Oily pollutant ultraclean treatment process and oily pollutant ultraclean treatment equipment

A technology for processing equipment and processing technology, which is applied in the direction of water pollutants, water/sludge/sewage treatment, petroleum industry, etc., and can solve the problems of intermittent and discontinuous pyrolysis technology and equipment, high safety risks, and large emissions. Achieve the effect of improving resource utilization efficiency, improving processing efficiency and saving fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

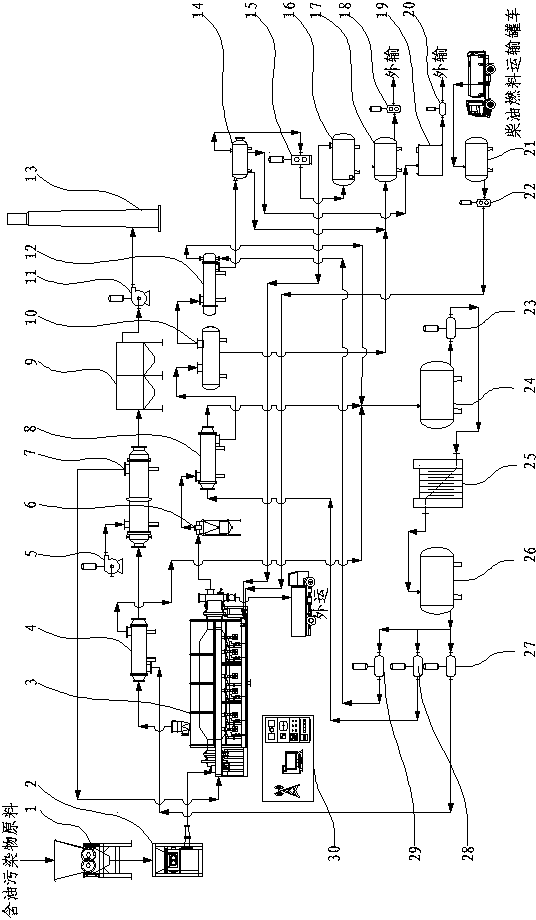

[0021] A kind of ultra-clean treatment equipment for oily pollutants of the present invention is composed of a crusher 1 and a separator. The feed port is connected to the pipeline, the gas phase outlet of the thermal desorption furnace 3 is connected to the oil-gas dust collector 6 pipeline, the oil-gas dust collector 6 is connected to the 1# oil-gas condenser 8 pipeline, and the 1# oil-gas condenser 8 is connected to the oil-gas two-phase separator 10 pipeline connection, the oil phase outlet of the oil-gas two-phase separator 10 is connected to the oil phase buffer tank 17, the gas phase outlet is connected to the 2# oil-gas condenser 12 pipeline, and the 2# oil-gas condenser 12 is connected to the three-phase separator 14 pipeline The oil phase outlet of the three-phase separator 14 is connected with the oil phase buffer tank 17, the water phase outlet is connected with the waste water tank 19, and the gas phase outlet is connected with the noncondensable gas buffer tank 16...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com