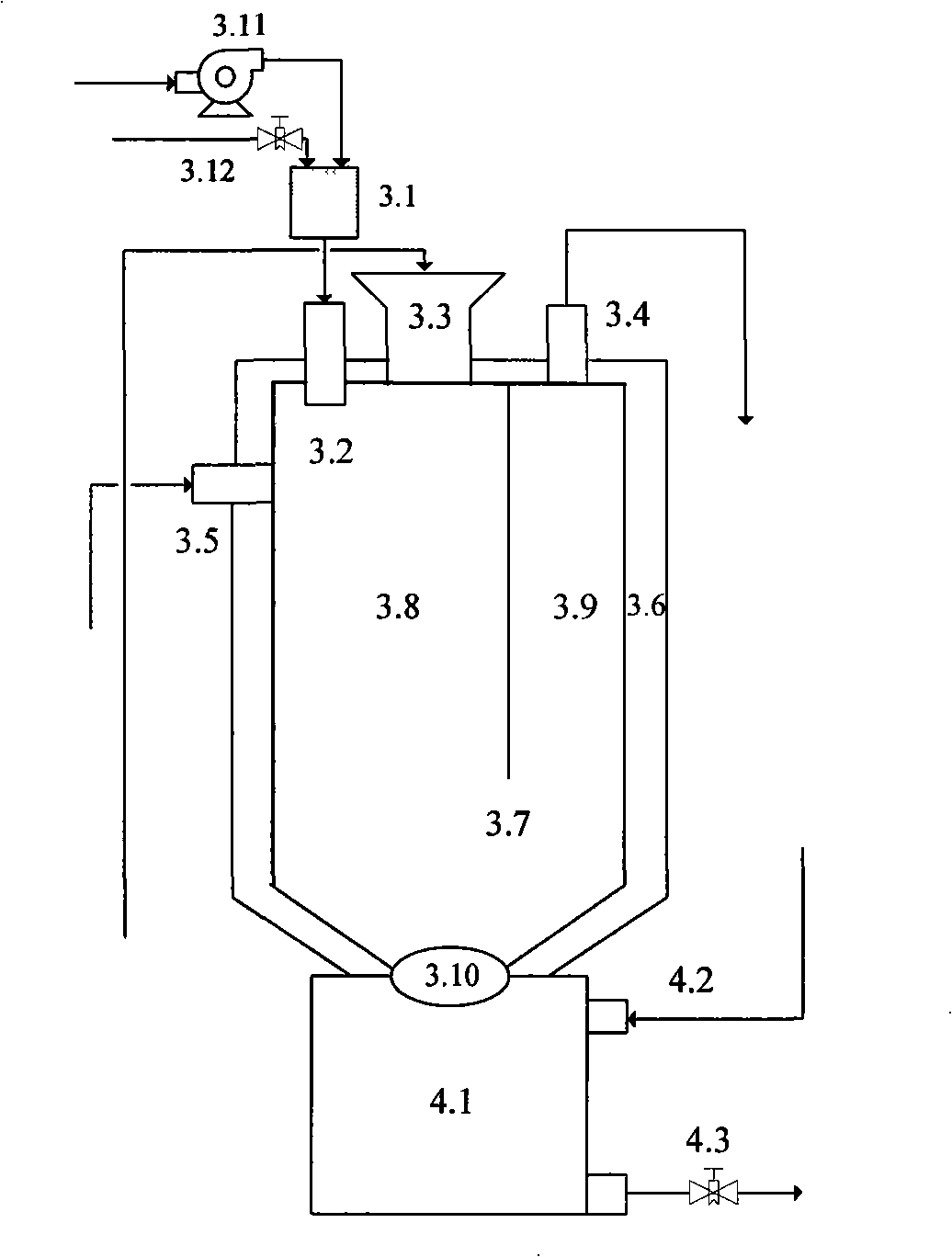

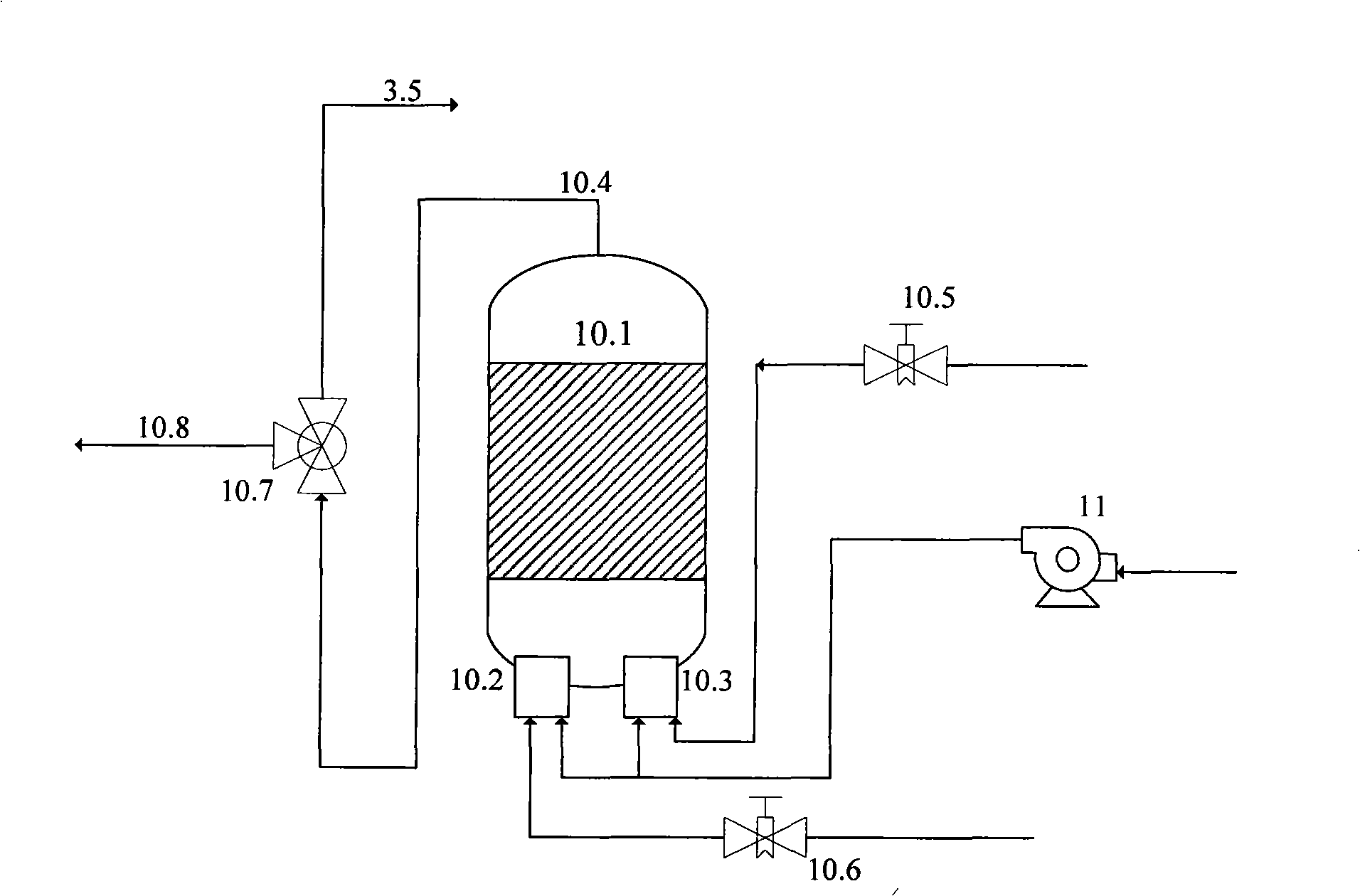

The invention belongs to the technical field of the chemical production, and relates to a technology for optimizing energy saving and integrating treatment of waste water, waste slag and waste gas in a furfural production process, which is suitable for the energy saving and the three-waste treatment and reformation of furfural production enterprises. The technology is characterized in that limestone and dolomite are used for neutralizing furfural waste water to convert acetic acid into calcium magnesium acetate, and then the water exchanges heat with high-temperature aldehyde gas generated by a hydrolysis kettle to enter an evaporator; high-temperature vapor generated by the vaporization of the waste water enters the hydrolysis kettle to be used as a reaction medium, the residual concentrated liquid is decolorized for extracting calcium magnesium acetate salt, and the residual liquid is used for smoke desulfurization and denitration. After the low-pressure automatic heating and vaporization of high-temperature aldehyde slag for furfural recovery, the high-temperature aldehyde slag is dried at a low temperature to reduce the water content of the aldehyde slag to be lower than 20 percent. The invention has the advantages that the utilization rates of materials and energy are greatly increased, the zero discharge of three wastes is realized without additional energy consumption, and the calcium magnesium acetate salt of high value is also prepared. After the automatic heating distillation and low-temperature drying of the aldehyde slag, the aldehyde slag is used for active carbon and is effectively and cleanly burnt.

Owner:DALIAN UNIV OF TECH

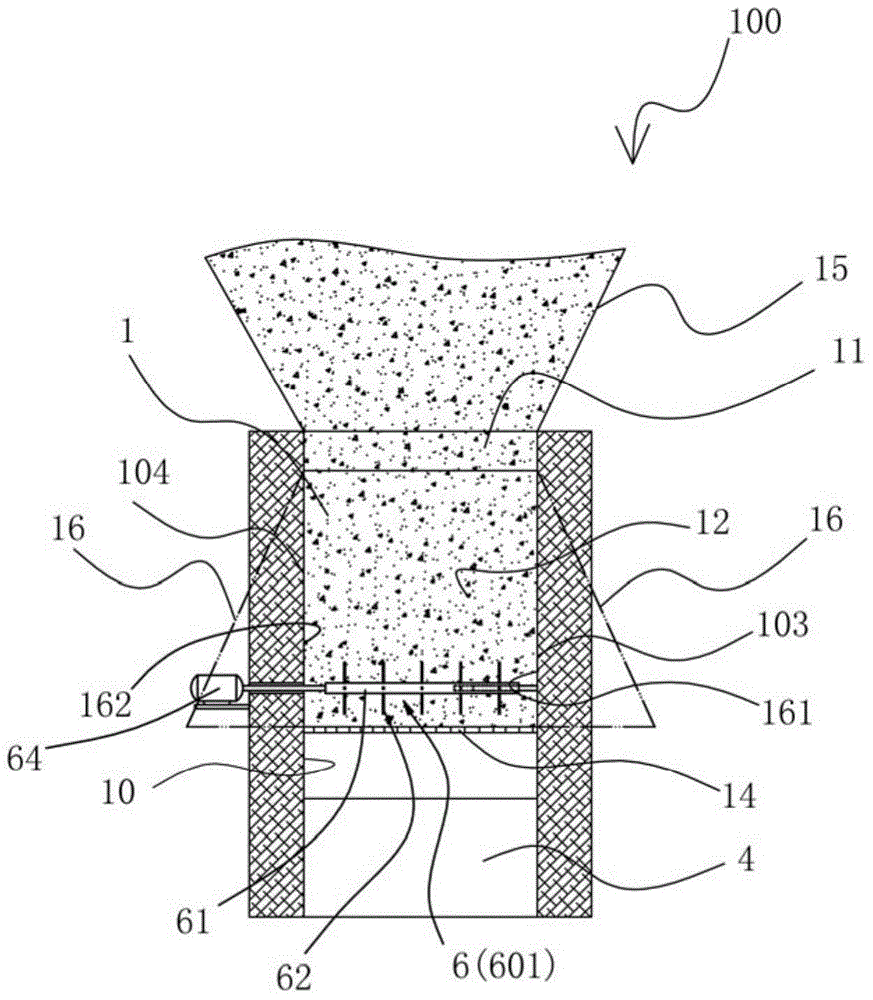

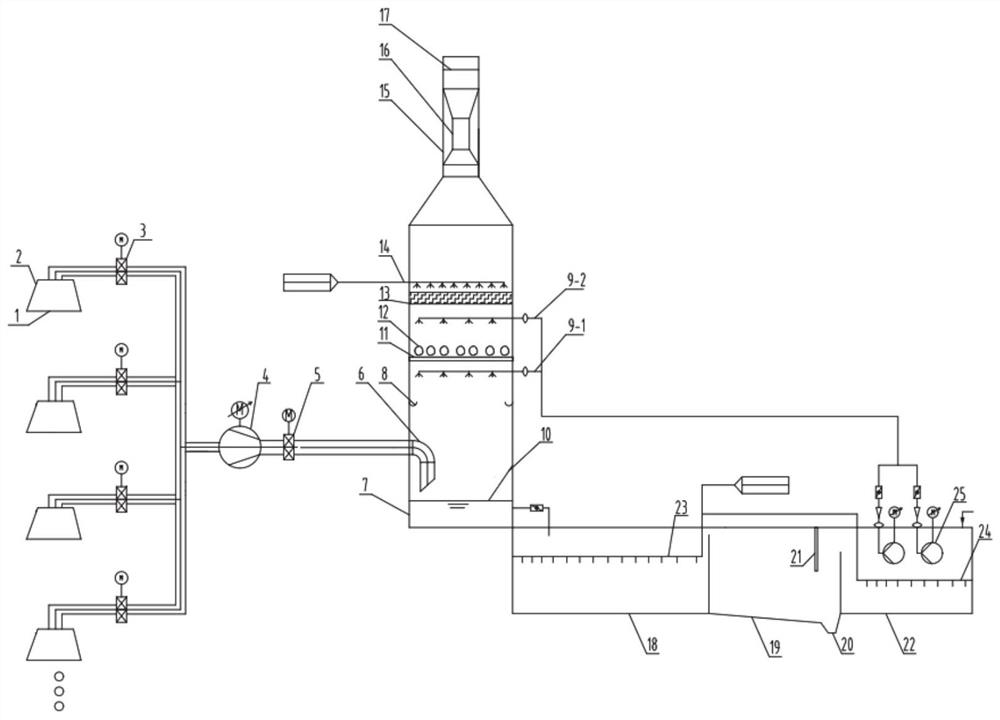

Downdraft type fixed bed gasifying steam power generation co-production device and process

ActiveCN105505469AImprove use valueImprove economic efficiencySteam useEnergy inputTarActivated carbon

The invention provides a downdraft type fixed bed gasifying steam power generation co-production device. The device comprises a gasifying system and a power generation system. The power generation system is driven by the gasifying system to work, and comprises a gas combustion chamber which is connected with a gas pyrolysis fan and a gas gasifying fan. An air preheater and a boiler heating face are arranged in a desulfuration chamber, the top of the desulfuration chamber is connected with a tail gas treatment device, a middle boiler body is connected with a low-pressure cylinder of a turbine through a pipeline, and a generator is mounted on the turbine. Biomass pyrolysis gas biomass charcoal-power co-production is based on the characteristic that the combustible components of biomass are composed of a volatile component and fixed carbon, a decoupling reaction mode is adopted, fixed carbon in biomass is converted into nitrogenous activated carbon with efficient desulfuration properties, the volatile component is converted into pyrolysis gas and gasified gas to be combusted, electric energy is obtained, macromolecular tar in the pyrolysis gas is utilized for reducing nitric oxide generated during gas combustion, and clean emissions of combustion tail gas are achieved.

Owner:HEFEI DEBO BIOENERGY SCI & TECH

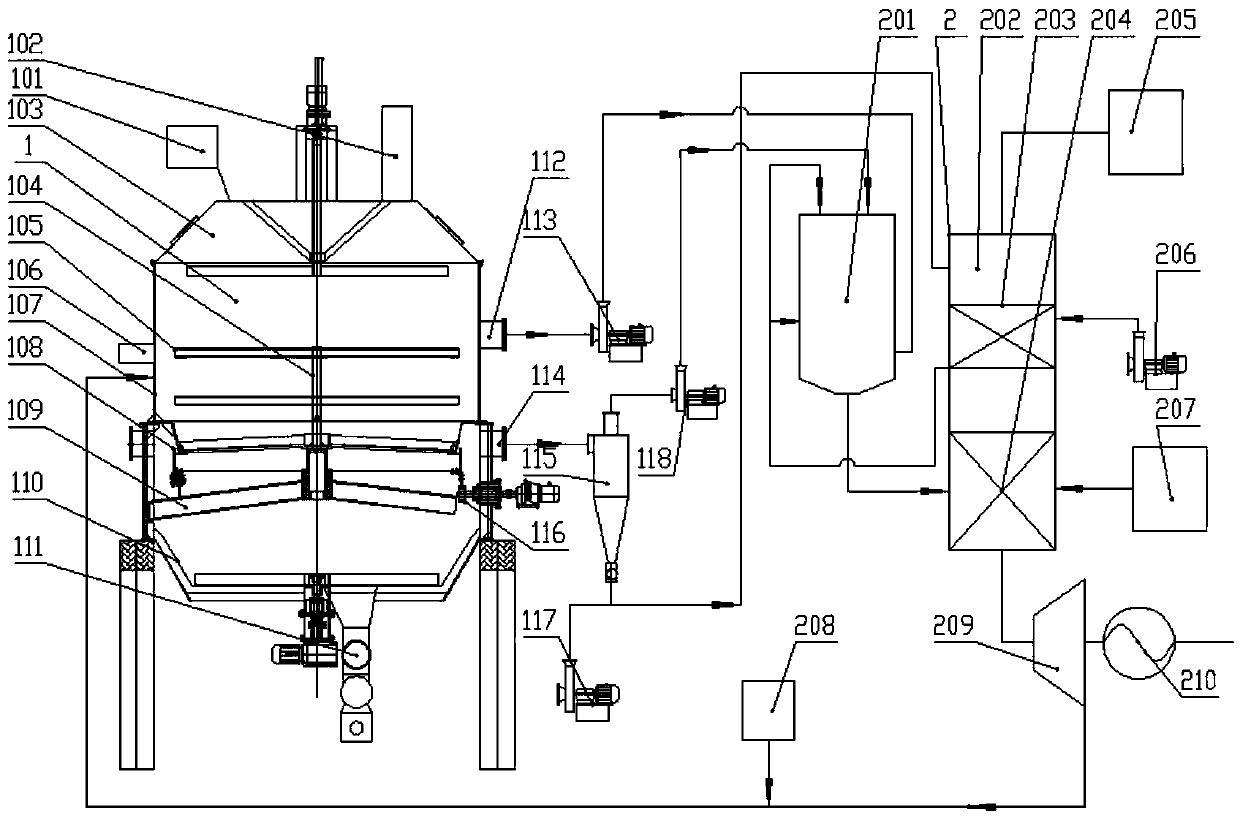

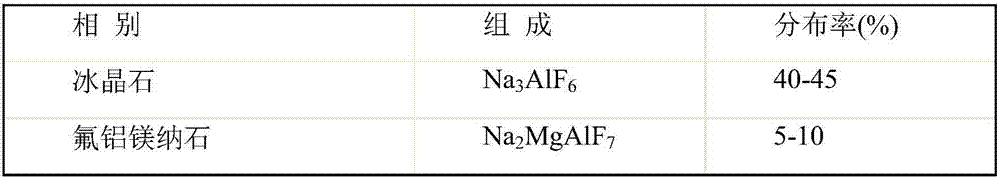

Treatment device and method for slag obtained after overhauling aluminum electrolysis cell

ActiveCN107401746ALose toxicityEliminate hazardsClinker productionIncinerator apparatusElectrolysisSlag

The invention provides a treatment device and method for slag obtained after overhauling an aluminum electrolysis cell. The treatment method comprises the following steps: crushing the slag obtained after overhauling the aluminum electrolysis cell, mixing the crushed slag with a lime fluoride retention additive, grinding the mixture, performing powder selection circulation to obtain powder, and combusting the powder in a cement kiln, so as to completely eliminate hazards and enable the aluminum electrolysis cell to completely lose toxicity. According to the treatment device and method for slag obtained after overhauling the aluminum electrolysis cell, the overall treatment process is carried out in a sealing environment, exhaust gas generated is basically dry gas and finally discharged after being combusted, so that the clean emission is realized, and the secondary atmospheric pollution is avoided; besides, residue generated is used as a cement clinker and can be effectively reutilized, the risk of secondary pollution is completely eliminated, and the environment and production safety is also realized.

Owner:长沙中硅环保科技有限公司

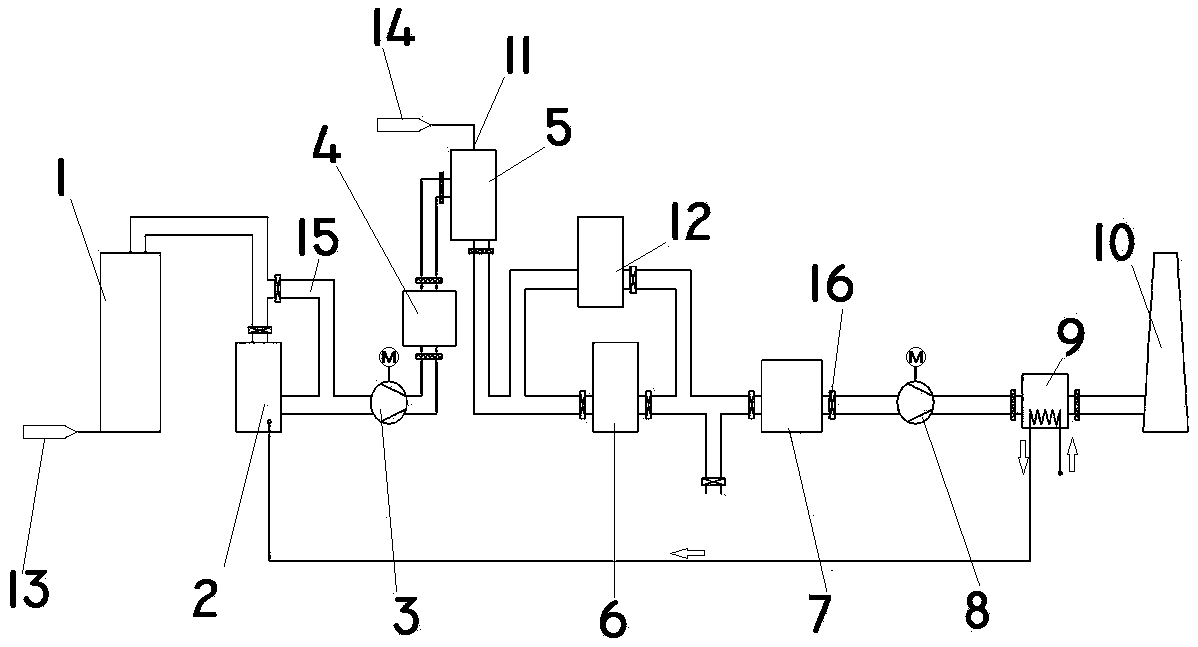

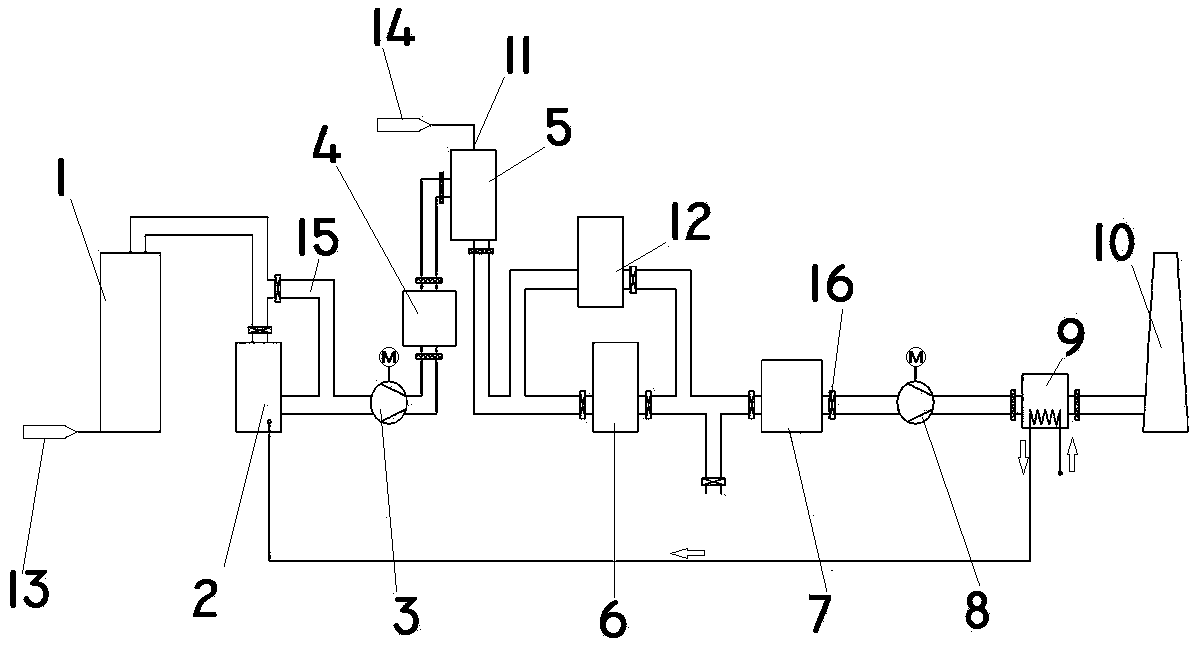

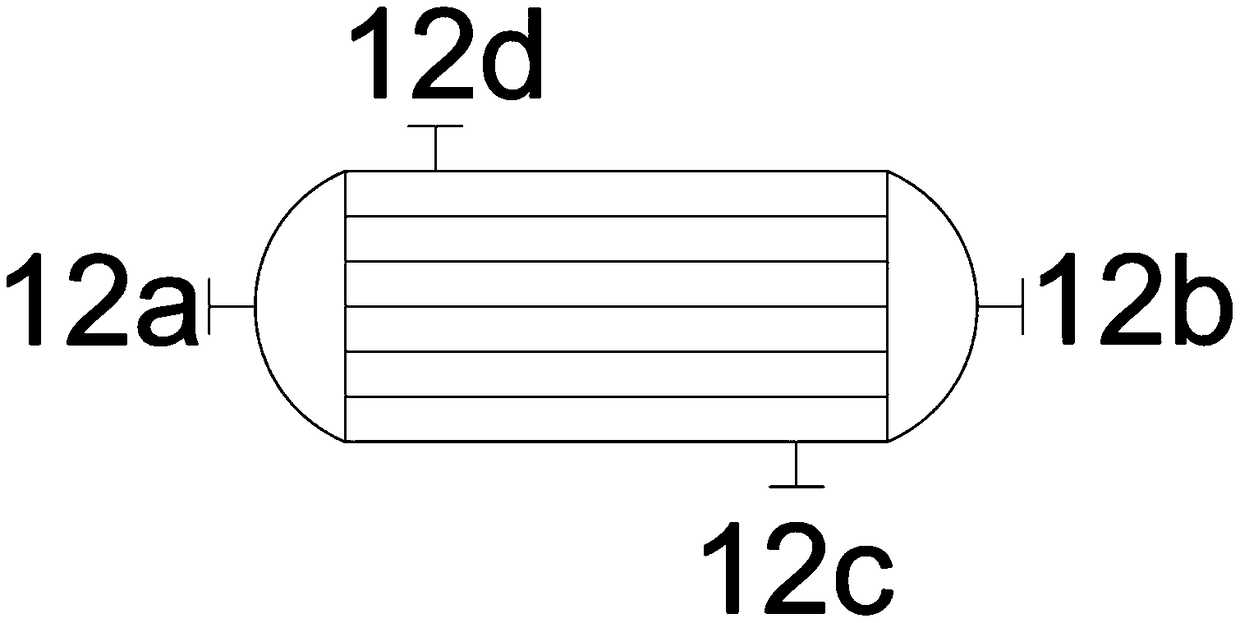

Waste heat recovery condensation water-saving device

InactiveCN103861420AAchieve clean emissionsImprove capture abilityCombination devicesVapor condensationWater savingFlue gas

The invention belongs to the technical field of waste gas purification, and particularly relates to a waste heat recovery condensation water-saving device used for flue gas which is treated by a wet desulfurization device. According to the waste heat recovery condensation water-saving device provided by the invention, the technical principles of a tubular heat exchanger, a tubular dust collector and a water collection drop catcher are combined together, so that waste heat recovery, condensation water recovery and deep dust removal for the wet saturated flue gas treated by the wet desulfurization device can be realized, the problems of dedusting and demisting the flue gas treated by the wet desulfurization device can be solved, and a great deal of water in the flue gas and part of latent heat of vaporization can be recycled. The waste heat recovery condensation water-saving device is generally applied to the energy source environmental protection industry, has the working position at the downstream part of the flue gas wet desulfurization device (FGD) of a thermal power plant, and can be used for catching fine particle dust and gypsum in the flue gas, so that the clean emission of the flue gas of the thermal power plant can be realized, and the dust removing efficiency and the long-term operation stability of equipment are guaranteed.

Owner:北京新世翼节能环保科技股份有限公司

Harmless fixed bed thermolysis system for zinc and cadmium super accumulator plant

InactiveCN101513640AImprove patencyImprove reaction efficiencySolid waste disposalActivated carbonFixed bed

The invention discloses a harmless fixed bed thermolysis system for zinc and cadmium super accumulator plant. The dried zinc and cadmium supper accumulator plant is in the thermolysis in the thermolysis furnace, the thermolysis gas produced in the thermolysis is treated again and is burnt by the burning comprehensive utilization system, the hot smoke from the burning comprehensive utilization system is used partly for drying the zinc and cadmium super accumulator plant and partly for supplying the heat for the thermolysis furnace, the thermolysis temperature depends on the heat released from the hot smoke produced in the burning of fuel oil, part hot smoke from the burning comprehensive utilization system and the thermolysis and burning reaction of the zinc and cadmium supper accumulator plant in the thermolysis furnace, after the hot smoke from the burning comprehensive utilization system is used for drying zinc and cadmium super accumulator plant, the smoke is purified by the adsorption of the activated carbon and discharged. The thermolysis is adopted, over 90% of cadmium and over 99% of zinc can be fixed in the thermolysis coke, the harmless treatment of the zinc and cadmium super accumulator plant and the energy comprehensive utilization.

Owner:ZHEJIANG UNIV +1

Photoreduction/liquid-liquid-liquid three-phase extraction coupled method for removing and recycling chromium

InactiveCN102503003ASolve the de-extraction problemImprove recovery rateWater/sewage treatment by irradiationWater contaminantsSludgeStrong electrolyte

The invention relates to a photoreduction / liquid-liquid-liquid three-phase extraction coupled method for removing and recycling chromium, belonging to field of heavy metal ion treatment in waste water. The method comprises the following steps: adding inorganic strong electrolyte salts and water-soluble high polymers into a water solution containing Cr (VI) to regulate the pH value of the water phase; adding an organic solvent, thoroughly mixing, and standing or carrying out centrifugal phase splitting to obtain the liquid-liquid-liquid three-phase system; putting the solution under illumination so that the Cr (VI) is reduced to Cr (III) and completely transferred to the upper phase; and finally, carrying out back extraction to recycle the Cr (III) loaded on the upper phase. The invention not only can remove hexavalent chromium in the chrome-containing waste water, but also can reduce the hexavalent chromium into trivalent chromium to be extracted and recycled, thereby achieving the goal of clean discharge of chrome-containing waste water and bringing about economic benefits to the enterprise. No sludge is generated in the whole process, so the invention has wide application prospects in environmental sewage treatment and resource comprehensive utilization.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Self-heat-supply type sludge dewatering and drying method and system

PendingCN107867790AImprove the coagulation effectReduce dosageSludge treatment by de-watering/drying/thickeningGas treatmentFlocculationCombustion

The invention relates to a self-heat-supply type sludge dewatering and drying method and system. The dewatering and drying method comprises the following steps: firstly, adding a flocculation chemicalto to-be-treated sludge, and performing concentration and dewatering to obtain concentrated sludge; adding a sludge conditioner to the concentrated sludge, and stirring the sludge uniformly to obtainconditioned sludge; performing press filtration dewatering on the conditioned sludge to obtain a sludge filter cake; crushing and drying the sludge filter cake in high-temperature flue gas to obtaina dust and sludge mixture; conveying the dust and sludge mixture to a gas-solid separation device, and separating the sludge from the flue gas to obtain powdery sludge with water content being 15wt.%-20wt.%; feeding the sludge into a combustion heat supply mechanism after granulation, performing combustion to obtain high-temperature flue gas, cooling the high-temperature flue gas and conveying thehigh-temperature flue gas to a crushing and drying device. The method and the system are high in continuity and dewatering degree, the sludge treatment process is short, the operation cost is low, anexternally added heat source is not needed, so that energy cost is reduced greatly, and the sludge mass is further reduced by combustion.

Owner:HUNAN BAILIN BIOLOGICAL TECH

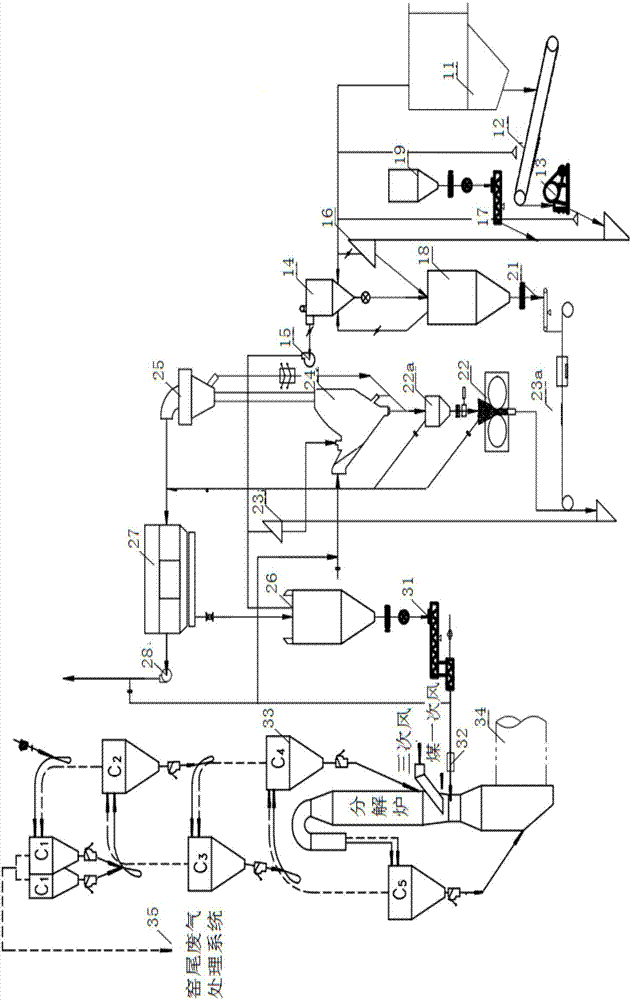

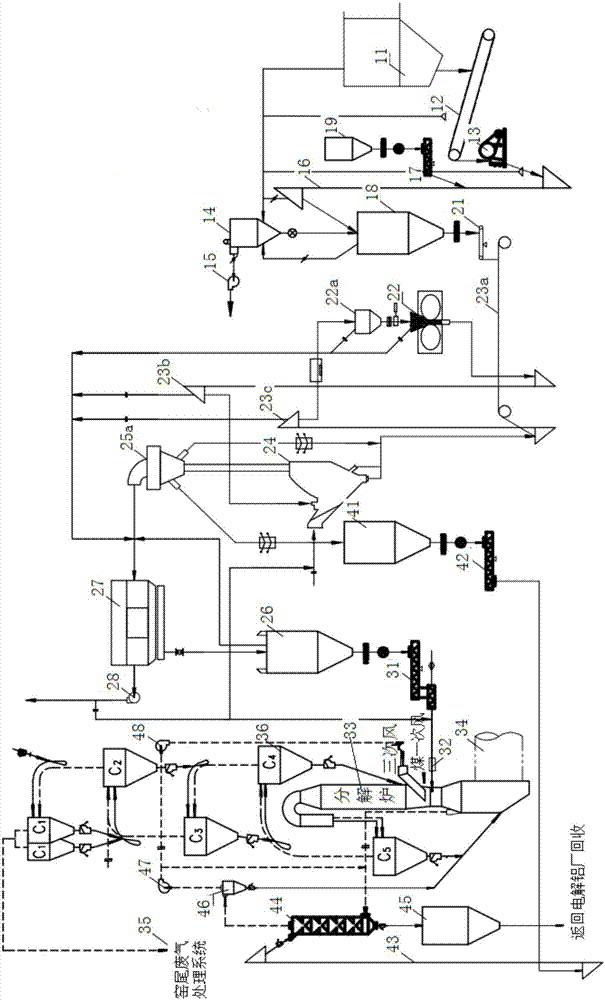

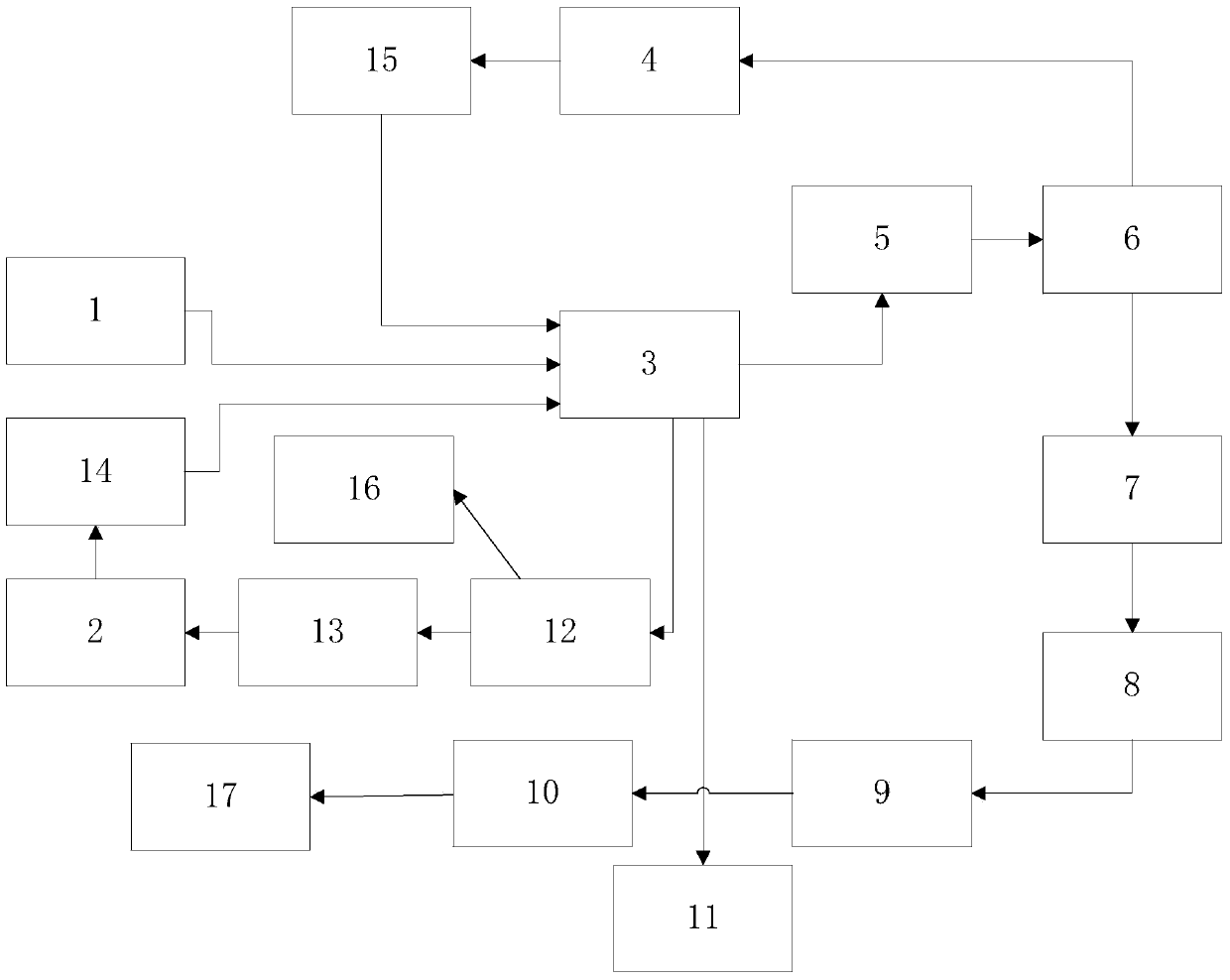

System, technology and method for de-nitrating flue gas of cement kiln and recovering waste heat of flue gas of cement kiln

PendingCN109966812AAchieve clean emissionsReduce contentCombination devicesGas treatmentFlue gasProcess engineering

The invention discloses a system, technology and method for de-nitrating flue gas of a cement kiln and recovering the waste heat of flue gas of a cement kiln. The system comprises a preheater, a wasteheat boiler, a highly hot air blower, a high temperature bag deduster, an SCR denitration reactor, a raw mill, a kiln tail deduster, an induced draft fan, a heat exchanger, and a chimney. A flue gasoutlet in the tail part of a rotary cement kiln is communicated with an inlet in the lower part of the preheater through a pipeline. The outlet in the top of the preheater is communicated with the inlet in the top of the waste heat boiler through a pipeline. The outlet in the lower part of the waste heat boiler is communicated with the inlet of the high temperature bag deduster through a pipeline.The outlet of the high temperature bag deduster is communicated with the inlet of the SCR denitration reactor through a pipeline. The outlet in the bottom of the SCR denitration reactor is communicated with the inlet of the raw mill through a pipeline. The outlet of the raw mill is communicated with the inlet of the kiln tail deduster through a pipeline. The ultralow temperature waste heat utilization and ultralow pollutant discharge are effectively co-researched. The content of NOx in flue gas of a cement kiln is efficiently reduced, the energy consumption is low, and finally discharged fluegas meets the discharge requirements.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

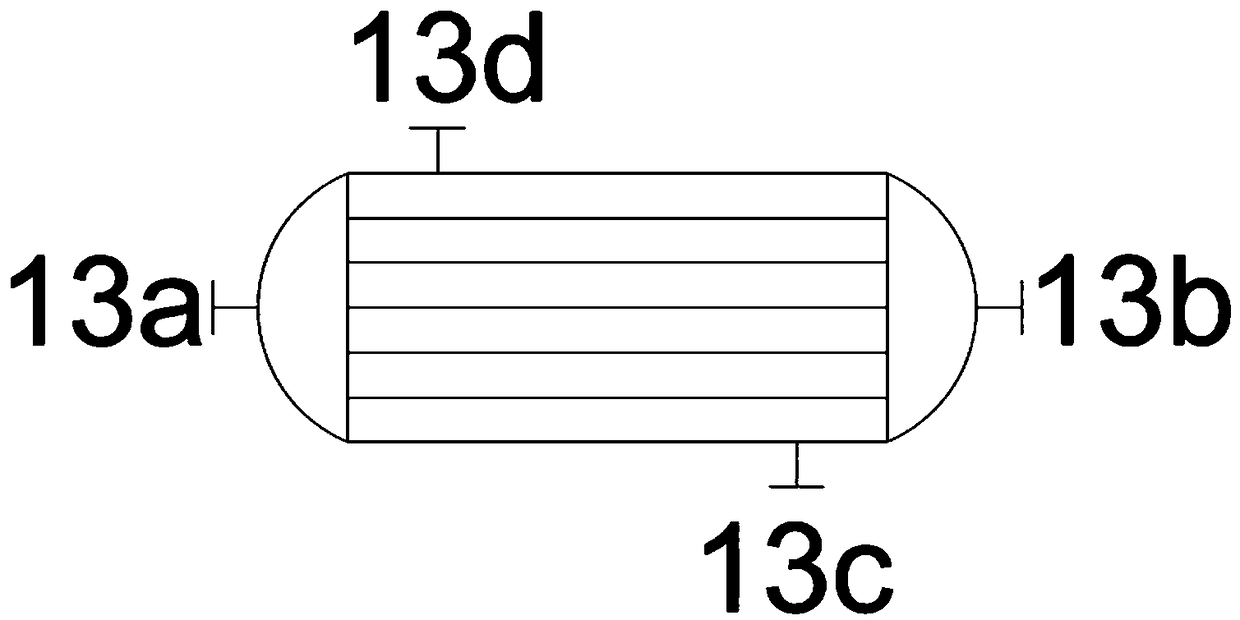

Water-spray-type tubular dust collector

InactiveCN103861402AAchieve clean emissionsGuaranteed dust removal efficiencyUsing liquid separation agentFlue gasLiquid water

The invention belongs to the technical field of waste gas purification, and particularly relates to a water-spray-type tubular dust collector. According to the water-spray-type tubular dust collector provided by the invention, the technical principles of an impingement dust collector and a water-film-type dust collector are combined together, the dust of the saturated wet flue gas can be removed, and the problems of dedusting and demisting the flue gas treated by a wet desulfurization device can be solved. The water-spray-type tubular dust collector is generally applied to the electric power environmental protection industry, and has the working position at the downstream part of the flue gas wet desulfurization device (FGD) of a thermal power plant; a water film is formed on the surface of a dust collection tube bundle in a water pouring way or a water spray way, so that impurities such as fine particle dust, gypsum, liquid water and the like in the flue gas can be caught; therefore, the clean emission of the flue gas of the thermal power plant can be realized, and the dust removing efficiency and the long-term work stability of equipment are guaranteed.

Owner:北京新世翼节能环保科技股份有限公司

Efficient method and device for removal of acidic gas from fume or coal gas

InactiveCN102133501AEfficient use ofRealize cooling and dust removalDispersed particle separationPerfluorocarbons/hydrofluorocarbons captureHydrogen fluorideCombustion

The invention provides an efficient method and an efficient device for removal of acidic gas from fume or coal gas. The method is characterized by comprising a step of using an aluminium hydroxide (Al(OH)3) or an iron hydroxide (Fe(OH)3) as a deacidification agent for the removal of hydrogen chloride (HCl) or hydrogen fluoride (HF) gas from the fume or the coal gas, wherein the deacidification agent and a carbon dioxide (CO2) in the fume or the coal gas cannot undergo a side reaction, so that the efficient utilization of the deacidification agent is guaranteed. The efficient device for the removal of the acidic gas from the fume or the coal gas comprises an acid-resisting temperature reduction device, an acid-resisting bag dust removal system, a primary deacidification system, a secondary deacidification system and a draught fan. After the fume or the coal gas passes through the acid-resisting temperature reduction device, the acid-resisting bag dust removal system, the primary deacidification system and the secondary deacidification system sequentially, temperature reduction and dust removal of the fume or the coal gas can be realized, and the HCl or HF gas can be efficiently removed from the fume or the coal gas more importantly, so that the aims of cleaning discharge and prevention of combustion equipment corrosion are achieved.

Owner:魏欢

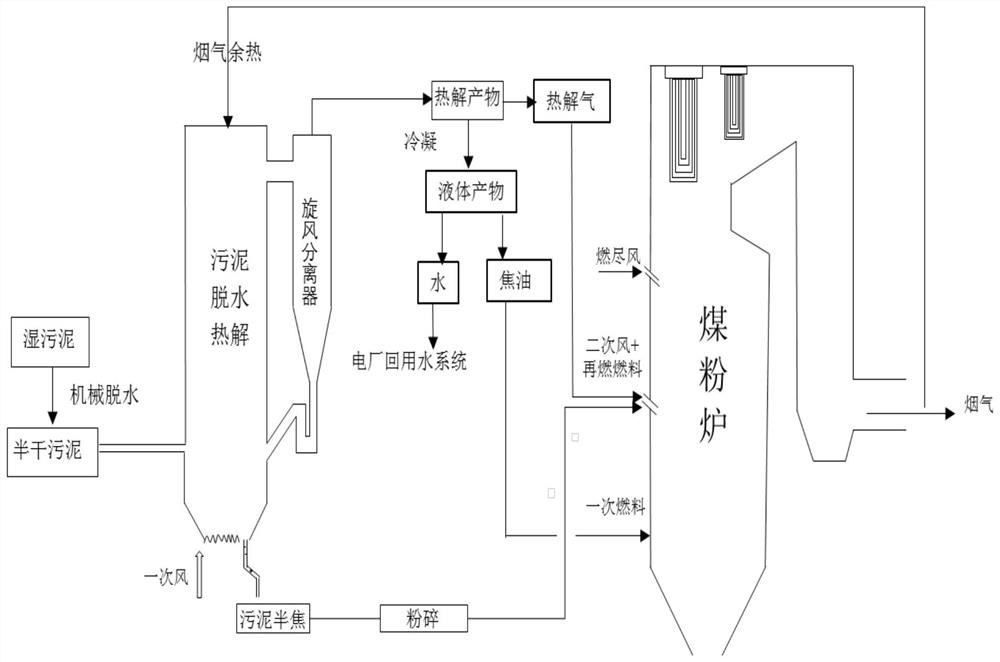

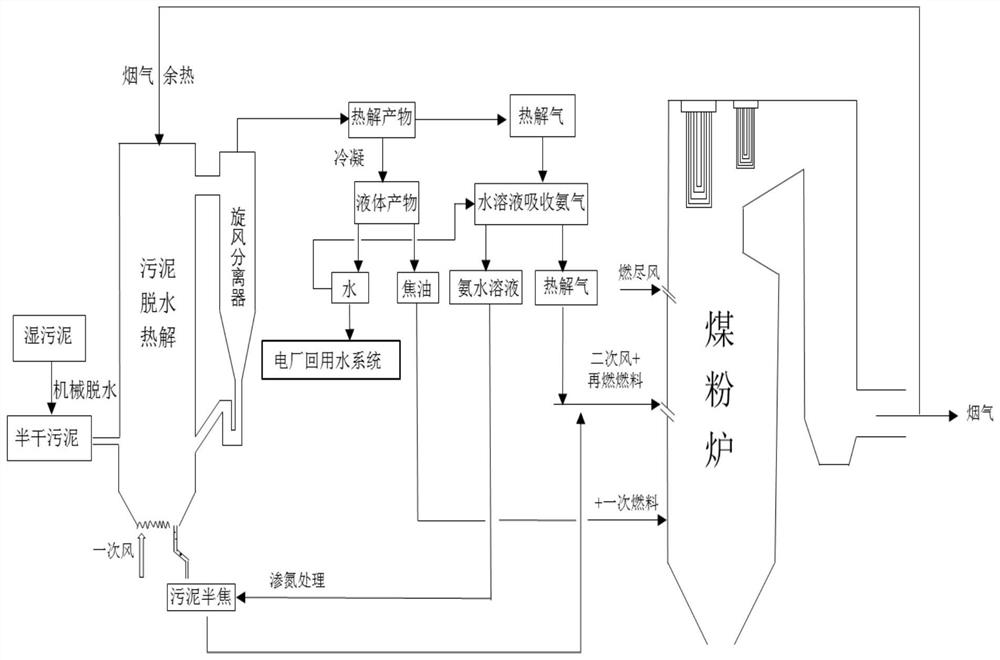

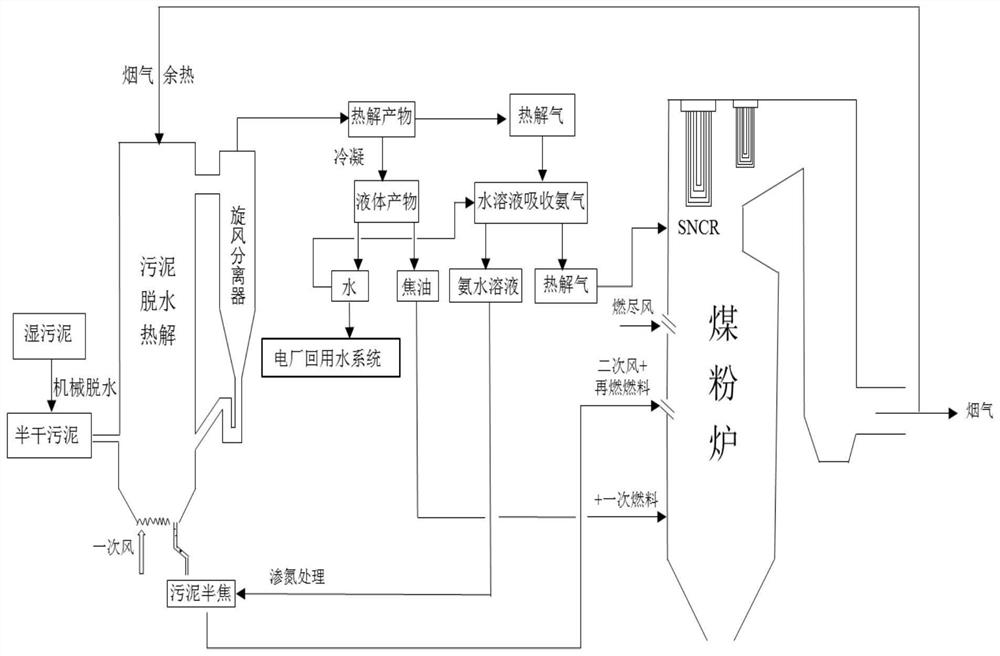

Method for denitration of coal-fired power plant boiler through synergistic recycling of sludge and coal slime

PendingCN112377917APromote combustionImprove denitrification efficiencySludge treatment by de-watering/drying/thickeningDispersed particle separationSludgeRefuse Disposals

The invention belongs to the field of municipal solid waste treatment and the technical field of coal-fired boiler flue gas denitration, and particularly relates to a method for denitration of a coal-fired power plant boiler through synergistic recycling of sludge and coal slime. The sludge or the coal slime or a sludge and coal slime mixture is subjected to preliminary dehydration through a mechanical device, the semi-dry sludge or coal slime or sludge and coal slime mixture is subjected to pyrolysis gasification by using flue gas waste heat of a power plant, gasified gas, liquid and solid products are added into the coal-fired boiler of the power plant from reasonable positions, pyrolysis gas and coke are used for strengthening denitration independently or in cooperation with SNCR reaction, liquid tar and the coke are effectively used for supporting combustion, resource clean utilization and harmless treatment of the coal slime and the sludge are achieved while the denitration efficiency of the boiler is improved, heat energy is fully coupled and utilized, and economic benefits and social benefits are remarkable.

Owner:SHANXI UNIV

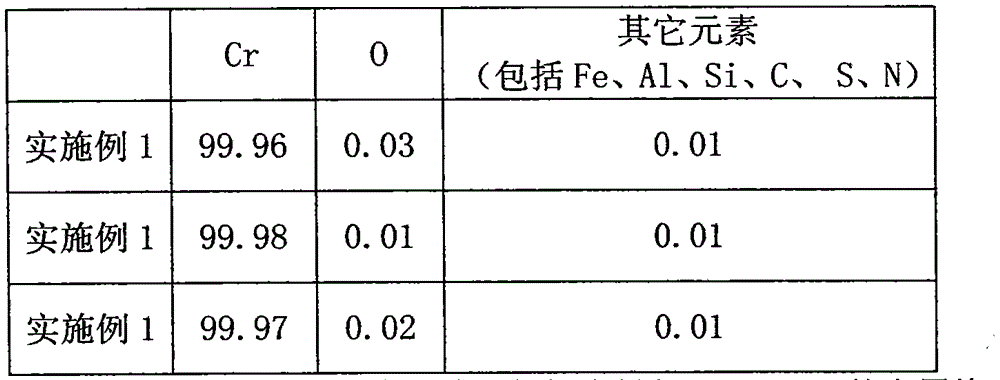

Method for recycling and preparing metal chromium

InactiveCN104099478AImprove recovery rateAchieve removalProcess efficiency improvementChromium productScrap

A method for recycling and preparing metal chromium comprises the steps of recycling chromium element from discharged waste liquid and discharged waste material, and utilizing the recycled chromium element to prepare metal chromium. The method prevents environmental pollution, realizes application of chromium resources, is simple in technology and low in cost, and can obtain metal chromium products which can meet the use requirement.

Owner:GUANGXI SHENGLONG METALLURGICAL CO LTD

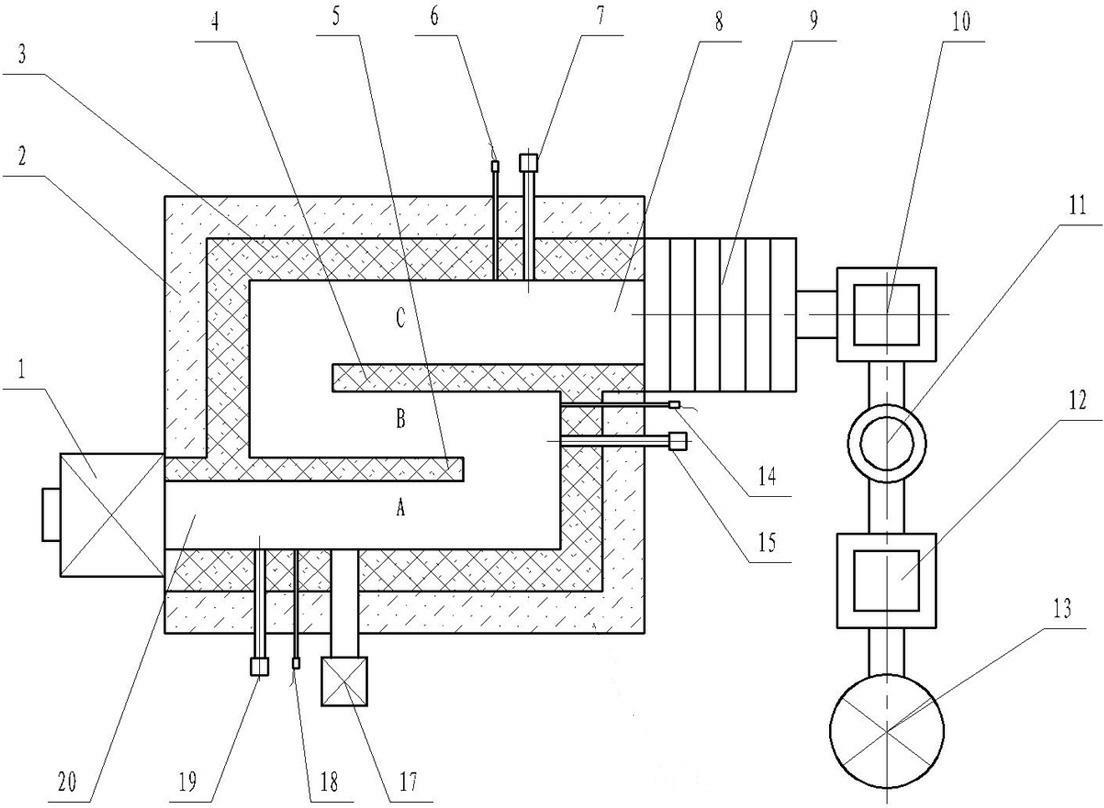

Device and method for high polymer material burning harmless treatment

InactiveCN102434888AReduce pollutionAchieve clean emissionsIncinerator apparatusTunnel kilnToxic gas

The invention discloses a device and a method for high polymer material burning harmless treatment. A high temperature pyrolysis tunnel furnace with an insulating layer is arranged between a combustion furnace and a heat exchange device, a smoke inlet of the tunnel furnace is connected with a smoke outlet of the combustion furnace, and a smoke outlet of the tunnel furnace is connected with the heat exchange device. A tunnel in the tunnel furnace is isolated to be an A tunnel cavity, a B tunnel cavity and a C tunnel cavity which are communicated in a head-and-tail mode and in a shape of an S through a front partition wall and a back partition wall. A furnace opening fan, a furnace opening temperature measurement device and an external heating source are respectively arranged at the smoke inlet of the tunnel furnace. An excess air measurement device and a furnace end temperature measurement device are respectively arranged at the smoke outlet of the tunnel furnace. A tunnel temperature measurement device and a tunnel fan are respectively arranged in the middle of the tunnel furnace. Dioxin, cyanide and other toxic gas in the smoke can complete a pintsch process to become nontoxic micromolecule gas, harmless clean discharge of the combustion furnace is achieved, pollution to the neighboring environment is reduced, and safety hidden dangers of people are removed.

Owner:冯之军

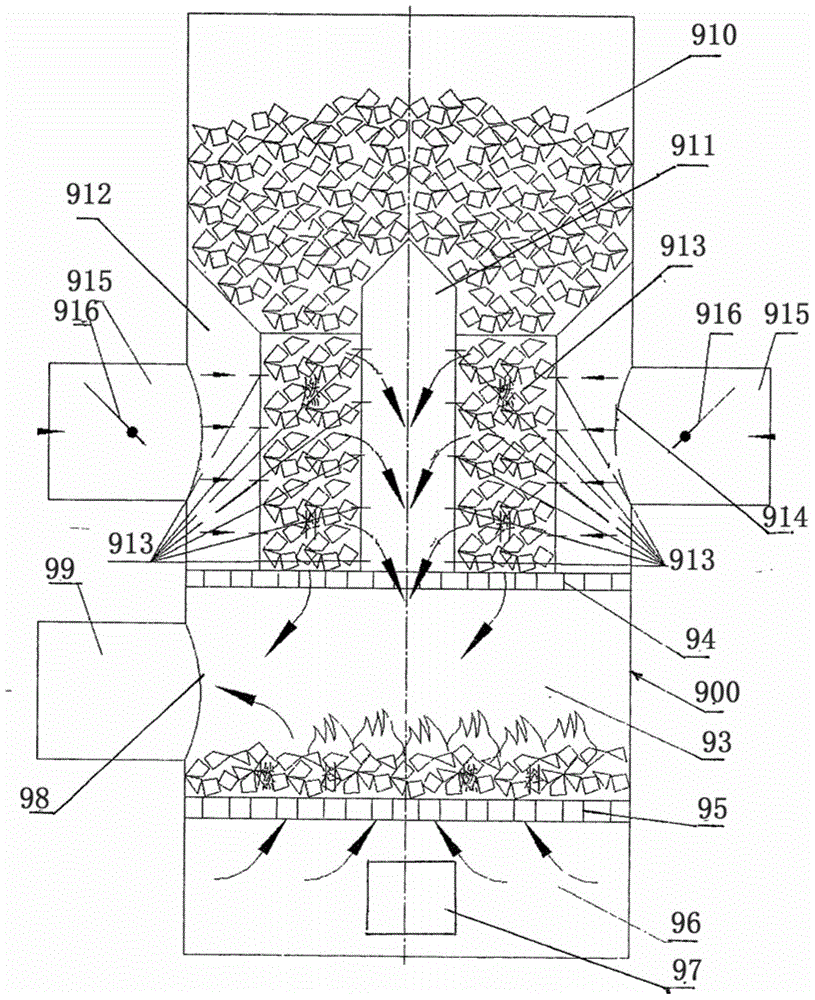

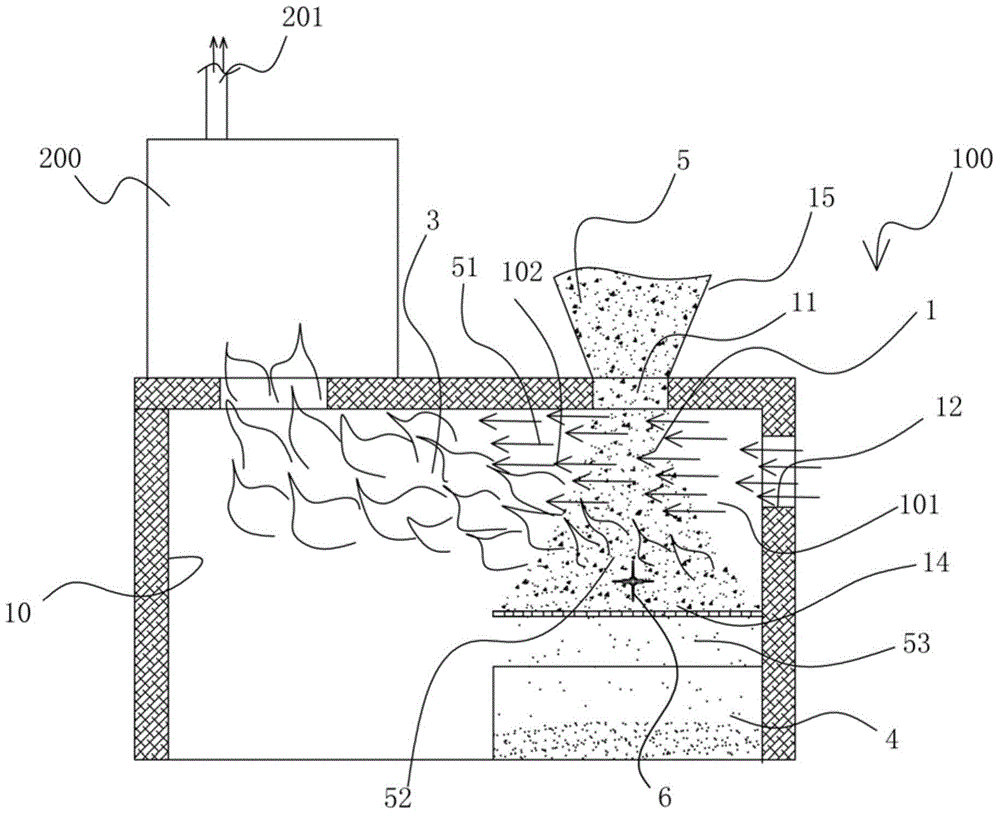

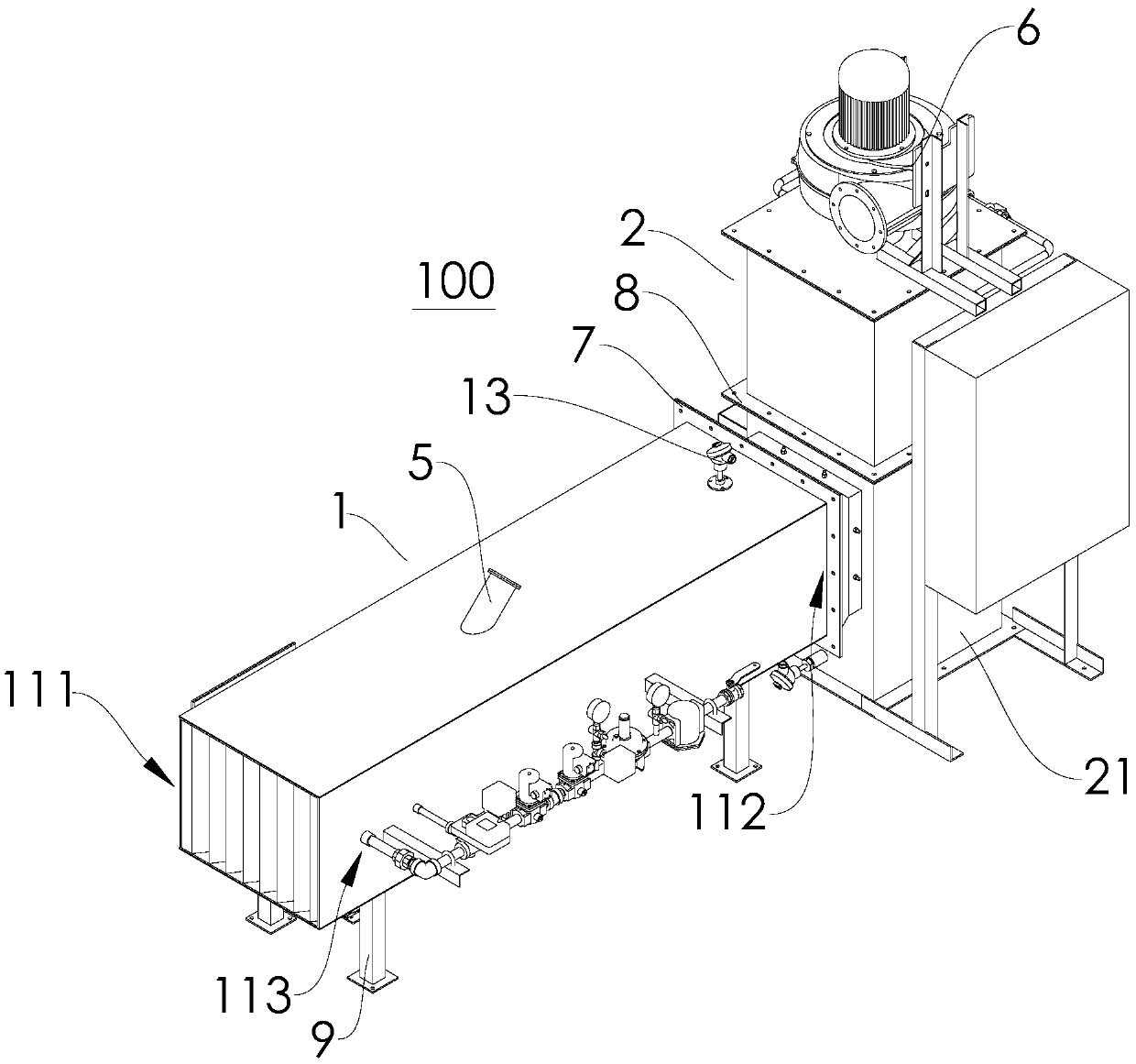

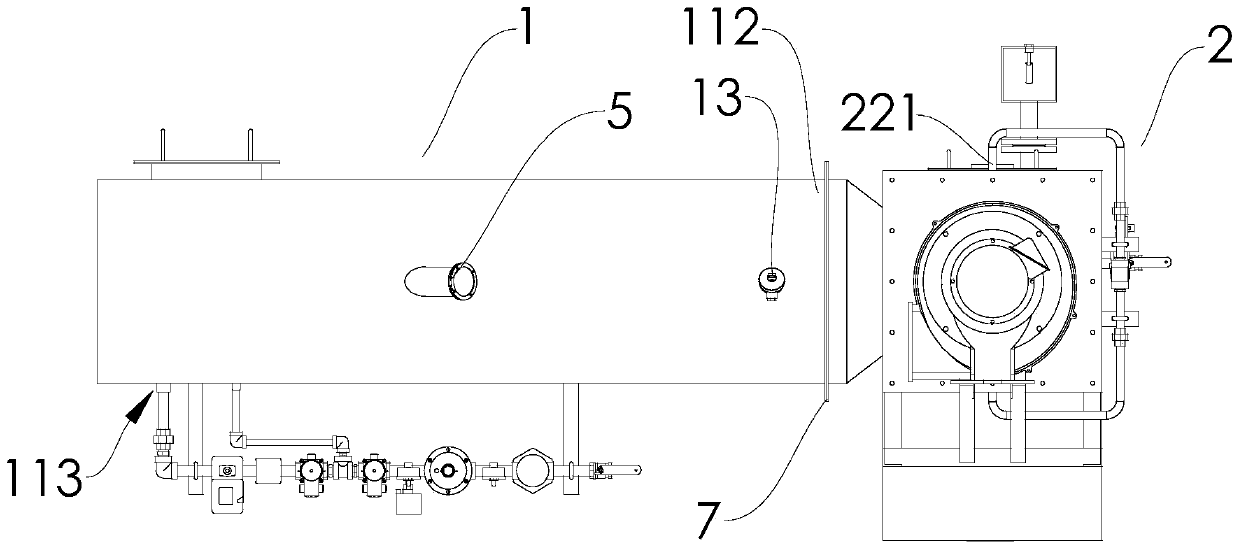

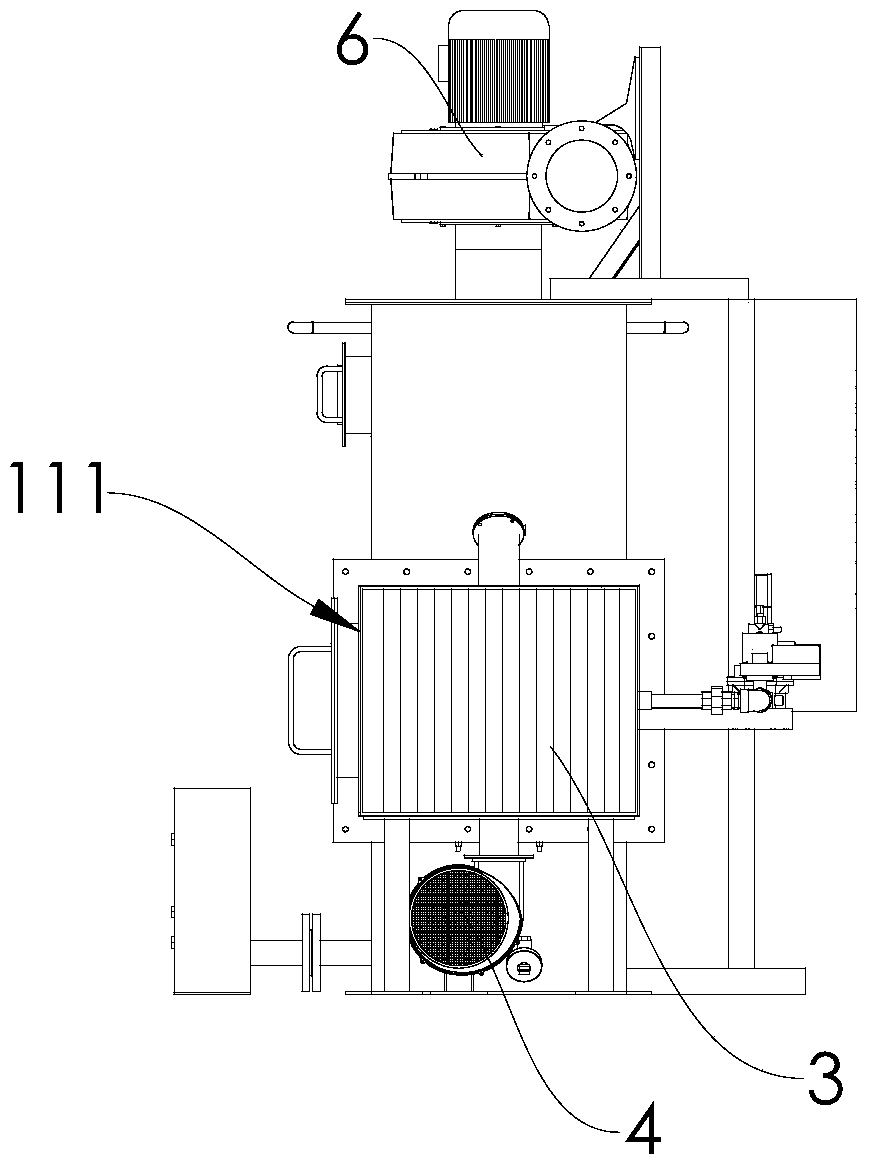

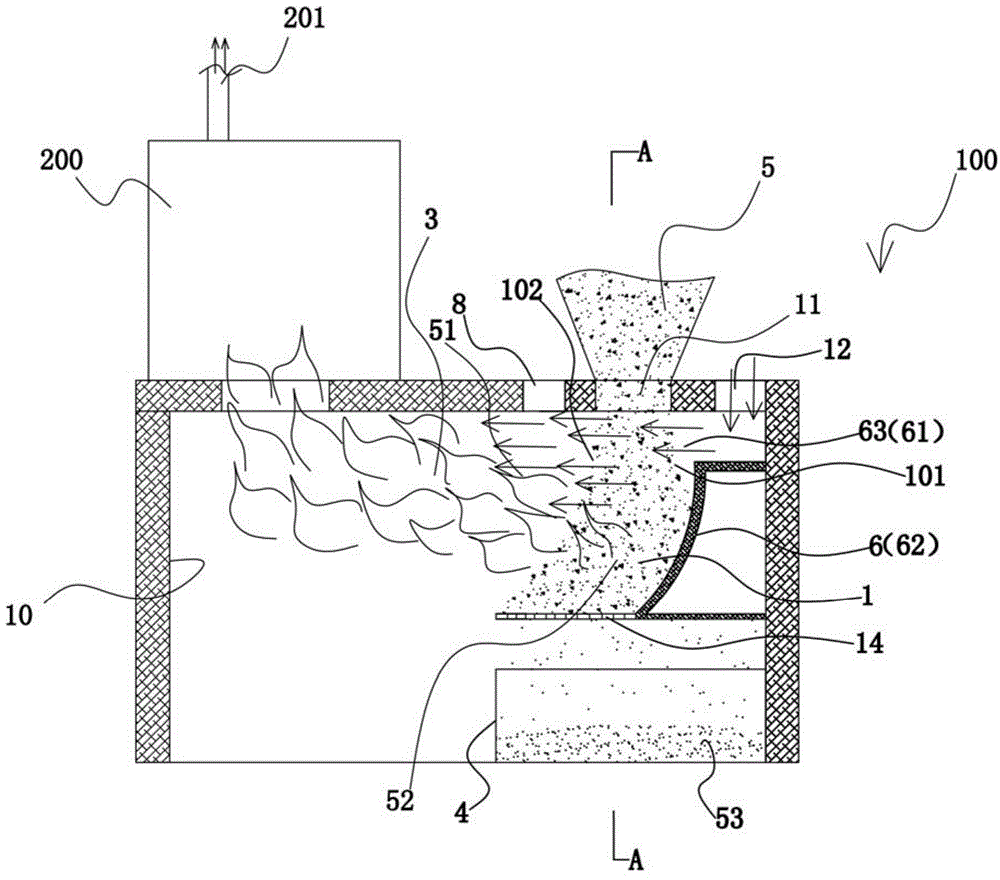

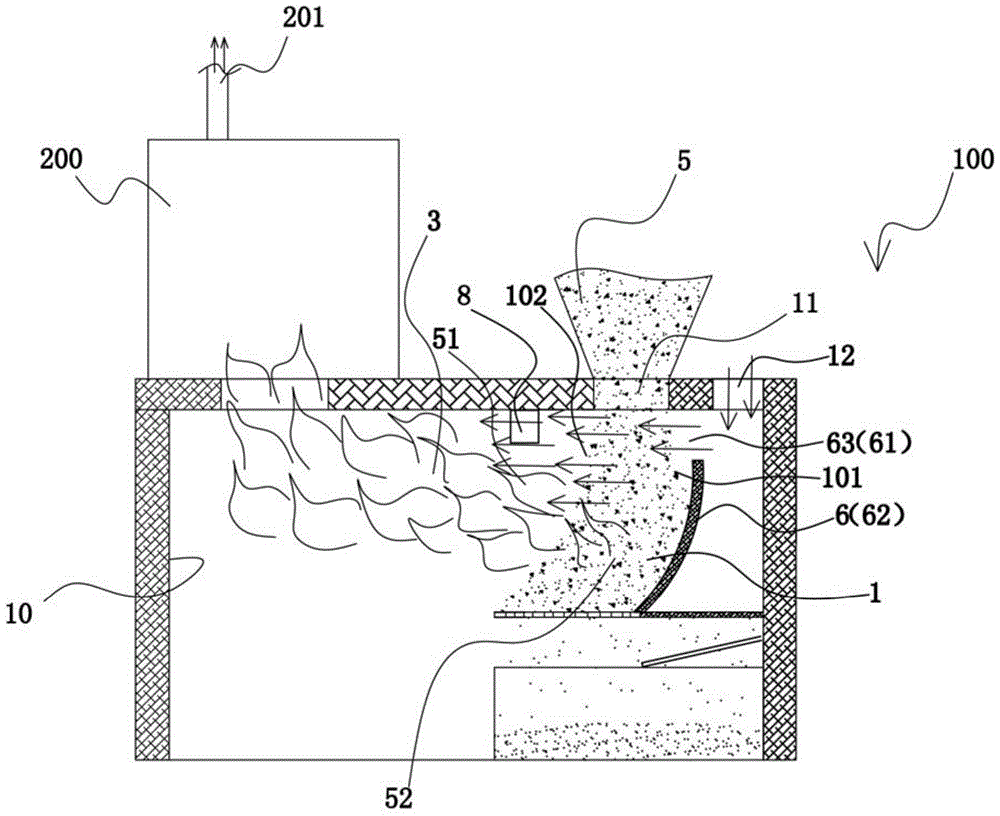

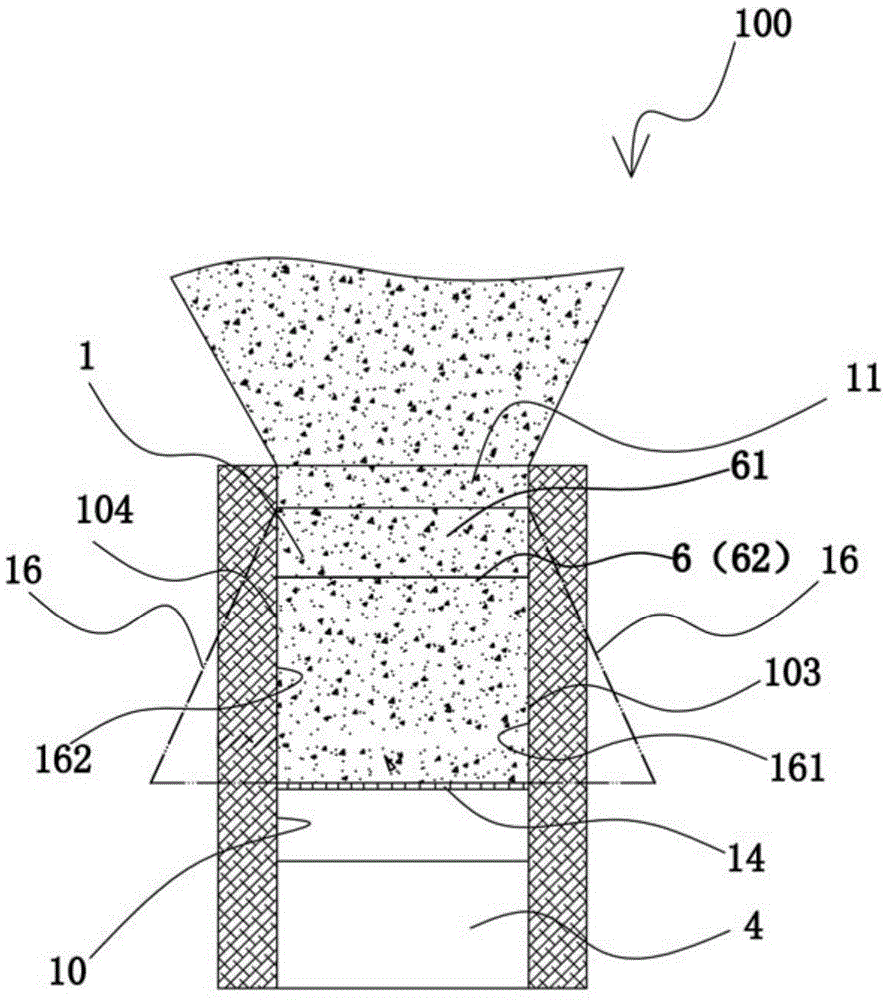

Solid fuel combustion apparatus

InactiveCN104976613ASave human effortImprove combustion efficiencySolid fuel combustionCombustion apparatusExhaust gasAutomotive engineering

Disclosed is a combustion device (100) for solid fuels. An air inlet side (101) is formed above a furnace grate (14) in a furnace (10) and on one side of a fuel stocking layer (1) of the combustion device (100), a combustion side (102) is formed in the furnace (10) on the other side opposite to the fuel stocking layer (1); a shuffle mechanism (6) is arranged in the fuel stocking layer (1) above the furnace grate (14) for receiving the solid fuels, and the fuels in a combustion state can be shuffled by controlling the movement of the shuffle mechanism (6), which is beneficial for discharging ash.

Owner:车战斌

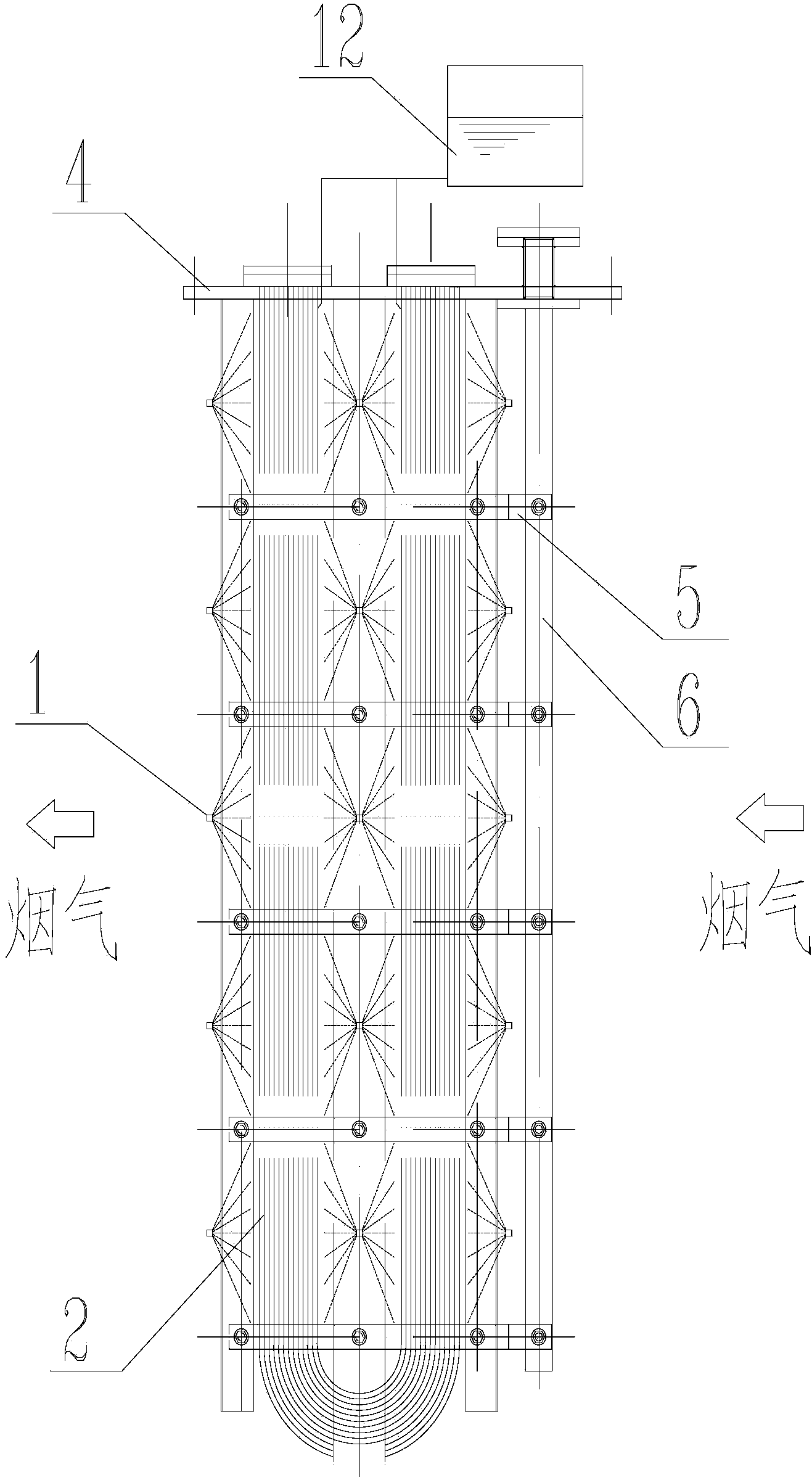

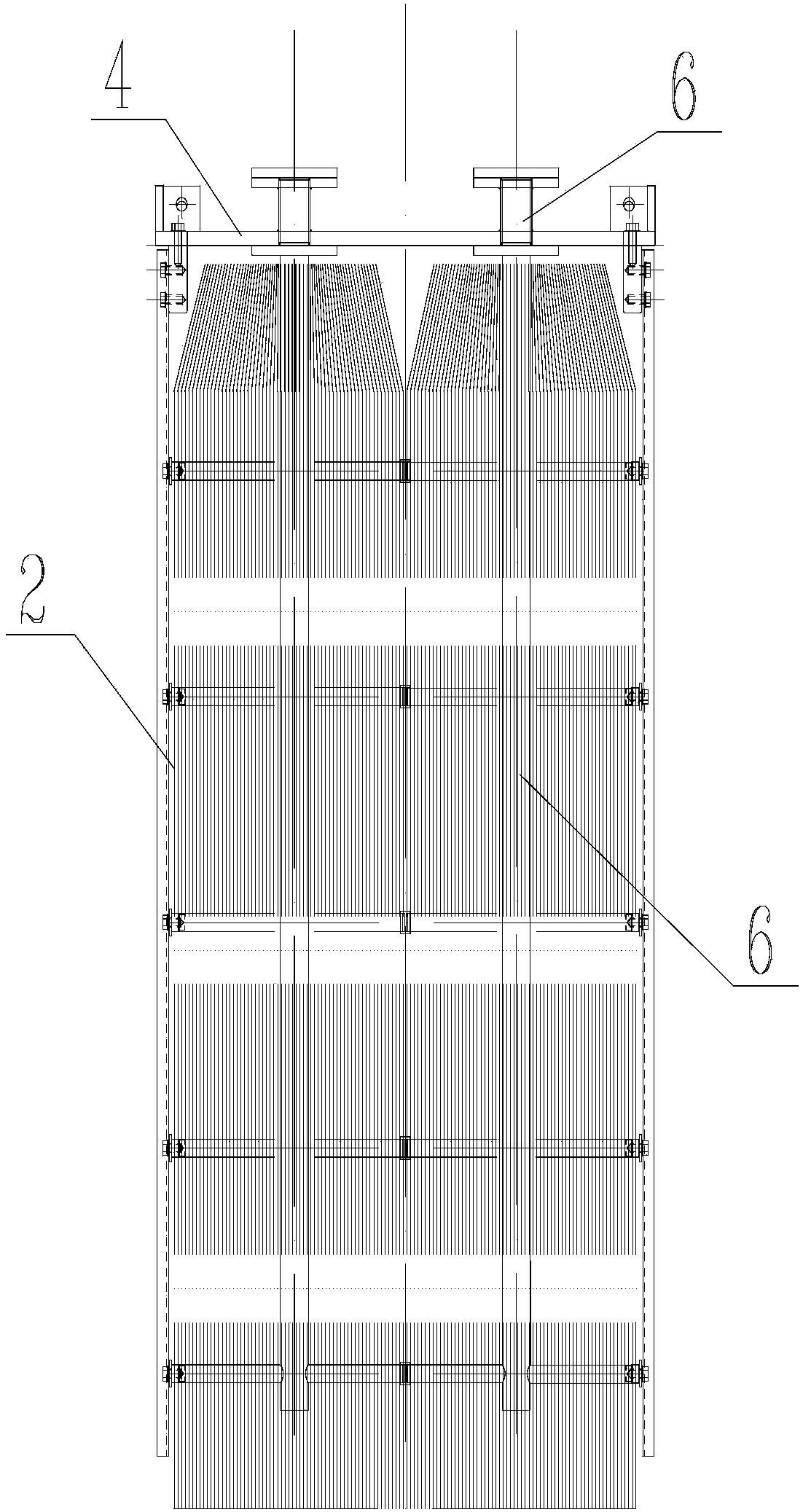

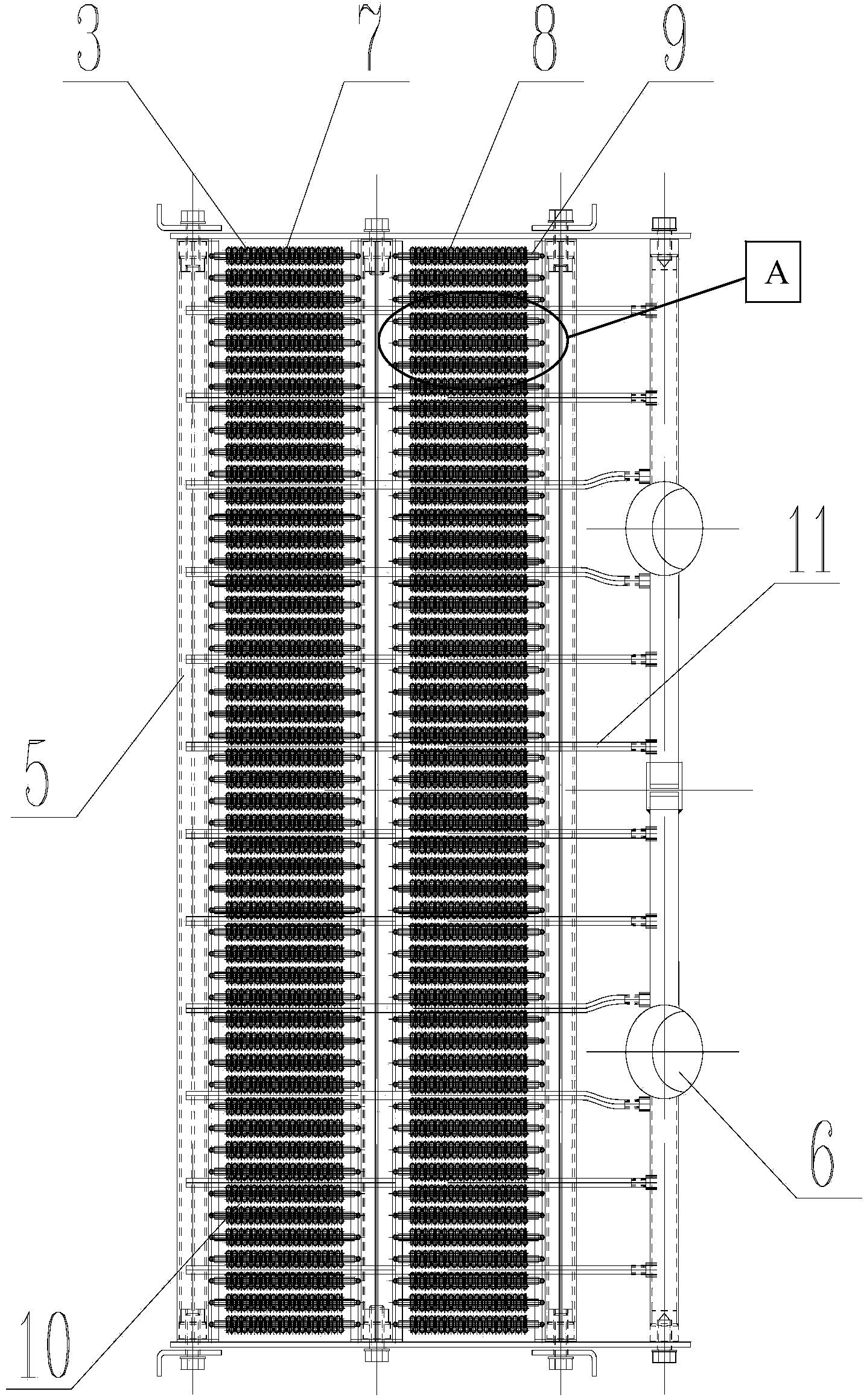

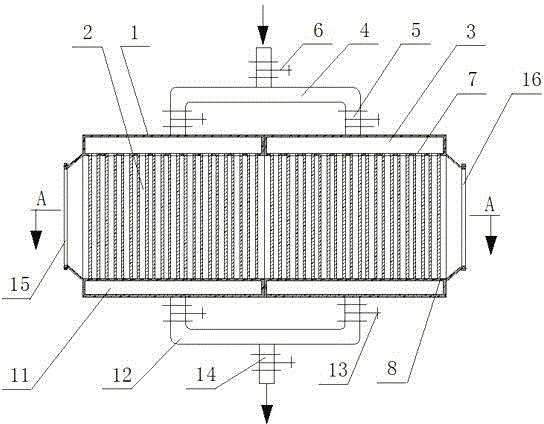

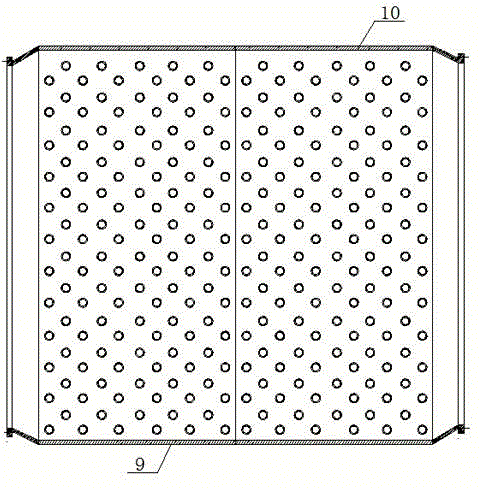

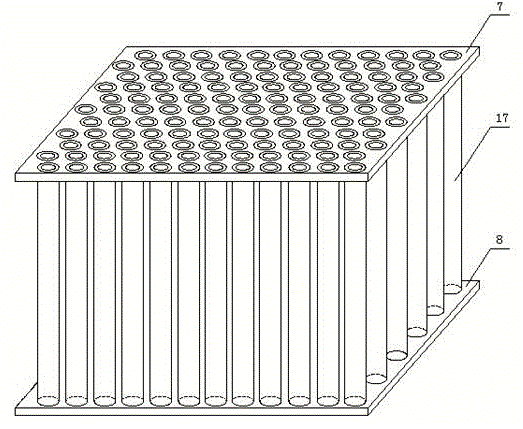

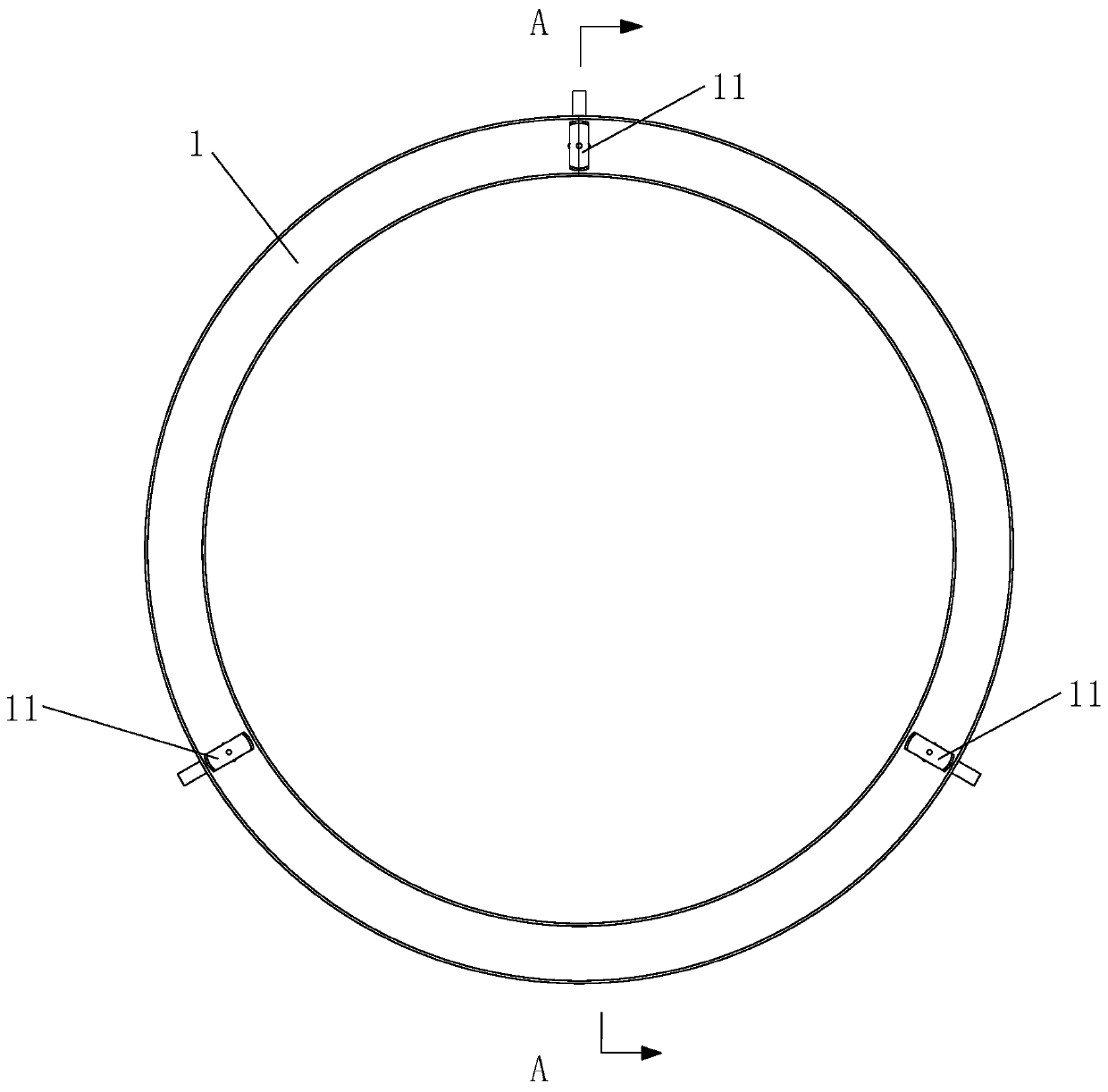

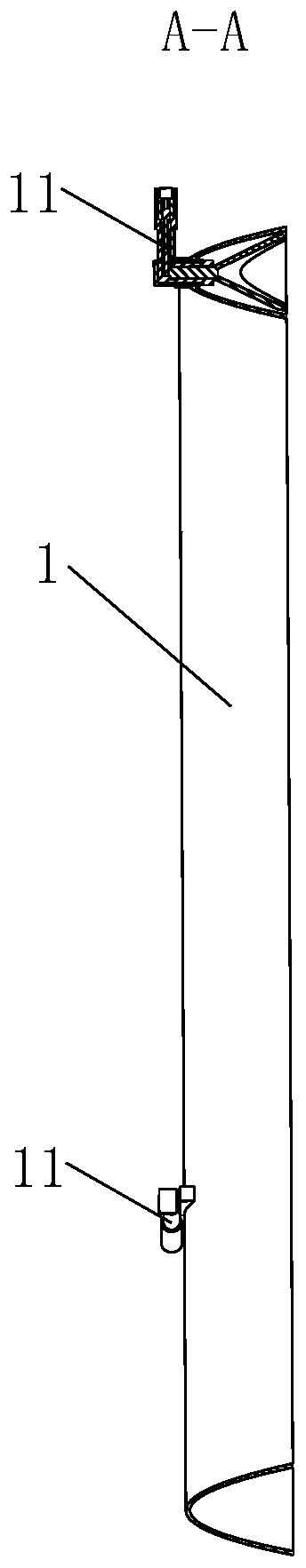

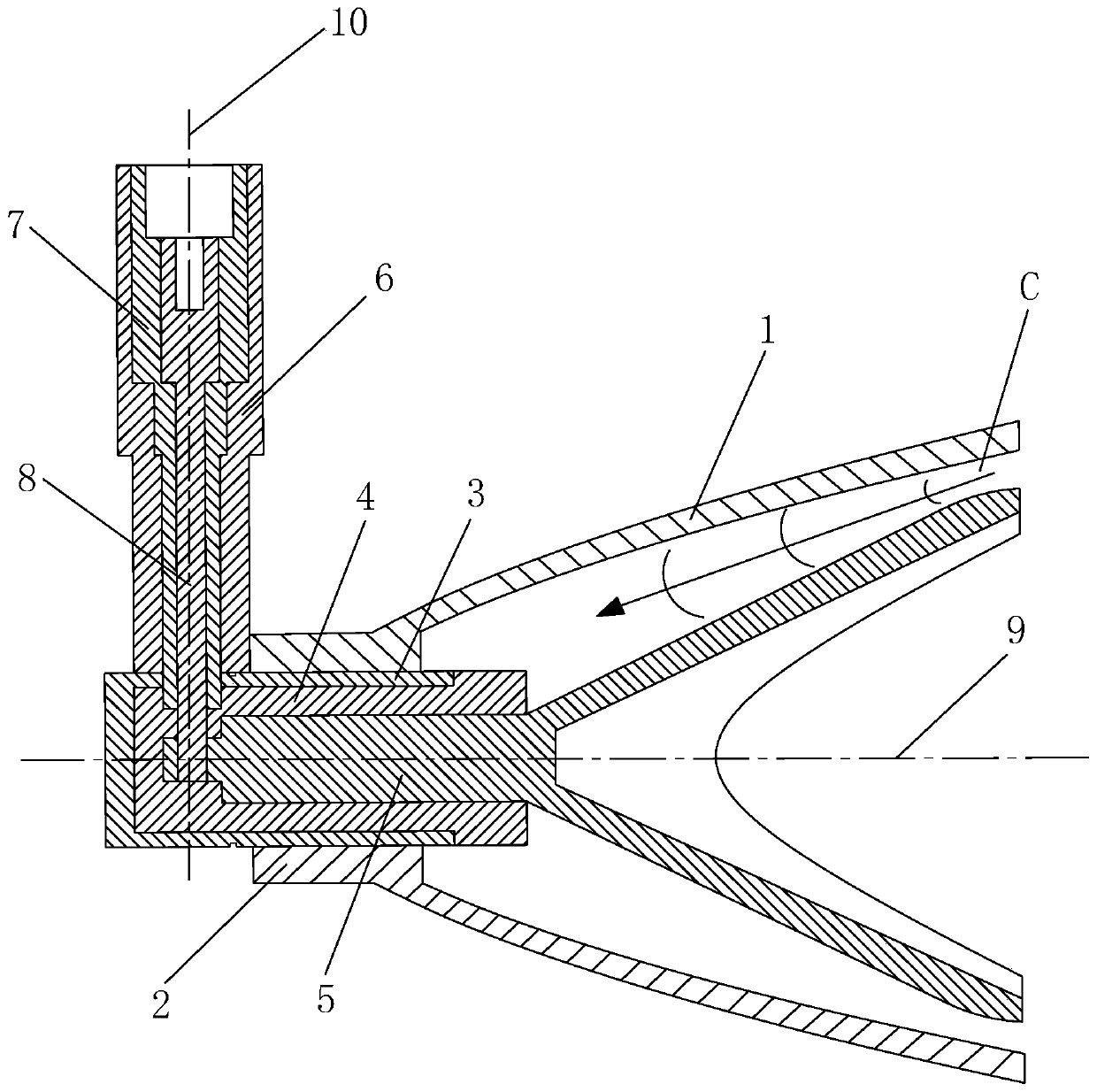

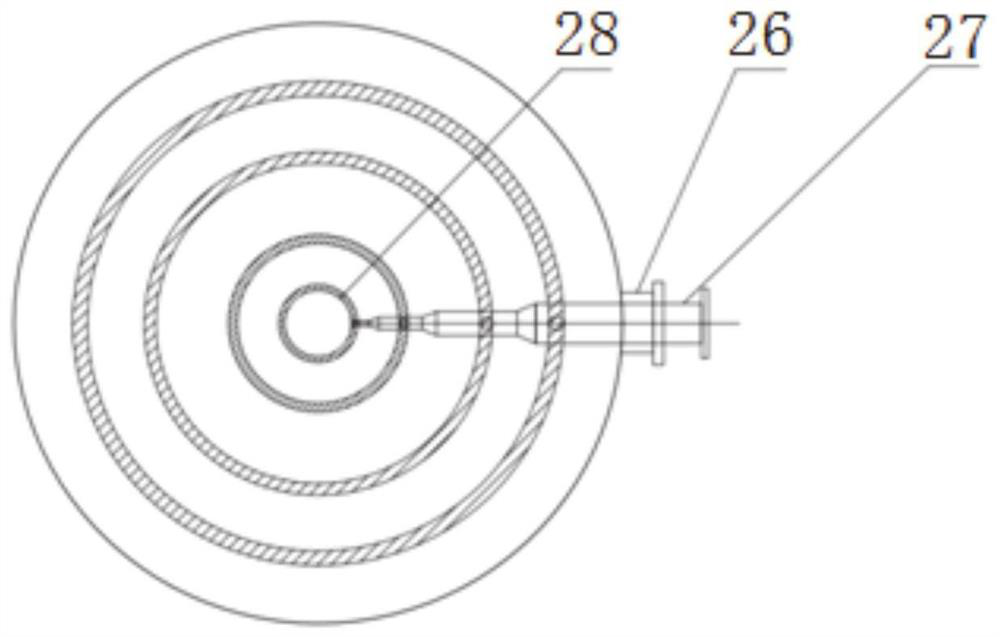

Micro-nano ceramic-tube-beam water-film type integrated removal apparatus for flue gas pollutants

InactiveCN105477955AEfficient removalEfficient emissionsUsing liquid separation agentMicro nanoWater vapor

The invention discloses a hollow porous micro-nano ceramic-tube-beam water-film type integrated removal apparatus for flue gas pollutants, and belongs to the coal-fired power plant energy-saving emission-reduction technologies. The apparatus comprises an upper cover plate (1), a hollow porous micro-nano ceramic-tube-beam assembly (2), a water inlet chamber (3) and associated pipelines (4) thereof, a sewage chamber (11) and associated pipelines (12) thereof, an upper glass fiber reinforced plastic support plate (7), a lower glass fiber reinforced plastic support plate (8), a front side plate (9), a rear side plate (10), and sealing fixing parts. Under driving of pressure difference, a dense water film is formed on the outer surface of a ceramic pipe (17), when flue gas transversely skims over the ceramic-tube-beam assembly (2), gypsum liquid drops, water vapor, tiny particles, and SO2, H2SO4(SO3) aerosol and other acidic compositions in flue gas are captured by the water film, the captured pollutants and condensed water float down the stream, are gathered in the sewage chamber (11), and are sent to a sewage disposal plant through the sewage pipelines (12). The apparatus is simple in structure, low in cost, resistant to corrosion and long in service life, is capable of realizing clean discharge of a coal-fired power plant, also is capable of recovering and utilizing water source in flue gas, and possesses extensive engineering application prospect.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Gas water heater

ActiveCN105588323AGood energy saving effectReduce generationWater heatersCombustion chamberWater storage tank

The invention discloses a gas water heater which comprises an air heater, a heat exchanger and a smoke exhaust fan. The air heater comprises a combustion chamber and a combustor arranged in the combustion chamber. The combustion chamber is provided with a cold air inlet, a hot air outlet and a gas inlet. The combustor is configured to enable the concentration of nitrogen oxide in generated hot air to be smaller than or equal to 30 mg / m<3> and the concentration of carbon monoxide in the generated hot air to be smaller than or equal to 50 mg / m<3>. The heat exchanger comprises a water storage tank and a heat exchange part. The heat exchange part is provided with a water inlet, a water outlet, an air inlet and an air exhaust opening. The water outlet communicates with the water storage tank. The air inlet communicates with the hot air outlet. The heat exchange part is configured to enable water entering from the water inlet to exchange heat with air entering from the air inlet. The smoke exhaust fan is used for sucking hot air generated by the combustor into the heat exchange part. By means of the gas water heater, generation of harmful gas of CO, nitrogen oxide and the like can better reduced, clean exhausting can be achieved, and the heat exchange efficiency between hot air and water can be improved.

Owner:BEIJING ORIENT DELTA SCI & TECH CO LTD

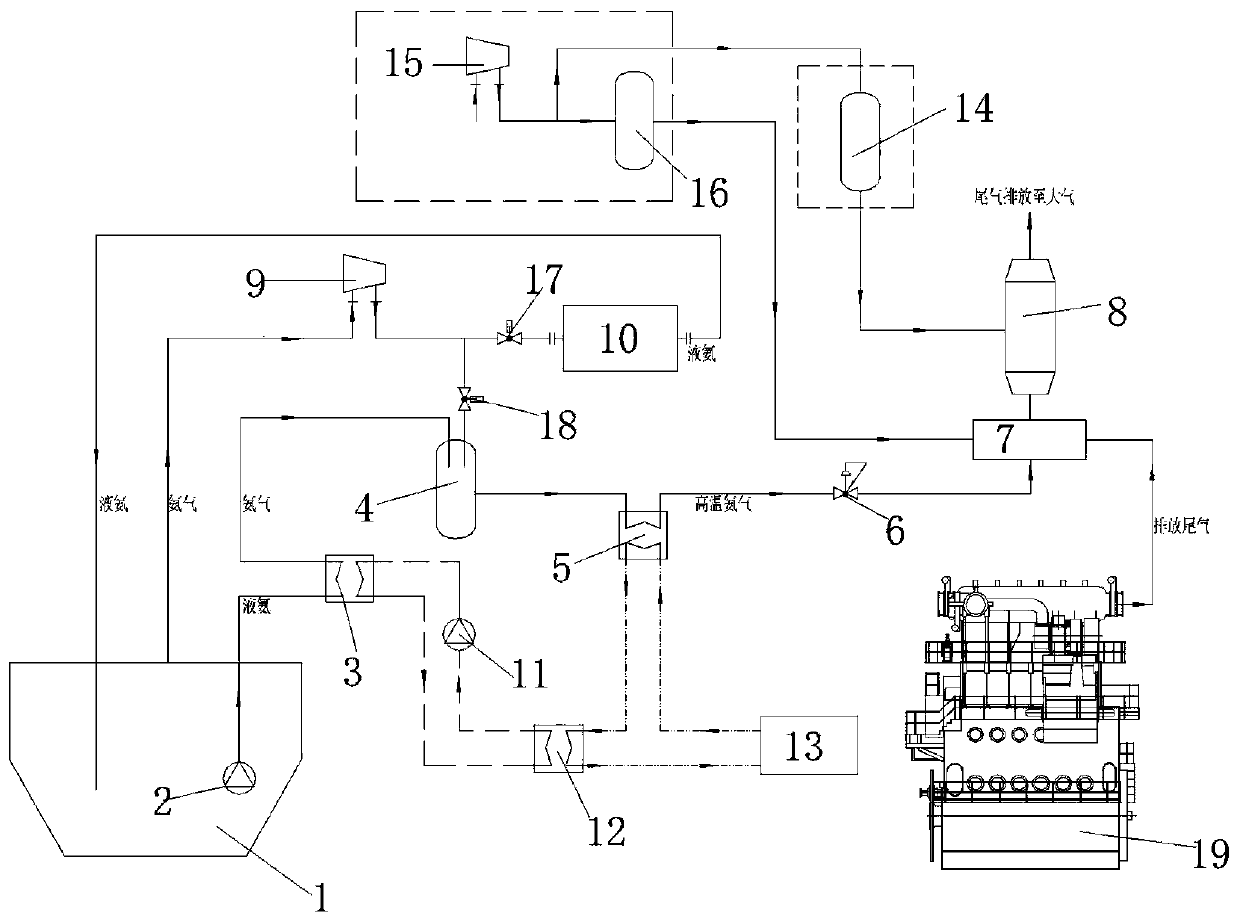

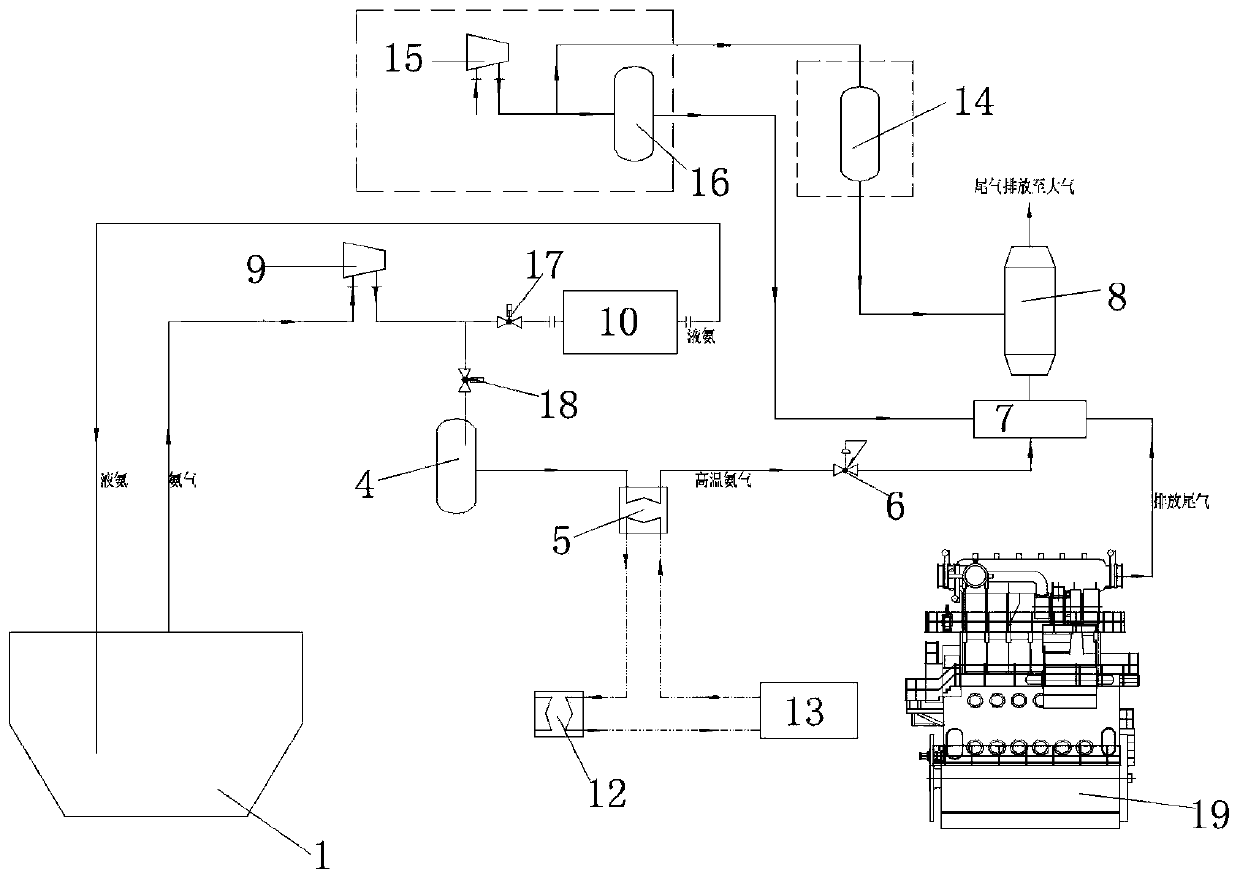

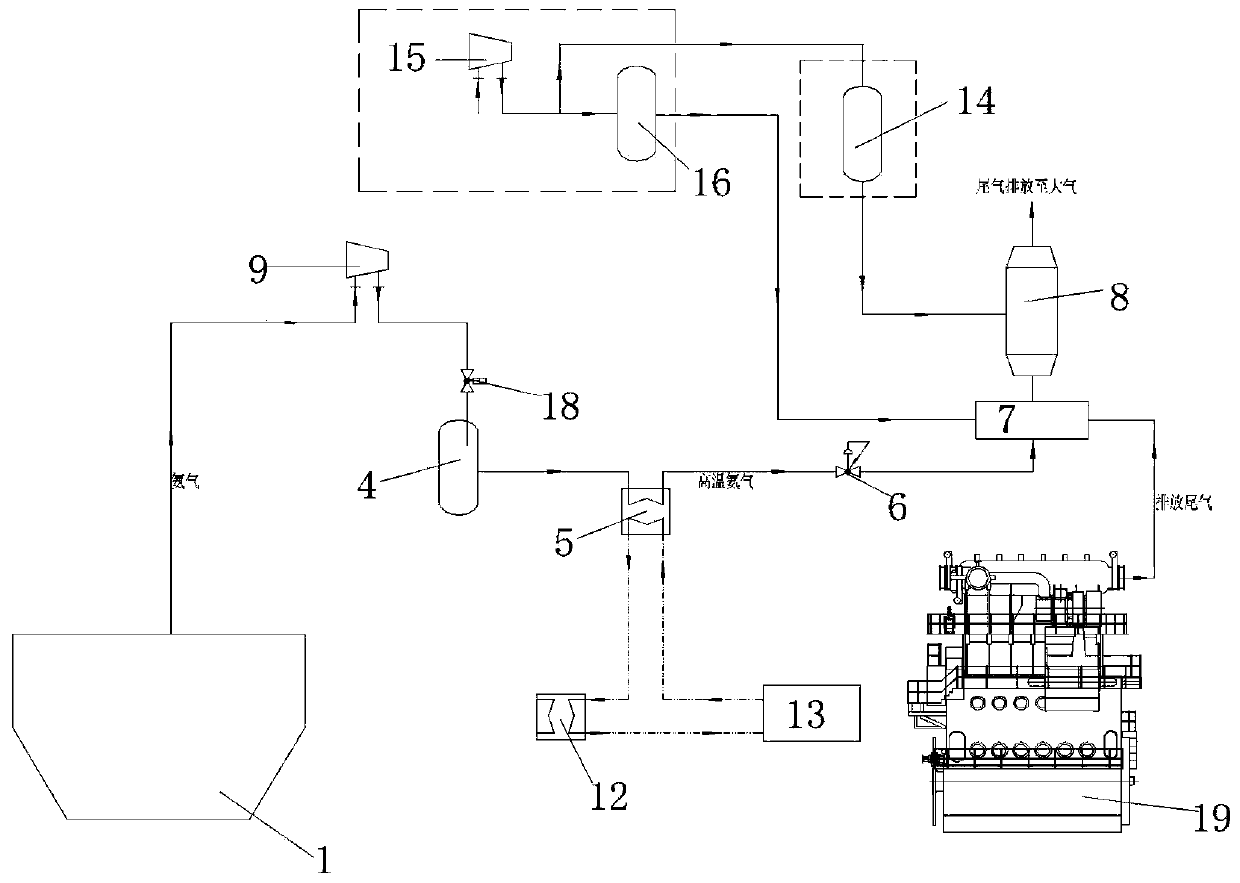

Novel ship tail gas treatment system

A novel ship tail gas treatment system is provided with an air compression system and a soot blower, the air compression system is connected with a flue gas mixer, the flue gas mixer is connected withan SCR reactor, the soot blower is connected with the SCR reactor, tail gas exhausted by a fuel main engine enters the flue gas mixer, and the flue gas mixer is connected with an ammonia gas conveying system. The ammonia gas conveying system is provided with a liquid ammonia fuel storage tank and an ammonia gas liquefaction device, a liquid ammonia low-pressure pump is arranged in the liquid ammonia fuel storage tank, and liquid ammonia is pumped out through the liquid ammonia low-pressure pump and finally enters the flue gas mixer. Volatile gas in the liquid ammonia fuel storage tank is fully utilized, the method is preferentially applied to ammonia fuel main engine tail gas denitrification treatment, and the ammonia gas liquefaction device is arranged as a supplement means for ammonia volatile gas treatment, so that the volatile gas in the liquid ammonia storage tank can be completely treated, the pressure rise and structural damage of the liquid ammonia storage tank caused by continuous accumulation of the ammonia volatile gas are avoided, a large amount of the ammonia volatile gas is prevented from being discharged to the atmosphere, and the safety of the liquid ammonia storage tank and a ship is guaranteed.

Owner:DALIAN SHIPBUILDING IND

Water-recyclable superheat steam drying lignite system and process method thereof

ActiveCN104197684ALow costRun economyDrying gas arrangementsDrying solid materialsBaghouseSuperheated steam

The invention discloses a water-recyclable superheat steam drying lignite system and a process method thereof. The water-recyclable superheat steam drying lignite system comprises a dryer which is respectively connected with a moisture-carrying gas cycle unit, a water recycling unit and a condensate water flash unit; the moisture-carrying gas cycle unit comprises an electric heater, the input end of the electric heater is connected with a bag-type dust collector which is connected with a cyclone storage device, a cyclone dust collector is connected with the output end of the dryer, and the output end of the electric heater is connected with the input end of the dryer; the water recycling unit comprises the cyclone dust collector, the bag-type dust collector, a wet-type electrostatic precipitator, an air cooling device, a water cooling device and a water treatment unit, and the cyclone dust collector, the bag-type dust collector, the wet-type electrostatic precipitator, the air cooling device, the water cooling device and the water treatment unit are connected in sequence; the saturated condensate water flash unit comprises a flash tank, a cooling device and a boiler, and the flash tank, the cooling device and the boiler are sequentially connected. The wet-type electric precipitation technology is adopted for the water recycling unit, and the goals of lignite heat value increase, a high water recycling rate, multistage heat utilization and the like are achieved.

Owner:SHANDONG SHENHUA SHANDA ENERGY ENVIRONMENTAL

Solid fuel combustion method and combustion device

InactiveCN105090935ASolve the melting ash problemContinuous and stable combustionSolid fuel combustionCombustion apparatusSolid fuelExhaust gas

A solid fuel combustion method and combustion device (100). The combustion device (100) comprises a furnace (10). The side of a fuel stack layer (1) close to a combustion cavity (3) forms a combustion side (102), and the other side opposite the combustion side (102) forms an air inlet side (101). The air inlet side (101) is provided with a side wall (6) that provides air only to the upper portion of the fuel stack layer (1).

Owner:车战斌

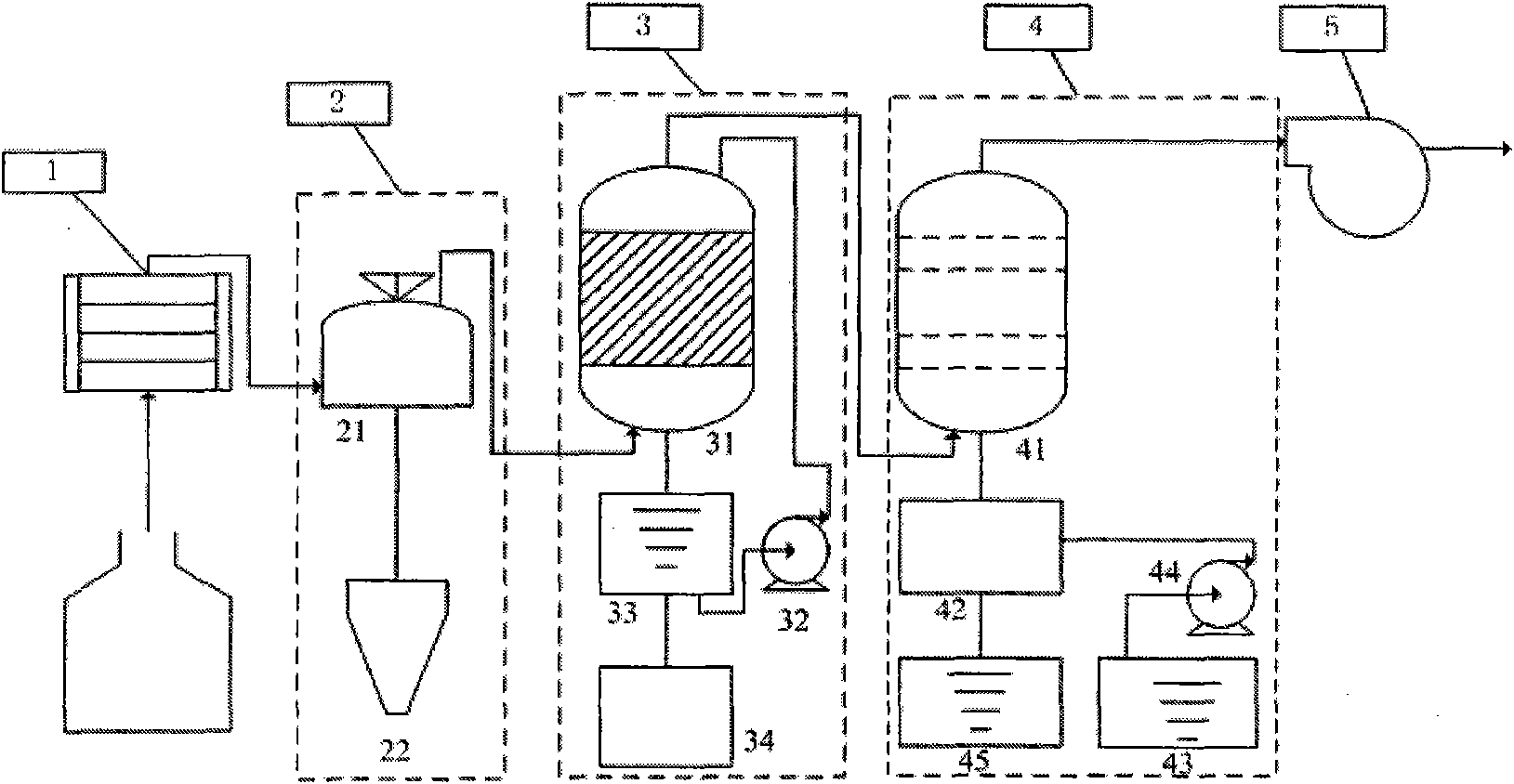

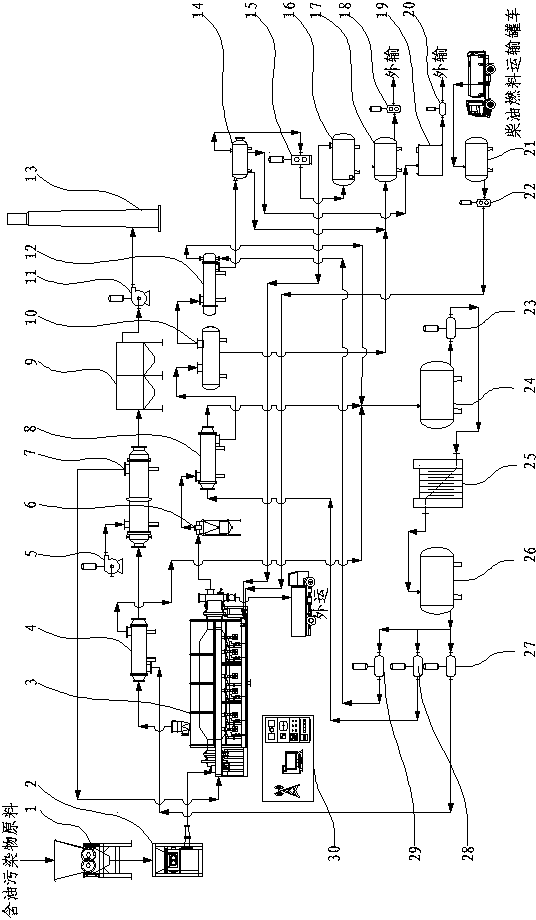

Oily pollutant ultraclean treatment process and oily pollutant ultraclean treatment equipment

PendingCN108383350AReduce labor intensityImprove processing efficiencySludge treatment by pyrolysisWater contaminantsOil phaseCrusher

The invention provides an oily pollutant ultraclean treatment process and oily pollutant ultraclean treatment equipment, and relates to the technical field of oily pollutant ultraclean treatment. Theoily pollutant ultraclean treatment equipment comprises a crusher, a feeder, a thermal desorption furnace, a combustion fan, an oil-gas dust collector, a combustion-supporting air heater, an oil-gas two-phase separator, an oil-gas condenser, a three-phase separator, a non-condensable gas buffer tank, an oil phase buffer tank, a wastewater tank, a high temperature heat conductive oil storage tank,a generator set, a low temperature heat conductive oil storage tank and a distributed control system (DCS) intelligent autonomous control system. Oily pollutants are quantitatively conveyed to the feeder in an airtight way through a pipeline after being crushed by means of the crusher, and is then transported to a thermal desorption device, so that the labor intensity is lightened; an anaerobic thermal desorption reaction is realized by means of high temperature anaerobic operation; the non-condensable gas is recycled as fuel; the total petroleum hydrocarbon (TPH) of the treated solid phase residue is less than 0.05 percent; a closed dry slagging technology is adopted, so that clean discharge of the residue is realized; a flue gas waste heat recovery heat exchanger and the oil-gas condenser are used for realizing waste heat recovery; after the generator set is used for power generation for reuse, the recovery utilization rate of the waste heat can reach 90%.

Owner:大庆百世环保科技开发有限公司

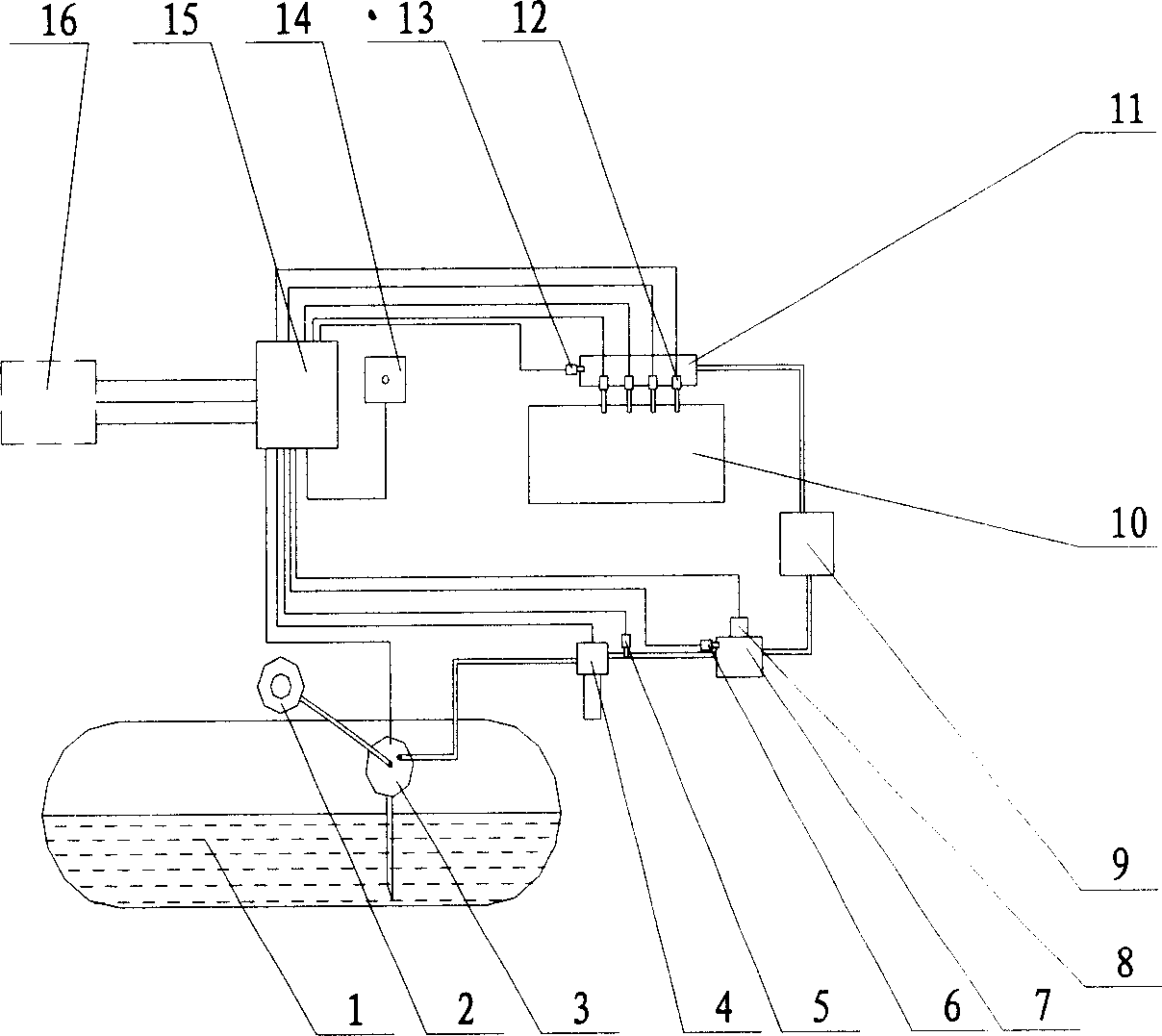

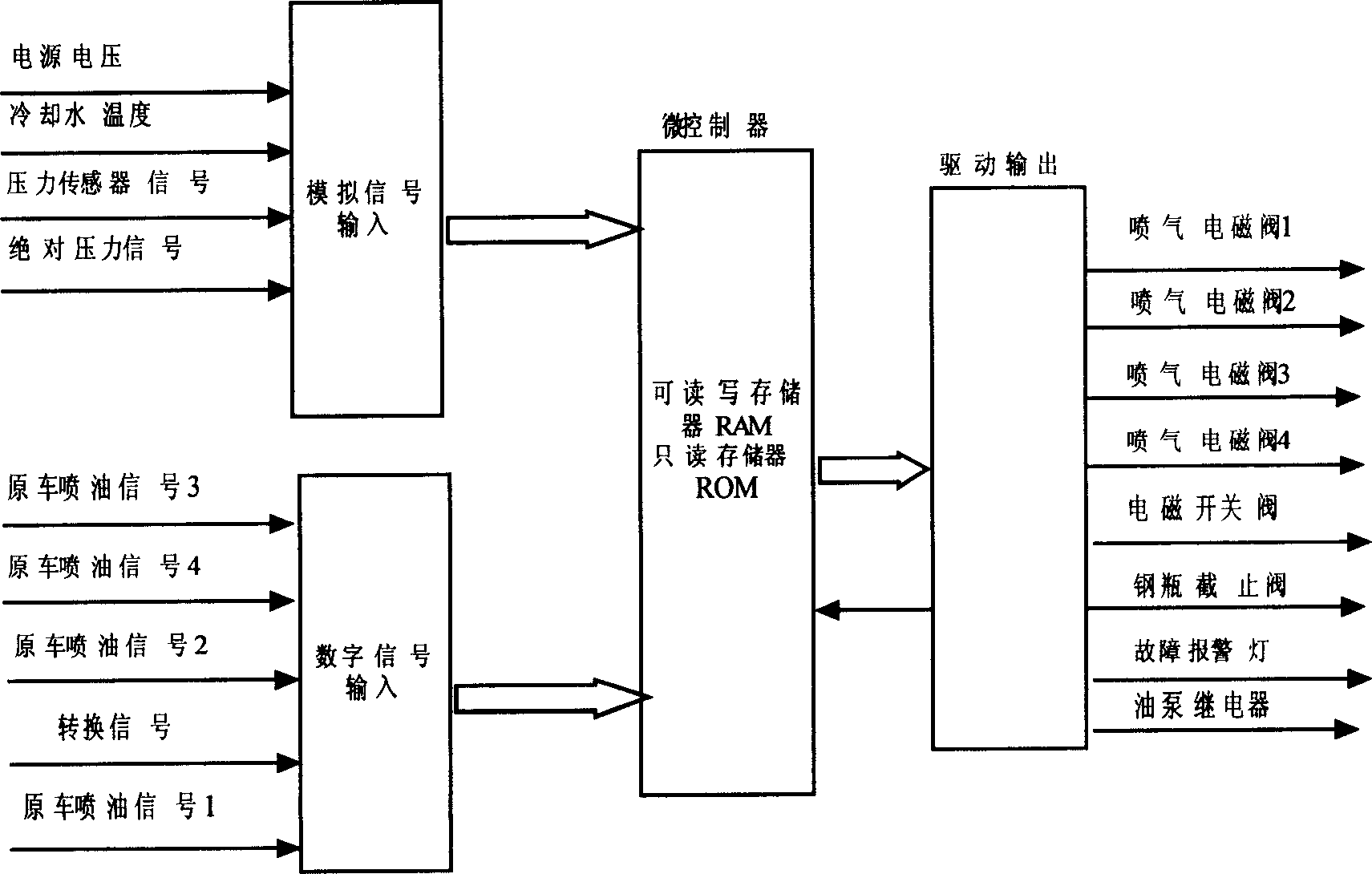

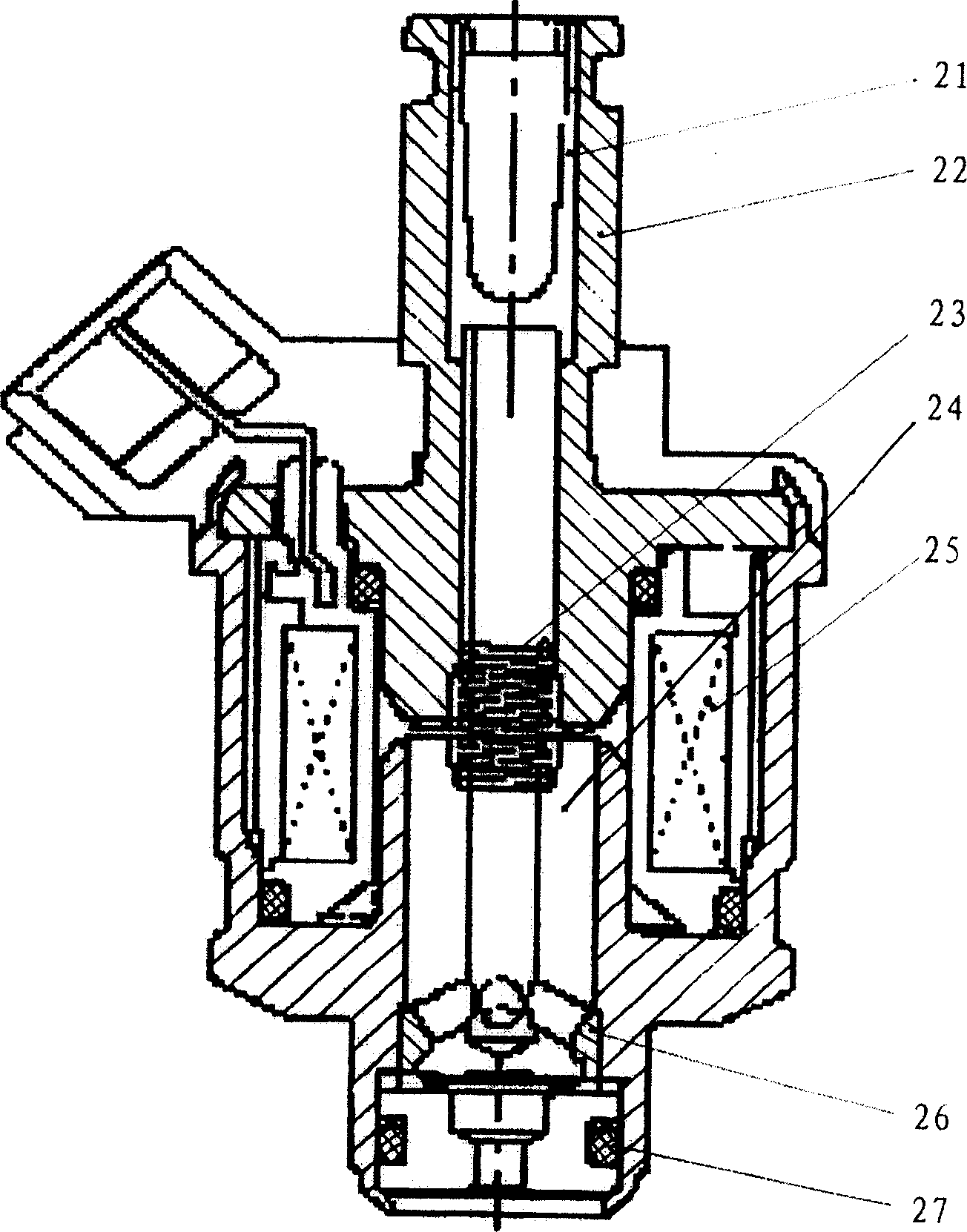

Liquified gas or compressed natural gas automobile fuel gas multipoint sequencial jet system

InactiveCN1904335AAchieve emissionsAchieve clean emissionsElectrical controlMachines/enginesCompressed natural gasControl line

The invention comprises a steel cylinder, an air-filled composite valve, an integrated valve, a magnetic switch valve, a pressure-relief valve, a stop valve, a gas filter, a changeover switch, a gas common rail pipe, a jet magnetic valve, an absolute pressure transducer and a controller. Several jet magnetic valves and the absolute pressure transducer are mounted on the gas common rail pipe. The control lines of the stop valve, the magnetic switch valve, the integrated valve and the jet magnetic valve and the signal wire of the absolute pressure transducer are connected with the controller separately.

Owner:SHANGHAI INTERNAL COMBASTION ENGINE INST

Plasma on-duty flame igniter based on aero-engine afterburner

ActiveCN110439691ASimple structureSmall sizeGas turbine plantsJet propulsion plantsCombustion chamberAviation

The invention discloses a plasma on-duty flame igniter based on an aero-engine afterburner. The plasma on-duty flame igniter comprises a flame stabilizer and an embedded cathode combination. The embedded cathode combination comprises a connecting sleeve, a cathode shell, a transverse insulating pipe, a Y type cathode, a guide rod shell, a longitudinal insulating pipe and a power-on guide rod. Theconnecting sleeve is in threaded connection with the cathode shell, the right end of the connecting sleeve is welded to the flame stabilizer, the left middle portion of the transverse insulating pipeis arranged in the cathode shell, and the closed end of the Y type cathode is arranged in the transverse insulating pipe. The guide rod shell is vertically arranged on the top of the left side of thecathode shell, the upper middle portion of the longitudinal insulating pipe is arranged in the guide rod shell, after the lower end of the longitudinal insulating pipe penetrates through the cathode shell, the end of the longitudinal insulating pipe is located in the right portion of the transverse insulating pipe, and the upper middle portion of the power-on guide rod is arranged in the longitudinal insulating pipe. The problems that an existing aero-engine afterburner is bad in working environment and complex in structure, and stable rapid ignition and continuous organized combustion are notfacilitated.

Owner:AIR FORCE UNIV PLA

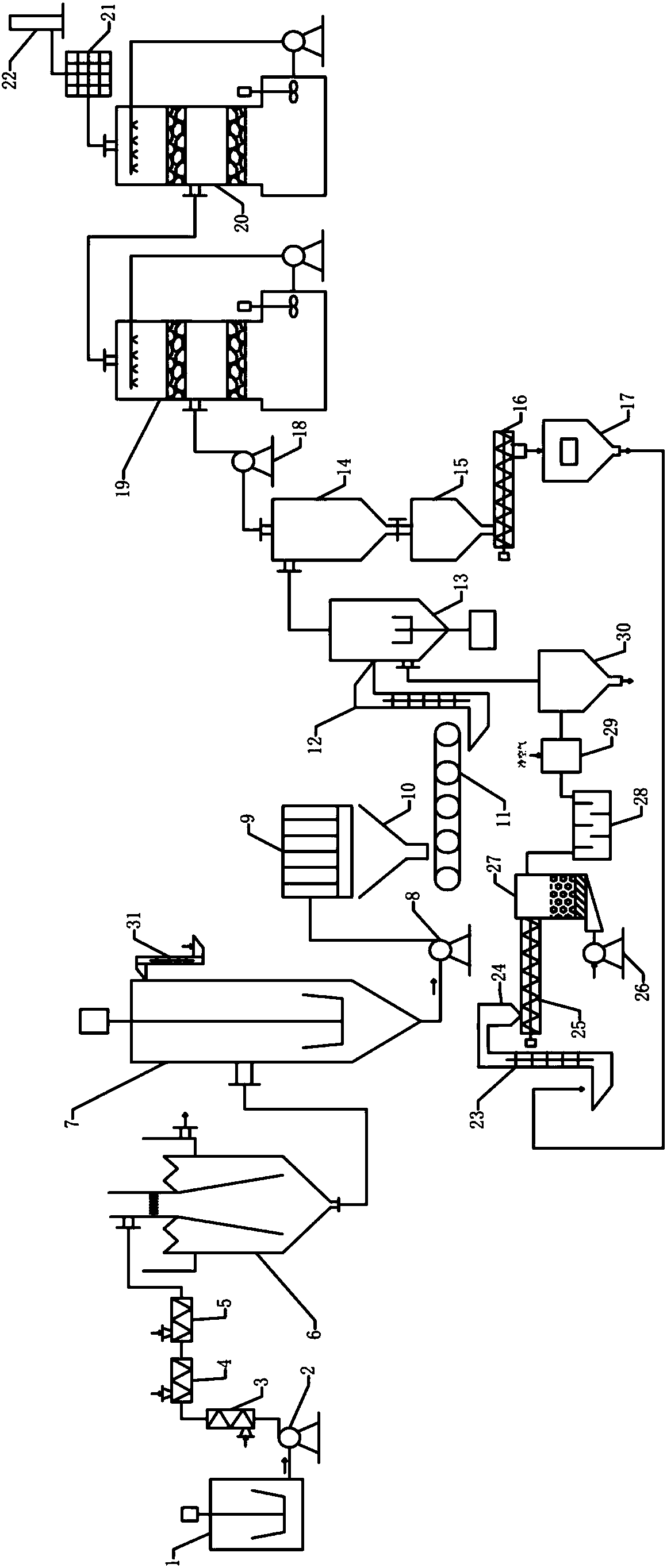

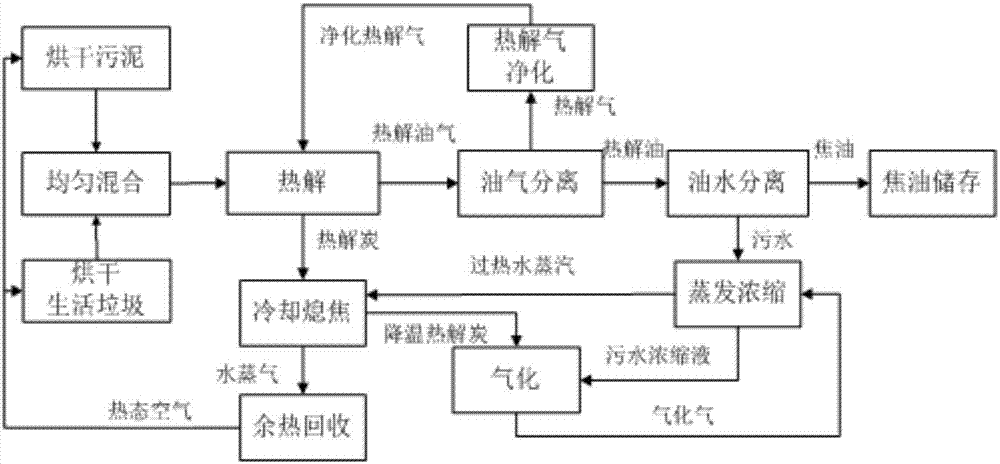

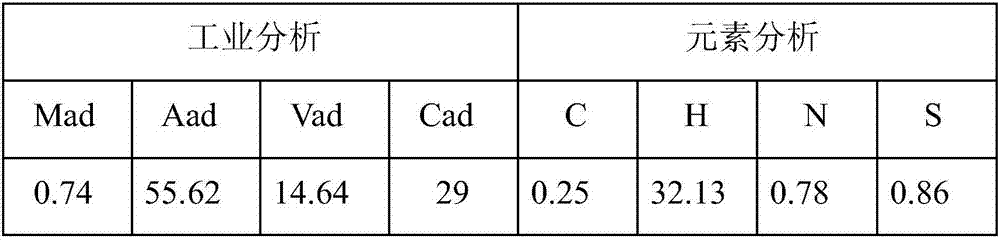

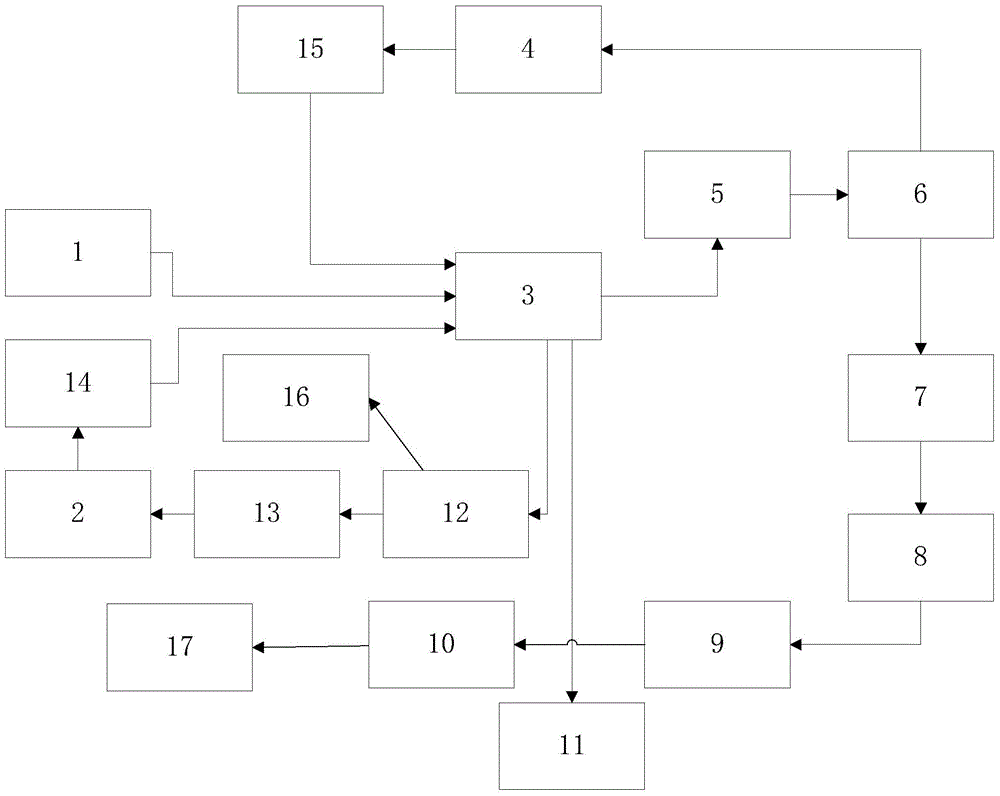

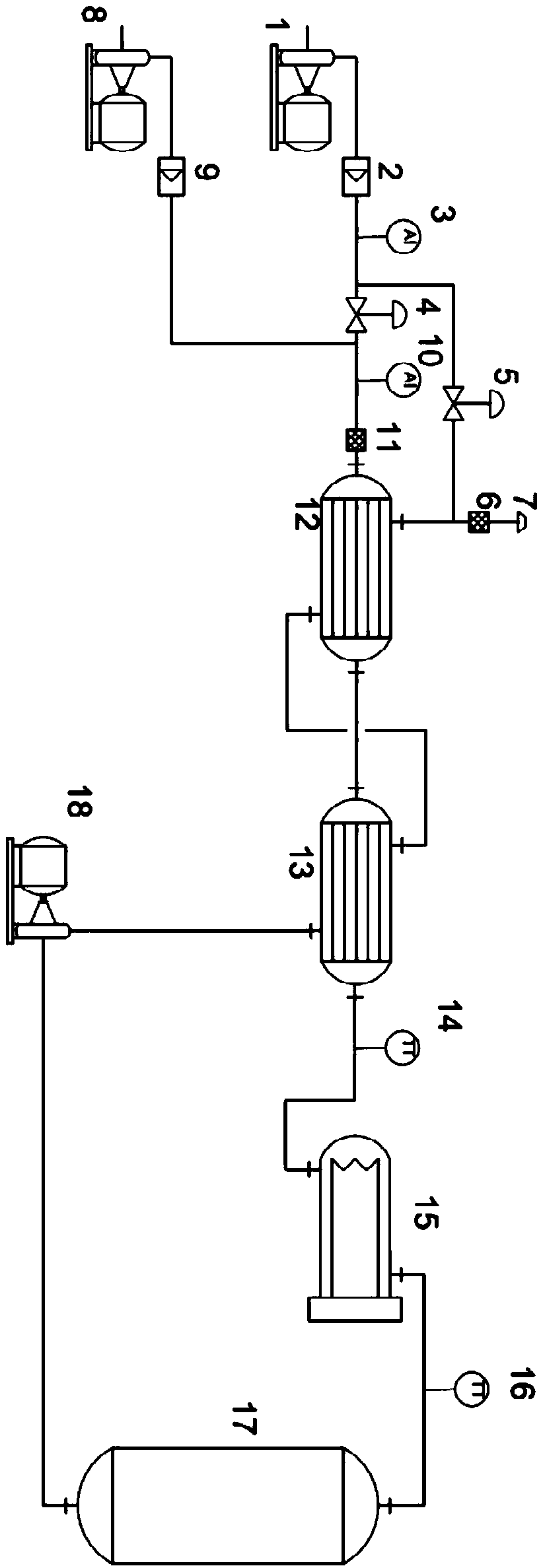

System and method for treating domestic garbage and sewage sludge

PendingCN107513392AEnables hybrid pyrolysisAchieve clean emissionsSludge treatment by pyrolysisByproduct vaporizationWater vaporSludge

The invention relates to a system and a method for treating domestic garbage and sewage sludge. In a pyrolysis unit of the system, a pyrolysis device is equipped with a feeding port, a pyrolytic oil gas outlet and a pyrolytic carbon outlet; in a pyrolytic oil gas treating unit, an oil gas separating device is equipped with a pyrolytic oil gas inlet, a pyrolytic gas outlet and a pyrolytic oil outlet; the pyrolytic oil gas inlet is connected with the pyrolytic gas outlet; an oil water separating device is equipped with a pyrolytic oil inlet, a tar outlet and a sewage outlet; the pyrolytic oil inlet is connected with the pyrolytic oil outlet; an evaporation device is equipped with a sewage inlet, a steam outlet and a sewage concentrated liquid outlet; the sewage inlet is connected with the sewage outlet; in a pyrolytic carbon treating unit, a cooling device is equipped with a pyrolytic carbon inlet, a water vapor inlet, a cooling pyrolytic carbon outlet and a water vapor outlet; the pyrolytic carbon inlet is connected with the pyrolytic carbon outlet; and the water vapor inlet is connected with the water vapor outlet. According to the invention, the pyrolytic gas, tar and pyrolytic carbon energy with high calorific value can be acquired, the yield is higher, the energy consumption of the system is lower and the running cost is lower.

Owner:BEIJING SHENYUAN ENVIRONMENTAL PROTECTION CO LTD

Water recyclable superheated steam drying lignite system and process method thereof

ActiveCN104197684BLow costRun economyDrying gas arrangementsDrying solid materialsBaghouseProduct gas

The invention discloses a water-recyclable superheat steam drying lignite system and a process method thereof. The water-recyclable superheat steam drying lignite system comprises a dryer which is respectively connected with a moisture-carrying gas cycle unit, a water recycling unit and a condensate water flash unit; the moisture-carrying gas cycle unit comprises an electric heater, the input end of the electric heater is connected with a bag-type dust collector which is connected with a cyclone storage device, a cyclone dust collector is connected with the output end of the dryer, and the output end of the electric heater is connected with the input end of the dryer; the water recycling unit comprises the cyclone dust collector, the bag-type dust collector, a wet-type electrostatic precipitator, an air cooling device, a water cooling device and a water treatment unit, and the cyclone dust collector, the bag-type dust collector, the wet-type electrostatic precipitator, the air cooling device, the water cooling device and the water treatment unit are connected in sequence; the saturated condensate water flash unit comprises a flash tank, a cooling device and a boiler, and the flash tank, the cooling device and the boiler are sequentially connected. The wet-type electric precipitation technology is adopted for the water recycling unit, and the goals of lignite heat value increase, a high water recycling rate, multistage heat utilization and the like are achieved.

Owner:SHANDONG SHENHUA SHANDA ENERGY ENVIRONMENTAL +1

Multi-level heat exchange split-building type catalytic oxidation system and processing method thereof

PendingCN108844085AAchieve clean emissionsReached ignition temperatureGas treatmentDispersed particle separationElectricityControl system

The invention discloses a multi-level heat exchange split-building type catalytic oxidation system and a processing method thereof. The system comprises a waste gas fan, an air supplement fan, a heatexchange system, an electric heater, a catalytic oxidizer, an induced draft fan, a control system, a safety system and a connection pipeline, wherein the waste gas fan and the air supplement fan are arranged in parallel and are sequentially connected with the heat exchange system, the electric heater and the catalytic oxidizer through pipelines. The processing method comprises the steps that gas containing VOCs is pressurized by the fan and then enters the two-level heat exchange system in sequence to conduct heat exchange with high-temperature tail gas from a catalytic reactor, heat supplement is conducted through the electric heater, the gas enters the catalytic reactor after reaching the ignition temperature, catalytic oxidation reaction is conducted in the catalytic reactor, waste gascontaining VOCs entering the system is heated by entering the two-level heat exchange system, and then the tail gas is drained at high temperature. The system is suitable for ultraclean emission control and tail end treatment of waste gas containing VOCs with low concentration.

Owner:JIANGSU GOLDEN GATE ENERGY & EQUIP CO LTD +1

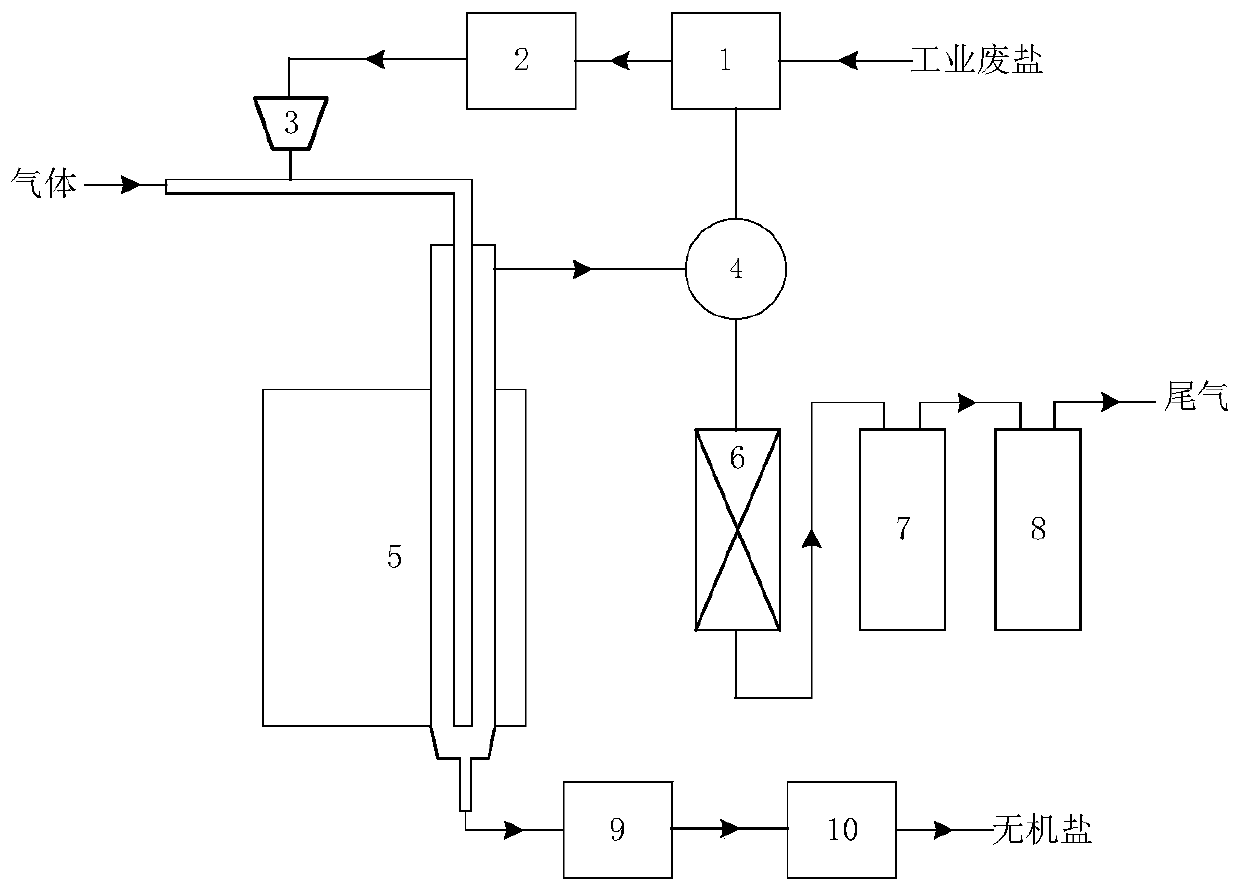

Method and device for harmless treatment of industrial waste salt by utilizing alkaline melt

ActiveCN110479734AReduce the temperatureImprove efficiencySolid waste disposalTransportation and packagingIndustrial wasteEnvironmental resistance

The invention relates to a method and device for harmless treatment of industrial waste salt by utilizing alkaline melt. Aiming at the characteristics that the organic matter contained in industrial waste salt is complicated and is difficult to remove, a melting reaction furnace device is adopted to heat and melt inorganic salt; industrial waste salt and oxidizing gas are fed; the organic matter contained in the industrial waste salt can decompose and gasify in the reaction furnace; the residues are high-purity salt products; and the industrial salt product not containing the organic matter isobtained through dissolving, washing and multiple evaporative crystallization. Compared with the prior art, the raw materials are available, the operation is simple, and secondary pollution includingharmful acid gas and Dioxin is not generated; harmless treatment of the industrial waste salt containing the organic matter and resource recycling of the salt components are realized; and the methodis low in investment cost, and wide in applicable range and has higher environmentally-friendly and economic benefits.

Owner:TONGJI UNIV

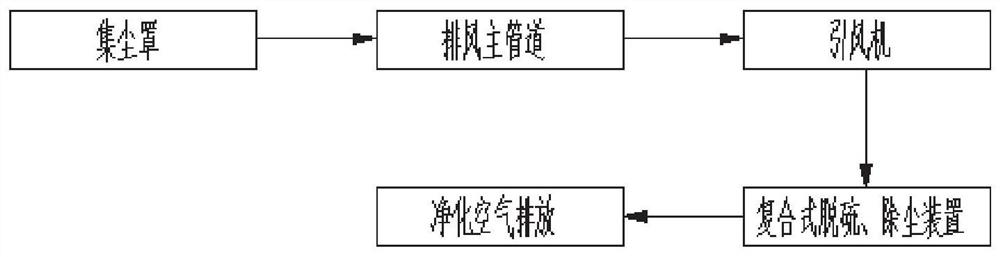

Composite purification device and process suitable for dusty gas

InactiveCN111760405AReduce pollutionLow operation and maintenance costsGas treatmentUsing liquid separation agentProcess engineeringFlue gas

The invention discloses a composite purification device and process suitable for dusty gas, and a purification device. The purification device comprises: a dust hood for collecting dusty flue gas; aninduced draft fan used for providing power for conveying the dusty flue gas; and a purification tower, wherein a flow guide device, a first spraying layer, a liquid holding turbulator, a filler layerand a second spraying layer are sequentially arranged in the purification tower from bottom to top, a flue gas inlet of the purification tower is positioned below the first spraying layer and is communicated with the dust hood through the induced draft fan, and the flow guide device is a half-tube type flow guide device. Due to the fact that the dust removal device of the process system adopts thecomposite purification tower, clean emission of gas can be achieved, and pollution to the surrounding environment is reduced.

Owner:SHANDONG SHENHUA SHANDA ENERGY ENVIRONMENTAL

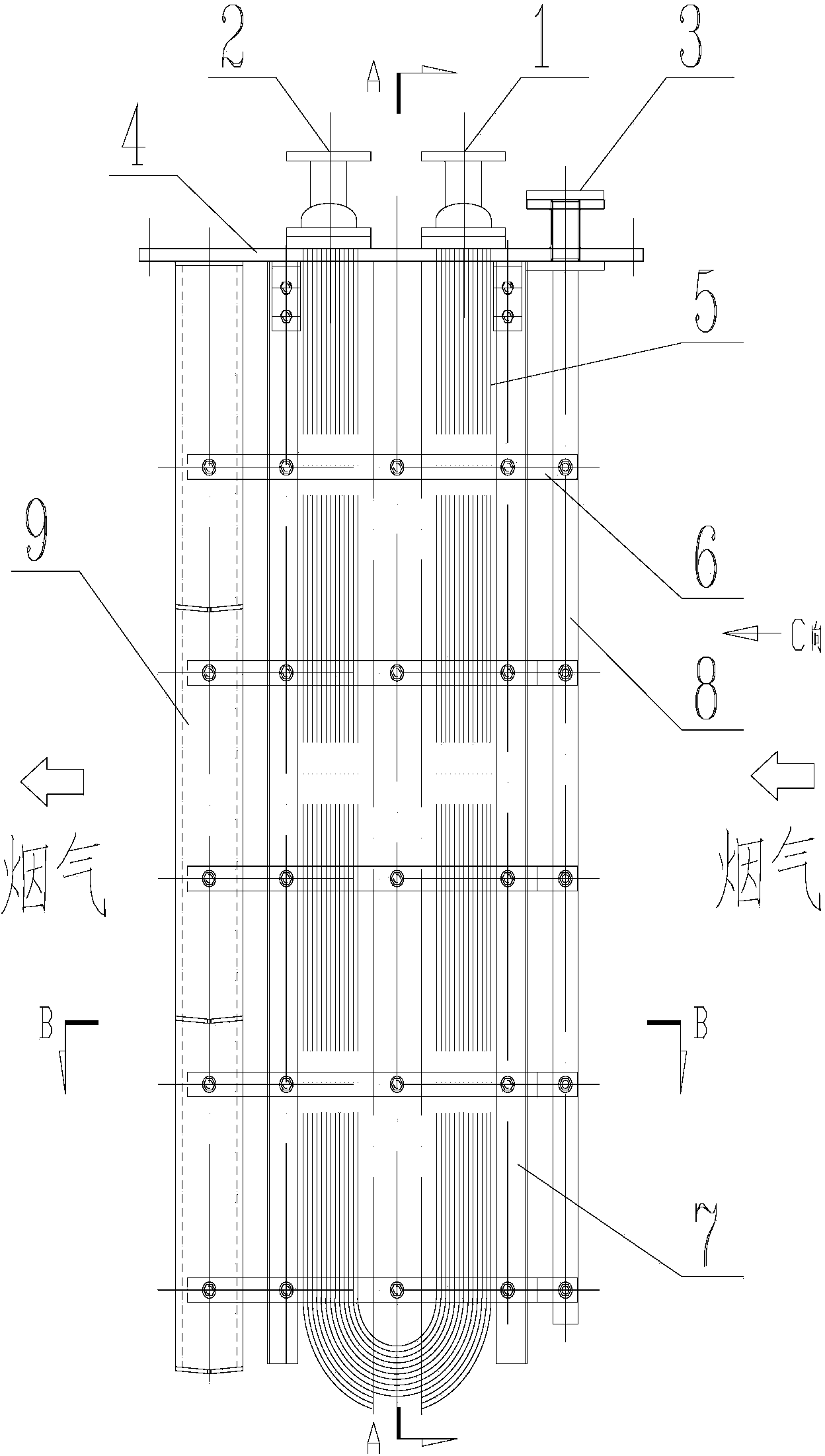

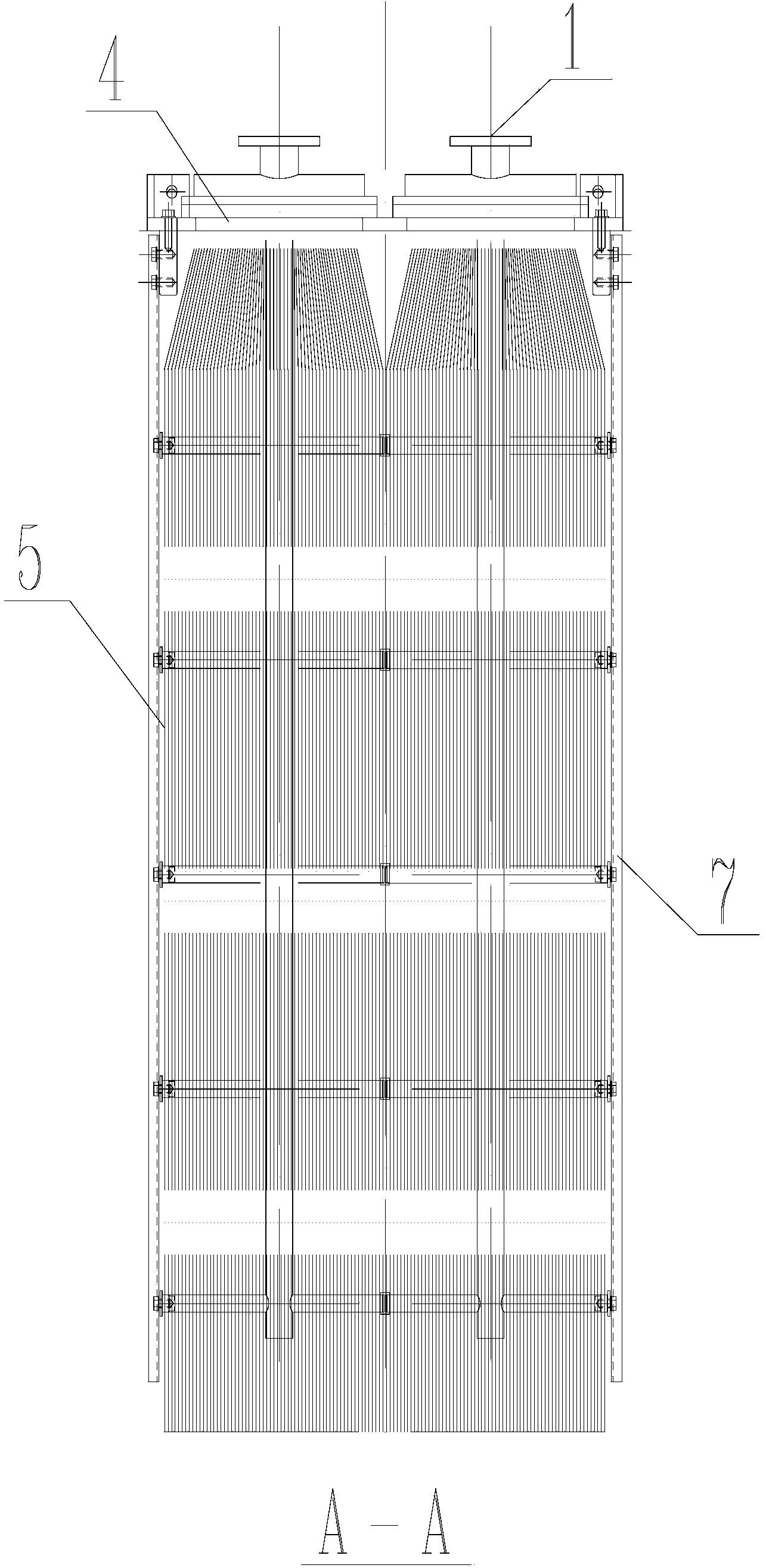

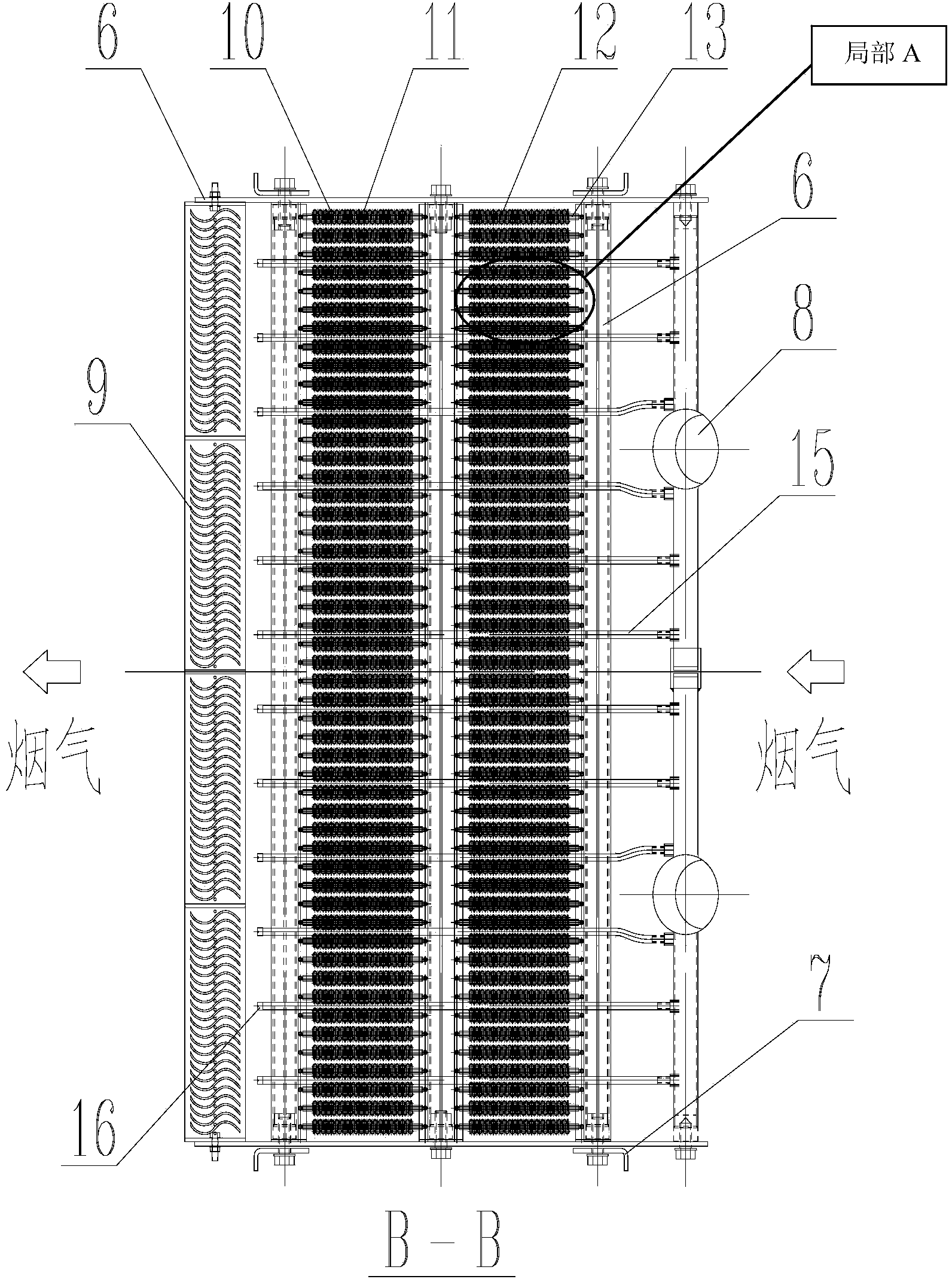

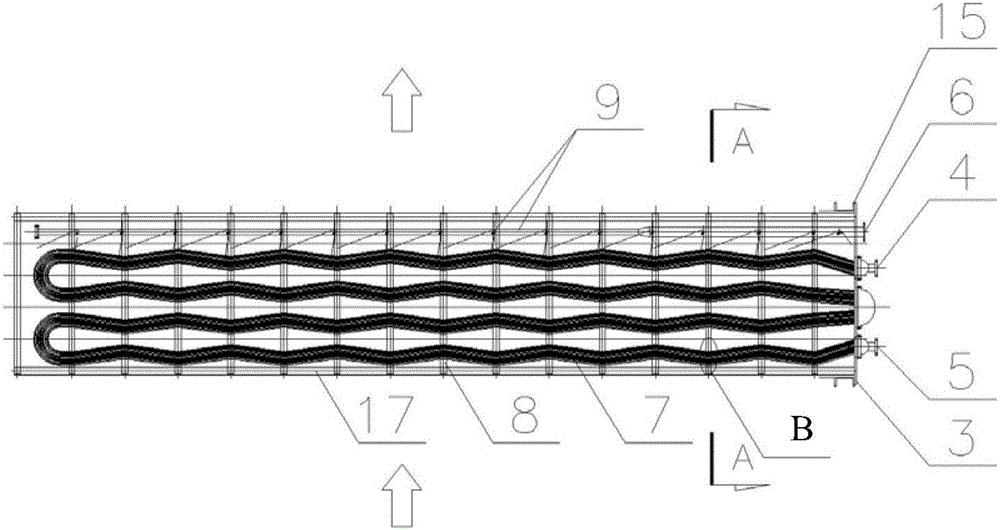

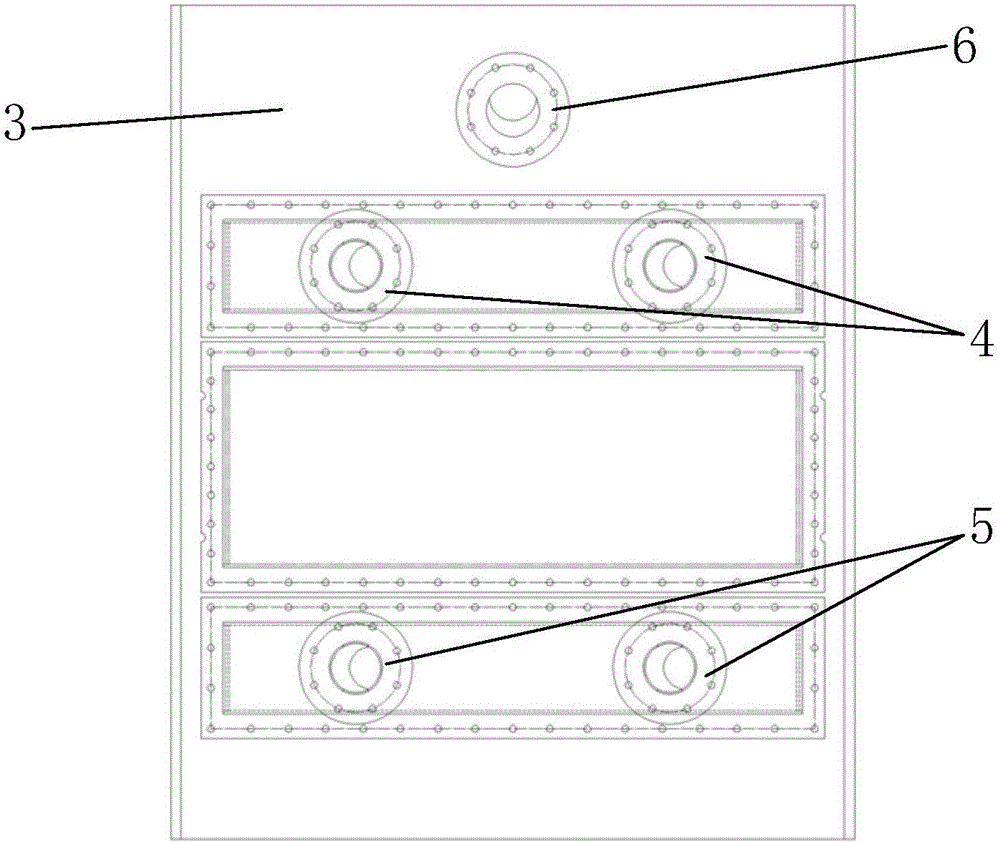

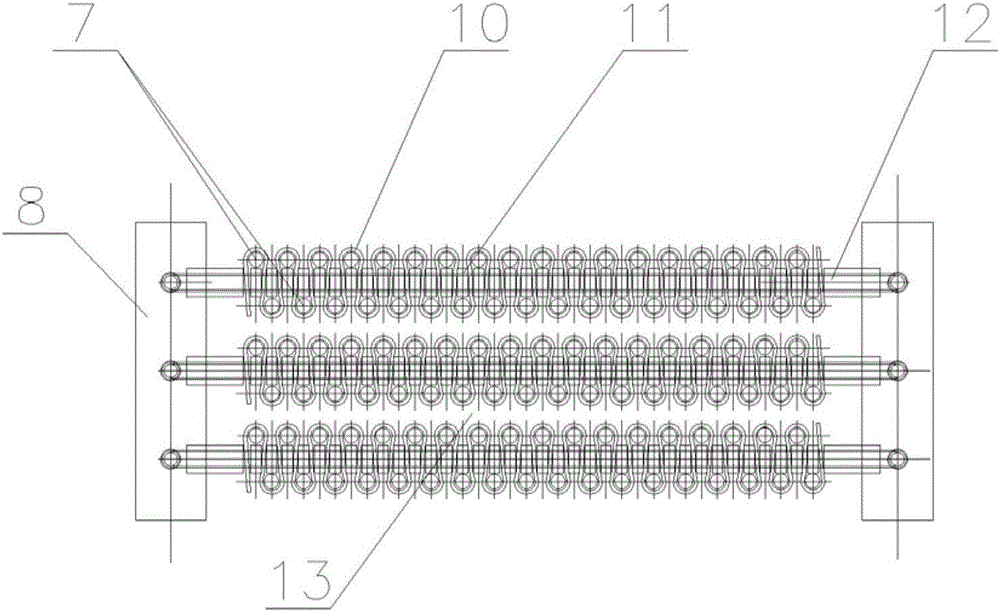

Horizontal fluorine plastic tube type dust and mist collection device mounted inside absorption tower

InactiveCN106582153ASolve the problem of "ultra-clean emission" transformationAchieve clean emissionsUsing liquid separation agentLiquid waterEngineering

The invention belongs to the technical field of waste gas purification, and in particular relates to a horizontal fluorine plastic tube type dust and mist collection device mounted inside an absorption tower. The horizontal fluorine plastic tube type dust and mist collection device is mounted inside an absorption tower (1) and comprises dust and mist collection tube bundles (7), a support unit and a water flushing unit, wherein the dust and mist collection tube bundles (7) consist of ''U''-shaped tubes and are arranged in a wave manner in a horizontal direction; a plurality of the horizontal fluorine plastic tube type dust and mist collection devices are horizontally mounted in parallel inside the absorption tower (1); and one end with a surface plate (3), of each horizontal fluorine plastic tube type dust and mist collection device, extends outside the absorption tower through an absorption tower flange (15). The horizontal fluorine plastic tube type dust and mist collection device is applied to the power environmental protection industry and works in the absorption tower of a flue gas desulfurization (FGD) device of a thermal power plant, fume is purified by using a cold source in a cooling manner, or liquid membranes are formed on surfaces of the fluorine dust and mist collection tube bundles in a water spraying mode to capture impurities such as fine particle dust, gypsum and liquid water, and thus cleaning discharge of fume of the thermal power plant can be achieved.

Owner:北京新世翼节能环保科技股份有限公司

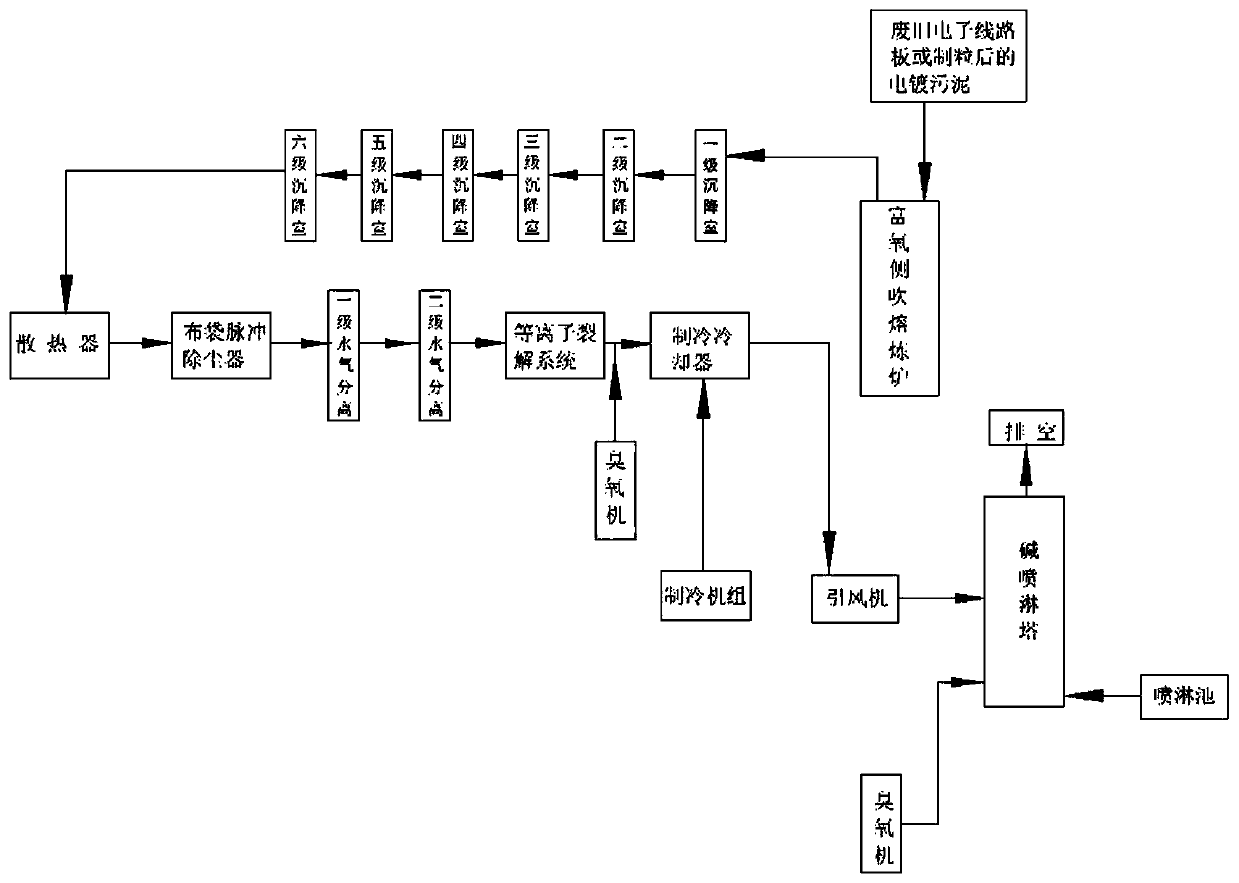

Waste electronic circuit board or electroplating sludge smelting flue gas treatment method

The invention discloses a waste electronic circuit board or electroplating sludge smelting flue gas treatment method. The method comprises the steps of putting waste electronic circuit boards or granulated electroplating sludge into an oxygen-enriched furnace for smelting to obtain a metal phase and smoke dust; settling and purifying the obtained smoke dust through a six-stage settling chamber; radiating and cooling the purified flue gas; after cooling, dedusting again, separating water and gas after dedusting, and then carrying out a plasma cracking oxidation reaction; filling ozone into thecracked flue gas for an oxidation reaction; introducing the oxidized flue gas into a refrigeration cooler for cooling; and introducing the cooled flue gas into an alkaline spray tower for neutralization and oxidation reactions, discharging the generated salt from the bottom of the tower, and discharging the generated gas after standard-reaching separation. The waste electronic circuit board or electroplating sludge smelting flue gas treatment method is efficient, environmentally friendly, safe and free of pollution.

Owner:河南林兰科技有限公司

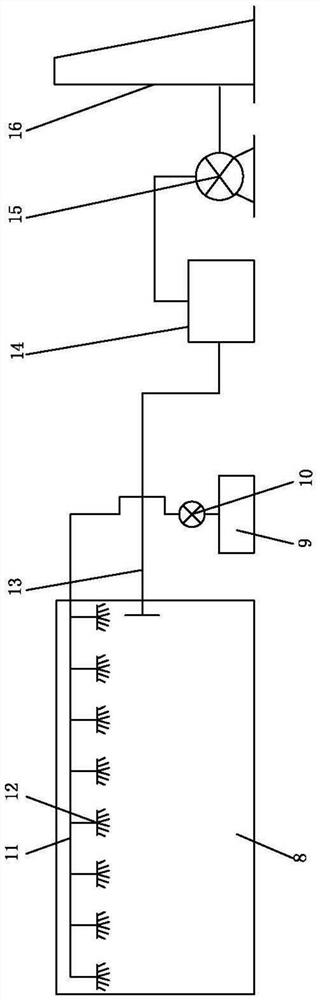

Sludge biomass high-temperature gasification treatment method and treatment system

PendingCN112126474AReduce energy consumptionEffective deodorizationSludge treatmentSpecific water treatment objectivesSludgeProcess engineering

The invention discloses a sludge biomass high-temperature gasification treatment method and treatment system which are low in energy consumption, capable of effectively deodorizing, more sufficient incombustion, capable of greatly increasing the burn-off rate, more energy-saving and more environmentally friendly. The method mainly comprises the following steps: 1, mixing sludge and wood waste; 2,carrying out aging treatment; 3, gasification treatment; 4, utilization of biomass gas; the system comprises a sludge bin, a wood waste bin, a belt conveyor, a mixing machine, an aging device and a biomass gasification furnace, the sludge bin and the wood waste bin are conveyed to the mixing machine through the belt conveyor to form a mixture, the mixture is subjected to aging treatment through the aging device, and finally the mixture is combusted into biomass gas through the biomass gasification furnace to be recycled.

Owner:苏韶华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com